Method for synthesizing SAPO-34 molecular sieve by using hectorite

A technology of SAPO-34 and laponite, which is applied in the production of molecular sieves and alkali-exchanged phosphates, molecular sieve-specific silicoaluminophosphates, and bulk chemicals, can solve problems such as crystal structure damage, achieve short synthesis cycles, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

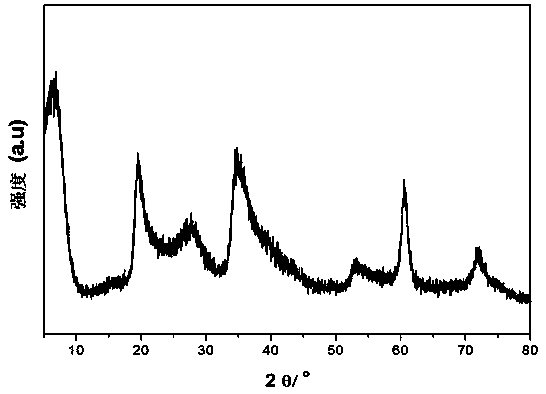

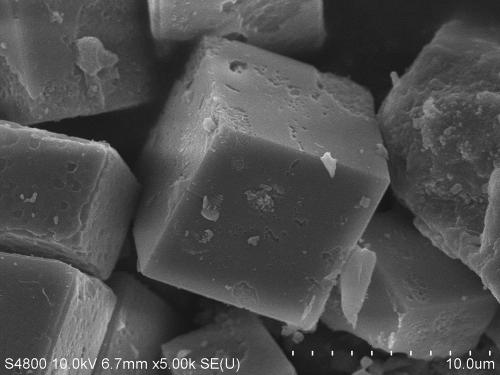

[0035] Add 5.2g of morpholine to 15.5g of water to disperse evenly, add 8.16g of aluminum isopropoxide, stir magnetically at room temperature for 2h, take 3.92g of phosphoric acid and continue stirring for 1h, and finally add 14.5g of hectorite with a mass fraction of 8% to disperse The solution was stirred for 3 hours to obtain a mixed material, and then the mixed material was transferred to a stainless steel reactor with a polytetrafluoroethylene liner, crystallized at 180°C for 9 hours under hydrothermal conditions, cooled to room temperature, and centrifugally washed until neutral. After drying in an oven for 12 hours, the product was calcined in a muffle furnace at 550ºC for 6 hours, and the product obtained was SAPO-34 molecular sieve. Such as Figure 6 As shown, after XRD characterization, the sample is SAPO-34 zeolite molecular sieve. Such as image 3 As shown, it can be seen that the overall shape of the sample is a cube, and the particle size is 10 μm.

Embodiment 2

[0037] Add 5.2g of morpholine to 15.5g of water and disperse evenly, add 8.16g of aluminum isopropoxide and stir magnetically at room temperature for 2 hours, take 3.92g of phosphoric acid and continue stirring for 1 hour, and finally add 14.5g of hectorite dispersion with a mass fraction of 8%. Stir for 3 hours to obtain the mixed material, then transfer the mixed material to a stainless steel reactor with a polytetrafluoroethylene liner, crystallize at 180ºC for 18 hours under hydrothermal conditions, cool to room temperature, and centrifugally wash until neutral. The product was dried for 12 hours in a muffle furnace at 550ºC for 6 hours to obtain a SAPO-34 molecular sieve.

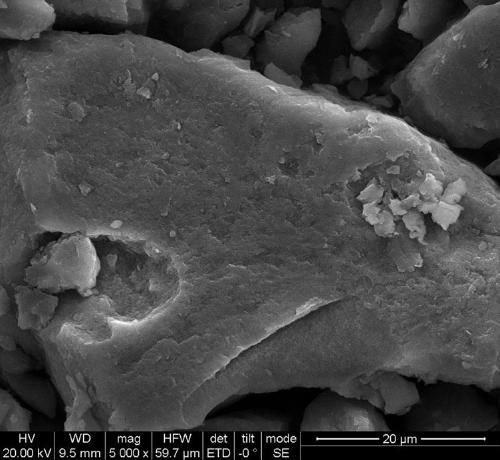

[0038] Such as Figure 4As shown, the molecular sieve prepared in this example is analyzed as a molecular sieve by XRD (X-ray diffraction), has a typical CHA topology, and the purity and quality of the sample are high. Such as Figure 5 The SEM (scanning electron microscope) picture shown shows that ...

Embodiment 3

[0040] Add 5.2g of morpholine to 15.5g of water and disperse evenly, add 8.16g of aluminum isopropoxide and stir magnetically at room temperature for 2 hours, take 3.92g of phosphoric acid and continue stirring for 1 hour, and finally add 14.5g of hectorite dispersion with a mass fraction of 8%. Stir for 3 hours to obtain the mixed material, then transfer the mixed material to a stainless steel reactor with a polytetrafluoroethylene liner, age for 24 hours, crystallize at 180ºC for 36 hours under hydrothermal conditions, cool to room temperature, and centrifugally wash until neutral, the obtained solid Dry in an oven at 100ºC for 12h, and calcinate the product in a muffle furnace at 550ºC for 6h to obtain SAPO-34 molecular sieve. Such as Figure 6 As shown, the molecular sieve prepared in this embodiment is analyzed as SAPO-34 molecular sieve by XRD (X-ray diffraction), which has a typical CHA topological structure, and the purity and quality of the sample are relatively high....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com