Porous high-entropy alloy and preparation method thereof

A high-entropy alloy and mechanical alloying technology, applied in the field of porous metal materials, can solve the problems of high melting point, slow diffusion of high-entropy alloy, long preparation time, etc., and achieve excellent comprehensive mechanical properties, energy saving, emission reduction, environmental protection, and pore distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

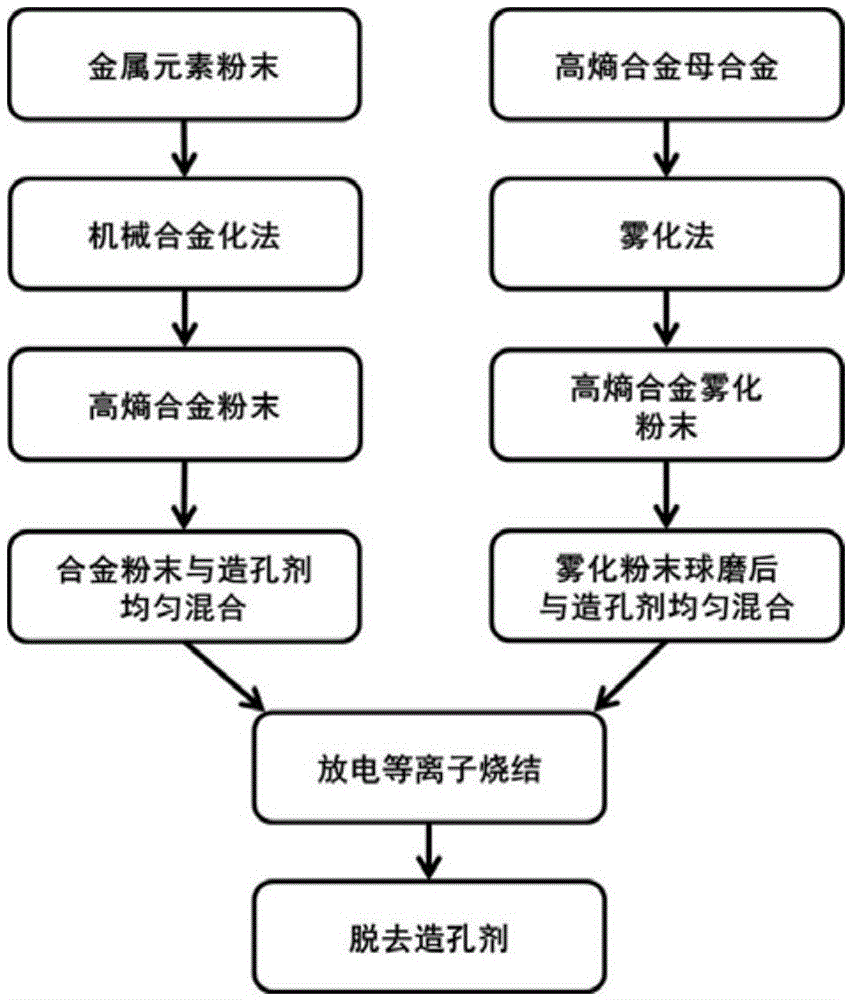

[0041] A method for preparing a porous high-entropy alloy. The method uses ball-milled atomized high-entropy alloy powder (or high-entropy alloy powder prepared by mechanical alloying) and a sieved pore-forming agent according to the preparation requirements. Proportionate ingredients, after being uniformly mixed by a mixer, sintered with SPS, then put the sintered sample into deionized water for ultrasonic cleaning, remove the pore-forming agent particles, and ventilate and dry to obtain a porous high-entropy alloy material. Described method comprises the steps:

[0042] Step 1. Ball milling of high-entropy alloy powder: use an omnidirectional planetary ball mill to perform ball milling on the atomized high-entropy alloy powder. The ball milling process is carried out under the protection of argon with a ball-to-material ratio of 10:1. Alkane is used as a process control agent, the ball milling speed is 250~300rpm, and the ball milling time is 15~20h;

[0043] Or use an all-...

