Patents

Literature

124 results about "Polymeric liquid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

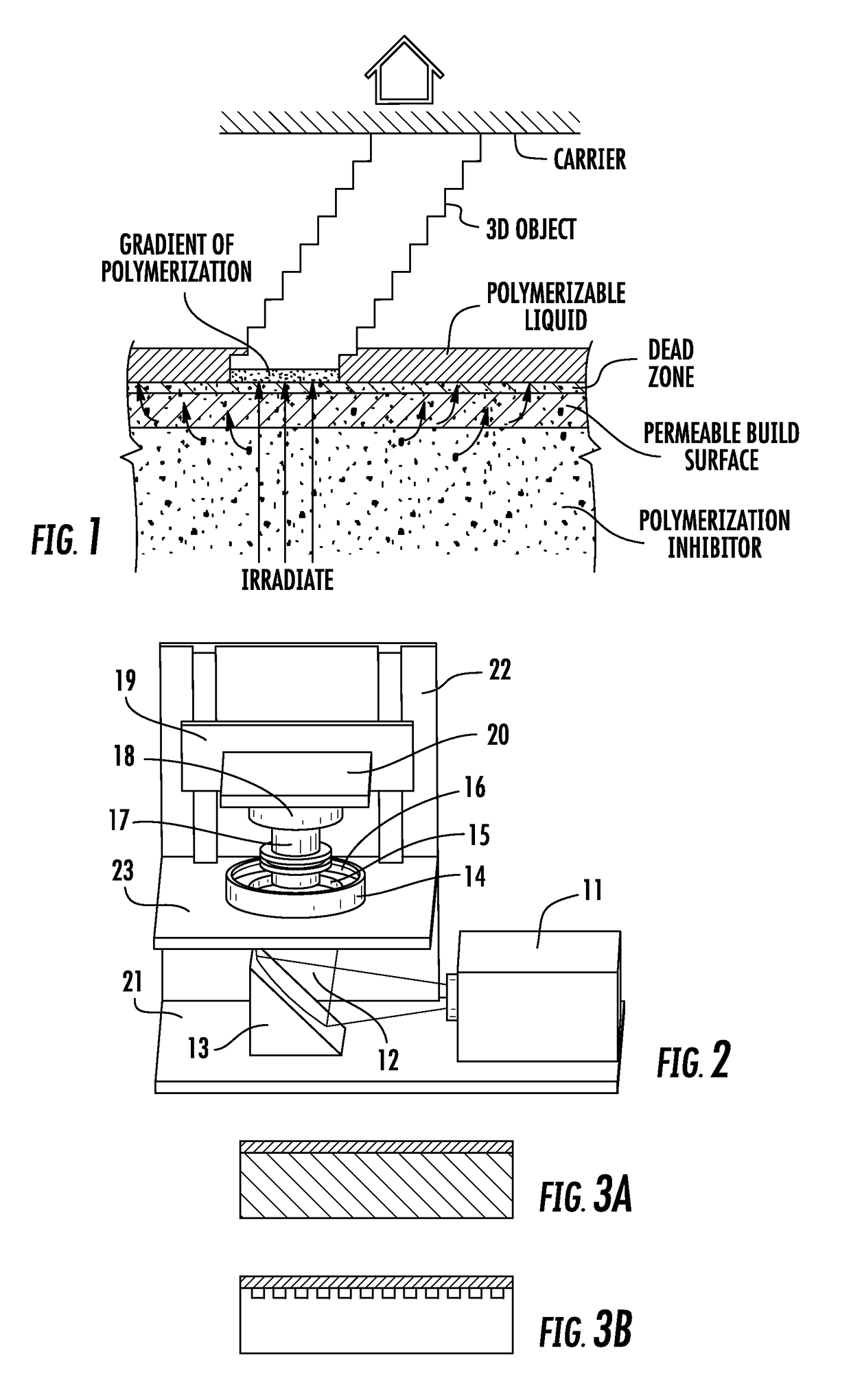

Method and apparatus for three-dimensional fabrication with feed through carrier

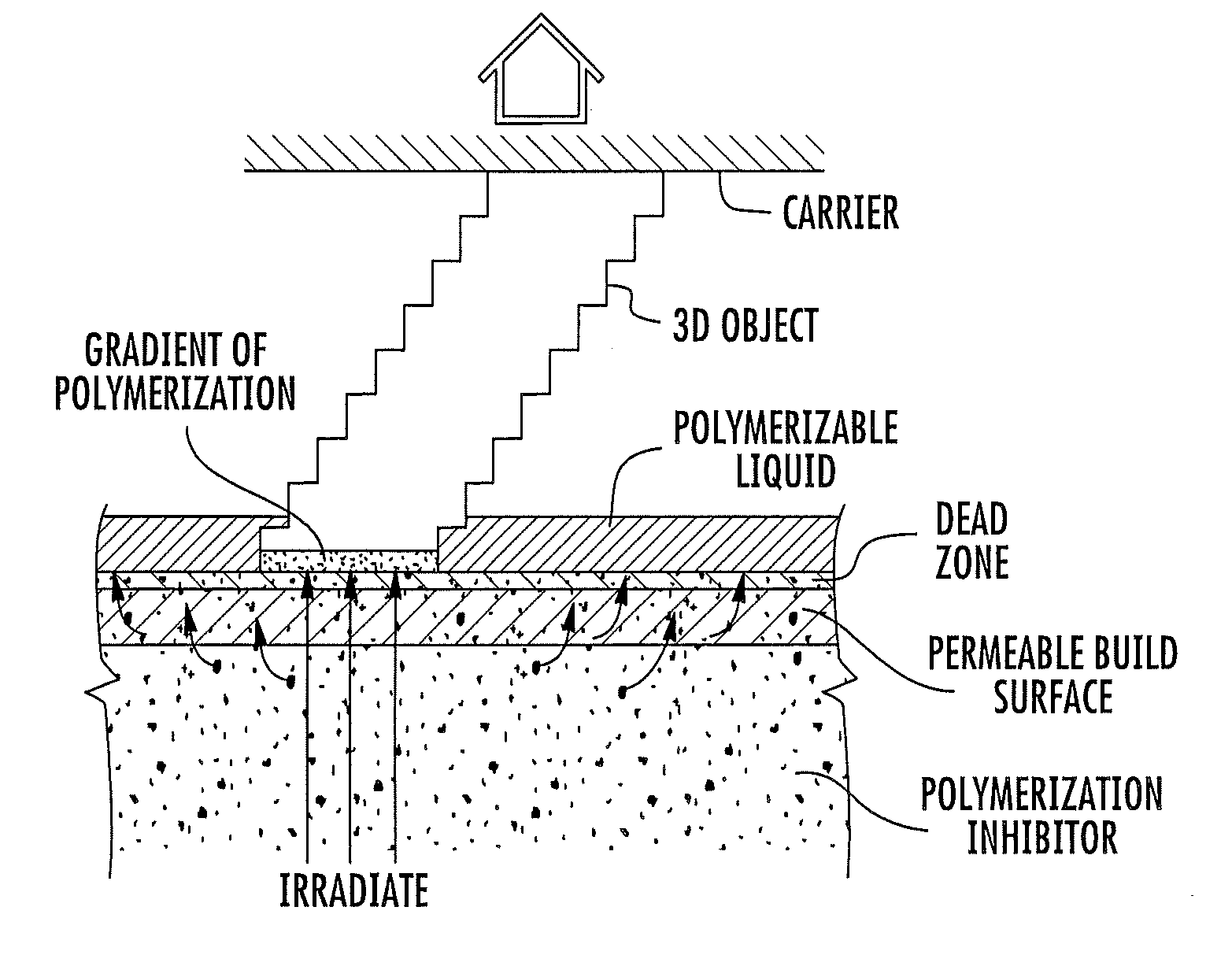

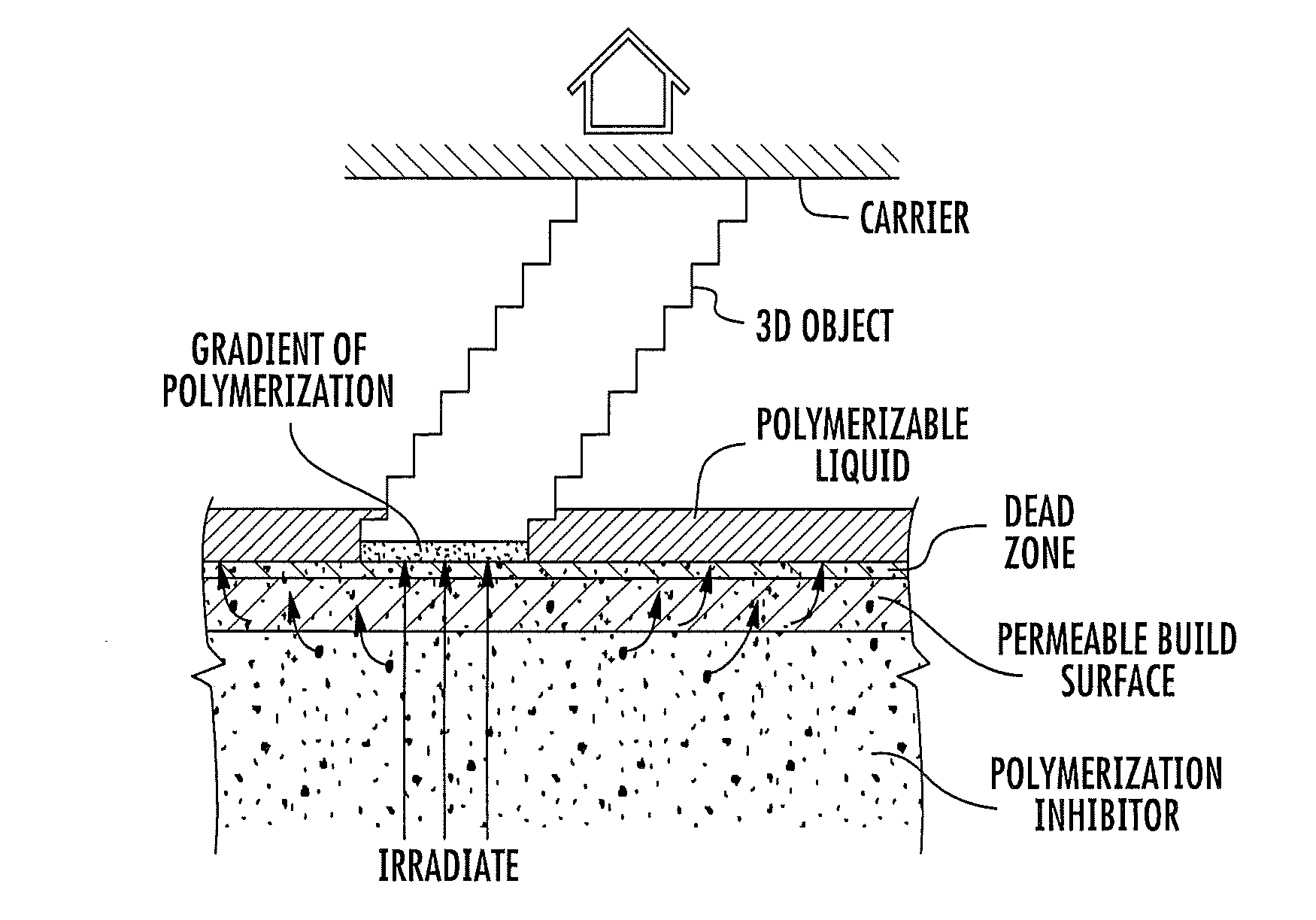

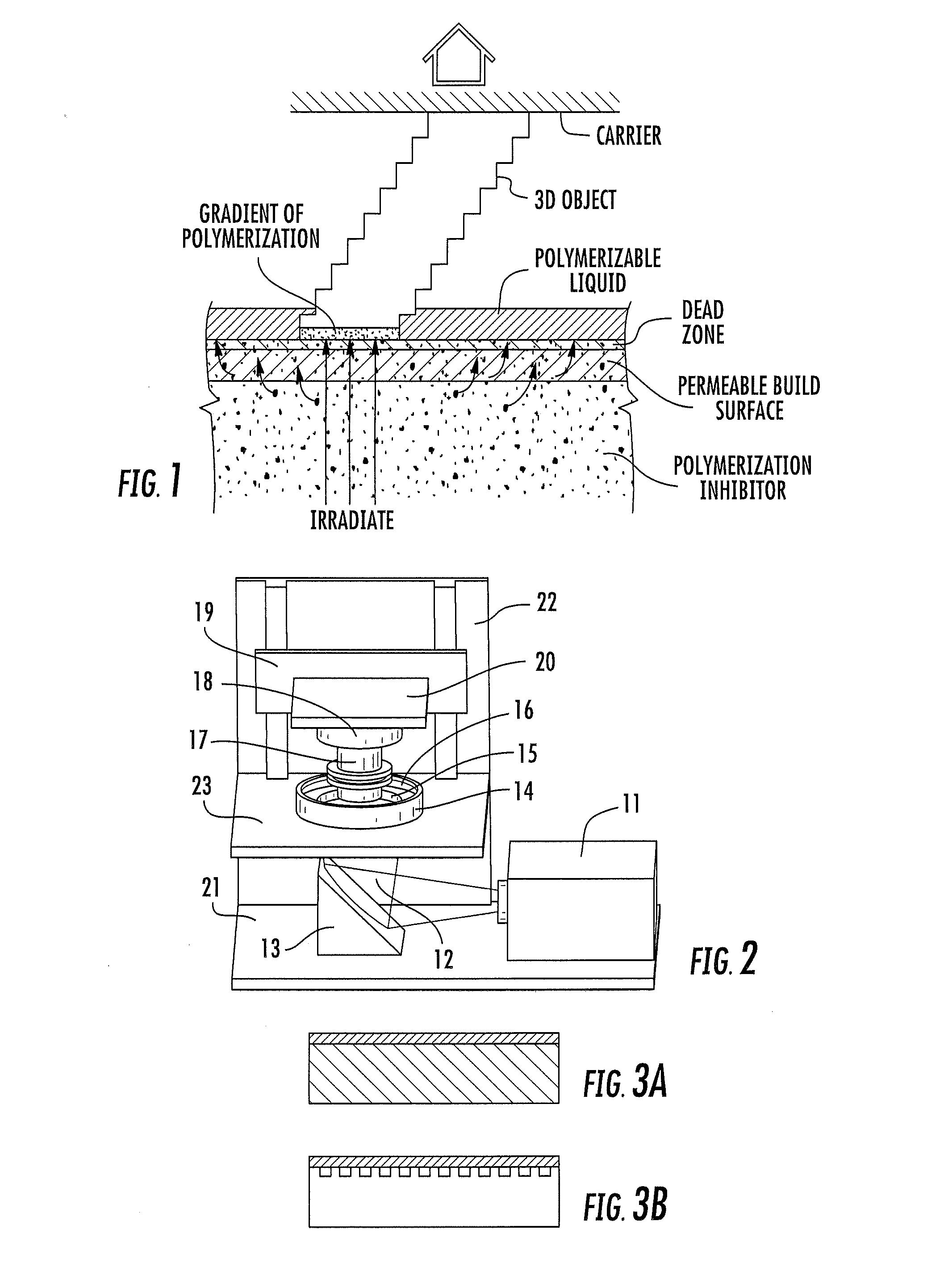

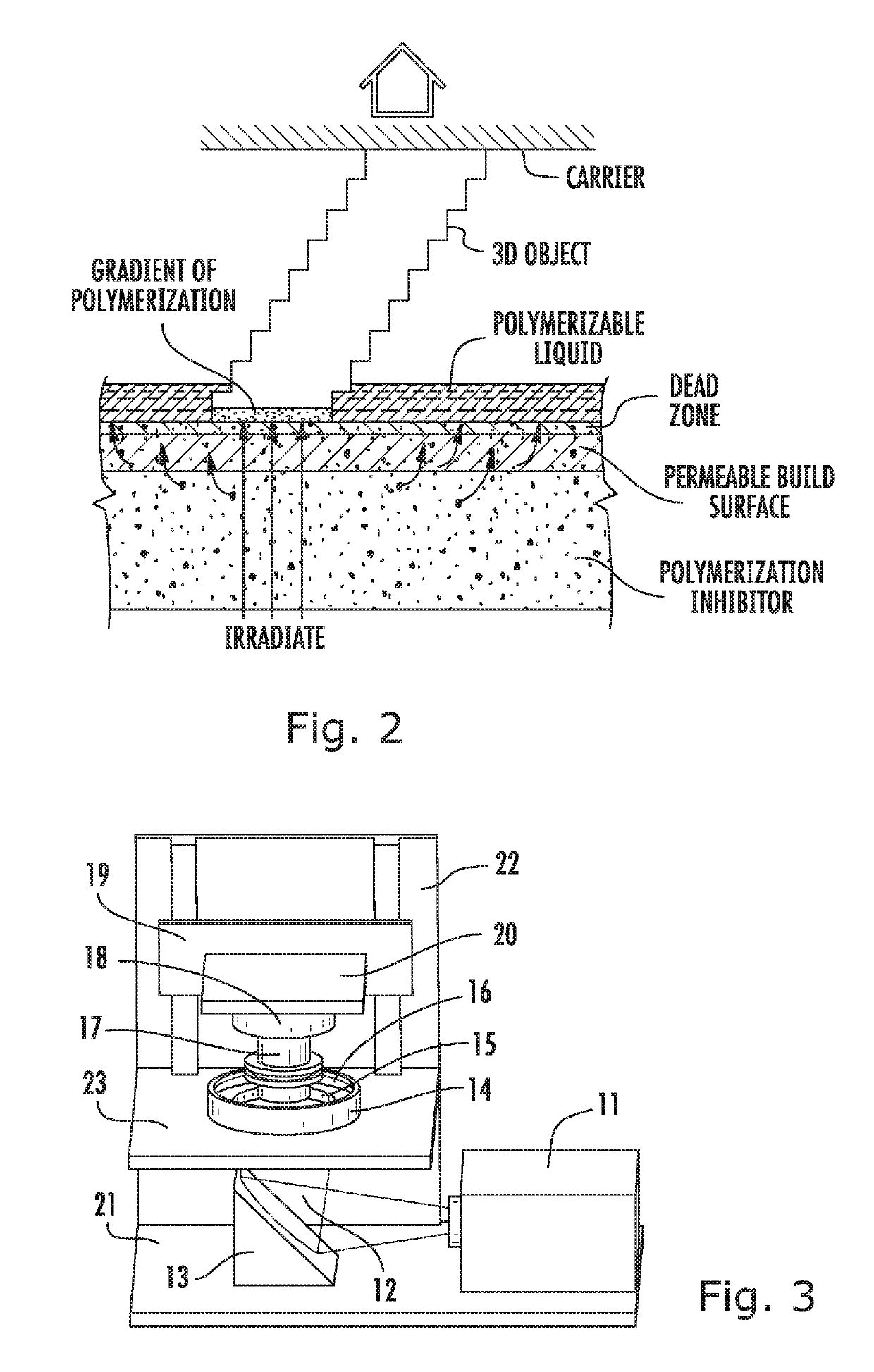

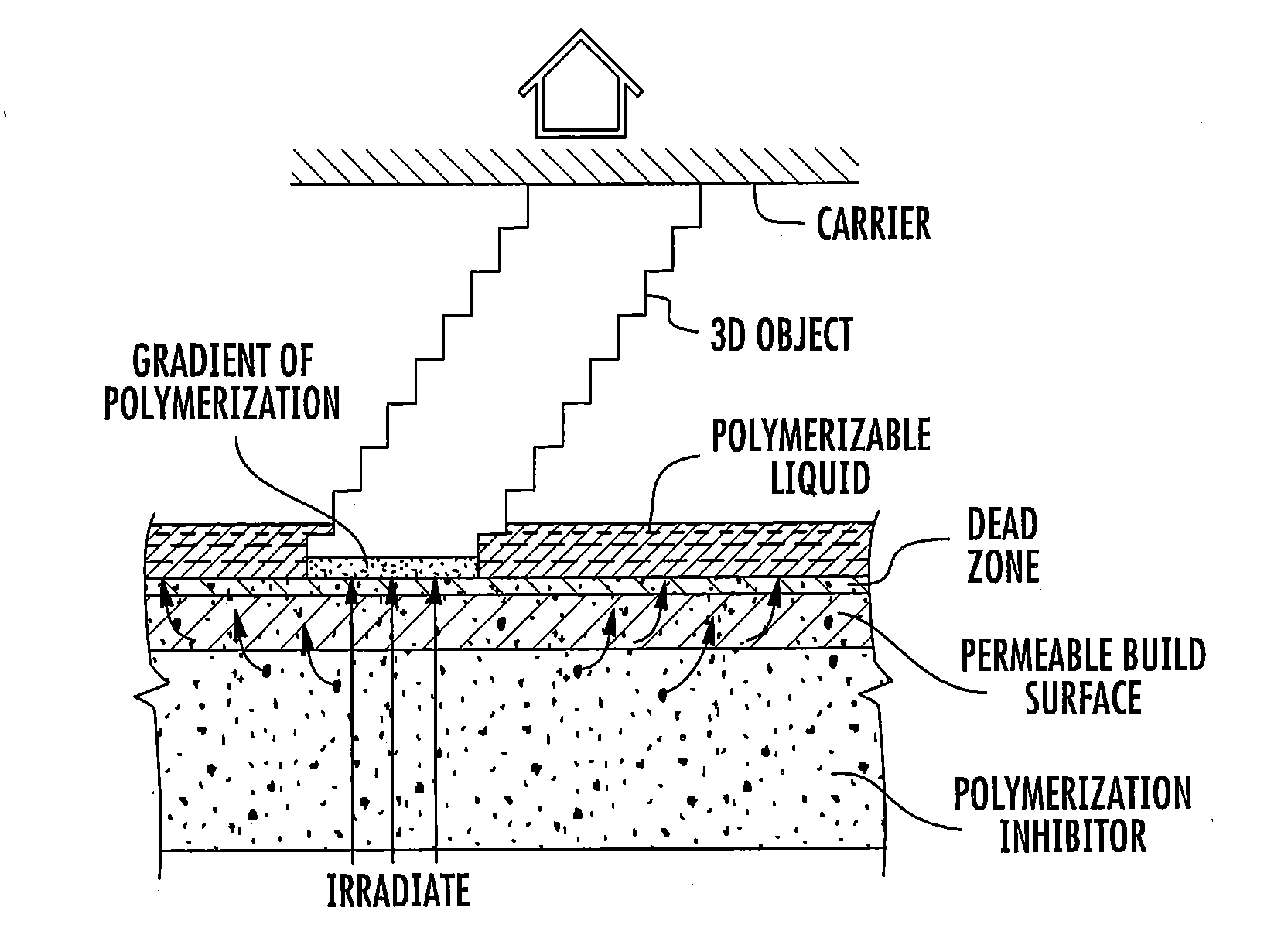

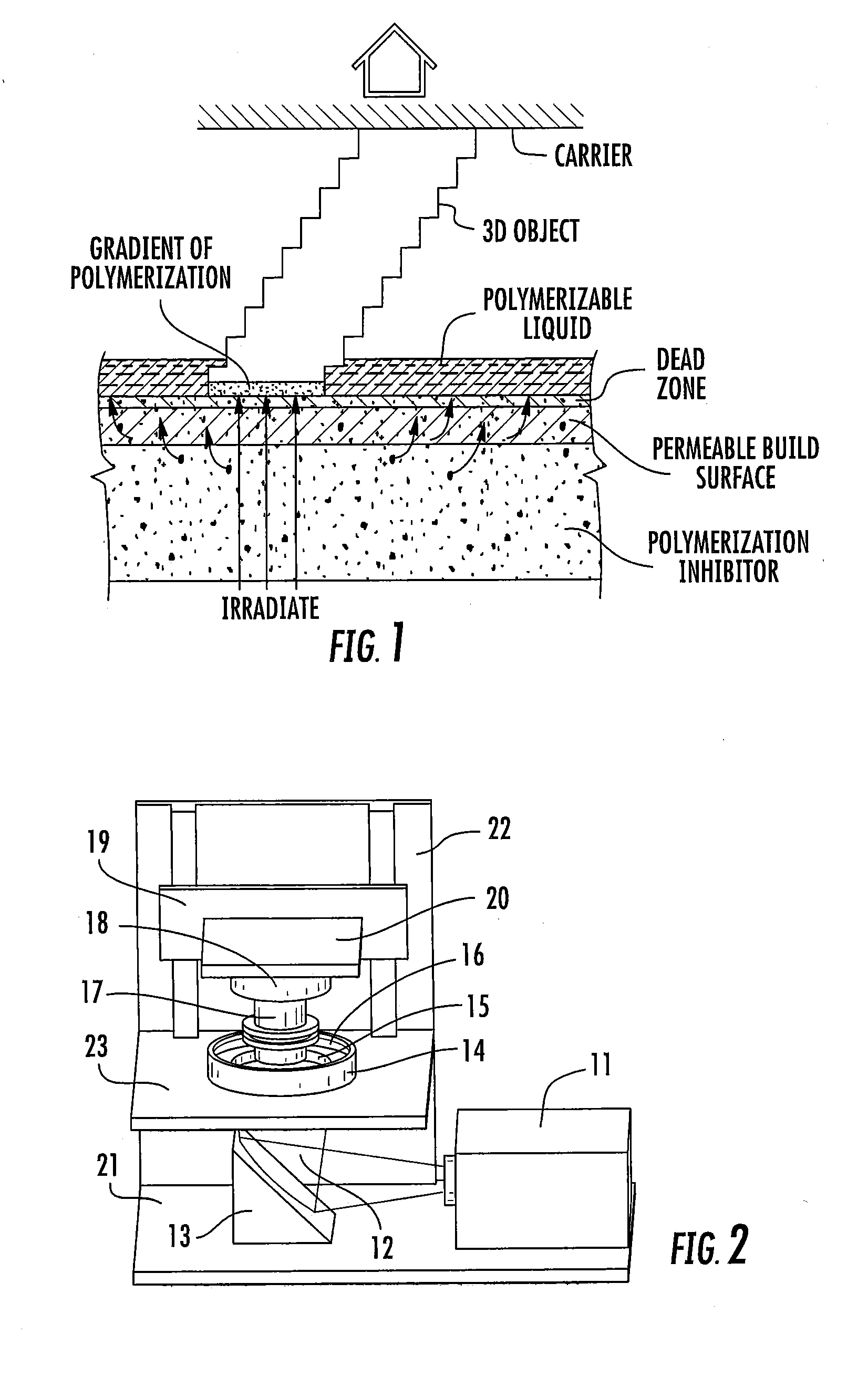

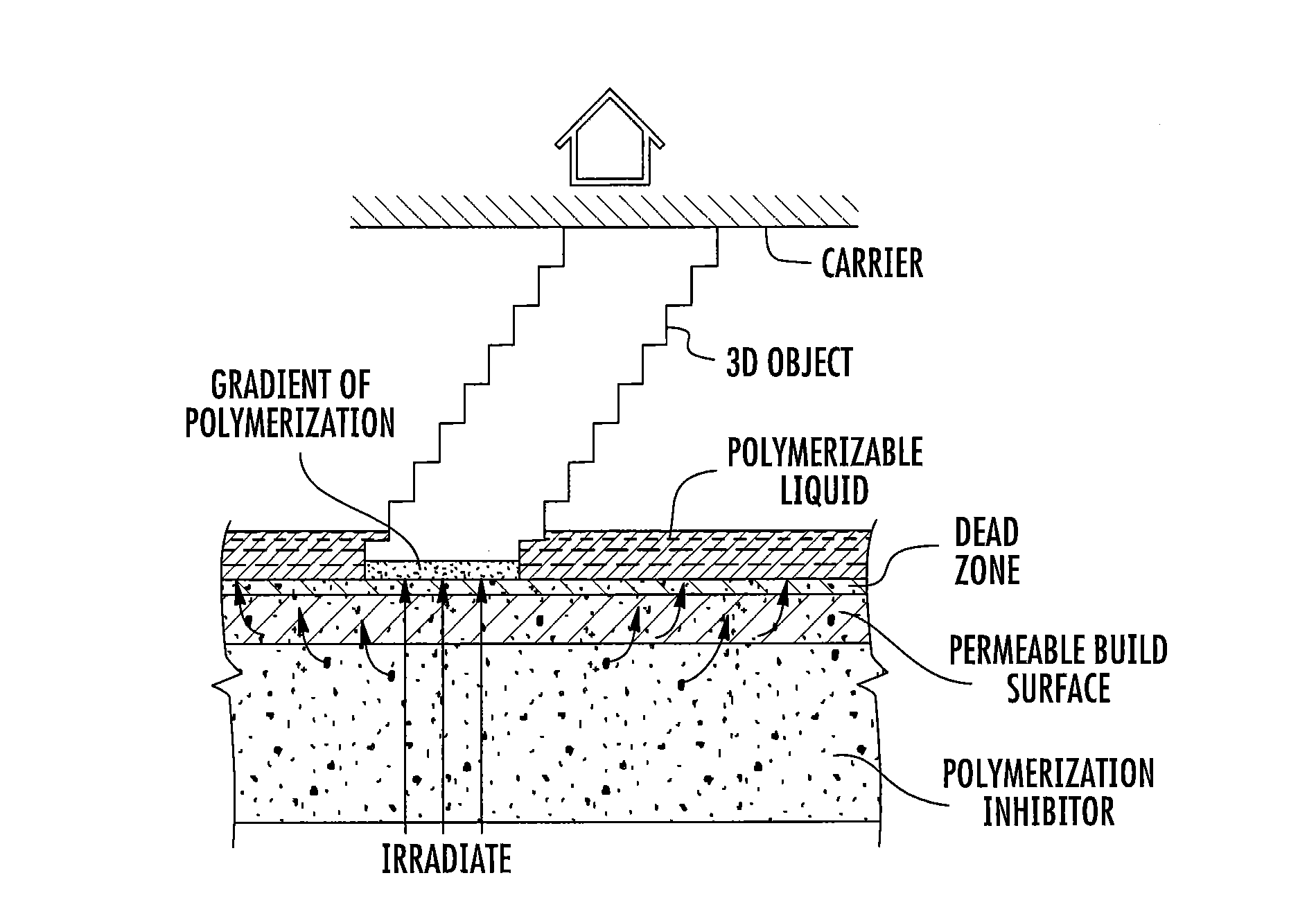

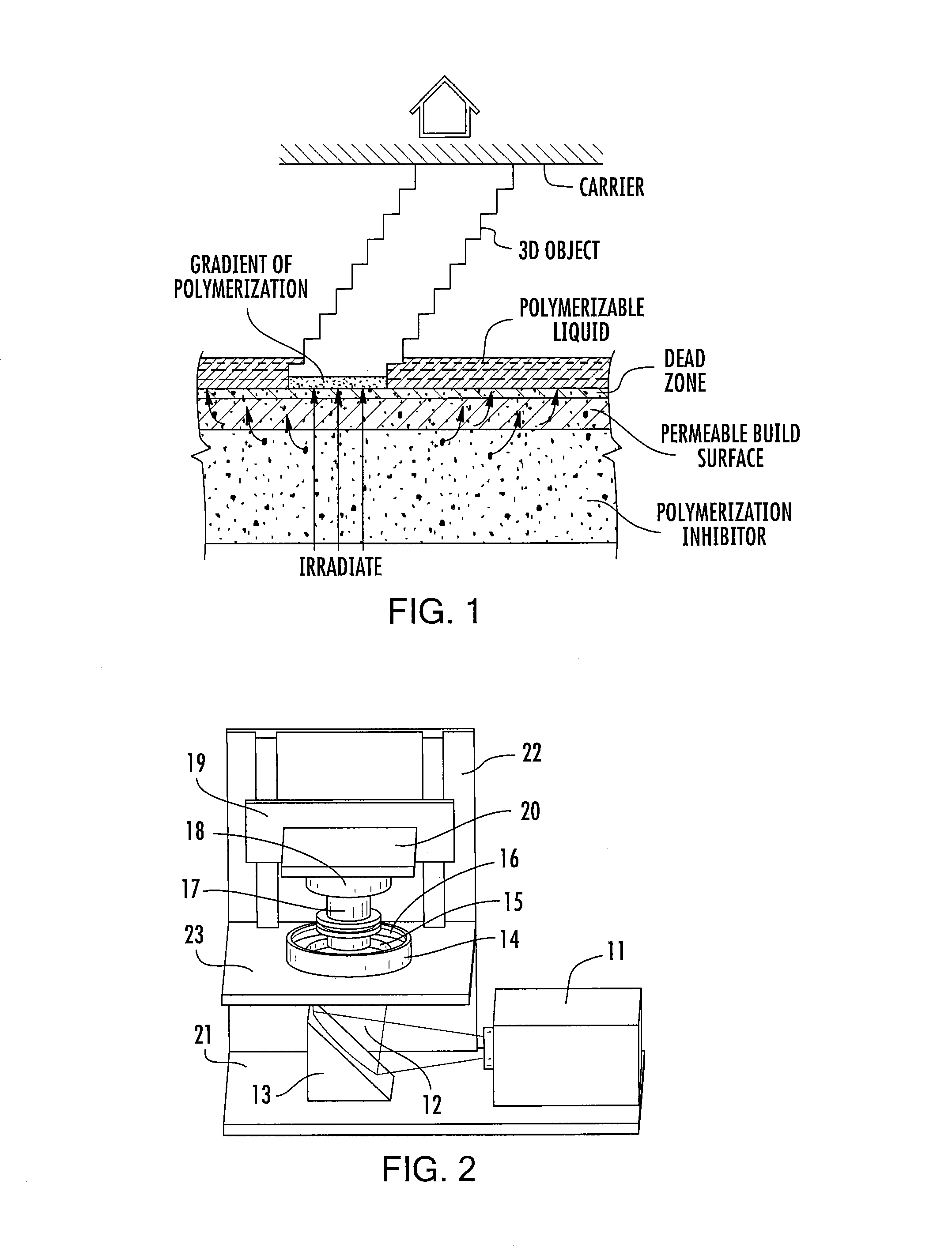

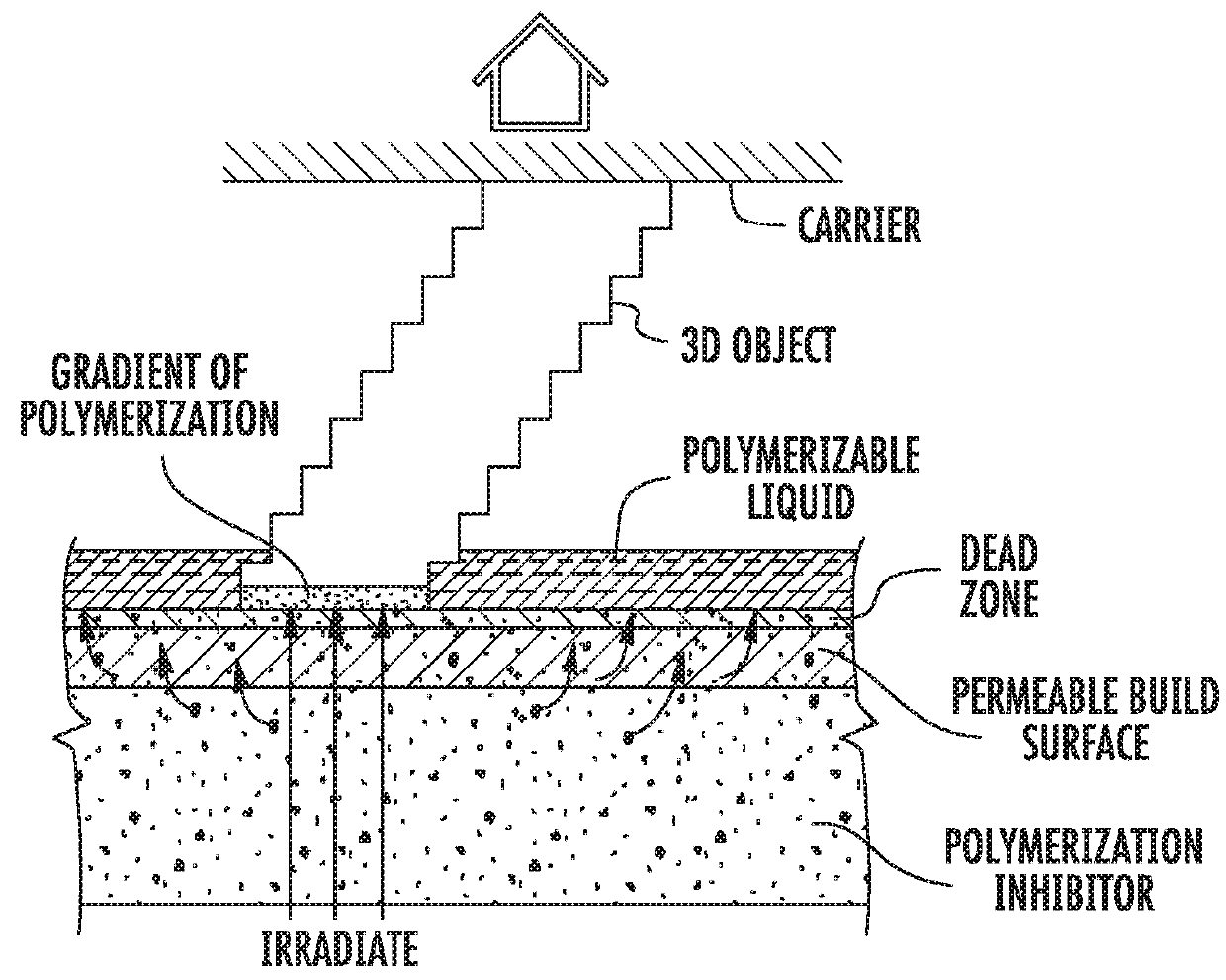

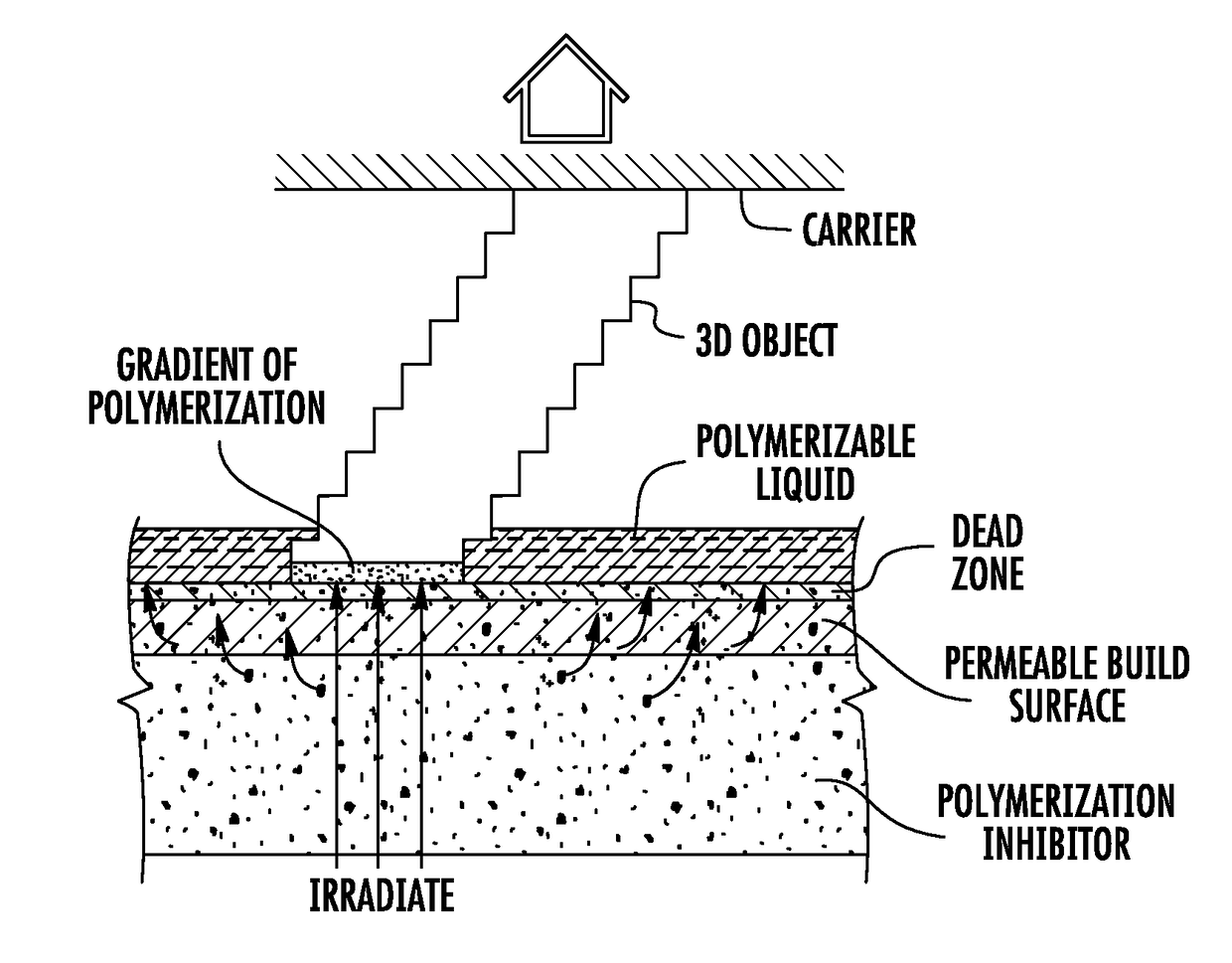

