Molecular sieve composite membrane

A molecular sieve and composite membrane technology, applied in the field of composite membranes, can solve problems such as unsuitability for preparation, long molecular sieve membranes, mechanical strength problems, etc., and achieve high industrial application value, high film forming repeatability, and prevent pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

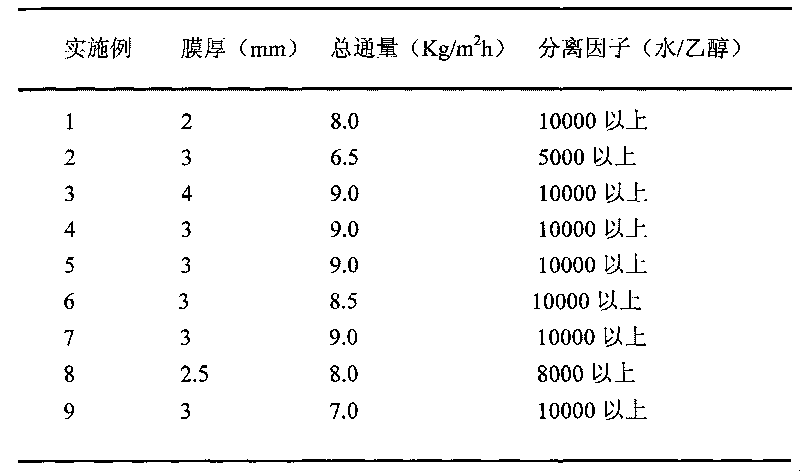

Examples

preparation example Construction

[0018] The molecular sieve composite membrane is composed of 40-90wt% molecular sieve particles with a particle size of 0.1-5m and 10-60wt% organic polymers or organic polymer mixtures on the inner surface of a porous multi-channel composite support. The specific preparation method of a multi-channel molecular sieve composite membrane composed of molecular sieve polycrystalline membranes of the same type of micro particles includes the following steps:

[0019] 1) Add sodium aluminate to distilled water and stir fully to form an aluminum solution, dissolve sodium hydroxide in distilled water, add silicon source after clarification, heat and stir to form a silicon solution, add aluminum solution to silicon solution and stir to make The composition of the reaction solution for the synthesis of molecular sieve membrane: Na 2 O: Al 2 O 3 : SiO 2 : H 2 O=1-20:1:1:1-200:50-5000;

[0020] 2) Pour the reaction solution of the synthetic molecular sieve membrane into the high pressure reacto...

Embodiment 1

[0025] 1) Take 100g of polyethersulfone resin (PES), 300g of 1-methyl-2-pyrrolidone and mix, then add 150g of tetraethylene glycol and stir to form a uniform solution. Then add 400g of A molecular sieve with an average particle size of 2m to prepare a uniform slurry as the spinning dope. A multi-channel spinning head is used, and the core liquid and the coagulation bath are wet-spinning with 40℃ heat preservation water and an air distance of 10cm. The obtained multi-channel support was immersed in a 60°C pool for 6 hours, and finally the support was placed in an oven at 60°C and dried for 3 hours. A multi-channel composite support with an outer diameter of 31mm and 19 channels was prepared;

[0026] 2) Add sodium metaaluminate to distilled water and stir fully to form an aluminum solution, dissolve sodium hydroxide in distilled water, add sodium silicate after clarification, heat and stir to form silicon solution, add aluminum solution to silicon solution and stir to prepare Th...

Embodiment 2

[0029] 1) Take 100 g of polyacrylonitrile and 300 g of 1-methyl-2-pyrrolidone and mix, then add 150 g of tetraethylene glycol and stir to form a uniform solution. Then add 900g of A molecular sieve with an average particle size of 2m to form a uniform slurry and use it as a spinning dope. A multi-channel spinning head is used, the core liquid and the coagulation bath are made of water at 40°C, and the air distance is 10cm for wet spinning. The obtained multi-channel support was immersed in a 60°C pool for 6 hours, and finally the support was placed in an oven at 60°C and dried for 3 hours. A multi-channel composite support with an outer diameter of 31mm and 19 channels is produced;

[0030] 2) Add sodium metaaluminate to distilled water and stir thoroughly to form an aluminum solution, dissolve sodium hydroxide in distilled water, add sodium metasilicate after clarification, heat and stir to form silicon solution, add aluminum solution to silicon solution and stir, The reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com