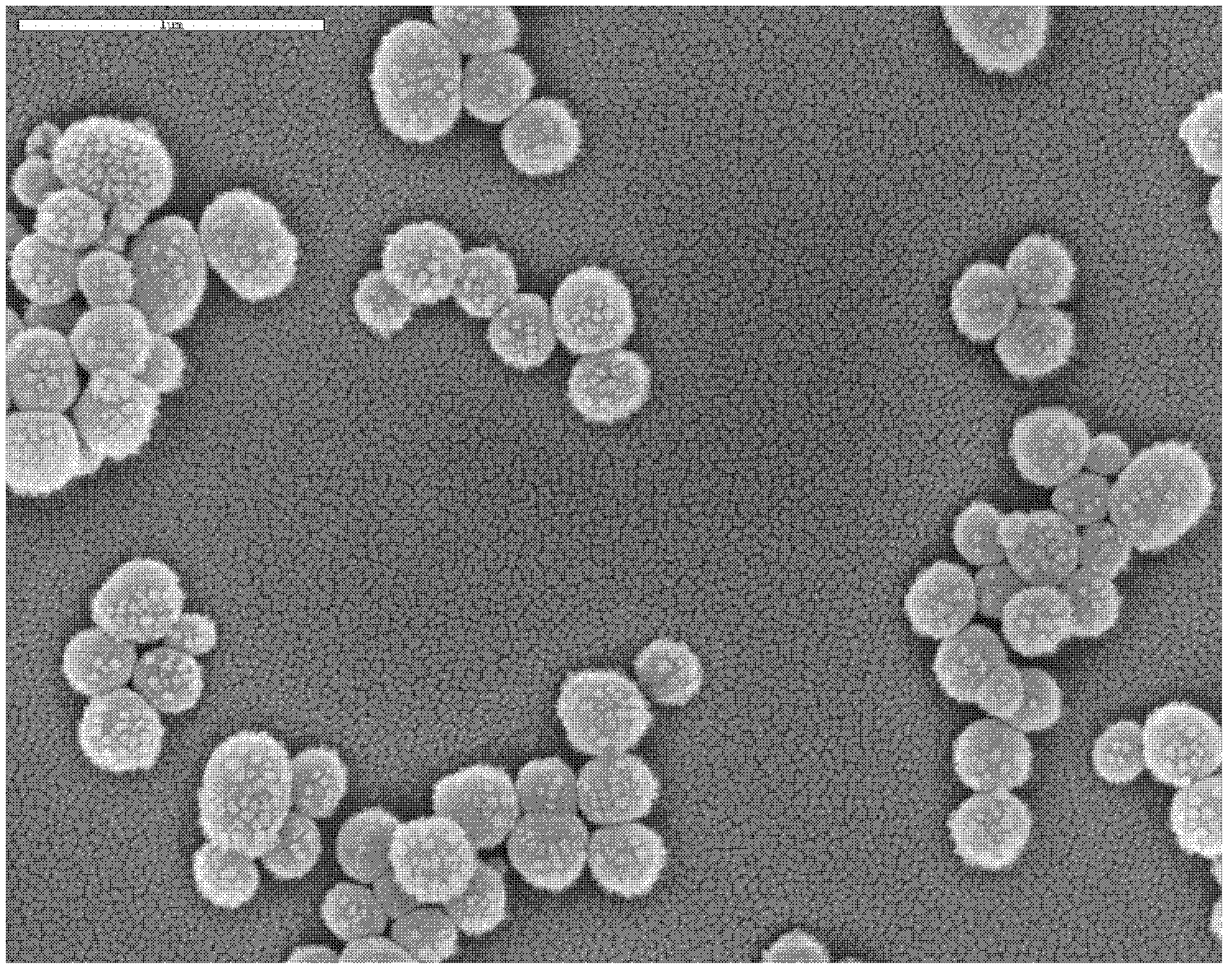

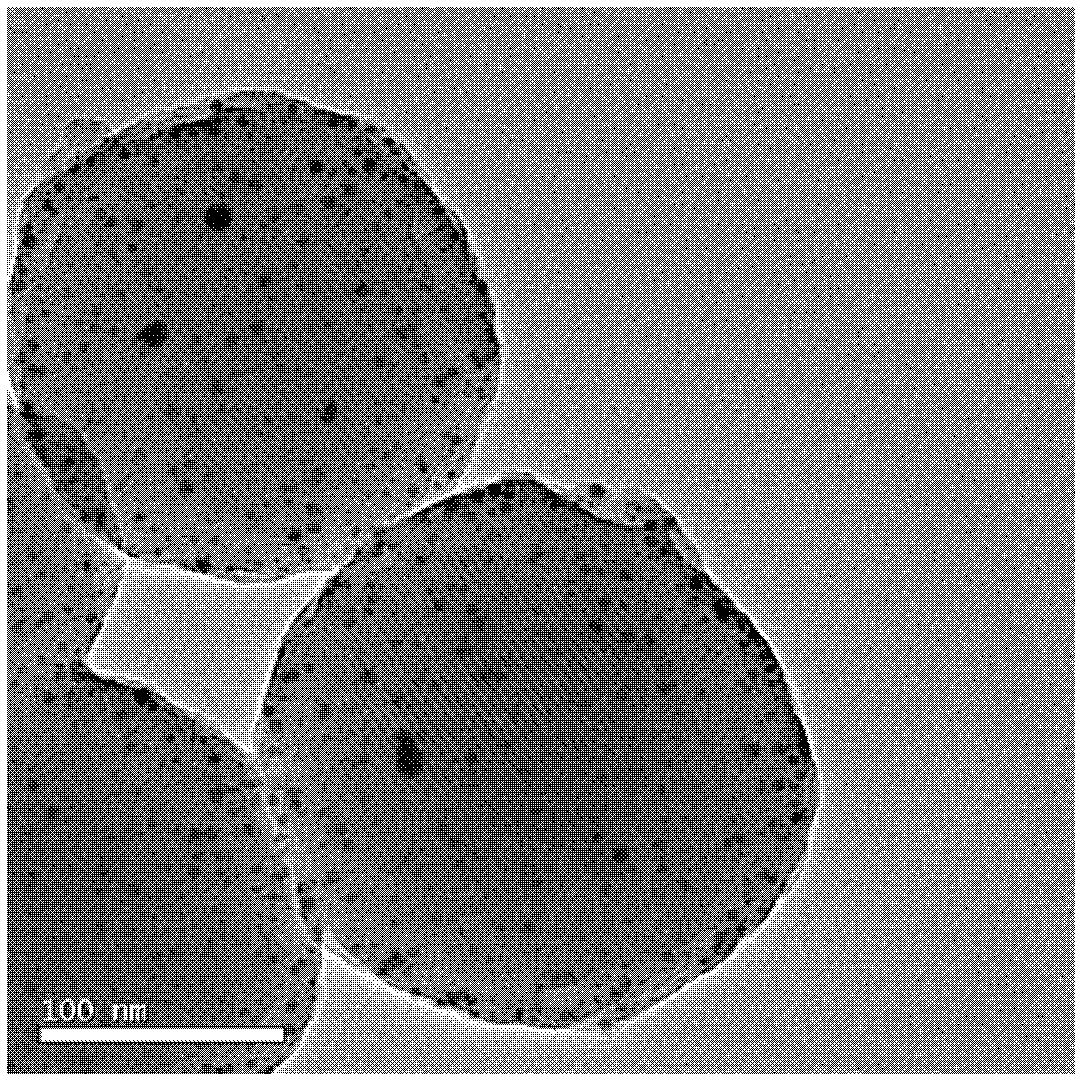

Method for preparing antibacterial powder loaded with monodisperse silver nanometer mesoporous silica

A technology of mesoporous silica and antibacterial powder is applied in the field of antibacterial materials, which can solve the problems of easy falling off and the inability of nano silver to be firmly fixed, and achieve the effects of lasting antibacterial effect, high sterilization rate and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. The reaction raw materials are as follows:

[0057] CTAB (0.2g), deionized water (100ml), 2M NaOH solution (1.0ml), methanol solution of TEOS (2ml of TEOS diluted with 5ml of methanol), TSD (0.5ml) modified AgNO 3 (1.0wt%, this concentration is the concentration of the silver salt solution before modification) solution, 35-40wt% formaldehyde aqueous solution is formalin (2ml)

[0058] 2. Reaction temperature: 75°C

[0059] 3. Preparation steps of antibacterial powder:

[0060] 1) Add 0.2g of CTAB into a three-necked flask equipped with 100ml of deionized water and 1.0ml of NaOH solution (2M), the reaction temperature is 75°C, after the solution is stirred and clarified, first add 3ml of methanol solution of TEOS dropwise , stir for 10min;

[0061] 2) Add 10ml of AgNO modified with TSD (0.5ml) dropwise to the reaction system of step 1) by double injection 3 (1.0wt%, this concentration is the concentration of the silver salt solution before modification) solution a...

Embodiment 2

[0078] 1. The reaction raw materials are as follows:

[0079] CTAB (0.4g), deionized water (130ml), 2M NaOH solution (1.5ml), methanol solution of TEOS (3ml of TEOS diluted with 10ml of methanol), TSD (1.5ml) modified AgNO 3 (0.6wt%, this concentration is the concentration of silver salt solution before modification) solution, 35-40wt% formaldehyde aqueous solution is formalin (5ml)

