Patents

Literature

2226 results about "Sodium aluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium aluminate is an inorganic chemical that is used as an effective source of aluminium hydroxide for many industrial and technical applications. Pure sodium aluminate (anhydrous) is a white crystalline solid having a formula variously given as NaAlO₂, NaAl(OH)₄ (hydrated), Na₂O·Al₂O₃, or Na₂Al₂O₄. Commercial sodium aluminate is available as a solution or a solid. Other related compounds, sometimes called sodium aluminate, prepared by reaction of Na₂O and Al₂O₃ are Na₅AlO₄ which contains discrete AlO₄⁵⁻ anions, Na₇Al₃O₈ and Na₁₇Al₅O₁₆ which contain complex polymeric anions, and NaAl₁₁O₁₇, once mistakenly believed to be β-alumina, a phase of aluminium oxide.

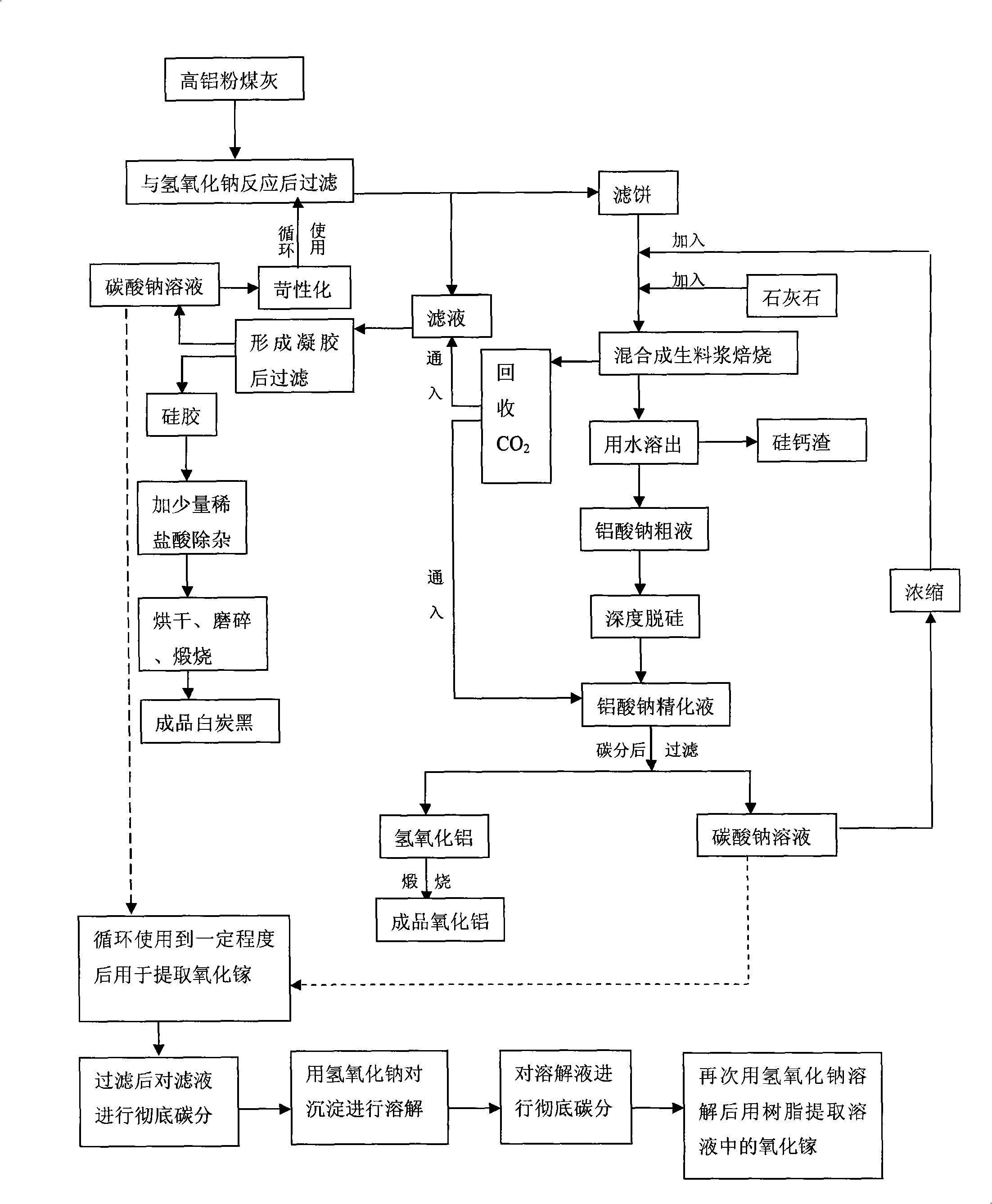

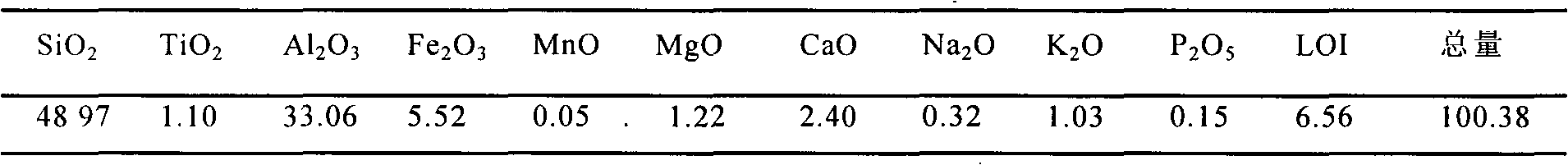

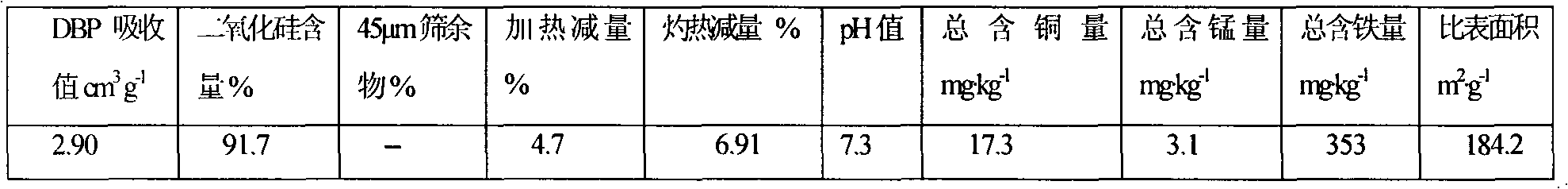

Process for abstracting earth silicon, oxide of alumina and gallium oxide from high-alumina flying ash

ActiveCN101284668AReduce the total massLow firing temperatureGallium/indium/thallium compoundsSilicon oxidesChemical industryFiltration

A method for extracting silicon dioxide, alumina and gallium oxide from high-alumina fly ash relates to the technology fields of environmental mineralogy and material, chemical industry and metallurgy. The method comprises the main steps as follows: causing the high-alumina fly ash to react with sodium hydroxide solution; filtering the solution; introducing CO2 to the filtrate for full gelation; cleaning, purifying, drying, grinding and calcining the silica gel after gel filtration to obtain finished white carbon black; adding limestone and a sodium carbonate solution into the filter mass after the reaction and filtration of the high-alumina fly ash and the sodium hydroxide solution; ball grinding the mixture into raw slurry; dissolving out the clinker obtained by baking the raw slurry; subjecting the filtrate to deep desiliconization to obtain sodium aluminate extraction liquid; filtrating the sodium aluminate extraction liquid after subjecting the sodium aluminate extraction liquid to carbon dioxide decomposition; baking the aluminum hydroxide after washing the filter mass to form the aluminum hydroxide product; and extracting the gallium oxide from the carbon dioxide decomposition mother solution and desiliconized solution. The method has the advantages of low material price, simple operating procedures, low investment, low production cost, low energy consumption and less slag.

Owner:TSINGHUA UNIV +1

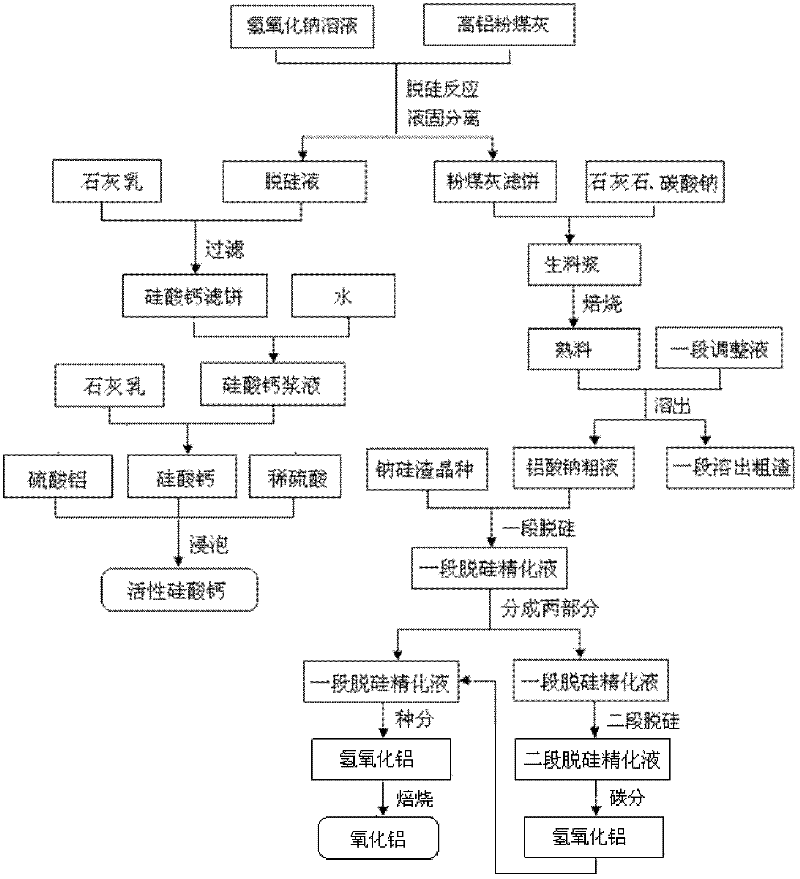

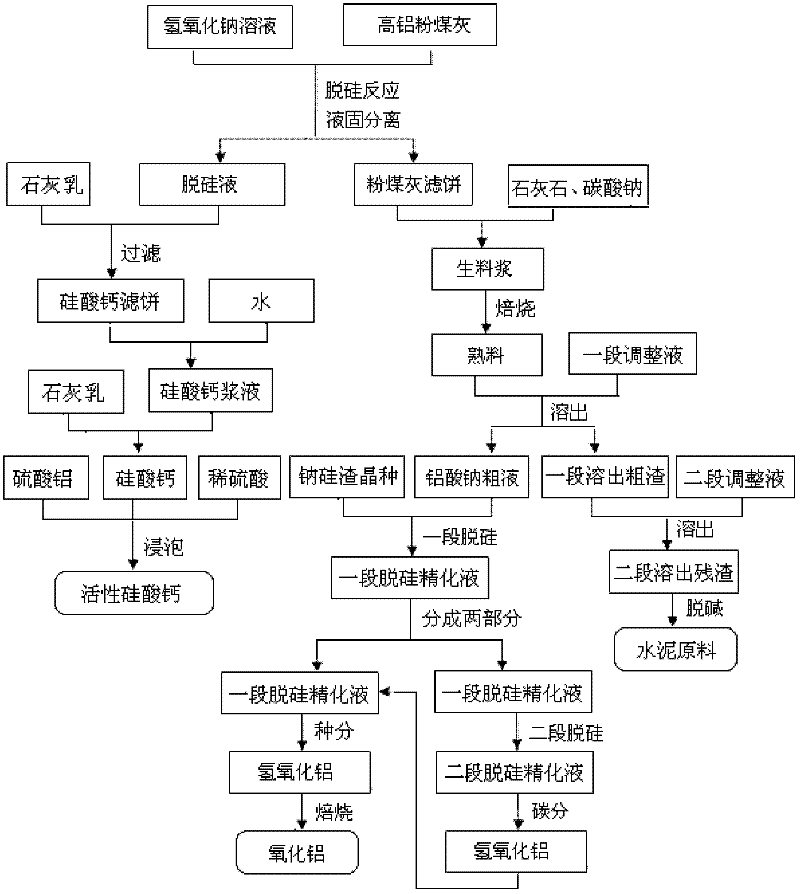

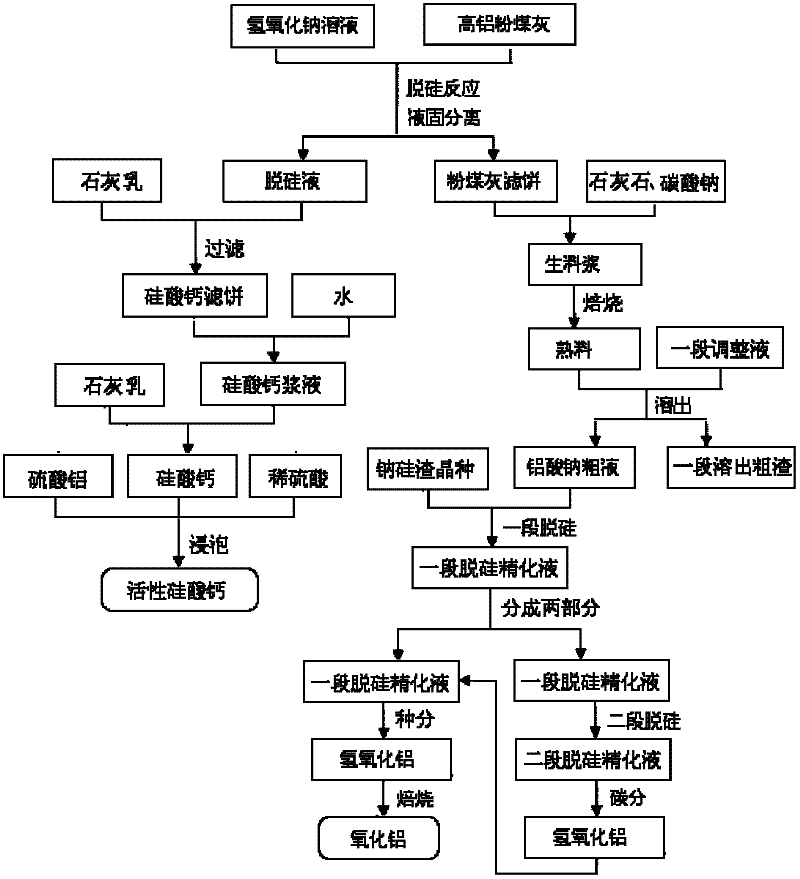

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Preparation method of alumina

