Patents

Literature

49results about How to "Overcome adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multilayered gradient diamond like nano composite coating for aluminum alloy piston and preparation method thereof

InactiveCN102092166AOvercome stressOvercome adhesionLayered productsVacuum evaporation coatingDiamond-like carbonSurface layer

The invention discloses a multilayered gradient diamond like nano composite coating for an aluminum alloy piston and a preparation method thereof. The coating consists of a piston matrix, a bottom adhesive layer, a middle transition layer and a surface layer in turn, wherein the bottom is provided with a metal Ti or Cr adhesive layer; the middle transition layer is metal nitride and a Si layer; and the surface layer is a metal-doped diamond like carbon film. The wear life of the coating is improved by more than 40 times compared with that of a single-layer diamond like coating with the same thickness directly formed on the surface of aluminum alloy, and the friction coefficient under the oil lubricating condition is stabilized to be 0.05. The piston with the diamond like coating has better comprehensive performance than a piston of which the skirt is treated by MoS2, and can meet the requirements on high speed, high efficiency and low emission of a modern engine.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

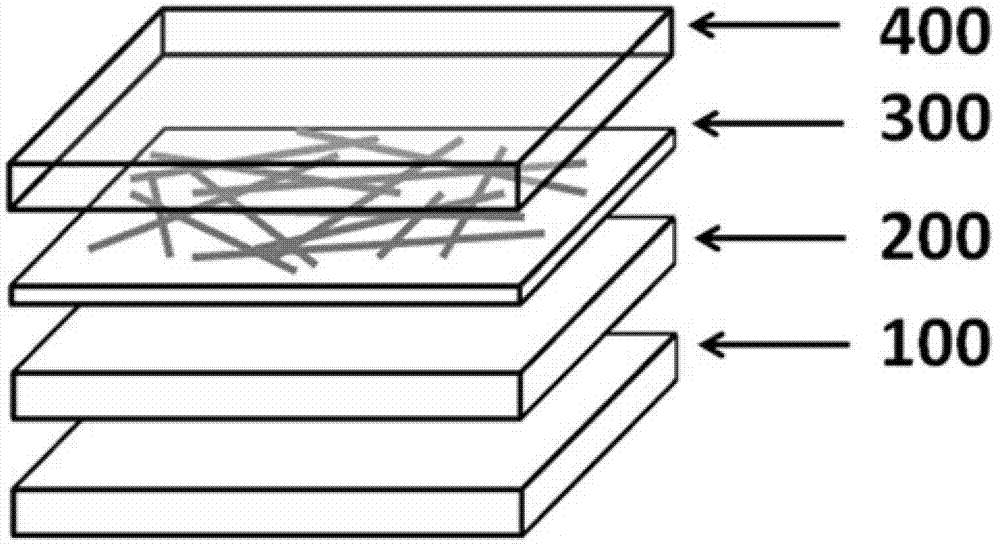

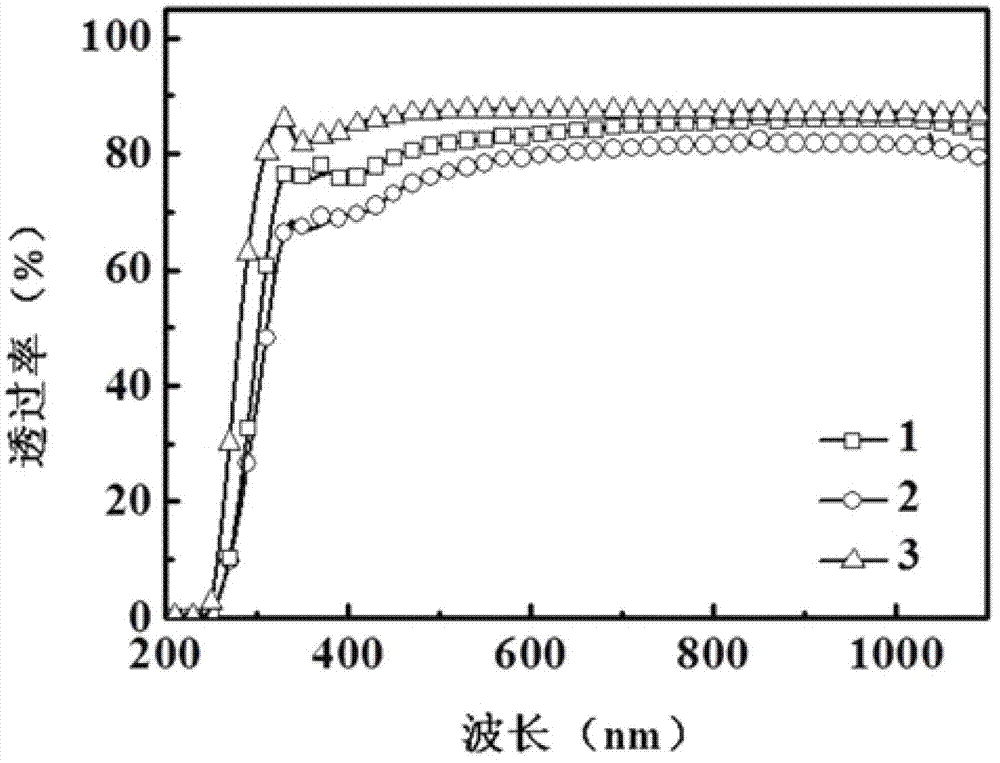

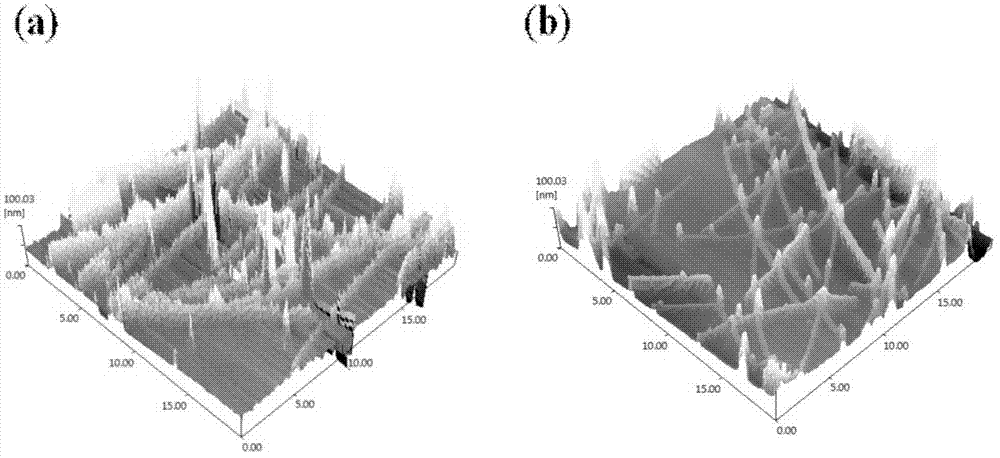

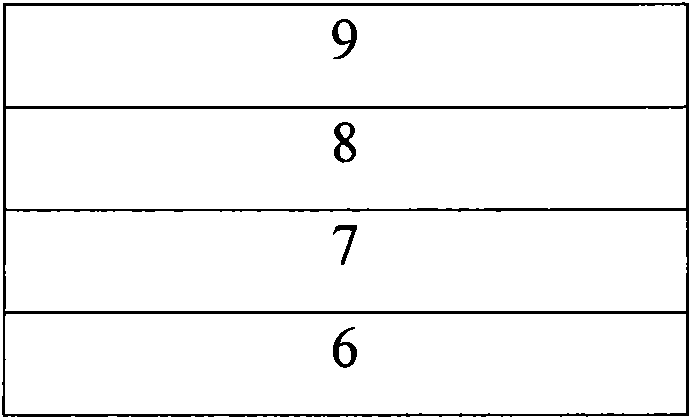

Full-solution-processed multilayered-structure transparent conductive thin film and preparation method thereof

ActiveCN103198884ARealize large-area flexible productionEasy to operateConductive layers on insulating-supportsCable/conductor manufactureHYDROSOLSolution processed

The invention provides a full-solution-processed multilayered-structure transparent conductive thin film and a preparation method of the full-solution-processed multilayered-structure transparent conductive thin film, belongs to the technical field of conductive thin film materials, and solves technical problems that in the prior art, a single-layer-structure metal nanowire transparent conductive thin film is high in roughness, small in adhesive force and poor in stability, a preparation method of a multilayered-structure transparent conductive thin film is not in favor of preparing a large-area flexible transparent conductive thin film and cannot be engineered. According to the preparation method of the full-solution-processed multilayered-structure transparent conductive thin film, metal oxide semiconductor sols are used as raw materials of a dielectric layer, metal nanowires dispersed by organic solvents are used as raw materials of a metal layer, and the multilayered-structure transparent conductive thin film is prepared with adoption of a solution processing method. The preparation method of the full-solution-processed multilayered-structure transparent conductive thin film achieves large-area flexible production of the multilayered-structure transparent conductive thin film, and the prepared transparent conductive thin film is strong in adhesive force, high in visible light average transmittance (81.5%), low in surface roughness (2.1nm), high in environmental stability, and outstanding in photoelectric performance.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Preparation method of superhydrophobic nanomaterial

ActiveCN108504284AOvercoming weak hydrophobicityOvercome rangeAntifouling/underwater paintsPaints with biocidesWater bathsAlcohol

The invention relates to a preparation method of a superhydrophobic nanomaterial. The preparation method comprises steps as follows: firstly, nano silica is ultrasonically dispersed in a part of an absolute ethyl alcohol solution, then, a silane coupling agent is added to a mixed solution to be rapidly stirred for 2 h (at the water bath temperature of 60 DEG C), the mixture is aged at the room temperature for 24 h, and a solution A is obtained; secondly, the silane coupling agent is added to the remaining absolute ethyl alcohol solution to be rapidly stirred for 2 h, fumed silica is added, andthe mixture is continuously stirred for 30 min, finally, perfluorinated silane is slowly dropwise added, the mixture is stirred intensely for 5 h, and a solution B is obtained; finally, the solutionA and the solution B are mixed and stirred for 2 h, a film-forming agent is added, the mixture is continuously stirred for 2 h, and the superhydrophobic nanomaterial is obtained. The preparation method has the advantages as follows: the superhydrophobic nanomaterial has stable and durable superhydrophobic performance, is non-corrosive, free from environmental pollution, low in cost and wide in application range and adopts a simple process.

Owner:北京中科东亚纳米材料科技有限公司

Manufacture method of multilayer gradient nano-composite diamond film of surface of die steel

ActiveCN103160781AImprove bindingOvercome stressVacuum evaporation coatingSputtering coatingGas phaseBinding force

The invention discloses a manufacture method of a multilayer gradient nano-composite diamond film of the surface of die steel. The manufacture method includes that a plunger undergoing conventional pretreatment is arranged in a vacuum system of a magnetron sputtering composite vapor deposition system, and multiple layers of gradient films are sequentially deposited. Each layer of the multiple gradient transition layers undergoes high-temperature annealing treatment and argon ion surface etching treatment so as to improve binding force of the films and a base. The defects of high internal stress and poor adhesive force and the like of a conventional diamond film on the surface of the mold steel are overcome.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

