Preparation method and application of carbon material modified graphite phase carbon nitride nanosheet supported platinum nanoelectrocatalyst

A graphite-phase carbon nitride and electrocatalyst technology, applied in circuits, electrical components, battery electrodes, etc., can solve performance limitations and other problems, achieve the effects of improving stability, increasing electrochemical specific surface area, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

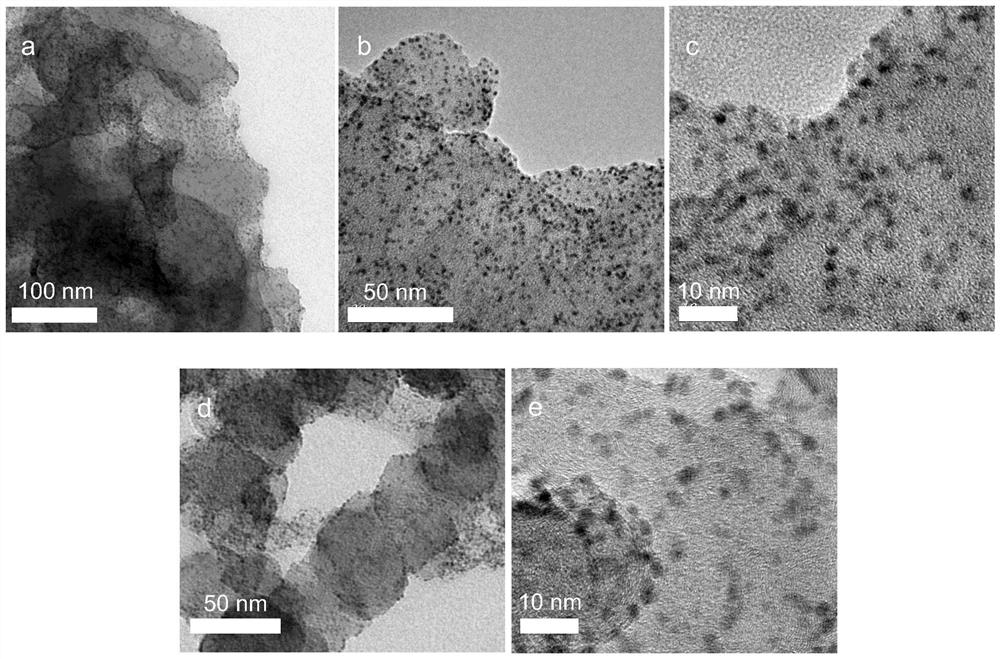

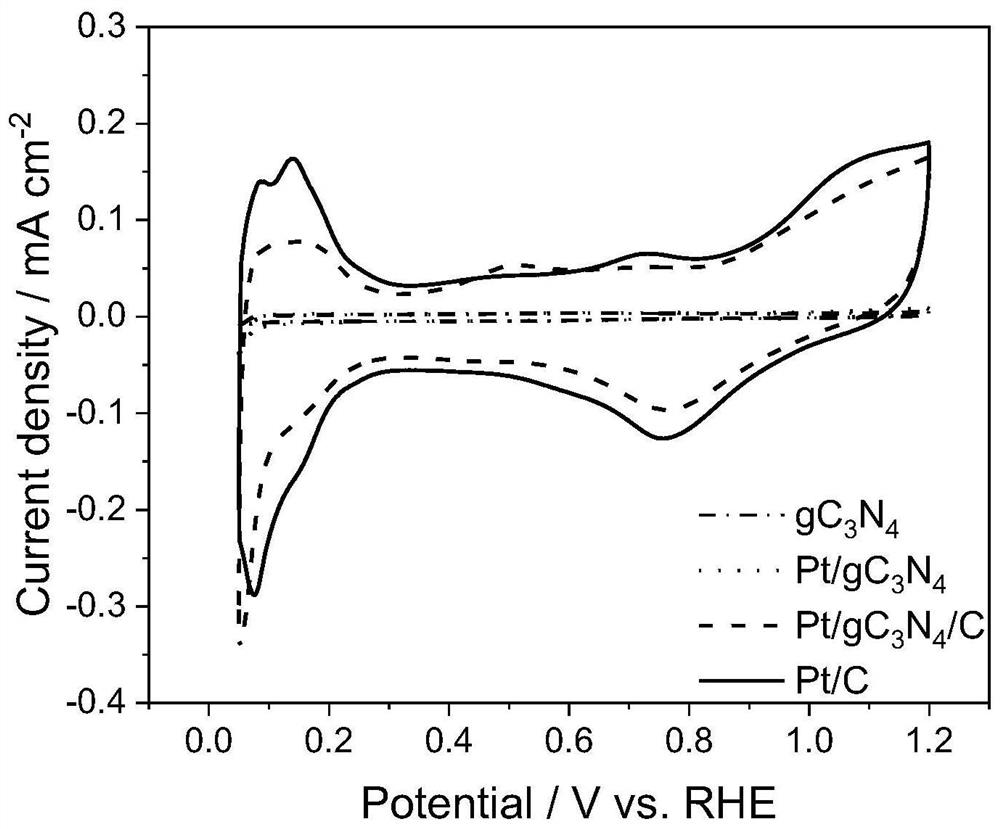

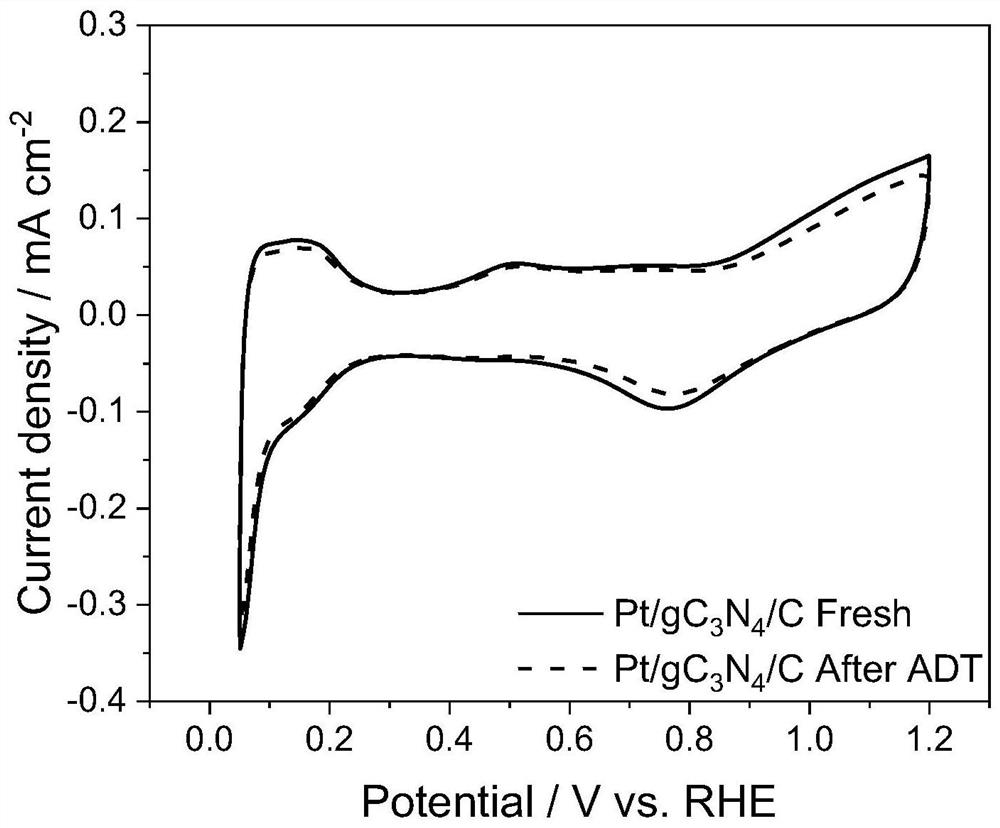

Image

Examples

Embodiment 1

[0041] Step 1, preparing a graphite phase carbon nitride nanosheet precursor;

[0042] Weigh 1g of melamine and 1.2g of phosphorous acid and dissolve them in 100mL of deionized water, then stir in a water bath at 80°C for 1h, then place them in a sealed autoclave, react at 180°C for 10h, and then naturally cool to room temperature ; The obtained product was suction filtered, washed several times with deionized water, and dried at 60 °C for 8 h to obtain the precursor;

[0043] Step 2, preparing graphitic carbon nitride nanosheets;

[0044] Mix 5 ml of glycerol and 15 ml of ethanol to obtain a mixed solution, then add 0.6 g of the precursor obtained in step 1, and stir vigorously until the mixture is uniform; then reflux for 3 hours in an oil bath at 90 °C, and cool to room temperature naturally; then perform suction filtration, Wash with absolute ethanol for several times and dry at 60°C for 8h; put the dried intermediate product into a covered porcelain crucible, heat up to ...

Embodiment 2

[0054] Step 1, preparing a graphite phase carbon nitride nanosheet precursor;

