Patents

Literature

439 results about "Alumina gel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

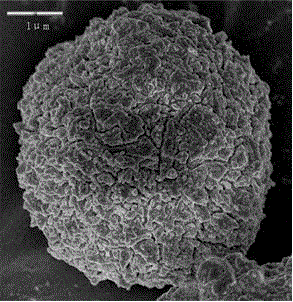

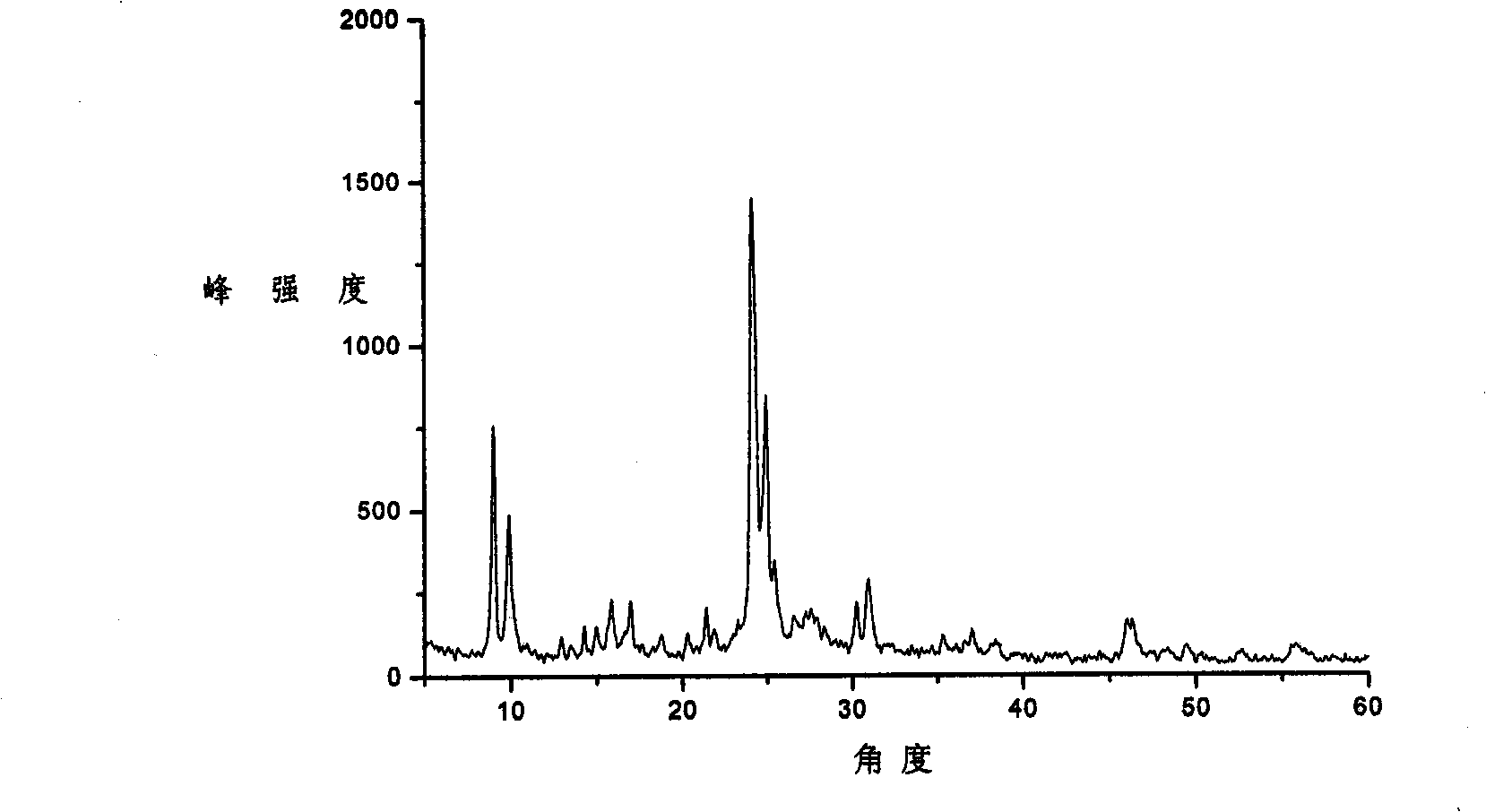

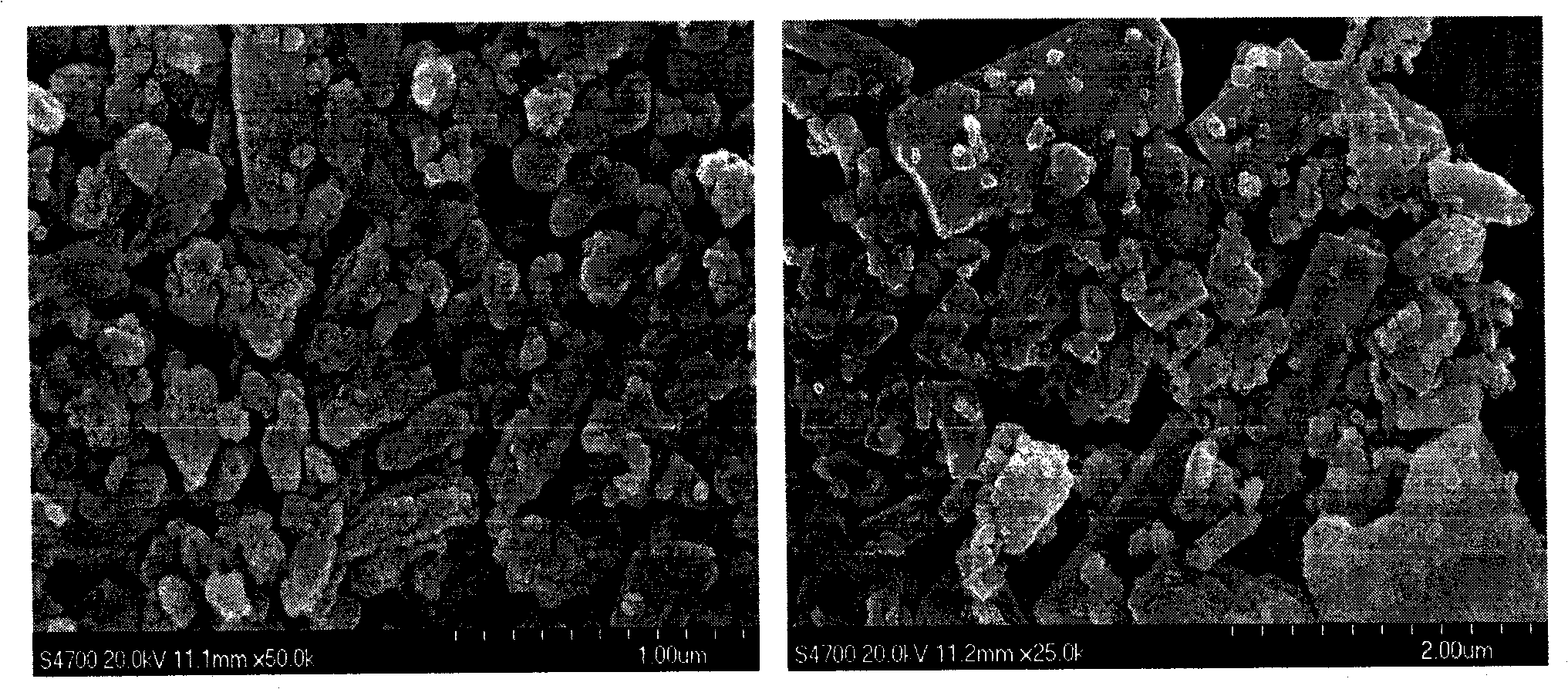

Three-dimensional ordered macroporous alumina and preparation method thereof

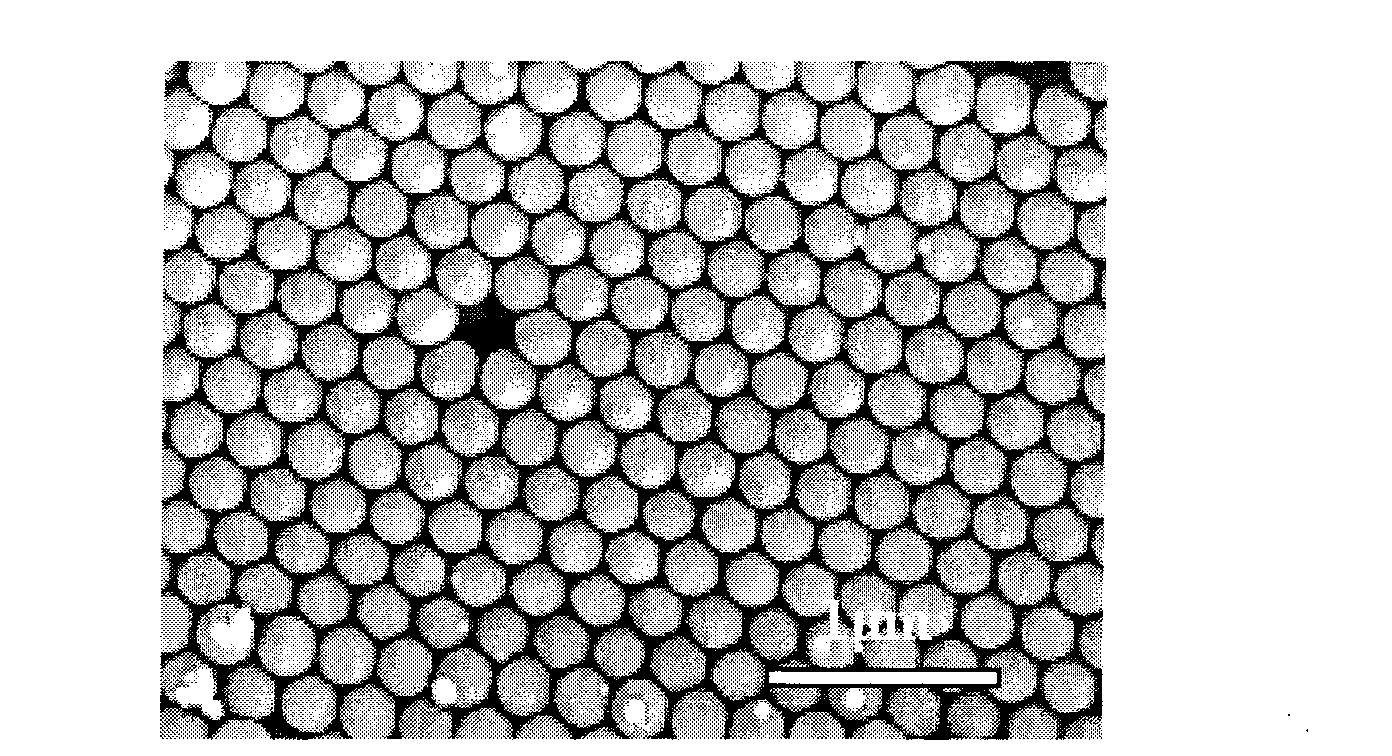

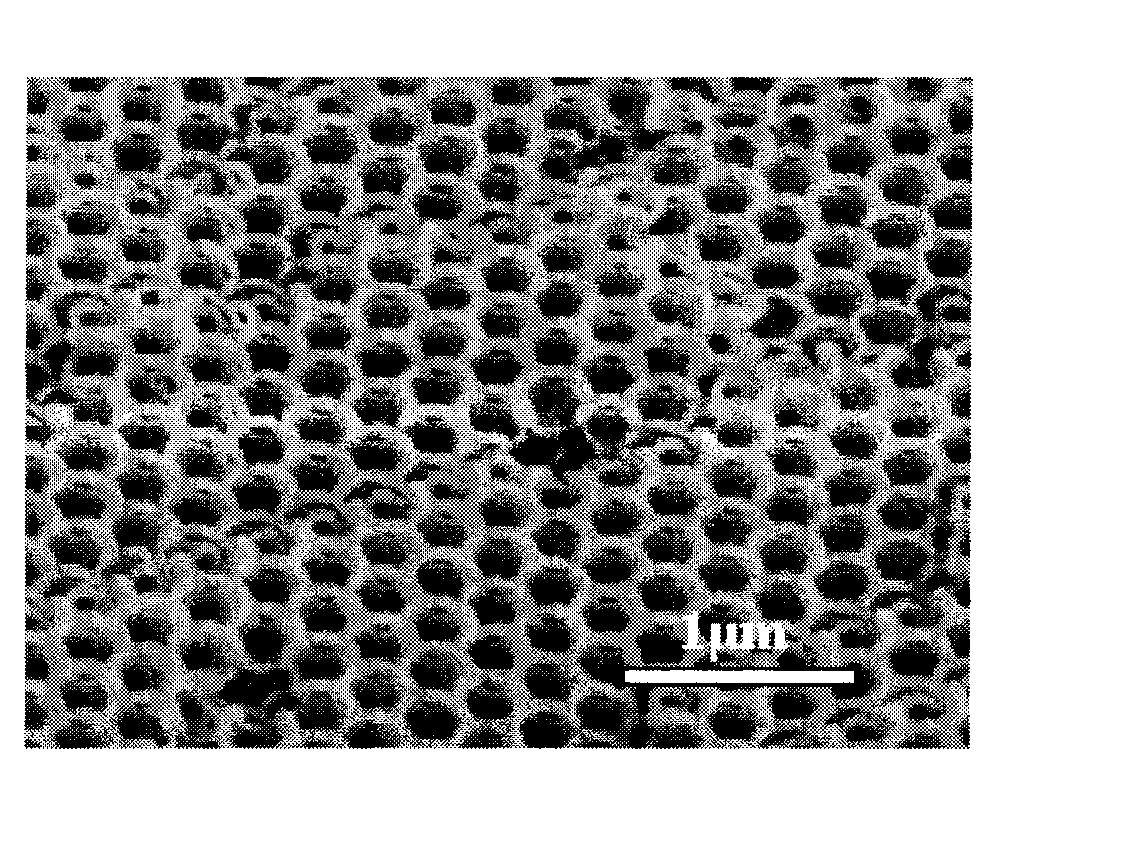

ActiveCN102040235AHigh activityGood choiceOther chemical processesAluminium oxides/hydroxidesMicrosphereNetwork structure