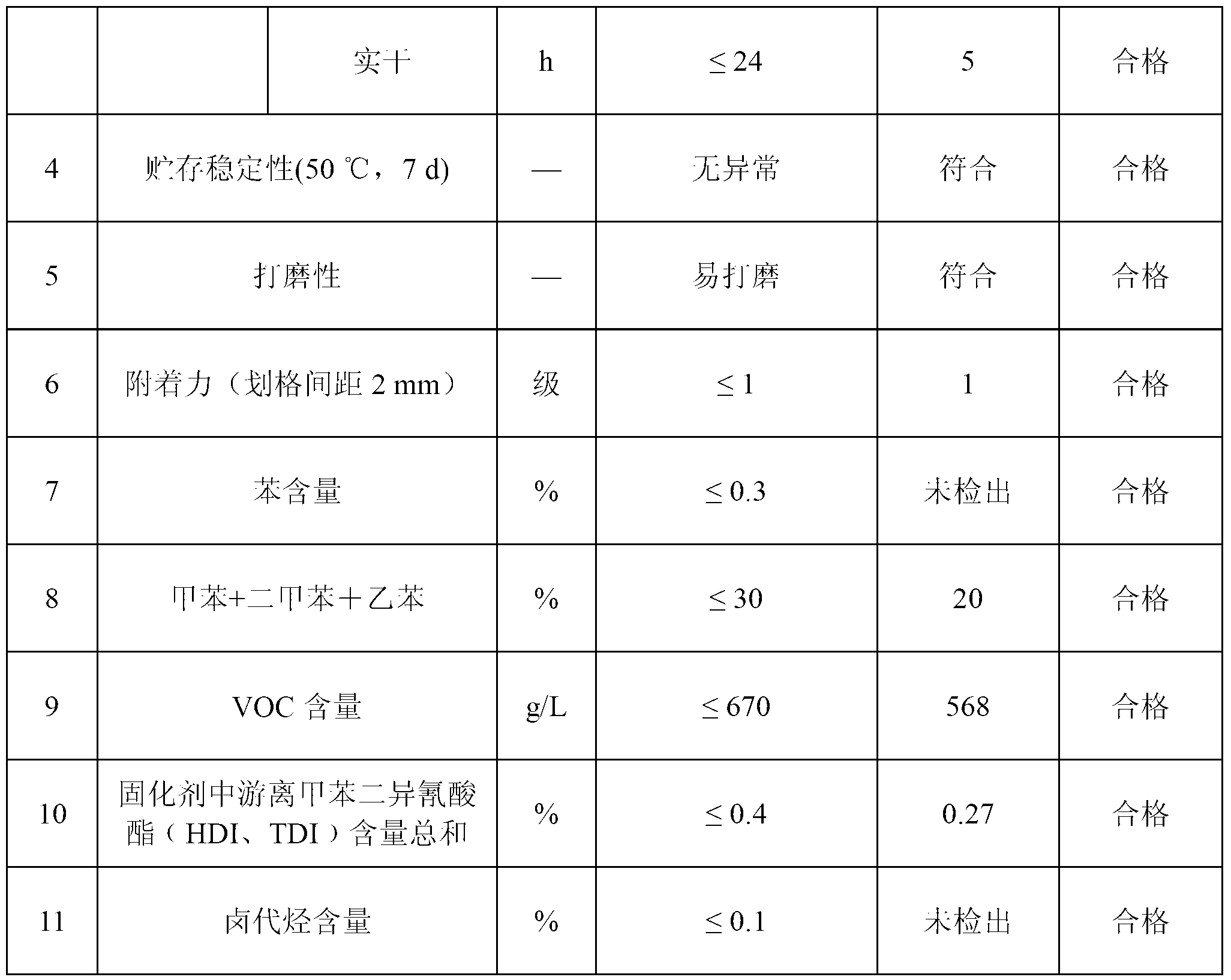

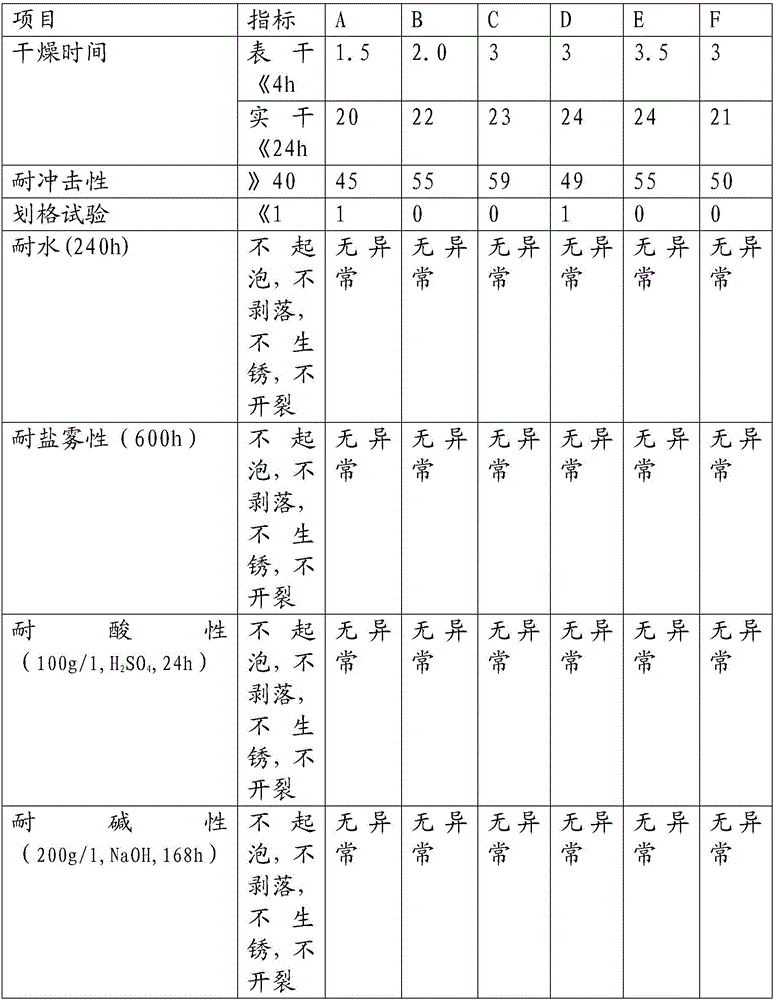

Anti-sinking PU extra-clear primer and preparation method thereof

ActiveCN103305113AGood anti-sag performanceHigh transparencyPolyurea/polyurethane coatingsMethyl carbonateSlurry

The invention provides an anti-sinking PU extra-clear primer which is prepared by mixing an anti-sinking PU polyurethane primer, a PU anti-sinking curing agent and a PU anti-sinking diluent, wherein the anti-sinking PU polyurethane primer is prepared from soybean oil alkyd resin, a dispersant, an antifoaming agent, anti-settling slurry, pigment and filler, nitrocotton liquid, a leveling agent, a dryer and the like in addition with an environment-friendly solvent; the PU anti-sinking curing agent is prepared from n-butyl acetate, isocyanate tripolymer and isocyanate heteropolymer; and the PU anti-sinking diluent is prepared from the solvents such as n-butyl acetate, propylene glycol monomethyl ether acetate, dimethyl carbonate and the like. The anti-sinking PU polyurethane primer, the PU anti-sinking curing agent and the PU anti-sinking diluent are sufficiently and uniformly mixed to prepare the anti-sinking PU extra-clear primer which has excellent anti-sinking property and extra high transparency and is easy to polish; and the shortcomings of slow drying, poor anti-sinking property, common adhesion, low transparency, common polishing property and the like of the commercially available products are overcome.

Owner:广东花王涂料有限公司

Self-emulsified epoxy curing agent and reinforced varnish, and preparation method of self-emulsified epoxy curing agent and reinforced varnish

InactiveCN106188502AImprove water resistanceStrong adhesionEpoxy resin coatingsGlycidyl ethersRoom temperature

The invention relates to a preparation method of a self-emulsified epoxy curing agent, wherein the preparation method comprises the following steps: a first step, adding an amine component and single epoxy functionality glycidyl ether to a container having nitrogen protection, and carrying out a reaction for 2-8 h at the temperature of 50-105 DEG C, to obtain an end-capped amine epoxy addition product; a second step, dropwise adding epoxy resin into the end-capped amine epoxy addition product, and carrying out a reaction for 1-8 h at the temperature of 20-100 DEG C, to obtain an intermediate product; and a third step, dropwise adding small molecular diglycidyl ether into the intermediate product, and carrying out an addition reaction for 2-8 h at the temperature of 20-100 DEG C, to obtain the self-emulsified epoxy curing agent. The self-emulsified epoxy curing agent has more excellent application period and physical properties, has shorter surface drying time, and can make epoxy resin cured at room temperature to form a hard paint film.

Owner:江苏丰彩建材(集团)有限公司

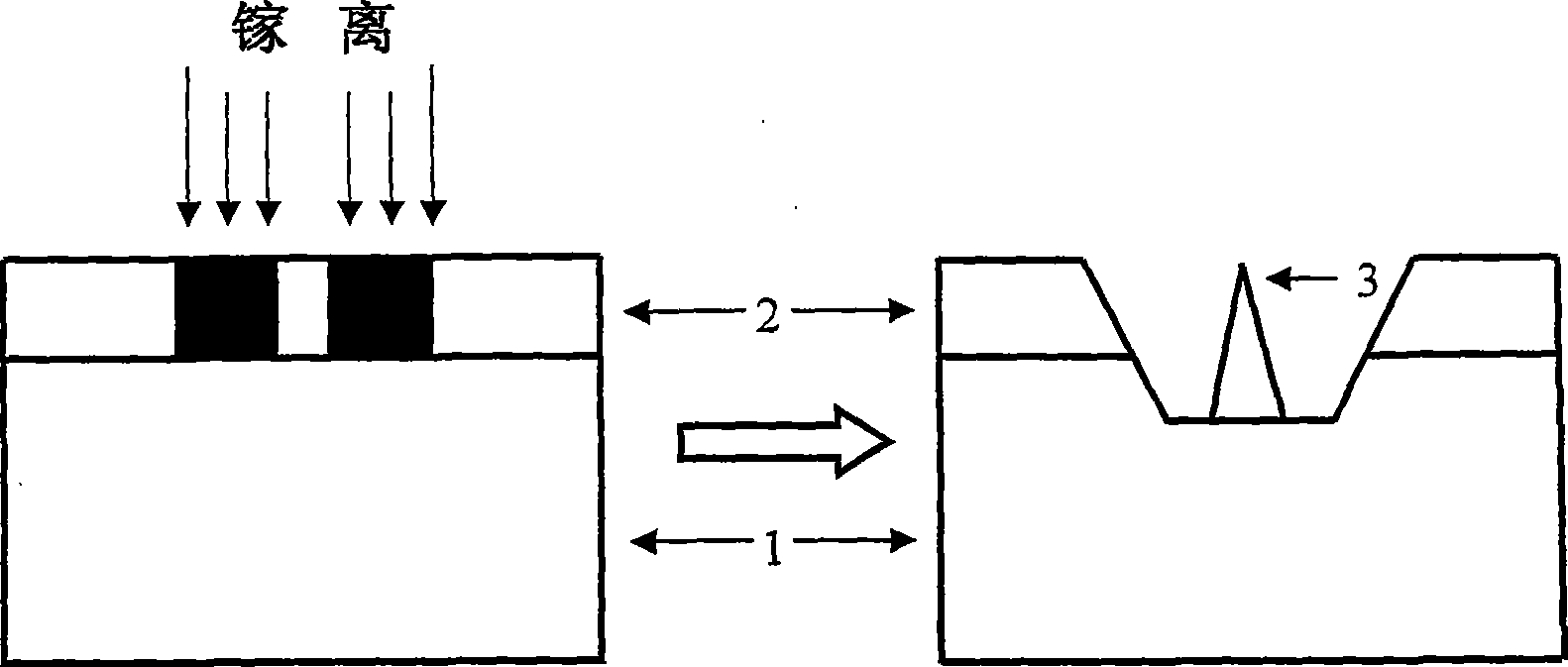

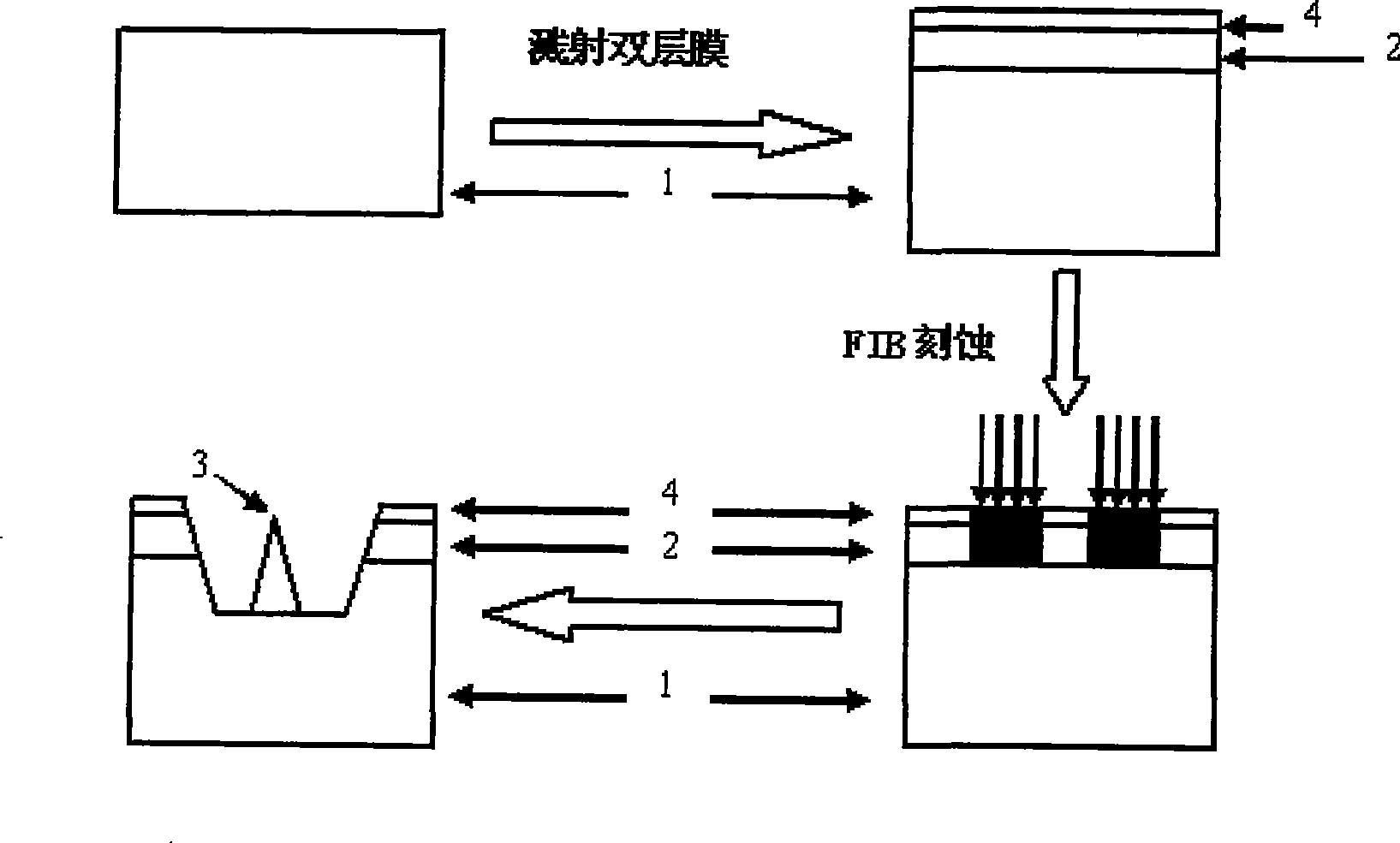

Method for manufacturing aluminum nitride silicon tip and grids structure

ActiveCN101497991APrecise control of cone densityOvercome consistencyVacuum evaporation coatingSputtering coatingEtchingRadio frequency magnetron sputtering

The invention relates to a preparation method of an aluminum nitride conical tip and a grid conical tip structure thereof. The method comprises the following steps: a layer of aluminum nitride film grows on a clean silicon substrate or a layer of gold film is then deposited on the clean silicon substrate by a radio-frequency magnetic control sputtering method; the silicon substrate is then put in a focused ion beam etching system; when the vacuum degree reaches 5.5 multiplied by 5-10mbar, a 5kV electron beam high voltage is applied to observe and position the appearance of a sample; an ion beam source is applied, and a beam current is arranged; finally, an etching pattern is arranged finally, and the focused ion beam etching is implemented to the aluminum nitride film sample according to the etching pattern to obtain the aluminum nitride conical tip 3 structure or the grid conical tip structure. The length-diameter ratio of a single cone of the aluminum nitride conical tip 3 structure is between (3-30):1, the minimum curvature radius of the tip part is less than 20 nanometer, and the diameter at the bottom is 100 nanometer to few microns. The invention can prepare the aluminum nitride conical tip and the grid conical tip structure thereof with controllable length-diameter ratio, omits a plurality of working procedures of depositing an insulating layer, photoetching, and the like which are necessary in the traditional process and has simple process and low cost.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Antibacterial and anti-fingerprint paint for mobile phones

PendingCN110791194AImprove cure rateImprove adhesionAntifouling/underwater paintsPaints with biocidesPolymer scienceMeth-

The invention discloses an antibacterial and anti-fingerprint paint for mobile phones. The paint comprise the following raw materials by weight: 20-38 parts of a urethane acrylate oligomer, 10-30 parts of epoxy acrylic resin, 2.5-5.5 parts of an antibacterial agent, 15-28 parts of trimethylolpropane triacrylate, 5-9 parts of N-vinyl pyrrolidone, 13-30 parts of 1, 6-hexanediol diacrylate, 3-4.8 parts of a photoinitiator, 8-14 parts of nano-filler, and 0.5-1.3 pars of an assistant. The antibacterial and anti-fingerprint paint for mobile phones provided by the invention has good antibacterial properties and scratch resistance, and excellent antifouling and anti-fingerprint properties.