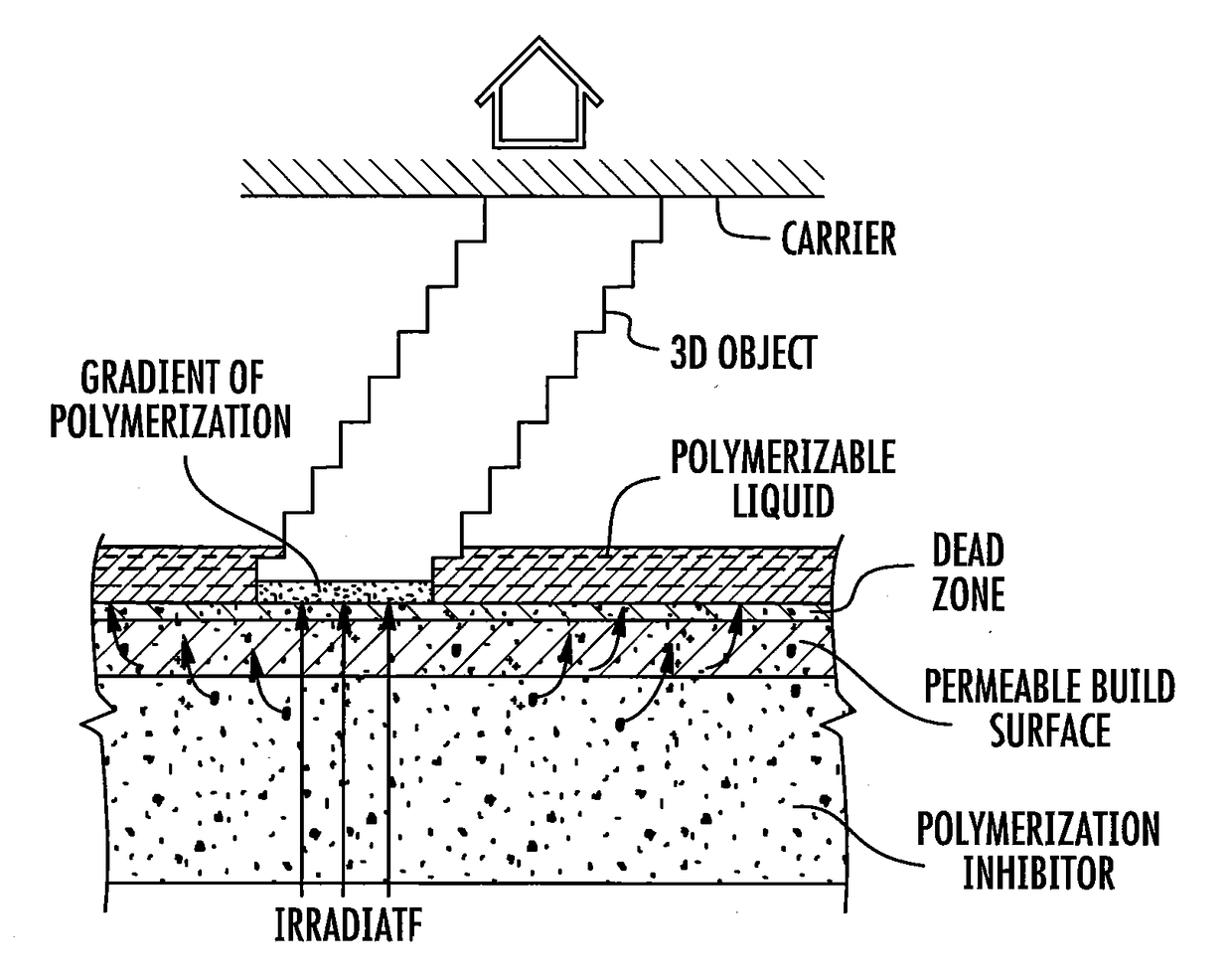

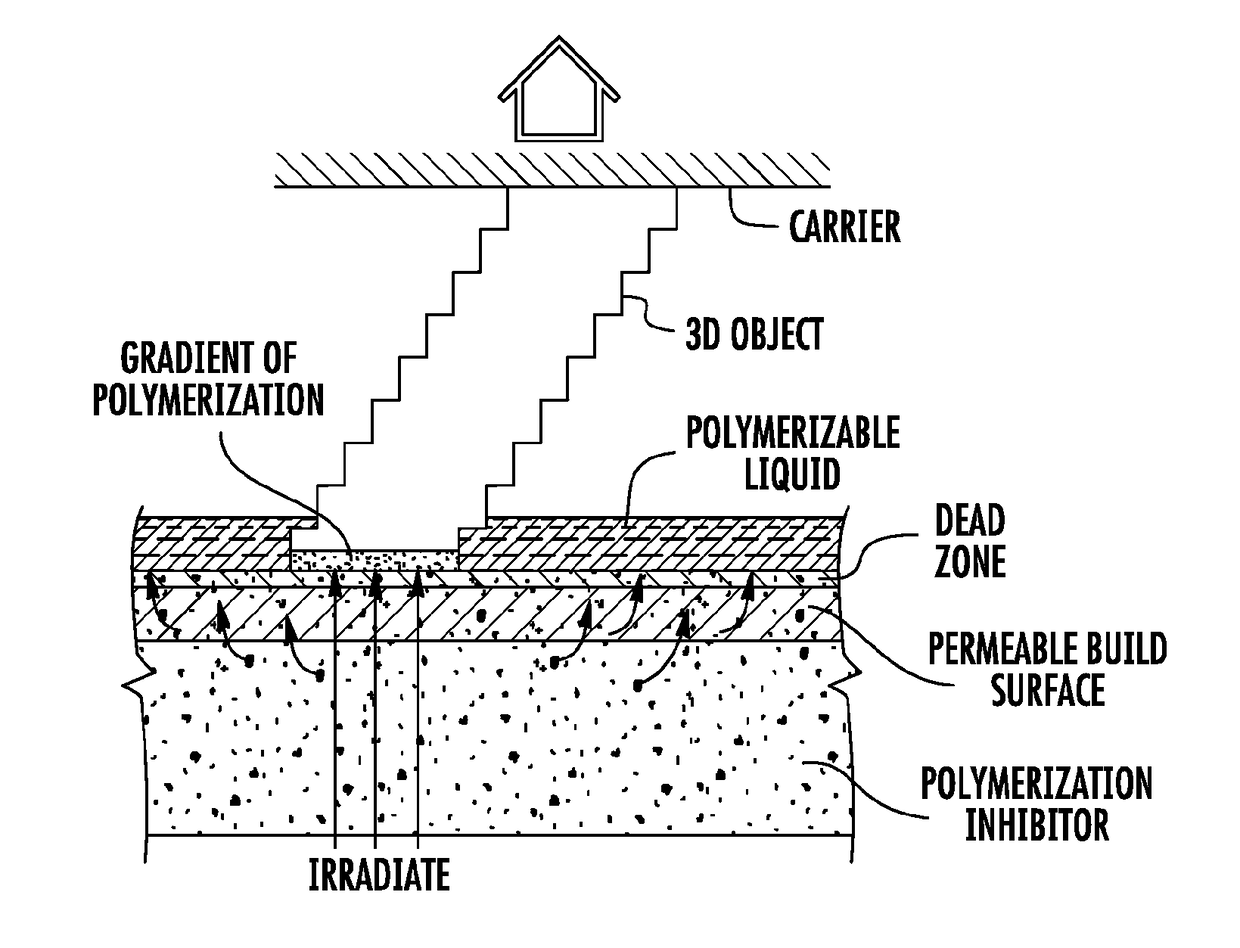

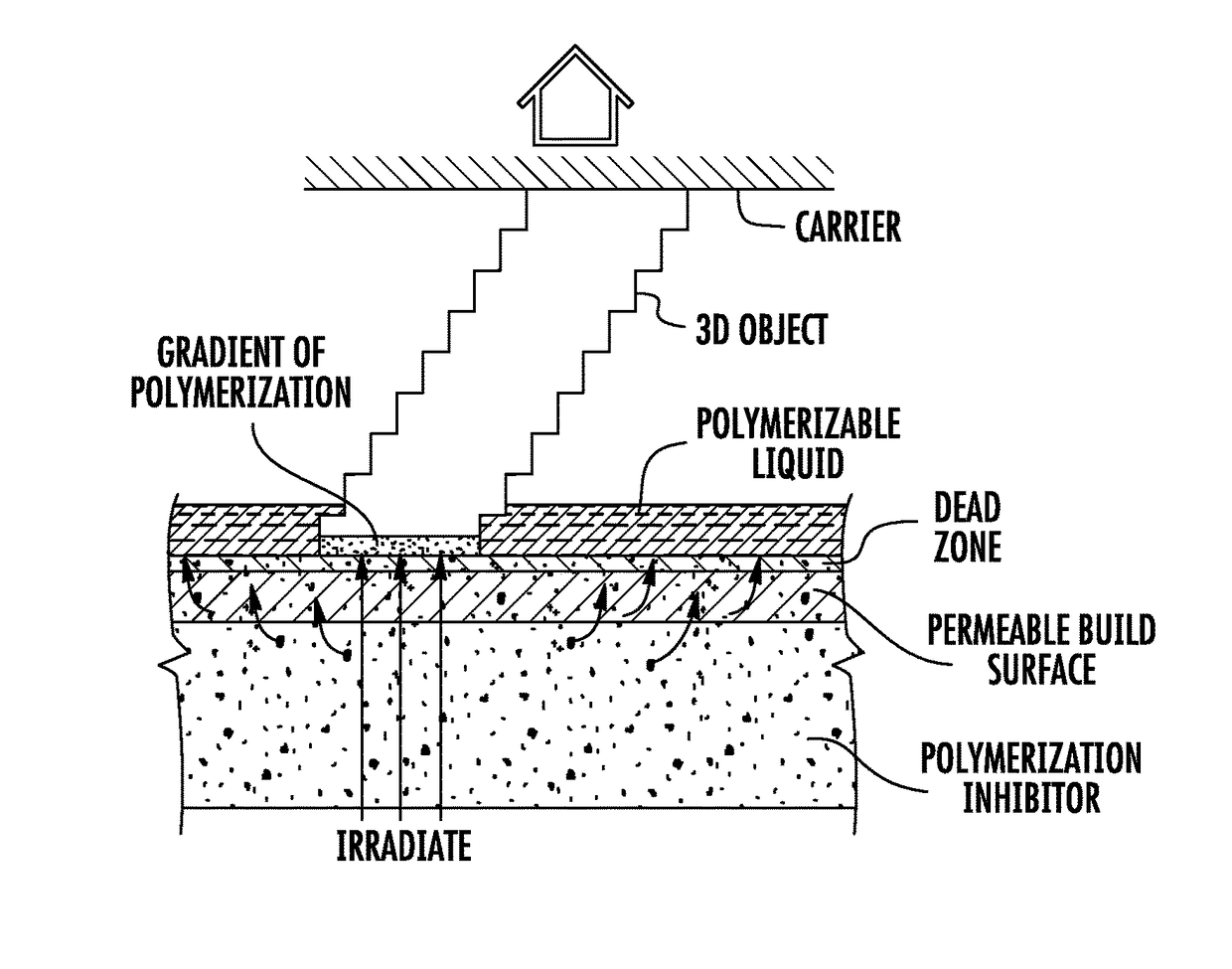

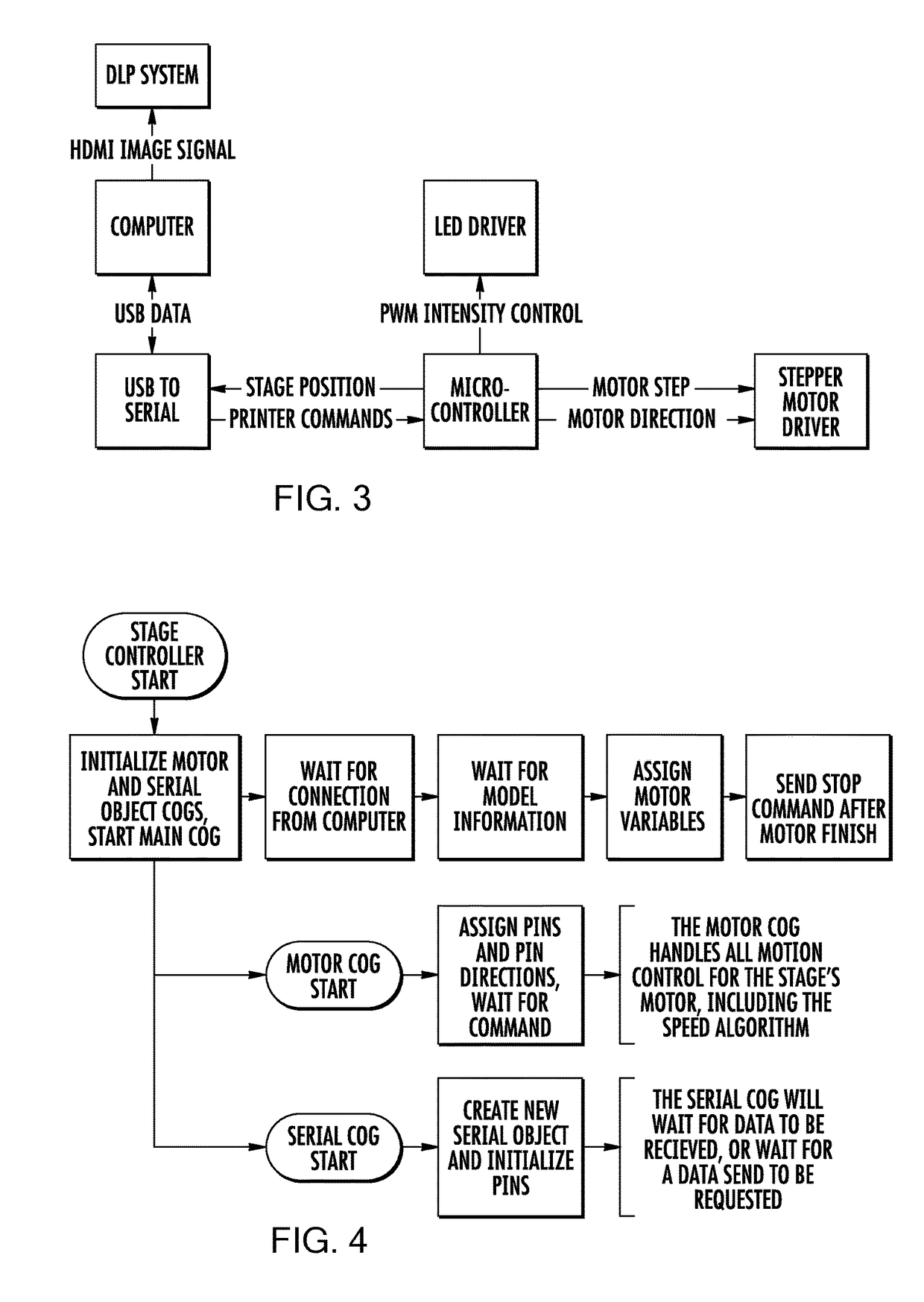

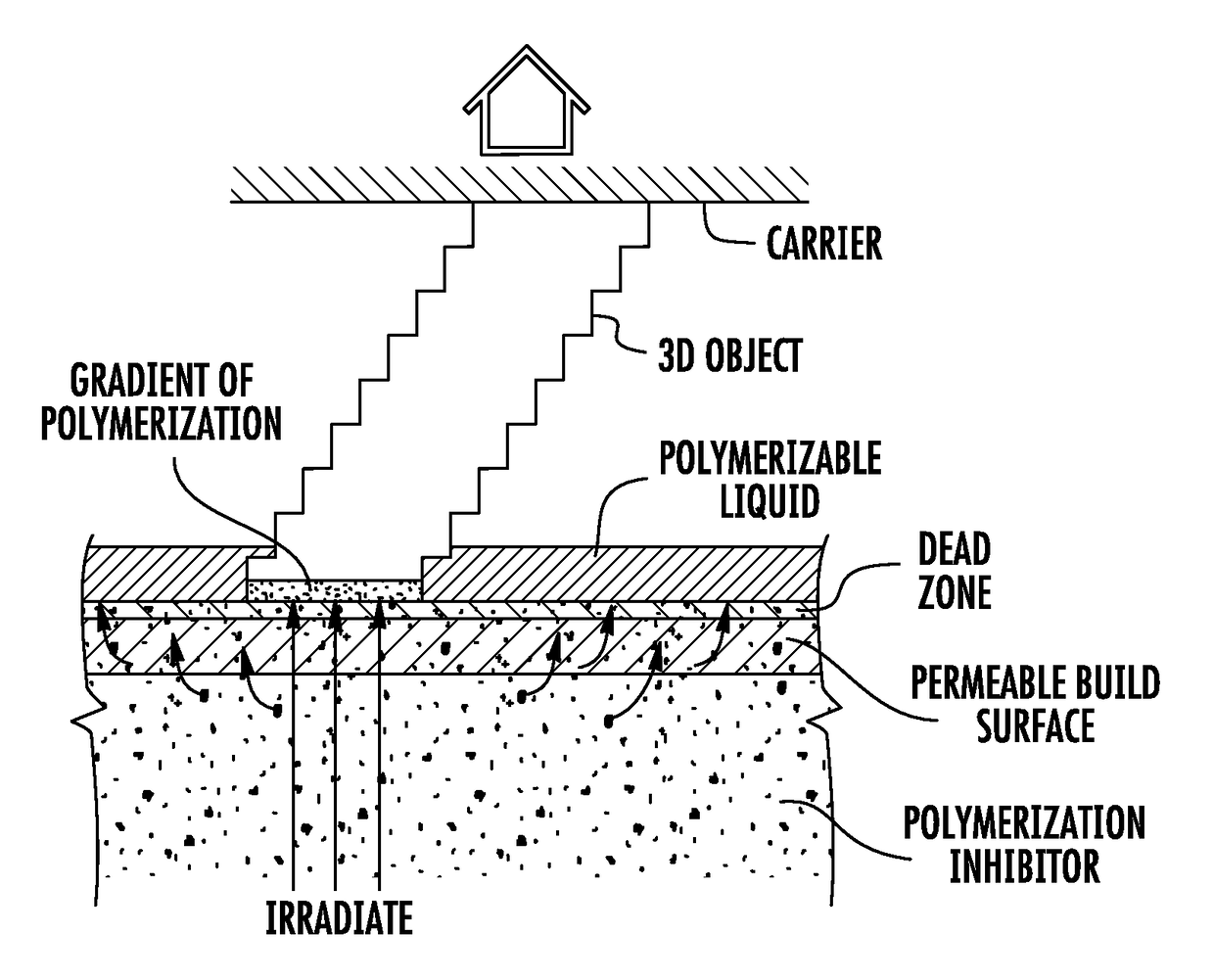

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquid contacting the build surface; (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface; (e) wherein the carrier has at least one channel formed therein, and the filling step is carried out by passing or forcing the polymerizable liquid into the build region through the at least one channel. Apparatus for carrying out the method is also described

