Patents

Literature

483results about How to "Uniform distribution of pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

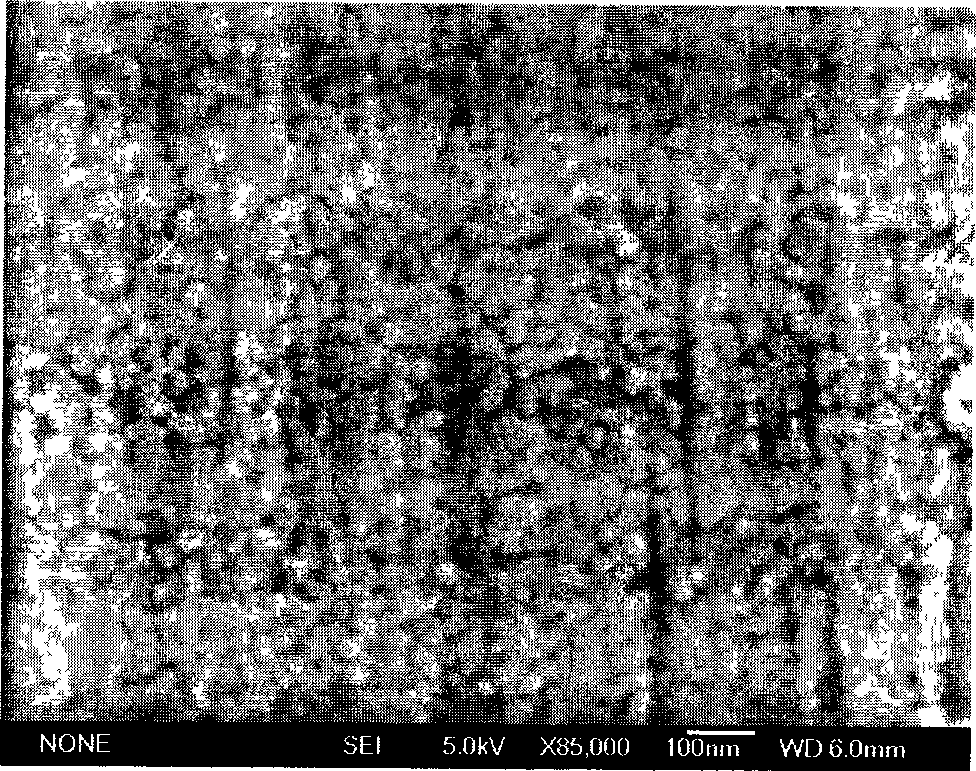

Catalyst for denitration of power plant soot fume SCR and preparation method thereof

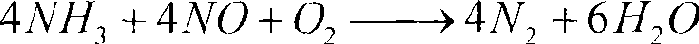

InactiveCN101422728AImprove wear resistanceStrong anti-poison abilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporWorking temperature

The invention relates to a catalyst carrier, an SCR denitrifying catalyst of electric plant flue gas that is prepared by the catalyst carrier and a preparation method of the SCR denitrifying catalyst. The invention adopts purple mud clay and anatase TiO2 to form the carrier; by weight, the content of the TiO2 is 50 to 99 percent and the content of the purple mud clay is 1 to 50 percent. The catalyst carrier can further contain active carbon, CaSO4 and ammonia-typed Y molecular sieve, which respectively account for 0 to 20 percent of the weight of the catalyst carrier. The active ingredients of the catalyst comprise V2O5 accounting for 1.0 to 6.0 percent of the weight of the catalyst, WO3 accounting for 4.0 to 10.0 percent of the weight of the catalyst, MoO3 accounting for 0 to 9.0 percent of the weight of the catalyst, and CeO2 accounting for 0 to 2.0 percent of the weight of the catalyst. The working temperature of the catalyst is 200 to 500 DEG C, has high catalytic activity, large specific surface and strong toxin immunity, hardly has inactivation phenomenon in long-time running, and is insensitive to vapor and sulfur dioxide.

Owner:HARBIN INST OF TECH

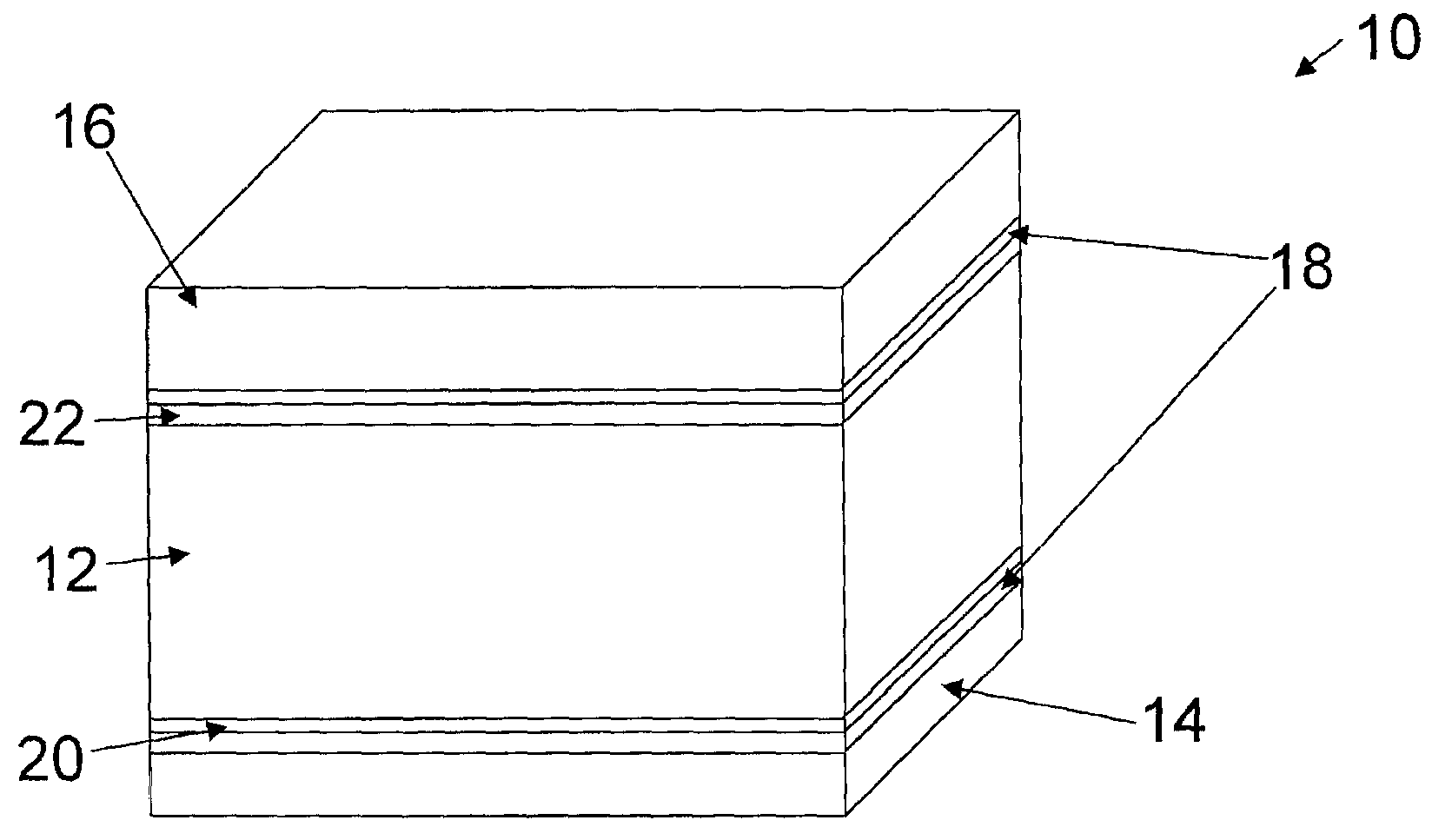

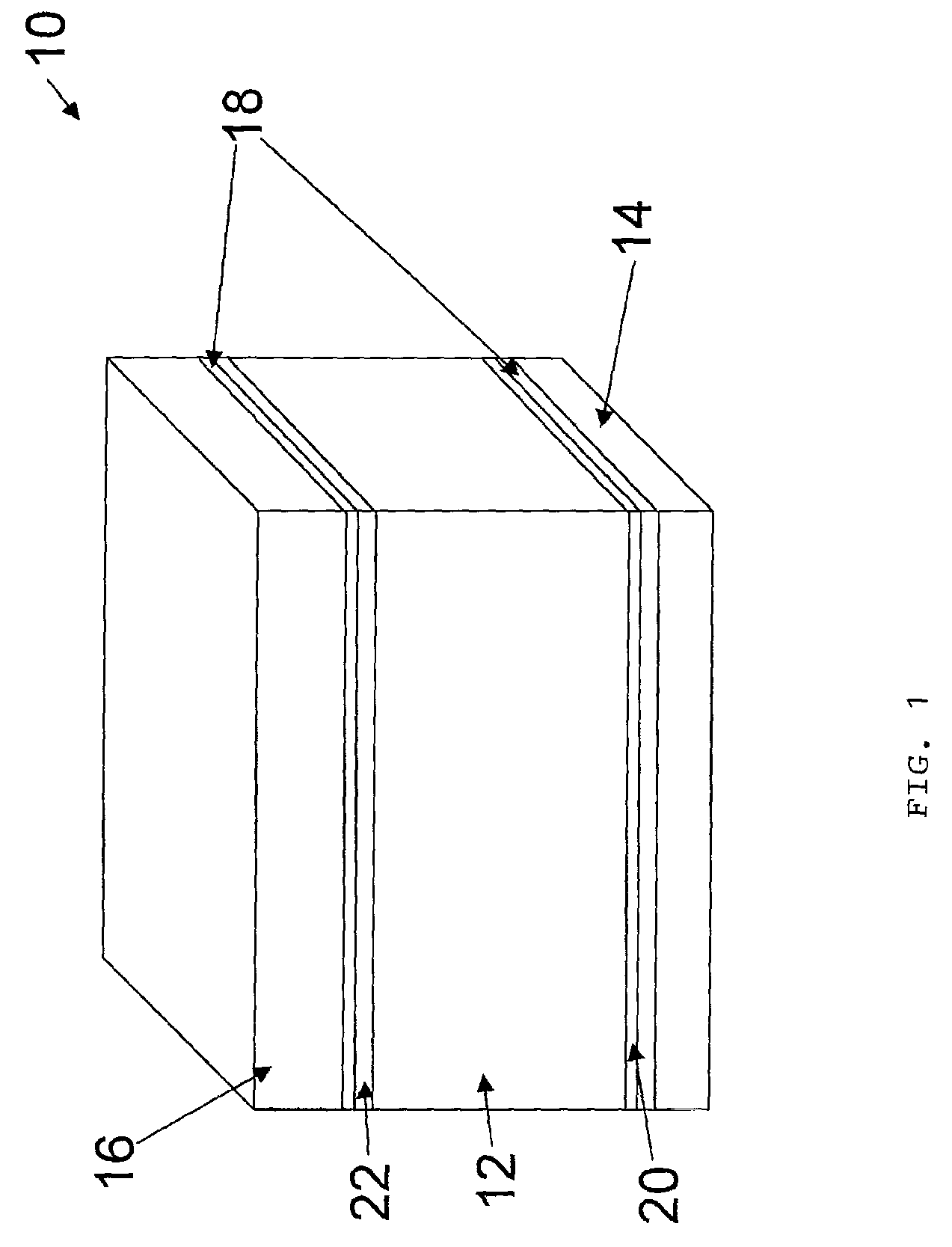

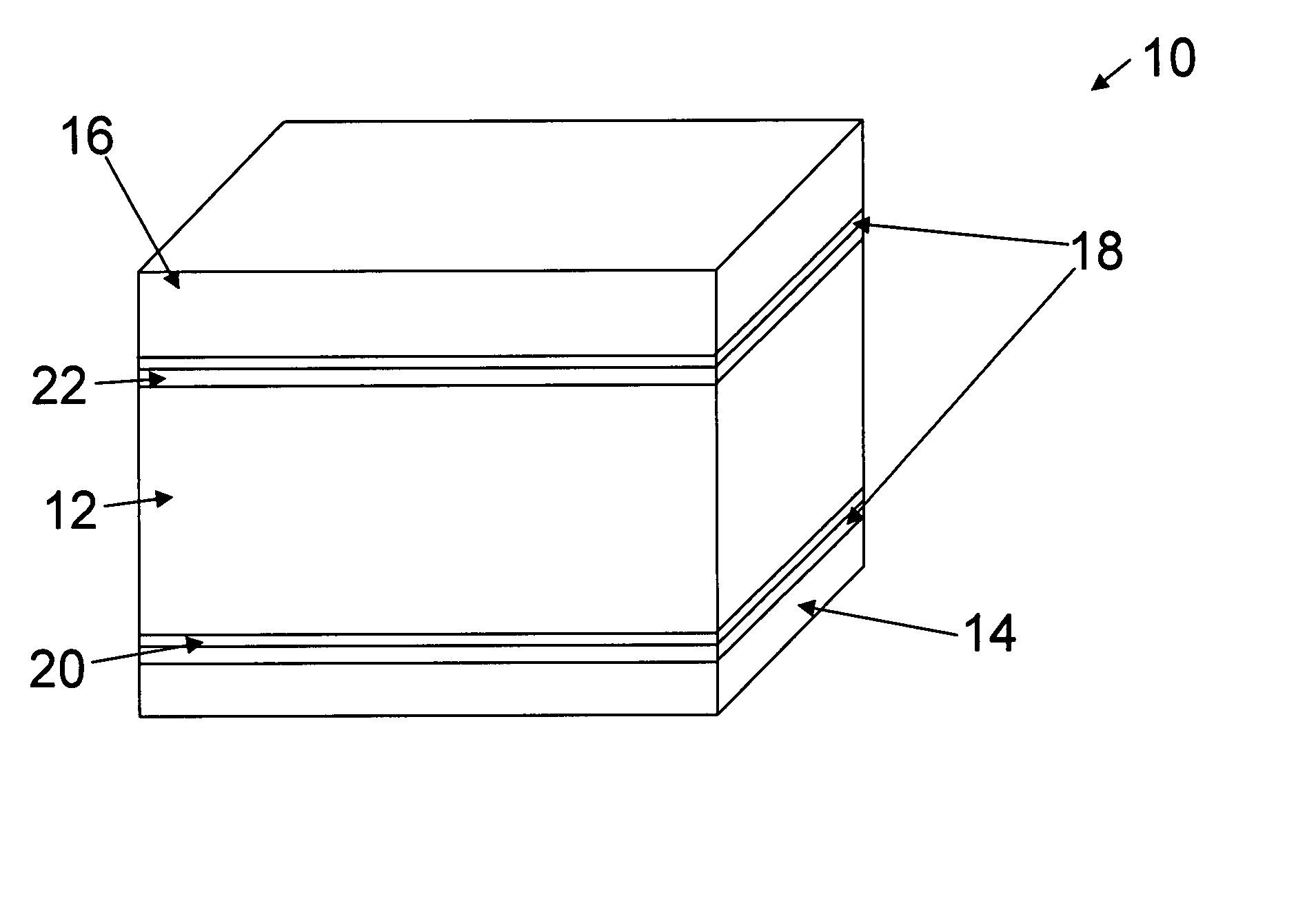

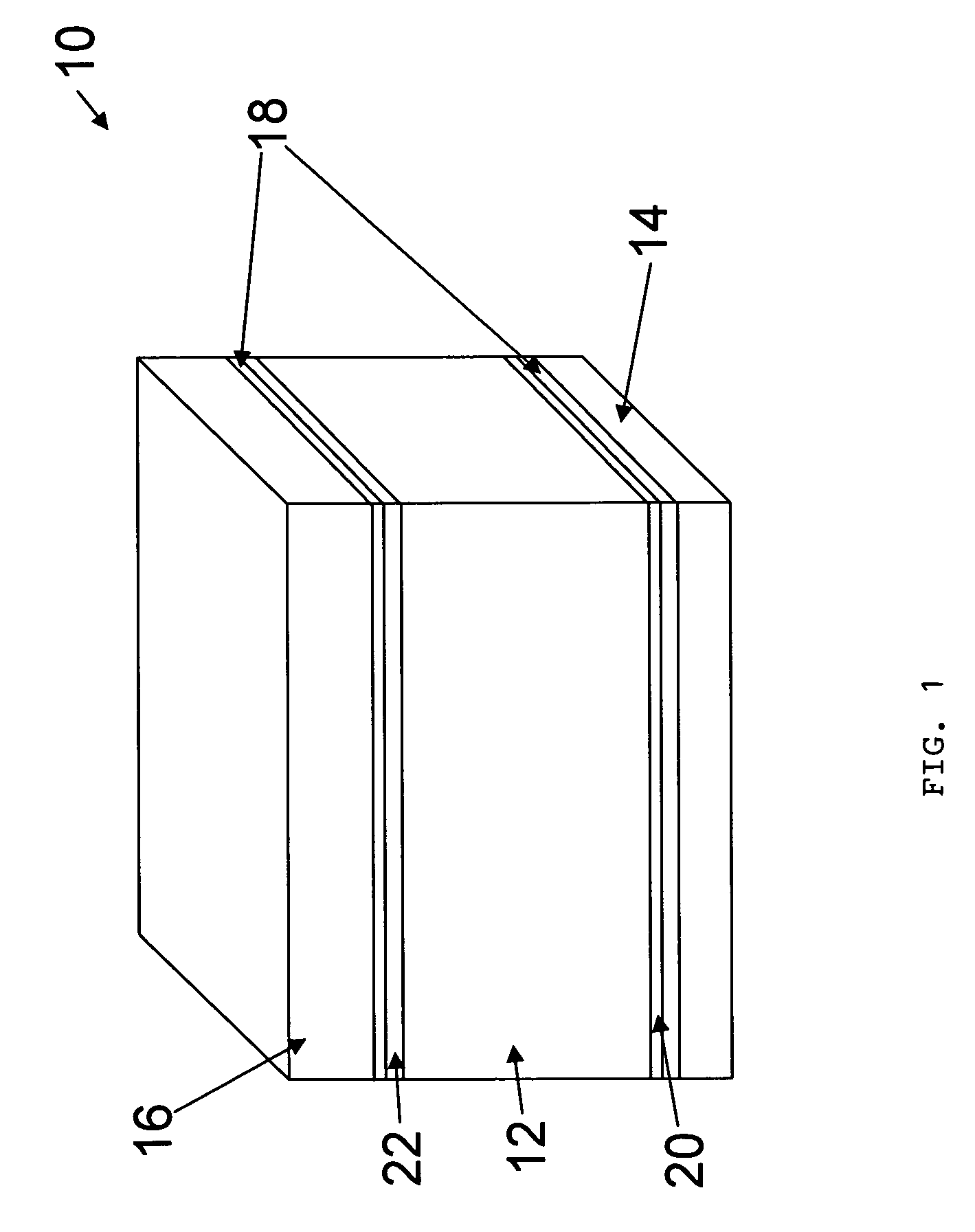

Carbon foam structural insulated panel

InactiveUS7785712B2High strengthEasy to processLayered productsThin material handlingVolumetric Mass DensityCompressive strength

A structural insulated panel, which includes a carbon foam core having a high ratio of compressive strength to density, desirable fire retardant properties, and resistance to environmental stress. The carbon foam structural insulated panel also includes a first layer and a second layer bound to a first surface and second surface of the carbon foam core. Applications of the carbon foam structural insulated panel include structural and fire retardant elements of residential and commercial buildings, aircraft and also watercraft.

