Patents

Literature

3366results about How to "Avoid gathering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

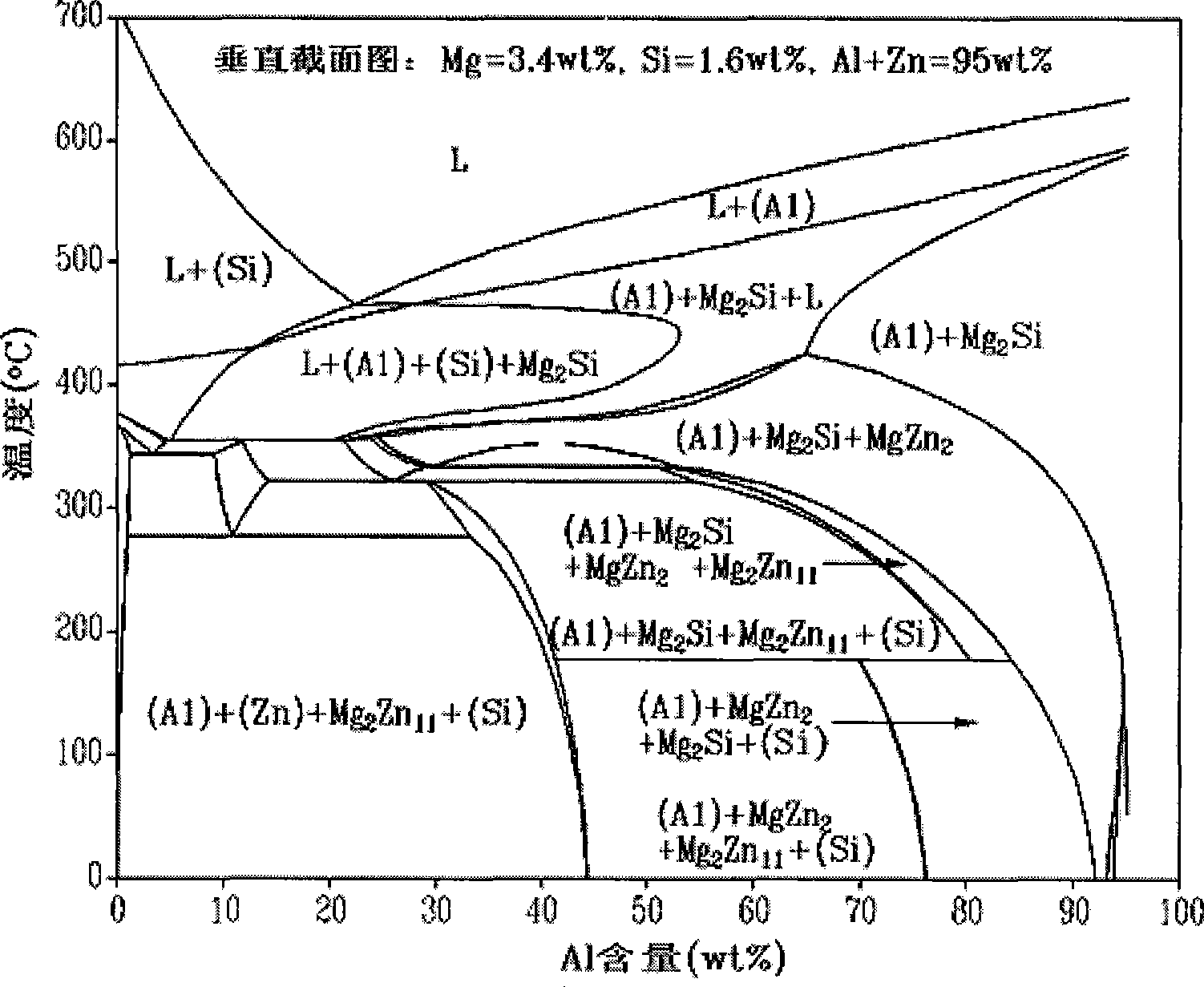

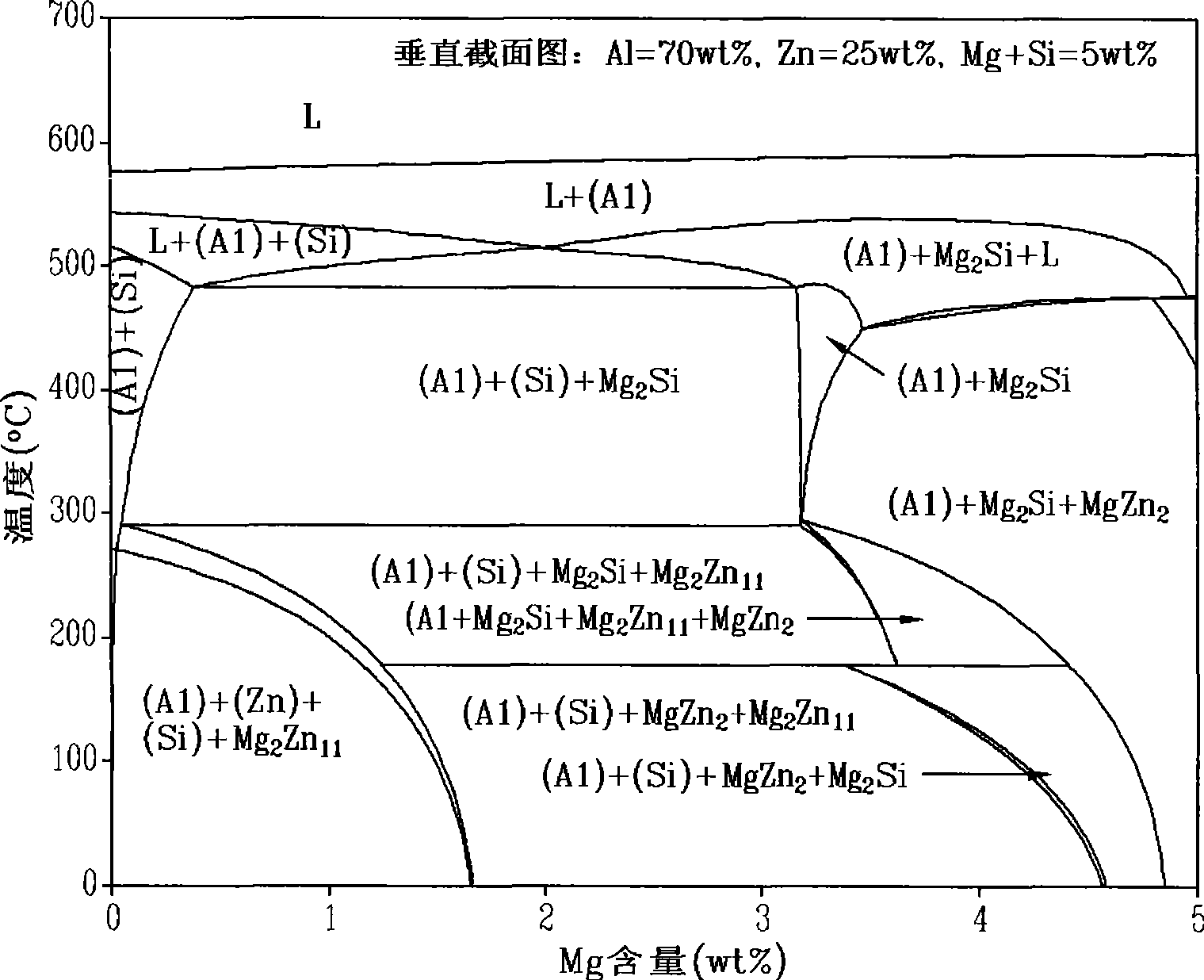

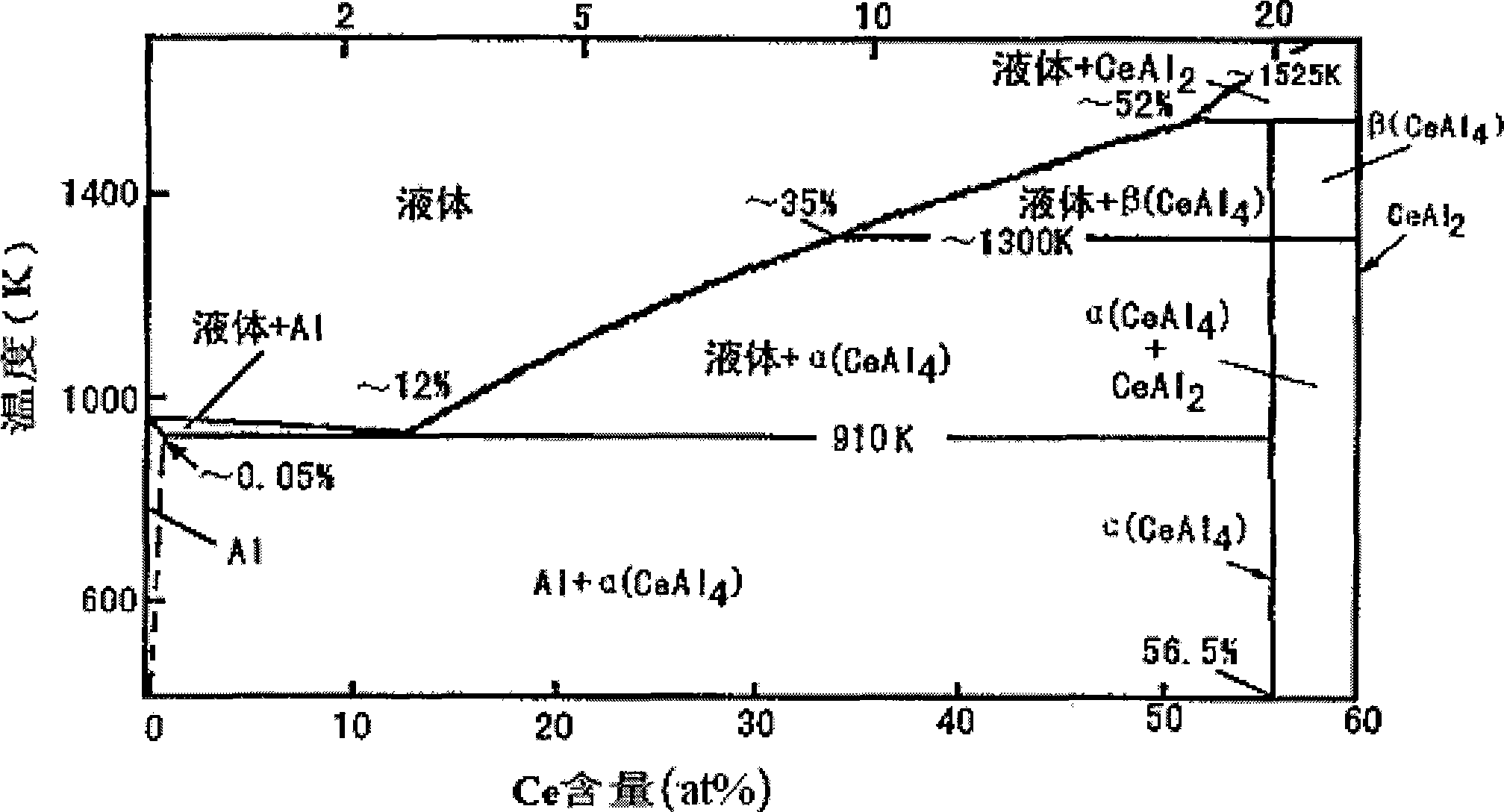

Al-Zn-Mg-Si alloy for hot dipping steel

InactiveCN101457320AAvoid gatheringDeterioration of surface propertiesHot-dipping/immersion processesRare earthZinc alloys

The invention provides a rare earth-containing Al-Zn-Mg-Si alloy with high aluminum content for hot-dipping steel products, comprising the following compositions by weight percent as follows; Al: 50-75%, Mg: 1-5%, Si: 0.5-2.5%, the addition of 0.002-0.1% of Ti, 0.001-0.045% of B and 0.05-1% of rare earth (La or Ce), and the balance of Zn and unavoidable impurities. The invention utilizes corrosion resistance of Mg2Si and grain-refining effect of the rare earth, the Ti and the Bi elements to improve quality of plating solution and obtain a high aluminum content aluminum-zinc alloy cladding with ,a bright and smooth surface and great corrosion resistance property. In addition, the content of aluminum in the alloy is up to 50-75%, thereby lowering production cost.

Owner:SHANGHAI UNIV

Preparation method of hydro-treatment catalyst

ActiveCN103769125AModerate decrease in viscosityImprove permeabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystUltrasonic cavitation

The invention discloses a preparation method of a hydro-treatment catalyst. The preparation method comprises the following steps: preparing an alumina carrier, preparing an impregnation solution containing the VIII group metal and VIB group metal, wherein the impregnation solution comprises a proper amount of an organic auxiliary agent containing chelating ligand, then impregnating the alumina carrier into the impregnation solution under a proper ultrasonic treatment condition, and drying so as to obtain the hydro-treatment catalyst. The preparation method utilizes the ultrasonic cavitation effect to properly reduce the viscosity of the impregnation solution; at the same time the complexing capacity between the chelating ligand in the organic auxiliary agent and nickel / cobalt is improved by the catalytic function of the ultrasonic, the interaction force between the chelating ligand and nickel / cobalt is strengthened, thus the active metal component is promoted to highly disperse on the carrier surface, furthermore, the existing state of the active metal on the catalyst surface is improved at the same time, the sulfurization degree and sulfurization uniformity of the active metal are both improved, so the activity and stability of the catalyst are both improved. The catalyst is especially suitable for being used in the hydro-denitrogenation process and hydro-desulfurization process of heavy distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