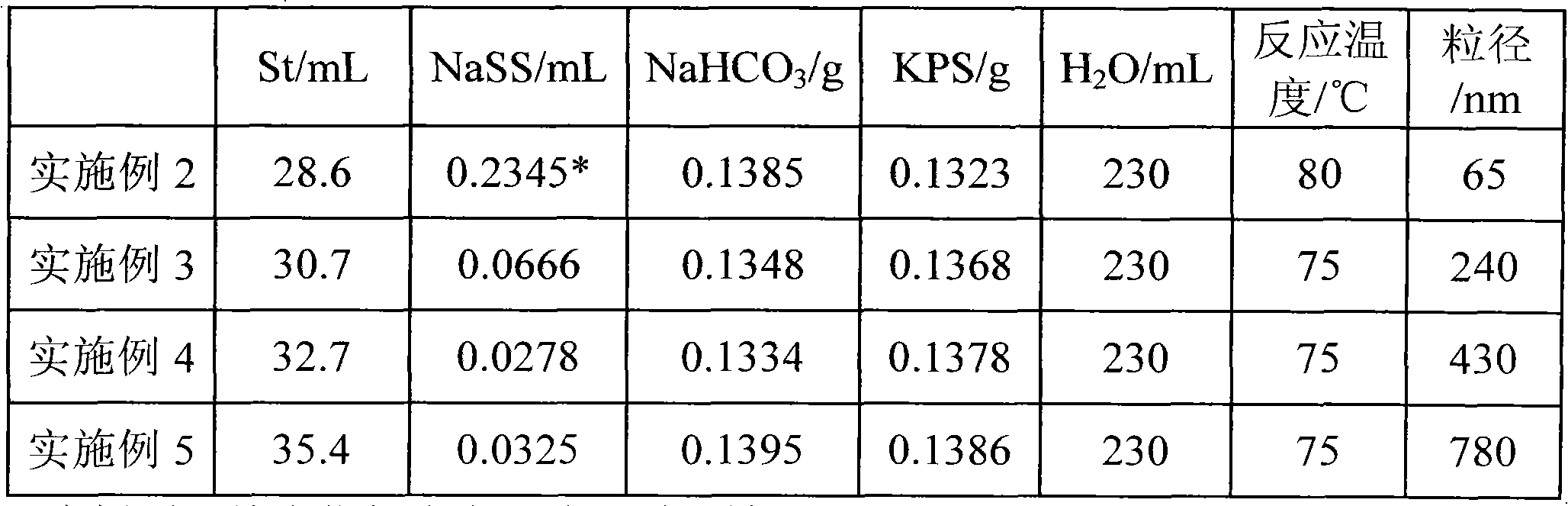

The invention provides a three-dimensional ordered macroporous alumina and a preparation method thereof, wherein the method comprises the following steps of: assembling polymer microspheres which are singly dispersed to form a colloidal crystal template, filling the alumina sol which is prepared by means of a special method into the template, and drying and roasting to obtain macroporous alumina. The method provided by the invention has the advantages that the alumina sol and the compounding process of the alumina sol and the polymer microspheres can be controlled well, the network structure of the alumina sol is protected possibly, the alumina which is prepared by means of the method not only has three-dimensional ordered macroporous channels but also has a high specific surface area. Furthermore, the macropores within the material are communicated to the surrounding macropores by means of 12 small window holes, and the window holes are formed by sintering the template properly. The alumina prepared by means of the method provided by the invention is suitable for being used as a catalyst carrier of heavy oil and an adsorption and separation material of organic macromolecule. The alumina prepared by means of the method which is provided by the invention is suitable for improving the mass transfer capability of the material within the catalyst and is suitable for improving the activity and the selectivity of the catalyst during the application process as a catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

