Paint special for surface of special non-ferrous metal and preparation method of paint

A non-ferrous metal, special technology, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems of easy back-sticking, general weather resistance and anti-corrosion, poor surface adhesion of non-ferrous metals, etc., to achieve super adhesion and overcome adhesion poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

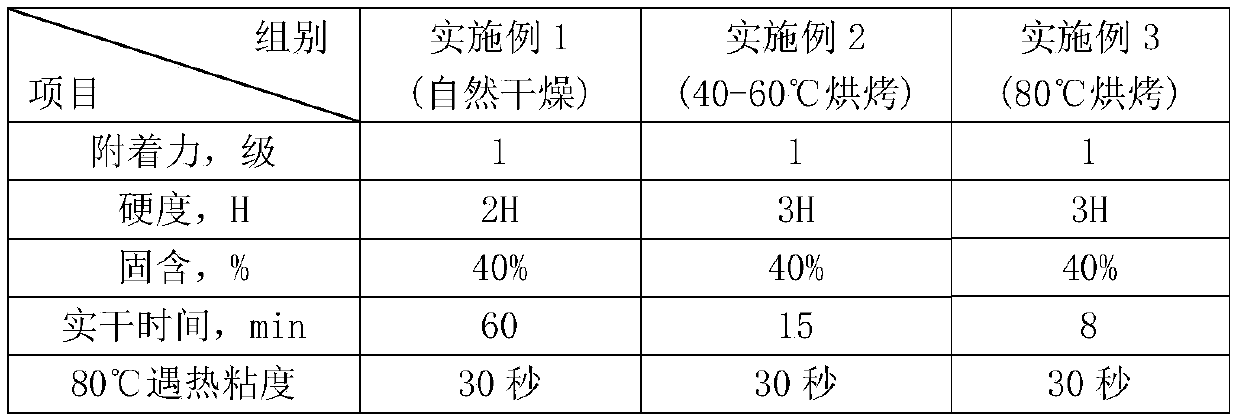

Embodiment 1

[0056]Application on titanium alloy plates: Most titanium alloys are military products or precision instruments, which require metallic luster and good adhesion. Silver metallic glitter paint can be sprayed directly on the metal, and it can be stored after 1 hour of natural drying.

Embodiment 2

[0058] Application on non-standard containers: the sheet is hot-dip galvanized sheet, the color is consistent with the color of hot-dip galvanized sheet, air spraying is used during construction, and it is divided into inside and outside the box, and epoxy zinc-rich primer is used for leveling inside the box 1-2 minutes, then spray silver metallic glitter paint leveling for 1-2 minutes, spray silver metallic glitter paint directly outside the box, enter 40-60 ℃ drying tunnel to bake for 10-15 minutes, leave the drying tunnel to cool for about 2 minutes, and stack.

Embodiment 3

[0060] Application on aluminum alloys: decorative panels, aluminum alloy panels, and applications on building exterior walls, spray silver metallic flash paint directly, and then bake in an oven at 80°C for about 8 minutes, completely dry, and after cooling, storage.

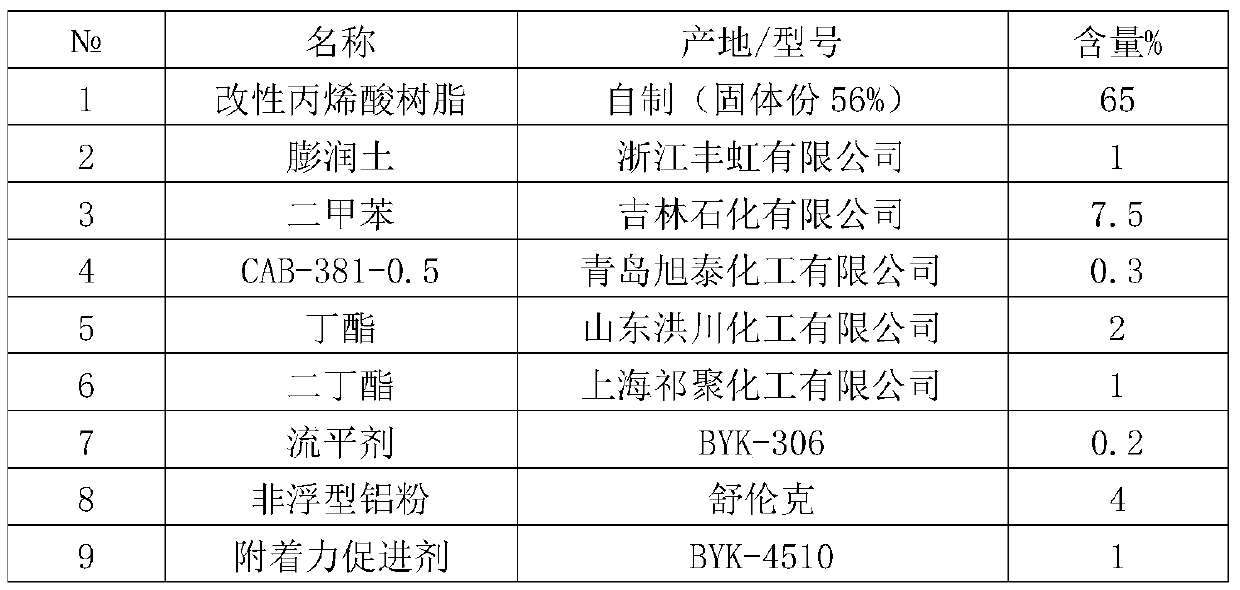

[0061] The formulations of the silver metallic glitter paint used in the above three examples are as follows:

[0062]

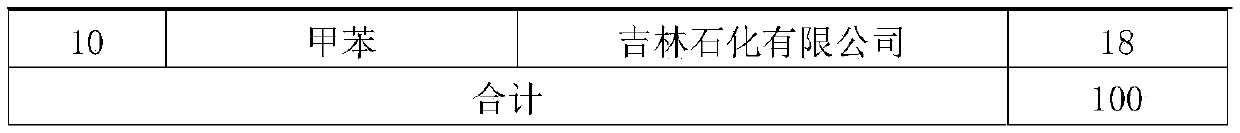

[0063]

[0064] Production Process:

[0065] (1) The paint making equipment must be clean, check whether the stirring is regular and whether the paint outlet valve is closed.

[0066] (2) Use 3 materials to pre-disperse 2 materials, and use a stirring device with a motor power of 45 kilowatts at a dispersing speed of 800r / min to stir for 10 minutes until the uniform fineness of no dispersion is ≤ 20 microns. Component A is obtained.

[0067] (3) Use 5 ingredients to pre-disperse 3 ingredients, and use a stirring device with a motor power of 45 kilowatts at a dispersing speed of 800r / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com