Owner:SHAOXING XUYUAN NEW MATERIAL TECH

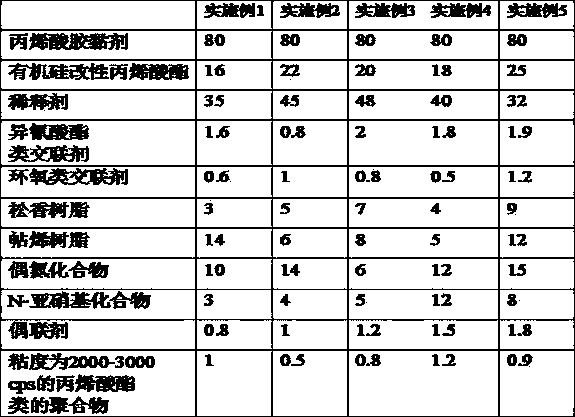

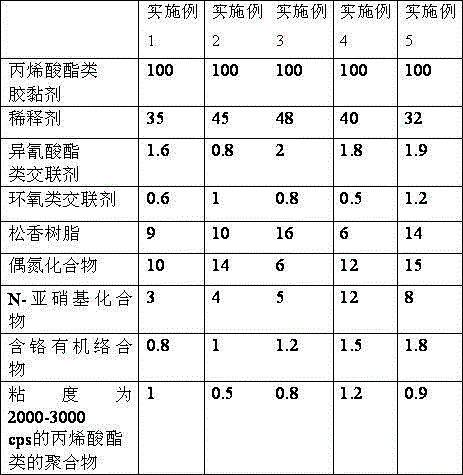

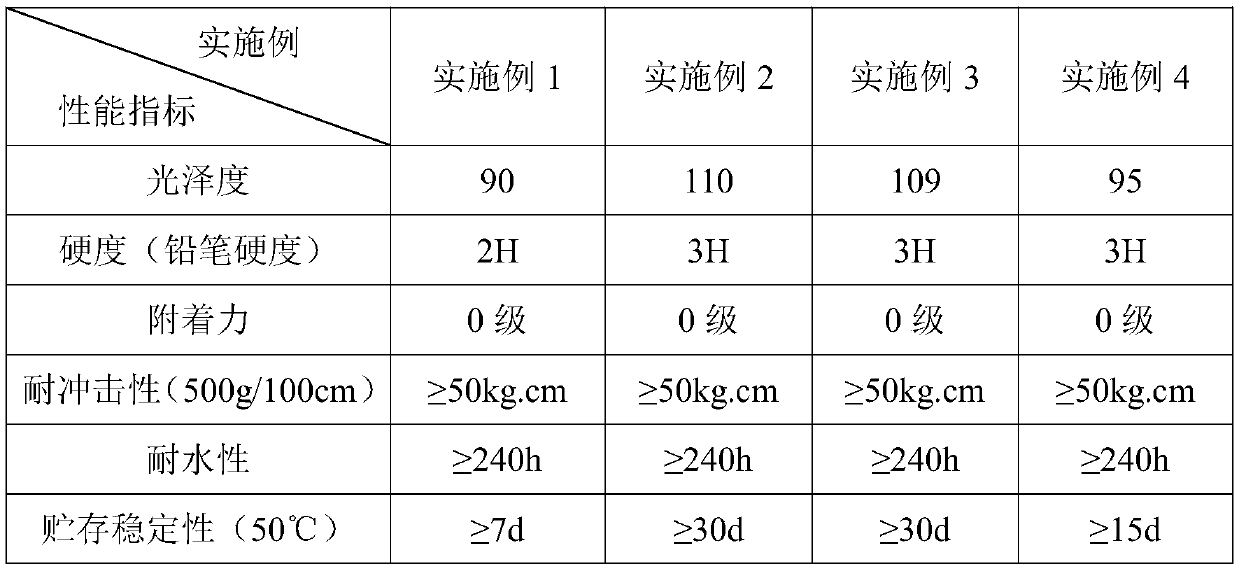

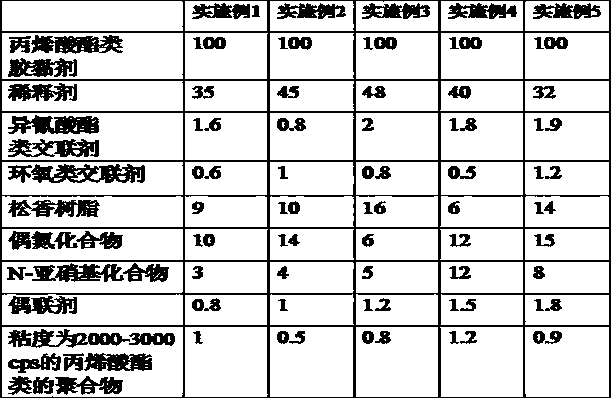

Mist side pressure-sensitive adhesive

ActiveCN103374322AUniform distribution of microporesUniform pore diameterNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesTemperature resistanceIsocyanate

The invention discloses a mist side pressure-sensitive adhesive. The pressure-sensitive adhesive consists of the following components in parts by weight: 100 parts of an acrylic ester adhesive, 30-50 parts of a diluting agent, 0.5-2 parts of an isocyanate crosslinking agent, 0.5-2 parts of an epoxy crosslinking agent, 5-20 parts of rosin resin, 2-15 parts of an azo compound, 2-15 parts of an N-nitroso compound, 0.5-2 parts of a coupling agent and 0.3-1.5 parts of an acrylic ester polymer. The mist side pressure-sensitive adhesive realizes uniformity and a mist side of light, improves the transmittance of the light and the adhesive force between a polyester film layer and a lamp shade at the same time, has high-temperature resistance, and ensures the reliability of product performance.

Owner:太仓斯迪克新材料科技有限公司

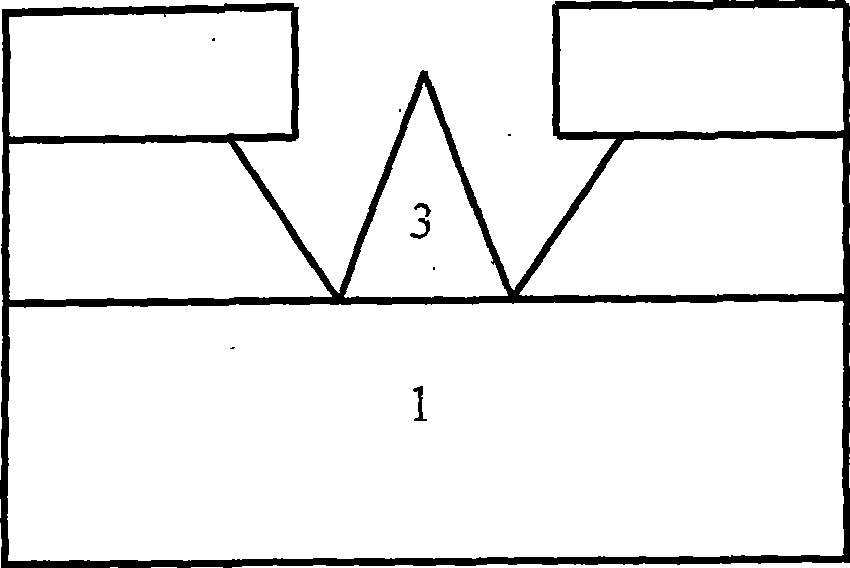

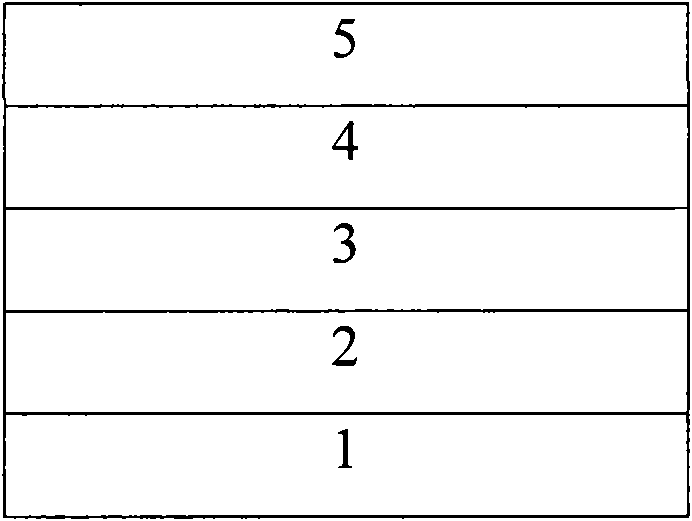

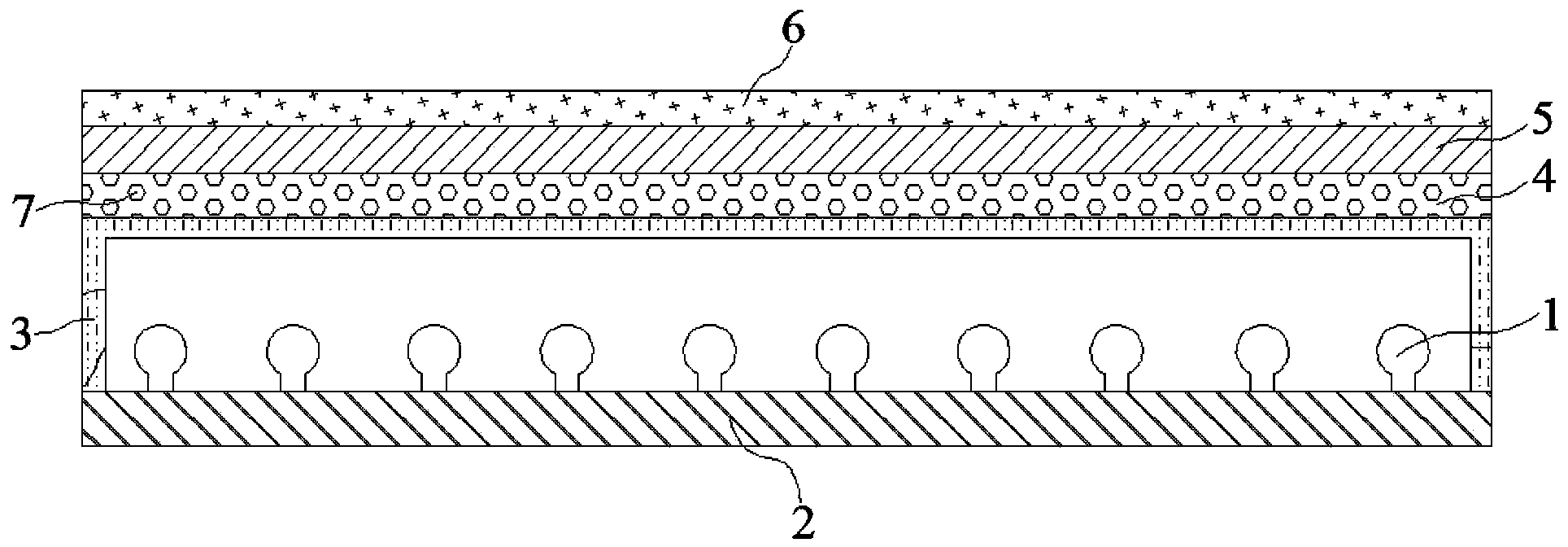

Plastics and preparation method thereof

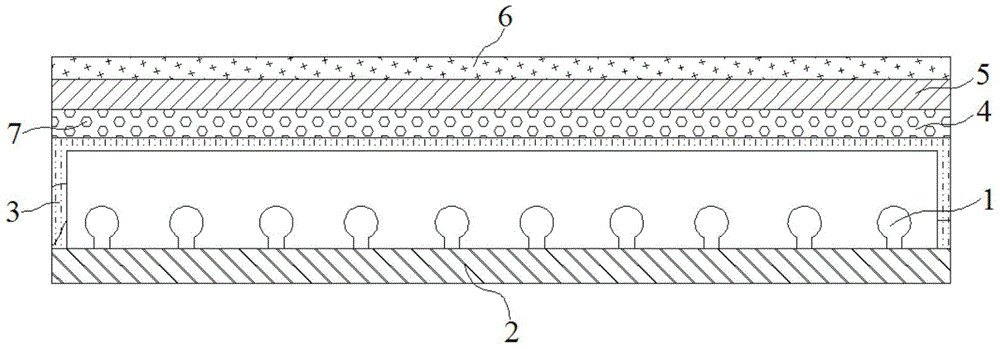

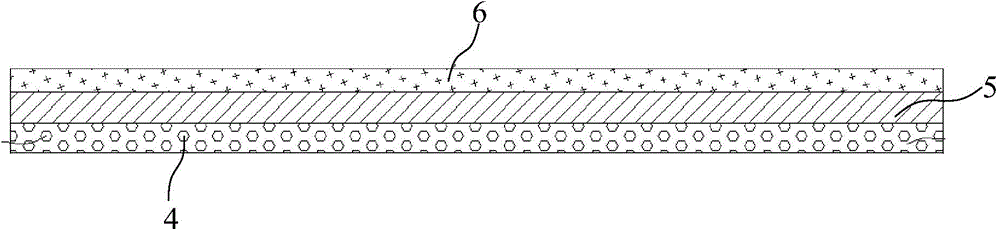

InactiveCN101549577AOvercome adhesionImprove adhesionSynthetic resin layered productsSpecial ornamental structuresMetalMaterials science

The invention relates to plastics and a preparation method thereof. The plastics comprises plastic base material (1), wherein a first metal layer (2), a base paint layer (3), a second metal layer (4) and a surface paint layer (5) are sequentially adhered on the surface of the plastic base material from inside to outside. The preparation method comprises the step of forming the first metal layer (2), the base paint layer (3), the second metal layer (4) and the surface paint layer (5) sequentially on the surface of the plastic base material (1). The plastics has best adhesive force and smooth metal mirror effect.