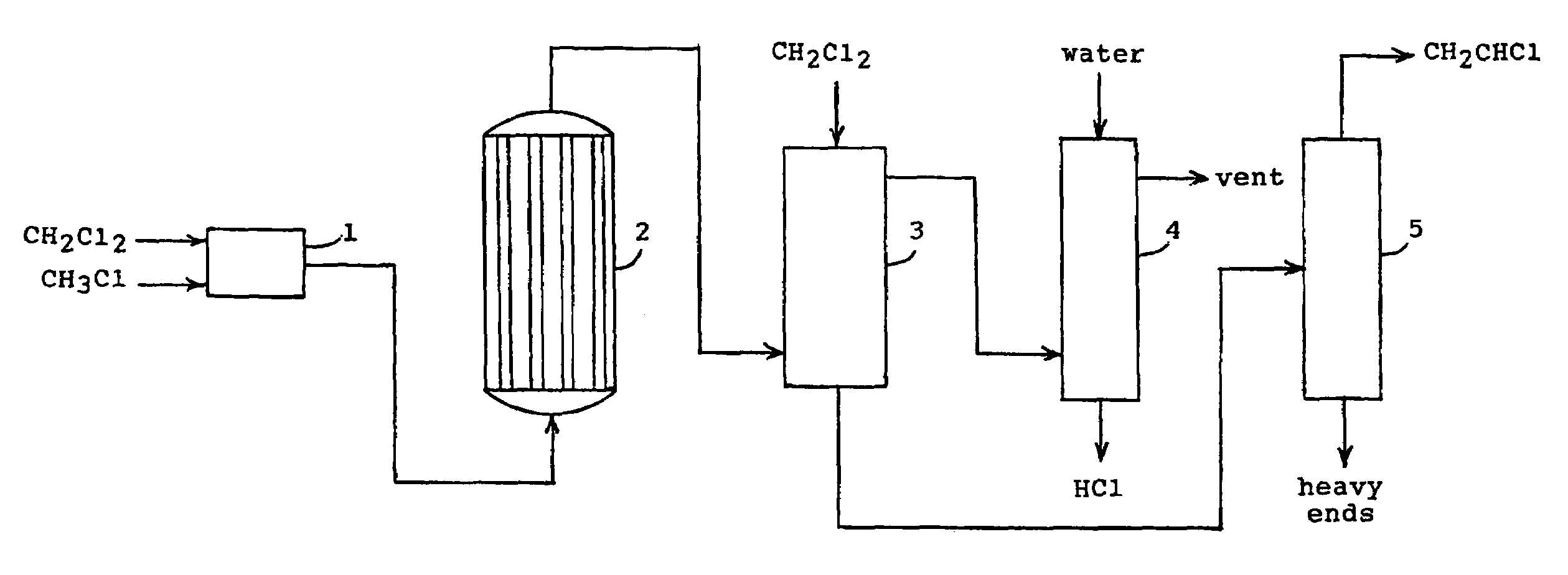

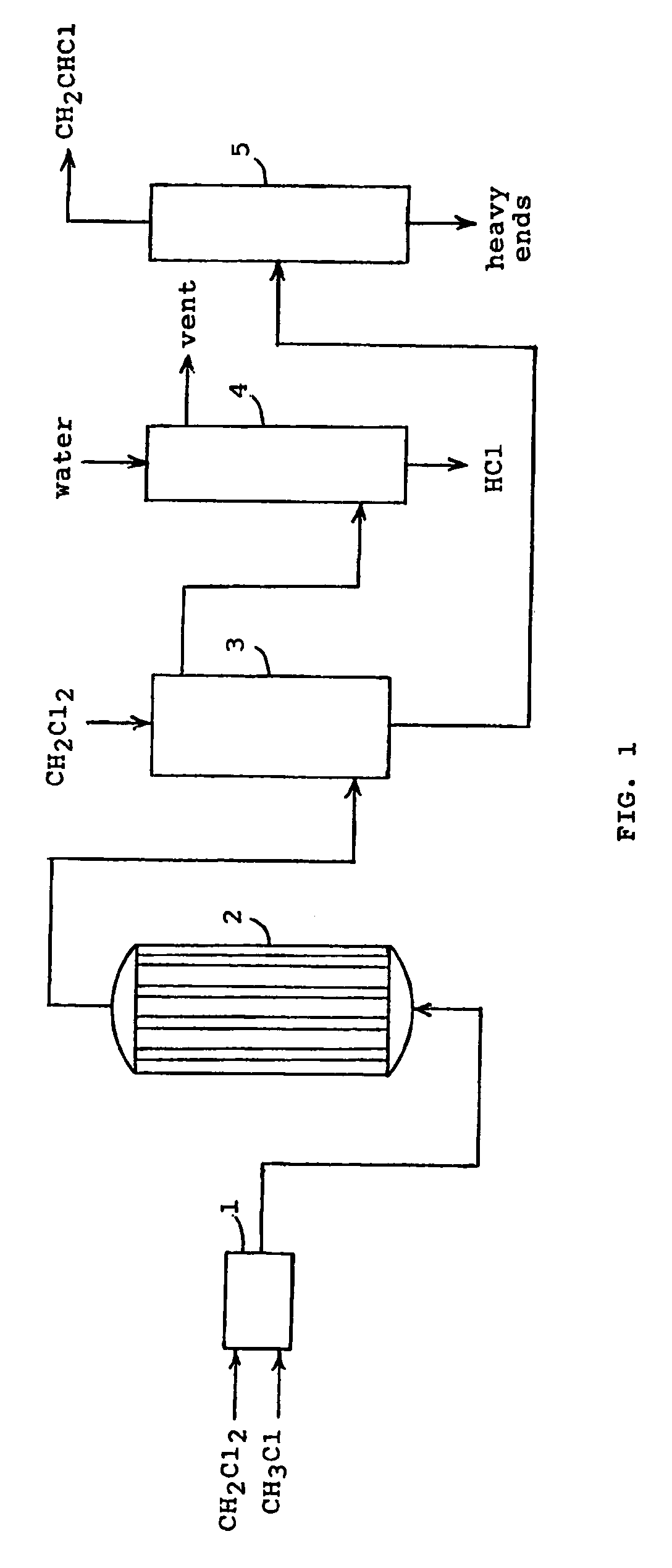

Method for producing vinyl chloride monomer

Owner:STAUFFER VALERIE +1

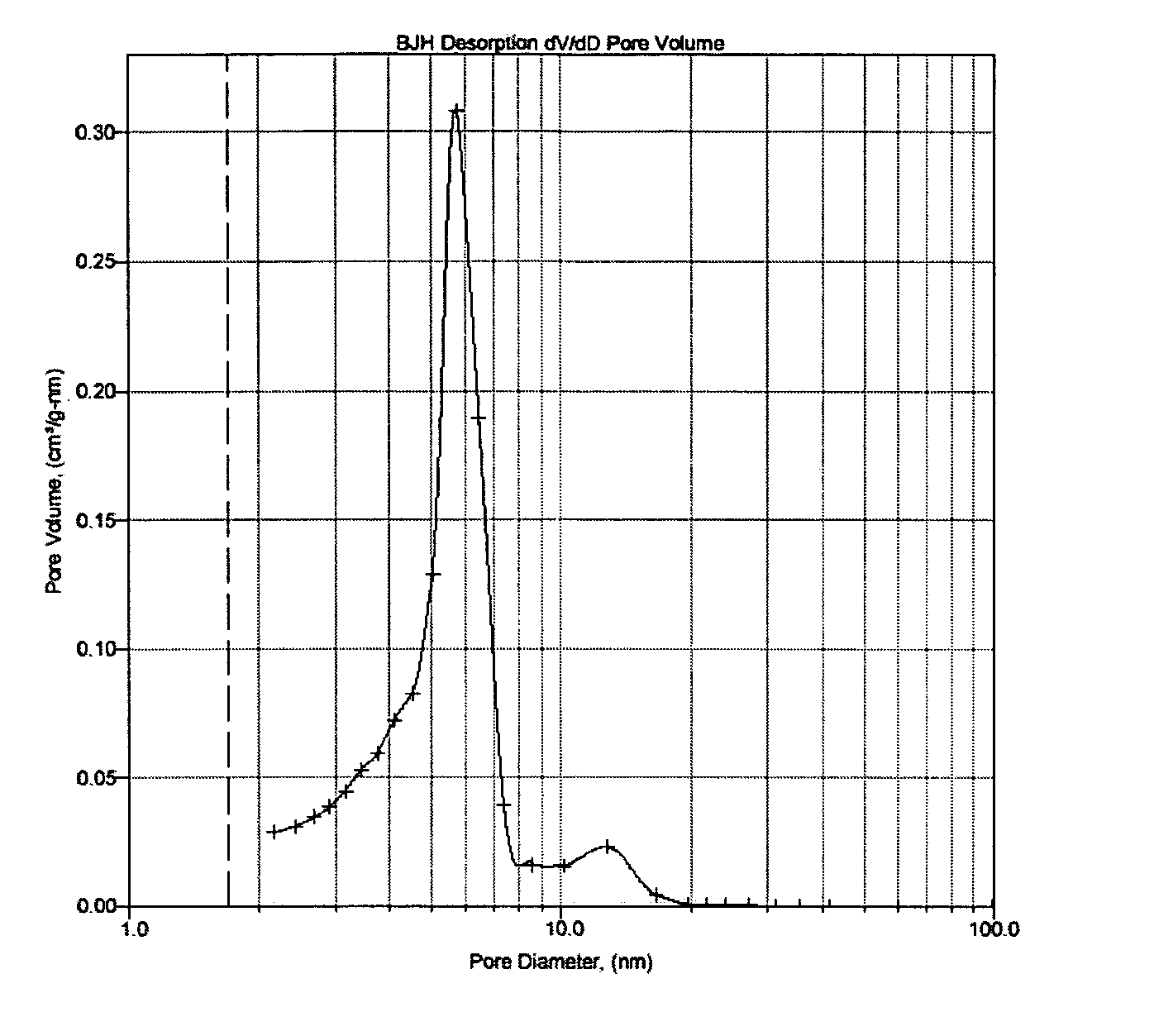

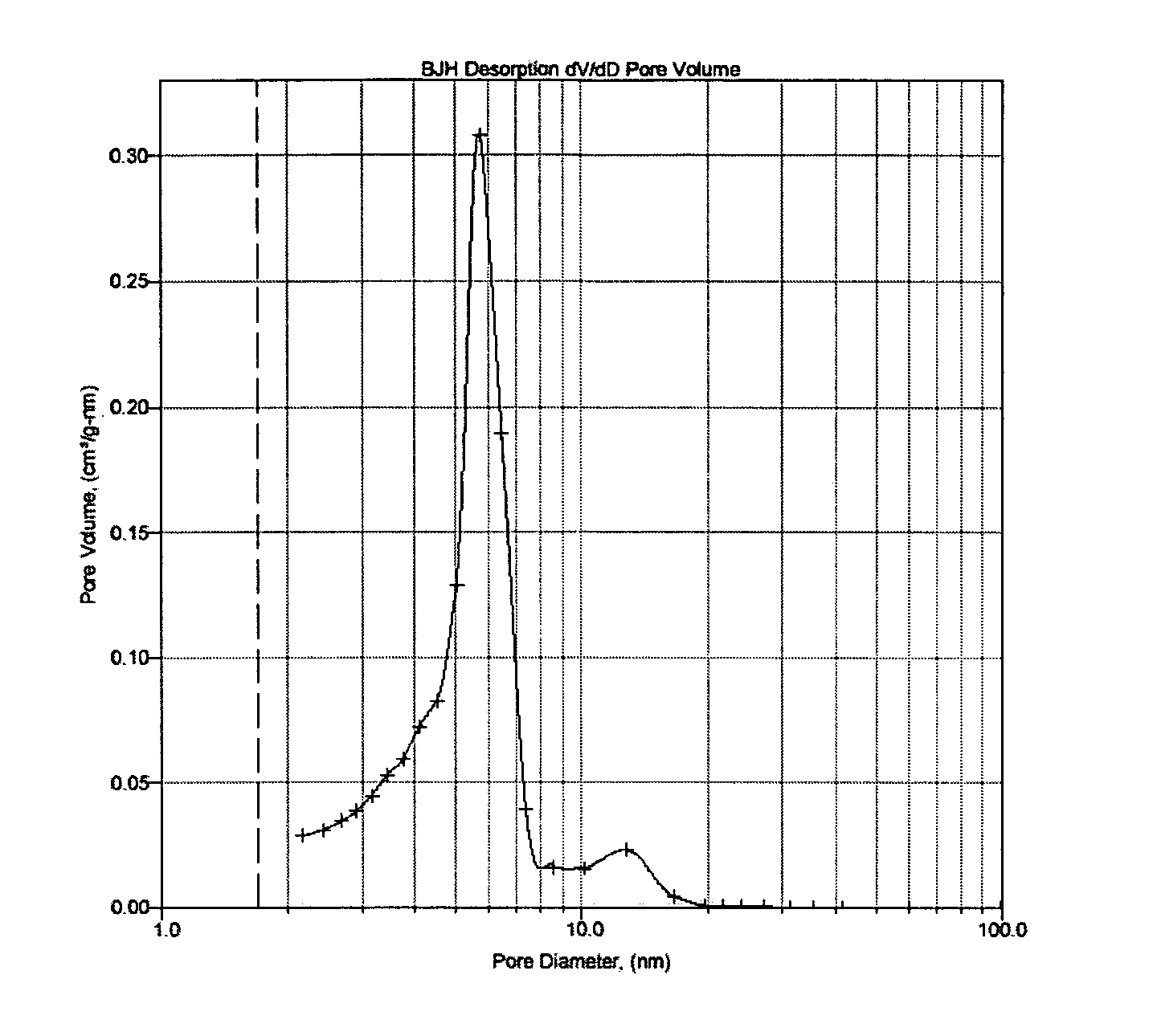

Silica-alumina catalyst support with bimodal pore distribution, catalysts, methods of making and using same

ActiveUS20050107479A1Dispersion of catalytic metal and product diffusion can be optimizedMolecular sieve catalystsOrganic compound preparationPore distributionSilicon dioxide

An effective catalyst includes an amorphous silica-alumina support having a bimodal pore size-distribution. The support may be prepared by a method that includes the physical mixing of two silica-alumina gels prepared so as to have two different average pore sizes. The catalyst has the advantage that both metal dispersion on the support and product diffusion in the pores are optimized. Further, the catalyst has improved performance in the production of hydrocarbons from synthesis gas.

Owner:CLARIANT INT LTD

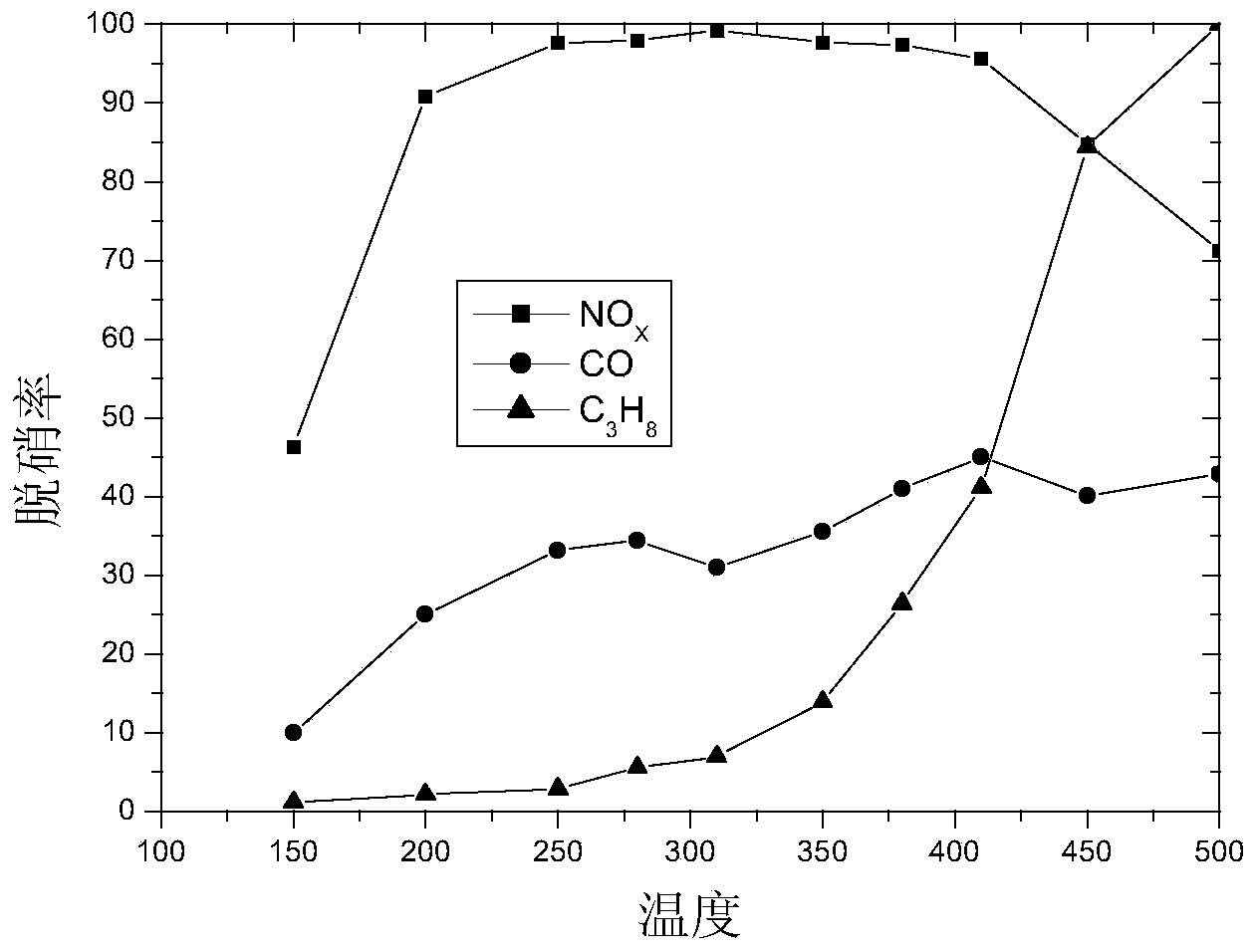

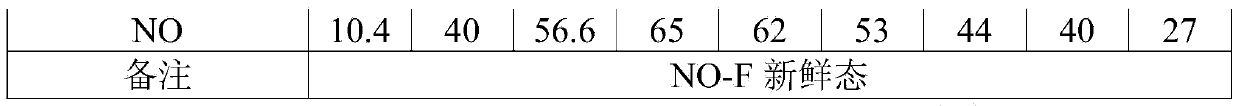

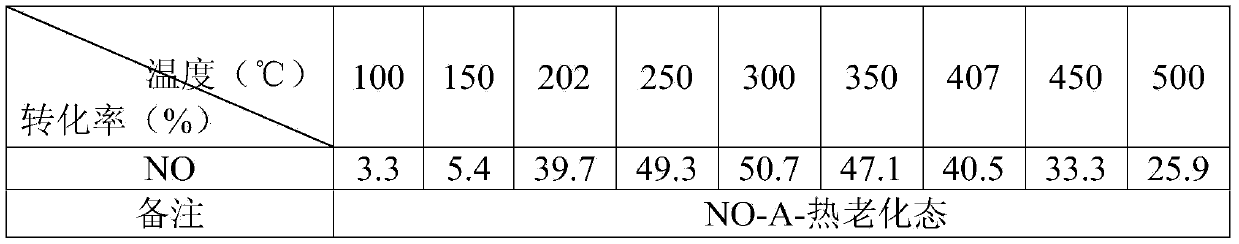

Three-way NOx, CO and HC removing catalyst used in marine engine, and preparation method thereof

ActiveCN103433028AImprove denitrification activityComponents are non-toxicDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCobalt

The invention relates to a three-way NOx, CO and HC removing catalyst used in a marine engine, and a preparation method thereof. The catalyst takes cerium-tin-tungsten composite oxide as an active component, takes one or more oxides of cobalt, ferrum, nickel, copper, lanthanum, molybdenum, manganese, zirconium, silver and yttrium as a promoter, and takes AlSiTi composite oxide as a carrier. A saturated active component solution, a saturated cobalt promoter ionic solution, strong acid alumina gel, diaspore, clayey, titanium dioxide and an organic forming agent are stirred uniformly, mixed, aged and extruded for formation, and the integral type catalyst is obtained through drying and roasting. According to the invention, the catalyst has high NOx removing efficiency, the active temperature window is wide, and the CO and HC removing efficiency is high in a low-temperature collaborated catalyzing manner. According to the catalyst, as the components of the catalyst are nontoxic and environmental-friendly, the catalyst has the advantages that the mechanical strength is high, the vibration resistance as well as the heat resistance is excellent, the preparation technology is simple, and the cost is low. The three-way NOx, CO and HC removing catalyst is applicable to treatment of NOx, CO and HC in tail gas of a marine diesel engine, and is also applicable to treatment to tail gas of other moving sources diesel engines such as automobiles.