Owner:GRAFTECH INT HLDG INC

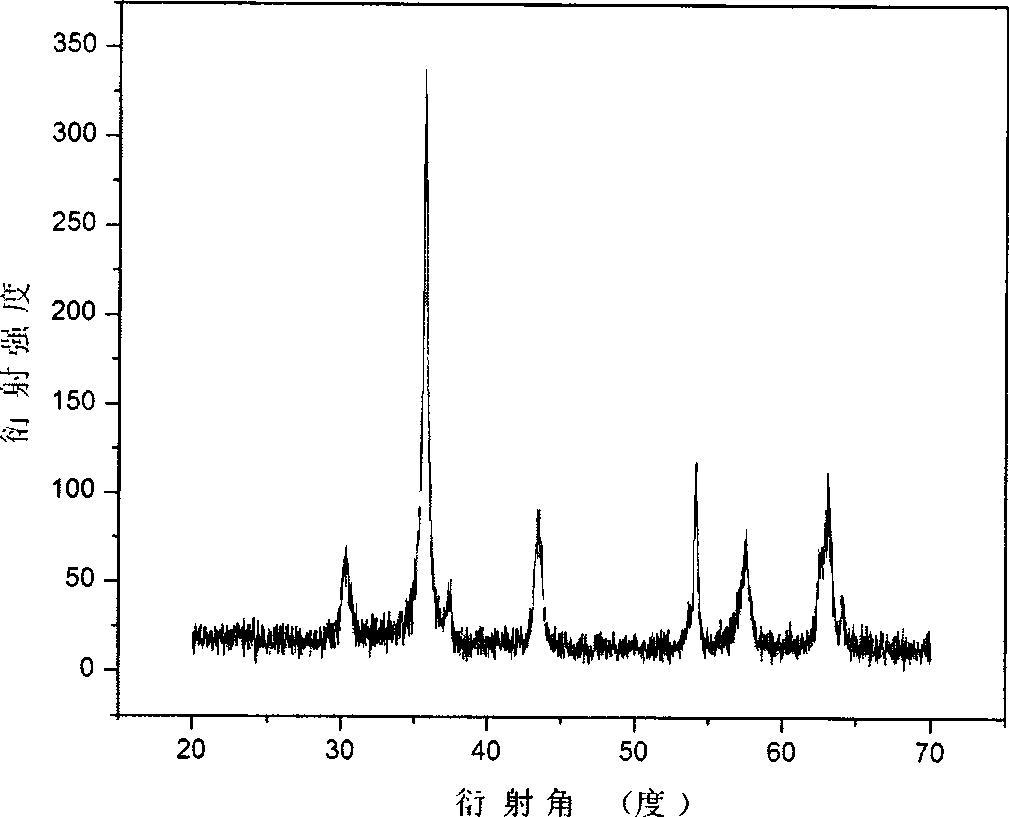

Preparation method of nanometer zirconia heat barrier coating

InactiveCN101660115AImprove applicabilityGood dispersionMolten spray coatingEfficient propulsion technologiesRare earthShock resistance

The invention relates to a preparation method of a nanometer zirconia heat barrier coating which is mixed with rare-earth oxide and used for liquid-phase plasma spraying. The method comprises that precursor sol is used as a spraying raw material, atomized into fine liquid drops under atomized gas pressure, sent into plasma flame flow and sprayed and deposited on a matrix to obtain the nanometer zirconia heat barrier coating. The precursor sol is hydroxid precursor sol. According to weight proportion, the raw material includes 63 to 73 percent of ZrOCl2.8H2O and 27 to 37 percent of crystalline-state stabilizer oxide which is rare earth oxide. The invention can overcome the problems of poor sol distribution, poor sol flowing performance, chlorid ion erosion, poor sol granule atomizing effect, uneven granule sizes, and the like in the the traditional liquid-phase plasma spraying process. In the invention, a composite coating is prepared, and has the advantages of high depositing efficiency, low cost, wide spraying material, strong adaptability of the liquid-phase precursor, low heat conductivity, good heat and shock resistance, and the like.

Owner:WUHAN UNIV OF TECH

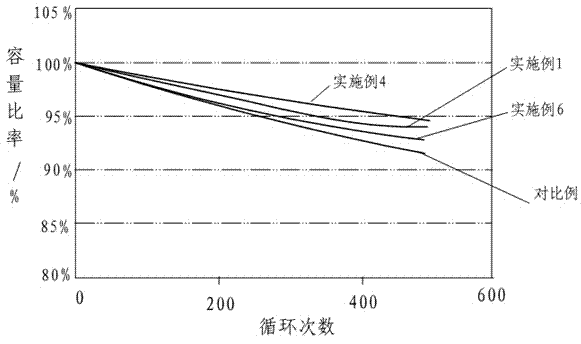

Composite lithium ion battery diaphragm and preparation method thereof

ActiveCN104269505AImprove uniformityGood dispersionCell component detailsPolymer adhesivePore distribution

The invention relates to a composite lithium ion battery diaphragm and a preparation method thereof. The composite lithium ion battery diaphragm comprises a base film and a coating (s) coated on the single side or the two sides of the base film; the coating is obtained by coating and drying slurry, the slurry contains 20-60 percent of a base material by weight percentage, and the balance is deionized water; the base material comprises the following substances in parts by weight: 0.2-4 parts of thickening agent, 0.2-3 parts of inorganic nanometer dispersing agent, 1-5 parts of polymer adhesive and 88-98 parts of nano alumina and nano barium sulfate, wherein the mass ratio of the nano alumina to the nano barium sulfate is 1: (1-10). The composite lithium ion battery diaphragm provided by the invention has the benefits that the coating uniformity is good, the bonding strength is high and the process is good; the abrasion of mechanical equipment can be reduced on the basis of ensuring uniform pore distribution, excellent air permeability and good foreign body puncture resistance, and continuous and stable mass production is facilitated.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

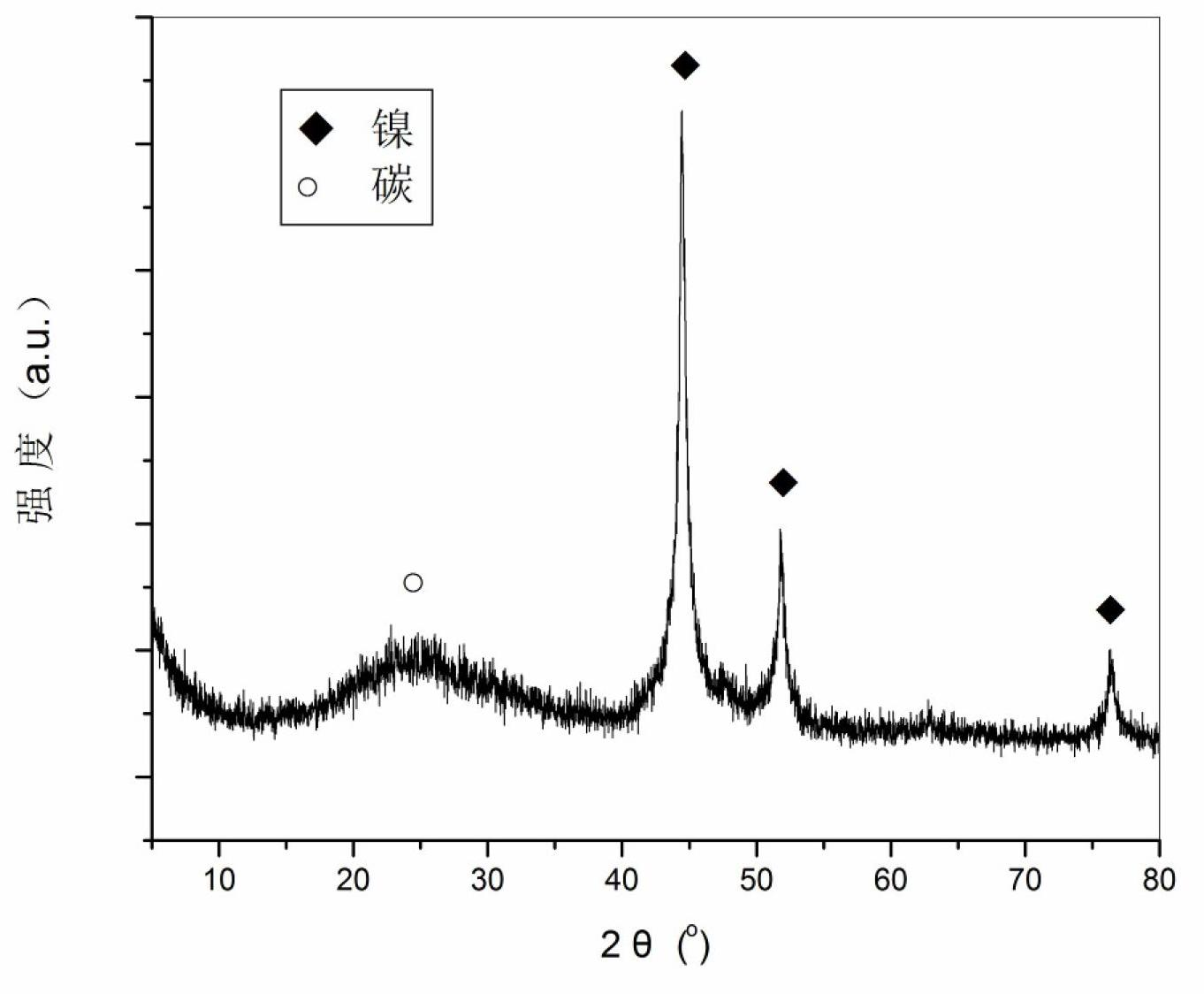

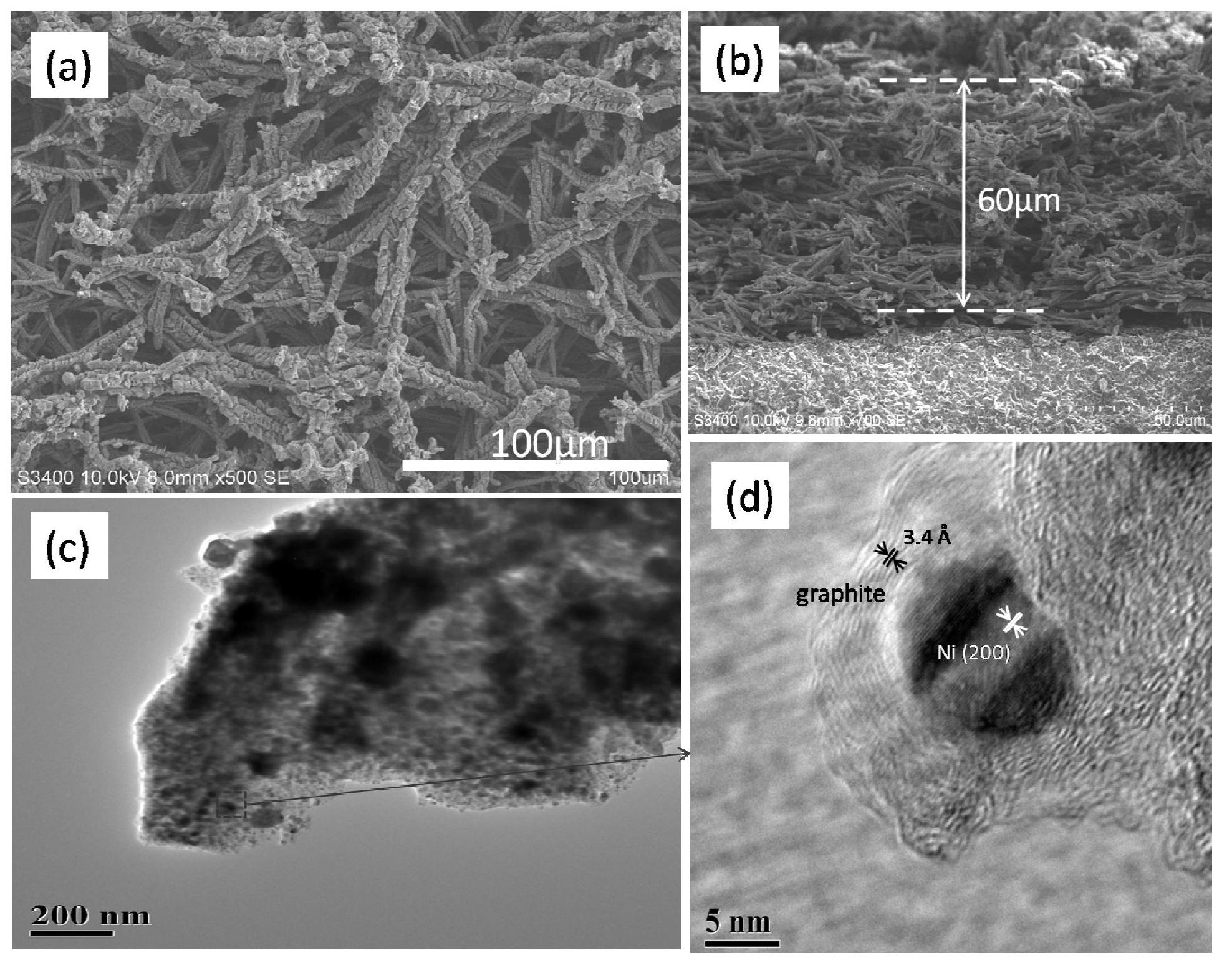

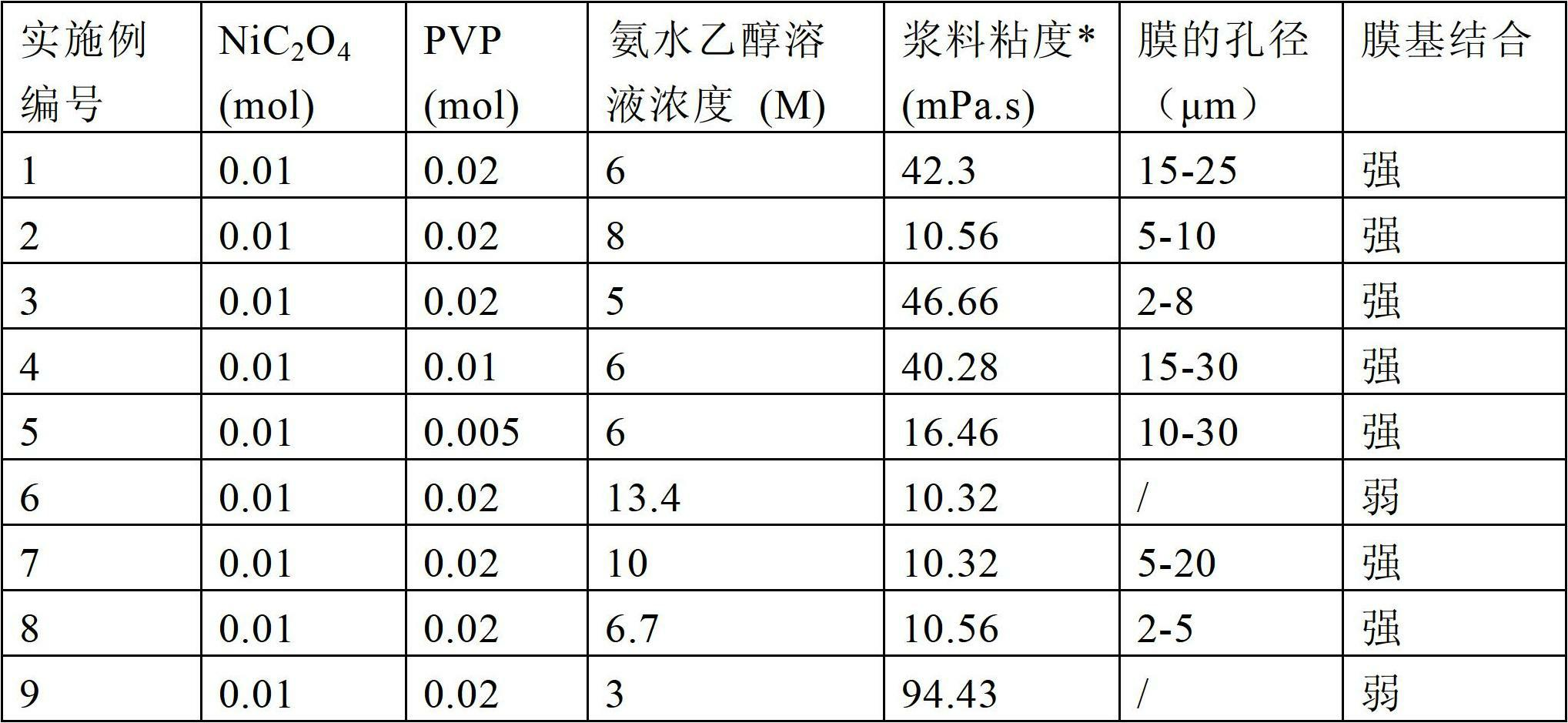

Metal/carbon nano composite porous membrane and preparation method thereof

ActiveCN102677031AEvenly dispersedUniform thicknessMaterial nanotechnologySolid/suspension decomposition chemical coatingPorous membraneSolid substrate