Owner:BYD CO LTD

Microporous acrylic adhesive tape

ActiveCN104566193AGuaranteed uniformityReduce the chance of breakagePoint-like light sourceFilm/foil adhesivesEpoxyPolyester

The invention discloses a microporous acrylic adhesive tape. A pressure-sensitive adhesive layer of the microporous acrylic adhesive tape is adhered to the outer surface of an LED light; the surface of the pressure-sensitive adhesive lay which is opposite to a lamp shade is adhered to a polyester film layer, and the surface of the polyester film layer is coated with a foggy surface coating layer. The surface roughness of the fogging surface coating layer is 0.1-0.8 microns; the pressure-sensitive adhesive layer comprises 100 parts of acrylic ester adhesive, 30-50 parts of diluent, 0.5-2 parts of isocyanate cross-linking agent, 0.5-2 parts of epoxy cross-linking agent, 5-20 parts of rosin resin, 2-15 parts of azo compound, N2-15 parts of N-nitroso-compounds, 0.5-2 parts of coupling agent, and 0.3-1.5 parts of acrylic ester polymer. The microporous acrylic adhesive tape overcomes the deflect of viscosity and adhesive force reduction caused by air holes while realizing uniform light and fogging surface, so that the adhesive strength and adhesive force between polyester film layer and the lamp shade are improved, and then the product reliability is improved.

Owner:太仓斯迪克新材料科技有限公司

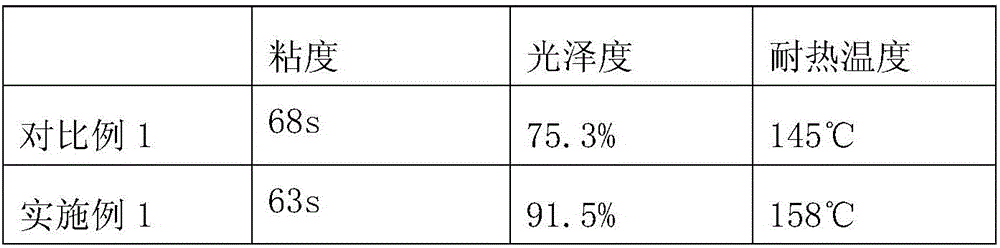

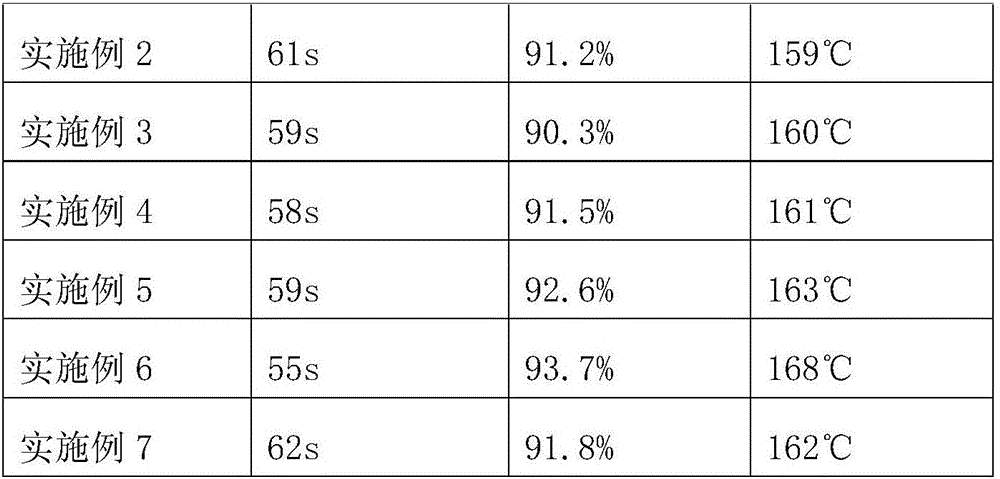

Aqueous polyester-acrylic resin hybrid body and preparation method

The invention discloses an aqueous polyester-acrylic resin hybrid body and a preparation method. The hybrid body is characterized in that a hybrid body copolymer has an acid value of 40-50mgKOH / g, andcomprises the following raw materials in parts by weight: 100 parts of a polyester prepolymer, 50-150 parts of acrylic resin, 50-100 parts of a hybridization cosolvent, 8-16 parts of a neutralizing agent and 150-250 parts of deionized water, wherein the polyester prepolymer has an acid value of 45-65mgKOH / g, and the acrylic resin has an acid value of 15-45mgKOH / g. The aqueous polyester-acrylic resin hybrid body disclosed by the invention can be adopted to prepare an amino stoving varnish together with excellent performance when being baked with amino resin (AR) at 150 DEG C. A stoving varnishmembrane has excellent mechanical properties such as wearing resistance, impact resistance, hardness, adhesiveness and the like, and excellent chemical properties such as water resistance, solvent resistance, corrosion resistance and the like, and the stoving varnish membrane is uniform and flat and good in glossiness. The hybrid body can be widely applied to the field of high-end automotive topcoats.

Owner:江西高信前沿科技有限公司

Tungsten probe composite diamond-like coating layer and preparation method thereof

ActiveCN107587133AReduce stressImprove adhesionVacuum evaporation coatingSputtering coatingCoatingCathode

The invention discloses a tungsten probe composite diamond-like coating layer; the coating layer is composed of a tungsten probe matrix, a bottom adhesive layer and a surface layer in sequence, the bottom adhesive layer is metal titanium, and the surface layer is a diamond-like coating layer. The preparation method adopts a negative electrode filter electric arc technology, an ion beam technologyand a vacuum sputtering technology are combined, the composite diamond-like coating layer is deposited on a sample substrate, and the obtained composite diamond-like coating layer has the advantages of high film-substrate bonding strength, low internal stress, low friction coefficient, good uniformity and long wear resistance.

Owner:GUANGDONG NAISENSE COATING TECH LTD

Inorganic dry powder solid color prime coat and application thereof

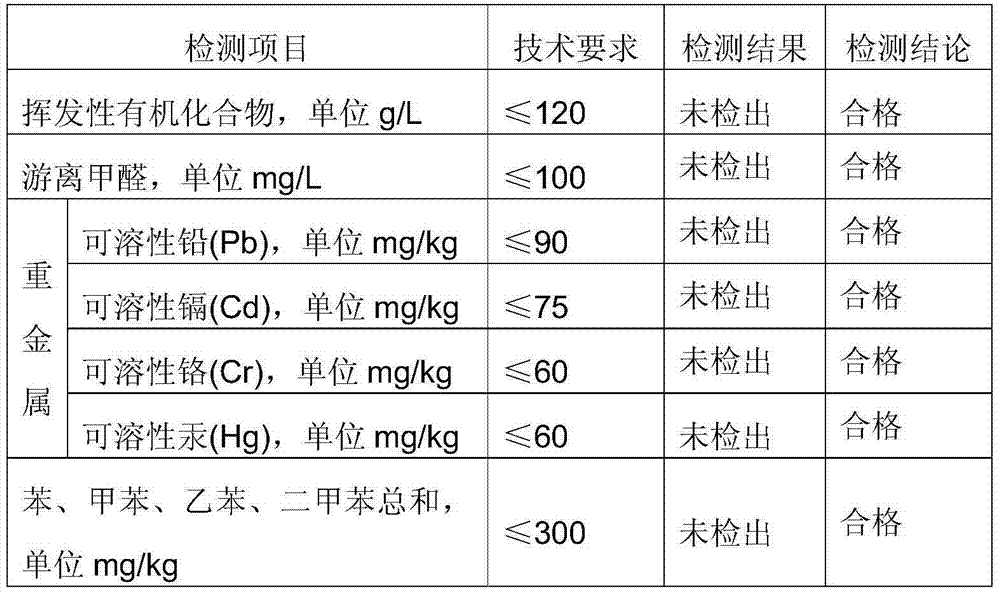

The invention discloses an inorganic dry powder solid color prime coat and application thereof. The inorganic dry powder solid color prime coat comprises the following components: an inorganic gelation system and a binding agent composed of redispersable gelatin powder, pigment, filler and additive, wherein the inorganic gelation system is selected from any one or a mixture of several of silicate, aluminate, calcium carbonate and calcium sulfate. The solid color prime coat can be used for indoor wall decoration. The inorganic dry powder solid color prime coat can be applied to the building by adding water and uniformly mixing in site under a single-component dry powder state, and has good tinting strength, closure, binding power and stability through test detection, and has good covering power and rubbing property. The defects that the dry powder coat for indoor wall is bad in adhesive force and the color is single can be overcome, and meanwhile, harmful substances such as VOC (volatile organic compound) or heavy metal cannot be produced; and the inorganic dry powder solid color prime coat is a novel, environment-friendly and stable inorganic dry powder solid color prime coat with excellent effect.

Owner:SHANGHAI GIANT ENERGY SAVING MATERIALS

Method for improving ink adhesion in plastic printing product

ActiveCN106480416AFastGood response controllabilityVacuum evaporation coatingSputtering coatingEpoxyDimethylaniline N-oxide

The invention belongs to the field of printing machining and particularly relates to a method for improving ink adhesion in a plastic printing product. The method includes the following steps of (1) pretreatment of the plastic product and (2) printing. An ion sputtering method is adopted to conduct oxidation treatment on the surface of the plastic product, energy can be rapidly transferred to a special functional group on the plastic surface, and purposes of even heating and even oxidization are achieved; printing ink is prepared in the manner that based on ordinary ink, microcrystalline wax, N, N-dimethylaniline, lignin-based epoxy resin and a surface active agent are added, and consistency and permeability of the ink and the plastic product are increased. The plastic printing product prepared through the method has the advantages that adhesion between the plastic product and the ink is high, and friction resistance is achieved.