Owner:CARBON INC

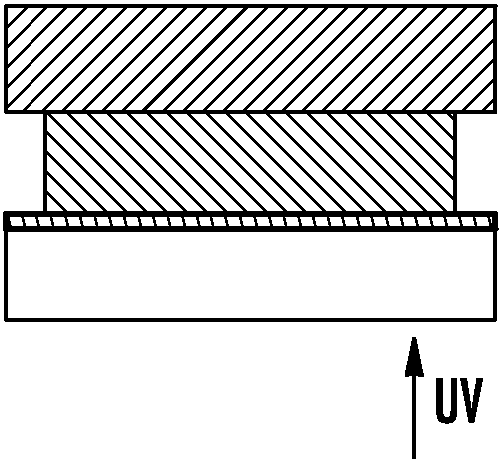

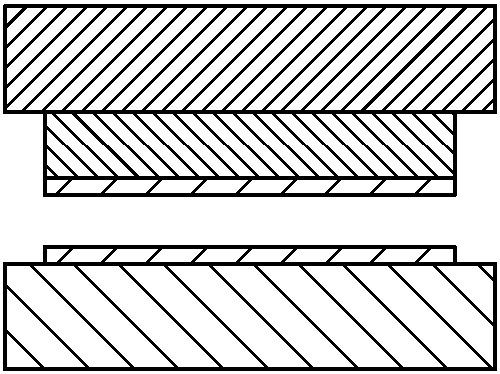

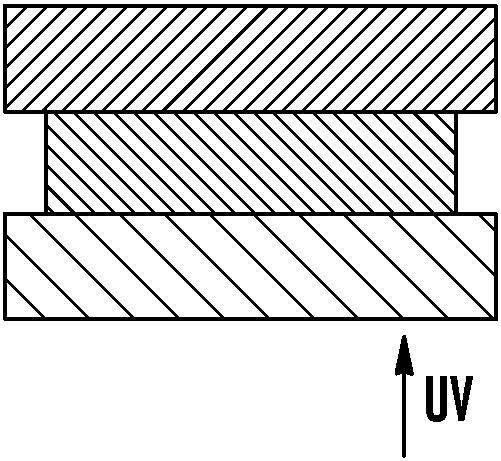

Method and apparatus for three-dimensional fabrication

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquidcontacting the build surface, (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, wherein the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface while concurrently filling the subsequent build region with polymerizable liquid as in step (b). Apparatus for carrying out the method is also described.

Owner:CARBON INC

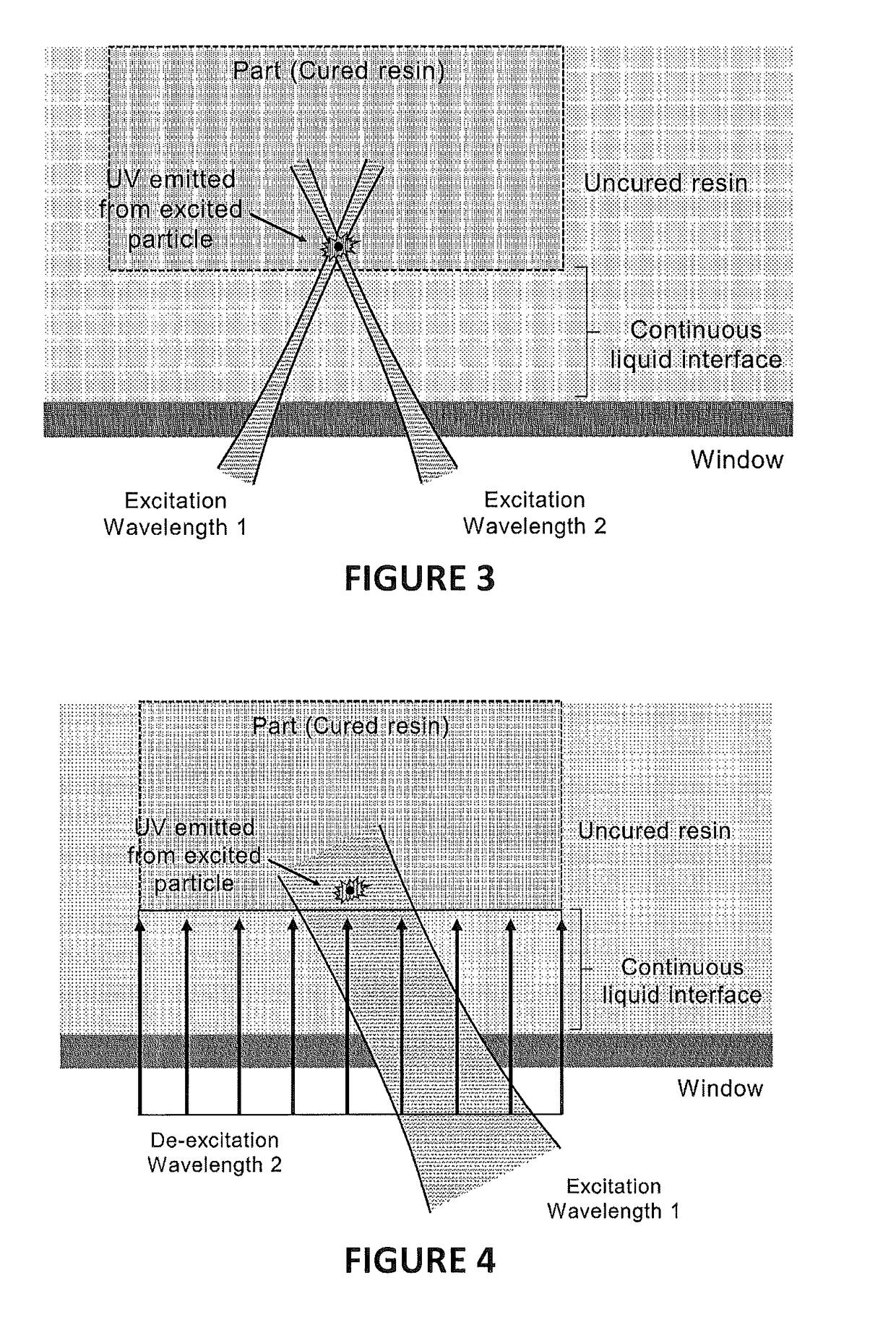

Continuous liquid interface production with upconversion photopolymerization

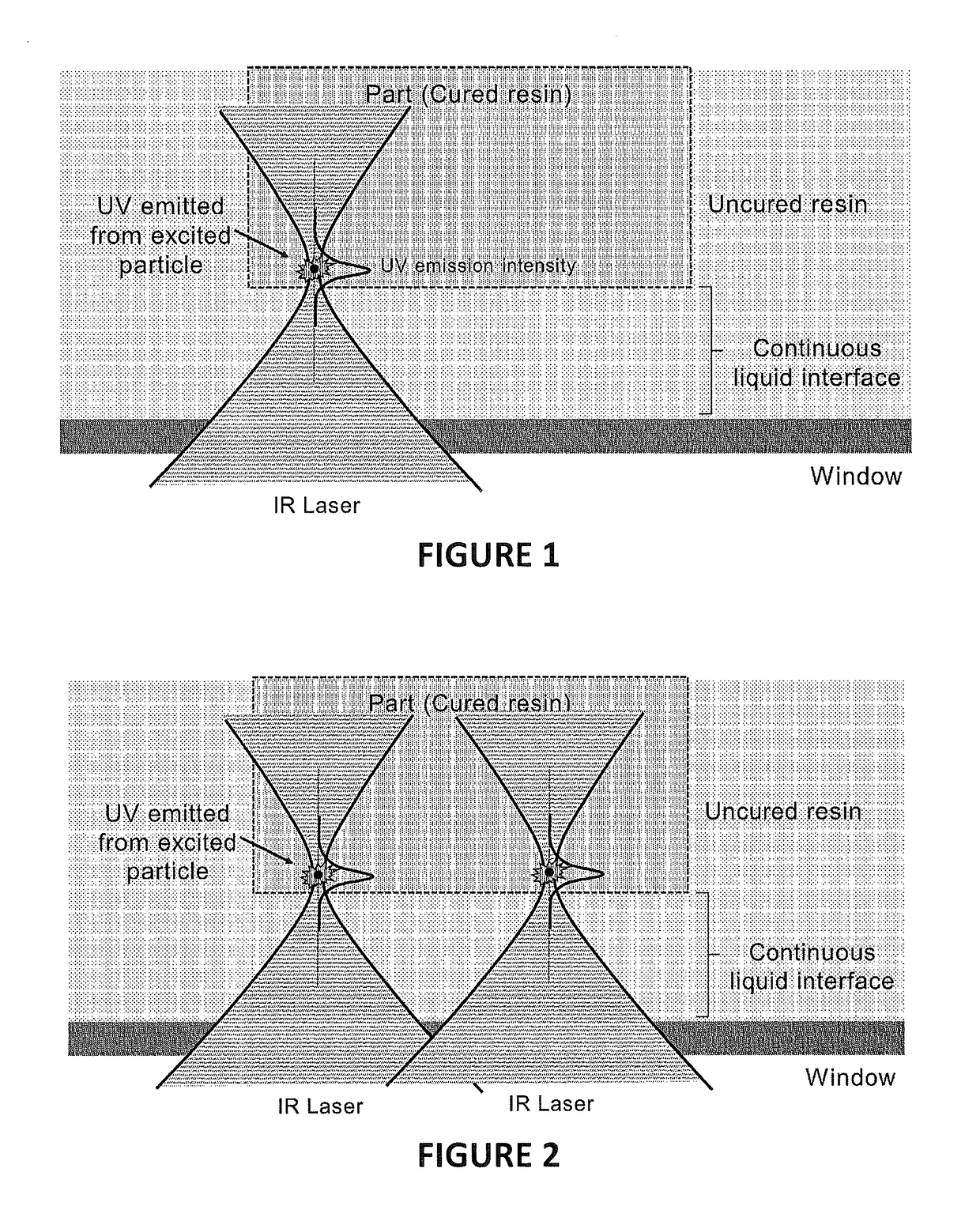

ActiveUS20180126630A1Additive manufacturing apparatus3D object support structuresLight excitationPolymeric liquid

A method of forming a three-dimensional object can be carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid comprising: (i) a polymerizable component; (ii) upconverting particles that are excited by light at a first wavelength and upon excitation emit light at a second wavelength that is shorter than the first wavelength; and (iii) a photoiniator that catalyzes polymerization of the polymerizable component upon excitation by light at the second wavelength; (c) irradiating the build region through the optically transparent member with an excitation light at the first wavelength, and optionally but in some embodiments preferably also advancing the carrier away from the build surface, wherein the excitation light is temporally and / or spatially modulated, to thereby form the three-dimensional object from the polymerizable liquid.

Owner:CARBON INC

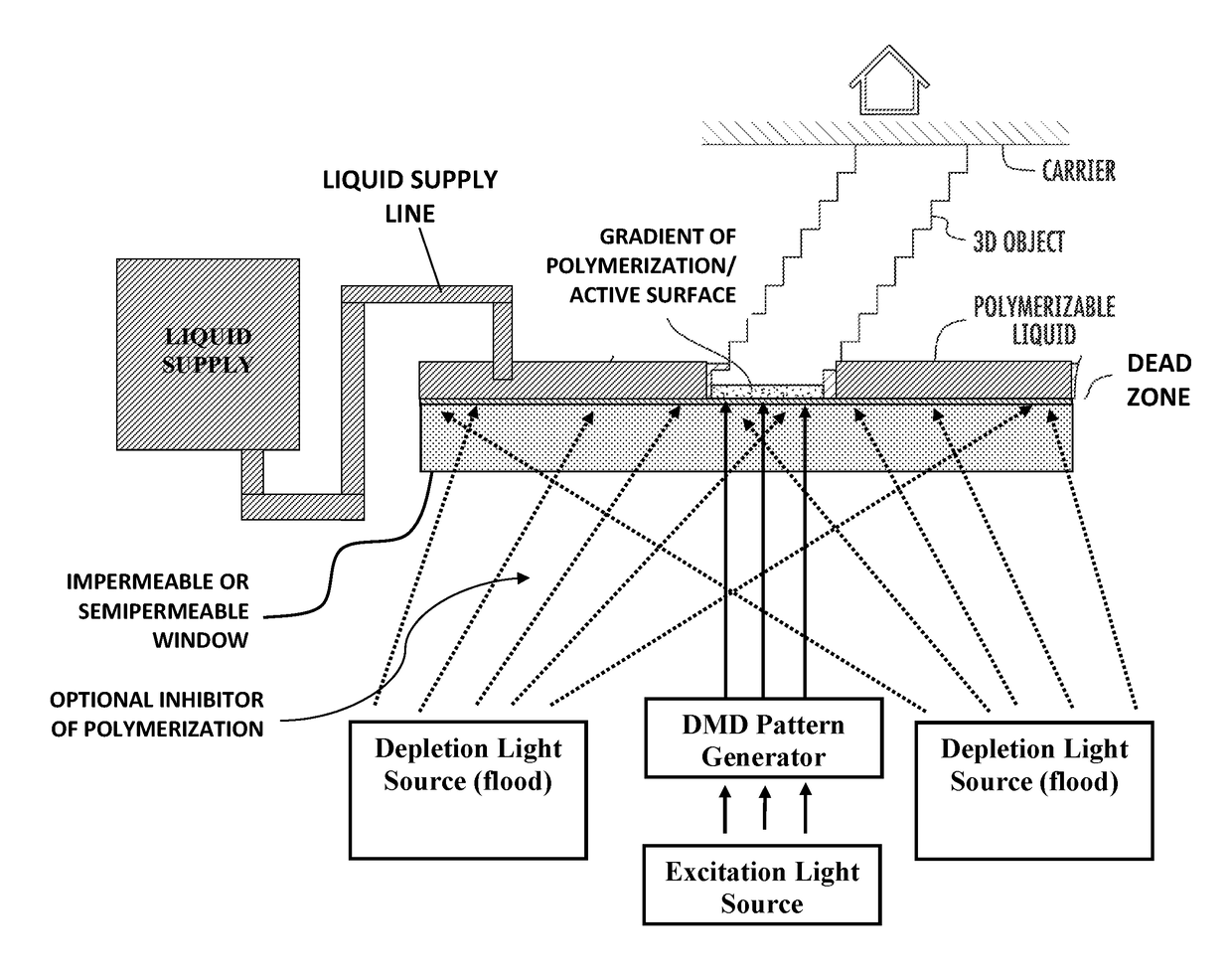

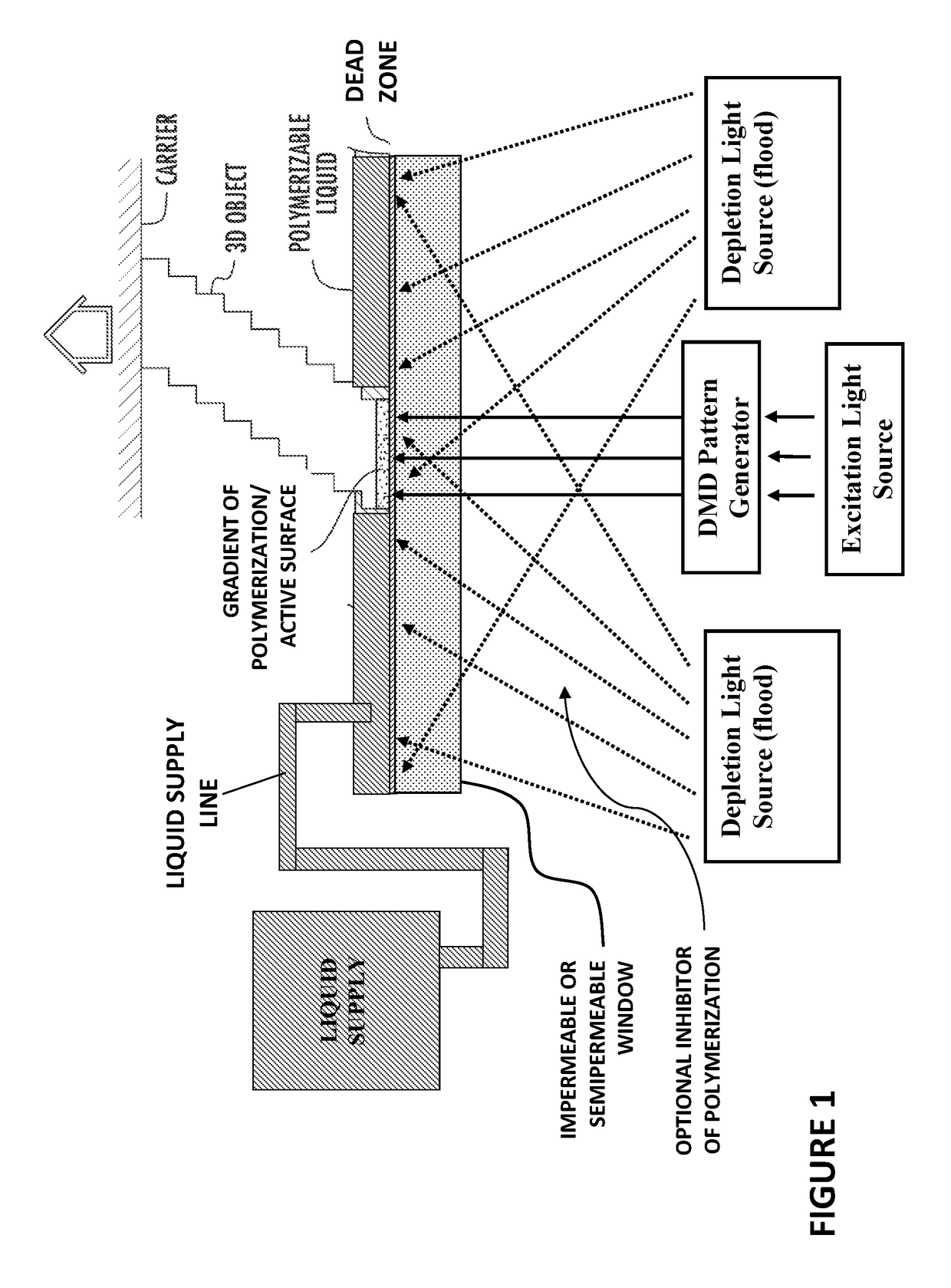

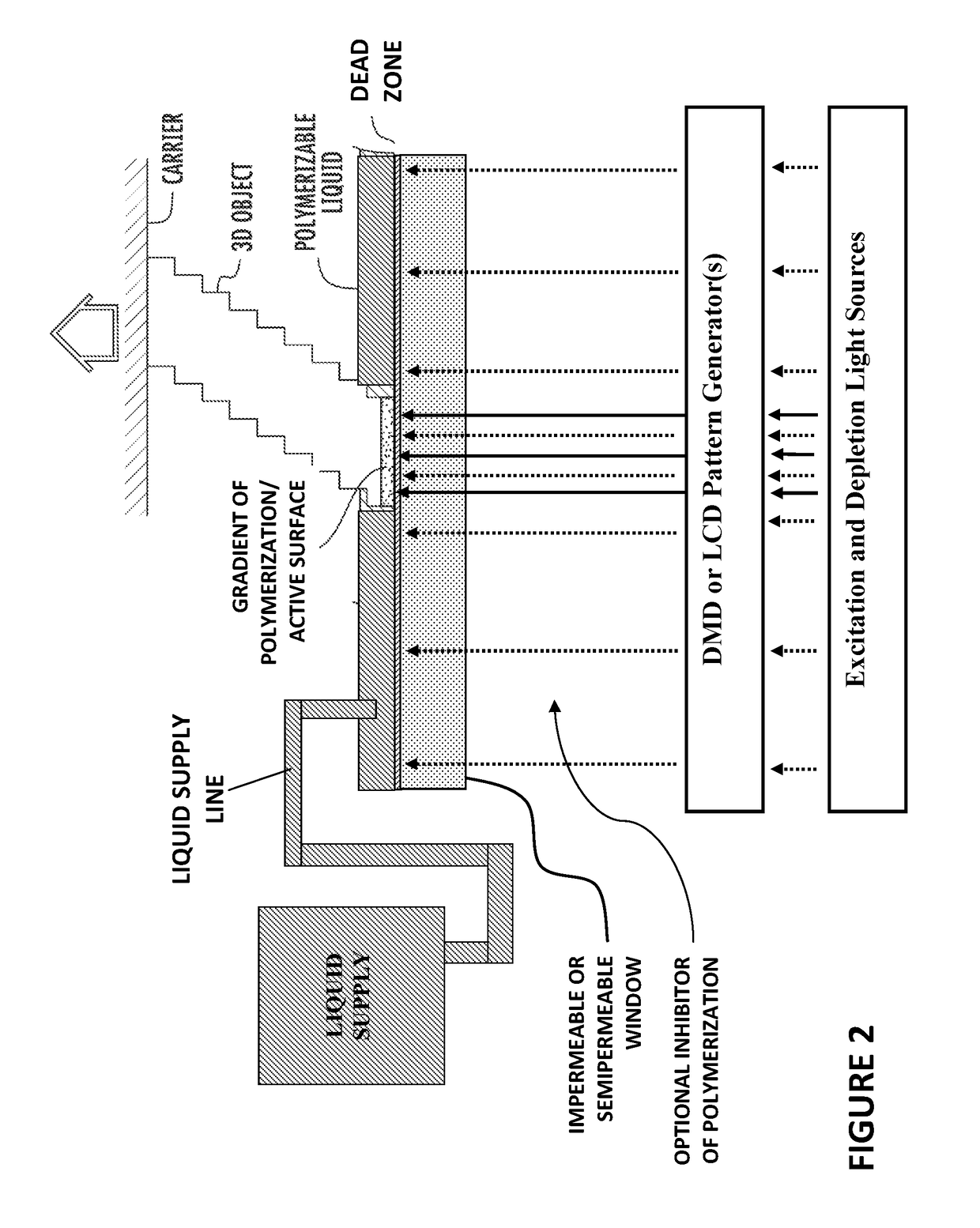

Method and Apparatus for Producing Three- Dimensional Objects

InactiveUS20180243976A1Inhibition of polymerizationAdditive manufacturing apparatus3D object support structuresEngineeringLength wave

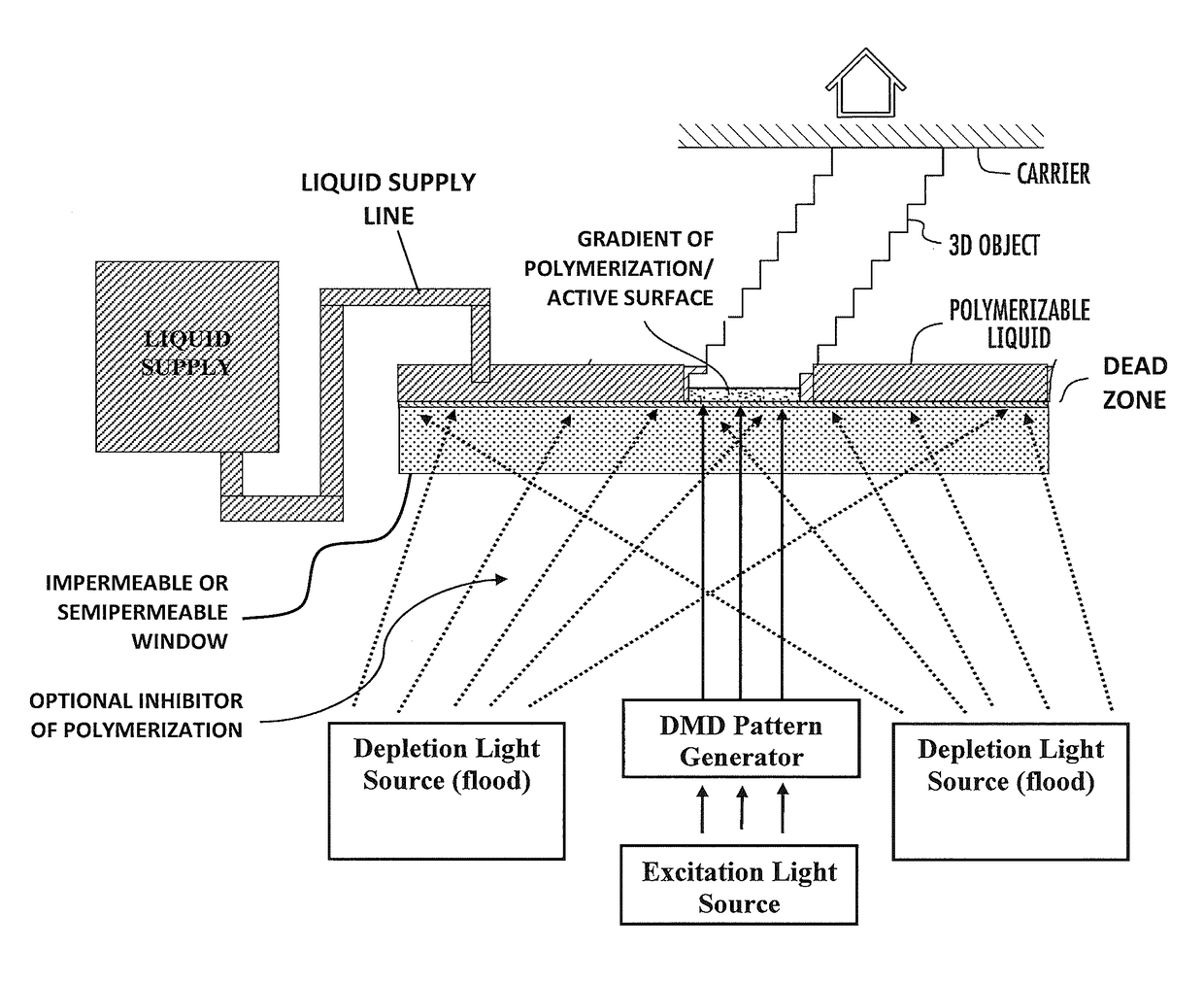

A method of forming a three-dimensional object is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, (c) irradiating the build region with light through the optically transparent member and also advancing the carrier away from the build surface to form a three-dimensional solidified polymer object from the polymerizable liquid. The irradiating is carried out with both: (i) an excitation light at a first wavelength that polymerizes the polymerizable liquid, and (ii) a depletion light at a second wavelength, different from the first wavelength, that inhibits the polymerization of the polymerizable liquid. At least one of the excitation and depletion lights is temporally and / or spatially modulated to form the three-dimensional object.

