Long-service-life organic silicon polymer antibacterial liquid, preparation method thereof and preparation method of antibacterial coating

A silicone and polymer technology, applied in the field of antibacterial materials, can solve problems such as toxicity, surface discoloration and failure of silver-loaded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Organosilicon polymer antibacterial liquid, which consists of: 76 parts of dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, 3 parts of glacial acetic acid, 7 parts of methyl tributyl ketone oxime base silane, 1 part organic bismuth DY-20, 13 parts 3-aminopropyltriethoxysilane.

[0049] First add dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride, glacial acetic acid, methyltributanoximinosilane, organic bismuth DY-20 to the reaction kettle in sequence , heated to 70°C under stirring conditions, and reacted for 2 hours to stop the reaction, and the heating rate was 10°C / min. After cooling, add 3-aminopropyltriethoxysilane to the system to obtain the organic silicon polymer antibacterial liquid.

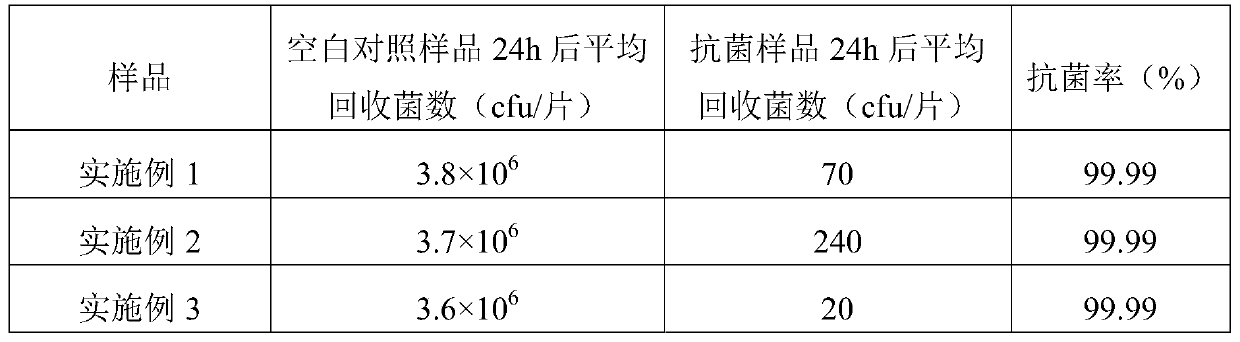

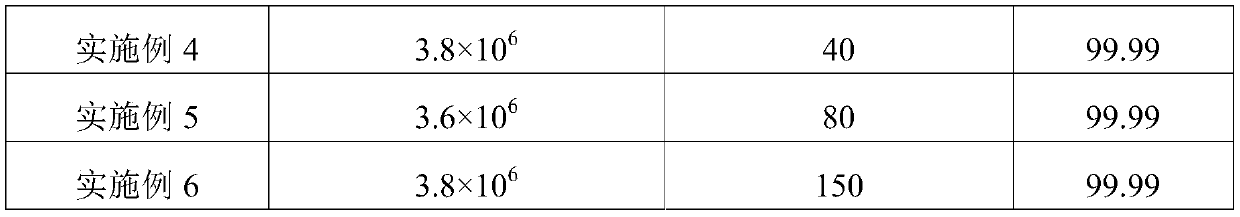

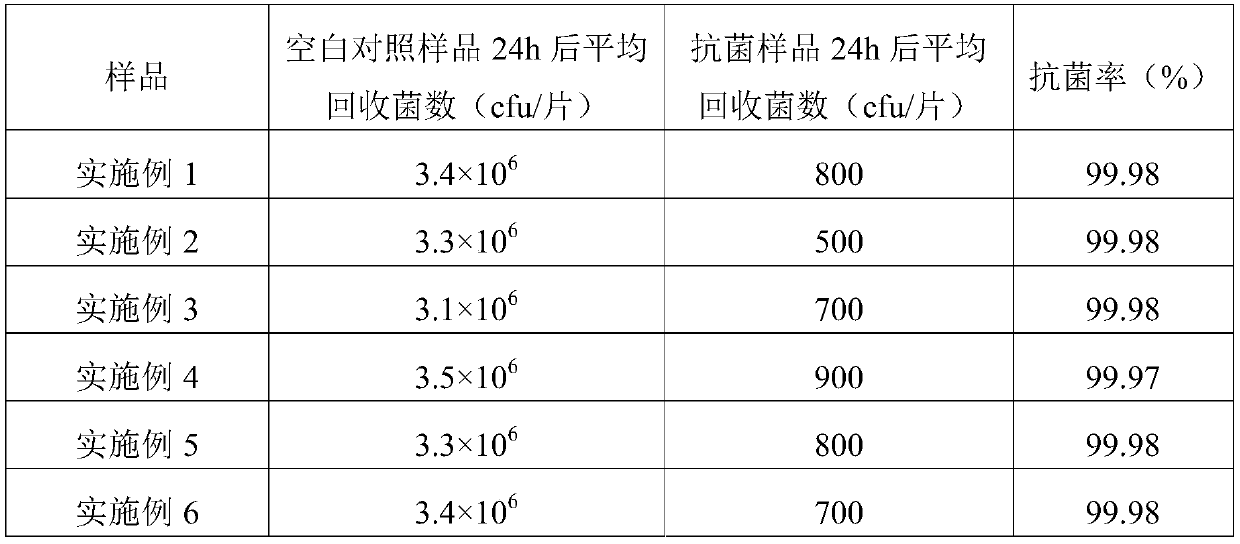

[0050] The above-mentioned organic silicon polymer antibacterial liquid is evenly coated on the stainless steel sheet by spraying equipment, and the antibacterial liquid layer cannot have appearance spraying problems such as orange peel, rainbow patt...

Embodiment 2

[0053] Organosilicon polymer antibacterial liquid, which consists of: 79 parts of dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, 6 parts of glacial acetic acid, 5 parts of methyl tributyl ketone oxime base silane, 1 part organic bismuth DY-20, 15 parts 3-aminopropyltriethoxysilane.

[0054] First add dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride, glacial acetic acid, methyltributanoximinosilane, organic bismuth DY-20 to the reaction kettle in sequence , heated to 70°C under stirring conditions, and reacted for 1 hour to stop the reaction, and the heating rate was 15°C / min. After cooling, add 3-aminopropyltriethoxysilane to the system to obtain the organic silicon polymer antibacterial liquid.

[0055] The above-mentioned organic silicon polymer antibacterial liquid is evenly coated on the stainless steel sheet by spraying equipment, and the antibacterial liquid layer cannot have appearance spraying problems such as orange peel, rainbow patte...

Embodiment 3

[0058] Organosilicon polymer antibacterial liquid, which consists of: 74 parts of dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, 5 parts of glacial acetic acid, 7 parts of methyl tributyl ketone oxime silane, 1 part of bismuth isooctanoate, 10 parts of 3-aminopropyltriethoxysilane.

[0059] First, dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, glacial acetic acid, methyl tributylketoximosilane, and bismuth isooctanoate are added to the reaction kettle in sequence, Heating to 50°C under stirring conditions, and reacting for 4 hours, the reaction can be stopped, and the heating rate is 10°C / min. After cooling, add 3-aminopropyltriethoxysilane to the system to obtain the organic silicon polymer antibacterial liquid.

[0060] The above-mentioned organosilicon polymer antibacterial liquid is uniformly coated on the glass sheet by spraying equipment, and the antibacterial liquid layer cannot have appearance spraying problems such as orange peel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dry film thickness | aaaaa | aaaaa |

| Dry film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com