Owner:义乌市双杰日用品有限公司

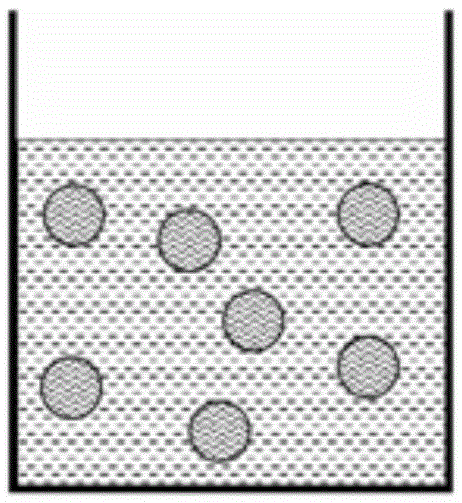

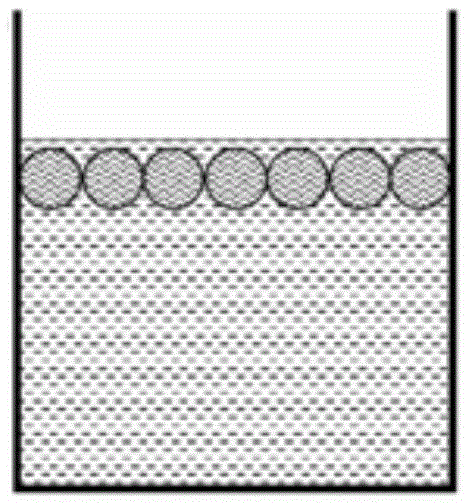

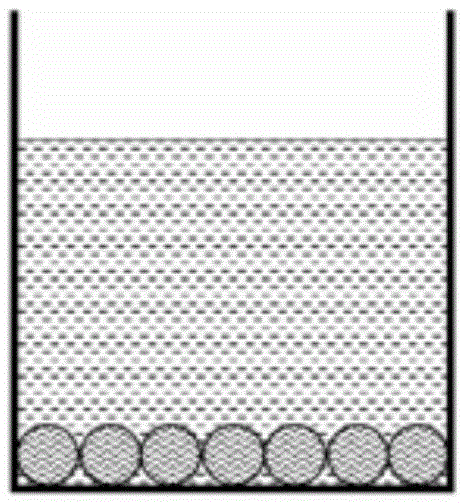

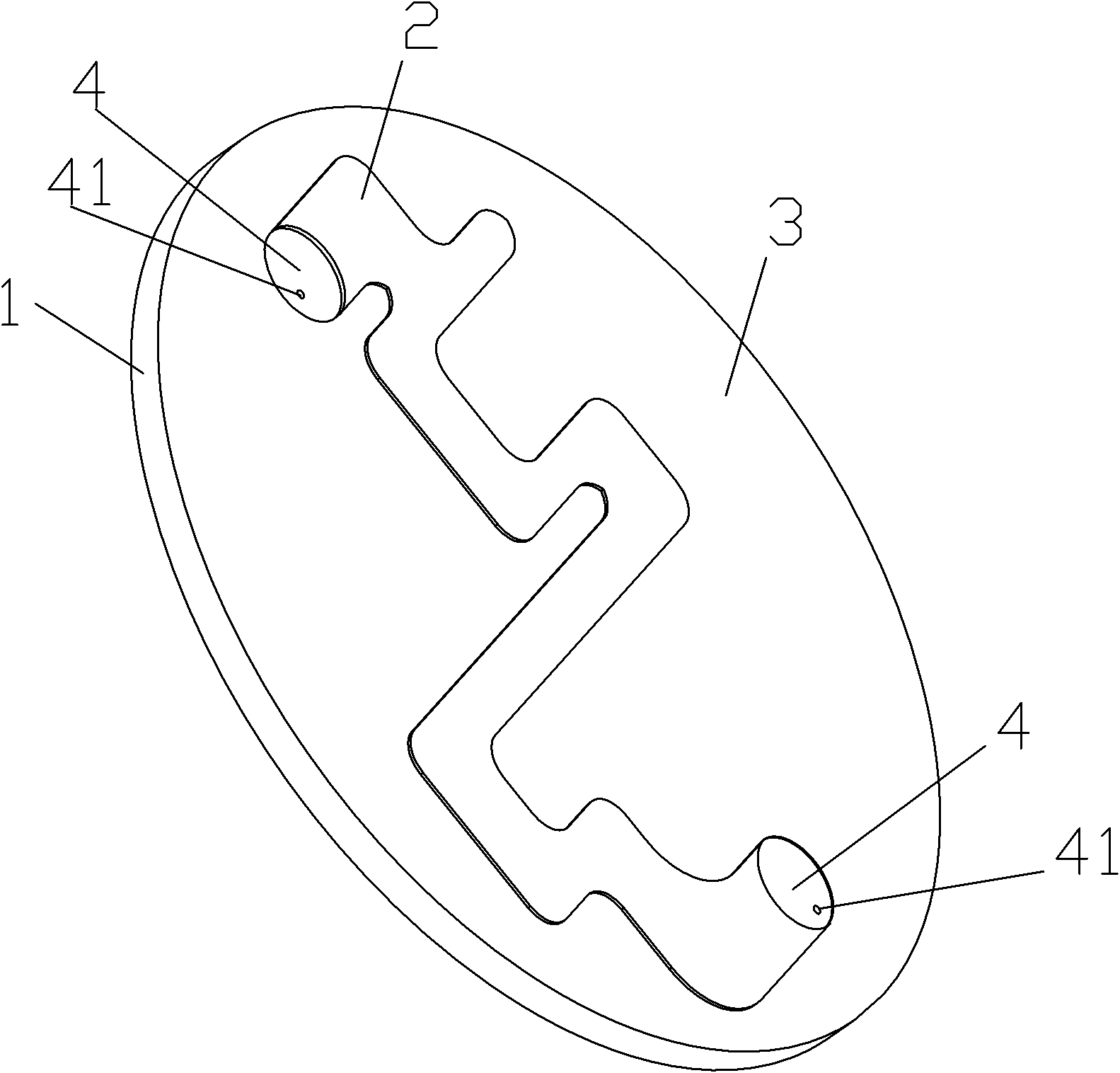

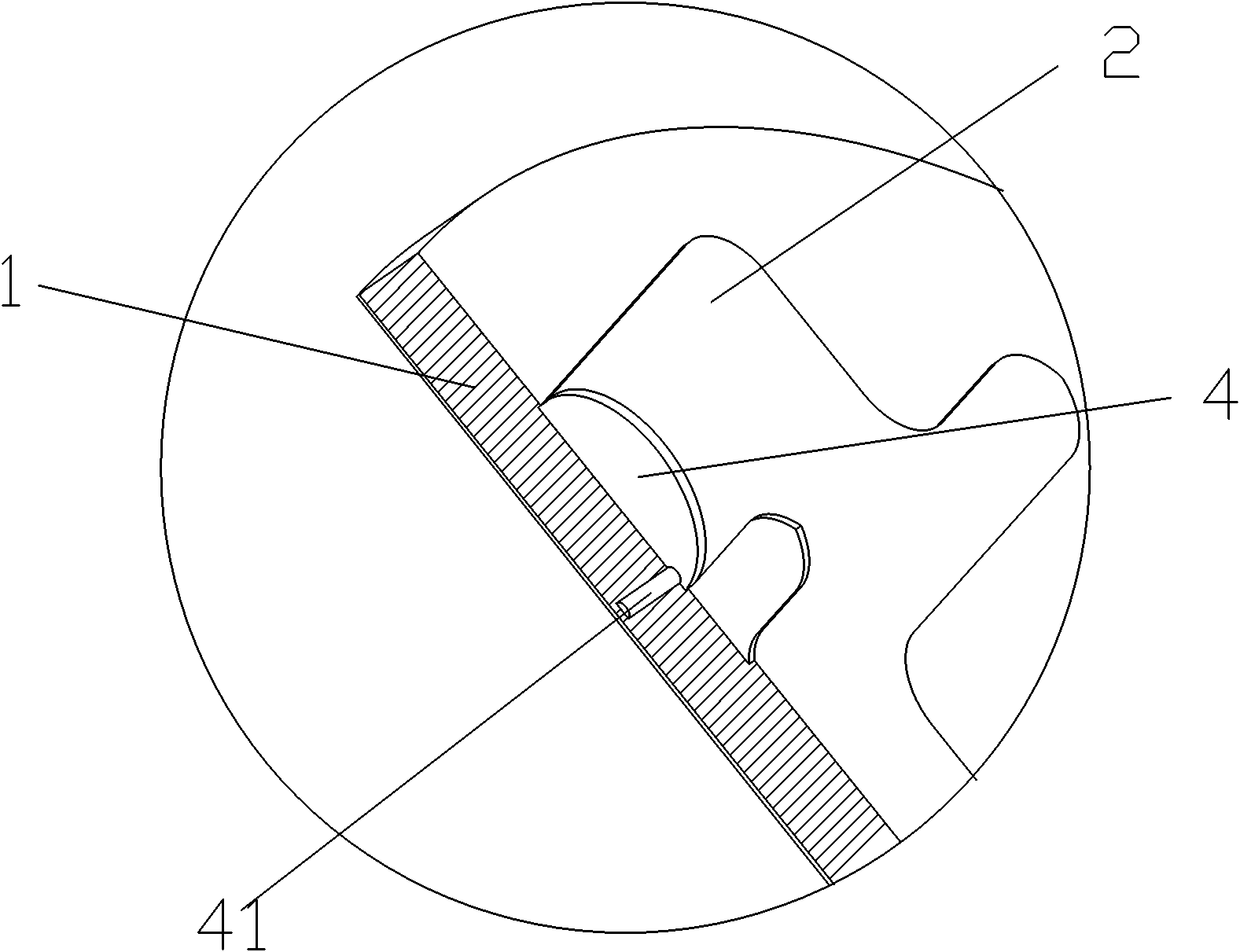

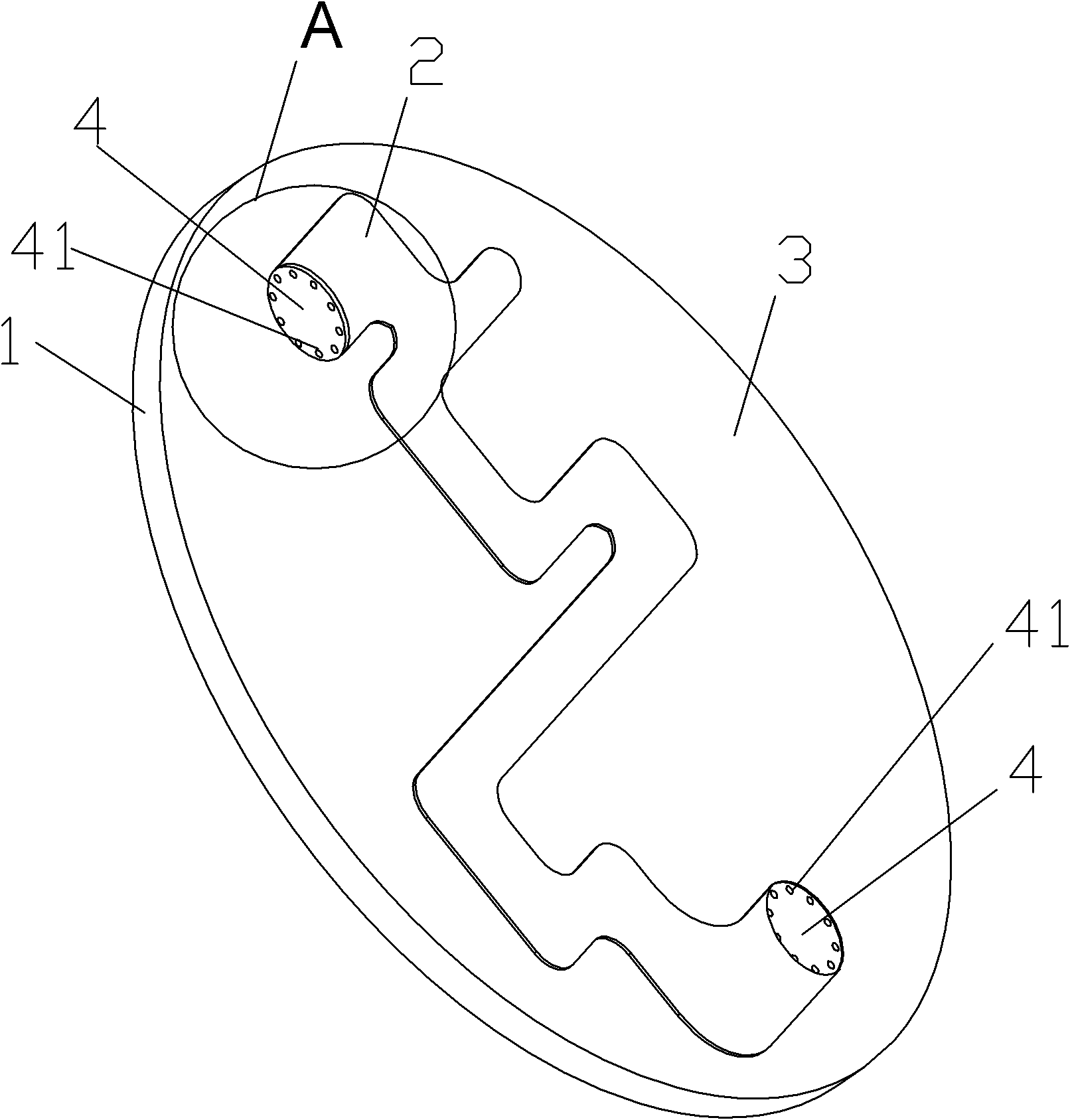

Droplet Generation Method Based on Microchannel

ActiveCN104324769BGenerated smoothlyQuick buildMixing methodsMixersMechanical engineeringEngineering

Owner:MACCURA MEDICAL INSTR CO LTD

Ultraviolet-cured transparent finishing coat with high colouring capacity for carpentry

InactiveCN104559748AIncrease dosageConvenient and quick escapePolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolHigh concentration

The technical scheme for realizing the objective of the invention is as follows: an ultraviolet-cured transparent finishing coat with high colouring capacity for carpentry is composed of the following ingredients in parts by weight: 15-25 parts of urethane acrylate, 10-15 parts of epoxy acrylate, 5-10 parts of tripropylene glycol diacrylate, 5-10 parts of trimethylolpropane triacrylate, 5-15 parts of pentaerythritol triacrylate, 5-10 parts of a photoinitiator, 5-10 parts of active amine, 0.5-1.0 part of a dispersant, 0.5-1.0 part of a defoamer, 0.5-1.0 part of a leveller, 3-5 parts of wear-resistant powder, 3-5 parts of matt powder and 10-20 parts of an oily dye. The high-concentration oily dye is used in the ultraviolet-cured transparent finishing coat disclosed by the invention as a breakthrough, meanwhile, the dosage of active amine is increased in a formula, thus greatly solving the problem of achieving the high colouring capacity in one step, ensuring the adhesion force of the finishing coat, achieving the purpose of curing a coating film, and increasing the production efficiency.

Owner:FUJIAN DEZHIXIAN ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

Preparation method and application of polypyrrole/phytic acid/graphene oxide composite anti-corrosion coating

ActiveCN111850657ASimple processOvercoming poor compactnessElectrolytic inorganic material coatingElectrolytic organic material coatingPolypyrroleConductive polymer

The invention discloses a preparation method and application of a polypyrrole / phytic acid / graphene oxide composite anti-corrosion coating. The preparation method comprises the following steps: systematically adjusting and controlling the concentration and ratio of pyrrole monomer, phytic acid and graphene oxide dispersion liquid, and carrying out direct electro-deposition of the composite coatingmaterial on the surface of stainless steel through the convenient one-step galvanostatic method. The polypyrrole / phytic acid / graphene oxide composite anti-corrosion coating is applied to corrosion protection of stainless steel in an acid environment to solve the problems that an existing conducting polymer anti-corrosion coating has micropores and is poor in adhesive force and does not have high stability. The preparation method is simple and can realize direct, rapid and large-area deposition of the coating material on the surface of stainless steel; and in addition, the coating is dense in structure and stable in anti-corrosion performance, and has excellent application prospect in the stainless steel material used in an oil and gas well and acid soil and a metal bipolar plate of a fuelcell.

Owner:SUZHOU UNIV OF SCI & TECH

Green and environment-friendly UV coating and preparation method thereof

The invention discloses a green and environment-friendly UV coating. The composition comprises the following components in parts by weight: 25-35 parts of polymerized water-soluble hyperbranched polyamide, 10-15 parts of N, N-dimethylformamide. N, N'-bis(2-ethoxyl)-N, N'-bis(trimethoxysilylpropyl)-ethylenediamine / 2, 3'-difluoro fumarate oligomer, 1-2 parts of 2-(5-phenyl-1H-tetrazole-1-base)-3-thiophene-crylic acid, 3-5 parts of an aqueous photoinitiator, 10-20 parts of inorganic filler, 0.5-1.5 parts of a dispersing agent, 0.3-0.6 parts of a flatting agent, 0.4-0.8 parts of a defoamer, 1-2 parts of an emulsifier and 10-20 parts of water. The invention further discloses a preparation method of the green and environment-friendly UV coating. The green and environment-friendly UV coating disclosed by the invention is excellent in comprehensive performance, good in mechanical property, performance stability, weather resistance, water resistance and fire resistance, high in adhesive force to a base material, safe to use and environment-friendly.