[0080] 2. Reaction temperature: 85°C

[0081] 3. Preparation steps of antibacterial powder:

[0082] 1) Add 0.4g of CTAB into a three-necked flask equipped with 130ml of deionized water and 1.5ml of NaOH solution (2M), the reaction temperature is 85°C, after the solution is stirred and clarified, first add 3ml of methanol solution of TEOS dropwise , stir for 10min;

[0083]2) Add 10ml of AgNO modified with TSD (1.5ml) dropwise to the reaction system in step 1) by double injection 3 (0.6wt%, this concentration is the concentration of the silver salt solution before modification) solution and s...

Embodiment 3

[0090] 1. The reaction raw materials are as follows:

[0091] CTAB (0.3g), deionized water (110ml), 2M NaOH solution (2.0ml), methanol solution of TEOS (3ml of TEOS diluted with 8ml of methanol), TSD (0.3ml) modified AgNO 3 (0.3wt%, this concentration is the concentration of the silver salt solution before modification) solution, the formaldehyde aqueous solution of 35-40wt% is formalin (3ml)

[0092] 2. Reaction temperature: 60°C

[0093] 3. Preparation steps of antibacterial powder:

[0094] 1) Add 0.3g of CTAB into a three-necked flask equipped with 110ml of deionized water and 2.0ml of NaOH solution (2M), the reaction temperature is 60°C, after the solution is stirred and clarified, first add 1ml of TEOS methanol solution dropwise , stir for 10min;

[0095] 2) Add 10ml of AgNO modified with TSD (0.3ml) dropwise to the reaction system of step 1) by double injection 3 (1.0wt%, this concentration is the concentration of the silver salt solution before modification) soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Minimum inhibitory concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com