Embodiment 1

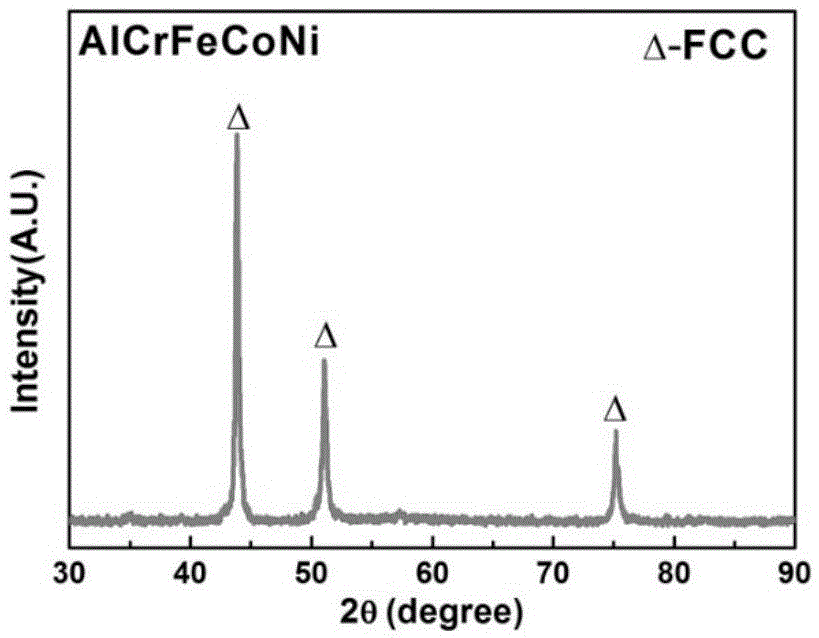

[0050] (1) AlFeCoNiCr high-entropy alloy powder is prepared by mechanical alloying, using an all-round planetary ball mill, the purity of the metal element powder raw materials is higher than 99%, the particle size is 200-325 mesh, and the ball-to-material ratio in the ball milling process is 15:1 , using n-heptane as the process control agent, the ball milling speed is 300rpm, and the ball milling time is 60h.

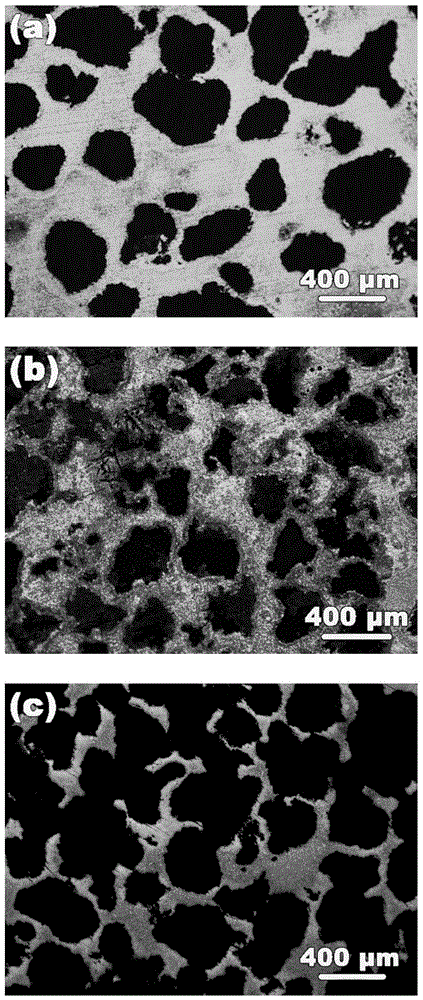

[0051] (2) Select sodium metaaluminate (NaAlO2) with a particle size of 40-60 mesh (250-425 μm) as the pore-forming agent, and use a standard sieve to sieve the pore-forming agent particles.

[0052] (3) Sodium metaaluminate is mixed according to the volume of 45%, 55% and 65% of the total volume, and is fully and uniformly mixed with a V-shaped mixer, and the mixing time is 30 minutes.

[0053] (4) The homogeneously mixed high-entropy alloy-pore-forming agent mixed powder was sintered by SPS, the sintering temperature was 1100°C, graphite mold was used, the sintering...

Embodiment 2

[0056] (1) AlFeCoNiCr high-entropy alloy powder is prepared by mechanical alloying, using an all-round planetary ball mill, the purity of the metal element powder raw materials is higher than 99%, the particle size is 200-325 mesh, and the ball-to-material ratio in the ball milling process is 15:1 , using n-heptane as the process control agent, the ball milling speed is 300rpm, and the ball milling time is 60h.

[0057] (2) Select sodium metaaluminate (NaAlO2) with a particle size of 60-80 mesh (180-250 μm) as the pore-forming agent, and use a standard sieve to sieve the pore-forming agent particles.

[0058] (3) Sodium metaaluminate is mixed according to the volume of 45%, 55% and 65% of the total volume, and is fully and uniformly mixed with a V-shaped mixer, and the mixing time is 30 minutes.

[0059] (4) The homogeneously mixed high-entropy alloy-pore-forming agent mixed powder was sintered by SPS, the sintering temperature was 1100°C, graphite mold was used, the sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com