Owner:CARBON INC

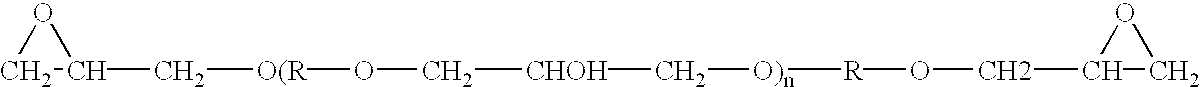

Polymeric precursors of non-absorbable, in situ-forming hydrogels and applications thereof

InactiveUS20070202074A1Pharmaceutical delivery mechanismPharmaceutical non-active ingredientsInvasive treatmentsSemi solid

The present invention is directed toward an injectable, single- or multiple-component polymeric liquid precursor of an in situ-forming, non-absorbable, flexible, and resilient hydrogel or semi-solid that can be used in non-surgical, minimally invasive treatment of herniated disc.

Owner:POLY MED

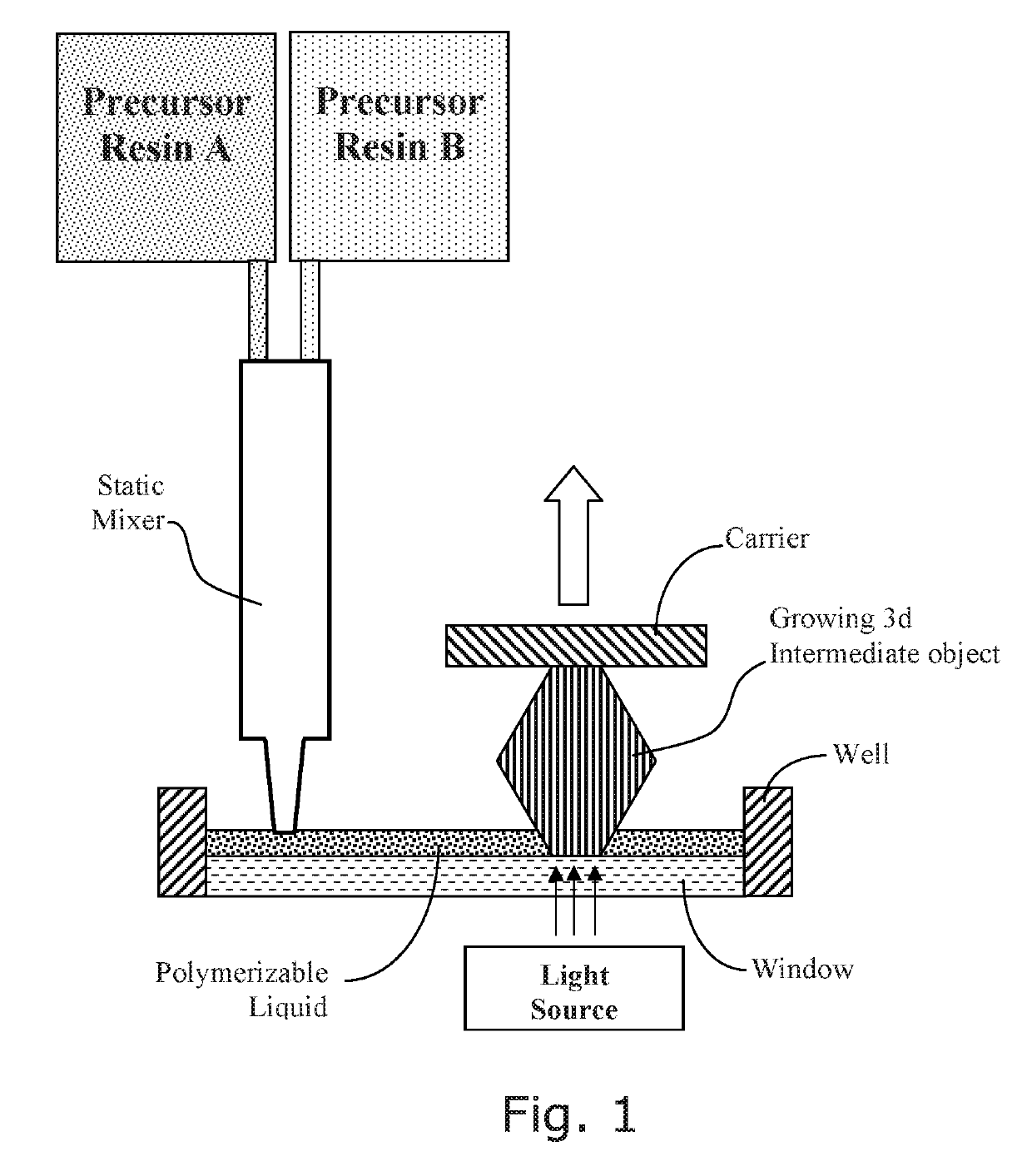

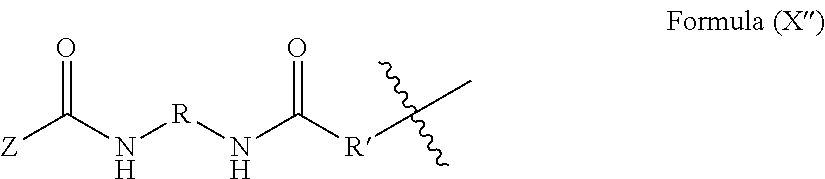

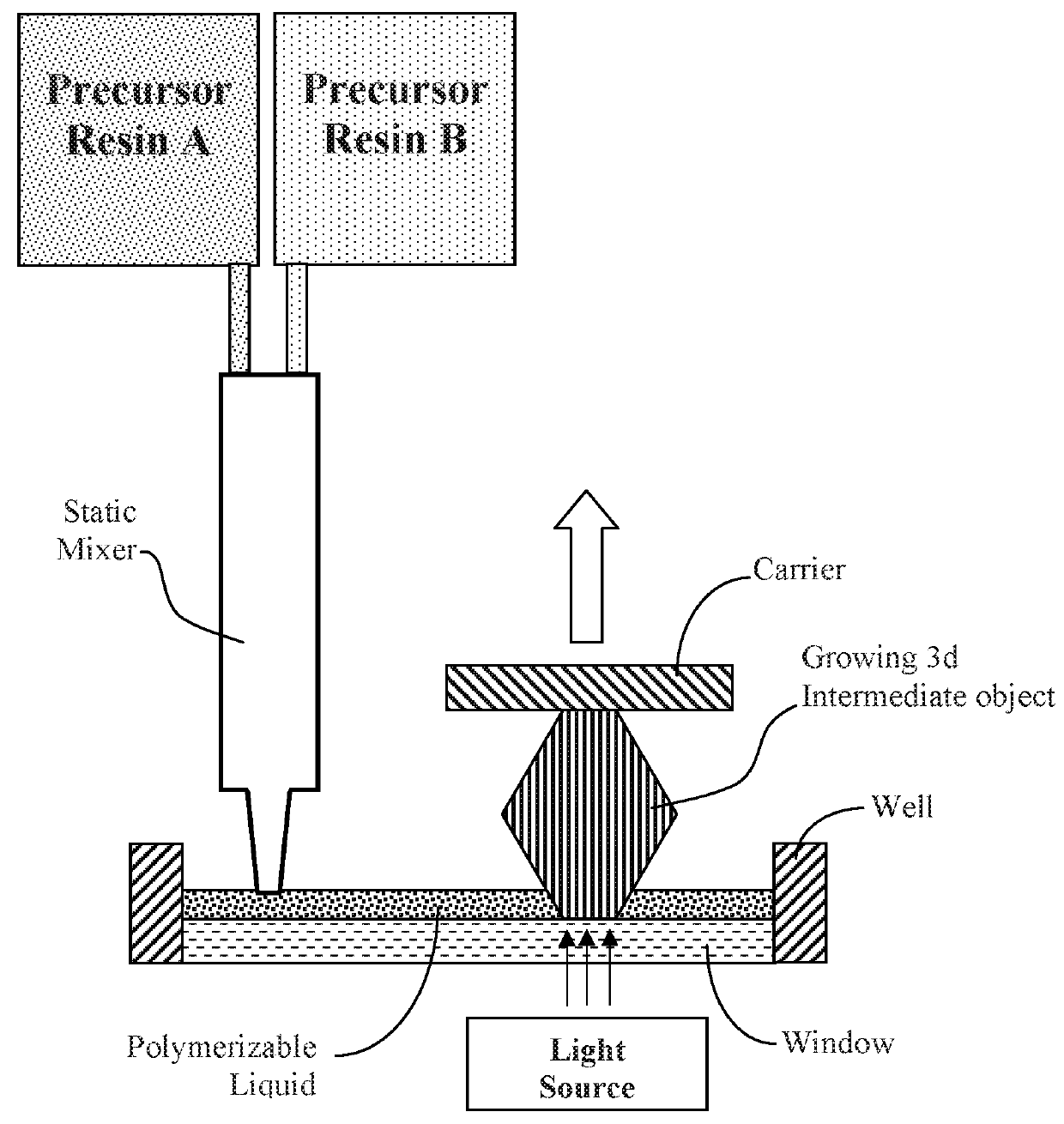

Dual precursor resin systems for additive manufacturing with dual cure resins

ActiveUS10350823B2Enhance or speed the refilling of the build regionIncreased formationAdditive manufacturing apparatusSolesDual curePolymer science

A method of forming a dual cure three-dimensional object by additive manufacturing may be carried out by mixing a first precursor liquid and a second precursor liquid to produce a polymerizable liquid comprising a mixture of (i) a light polymerizable liquid first component, and (ii) a second solidifiable component (e.g., a second reactive component) that is different from the first component (e.g., that does not contain a cationic photoinitiator, or is further solidified by a different physical mechanism, or further reacted, polymerized or chain extended by a different chemical reaction). In the foregoing: (i′) at least one reactant of the second solidifiable component is contained in the first precursor liquid, and (ii′) at least one reactant or catalyst of the second solidifiable component is contained in the second precursor liquid. Once mixed, the three-dimensional object may be formed from the resin by a dual cure additive manufacturing process.

Owner:CARBON INC

Methods of producing polyurethane three-dimensional objects from materials having multiple mechanisms of hardening

ActiveUS20160137838A1Increased formationEnhance or speed the refilling of the build regionManufacturing enclosuresOptical articlesEndcappingPolymer science

A method of forming a three-dimensional object of polyurethane, polyurea, or copolymer thereof is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid including at least one of: (i) a blocked or reactive blocked prepolymer, (ii) a blocked or reactive blocked diisocyanate, or (iii) a blocked or reactive blocked diisocyanate chain extender; (c) irradiating the build region with light through the optically transparent member to form a solid blocked polymer scaffold and advancing the carrier away from the build surface to form a three-dimensional intermediate having the same shape as, or a shape to be imparted to, the three-dimensional object, with the intermediate containing the chain extender; and then (d) heating or microwave irradiating the three-dimensional intermediate sufficiently to form from the three-dimensional intermediate the three-dimensional object of polyurethane, polyurea, or copolymer thereof.

Owner:CARBON INC

Method of additive manufacturing by fabrication through multiple zones

ActiveUS20160303793A1Enhance or speed the refilling of the build regionEnhance or speed the refilling of said build regionManufacturing platforms/substratesAdditive manufacturing with liquidsEngineeringLaser additive manufacturing

A method of forming a three-dimensional object is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween, with the carrier positioned adjacent and spaced apart from the build surface at a start position; then (b) forming an adhesion segment of the three-dimensional object (c) optionally but preferably forming a transition segment of the three dimensional object; and then (d) forming a body segment of the three dimensional object. In each case, the segment can be formed by: (i) filling the build region with a polymerizable liquid, (ii) continuously or intermittently irradiating the build region with light through the optically transparent, and (iii) continuously or intermittently advancing the carrier away from the build surface, to thereby form that segment from the polymerizable liquid.

Owner:CARBON INC

Siloxane matrix polymers and SPD light valve films incorporating same

A film suitable for use as a light-modulating unit of a suspended particle device (SPD) light valve. The film comprises a siloxane matrix polymer which has a refractive index>1.4630 and has droplets of a liquid light valve suspension distributed within the matrix. The liquid light valve suspension preferably comprises a polyalkyl (meth)acrylate and / or fluorinated (meth)acrylate suspending polymer and optionally may comprise one or more non-polymeric liquids.

Owner:RES FRONTIERS

Wash liquids for use in additive manufacturing with dual cure resins

ActiveUS10343331B2Enhance or speed the refilling of the build regionIncreased formationAdditive manufacturing apparatus3D object support structuresDual curePolymeric liquid

Owner:CARBON INC

Wash liquids for use in additive manufacturing with dual cure resins

ActiveUS20170173872A1Increased formationEnhance or speed the refilling of the build regionAdditive manufacturing apparatus3D object support structuresDual curePolymeric liquid

A method of forming a three-dimensional object, which method includes a cleaning or washing step, is carried out by: (a) providing a carrier and a fill level, and optionally an optically transparent member having a build surface defining the fill level, the carrier and the fill level having a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid comprising a mixture of (i) a light polymerizable liquid first component, and (ii) a second solidifiable component that is different from the first component; (c) irradiating the build region with light, to form a solid polymer scaffold from the first component and also advancing the carrier away from the build surface to form a three-dimensional intermediate having the same shape as, or a shape to be imparted to, the three-dimensional object and containing the second solidifiable component carried in the scaffold in unsolidified and / or uncured form; (d) washing the three-dimensional intermediate; and (e) concurrently with or subsequent to the irradiating step, and / or the washing step, solidifying and / or curing the second solidifiable component in the three-dimensional intermediate to form the three-dimensional object.

Owner:CARBON INC

Dual precursor resin systems for additive manufacturing with dual cure resins

ActiveUS20180264719A1Enhance or speed the refilling of the build regionIncreased formationAdditive manufacturing apparatusSolesDual curePolymer science

A method of forming a dual cure three-dimensional object by additive manufacturing may be carried out by mixing a first precursor liquid and a second precursor liquid to produce a polymerizable liquid comprising a mixture of (i) a light polymerizable liquid first component, and (ii) a second solidifiable component (e.g., a second reactive component) that is different from the first component (e.g., that does not contain a cationic photoinitiator, or is further solidified by a different physical mechanism, or further reacted, polymerized or chain extended by a different chemical reaction). In the foregoing: (i′) at least one reactant of the second solidifiable component is contained in the first precursor liquid, and (ii′) at least one reactant or catalyst of the second solidifiable component is contained in the second precursor liquid. Once mixed, the three-dimensional object may be formed from the resin by a dual cure additive manufacturing process.

Owner:CARBON INC

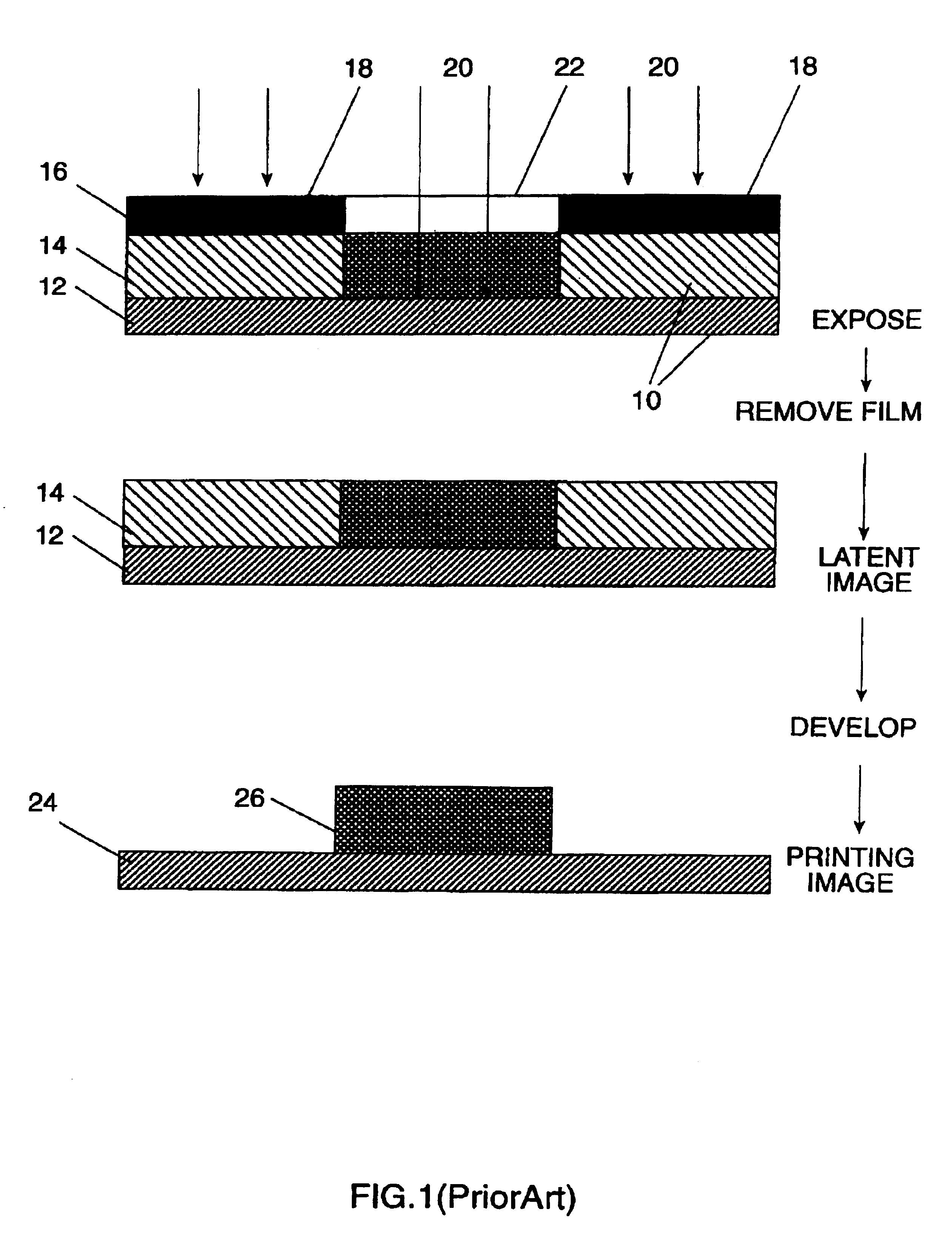

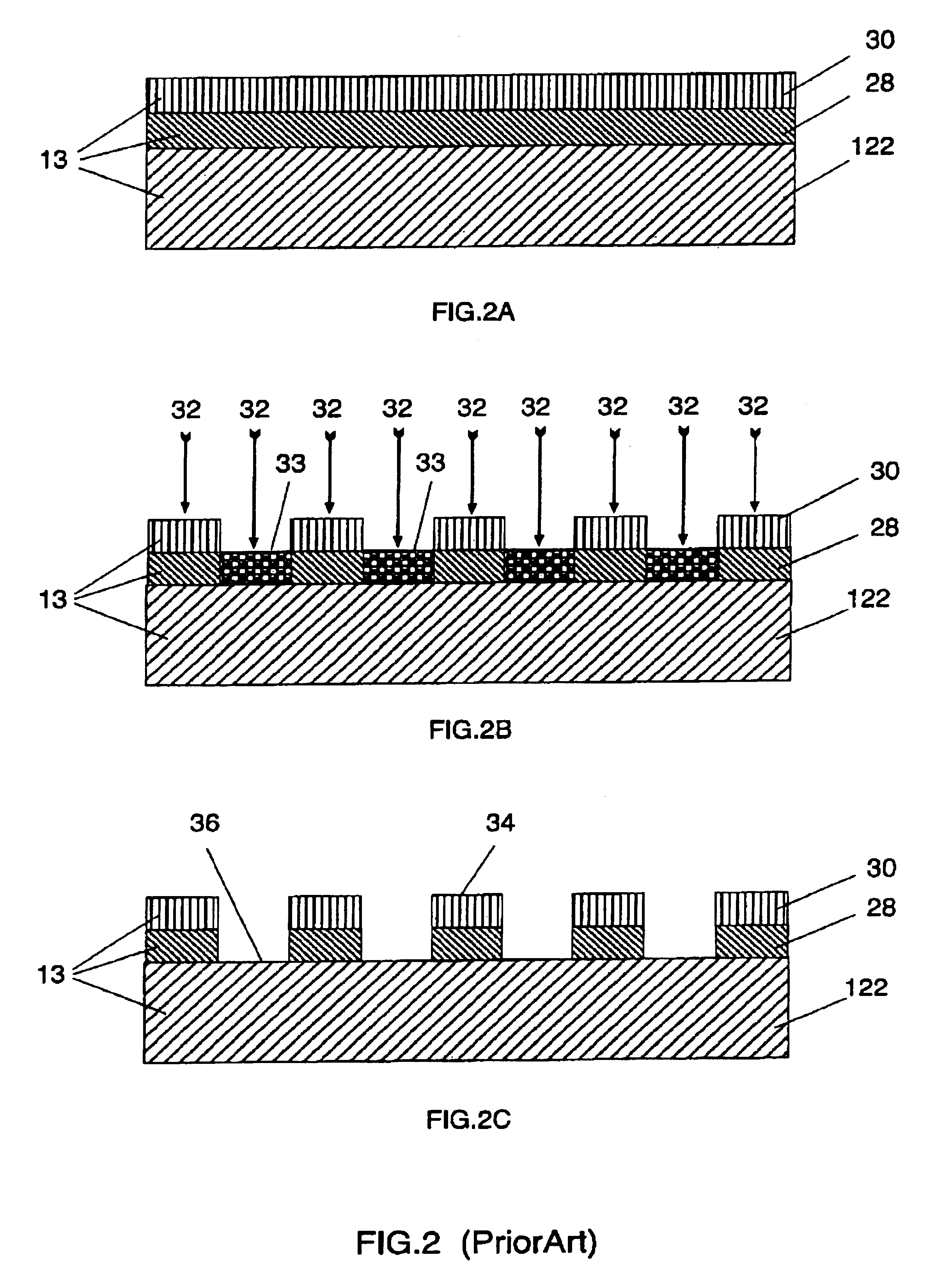

Method and a plate for digitally-imaged offset printing

InactiveUS6899998B2Simple and inexpensiveSimple wayX-ray/infra-red processesPhotosensitive materialsDigital imagingPhotopolymer

An offset plate sensitive to UV or visible light, prepared simply and imaged digitally therewith in a CTP method, and also processed in a simple manner. The plate is provided as a photopolymer plate with increased sensitivity, and is used in a simple imaging-on-press system, using the surface of a lithographic printing cylinder itself as a plate substrate. The method of preparing the printing plate begins by applying a photosensitive liquid coating to the substrate, digitally imaging the coated substrate, using an actinic light source to polymerize portions of the liquid coating in accordance with the imaging, and washing the liquid.

Owner:KODAK IL

Electro-optic displays, and materials for use therein

InactiveUS20110164301A1Lamination ancillary operationsPolyureas/polyurethane adhesivesCross-linkDisplay device

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes. A third electro-optic display, intended for writing with a stylus or similar instrument, is produced by forming a layer of an electro-optic material on an electrode; depositing a substantially solvent-free polymerizable liquid material over the electro-optic material; and polymerizing the polymerizable liquid material.

Owner:E INK CORPORATION

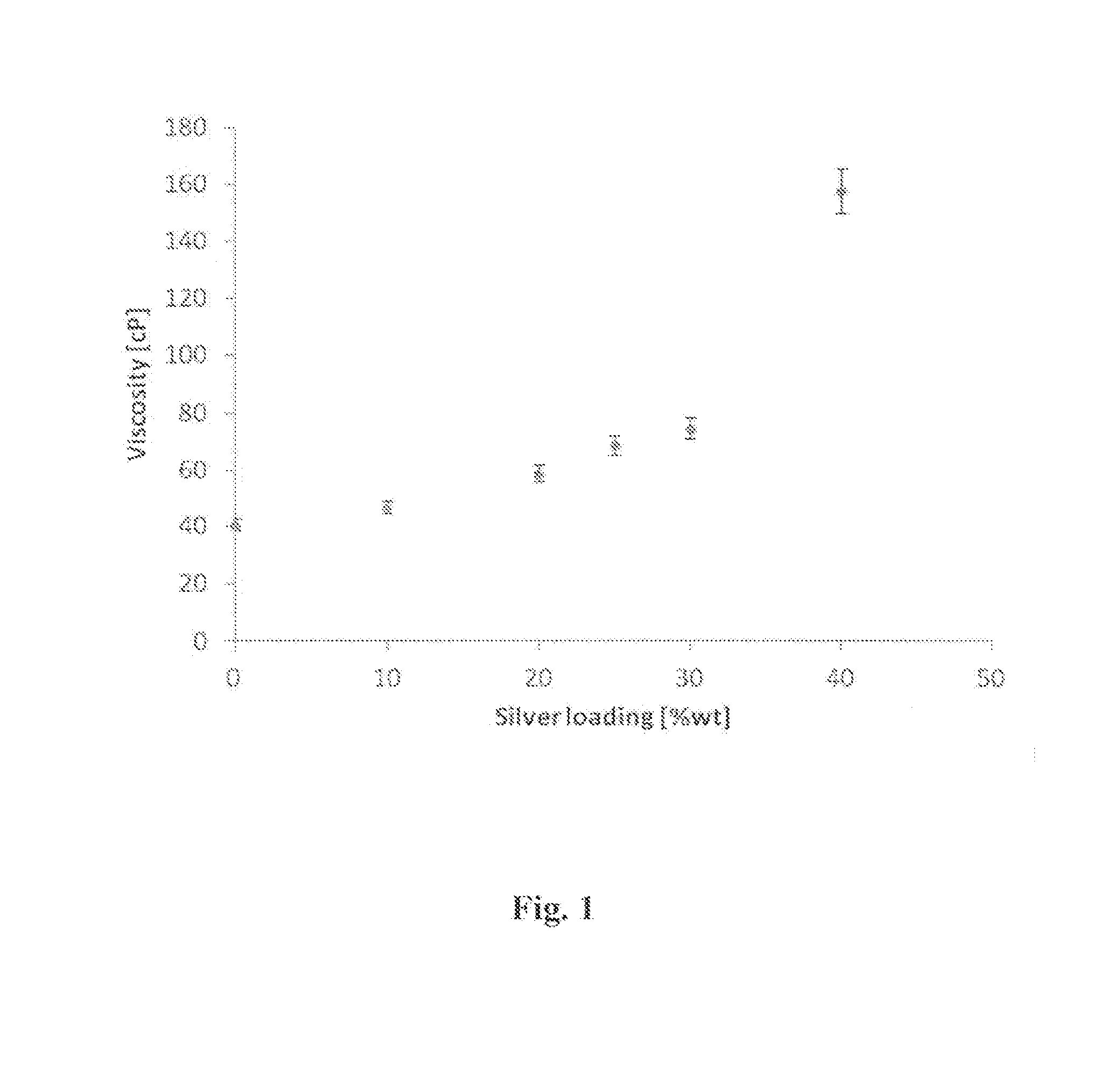

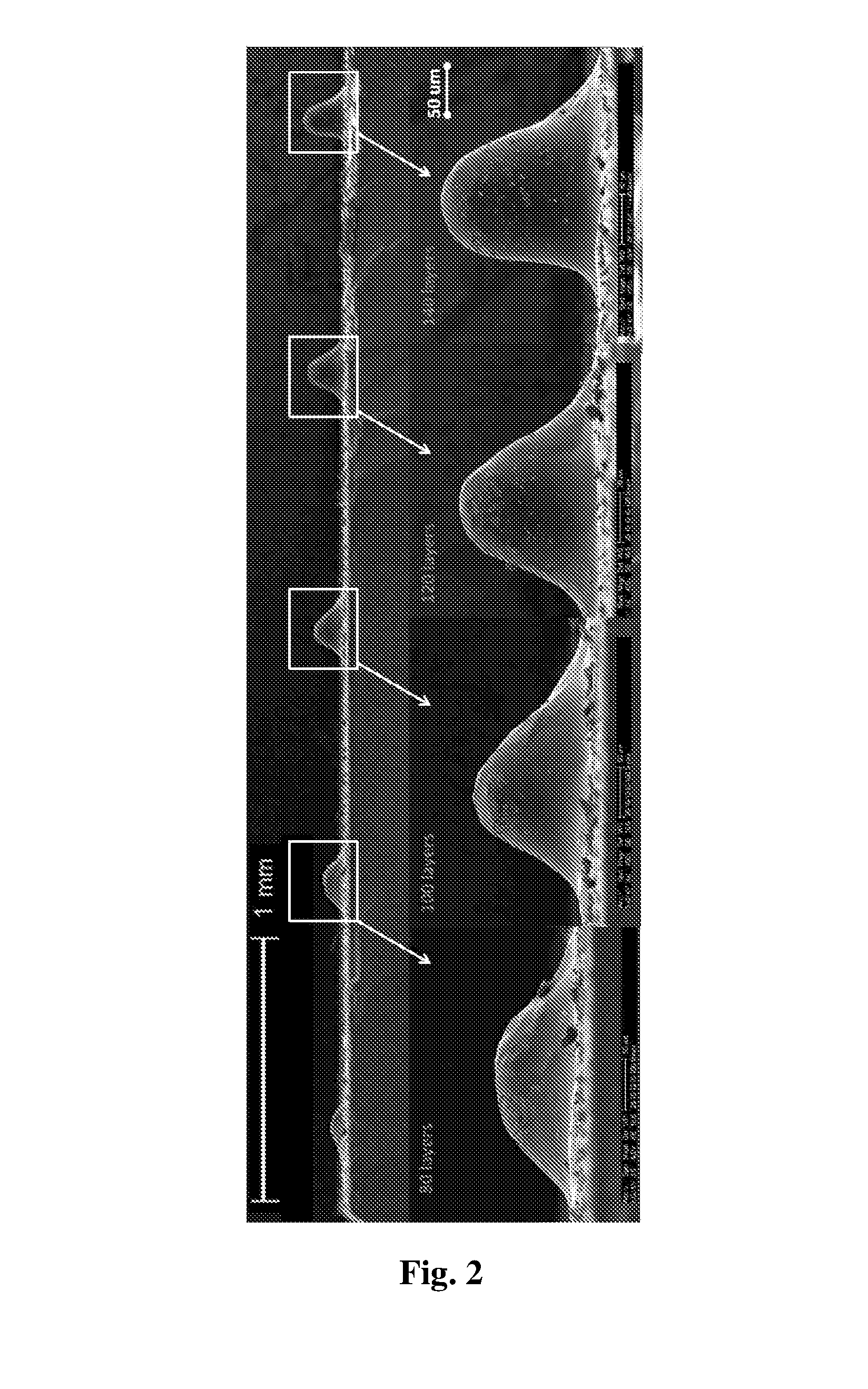

Three-dimensional conductive patterns and inks for making same

InactiveUS20150366073A1Inhibit aggregationGood dispersionAdditive manufacturing apparatusTransportation and packagingPolymer scienceOligomer

