Patents

Literature

251 results about "Double injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double Injection in performed on one machine that is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The mold is then automatically rotated and a different type of plastic is injected into the mold from a second nozzle.

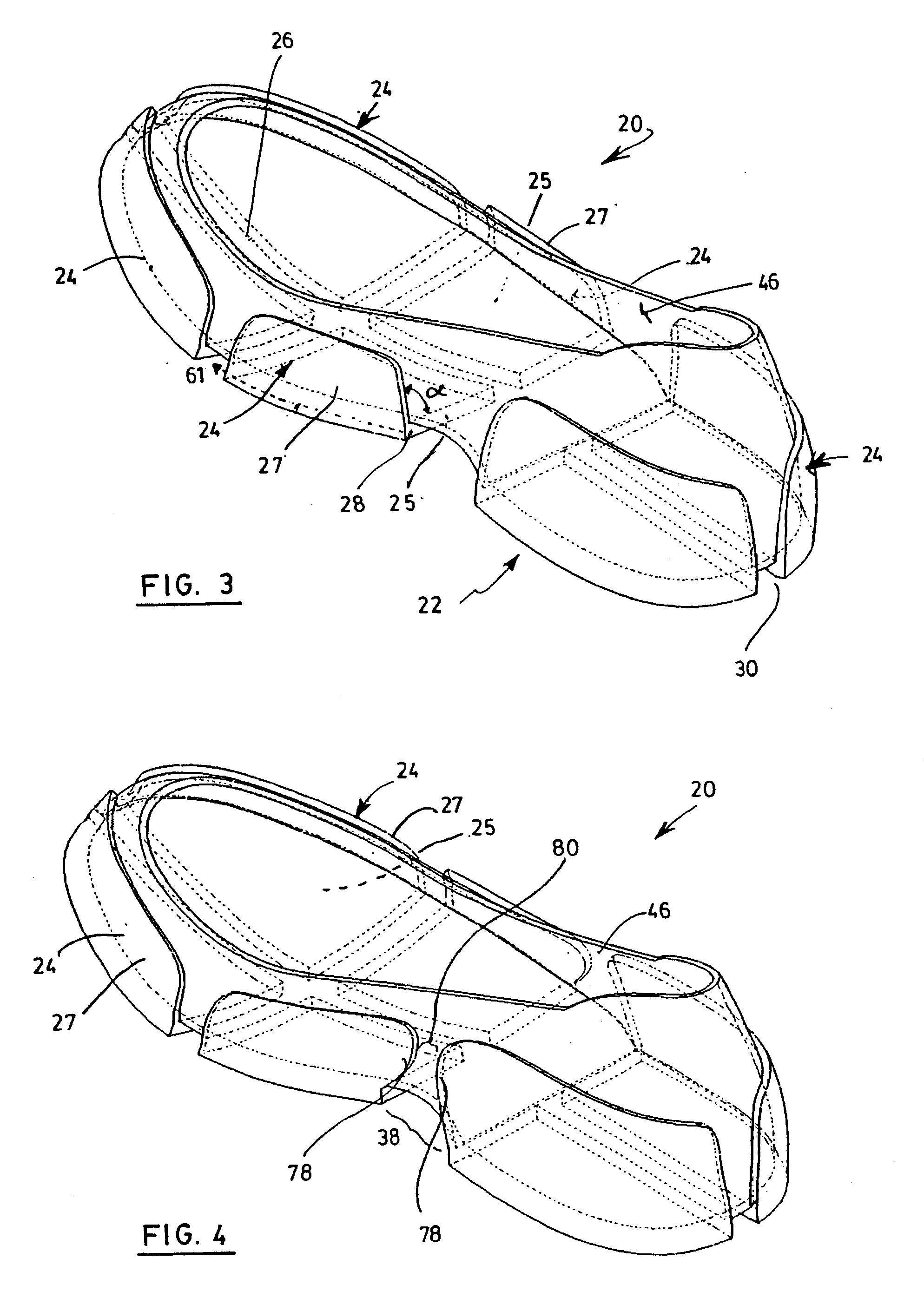

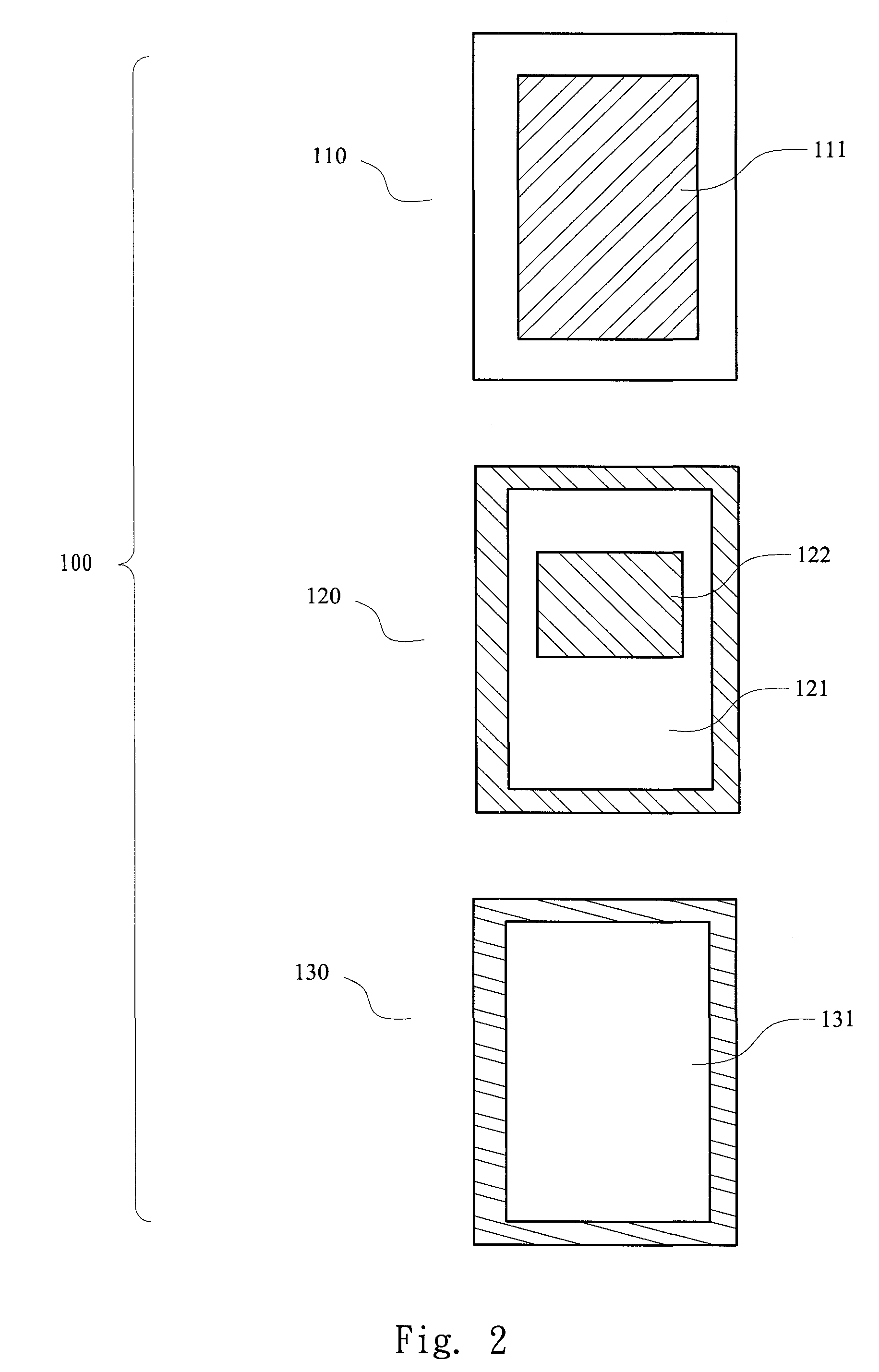

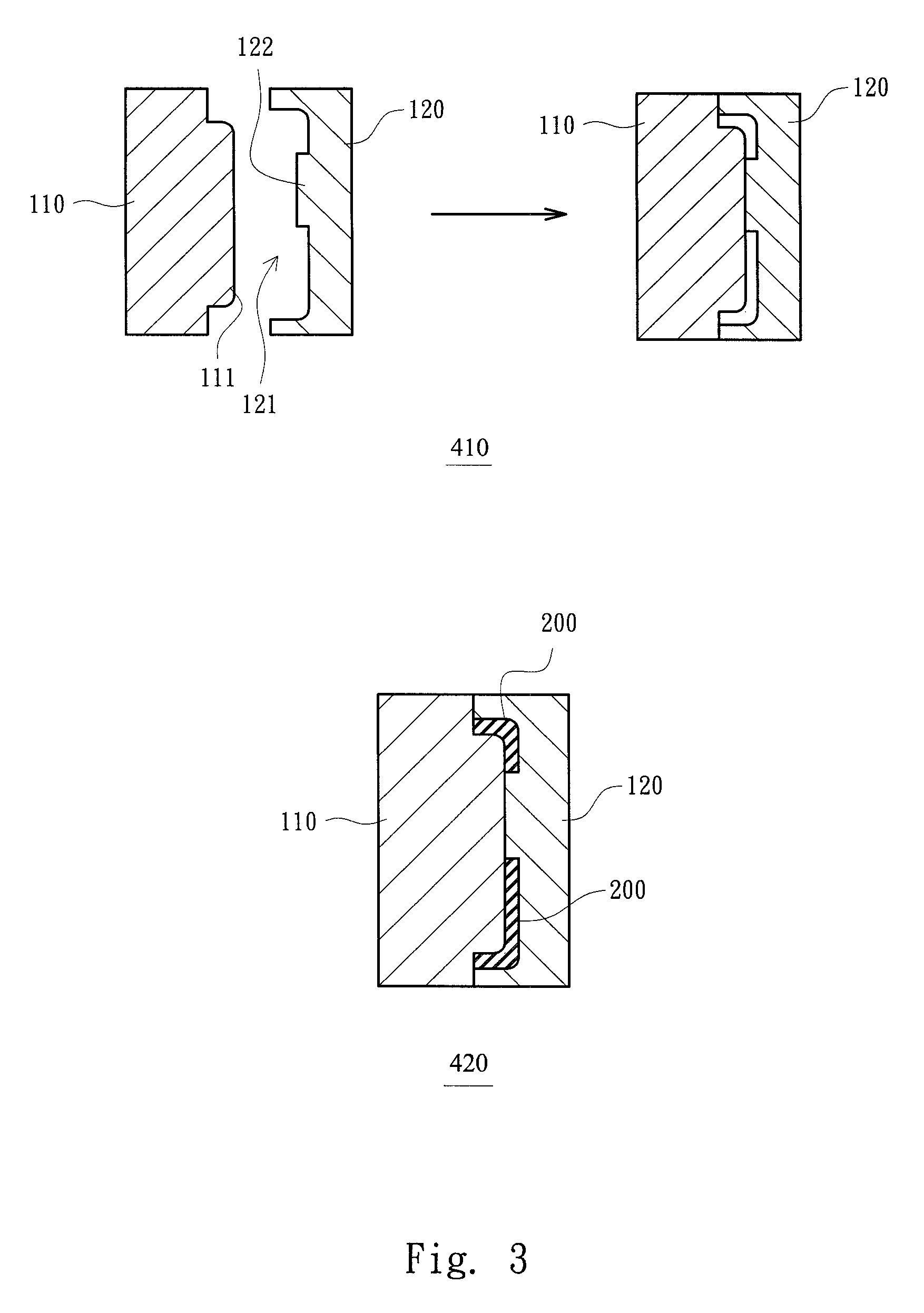

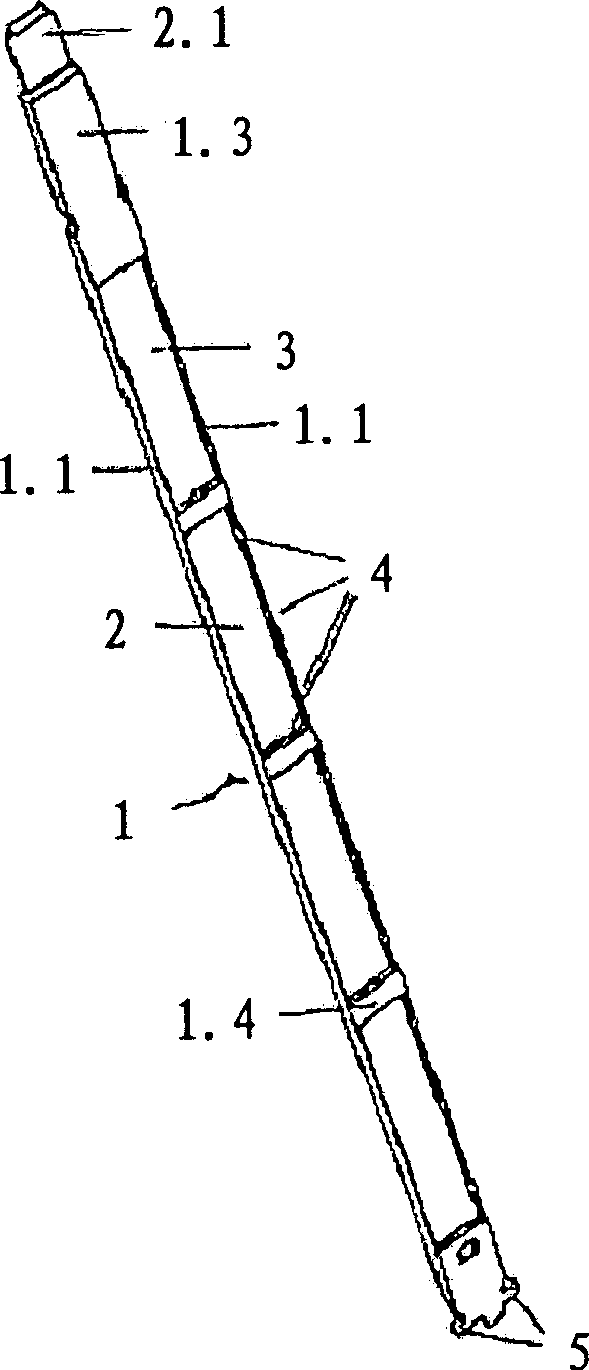

Adaptable shoe cover

InactiveUS8474153B2Easy to adaptIncrease flexibilitySolesDomestic footwearEngineeringDouble injection

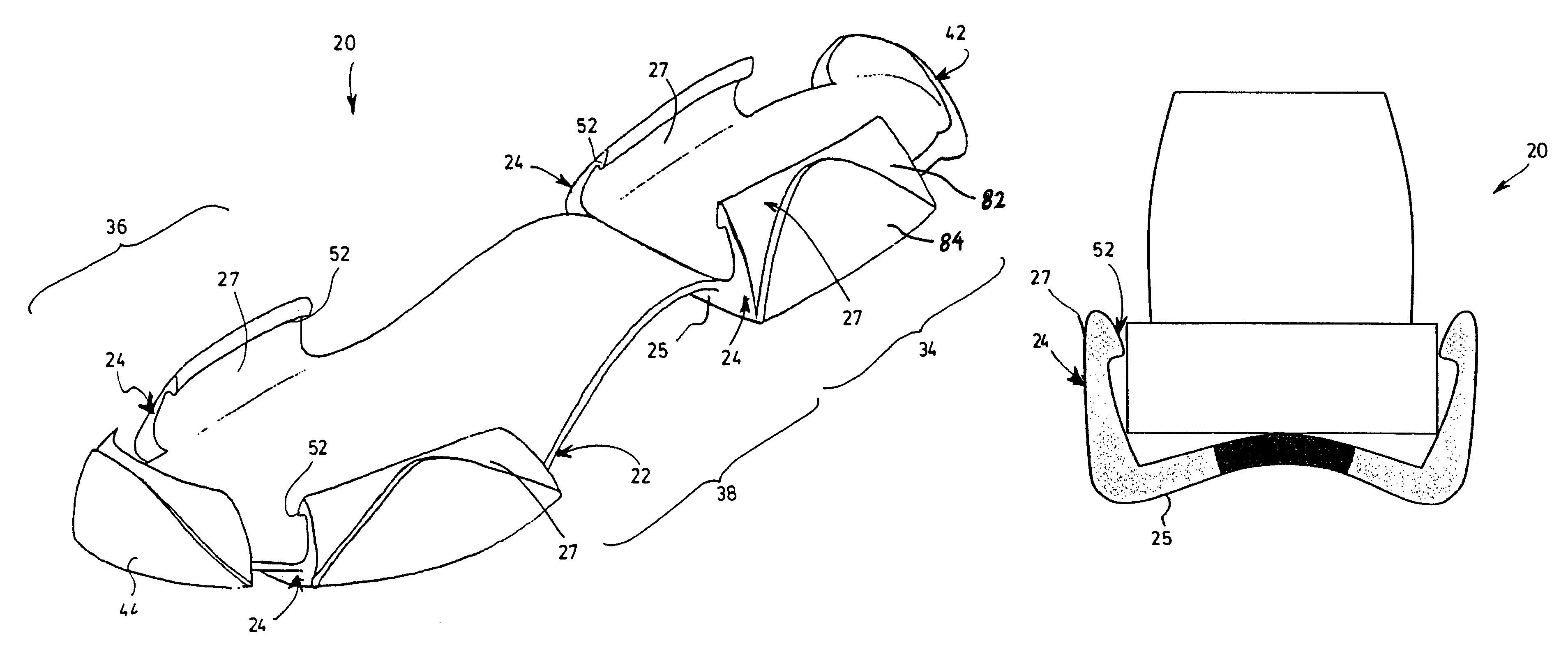

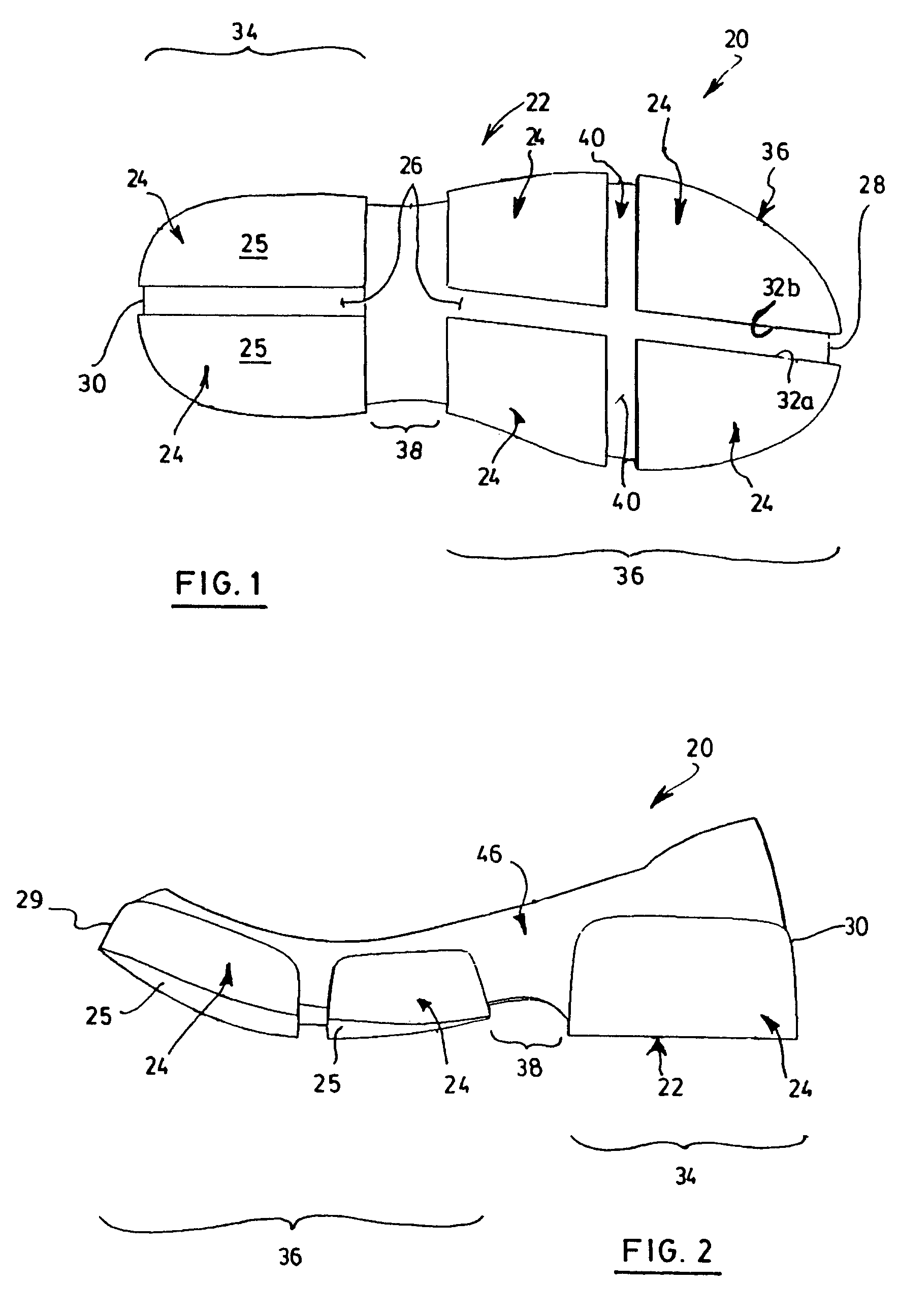

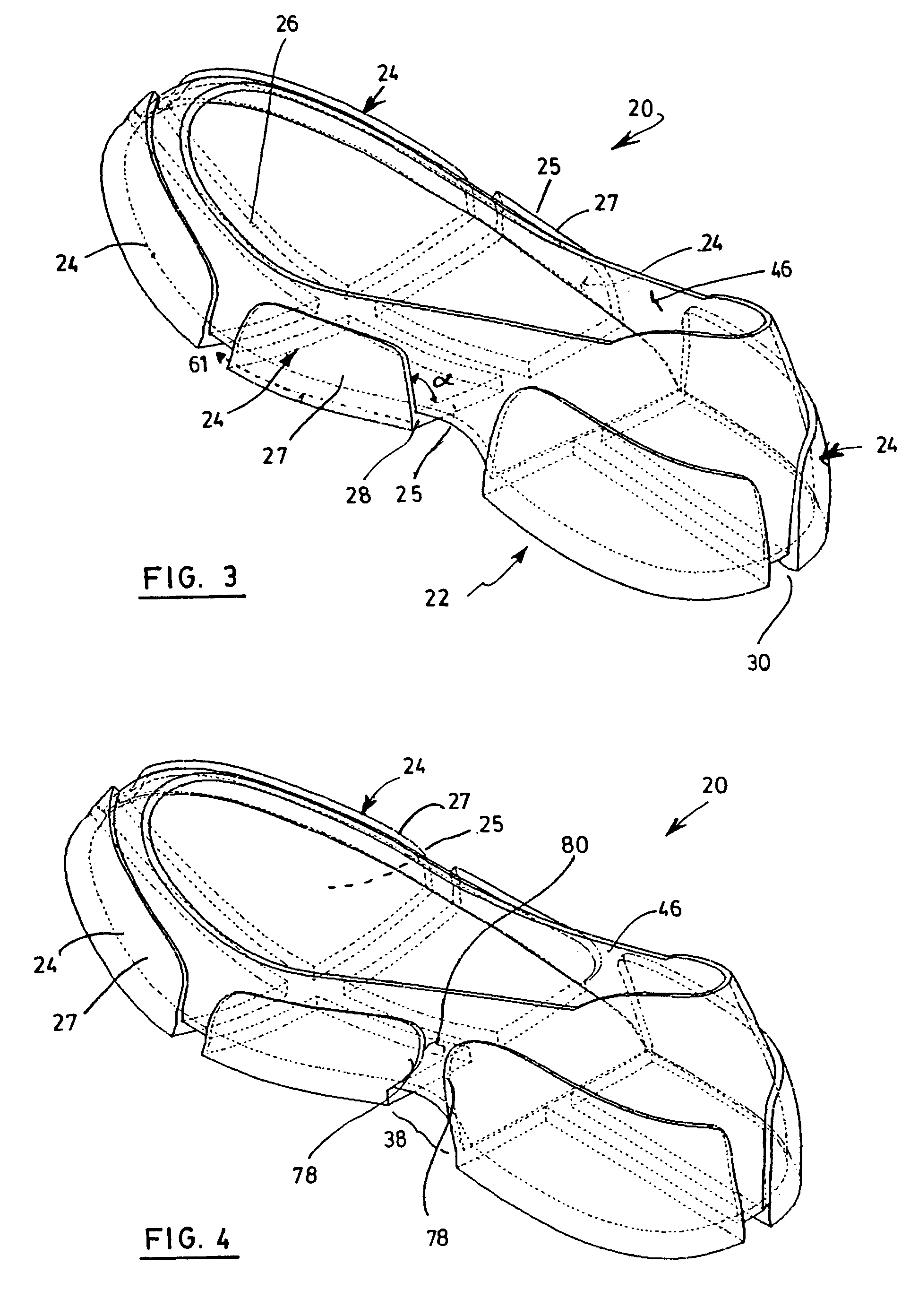

The present invention provides a shoe cover to adaptively fit over a shoe. The show cover has a sole, which includes at least two rigid bands of rigid material, disposed on the bottom of the sole and arranged in spaced relation to each other on opposite sides of a longitudinal axis of the sole, thereby rigidifying the sole. The sole also has an elastic band of the flexible material, spanning longitudinally between the two rigid bands from the front to the rear of the sole, thereby enabling lateral flexibility to adapt to a shoe. The present invention also provides a rigid L-shaped element, each including a first portion on the ground side, a second portion on the side wall, and a fulcrum joining them, to clamp an inserted shoe. A double injection method for producing the above is also provided.

Owner:ALFRED CLOUTIER

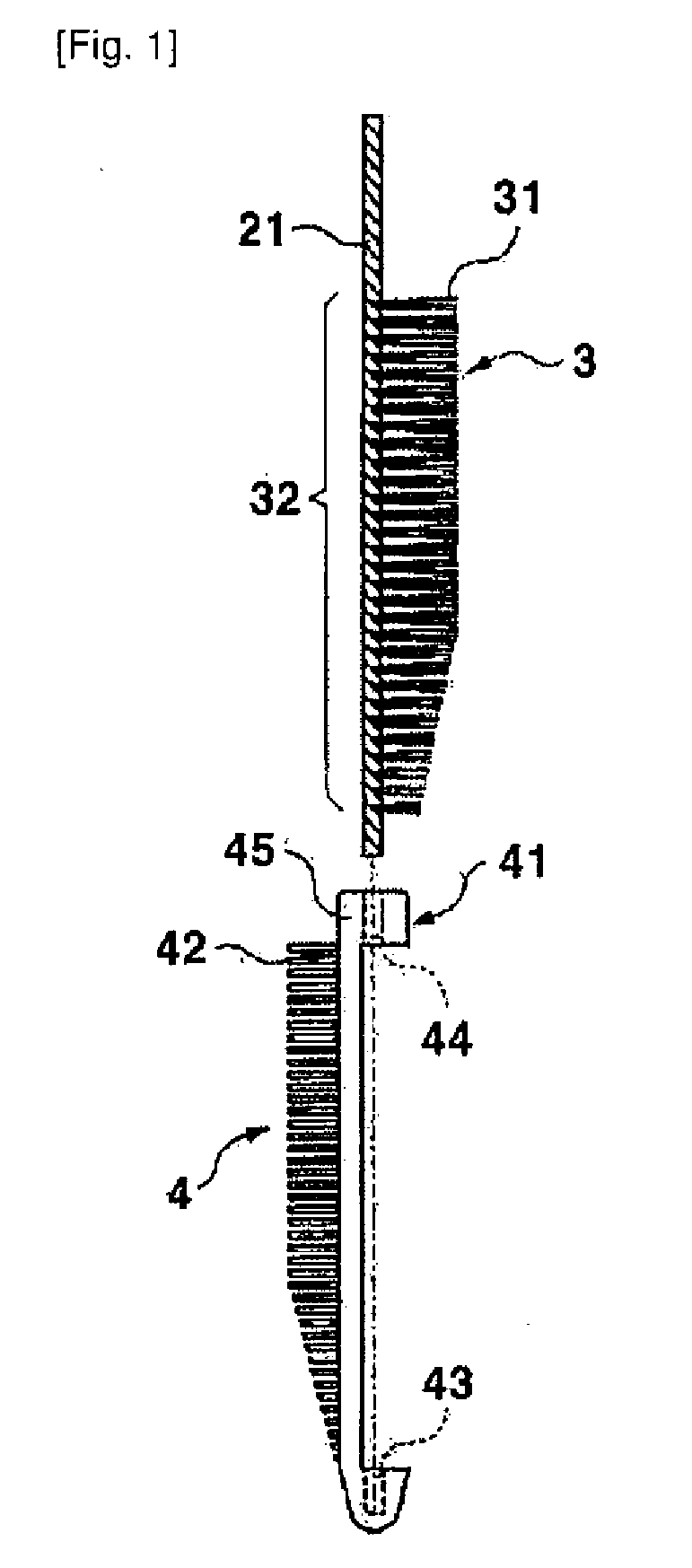

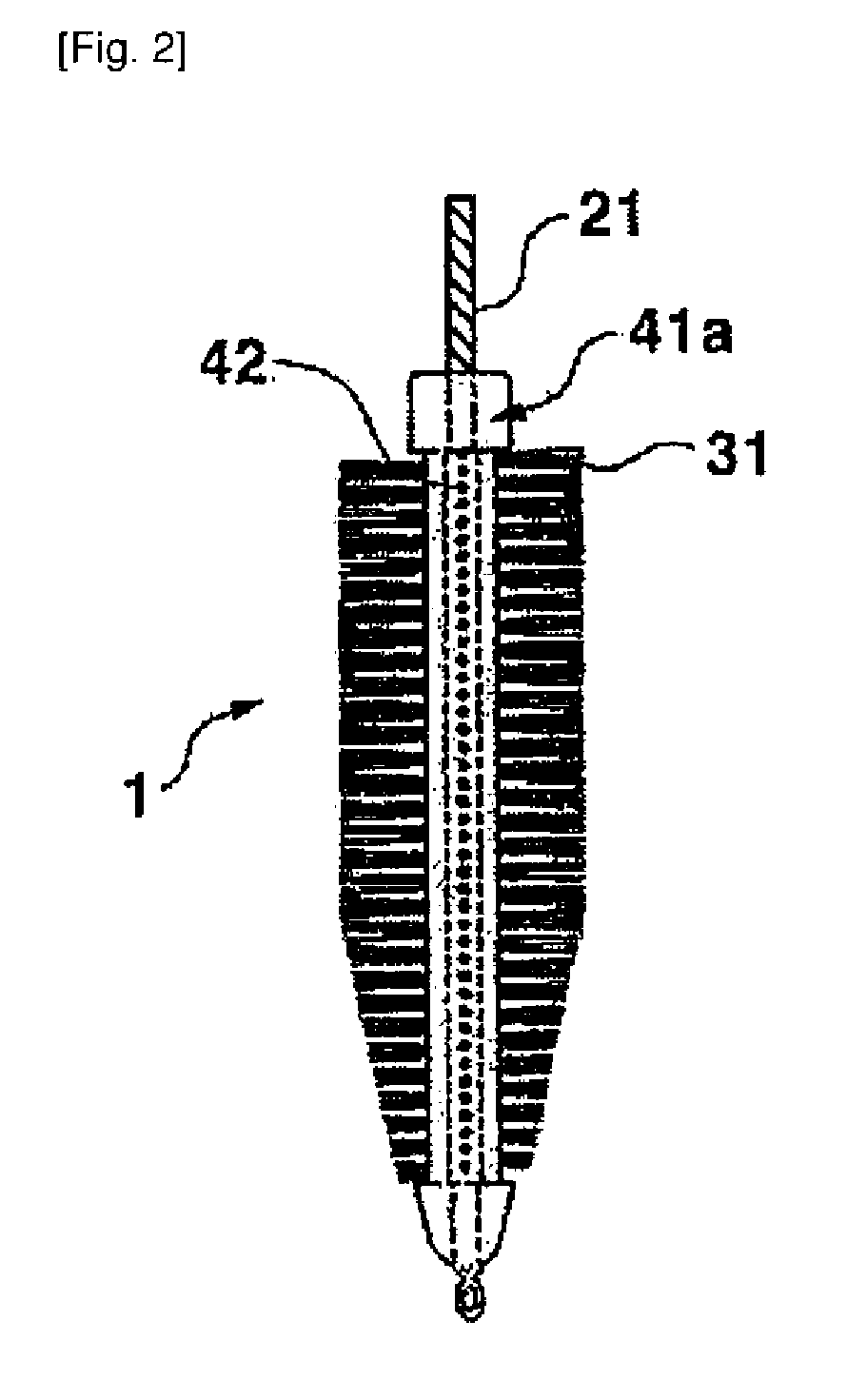

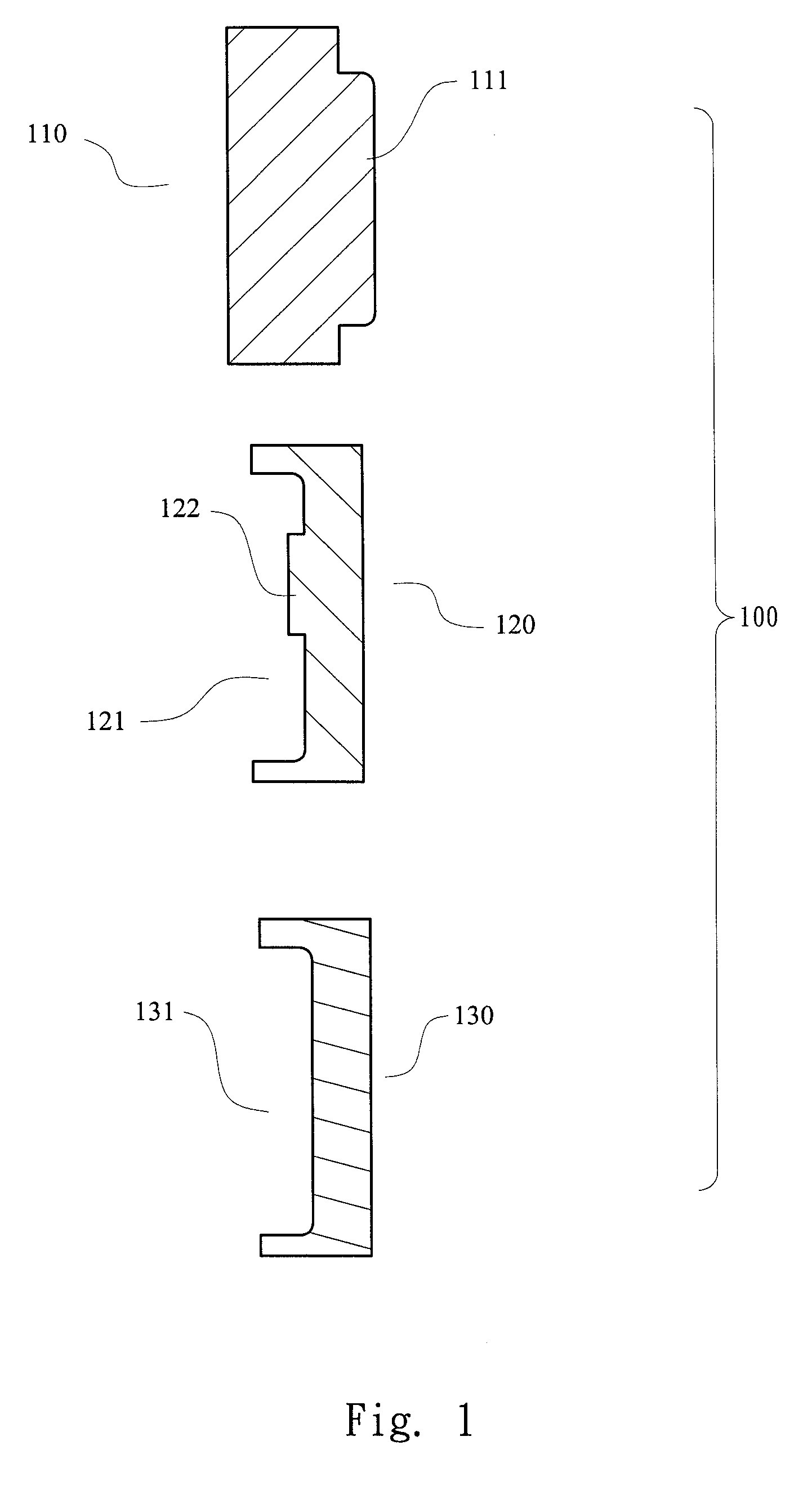

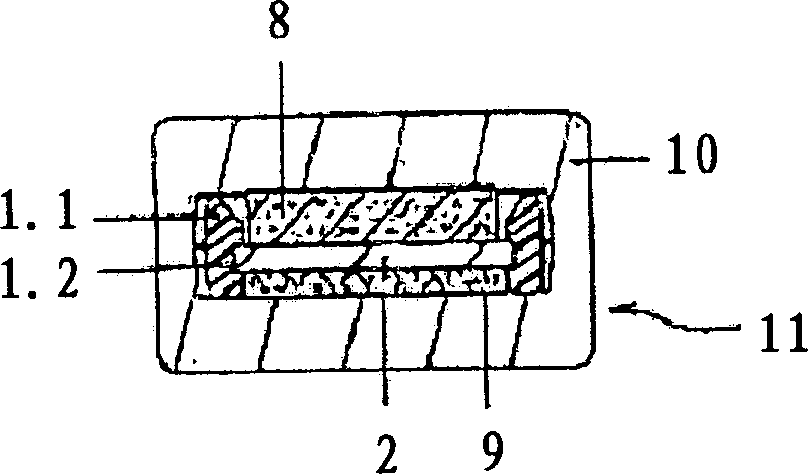

Mascara brush

InactiveUS20100175708A1Low production costImprove workabilityBristlePackaging toiletriesProduction rateBristle

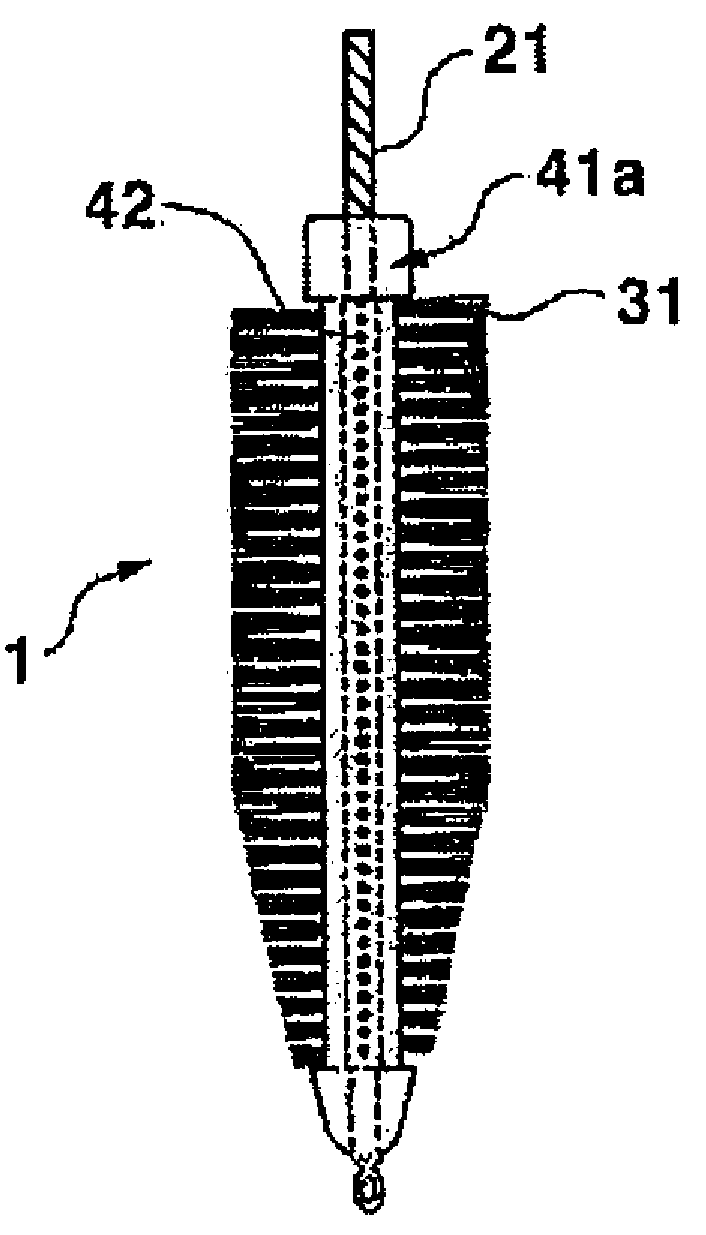

The present invention provides a mascara brush, which is manufactured through a double injection molding process, thus reducing production costs and enhancing workability and productivity. The mascara brush of the present invention includes a bristle part (120), for applying mascara to eyelashes, and a comb part (130) for tidying the eyelashes. The bristle part has a cylindrical brush body (110) and bristles (121), which are formed around the brush body through an injection molding process. The comb part is formed such that part of the comb part is embedded in the brush body. The bristle part and the comb part are formed through double injection molding. Furthermore, each bristle may have branches to thus have a snowflake shape, thus increasing its ability to absorb mascara.