The invention relates to a metal / carbon nano composite porous membrane and a preparation method thereof. The method comprises the following steps: a) adding a metal salt and a polymer, which can be pyrolyzed into carbon in an inert atmosphere, into an ammonia water solution, continuously stirring to obtain a uniform sol, and continuing stirring the uniform sol until the sol is pregelated into a pulp; b) applying the pulp obtained in the step a) onto the surface of a solid substrate, and drying to obtain a coating; and c) carrying out heat treatment on the coating obtained in the step b), thereby obtaining the metal / carbon nano composite porous membrane on the surface of the solid substrate.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

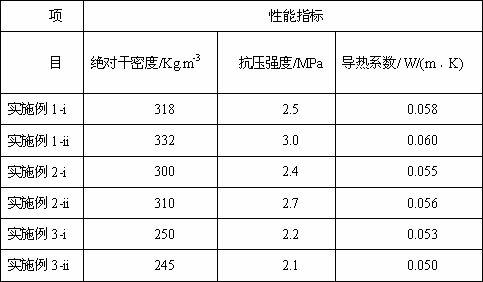

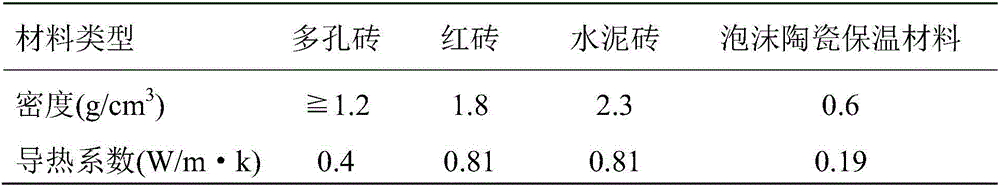

Low-thermal-conductivity aerated concrete and preparation method thereof

ActiveCN102167619ASolve insulation problemsSolve coordination problemsSolid waste managementCeramicwareFoaming agentThermal bridge

The invention discloses low-thermal-conductivity aerated concrete and a preparation method thereof, which belong to the technical field of material science and engineering science and are used for solving the key technical problem of enhancement of extra light aerated concrete. The preparation method comprises the following steps of: stirring a compound foaming agent component and a silicate substrate sizing agent according to a certain weight part ratio; molding; standing; performing autoclave curing; and cutting to obtain a hardened hydrated silicate substrate, wherein the rubber hole ratioof the obtained hardened hydrated silicate substrate is more than 0.95, the porosity is less than 3 percent, the volume ratio of a calcium hydrosilicate crystal to colloid is 1-2.5, self-heat-preserving performance and appropriate intensity of a product are realized, and when the thermal conductivity coefficient is less than 0.06 W / (m.K) and the absolute dry volume density is less than 250 kg / m<3>, the compressive strength of the aerated concrete is still higher than 2Mpa. The low-thermal-conductivity aerated concrete can be applied to self-heat-preserving wall bodies with the energy saving rates of more than 70 percent, fire-proof isolation belts for outer heat-preserving systems of polystyrene plate thin plastered outer walls, treatment of wall body heat bridge positions, shear wall heat-preserving systems and roof heat preserving.

Owner:HOHAI UNIV

Ceramic material of porous spinel, and preparation method

InactiveCN1915903ASmall average pore sizeHigh purityCeramic shaping apparatusCeramicwarePericlasePore distribution

This invention relates to a method for preparing porous spinel ceramic material. The method comprises: (1) mixing magnesite powder 10-90 wt.%, Al(OH)3 powder 10-90 wt.%, water 2-10 wt.% and adhesive 0-3 wt.%; (2) molding; (3) drying the green bodies at 110 deg.C for 4-24 h; (4) sintering at 1600-1800 deg.C, and keeping the temperature for 1-8 h. The porous spinel ceramic material mainly contains MgO and Al2O3, and has main crystal phase of periclase-spinel, spinel or spinel-corundum. The porous spinel ceramic material can be directly contacted with flame retardant magmesium and spinel materials, and is a lightweight heat-insulating flame retardant with uniform pore distribution and high strength.

Owner:WUHAN UNIV OF SCI & TECH

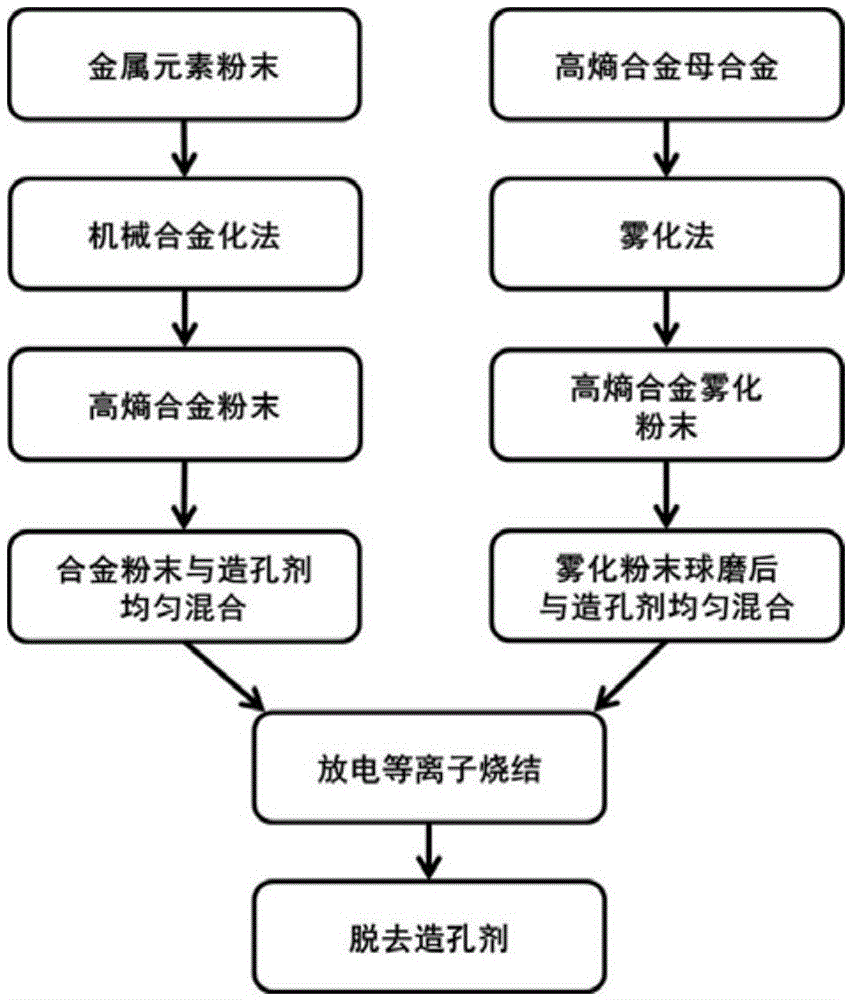

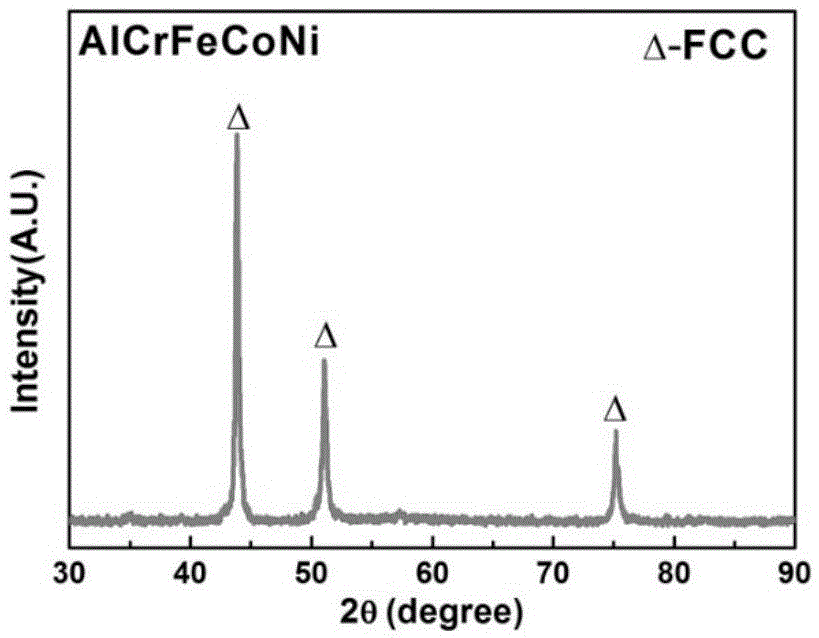

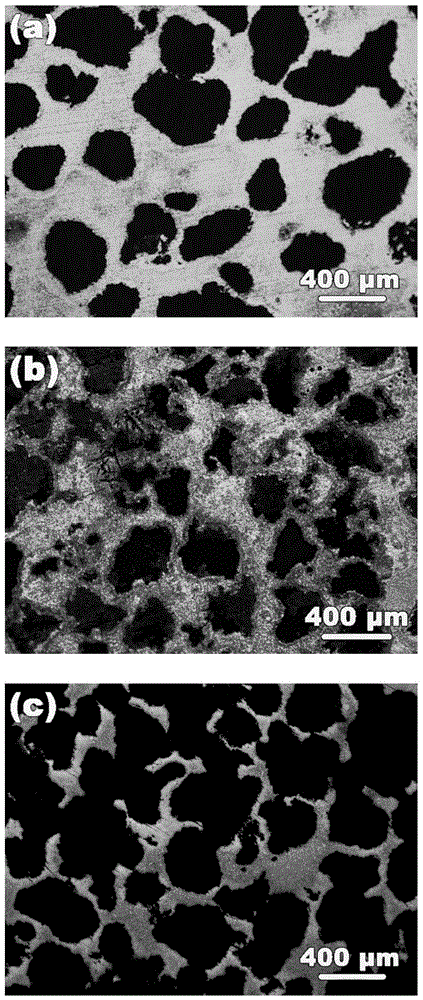

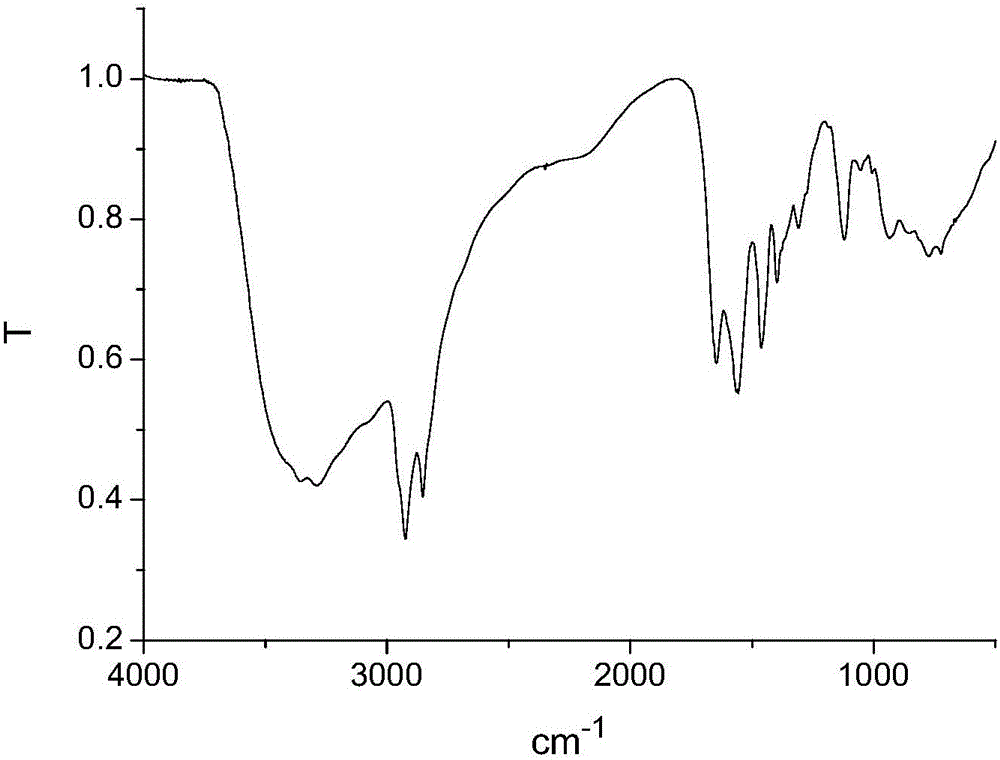

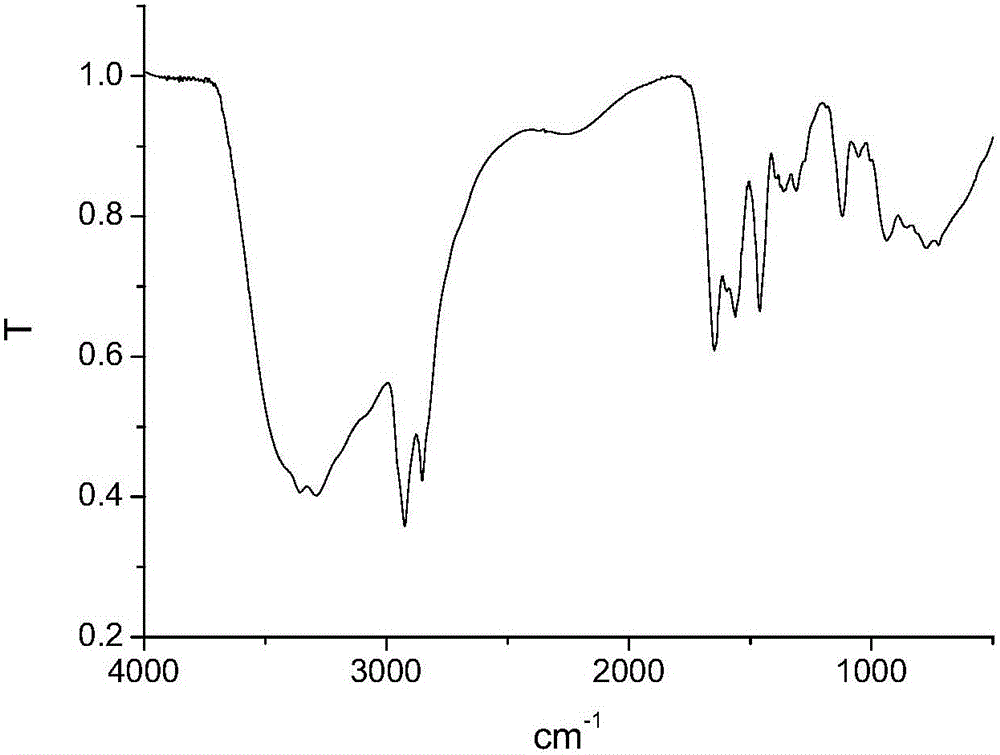

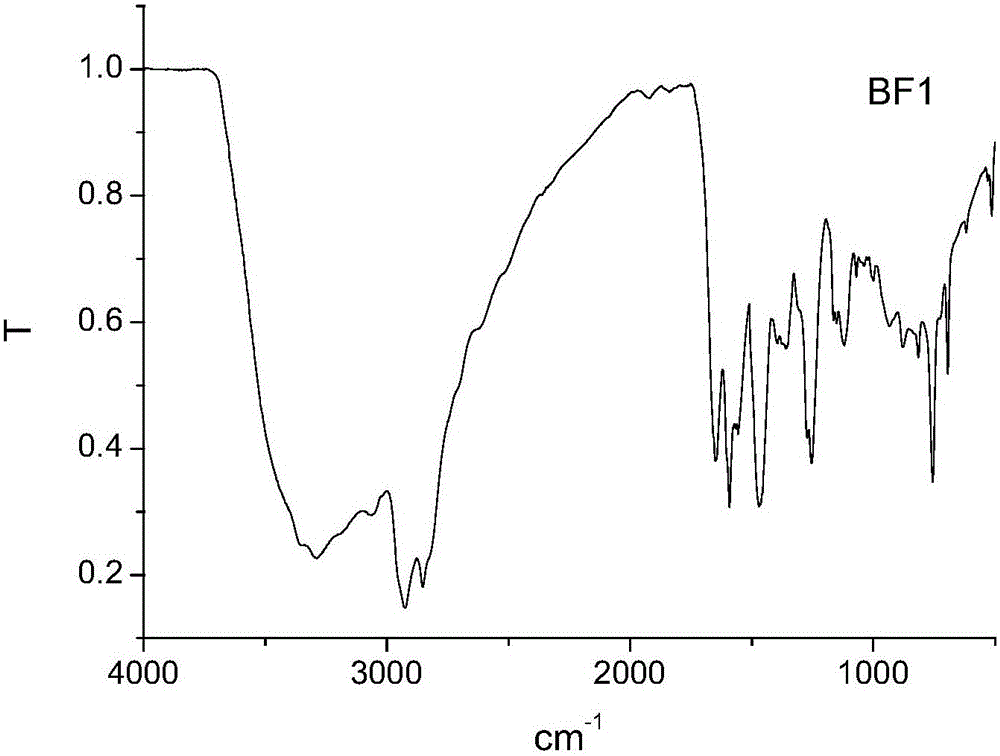

Porous high-entropy alloy and preparation method thereof

The invention discloses porous high-entropy alloy and a preparation method thereof and belongs to the field of porous foam metal. The preparation method of the porous high-entropy alloy specifically comprises the steps that high-entropy alloy powder and screened pore-forming agents are mixed proportionally according to the requirements for the porosity and the pore size, and the high-entropy alloy powder and the screened pore-forming agents are sintered through spark plasma sintering (SPS) directly after being uniformly mixed by a blender mixer; after sintering is completed, a sintered sample is put into deionized water to be subjected to ultrasonic cleaning, and particles of the pore-forming agents are removed by using the characteristic that the pore-forming agents are soluble in water; and finally the porous high-entropy alloy is obtained. The preparation method is simple in process, particularly, the preparation time is shortened greatly through the SPS method, and the efficiency is improved. The prepared porous high-entropy alloy has the characteristics of being high in porosity, uniform in pore size distribution, controllable in porosity and pore size and the like and has potential application prospects in the fields of biology, petroleum, metallurgy, chemical industry and the like.

