Carrier surface modified hydrophilic molecular sieve membrane and preparation method thereof

A carrier surface and surface modification technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of low flux, low technical repeatability, and increased cost, and achieve high separation selectivity, Effects of separation selectivity and high throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

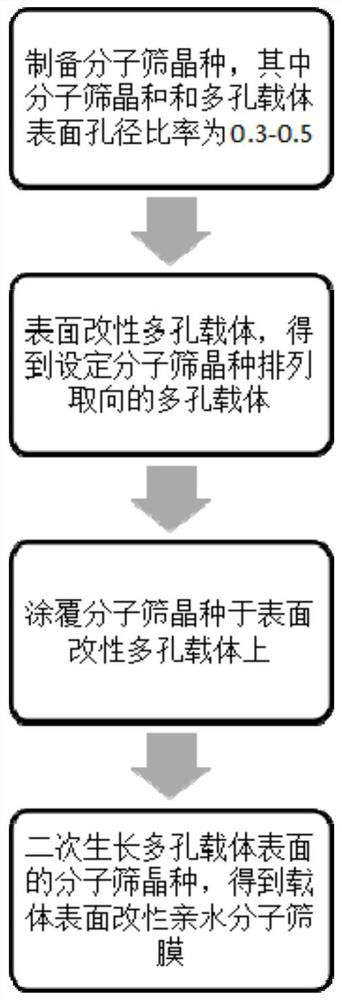

Method used

Image

Examples

Embodiment 1

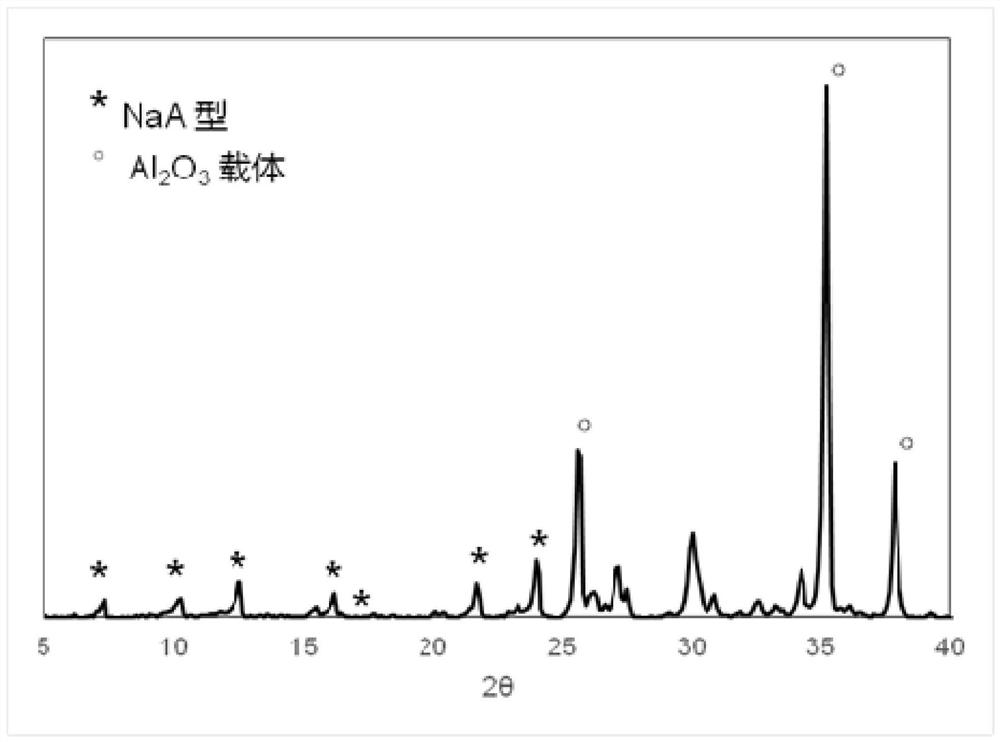

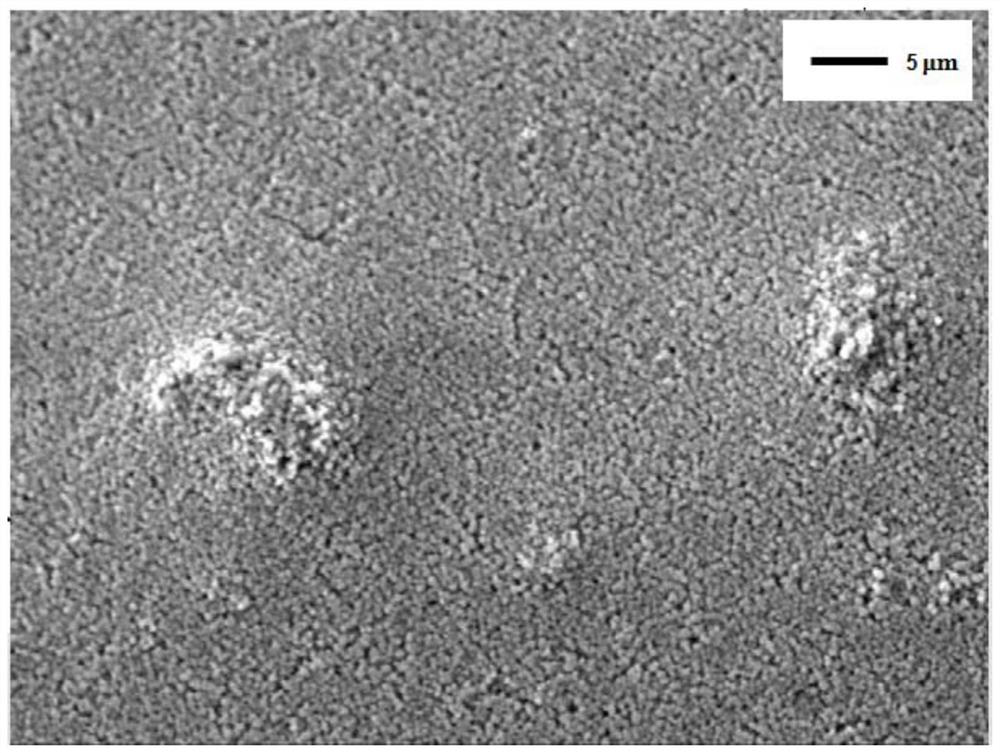

[0032] Taking the preparation of NaA molecular sieve membrane as an example, Na 2 O, Al 2 o 3 , SiO 2 、H 2 O prepared seed crystal growth solution.

[0033] 1. Preparation of NaA-type seed crystals: Take sodium metasilicate and deionized water, mix and stir evenly for 30 minutes until completely dissolved, then slowly add quantitative sodium hydroxide solution and stir for 5 minutes, and at the same time take sodium aluminate in another beaker Mix with deionized water and stir vigorously for 30 minutes, then slowly add the dissolved sodium metasilicate and sodium hydroxide solution to the dissolved sodium aluminate solution, the final ratio is 2.9Na 2 O:0.48Al 2 o 3 :1SiO2 2 : 98H 2 O, aged at room temperature for 50 