Owner:CPI KOREA

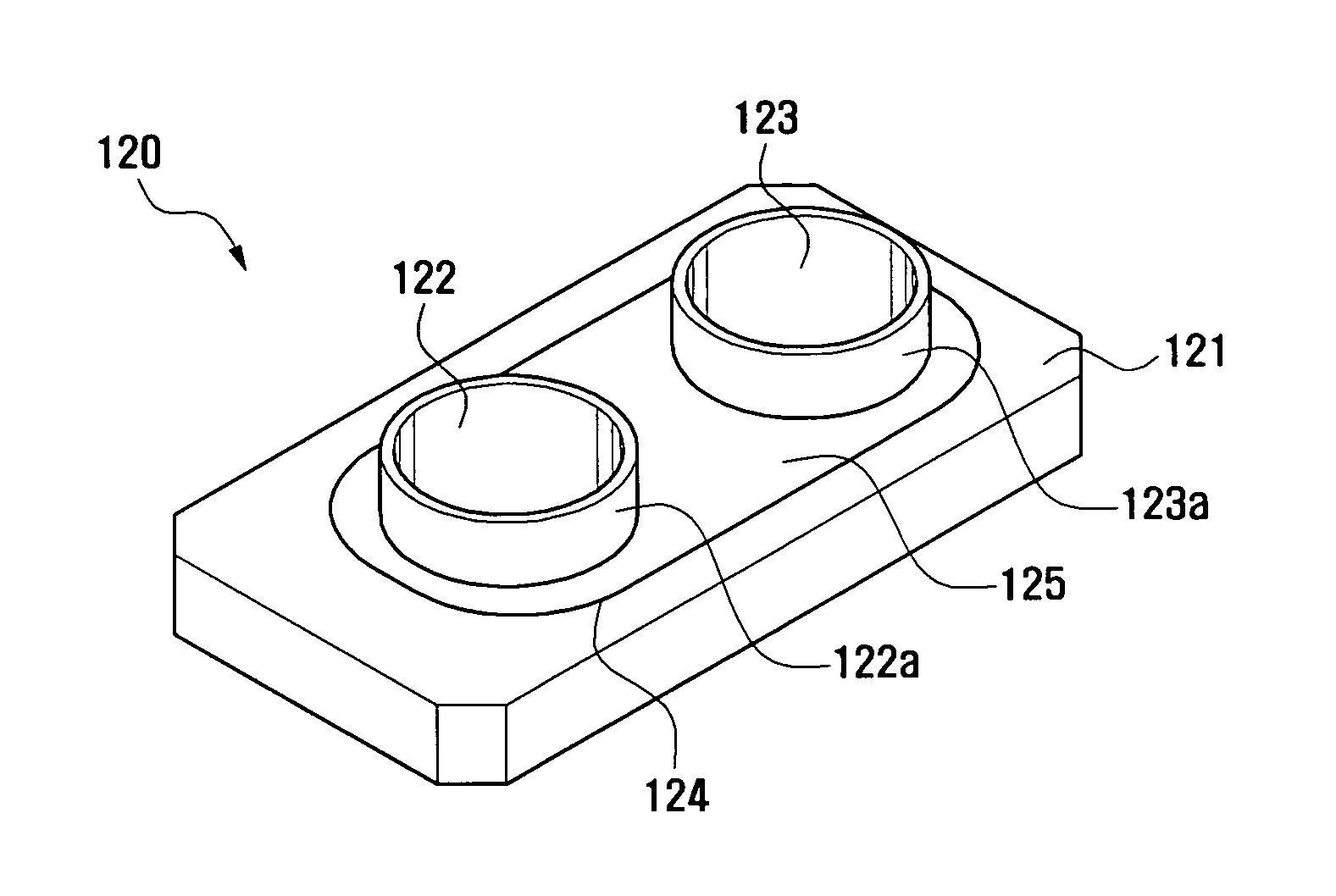

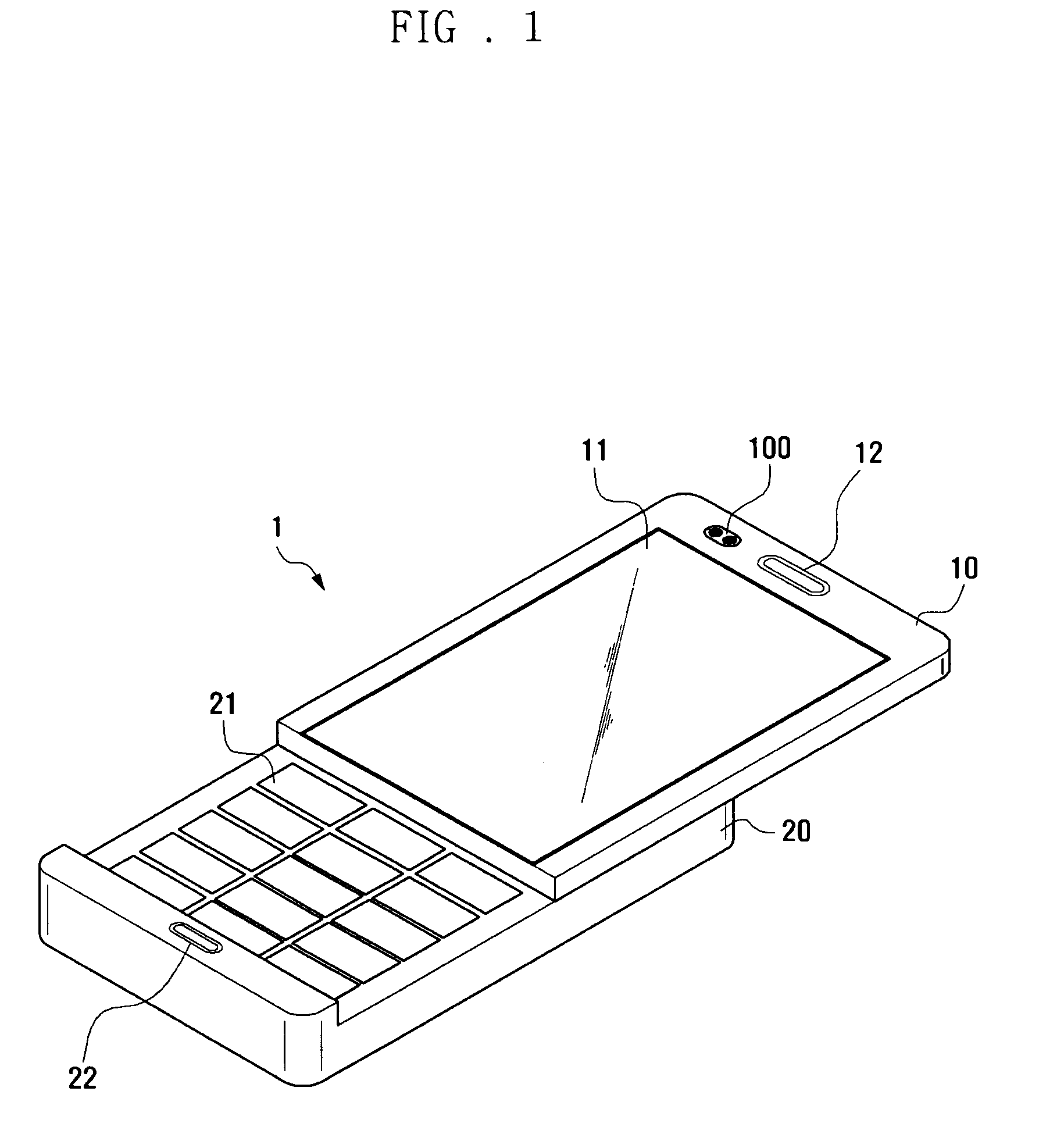

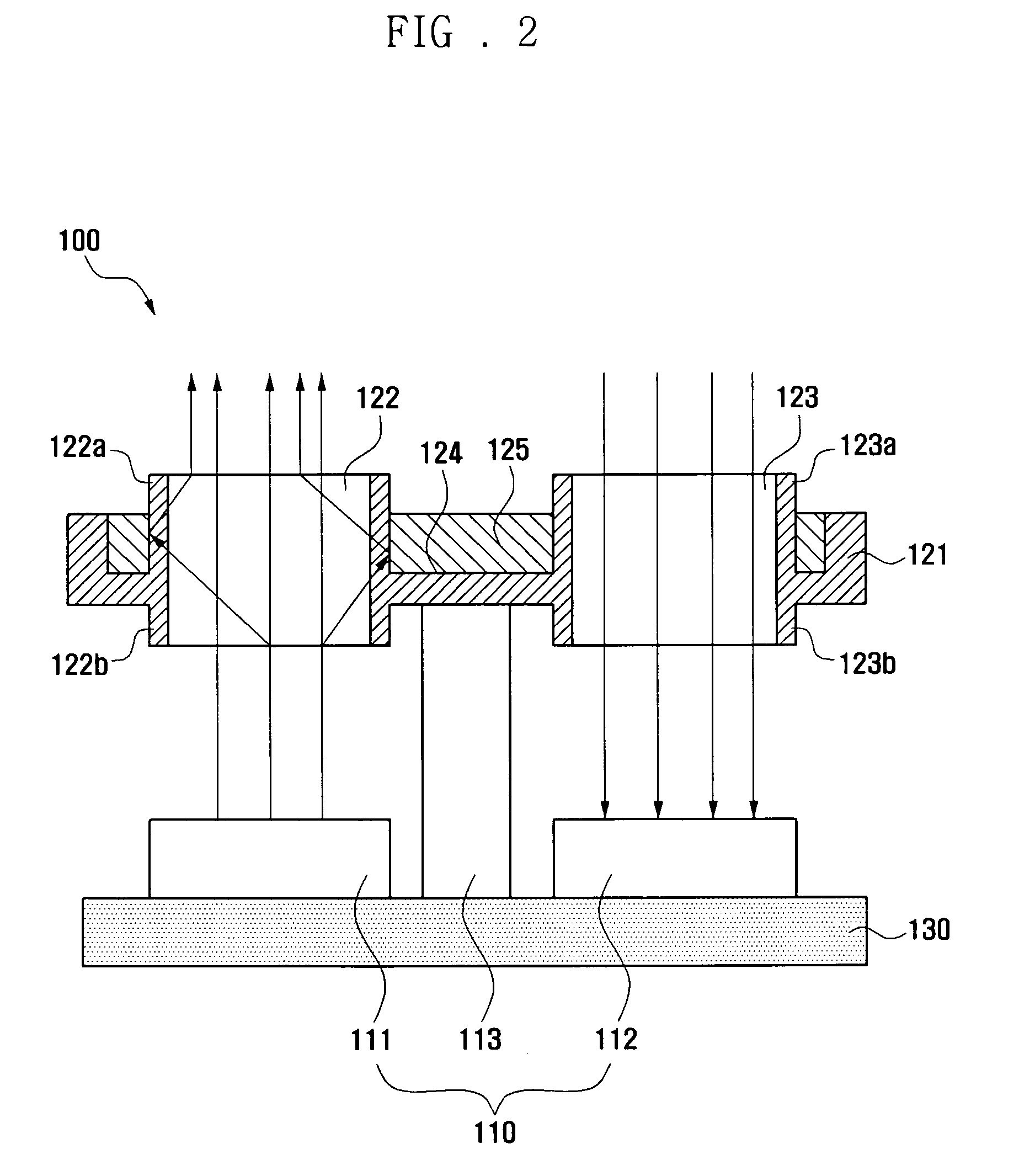

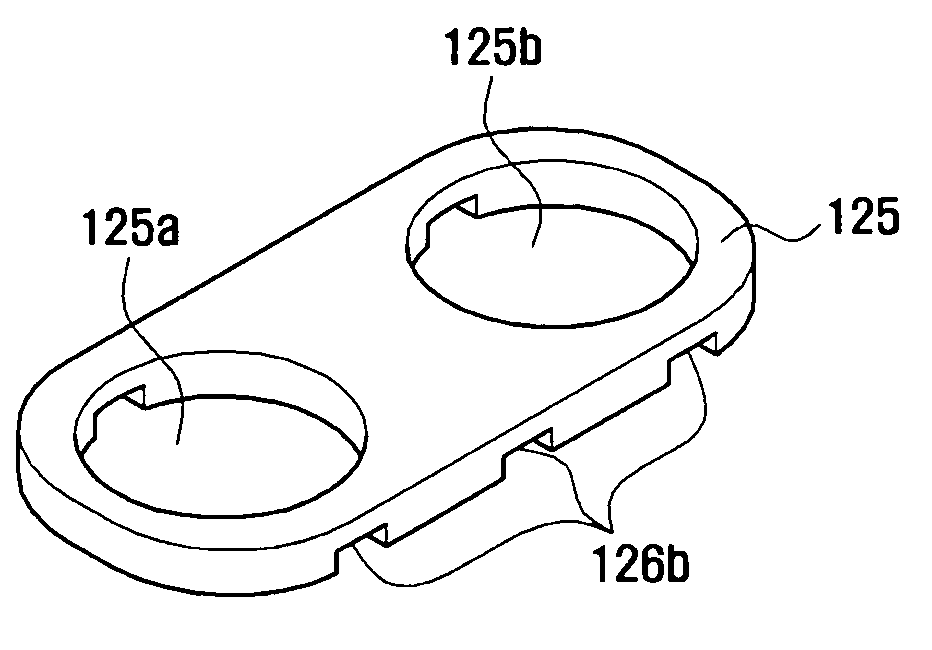

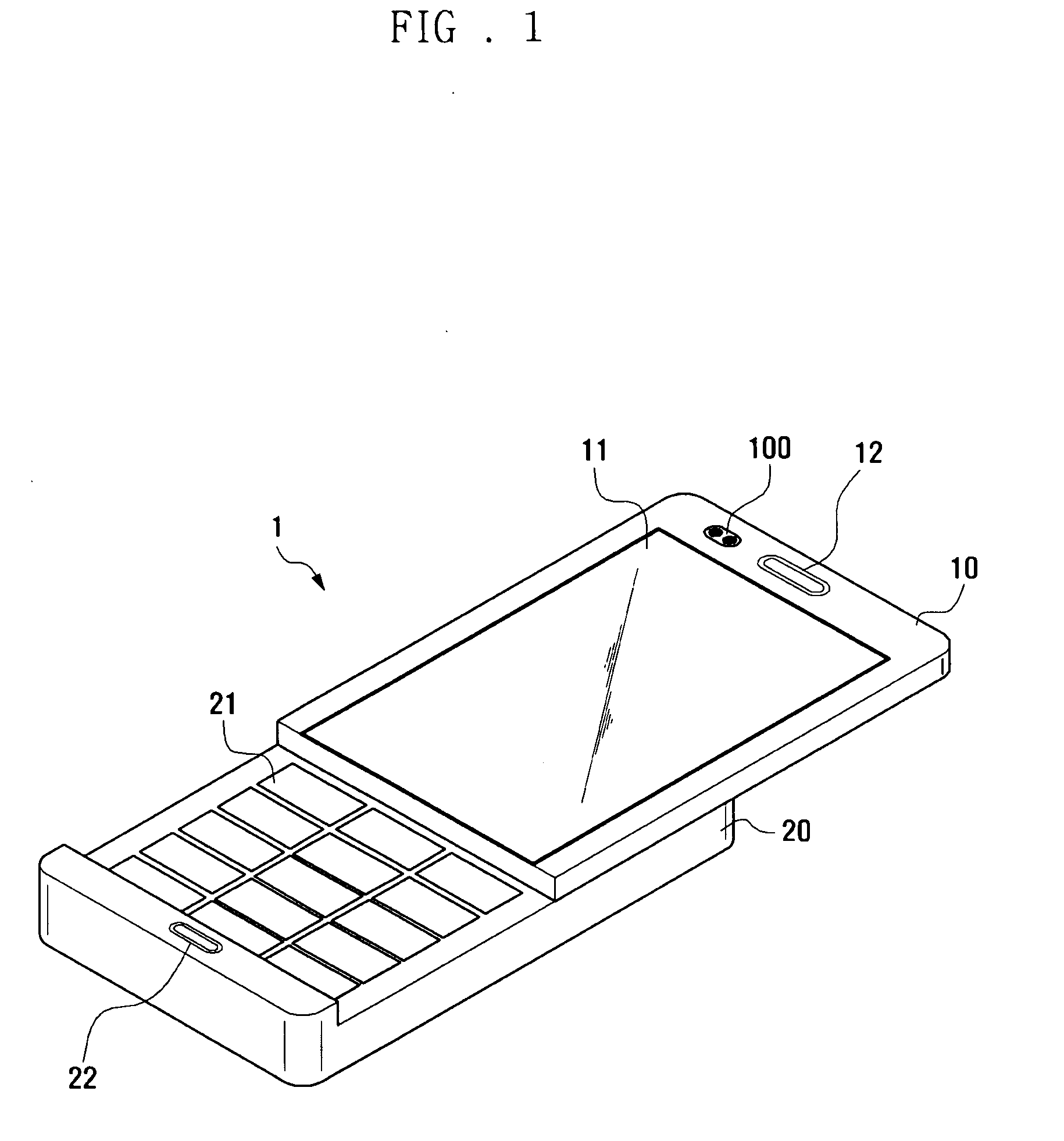

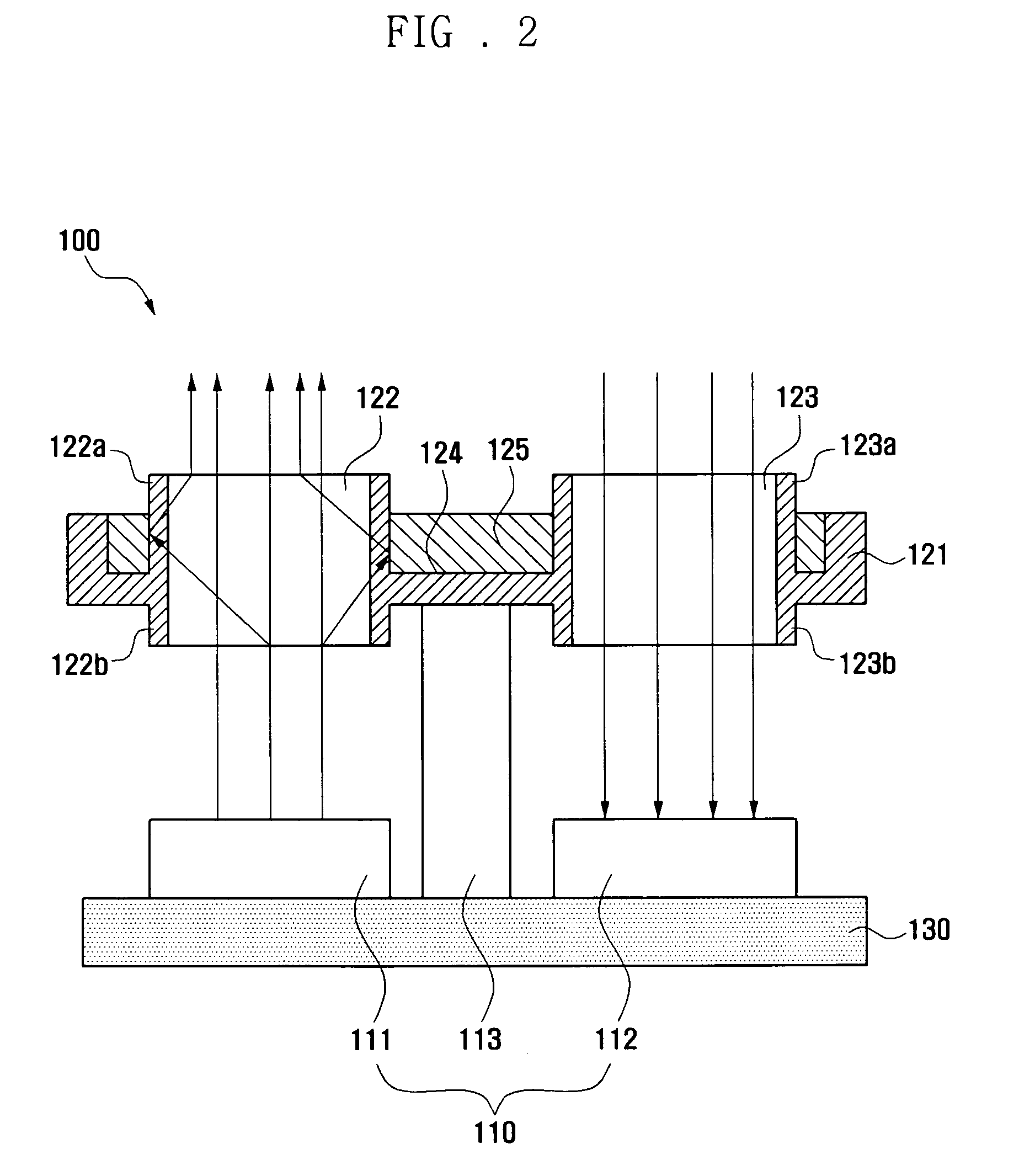

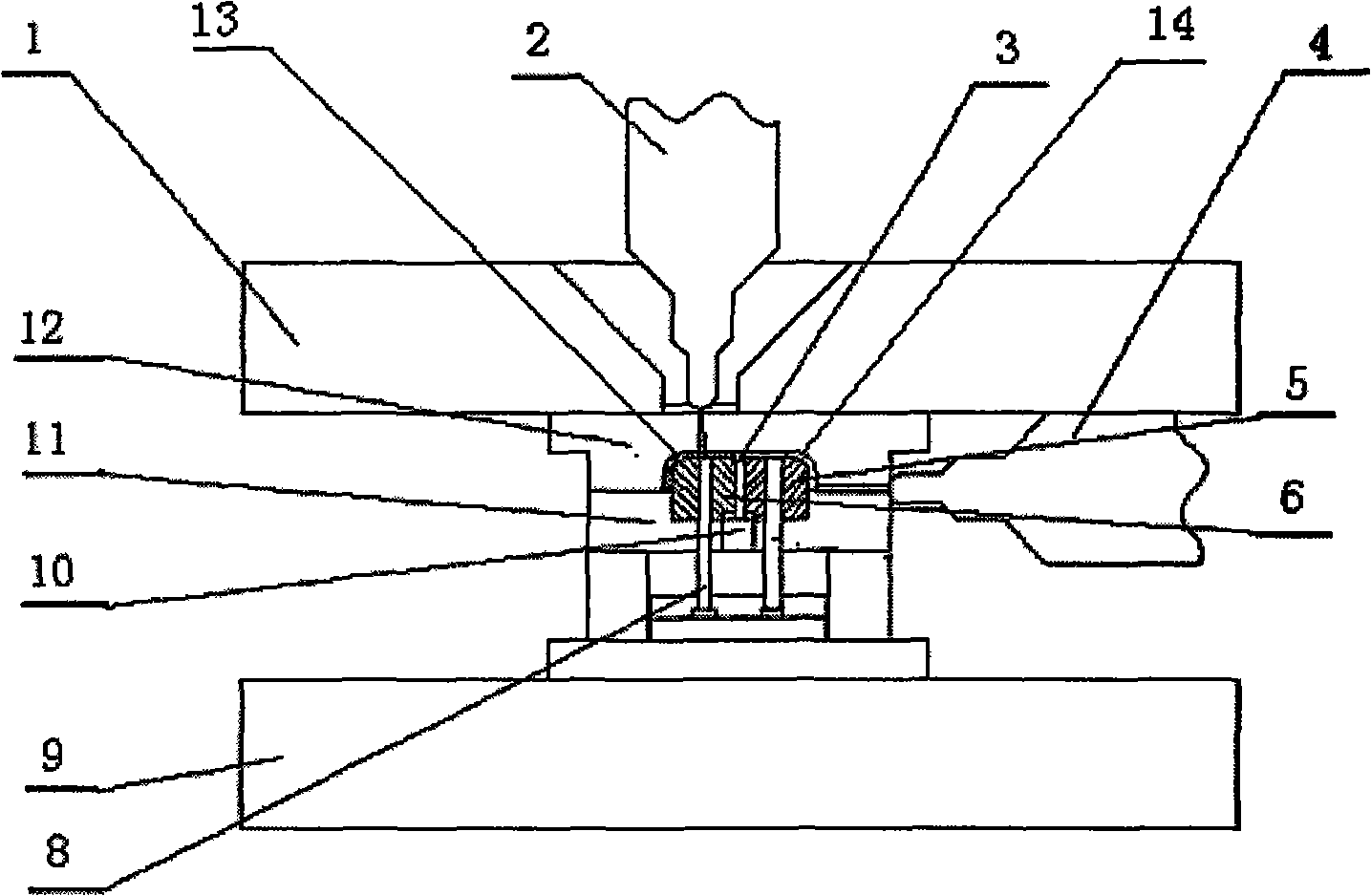

Sensing device using proximity sensor and mobile terminal having the same

ActiveUS8450679B2Avoid failureSensing device using the proximity sensor may be simplifiedPhotometryDevices with sensorProximity sensorOptoelectronics

A mobile terminal includes a sensing device that uses a proximity sensor. The sensing device includes: a proximity sensor sensing approach of an external object; and a lens unit installed on top of the proximity sensor. The lens unit includes: a lens body having a first through-opening through which light emitted from a light emitting unit of the proximity sensor passes and a second through-opening through which light, reflected from the external object and entering into a light receiving unit of the proximity sensor, passes; and a reflective film formed in the lens body to surround edges of the first through-opening and the second through-opening. The lens body and the reflective film are integrated with each other by double injection molding. The lens body and the reflecting film are manufactured in a single body by double injection molding.

Owner:SAMSUNG ELECTRONICS CO LTD

Sensing device using proximity sensor and mobile terminal having the same

ActiveUS20100171027A1Avoid failureSensing device using the proximity sensor may be simplifiedPhotometryMaterial analysis by optical meansProximity sensorOptoelectronics

A mobile terminal includes a sensing device that uses a proximity sensor. The sensing device includes: a proximity sensor sensing approach of an external object; and a lens unit installed on top of the proximity sensor. The lens unit includes: a lens body having a first through-opening through which light emitted from a light emitting unit of the proximity sensor passes and a second through-opening through which light, reflected from the external object and entering into a light receiving unit of the proximity sensor, passes; and a reflective film formed in the lens body to surround edges of the first through-opening and the second through-opening. The lens body and the reflective film are integrated with each other by double injection molding. The lens body and the reflecting film are manufactured in a single body by double injection molding.