The invention generally relates to polymerizable conductive ink formulations comprising at least one metal source, at least one monomer and / or oligomer and a polymerization initiator, and uses thereof for printing three-dimensional functional structures. In particular a method of fabricating a three-dimensional conductive pattern on a substrate is disclosed, the method comprising: a) forming a pattern on a surface region of a substrate by using an ink comprising at least one metal source, at least one liquid polymerizable monomer and / or oligomer, and at least one polymerization initiator; b) polymerizing at least a portion of said liquid monomer and / or oligomer; c) rendering the metal source a continuous percolation path for electrical conductivity (sintering); d) repeating steps (a), (b) and optionally (c) to obtain a three-dimensional conductive pattern.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

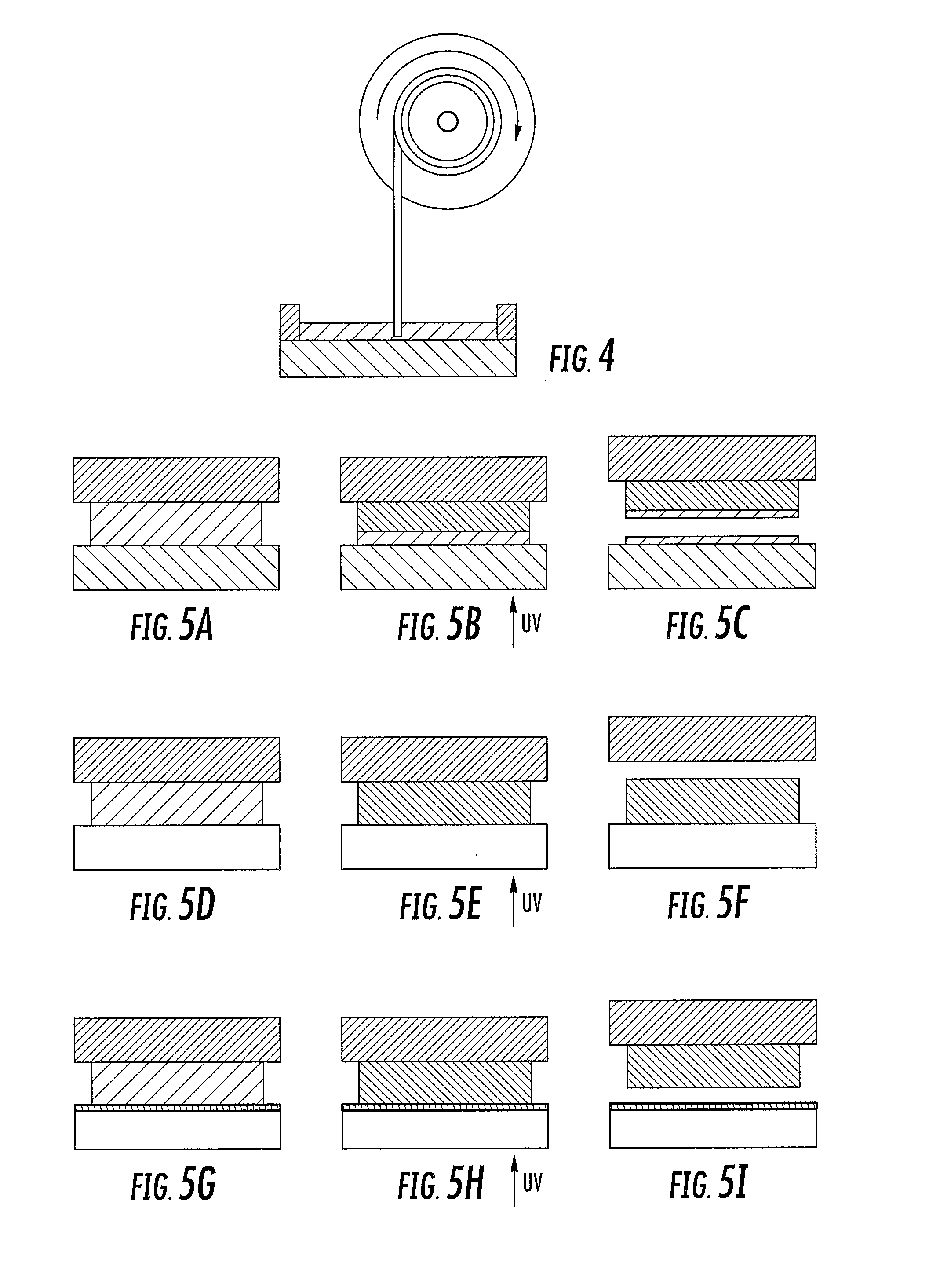

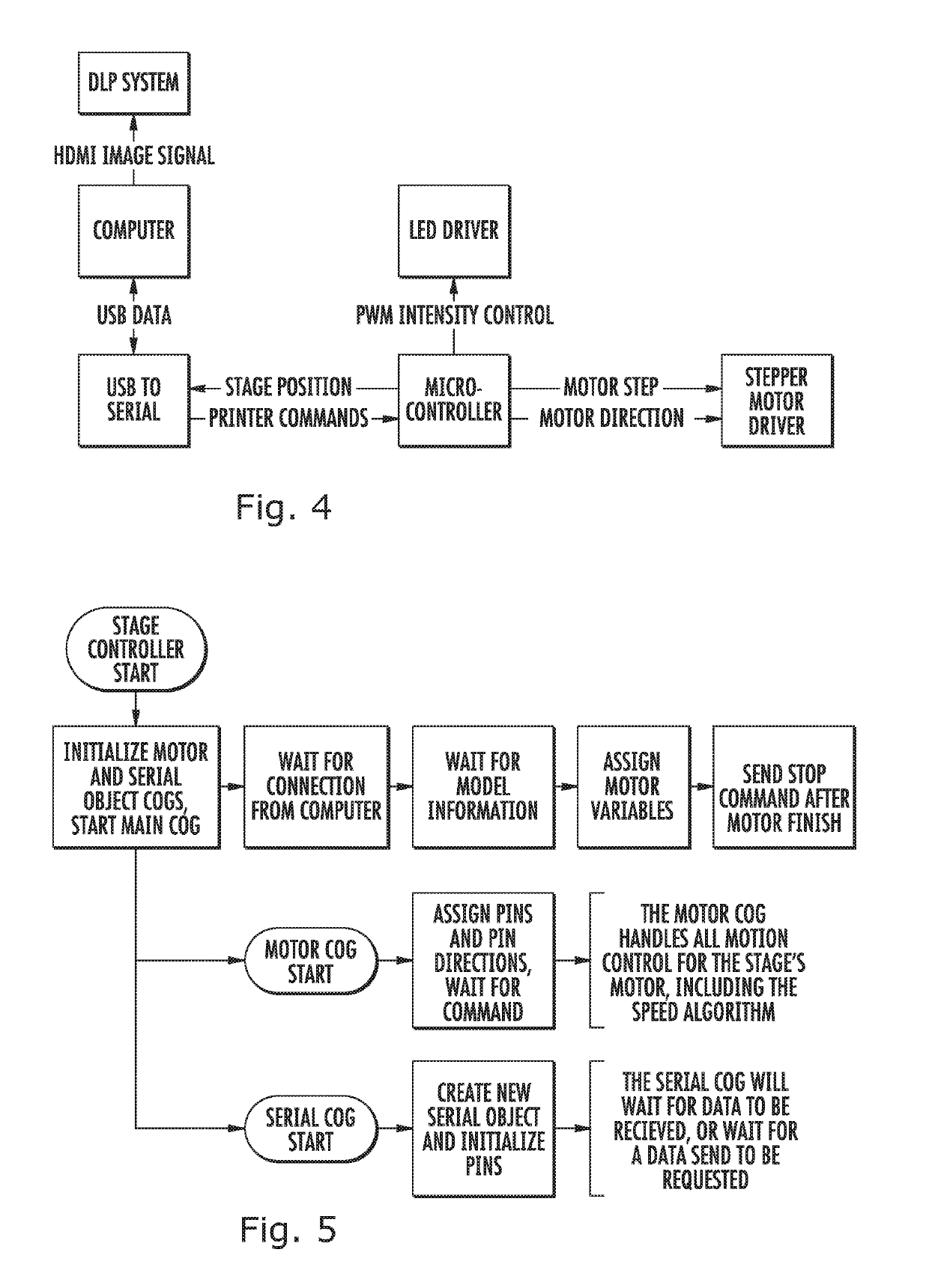

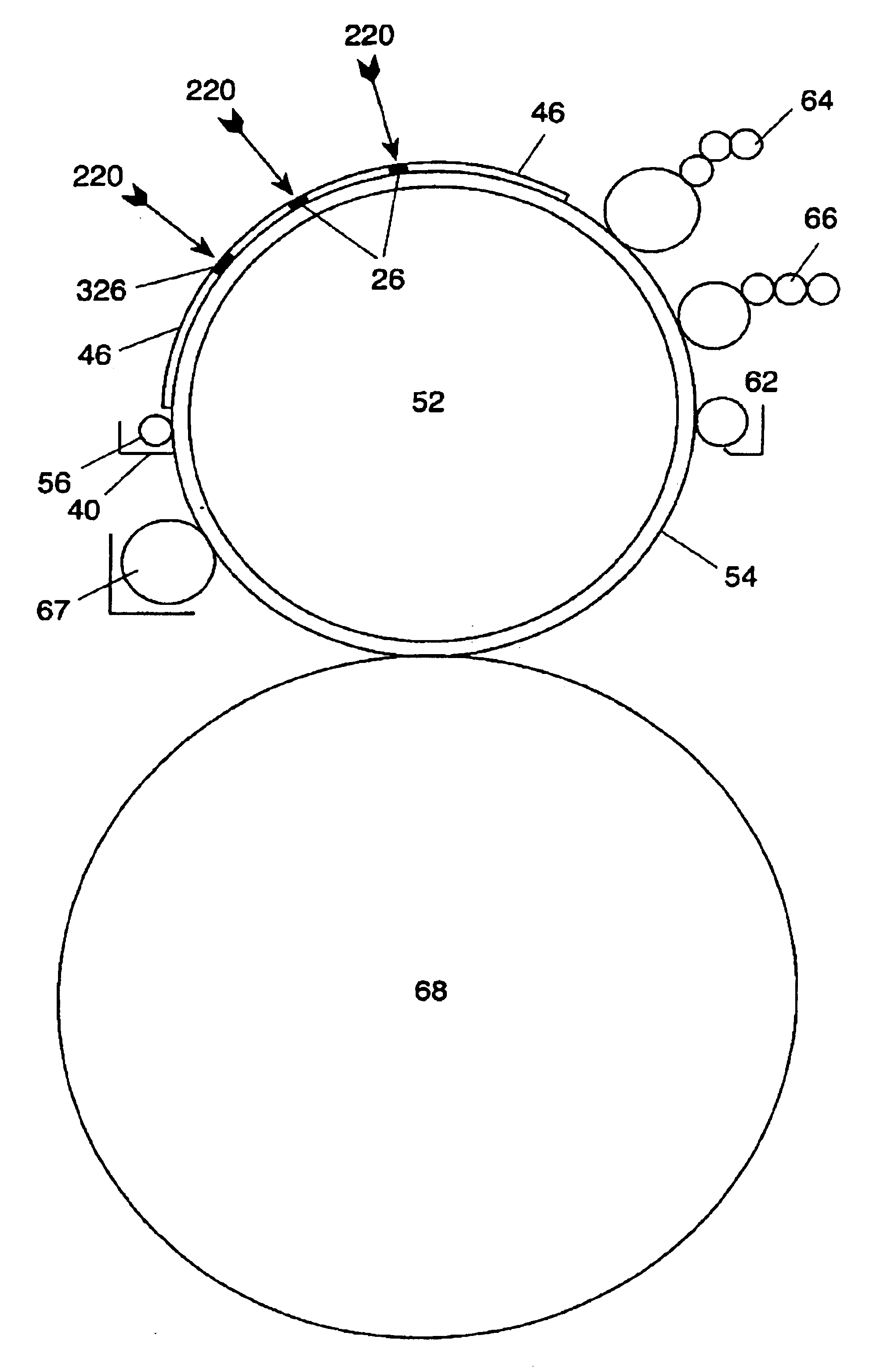

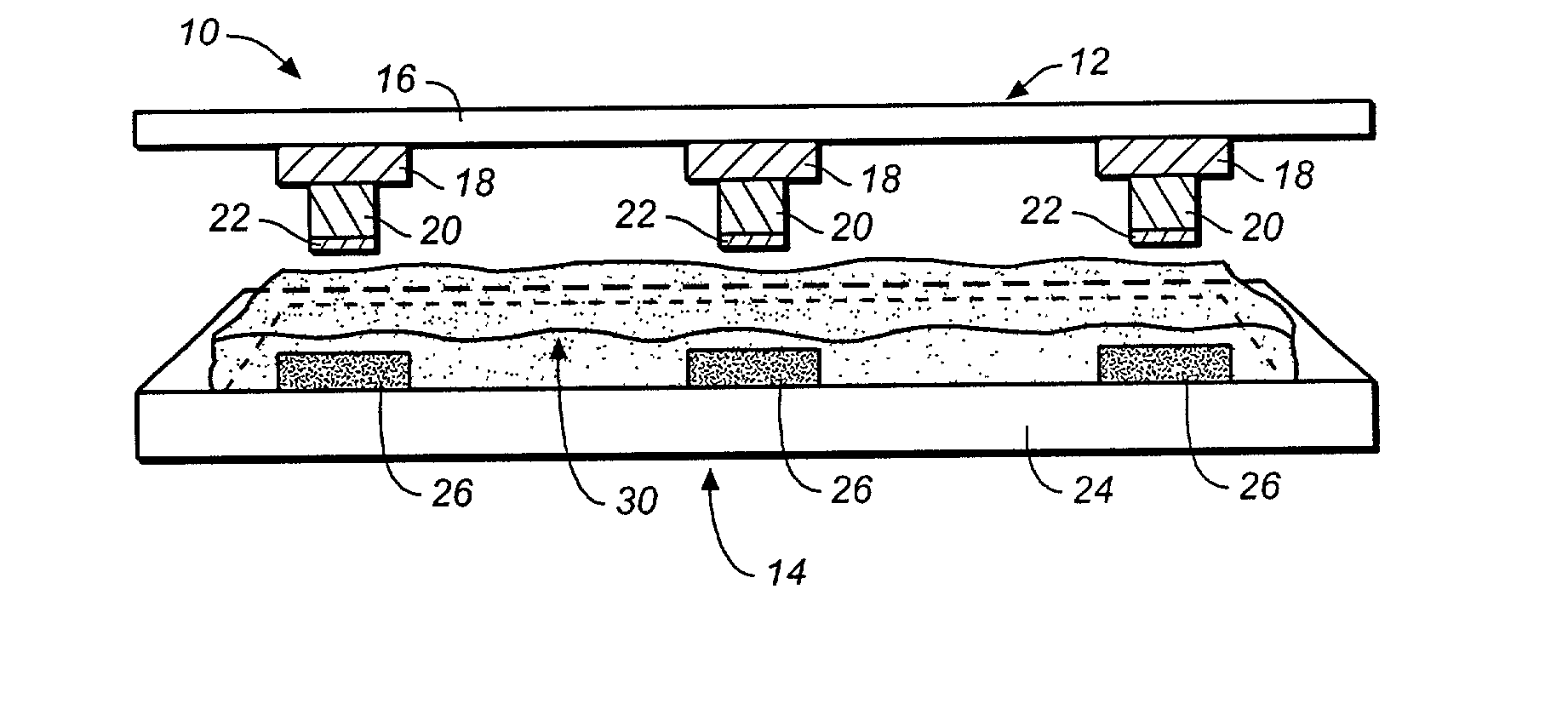

Methods and Apparatus for Continuous Liquid Interface Production with Rotation

ActiveUS20170113416A1Facilitate re-fillingReduce decreaseManufacturing platforms/substrates3D object support structuresRotation methodLiquid interface

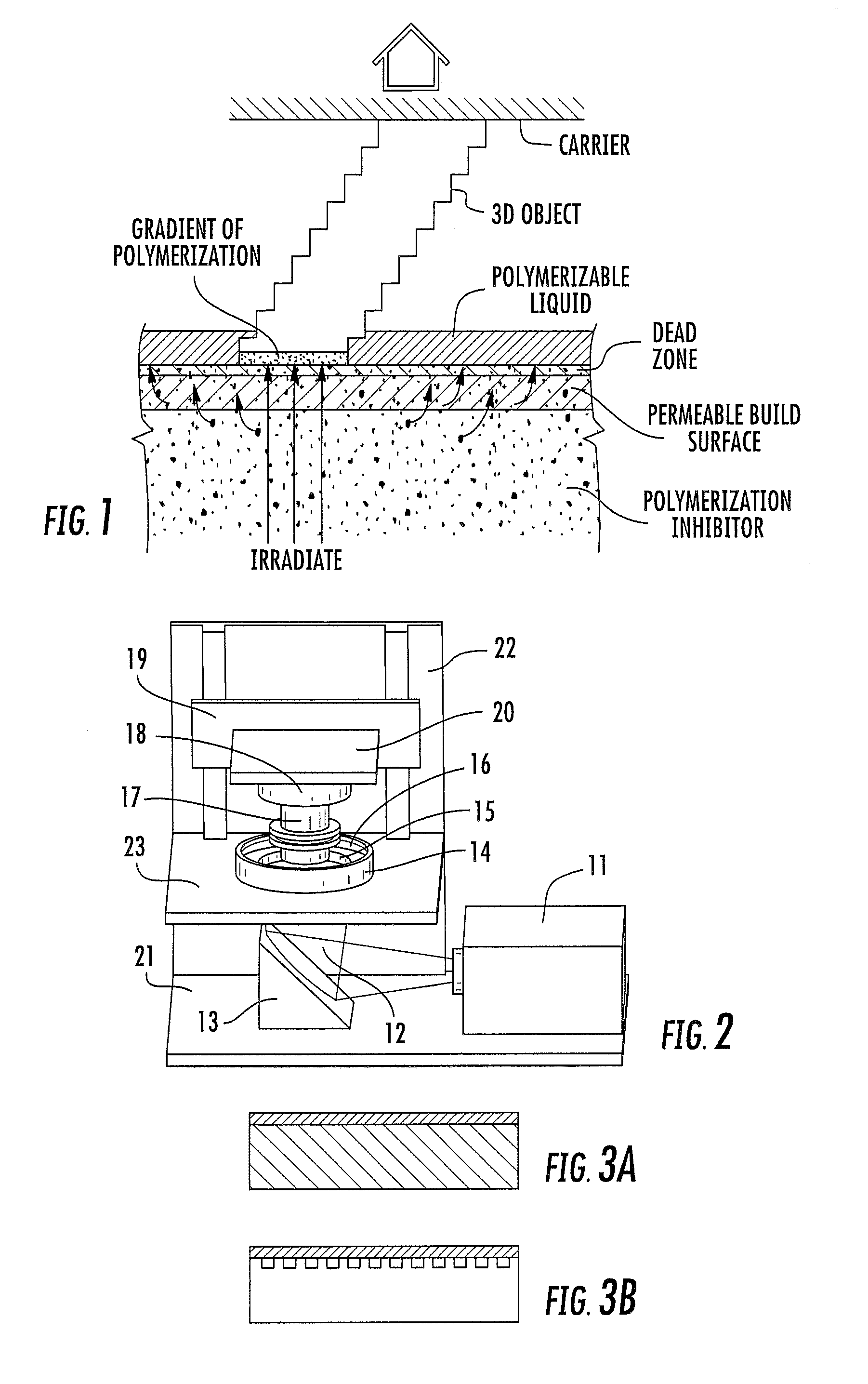

Methods and apparatus for additive manufacturing of three-dimensional objects from polymerizable liquids are described. The methods and apparatus are implemented in the form of a bottom up additive manufacturing apparatus, and in preferred embodiments are implemented in the form of Continuous Liquid Interface Production (or “CLIP”) methods and apparatus. Rotation of at least one of the carrier and the build plate is preferably included, for example to facilitate the filling of the build region with the polymerizable liquid.