ActiveCN1927716AReduce pollutionReduce consumptionAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideDecomposition

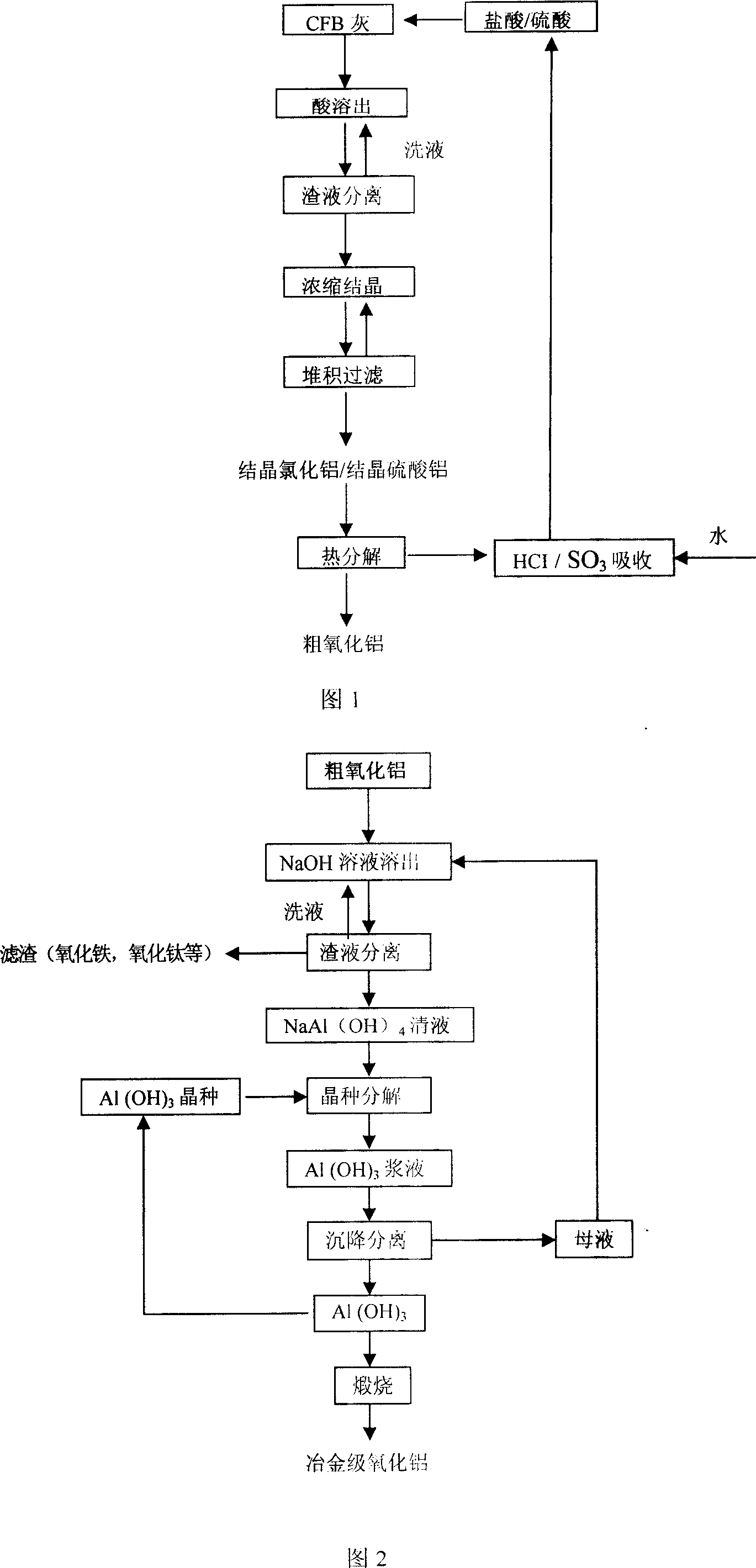

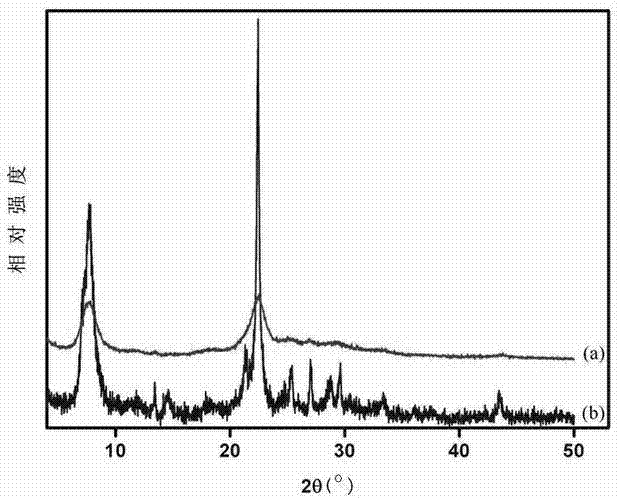

The process of preparing alumina includes: the reaction of flyash from circular fluidizing bed and acid to obtain aluminum chloride solution, eliminating silicon impurity, concentrating to crystallize and heating to decompose and to obtain crude alumina product; reaction of crude alumina product and hot alkali solution to obtain sodium aluminate solution; eliminating iron, titanium and other impurity, adding aluminum hydroxide crystal seed into sodium aluminate solution for seed separating decomposition to obtain aluminum hydroxide precipitate; and final calcining aluminum hydroxide to obtain metallurgical alumina. The normal pressure process has no any cosolvent added, and the alumina product has Al2O3 content up to 98 %. The process has small sodium hydroxide consumption, reuse of most of sodium hydroxide, simple operation, low cost, low power consumption, capacity of reducing flyash pollution and other advantages.

Owner:SHENHUA ZHUNGER ENERGY

Method of preparing amorphous silica-alumina using carbonization

InactiveCN1597093AEasy to controlSimple processCatalyst activation/preparationReaction temperatureSodium aluminate

A process for preparing the amorphous Si-Al material by the carbonizing method includes such steps as adding part of sodium silicate solution to sodium aluminate solution, introducing CO2 gas to it for a certain time, adding the rest of sodium silicate solution while reacting, stabilizing, filtering, washing and drying. It can be used as the carrier of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

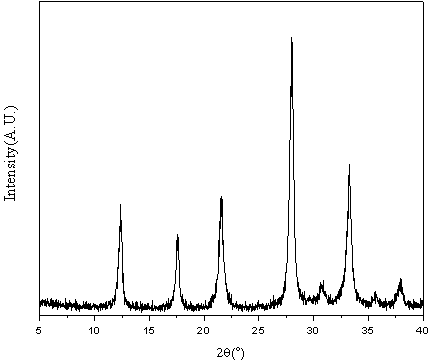

Preparation method for Beta zeolite molecular sieve with hierarchical porous structure

InactiveCN102826564APlay a structurally oriented roleThe synthesis steps are simpleCrystalline aluminosilicate zeolitesMolecular sieveActive agent

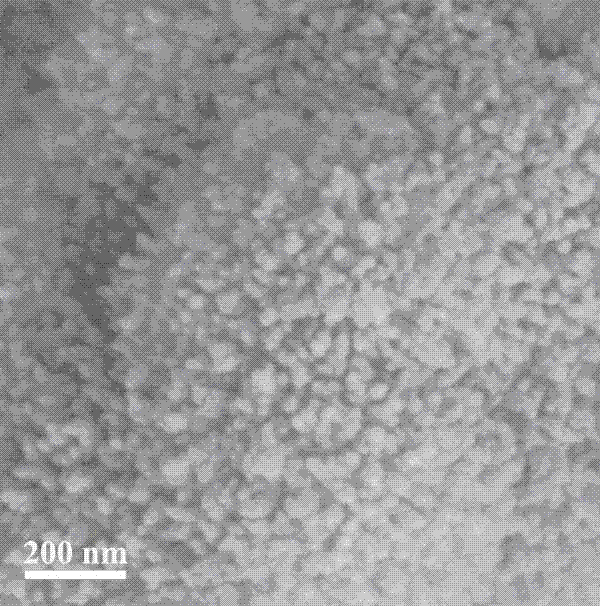

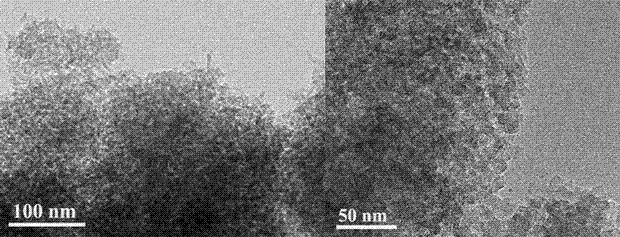

The invention discloses a preparation method for a Beta zeolite molecular sieve with a hierarchical porous structure. Ethyl orthosilicate is used as a silicon source, sodium metaaluminate is used as an aluminum source, hexaammonio cationic quaternary ammonium surfactant is used as a template, and then the hierarchical porous zeolite molecular sieve containing meso pores and Beta zeolite micropores is prepared by using a hydro-thermal synthesis process under an alkaline condition. According to the invention, the hexaammonio cationic quaternary ammonium surfactant is used as a Beta zeolite structure guiding agent and generates micropores, aggregation of hydrophobic long-chain alkyl groups on the surfactant forms the meso pores, so the prepared Beta zeolite molecular sieve has both meso pores and the crystalline micropores. The structure with both the meso pores and the micropores enables defects of a single pore structure to be avoided and mass transfer efficiency to be improved, and the Beta zeolite molecular sieve has a wide application prospect in aspects of macro-molecular catalysis, adsorption, separation, etc.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing alumina by using fly ash

InactiveCN101397146AEffective leachingPromote leachingAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

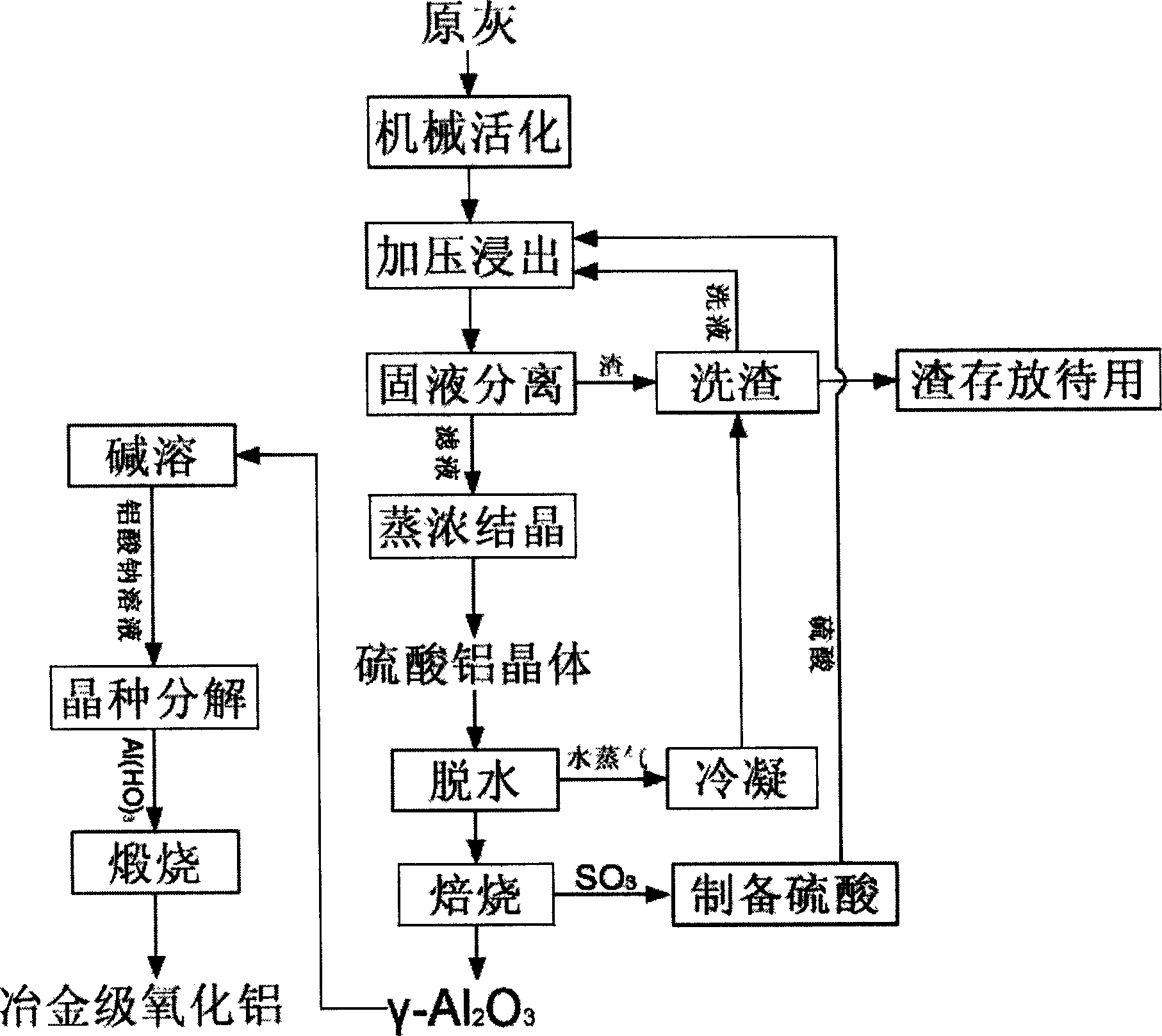

The invention discloses a method for producing alumina by disposing and utilizing industrial solid wastes, in particular to a method for preparing alumina by fly ash, comprising the steps as follows: the fly ash is mechanically activated; the activated fly ash, water and concentrated sulfuric acid react in a reaction kettle under the conditions of heating and pressurizing; the solid is separated from the liquid after the temperature of the reaction is reduced so as to gain aluminium sulfate liquid; the aluminium sulfate liquid is evaporated, concentrated and cooled so as to precipitate aluminium sulphate crystals; the aluminium sulphate crystals are dehydrated and decomposed to gain gama-Al2O3 and SO3; coarse gama-Al2O3 is dissolved in alkaline solution; after the solid is separated from the liquid, the pure sodium aluminate solution is gained; aluminum hydroxide crystal seed is added to the sodium aluminate solution so as to precipitate the aluminum hydroxide; the coarse gama-Al2O3 can be prepared by circularly dissolving the seed-precipitated alkaline solution after vaporization-concentration; the metallurgical alumina can be gained by baking the prepared aluminum hydroxide. The method adds no additive, can lead the alumina in the fly ash to be effectively leached out with the leaching rate more than 90% and saves the energy resource.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Method for preparing vanadium pentoxide

InactiveCN1843938AMeet the needs of domestic chemical productionVanadium oxidesCalcium hydroxideSodium aluminate

The invention relates to a method for preparing vanadic anhydride. It comprises following steps: employing ammonium vanadate, vanadic anhydride of technical grade or waste catalyst discharged in sulfuric acid preparation process; treating with ammonium hydroxide, sulfuric acid and ammonium chloride, washing with water; getting fine active vanadic anhydride; removing foreign matter with ammonium hydroxide, calcium hydroxide, sodium aluminate, sodium silicate, sulfuric acid and ammonium chloride; washing with water again; drying; calcing at 670 Deg. C and getting high-purity vanadic anhydride. The invention is characterized in that it makes use of current material to prepare chemical materials urgently needed by industrial production, and saves a large amount of foreigh exchange.