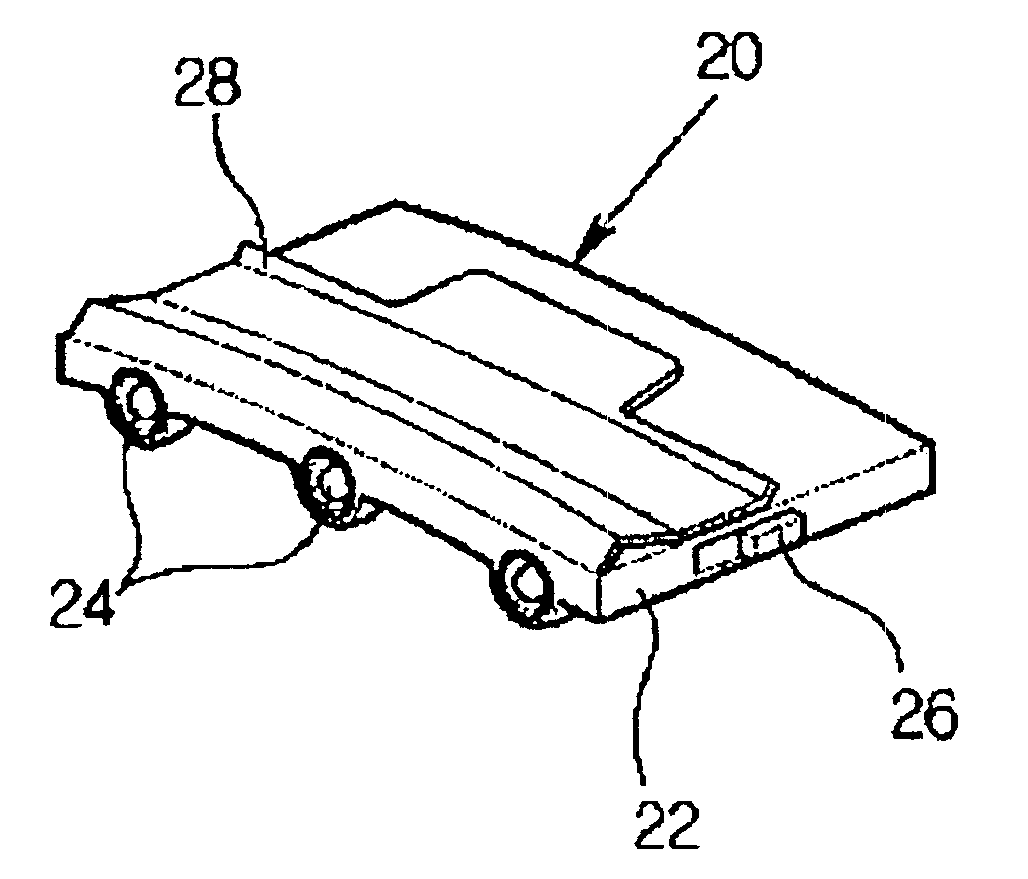

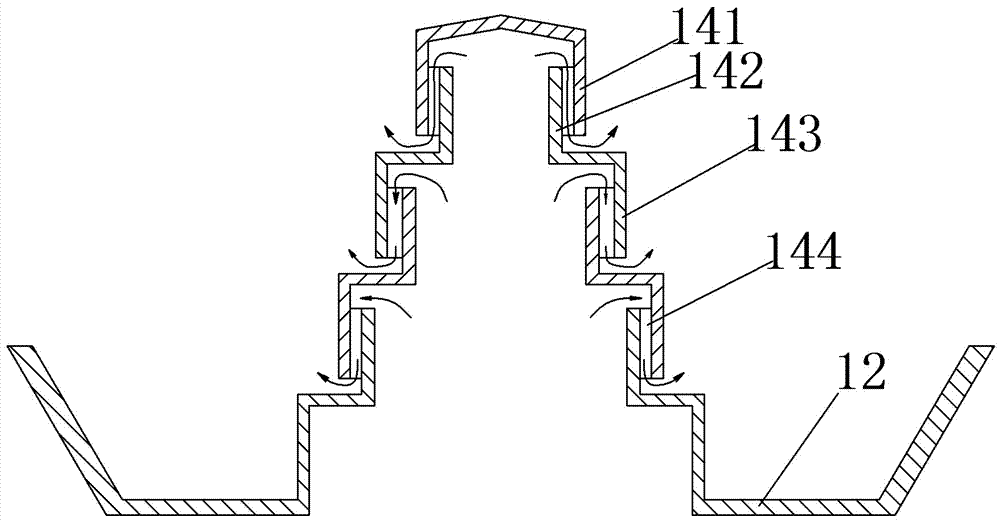

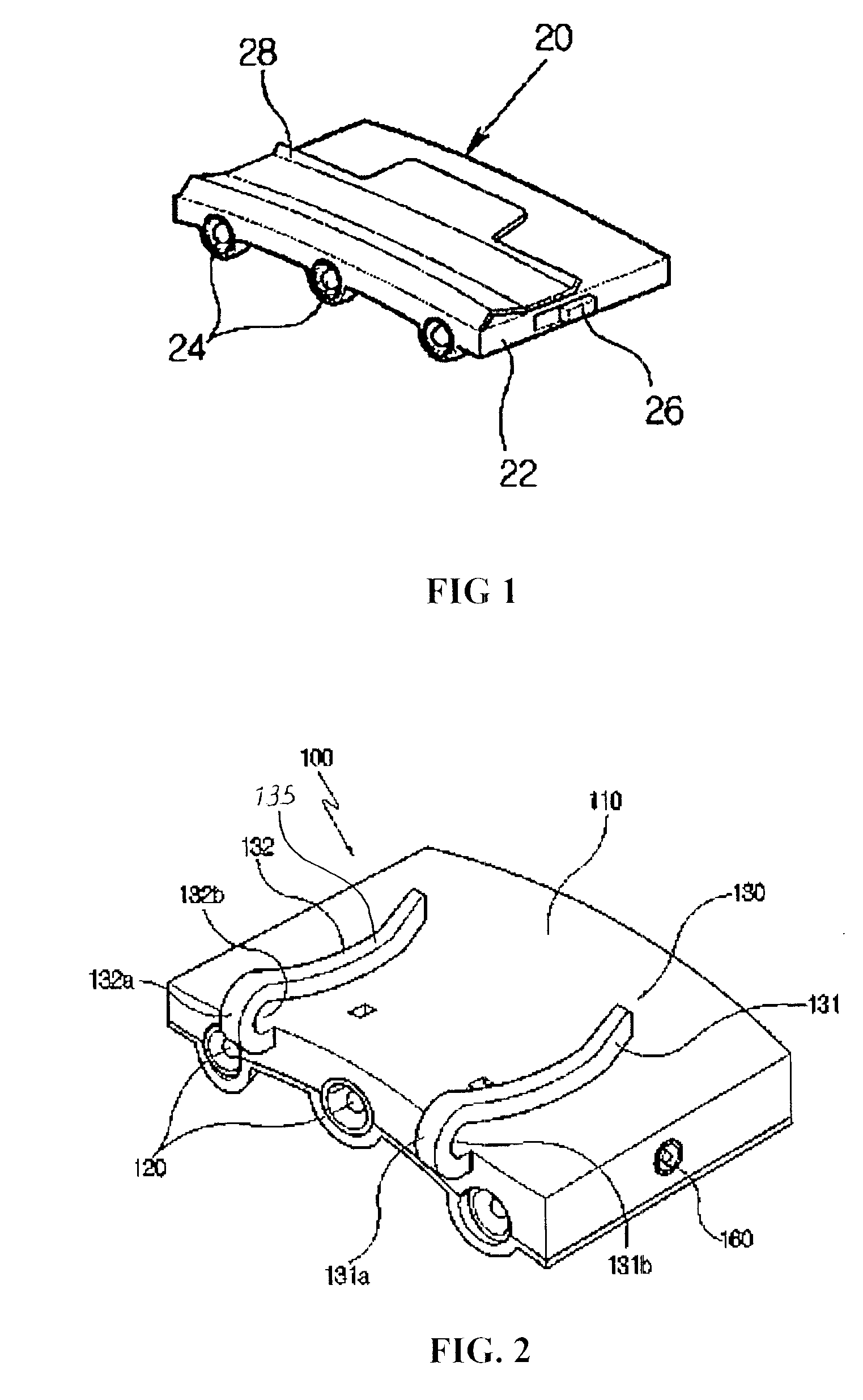

Evaporator

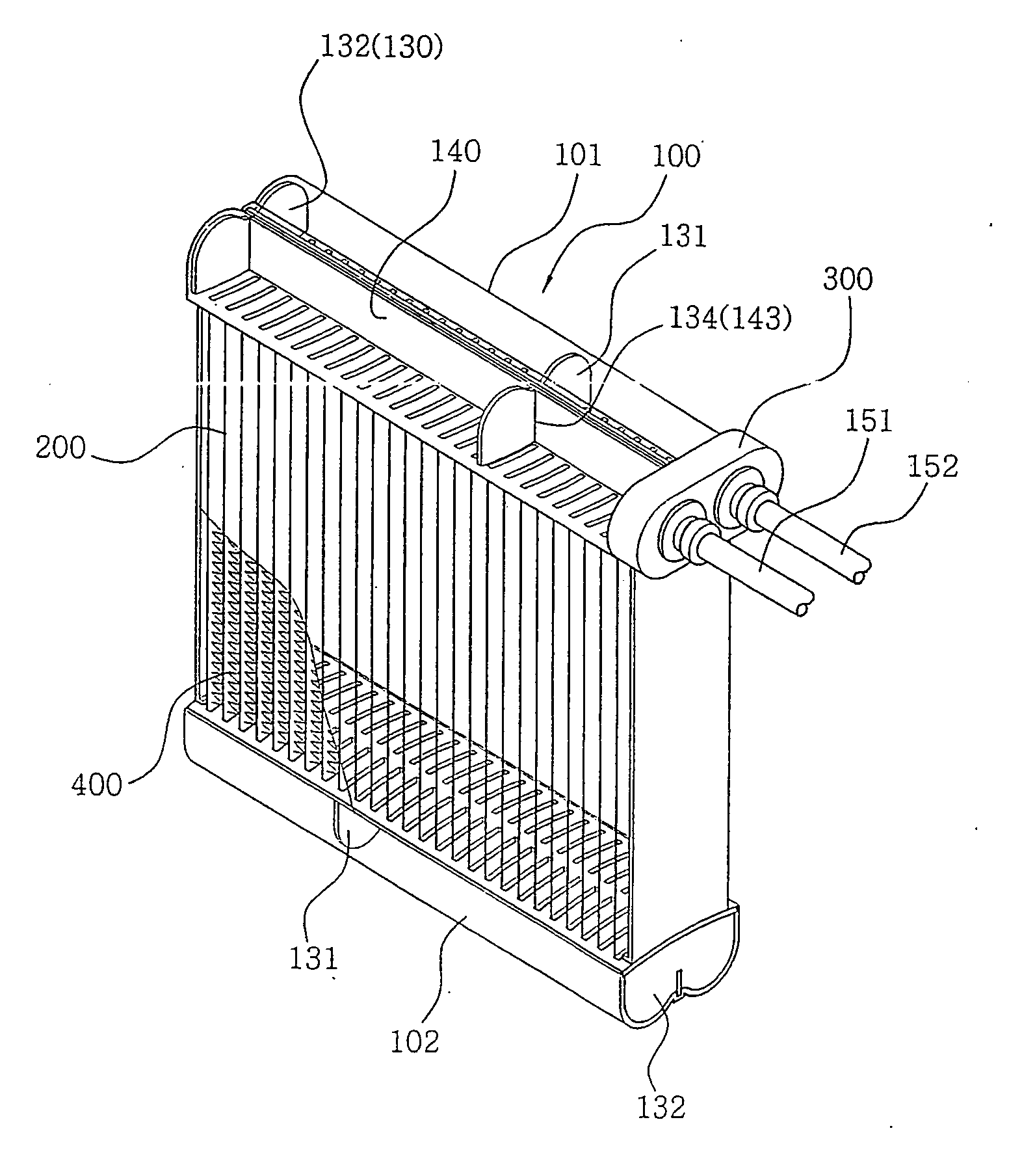

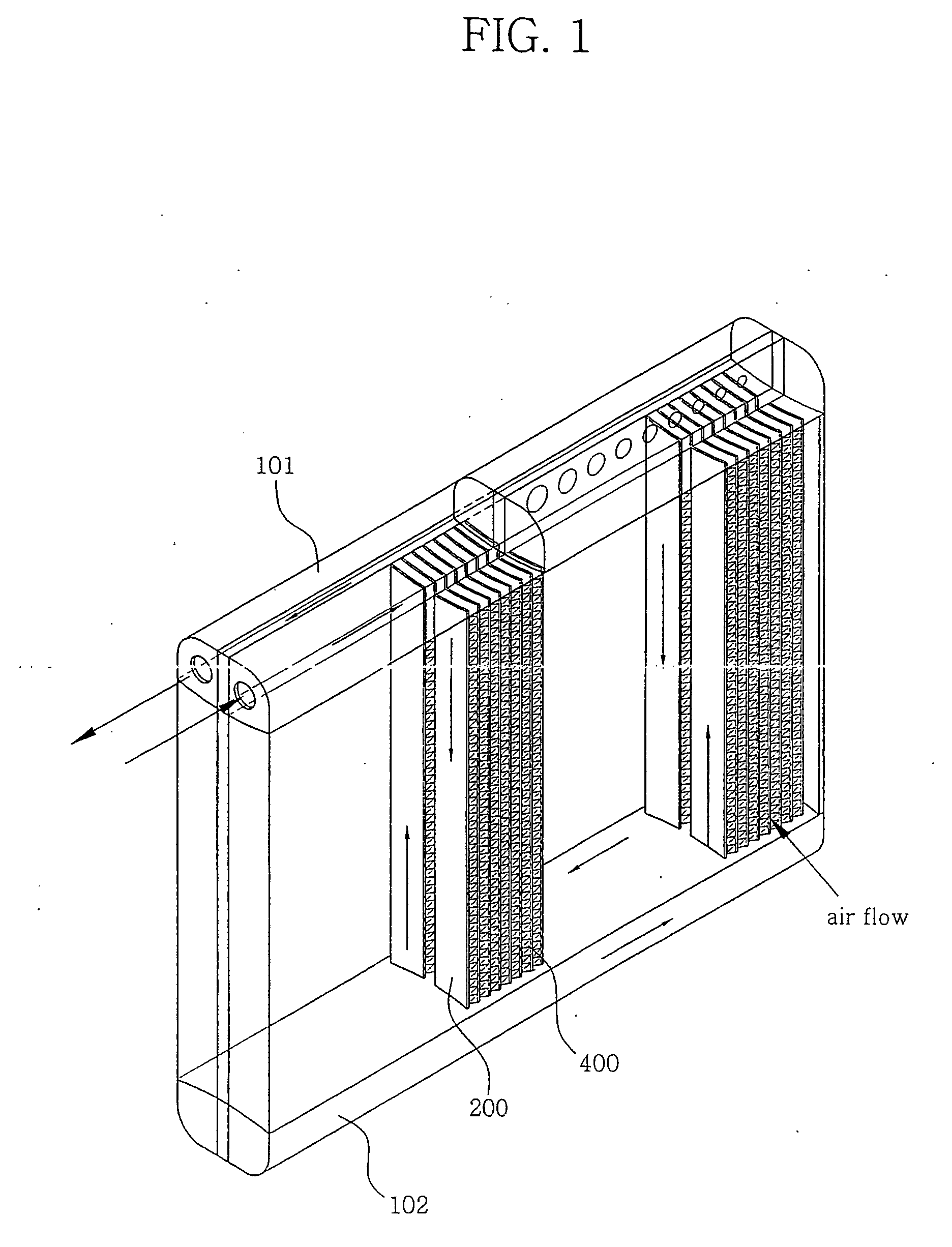

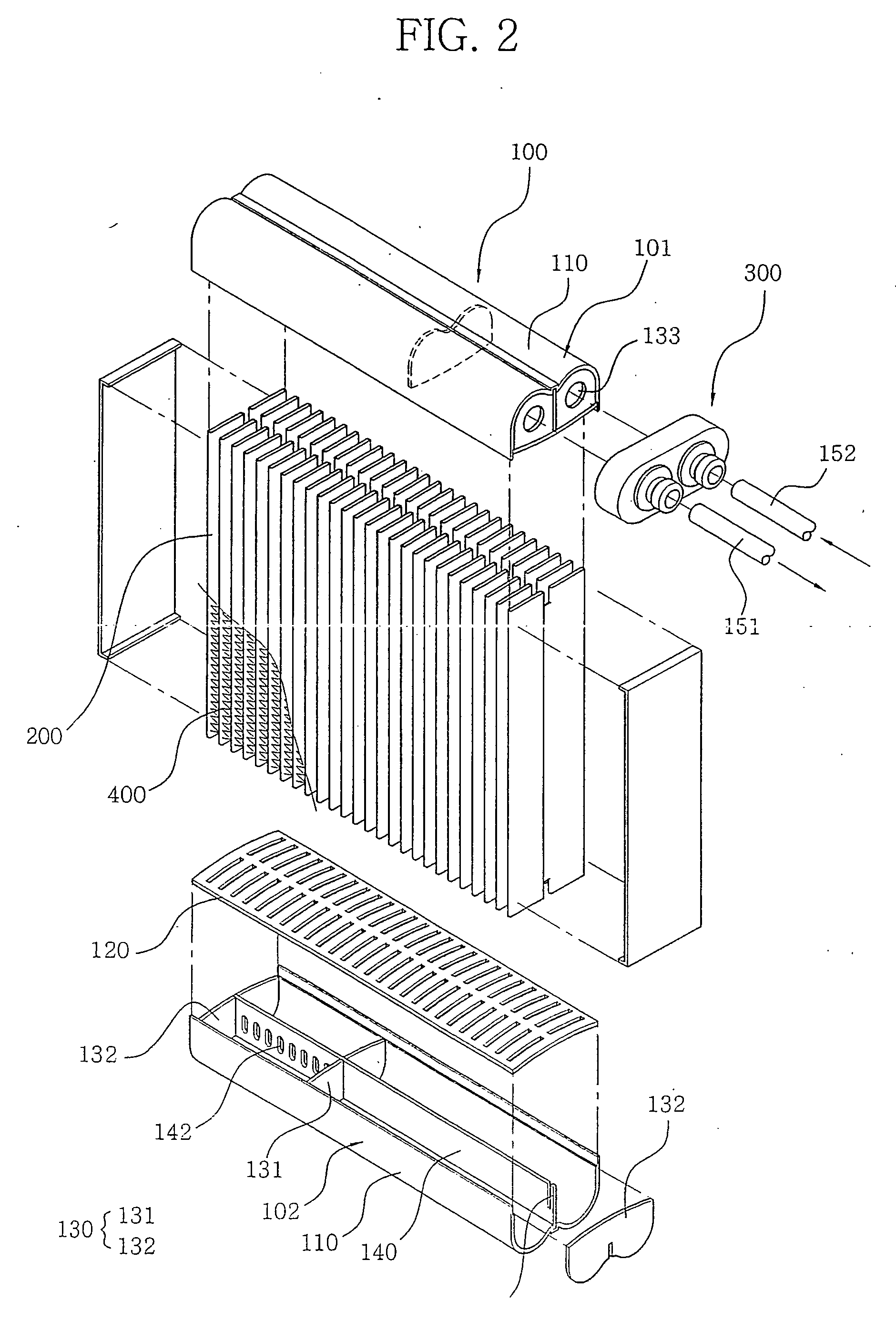

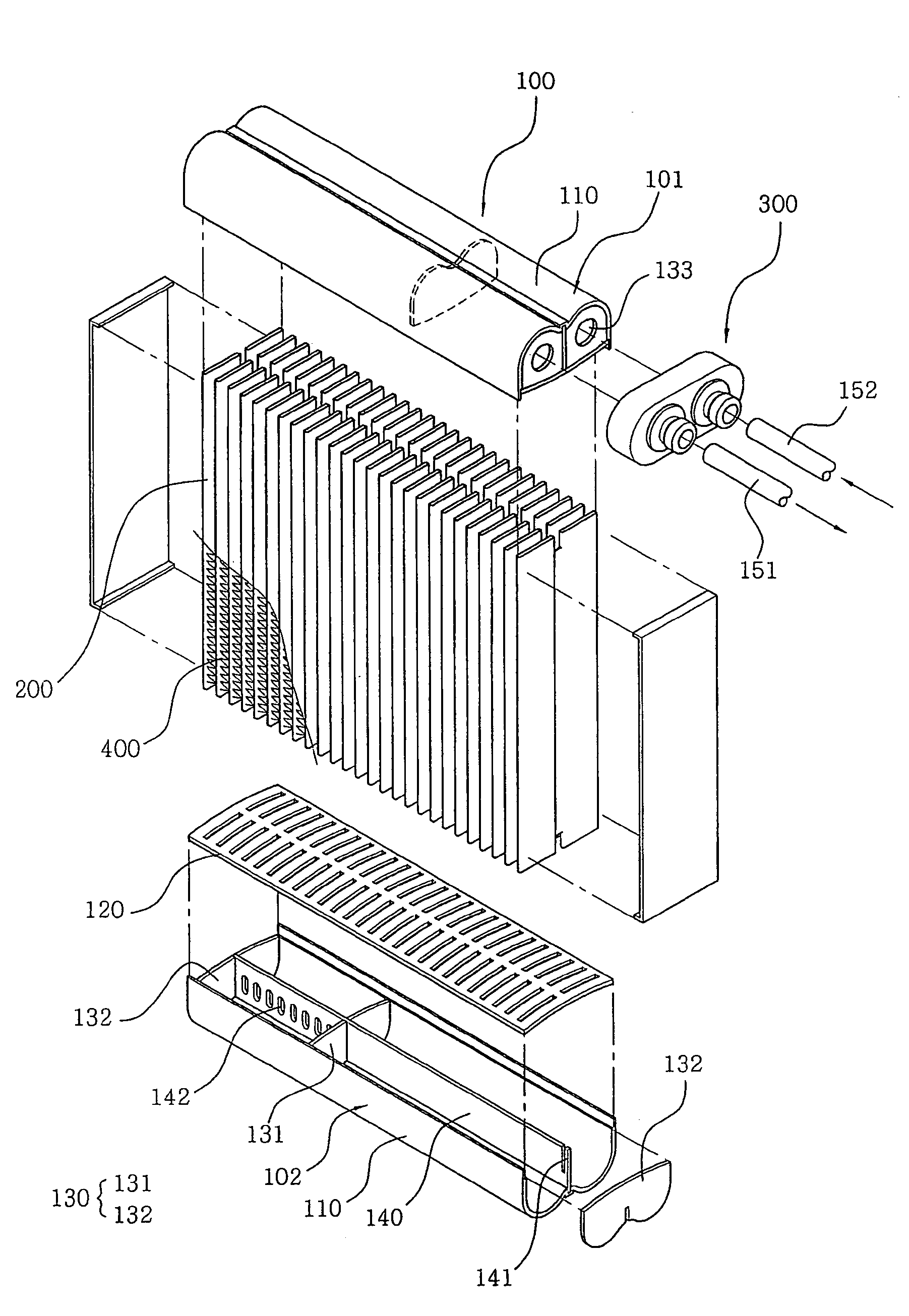

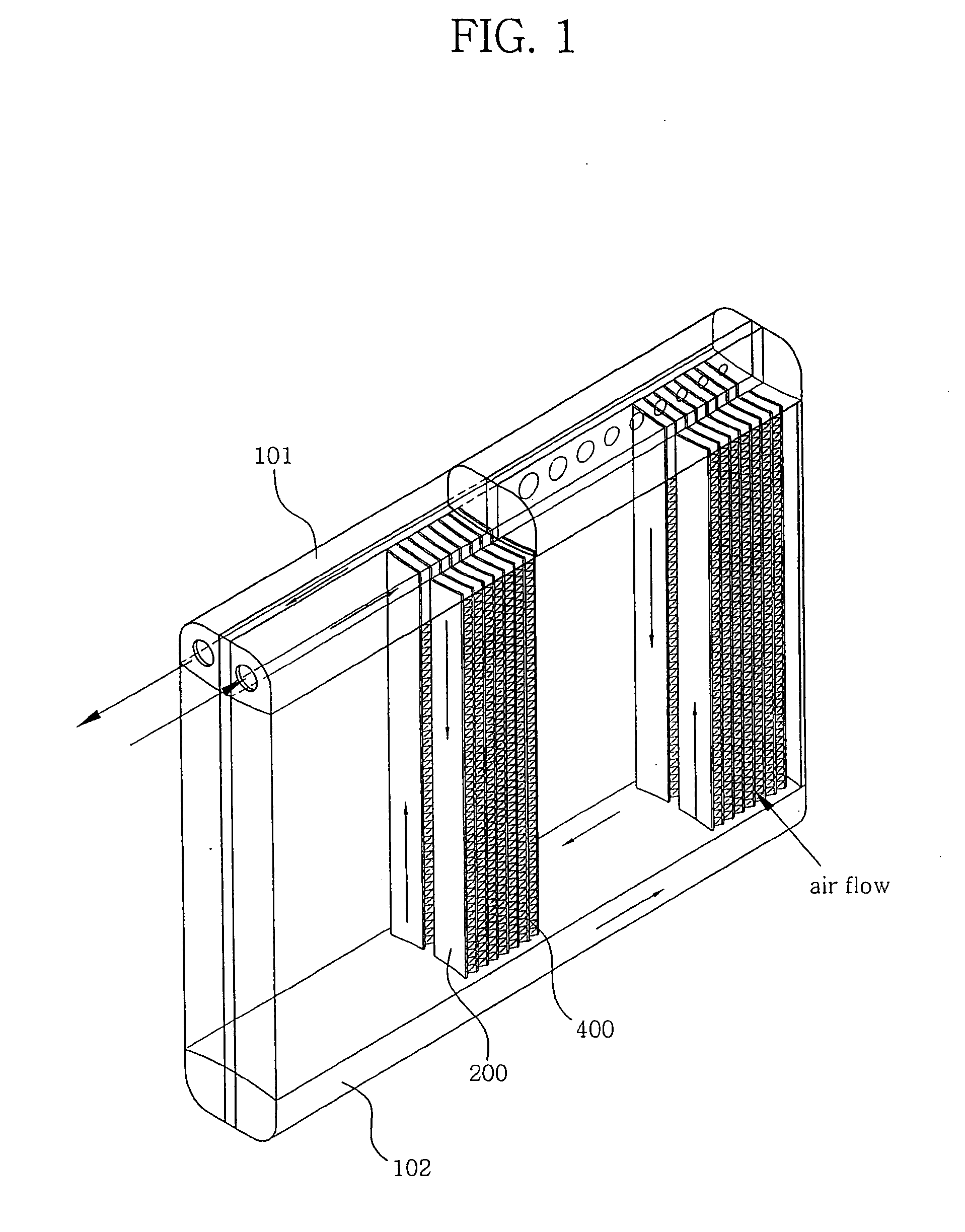

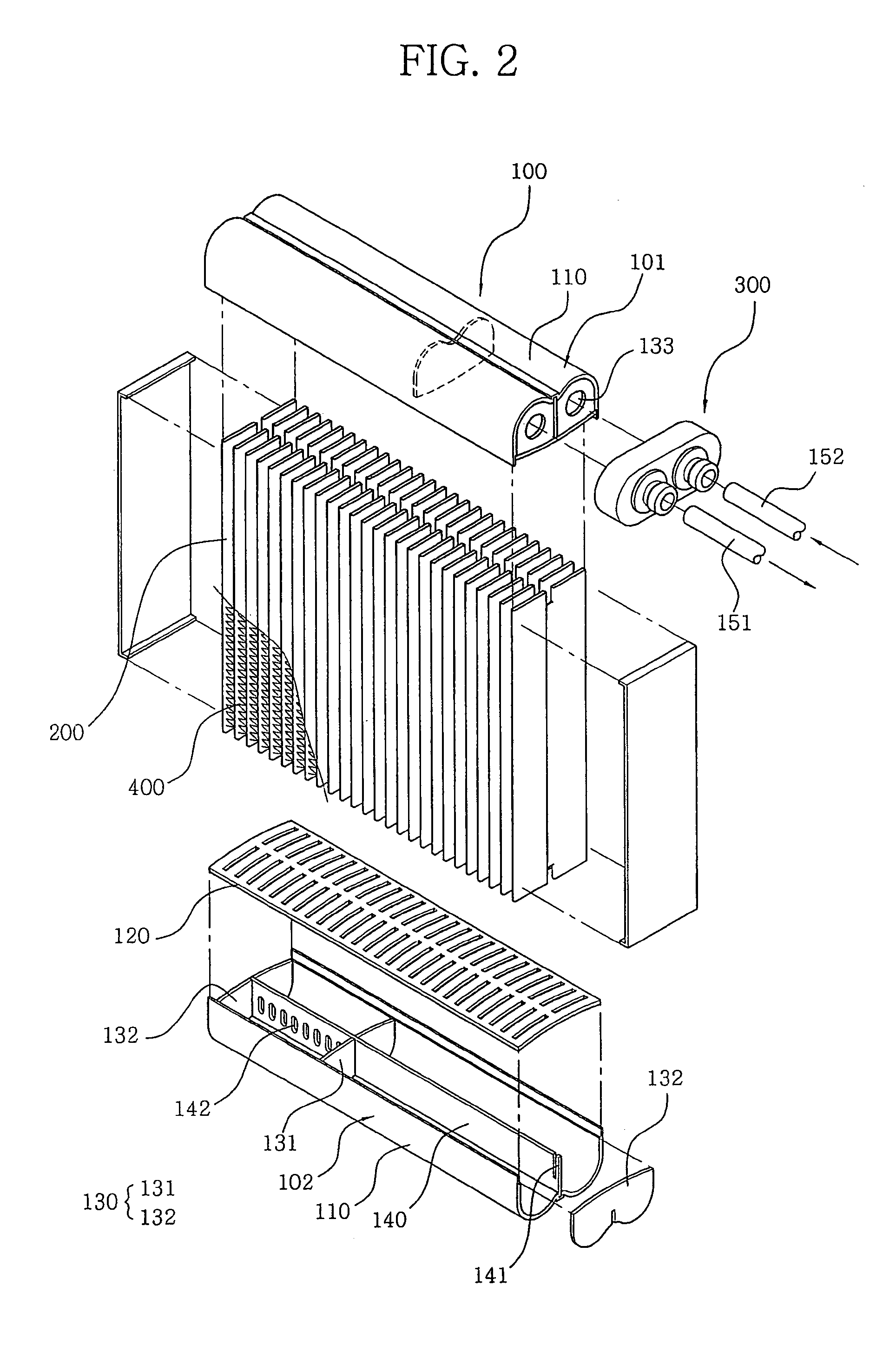

InactiveUS20050172664A1Good conditionReduce total pressure lossEvaporators/condensersStationary conduit assembliesEngineeringEvaporator

The present invention relates to an evaporator for an air conditioner of a vehicle, and the major object of the present invention is to provide the evaporator which is capable of decreasing the whole dimension of an evaporator and enhancing a heat exchange performance. To achieve the above objects, an evaporator includes an upper and lower header units comprising a tank member, a partition member, a header plate, an intermediate baffle, a finishing baffle; and a plurality of tubes comprising a front tube portion, a rear tube portion, a connection tube portion; and a wrinkle fin.