Owner:SAMSUNG ELECTRONICS CO LTD

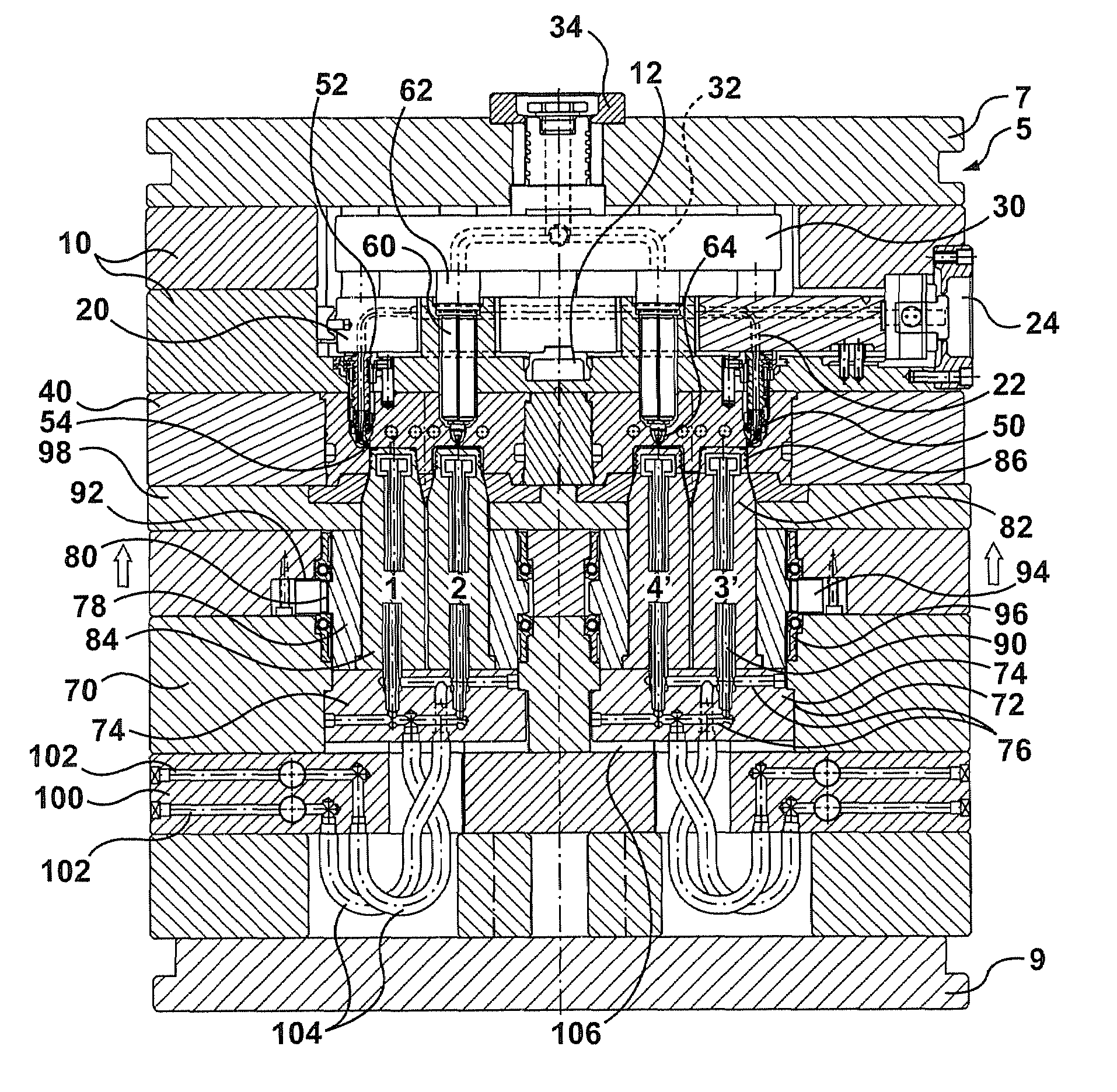

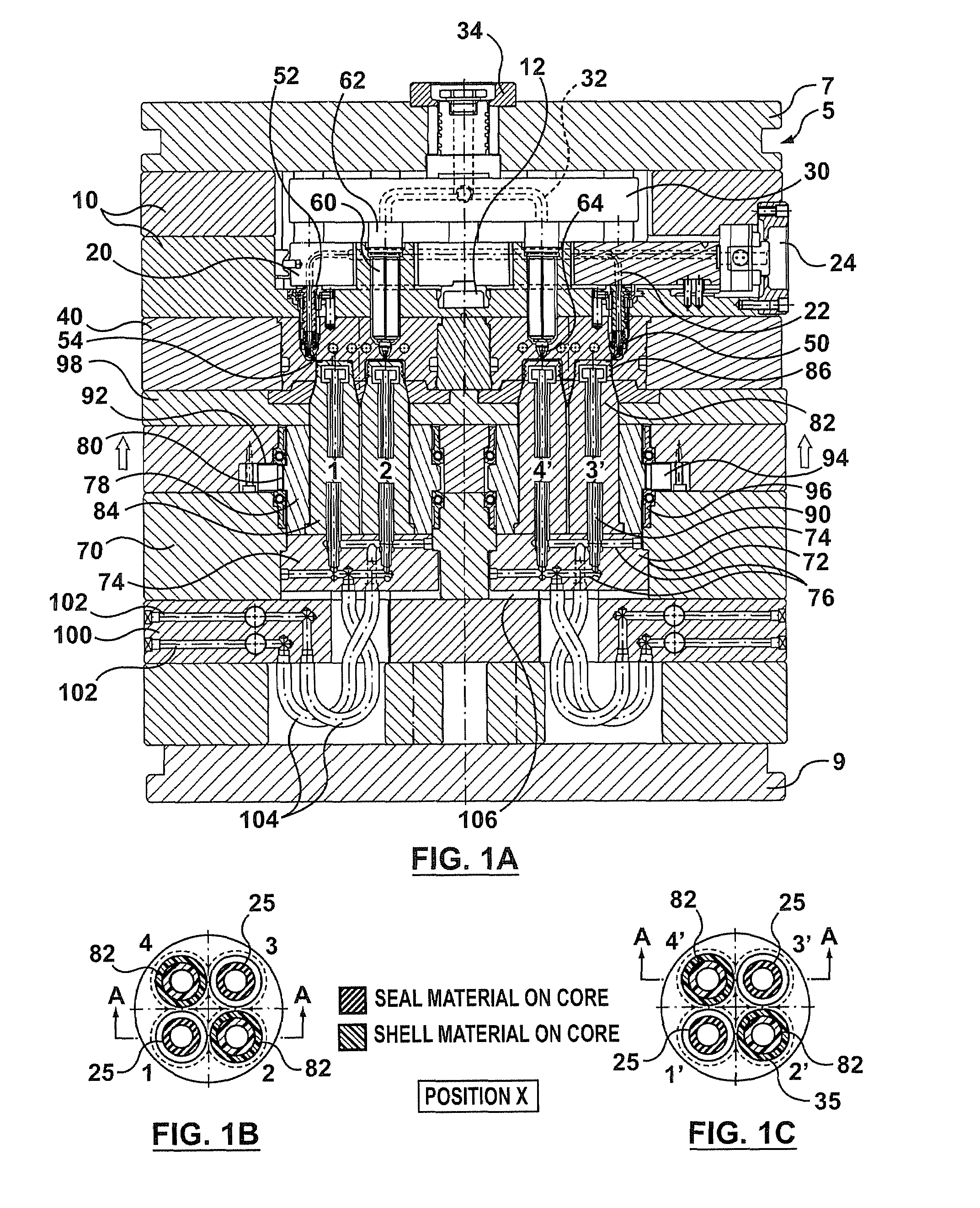

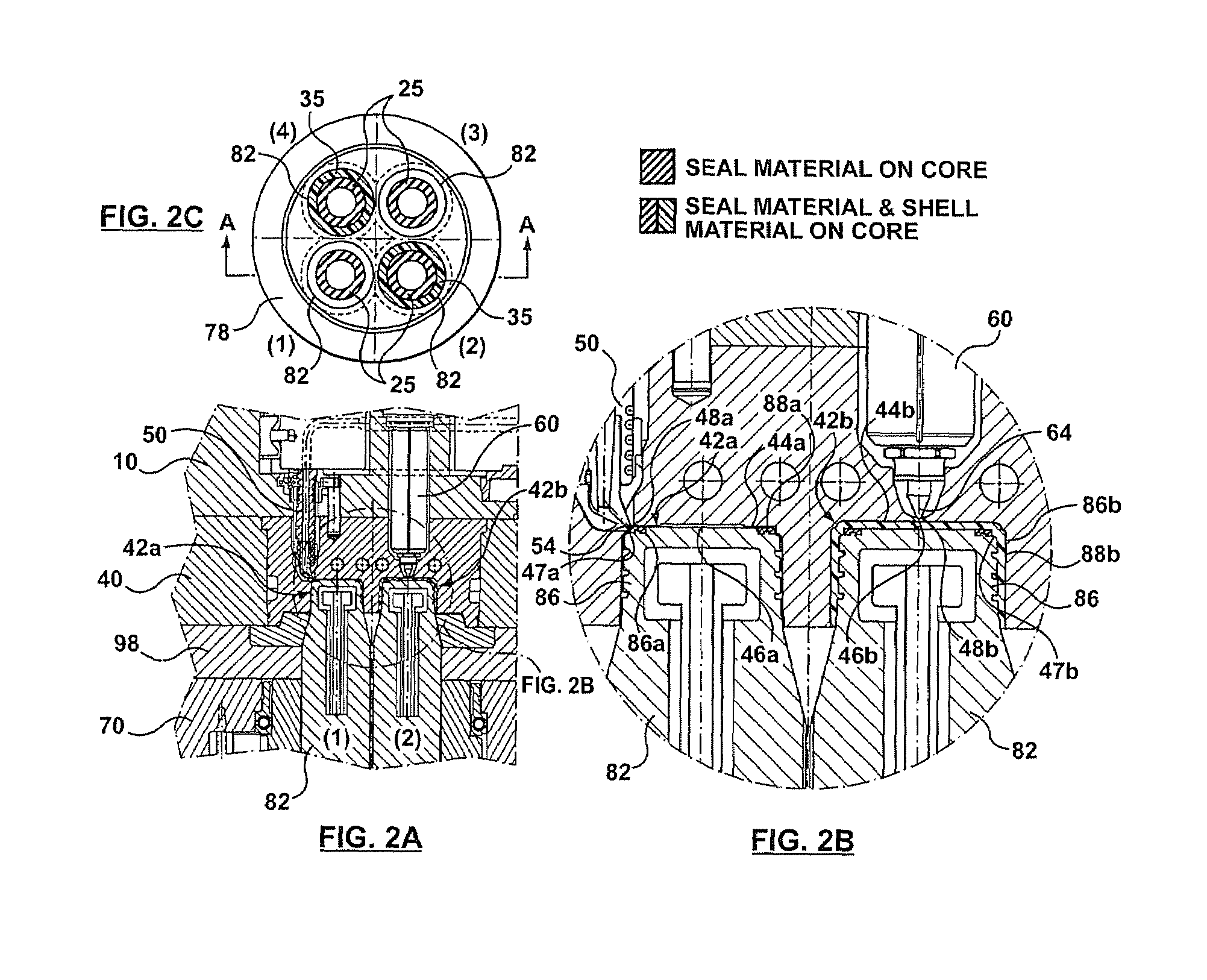

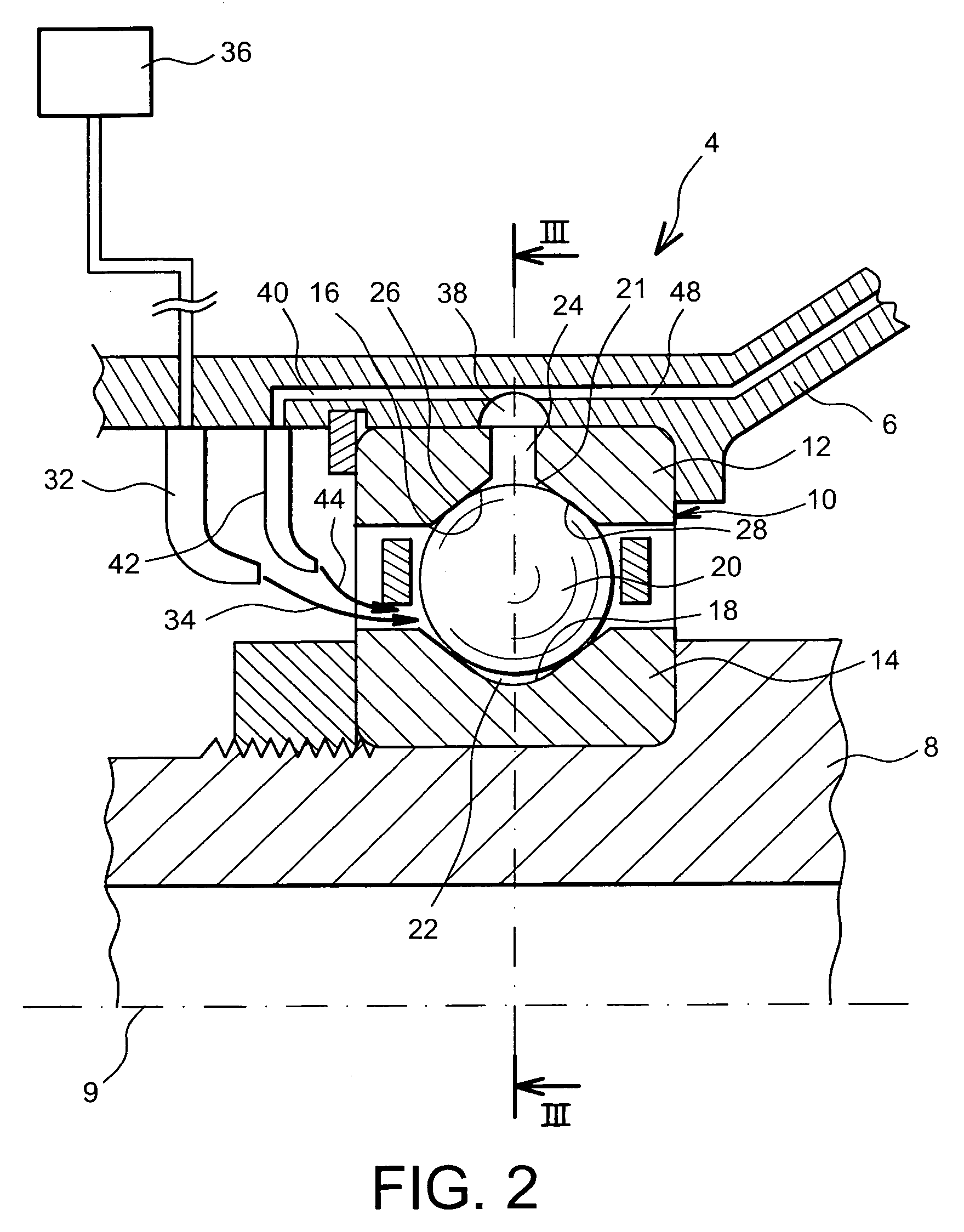

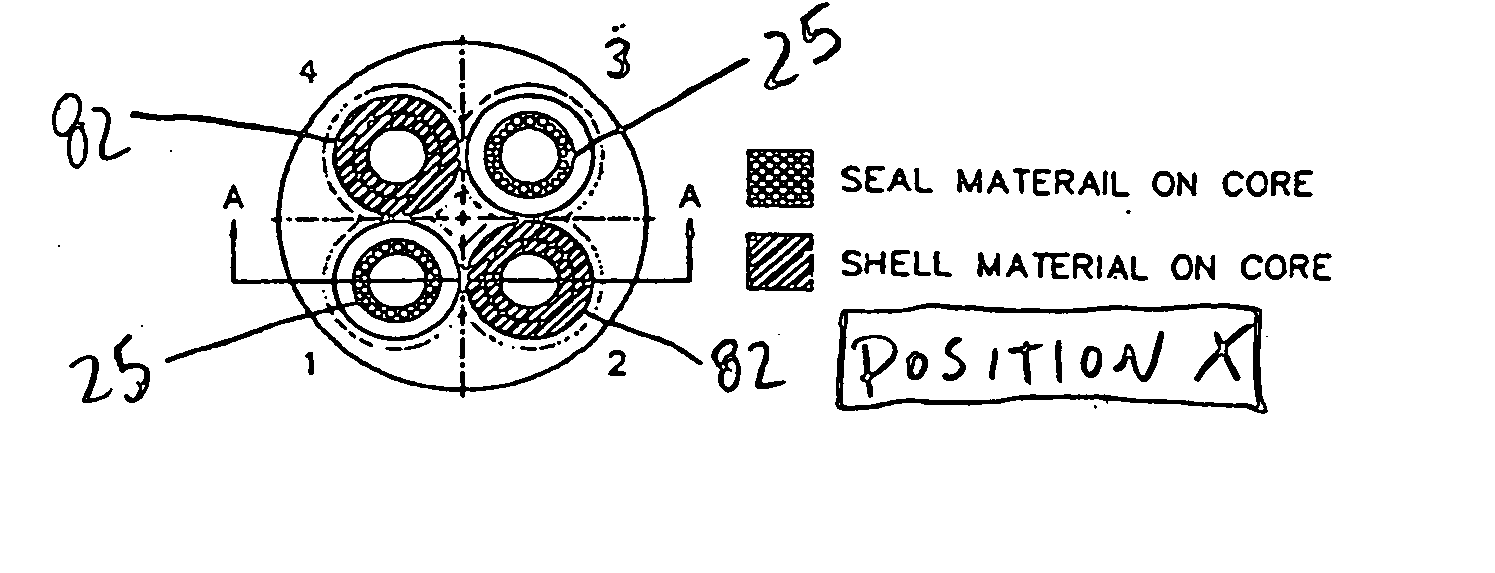

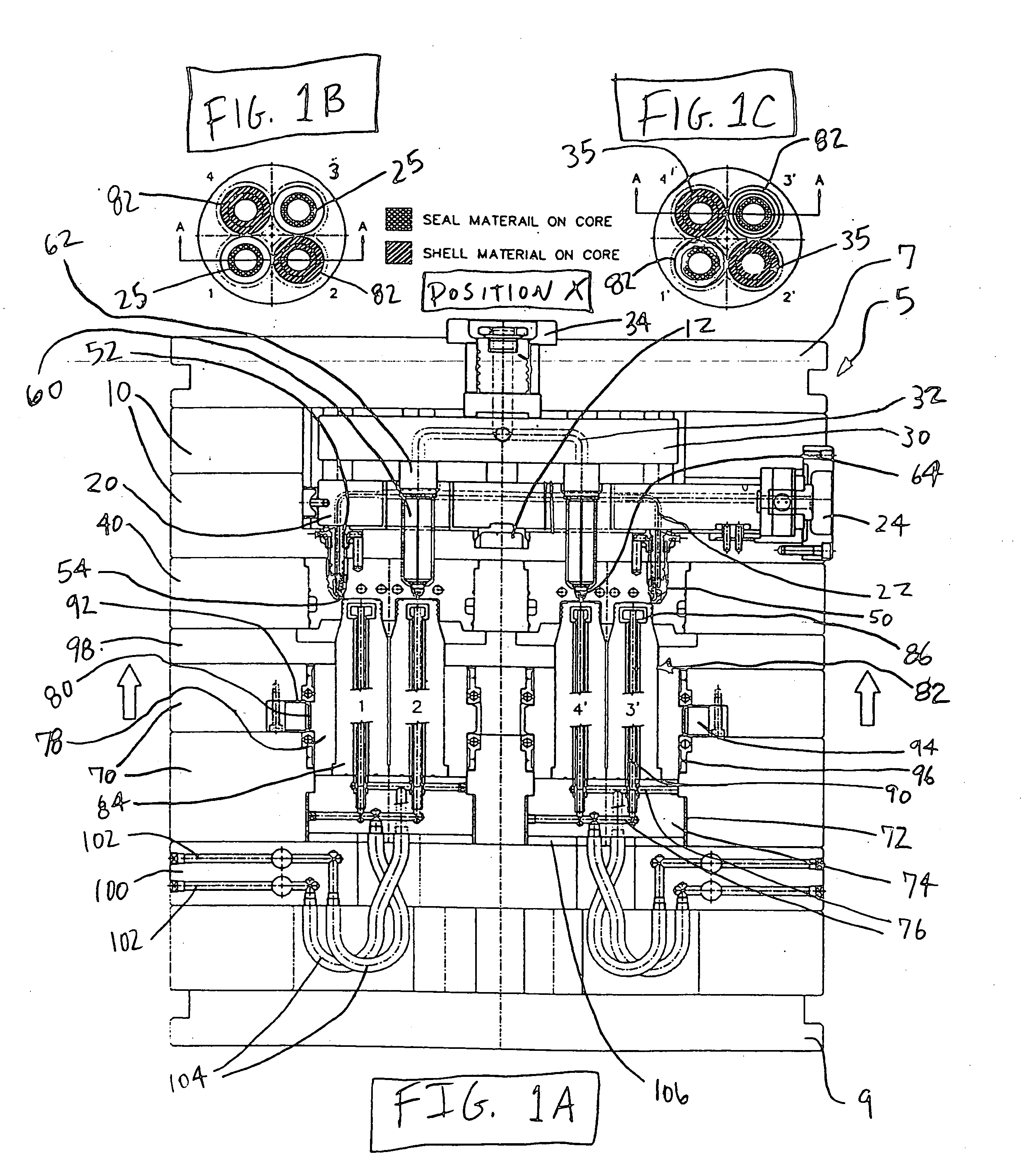

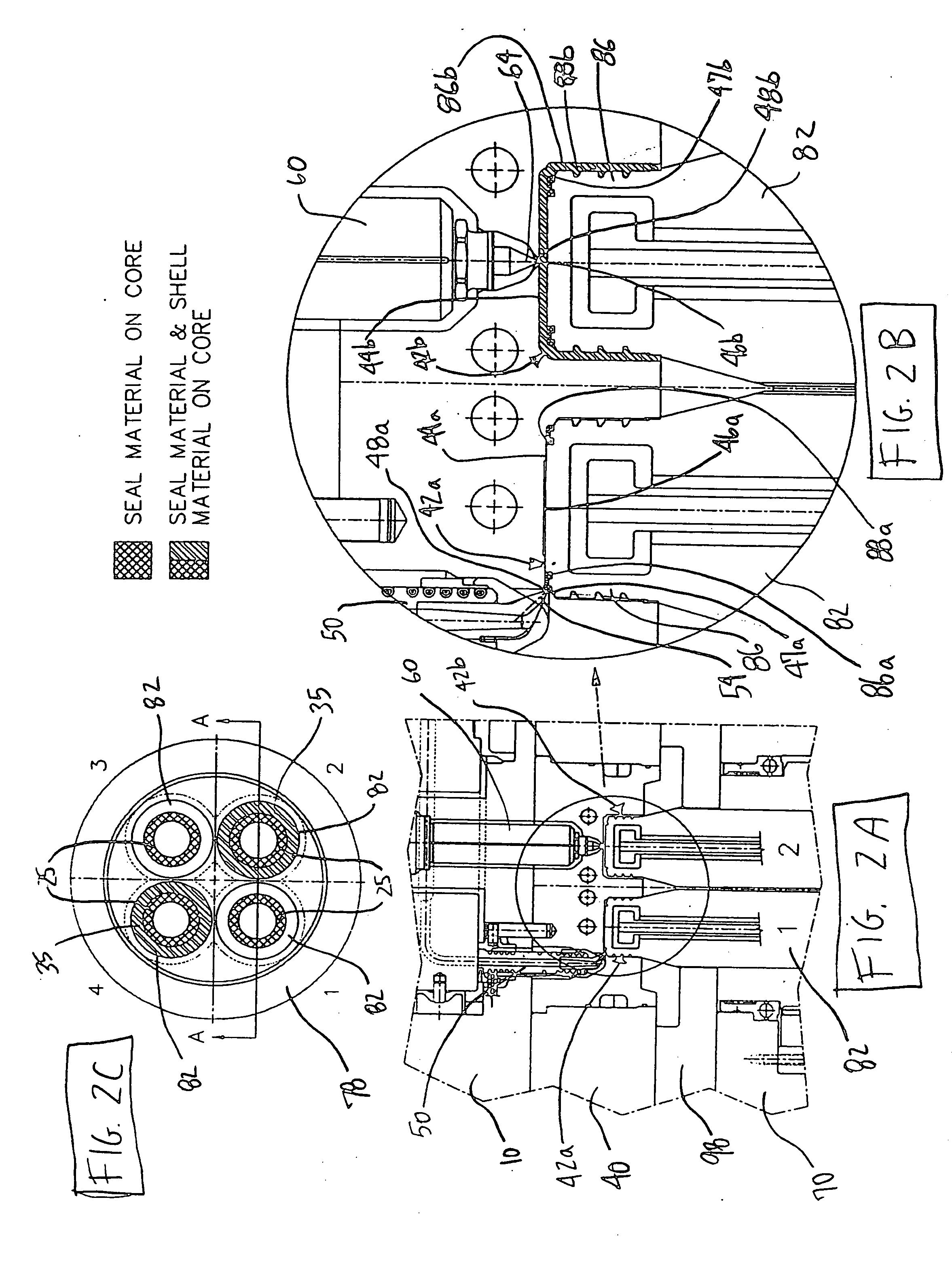

Two position double injection molding apparatus

An apparatus and method for injection molding of molded products including a first cavity chamber for forming a seal liner, with the first cavity chamber having an outer edge, and a second cavity chamber for forming a shell, with the second cavity chamber having a center and being adjacent to the first cavity chamber. The injection molding apparatus and method also includes a first nozzle for a seal liner material positioned near the outer edge of, and in communication with, the first cavity chamber, and a second nozzle for a shell material positioned near the center of, and in communication with, the second cavity chamber. The injection molding apparatus and method further includes a mold core capable of being positioned in and moved between the first and second cavity chambers.

Owner:MOLD MASTERS 2007

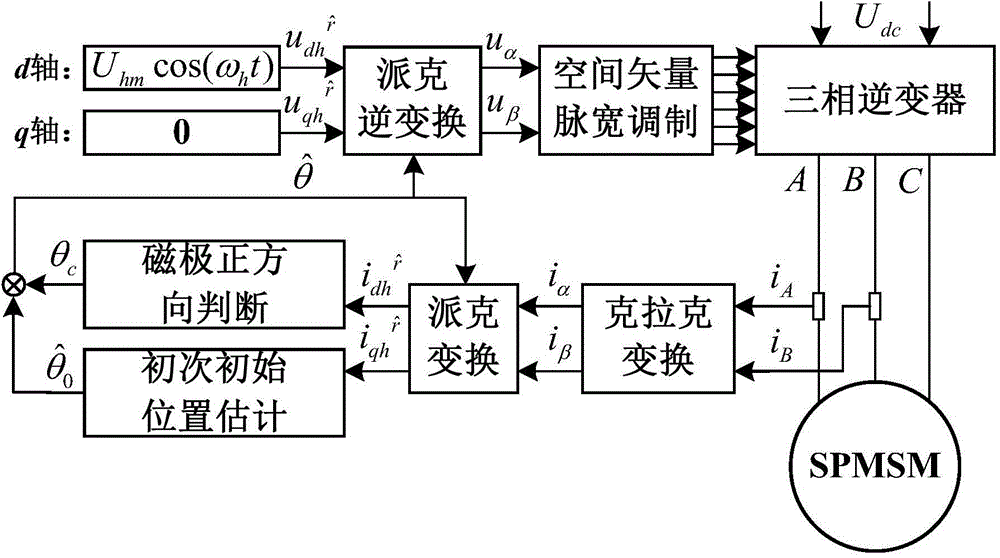

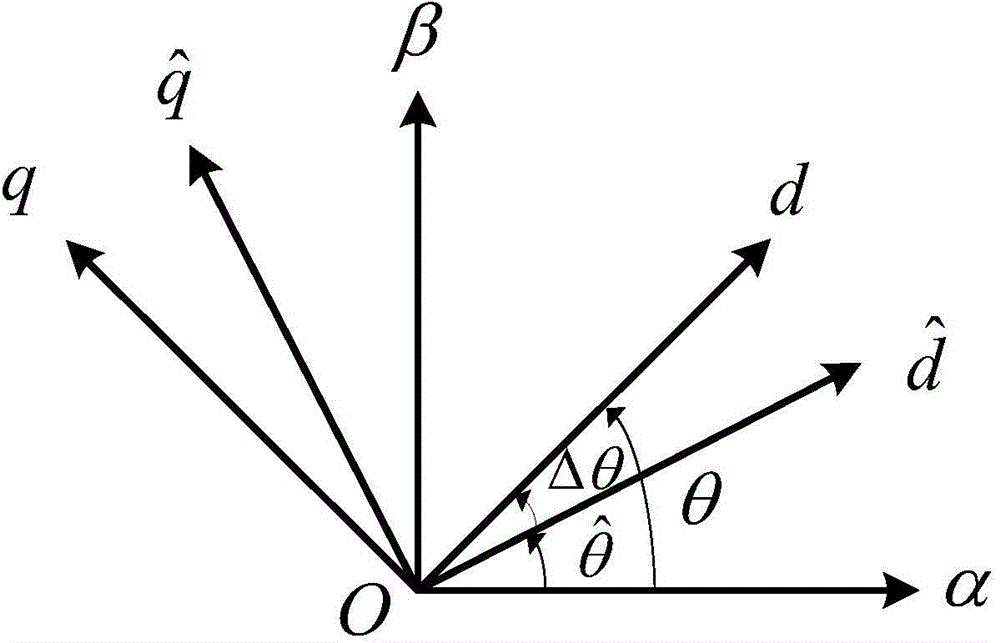

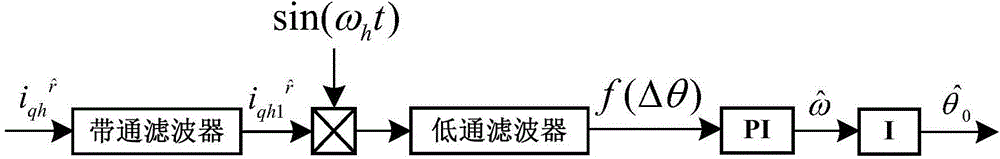

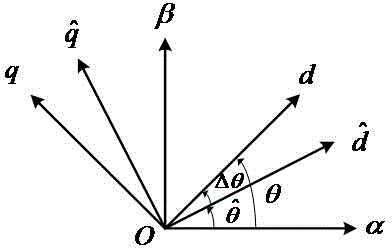

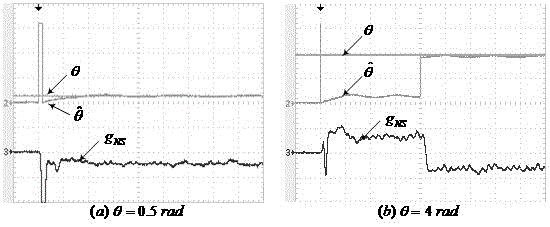

Surface-mount permanent magnet synchronous motor rotor initial position detection method

ActiveCN103986395AReduce detection accuracy requirementsWon't cause frettingElectronic commutation motor controlVector control systemsPermanent magnet synchronous motorPhysics

The invention discloses a surface-mount permanent magnet synchronous motor rotor initial position detection method. The method includes the steps that a high-frequency voltage injection method is adopted for achieving d-axis positive direction judging by extracting d-axis positive direction information included in double injection signal frequency subharmonic in d-axis current responses on the basis of achieving the estimation of an initial position. According to the method, the action of injecting positive and negative pulses additionally and then comparing values of amplitude of the current response is not needed, estimation time is shortened, the estimation process is simplified, the requirement for the precision of current detection is lowered, in addition, tender moving of a rotor can be avoided, and application occasions are broadened.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