Owner:肇庆英克斯化工有限公司

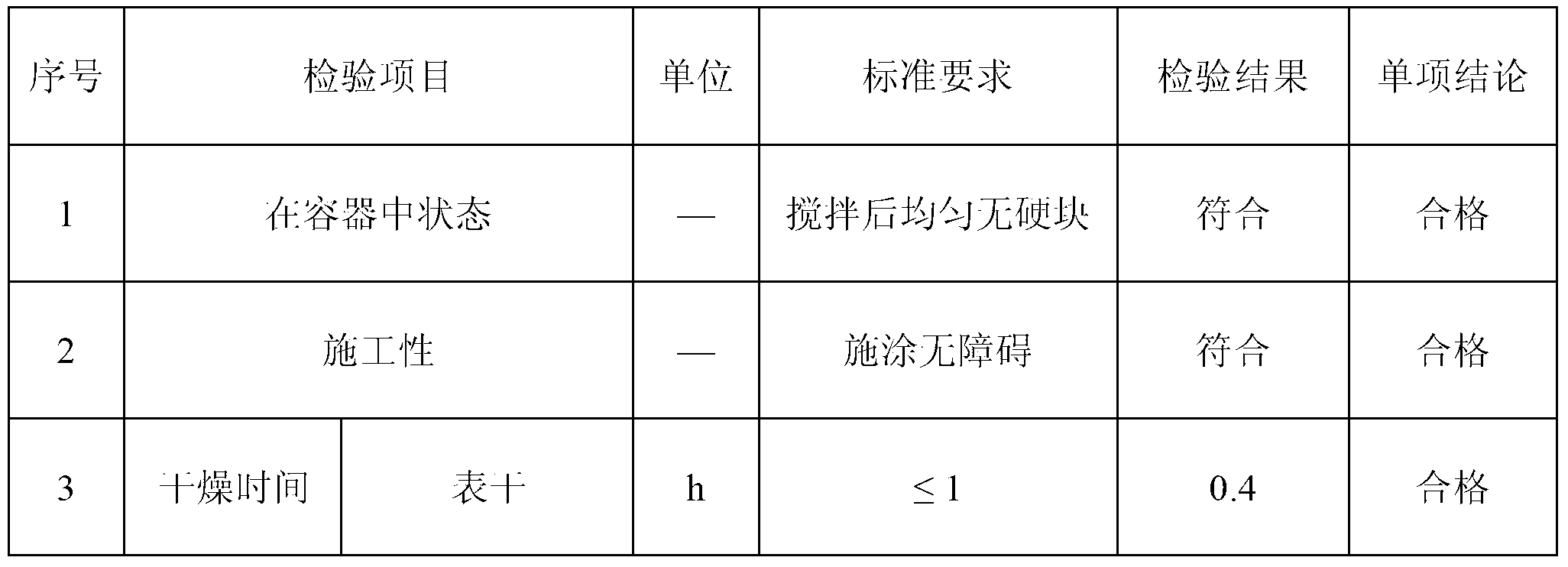

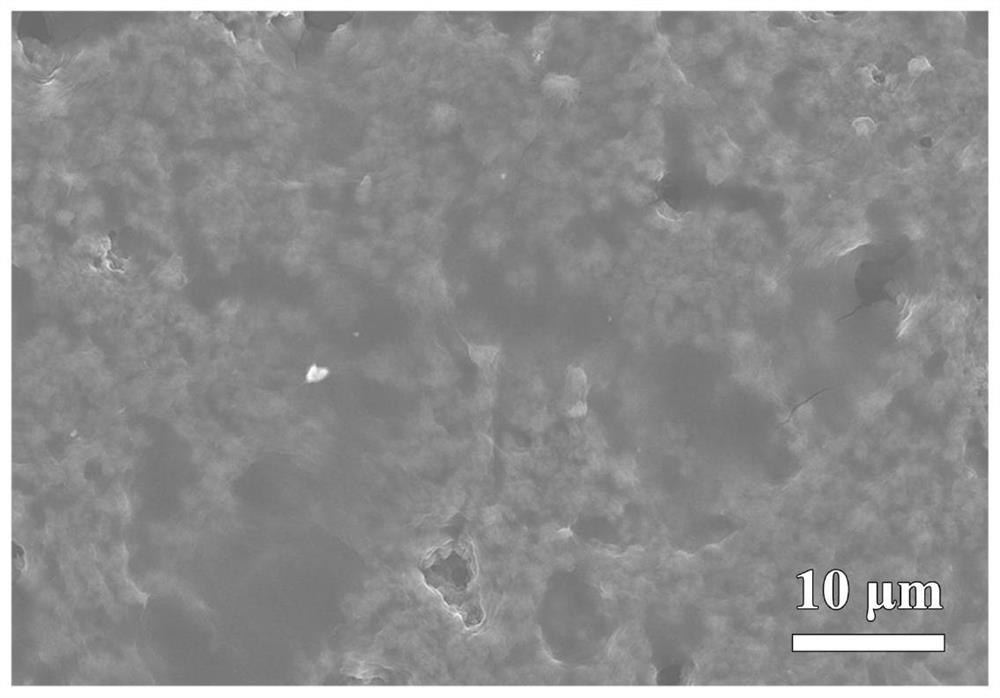

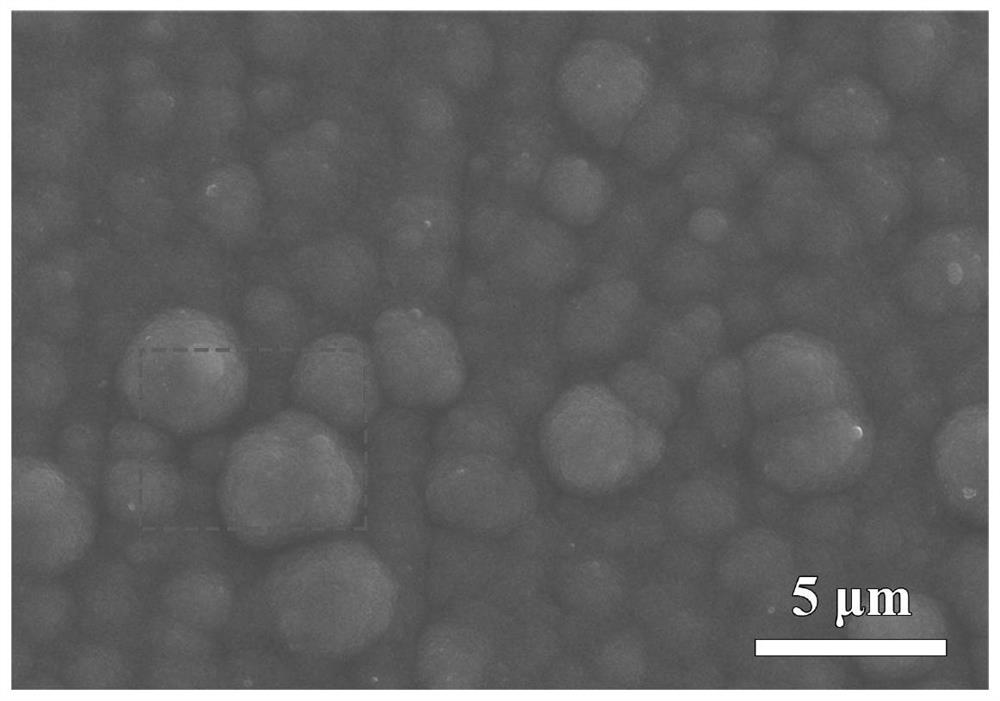

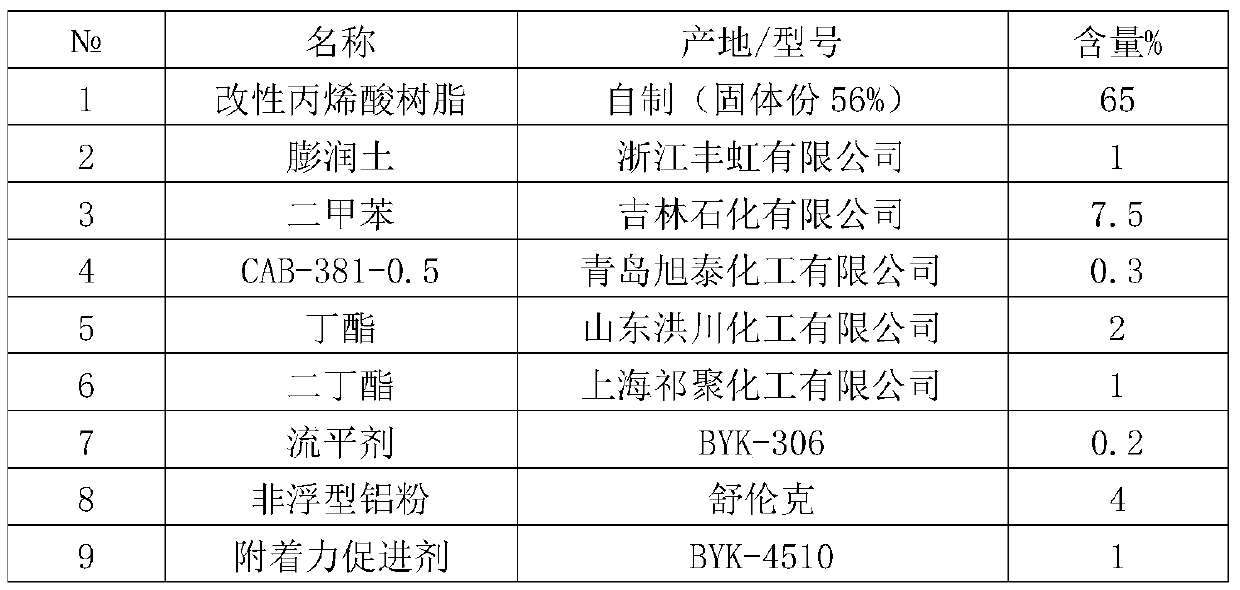

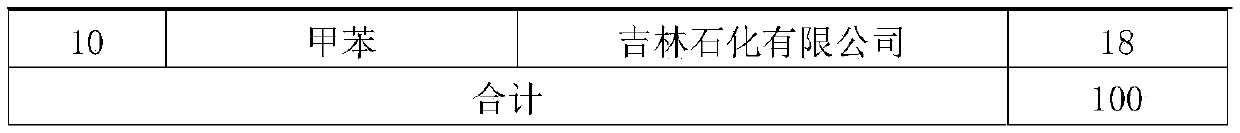

Paint special for surface of special non-ferrous metal and preparation method of paint

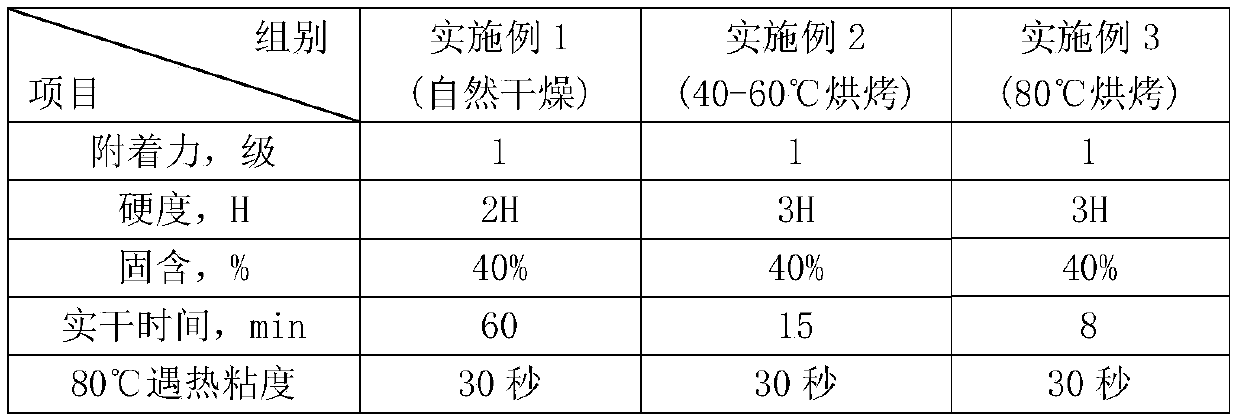

InactiveCN109897498AOvercome adhesionSlightly poorer corrosion resistanceAnti-corrosive paintsCelluloseMethacrylate

The invention belongs to the field of paint and particularly relates to paint special for the surface of special non-ferrous metal and a preparation method of the paint. The paint special for the surface of special non-ferrous metal comprises, by weight percentage, 65-68% of modified acrylic resin, 0.8-1.2% of bentonite, 7-11% of xylene, 0.1-0.3% of cellulose, 1-2% of butyl ester, 1-3% of dibutylester, 0.2-0.4% of leveling agent, 3-5% of non-floating type aluminum powder, 1-3% of adhesion promoter and 16-18% of toluene, wherein the modified acrylic resin is prepared by mixing butyl acetate, butyl acrylate, epoxy resin, methacrylic acid, styrene, methyl methacrylate, isopropyl methacrylate, toluene and benzoyl peroxide (BPO). The prepared paint special for the surface of special non-ferrous metal has the advantages that the paint is quick in drying and has super-high adhesion on the surface of the special non-ferrous metal, the paint film of the paint does not become sticky when meeting with heat, and the paint conforms to the national lead-free and environment-friendly regulations.

Owner:辽宁苏博特船牌制漆有限公司

New aqueous antirust coating

InactiveCN106381065AOvercoming poor anti-rust effectOvercome the hardnessAnti-corrosive paintsZinc phosphateEmulsion

The invention belongs to a coating, and specifically relates to a new aqueous antirust coating. The new aqueous antirust coating is characterized by comprising the following components, according to a weight part ratio, 5-7% of deionized water, 0.1-0.5% of a pH conditioning agent, 0.2-0.8% of a dispersant, 0.1-0.5% of a wetting agent, 0.2-0.8% of an antifoaming agent A, 6-8% of pigment powder of various colors, 2-4% of zinc phosphate, 2-5% of mica powder, 1-3% of barium sulfate, 59.7-78.4% of an antirust emulsion, 4-5.5% of a film-forming auxiliary agent, 0.1-0.5% of an antifoaming agent B, 0.1-0.2% of an antibacterial antiseptic, 0.1-1% of an anti-flash-rust agent, 0.2-1.5% of a nanometer reinforcing agent and 0.5-2% of a thickening agent. The new aqueous antirust coating overcomes defects of performance of a common aqueous antirust coating, and meets the eco-friendly requirements.

Owner:徐州聪慧装饰装潢工程有限公司

Polyester modified hydroxyl acrylic resin for automobile hub paint and synthetic method thereof

InactiveCN107236088AOvercome shockOvercome the hardnessAnti-corrosive paintsPolyesterIsooctyl acrylate

The invention discloses a polyester modified hydroxyl acrylic resin for automobile hub paint and a synthetic method thereof. The polyester modified hydroxyl acrylic resin for automobile hub paint is prepared from, by weight part, 15-30 parts of methyl methacrylate, 3-10 parts of hydroxyethyl methylacrylate, 5-10 parts of 2-ethylhexyl acrylate, 1-5 parts of butyl acrylate, 5-15 parts of polyester prepolymer, 40-60 parts of organic solvent and 0.3-0.6 part of initiator. A paint film prepared from the polyester modified hydroxyl acrylic resin for the automobile hub paint has the advantages of being good in corrosion resistance at normal temperature, high in hardness and impact resistance, good in adhesive force and flexibility and the like and accordingly can be applied to the field of hub paint.

Owner:江苏三木化工股份有限公司 +1

Method for improving adhesive power of ink in plastic prints

The invention belongs to the field of printing processing and particularly relates to a method for improving adhesive power of ink in plastic prints, comprising the steps of (1) pretreating a plastic article; (2) printing. The surface of the plastic article is oxidized by means of microwave radiation, energy can be transmitted quickly to specific functional groups on the surface of plastic by microwave, and uniform heating and uniform oxidation are achieved; preparation of printing ink is based on common ink, and the compatibility and permeability of ink with the plastic article are improved by adding a coupling agent and low-molecular-weight wax. The plastic prints prepared herein have the advantages of high adhesion between plastic articles with ink is high, and good friction resistance.