Owner:MODINE KOREA

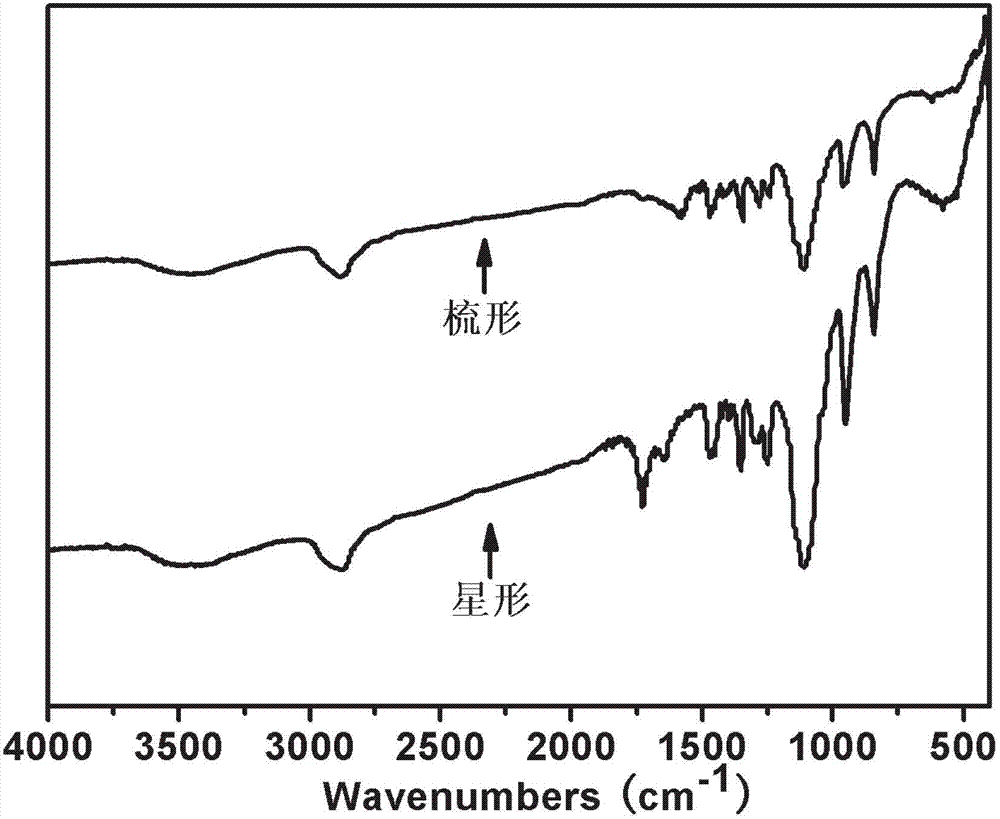

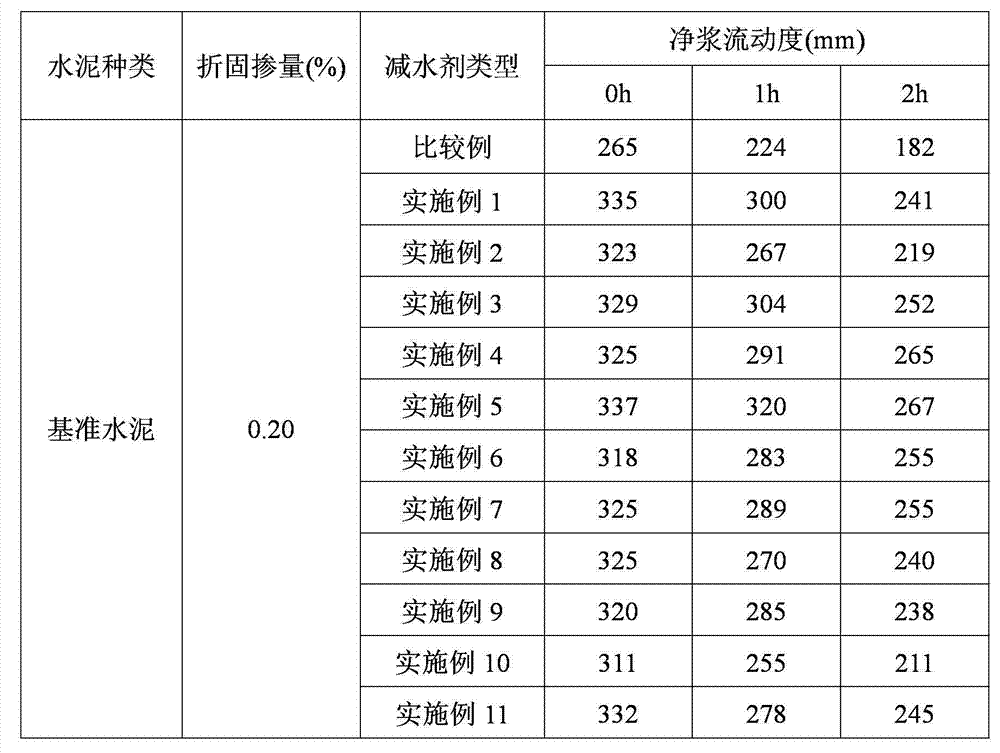

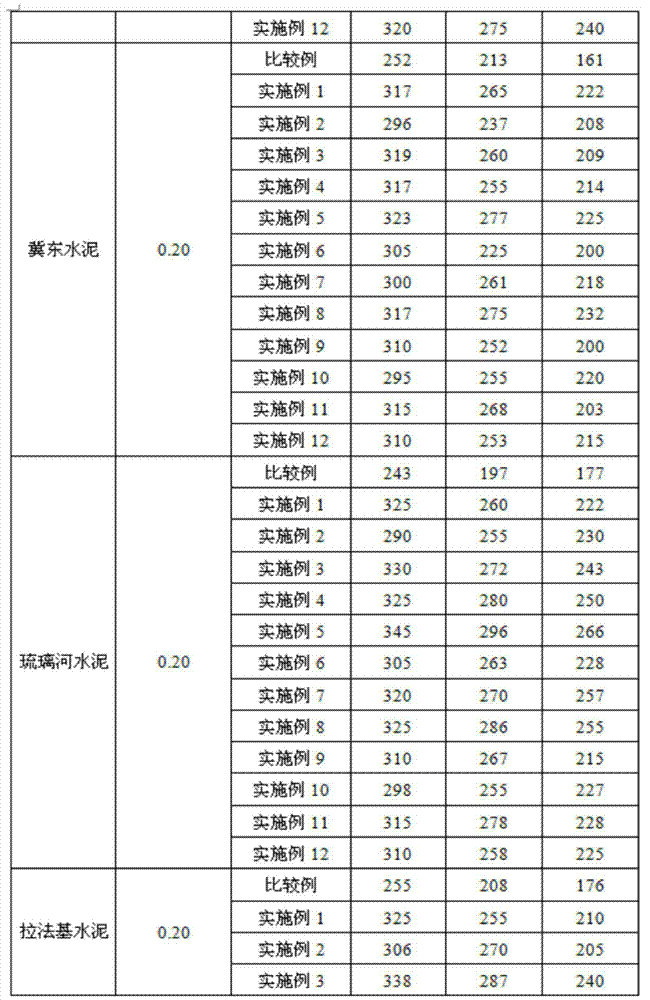

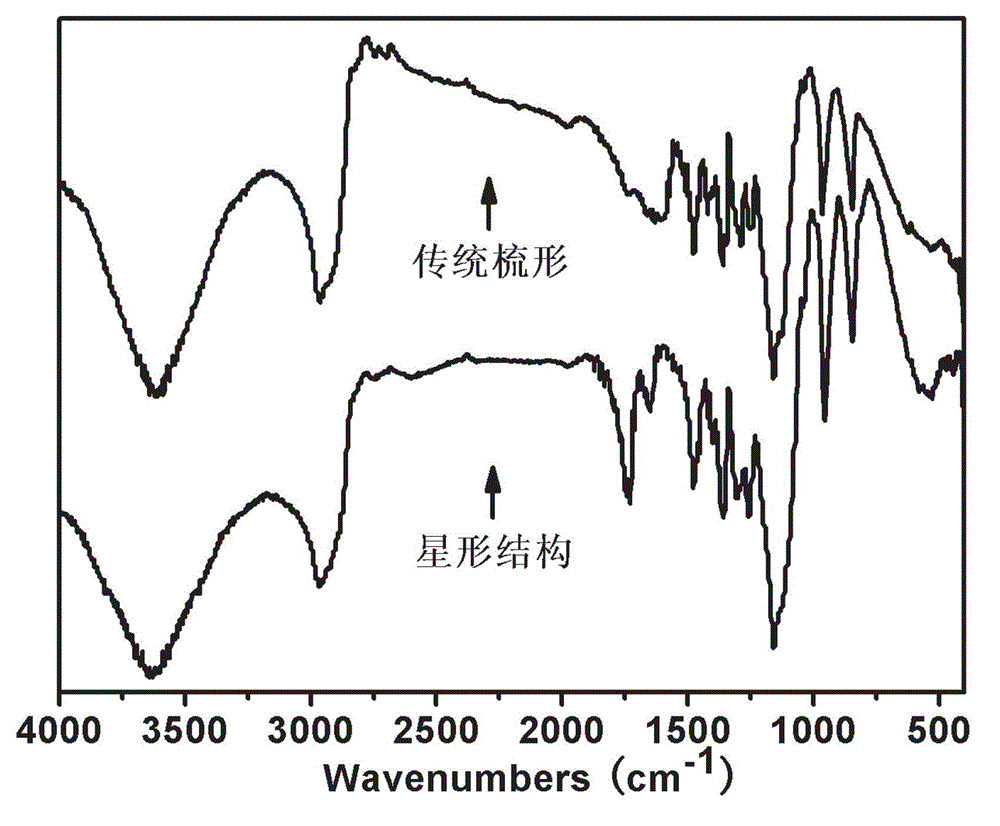

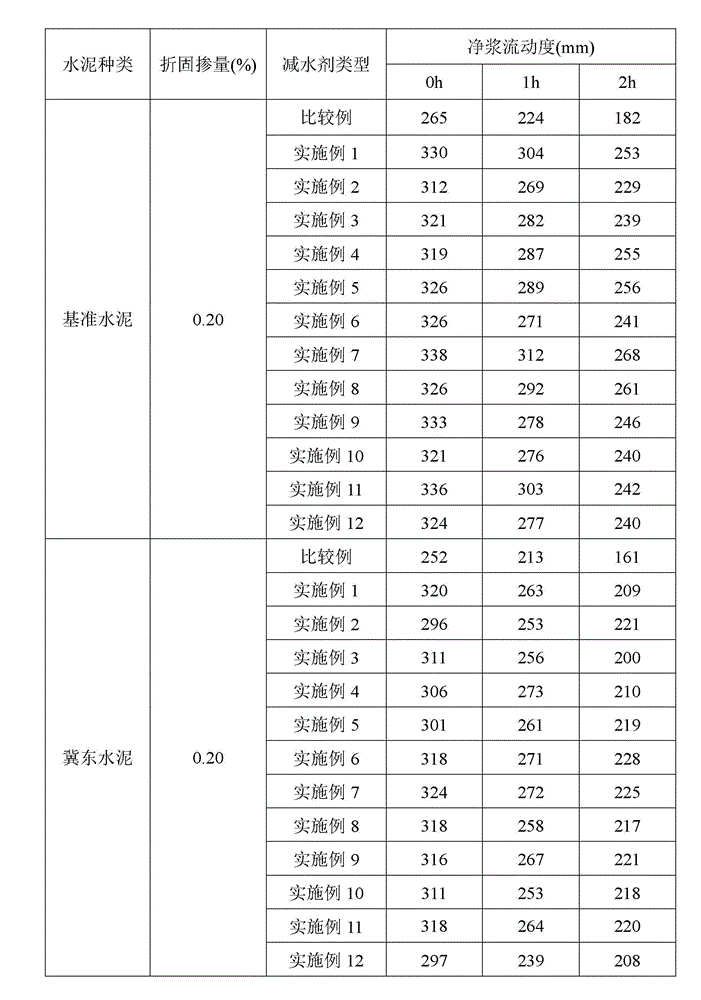

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesWater reducerPollution

The invention relates to a preparation method of a star polycarboxylic acid high-performance water reducing agent. Polybasic alcohol and (methyl) acrylic acid used as main raw materials for esterification are esterified and polymerized to prepare the star polycarboxylic acid high-performance water reducing agent material: the (methyl) acrylic acid and polybasic alcohol used as reactants are esterified under the action of a catalyst to firstly prepare a star polymerizable active terminal, and free-radical polymerization reaction is carried out with unsaturated polyethenoxy ether, molecular weight regulator and unsaturated carboxylic acid monomer under the action of an initiator to prepare the star polycarboxylic acid high-performance water reducing agent. The invention is easy to control, and has the advantages of high polymerization degree, low cost and no pollution; the esterification reaction is carried out form an active core, and the free-radical polymerization is carried out to generate the chain arm, thereby implementing the polycarboxylic acid high-performance water reducing agent in a star molecular structure; and under the condition of common doping amount and low doping amount, the star polycarboxylic acid high-performance water reducing agent has better cement paste flowability and holding capacity than the traditional linear and comb polycarboxylic acid water reducing agents, and has favorable cement adaptability and concrete application performance.

Owner:GUIZHOU DR SHI TECH

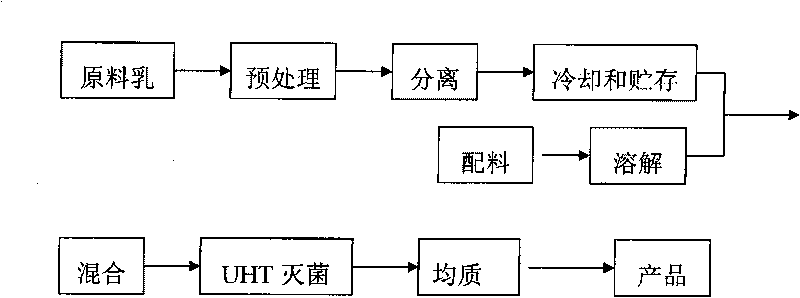

Cream and making method and use thereof

The invention discloses a cream which contains 20-45% of fat, 1-3% of protein, 0.1-0.55% of stabilizer, 0.05-0.35% of emulsifier, 0.005-0.15% of buffer salt and the balance water, and the percent is the weight percent of each component in the total weight of the cream. The invention further provides a making method of the cream. The making method can overcome the defects of short shelf life, strict preservation conditions and further limitation of the sales regions of the cream prepared by the conventional method, and the invention provides the cream and the making method thereof by improvingthe formula and the process of the cream. The cream produced and prepared by the method can be stored at room temperature, the use is convenient and fast, and the shelf life is long, thereby being suitable for long-distance transportation and being conductive to construction of a national sales network; meanwhile, the cream product has the advantages of uniformity, stability, no water separation,good whipability and thermal stability, thereby being applicable to making egg tarts, candies, cakes or cream soup.

Owner:BRIGHT DAIRY & FOOD

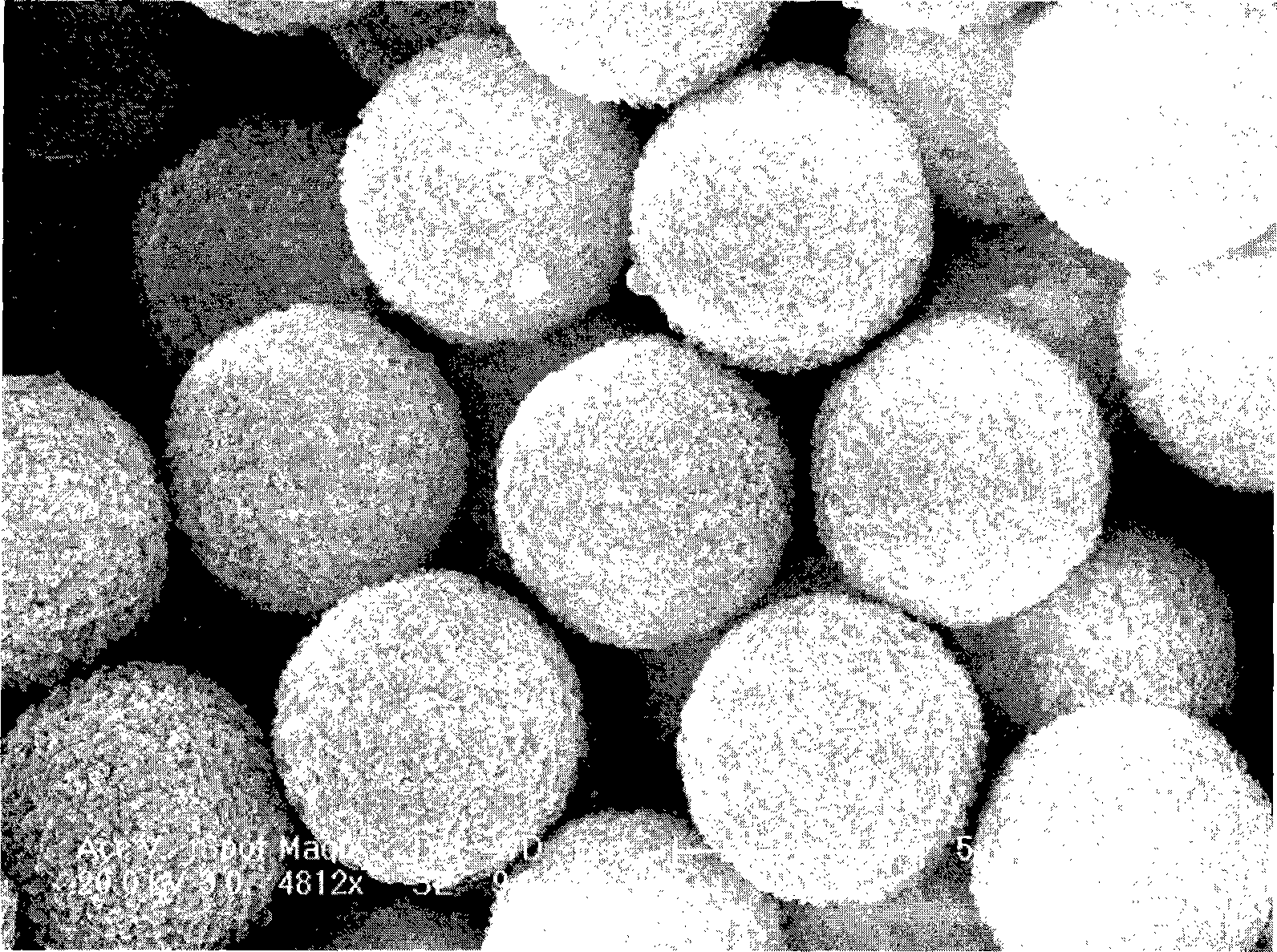

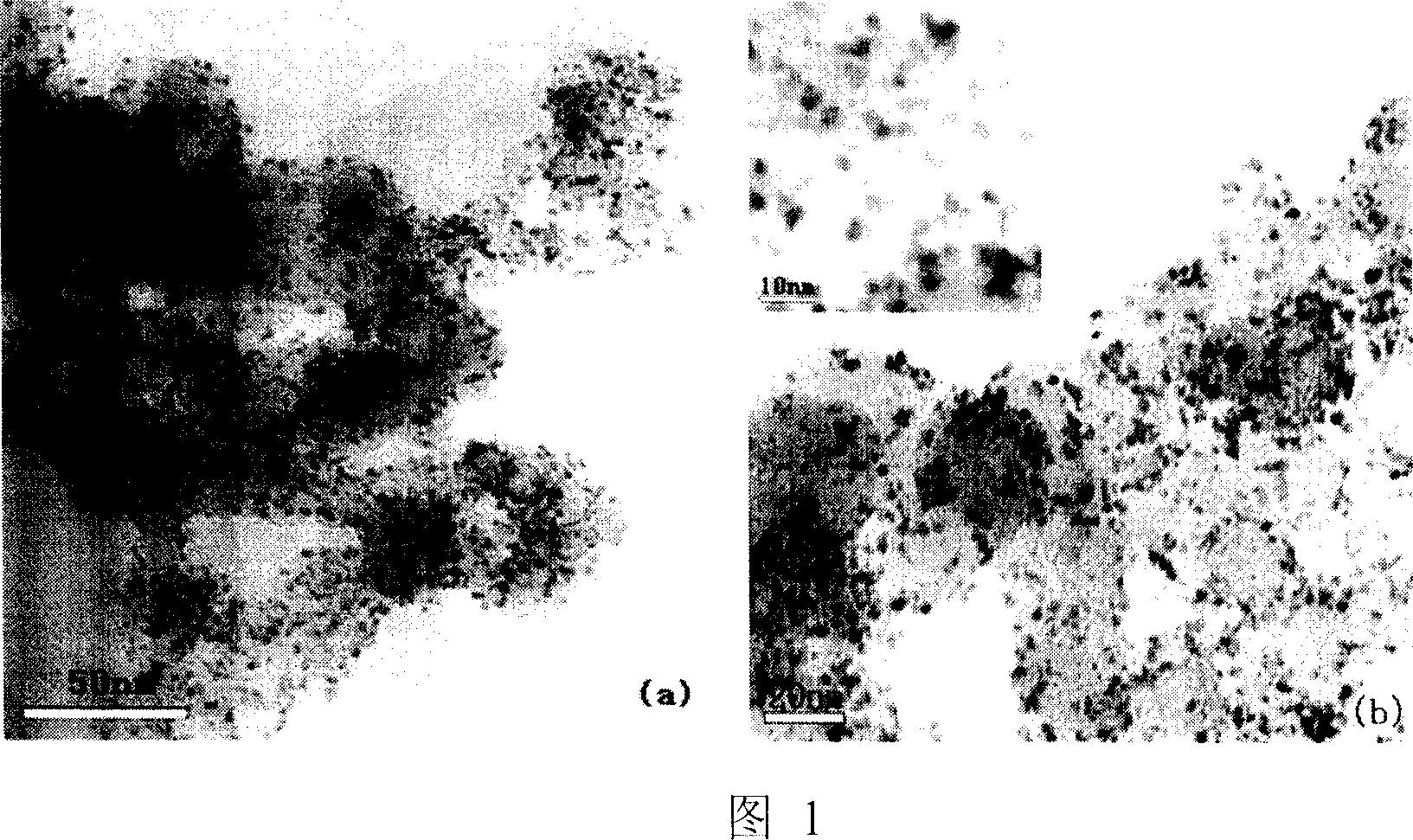

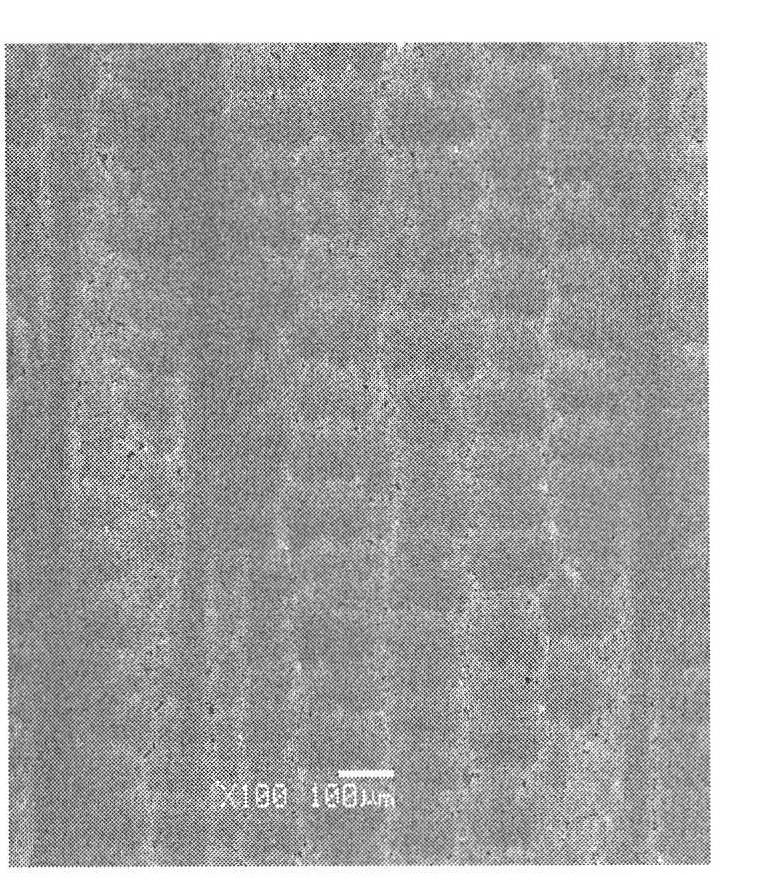

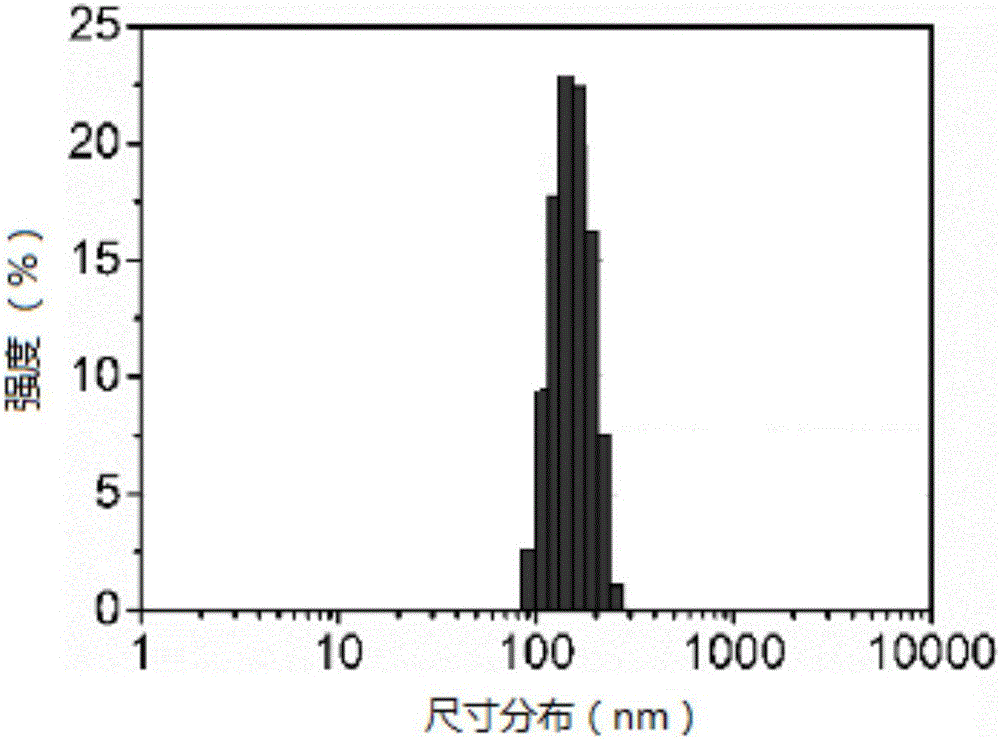

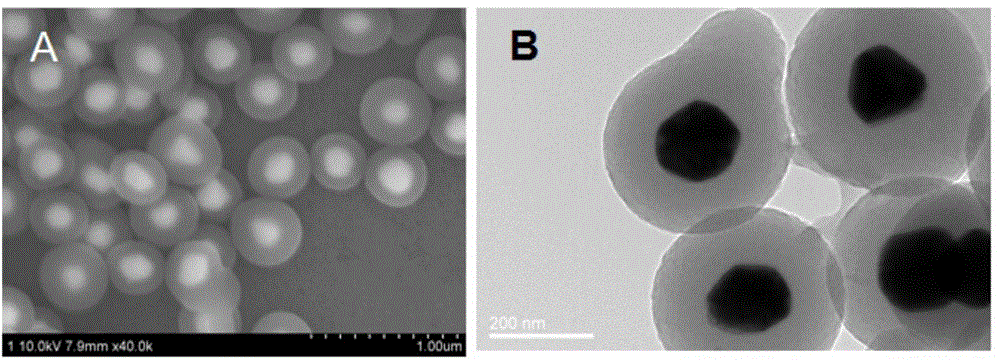

Preparation of monodisperse porous polymer microsphere

The invention provides a preparation method of a monodisperse porous polymer microsphere. After a second stage of swelling of two-stage seed swelling polymerization, remnant monomer separation technology is adopted to avoid the aggregation of the microspheres and the generation of secondary particles, thereby greatly improving the stability of preparing monodisperse porous polymer microsphere through the two-stage seed swelling polymerization. The two-stage seed swelling polymerization can stably prepare the following monodisperse porous polymer microspheres: P(St-co-DVB) (PSD for short) and P(St-co-DVB-co-MMA) (PSDA for short), wherein, St is referred to as styrene, DVB as divinybenzene, MMA as methyl methacrylate, AN as acrylonitrile and co as copolymerization. The monodisperse porous polymer microsphere PSDA prepared by the method can be seen in an attached drawing.

Owner:芜湖万隆新材料有限公司

Evaporator

InactiveUS7222501B2Reduced dimensionImprove heat transfer effectEvaporators/condensersStationary conduit assembliesEngineeringEvaporator

The present invention relates to an evaporator for an air conditioner of a vehicle, and the major object of the present invention is to provide the evaporator which is capable of decreasing the whole dimension of an evaporator and enhancing a heat exchange performance. To achieve the above objects, an evaporator includes an upper and lower header units comprising a tank member, a partition member, a header plate, an intermediate baffle, a finishing baffle; and a plurality of tubes comprising a front tube portion, a rear tube portion, a connection tube portion; and a wrinkle fin.