Owner:南京环福新材料科技有限公司

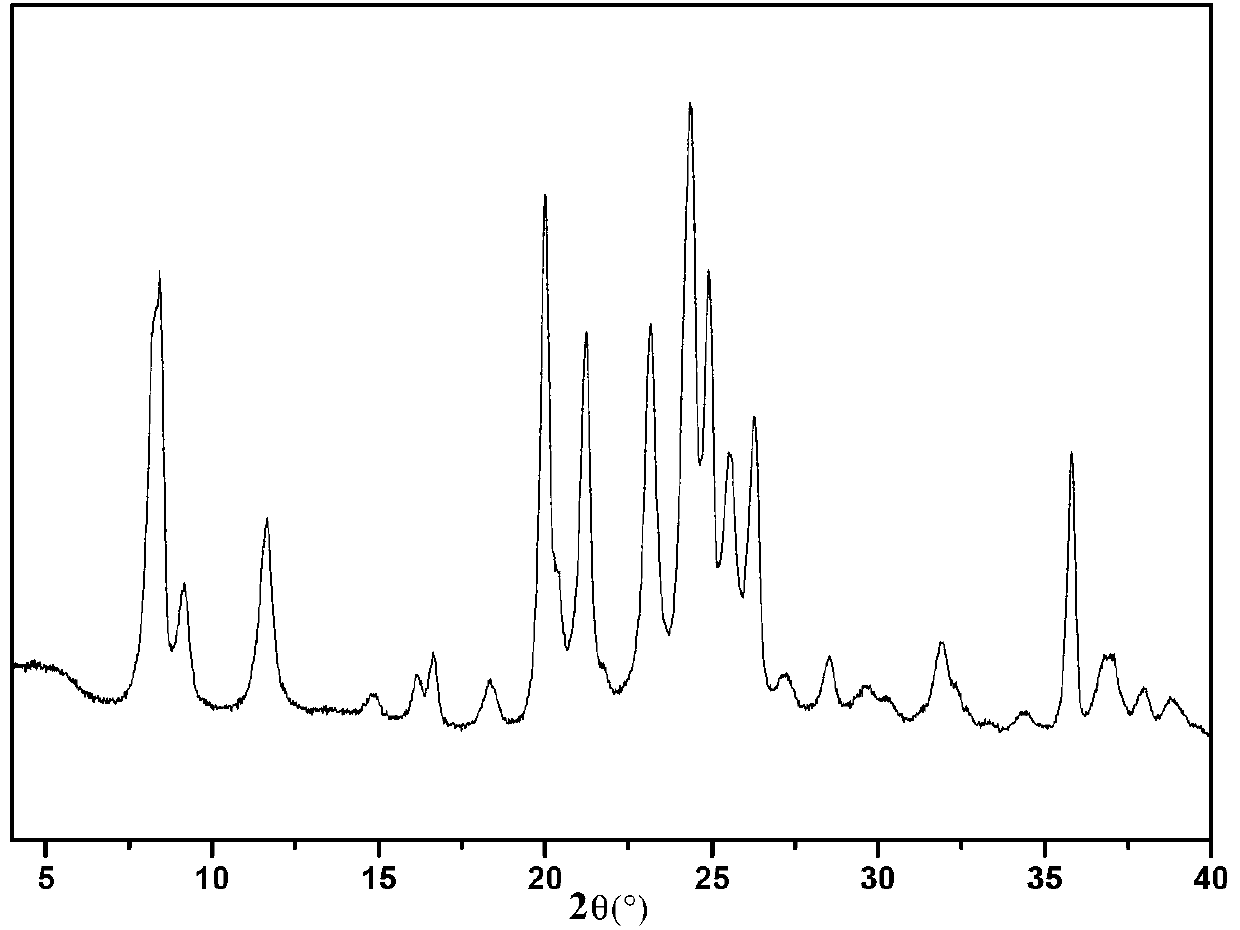

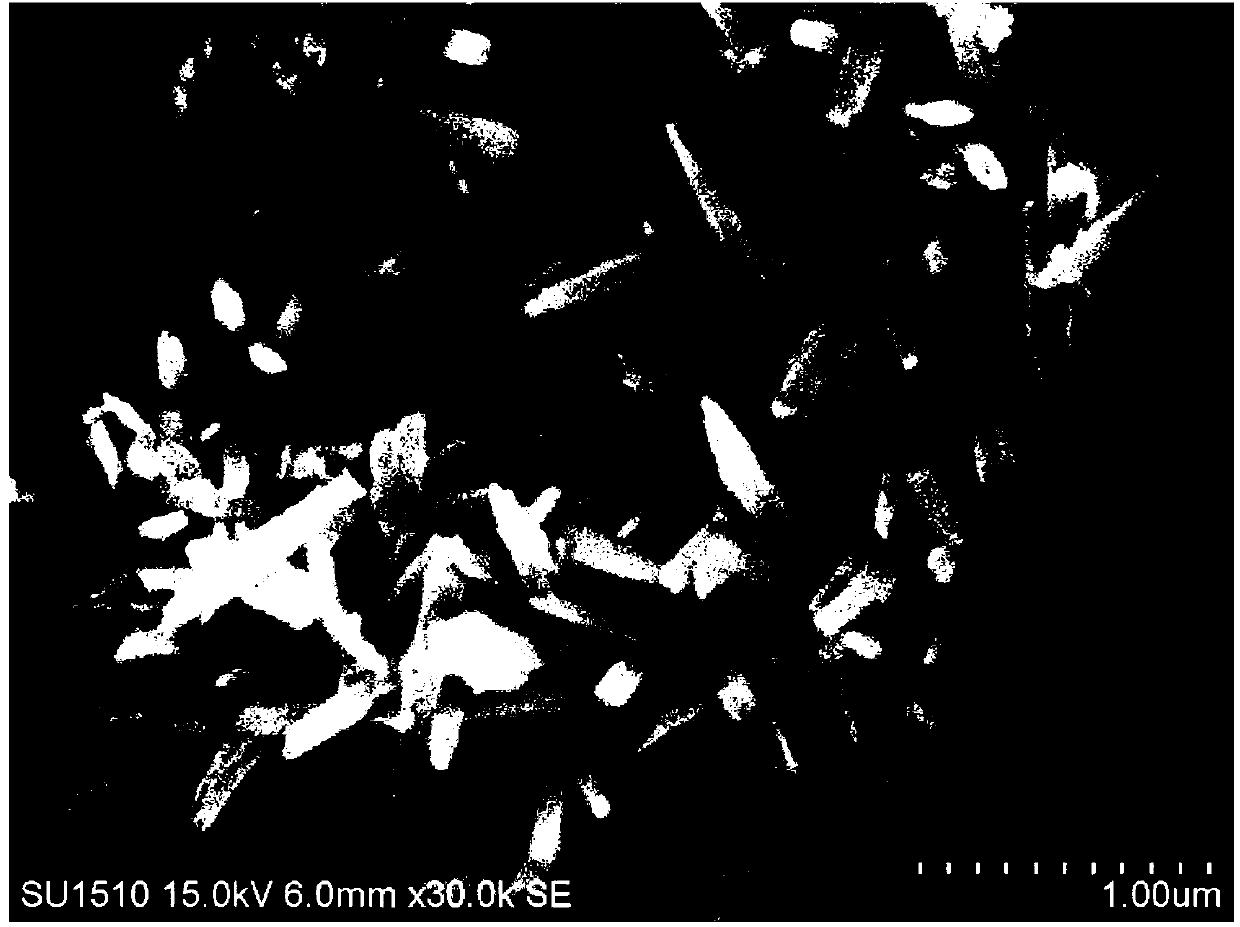

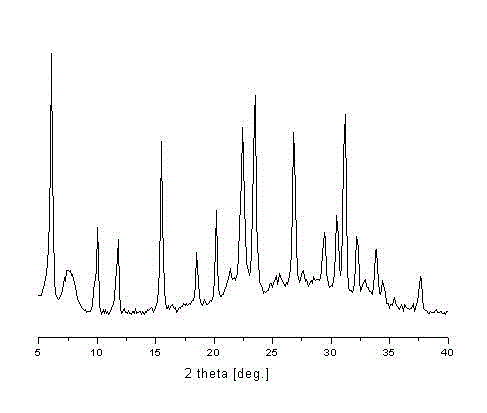

Method for preparing nano molecular sieve

ActiveCN101182004ANarrow particle size distributionMass transfer limitationNanostructure manufactureCrystalline aluminosilicate zeolitesSolubilityMolecular sieve

The invention discloses a preparation method of nanometer molecular sieve. The method is to firstly mix hydrocarbon components and surfactants evenly, then add silica gel and silica-alumina gel, and continue to stir until the raw materials are evenly mixed to obtain a super-solubilizing system of oil-in-melt, and then undergo crystallization, drying and roasting Finally, nano molecular sieves are obtained. The crystallization of the molecular sieve in the present invention is carried out in a supersolubilized micelle system of molten silica gel or silica-alumina gel in oil, and the growth of the molecular sieve crystal is limited in the nano-micelle to avoid excessive growth of the molecular sieve crystal. The surfactant and hydrocarbon components used in the method of the invention are used in small amounts and low in cost. The method has a simple process and can be used for large-scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