Owner:CARBON INC

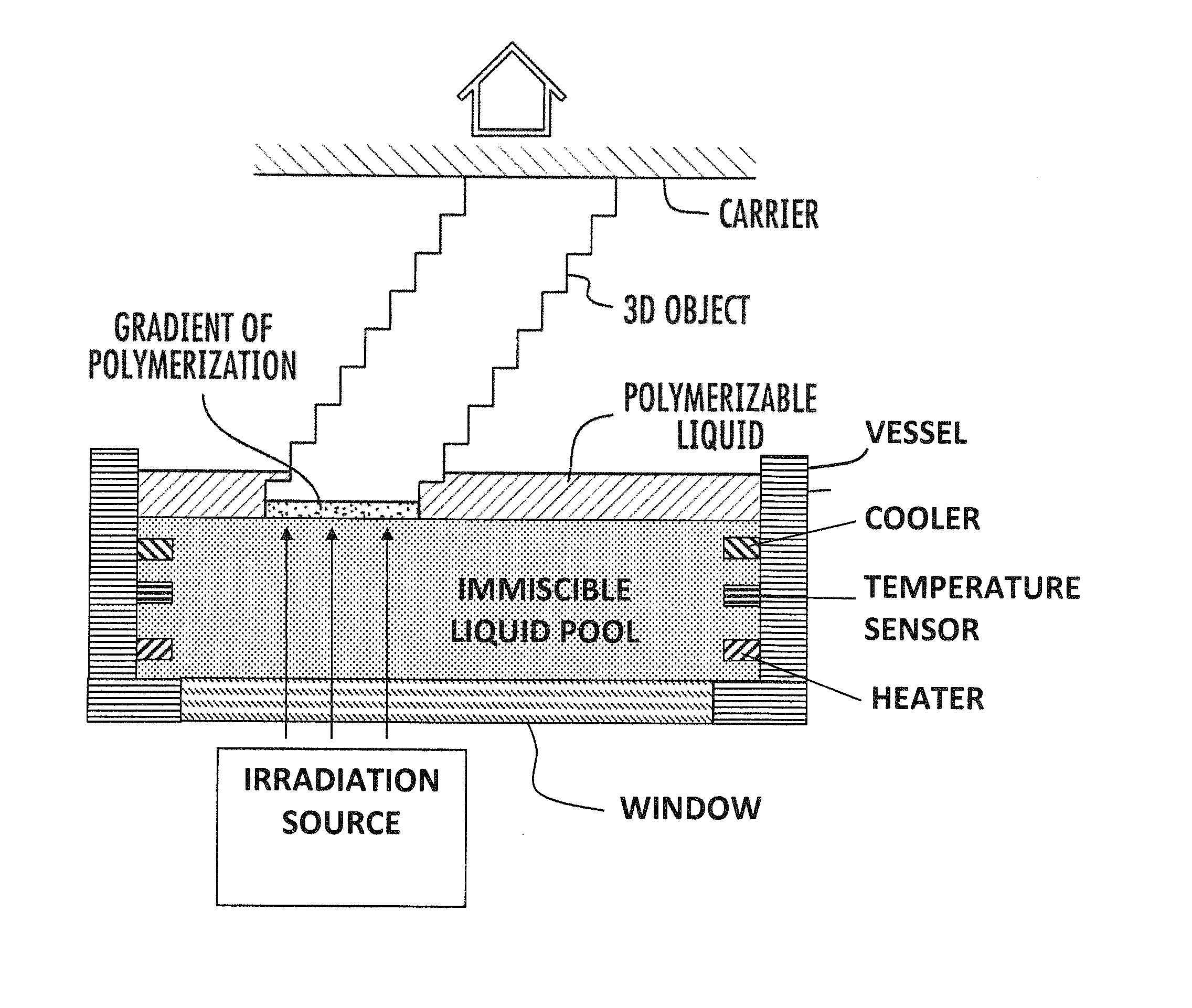

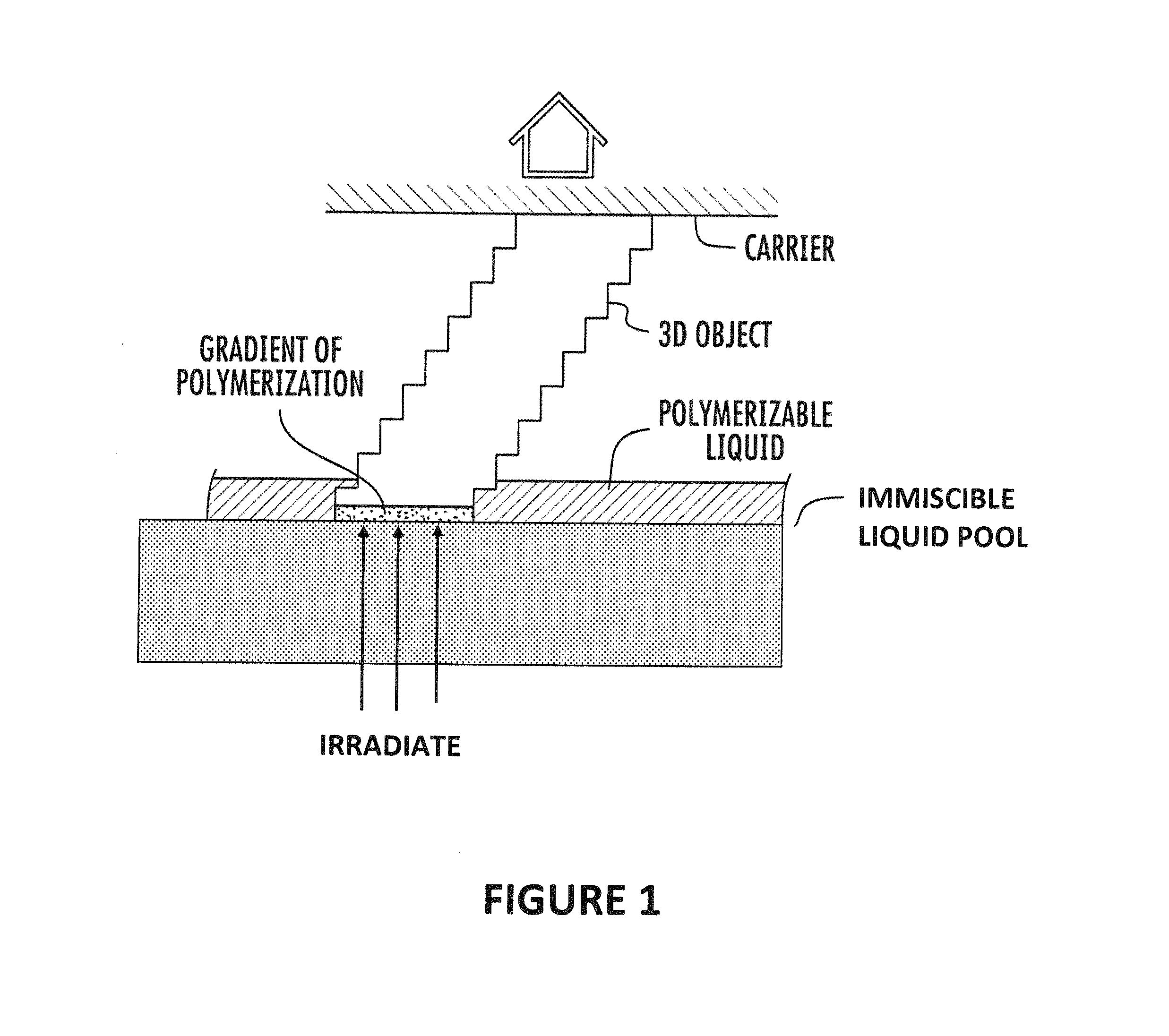

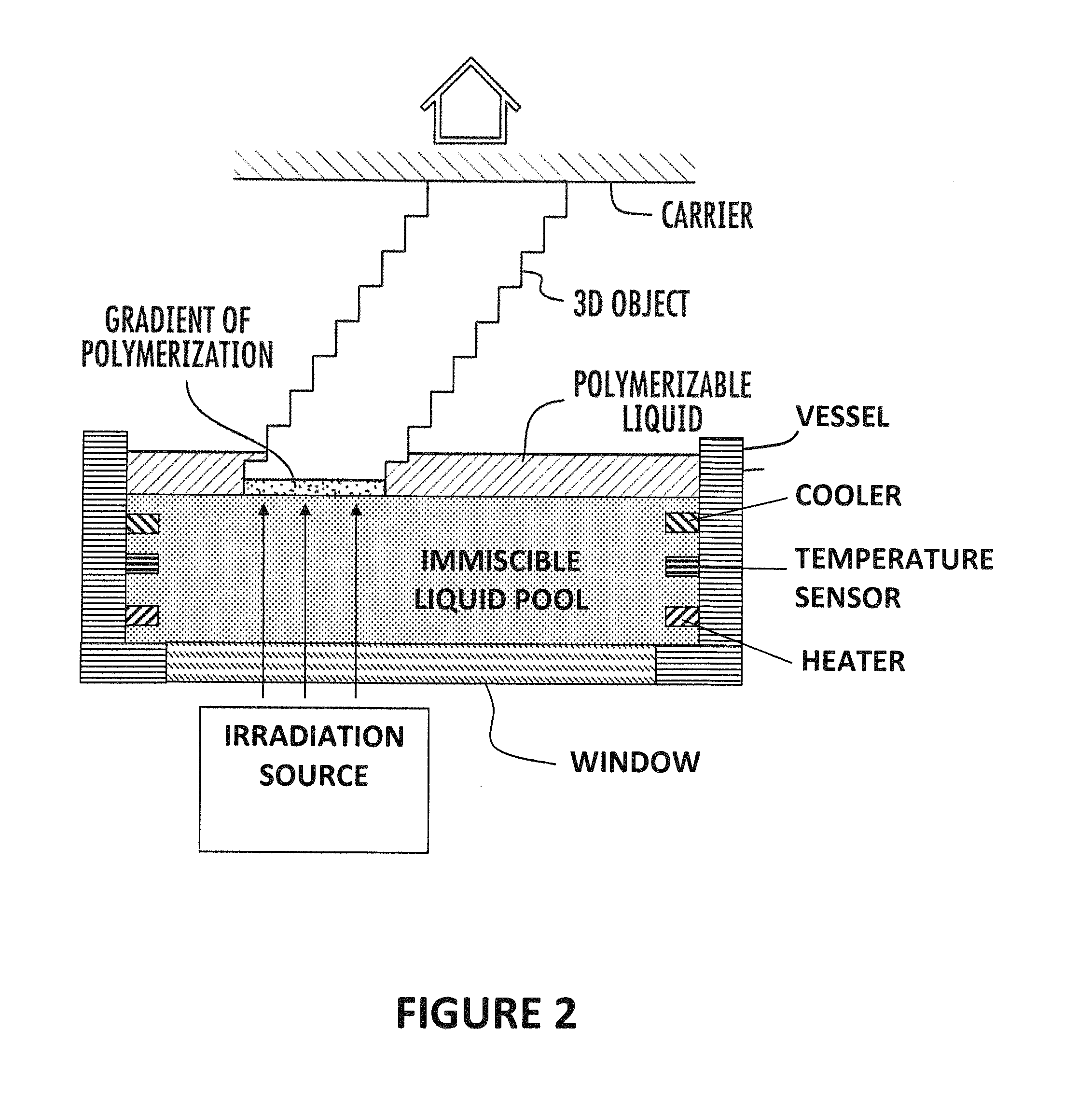

Continuous three dimensional fabrication from immiscible liquids

ActiveUS20170028618A1Low viscosityIncrease ratingsManufacturing platforms/substrates3D object support structuresEngineeringVolumetric Mass Density

A method of forming a three-dimensional object is carried out by: providing a carrier and a pool of immiscible liquid, the pool having a liquid build surface, the carrier and the liquid build surface defining a build region therebetween; filling the build region with a polymerizable liquid, wherein the immiscible liquid is immiscible with the polymerizable liquid (in some embodiments wherein the immiscible liquid has a density greater than the polymerizable liquid); irradiating the build region through at least a portion of the pool of immiscible liquid to form a solid polymer from the polymerizable liquid and advancing the carrier away from the liquid build surface to form the three-dimensional object comprised of the solid polymer from the polymerizable liquid. Optionally, but in some embodiments preferably, the method is carried out while also continuously maintaining a gradient of polymerization zone between the liquid build surface and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form.

Owner:CARBON INC

Electro-optic displays, and materials for use therein

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes. A third electro-optic display, intended for writing with a stylus or similar instrument, is produced by forming a layer of an electro-optic material on an electrode; depositing a substantially solvent-free polymerizable liquid material over the electro-optic material; and polymerizing the polymerizable liquid material.

Owner:E INK CORPORATION

Interconnect assembly and Z-connection method for fine pitch substrates

An interconnect assembly and a fluxless method for forming the interconnect assembly. The fluxless method includes providing a first semiconductor substrate having a first pad connected thereto. A post is connected to the first pad and includes a length greater than a thickness of the first pad, and a metallic solder disposed on an associated end of the post. A second semiconductor substrate is provided as having a second pad connected thereto. The fluxless method further includes depositing an unfilled polymeric liquid on the second pad, aligning and contacting the metallic solder with the unfilled polymeric liquid, and forcing by pressure the first and second semiconductor substrate toward each while simultaneously heating the metallic solder and the unfilled polymeric liquid to form a metallurgical joint between the second pad and the metallic solder.

Owner:FUJITSU LTD

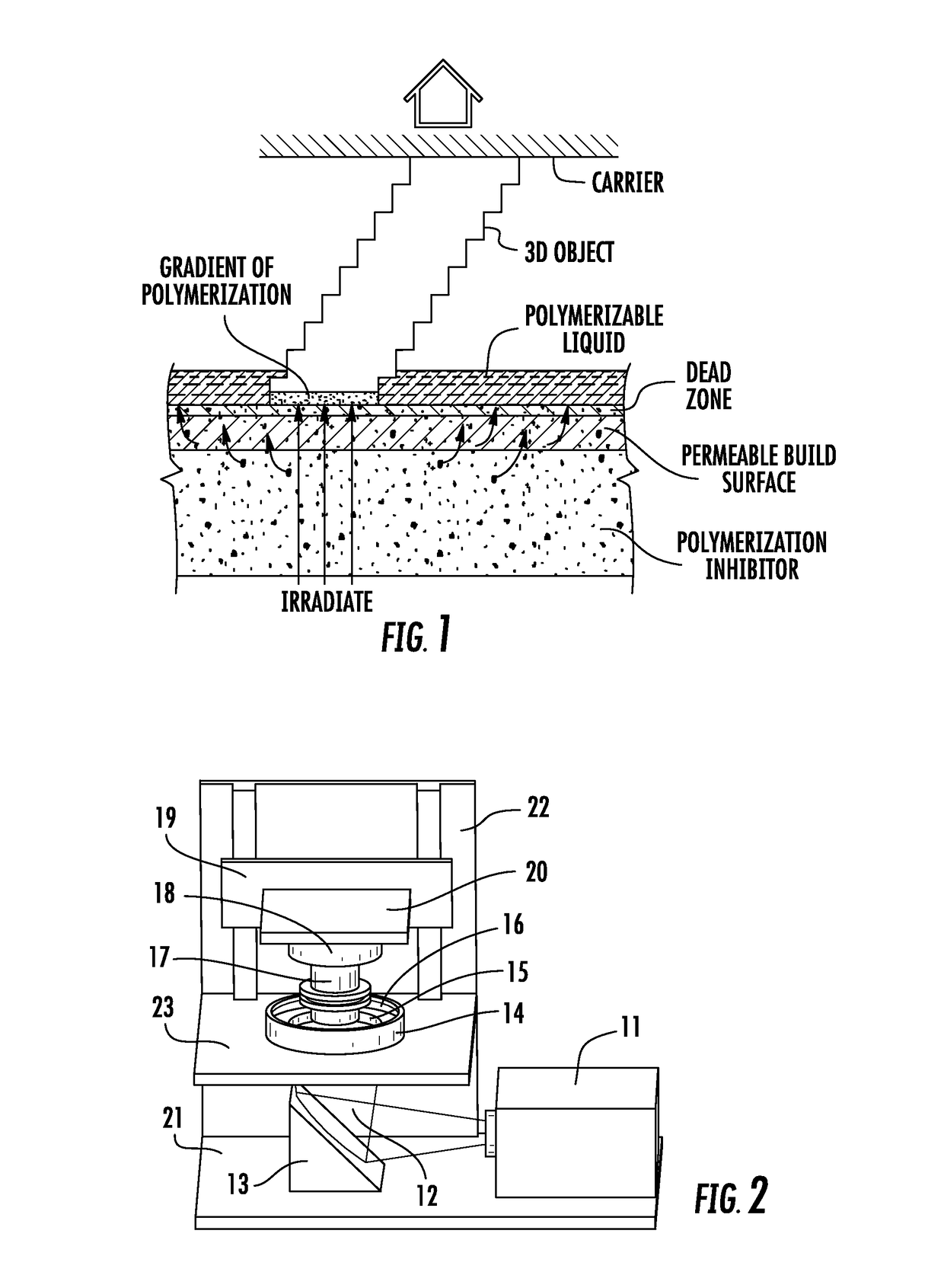

Method and apparatus for three-dimensional fabrication

Owner:CARBON INC

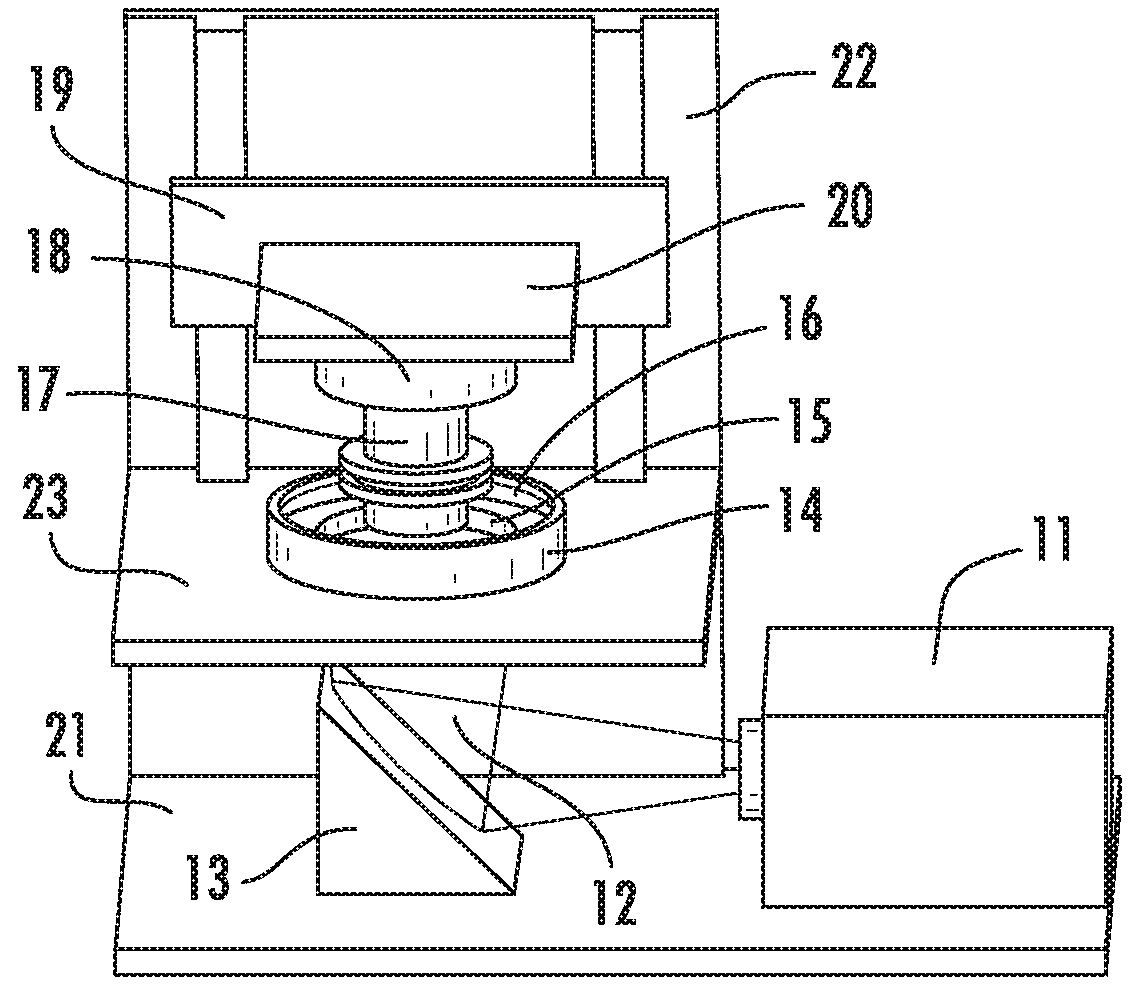

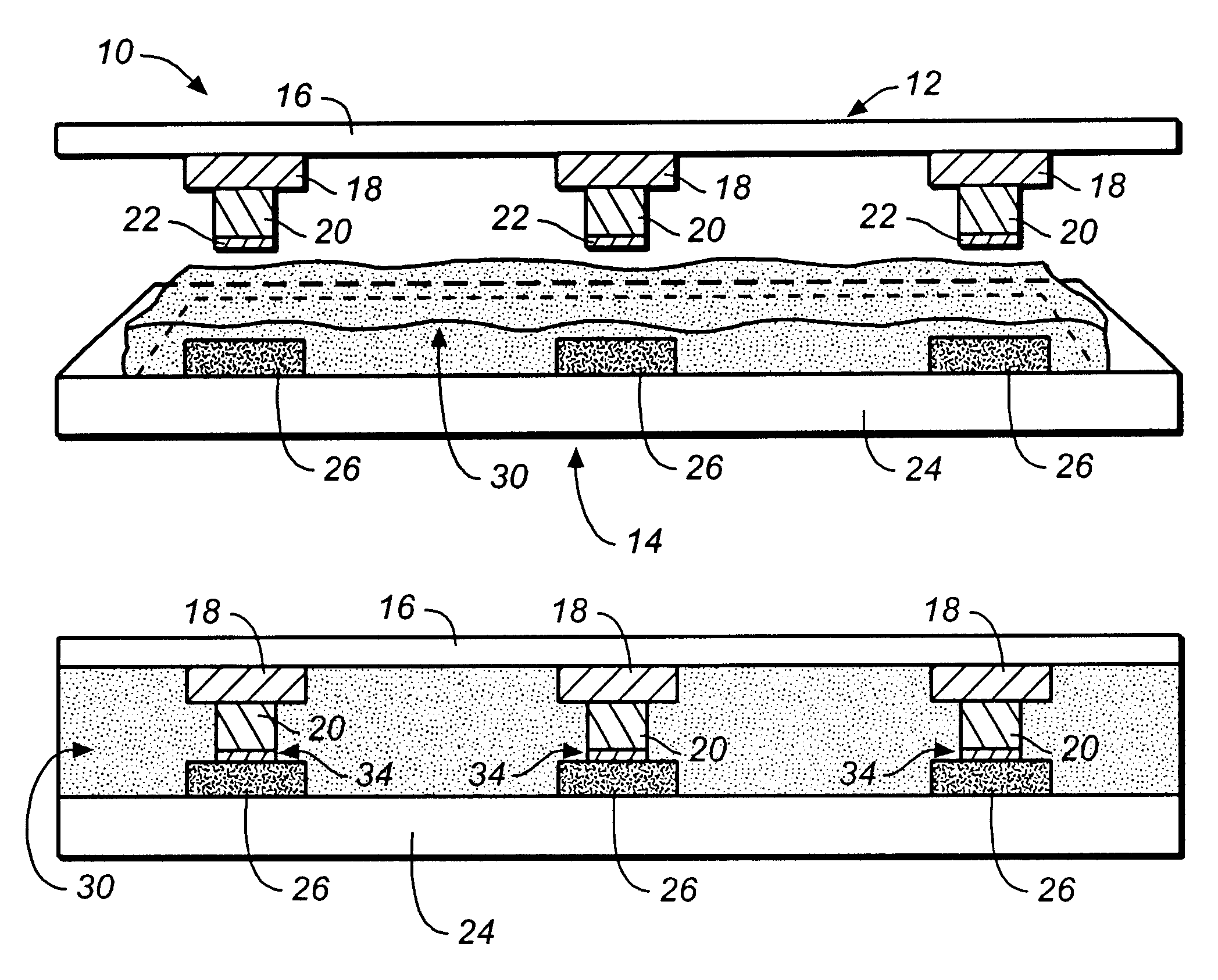

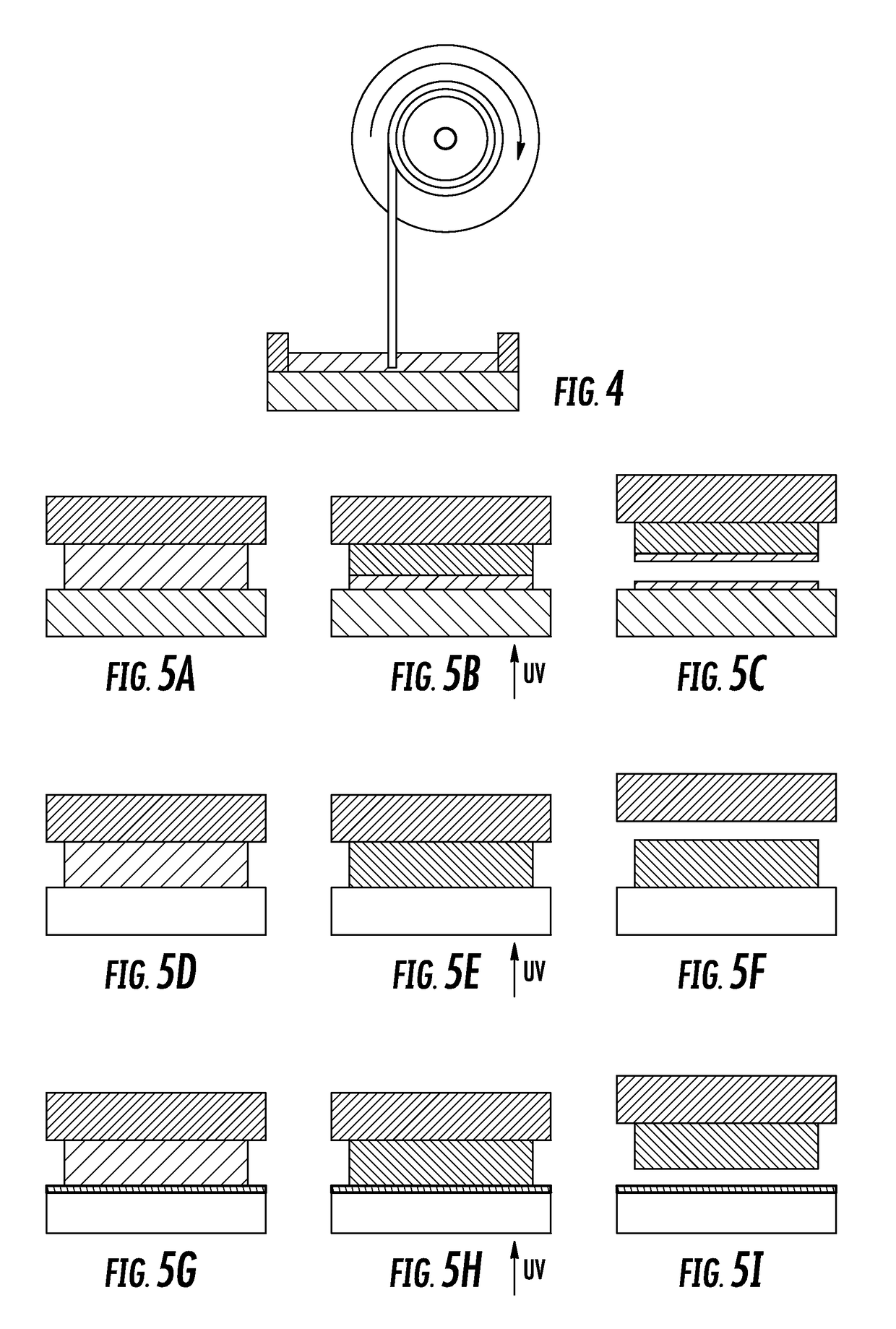

Three-Dimensional Printing Using Carriers with Release Mechanisms

ActiveUS20170210077A1Facilitated releaseEnhance or speed the refilling of the build regionManufacturing platforms/substrates3D object support structuresEngineering3 dimensional printing

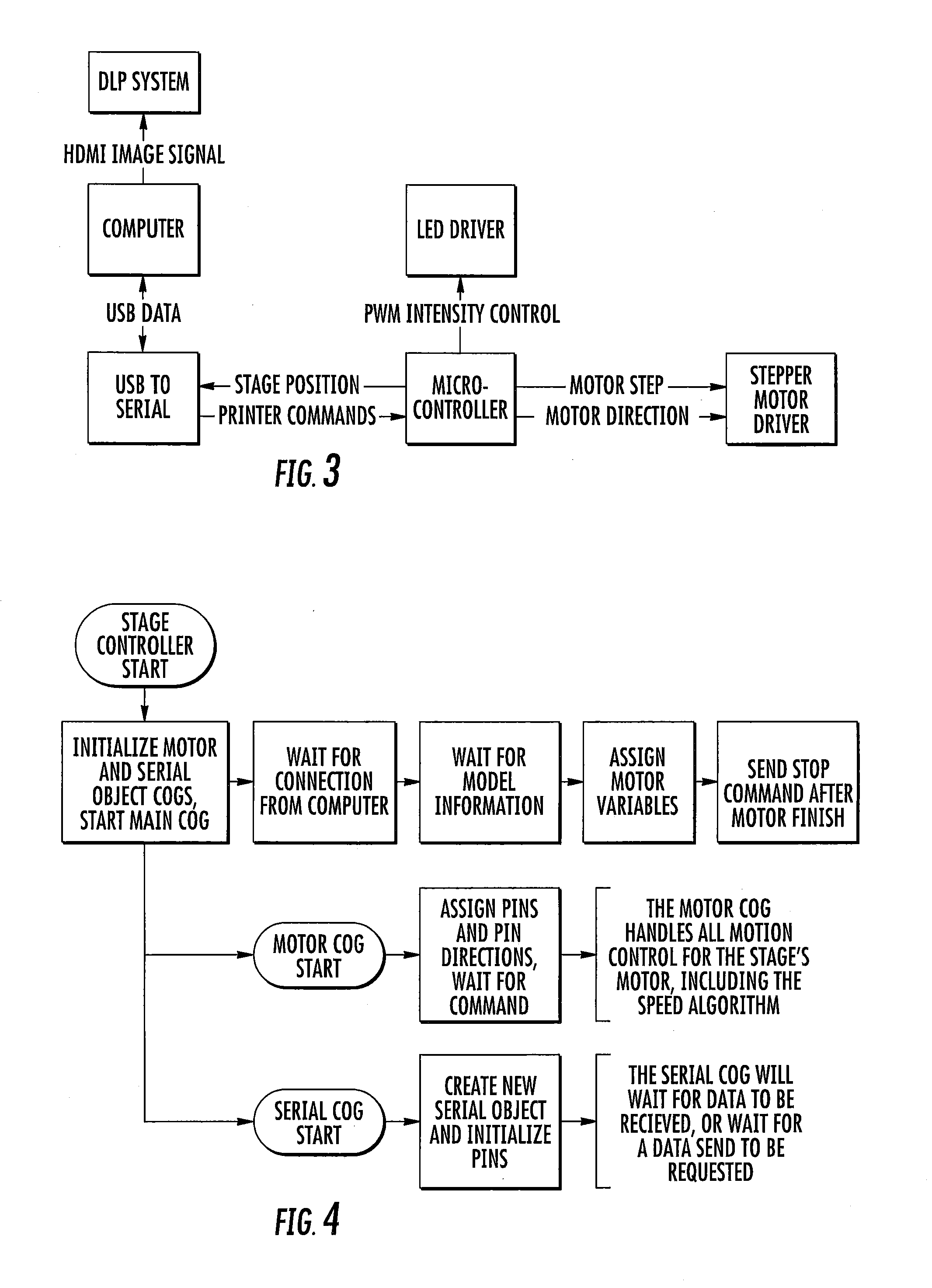

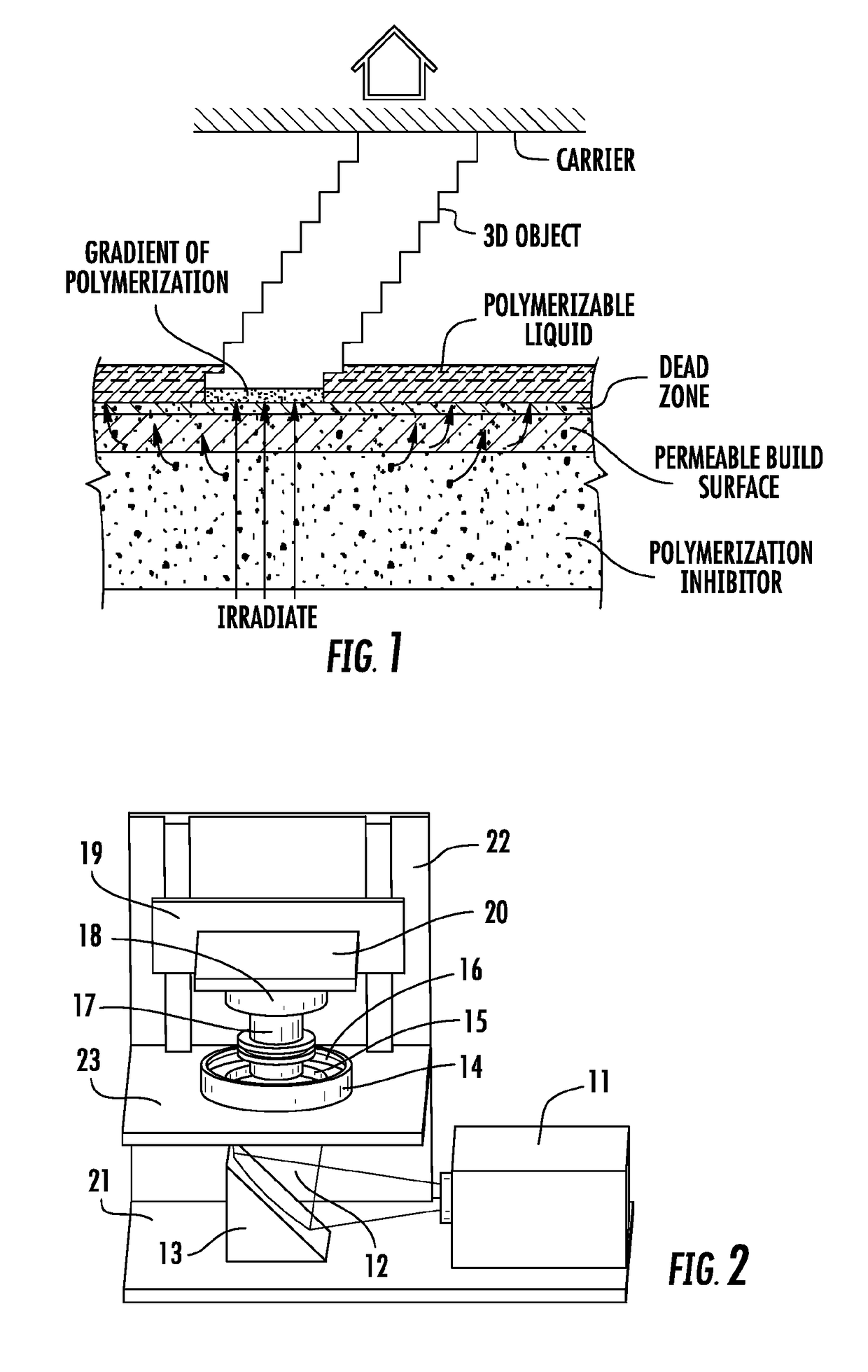

A method of forming a three-dimensional object (17) includes: providing a carrier (18) and an optically transparent member (15) having a build surface, the carrier (18) and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid (16); irradiating the build region with light (12) through the optically transparent member (15) to form a solid polymer from the polymerizable liquid; and advancing the carrier (18) away from the build surface to form the three-dimensional object (17) from the solid polymer. The carrier (18) includes at least one retain and release (34) feature that is configured to: i) retain the three-dimensional object (17) formed from the solid polymer on the carrier (18) in a first state; and ii) facilitate release of the three-dimensional object (17) formed from the solid polymer from the carrier (18) in a second state.