Owner:MODINE KOREA

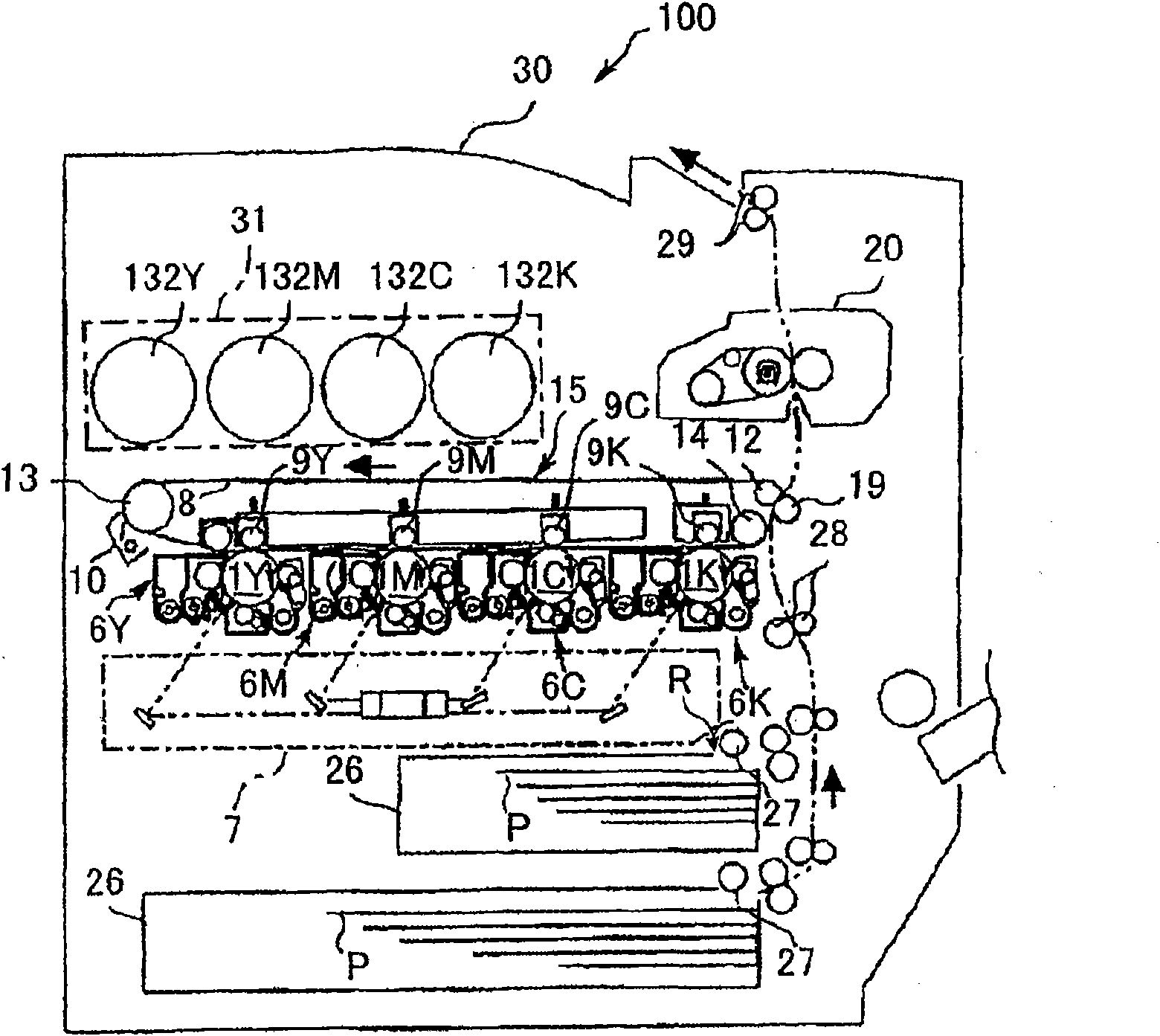

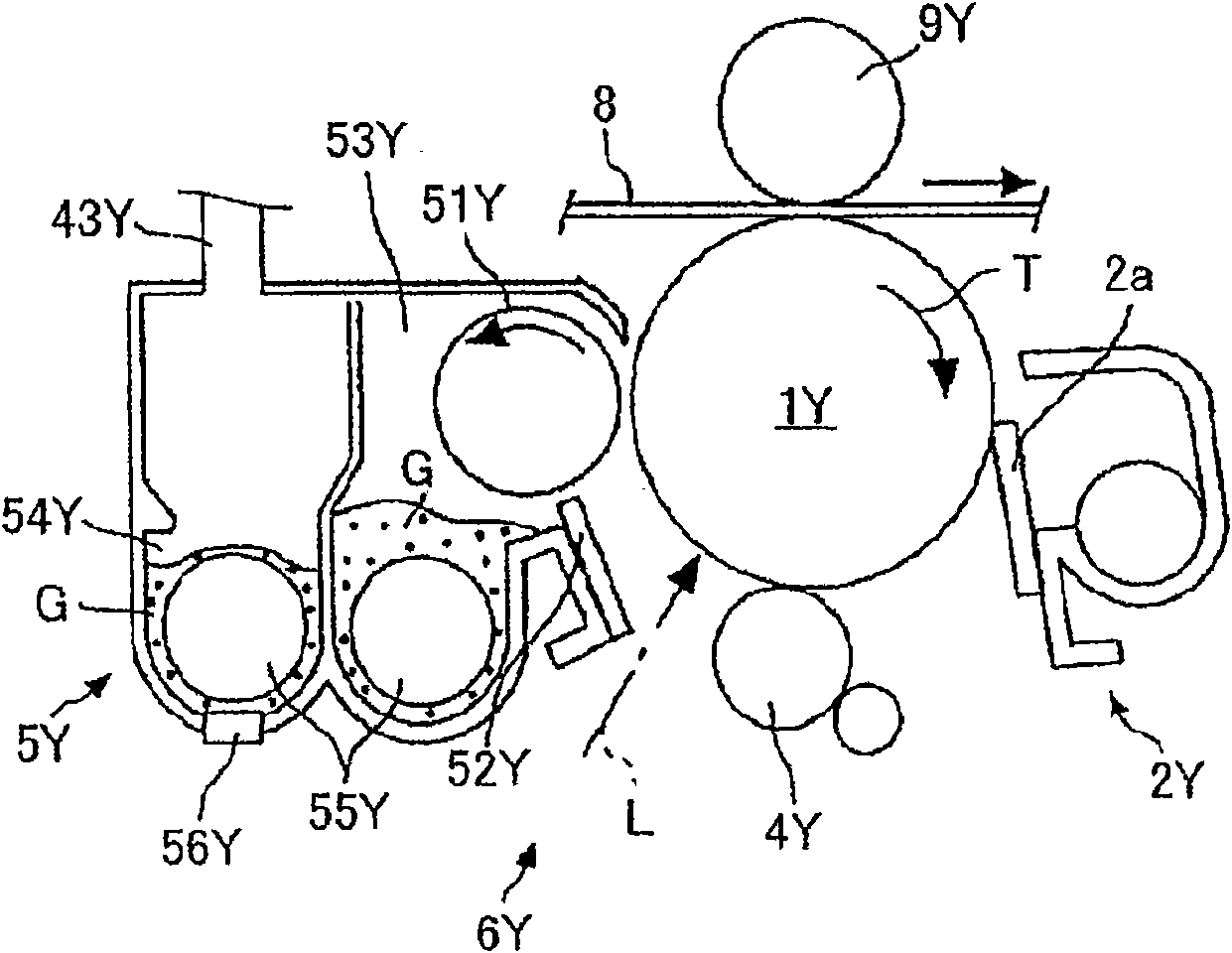

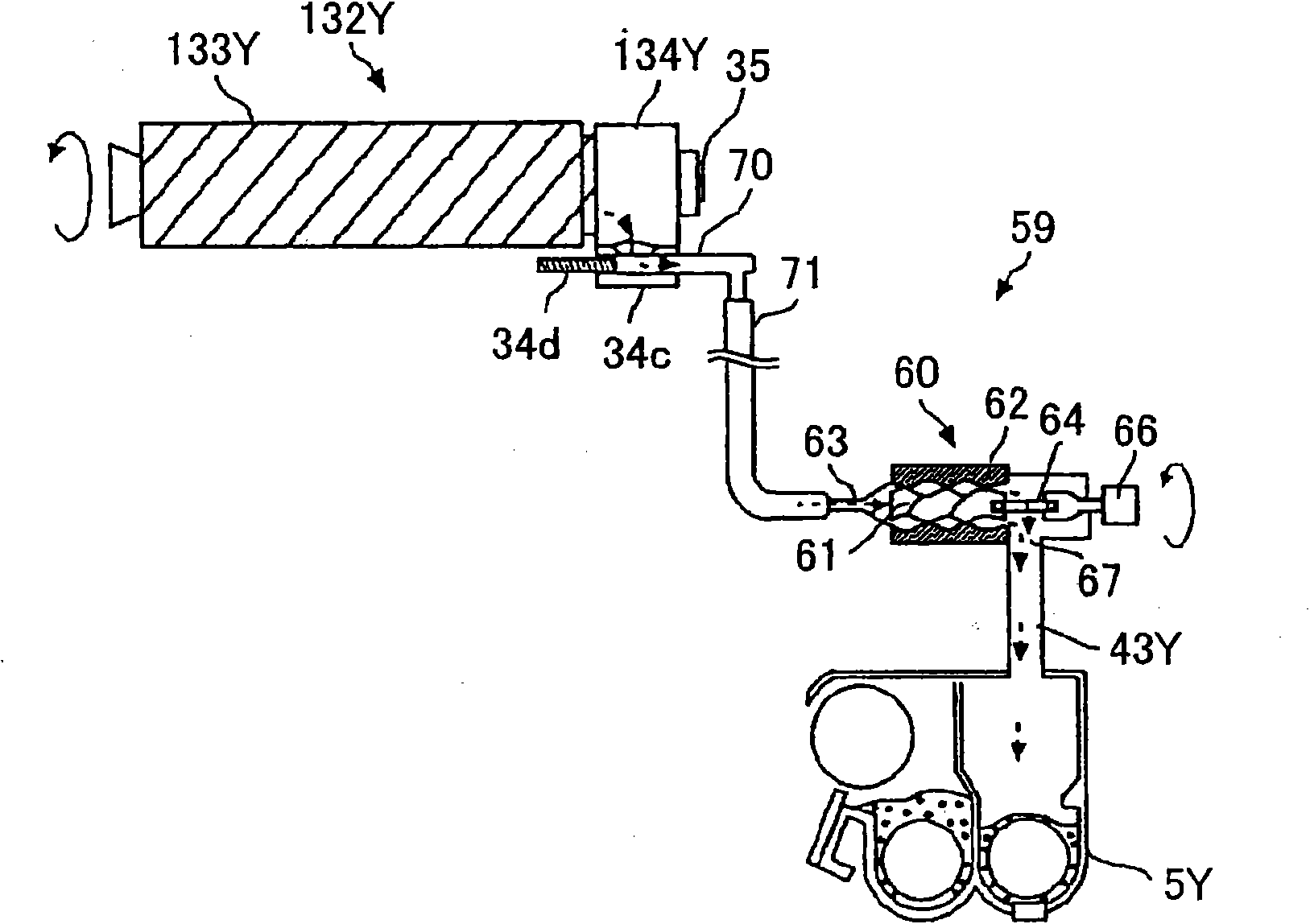

Toner container and image forming device

A toner container (132Y) detachably installed in the toner container storage part of the image forming device body of an image forming device. The toner container comprises a container body (133Y) storing a toner therein, a held part (134Y) fitted to the longitudinal end part of the container body (133Y), having a toner discharge port (B) for discharging the toner stored in the container body (133Y), and held on the toner container storage part, and a still standing suppressing means fitted to the held part (134Y) and suppressing the still standing of the toner container on a still standing surface in the state of the held part (134Y) positioned in the vertical lower direction to the container body (133Y).

Owner:RICOH KK

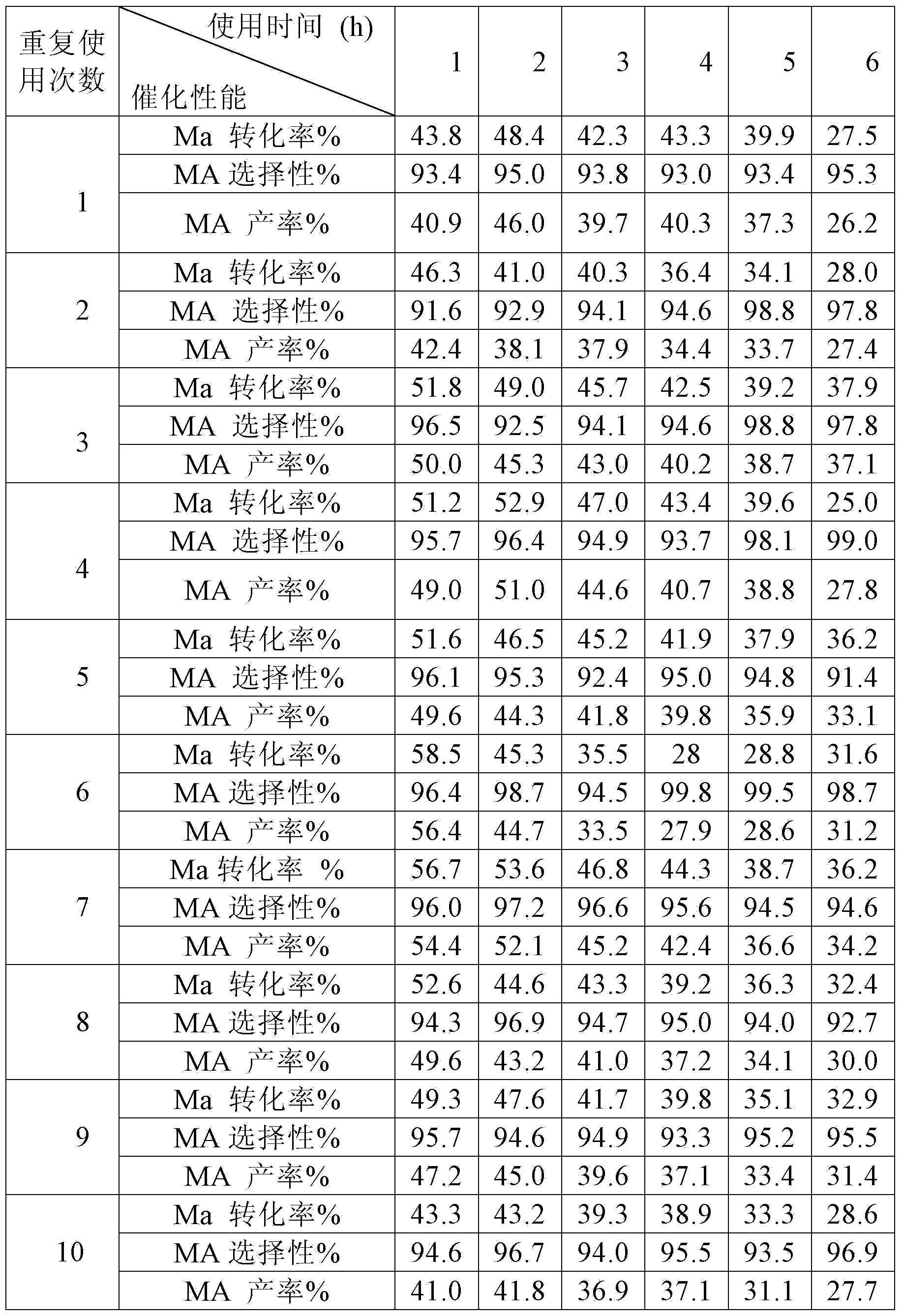

Cs-supported silica-based catalyst and preparation method and application thereof

InactiveCN103801280AImprove stabilityContinuous productionMolecular sieve catalystsOrganic compound preparationGas phaseMethyl acetate

The invention provides a Cs-supported silica-based catalyst. One of SBA-15, SiO2 or silicon dioxide prepared by a silica sol method is used as a carrier, the support is selected from one of Cs salt and a mixture of Cs and modified elements, the catalyst is prepared by a dipping method, the Cs content is 0.1wt%-10wt%, and the content of the modified elements is 0-2wt%. Meanwhile, the invention further provides a preparation method of the Cs-supported silica-based catalyst and application of the Cs-supported silica-based catalyst to the process of preparing methyl acrylate by catalyzing condensation reaction of methyl acetate and a methanal gas phase. The prepared catalyst is capable of realizing the aldol condensation of the methyl acetate and the methanal gas phase under proper conditions so as to prepare the methyl acrylate, wherein the activity of the Cs / SBA-15 catalyst is higher than that of other Cs-supported silica-based catalysts, and the selectivity on the methyl acrylate is good.

Owner:SHANGHAI HUAYI GRP CO

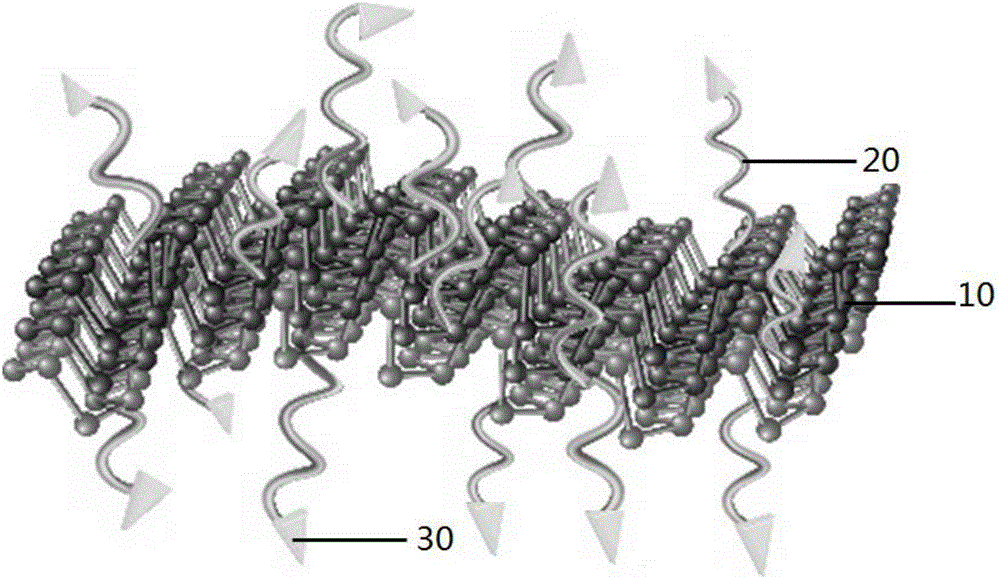

Synthesis method of polycarboxylic acid high-performance water reducing agent of star-like structure

ActiveCN102911322AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSynthesis methodsPolyethylene glycol

The invention discloses a synthesis method of a polycarboxylic acid high-performance water reducing agent of a star-like structure, belonging to the field of a water reducing agent. According to the synthesis method, polybasic alcohol, (methyl) acrylic acid, a polyethylene glycol compound and the like are used as esterification raw materials, and the polycarboxylic acid high-performance water reducing agent of the star-like structure is prepared through a sequential esterification and polymerization method, i.e., the (methyl) acrylic acid and the polybasic alcohol are used as reactants, a star-like polymerizable active end is prepared through esterification reaction under the action of a catalyst, and then the polycarboxylic acid high-performance water reducing agent is prepared from the star-like polymerizable active end and esterification macromolecule, a molecular weight regulator and an unsaturated carboxylic acid monomer under the action of an initiator through free radical polymerization reaction. The synthesis method has the advantages of simplicity, easiness in control, high polymerization degree, low cost, no pollution, capability of realizing the polycarboxylic acid high-performance water reducing agent of the star-like structure connected with a plurality of polycarboxylic acid molecules, and more superior cement paste fluidity and holding capacity, good cement adaptability and concrete application performance compared with the conventional linear and comb-shaped polycarboxylic acid water reducing agent in the case of normal and low added amount.