Owner:NANNING RIJIAN PLASTIC PACKAGING

Printed circuit board

InactiveCN101873763AProtection reliabilityOvercome adhesionElectrical connection printed elementsCopperHorizontal and vertical

The invention relates to a printed circuit board. The printed circuit board comprises a substrate, a copper sheet laid on the front surface of the substrate, and a front-surface insulating layer which is pressed outside the copper sheet and provided with a copper-exposed region, wherein the copper-exposed region is provided with holes along a thickness direction of the substrate, and the copper sheet in the copper-exposed region extends to the inside walls of the holes. The copper-exposed region of the printed circuit board is provided with the holes along the thickness direction of the substrate, and the copper sheet is laid on the inside walls of the holes, so that solder joints in the copper-exposed region grasp the substrate tightly as a hand; when the copper sheet at the solder joints is peeled off or torn down from the substrate, a wire soldered in the copper-exposed region overcomes adhesive forces in horizontal and vertical directions, and also overcomes an additional adhesiveforce due to the area increase of the laid copper sheet; therefore, the reliability of the printed circuit board can be protected effectively.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

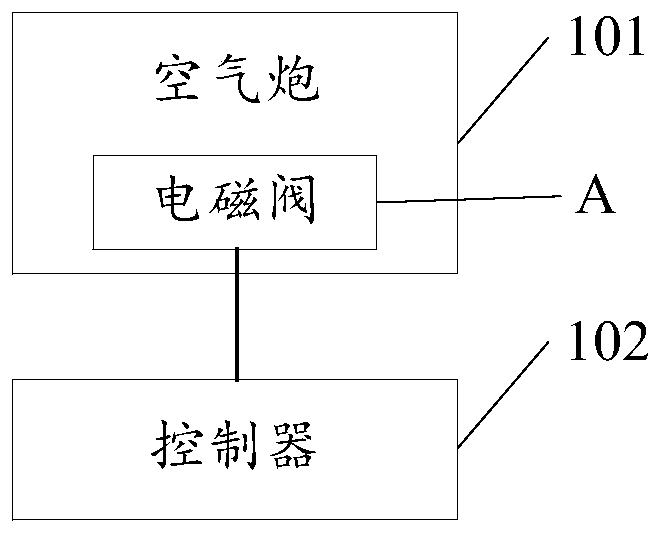

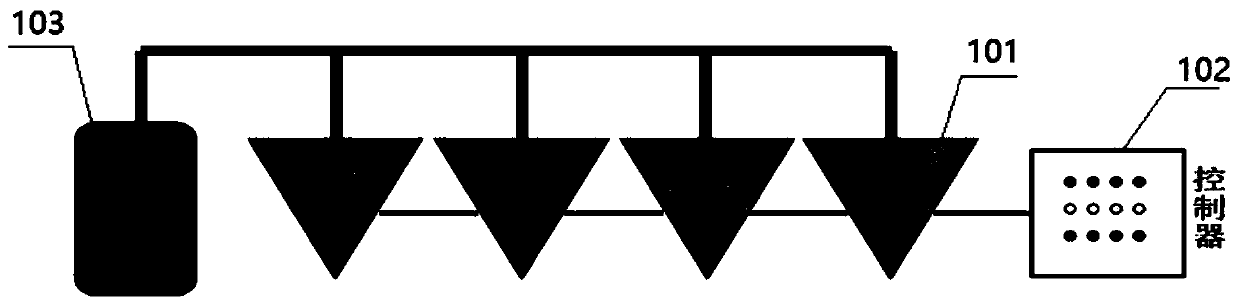

Device for cleaning materials attached to wall of Australian ore bin

InactiveCN110745391AEasy to cleanOvercome static frictionLarge containersMining engineeringStatic friction

The invention relates to the technical field of steel smelting, in particular to a device for cleaning materials attached to the wall of an Australian ore bin. The device comprises air cannons and a controller. Each air cannon is arranged on one surface of a lower cone body of each Australian ore bin, and an electromagnetic valve is arranged on each air cannon; the controller is connected with theelectromagnetic valves and used for controlling the opening and closing of the electromagnetic valves; when the controller controls each electromagnetic valve to be opened, a pressure air airflow isejected by the corresponding air cannon to impact the wall of the Australian ore bin, so that the pressure air cleans the materials attached to the wall of the Australian ore bin; and by adopting theexpansion impact wave suddenly released by the air cannons, static friction and adhesion force are overcome by impact and vibration, Australian ores in the ore bin are smoothly discharged, the materials attached to the bin wall are rapidly away from the bin wall, and therefore, the purpose of quickly and effectively cleaning the materials attached to the wall of the Australian ore bin is achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Energy-saving LED illuminating lamp

ActiveCN103363356AReduce the chance of breakageGuaranteed uniformityPoint-like light sourceElectric lightingNitrosoPolyester

The invention discloses an energy-saving LED illuminating lamp. The LED illuminating lamp comprises a substrate in which a plurality of light emitting diodes are embedded and a lamp shade covering the substrate, wherein a pressure-sensitive adhesive layer is applied on the outer surface of the lamp shade; a surface back to the lamp shade, of the pressure-sensitive adhesive layer is affixed with a polyester layer; the surface of the polyester layer is coated with a fog surface coating layer; a plurality of gas pores are formed in the pressure-sensitive adhesive layer, and the density of the gas pores is 2000-3000 per cubic centimetre; the surface roughness of the fog surface coating layer is 0.1-0.8 mum; the pressure-sensitive adhesive layer comprises the following components in parts by weight: 100 parts of acrylic ester adhesive, 30 to 50 parts of diluent, 0.5 to 2 parts of isocyanate crosslinking agent, 0.5 to 2 parts of epoxy-based crosslinking agent, 5 to 20 parts of rosin resin, 2 to 15 parts of azo compound, 2 to 15 parts of N-nitroso compound, 0.5 to 2 parts of coupling agent, and 0.3 to 1.5 parts of acrylic acid ester polymer. The energy-saving LED illuminating lamp provided by the invention can effectively reduce the cracking rate of an LED lamp tube, and can realize uniform light; as the arrangement of the fog surface, the adhesive ability between the polyester layer and the lamp shade is improved, the high-temperature resistance performance is provided, and the reliability of the product is ensured.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

