Modified polyacrylate flame-retardant emulsion, modified polyacrylate flame-retardant pressure-sensitive adhesive containing modified polyacrylate flame-retardant emulsion and preparation method of modified polyacrylate flame-retardant pressure-sensitive adhesive

A polyacrylate, flame retardant emulsion technology, used in adhesives, graft polymer adhesives, adhesive types, etc., can solve problems affecting the overall thickness of the product, affecting the pressure-sensitive properties of acrylic pressure-sensitive adhesives, etc. Achieve the effect of good fire resistance, excellent adhesion, and excellent expansion and foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

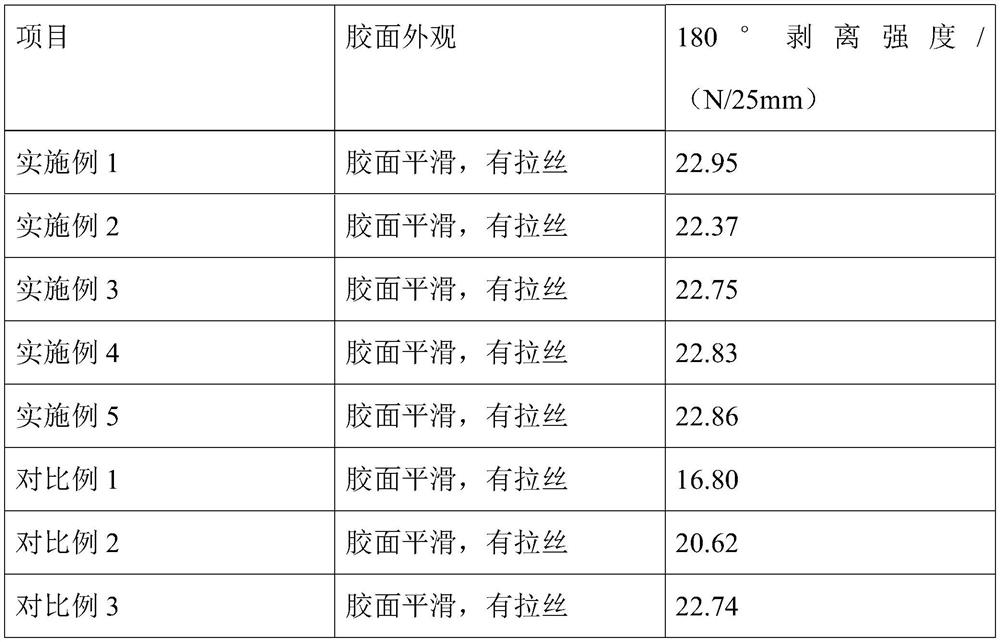

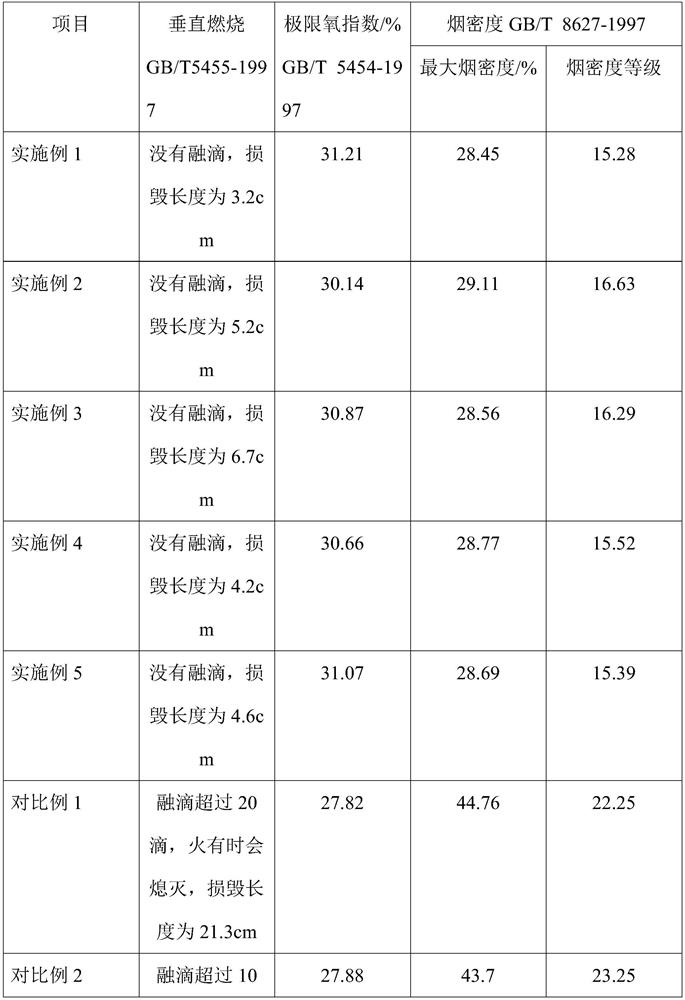

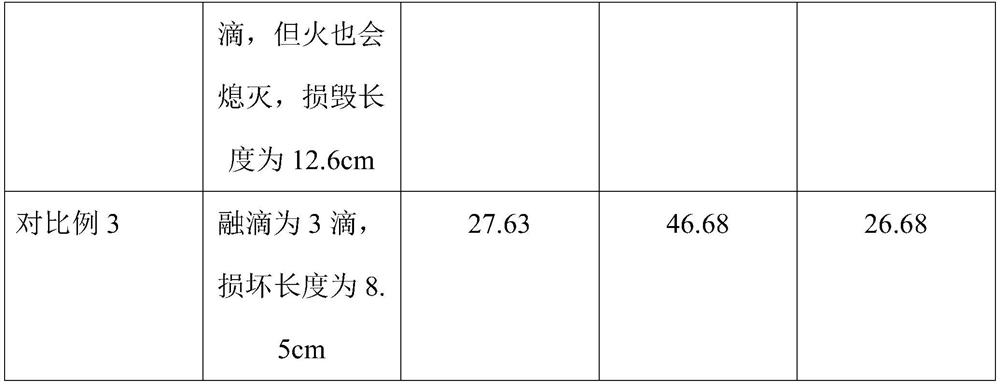

Examples

Embodiment 1

[0032] A modified polyacrylate flame retardant pressure-sensitive adhesive, comprising the following raw materials in parts by mass:

[0033] 35 parts of modified polyacrylate flame retardant emulsion, 13 parts of melamine, 16 parts of ammonium polyphosphate, 18 parts of dipentaerythritol, 3 parts of titanium dioxide, 4 parts of zinc oxide, 2 parts of graphene, 1.5 parts of diatomaceous earth, dispersed 0.2 part of antifoaming agent and 0.3 part of defoamer.

[0034] The preparation method of the modified polyacrylate flame retardant pressure-sensitive adhesive comprises the following steps:

[0035] 1) Mix the modified polyacrylate flame retardant emulsion, dispersant and dispersant, and disperse for 15min at a rotating speed of 1500r / min to obtain a mixed solution;