Owner:GUIZHOU DR SHI TECH

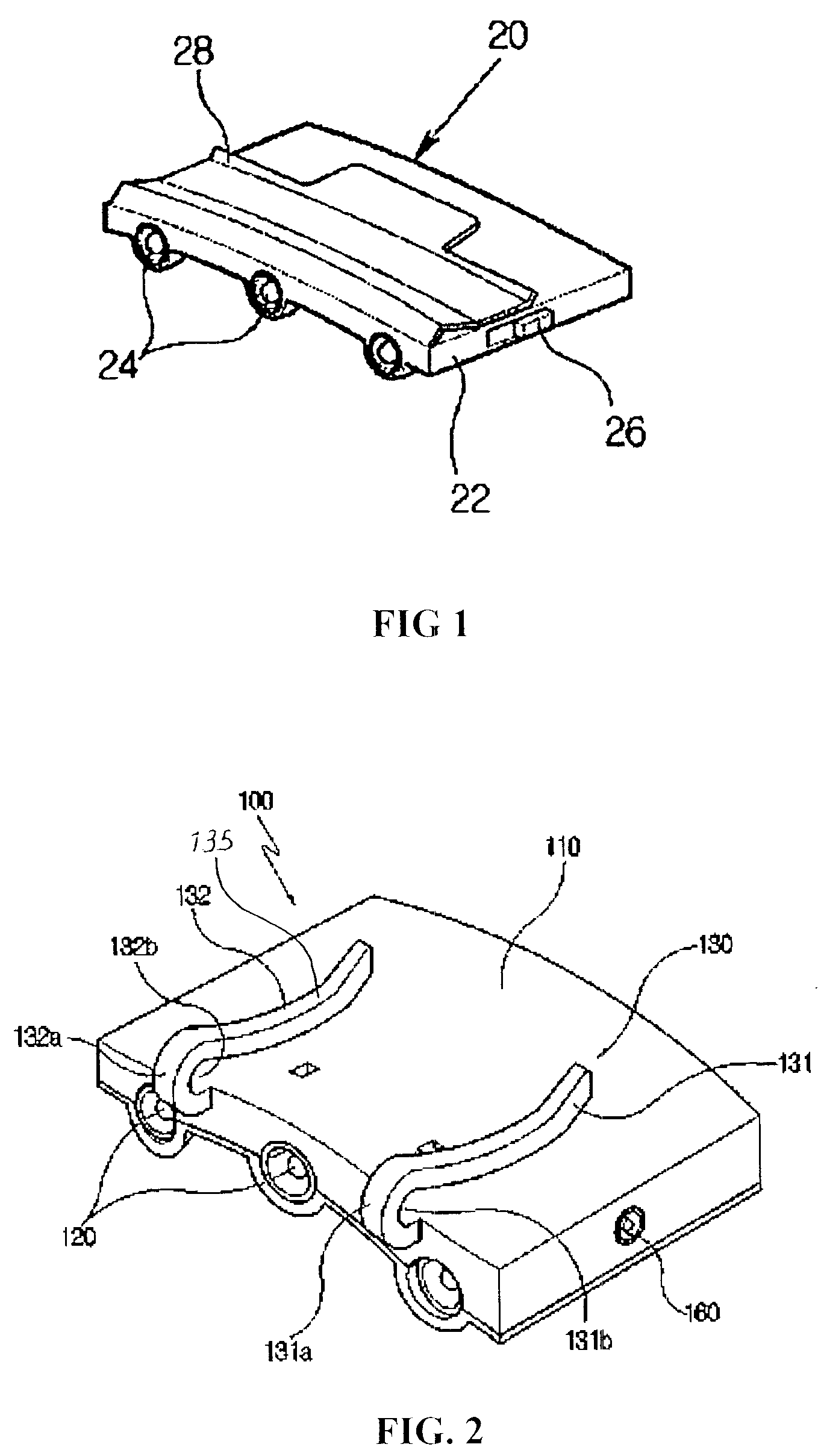

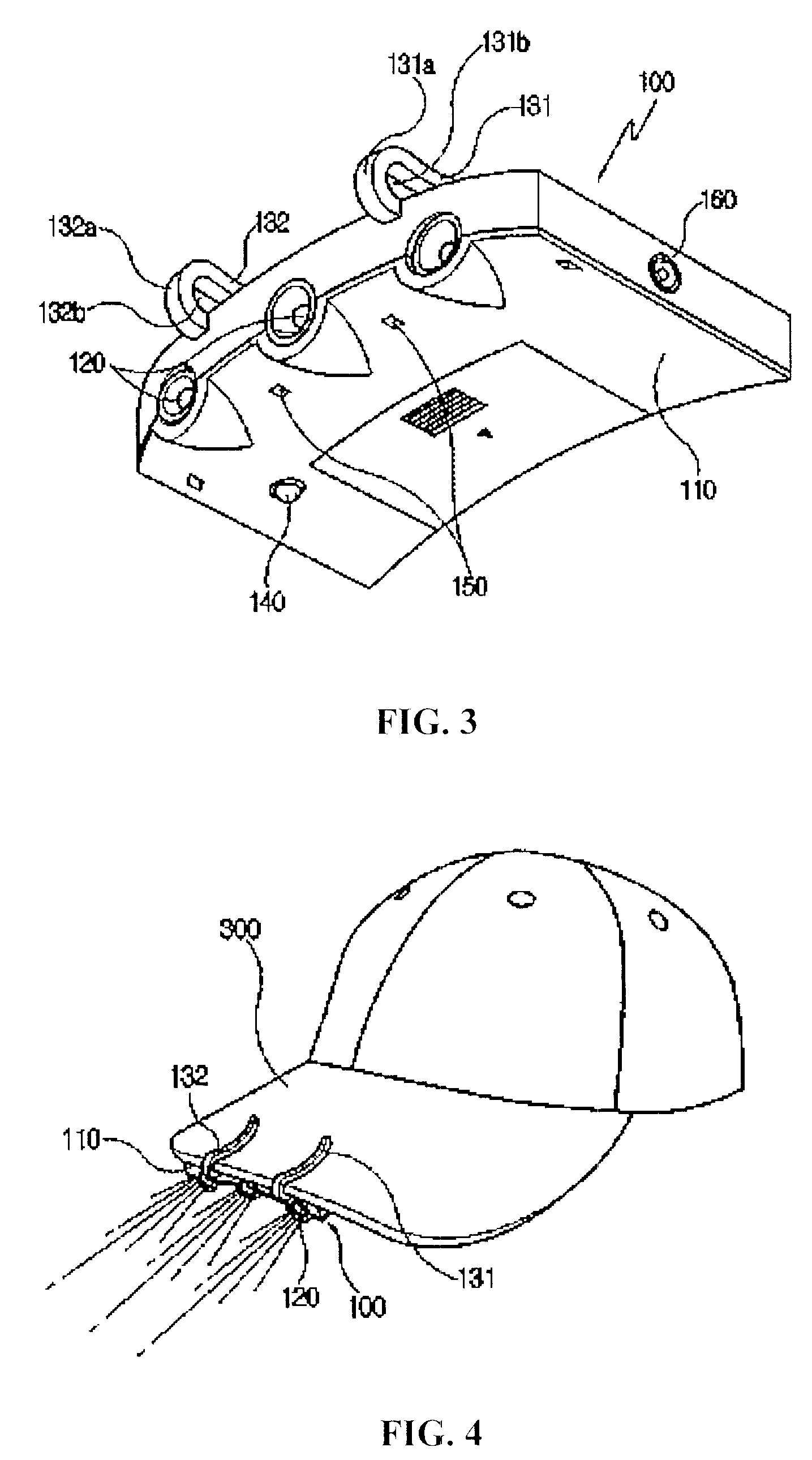

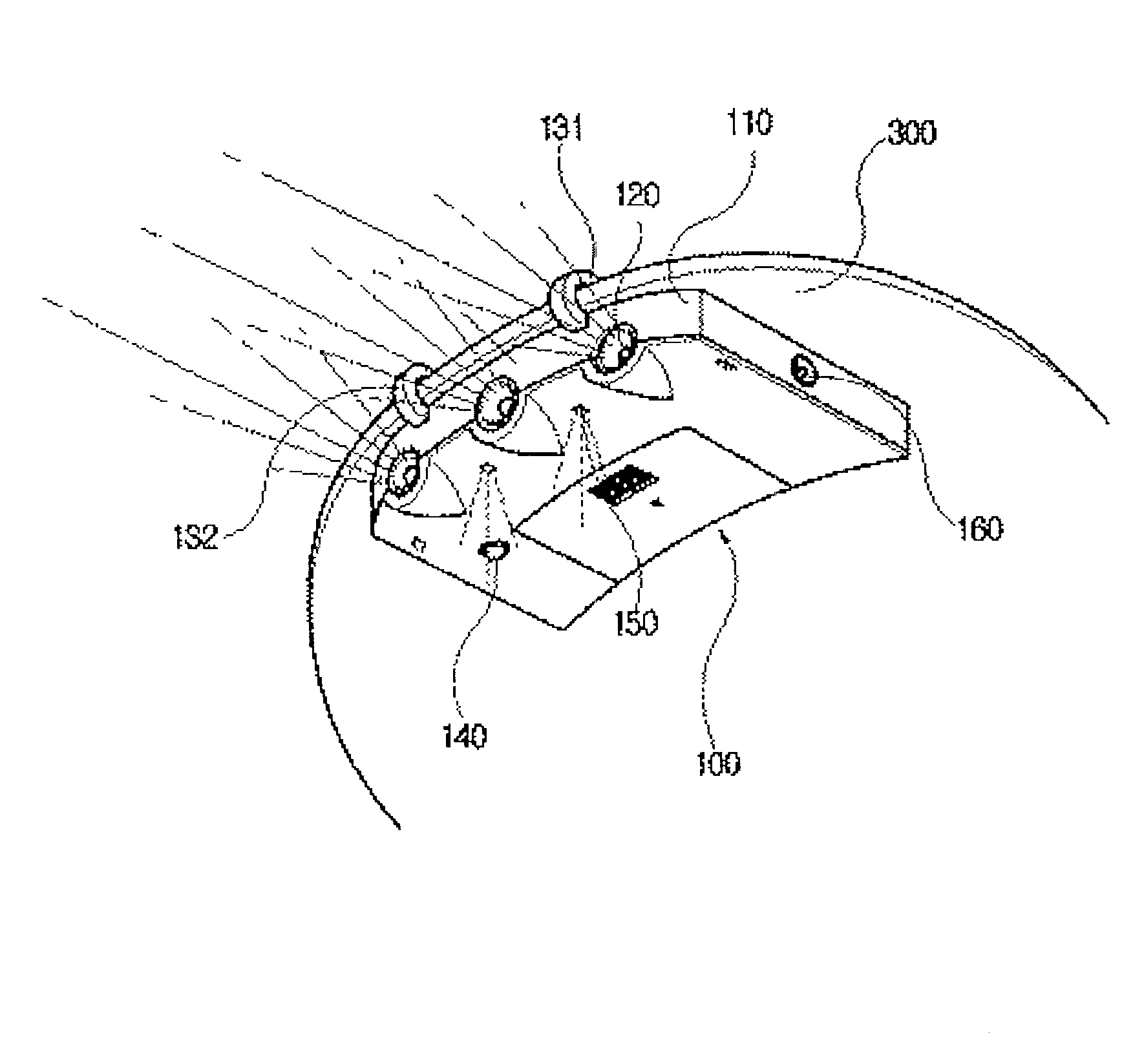

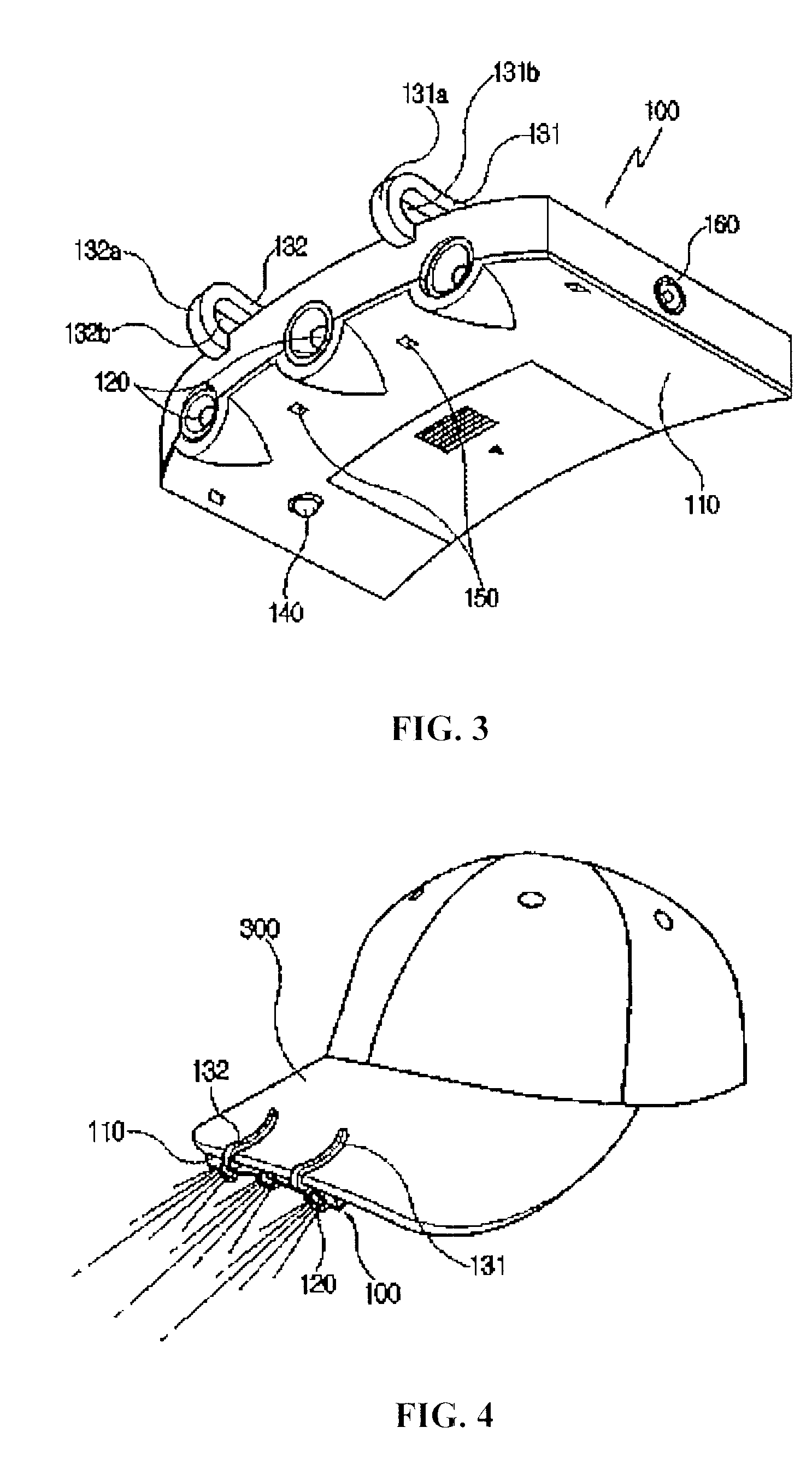

Clip type light detachably coupled with cap

ActiveUS7427149B2Good adhesionEasy detachmentLighting support devicesLighting elementsEngineeringSolar cell

A clip type light is detachably attached to a cap visor so as to ensure the user's field of vision. Two clips are integrally formed with both sides of a front section of a lamp body such that the two clips can be fixedly coupled with a front section of the cap visor regardless of the curved configuration of the visor. The clip type light can be easily attached to or detached from the cap visor without causing damage to the visor, and a switch for operating an electric lamp and an ultrasonic wave generator is provided at a lower portion of the lamp body in such a manner that the user can easily activate the electric lamp and the ultrasonic wave generator while wearing the cap equipped with the clip type light. A solar cell may also be provided to power the lamp and wave generator.

Owner:SOHN

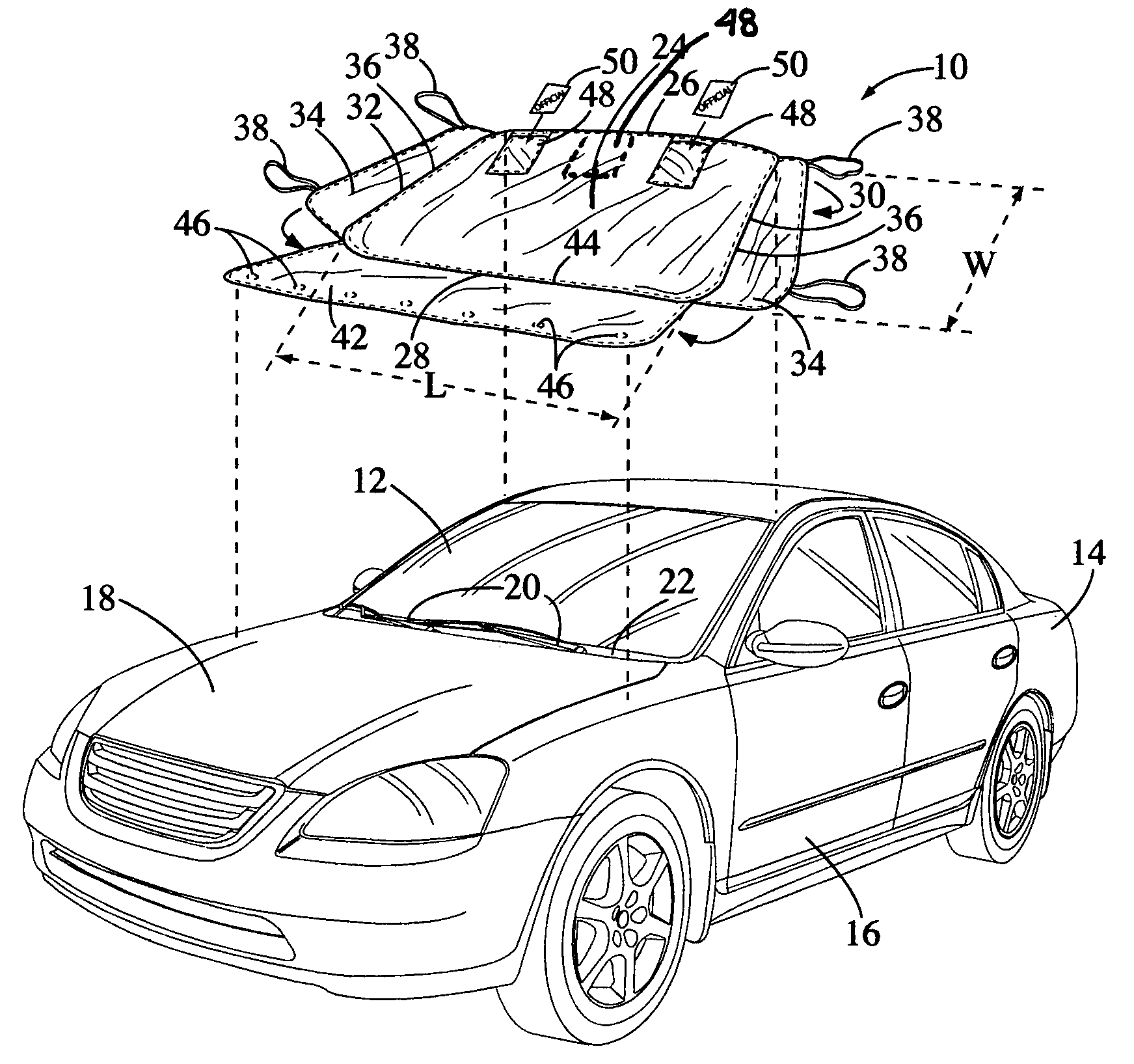

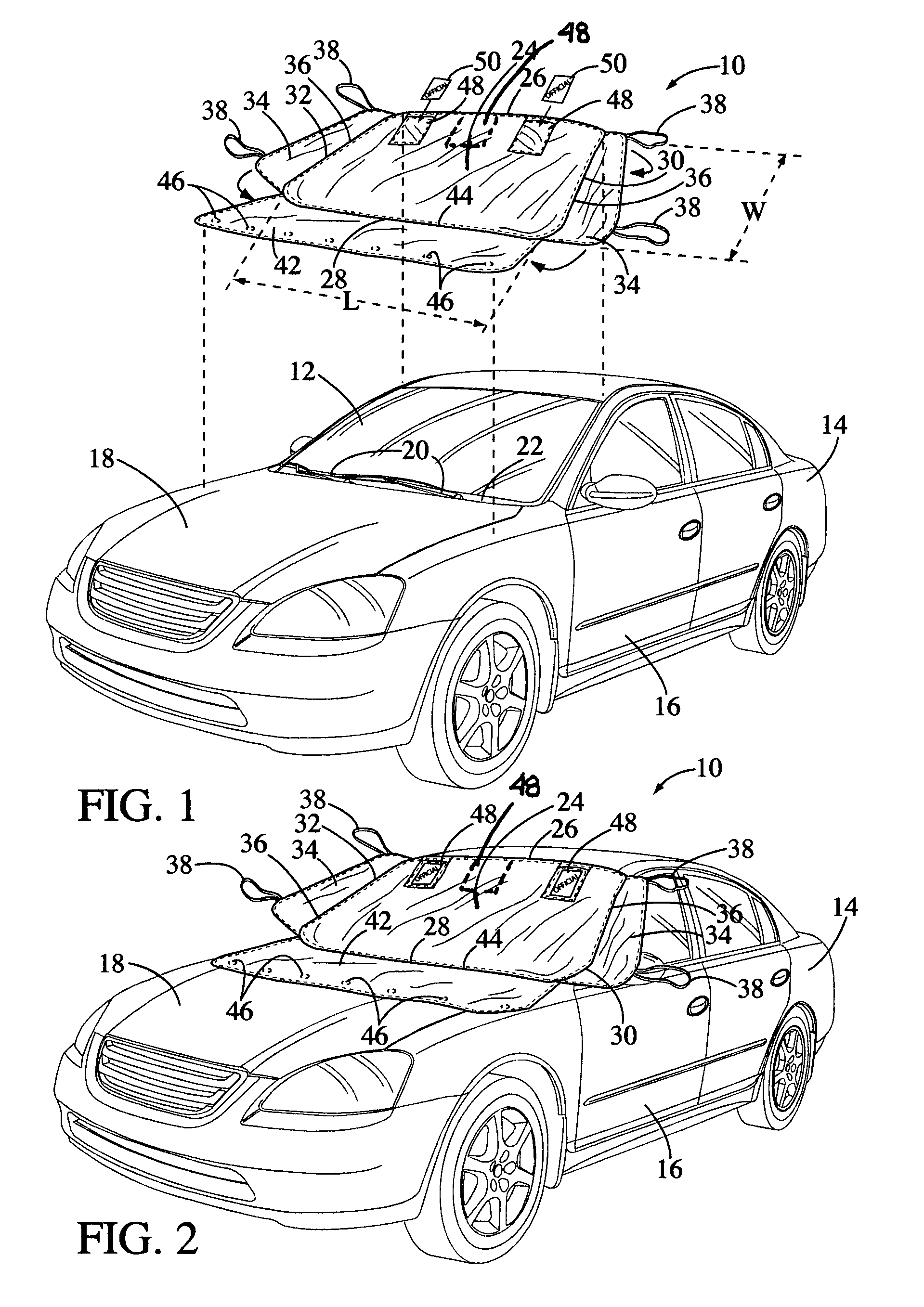

Vehicle exterior windshield protective cover for protection against sun, wind, snow and ice

An exterior vehicle windshield protective cover used to cover the outside of a vehicle front windshield. The protective cover reflects the sun's ray in the summer to help keep the vehicle cool and protect the windshield from snow and ice when the vehicle is parked outside. The protective cover includes a flexible exterior windshield cover member dimensioned to cover the exterior of a vehicle's windshield. The cover member includes a pair of flexible wings hinged along fold lines and attached to the sides of the cover member. The wings include a pair of elastic loops. When the front doors of the vehicle are opened, the wings are inserted inside the vehicle with the elastic loops attached to windshield visor posts for holding the cover member securely against the windshield in tension. A windshield wiper well cover is hinged along a fold line attached to the bottom of the cover member. The well cover is held in place on a portion of the vehicle's hood using a plurality of magnets. The well cover covers the windshield wipers in a wiper well and prevents snow and ice from gathering inside the wiper well.

Owner:LAU KATHY

Process for preparing nano silver colloidal water solution

The present invention relates to the preparation process of nano silver colloidal water solution. By means of double injection controlling technology and under the stirring with the stirrer, argentamine and reductant aqua are injected simultaneously into the reaction system containing protecting agent aqua to generate nano silver particle, and through ultrafiltering to desalt, nano silver colloidal water solution with average size smaller than 50 nm is obtained. Thus obtained nano silver colloidal water solution is stable, good in dispersion, small and homogeneous in size, and the preparation process is automatic, short in production period, low in cost and suitable for industrial production.

Owner:CHINA LUCKY FILM CORP

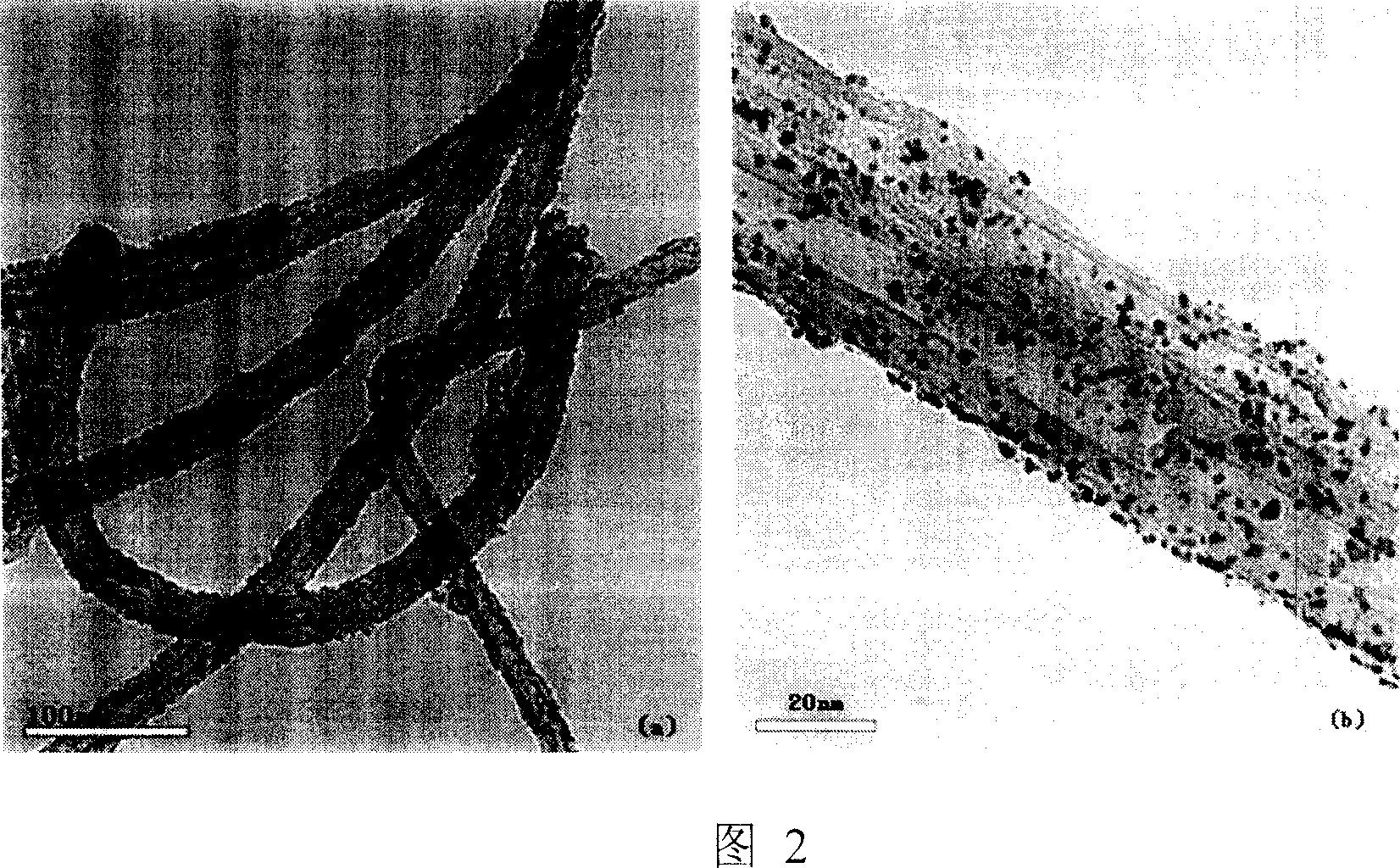

Preparation method of nano-silver alginate fiber

ActiveCN103147167ASmall particle sizeUniform particle size distributionAlginate artificial filamentsWet spinning methodsFiberBiocompatibility Testing

The invention discloses a preparation method of a nano-silver alginate fiber. The preparation method comprises the following steps of: preparing an alginic acid silver complex which is a precursor of nano-silver by using algal polysaccharides and soluble silver salts, and then preparing a sodium alginate based nano-silver colloid system through a chemical reduction method; then adding fiber-grade sodium alginate into the sodium alginate based nano-silver colloid system to obtain a nano-silver algae spinning solution; and finally, obtaining a nano-silver algae primary fiber through wet spinning, and carrying out stretching, sizing, drying and oiling treatments to obtain the nano-silver alginate fiber. The prepared nano-silver alginate fiber integrates the excellent performances of the nano-silver and the alginate fiber, so that the novel fiber has excellent flame retardance, biocompatibility, moisture absorption permeability and the like, also has excellent antimicrobial performance, antistatic performance and irradiation resistance and can be widely used in medical treatment, the fire-fighting field, the military field, the aerospace field, the health textile field and the like.

Owner:QINGDAO UNIV

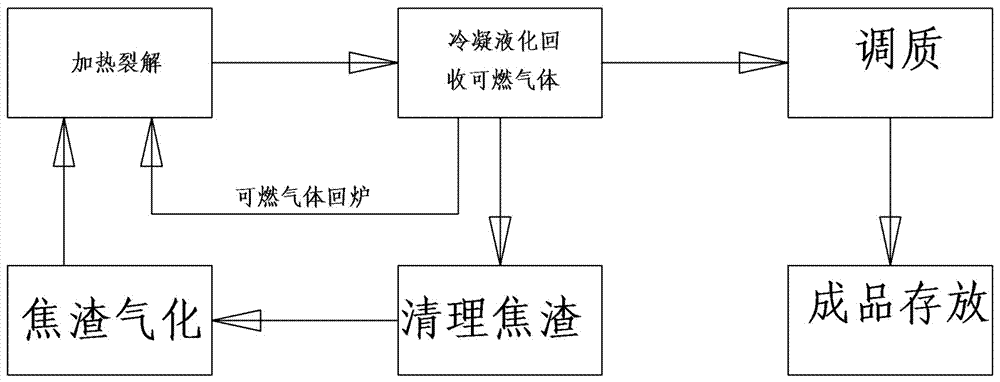

Process for recycling waste mineral oil without hazardous material emission

ActiveCN107099328ANo emissionsTake advantage ofTreatment with plural serial stages onlyGasification processes detailsClosed loopCombustible gas

The invention discloses a process for recycling waste mineral oil without hazardous material emission. The process includes steps of 1, carrying out heating pyrolysis; 2, carrying out condensation and liquefaction and simultaneously recycling combustible gas; 3, carrying out conditioning; 4, storing finished products; 5, clearing coke residues, and to be more specific, clearing solid residual substances-coke residues obtained after clearing pyrolysis is carried out in reaction kettles; 6, gasifying the coke residues, to be more specific, crushing the coke residues cleared at the step 5 to obtain granules, then feeding the granules into a coke residue gasification furnace, gasifying the granules by the aid of the gasification furnace to obtain combustible gas, leading the combustible gas into a gas furnace used at the step 1 and combusting the combustible gas in the combustible furnace. The process has the advantages that certain waste gas and waste residues which are generated during pyrolysis on the waste mineral oil can be used as fuel to be fed into heating furnaces for the reaction kettles in closed-loop procedures, and accordingly the process is basically free of emission of toxic waste gas and toxic waste residues; all combustible substances in the waste mineral oil can be comprehensively sufficiently utilized, accordingly, environments can be protected, energy can be saved, and the process is favorable for society and people.

