Preparation method for Beta zeolite molecular sieve with hierarchical porous structure

A beta zeolite and multi-stage pore technology, which is applied in the field of preparation of Beta zeolite molecular sieves, can solve the problems that the acidity and hydrothermal stability of mesoporous materials cannot be fundamentally improved, so as to improve hydrothermal stability and strong acidity, simplify Synthesis steps, the effect of improving the order degree of the pore wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Mix 0.2428g sodium hydroxide, 0.0745g sodium metaaluminate (44.7wt% Na 2 O, 52wt% Al 2 o 3 ), 1.1842g of hexaammonium-based quaternary ammonium salt surfactant and 21mL of water were stirred to obtain a clear solution;

[0035] (2) Add dropwise a mixed solution of 3.6 mL tetraethyl orthosilicate (98%, J£K) and 3.8 mL ethanol to the clear solution obtained in step (1) under magnetic stirring at 50 °C to obtain a silica-alumina gel;

[0036] (3) Keep the silica-alumina gel obtained in step (2) at 50°C and continue to stir for 6 hours, then stand and age at 30°C for 16 hours;

[0037] (4) Put the product of step (3) into a sealed stainless steel reaction kettle, and crystallize at 145°C for 120 hours. After the crystallization, the solid is suction filtered, washed and dried, and then calcined in air at 550°C After 5 hours, the organic template was removed to obtain a Beta zeolite molecular sieve with a hierarchical pore structure.

Embodiment 2

[0039] (1) Mix 0.3623g sodium hydroxide, 0.1112g sodium metaaluminate (44.7wt% Na 2 O, 52wt% Al 2 o 3 ), 1.7675g of hexaammonium-based quaternary ammonium salt surfactant and 32mL of water were stirred to obtain a clear solution;

[0040] (2) Add dropwise a mixed solution of 5.4 mL of ethyl orthosilicate (98%, J£K) and 5.6 mL of ethanol to the clear solution obtained in step (1) under magnetic stirring at 60°C to obtain a silica-alumina gel;

[0041] (3) Keep the silica-alumina gel obtained in step (2) at 60°C and continue to stir for 10 hours, then stand and age at 35°C for 18 hours;

[0042] (4) Put the product of step (3) into a sealed stainless steel reaction kettle, and crystallize at 140°C for 110 hours. After the crystallization, the solid is suction filtered, washed and dried, and then calcined in air at 500°C After 8 hours, the organic template was removed to obtain a Beta zeolite molecular sieve with a hierarchical pore structure.

Embodiment 3

[0044] (1) Mix 0.4536g sodium hydroxide, 0.1395g sodium metaaluminate (44.7wt% Na 2 O, 52wt% Al 2 o 3 ), 2.2094g of hexaammonium-based quaternary ammonium salt surfactant and 39.4mL of water were stirred to obtain a clear solution;

[0045] (2) Under magnetic stirring at 55°C, add dropwise a mixed solution of 6.8 mL of ethyl orthosilicate (98%, J£K) and 7 mL of ethanol to the clear solution obtained in step (1) to obtain a silica-alumina gel;

[0046] (3) Keep the silica-alumina gel obtained in step (2) at 55°C and continue to stir for 12 hours, then stand and age at 40°C for 20 hours;

[0047] (4) Put the product of step (3) into a sealed stainless steel reaction kettle, and crystallize at 150°C for 130 hours. After the crystallization, the solid is suction filtered, washed and dried, and then calcined in air at 550°C After 6h, the organic template was removed to obtain a Beta zeolite molecular sieve with a hierarchical pore structure.

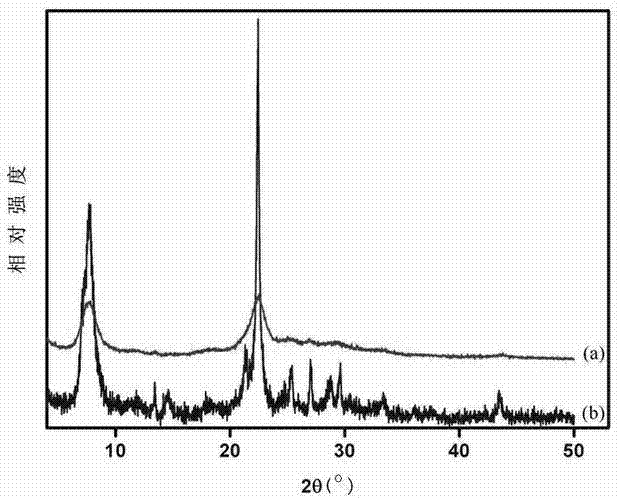

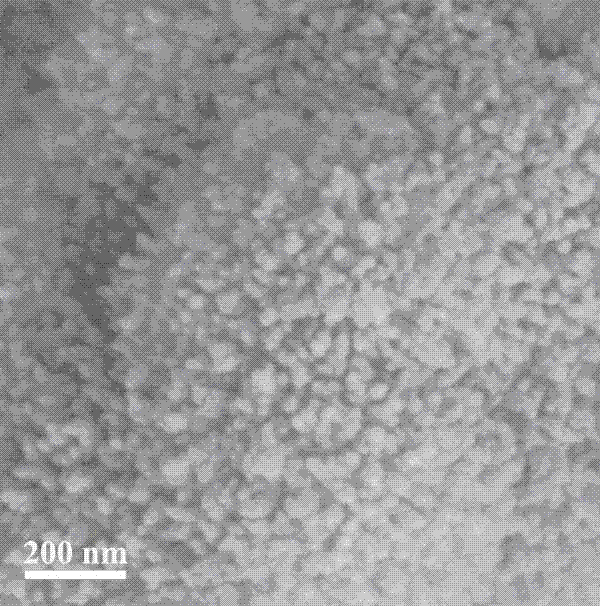

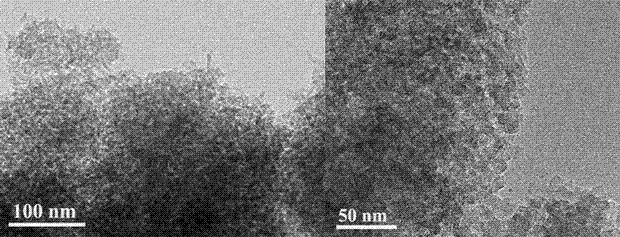

[0048] The Beta zeolite molecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com