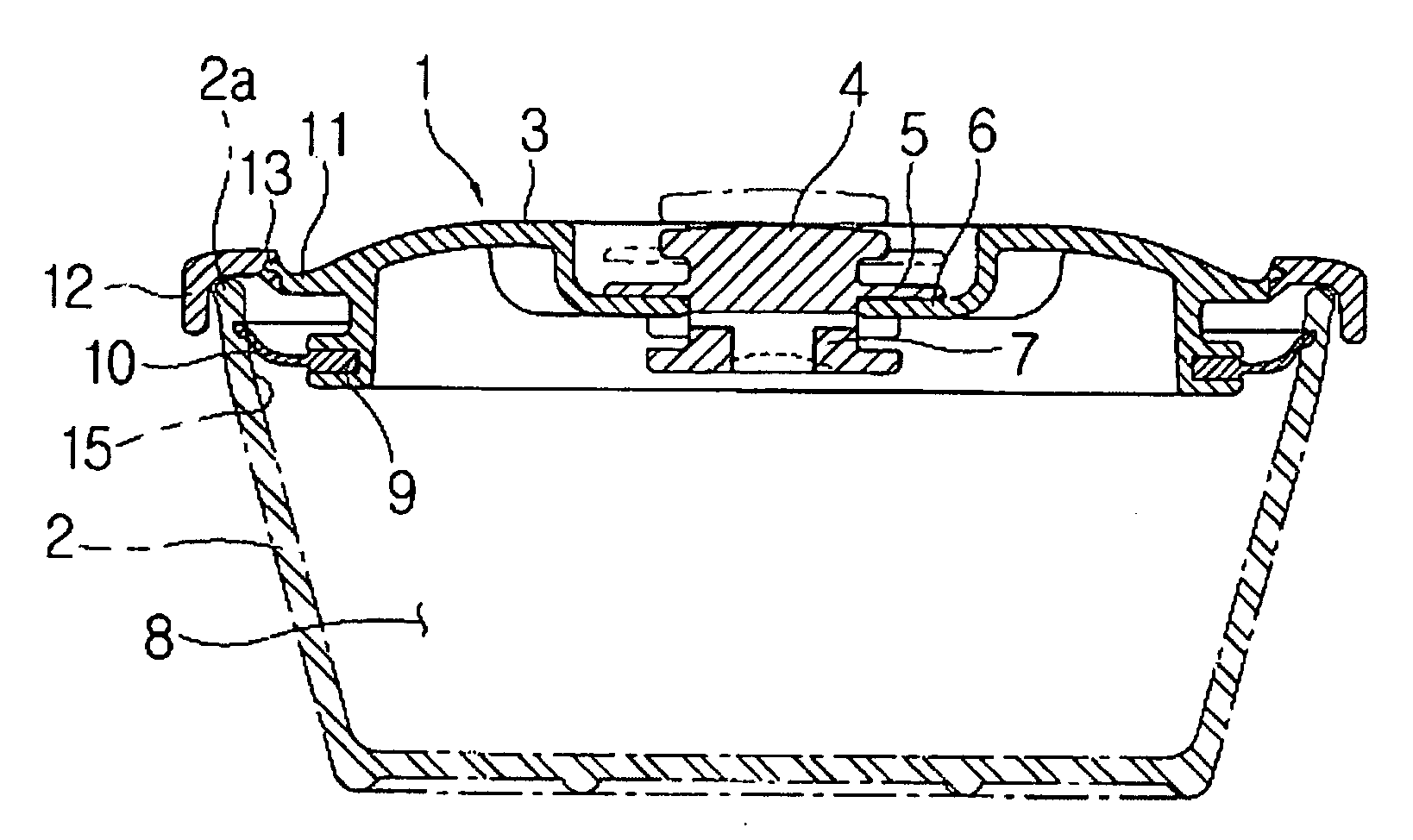

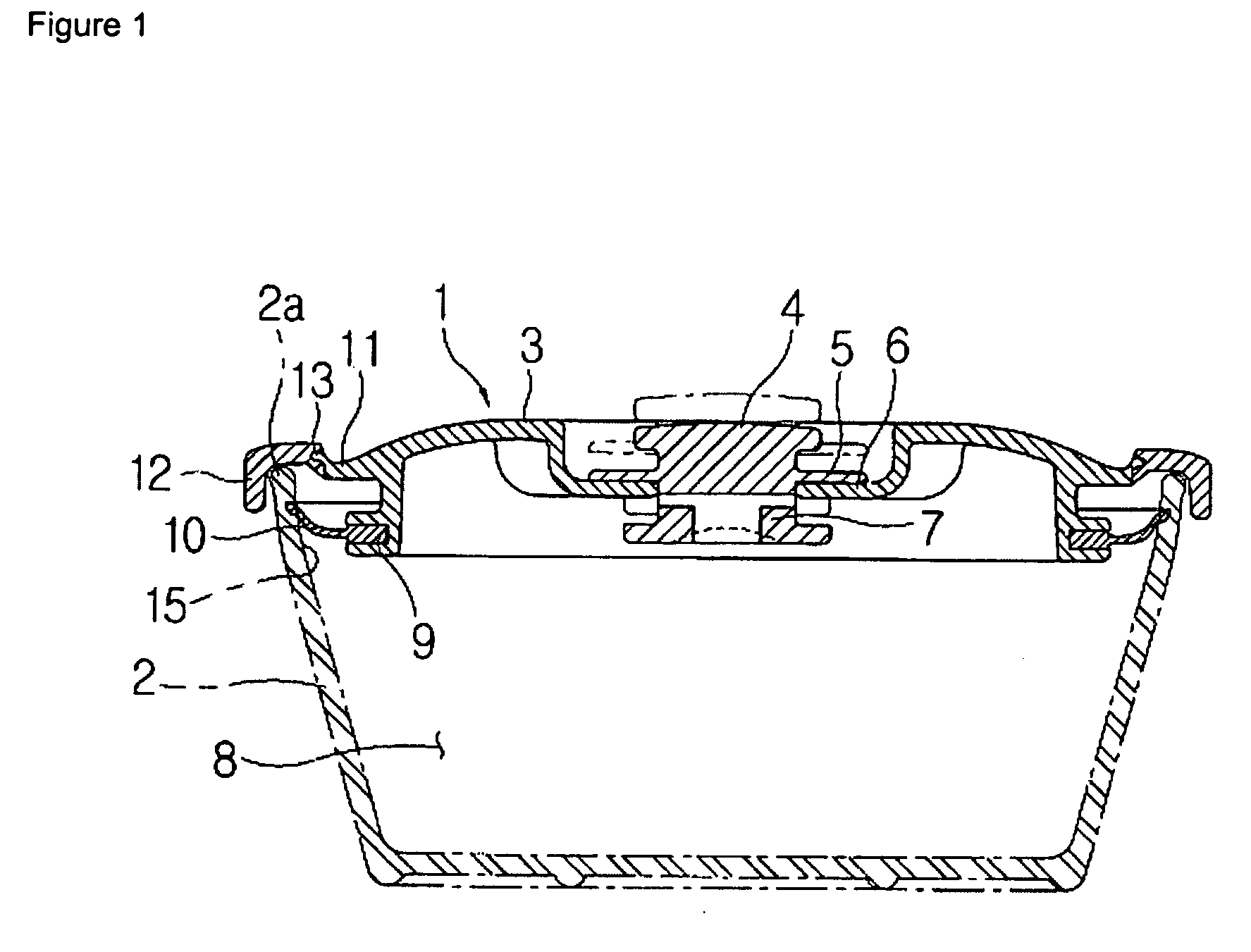

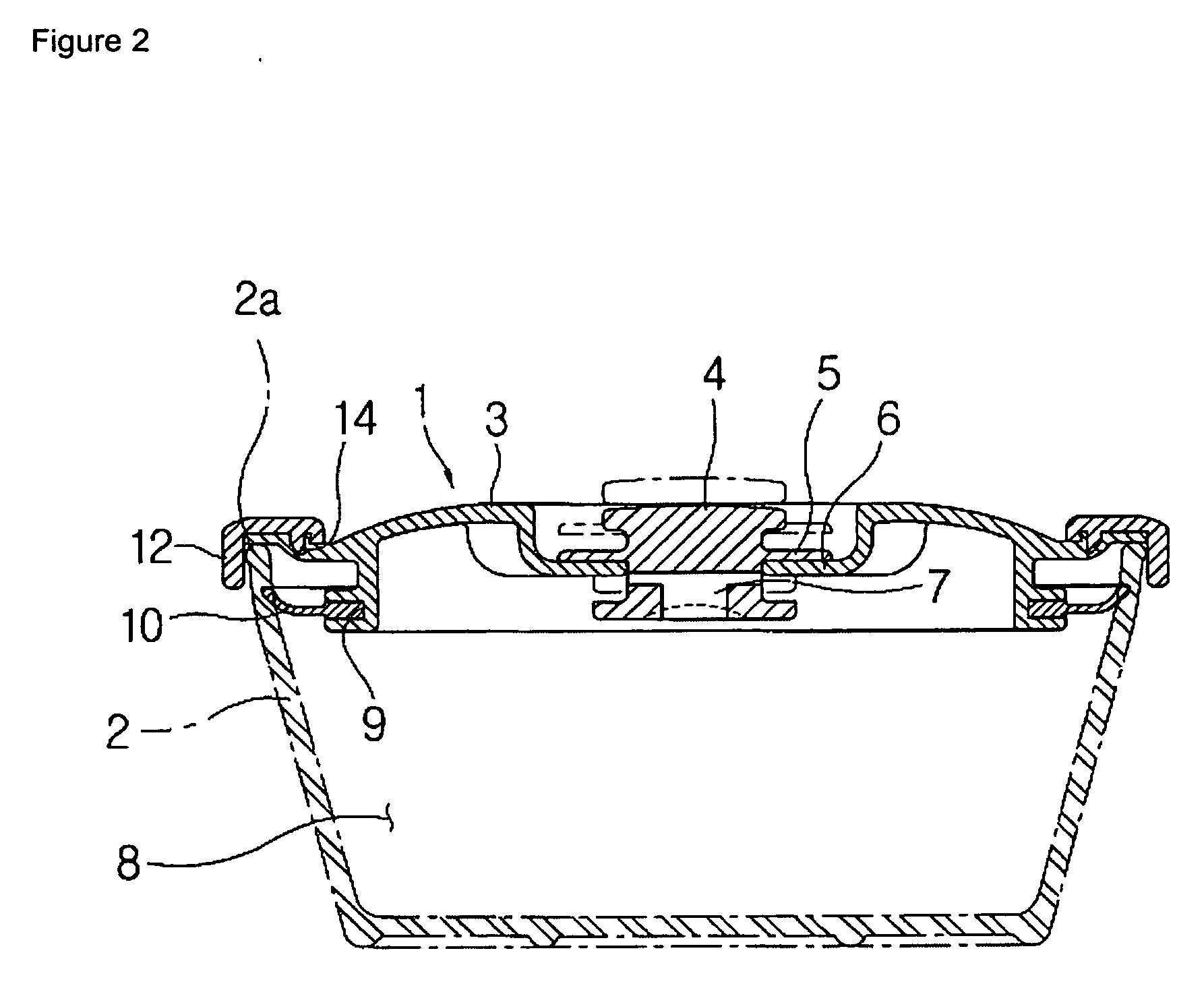

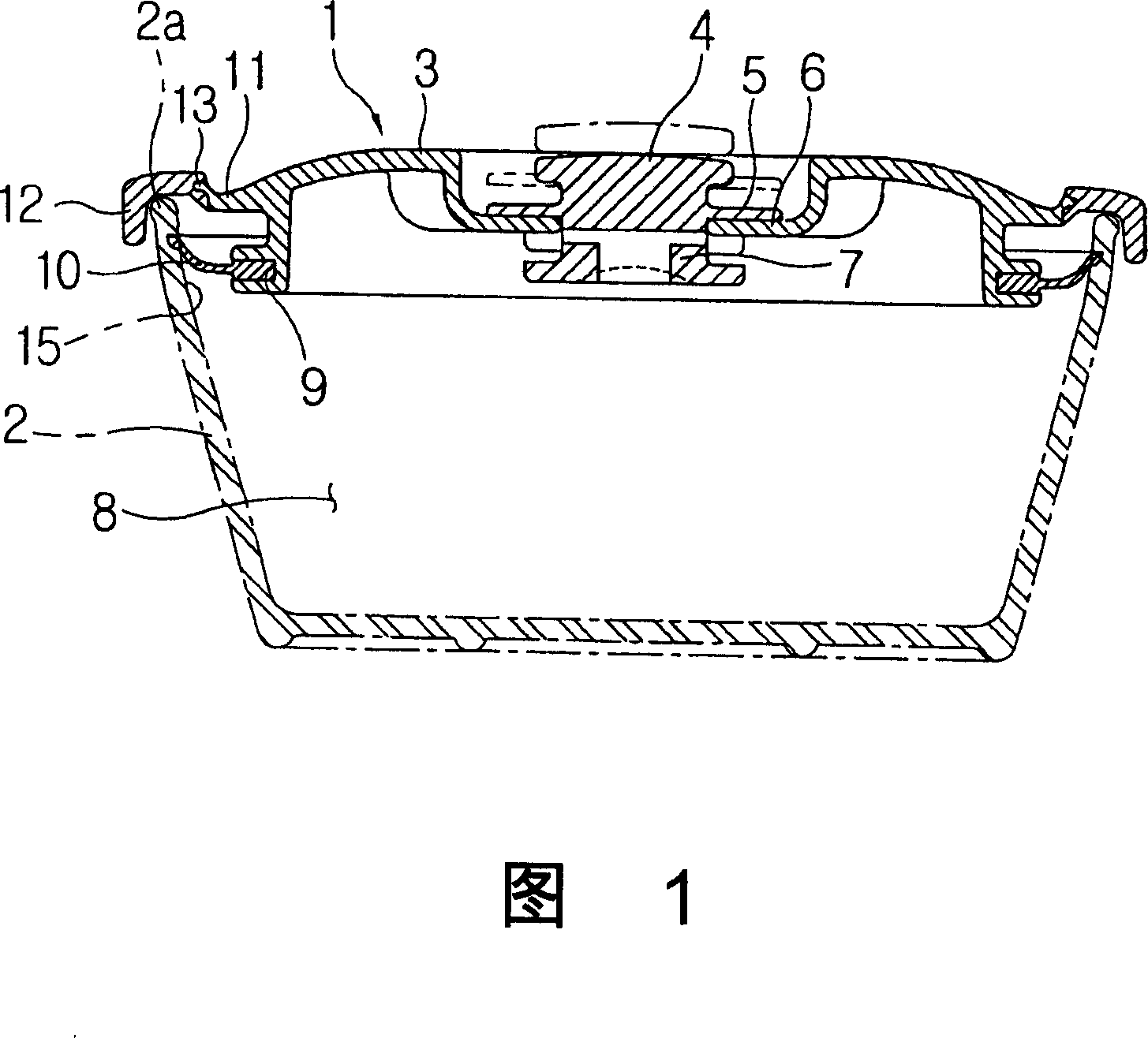

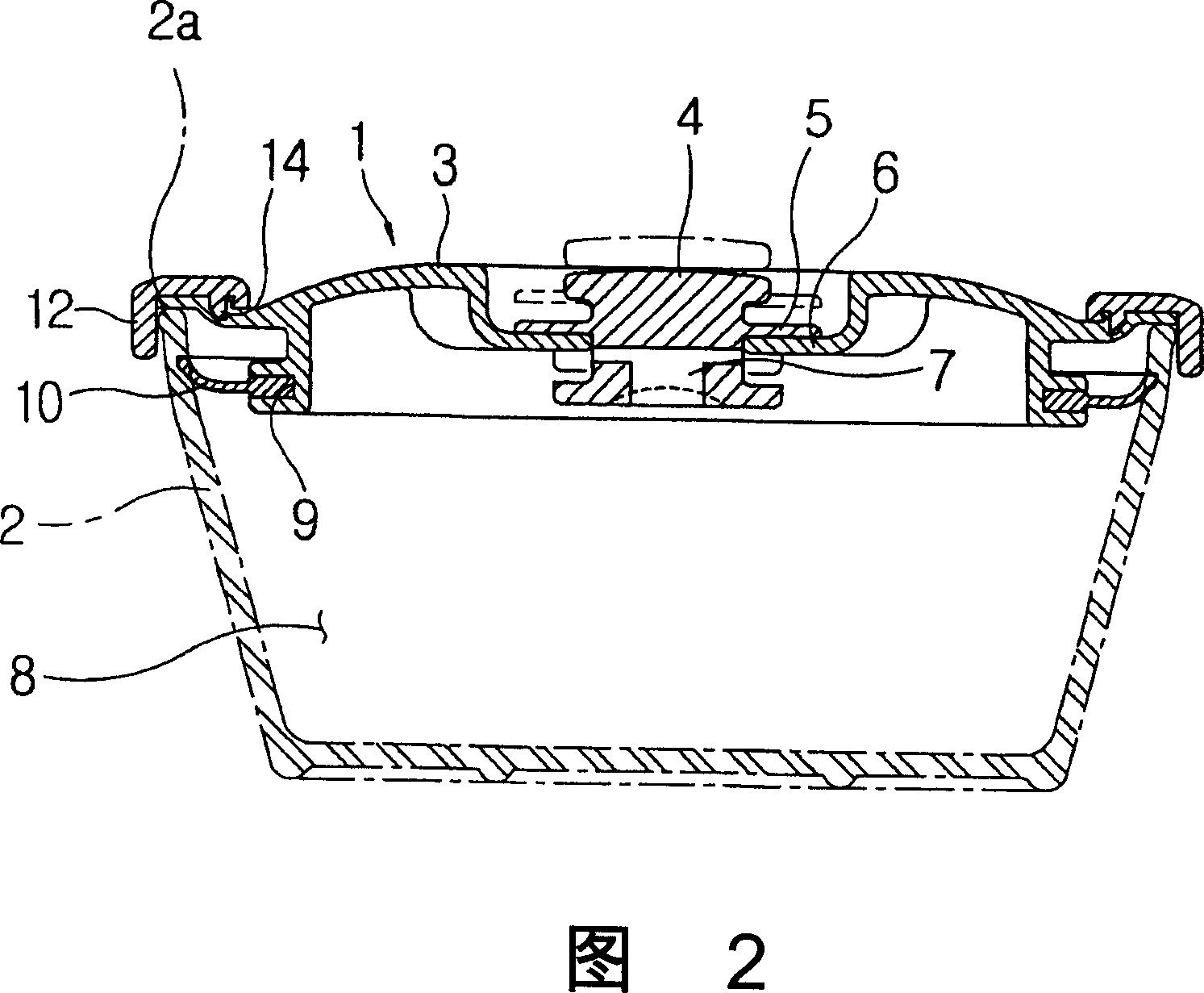

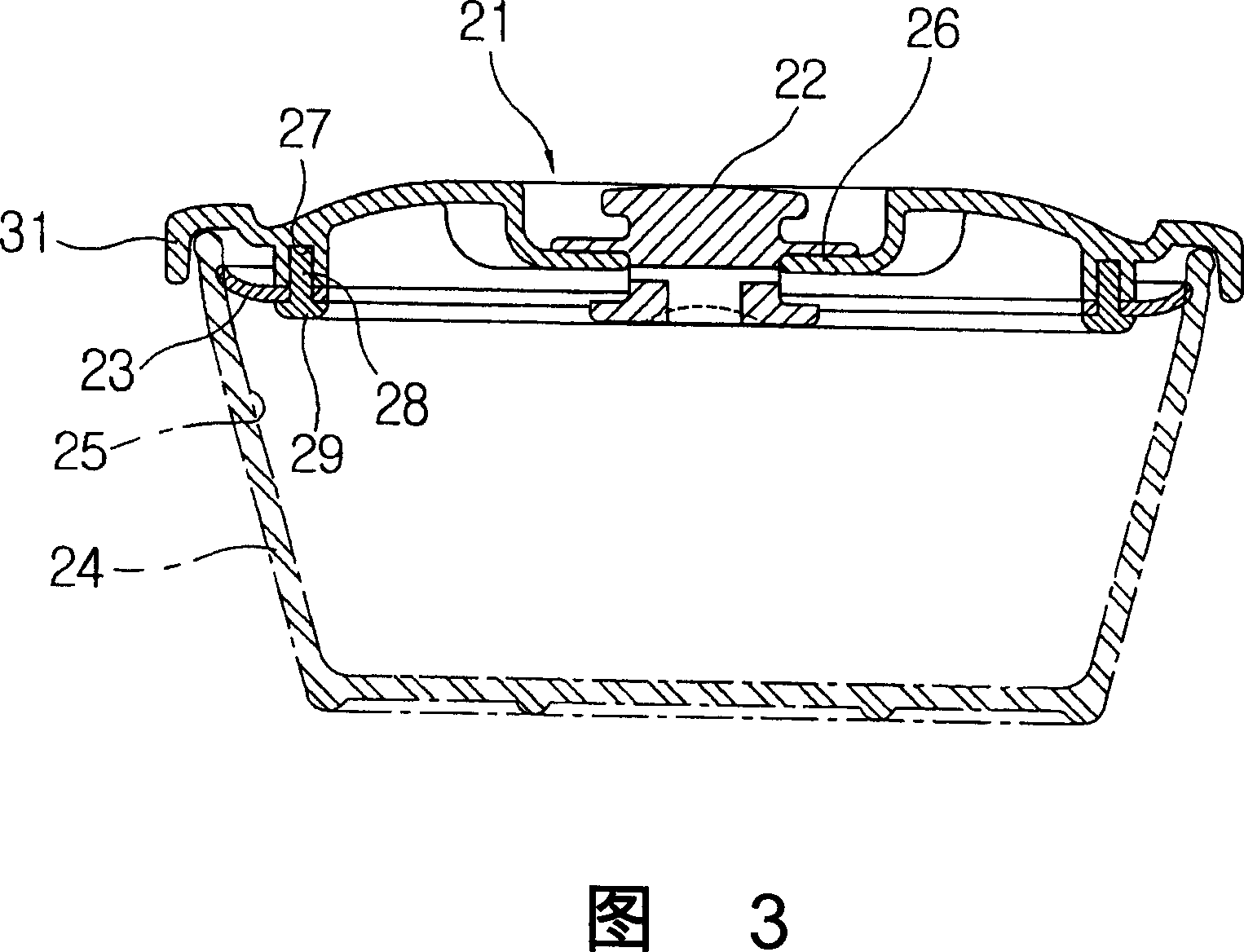

Sealed container lid of vacuum valve operation type

InactiveUS20070095849A1Strong sealing forceSimplifying engagement structureBagsRemovable lids/coversEngineeringInjection moulding

A sealed container lid of a vacuum valve operation type is provided, in which an engagement structure of a silicon packing is simple, and a relatively strong sealing force is obtained. A process for engaging or disengaging a lid to a container body may be performed based one-touch method. The sealed contained lid of a vacuum valve operation type comprises a body which is injection-molded and has a circular groove formed in a horizontally and outwardly opened shape for an engagement of the silicon packing, and a downwardly bent peripheral part which is formed at an outer peripheral part of the body based on a double injection method while surrounding the same.

Owner:HANA COBI PLASTIC

Process for preparing nano silver colloidal water solution

The present invention relates to the preparation process of nano silver colloidal water solution. By means of double injection controlling technology and under the stirring with the stirrer, argentamine and reductant aqua are injected simultaneously into the reaction system containing protecting agent aqua to generate nano silver particle, and through ultrafiltering to desalt, nano silver colloidal water solution with average size smaller than 50 nm is obtained. Thus obtained nano silver colloidal water solution is stable, good in dispersion, small and homogeneous in size, and the preparation process is automatic, short in production period, low in cost and suitable for industrial production.

Owner:CHINA LUCKY FILM CORP

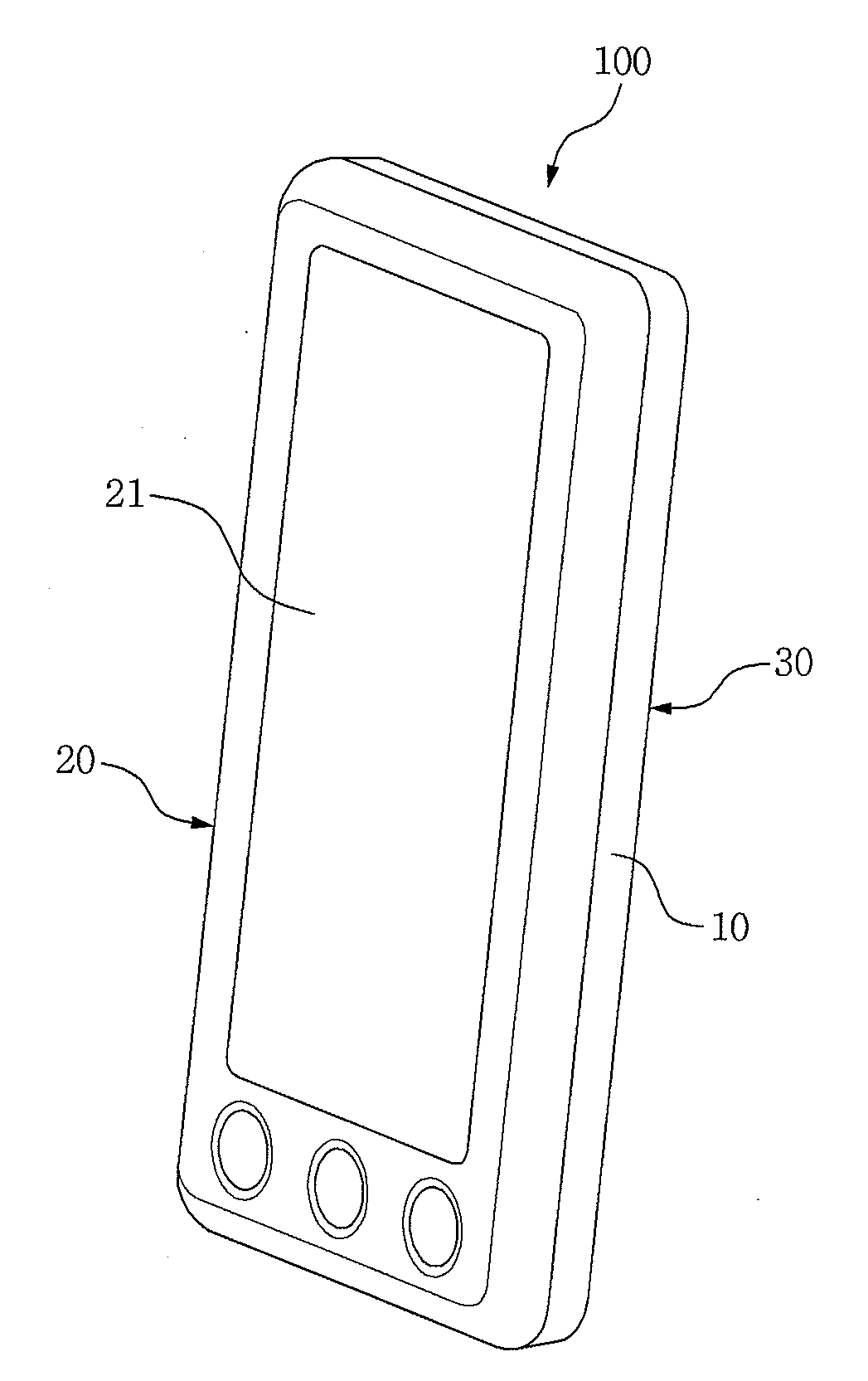

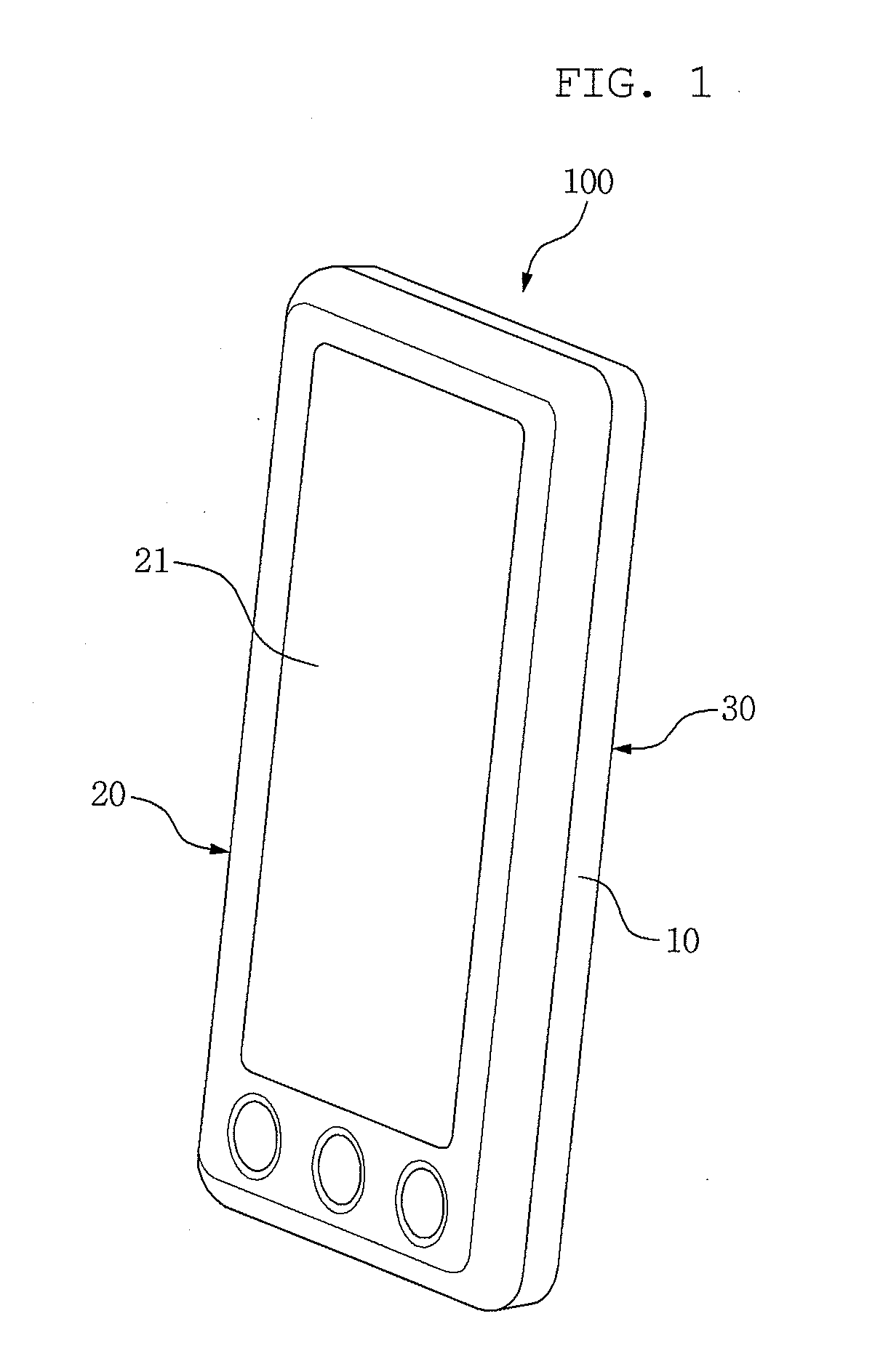

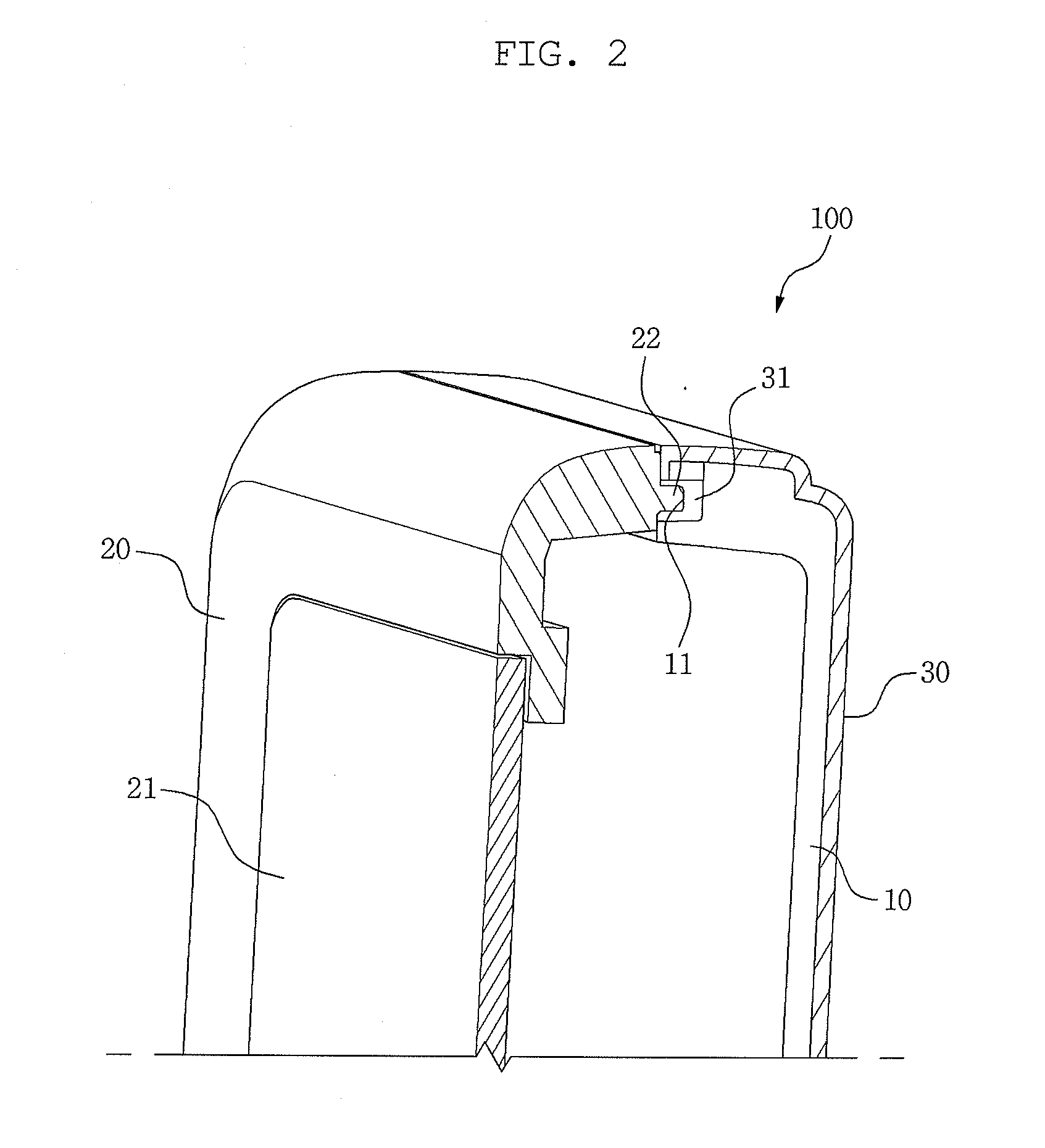

Portable electronic products integrated with silicone

InactiveUS20110136553A1Soft gripGood touchDigital data processing detailsTransmissionSilica gelDouble injection

Disclosed is a portable electronic products integrated with a silicone in which a molding silicone is integrated with an outer side surface of a body housing of the portable electronic products through a double injection or an insert injection molding methods, so that it can feel the soft grip when an user is touched on the outer surface of the portable electronic products. Also, a water proof injection silicone packing part is integrally formed at a combining portion between a cover housing and a body housing, so that it can closely adhere to them, whereby it can be perfectly cut off the moisture from outside.

Owner:WOOJEON & HANDAN CO LTD

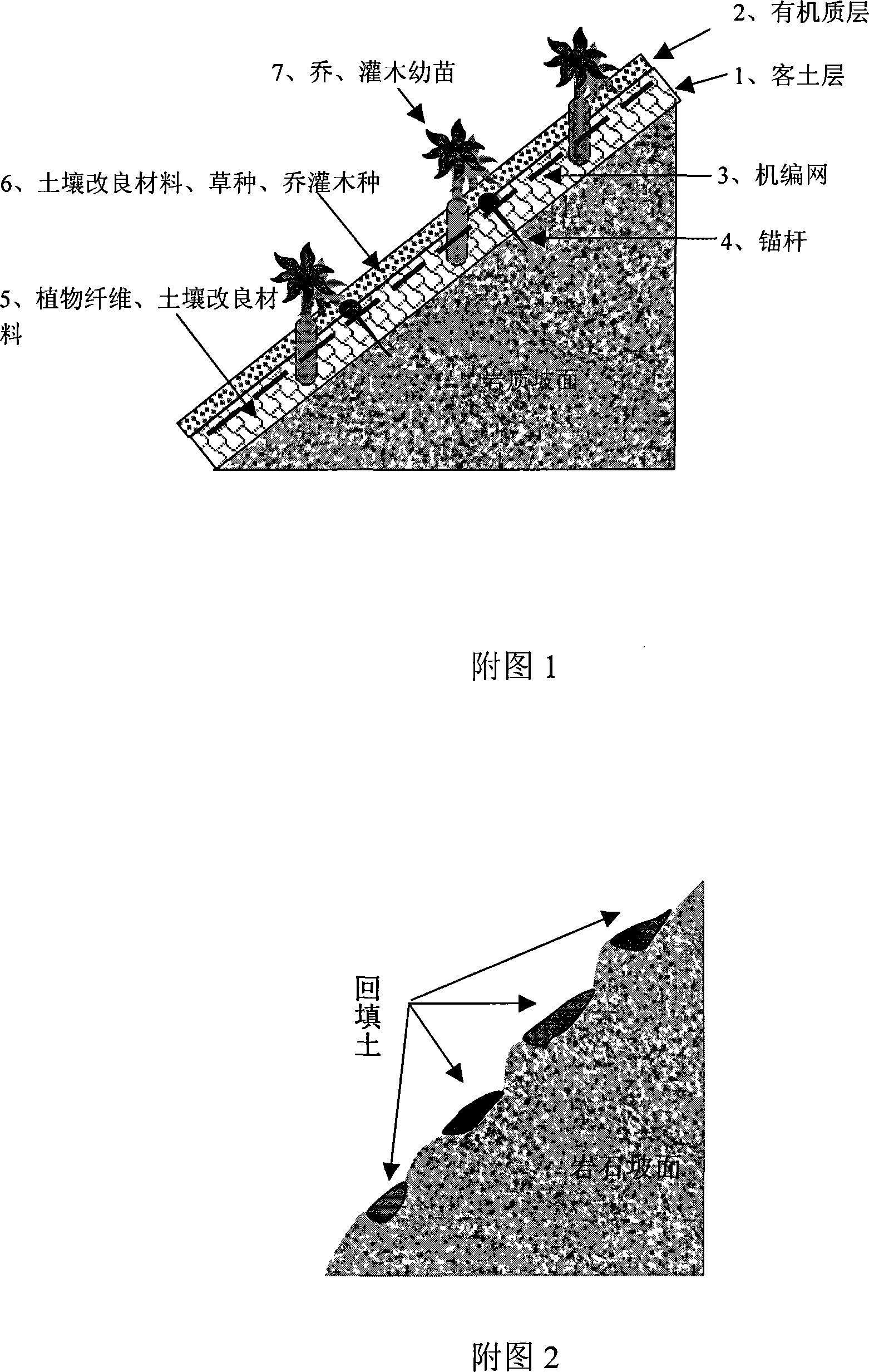

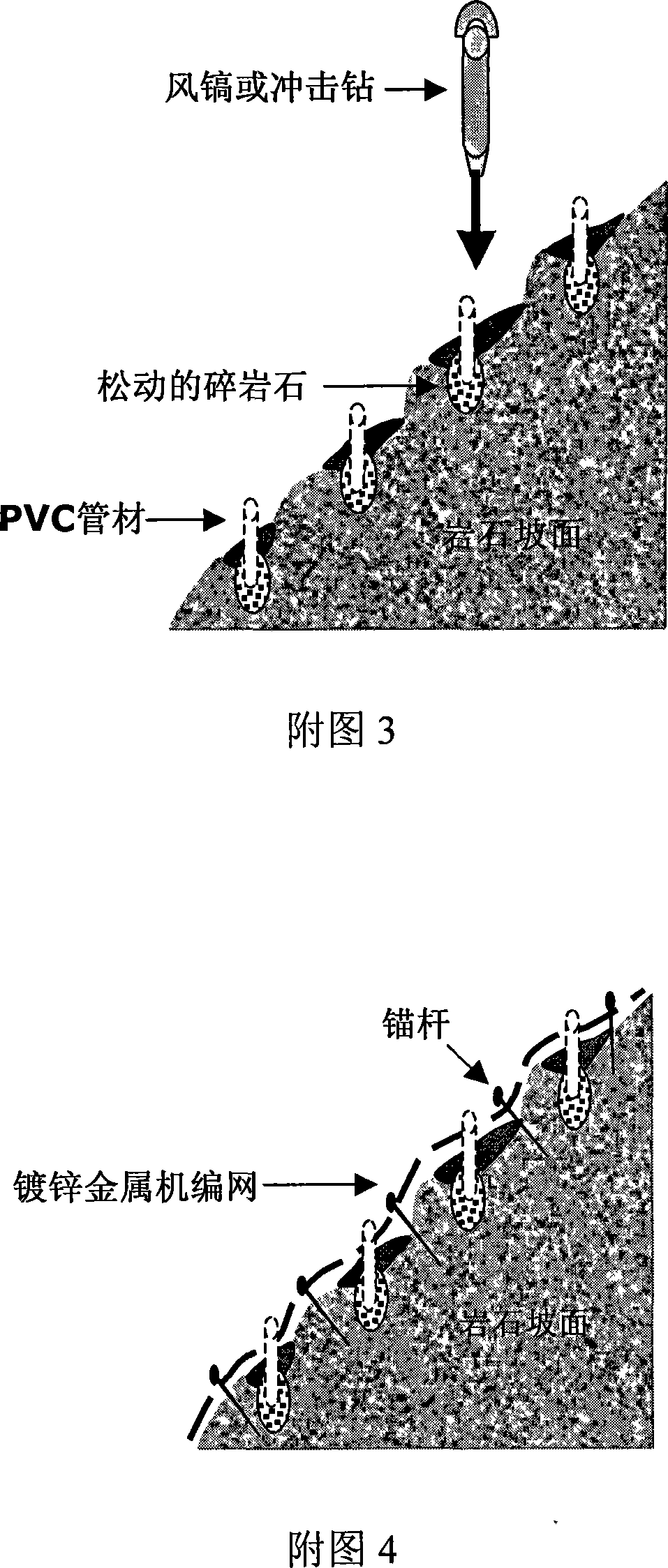

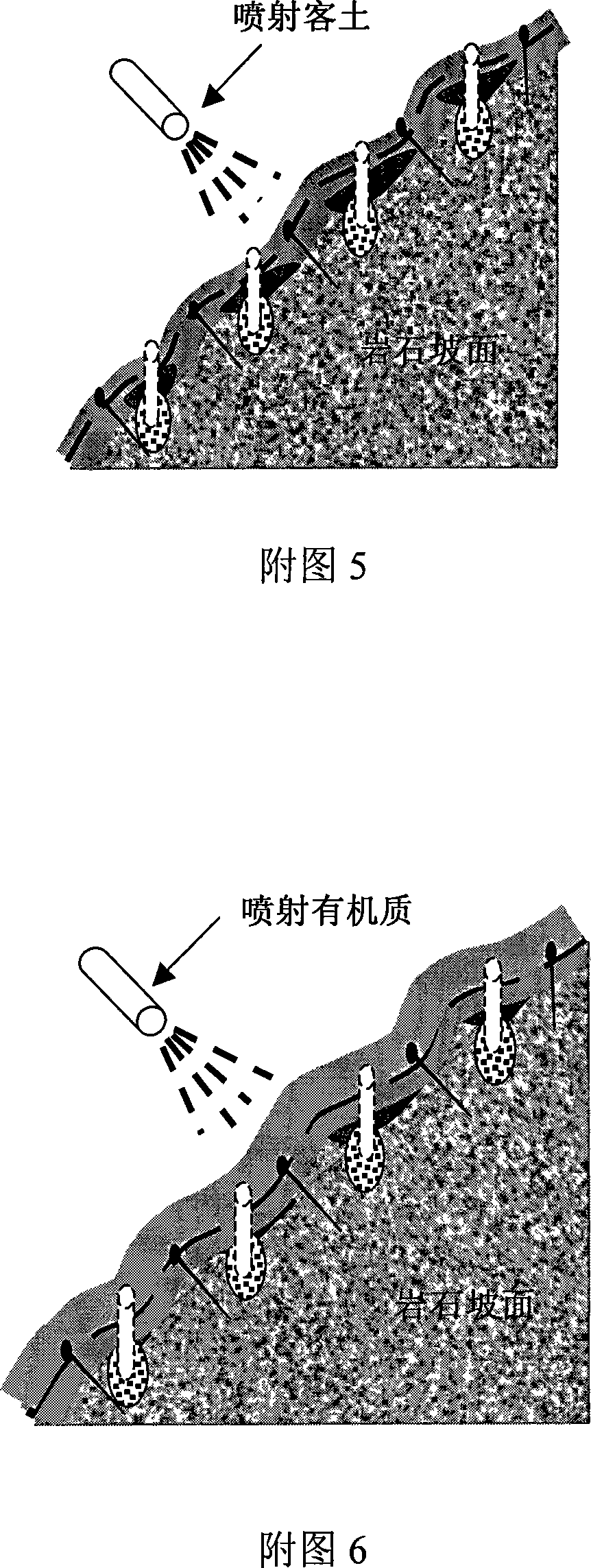

Technology for recovering vegetation on slope of rock and application thereof

The invention discloses a rock slope vegetation restoration method, which comprises the double layer injection of carrying soil and organic matter and the combination of directly sowing seeds and arbor, shrub transplanting seedlings. The double injection bottom layer is a carrying soil layer, and the surface is an organic matter layer. The joint part of the carrying soil layer and the organic matter layer is sandwiched with a galvanized machine-made metal net fixed on a slope through a bolt. The plant fibbers and the soil improvement materials are blended inside the carrying soil layer. The soil improvement materials, the grass species as well as the arbor and shrub seeds are blended inside the organic matter layer. The arbor and shrub seedlings are transplanted inside the artificial soil layer formed by the carrying soil and the organic matter. The invention provides a new method for the ecological construction and environmental protection in China, which has great social, economic and ecological benefits.

Owner:BEIJING NORMAL UNIVERSITY

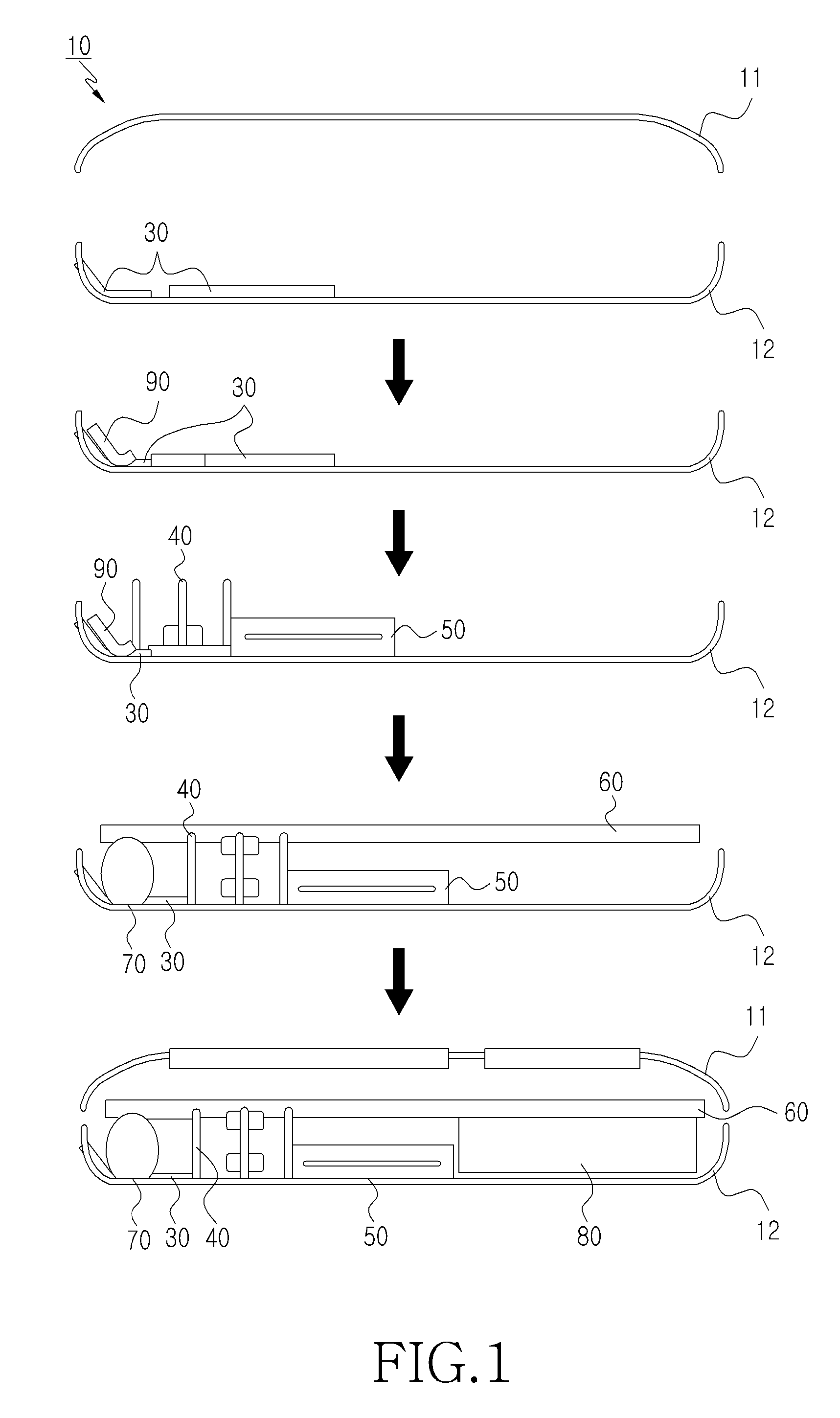

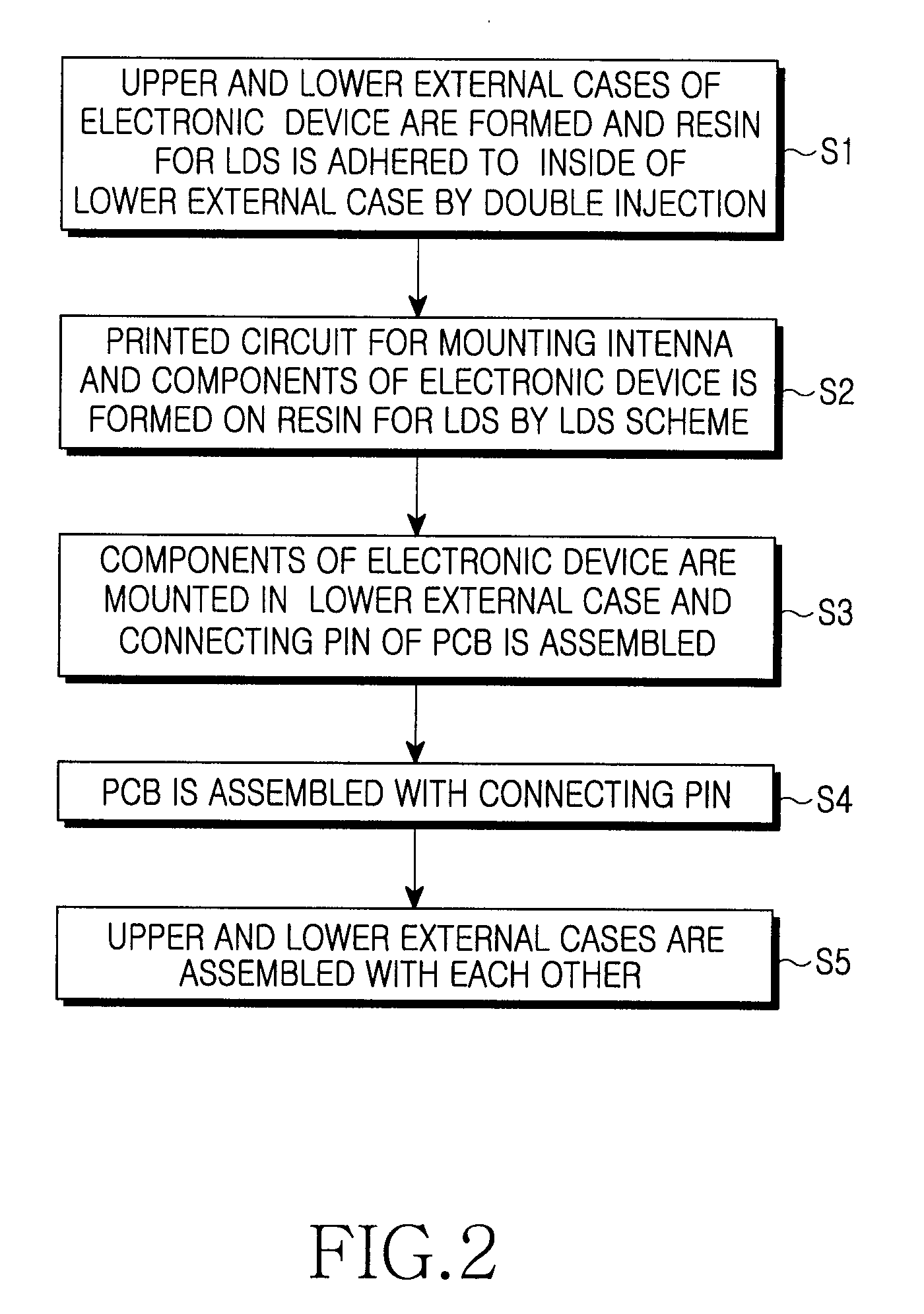

Electronic device manufacturing method using lds and electronic device manufactured by the method

InactiveUS20090059543A1Improve resin strengthHigh strength3D rigid printed circuitsPrinted circuit aspectsEngineeringDouble injection

Disclosed is a method for manufacturing an electronic device using LDS and an electronic manufacturing by the method, in which resin for LDS is adhered to an inner surface of an external case by double injection or insert injection so as to implement a circuit. The electronic device using LDS includes upper and lower external cases, wherein resin for LDS is adhered to an inner surface of the lower external case by double injection or insert injection. Components of the electronic device are mounted on the resin, and the upper and lower external case are assembled with each other.