Owner:UNIV OF SCI & TECH BEIJING

Environment-friendly permeable high-strength waterborne epoxy slurry and preparation method and application thereof

ActiveCN105885755APromote environmental protectionImprove permeabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesMass ratioPolyamide

The invention discloses environment-friendly permeable high-strength waterborne epoxy slurry and a preparation method and an application thereof. The method comprises the following steps: mixing 40-70wt% of liquid epoxy resin and 60-30wt% of glycidyl ether to obtain a 100wt% of a component A; mixing 10-50wt% of water-swellable self-emulsified polyamide-amine, 85-30wt% of hydrophobic modified aliphatic amine and 5-20wt% of aliphatic amine polyoxyethylene-polyoxypropylene to obtain a 100wt% of a component B; premixing the component A and the component B at the mass ratio of 100 to (60-90) to obtain environment-friendly permeable epoxy net slurry with low initial viscosity; and mixing the epoxy net slurry and a component C (including 50-100wt% of an inorganic filler, 0-50wt% of water and 0-1wt% of an assistant) at the mass ratio of 100 to (60-300), and curing to obtain a high-strength non-shrinkage epoxy-based composite material. The high-strength non-shrinkage epoxy-based composite material can be used for preparing a high-strength open-cell or closed-cell material, and has a wide application prospect in the field of grouting, a mold and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

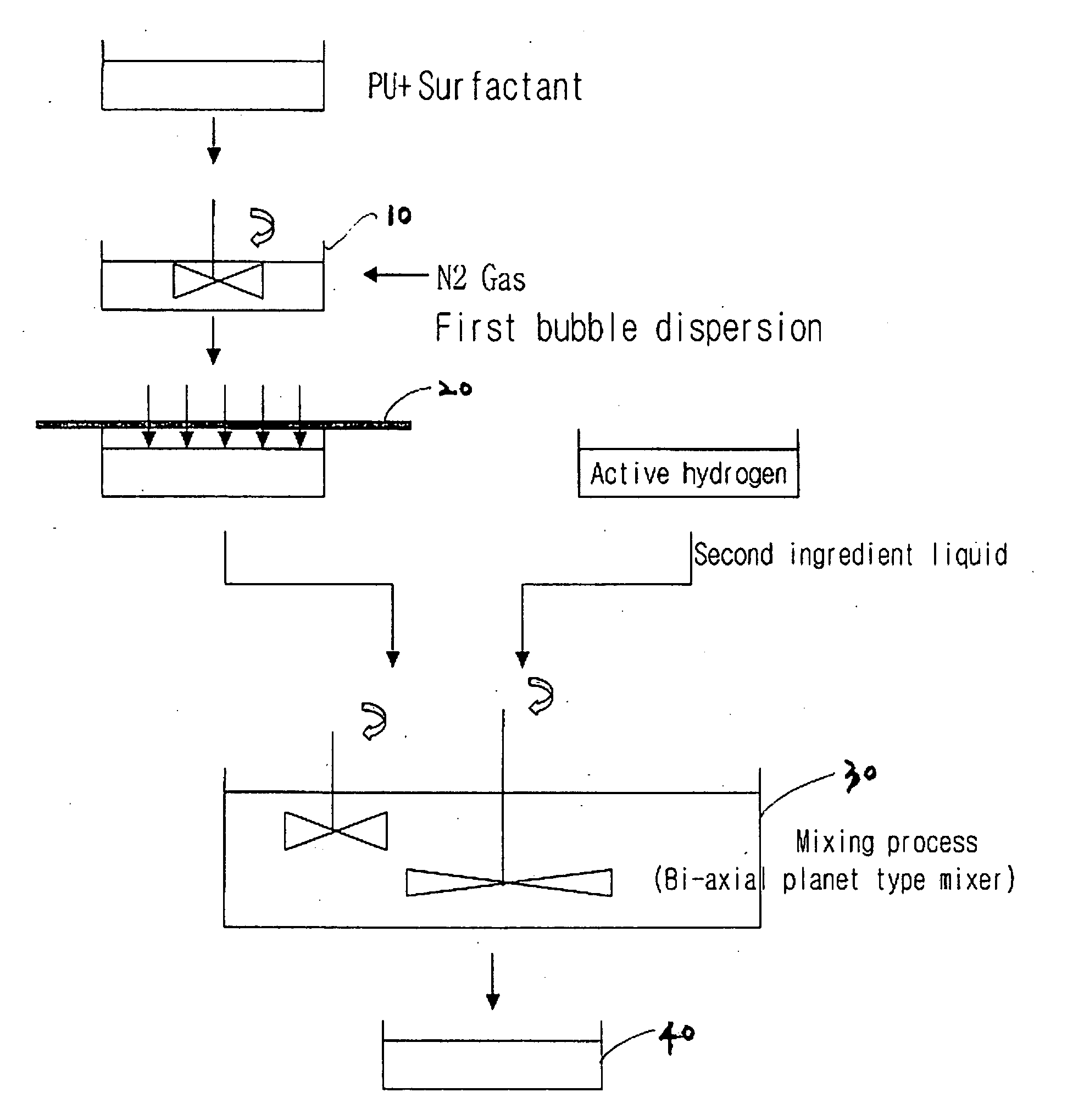

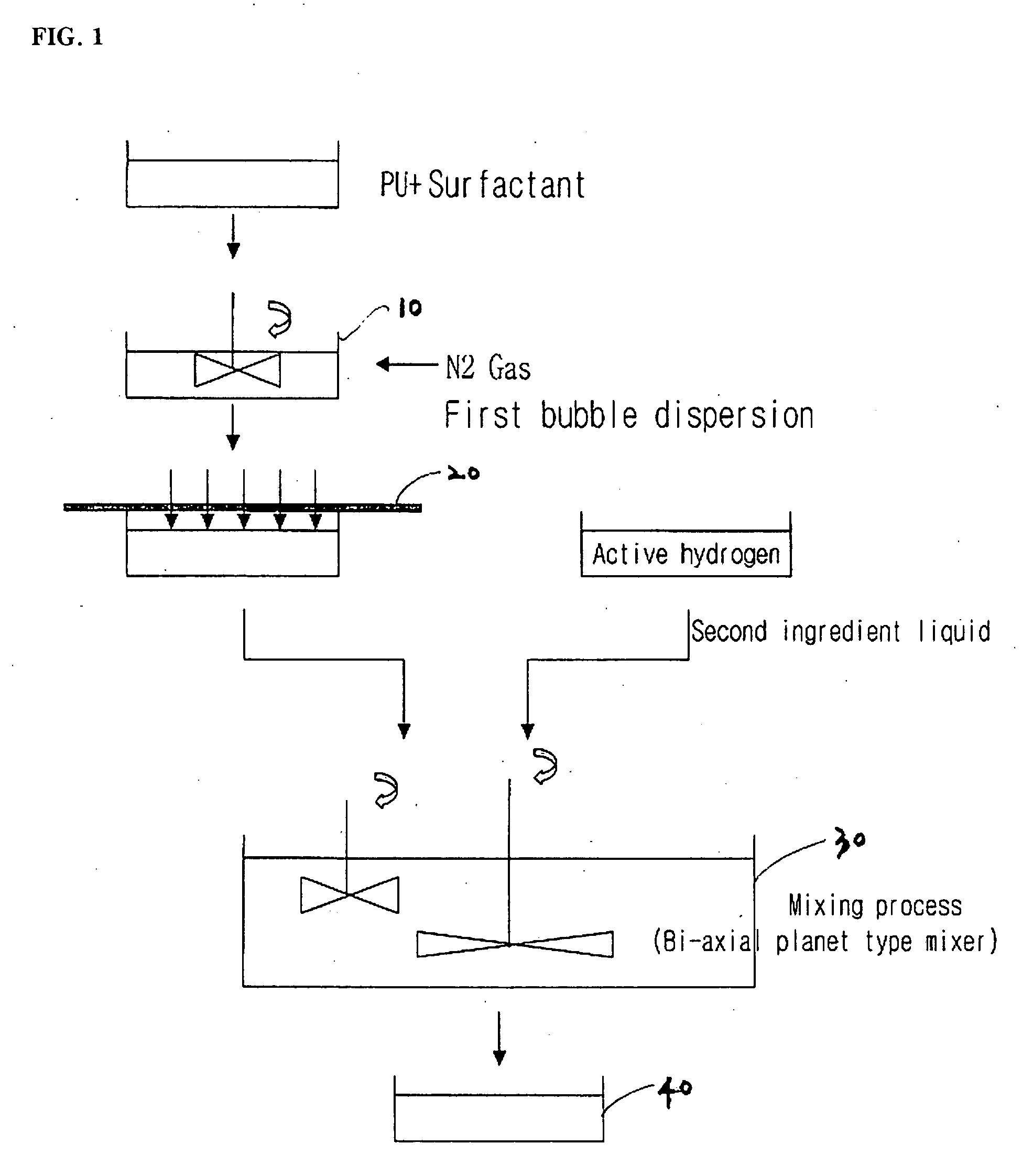

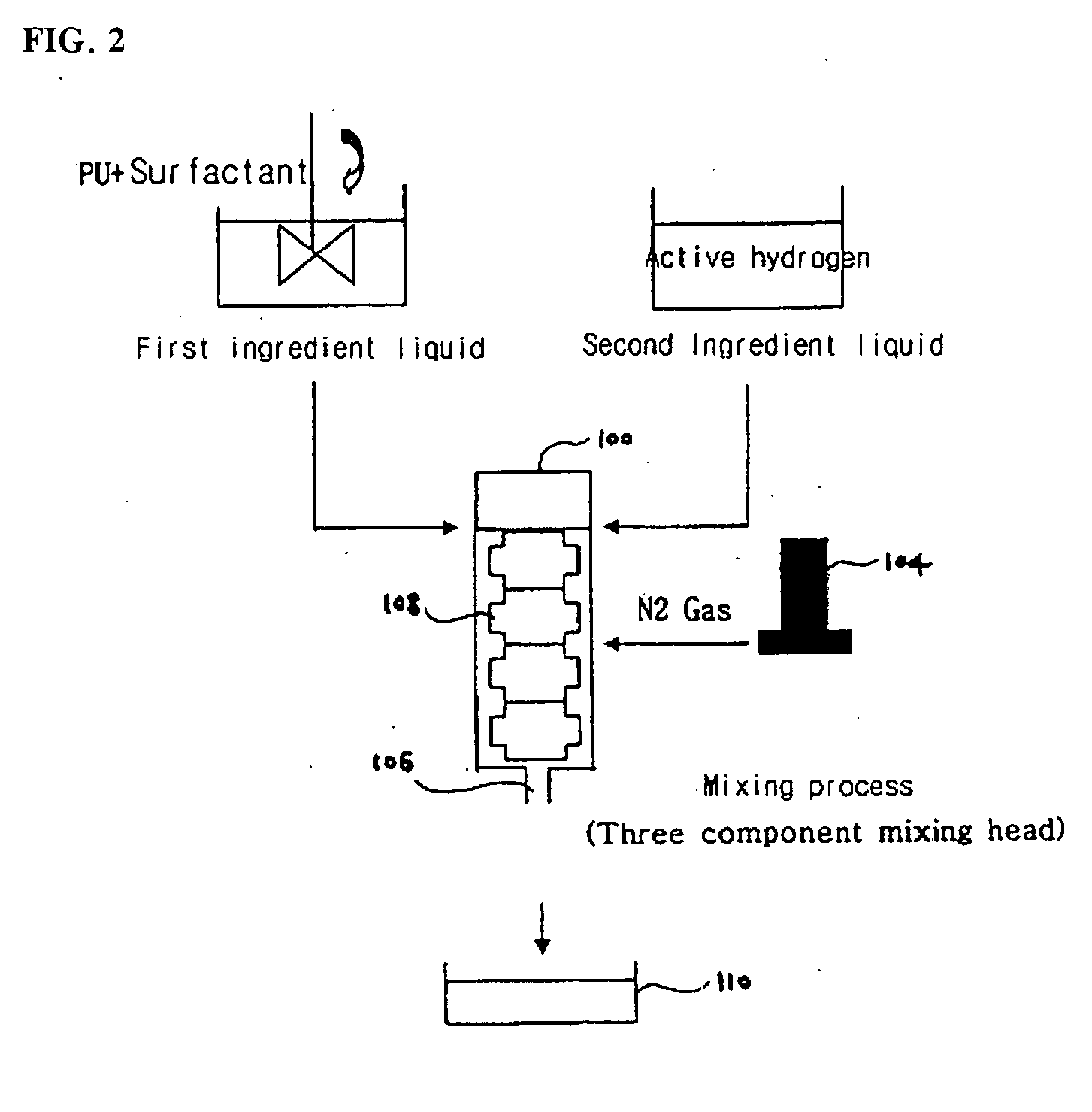

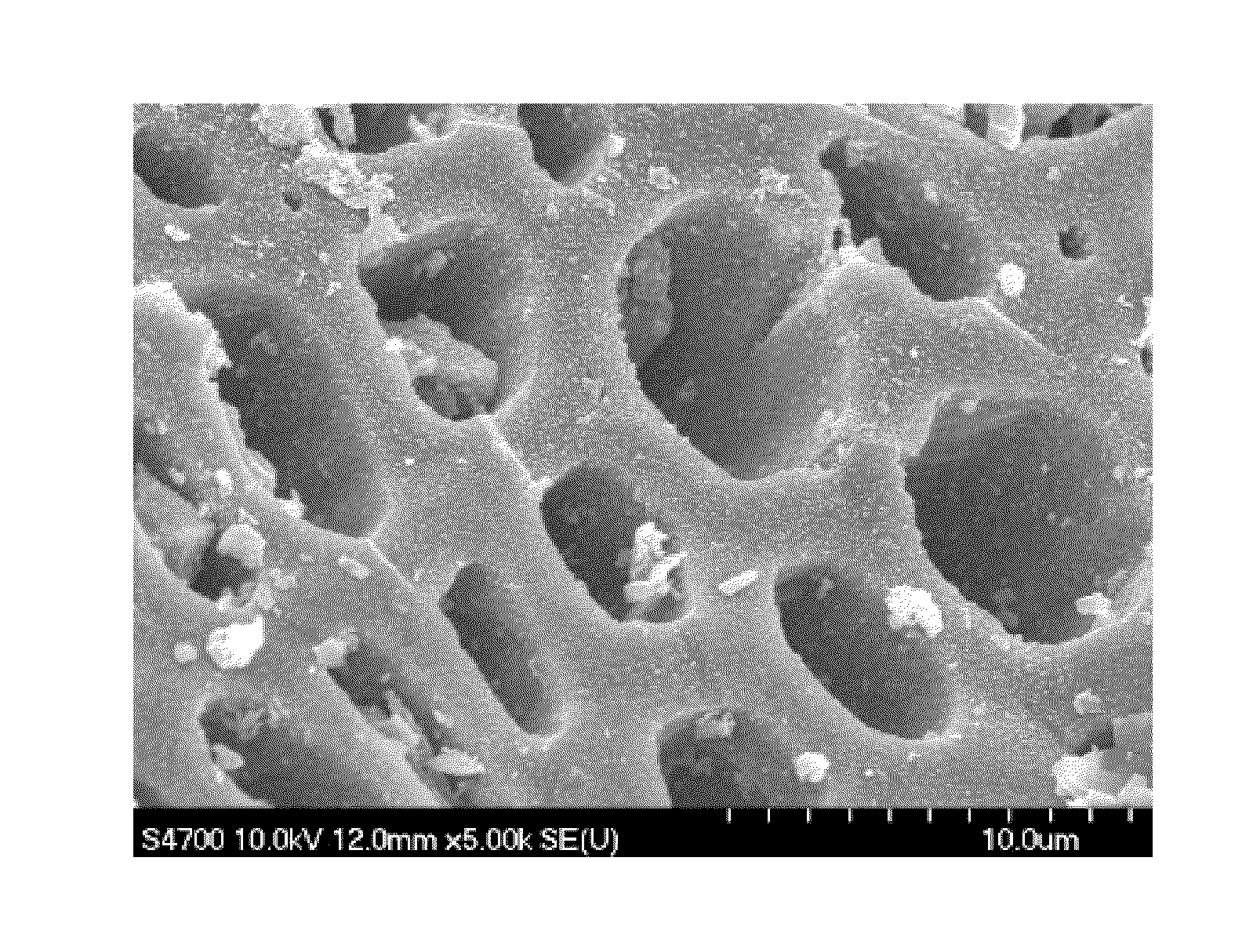

Method of fabricating polyurethane foam with micro pores and polishing pad therefrom

InactiveUS20060022368A1Good flexibilitySimplify the manufacturing processSemiconductor/solid-state device manufacturingFlexible-parts wheelsHydrogenAdditive ingredient

To provide a method of fabricating a polyurethane foam with micro pores, and a polishing pad therefrom, the method including steps of (a) adding a nonionic surfactant into at least one of a first ingredient including an isocyanate group-containing compound and a second ingredient including an active hydrogen group-containing compound, (b) agitating and mixing the mixture of the first ingredient and the second ingredient while adding a non-reactive gas thereto, (c) discharging the mixture out of a container at a predetermined rate, and (d) injecting the discharged mixture into a mold so as to form a mold body into a predetermined shape.