Owner:宿素满

Method for dissolving Bayer process red mud

ActiveCN102757060AMeet industrial requirementsReduce sodiumCalcium/strontium/barium carbonatesSludge treatmentCalcium silicateAluminium hydroxide

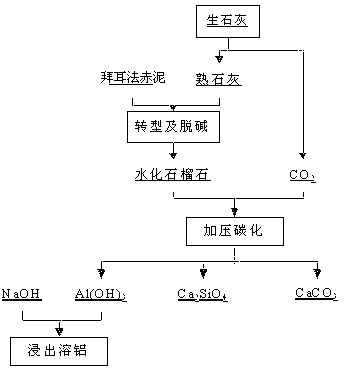

The invention discloses a method for dissolving red mud. The method comprises the following specific steps of: mixing Bayer process red mud with white lime in the mass ratio of 1:(0.3-0.9); stirring at the temperature of 80-140 DEG C for reacting for 1-15 hours for calcifying, transforming and dealkalizing; mixing calcified, deformed and dealkalized Bayer process red mud with clear water or a low-concentration sodium aluminate solution in an enclosed container; introducing CO2 into the container to obtain calcified slag containing calcium silicate, calcium carbonate and aluminum hydroxide serving as main components; and extracting aluminum hydroxide from the calcified slag by using a sodium hydroxide solution or an aluminum hydroxide solution. In the method disclosed by the invention, the structure and composition of red mud are changed by adopting calcification transformation and pressurizing calcification transformation methods, so that dealkalization and extraction of aluminum can be realized; and iron is extracted properly, so that the structure and the composition of red mud can meet the requirements of cement production, and the aim of dissolving red mud on a large scale at low cost is fulfilled.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

Method for harmless disposal and recycling of aluminum ash

ActiveCN105271327ATo achieve the purpose of comprehensive recycling of resourcesGreat social valueAmmonia preparation/separationAluminium oxides/hydroxidesMetallic aluminumSodium aluminate

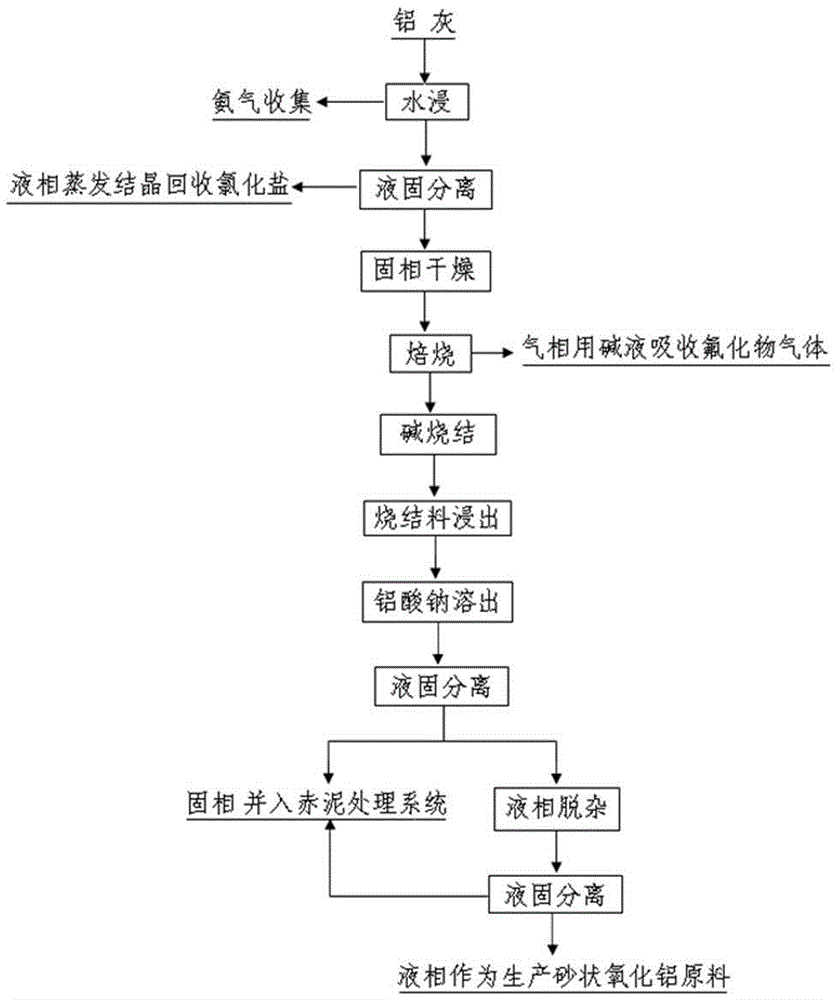

The invention discloses a method for harmless disposal and recycling of aluminum ash. The method comprises steps of raw material water immersion nitrogen and chlorine removal, calcination fluorine removal, alkali fusion sintering, sintering material dissolving-out and purifying impurity removal. Aluminum ash generated in metal aluminum smelting process is employed as a raw material, after metal aluminum is recycled through secondary processing, nitrides are removed through water immersion, fluorides are removed through calcinations, alkali fusion sintering is carried out, the sintering materials are dissolved out, impurities are removed through a sodium aluminate solution, the processed aluminum ash is employed as a raw material for producing sand-shaped aluminum oxide. Ammonia gas generated in the aluminum ash harmless disposal process can be employed as an ammonium production raw material, a chlorination liquid generated can be employed as a chlorate production raw material, and silicon fluoride gas generated in the calcination process is absorbed by an aqueous solution. The method is simple and practical, environmental protection benefits are high, the production efficiency is high, the device investment is low, and energy consumption is low. Harmless and recycling disposal of hazardous wastes can be achieved. The obtained product can be applied in practical production.

Owner:YUNNAN WENSHAN ALUMINUM

Preparation of aluminum phosphate or polyphosphate particles

InactiveUS20080038556A1High mixingHigh shear stress performanceMaterial nanotechnologyPigmenting treatmentSodium aluminatePolyphosphate

A process for the preparation of amorphous aluminum phosphate or polyphosphate-based pigment by reacting aluminum phosphate and sodium aluminate is provided. The amorphous aluminum phosphate or polyphosphate is characterized by a skeletal density of less than 2.50 grams per cubic centimeter and a phosphorus to aluminum mole ratio of greater than 0.8. In one embodiment, the composition is useful in paints as a substitute for titanium dioxide.

Owner:BUNGE AMORPHIC SOLUTIONS +1

Preparation process for large pore volume and light bulk density activated alumina

InactiveCN102730724AChange the stacking methodFine grainAluminium oxides/hydroxidesWater vaporSodium aluminate

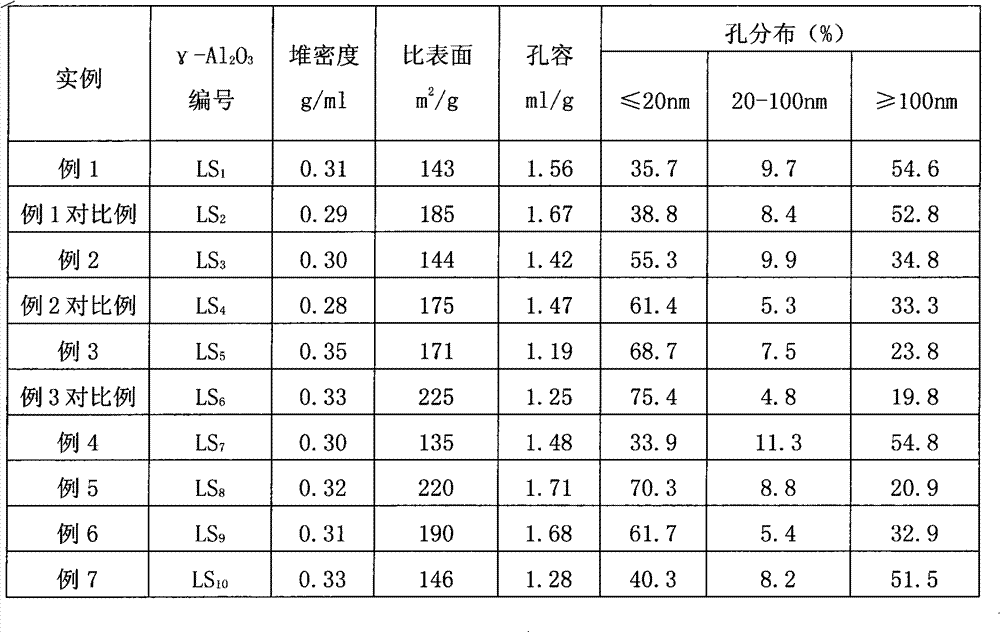

The invention relates to a preparation process for large pore volume and light bulk density activated alumina, and belongs to the technical field of activated alumina preparation. According to the process, an aluminum sulfate solution and a sodium aluminate solution form a glue in a stainless steel neutralization kettle through a continuous co-current flow method; then an aging treatment is performed for a certain time in a stainless steel aging washing tank; the resulting material is pressed to a plate and frame filter press with a material pressing pump to carry out continuous washing to prepare primary pseudo-boehmite particles with large grains; the removed filter cake is acidified, and proper amounts of a pore expanding agent and a surfactant are added during the acidification process to carry out forming; the formed wet balls are placed in a drying box to carry out drying; and the dried small balls are loaded into a calcination activation furnace to carry out high temperature calcination and pore expanding. The process of the present invention has characteristics of low cost and low equipment corrosion, can performs continuous washing cycle, and has advantages of low wastewater discharging, less pollution, and the like. With the process of the present invention, the production cycle can be reduced, the labor intensity can be reduced, and various performance indicators of the prepared gamma-Al2O3 can meet the international advanced level after pore expanding by water vapor.

Owner:JIANGSU JINGJING NEW MATERIALS

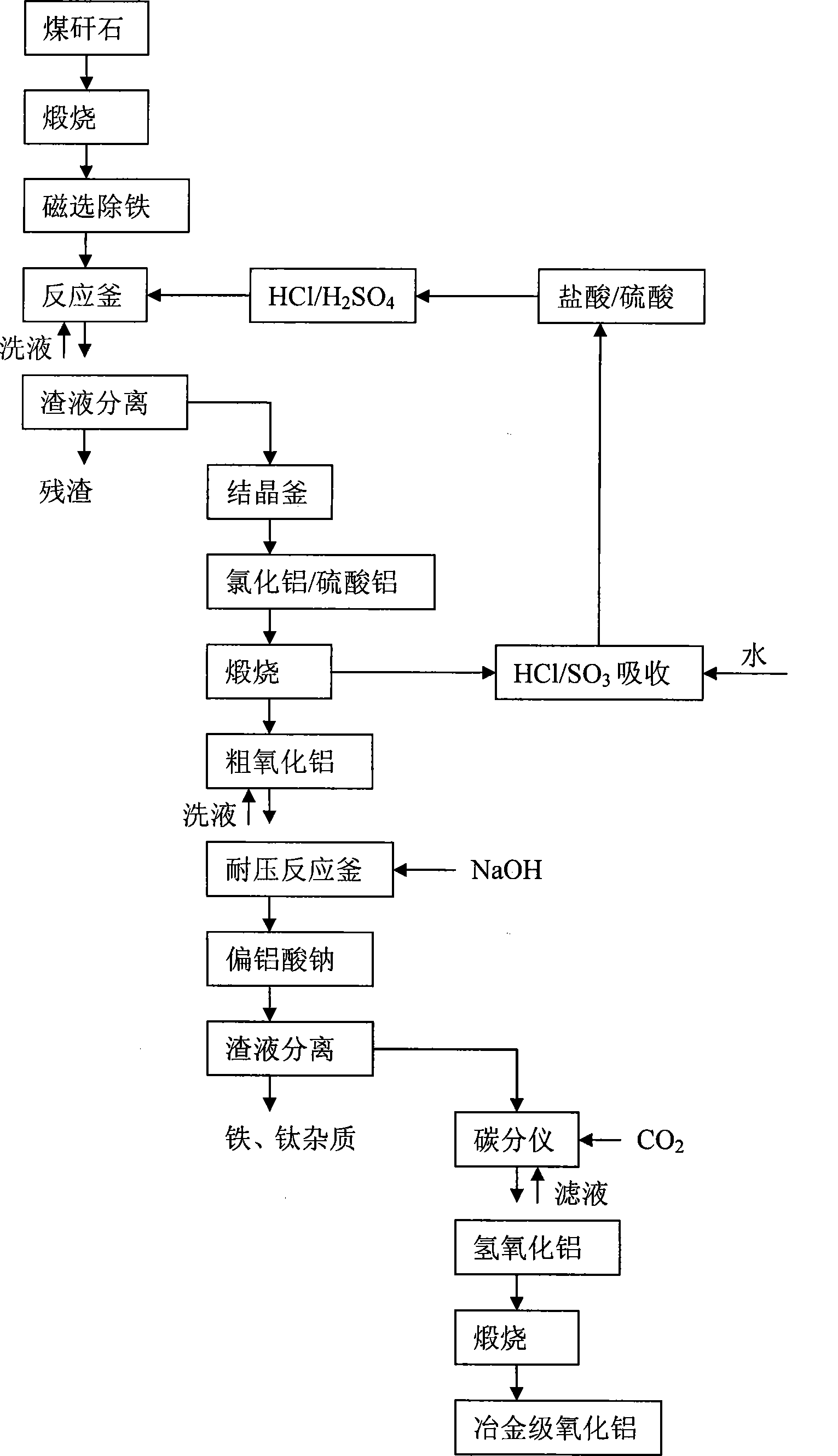

Method for extracting alumina from coal gangue

InactiveCN101450811AAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

The invention mainly relates to a method for extracting alumina from coal gangue. The coal gangue is ground, and then is calcined through a fluidized furnace and iron is removed through a magnetic separator, the coal gangue with the iron removal reacts with an acid to obtain an aluminum chloride solution without silicon impurities, the solution containing the aluminum is concentrated and crystallized and then is subjected to low-temperature calcination to obtain crude aluminum oxide, then the crude aluminum oxide reacts with sodium hydroxide to obtain a sodium aluminate mother solution, impurities such as iron and titanium are removed, an aluminum hydroxide crystal seed is added to the mother solution, and carbon dioxide gas is introduced for seed precipitation to obtain an aluminum hydroxide precipitate, and metallurgical grade alumina can be obtained through the calcinations. The method does not use any auxiliary agent at normal pressure, and uses hydrochloric acid and sulfuric acid to directly leach and extract alumina; the content of the alumina prepared by the method can reach more than 99 percent; and the method has the advantages of simple process flow, adequate raw material sources, less energy consumption, low cost, and high utilization value of the coal gangue.