Owner:SAMSUNG ELECTRONICS CO LTD

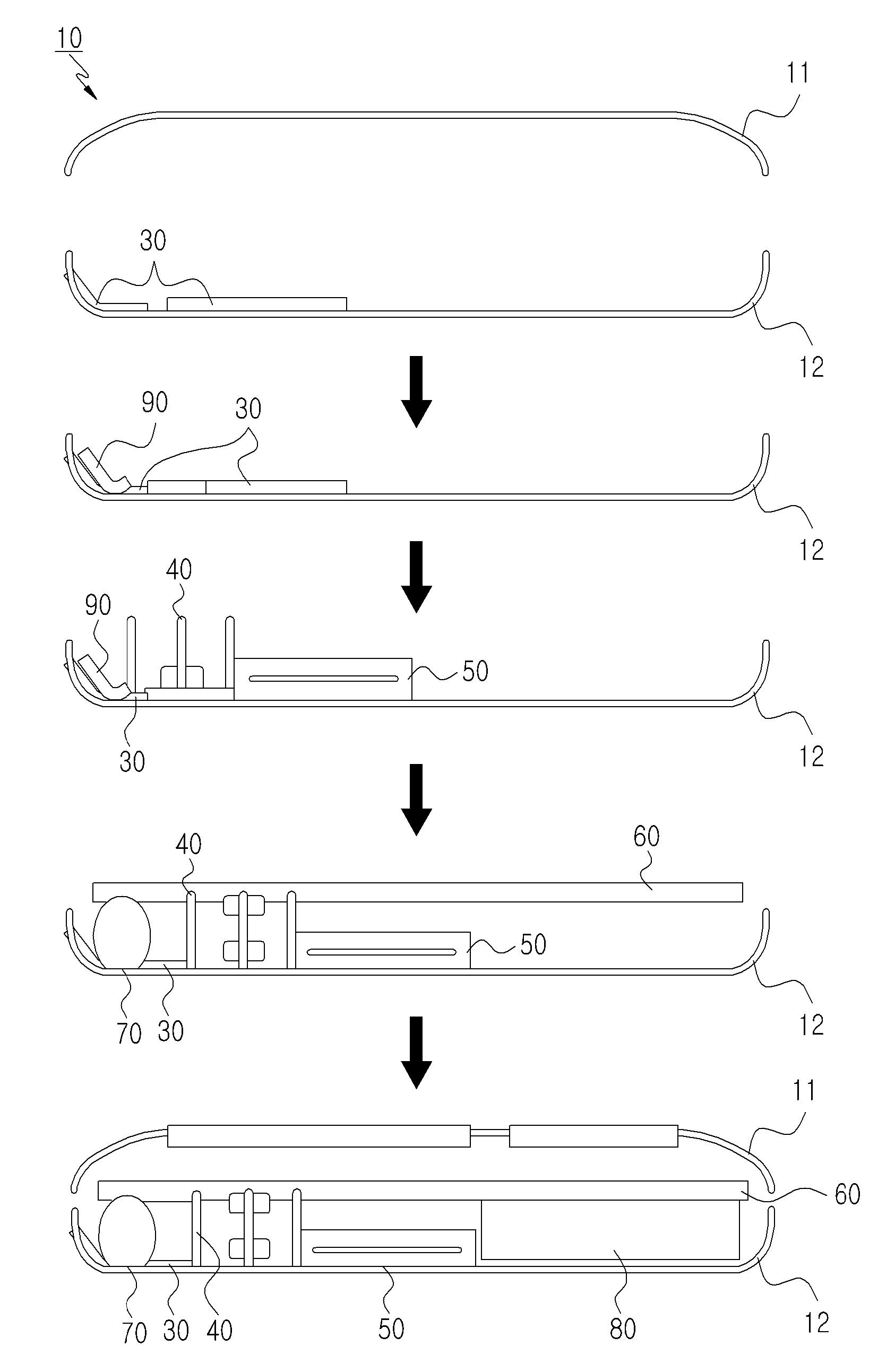

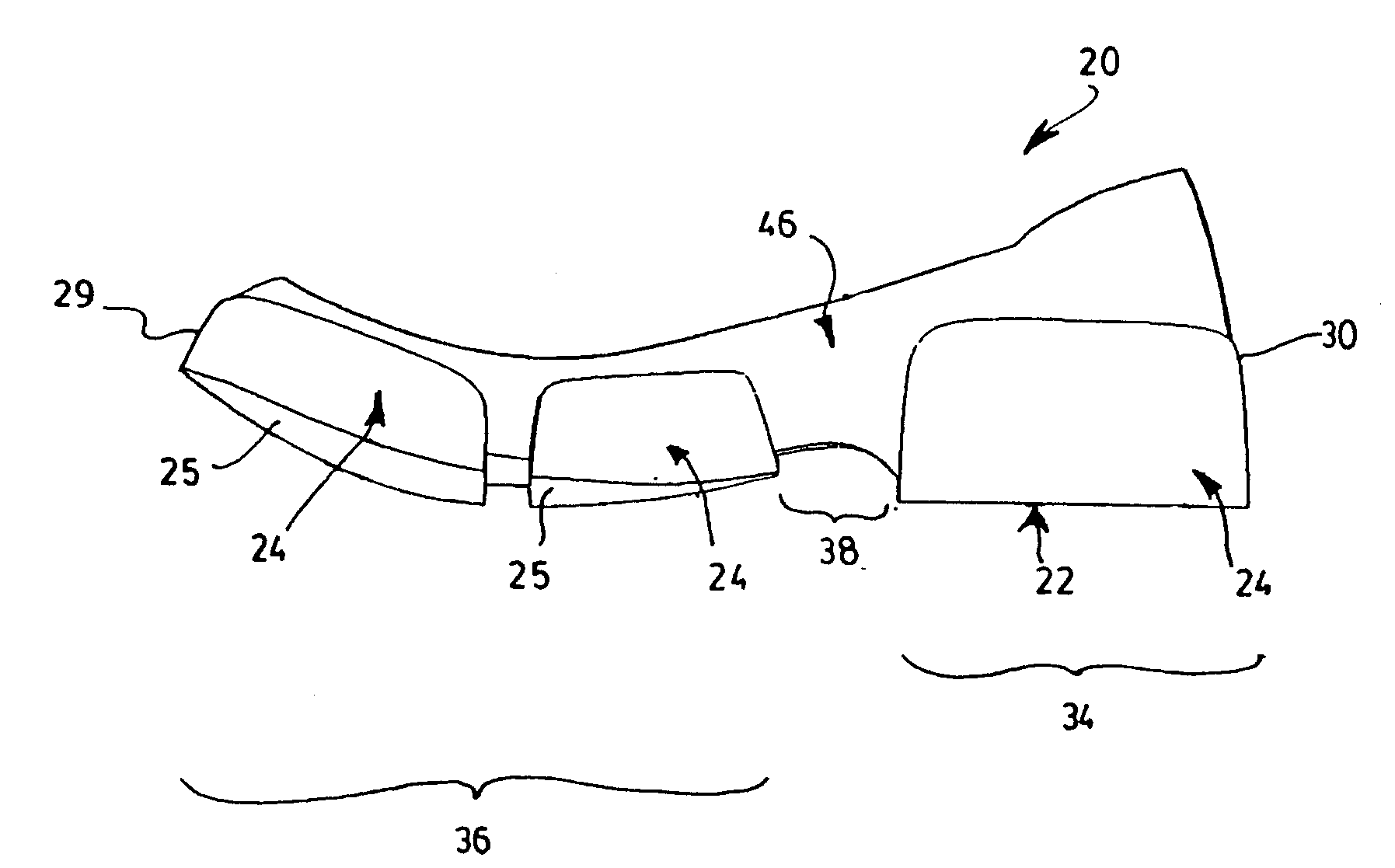

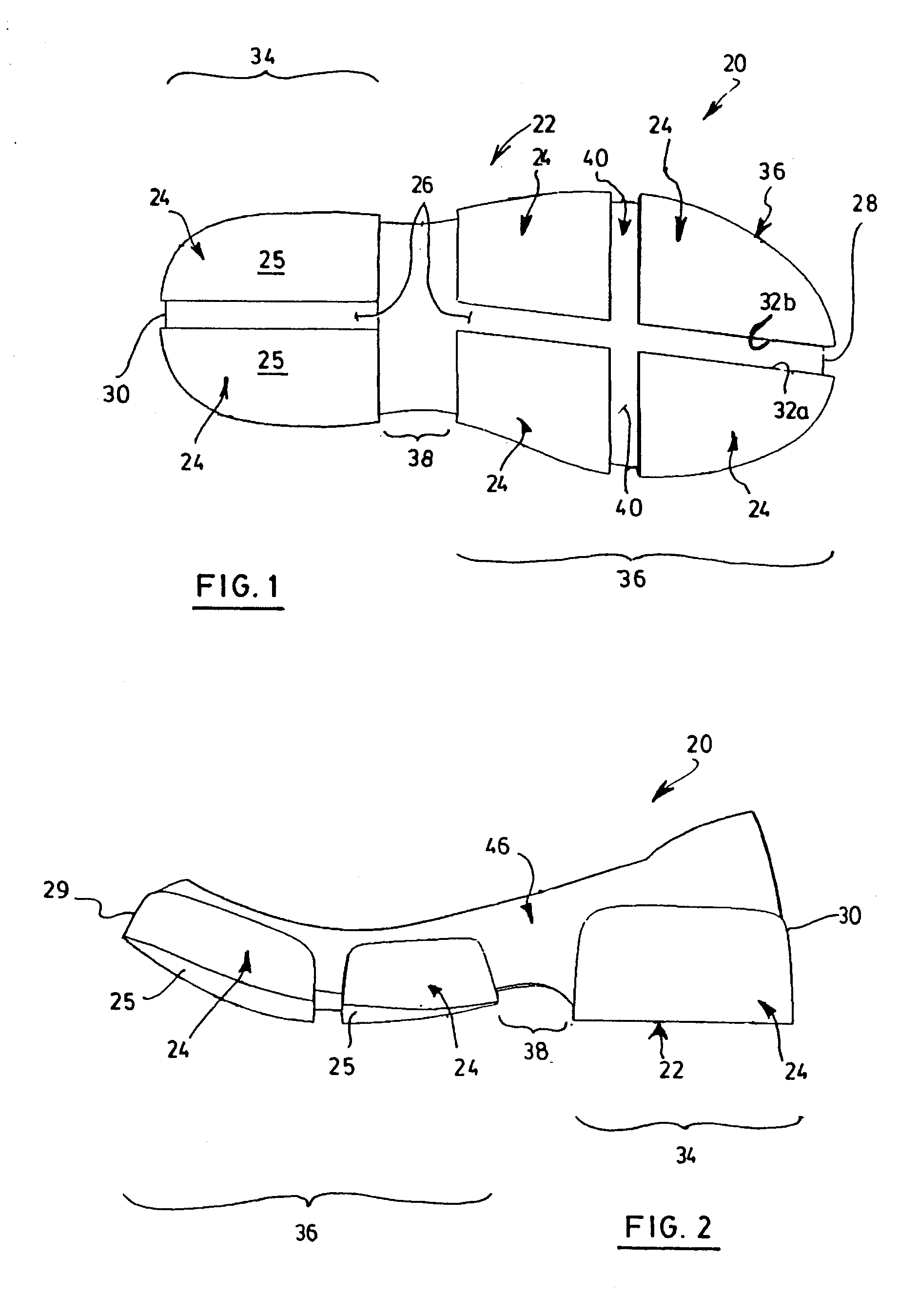

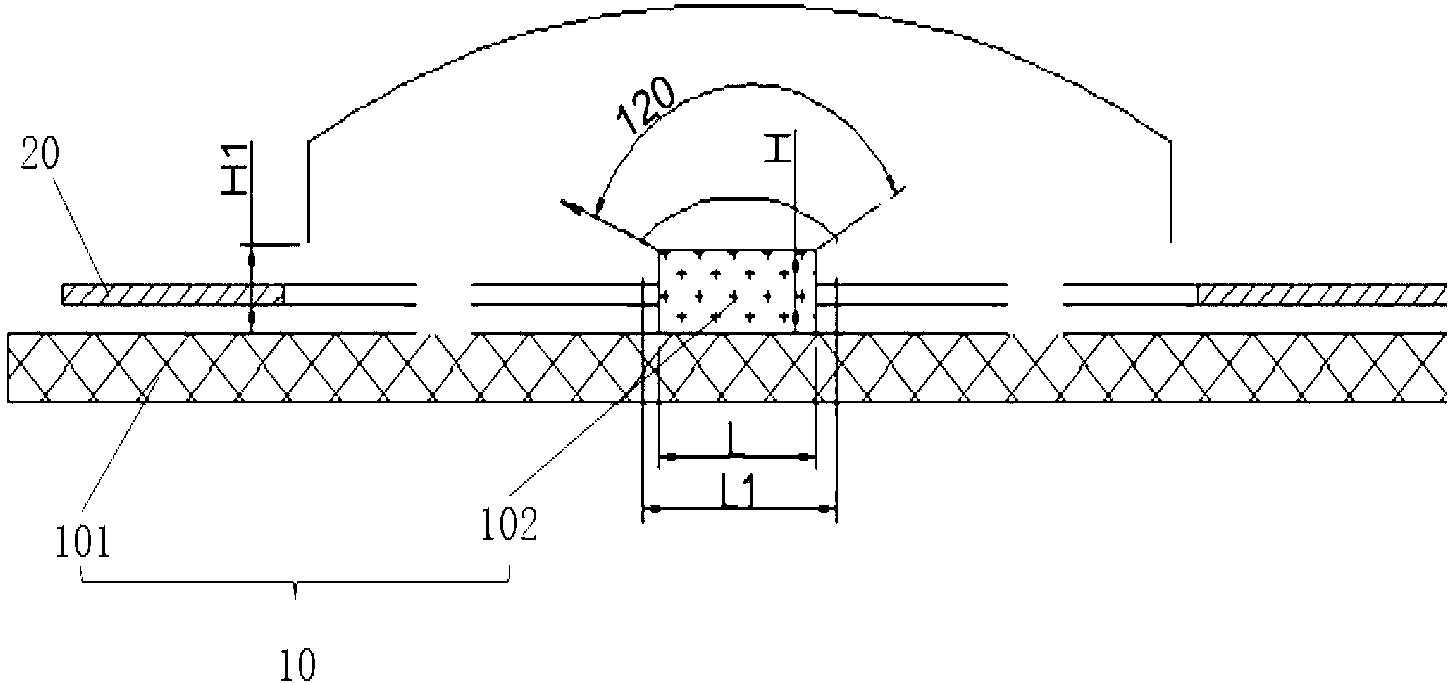

Adaptable Shoe Cover

The present invention provides a shoe cover to adaptively fit over a shoe. The show cover has a sole, which includes at least two rigid bands of rigid material, disposed on the bottom of the sole and arranged in spaced relation to each other on opposite sides of a longitudinal axis of the sole, thereby rigidifying the sole. The sole also has an elastic band of the flexible material, spanning longitudinally between the two rigid bands from the front to the rear of the sole, thereby enabling lateral flexibility to adapt to a shoe. The present invention also provides a rigid L-shaped element, each including a first portion on the ground side, a second portion on the side wall, and a fulcrum joining them, to clamp an inserted shoe. A double injection method for producing the above is also provided.

Owner:ALFRED CLOUTIER

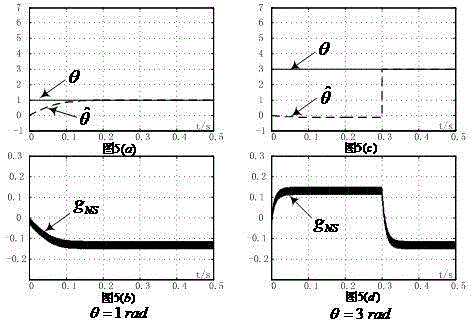

Permanent magnet synchronous motor initial position detection method based on high-frequency current signal injection

InactiveCN104660140ASimplify the estimation processShorten the timeElectronic commutation motor controlVector control systemsPermanent magnet synchronous motorVoltage response

The invention discloses a permanent magnet synchronous motor initial position detection method based on high-frequency current signal injection. The method comprises the following step: on the basis of realizing estimation of an initial position by utilizing a fluctuating high frequency current injection method, carrying out d-axis positive direction judgment by extracting d-axis positive direction information included in double injection signal frequency sub-harmonics in d-axis voltage response. According to the method, only high frequency current signals need to be injected in the whole initial position estimation process, and extra signal injection in other forms such as square-wave pulse during the d-axis positive direction judgment process is not needed, so that the estimation time is shortened, and the estimation process is simplified.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

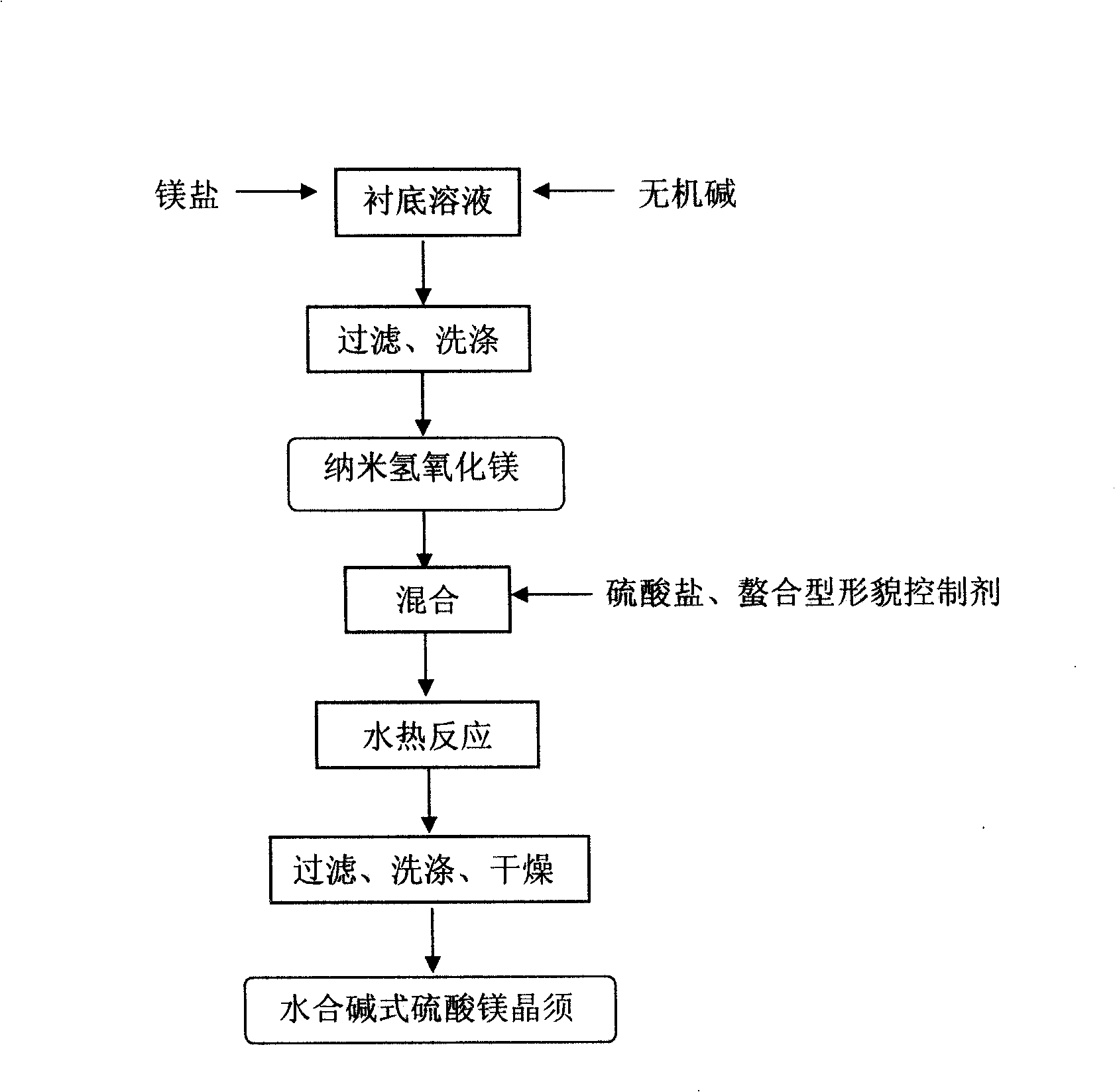

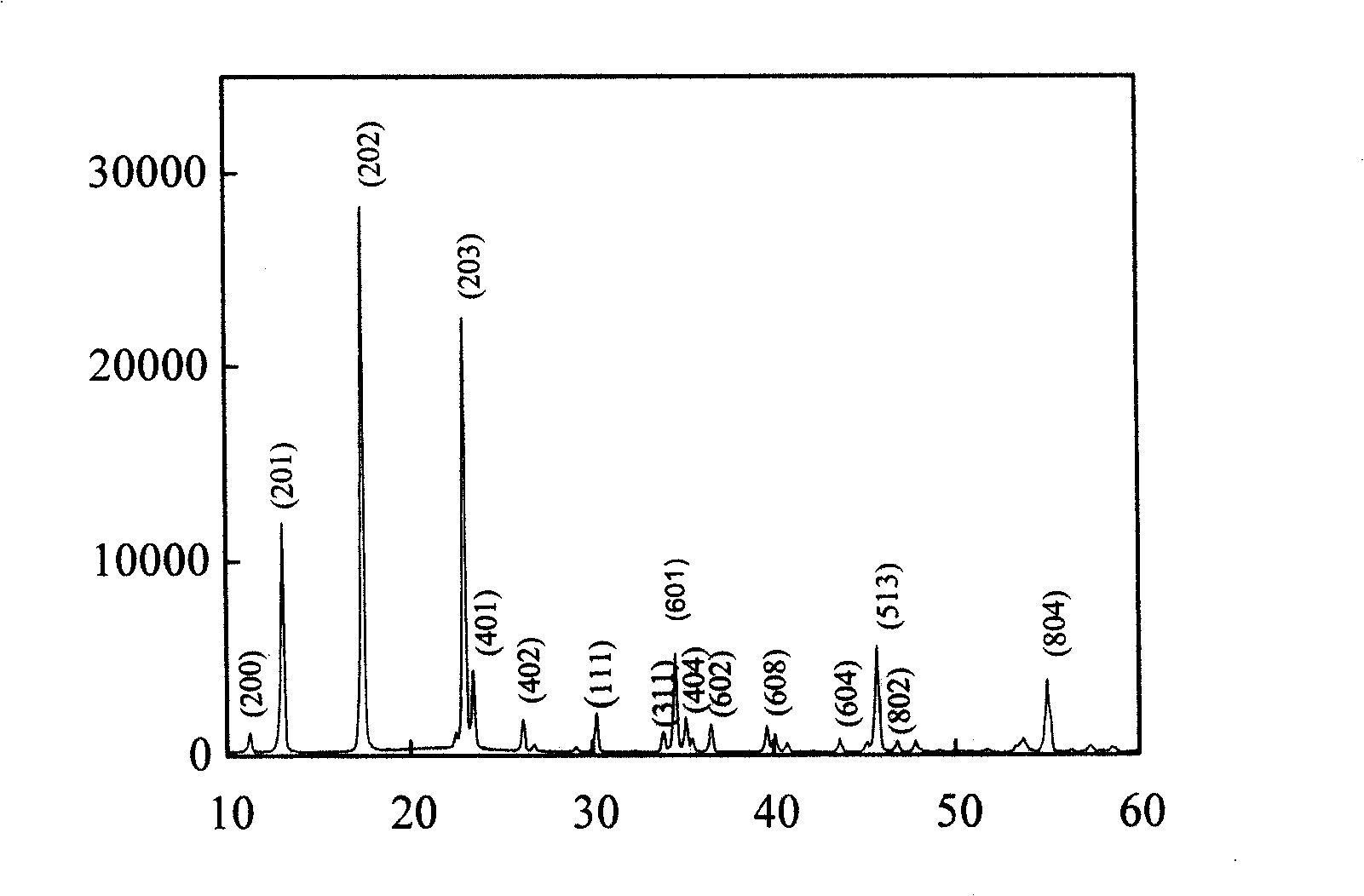

Preparation of high length-diameter ratio magnesium hydroxide sulfate hydrate whisker

InactiveCN101348937AReduce supersaturationHigh crystallinityPolycrystalline material growthFrom normal temperature solutionsMagnesium saltCrystallinity

A preparation method for hydrated basic magnesium sulfate crystal whisker with high-aspect ratio belongs to the technical field of inorganic chemical material preparation. The method comprises the following steps: water-soluble magnesium salt and inorganic base are taken as raw materials so as to prepare a precursor for nano magnesium hydroxide with better crystallinity and dispersivity in a substrate double-injection synthesis mode at a temperature between 10 and 90 DEG C; then the precursor is added into aqueous solution containing sulfate and micro chelated morphological control agent so as to carry out hydrothermal reaction at a temperature between 100 and 250 DEG C for 2 to 20 hours; and finally, one-dimensional growth of hydrothermal products is promoted by means of the selective adsorption and slow release action of the morphological control agent so as to prepare the hydrated basic magnesium sulfate crystal whisker with the average length of between 40 and 400mu m, the average diameter of between 0.05 and 0.2 mu m, the aspect ratio of between 200 and 2,000 and the main content more than 98 percent. The preparation method has the advantages of simple process, low cost, high added value of the product and easy industrial popularization; moreover, the product can be used in industries such as plastics, rubber, resin and ceramics as a reinforcing material.

Owner:TSINGHUA UNIV

Double-injection molding method

InactiveUS20070252305A1High strengthIncreased durabilityMouldsDomestic articlesDouble injectionComposite material

Double-injection molding methods through which the products do not have any parting lines between the molding materials comprise a mold, which has at least a male mold and a female mold. The male mold comprises at least one core. The female mold comprises at least one cavity and one core. The core of the male mold and the core of the female mold can be combined tightly. The male mold is stationary but the female mold is removable. The molding method of the present invention is to manufacture a product with two different plastic materials, where these two different plastic materials are injected into the mold in a specific order. And these two different plastic materials connect each other directly. After packing and cooling process, these two different plastic materials are shaped in the mold. A product with a smooth profile at the boundary of two materials is thus performed.

Owner:TAIWAN GREEN POINT ENTERPRISE

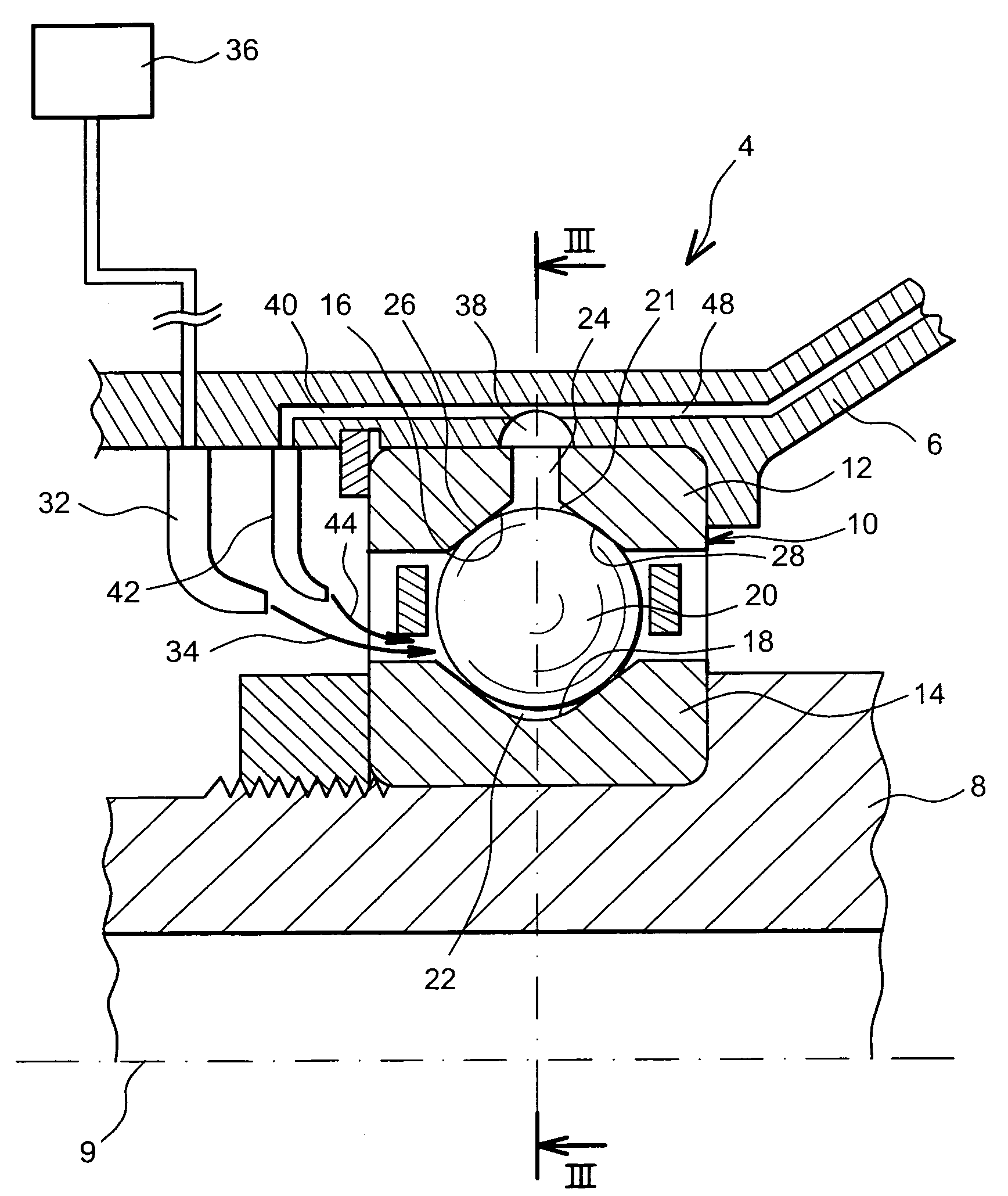

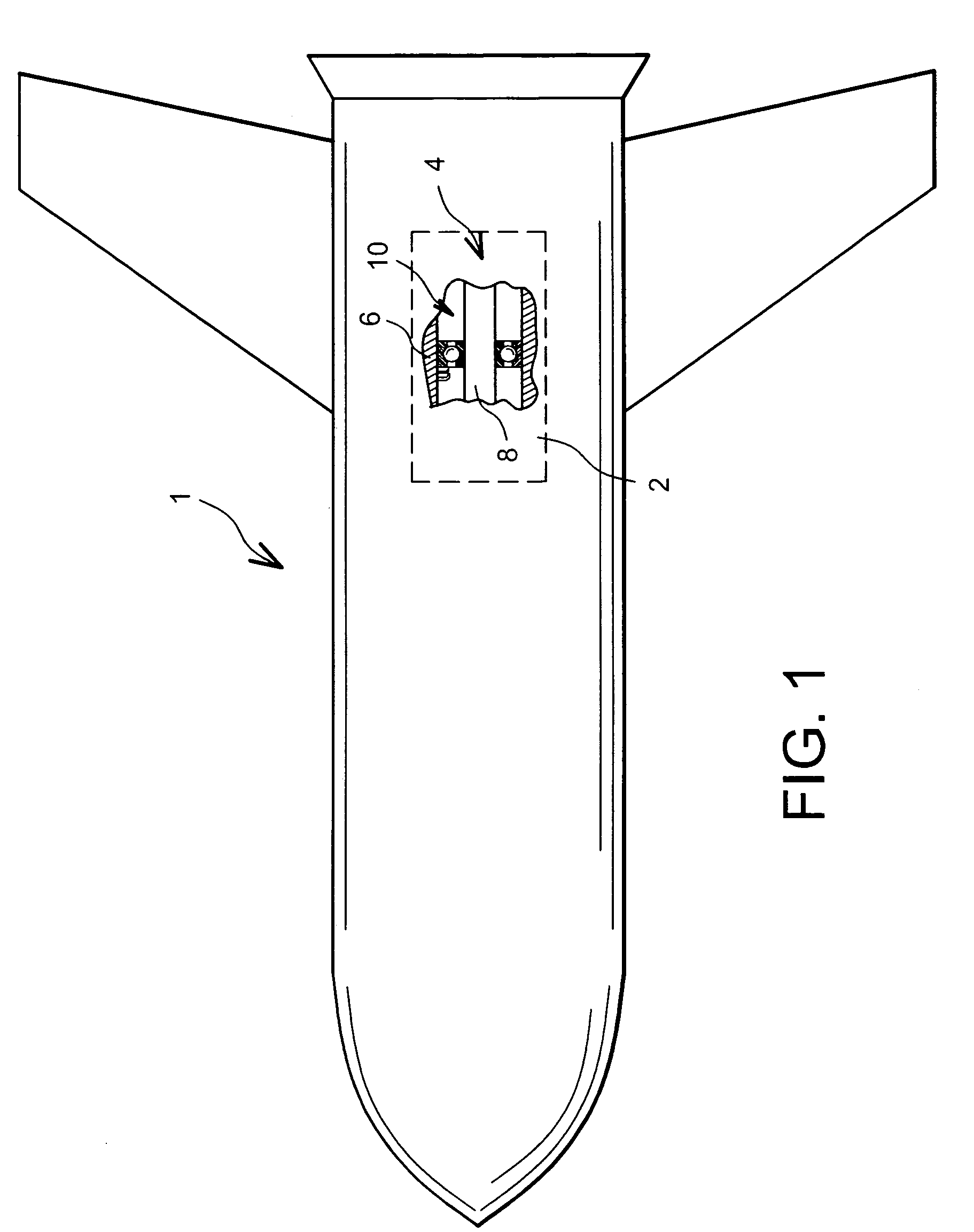

Bearing assembly comprising double injection of liquid lubricant, and aeronautical vehicle comprising at least one such assembly

A bearing assembly includes a first liquid lubricant injector designed to be fed exclusively with non-recycled liquid lubricant to lubricate a bearing. A plurality of drain orifices passes through a bearing ring fixed to a fixed part, and the assembly also includes a second liquid lubricant injector fed with liquid lubricant drained through a collection device for collecting liquid lubricant drained from the orifices, the collection device communicating firstly with a reinjection circuit connected to the second injector, and with a bypass circuit designed to evacuate surplus drained liquid lubricant.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Two position double injection molding apparatus and method

An apparatus and method for injection molding of molded products including a first cavity chamber for forming a seal liner, with the first cavity chamber having an outer edge, and a second cavity chamber for forming a shell, with the second cavity chamber having a center and being adjacent to the first cavity chamber. The injection molding apparatus and method also includes a first nozzle for a seal liner material positioned near the outer edge of, and in communication with, the first cavity chamber, and a second nozzle for a shell material positioned near the center of, and in communication with, the second cavity chamber. The injection molding apparatus and method further includes a mold core capable of being positioned in and moved between the first and second cavity chambers.