Owner:DONG SUNG A & T

Periclase-olivine light thermal-insulated fireproof materials and method for preparing same

The invention relates to Periclase-olivine light thermal-insulated fireproof materials and method for preparation, which comprises mixing 20-80% magnesite powder, 0-50 wt% of magnesium oxide powder, 10-30% of silicon oxide powder, 0-15% of combustible powder, 0-3% of anchoring agent, and 4-10% of water, mixing homogeneously, press forming, drying the formed blank 4-24 hours at 110 deg. C, then burning at 1300-1500 deg. C, thermally insulating 1-8 hours.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing porose glass composite material using iron ore tailings

The invention is a method for preparing multiporous glass composite with ironstone gangue, adopting two steps: 1. adopting iron gangue, bauxite, calcium carbonate and waste glass as raw materials to prepare basic glass powder, crushing and finely grinding the iron gangue, and batching the iron gangue 48-65wt%, bauxite 5-9wt%, calcium carbonate 10-20wt%, and waste glass 15-30wt%; mixing them uniformly, melting and baking, water- quenching and grinding and finally obtaining the glass powder; 2. preparing multiporous glass ceramic materials, and adding in calcium carbonate in 1-5wt% of the basic glass, sodium phosphate in 6-10wt% of the basic glass, anhydrous sodium carbonate in 1-3wt% of the basic glass and borax in 1-6wt% of the basic glass, grinding and mixing them, and moulding and obtaining raw blanks, sintering the raw blanks at high temperature and cooling to normal temperature and finally obtaining the products. And the products have bulk densities of 1.5-2.8 g / cm3, normal- temperature tensile strength of 32-60 MPa and are good heat- insulating materials.

Owner:NORTHEASTERN UNIV

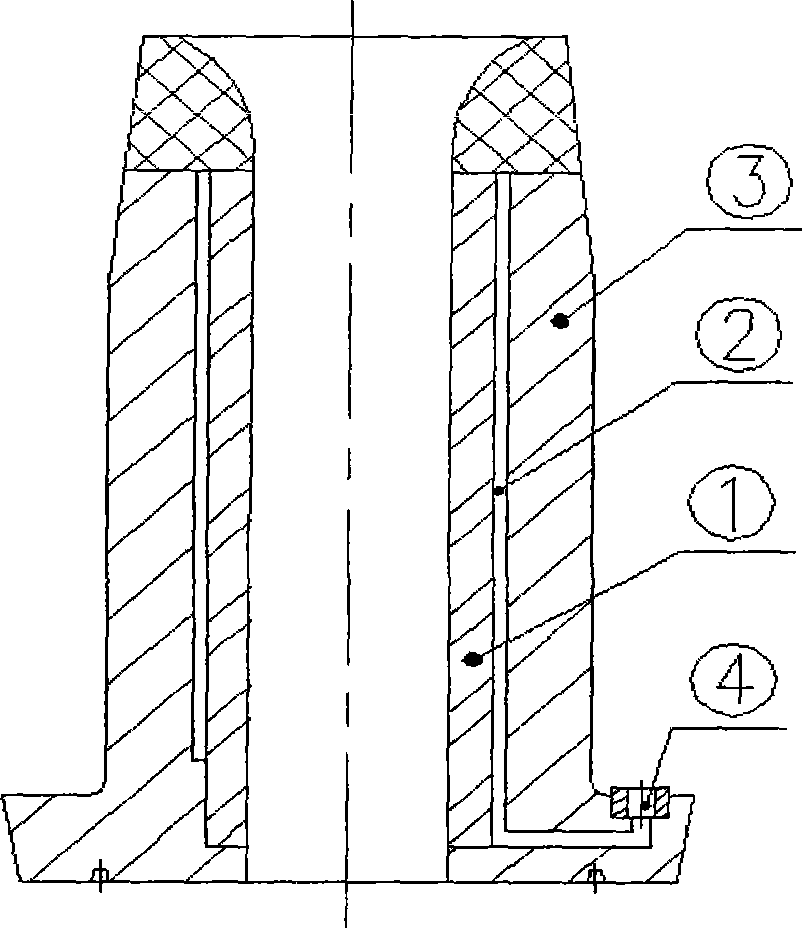

Spinelle ventilated tundish filling pipe end and method for producing the same

The invention relates to a novel spinel permeable and anti-clogging tundish upper nozzle and a production method thereof. An inner wall of the spinel permeable tundish upper nozzle is made of permeable spinel, an outer wall is made of a common alumina-carbon material, and a gas passage is provided between the inner wall and the outer wall and is communicated with a gas inlet hole at an upper surface of a base. A burning schedule is controlled to cause air porosity of a spinel liner formed at high pressure to meet argon blowing requirements and to cause the spinel liner to be subject to secondary forming with outer wall materials and an argon passage to be reserved. The permeable and anti-clogging tundish upper nozzle made by the method can meet the argon blowing requirements, and the spinel liner has functions of blowing argon, anti-clogging and resisting.

Owner:马鞍山市益江高温陶瓷制造有限公司

Coating slurry for bonding lithium battery separator and pole piece and preparation method of coating slurry

InactiveCN105845872ATo achieve the purpose of making holesAvoid clogging of the diaphragm baseSecondary cellsCell component detailsCoated surfaceInorganic particle

The invention discloses coating slurry for bonding a lithium battery separator and a pole piece and a preparation method of the coating slurry. The coating slurry coats the lithium battery separator or the pole piece to bond the lithium battery separator and the pole piece, and then is dried; pores are formed in a coating; and the coating slurry is prepared from the following components in parts by weight: 1-10 parts of a pore-forming agent, 1-20 parts of inorganic particles and 3-10 parts of a binder. Uniform distribution of coating pores is achieved through gas release in the high-temperature drying process; and the phenomenon that the slurry blocks a base in the surface coating process of the coating can be effectively avoided, so that the problem that the properties of rate cycle performance and the like are affected due to large internal resistance when the gummed separator or other gummed pole piece is applied to a lithium-ion battery is solved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Preparation method of macroporous strong-alkaline anion exchange resin for removing nitrate in water

ActiveCN103524657AUniform distribution of poresGood physical and chemical propertiesWater/sewage treatment by ion-exchangeAnion exchangersPore distributionDichloromethane

The invention discloses a preparation method of styrene macroporous strong-alkaline anion exchange resin for removing nitrate in water. Styrene, divinyl benzene, benzoyl peroxide, liquid paraffin, polyvinyl alcohol, gelatin, methylene blue, dichloromethane, 1,4-bis(chloromethoxy)butane, anhydrous tin tetrachloride and triethylamine are used as main raw materials; the macroporous strong-alkaline anion exchange resin is prepared through suspension polymerization reaction, chloromethylation reaction and amination reaction. The preparation comprises the following steps: synthesis of styrene divinyl benzene cross-linked polymer by the suspension polymerization method, chloromethylation reaction of styrene divinyl benzene cross-linked polymer, and amination reaction of chloromethylated styrene divinyl benzene cross-linked polymer. The particle size of the prepared resin is 0.5-1.5mm; the resin has the advantages of uniform pore distribution, strong adsorbability against nitrate, high selectivity on nitrate and the like; the physicochemical properties of the resin are good. The resin can be applied to the nitrate removal treatment process of water, and has good development prospect and practical significance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

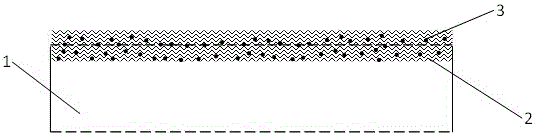

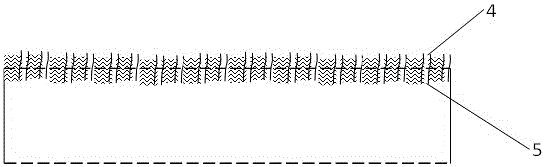

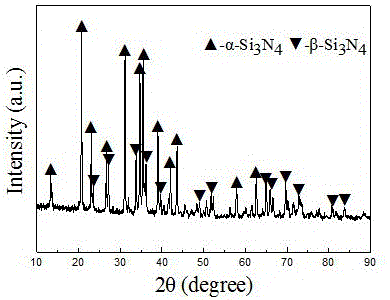

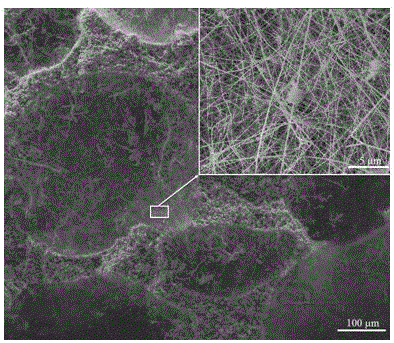

Nanowire self-reinforced porous silicon nitride ceramic and preparation method thereof

The invention relates to a nanowire self-reinforced porous silicon nitride ceramic and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: using 70-80 wt% of silicon powder, 5-10 wt% of catalyst and 10-20 wt% of nitrogen source as raw materials, adding deionized water which accounts for 20-30 wt% of the raw materials, and stirring to obtain a ceramic slurry; adding foam prepared by adding a foaming agent (accounting for 10-20 wt% of the raw materials) into the ceramic slurry, and continuously stirring for 30-60 minutes to obtain a ceramic foam slurry; pouring the ceramic foam slurry into a mold, standing in a nitrogen environment, drying, and demolding to obtain a ceramic body; in a nitrogen atmosphere, heating the ceramic body to 1100-1150 DEG C, and keeping the temperature; heating to 1200-1600 DEG C, and keeping the temperature; and naturally cooling to obtain the nanowire self-reinforced porous silicon nitride ceramic. The method has the advantages of simple technique, low cost, high utilization ratio of raw materials and controllable process. The prepared product has the advantages of uniform pore size, uniform pore size distribution and high mechanical strength.