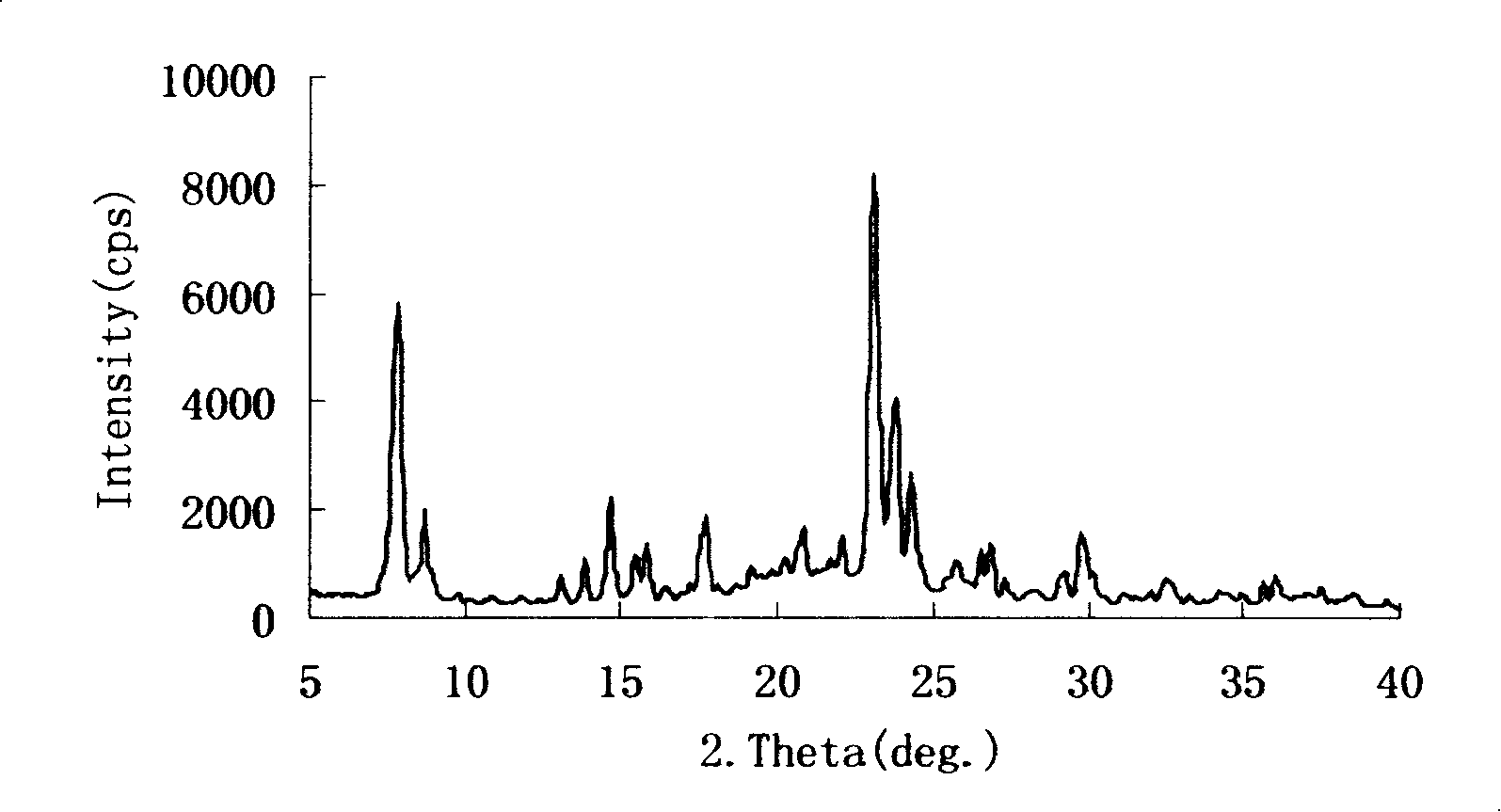

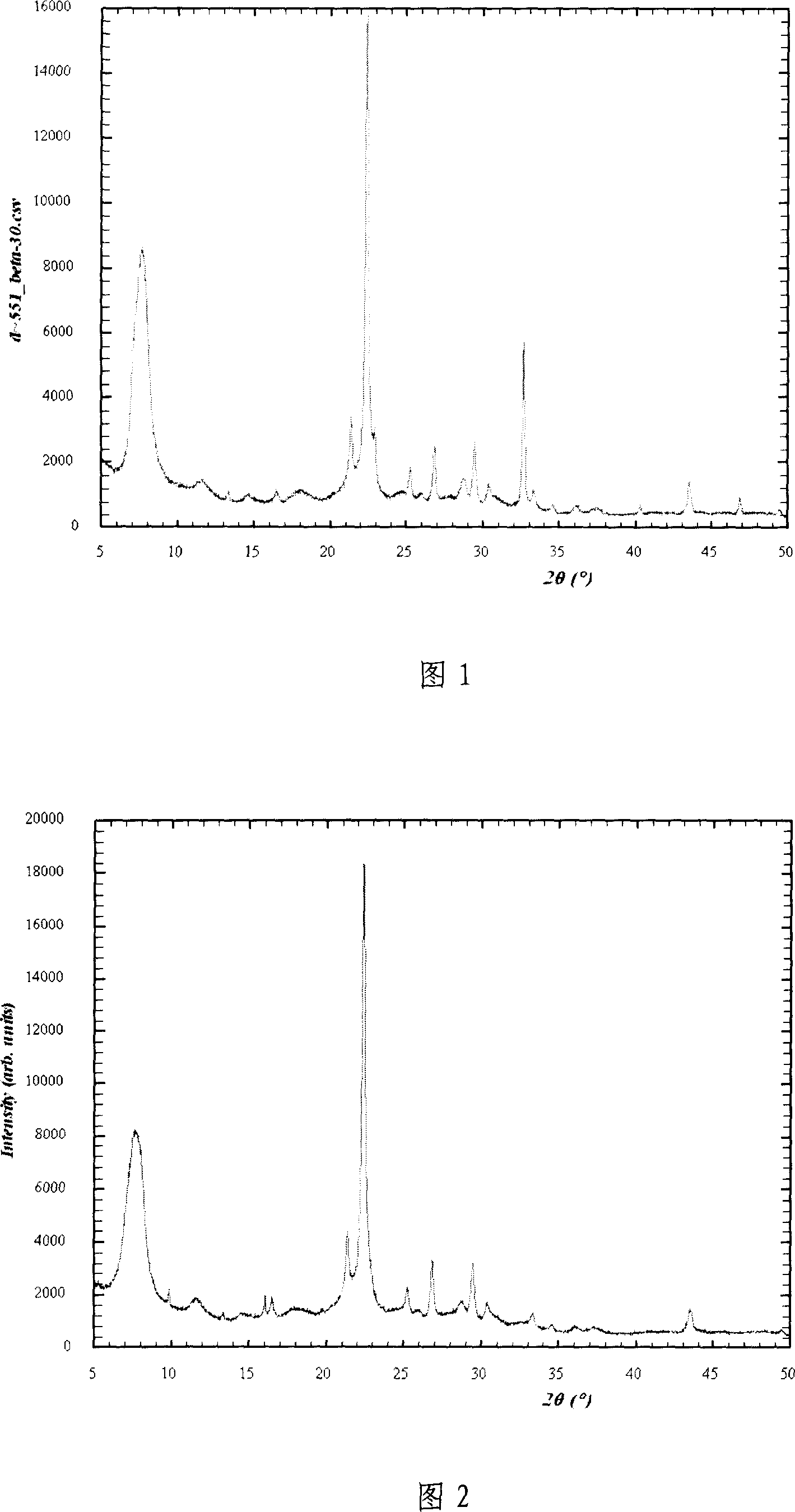

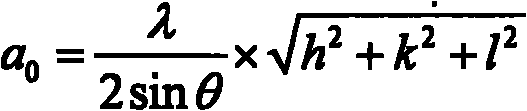

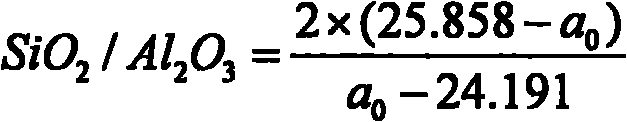

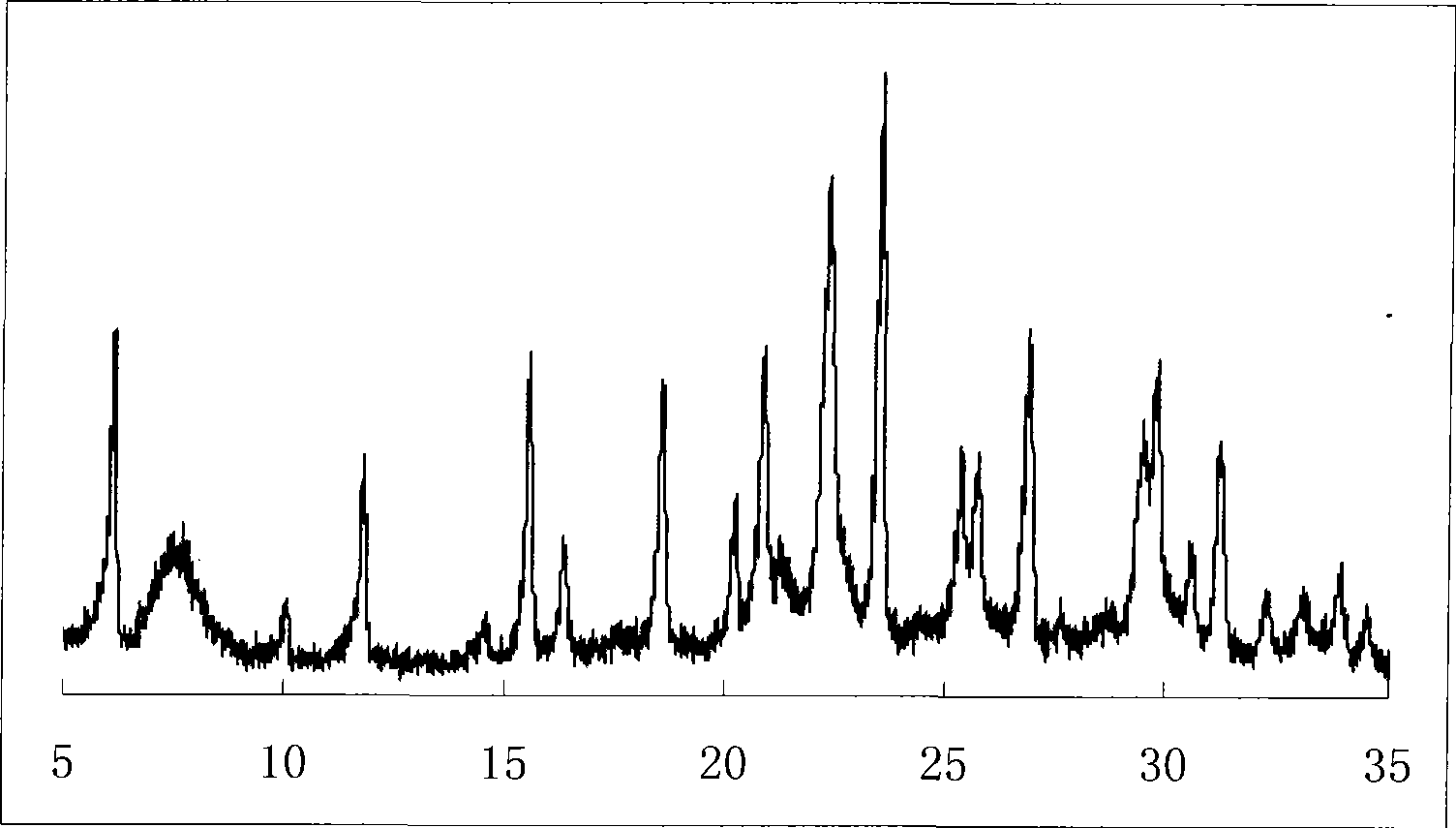

Preparation method of aluminum-enriched beta zeolite

ActiveCN101096274AHigh crystallinityHigh yieldMolecular sieve catalystsOther chemical processesSiliconReagent

The invention discloses a making method of allitic beta-zeolite, which comprises the following steps: making silica-alumina gel through silicon source and aluminium source under hydrolytic reagent; aging at 20-220 deg. c; roasting at 300-1400 deg. c; grinding the gel into silica-alumina source; adding the solution with ammonium tetraethyl cation, ammonium ion, fluorine ion and water; crystallizing; recycling the crystallized product as zeolite.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high silica alumina ratio NaY molecular sieve

ActiveCN101254929AImprove structural stabilityHigh catalytic activityFaujasite aluminosilicate zeoliteMolecular sieveAlkalinity

A preparation method of the NaY molecular sieve with high silica-alumina ratio includes: preparing the high alkalinity silica-alumina gel (3.0-6.0)Na2O:Al2O3:(7-20)SiO2:(100-600)H2O and the low alkalinity silica-alumina gel (0.5-3.0)Na2O:Al2O3:(7-20)SiO2:(100-600)H2O obtained by evenly mixing conventional directing agent, silicon source, aluminum source and water, heating up the high alkalinity silica-alumina gel to 90-110 DEG C, crystallizing for 0.5-20 hours, adding the low alkalinity silica-alumina gel, filtering, washing, drying and obtaining the NaY molecular sieve. The modified NaY molecular sieve is applicable to the catalyst preparation of catalytic cracking, hydrogen cracking and isomerization.