Owner:MOLD MASTERS 2007

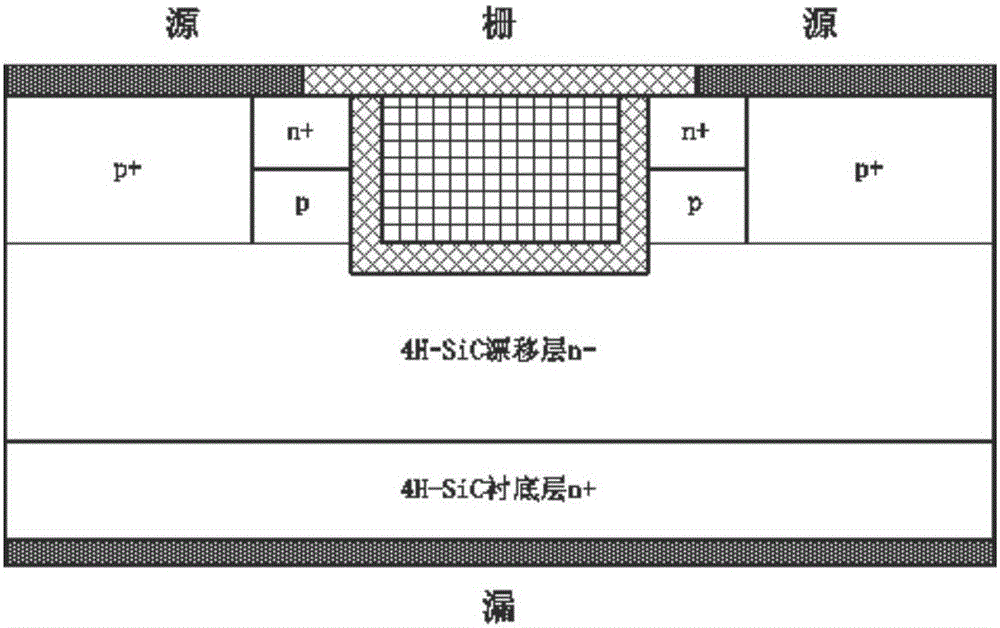

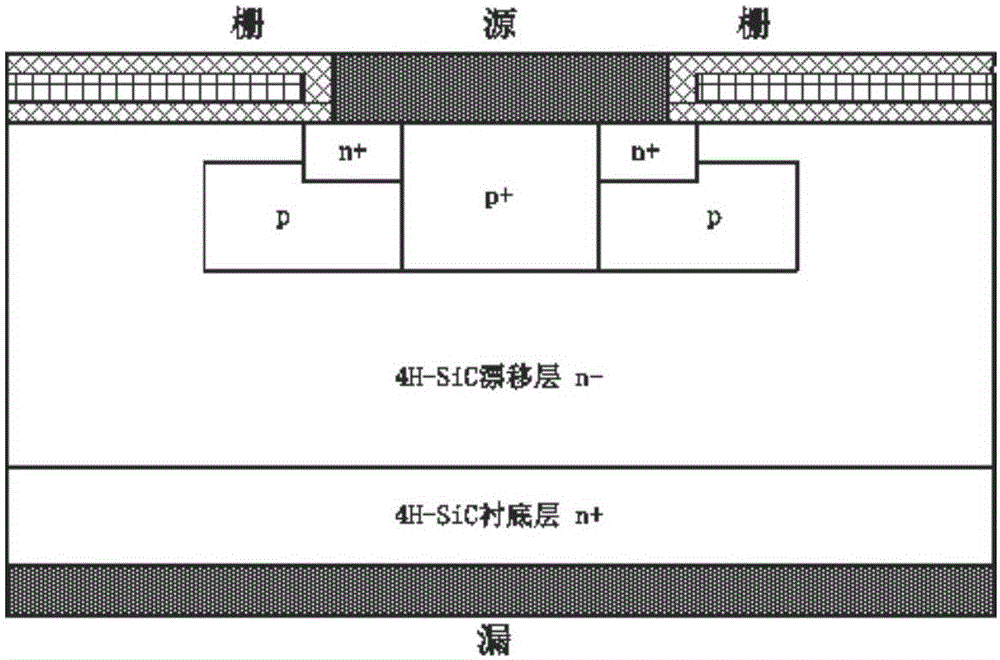

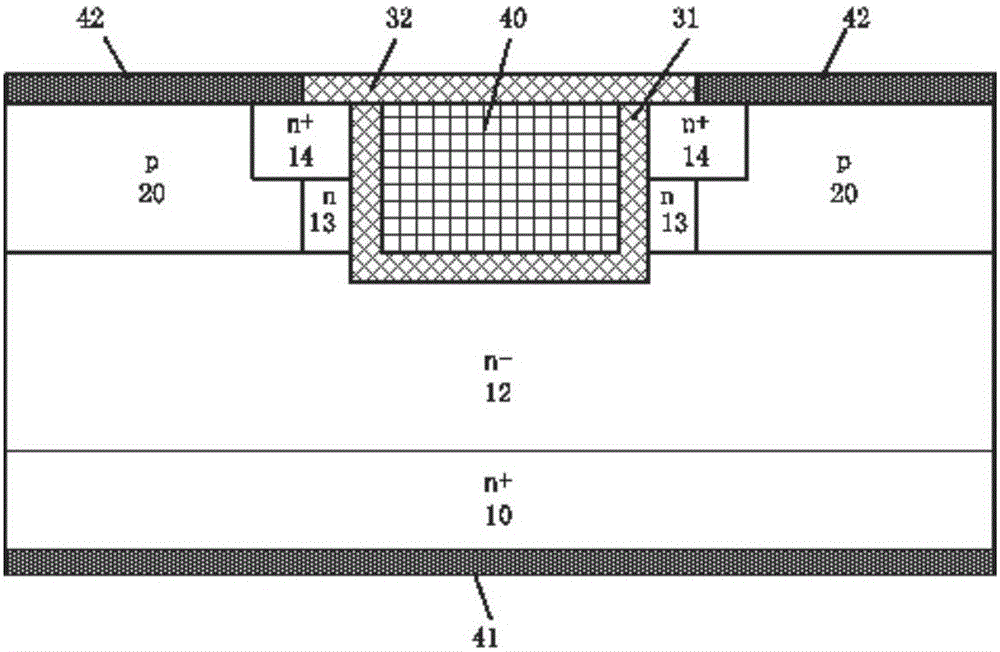

Silicon carbide trench gate power metal-oxide-semiconductor field effect transistors (MOSFETs) device and manufacturing method thereof

InactiveCN105047721AReduced effective mobilityAvoid High Threshold VoltageSemiconductor/solid-state device manufacturingSemiconductor devicesHigh energyP type silicon

The invention provides a silicon carbide trench gate power metal-oxide-semiconductor field effect transistors (MOSFETs) device and a manufacturing method thereof. The device comprises an n-type silicon carbide substrate, an n-type trench, a trench gate medium, a gate contact, a source contact and a drain contact, wherein an n-type silicon carbide drift layer is arranged on the substrate, and comprises p-type silicon carbide regions with intervals; an n+ silicon carbide source region is formed between the p-type silicon carbide regions; and the n-type trench is located between the p-type silicon carbide regions and is arranged in the n-type silicon carbide drift layer below the n+ silicon carbide source region. On the basis of a vertical double-injection MOSFET structure, the surface of the trench is counter-doped with an n-type doped impurity, so that a surface accumulation layer is realized; reduction of the effective electron mobility of the surface accumulation layer of the trench caused by high-energy and large-dose ion injection and high-temperature annealing is avoided; performance degradation of the device is reduced; the anti-latch-up capacity is improved; the manufacturing method of the silicon carbide MOSFET device is simplified; and the silicon carbide trench gate power MOSFETs device is suitable for industrial production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Container lid of operation type vacuum valve

A sealed container lid of a vacuum valve operation type is provided, in which an engagement structure of a silicon packing is simple, and a relatively strong sealing force is obtained. A process for engaging or disengaging a lid to a container body may be performed based one-touch method. The sealed contained lid of a vacuum valve operation type comprises a body which is injection-molded and has a circular groove formed in a horizontally and outwardly opened shape for an engagement of the silicon packing, and a downwardly bent peripheral part which is formed at an outer peripheral part of the body based on a double injection method while surrounding the same.

Owner:HANA COBI PLASTIC

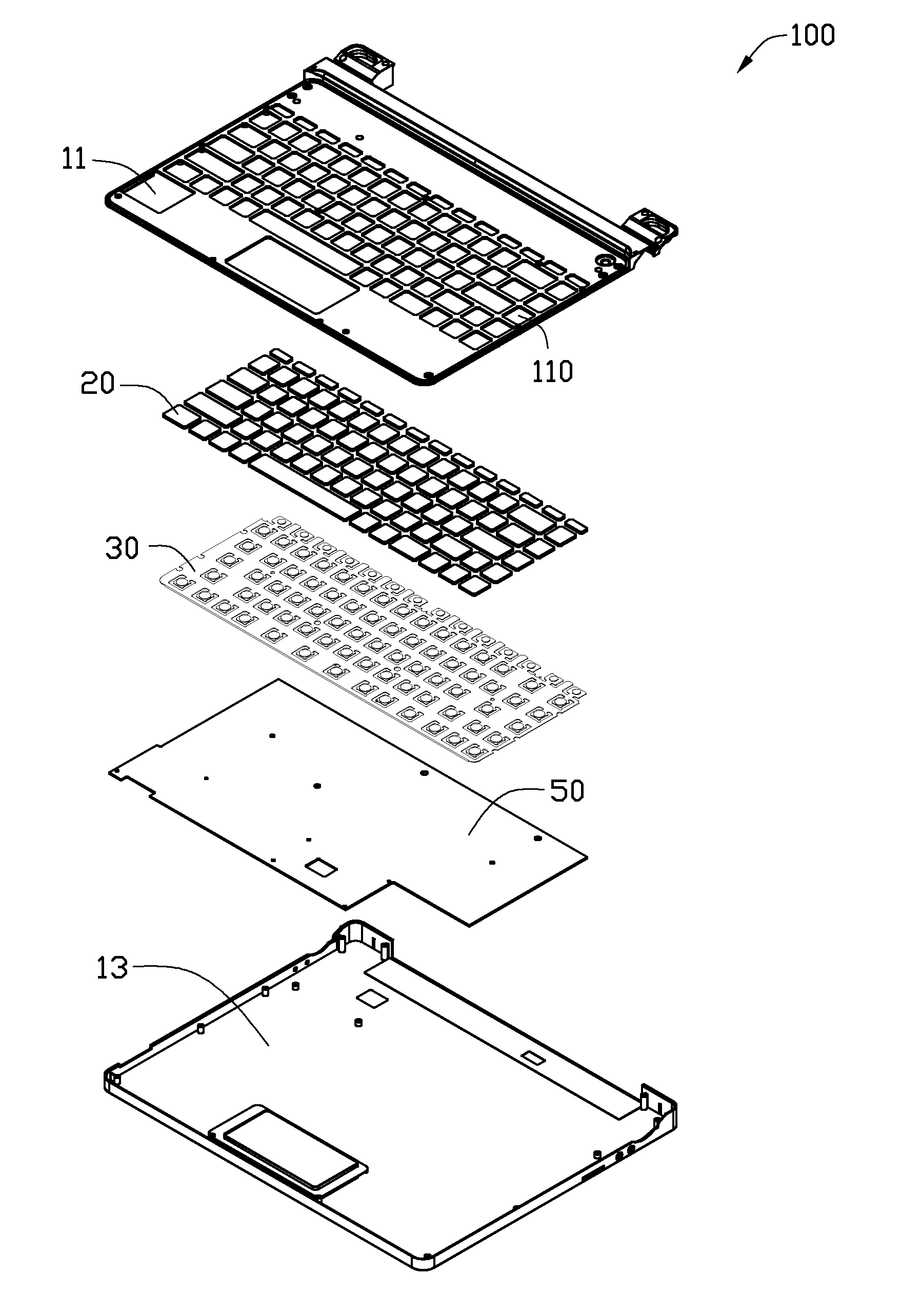

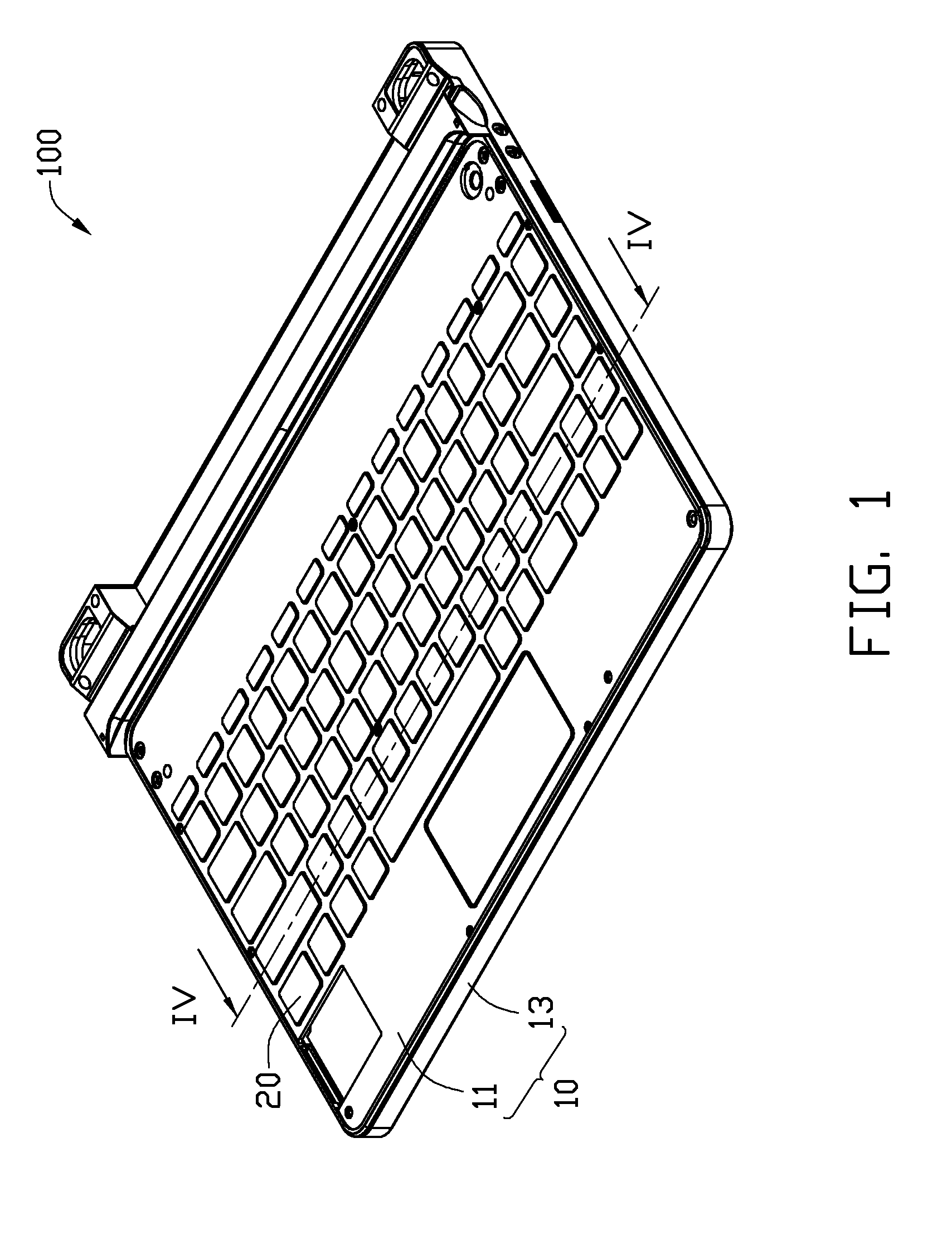

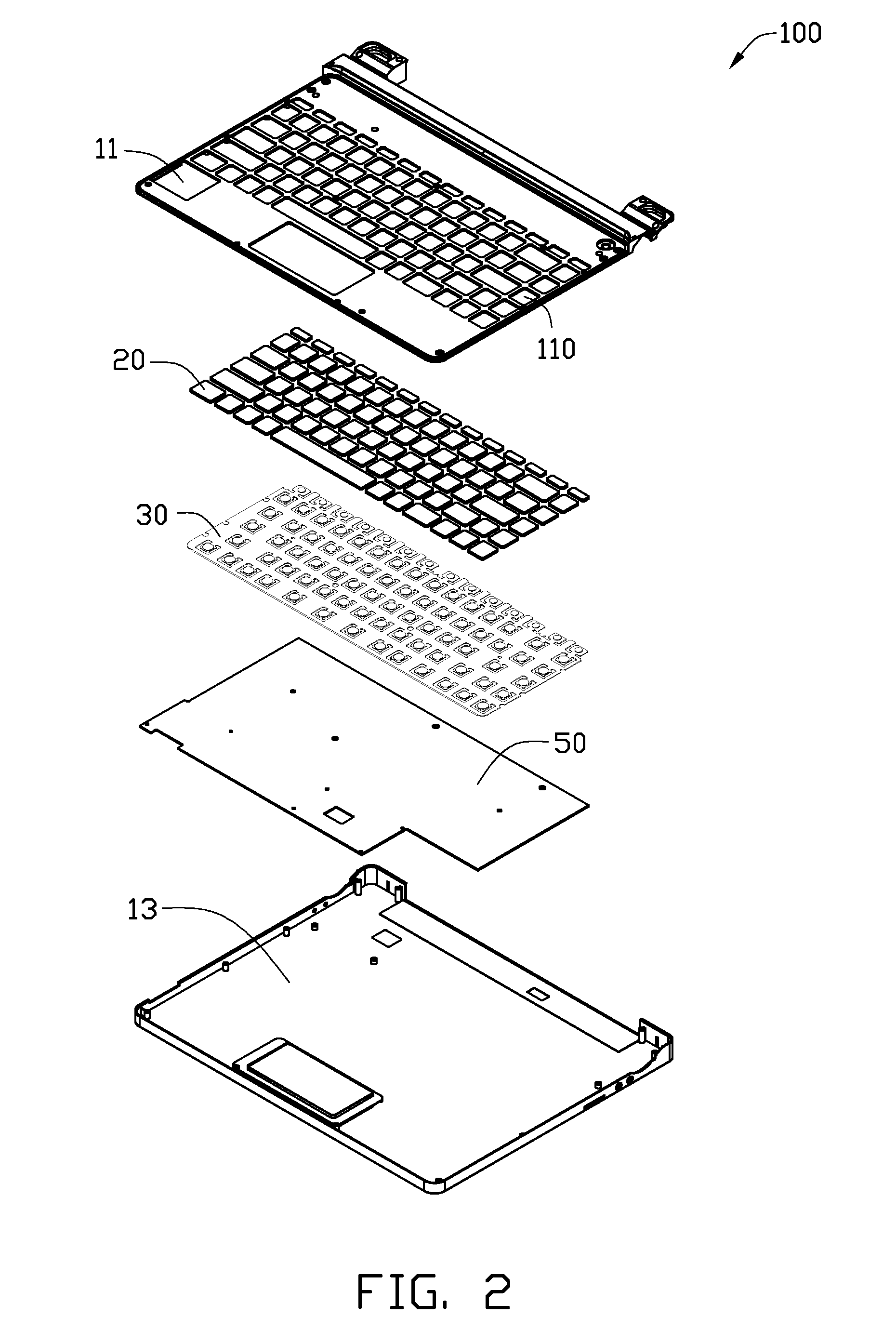

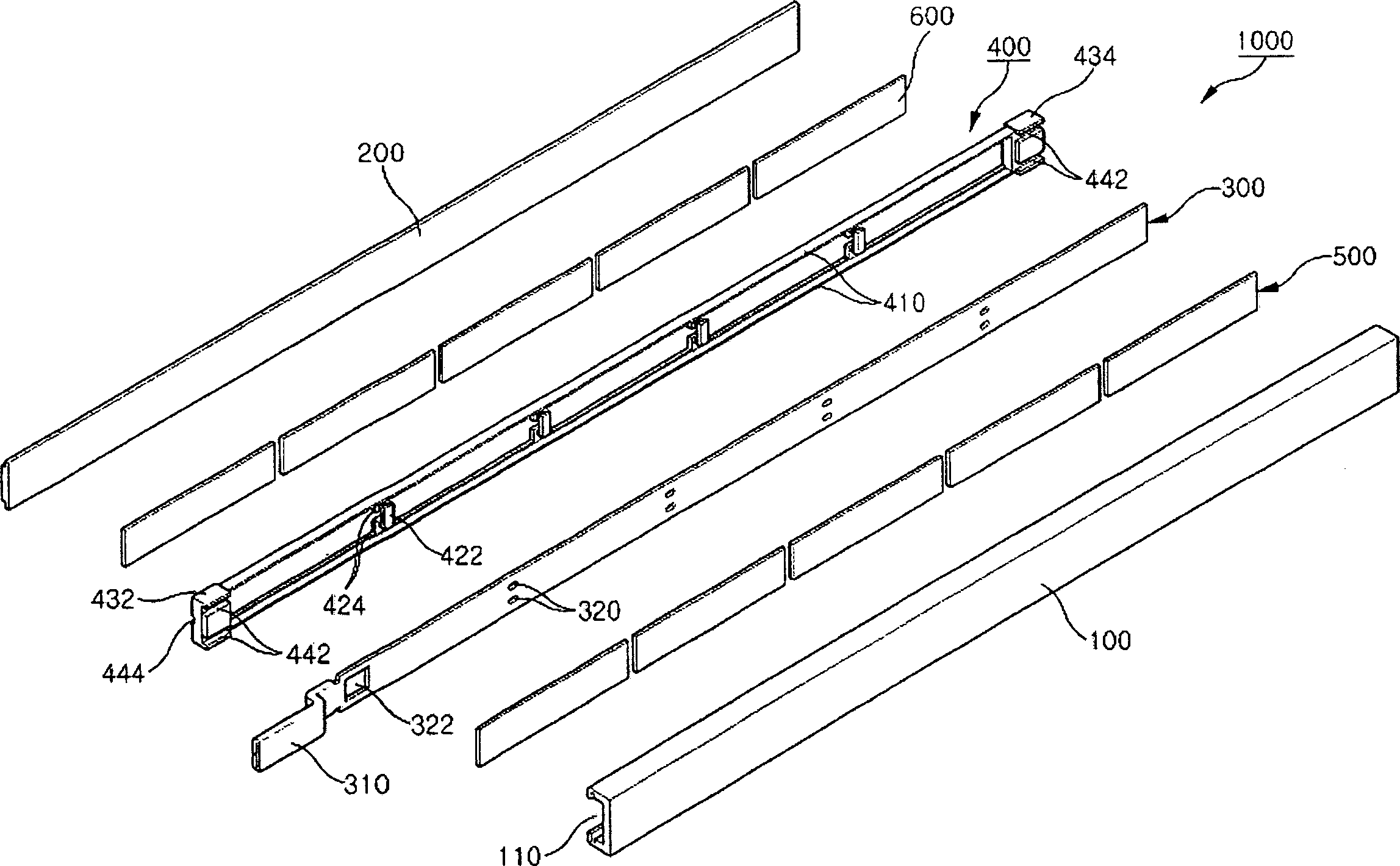

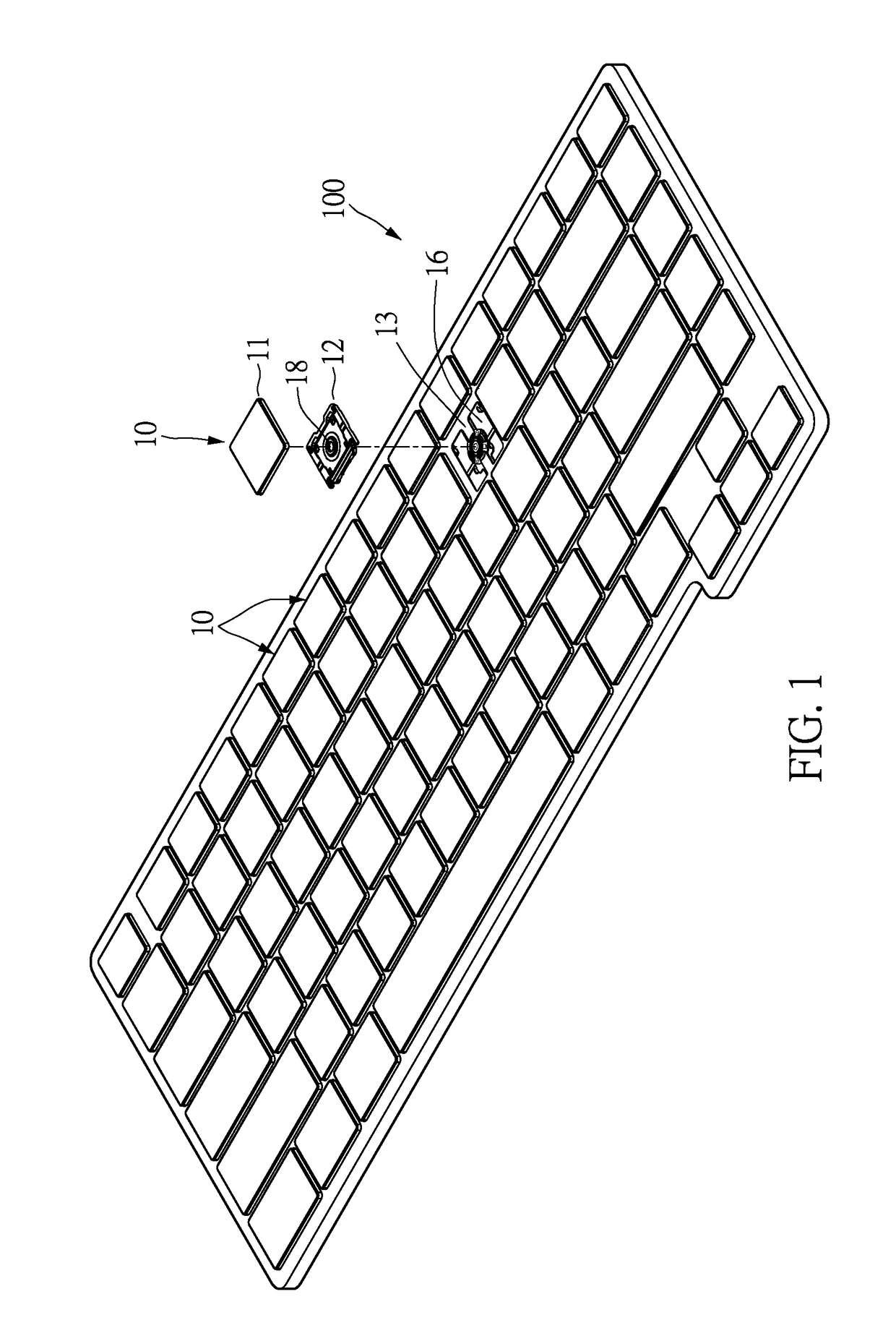

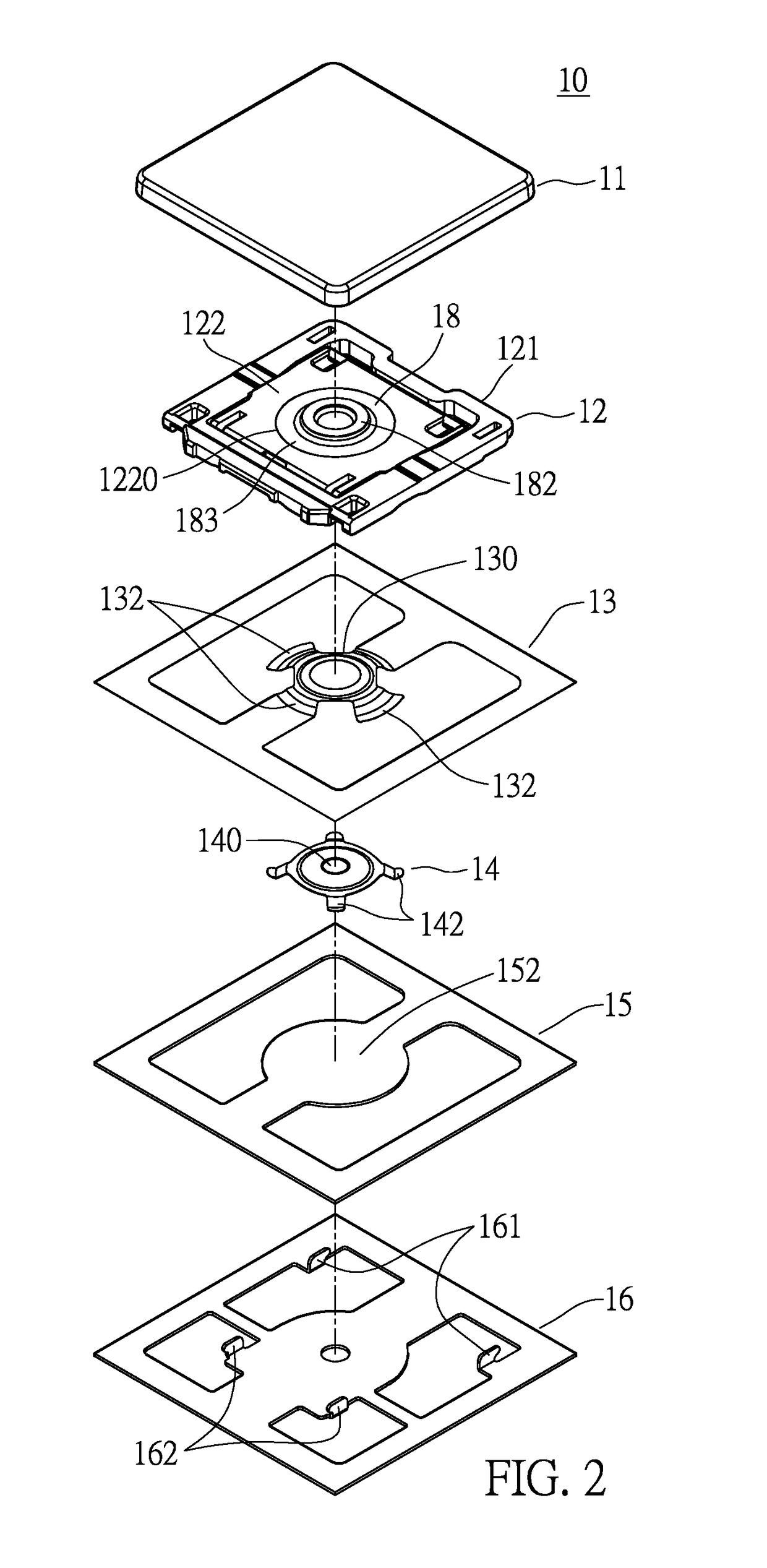

Keyboard

A keyboard includes a pressable structure and a plurality of keycaps. The pressable structure includes a flat member and a plurality of elastic members. The flat member defines a plurality of through holes corresponding to the plurality of the elastic members. The plurality of the elastic members is integrated with the flat member as a single element by a double injection process. The plurality of keycaps are resiliently supported by the plurality of elastic members correspondingly.

Owner:HON HAI PRECISION IND CO LTD

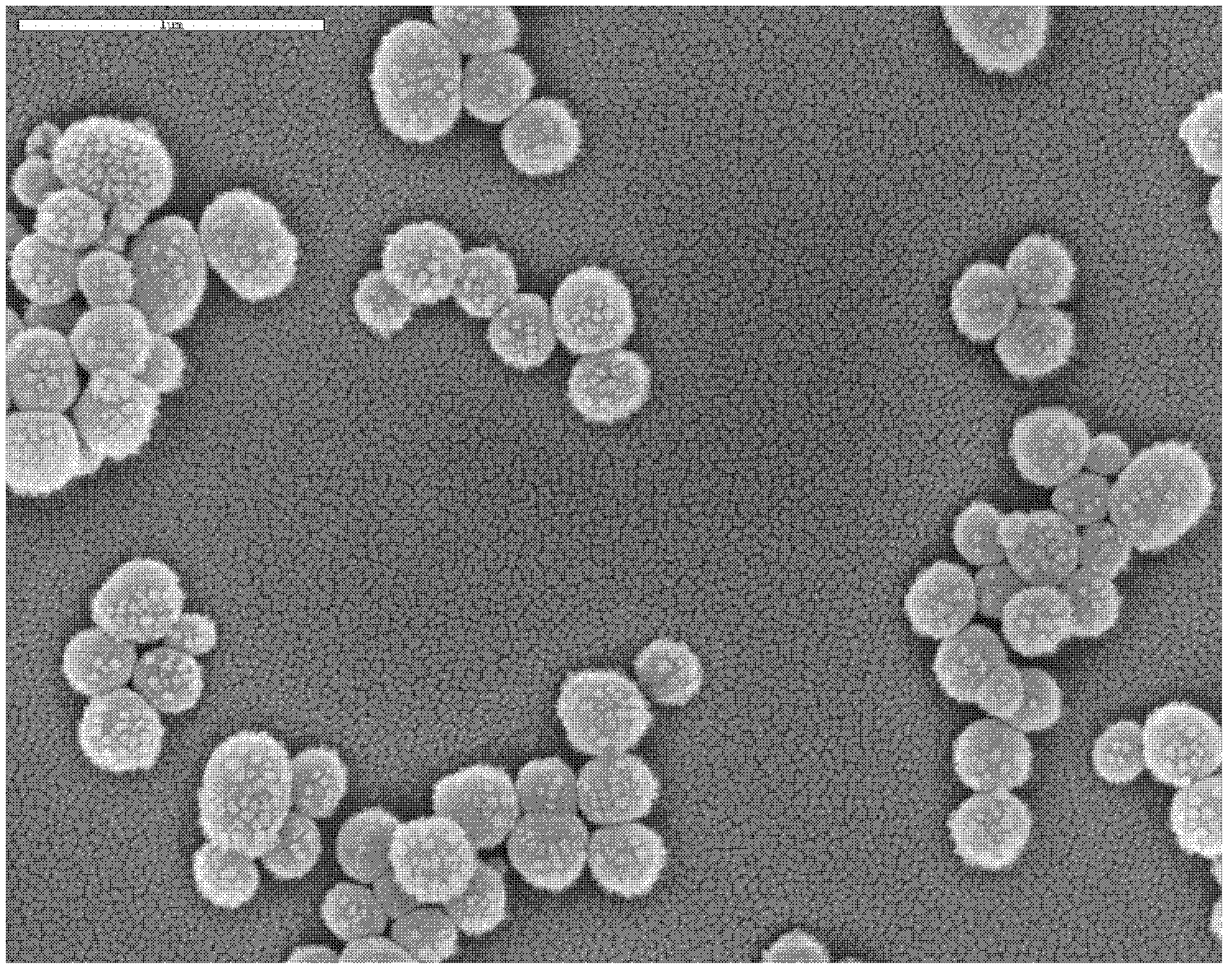

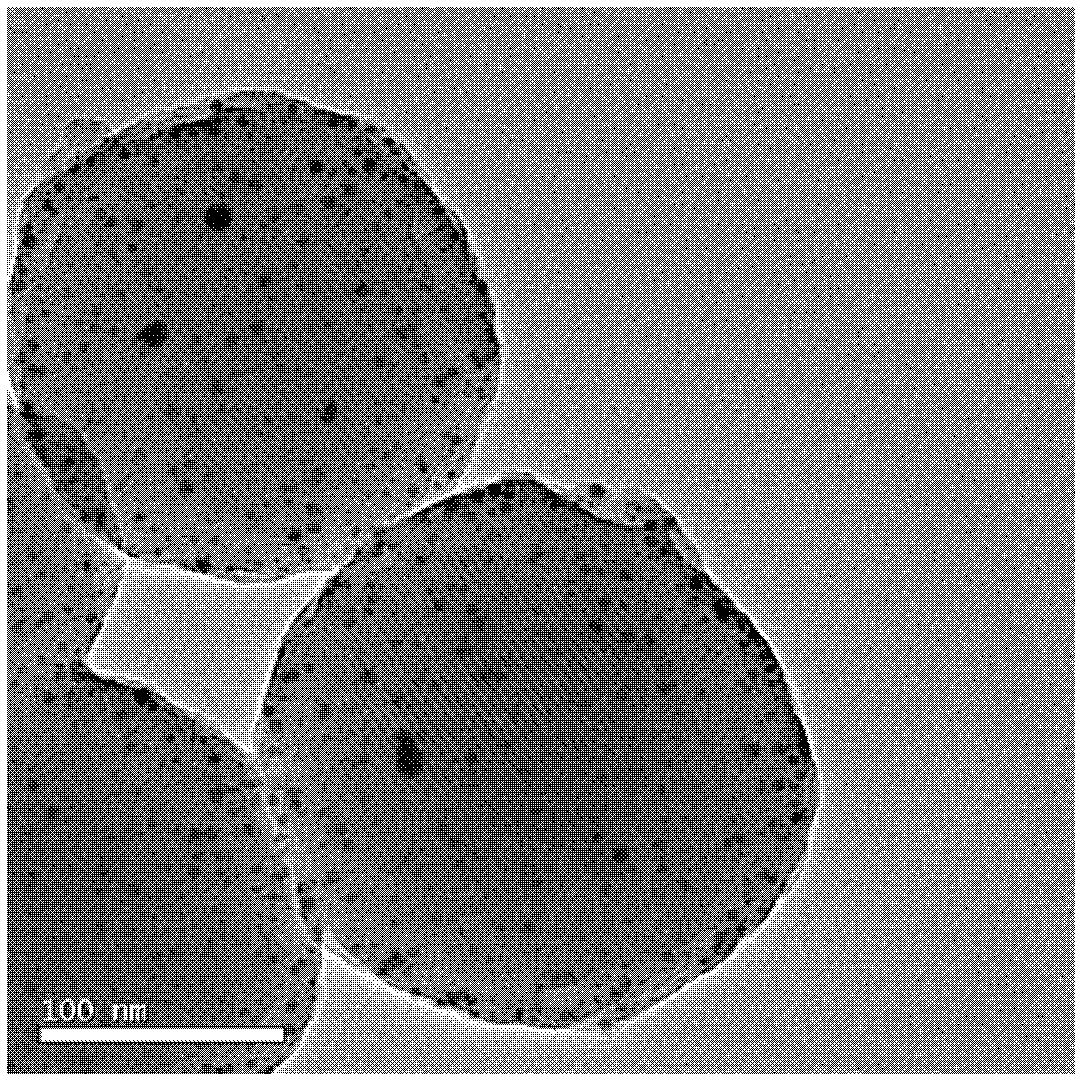

Method for preparing antibacterial powder loaded with monodisperse silver nanometer mesoporous silica

InactiveCN103039521AHigh sterilization rateImprove bindingMaterial nanotechnologyBiocideFiberMesoporous silica

The invention provides a method for preparing antibacterial powder loaded with monodisperse silver nanometer mesoporous silica, and belongs to the technical field of antibacterial materials; the preparation method adopts a quaternary ammonium salt cationic surfactant as a template, and adopts ethyl orthosilicate as a silicon source; the antibacterial powder is prepared by using a double injection method under an alkaline condition; the obtained powder has a particle size being between dozens of nanometers and hundreds of nanometers; the nanometer silver on the powder has good dispersibility; the original ordered channel structure of mesoporous silica is maintained; the product has a high bacteriostasis rate, and simple synthetic steps, and is widely applicable to antibacterial materials such as fibers, plastics, ceramics, and the like.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