Owner:CHANGCHUN CHAOWEI NEW MATERIALS TECH

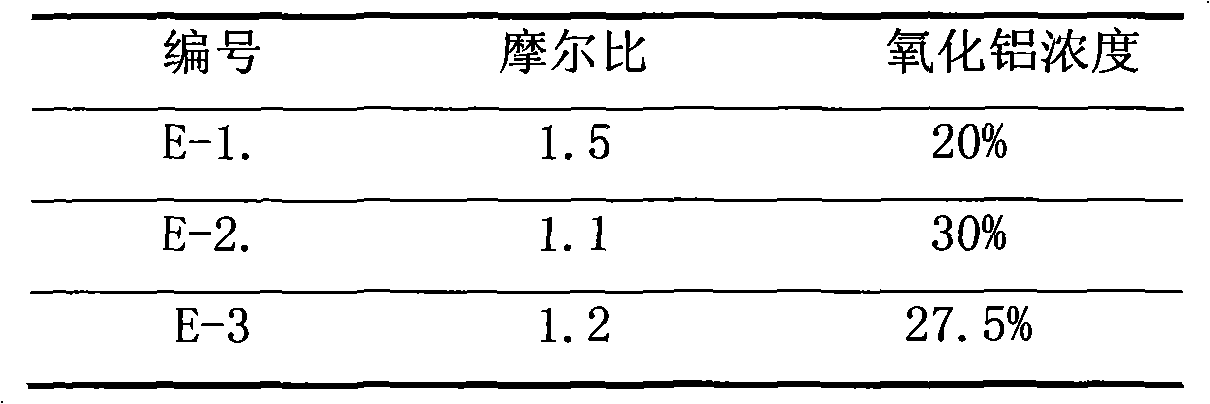

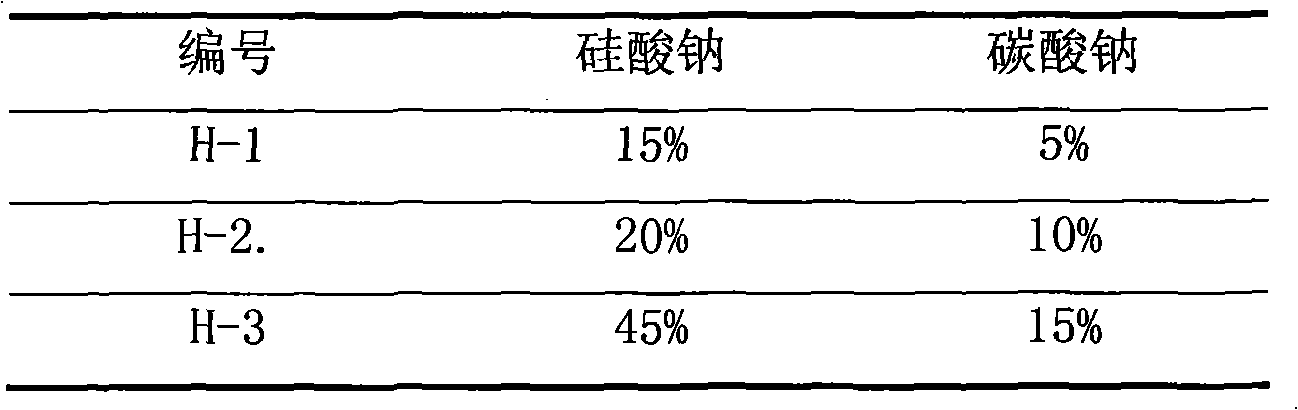

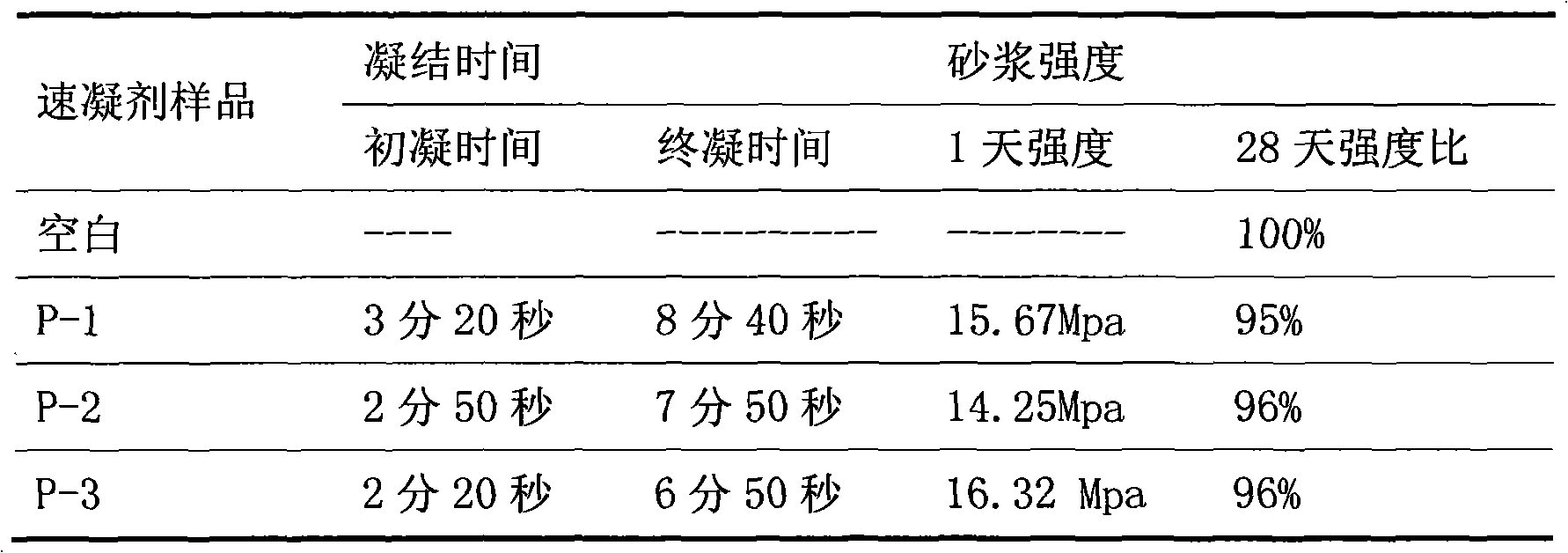

Low-alkaline liquid accelerating agent and preparation method thereof

The invention belongs to the technical field of tunnel construction, and relates to a low-alkaline liquid accelerating agent and a preparation method thereof. For the low-alkaline liquid accelerating agent, aluminium sulfate solution is neutralized with sodium aluminate solution to produce aluminium hydroxide collosol, and then aluminium sulfate and aluminium hydroxide collosol conduct polymerization reaction in an original solution system to produce polymerized aluminium sulfate, so that the accelerating agent solution has higher aluminium ion content and liquid stability; the low-alkaline liquid accelerating agent is prepared by aluminium sulfate, sodium aluminate and stabilizing agent; and the mass percentage of the components are as follows: 40 to 60 percent of aluminium sulfate, 6 to12 percent of sodium aluminate, 0 to 0.2 percent of stabilizing agent, and the balance of water. The invention has the following positive effects to sprayed concrete: initial set of common cement can be realized in five minutes and final set of the common cement can be realized in eight minutes under lower doping amount; the 1d strength of cement mortar can reach more than 12MPa, and the 28d compression strength ratio of the cement mortar is more than 100 percent; and the invention has good adaptability to cement of different varieties.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Method for preparing multifunctional titanium dioxide pigment with chlorination method

ActiveCN102079885AGood weather resistanceGood light fastnessPigment physical treatmentPhosphatePapermaking

The invention relates to a method for preparing multifunctional titanium dioxide pigment with a chlorination method, which comprises the following steps of: blending a titanium dioxide primary product into titanium dioxide slurry by adopting a chlorination method and adjusting a pH value between 9.0 and 11.0; adding a phosphate dispersing agent and carrying out grinding treatment; removing a grinding medium from the slurry and heating; adding a water-soluble silicate solution for curing; adjusting the pH value of the slurry for forming amorphous silica and curing for forming a first coating layer; cooling the slurry to 50-70 DEG C; adding a sodium metaaluminate solution and curing; adjusting the pH value of the slurry between 8.0 and 9.0, curing and forming an amorphous alumina coating layer on the first coating layer; adding an aluminum salt solution, maintaining the pH of the slurry between 7.0 and 9.0 and curing; adjusting the pH value of the slurry between 6.0 and 7.0 and curing; and washing the slurry with deionized water till the conductivity of a filter cake is larger than 15,000 ohm.cm, and carrying out drying and steaming pulverizing treatment to obtain a finished product. The multifunctional titanium dioxide pigment prepared with the method has higher weather resistance, whiteness, covering capability, opacity and dispersibility and excellent processing performance in the fields of coating, plastics, papermaking, and the like.

Owner:中信钛业股份有限公司

Self-dispersion type nanometer gamma A100H and its preparation method and use

A gamma-AlOOH nanocrystal powder able to be automatically dispersed in aqueous and some organic solvents for preparing self-dispersing superfine non-toxic aluminum hydroxide flame-retarding agent, or the high-molecular polymer / inorganic nano-material composition, or the microcrystalline alumina ceramics or high-performance alumina ceramics as grinding medium is prepared through reaction of sodium aluminate or Al salt solution in alkaline medium, extracting the generated deposit, adding peptizing agent and disperser, peptizing and dispersing to obtain aluminum hydroxide colloid, reacting on additive and surfactant for surface modifying, and spray drying.

Owner:GUANGXI UNIV FOR NATITIES

Preparation method of low-alkaline liquid accelerating agent

The invention relates to a preparation method of low-alkaline liquid accelerating agent, comprising the following steps: 1) preparing sodium aluminate liquid; 2) modifying sodium aluminate liquid; 3)carrying out a reaction between the modified sodium aluminate and the aluminum sulfate; and 4) adding hydramine and hydroxycarboxylic acid and stirring evenly to prepare the finished product. The low-alkaline liquid accelerating agent prepared by the invention has low alkali content, namely, the sum of Na2O and K2O is less than 5%, low preparation cost, is suitable for cement such as ordinary Portland cement, moderate-heat cement, low-heat cement and other brands and types, is applicable to the sprayed concrete construction, can significantly improve initial strength and ensure later strength.