Owner:WUHAN UNIV OF SCI & TECH

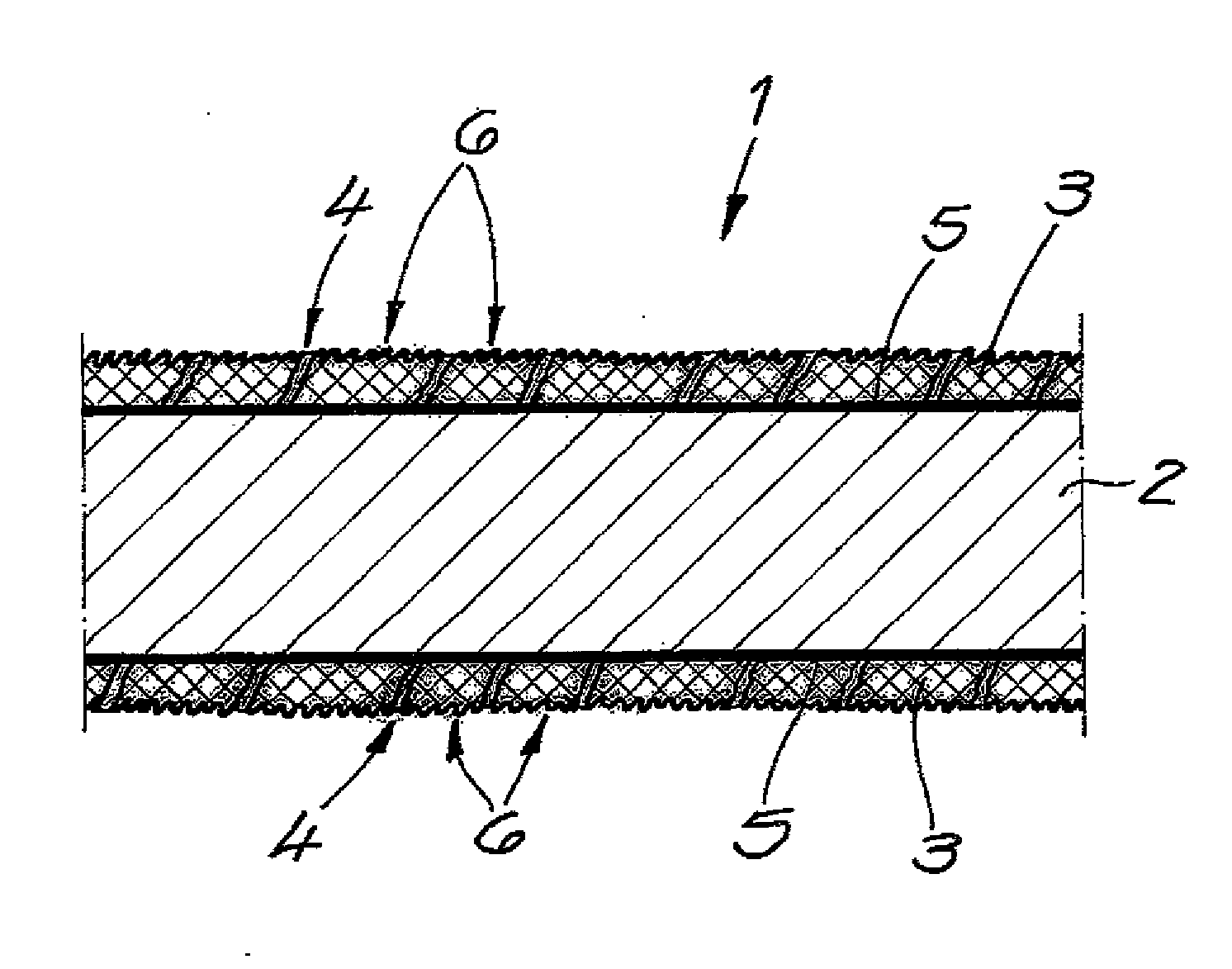

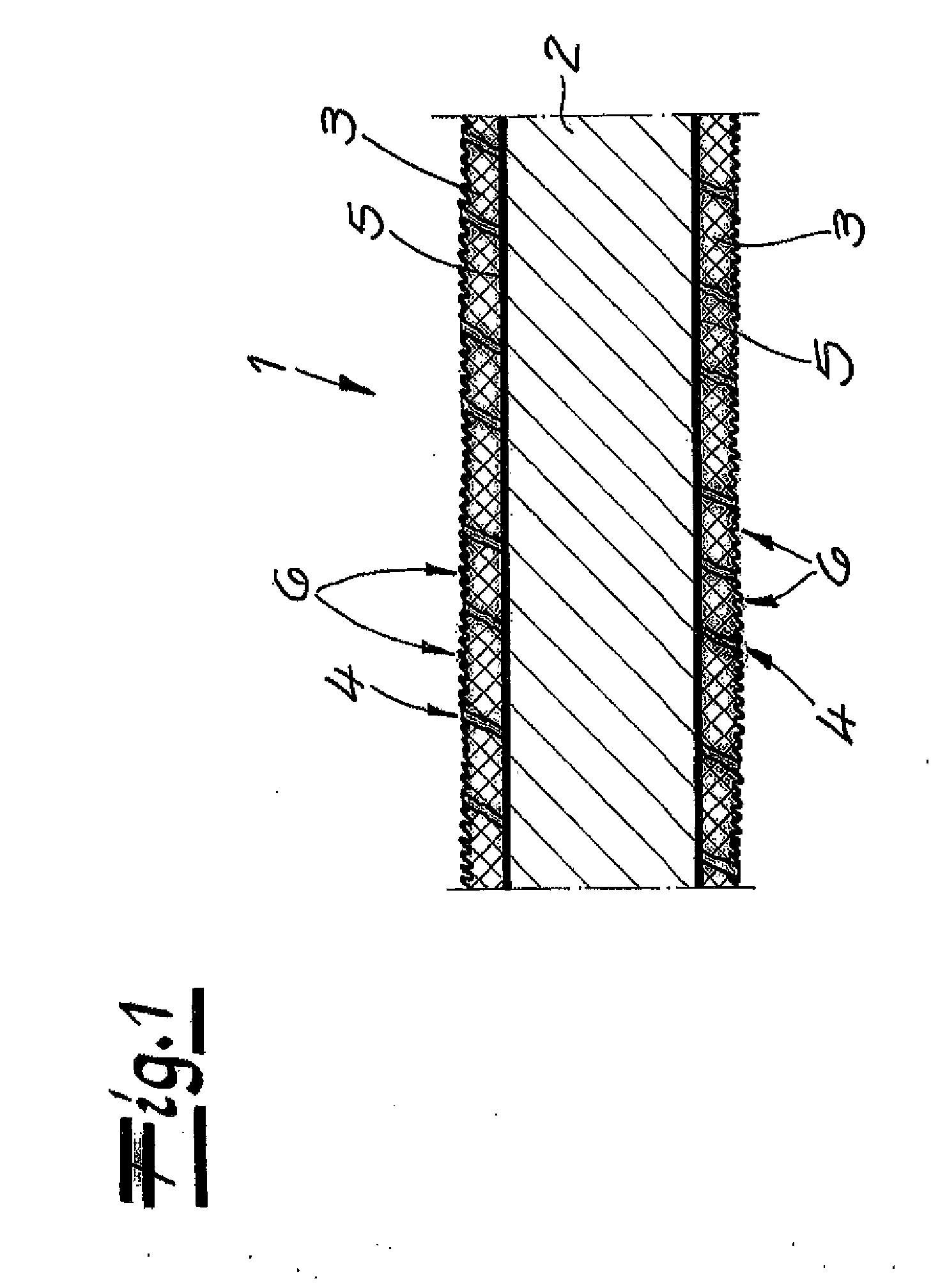

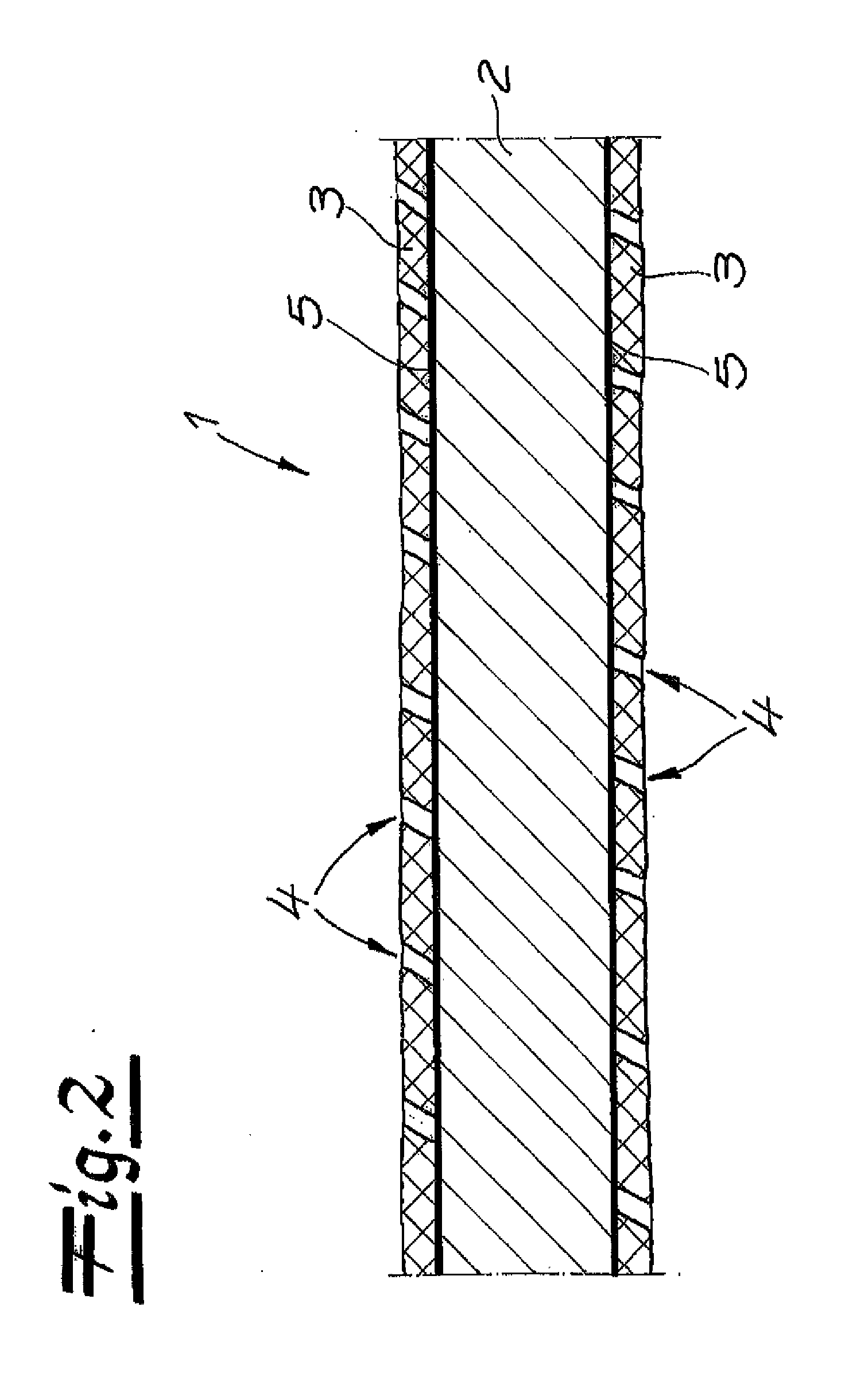

Elastomer laminate and method for its production

InactiveUS20120164383A1Increase elasticityImproved microtextureLamination ancillary operationsLaminationElastomerThermoplastic elastomer

An elastomer laminate has an elastomer carrier layer composed of a thermoplastic elastomer, and at least one microtextured cover layer composed of a polymer that has a lower elasticity than the material of the carrier layer. The microtexture is produced by stretching the laminate beyond the elasticity limit of the cover layer and elastic recovery of the stretched laminate. The microtextured cover layer contains a plurality of pores.

Owner:MONDI CONSUMER PACKAGING TECH

Porous mullite ceramic materials and method for preparing same

InactiveCN1884193AHigh porosityHigh strengthCeramic shaping apparatusCeramicwareChemical compositionMetallurgy

The invention discloses a porous mullite ceramic material and preparing method, which comprises the following steps: dispensing 10-50 percent coal gangue powder, 50-90 percent Al (OH) 3, 2-10 percent water and 0-10 percent addictive; stirring; moulding; drying the mould at 110 deg.c for 4-24 h; sintering at 1400-1600 deg.c for 1-8 h. The chemical component of product is SiO2 and Al2O3, wherein the main crystal phase is mullite or mullite-alumina, which can be high-strength and light-quality insulating flame-proof material.

Owner:WUHAN UNIV OF SCI & TECH

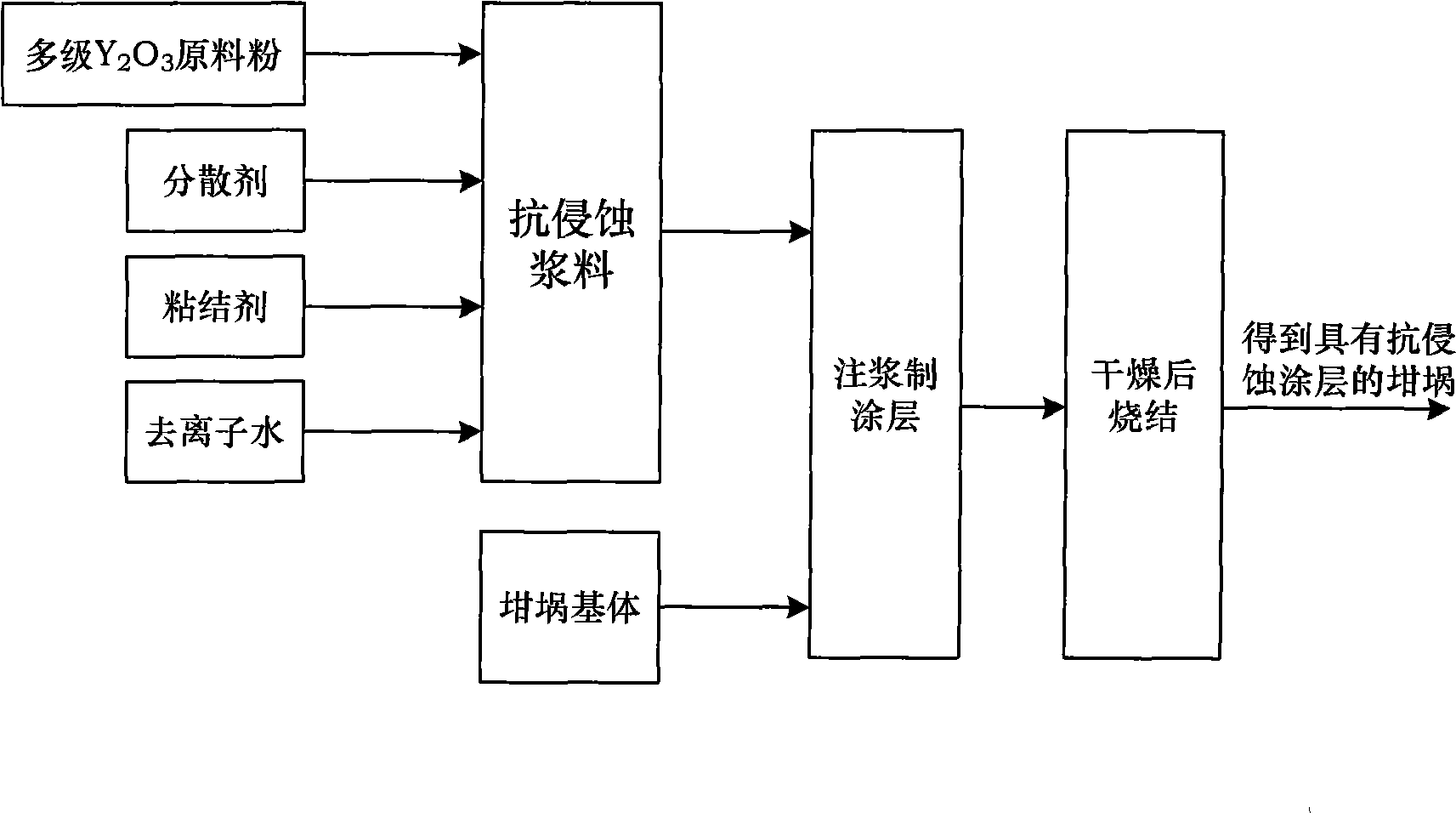

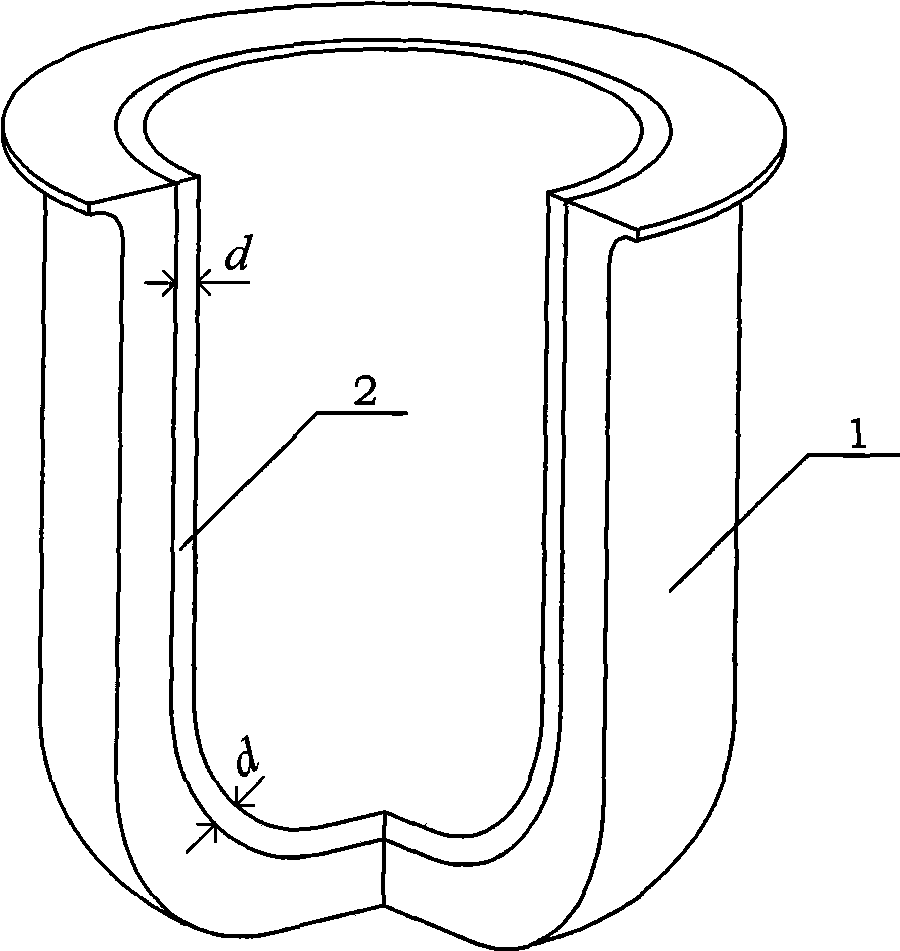

Crucible with Y2O3 anti-corrosion coating and method for producing Y2O3 anti-corrosion coating by slip-casting shaping process

The invention discloses a copple with an Y2O3 erosion-resistant coating and a method for preparing the Y2O3 erosion-resistant coating with a slip casting moulding process. The copple with the Y2O3 erosion-resistant coating is formed by preparing an Y2O3 erosion-resistant sizing agent on the inner wall of the copple base with the slip casting moulding process, forming the Y2O3 erosion-resistant coating with depth from 0.5 mm to 8 mm. The Y2O3 erosion-resistant sizing agent is obtained by evenly mixing multilevel Y2O3 raw material powder, dispersant, adhesive and deionized water. The copple with the Y2O3 erosion-resistant coating has melting temperature from 1600 DEG C to 2000 DEG C, thereby being capable of meeting melting of high-activity metal alloy such as Ti alloy, Nb alloy, rare earth alloy and alloy with high-activity elements of Ti, Al, Nb, Hf, rare earth, and the like.

Owner:BEIHANG UNIV

Preparation method for composite crosslinked adsorbent for waste water treatment

ActiveCN101934223AIncrease elasticityHigh wear resistanceOther chemical processesWater/sewage treatment by sorptionSorbentBoric acid

The invention discloses a preparation method for a composite crosslinked absorbent for waste water treatment, which comprises: firstly, preparing solution of biological macromolecular material; secondly, heating to dissolve polyvinyl alcohol (PVA), and uniformly mixing the solution of PVA, the solution of biological macromolecular material and mineral powder; thirdly, adding the mixed solution into solution of boric acid to perform immobilized crosslinking, and after crosslinking is finished, washing and drying an immobilized material to obtain the composite crosslinked adsorbent. The method has the advantages of simple and quick process, low cost, economy, applicability and the like. The crosslinked absorbent contains rich active groups and porous structures and has high stability, good absorbing effect and wide application range. The crosslinked absorbent can be widely used for treating waste water.