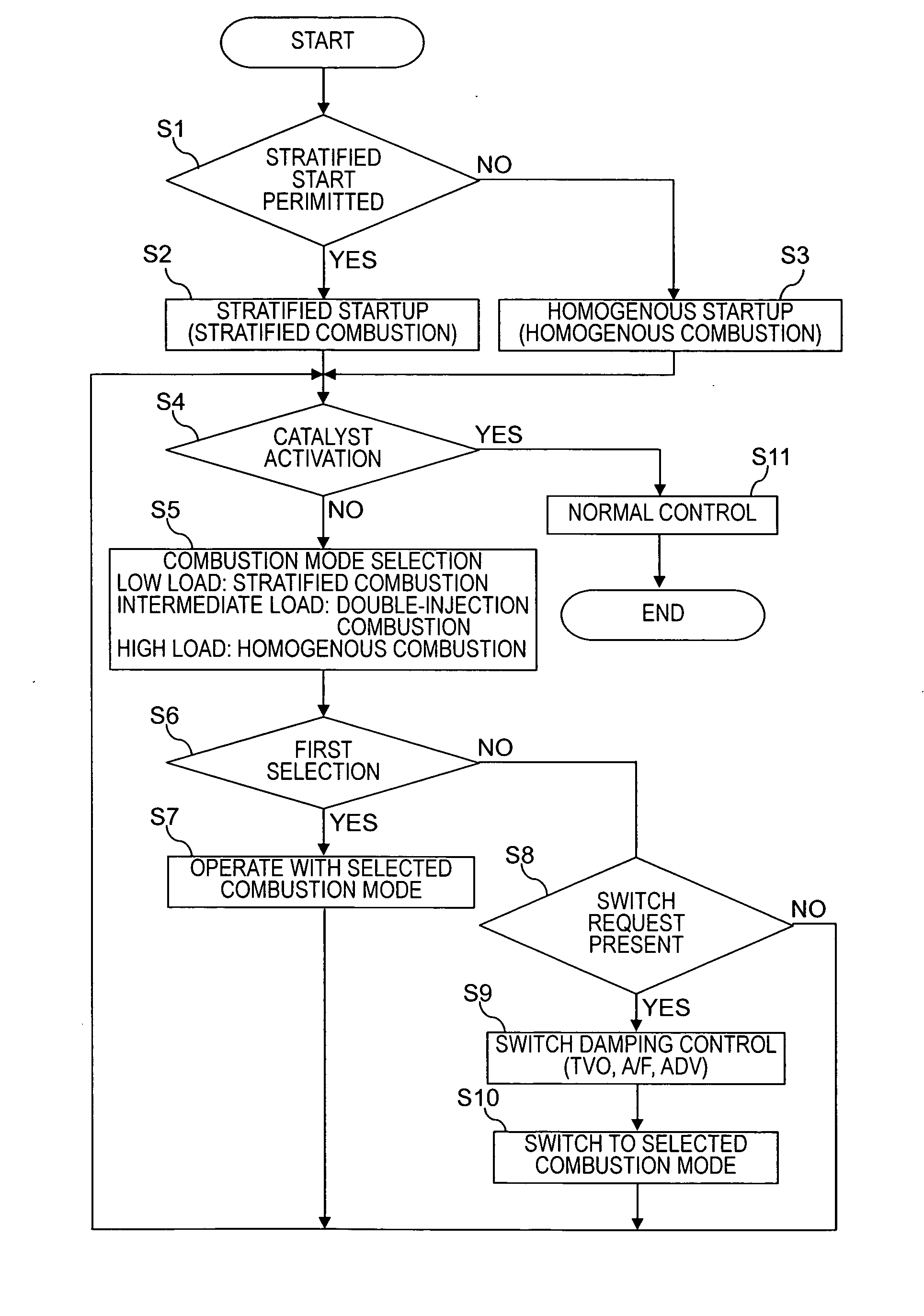

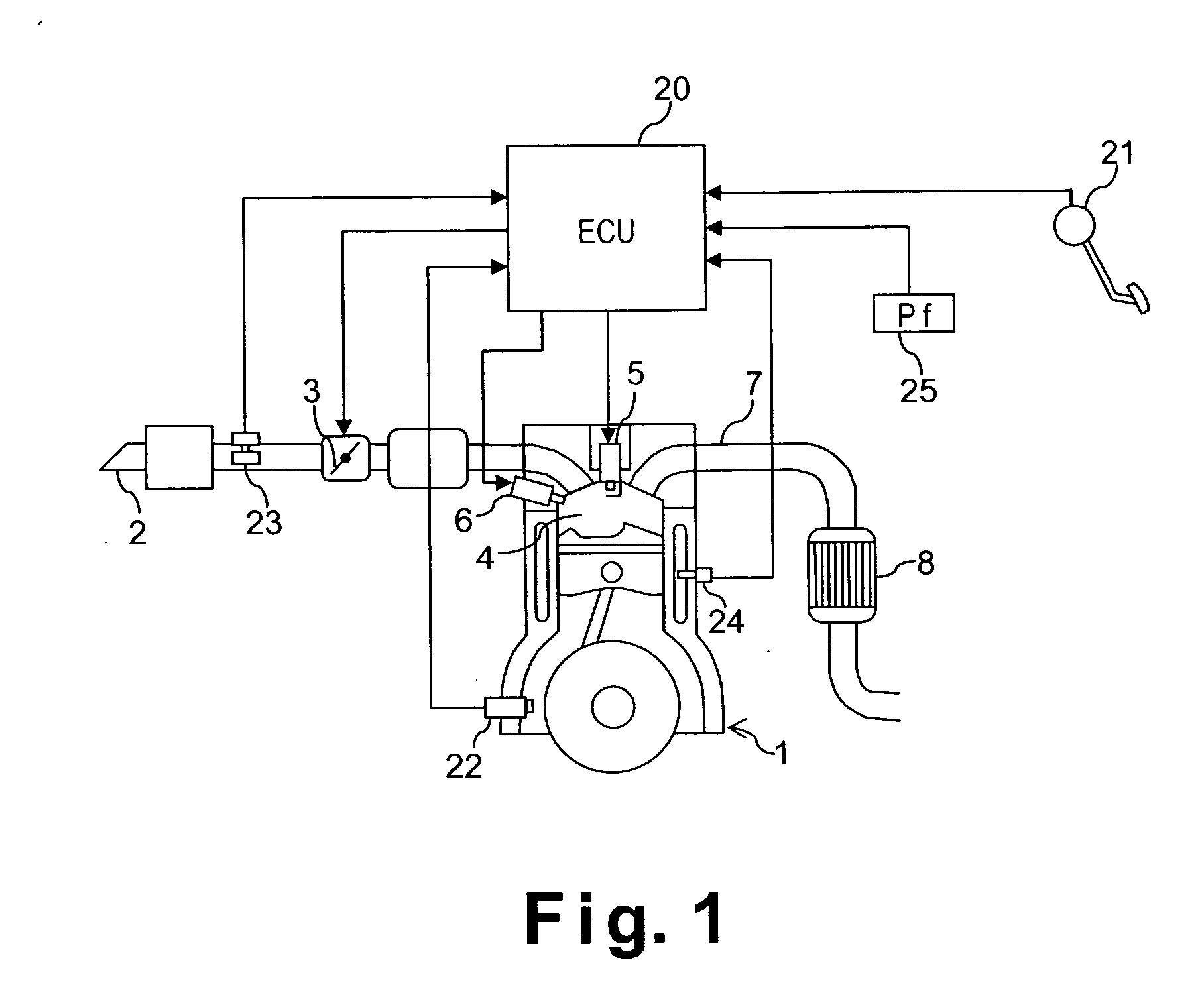

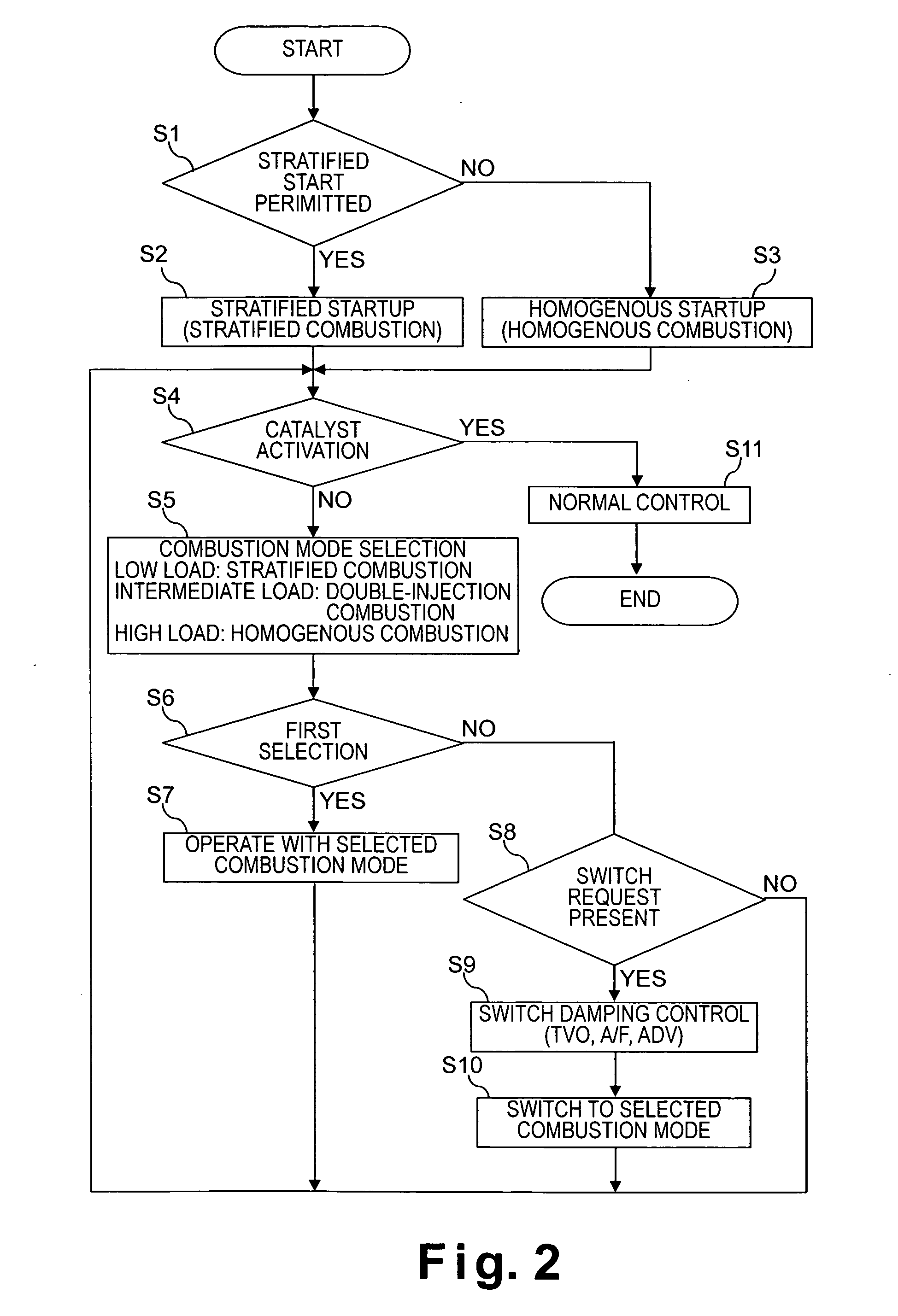

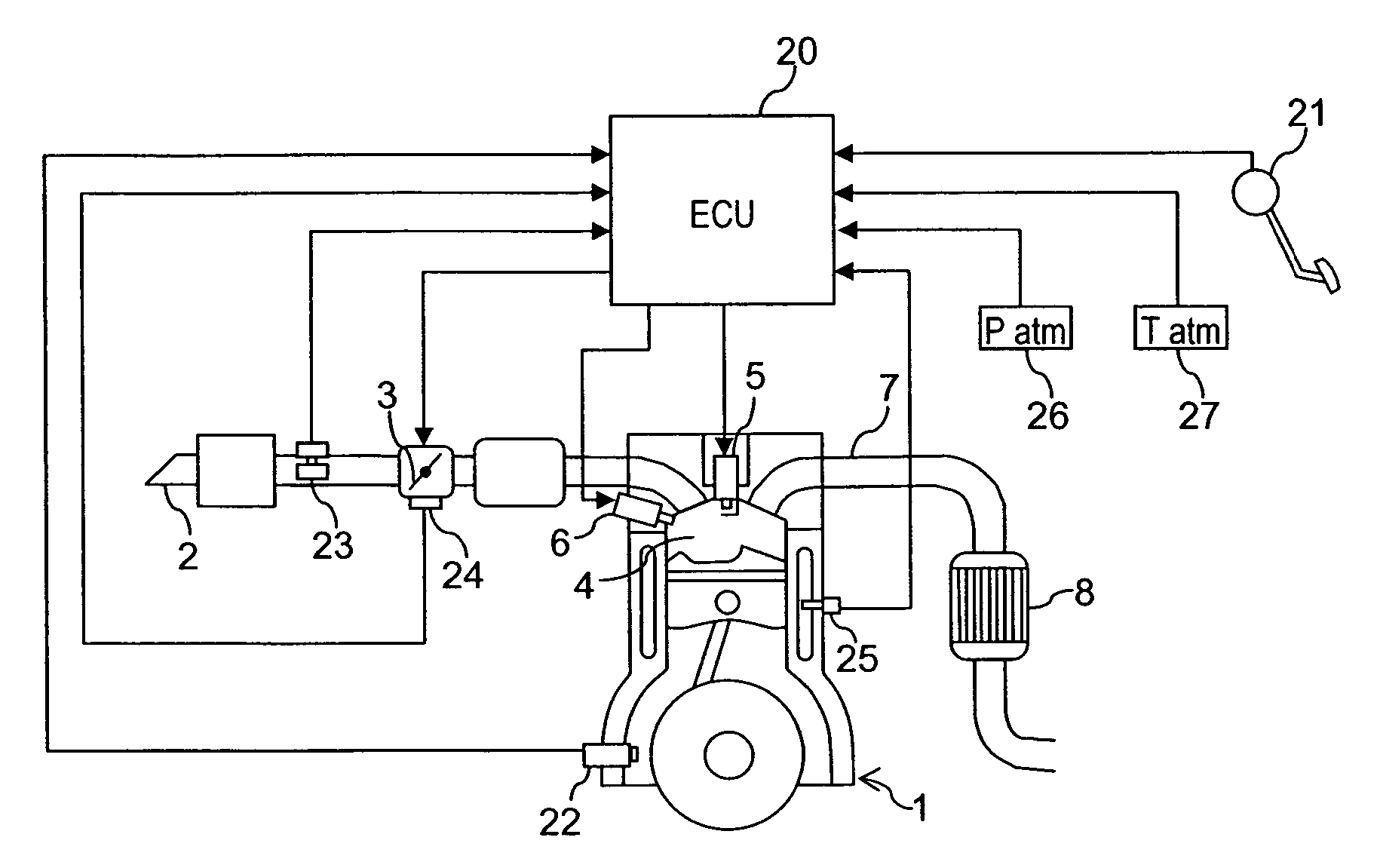

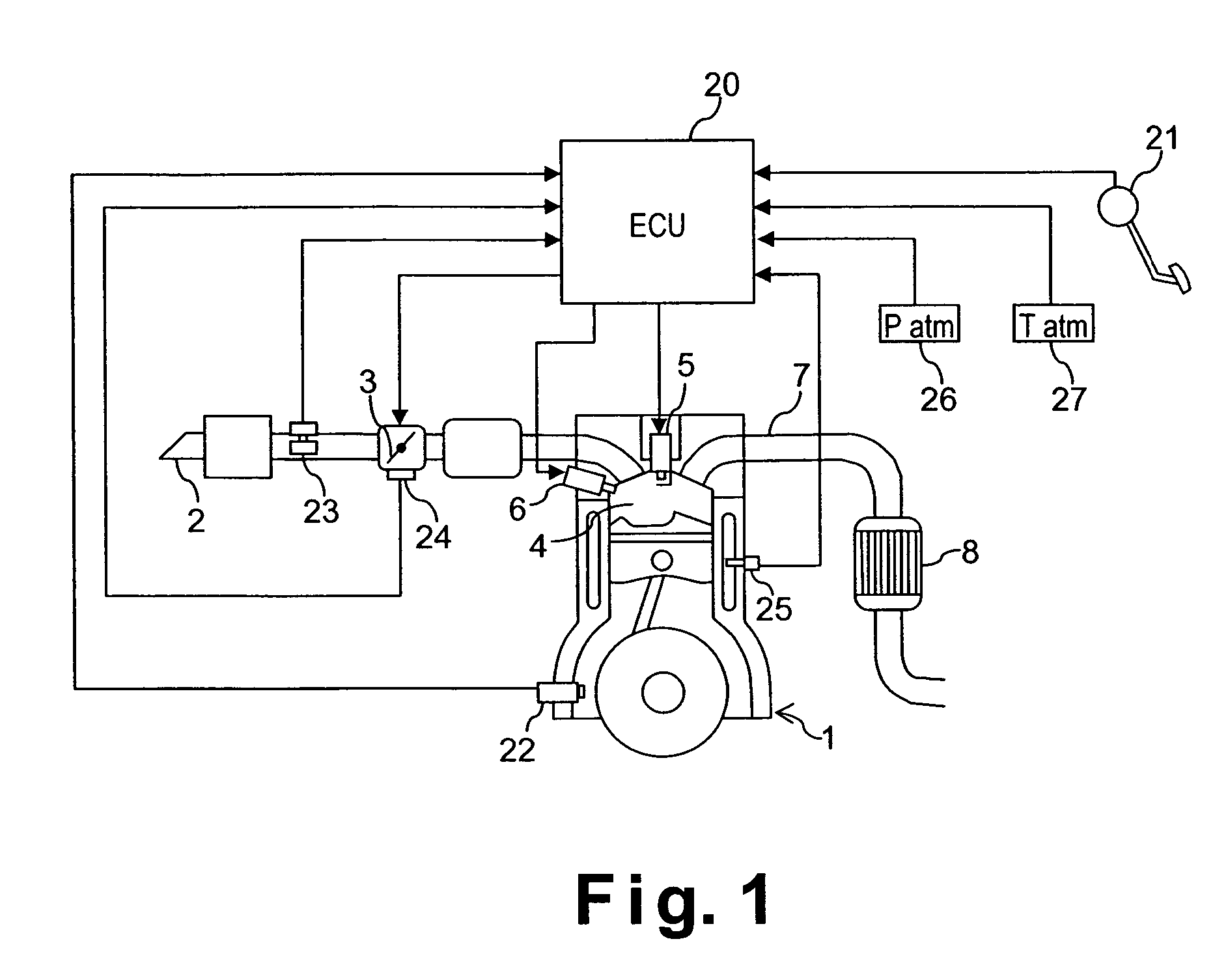

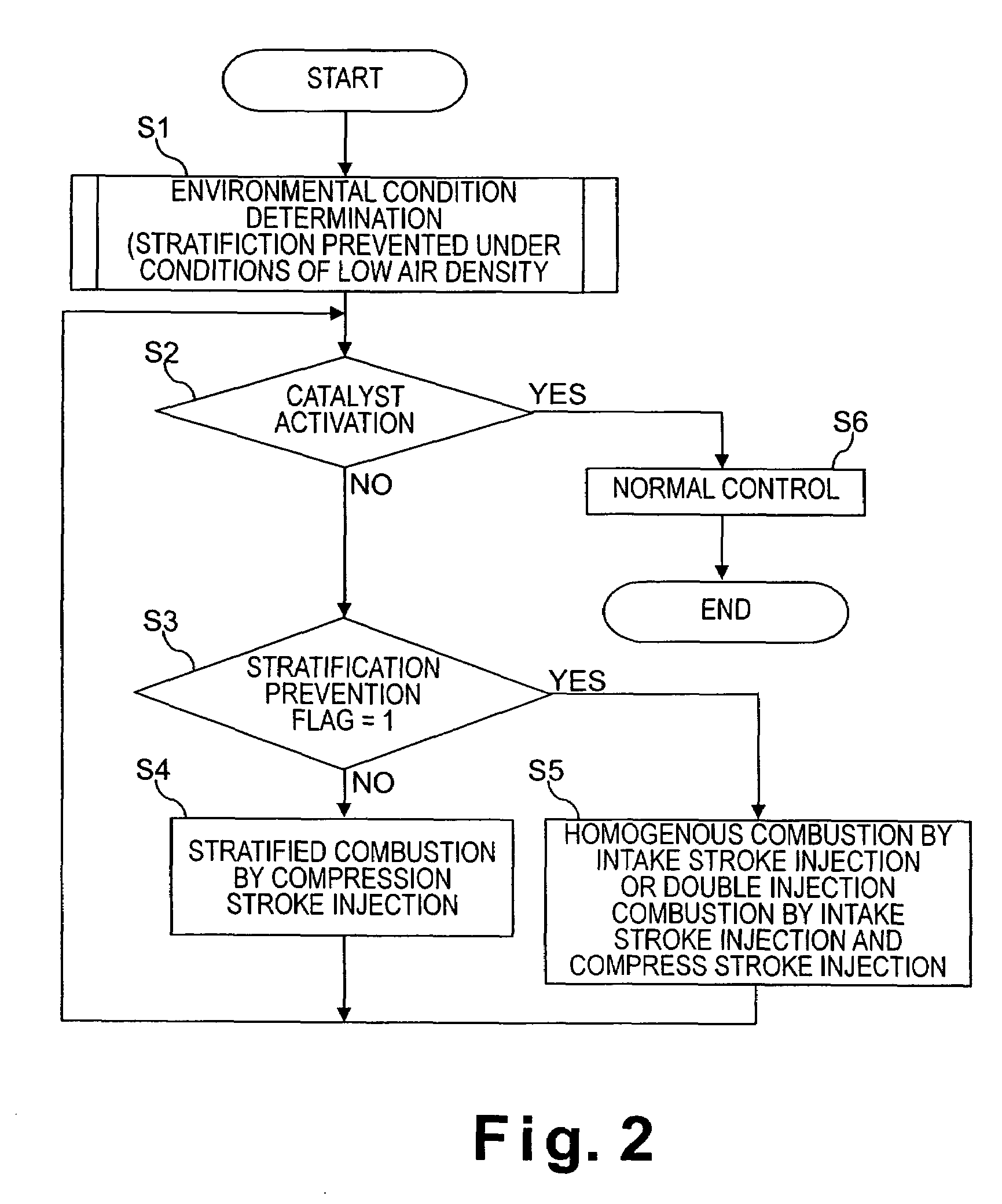

Direct fuel injection/spark ignition engine control device

An engine control device is configured to cause an engine to operate at the optimum combustion mode according to the load when warming up of an emissions purification catalyst is required, and to obtain reduced HC discharged from the engine and accelerated warm-up of the catalyst. The engine control device performs stratified combustion with a compression stroke injection in a low-load region according to the engine load, and performs double-injection combustion with an intake stroke injection and a compression stroke injection in an intermediate load region, when warming up of the catalyst is required. In a high-load region, the engine control device performs homogenous combustion with an intake stroke injection.

Owner:NISSAN MOTOR CO LTD

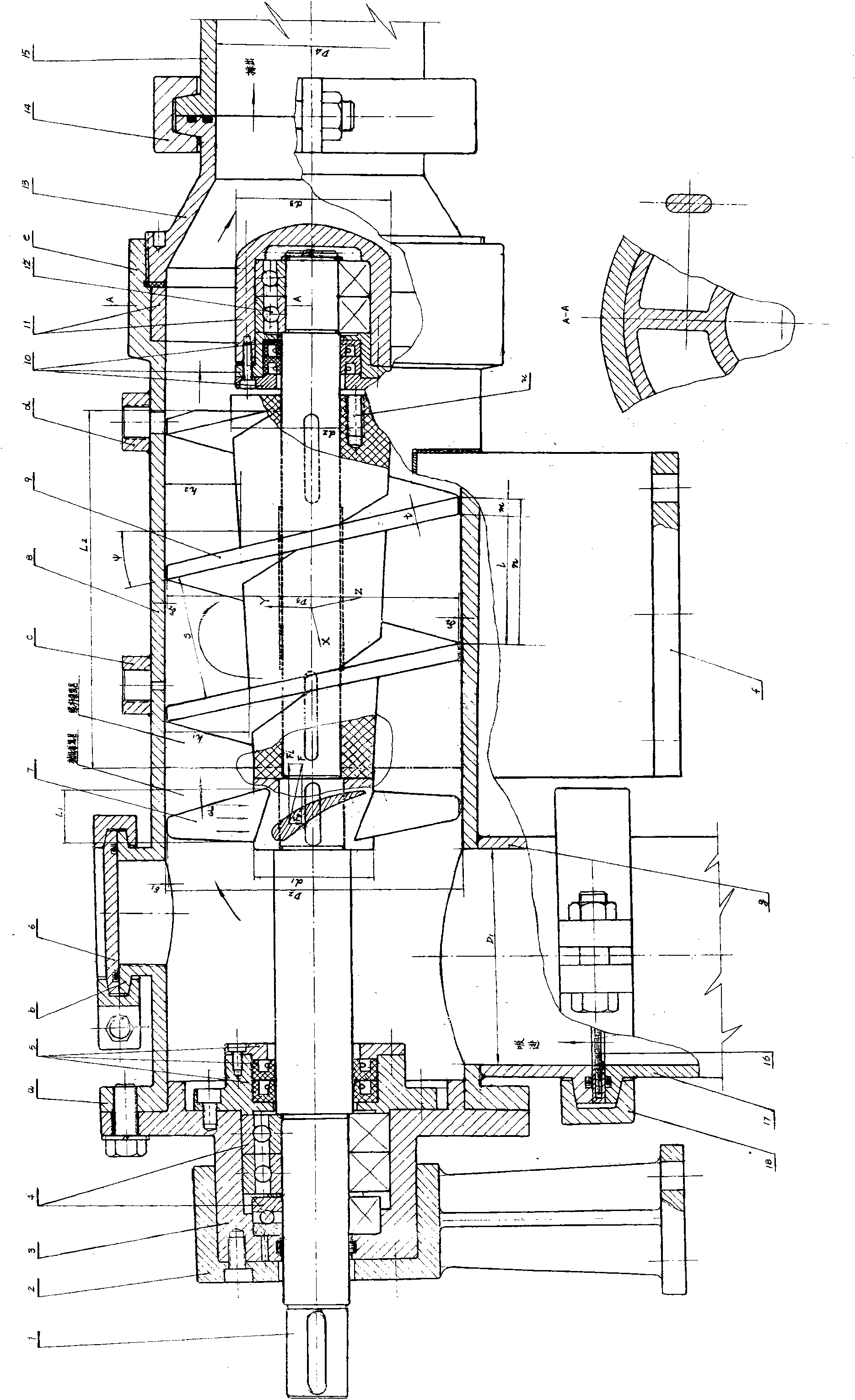

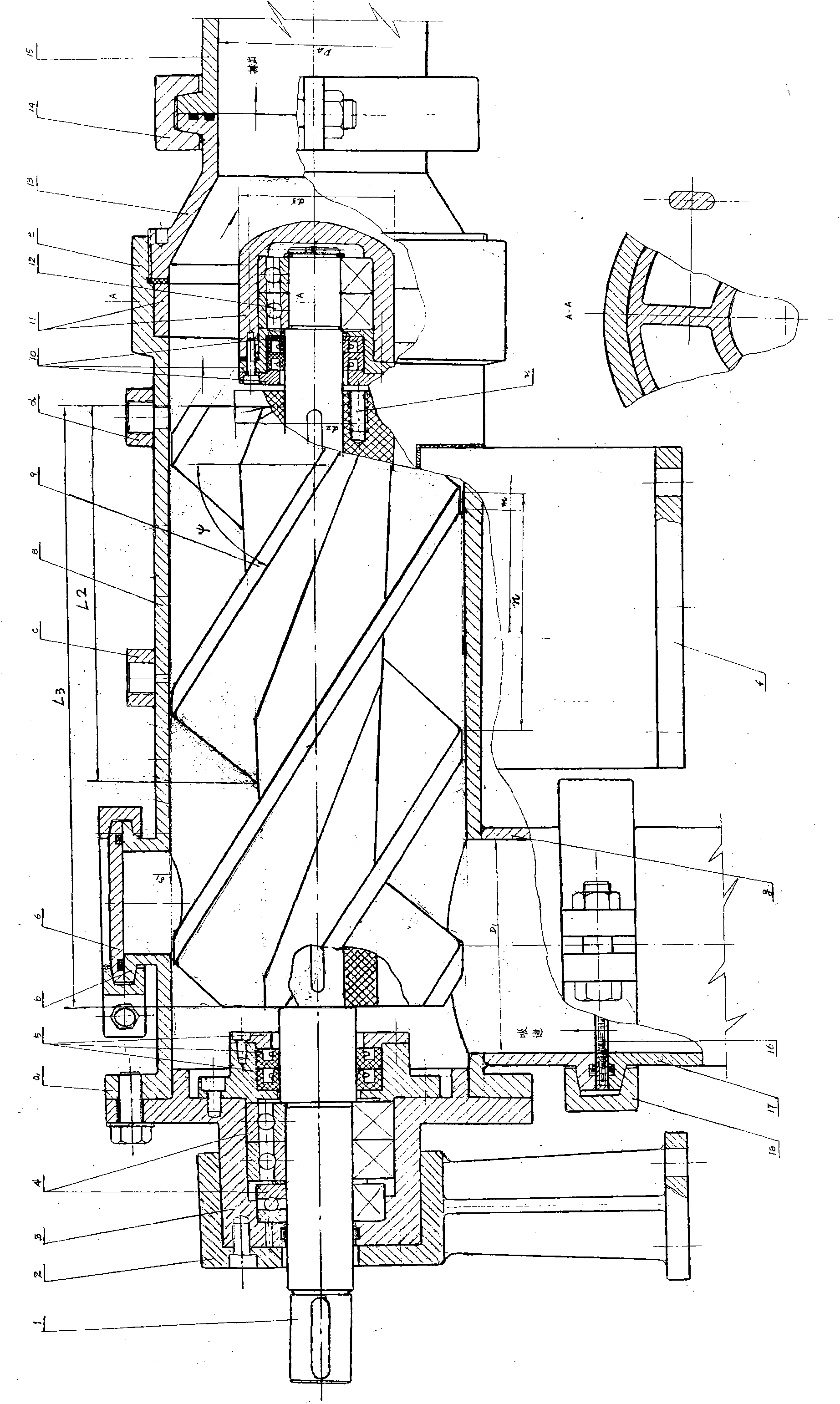

High-efficiency axial flow and screw combined pump for ship

InactiveCN102486169AGuaranteed coaxial accuracyImprove machining accuracyPropulsive elementsPump installationsAxial-flow pumpLow speed

The invention relates to a structure of a high-efficiency axial flow and screw combined pump. A large flow and a high pressure are obtained by high speed rotation. A transmission chain in a ship is greatly simplified. The high-efficiency axial flow and screw combined pump has light weight and is suitable for high-speed sailing. The high-efficiency axial flow and screw combined pump is characterized in that an axial flow pump impeller and a screw of a screw pump which are driven coaxially are arranged in a big sleeve to form a structure of an axial flow pump and the screw pump; if the positions of the axial flow pump and the screw pump are exchanged, a structure of the screw pump and the multi-stage axial pump is formed; and water is sucked from the front of the ship bottom, obtains kinetic energy through the front-mounted pump and then is fed to the rear-mounted pump to be boosted to be sprayed, so that the ship is propelled. One single screw is arranged and is provided with a plurality of heads; screw edges are very narrow and have large screw pitch, so that the depth of a screw thread gradually becomes shallow to achieve the effects of large flow and high pressure; and the axial flow pump is designed by combining excellent aerofoils according to a variable-circulation variable-axis surface. The pump has a very simple structure, has good manufacturability and is easy to manufacture; the high-efficiency axial flow and screw combined pump is convenient to install; the high-efficiency axial flow and screw combined pump rotates at the high speed, has small volume and light weight, is efficient and energy-saving; the high-efficiency axial flow and screw combined pump has the self-adsorption capability and the ship has high sailing speed; the high-efficiency axial flow and screw combined pump can be made to have large power; the high-efficiency axial flow and screw combined pump has double-injection capability, a steering engine is saved and the high-efficiency axial flow and screw combined pump has high performances which cannot be realized by a single low speed axial flow pump or mixed-flow pump injection propeller.