Owner:JIANGSU SOBUTE NEW MATERIALS

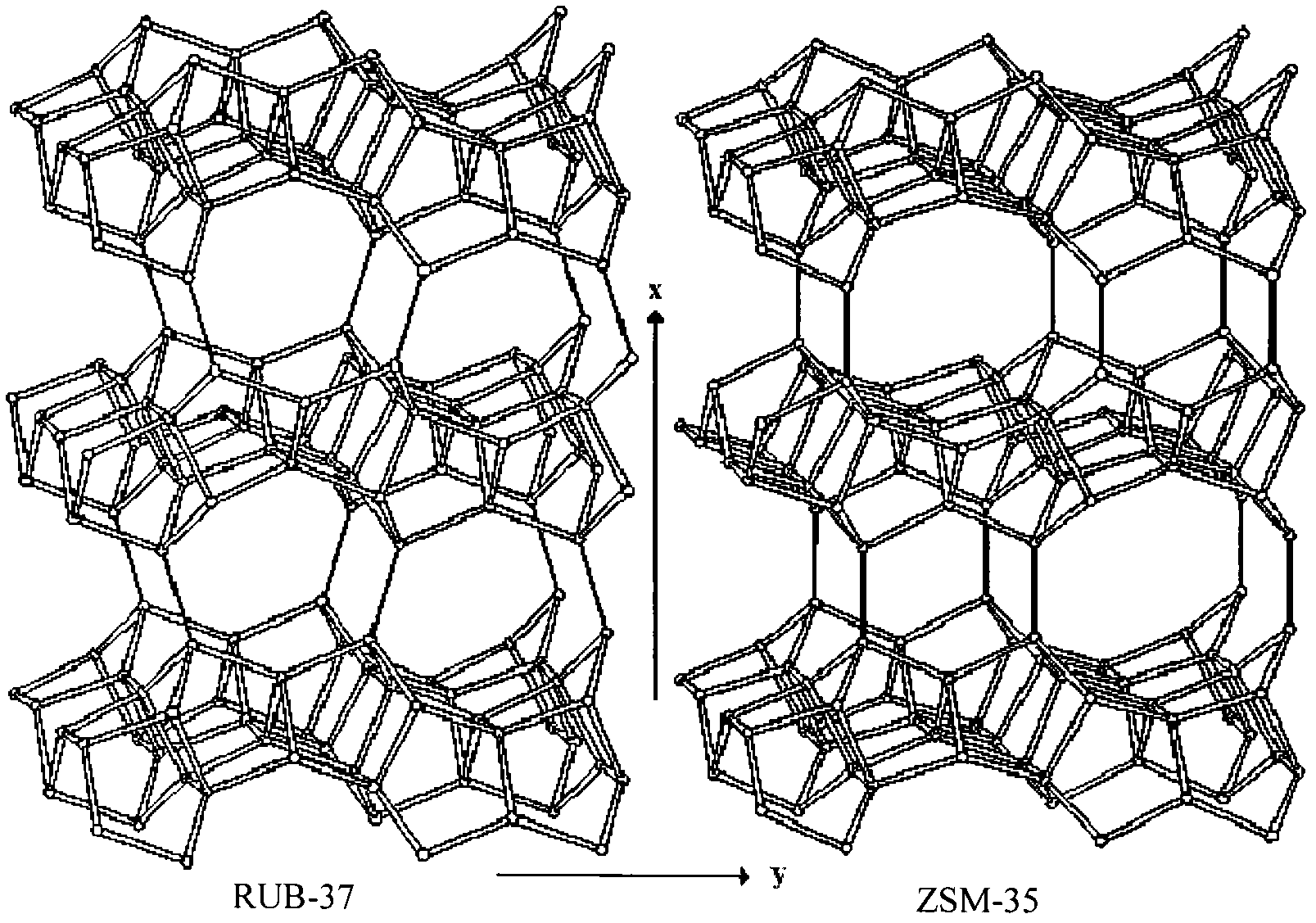

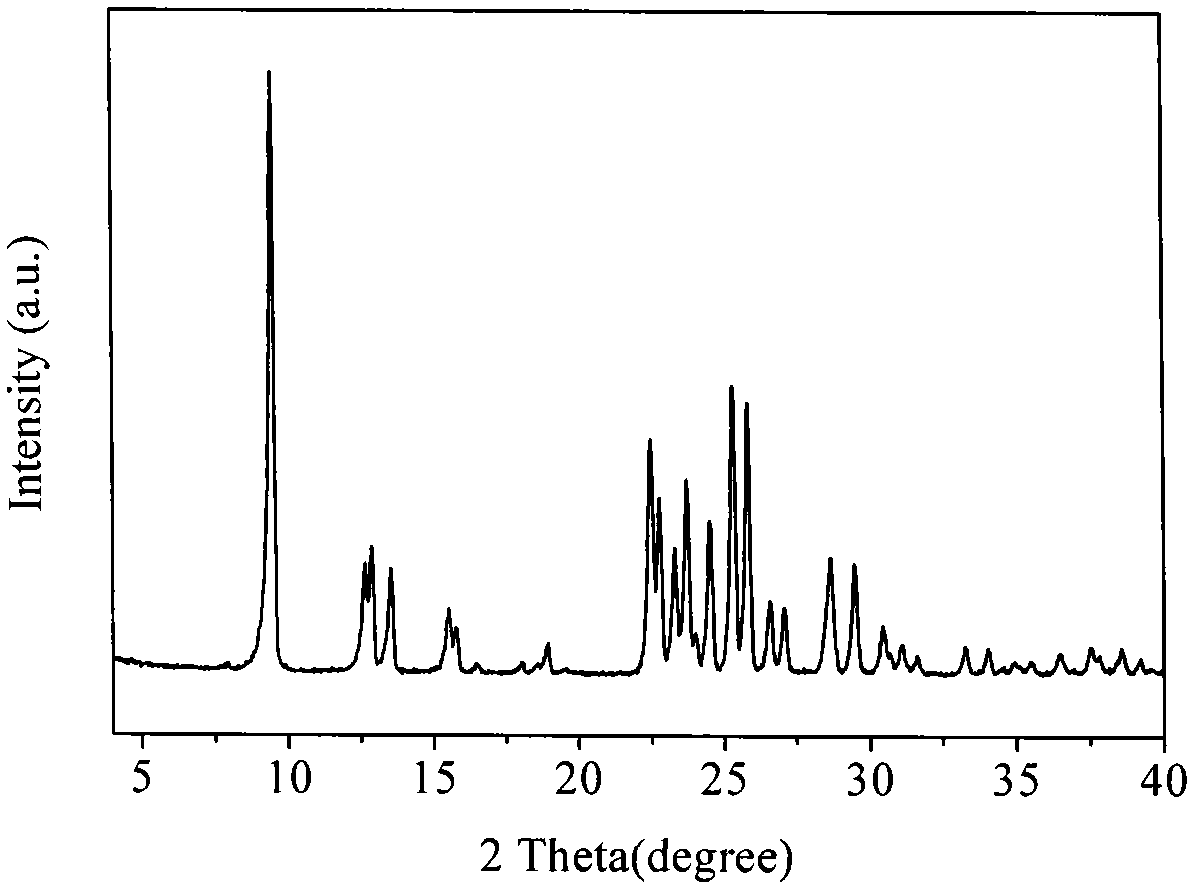

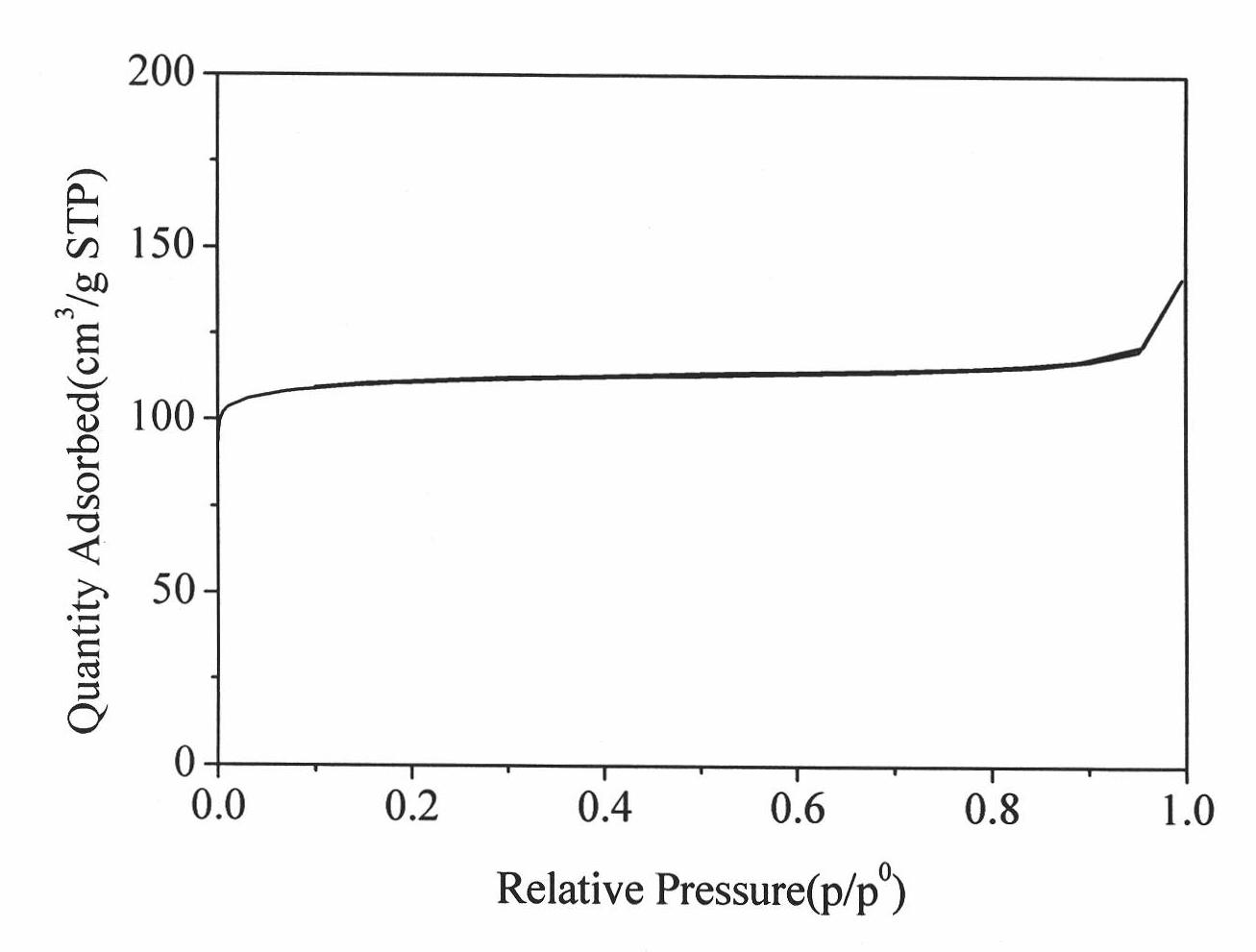

Method for synthetizing ZSM-35 molecular sieve by seed crystal process

InactiveCN101973563AHigh crystallinityHigh purityFerrierite aluminosilicate zeoliteMolecular sievePotassium ions

The invention relates to a molecular sieve preparation method, aiming to provide a method for synthetizing a ZSM-35 molecular sieve by a seed crystal process. After sodium aluminate is dissolved in water, adding NaOH and stirring; after a settled solution is obtained, adding white carbon black, and stirring the mixture at room temperature until forming even sialsphere gel; then adding zeolite seed crystal RUB-37 or ZSM-35 and evenly stirring; transferring the mixture to an agitated reactor and crystallizing at the temperature of 120-150 DEG C for 3-10 days; and filtering and drying to obtain the ZSM-35 molecular sieve. The product of the invention keeps good degree of crystallization and purity and has good catalytic reaction activity. The whole production process does not use organic template agent or potassium ion and can greatly shorten crystallization time by the seed crystal process, thus reducing unnecessary loss in the production process; and meanwhile, the product has larger specific surface area. The adopted inorganic raw materials for production protect environment and have low price.

Owner:ZHEJIANG UNIV

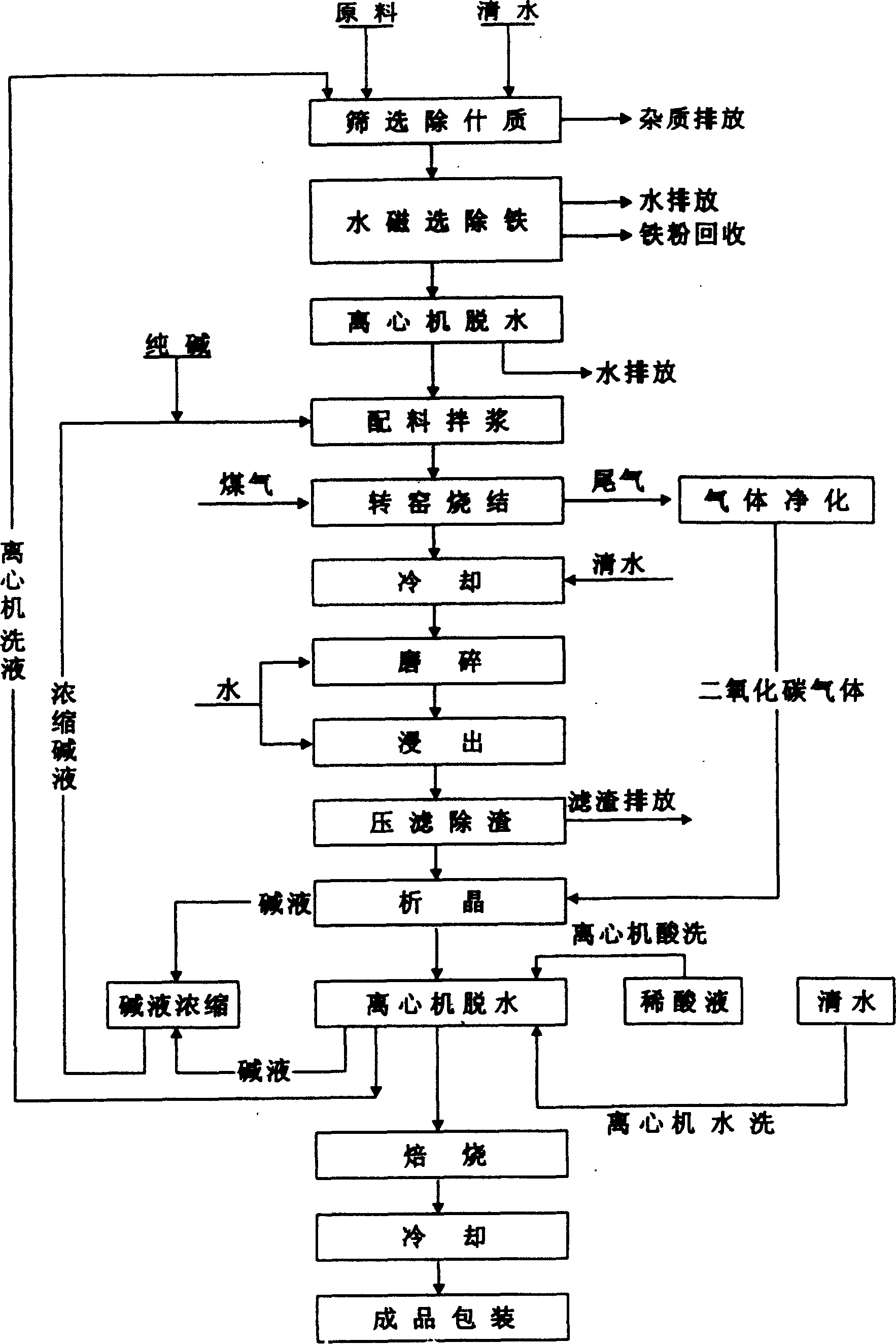

Process of producing alumina with waste aluminium ash

InactiveCN1673084ASimple processReduce manufacturing costSolid waste disposalAluminium oxides/hydroxidesSodium aluminateSlurry

The process of producing alumina with waste aluminum ash includes the following steps: sieving waste aluminum ash in 40-60 mesh; eliminating iron magnetically; dewatering to water content lower than 15 %; adding Na2CO3 solution via stirring to obtain chamotte; sintering aluminum ash slurry at 1100-1200 deg.c; cooling to 100-200 deg.c; adding water and grinding to obtain chamotte slurry of 120-150 mesh with sodium aluminate content of 120-150 g / L; heating to leach out sodium aluminiate at 80-100 deg.c for 1-2 hr; pressure filtering to obtain concentrated sodium aluminiate solution; introducing CO2 gas to separate crystal at 50-70 deg.c; solid-liquid separation in centrifuge to obtain aluminum hydroxide crystal; and roasting at 1100-1200 deg.c to obtain alumina product.

Owner:潘坤涛 +1

Method for preparing NaY molecular sieve with high aluminum-silicon ratio

ActiveCN102198950AShorten crystallization timeHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveSodium aluminate

The invention relates to a method for preparing a NaY molecular sieve with a high aluminum-silicon ratio, which comprises the following steps of: mixing a silicon source, an aluminum source and deionized water, uniformly mixing two guide agents in different molar ratios, water glass, acidic aluminum salt and sodium aluminate solution in a molar ratio of gel materials to prepare two gels, and crystallizing respectively, wherein the molar ratio of the gel materials is (1.0-6.5)Na2O:Al2O3:(5.0-18)SiO2:(100-280)H2O, and Al2O3 in the guide agents accounts for 0.01 to 15 percent of the total weightof Al2O3; uniformly mixing the two gels in a mass ratio of 1:(0.1-10) to prepare a mixed gel; and crystallizing the prepared mixed gel at the temperature of between 80 and 120 DEG C for 2 to 50 hoursto prepare the NaY molecular sieve. Compared with the prior art, the method has the advantages that: the NaY molecular sieve with the high aluminum-silicon ratio can be prepared in shorter time underthe condition of the same feeding molar ratio.