[0036] 2) Grinding melamine, dipentaerythritol, titanium dioxide, zinc oxide and diatomaceous earth to a fineness of 60 μm, then adding the mixed solution, stirring evenly, then adding ammonium polyphosphate an...

Embodiment 2

[0044] A modified polyacrylate flame retardant pressure-sensitive adhesive, comprising the following raw materials in parts by mass:

[0045] 30 parts of modified polyacrylate flame retardant emulsion, 10 parts of melamine, 15 parts of ammonium polyphosphate, 15 parts of dipentaerythritol, 1 part of titanium dioxide, 1 part of zinc oxide, 1 part of graphene, 1 part of diatomaceous earth, dispersed 0.1 part of antifoaming agent and 0.1 part of defoamer.

[0046] The preparation method of the modified polyacrylate flame retardant pressure-sensitive adhesive in this example is the same as that in Example 1.

Embodiment 3

[0048] A modified polyacrylate flame retardant pressure-sensitive adhesive, comprising the following raw materials in parts by mass:

[0049] 40 parts of modified polyacrylate flame retardant emulsion, 15 parts of melamine, 20 parts of ammonium polyphosphate, 20 parts of dipentaerythritol, 5 parts of titanium dioxide, 1 to 5 parts of zinc oxide, 1 to 5 parts of graphene, diatomaceous earth 1-5 parts, dispersant 0.1-0.5 part and defoamer 0.1-0.5 part.

[0050] The preparation method of the modified polyacrylate flame retardant pressure-sensitive adhesive in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com