Owner:赵明

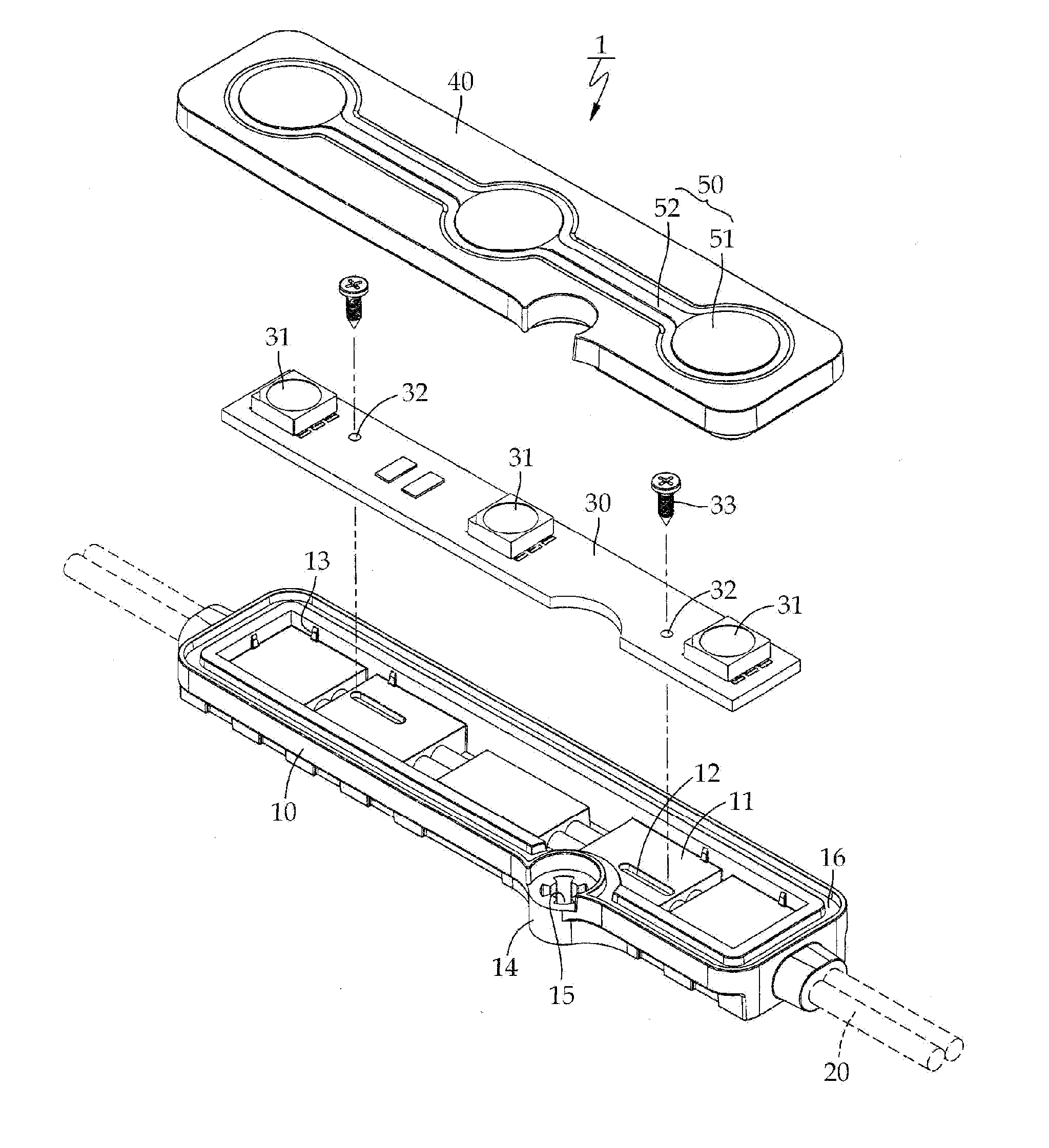

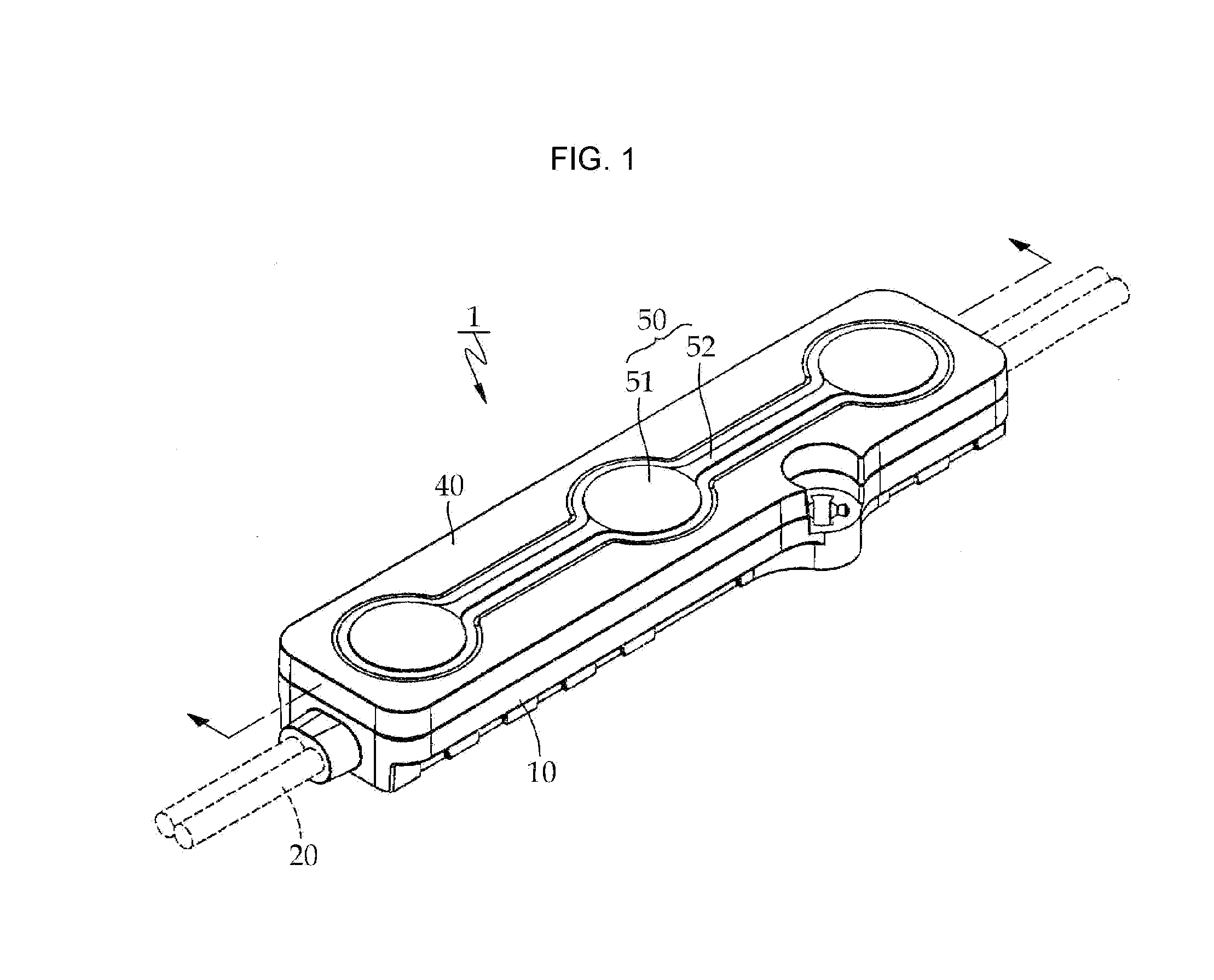

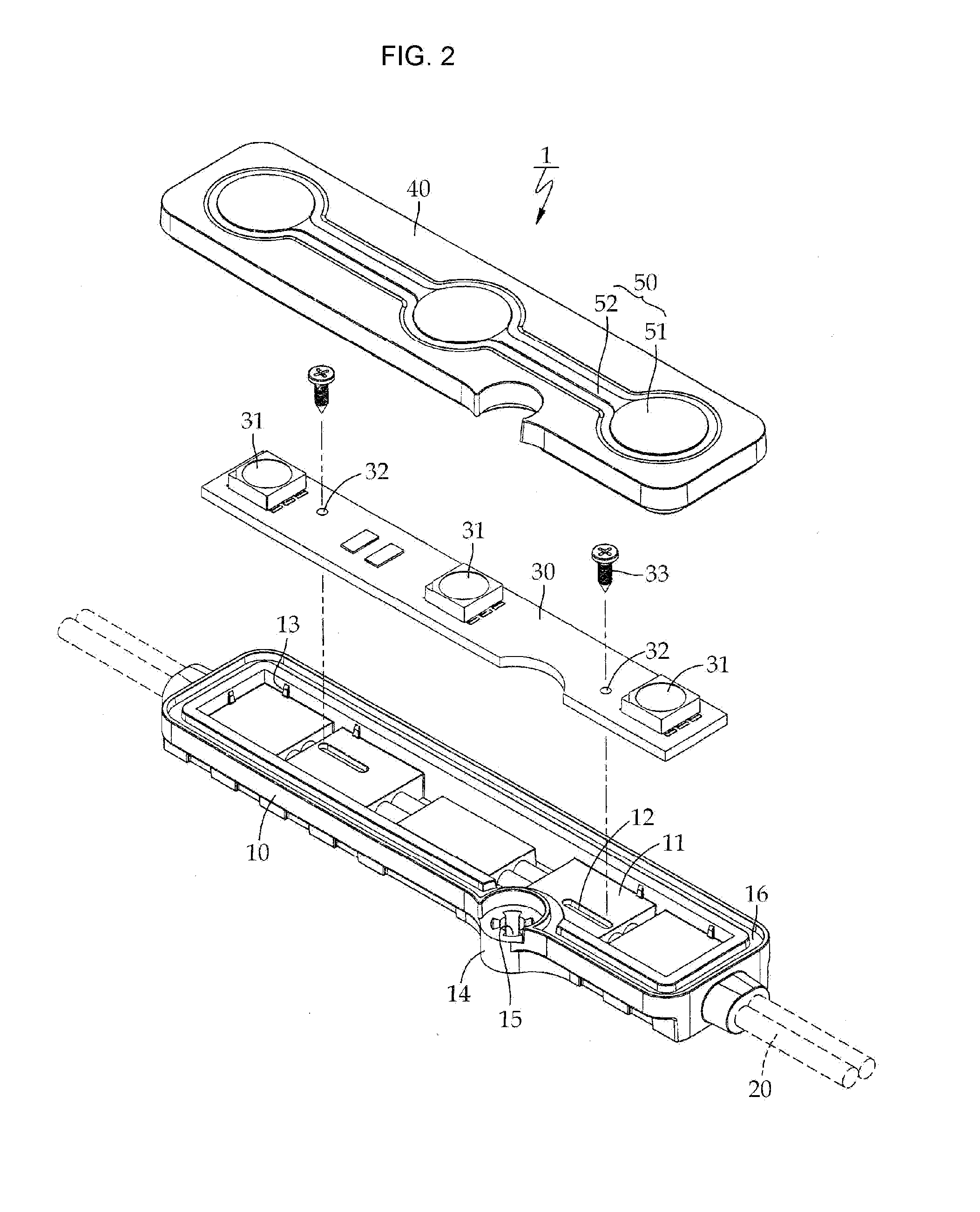

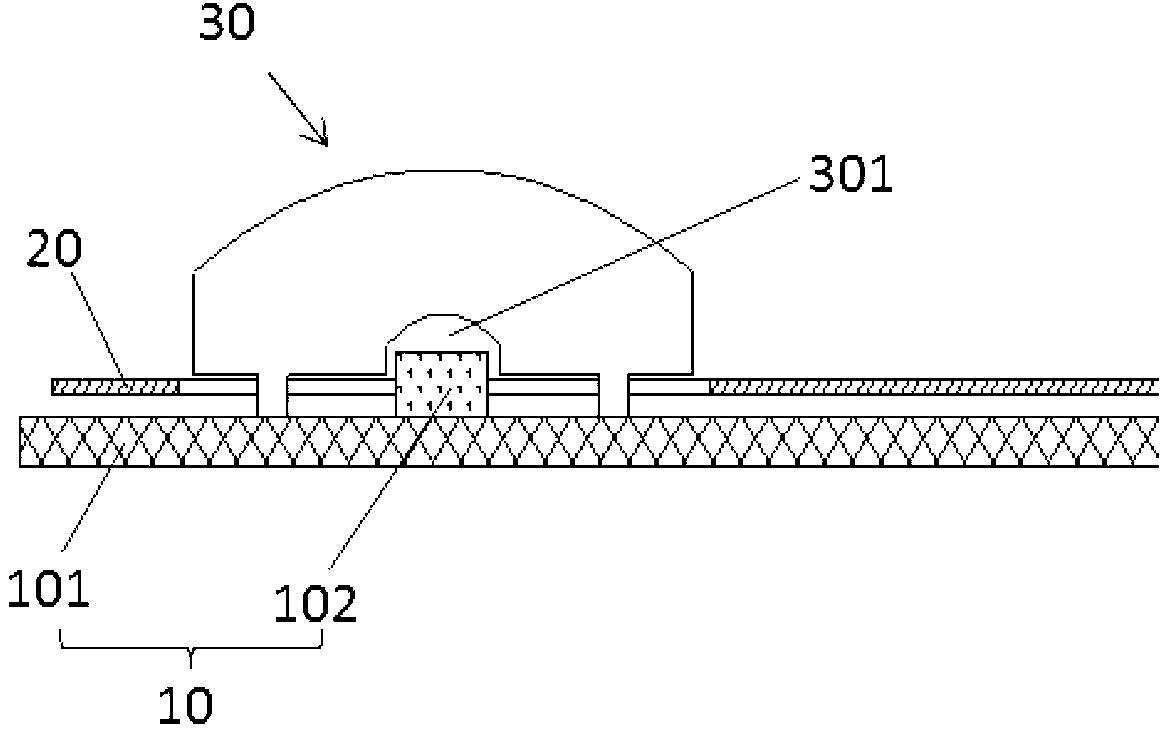

LED module

InactiveUS20140118990A1Reduce manufacturing costShort timeLighting support devicesElectric lightingUltrasonic weldingEngineering

A light emitting diode (LED) module is provided that emits uniform light in terms of the distribution of diffused light. The LED module comprises: a base plate integrally formed with electrical wires via an injection molding, wherein the base plate forms a reception space; a plate on which a number of LEDs are installed, wherein the plate is placed in the reception space of the base plate; bolts coupling the plate to the base plate; a cover that is fixed to the base plate via ultrasonic welding; and a lens part that is formed in the cover via a double injection molding, wherein the lens part comprises fluorescent materials and has various colors.

Owner:KI NO CHUL

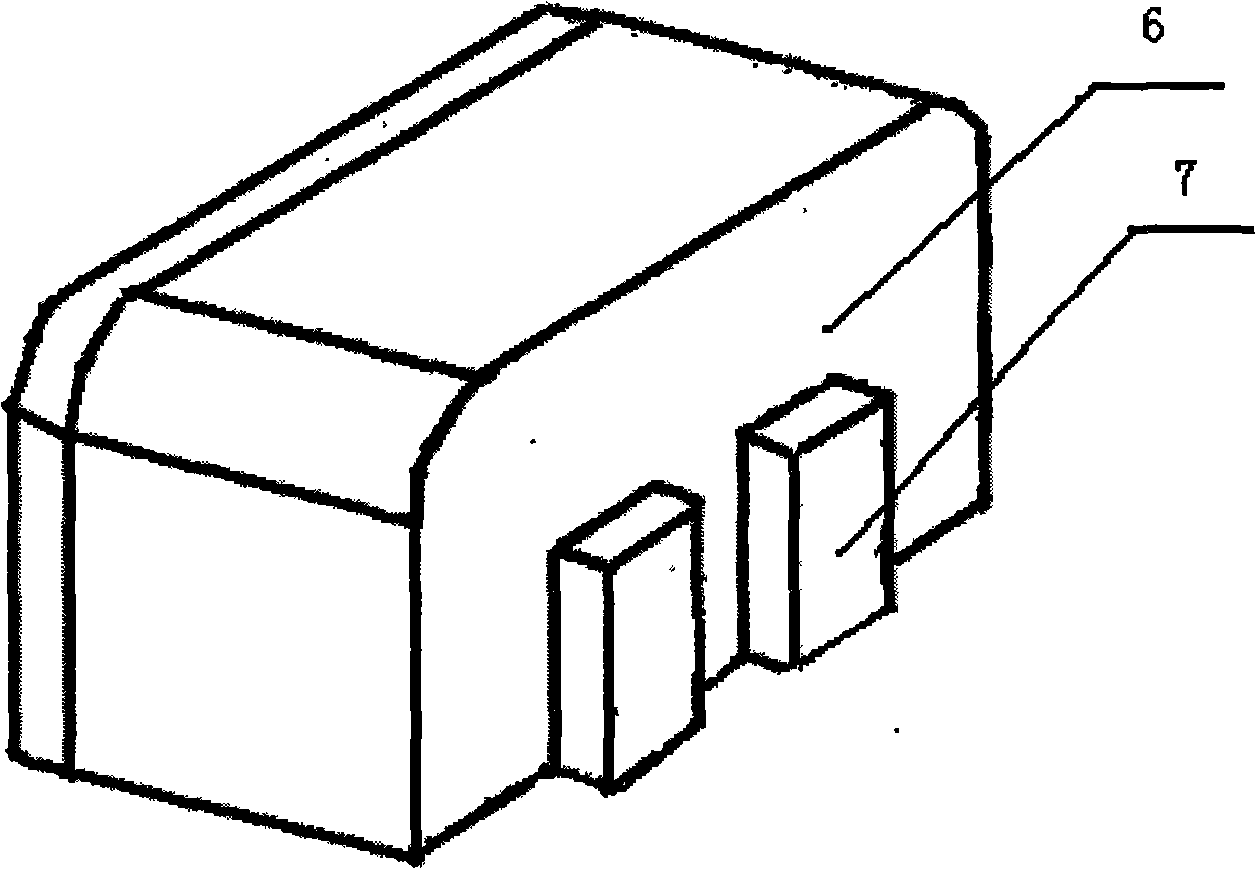

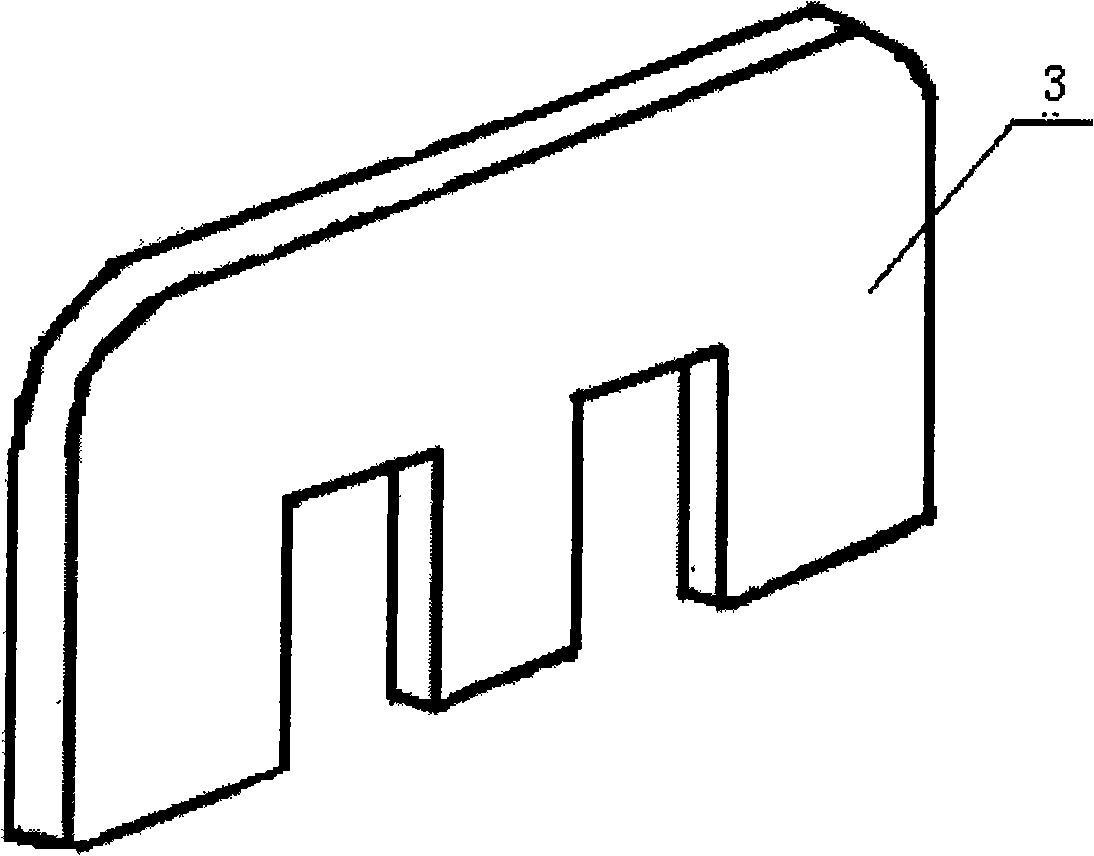

Ptc rod assembly and pre-heater including the same

The invention provides a positive temperature coefficient (PTC) rod device, comprising: electrode terminals; Supporting parts, the above-mentioned first and second supporting parts are connected to each other; PTC elements and heat transfer blocks respectively connected between adjacent pairs of first supporting parts and between adjacent pairs of second supporting parts; The groove-shaped first and second PTC rods are used to accommodate the above-mentioned devices. According to the PTC rod device described above, the coupling force between the electrode terminal and the insulator can be improved by integrally forming the electrode terminal and the insulator through double injection molding. Also, a support may be provided on the insulator to clearly define the coupling position of the PTC element and the heat transfer block, and a channel may be formed in the enlarged portion and the insulator support to exhaust gas generated when the PTC element is heated to the outside. The present invention also provides a vehicle preheater, comprising: a plurality of PTC rod devices constituted as above; one or more cooling fins that are in close contact with and coupled to both sides of each PTC rod device; and the outermost cooling fins A pair of frames coupled with the outer sides of the device; the first and second shells connected to the longitudinal ends of the above-mentioned device combination; the shell terminal set in the shell as the cathode terminal. According to the above-mentioned preheater, the heat generated on the PTC element is not transferred to the outside, but evenly transferred to the inside of the preheater, the coupling force of each element placed between the frames is increased, and the PTC rod device and heat sink The close contact between them has also been improved.

Owner:MODINE KOREA

Direct fuel injection/spark ignition engine control device

An engine control device is configured to perform optimum combustion control according to environmental conditions when warming up of a catalyst for emission purification is required. The engine control device performs stratified combustion by the compression stroke injection at the time of startup, when warming up of the catalyst is required. However, under conditions of low air density, stratified combustion by compression stroke injection is prevented, and either homogenous combustion by intake stroke injection is performed, or double injection combustion by intake stroke injection and compression stroke injection is performed. Thus, the engine control device maintains starting properties and prevents adverse effects on engine operability.

Owner:NISSAN MOTOR CO LTD

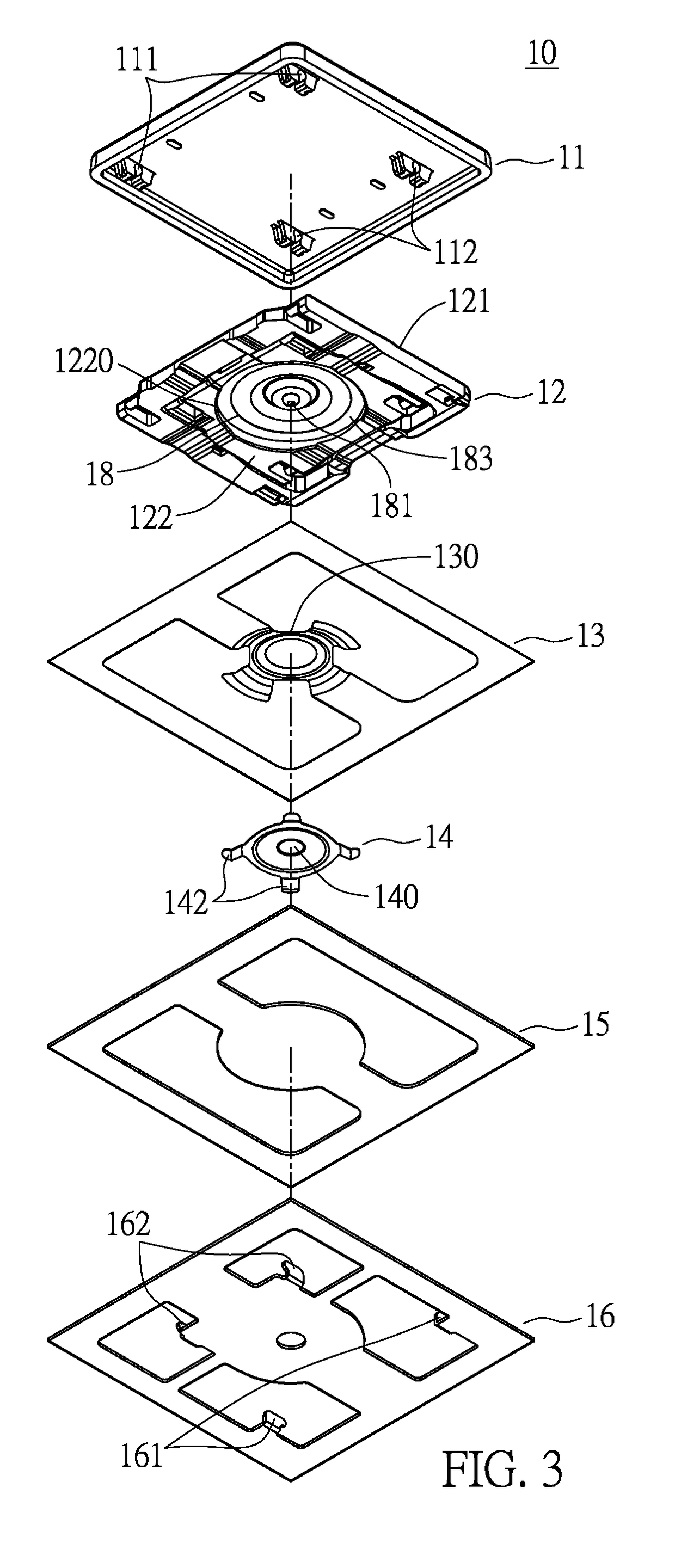

Keyboard, key module, movable switch mechanism and method for manufacturing movable switch mechanism

ActiveUS20180358193A1Extended service lifeGood touchEmergency actuatorsLegendsKey pressingComputer module

A keyboard includes a plurality of key modules. Each key module includes a baseplate, a circuit membrane disposed on the baseplate, a metal dome disposed on the circuit membrane, an elastic member disposed on the metal dome, and a keycap. The elastic member and the linkage member are configured to be a movable switch mechanism. The circuit membrane has a conductive circuit. The metal dome has an opening corresponding to the conductive circuit of the circuit membrane. A trigger portion protrudes from an underside of the elastic member. When the keycap is pressed, the trigger portion passes through the opening of the metal dome, and moves downwards to abut against the conductive circuit to induce a conducting signal. The movable switch mechanism can be made by a double injection molding method.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Double-color injection-molding die with active spacing block and preparation method thereof

The invention relates to a double-color injection moulding mould with a movable separator and a method for preparing the same. Compared with two forms of convex mould translation and convex mould rotation of the prior double-color injection moulding mould, the double-color injection moulding mould is a single-cavity double-injection mould and comprises a convex mould and a concave mould. The moulding surface of the concave mould and the moulding surface of the convex mould form an injection moulding cavity; the convex mould comprises a first convex mould and a second convex mould between which a gap exists; and the gap is provided with a movable separating slice inside, and the movable separating slice extends into the injection moulding cavity and divides the injection moulding cavity into a first injection moulding cavity and a second injection moulding cavity which are not communicated. The mould has the advantages of simple structure, small volume, small ground occupying range, small investment, low energy consumption and high injection moulding efficiency.

Owner:JIANGSU CHANGSANJIAO MOLD CITY DEV +2

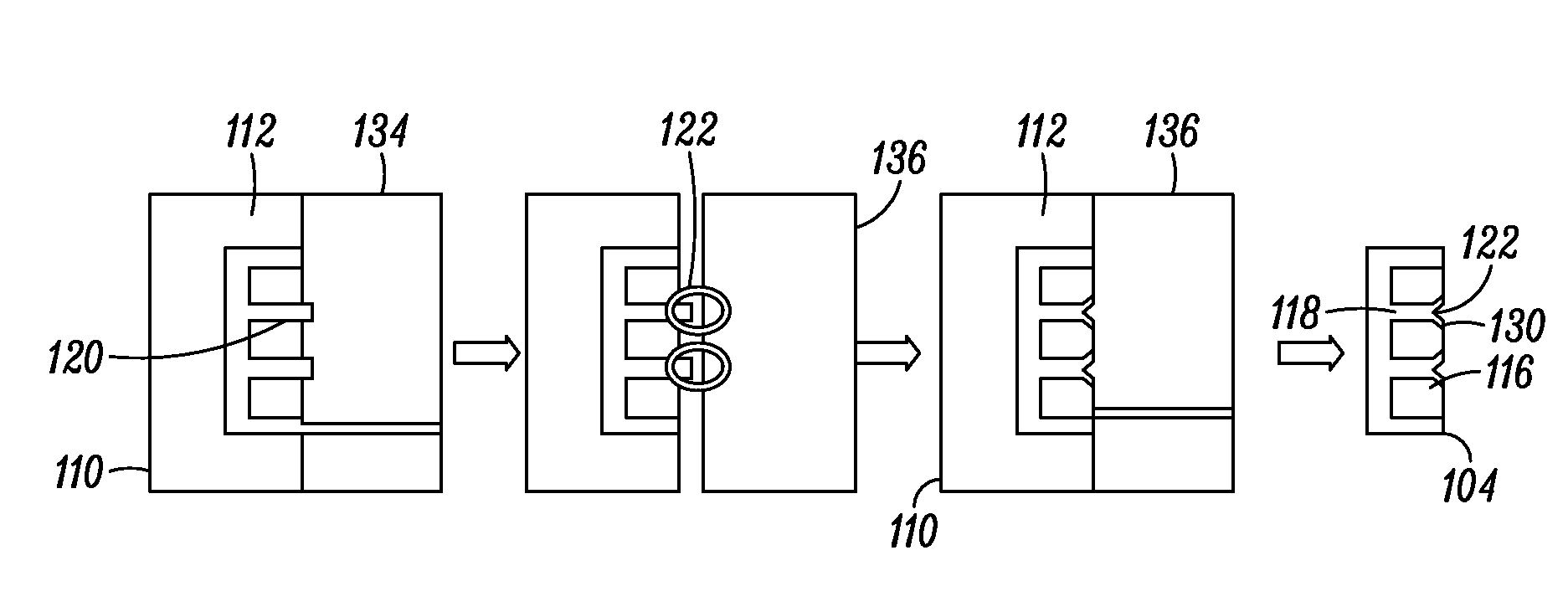

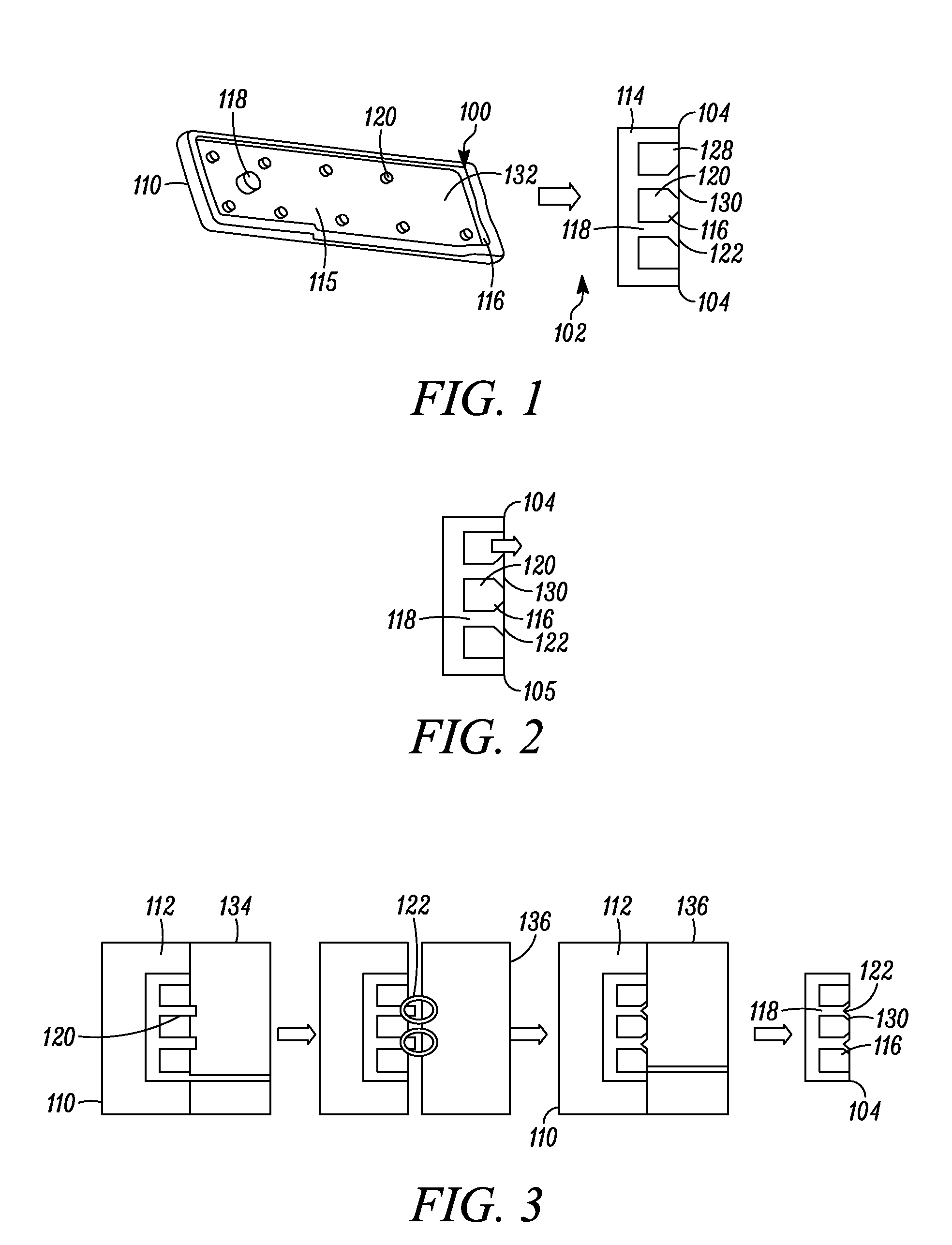

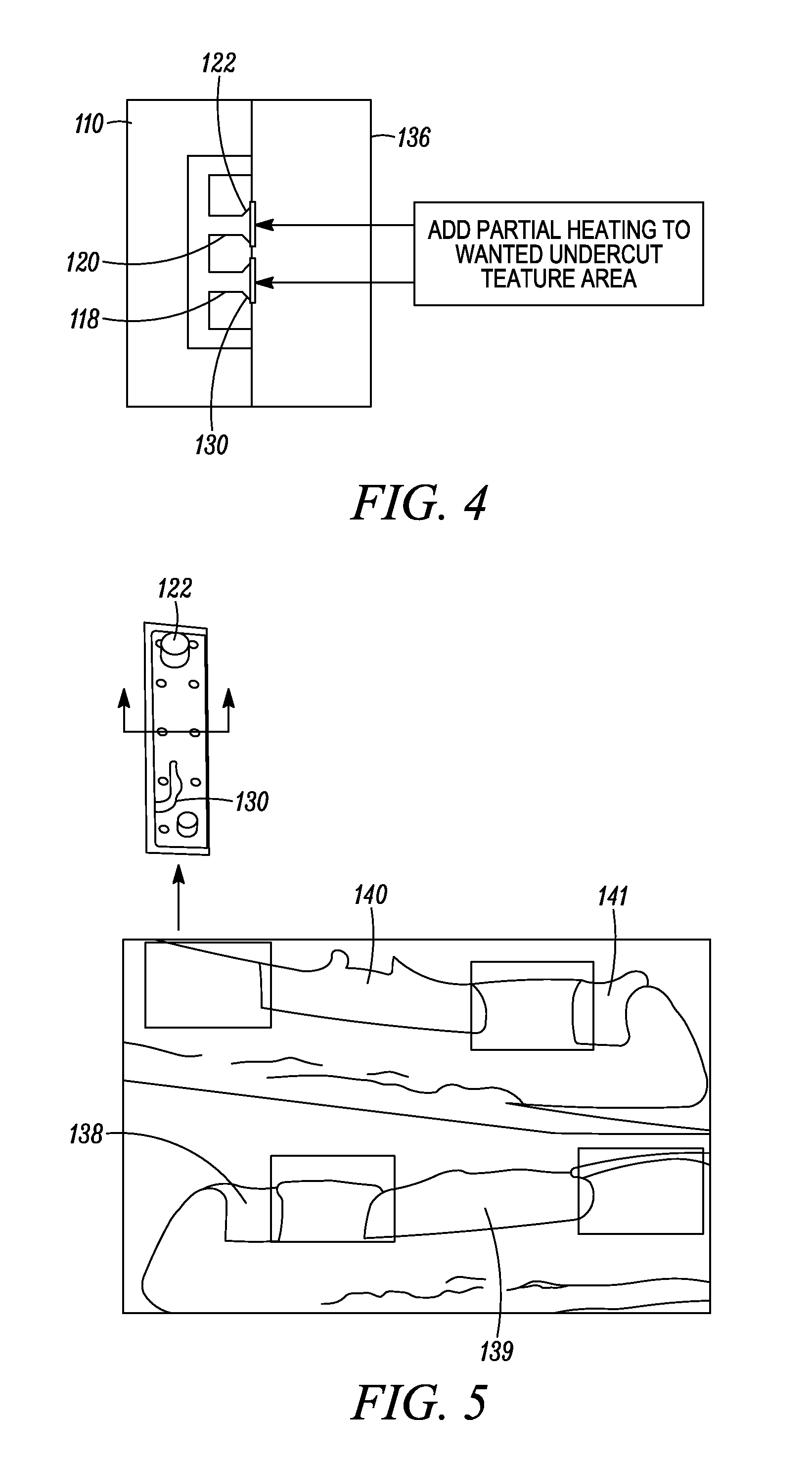

Anti-Delamination Feature For Double Injection Mold Parts

InactiveUS20110278759A1Avoid layeringImproved anti-delaminationCeramic shaping apparatusFood shapingElectronic communicationDouble injection

An effective economical anti-delamination feature 100 and process 102 for double injected molding is provided to mold attractive high quality products 104, such as, but not limited to, grommets 106 for use in electronic communications devices 108. In the process, after a first shot 114 is injected into a double injection mold 110, an undercut 116 comprising a delamination feature is formed in the double injection mold by tool compression or partial heating, before injecting a second shot 128 into the double injection mold.

Owner:GOOGLE TECH HLDG LLC

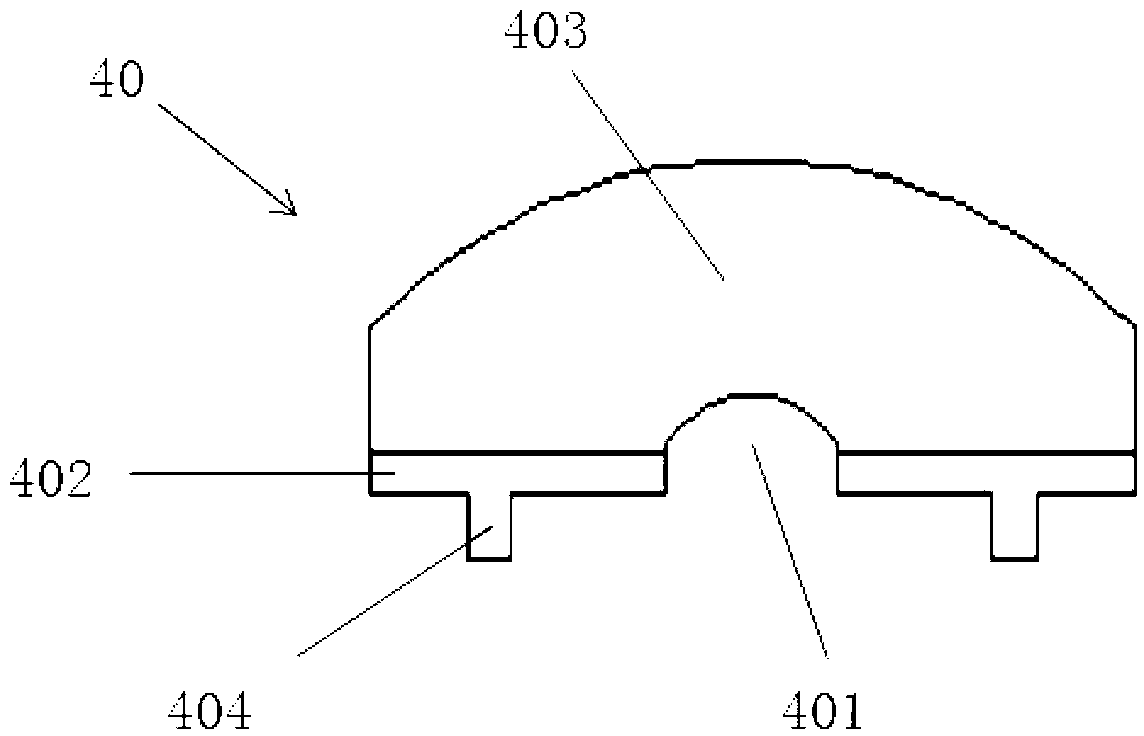

Direct-type LED backlight module

InactiveCN103256561AReduce dosageLow costPoint-like light sourceLight fasteningsPlastic materialsEngineering

The invention discloses a direct-type LED backlight module which comprises an LED light bar, a plurality of secondary lenses and a reflector plate, wherein the LED light bar is provided with a plurality of LEDs, and the secondary lenses are installed corresponding to the LEDs one by one. Each secondary lens comprises a bottom surface, a top, a concave part and a combined part, wherein each concave part is located at the center position, and each combined part is located below the corresponding bottom surface, and each LED is contained in the corresponding concave part. The reflector plate is attached to the LED light bar, opening holes are formed in the positions, corresponding to the secondary lenses, of the reflector plate, and the secondary lenses penetrate through the reflector plate to guide light. The secondary lenses are formed in a double injection molding mode, the bottom surface of each secondary lens is made of white and non-transparent plastic materials, and the top of each secondary lens is made of transparent plastic materials. By means of the scheme, both the white and non-transparent plastic bottom surface of each secondary lens and the reflector plate serve as a whole reflecting surface of the backlight module, namely, the reflectivity of the whole reflecting surface of the backlight module is close, meanwhile, a substrate of the LED light bar below the secondary lenses can be made to be small as much as possible, the using quantity of the substrate of the LED light bars is saved, and cost is effectively reduced.

Owner:NANJING CEC PANDA LCD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com