Owner:EAST CHINA UNIV OF SCI & TECH +1

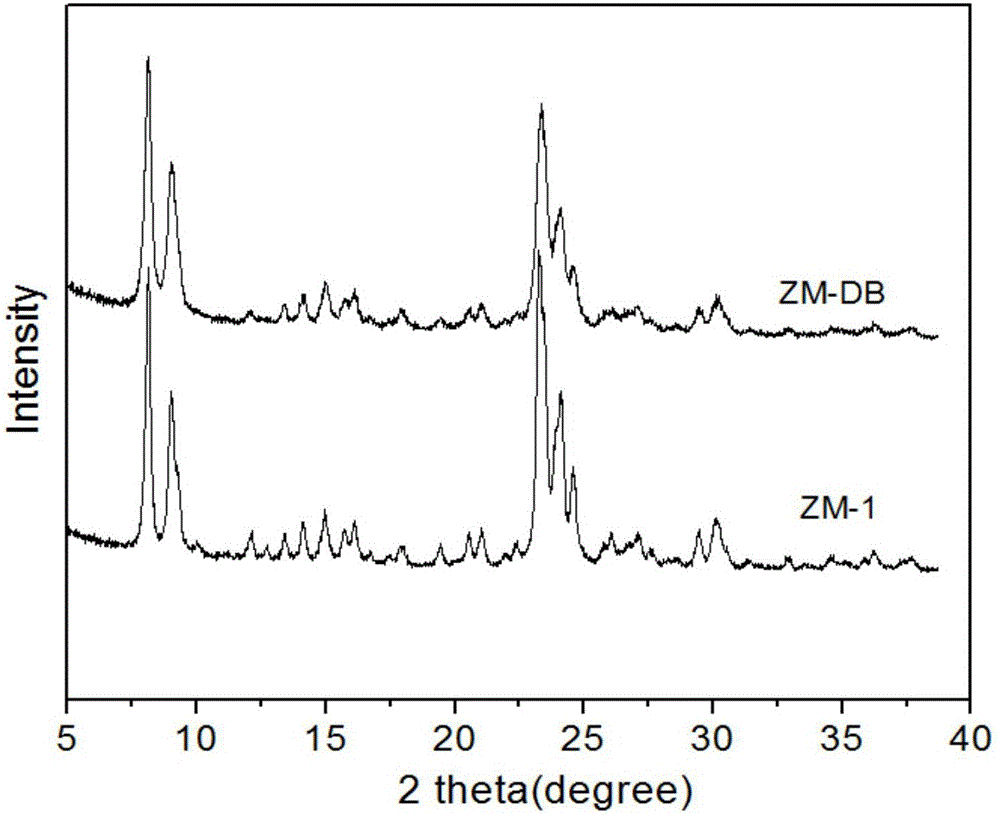

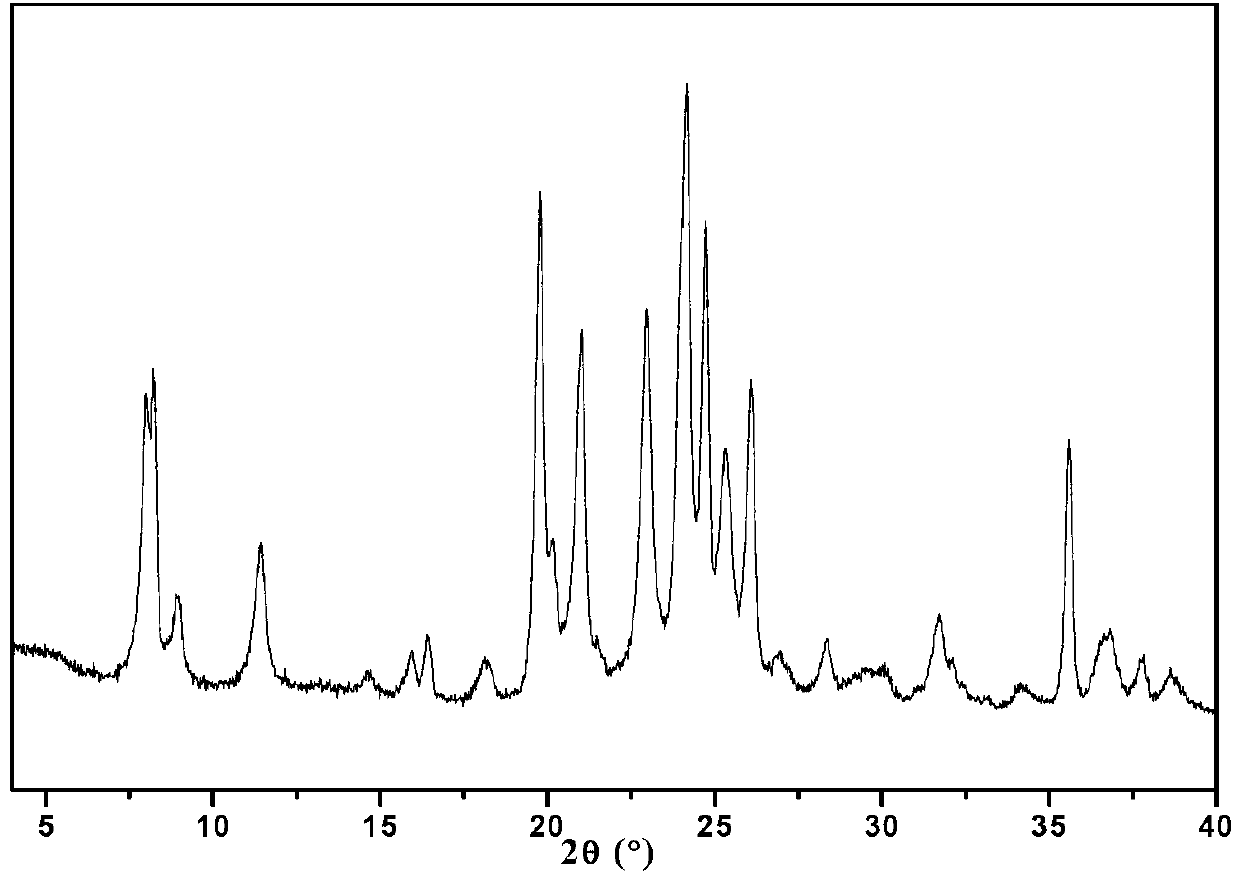

Method for preparing ZSM-34 and heteroatom substituted molecular sieve thereof by using crystal seed synthesis method

InactiveCN101962193ASmall sizeShorten crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

The invention relates to a molecular sieve preparation method, in particular to a method for synthesizing a ZSM-35 molecular sieve by using a crystal seed method. The method comprises the following steps of: uniformly mixing deionized water and an aluminum source together, adding a potassium source and NaOH, adding white carbon black while stirring, continuously stirring until the solution is uniform and becomes silica-alumina gel, adding a ZSM-35 molecular sieve crystal seed into the silica-alumina gel, and stirring; placing the mixture in a reaction kettle, crystallizing for 3 hours to 5 days at 100-180 DEG C, or crystallizing for 1-10 days at 70-100 DEG C; filtering the product by suction, and drying to obtain the ZSM-34 molecular sieve. The method not only maintains good crystallinity and purity, but also has good catalytic reaction activity. The entire production process not only does not use any organic template agents, but also can greatly shorten crystallization time by using the crystal seed method. Thus, unnecessary loss in the production process is reduced, the product also has larger specific surface area, and the product has potential application value to certain important catalytic reactions. The inorganic raw materials adopted during product are all friendly to environment and cheap.

Owner:ZHEJIANG UNIV

Application and preparation method of ZSM-5 molecular sieve with mesopores and micropores

ActiveCN105728019ASimple stepsEven stepsMolecular sieve catalystsPreparation by hydroxy group additionCyclohexeneCyclohexanol

The invention provides an application and a preparation method of a ZSM-5 molecular sieve with mesopores and micropores. The preparation method includes steps of precursor preparation, silica-alumina gel preparation and preparation of the ZSM-5 molecular sieve with the mesopores and micropores.In a preparation process of a hierarchical porous catalyst, consumption of a microporous templating agent and a mesoporous templating agent can be substantially reduced, synthesis steps of the hierarchical porous catalyst are simple, and the synthesized molecular sieve is large in specific surface area, uniform in particle size and controllable in mesopore quantity and size, and intrinsic lipophilicity of the molecular sieve is enhanced due to abundant surface terminal hydroxide radicals. By adoption of the molecular sieve as the catalyst, a method for preparing cyclohexanol by direct hydration of cyclohexene is established, and the catalyst is high in cyclohexene conversion rate and cyclohexanol selectivity.

Owner:CHINA TIANCHEN ENG +1

Nano Al2O3 film encapsulated carbon-aluminum spinelle refractory castable and preparation method thereof

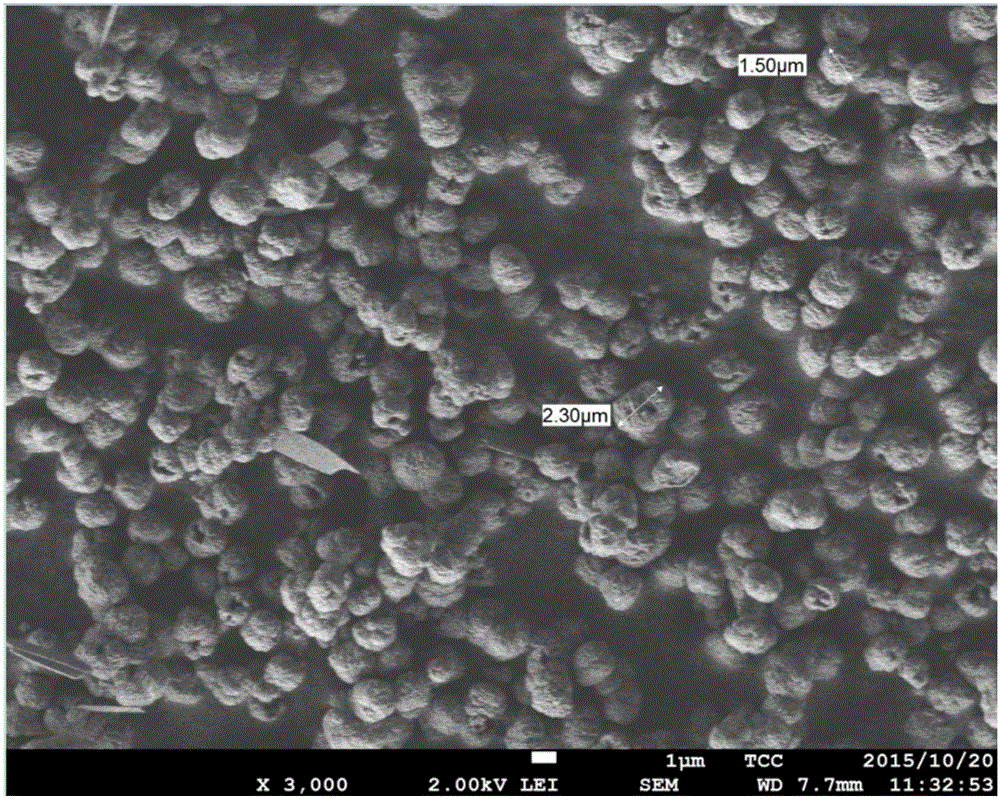

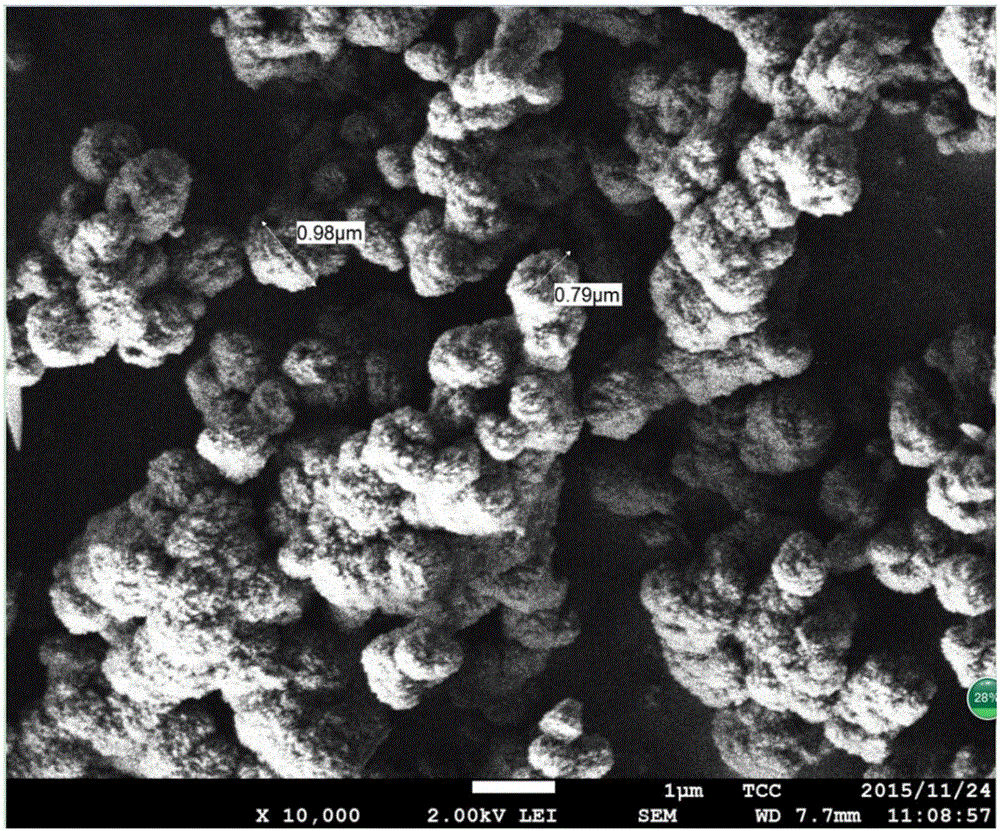

InactiveCN101417884APerformance indicators improved and enhancedDense tissue structureHydration reactionManufacturing technology

The invention relates to a carbon-aluminum spinel refractory castable material wrapped up by a nano AL2O3 film and a preparation method thereof. The preparation method of the carbon containing castable material firstly puts the mixture of hydrated alumina, carbon powders and water in a high speed impact mixing-stirring mill for coating processing treatment, the materials impact and collide with each other after high-speed impact treatment, thus forming a composite sol suspension liquid of carbon and aluminum hydroxide and causing the aluminum hydroxide to be strongly absorbed on the surface of the carbon, therefore, the manufacture technology for coating carbon powders by using aluminum hydroxide is realized, then the composite sol suspension liquid is directly added to the mixed materials for preparing alumina gel coatings by controlling the conversion process from the aluminum hydroxide to the gel, and hence the whole-covered, crack-free and high-strength compact alumina wrapping layer is formed; and during the mixing and stirring process of the castable material, magnesium hydroxide sols are generated by the hydration reaction of magnesia powders and mixed water in matrix powders, then the nanostructure matrix of carbon-aluminum-spinel is generated by the in-situ synthesized reaction of the magnesium hydroxide sol and aluminum hydroxide sol suspension liquid, and finally the carbon-aluminum refractory castable material is prepared.