Owner:PETROCHINA CO LTD +1

Super early strength accelerator for portland cement concrete

InactiveCN104710128AReduce lossesMeet the requirements for patching open trafficSuperplasticizerSodium aluminate

The invention discloses a super early strength accelerator for portland cement concrete. The super early strength accelerator is prepared from the following constituents in percent by weight: 20-50% of an early strength constituent, 10-40% of quick setting constituent, and 20-45% of a water reducing constituent, wherein the early strength constituent is obtained by compounding at least two of hydramine, an organic salt and an inorganic salt; the quick setting constituent is one of sodium aluminate, aluminum sulfate and sodium silicate; the water reducing constituent is one of a polycarboxylate type high performance water reducer, a high-performance naphthalene-based superplasticizer, and a high-performance aliphatic superplasticizer. The super early strength accelerator disclosed by the invention is free of chlorine and alkali; the 16 h compressive strength of the portland cement concrete prepared by using the super early strength accelerator in a low temperature environment in winter is up to 20 MPa above, so that the portland cement concrete can meet the requirement on quick road repair, and achieves the excellent construction performance.

Owner:SOUTHEAST UNIV

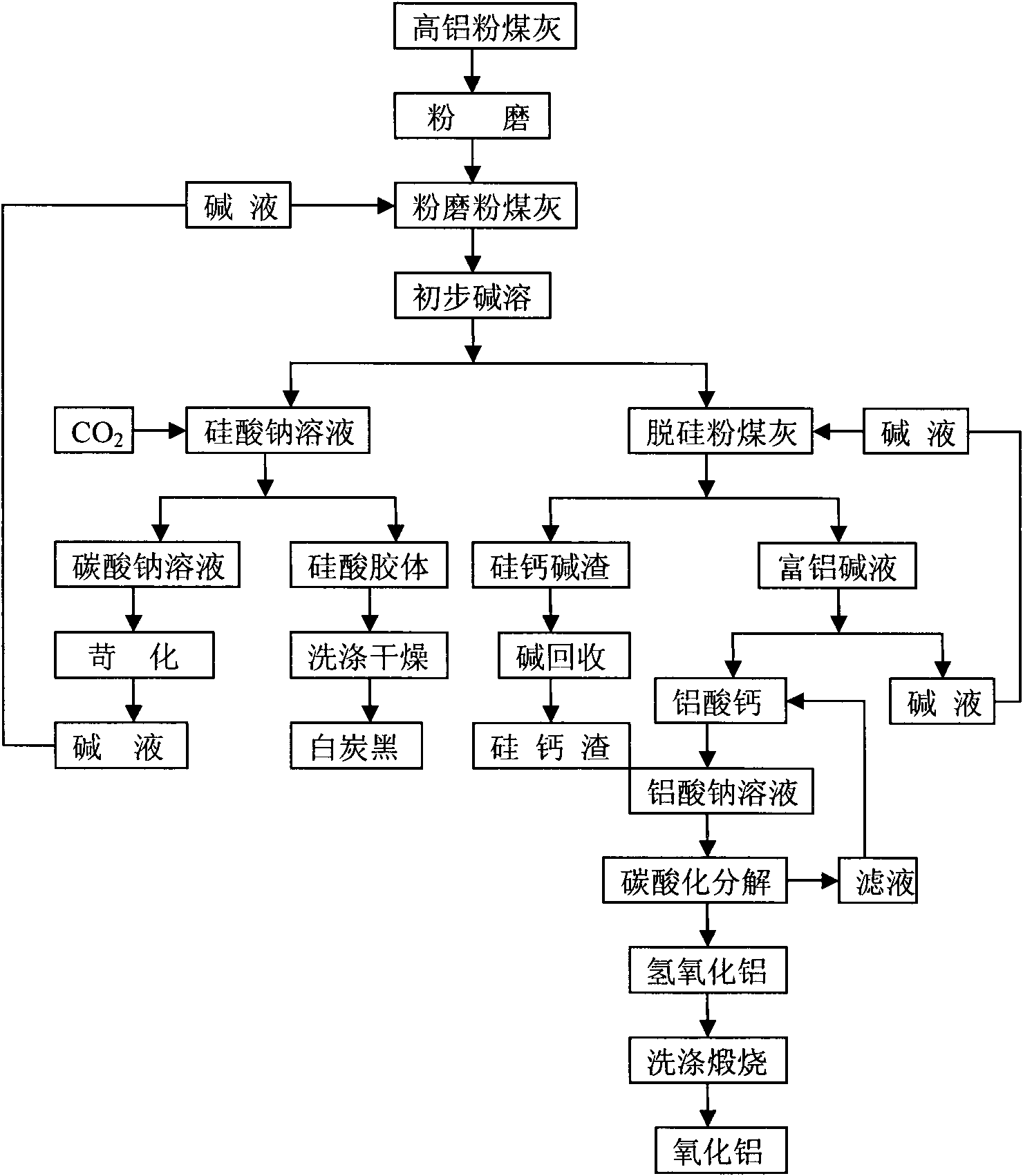

Method for extracting aluminum oxide and white carbon black through two-step alkaline leaching method by adopting high-alumina fly ash

ActiveCN101966999AReduce consumptionNo secondary pollutionSilicaSolid waste disposalSlagDecomposition

The invention discloses a process for preparing aluminum oxide and white carbon black by taking high-alumina fly ash as a raw material and adopting a two-step alkaline leaching method, comprising the following process steps of: preparing a sodium silicate solution by carrying out first-step alkaline leaching on the high-alumina fly ash; preparing the white carbon black by carrying out carbonation decomposition on the sodium silicate solution; preparing aluminum rich alkaline liquor by carrying out second-step alkaline leaching on desiliconization fly ash; preparing a sodium aluminate solution through the aluminum rich alkaline liquor; and preparing the aluminum oxide through the sodium aluminate solution, and the like. The invention prevents the high-temperature sintering in the process of the aluminum oxide prepared through the high-alumina fly ash, has low energy consumption and cyclic utilization of the alkaline liquor obtained through the first-step alkaline leaching and the second-step alkaline leaching, little material consumption; and in addition, silicon-calcium slag generated in the process course are used as raw materials for producing wall materials without generating secondary pollution, therefore the invention meets the requirements for clean production.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for producing high weathering resistance titanium dioxide pigment

The invention supplies a manufacture method for high weathering resistance titanium dioxide pigment that includes the following steps: making slurry; adjusting the pH value of the slurry; adding dispersing agent and filtering; heating; adding sodium silicate solution; adding mixture of sodium silicate and sulphuric acid solution; adding sulphuric acid; adding sodium aluminate solution and sulphuric acid solution; adjusting the pH value; filtering, washing, drying, taking gas smashing and organic process. The invention has strong covering power, good dispersibility and high weathering resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

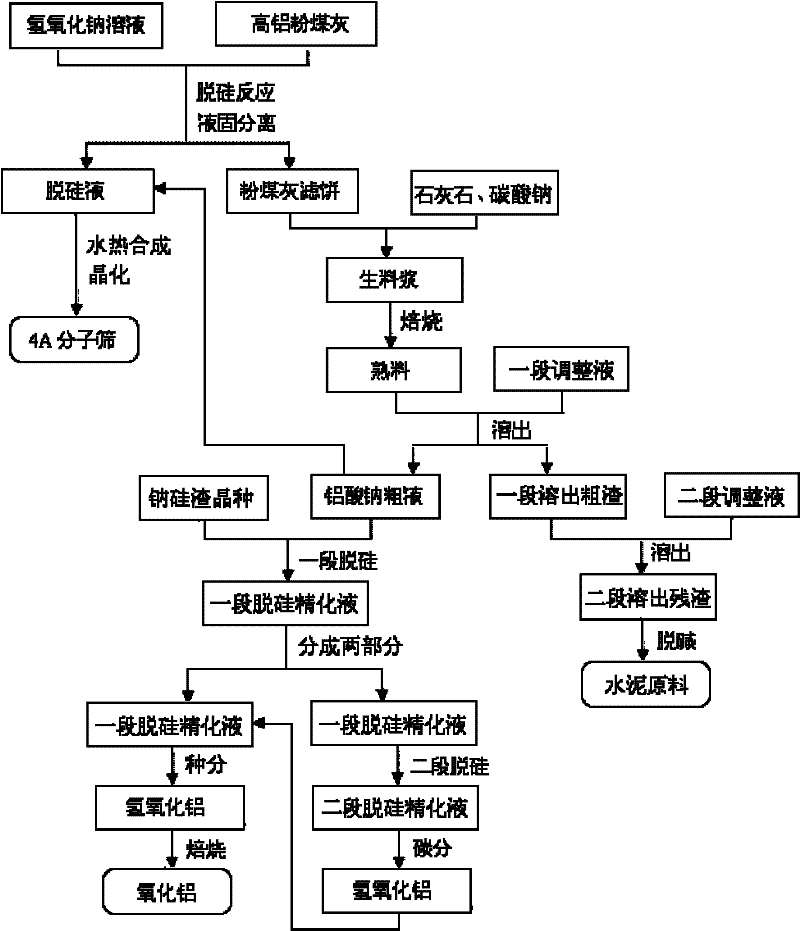

Method for production of alumina, joint product of cement and joint product of 4A zeolite molecular sieve with high aluminum fly ash

InactiveCN102225778AReduce dosageReduce trafficAluminium oxides/hydroxidesDecompositionAluminium hydroxide

The invention provides a method for production of alumina, a joint product of cement and a joint product of 4A zeolite molecular sieve with high aluminum fly ash. The production of alumina with high aluminum fly ash comprises the steps of: pre-desilication, raw slurry preparation, clinker calcination, clinker leaching, first and second stage deep desilication, carbon dioxide decomposition, seed precipitation, aluminum hydroxide calcination, thus obtaining alumina. Part of the sodium aluminate crude liquor generated from pre-desilication can be used to synthesize a 4A zeolite molecular sieve with desilication liquor, and residues from clinker leaching can be used for cement production after desilication. Characterized by simple process, low energy consumption, low cost and high utilization rate of raw material, the method of the invention is suitable for industrial application.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

A kind of separation and recovery method of NMP and catalyst lithium chloride in polyphenylene sulfide production

The invention relates to a separation and recovery method for n-methylpyrrolidone (NMP) and a lithium chloride catalyst during polyphenylene sulfide producing. The method is characterized by: directly carrying out vacuum distillation for a polyphenylene sulfide polycondensation mother liquid until the polyphenylene sulfide polycondensation mother liquid is dried to recover a solvent of the NMP, wherein the NMP can be used in the next recycling production; adding water to the distilled residues, then heating to a temperature of 40 DEG C, carrying out stirring and completely dissolving the distilled residues, carrying out filtering and washing the filter residues, mixing the resulting filtrate and the washing solution, and analyzing lithium content in the mixed solution; adding the mixed solution to a phosphoric acid solution or a sodium aluminate solution, wherein the phosphoric acid solution or the sodium aluminate solution has a lithium reaction equivalent of 105-115%, then completely stirring to enable lithium phosphate or lithium aluminate to be precipitated completely, then carrying out steps of filtering, washing, drying for the lithium phosphate or the lithium aluminate to recover the lithium salt having a purity more than 97%. According to the present invention, the operation of the method is simple; the cost is low; the recovered NMP and the recovered lithium salt havehigh purities.

