Method for making holes through electric spark-electrolysis combination via matching of thread pipe electrode with inner and outer liquid flushing

An electric spark and threaded pipe technology, which is applied in the field of threaded pipe electrodes matching internal and external flushing electric spark-electrolysis combined hole making, can solve the problems of aggravation, the difficulty of discharging small solid particles of electric corrosion, and the difficulty in ensuring the stability of the processing process. The effect of increasing traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

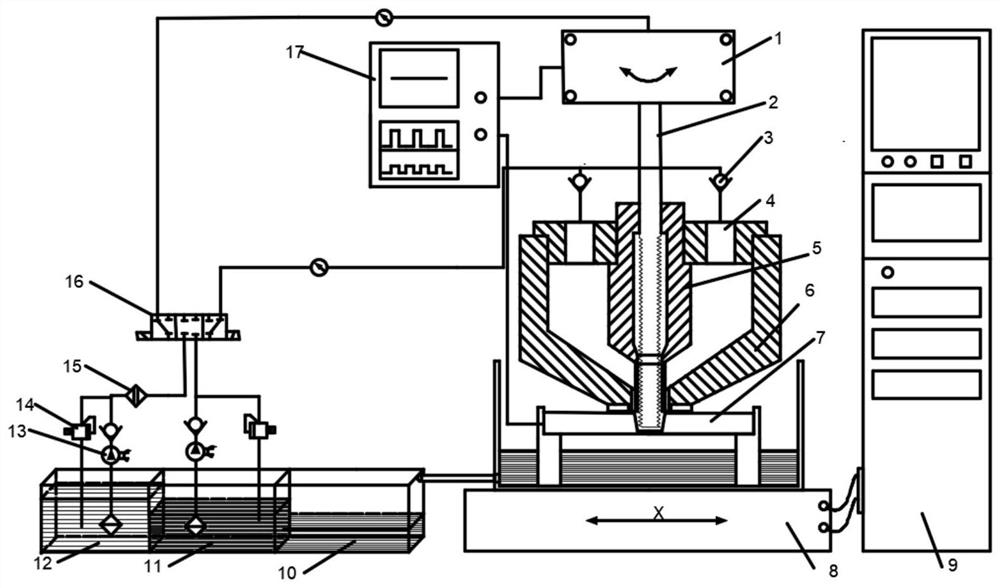

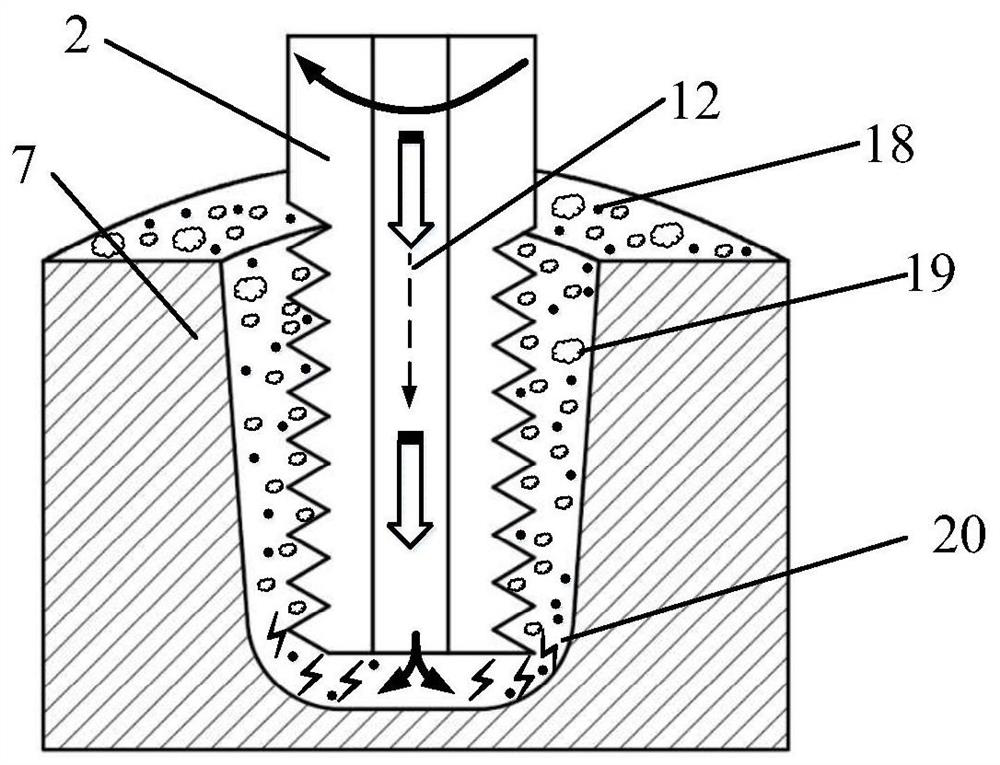

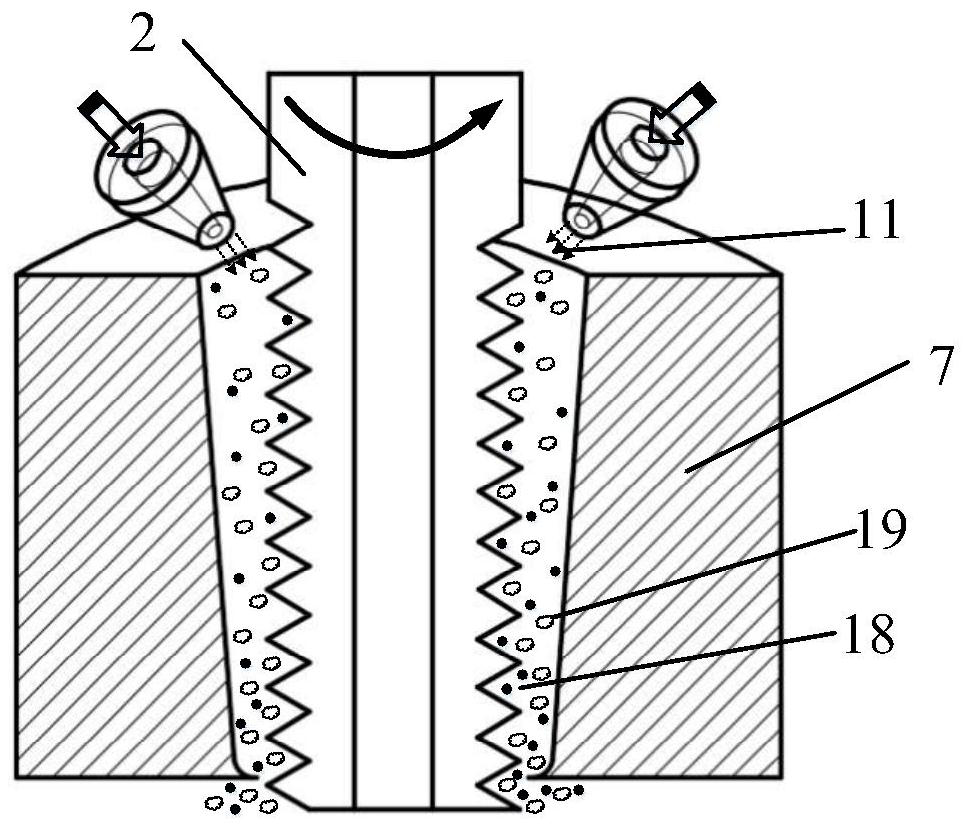

[0051] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0052] The embodiment of the invention discloses a threaded pipe electrode matching internal and external flushing electric spark-electrolysis combined hole making method, the method is applied to the film cooling hole of the turbine blade of the aeroengine, the group holes of the combustion chamber flame tube, and the small hole of the engine fuel injector , micro-hole processing of printed circuit board micro-holes, heat exchangers and other components. The hole-making method proposed by the invention can make holes on difficult-to-machine materials such as cast high-temperature alloys, titanium alloys, and cobalt-based alloys, and easy-to-cut metal materials such as stainless steel, copper-based alloys, and aluminum-based alloys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com