Owner:高树森

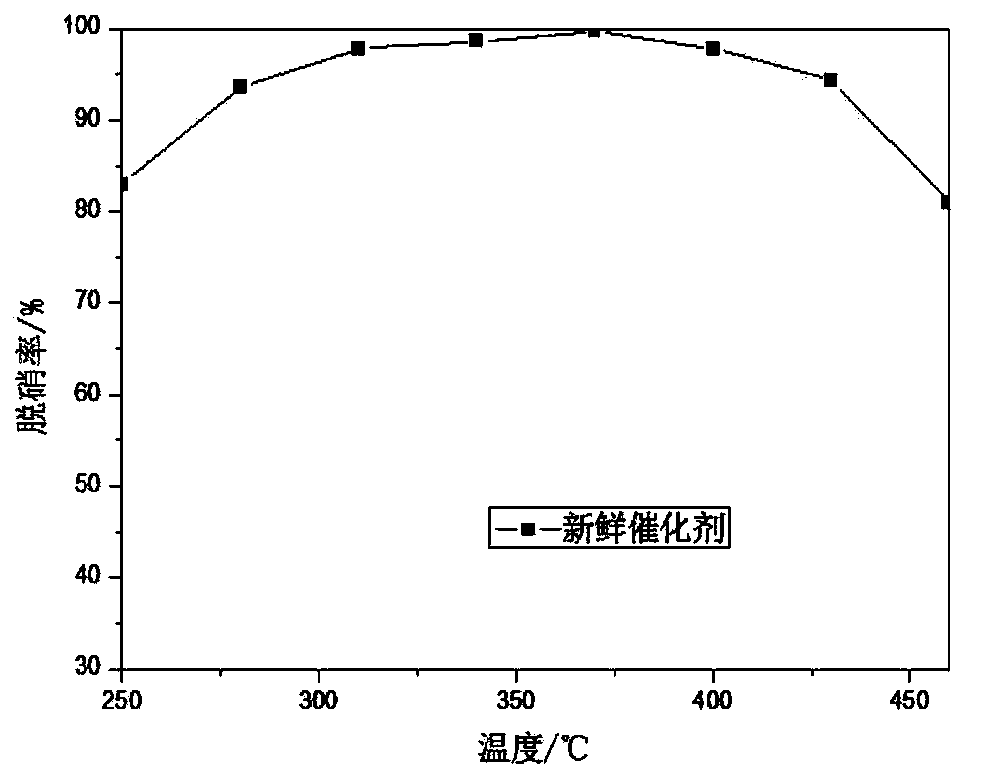

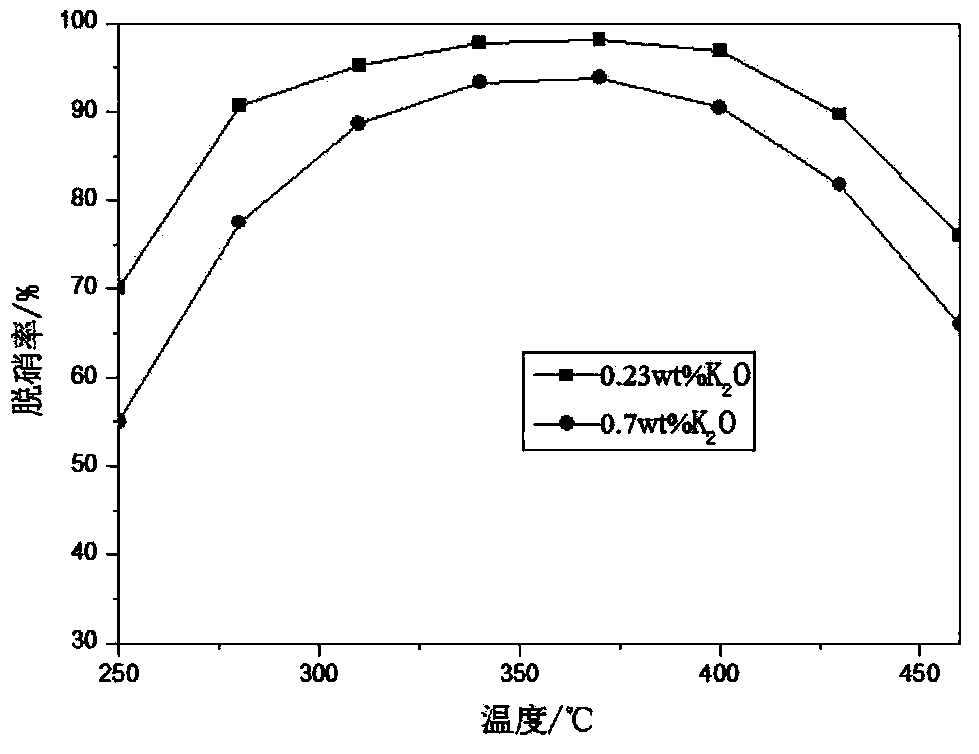

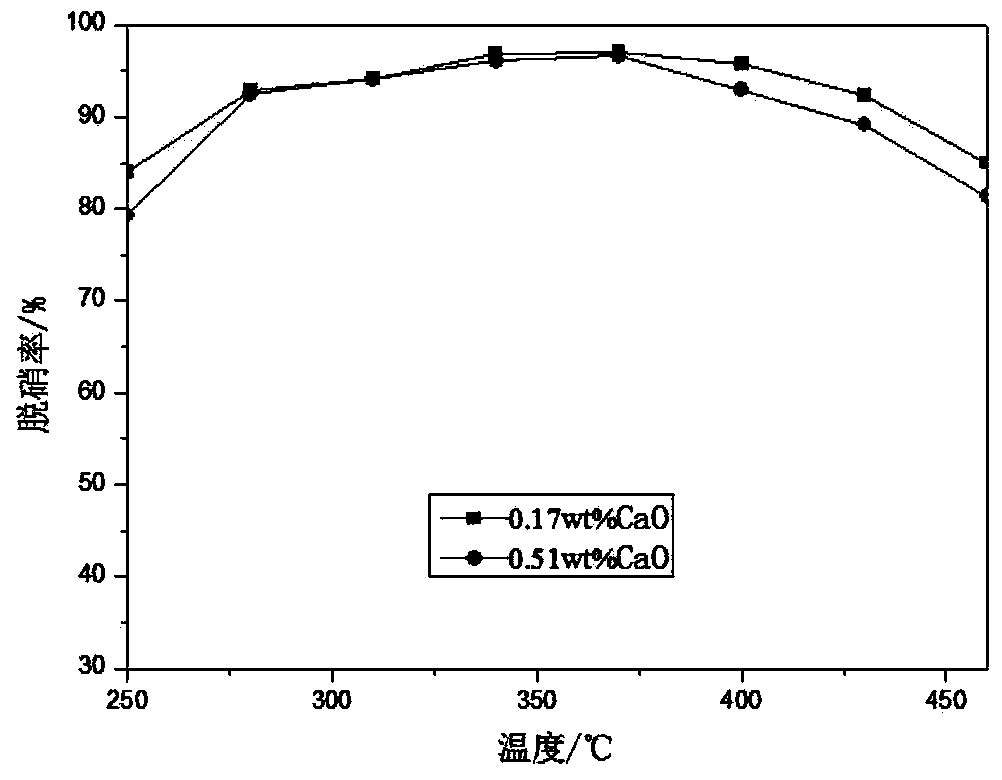

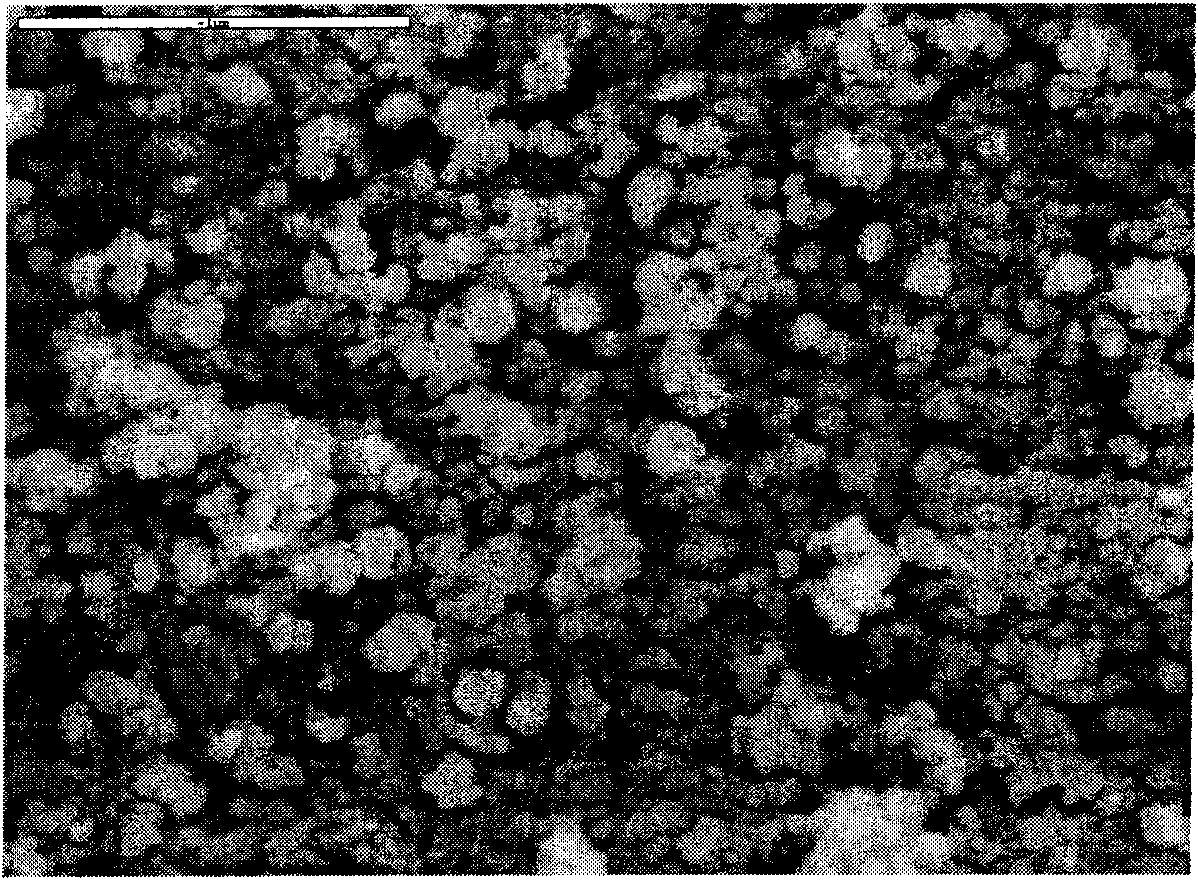

Catalyst for cement kiln gas denitration and preparation method thereof

ActiveCN103846094AStrong wear resistanceImprove thermal stabilityPhysical/chemical process catalystsDispersed particle separationAlkaline earth metalCerium

The invention relates to a catalyst for cement kiln gas denitration and a preparation method thereof. The catalyst is characterized in that cerium zirconium titanium tungsten composite sulfate is utilized as catalyst active components, one or more of iron, copper, molybdenum or lanthanum oxide is utilized as a cocatalyst, and an aluminum silicon titanium mixing oxide is utilized as a carrier. The preparation method comprises the steps of uniformly stirring a cerium zirconium titanium tungsten composite sulfate precursor, acid alumina gel, pseudo-boehmite, kieselguhr, titanium dioxide and an organic addition agent together, mixing, aging and carrying out extrusion molding on the mixture, and drying and roasting to obtain the integral catalyst. The catalyst provided by the invention has the advantages that the NOx removing efficiency is high, an active temperature window is wide, the catalytic denitration efficiency can achieve 90% above in the range of 280-430 DEG C, and the highest activity can achieve 99.7%; the catalyst has the strong alkali-resisting metal and alkaline earth poisoning capacity and has the high wear-resisting property; the components of the catalyst are non-poisonous and thus the catalyst has an environment-friendly effect; the mechanical strength is high, the preparation technology is simple, the cost is low, and the catalyst is particularly suitable for removing of high dust, high alkali metal and NOx in high alkaline earth smoke of a cement kiln.