Owner:NANJING UNIV

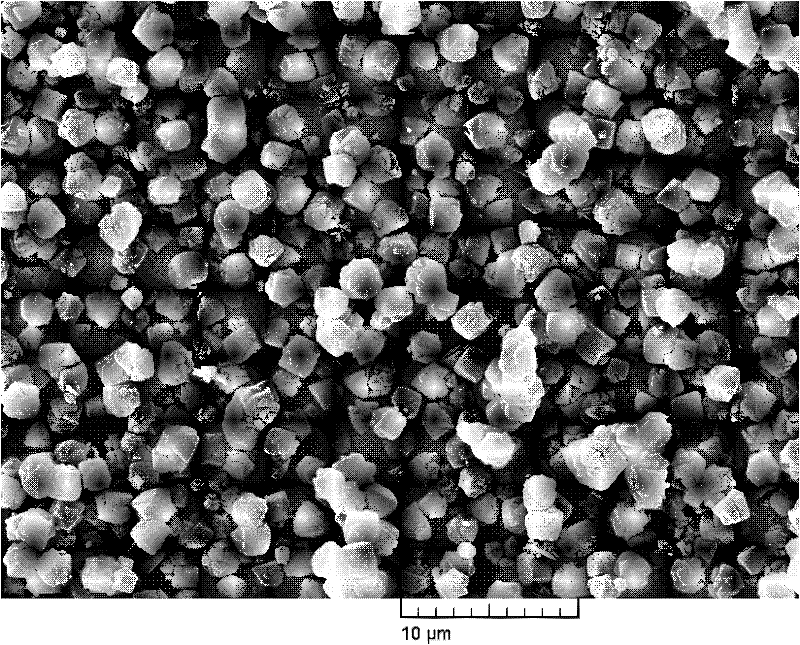

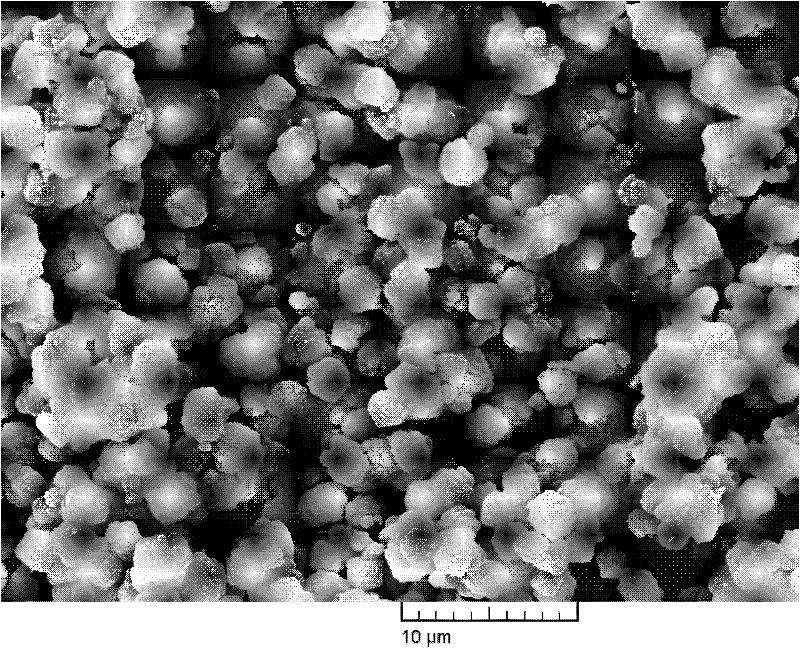

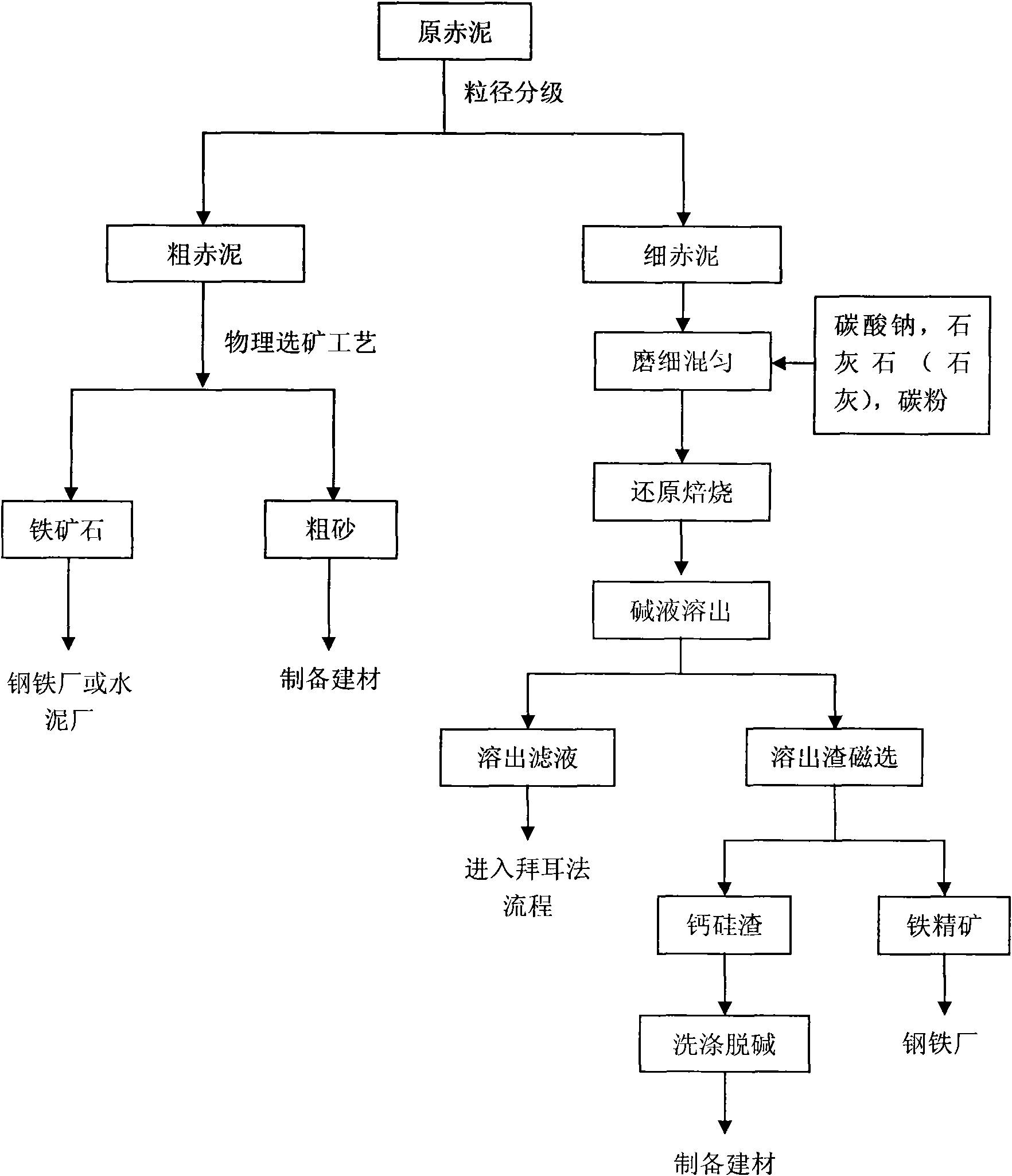

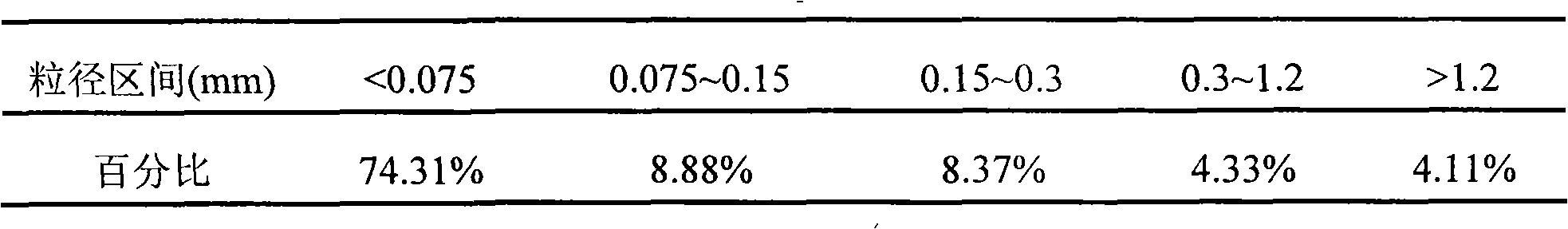

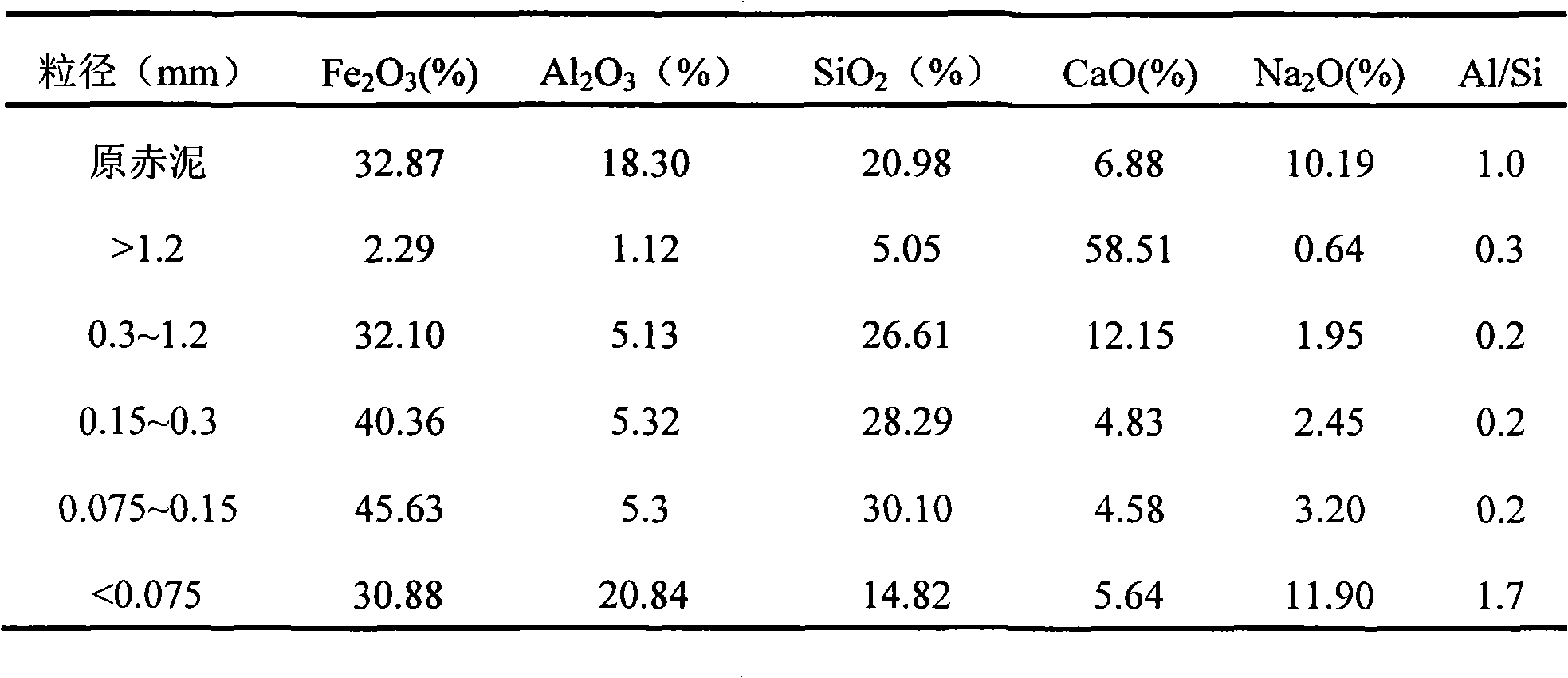

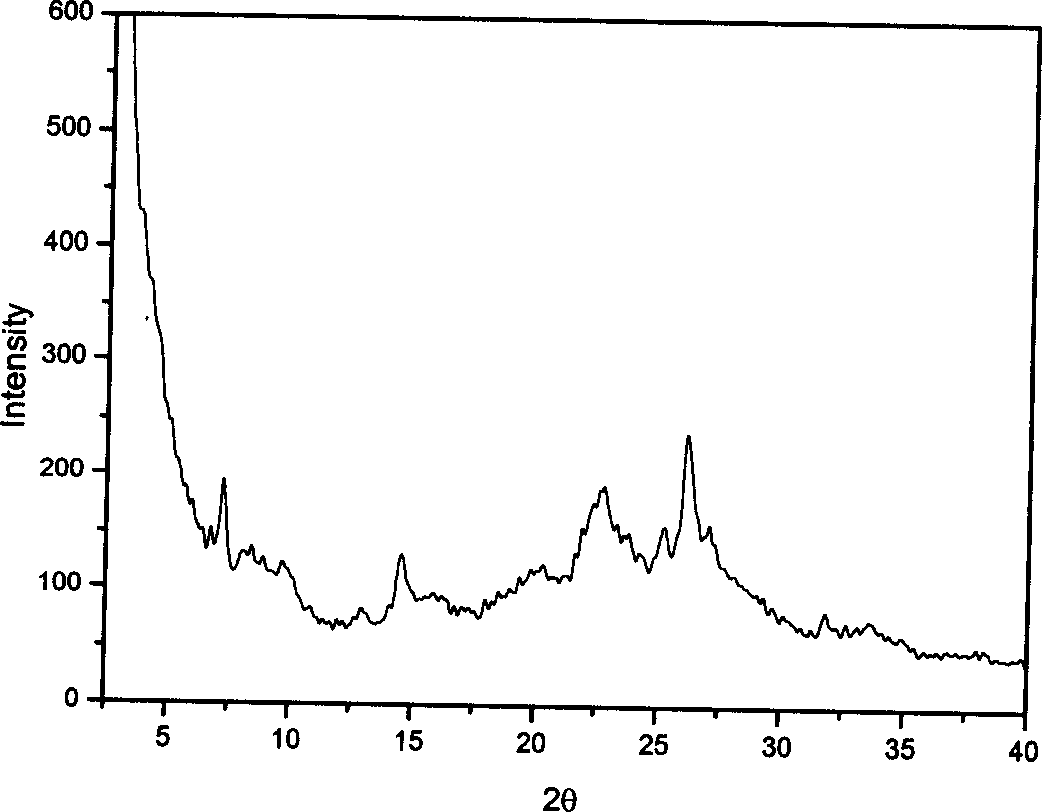

Method for recycling iron and aluminum by particle size grading pretreatment of Bayer process red mud

InactiveCN101624654AReduce difficultyReduce energy consumptionProcess efficiency improvementSlagRed mud

The invention relates to a method for recycling iron and aluminum by particle size grading pretreatment of Bayer process red mud, belonging to the technology for recycling red mud resources. The method comprises the following steps: firstly, Bayer process red mud is graded in terms of the particle size by using a physical method into coarse red mud and refined red mud; the coarse red mud is processed using physical mineral dressing processes, such as magnetic separation, gravity separation and the like, in order to obtain iron ore having high iron quality and coarse-grained sand, which are made use of respectively; the refined red mud is mixed with sodium carbonate, limestone and carbon power and is then subjected to reduction sintering, and two processes of magnetizing reduction roasting of iron and soda lime sintering of aluminum are implemented synchronously by means of the control of sintering conditions; sodium aluminate is dissolved out of clinker through dilute alkali solution, dissolved slag is subjected to magnetic separation to recover iron ore concentrate, and after being subjected to dealkalized cleaning, the residual calcium silicon slag is applied to building material industry. The method realizes combined recovery of iron, aluminum and other elements, magnificently achieves the comprehensive utilization of the Bayer process red mud, is capable of effectively relieving environment pollution resulting from the accumulation of the Bayer process red mud, and has excellent economic and social benefits.

Owner:HUAZHONG UNIV OF SCI & TECH

Porous material and its synthesis method

ActiveCN1751994AHas a compound pore structureMolecular sieve catalystsCrystalline aluminosilicate zeolitesSynthesis methodsAluminium hydroxide

A process material with compound artery is prepared from the Si source chosen from amorphous SiO2, si sol, silicon oxide solid, silicon gel, diatomite and water glass, the Al source chosen from sodium aluminate, sodium metaaluminate, aluminium sulfate, aluminium nitrate, etc, at least one of lithium hydroxide, sodium hydroxide, potassium hydroxide, rubidium hydroxide and cesium hydroxide, and template agent through proportional mixing, reaction, ageing and crystallizing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sprayed concrete with microorganism crack self-repairing capacity and preparation method of sprayed concrete

InactiveCN108017337AStrong adaptability to high alkaline environmentIncreased durabilityPorosityShotcrete

The invention discloses sprayed concrete with microorganism crack self-repairing capacity and a preparation method of the sprayed concrete. The sprayed concrete is prepared from components as follows:self-repairing particles carrying a microorganism repair agent and nutrients, cement, pebbles, sand, silica fume, water, polypropylene fibers, a sodium aluminate liquid accelerator and a polycarboxylate superplasticizer. The microorganism with mineralization and sedimentation characteristics is taken as the crack repair agent of the sprayed concrete, and expanded perlite or flyash pottery sand with high porosity is taken as a carrier of the repair agent; the carrier is coated with the nutrients and is isolated from a cement-based material by an isolating layer. The concrete cracks are repaired by calcium carbonate precipitate produced by the microorganism repair agent in a metabolism process, and the crack self-repairing capacity of the sprayed concrete in the service is improved, so thatimpervious performance and durability of the sprayed concrete are improved. The sprayed concrete with crack self-repairing capacity as a sprayed concrete material with crack self-diagnosis and self-repairing functions has great research value and application potential.