Owner:洛阳德正废弃资源再利用有限公司

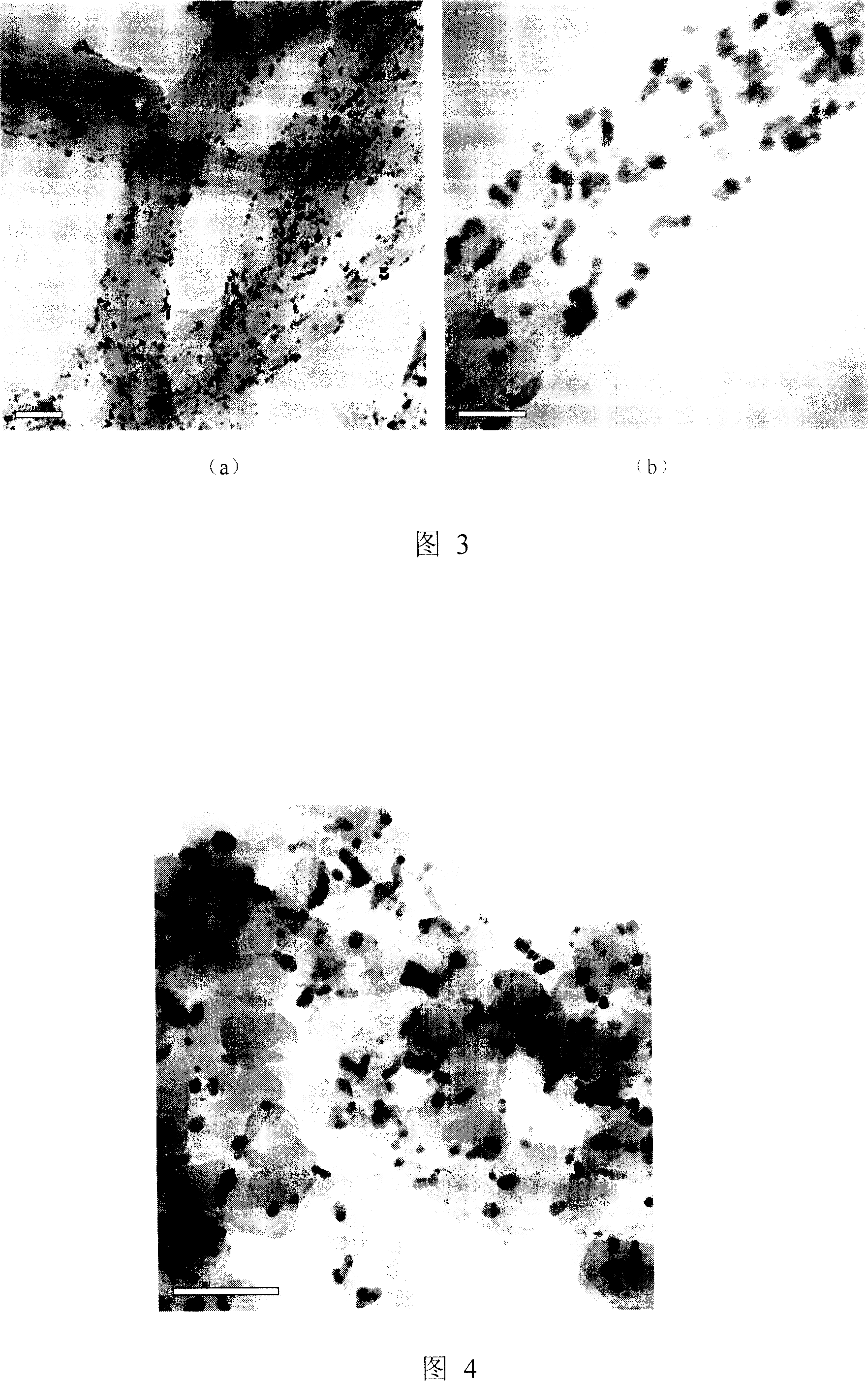

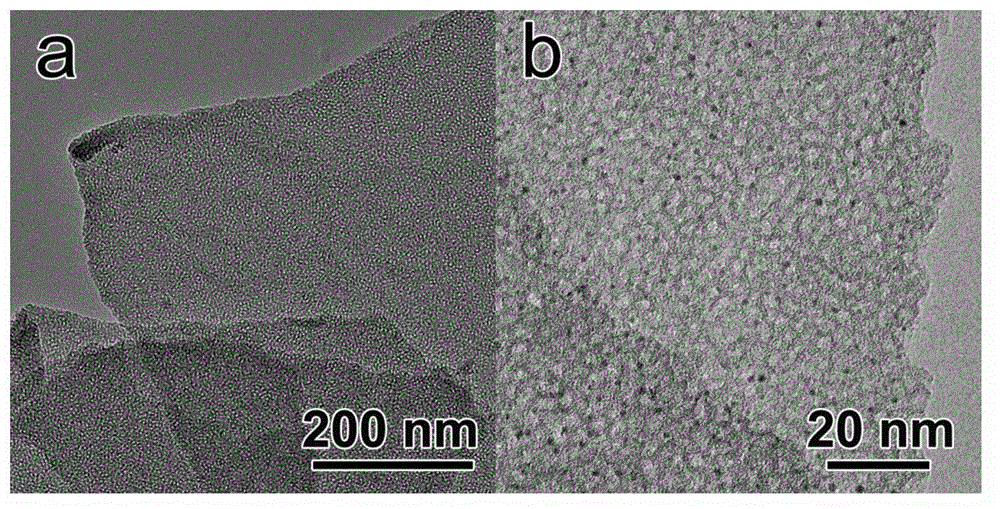

Carbon supported noble metal catalyst and method for preparing same

InactiveCN1994563AReduce surface tensionGood dispersionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSolventHigh pressure

The invention relates to a carbon-carrier metal catalyst, wherein the active component is 5-80%; the mol ration of metal atoms is 3:1-1:3; the metal diameter of catalyst is 1-4nm. And the production comprises that: adding active component, complex agent, alcohol reducer and carrier into solvent; functioning ultrasonic wave at room temperature, adding alkali material, adjusting the pH, adding nitrogen gas to protect reflux at normal pressure, or reacting at high-pressure kettle; cooling to room temperature, adding acid, breaking gel via ultrasonic wave; filtering, washing with water until there is no CI-ion detected; vacuum drying; thermally treating at inertia gas; cooling in nitrogen gas to obtain the carbon-carrier metal catalyst. The invention has simple process; the catalyst active component is two-dimension at the surface of carrier; it has small particles, low crystallization degree, high metal utilization, and high catalysis activity.

Owner:SOUTH CHINA UNIV OF TECH

Clip type light detachably coupled with cap

ActiveUS20070109768A1Good adhesionEasy detachmentLighting support devicesLighting elementsElectric lightEngineering

A clip type light is detachably attached to a cap visor so as to ensure the user's field of vision. Two clips are integrally formed with both sides of a front section of a lamp body such that the two clips can be fixedly coupled with a front section of the cap visor regardless of the curved configuration of the visor. The clip type light can be easily attached to or detached from the cap visor without causing damage to the visor, and a switch for operating an electric lamp and an ultrasonic wave generator is provided at a lower portion of the lamp body in such a manner that the user can easily activate the electric lamp and the ultrasonic wave generator while wearing the cap equipped with the clip type light. A solar cell may also be provided to power the lamp and wave generator.

Owner:SOHN

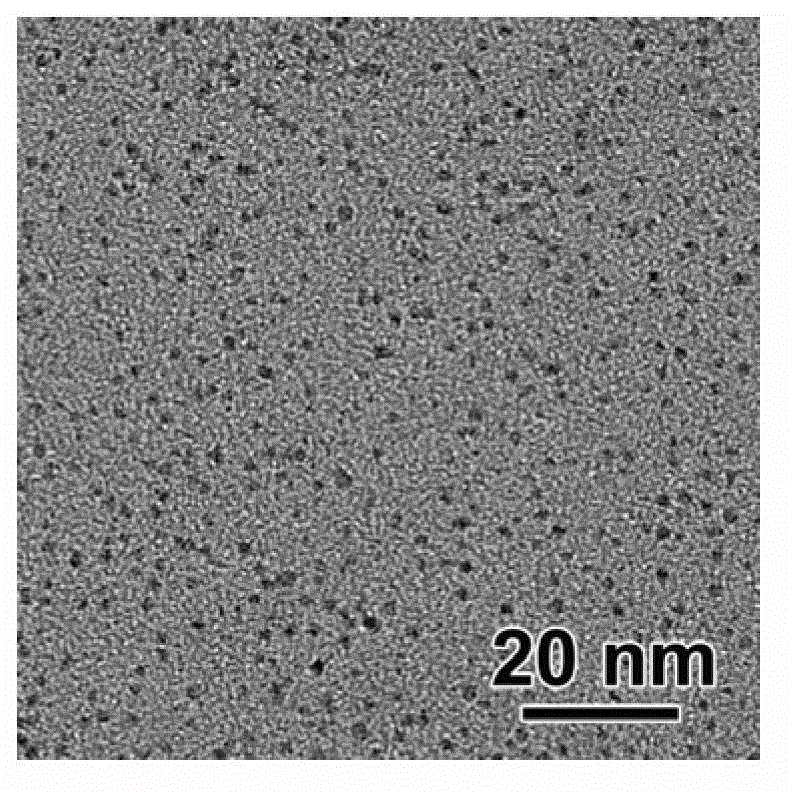

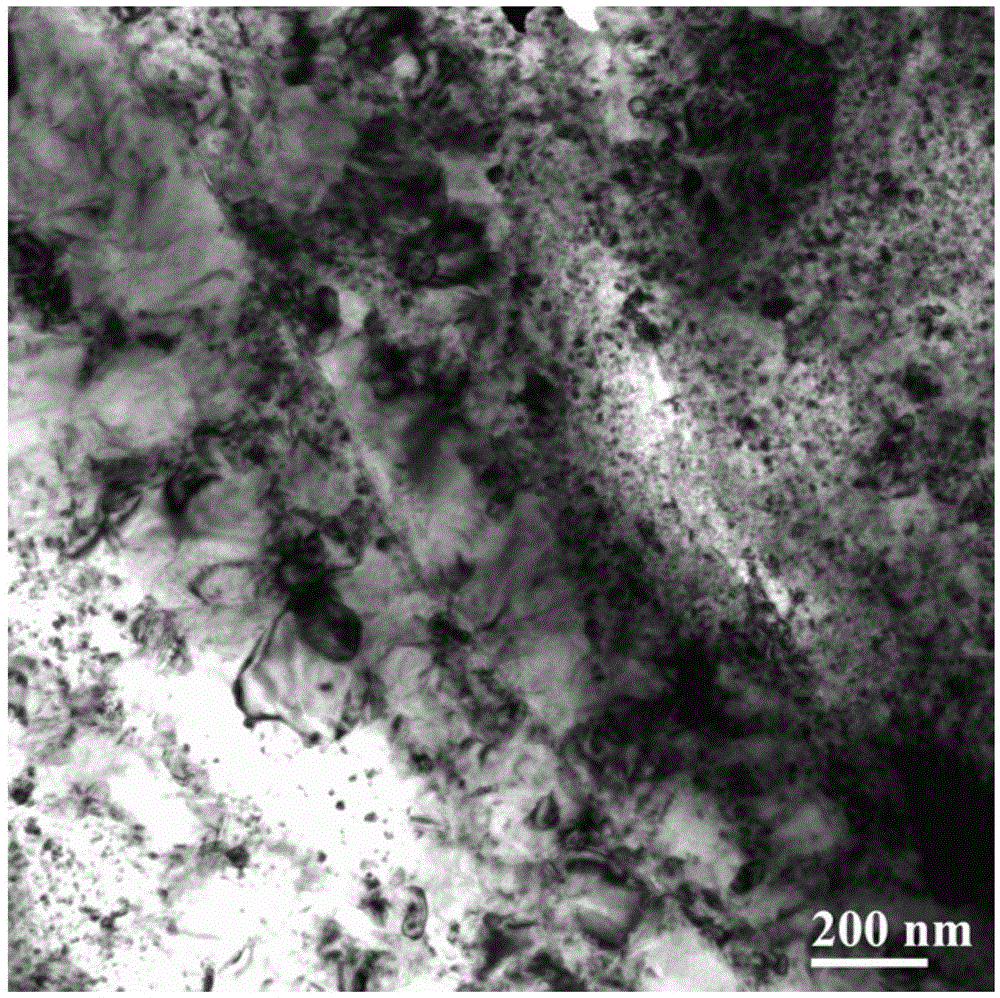

Graphene-based composite material with surface coated by mesoporous silica and loaded with noble metal nanoparticles, as well as preparation method and application of graphene-based composite material

ActiveCN102909005AAvoid interaction forceGood dispersionMetal/metal-oxides/metal-hydroxide catalystsPtru catalystActive agent

The invention discloses a graphene-based composite material with surface coated by mesoporous silica and loaded with noble metal nanoparticles, and a preparation method of the graphene-based composite material. The preparation method comprises the following steps of: loading noble metal precursors on the surface of oxidized graphene by the deposition-precipitation method, so as obtain the oxidized graphene loaded with the noble metal precursors; coating the surface of the oxidized graphene located with the noble metal precursors by a silica material with a mesoporous structure through the sol-gel method in the presence of a surface active agent and a silicon source, so as to obtain an original composite material; and reducing the original composite material to obtain the composite material. The preparation method is mild in condition and universal in application; products can be prepared as mass; the distance between laboratory investigation and industrial application can be effectively reduced; and the composite material can be used as a catalyst.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

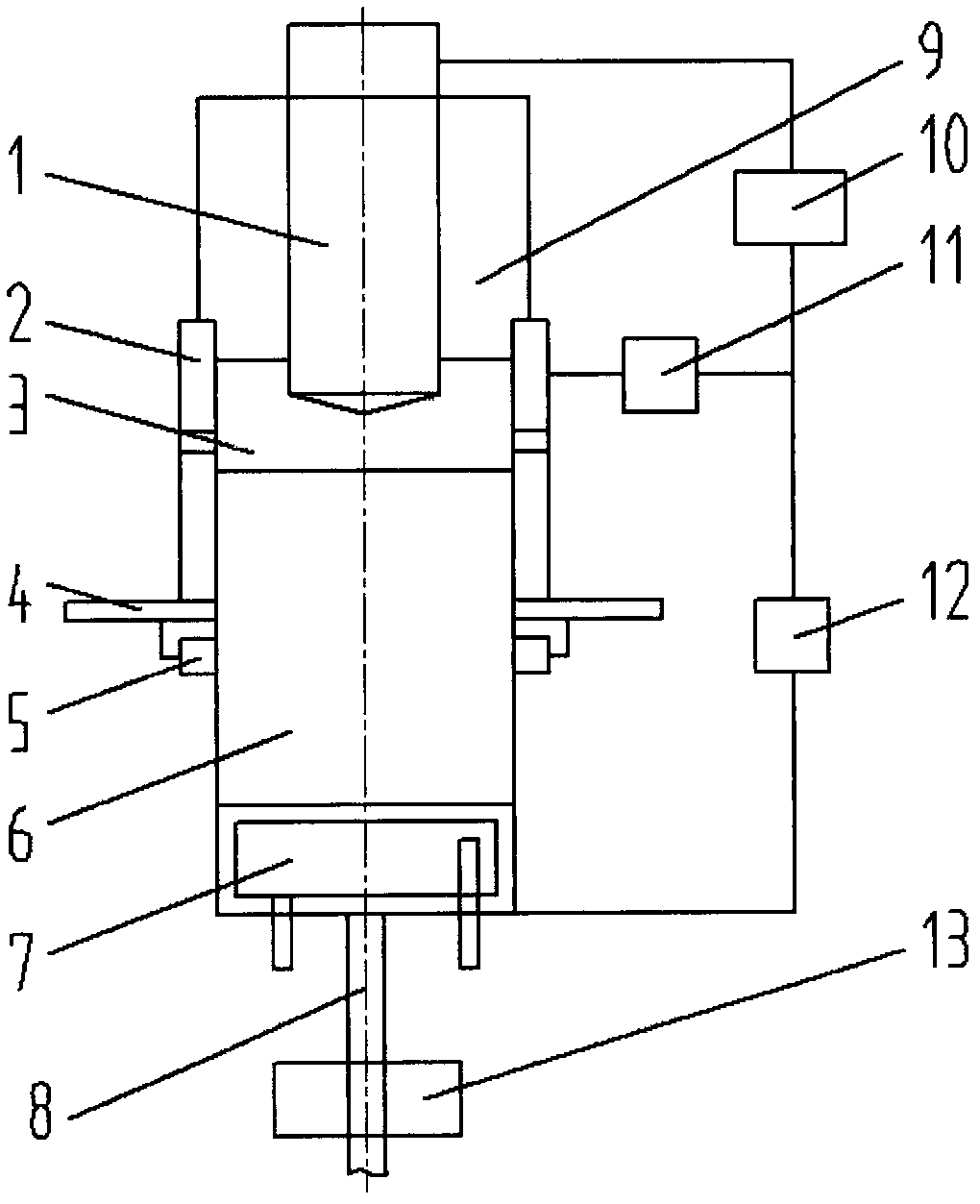

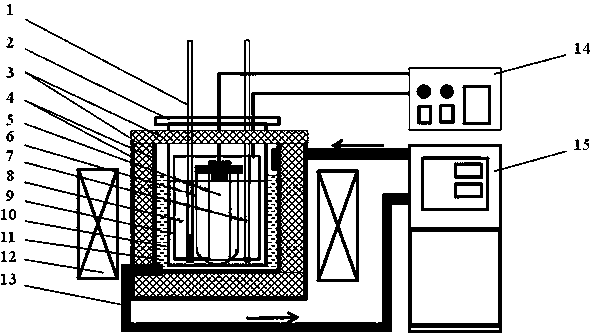

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348AEliminate aggregationEliminate coagulation and looseningElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

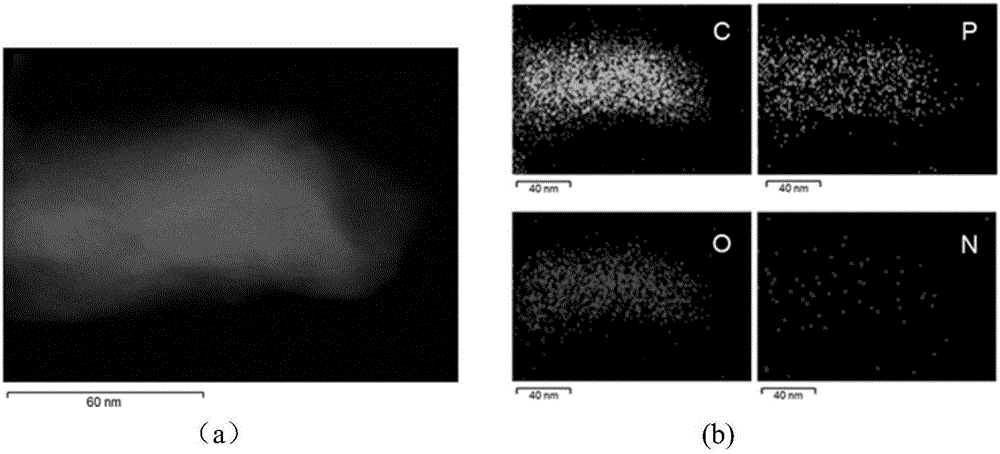

Targeted photothermal black phosphorus nano-preparation as well as preparation method and application thereof

InactiveCN106620699AAvoid gatheringProlong blood circulation timeEnergy modified materialsPharmaceutical non-active ingredientsCancer cellPolyethylene glycol

The invention provides a targeted photothermal black phosphorus nano-preparation, which is prepared from a black phosphorus nano-slice, polyethylene glycol absorbed on the surface of the black phosphorus nano-slice by means of electrostatic attraction, and folic acid connected to the polyethylene glycol by means of an amide bond, wherein one end of the polyethylene glycol is amino, and the other end of the polyethylene glycol is imino; nitrogen atom of the imino and carbonyl carbon atom of the folic acid are connected with each other so as to form the amide bond; the folic acid is exposed at the outermost layer of the nano-preparation. The targeted photothermal black phosphorus nano-preparation is high in stability, good in target recognition ability and excellent in light-heat property, is capable of effectively killing cancer cells, and can be used for performing targeted photothermal treatment on cancers at the cellular level. The invention also provides a preparation method and application of the targeted photothermal black phosphorus nano-preparation.

Owner:SHENZHEN UNIV

Multiple-face displayer

ActiveCN103176304ASimple structureAvoid damageNon-linear opticsIdentification meansLiquid-crystal displayDisplay device

The invention provides a multiple-face displayer. The multiple-face displayer comprises a plurality of liquid crystal display panels which respectively face multiple directions. The containing space is formed through surrounding of the plurality of liquid crystal display panels, and a light source which is used for providing light rays for the plurality of liquid crystal display panels is arranged in the containing space. When the multiple-face displayer works, only one light source is used for providing the light rays for the plurality of liquid crystal display panels, so that simultaneous work of a plurality of light sources is avoided, and then energy is greatly saved. A heating quantity of the single light source in the multiple-face displayer is limited, and a heat quantity cannot be gathered, so that damage of the liquid crystal display panels caused by the excess temperature in the environment is avoided. The multiple-face displayer is simple in structure. Compared with production and maintenance of a plurality of general displayers, the cost is greatly saved.

