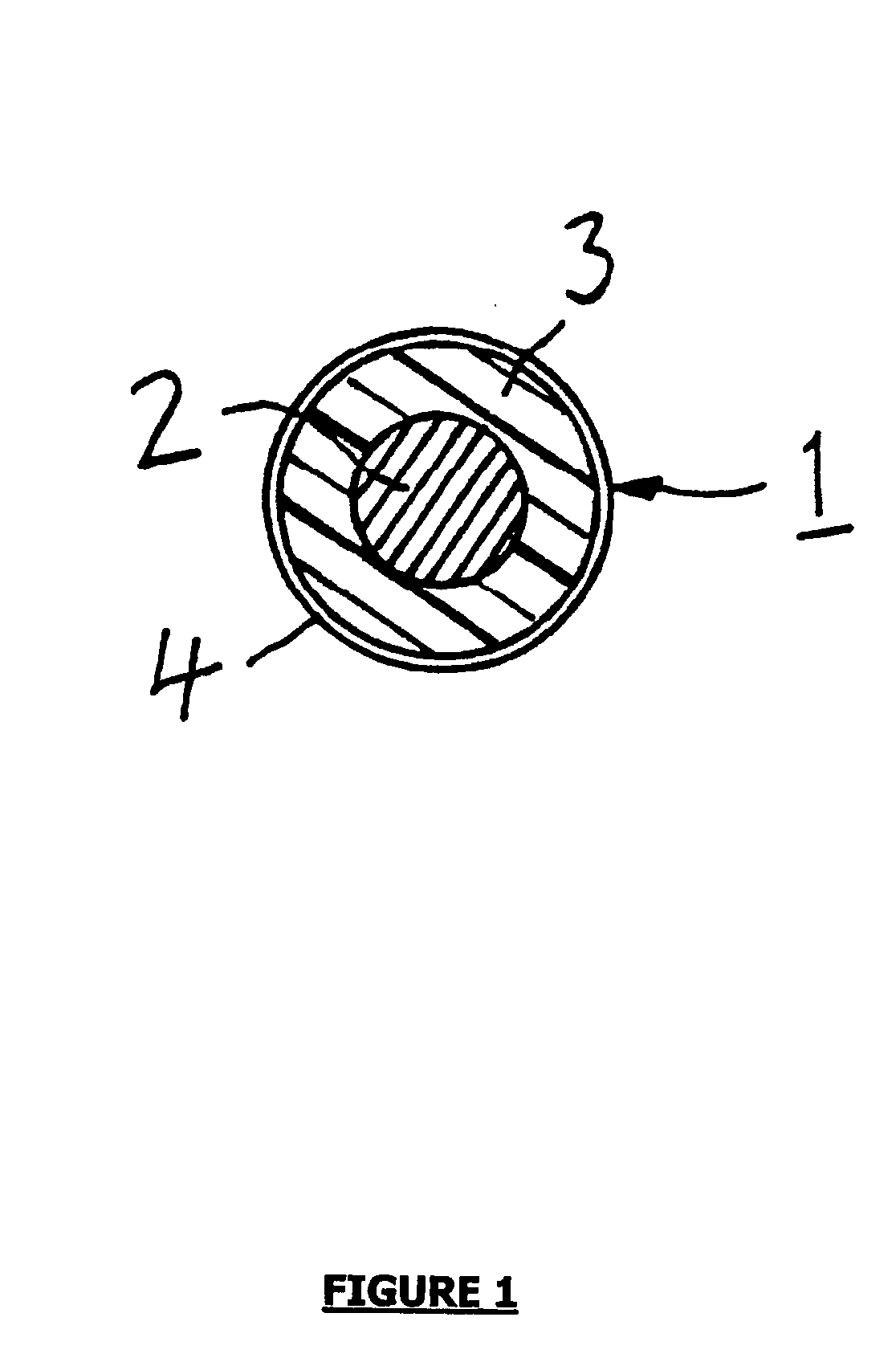

Flame-retardant cable

a flame-retardant cable and flame-retardant technology, applied in the direction of yarns, conductors, instruments, etc., to achieve the effect of quick and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Composition No. 1

[0036] 97 parts by weight of Ebecryl IRR 527 from UCB Chemicals, a halogen-free polyester acrylate oligomer having two acrylate functional groups and phosphorous groups; and

[0037] 3 parts by weight of the photoinitiator DAROCUR1173 (commercial name) from CIBA.

example 2

[0038] Composition No. 2

[0039] 80 parts by weight of Ebecryl IRR 527;

[0040] 17 parts by weight of an isobornyl acrylate of bicyclic structure such as Genomer 1121 from RAHN, having an acrylate equivalent weight equal to 208; and

[0041] 3 parts by weight of DAROCUR1173 (commercial name) photoinitiator.

[0042] Table 1 gives the properties of a coating No. 1 made of a material based on a polymer obtained by using ultraviolet radiation to polymerize composition No. 1, and of a coating No. 2 made of a material based on a polymer obtained by using ultraviolet radiation to polymerize composition No. 2.

[0043] In these examples, the precursor also contains phosphorous groups and the resulting polymer is chemically bonded to phosphorous groups.

1 TABLE 1 Coating No. 1 Coating No. 2 Breaking stress 13.4 21.4 (MPa) at 25.degree. C. Breaking 46 43.1 elongation (%) Hardness (Buchholz <59 123 method)

[0044] On heating to 60.degree. C., composition No. 1 presents viscosity that is equal to about 17,000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| travel speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com