Owner:DALIAN DAYU WATER TREATMENT TECH

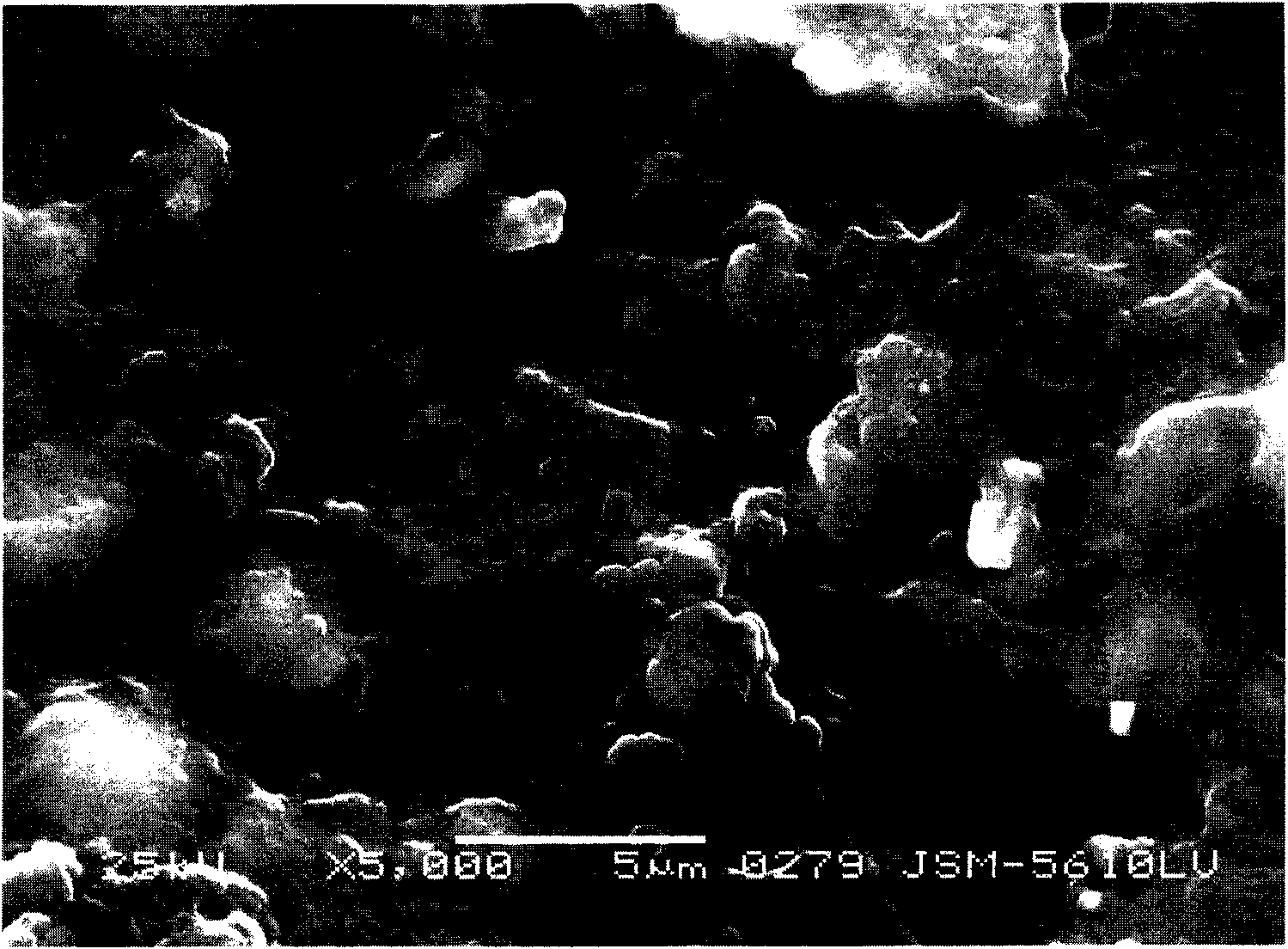

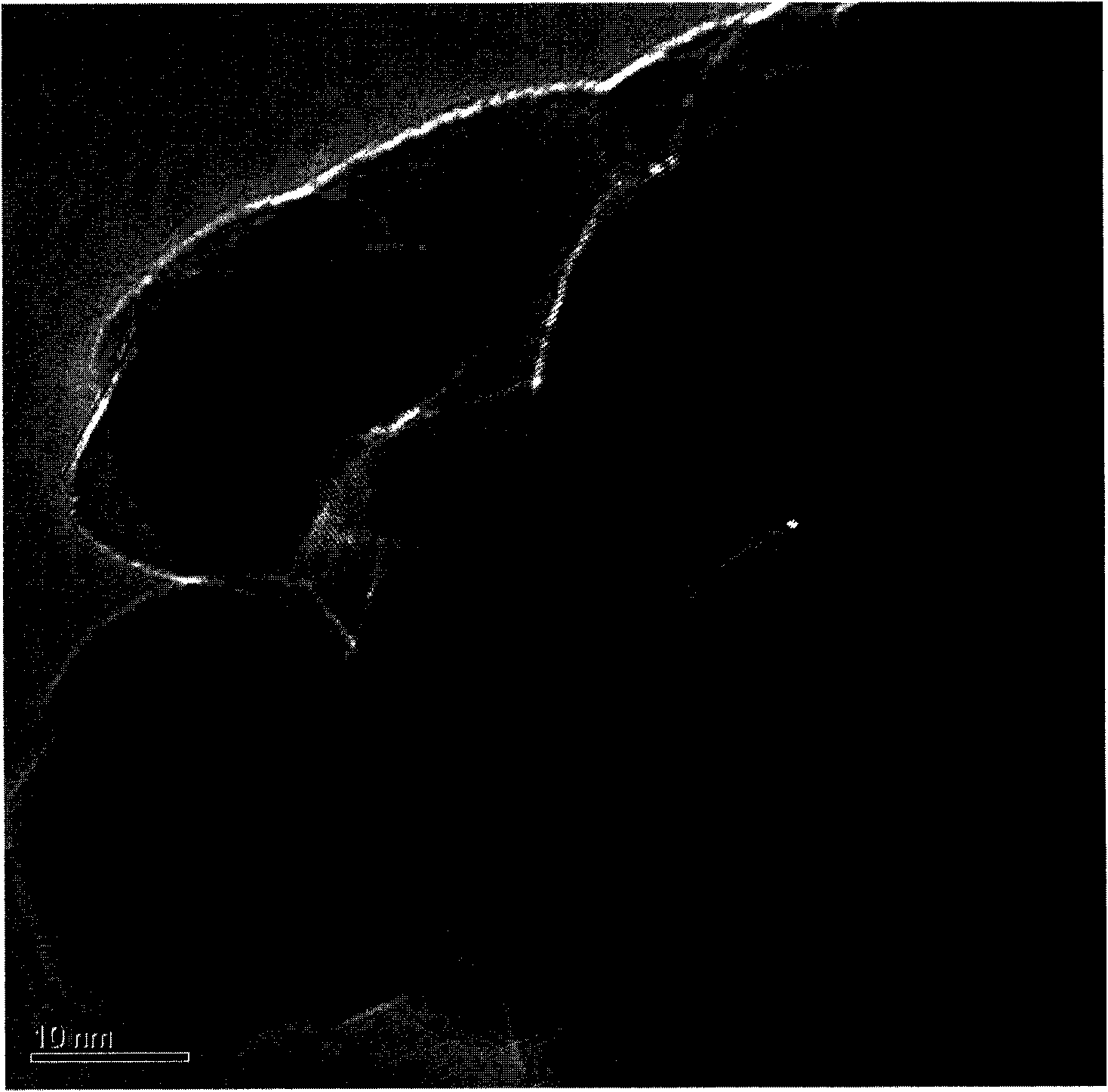

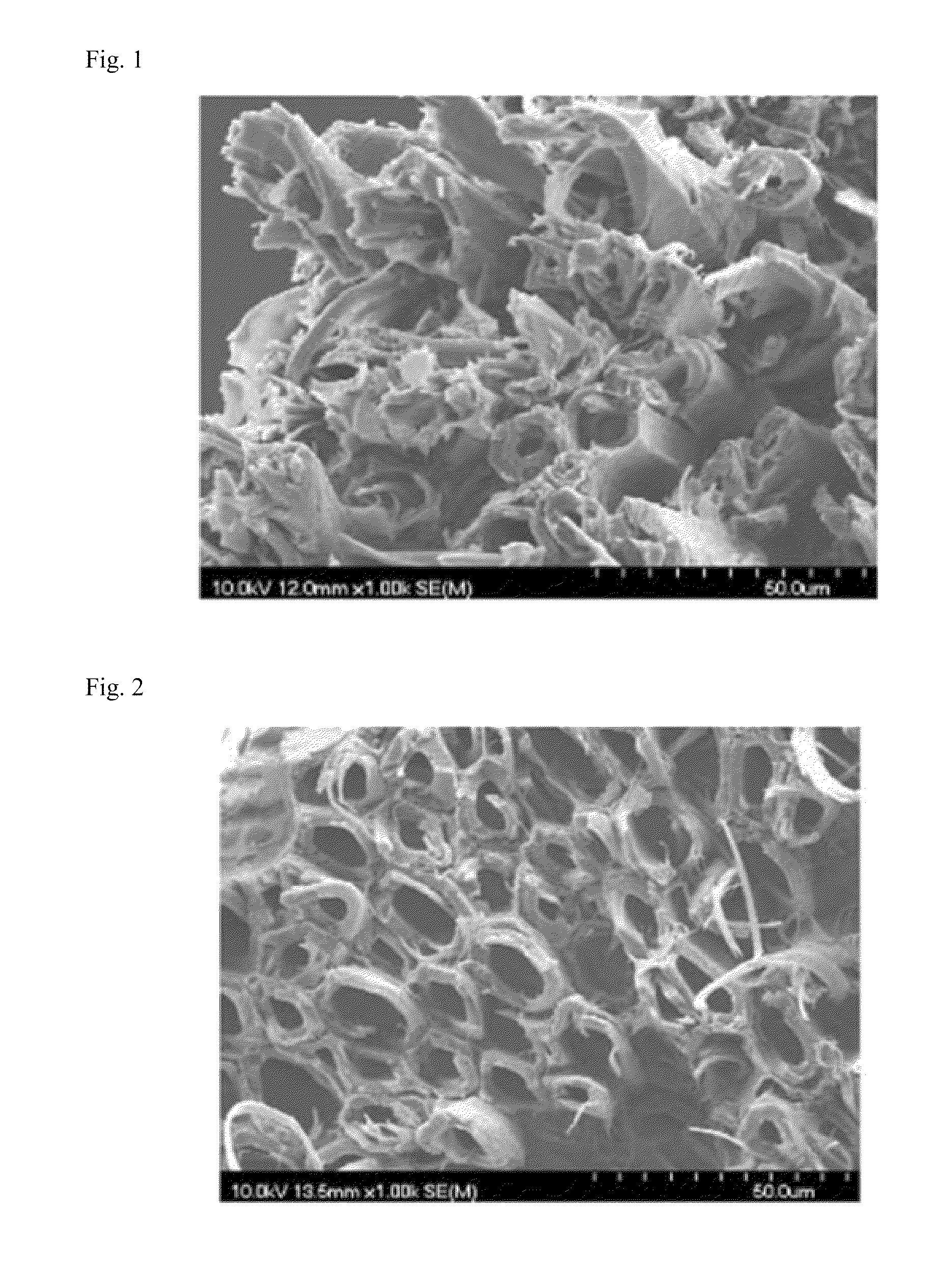

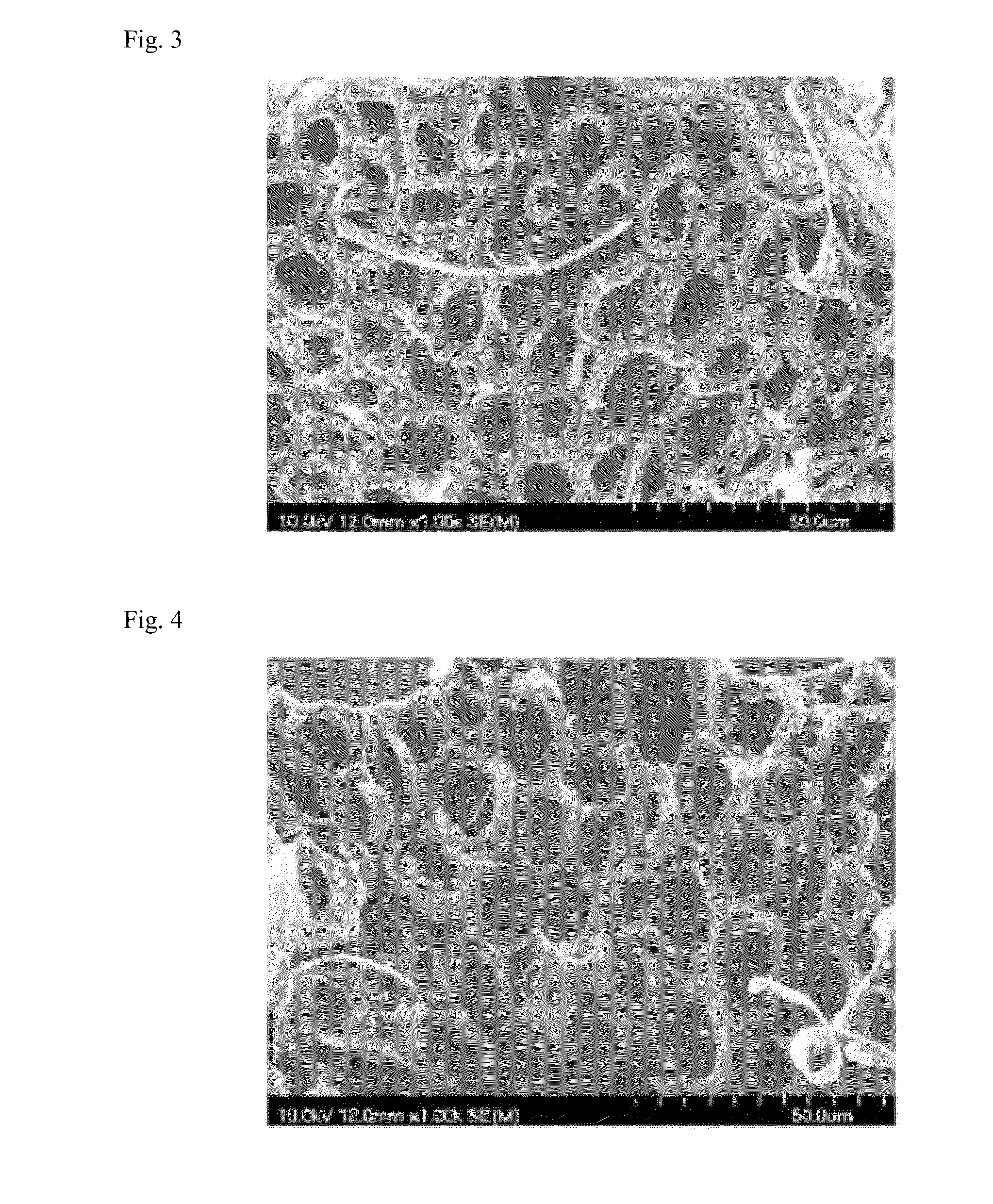

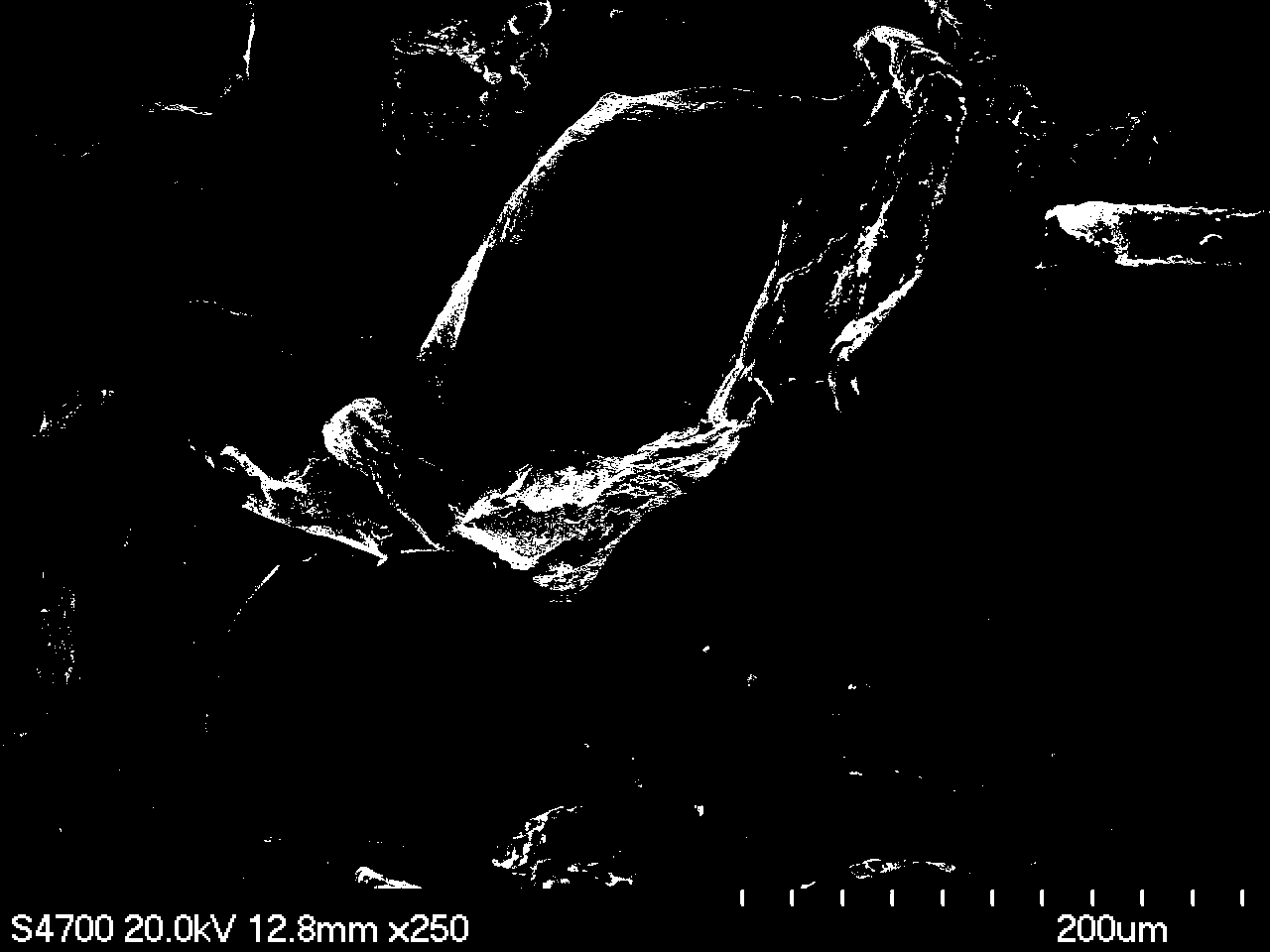

Catalysts having metal nano-particle catalyst supported on surface-treated natural cellulose fibers and preparation method thereof

ActiveUS20110111948A1Large surface areaBroad applicabilityMaterial nanotechnologyHydrogenNatural fiberCatalytic effect

The present disclosure relates to a catalyst having metal catalyst nanoparticles supported on natural cellulose fibers and a method of preparing the same, whereby natural cellulose fibers are subjected to specific pretreatment to increase a surface area and form defects on the surface thereof and metal catalyst nanoparticles are then supported on the cellulose catalyst support in a highly dispersed state, thereby providing improved catalysis while allowing production of the catalyst at low cost. The catalyst may be utilized for various catalytic reactions.