Owner:CARBON INC

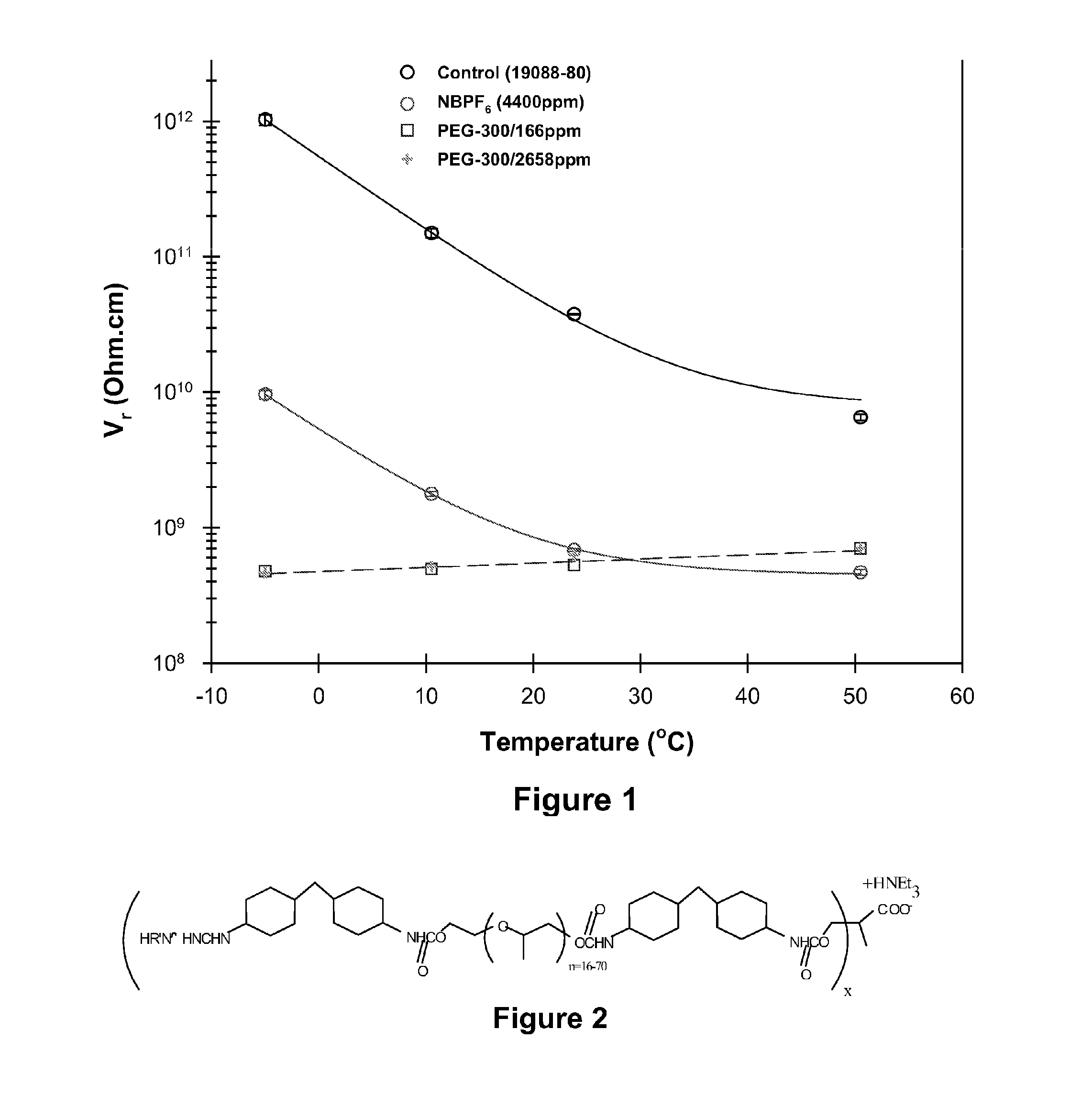

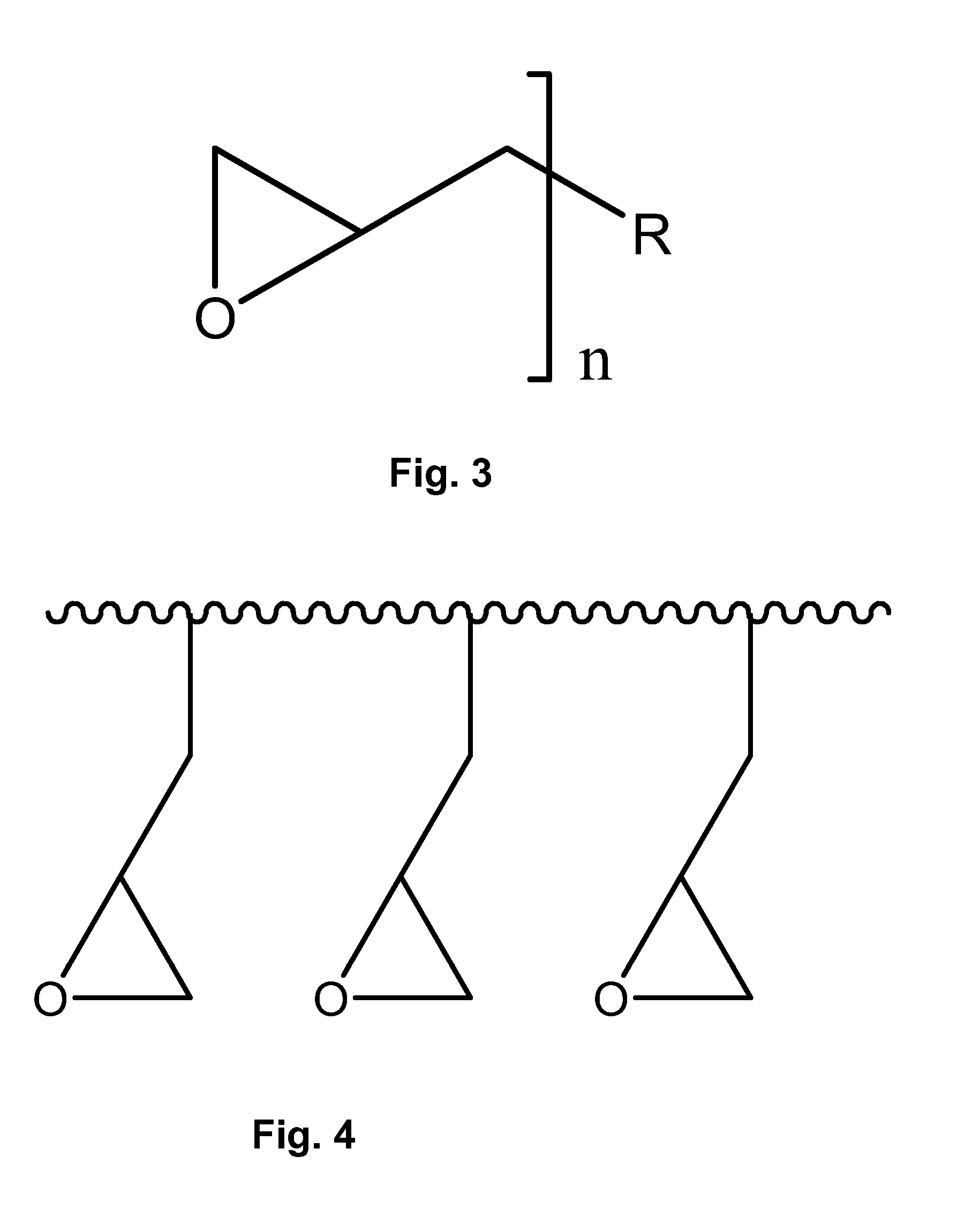

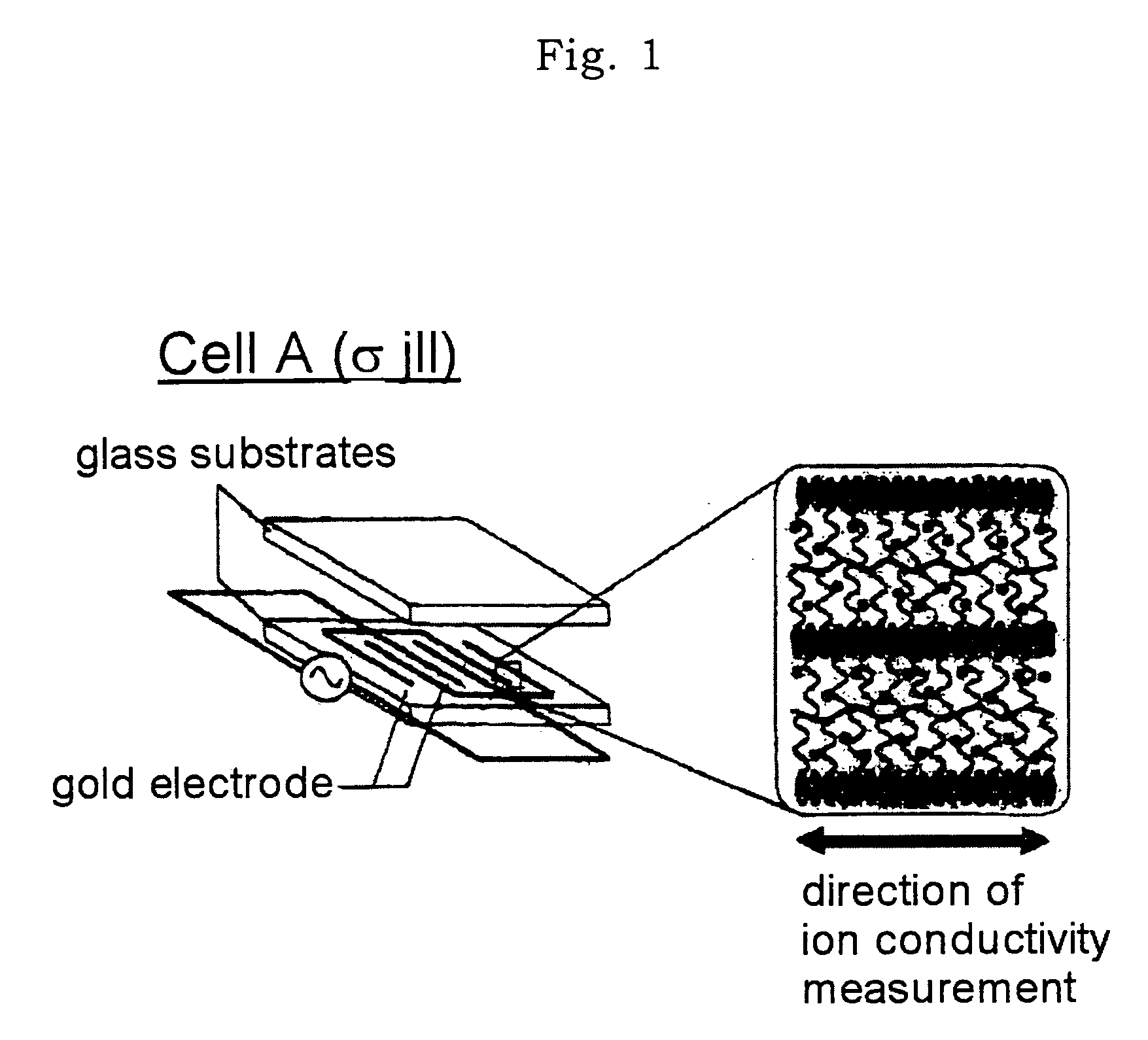

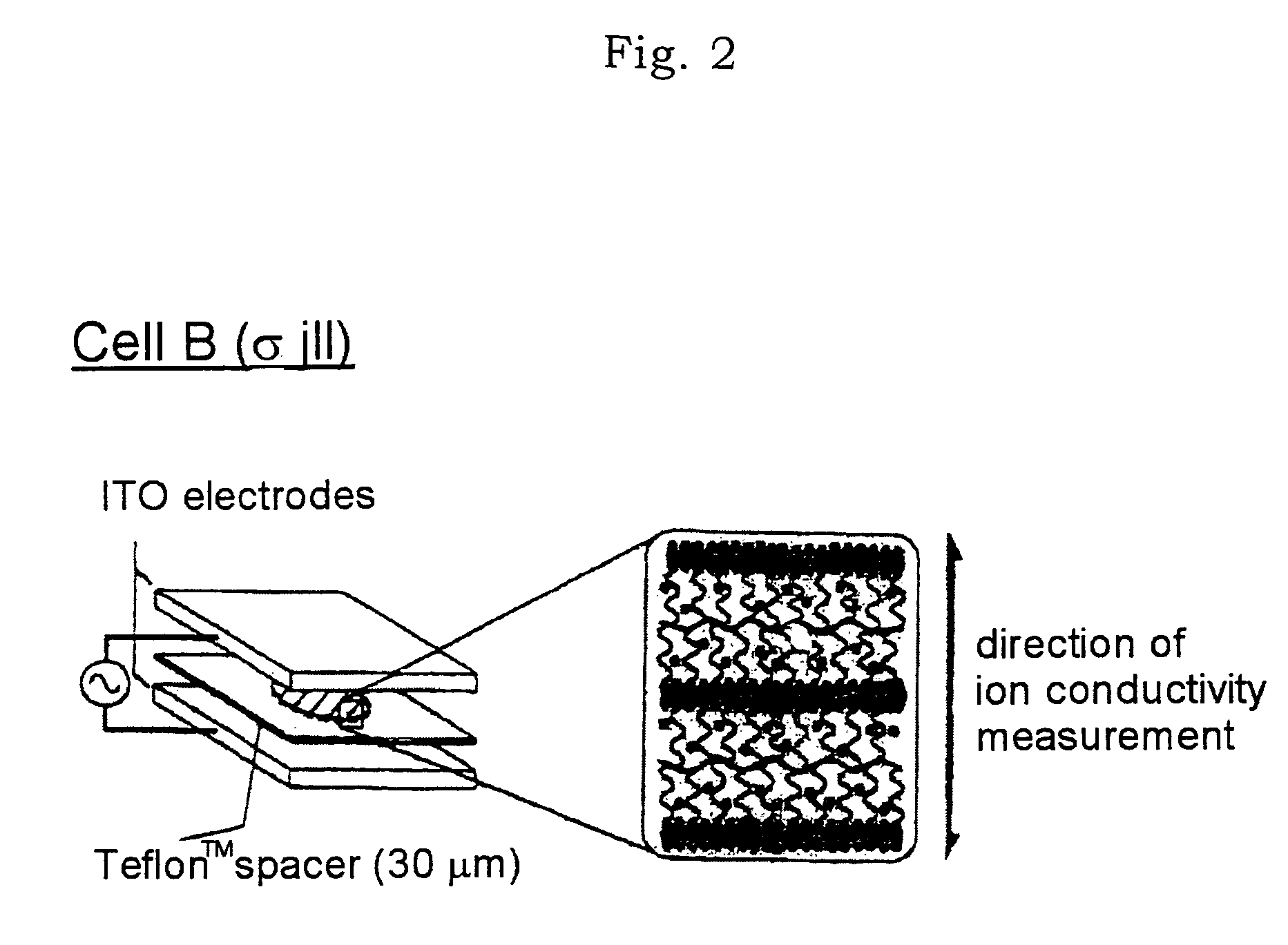

Polymerizable ion-conductive liquid-crystalline composite, anisotropically ion-conductive polymeric liquid-crystal composite, and process for producing the same

InactiveUS20050077498A1Improve ionic conductivityLiquid crystal compositionsLiquid crystallineInorganic salts

A composite of an organic monomer compound and an organic or inorganic salt, wherein the organic monomer compound comprises an ion-complexing moiety, a mesogen moiety that expresses a liquid crystalline phase and a polymerizable moiety in its molecular structure, is polymerized at the polymerizable moiety of the organic monomer compound, thereby forming an anisotropic ion-conductive polymeric liquid crystalline composite as a novel material having high ion conductivity characteristic of polymeric electrolytes, anisotropy due to orientation of a liquid crystal, and self-supporting properties characteristic of polymeric compounds.

