3D printing manufacturing method and equipment for porous three-dimensional part

A technology of 3D printing and production method, applied in the direction of additive processing, etc., can solve problems such as inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

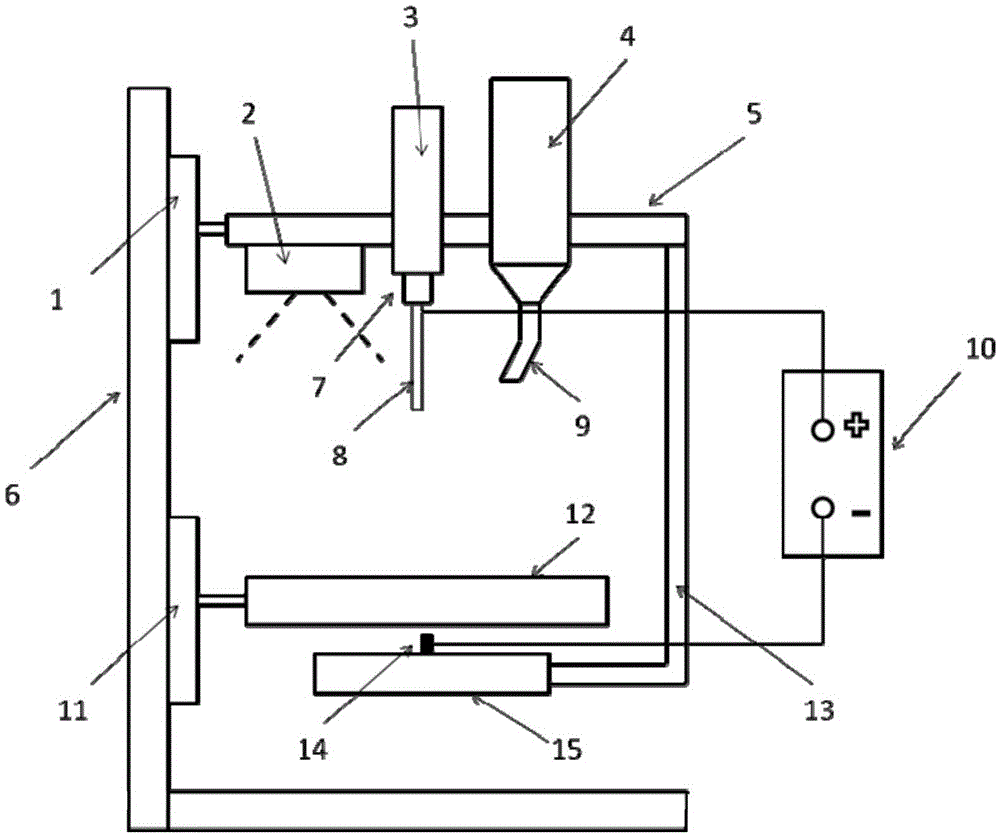

Embodiment 1

[0047] Firstly, a slurry for molding is prepared. The formula is as follows: 90% by mass of UV epoxy acrylate, and 10% by mass of polyethylene oxide aqueous solution. The above ingredients are mixed and stirred evenly to make a slurry for molding. A stainless steel needle with an inner diameter of 0.06 mm was selected as the nozzle, and connected to a high-voltage direct current power supply 10 device. The metal needle nozzle is connected with the positive pole of a high voltage direct current power supply 10 . An insulating receiving substrate 12 is arranged below the spray head, and a layer of polyvinyl alcohol (molecular weight: 98,000) powder is pre-laid on the receiving substrate 12, with a layer thickness of 50 microns. There is a needle-like or columnar electrode 14 below and is connected to the negative pole of the high-voltage DC power supply 10 . The slurry is stored in a container 3 and connected to the spray head through a conduit. Slicing and layering the thre...

Embodiment 2

[0049] Slurry composition for molding: 88% by mass of UV polyurethane acrylate, and 12% by mass of polyvinylpyrrolidone aqueous solution. A layer of polyacrylic acid (molecular weight: 100,000) powder is pre-laid on the receiving substrate 12 with a layer thickness of 40 microns. The voltage of the high-voltage DC power supply 10 is set at 25KV, an electric field is formed between the nozzle and the needle electrode 14, and the distance from the tip of the needle to the receiving substrate 12 is 12 cm. The molding process is the same as in Example 1. After the 3D printing is completed, the printed parts are cleaned several times with pure water and water vapor to dissolve the polyacrylic acid powder in the three-dimensional parts to form pores, thereby obtaining porous three-dimensional parts. Among them, the pore size is between 120 microns and 1000 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com