Owner:李珠

Method for preparing P type molecular sieve by using coal ash as raw material

InactiveCN104291349AInhibition of dissolutionCause dissolutionCrystalline aluminosilicate zeolitesMolecular sieveSodium aluminate

The invention relates to a method for preparing a P type molecular sieve by using coal ash as a raw material. The method for preparing the P type molecular sieve by using coal ash as the raw material comprises the following steps: I, pre-treating and activating coal ash; II, preparing sodium silicate and sodium metaaluminate by using activated coal ash; and III, synthesizing the P type molecular sieve: firstly, uniformly mixing a sodium silicate solution with a sodium salt, then, dropwise adding the sodium metaaluminate solution into the mixed liquid, and finally, adding an organic steric hindering agent and a proper amount of deionized water to form a reaction mixture, wherein the molar ratios of the reaction mixture are as follows: SiO2 / Al2O3=0.4-1.8, M / Al2O3=1-5, Na2O / Al2O3=2-4 and H2O / SiO2=20-150 and the organic spatial steric hindering agent is at least one of ethanol amine, diethanol amine and triethanol amine; packing the mixed materials in a polytetrafluoroethylene container, stirring, then putting in a stainless steel reaction kettle, and carrying out hydro-thermal synthesis for 2-8 hours; and taking out products in the reaction kettle, carrying out centrifugal separation and washing by deionized water, and drying to obtain the P type molecular sieve. The method provided by the invention is short in synthetic cost, short in crystallization time and high in yield of the P type molecular sieve.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for extracting alumina from coal ash through wet process

ActiveCN102476820AObvious superiorityReduce energy consumptionSolid waste disposalAluminium oxides/hydroxidesSlagDecomposition

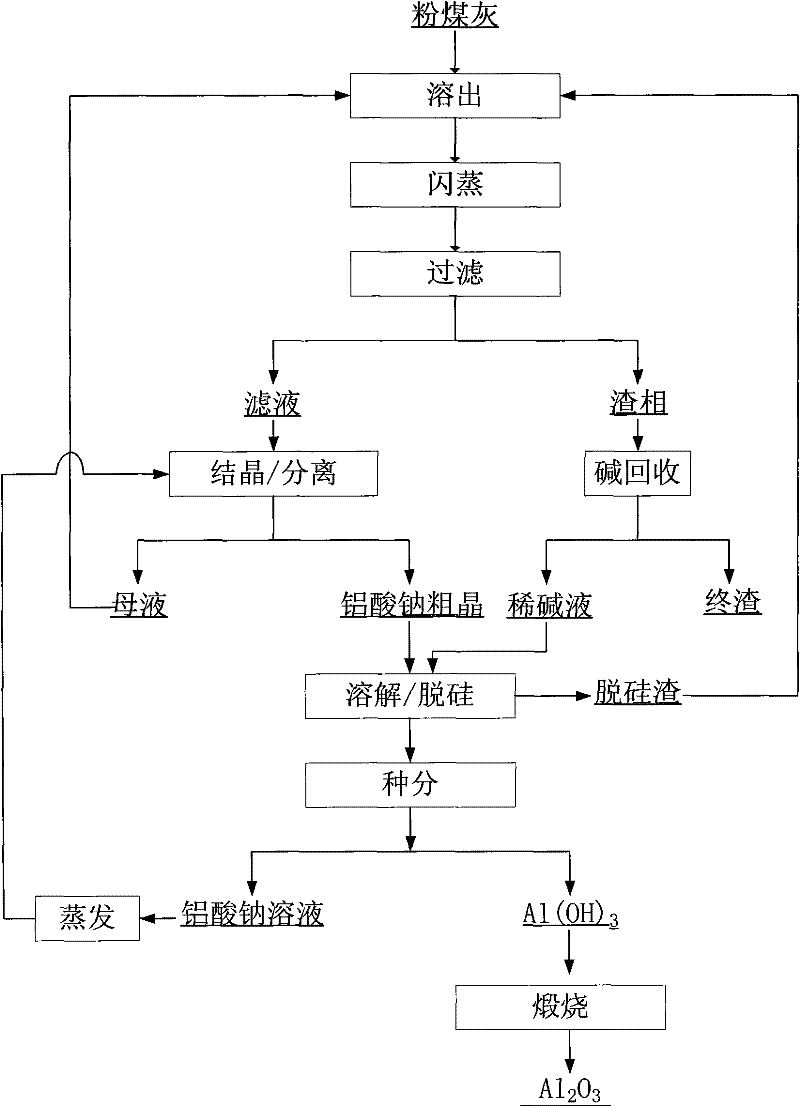

The invention provides a method for extracting alumina from coal ash through a wet process. The method comprises the following steps: 1, mixing the coal ash, calcium oxide and an alkaline solution, reacting, carrying out flash evaporation, and filtering to obtain an alkaline solution containing sodium aluminate and aluminum removed slag; 2, cooling and crystallizing the alkaline solution obtained in step 1 to obtain a coarse hydrated sodium aluminate crystal and a crystallization mother solution; 3, circulatingly applying the crystallization mother solution obtained in step 2 to a leaching reaction, dissolving the coarse hydrated sodium aluminate crystal with water or a diluted alkaline solution, carrying out silicon removal and seed decomposition to obtain aluminum hydroxide, and calcining aluminum hydroxide to obtain alumina; 4, evaporating the seed-decomposed mother solution, and mixing the evaporated seed-decomposed mother solution with the alkaline solution obtained in the step 1; and 5, carrying out hydrolysis sodium removal on the aluminum removed slag obtained in the step 1 in the diluted alkaline solution, filter-separating, and carrying out multistage countercurrent washing on the sodium removed slag. According to the method, the dissolving-out temperature and the dissolving-out pressure are low, the dissolving-out rate of alumina can reach above 90%, and the content of sodium oxide in the sodium removed slag is less than 1%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

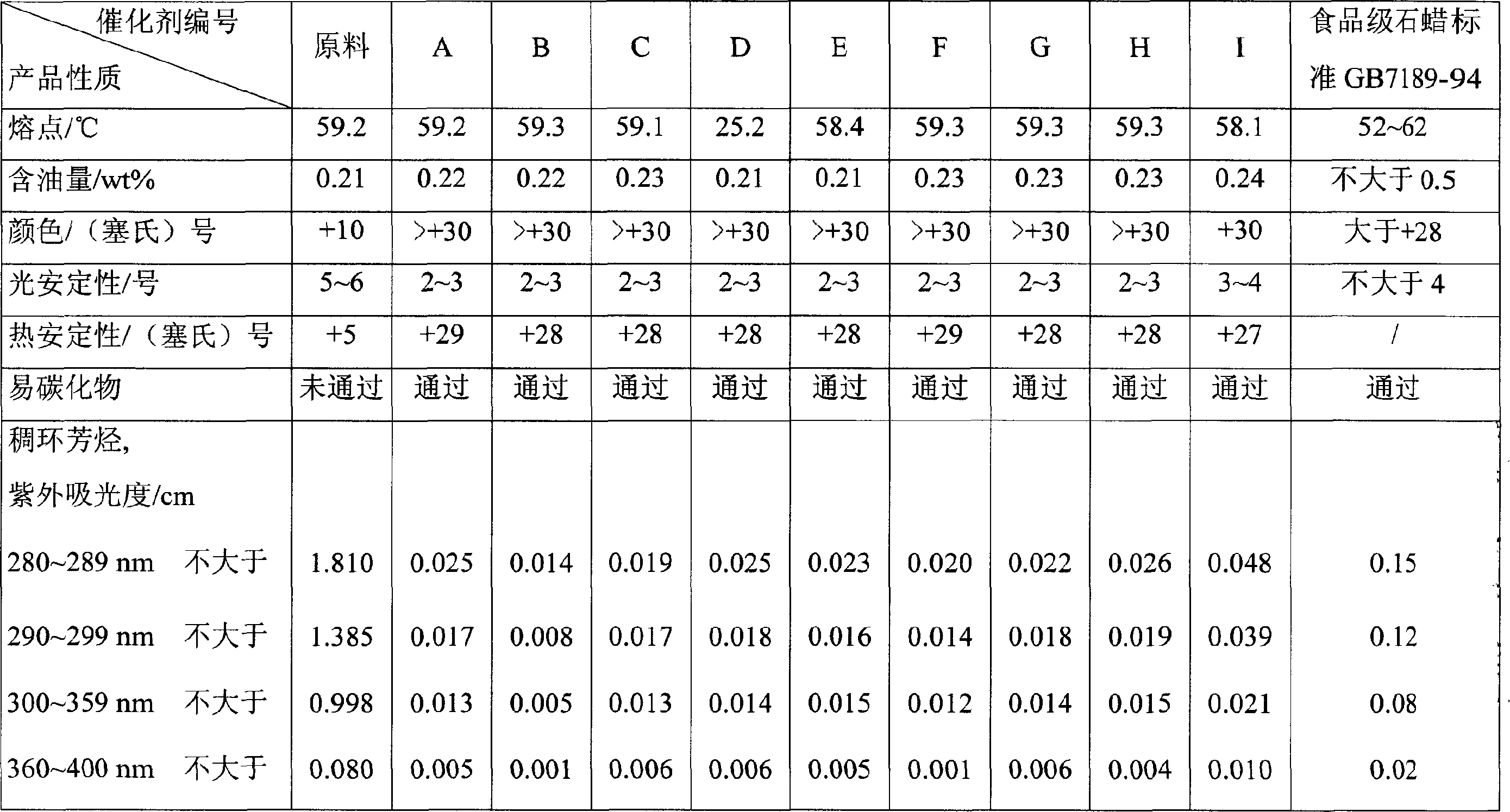

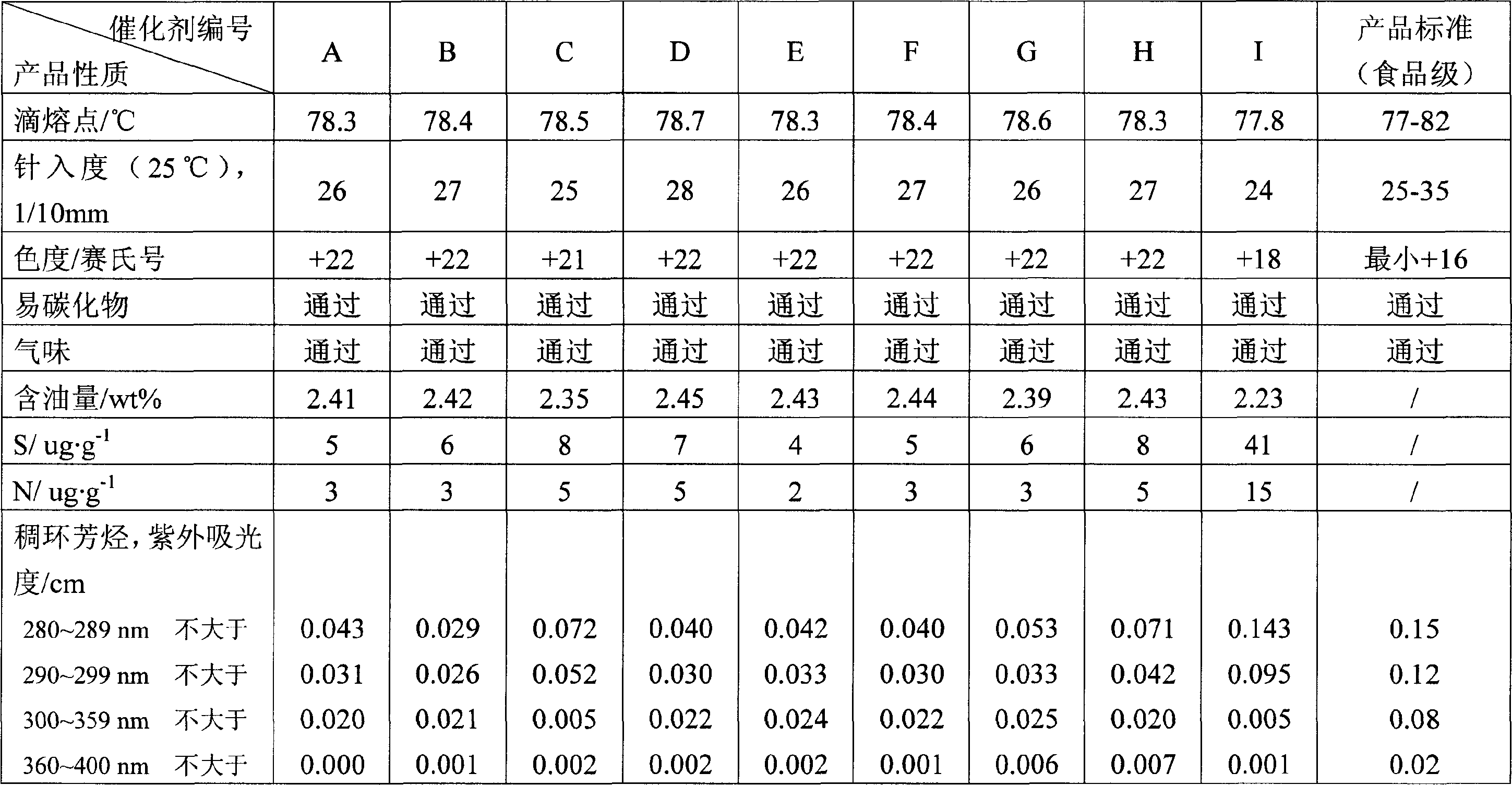

Hydrogenating catalyst for petroleum wax and its preparation process

ActiveCN1597868AGood physical and chemical propertiesLarge aperturePetroleum wax refiningAluminateWax

The invention discloses a petroleum wax hydrogenation catalyst and its preparing method, adopting the Si- and P- containing aluminum hydroxide prepared by CO2 netur neutralization process to act as a carrier material of catalyst, where the Si and P auxiliaries are added in steps, some Si- and P- containing compounds mix with sodium meta-aluminate solution to form a glue, some Si-containing compounds are added after the glue is formed or in the ageing process, and most P-containing compounds are added in the process of peptizing or pulping the produced aluminum hydroxide after washed, thus making most Si and P are distributed on the surface of aluminum hydroxide, effectively give full play to the Si and P cooperatively regulating surface physico-chemical property and hole structure of the catalyst. Its preparing process is simple and low-cost. It has good activity and selectivity as processing petroleum waxes including high-melting point petroleum wax.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com