Owner:BOE TECH GRP CO LTD +1

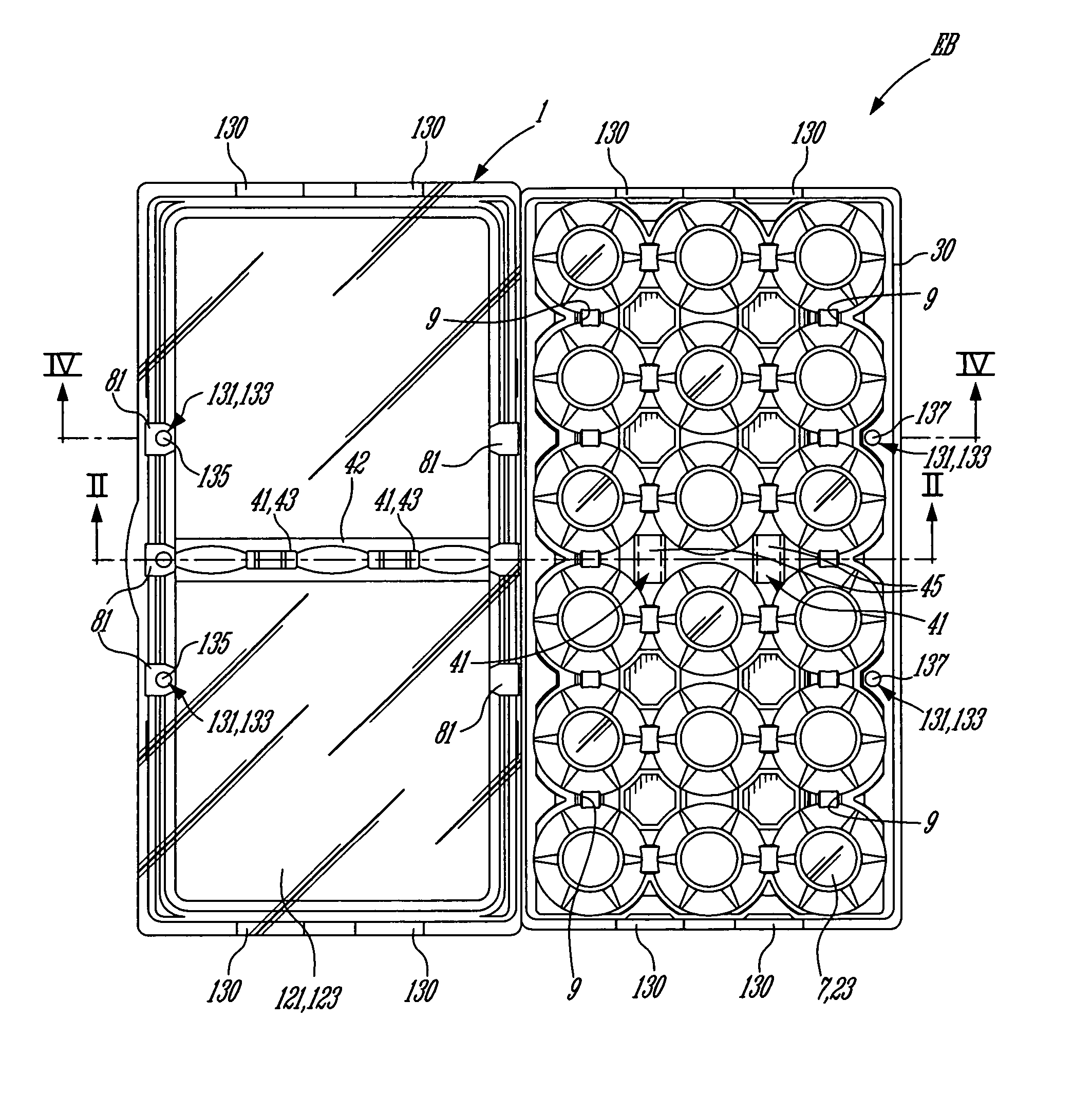

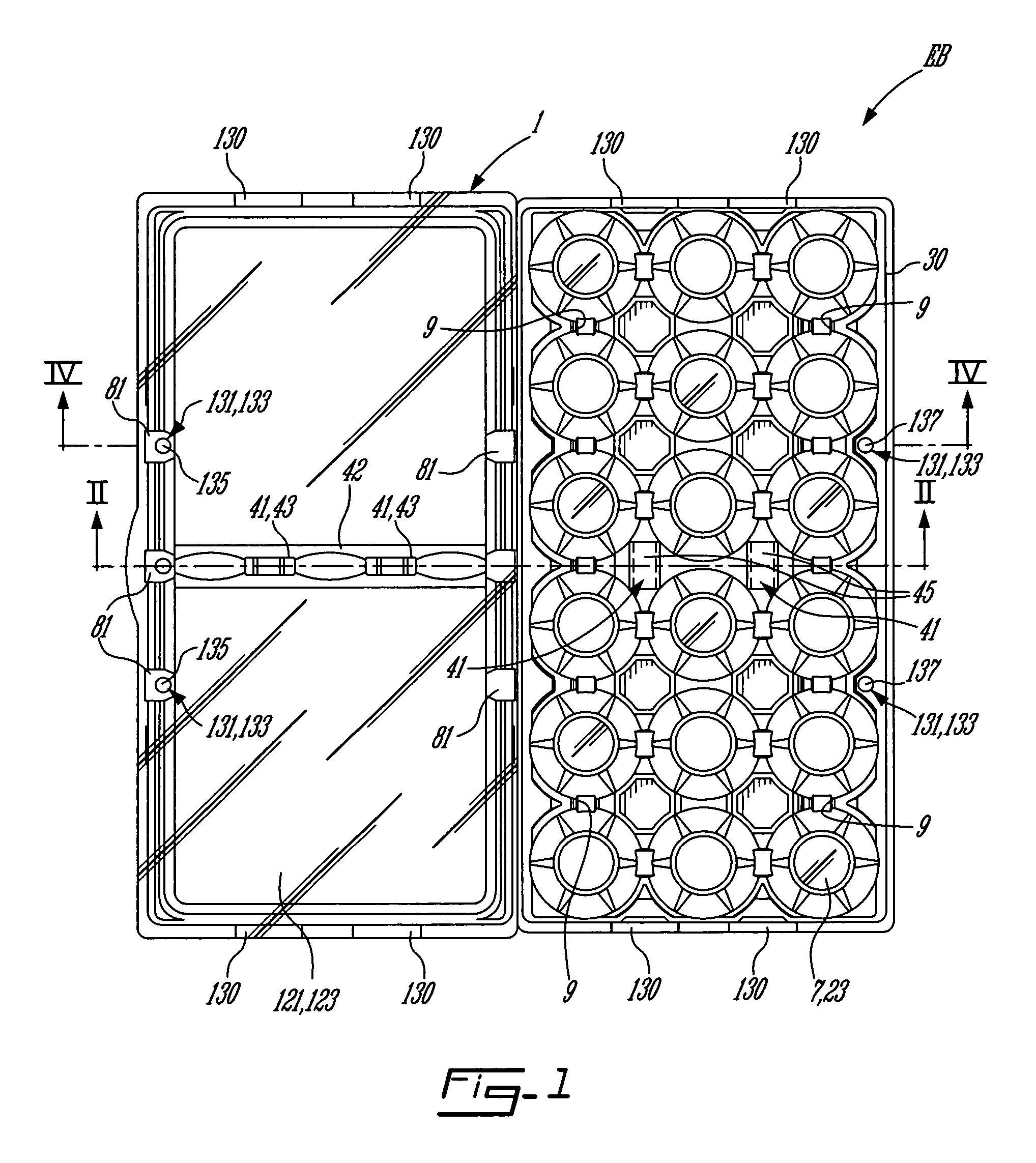

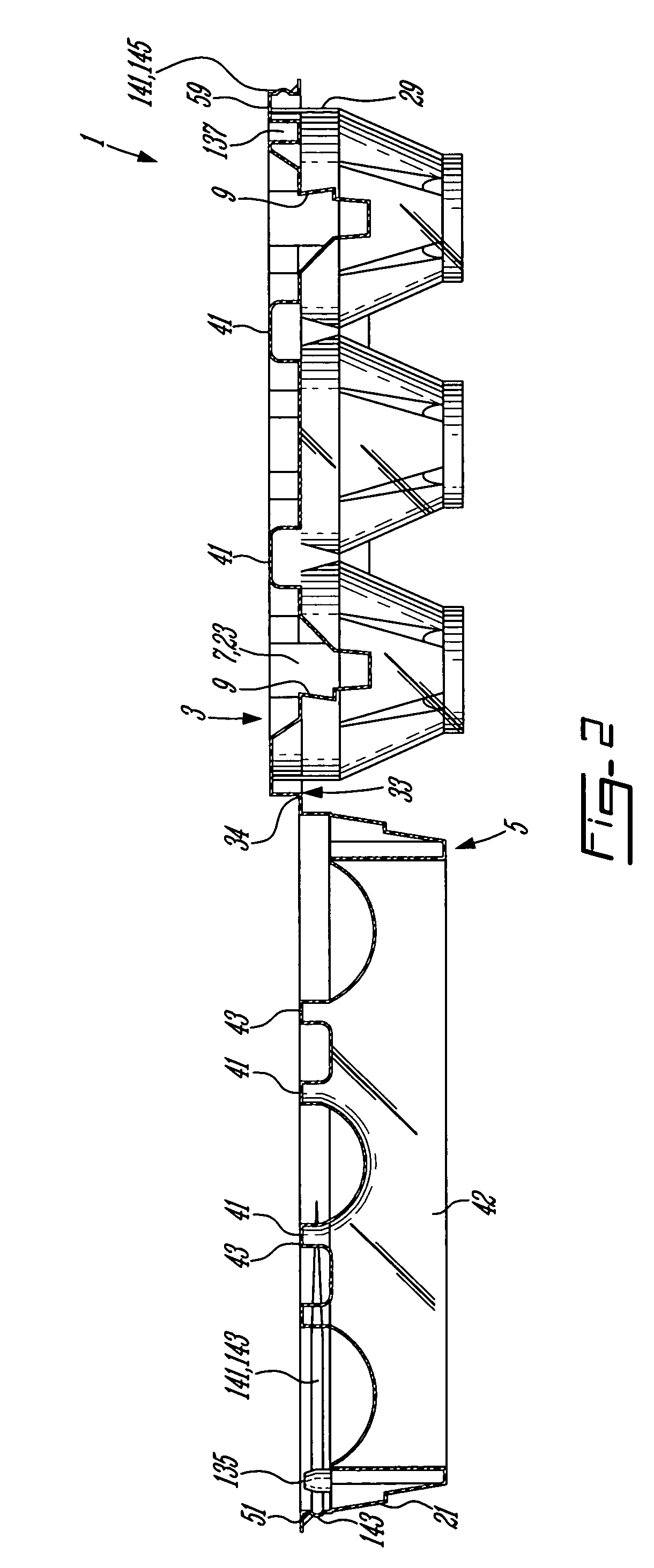

Stackable egg-box, stack of egg-boxes and method for destacking said egg-box

ActiveUS20070151892A1Easy to storeEasy fluid communicationInternal framesPackaging eggsPlastic materialsEngineering

A stackable tray obtained by vacuum molding of a sheet of plastic material, said tray comprising, in open position: a) a top and a bottom; b) at least one receiving cavity opened upwardly, c) a hinge portion dividing said tray into a cover portion and a base portion; said receiving cavity being at least provided in said base portion; d) spacing means to keep, in a stack of trays, the top portion and the bottom portion of neighboring trays at distance from each other to thereby prevent interlocking therebetween; and e) at least one two-part locking means, each part being provided in the top of the sheet and positioned to engaged one into the other when the cover portion is folded over the base portion along the hinge portion to bring the tray into a closed position defining a box. A stack of said trays and a method using said trays.

Owner:PACTIV CANADA

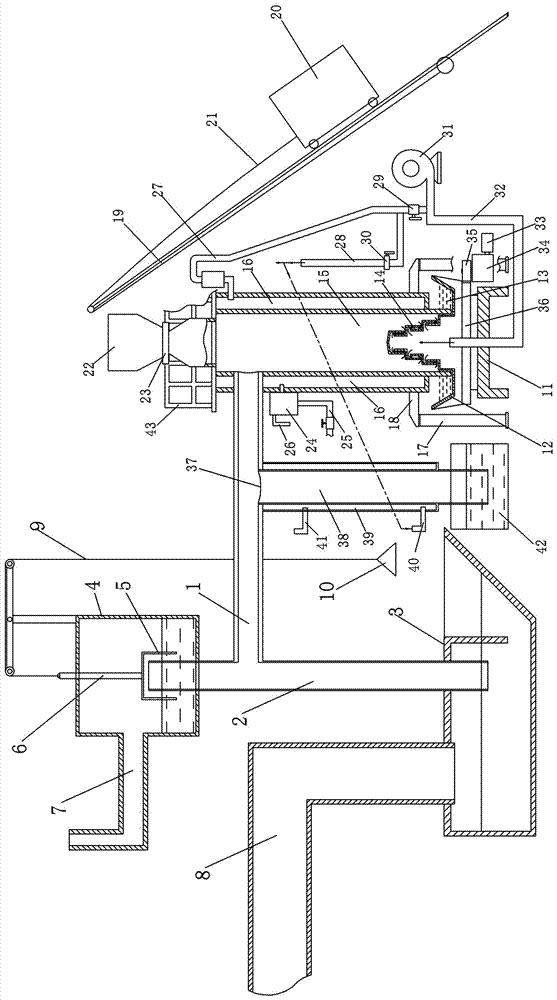

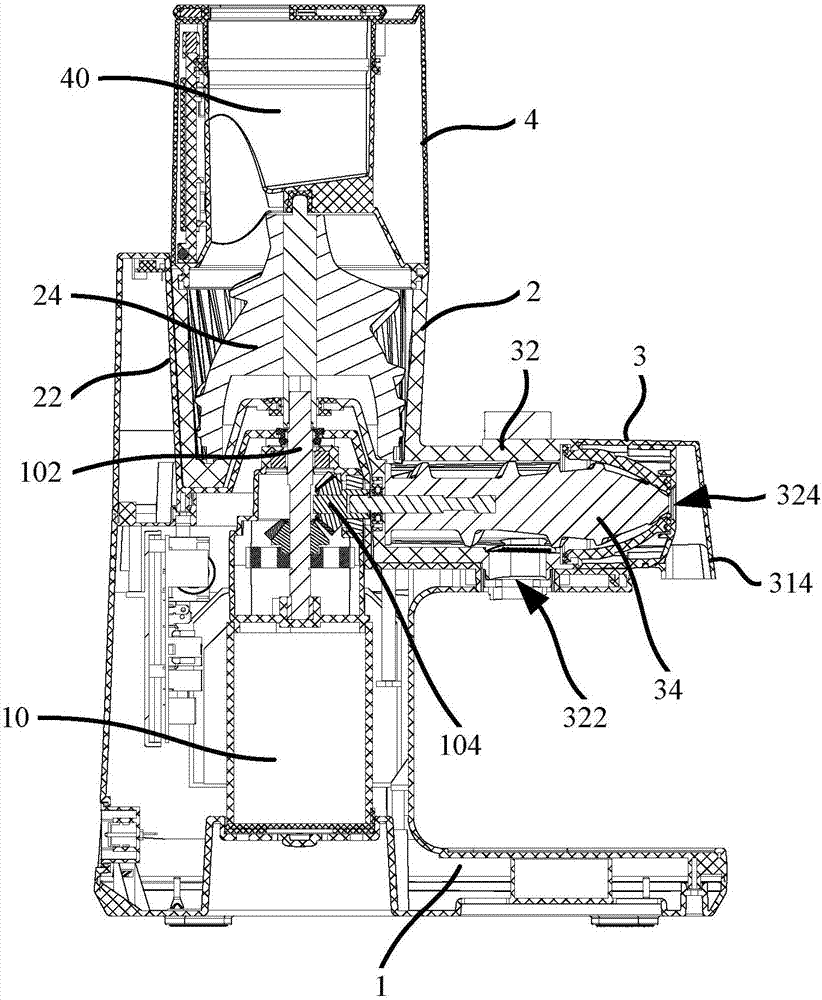

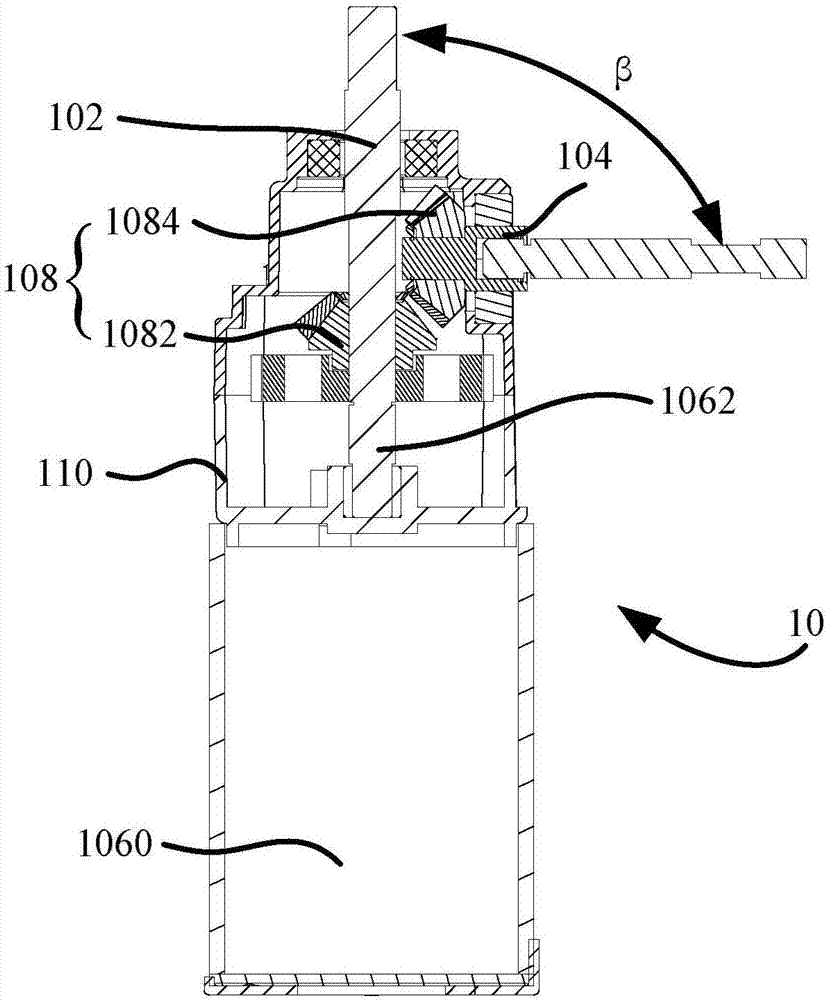

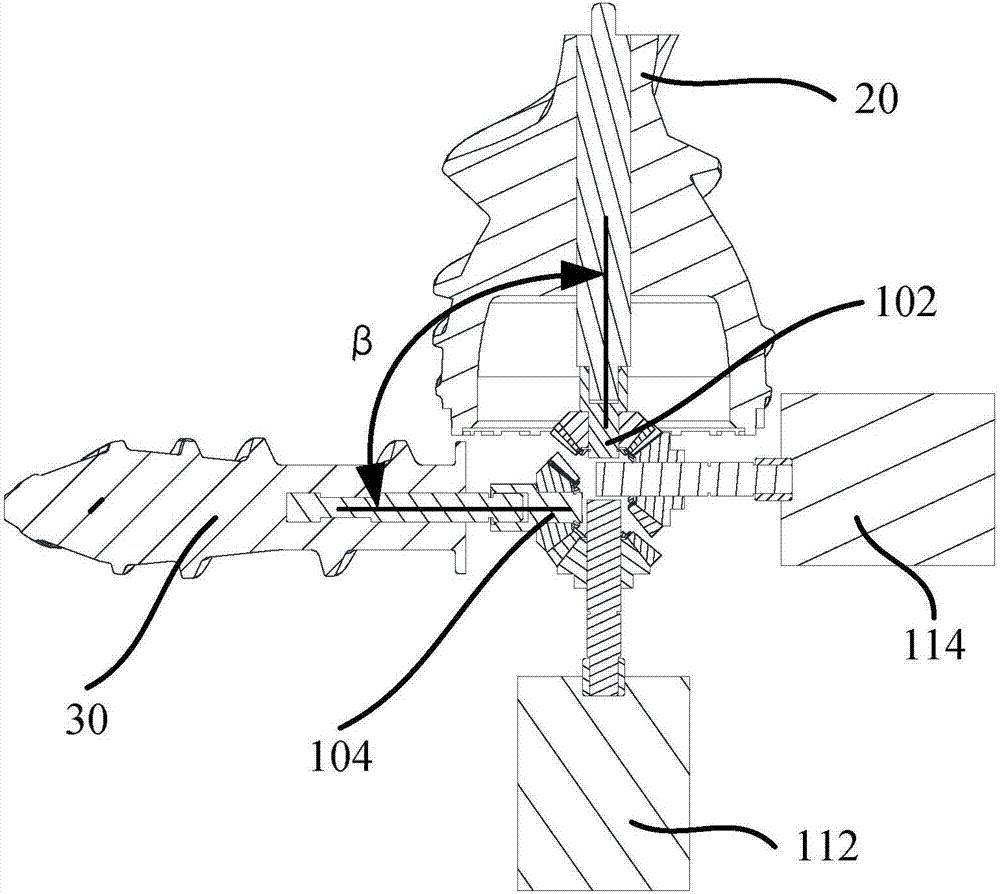

Food processor

The invention provides a food processor. The food processor comprises a machine base, a crushing barrel and an extruding barrel; a driving device is arranged in the machine base and comprises a first output shaft and a second output shaft; the crushing barrel can be detachably installed on the machine base and comprises a crushing barrel shell and a crushing device, wherein the crushing device is arranged in the crushing barrel shell and used for pushing and crushing food materials, the crushing barrel shell is arranged in an inclined mode, the gap between the crushing barrel shell and the crushing device gets smaller and smaller from top to bottom; the extruding barrel is connected to the crushing barrel and communicated with the crushing barrel and comprises an extruding barrel shell and an extruding device, wherein the extruding device is arranged in the extruding barrel shell and used for extruding the food materials and separating juice and residues of the food materials, a juice outlet and a residue outlet are formed in the extruding barrel, and an extruding rib is arranged on the side wall of the extruding barrel shell; the included angle between the first output shaft and the second output shaft is beta, and the included angle beta is larger than or equal to 75 degrees and smaller than or equal to 160 degrees. According to the scheme, crushing and extruding can be conducted on the food materials separately, and therefore the juice yield of the product can be increased, the structure of the product is simplified, and the product is easy to clean.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

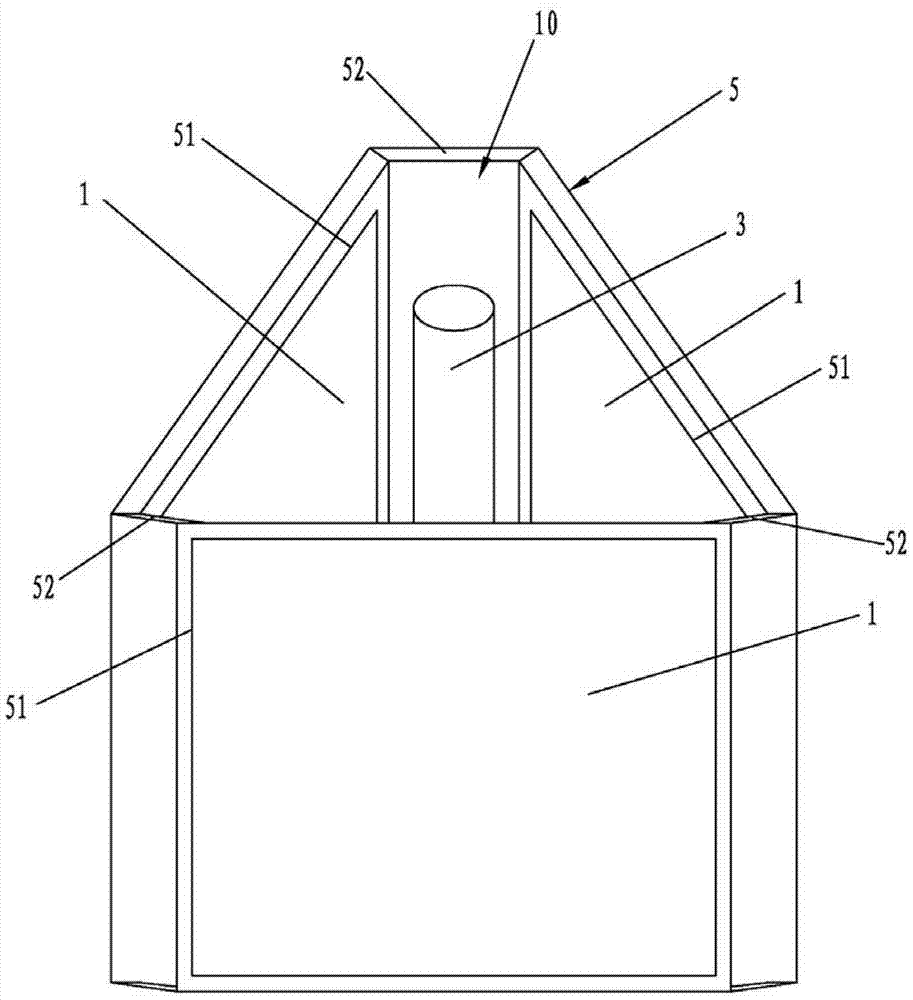

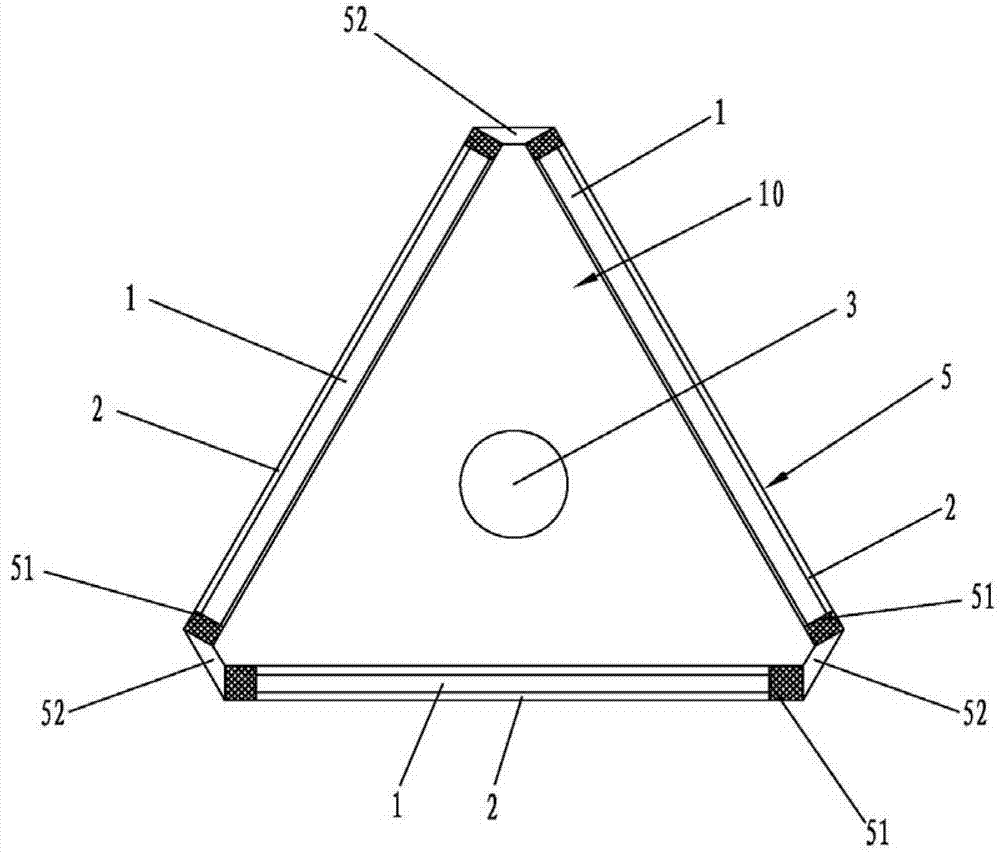

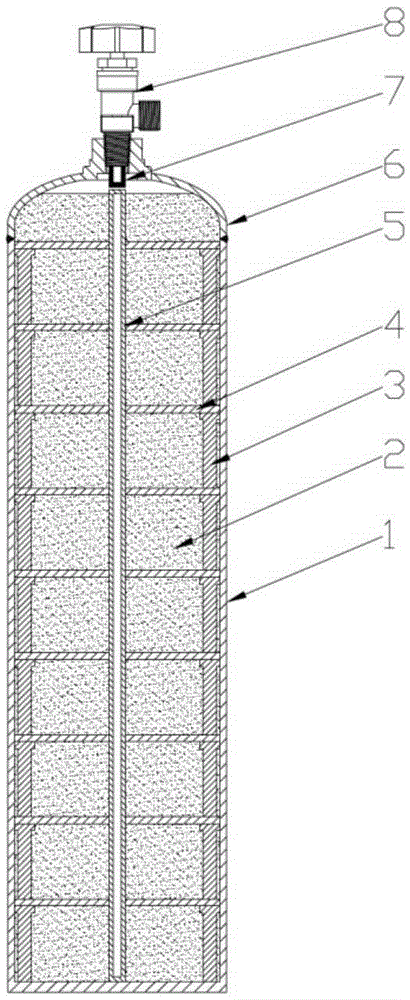

Metal hydride hydrogen storage tank

InactiveCN105387341ASimple structureEasy to processVessel mounting detailsVessel manufacturingVolume expansionHydride