hours, moved the stirred synthetic solution into a reactor heated by a microwave oven, and crystallized at 90°C for 1 hour. The product was centrifuged, washed with deionized water ultrasonically until neutral, and dried. The size of the obtained NaA type...

Embodiment 2

[0038] Take the preparation of CHA type molecular sieve membrane as an example.

[0039] 1. CHA type seed crystal preparation: get 16g potassium hydroxide, 25g Y type molecular sieve (SiO 2 / Al 2 o 3 =6-6.5) and 220gH 2 O Mix well for at least 15 minutes, age at room temperature for 1 hour, transfer the stirred synthetic solution into a hot water reactor, and crystallize at 100°C for 100 hours. The product is centrifuged and ultrasonically washed with deionized water until neutral, and dried dry, wherein the resulting CHA-type seeds had a size of 300-500 nm.

[0040] 2. Carrier modification: the same as in Example 1.

[0041] 3. Seed crystal coating: the same as in Embodiment 1.

[0042] 4. Take aluminum isopropoxide, potassium hydroxide, strontium nitrate and H 2 O Mix well for at least 30 minutes, under strong stirring, slowly add the quantitative silica gel, and stir for at least 30 minutes. The final ratio is 1SiO 2 : 0.2Al 2 o 3 :0.15-0.2K 2 O:0.05-0.08SrO:0.5-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com