[0055] Weigh 1g of melamine and 1.2g of phosphorous acid and dissolve them in 100mL of deionized water, then stir in a water bath at 80°C for 1h, then place them in a sealed autoclave, react at 180°C for 10h, and then naturally cool to room temperature ; The obtained product was suction filtered, washed several times with deionized water, and dried at 60 °C for 8 h to obtain the precursor;

[0056] Step 2, preparing graphitic carbon nitride nanosheets;

[0057] Mix 5 ml of glycerol and 15 ml of ethanol to obtain a mixed solution, then add 0.6 g of the precursor obtained in step 1, and stir vigorously until the mixture is uniform; then reflux for 3 hours in an oil bath at 90 °C, and cool to room temperature naturally; then perform suction filtration, Wash with absolute ethanol for several times and dry at 60°C for 8h; put the dried intermediate product into a covered porcelain crucible, heat up to ...

Embodiment 3

[0068] Step 1, preparing a graphite phase carbon nitride nanosheet precursor;

[0069] Weigh 1g of melamine and 1.2g of phosphorous acid and dissolve them in 100mL of deionized water, then stir in a water bath at 80°C for 1h, then place them in a sealed autoclave, react at 180°C for 10h, and then naturally cool to room temperature ; The obtained product was suction filtered, washed several times with deionized water, and dried at 60 °C for 8 h to obtain the precursor;

[0070] Step 2, preparing graphitic carbon nitride nanosheets;

[0071]Mix 5 ml of glycerol and 15 ml of ethanol to obtain a mixed solution, then add 0.6 g of the precursor obtained in step 1, and stir vigorously until the mixture is uniform; then reflux for 3 hours under the condition of an oil bath at 90 °C, and naturally cool to room temperature; then perform suction filtration, Wash with absolute ethanol for several times and dry at 60°C for 8h; put the dried intermediate product into a covered porcelain cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com