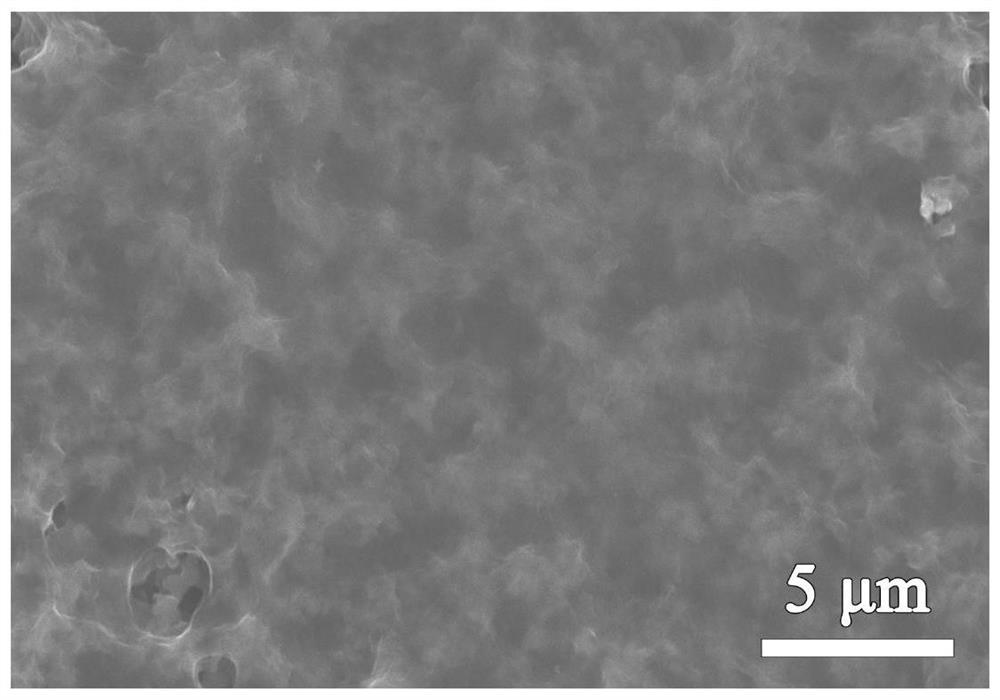

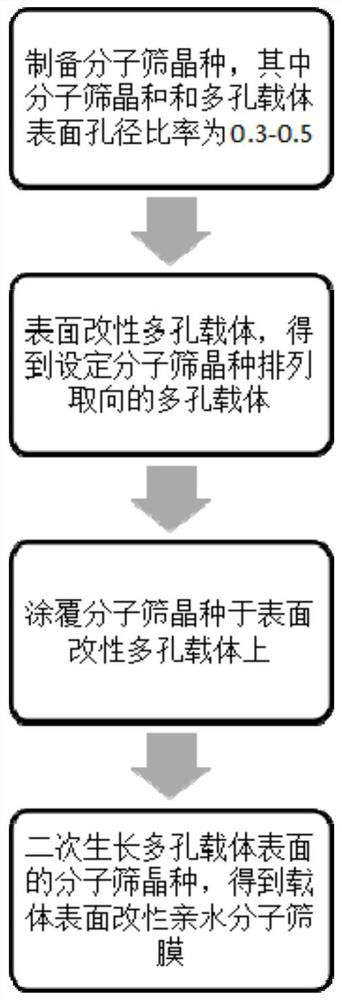

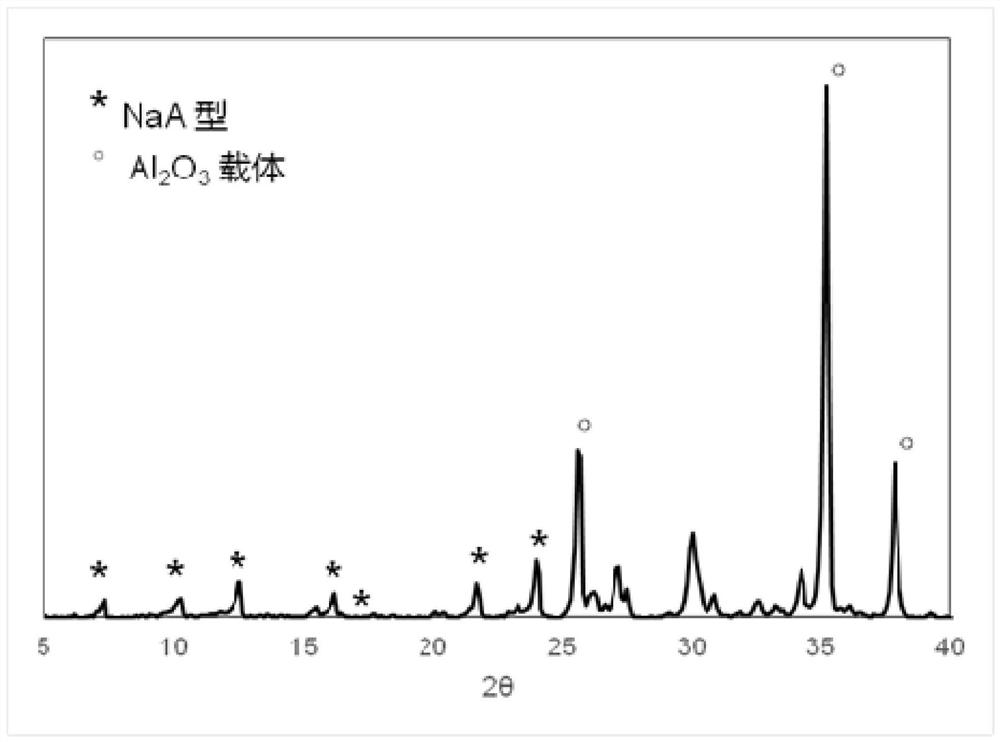

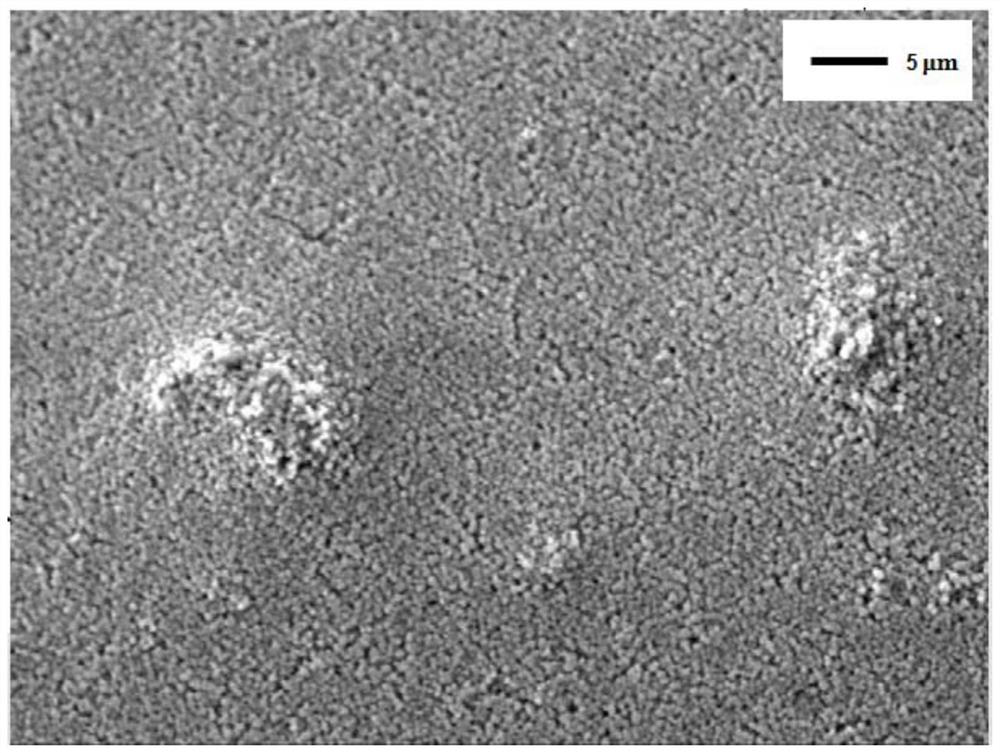

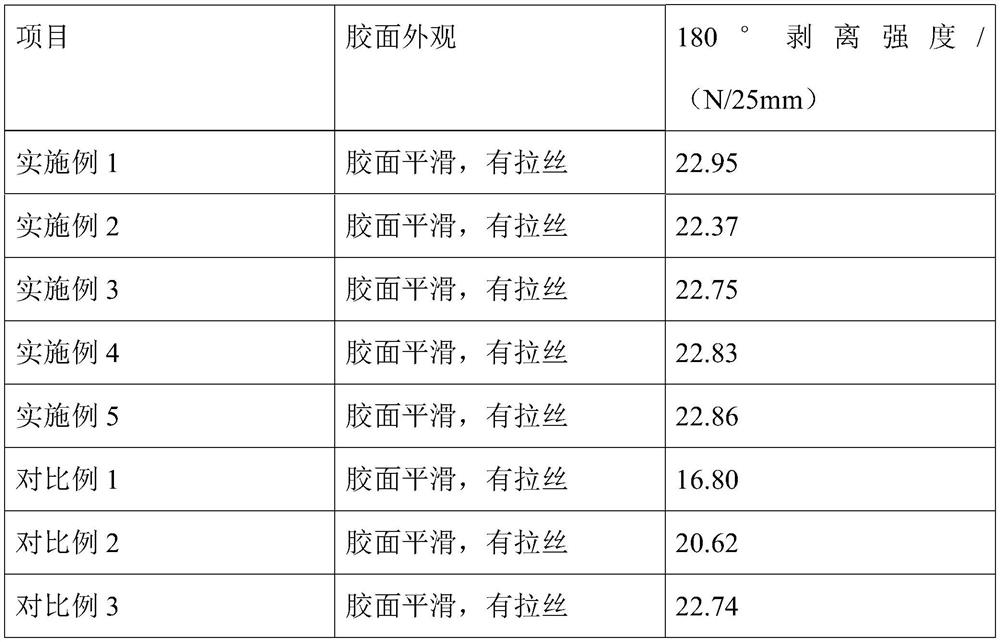

Carrier surface modified hydrophilic molecular sieve membrane and preparation method thereof

ActiveCN111992050AHigh separation selectivitySeparation selectivity and high throughputMembranesDistillationThin membraneChemistry

The invention provides a preparation method of a carrier surface modified hydrophilic molecular sieve membrane, which comprises the following steps: preparing a molecular sieve seed crystal in which the surface pore diameter ratio of the molecular sieve seed crystal to a porous carrier is 0.3-0.5; carrying out surface modification on the porous carrier to obtain a porous carrier with set molecularsieve seed crystal arrangement orientation; coating a molecular sieve seed crystal on the surface modified porous carrier; and carrying out secondary growth on the molecular sieve seed crystal on thesurface of the porous carrier to obtain the carrier surface modified hydrophilic molecular sieve membrane and obtain the ultrathin membrane, thereby implementing the advantages of high separation selectivity and high flux.

Owner:NANJING WEIXIN ENVIRONMENTAL PROTECTION EQUIP TECH RES INST CO LTD

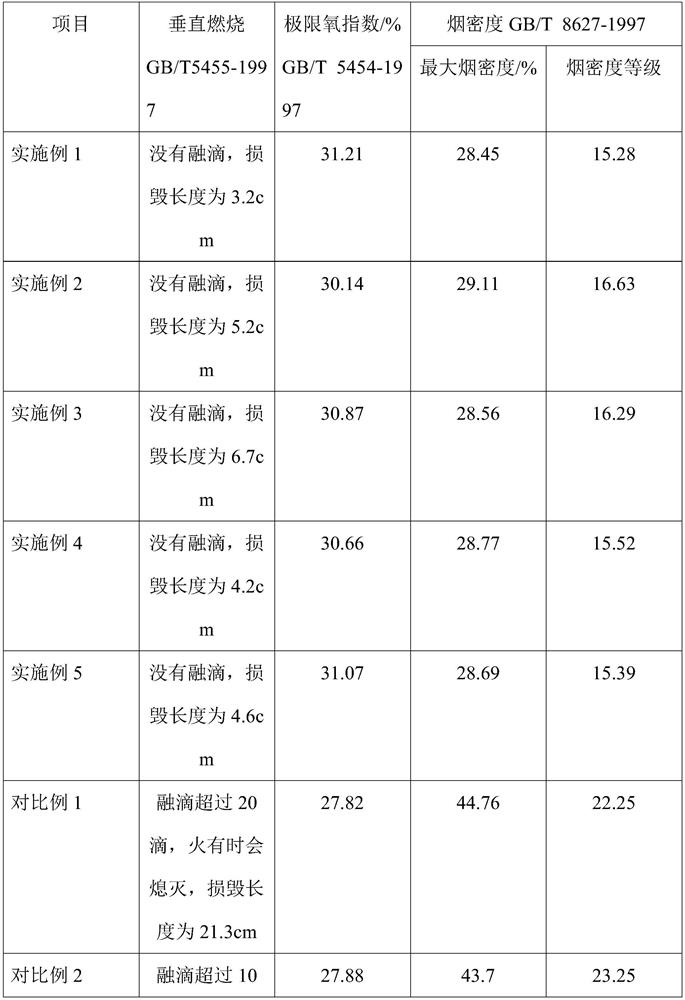

Modified polyacrylate flame-retardant emulsion, modified polyacrylate flame-retardant pressure-sensitive adhesive containing modified polyacrylate flame-retardant emulsion and preparation method of modified polyacrylate flame-retardant pressure-sensitive adhesive

PendingCN114716624AImprove fire resistanceImprove adhesionNon-macromolecular adhesive additivesGraft polymer adhesivesEpoxyPolymer science

The invention discloses a modified polyacrylate flame-retardant emulsion, a modified polyacrylate flame-retardant pressure-sensitive adhesive containing the emulsion and a preparation method of the modified polyacrylate flame-retardant emulsion, and the preparation method of the modified polyacrylate flame-retardant emulsion comprises the following steps: firstly, mixing epoxy resin and acrylic acid mixed monomers, then adding an emulsifier solution for pre-emulsification to obtain a pre-emulsion, and then adding the pre-emulsion into a reaction kettle for reaction to obtain the modified polyacrylate flame-retardant pressure-sensitive adhesive. And dropwise adding an initiator solution into the pre-emulsion, and carrying out semi-continuous seed-initiated polymerization to obtain a seed emulsion, namely the modified polyacrylate flame-retardant emulsion. The modified polyacrylate emulsion has good fire resistance, and also has excellent cohesiveness, weather resistance and film-forming property of the polyacrylate emulsion. The main component of the pressure-sensitive adhesive is modified polyacrylate flame-retardant emulsion, melamine-ammonium polyphosphate-dipentaerythritol is supplemented as an intumescent flame-retardant system, and titanium dioxide, zinc oxide, graphene and diatomite are added to reduce the smoke amount and improve the strength of a carbon layer, so that the flame-retardant property of the pressure-sensitive adhesive is improved.

Owner:ZHONGSHAN KINGLABEL ADHESIVE PRODS

Aqueous grease-proof paint and preparation thereof

InactiveCN101412888AOvercome water resistanceOvercome Oil ResistantPolyurea/polyurethane coatingsFirming agentKetone

The invention relates to a paint composition taking physical property of the composition or effect generated by the composition as characteristics and a production method thereof, and in particular belongs to aqueous grease sealing paint and a production method thereof. The method adopts the technical proposal as follows: mixing and stirring water, polyurethane, acrylic modified latex, aqueous acrylic modified latex, an isocyanate firming agent, a lyophobic modified polyacrylate type dispersing agent, an alkyl polyoxyethylene ether rheological additive, an alkali-swelling latex type thickening agent, a non-ionic interface foam suppressor, an isothiazoles ketone mildew inhibitor and other materials; and filtering the mixture through a filter to obtain the paint composition. The paint has the advantages that the paint overcomes the defects of various aqueous paints in water resistance, oil resistance, adhesive force, hardness, scraping resistance and other aspects, and can save cost for raw materials and manpower, and is an excellent environment-friendly product.

Owner:FUZHOU CANAAN & DECORATION MATERIALS

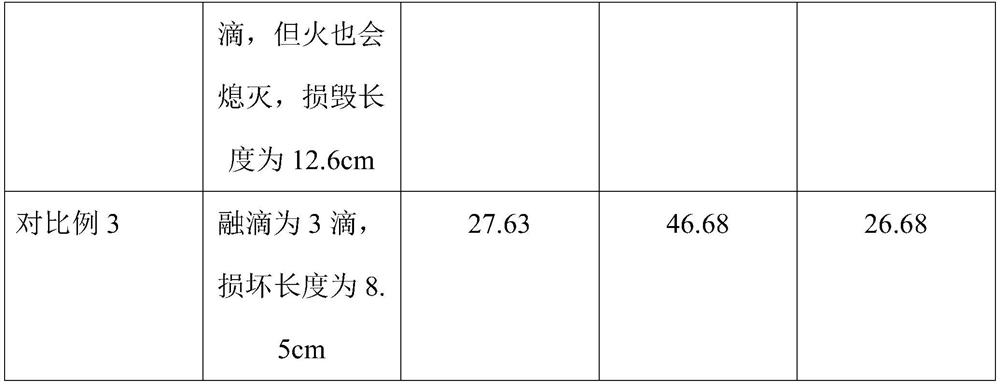

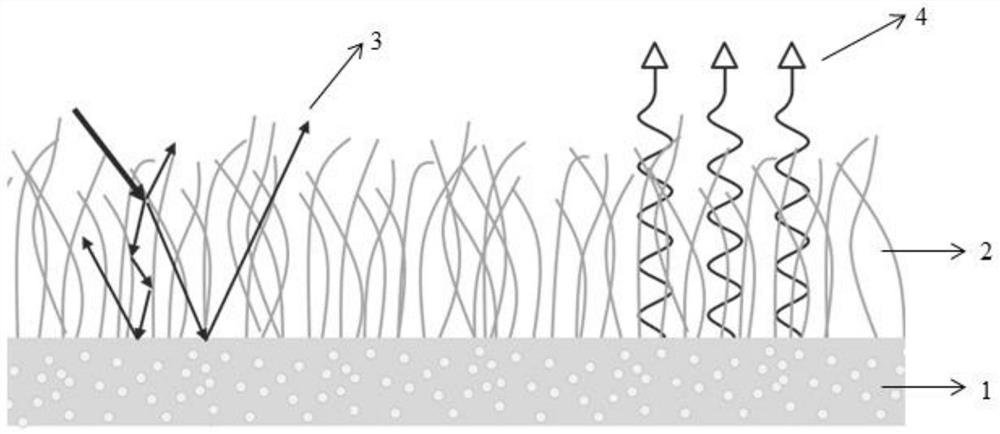

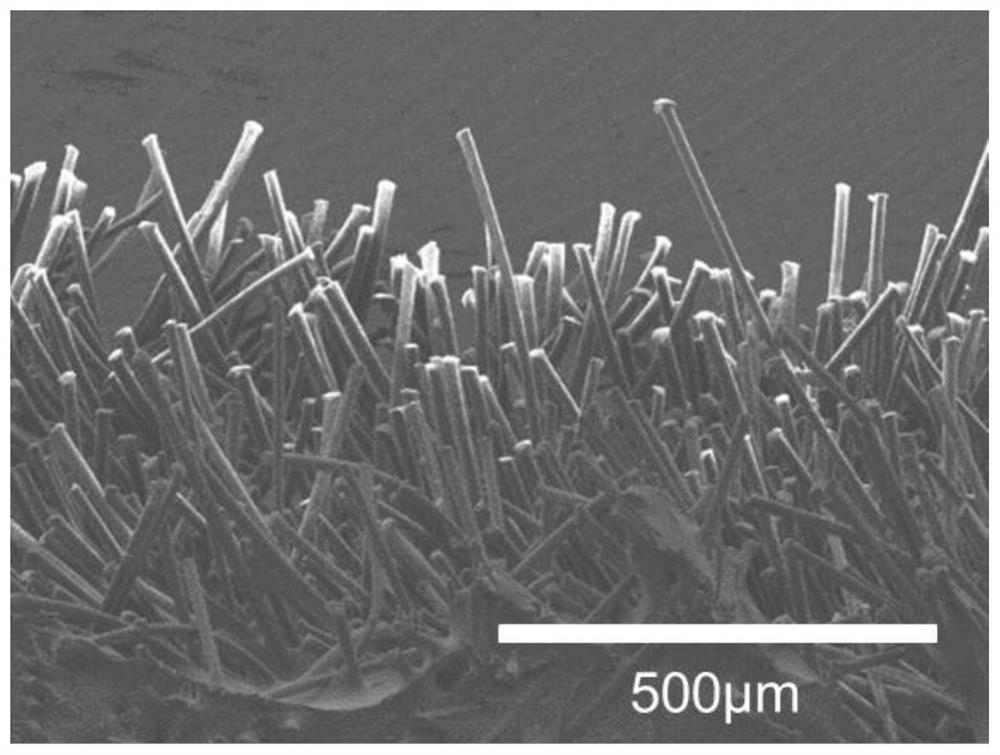

Radiation refrigeration surface based on fiber array and preparation method and application thereof

PendingCN114659290AImprove reflectivityOvercome the shortcomings of not being able to take care of bothRefrigeration machinesFiberEmissivity

The invention provides a radiation refrigeration surface based on a fiber array and a preparation method and application of the radiation refrigeration surface. The radiation refrigeration surface based on the fiber array comprises a bottom adhesive layer and a top fiber array structure. And the bottom adhesive layer is prepared from the following raw materials: a polymer matrix, inorganic filler particles and a curing agent. The radiation refrigeration surface based on the fiber array provided by the invention has a series of advantages of high sunlight reflectivity, high mid-infrared emissivity, strong adhesive force with a substrate and the like, and has excellent radiation refrigeration performance. The radiation refrigeration surface based on the fiber array can be used for building outer walls, thermal control mechanisms and the like to adjust the internal temperature of the building outer walls, the thermal control mechanisms and the like. In addition, the radiation refrigeration surface based on the fiber array is simple in preparation process, low in cost and suitable for large-area production and preparation.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com