Owner:KOREA INST OF ENERGY RES

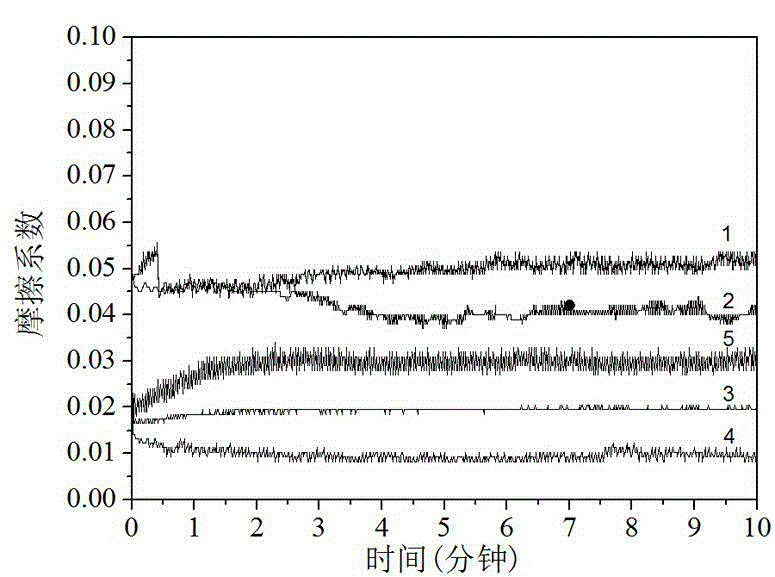

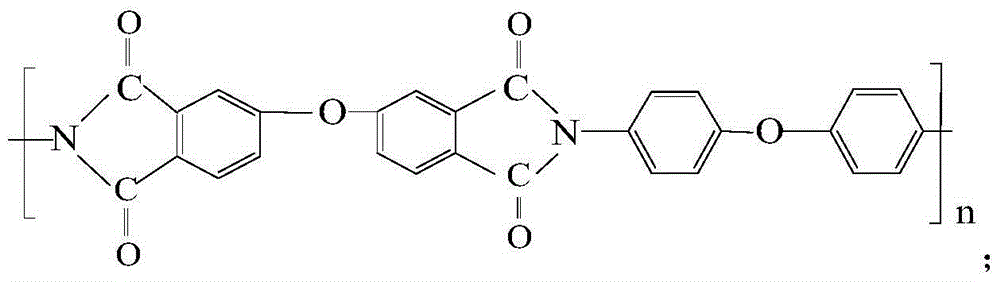

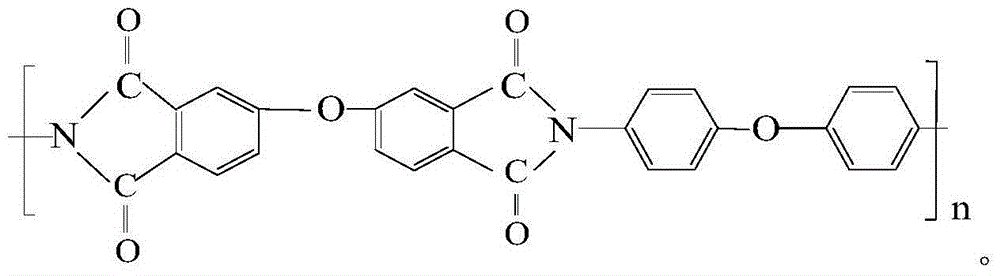

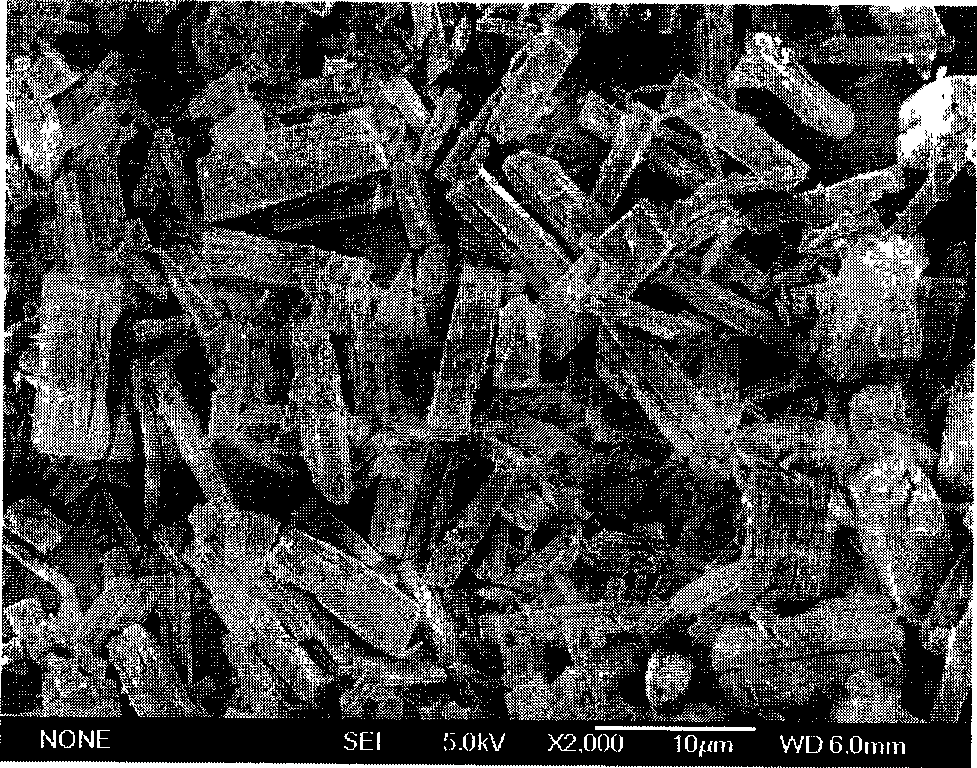

Porous oil-containing polyimide composite material for ultrasonic motor and preparation method thereof

The invention discloses a porous oil-containing polyimide composite material for an ultrasonic motor and belongs to the field of motor material preparation. The porous oil-containing polyimide composite material comprises, by mass, 60-80% of polyimide, 10-20% of carbon fibers and 10-20% of graphite. The porous oil-containing polyimide composite material has uniform aperture distribution, a stable friction coefficient, a very low wear rate and a good continuous lubrication capability, satisfies requirements on rotary ultrasonic motor stator and rotor friction, has a rated rotating speed greater than 80r / min, realizes long-term use of a rotary ultrasonic motor by a thin and uniform lubricating film formed on the contact surface and greatly prolongs a service life of the ultrasonic motor. The invention also provides a preparation method of the porous oil-containing polyimide composite material for an ultrasonic motor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Nano-superstructure polyporous material of ferrite and method of preparing the same

The invention relates to a ferrite nanometer superstructure porous material and a method for preparing the same, in particular to a method for preparing a nickel ferrite, cobalt ferrite or zinc ferrite nanometer superstructure porous material. The preparation method comprises that: sodium oxalate is used as a precipitator, the soluble nickel, cobalt or zinc salt used as a raw material reacts with the soluble iron salt to prepare a precursor of oxalate, and the precursor is degraded by calcination at certain temperature to obtain the nickel ferrite, cobalt ferrite or zinc ferrite nanometer superstructure porous material. The nickel ferrite, cobalt ferrite or zinc ferrite nanometer superstructure porous material synthesized by the method has the advantages of high purity, uniform size, good dispersibility, mild reaction conditions, simple equipment, easily controlled process conditions and low cost, and meets the need of the actual production.

Owner:HUAZHONG NORMAL UNIV

Foam ceramic insulation material and preparation method thereof

InactiveCN106082962AImprove insulation effectIncrease productivityCeramic materials productionCeramicwareLithiumFoaming agent

The invention relates to a foam ceramic insulation material and a preparation method thereof. The foam ceramic insulation material comprises the following raw materials in weight content: 30-95% of industrial waste material by mixing one or more of waste slag, waste stone flour or kaolin mine tailing, 1-18% of lithium porcelain stone, 1-20% of light-burnt magnesia, 1-30% of clay, and 0.5-20% of a foaming agent. The preparation method comprises the following steps: A) performing ball-milling on the raw materials of the foam ceramic insulation material to prepare the granular powder; B) performing burden distribution on powder and sintering the powder at the temperature of 1000-1400 DEG C, insulating for 2-5 hours to obtain the foam ceramic insulation material; and C)cutting the foam ceramic insulation material and processing the foam ceramic insulation material. According to the invention, waste slag, waste stone flour or kaolin mine tailing are used for preparing the foam ceramic insulation material, the preparation has advantage of environmental protection, the foam ceramic insulation material has the advantages of uniform distribution of inner pores, low heat conduction coefficient, high intensity and light weight, and can be used as building fireproof, insulation and energy-saving material and other insulation energy saving industries.

Owner:江西嘉陶无机材料有限公司

Method for preparing pitch-based foam carbon

The invention relates to a method for preparing a pitch-based foam carbon. The method comprises the following steps of: 1) mixing mesophase pitch with mesophase carbon micro sphere based on a mass ratio of 60 to 90:10 to 40, putting the mixture in a reactor, 2) guiding nitrogen to the reactor, rising temperature to 280-350 DEG C, maintaining for 1 to 2 h, rising temperature to 450-650 DEG C, maintaining for 2 to 4 h so as to obtain pitch-based foam carbon raw material, 3) rising temperature to 950-1050 DEG C, maintaining for 2 to 3 h, performing carbonization treatment under the protection of positive pressure nitrogen so as to obtain the carbonized pitch-based foam carbon base, and 4) based on a ratio of propylene to nitrogen of 1:1-2 under a pressure lower than 3kPa at 850 to 1000 DEG C, heating the carbonized pitch-based foam carbon base for 15 to 80 h so as to obtain the pitch-based foam carbon. The volume density of the pitch-based foam carbon prepared by using the method of the invention is 0.64-0.85 g / cm3 and the compression strength is 25.8-47.2 MPa. The pitch-based foam carbon can be wildly applied to carbon-base compound material, light structure material, catalyst carrier material, and the like.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

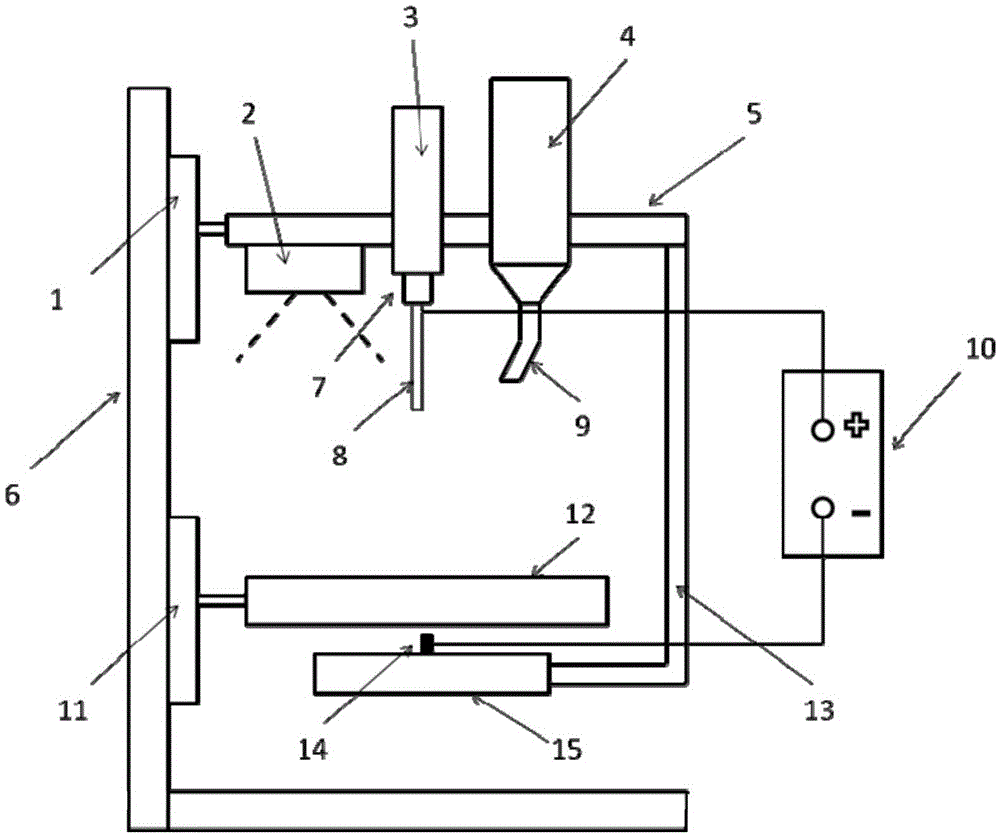

3D printing manufacturing method and equipment for porous three-dimensional part

InactiveCN105563841AThe size is easy to controlUniform distribution of poresAdditive manufacturing apparatusSolventPolymeric liquid

The invention discloses a 3D printing manufacturing method and equipment for a porous three-dimensional part. The method comprises the steps that a forming sizing agent comprising liquid photosensitive resin and a polymeric liquid additive is prepared, the liquid photosensitive resin can be cured through ultraviolet irradiation, and the polymeric liquid additive comprises a binder component and is provided with an electric conductor; the surface of a receiving substrate is coated with a layer of soluble polymeric powder; the sizing agent is sprayed to the receiving substrate according to a set program in an electrostatic spraying mode to form a layer of patterns; the sizing agent patterns on the receiving substrate is subjected to ultraviolet irradiation for curing; the cured sizing agent patterns are coated with another layer of the soluble polymeric powder, then sizing agent spraying and curing are conducted again, and the sizing agent and the soluble polymeric powder are overlaid layer by layer in this way to obtain a formed three-dimensional part; the formed three-dimensional part is cleaned through solvent and / or steam of the solvent, the soluble polymeric powder in the three-dimensional part is dissolved, pores are formed, and accordingly the porous three-dimensional part with the evenly distributed pores is obtained.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Preparation method of organic/inorganic composite porous scaffold material for bone tissue engineering

The invention belongs to the field of biomedical materials, and relates to a technology using an organic / inorganic composite porous scaffold material in the bone tissue engineering. The organic / inorganic composite porous scaffold material is prepared through the following steps: dissolving alpha-hydroxy acid (such as polycaprolactone, polylactic acid, polyglycolic acid, and lactic acid-glycolic acid copolymer) by a low-toxicity organic solvent 1,4-dioxane, dispersing bioactive ceramic (such as bioactive glass, hydroxyapatite, carbonated hydroxyapatite and tricalcium phosphate) by the same solvent, mixing the above obtained solutions, adding a water-soluble salt (such as sodium chloride, sodium bicarbonate and disodium hydrogen phosphate) as a pore forming agent, casting to a die having a certain shape, allowing the solvent to naturally volatilize, removing the pore forming agent through a simple water washing process, and carrying out vacuum drying to finally prepare the porous scaffold material. A preparation method of the porous scaffold material has the advantages of simple and easy operation, mild preparation conditions and good reappearance. The composite porous scaffold material prepared through the preparation method is expected to be applied in the bone tissue engineering in order to carry out bone restoration and substitution.

Owner:BEIJING UNIV OF CHEM TECH

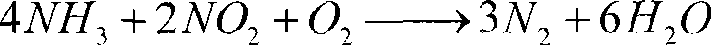

Carbon foam structural insulated panel

InactiveUS20070141343A1High strengthEasy to processCarbon compoundsSynthetic resin layered productsVolumetric Mass DensityCompressive strength

A structural insulated panel, which includes a carbon foam core having a high ratio of compressive strength to density, desirable fire retardant properties, and resistance to environmental stress. The carbon foam structural insulated panel also includes a first layer and a second layer bound to a first surface and second surface of the carbon foam core. Applications of the carbon foam structural insulated panel include structural and fire retardant elements of residential and commercial buildings, aircraft and also watercraft.

Owner:UCAR CARBON TECH

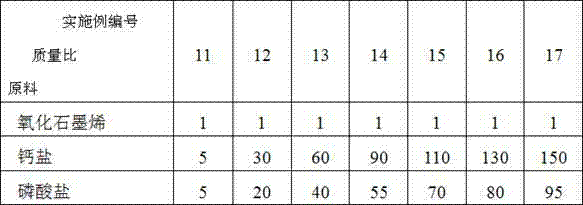

Production method of three-dimensional porous composite bar

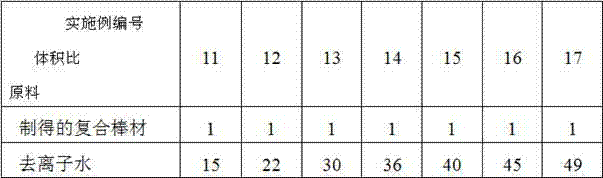

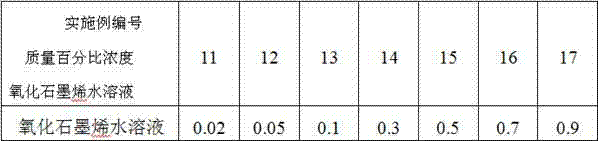

The invention discloses a production method of a three-dimensional porous composite bar. The method is characterized by comprising the following steps of: preparing a graphene oxide solution; adding calcium salt and phosphate into the graphene oxide aqueous solution to be uniformly stirred, thus obtaining a graphene oxide / hydroxyapatite precursor solution; and adding konjac glucomannan into the graphene oxide / hydroxyapatite precursor solution under stirring, stirring the solution for 10-120 minutes at 35-60 DEG C, standing, filling the obtained mixed solution into a dialysis bag, soaking the sealed dialysis bag into alkaline solidification liquid, soaking the dialysis bag for 5-15 days at 40-60 DEG C, soaking materials in the dialysis bag in deionized water, cleaning and drying the materials, freezing the materials at a super low temperature and performing vacuum freeze drying on the materials to obtain the three-dimensional porous composite bar. The mechanical property and porosity of the produced composite bar can meet the clinical use requirements of bone repair scaffold materials, and the composite bar can effectively promote bone tissues to quickly and spontaneously repair defects and has a good effect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com