Owner:JAPAN SCI & TECH CORP

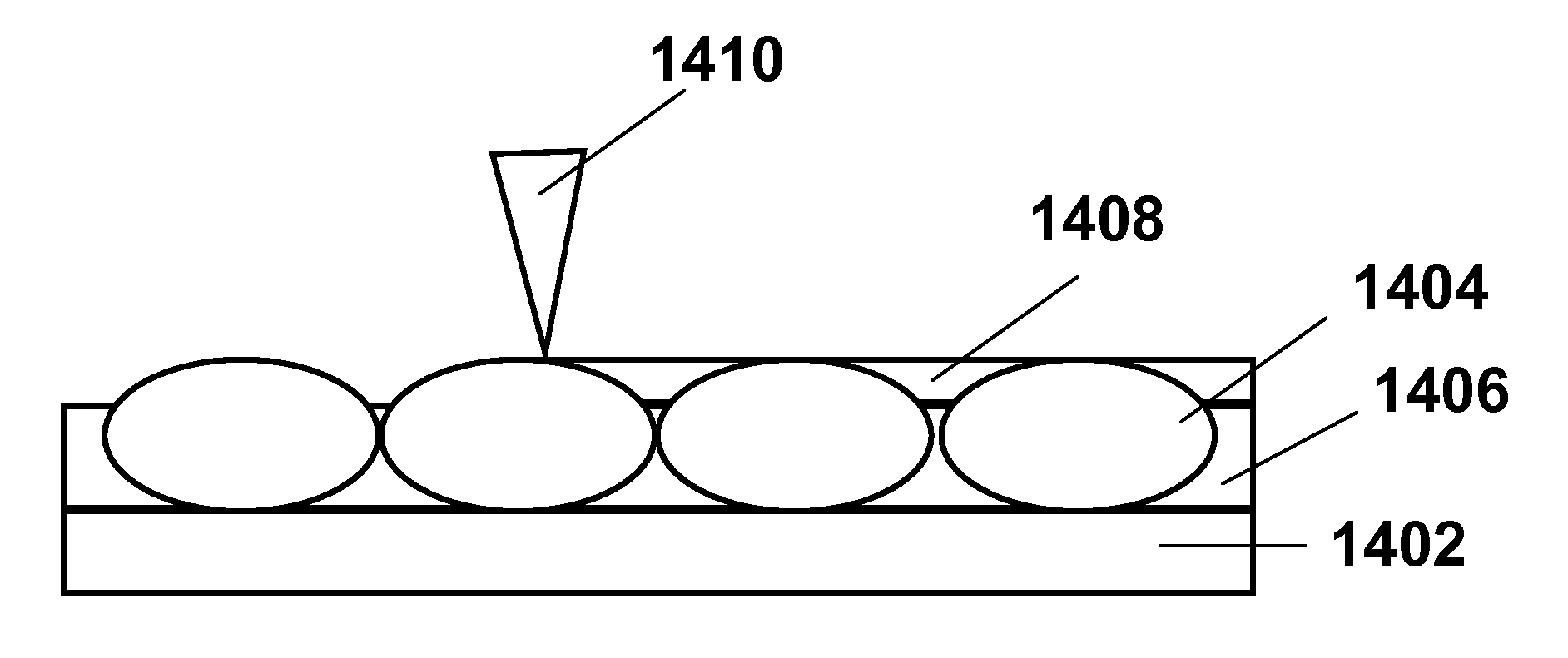

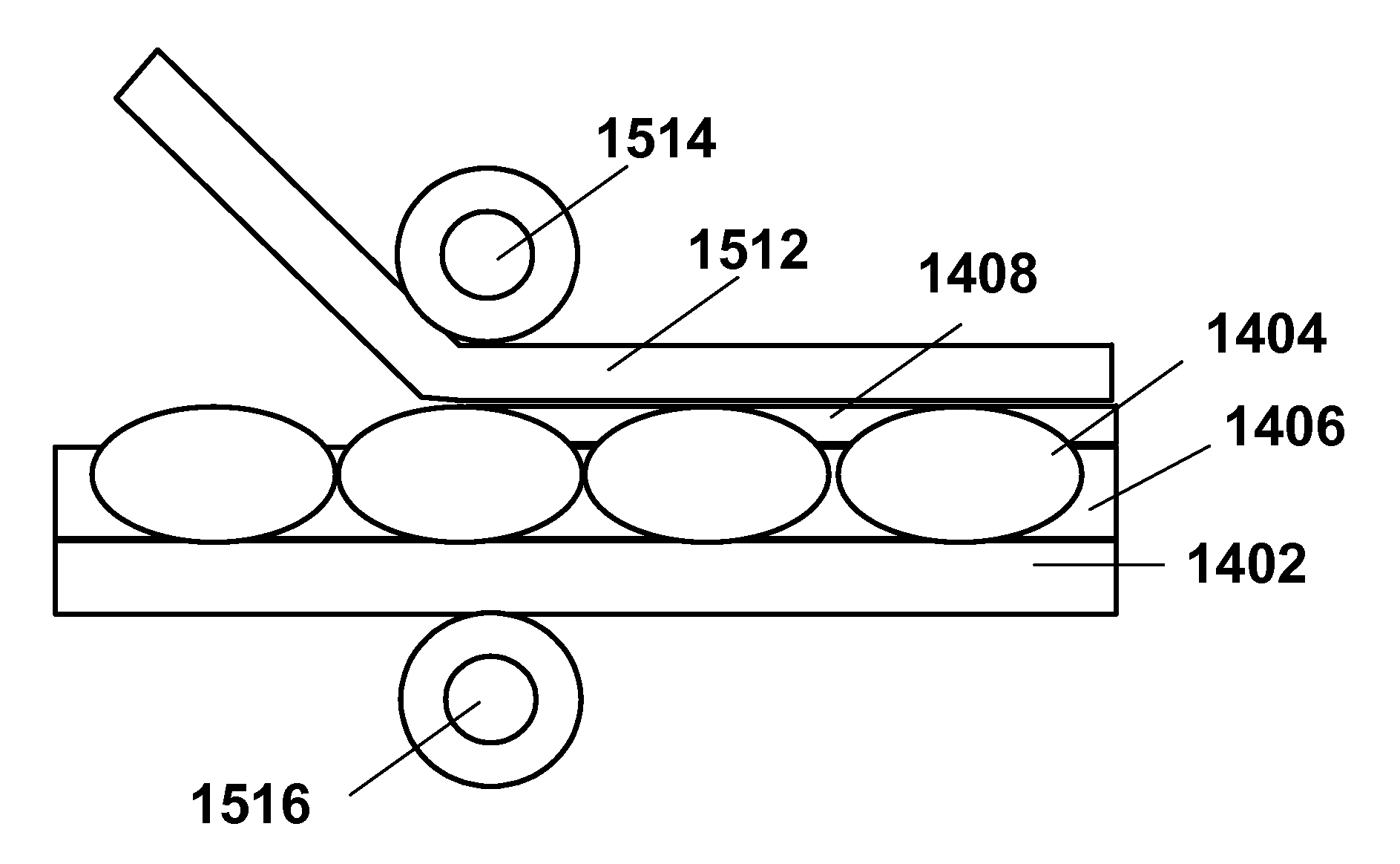

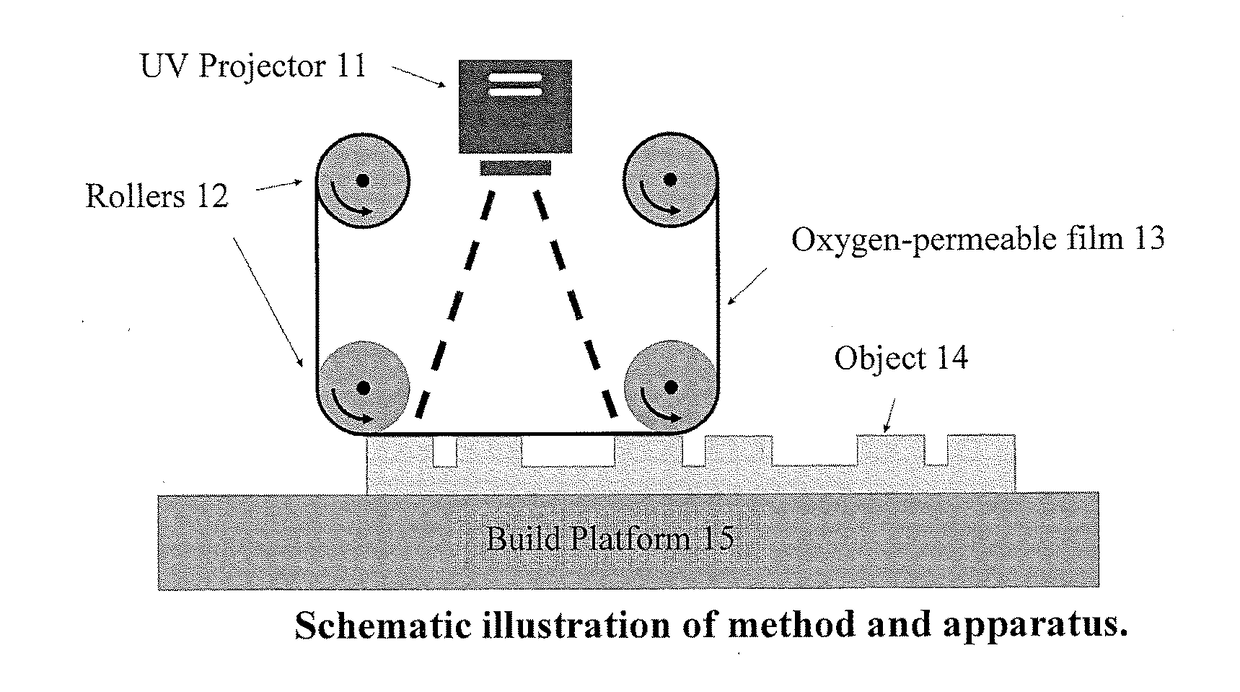

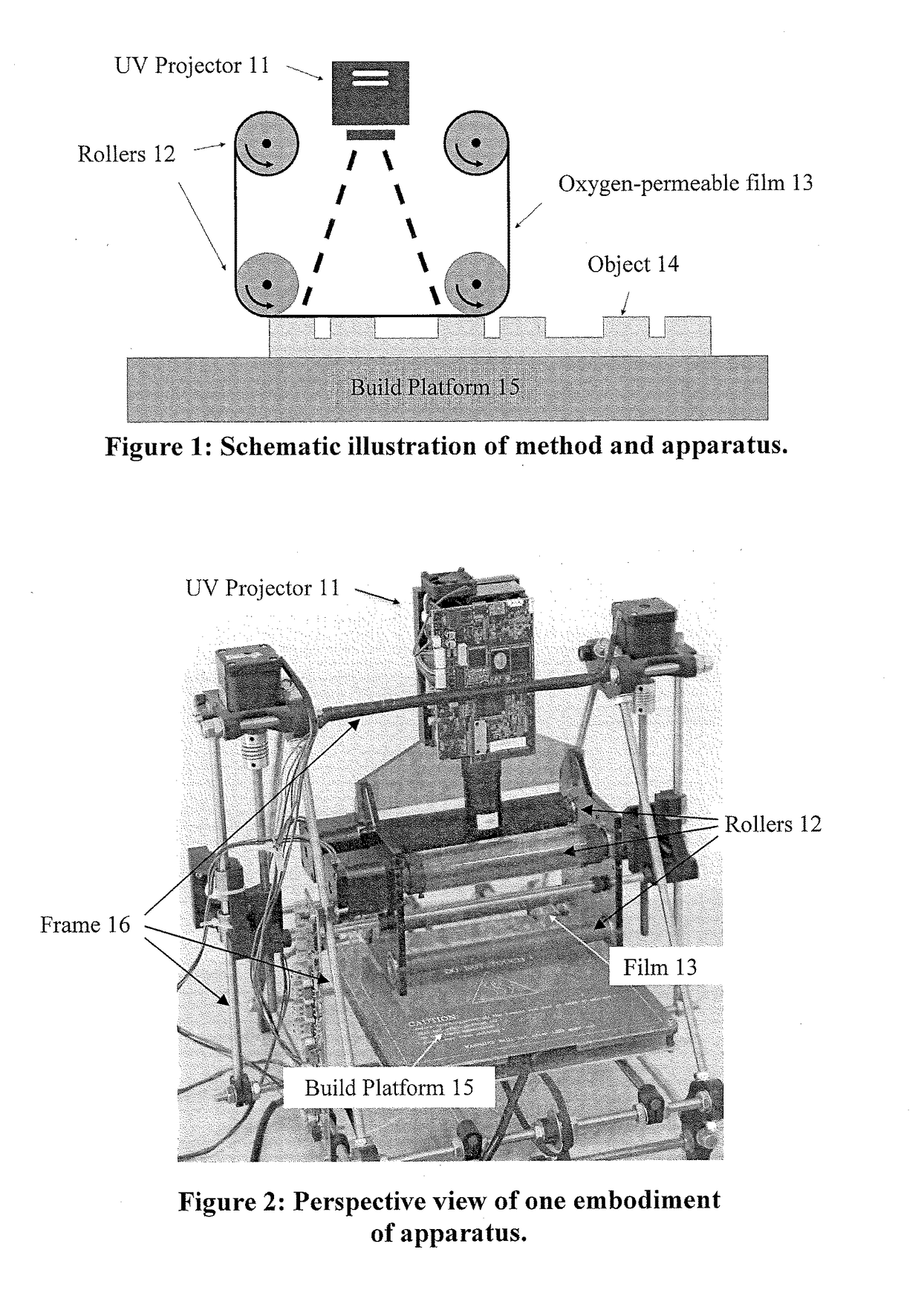

Method and apparatus for three-dimensional fabrication

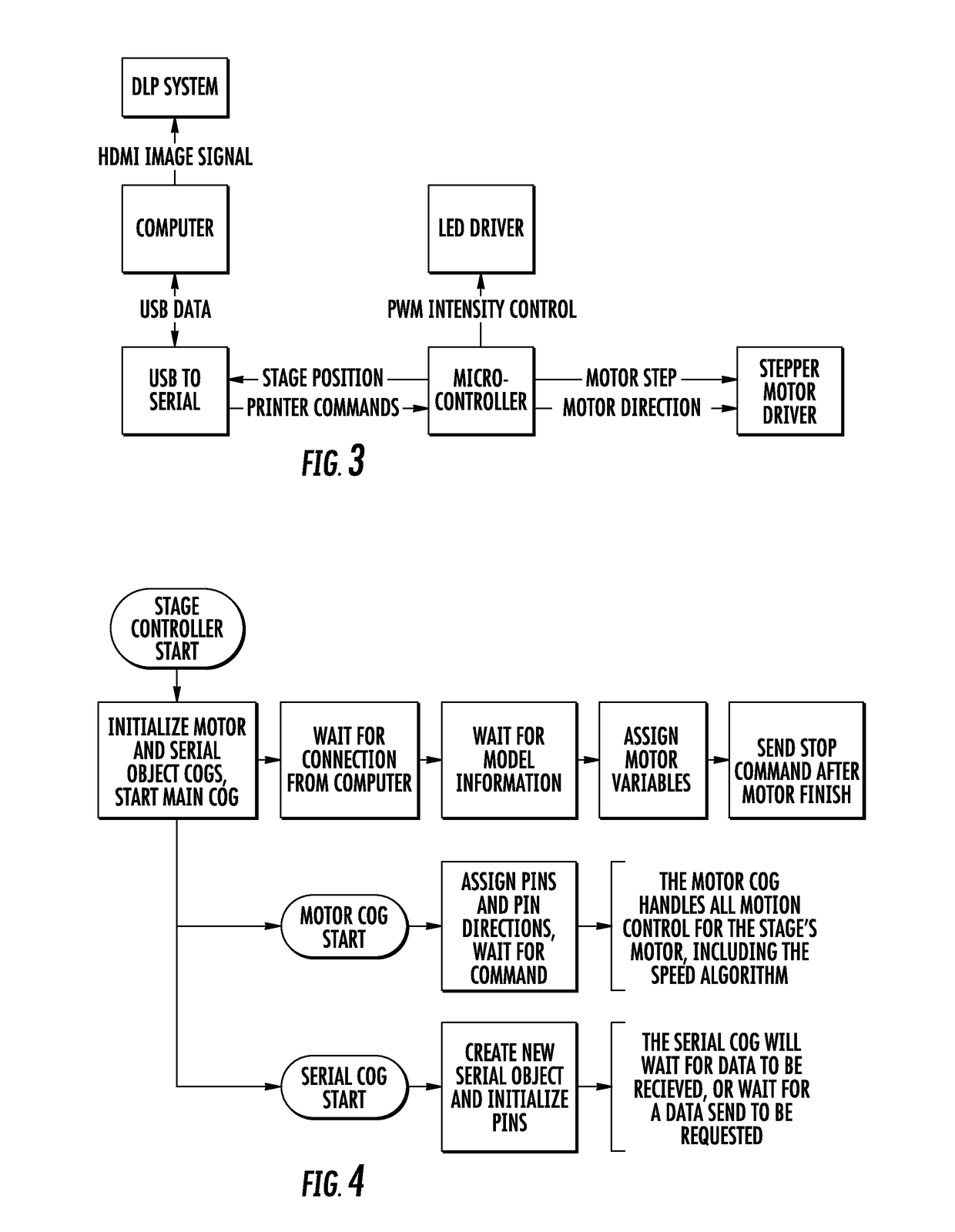

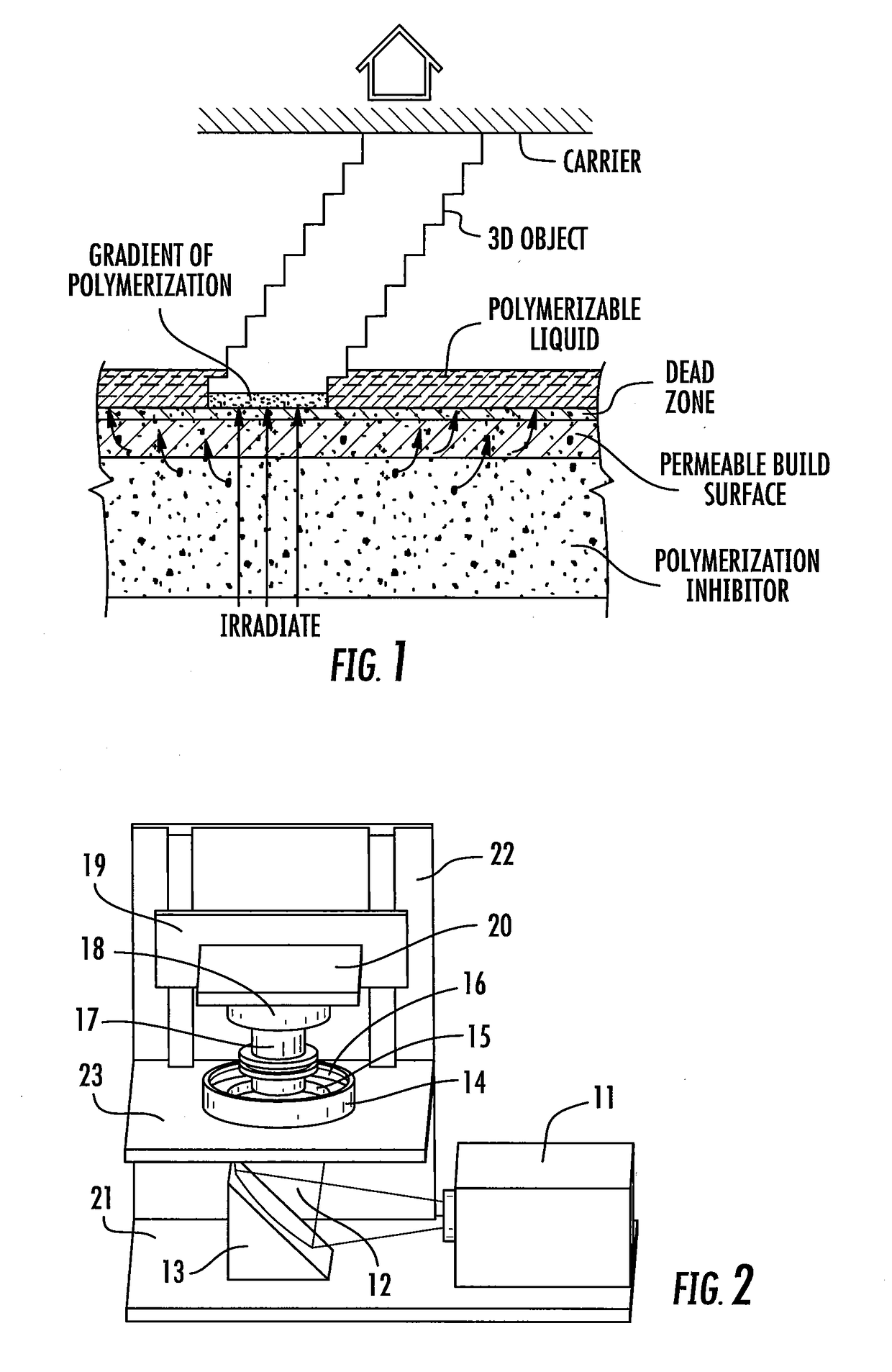

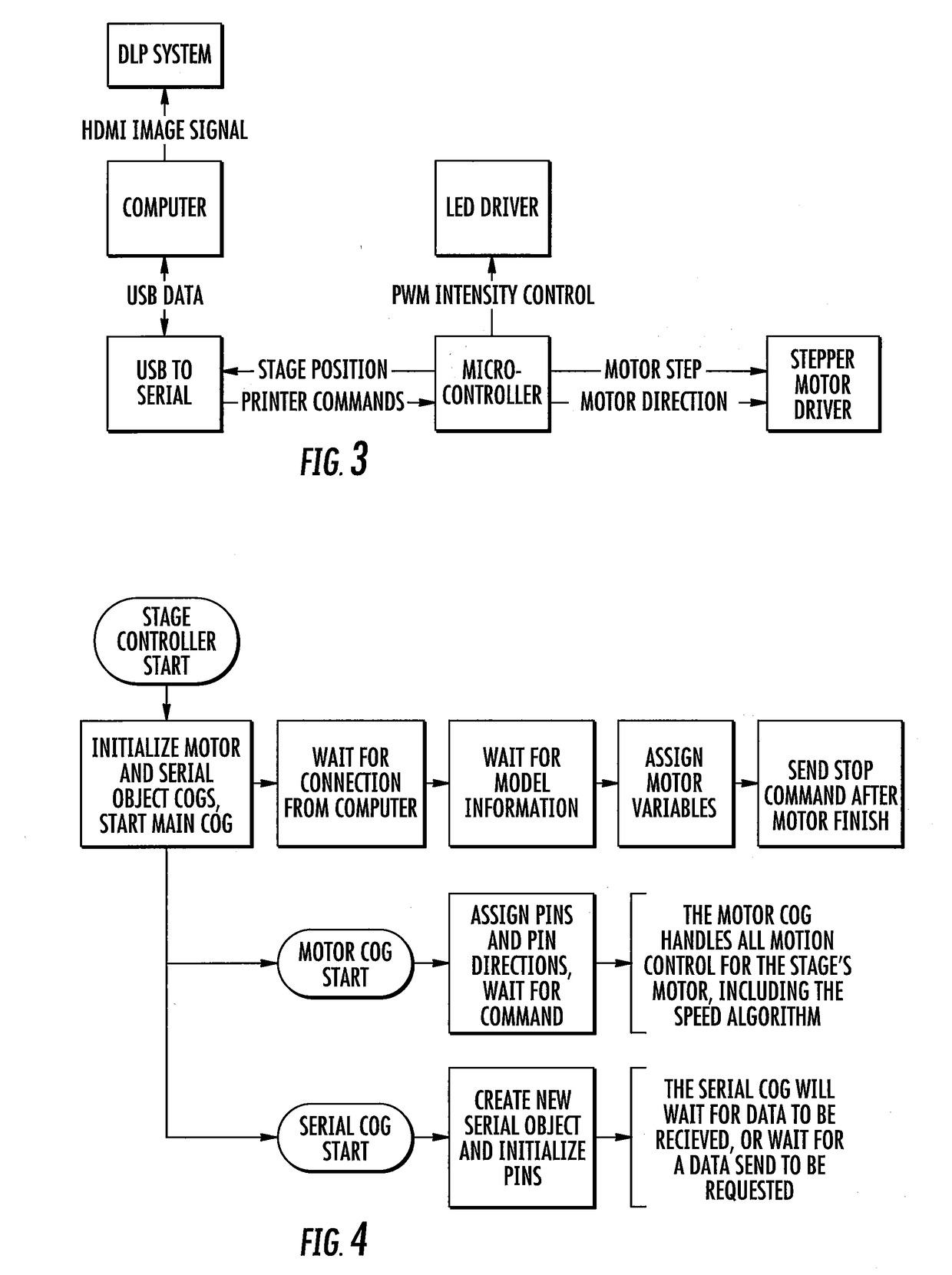

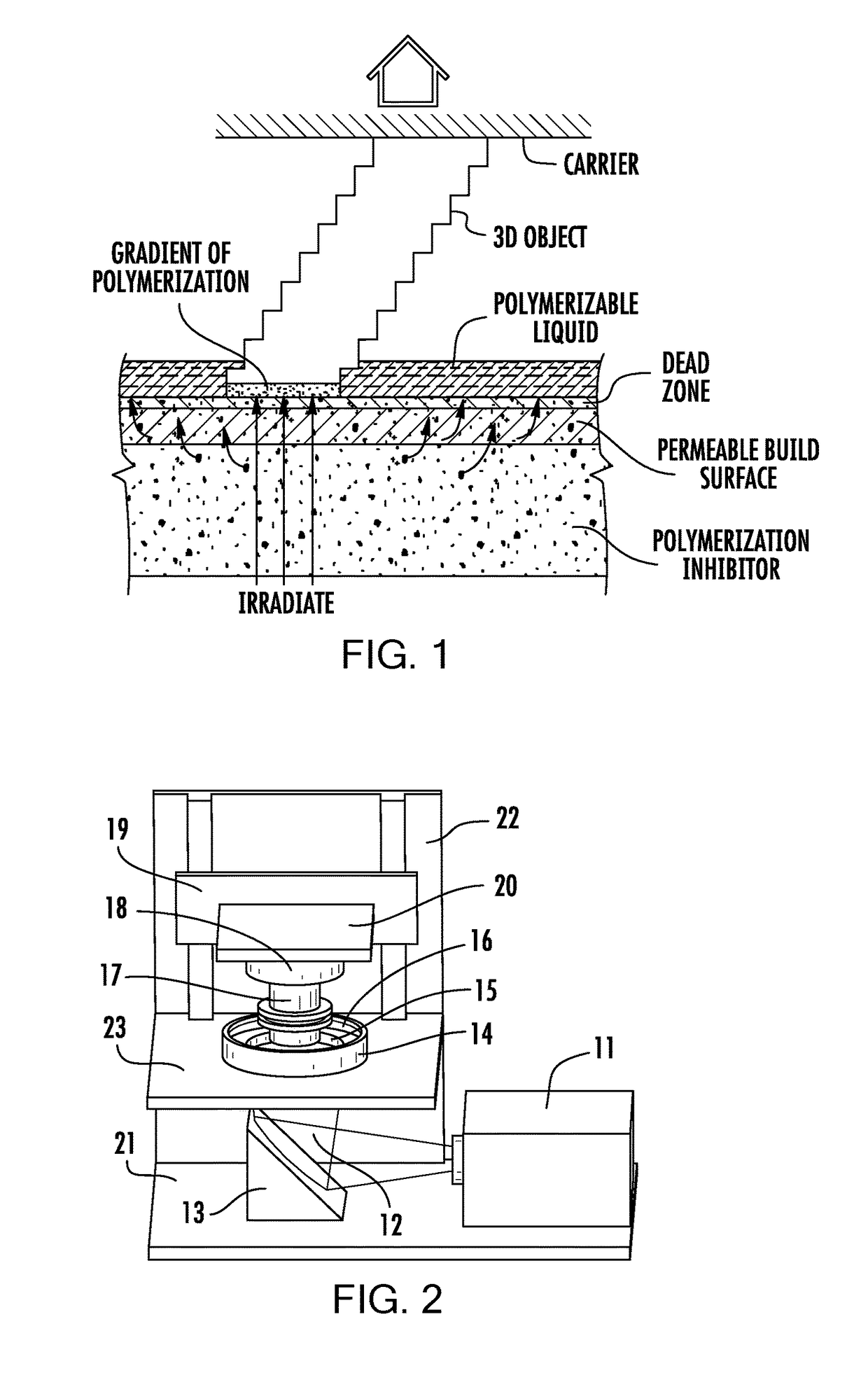

ActiveUS20170066185A1Additive manufacturing apparatus3D object support structuresPolymer scienceEngineering

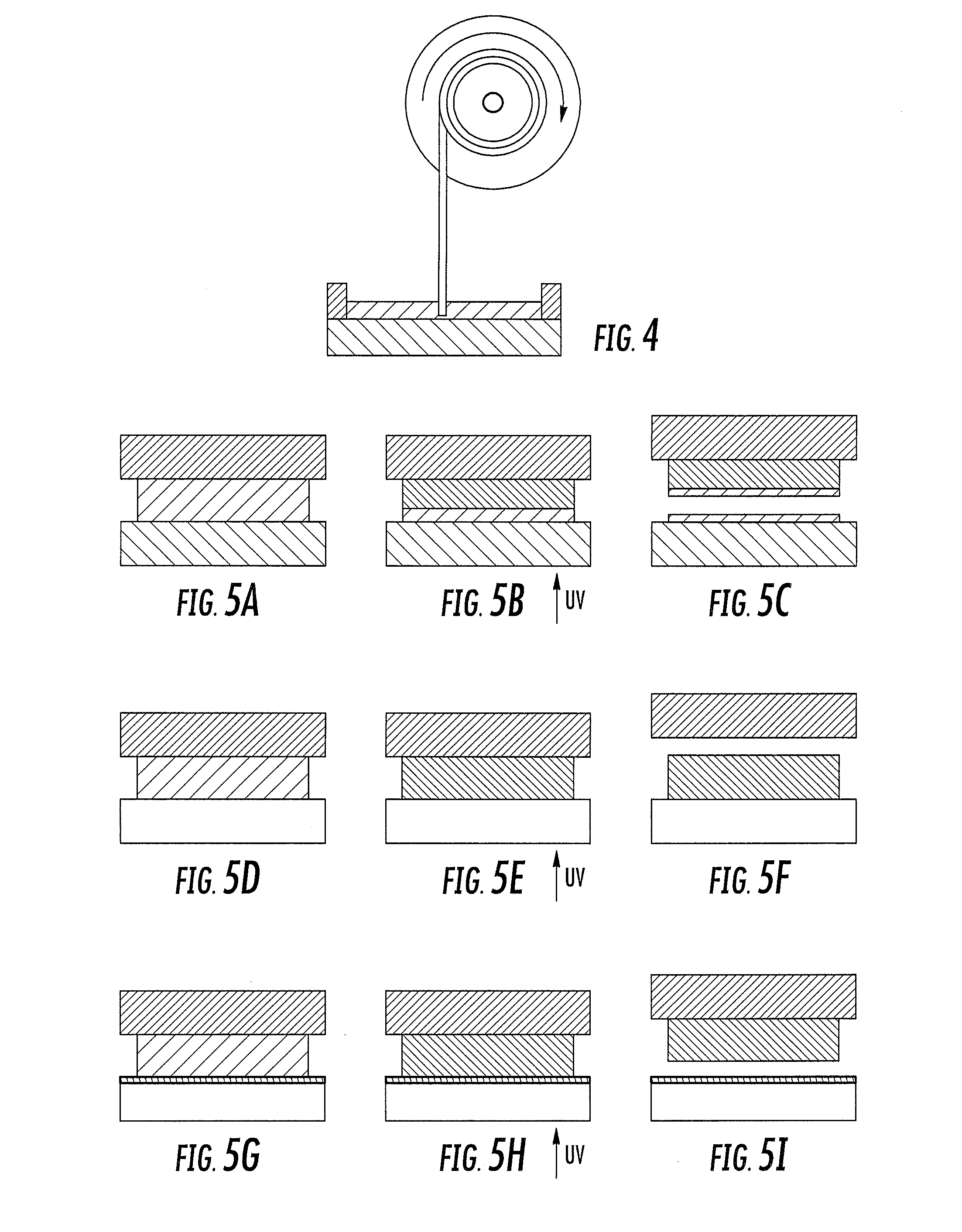

A method of making a three-dimensional object is carried out by: (a) providing an apparatus comprising a radiation source, a carrier on which the three dimensional object is made, and a movable belt positioned therebetween, the belt having a first surface and an opposite second surface, with the belt comprised of an optically transparent material, and with the belt permeable to a polymerization inhibitor; (b) applying a polymerizable liquid to the first surface of the belt, and contacting the second surface of the belt to the polymerization inhibitor, (c) contacting a portion of the belt first surface having the polymerizable liquid thereon to the carrier or the three dimensional object so that the belt adheres thereto with the polymerizable liquid positioned therebetween; (d) irradiating the polymerizable liquid with actinic radiation through the belt from the radiation source to polymerize the polymerizable liquid positioned therebetween; then (e) optionally separating the belt from the carrier or the three dimensional object; and then (f) repeating steps (b) through (e) until the three dimensional object is completed. Apparatus for carrying out the method is also described.

Owner:CARBON INC

Three-dimensional printing with reciprocal feeding of polymerizable liquid

ActiveUS20170173871A1Enhance or speed the refilling of the build regionEnhance or speed the refilling of said build regionManufacturing enclosures3D object support structuresReciprocating motionEngineering

Described herein are methods and apparatus for the production of a three-dimensional object by “bottom up” additive manufacturing, in which a carrier (112) is vertically reciprocated with respect to a build surface, to enhance or speed the refilling of the build region with a solidifiable liquid. In preferred embodiments, the three-dimensional object is produced from a liquid interface by continuous liquid interface production (i.e., “CLIP”).

Owner:CARBON INC

Method of additive manufacturing by intermittent exposure

ActiveUS20180009162A1Enhance or speed the refilling of the build regionEnhance or speed the refilling of said build regionAdditive manufacturing apparatus3D object support structuresPolymer sciencePolymeric liquid

A method of forming a three-dimensional object, is carried out by: providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid, intermittently irradiating the build region with light through the optically transparent member to form a solid polymer from the polymerizable liquid, and continuously or intermittently advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer. In some embodiments, the filling, irradiating, and / or advancing steps are carried out while also concurrently: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form.

Owner:CARBON INC

Method and apparatus for three-dimensional fabrication with gas injection through carrier

ActiveUS20170173880A1Manufacturing platforms/substratesManufacturing enclosuresEngineeringPolymeric liquid

A method of forming a three-dimensional object (17), is carried out by: (a) providing a carrier (18′) and an optically transparent member having a build surface, with the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid; (c) irradiating the build region with light through the optically transparent member to form a solid polymer from the polymerizable liquid; and (d) advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer; (e) wherein the carrier has at least one channel (32) formed therein, the method further including supplying pressurized gas into the build region through the at least one channel during at least a portion of the filling, irradiating and / or advancing steps. An apparatus for performing the method is also disclosed.

Owner:CARBON INC

Flame-retardant cable

InactiveUS20040151906A1Quick and easy to manufactureImprove abilitiesInsulated cablesFibre mechanical structuresEpoxyVinyl ether

The present invention relates to a flame-retardant cable comprising a transmission element, a flammable element, and a flame-retardant coating layer surrounding said flammable element, and made of a material based on a polymer obtained from a polymerizable liquid composition containing at least a precursor for said polymer including functional groups selected from acrylates, methacrylates, epoxies, vinyl ethers, allyl ethers, and oxetanes, wherein said material includes at least one phosphorous group.

Owner:NEXANS

Preparation method of gel electrolyte for lithium-sulfur battery

InactiveCN105789694AInhibition of dissolutionImprove cycle performanceSecondary cellsCross-linkPolymer science

The invention relates to a preparation method of a gel electrolyte for a lithium-sulfur battery. The method comprises the following steps: 1, preparing an electrolyte lithium salt and an organic solvent into a basic electrolyte; 2, adding a mixed liquid of a polymeric monomer, a cross-linking agent and a solvent into the basic electrolyte to prepare a cross-linking polymeric liquid; 3, adding an initiator into the cross-linking polymeric liquid, performing initiated polymerization at a temperature of 15-45 DEG C for 2-6 hours to finish a preparation process of the gel electrolyte for the lithium-sulfur battery, and injecting the gel electrolyte into the lithium-sulfur battery which is being assembled. According to the preparation method, the gel electrolyte formed after initiated polymerization is put into the lithium-sulfur battery in an assembling process, and the battery has a relatively high capacity retention ratio no matter the battery is under a high temperature condition or a low temperature condition, so that high and low temperature adaptability of the lithium-sulfur battery is improved effectively; a manufacturing process of the battery is improved; and the manufacturing cost of the battery is lowered. The preparation method is suitable for large-scale commercial production of the lithium-sulfur battery.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Interconnect assembly and z-connection method for fine pitch substrates

An interconnect assembly and a fluxless method for forming the interconnect assembly. The fluxless method includes providing a first semiconductor substrate having a first pad connected thereto. A post is connected to the first pad and includes a length greater than a thickness of the first pad, and a metallic solder disposed on an associated end of the post. A second semiconductor substrate is provided as having a second pad connected thereto. The fluxless method further includes depositing an unfilled polymeric liquid on the second pad, aligning and contacting the metallic solder with the unfilled polymeric liquid, and forcing by pressure the first and second semiconductor substrate toward each while simultaneously heating the metallic solder and the unfilled polymeric liquid to form a metallurgical joint between the second pad and the metallic solder.

Owner:FUJITSU LTD

Polymeric precursors of non-absorbable, in situ-forming hydrogels and applications thereof

InactiveUS20040166088A1Pharmaceutical delivery mechanismSynthetic polymeric active ingredientsInvasive treatmentsSemi solid

The present invention is directed toward an injectable, single- or multiple-component polymeric liquid precursor of an in situ-forming, non-absorbable, flexible, and resilient hydrogel or semi-solid that can be used in non-surgical, minimally invasive treatment of herniated disc.

Owner:POLY MED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com