The invention discloses a metal hydride hydrogen storage tank, and belongs to the technical field of hydrogen storage. The metal hydride hydrogen storage tank is composed of a tank body, a hydrogen storage alloy, a supporting frame, a porous metal gas guide segregation board, a gas guide pipe, a sealing head, a filter and a valve. The supporting frame is used for supporting the porous metal gas guide segregation board, and the hydrogen storage alloy is divided into a plurality of layers through the supporting frame and the porous metal gas guide segregation board; meanwhile, the diameter of a center hole of the porous metal gas guide segregation board is the same as the outer diameter of the gas guide pipe, and it is guaranteed that hydrogen between the layers of the hydrogen storage alloy is smooth. The metal hydride hydrogen storage tank is simple in structure and easy to manufacture and machine; as the supporting frame and the porous metal gas guide segregation board are arranged, the hydrogen storage alloy can be effectively prevented from being gathered to the bottom of the hydrogen storage tank due to volume expansion / shrinkage in the repeated hydrogen sucking / releasing process, tank deformation and cracking, caused by gathering of the hydrogen storage alloy and too-large stress, of the hydrogen storage tank are avoided, the using safety of the hydrogen storage tank is improved, and the service life of the hydrogen storage tank is prolonged.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

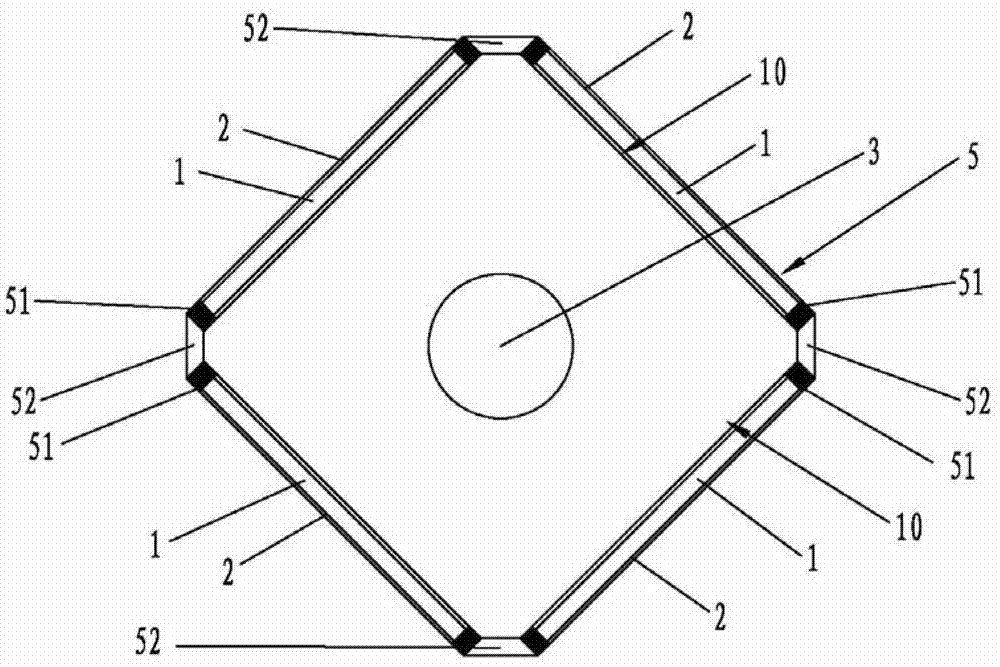

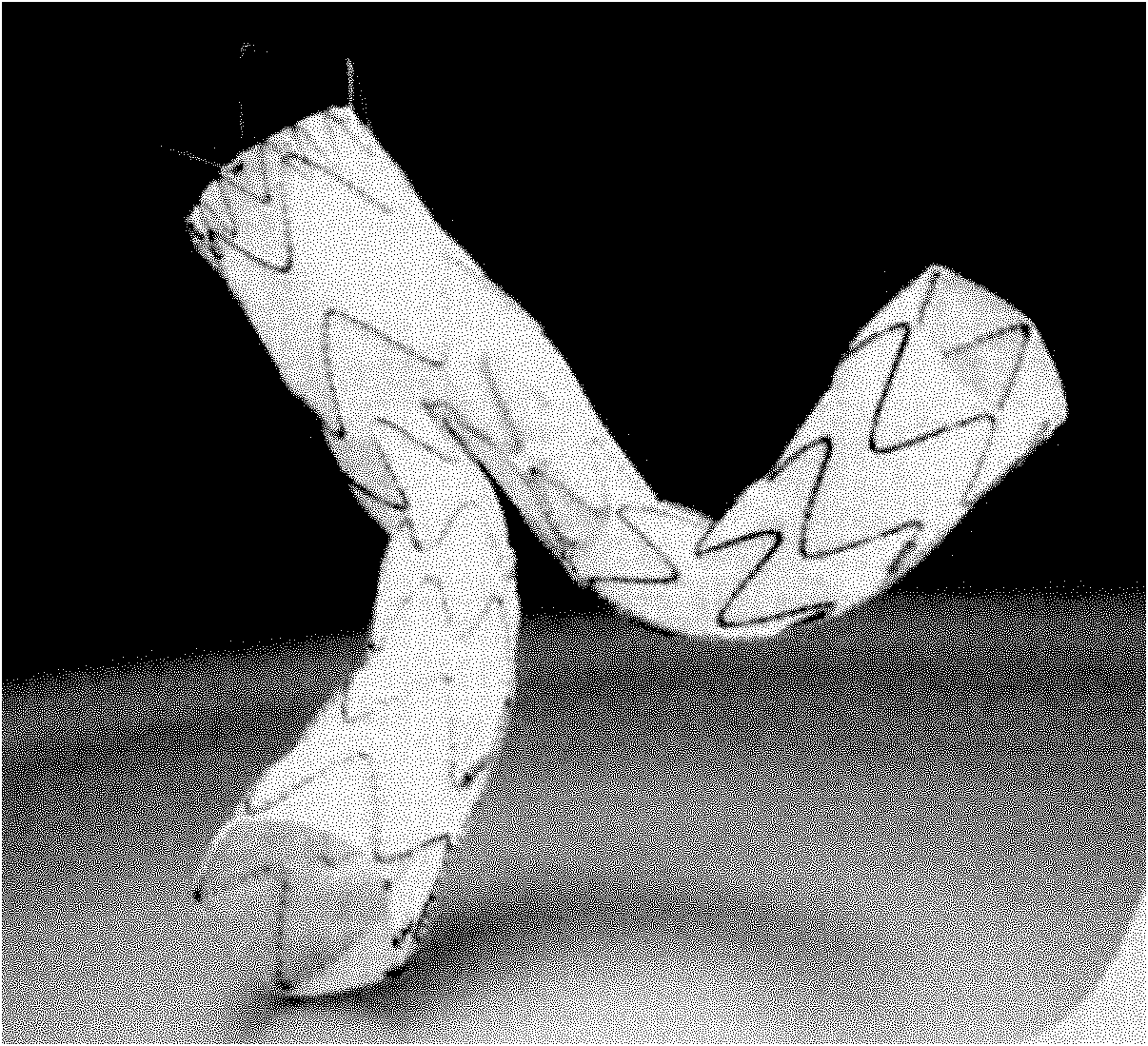

Stent vessel and dedicated traction tool for implanting stent vessel into human body

ActiveCN102125470ASimple structureEasy to manufactureStentsBlood vesselsInsertion stentInterventional therapy

The invention relates to a stent vessel for interventional therapy and a dedicated traction tool for implanting the stent vessel into a human body. The stent vessel comprises an artificial or animal vessel and support rings, wherein the support rings in three structures are used for fixation and respectively arranged at the outlet end and the inlet end of the artificial or animal vessel, and in the support rings, a detachable support ring with radial resilience force is further provided. The dedicated traction tool is especially suitable for dragging a Y-shaped stent into circuitous or narrow parts of the human body. The stent vessel provided by the invention is extremely flexible and easy to be implanted into a branch vessel until to the circuitous part. Because the main part and the branch of the stent vessel are integrated, the stent vessel is easy to position and safe and reliable without leakage after being implanted into the human body; and as the structure is simple and the cost is low, stent vessels in various diameters, variable diameters and lengths are be made, and the application range is wide because of no limit to lengths.

Owner:王嘉贤 +1

Organic electrolyte, method for extracting non-metallic inclusions from steel and electrolyzer

InactiveCN103898596AAvoid erosionFacilitates ion migrationElectrolysis componentsPreparing sample for investigationSurface-active agentsPlastic bag

The invention discloses an organic electrolyte comprising the following components in percentage by weight: 2%-5% of lithium chloride, 5%-8% of gamma-butyrolactone, 2%-5% of ethylene glycol, 0.1%-10% of phenyl surface active agent and balance of absolute ethyl alcohol. The invention also discloses a method for extracting non-metallic inclusions from steel. The method comprises the following steps: preparing the electrolyte, sleeving a microporous cellulose acetate plastic bag on the periphery of a steel sample to electrolyze the steel sample, and separating the inclusions in ultrasonic vibration and vacuum filtration manners. The organic electrolyte is environmentally friendly and low in toxicity. By utilizing the organic electrolyte, body injury to operation staff is obviously reduced, electrolysis time is shortened by accelerating electrolysis through an external magnetic field, the problem that a large number of iron and inclusions of iron and inclusions are difficult to be separated from the anode mud is overcome, and the non-metallic inclusions are accurately and roundly extracted with use of the cellulose acetate plastic bag.

Owner:SHANGHAI UNIV +1

Anti-corrosion super-hydrophobic heat reflecting paint and preparation method thereof

ActiveCN105925073AImprove lotus leaf effectImprove hydrophobicityAnti-corrosive paintsReflecting/signal paintsNano sio2Water contact

The invention discloses an anti-corrosion super-hydrophobic heat reflecting paint and a preparation method thereof. The anti-corrosion super-hydrophobic heat reflecting paint is prepared from the following raw materials: modified nano TiO2, modified nano SiO2, micron TiO2 and / or SiO2, fluorocarbon resin, a solvent, a curing agent, a defoaming agent, a wetting dispersant and a flatting agent. After experiments, the heat reflecting rate of the obtained product reaches 90 percent or more, the water contact angle reaches 145 degrees or more, and the product can meet the requirements on a coating under outdoor severe environments.

Owner:SHANDONG UNIV OF SCI & TECH

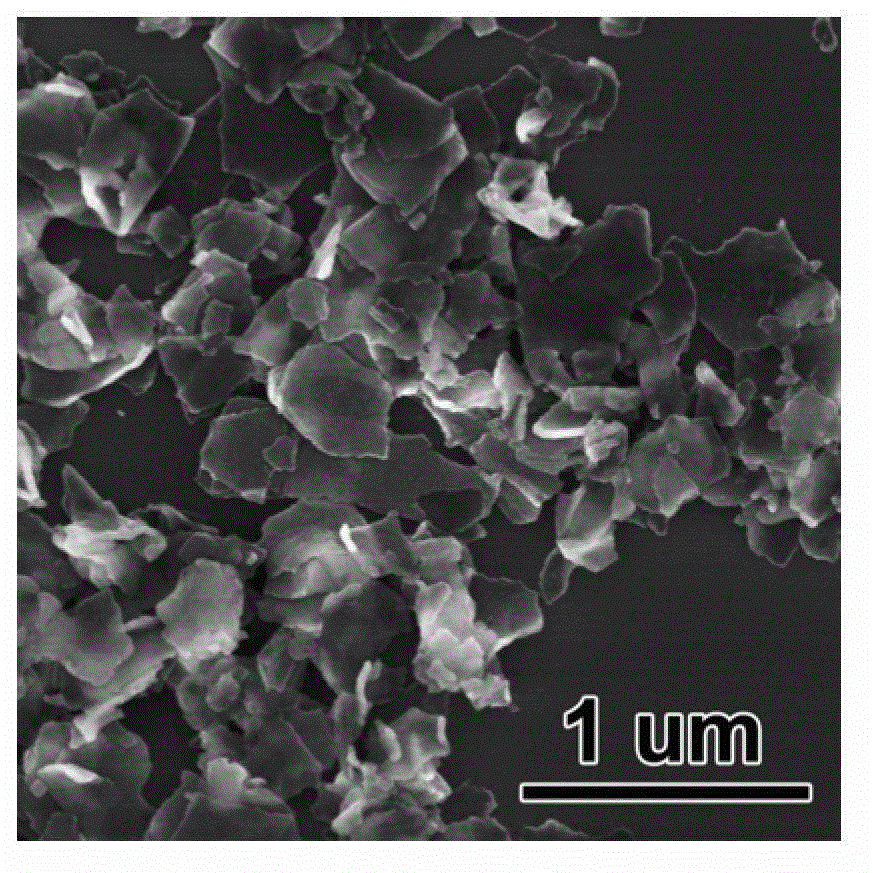

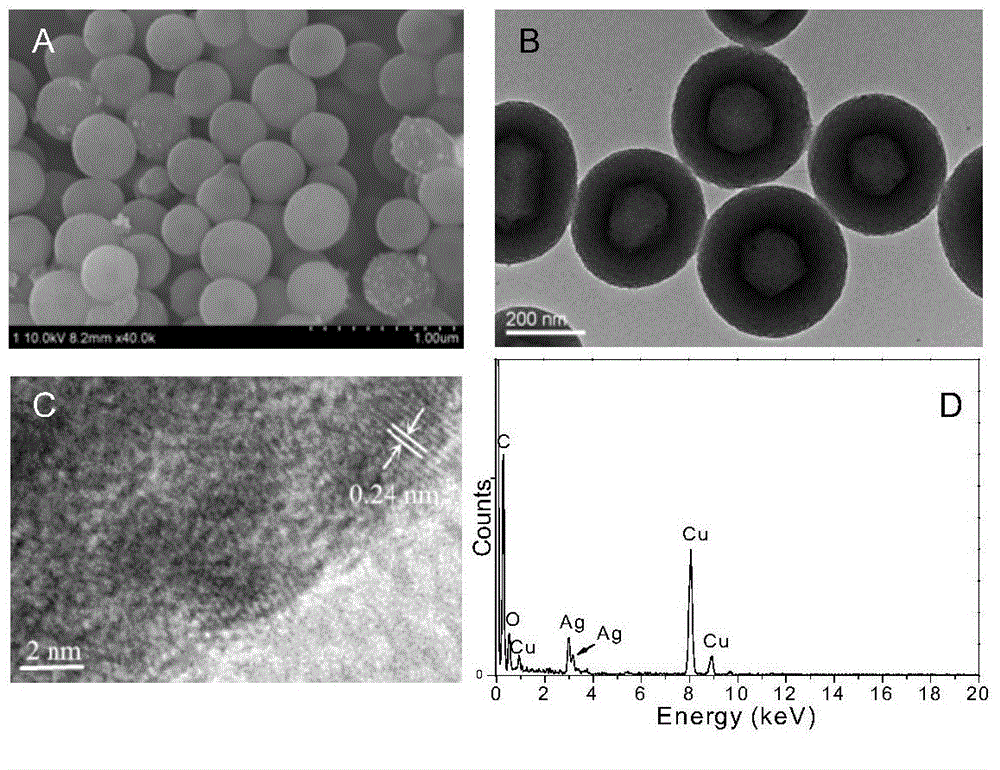

Ag/C (Silver/Carbon) hollow nano-sphere and preparation method thereof

ActiveCN104801724AAvoid gatheringPrevent oxidationMetal/metal-oxides/metal-hydroxide catalystsNano catalystCarbon layer

The invention discloses an Ag / C (Silver / Carbon) hollow nano-sphere and a preparation method thereof, and belongs to the field of a catalysis technique. The preparation method comprises the following steps: taking an amorphous carbon ball as a carrier, uniformly mixing and stirring glucose and silver nitride, and reducing to obtain a uninuclear carbon-coated silver core-shell structure through a one step hydro thermal method; then, corroding the uninuclear carbon-coated silver core-shell structure through H2O2 (Hydrogen Peroxide), gradually changing a Ag core of which the size is about 100nm into nano-silver particles of which the sizes are smaller, diffusing the nano-silver particles to a carbon shell layer from inside to outside, and embedding the nano-silver particles into a carbon layer to leave a cavity; and obtaining the Ag / C hollow nano-sphere of the core-shell structure. The Ag / C hollow nano-sphere provided by the invention has the advantages of being capable of loading nano-scale catalyst granules in the amorphous hollow carbon ball, and preventing the aggregation and oxidation of the nano-catalyst; furthermore, a catalyst is simple in preparation process, high in activity and good in stability, thereby being extensively applied to the preparation of para-aminophenol by the catalytic hydrogenation of nitro-phenol.

Owner:EAST EIGHT ENERGY (SHANGHAI) CO LTD

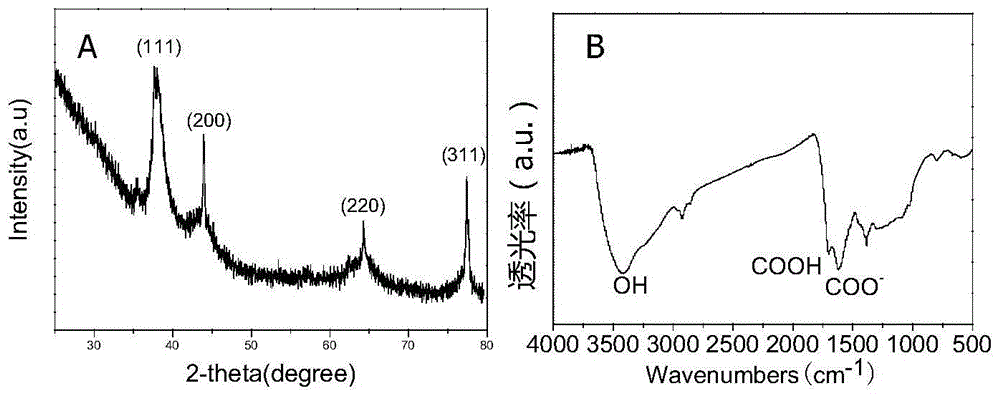

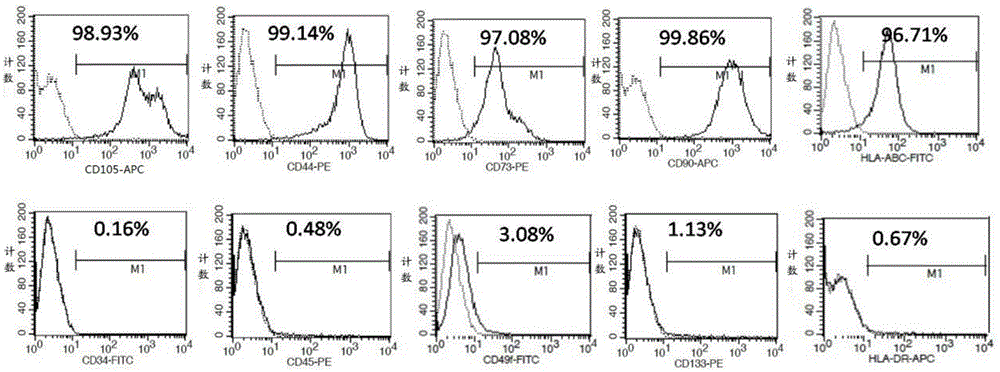

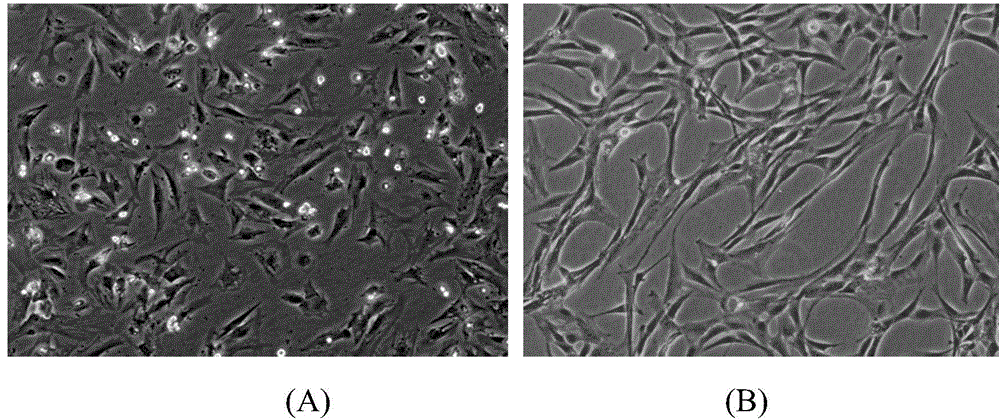

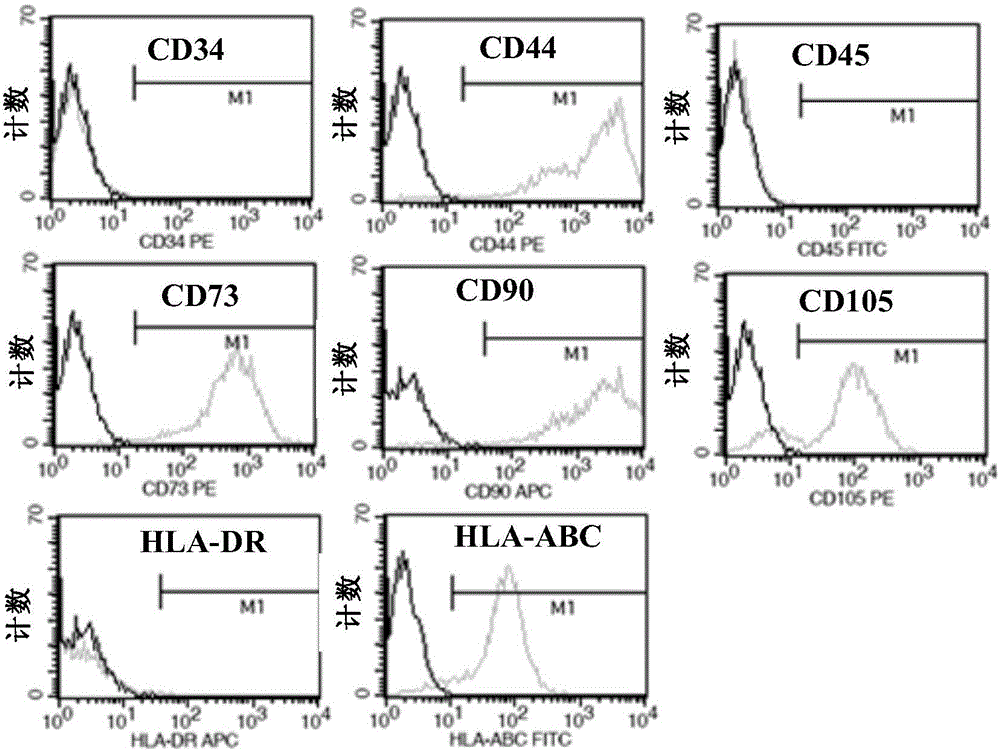

MSC (mesenchymal stem cell) injection as well as preparation and application thereof

InactiveCN104857022AImprove survival rateAvoid gatheringPharmaceutical delivery mechanismUnknown materialsClinical gradeHydroxyethyl starch

The invention relates to the field of biology, in particular to MSC (mesenchymal stem cell) injection as well as a preparation and an application thereof. The injection comprises MSCs and a cell cryopreservation solution, wherein the cryopreservation solution comprises components in percentage by volume as follows: 25%-70% of an electrolyte balance solution, 5%-20% of clinical-grade DMSO (dimethyl sulfoxide), 1%-50% of 20% human serum albumin, 1%-10% of hydroxyethyl starch 130 / 0.4 and 5%-20% of triphosadenine-disodium magnesium chloride freeze-drying powder. The injection is free of animal serum, has clear ingredients and good cell cryopreservation effect and is safe and controllable, long-term storage and long-distance transport are facilitated, the survival rate of cells after recovery is higher than 95%, the vitality is high, and the injection can effectively relieve injury and inflammation symptoms of lesion tissue of lungs and promote tissue regeneration of the lungs, so that acute lung injury can be fundamentally and comprehensively treated.

Owner:北京青藤谷禧干细胞科技研究院有限公司

Remanufacturing method for scrap titanium chips through ball milling-equal channel angularpressing

InactiveCN105618501AExcellent technical indicatorsSimple process operationCleaning using liquidsGrain treatmentsScrapSwarf

The invention provides a remanufacturing method for scrap titanium chips through ball milling-equal channel angular pressing. The remanufacturing method sequentially comprises the step of recovering and pretreating titanium chips, the step of performing ball milling treatment on the titanium chips, the step of loading the titanium chips into an equal channel angular pressing mold, the step of performing preprocessing at a room temperature through the equal channel angular pressing, the step of curing and processing at a high temperature, and the step of quenching. The ball milling-equal channel angular pressing composite technique provided by the invention is simple and practical to operate and high in controllability. Through remanufacturing, not only can nanometer block titanium materials (smaller than 200nanometers) with full densification be obtained, but also the metallurgical defect of the continuous distribution and gathering of large sliced oxides can be eliminated. In addition, the shapes of the titanium chips are refined and reformed, and anisotropy caused by deformation texture in hexagonal close packed titanium materials is restrained. The yield strength of the remanufactured nanometer titanium materials reaches to the level of 5-grade titanium, the distribution of nanometer particles of the oxides presents a dispersed uniform state, and through the isotropy of the properties of the materials, the remanufacturing of scrap titanium resources for value increase at low cost is realized.

Owner:SHANGHAI DIANJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com