Owner:NANJING UNIV OF TECH

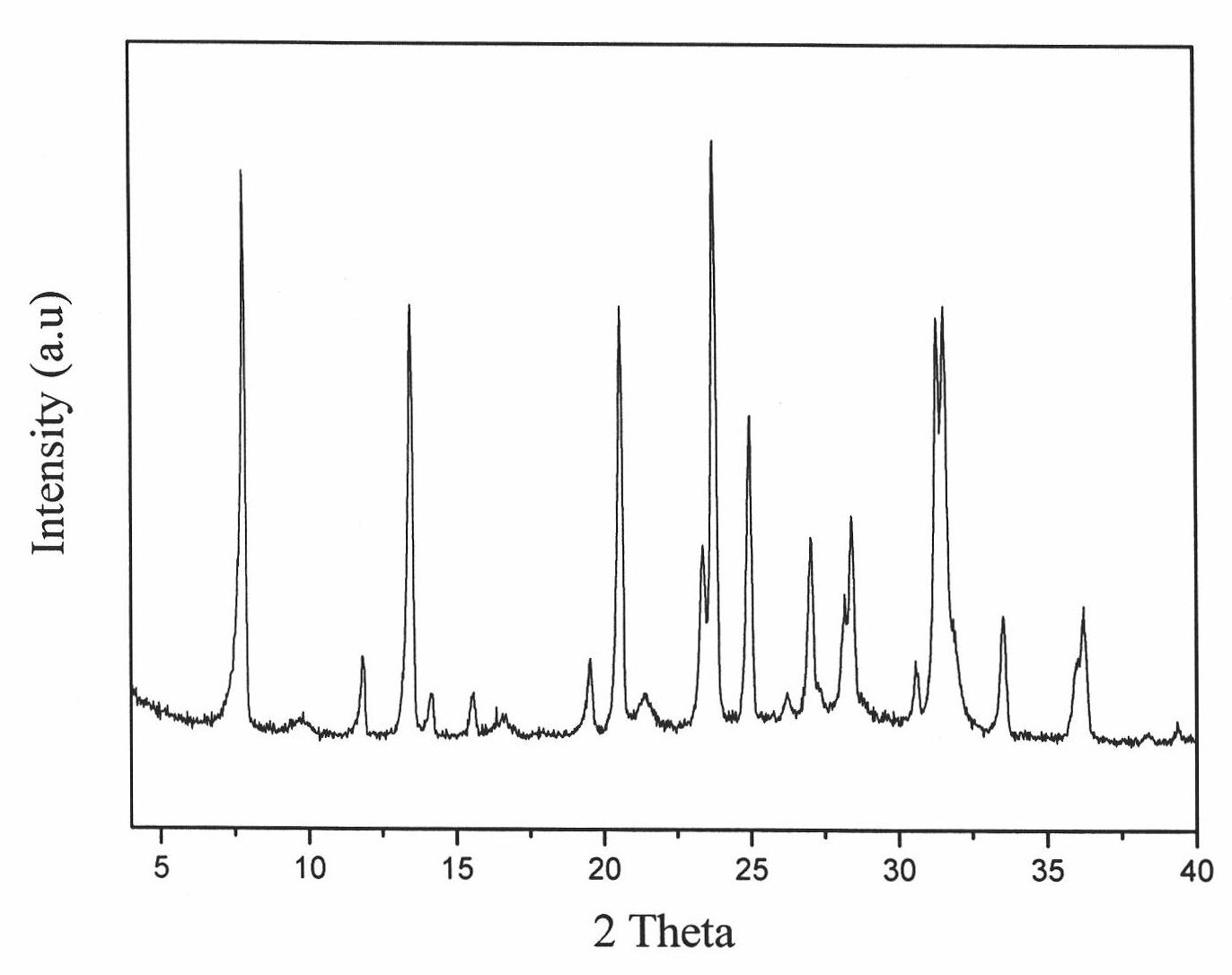

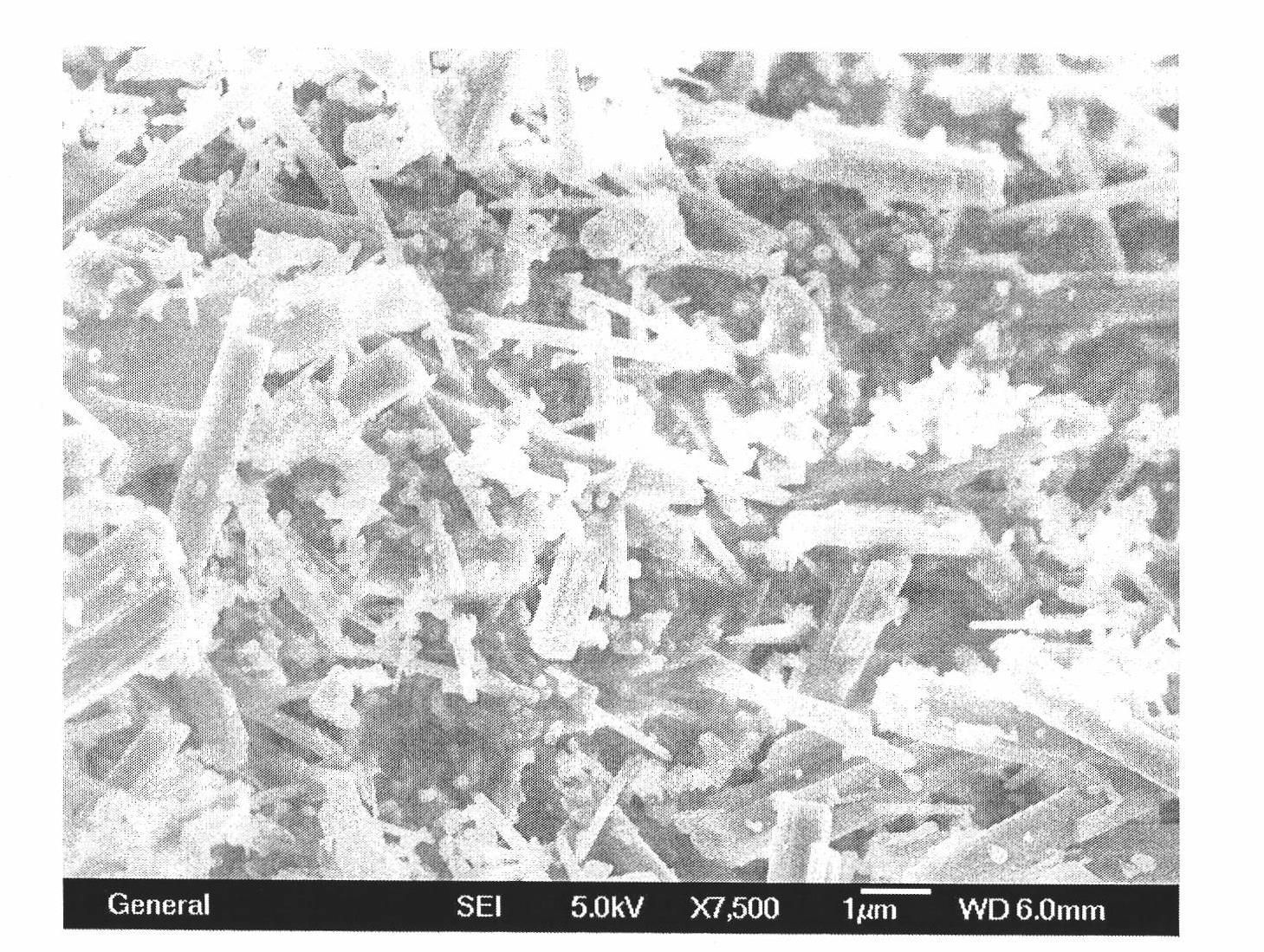

Titanium dioxide-aluminum oxide composite carrier and preparation method thereof

The invention discloses a titanium dioxide-aluminum oxide composite carrier and a preparation method thereof. Titanium hydroxide-aluminum hydroxide gel prepared by supersolubility micelles is used as a raw material, and the gel contains a surfactant and a hydrocarbon substance, so after the gel is molded and roasted, nanometer titanium dioxide and aluminum oxide particles formed by removing water from polymerized titanium hydroxide and aluminum hydroxide still have a rodlike basic structure and accumulate unorderly to form a frame structure. The composite carrier has the advantages of large pore volume, large pore diameter, high porosity, large orifices on the external surface, and high penetrability of pore channel; and particularly for macromolecules, a catalyst does not have ink bottle-shaped orifices, so the orifices cannot be blocked so as not to inactivate the catalyst. The composite carrier is favorable for increasing the sediment accumulation of impurities and prolonging the running period of the catalyst. The composite carrier can be used for catalytic reaction of macromolecular reactants or products.

Owner:CHINA PETROLEUM & CHEM CORP +1

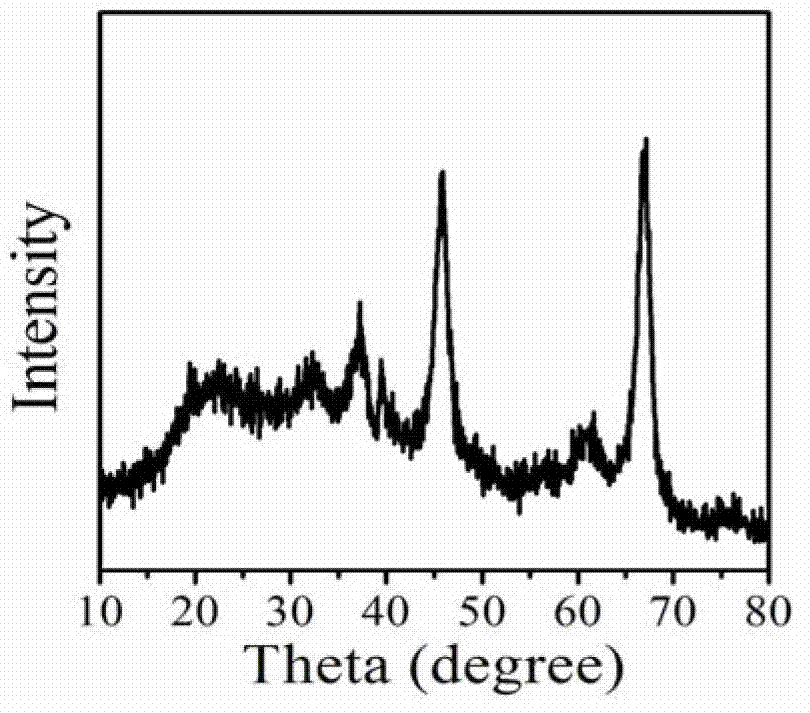

Method for synthesizing and preparing ZSM-22 molecular sieve under conditions of no organic template and no crystal seed

InactiveCN104671252AReduce usageAvoid pollutionCrystalline aluminosilicate zeolitesMolecular sieveAluminium sulfate

The invention relates to the field of preparation of molecular sieves, and aims to provide a method for synthesizing and preparing a ZSM-22 molecular sieve under the conditions of no organic template and no crystal seed. The method comprises the following steps: uniformly mixing deionized water and an alkali source, adding aluminum sulfate, adding a silicon source under stirring conditions, continuing stirring to form a silica-alumina gel, and carrying out crystallizing reaction on the obtained silica-alumina gel in a reaction kettle; after the reaction finishes, obtaining the product, carrying out vacuum filtration on the product, and drying to obtain the ZSM-22 molecular sieve raw powder. The method thoroughly avoids the use of the organic template agent, and lowers the crystallizing temperature on the premise that the crystallizing time is not obviously changed, thereby reducing the unnecessary energy consumption and environmental pollution in the production process. More importantly, the method has very high silicon raw material utilization ratio and high yield, thereby greatly saving the production cost and being beneficial to application in other industrial fields.

Owner:ZHEJIANG UNIV

Seed crystal synthesis method for preparing ZSM-23 molecular sieve

InactiveCN102992346ALow priceHigh crystallinityCrystalline aluminosilicate zeolitesMolecular sieveFiltration

The invention relates to a preparation method of a molecular sieve, and aims to provide a seed crystal synthesis method for preparing a ZSM-23 molecular sieve. The method comprises specific steps as follows: mixing water and an aluminum source; adding NaOH; adding a silicon source with stirring; continuing to stir until the solution to forms silica-alumina gel; adding ZSM-23 molecular sieve seed crystal into silica-alumina gel and stirring; then placing the mixture in a reaction kettle, and crystallizing at 140-180 DEG C for 2-50h; and conducting suction filtration and drying on the product to obtain a ZSM-23 molecular sieve raw powder. The whole production process of the invention does not use an organic template agent, greatly shortens crystallization time and lowers crystallization temperature, thus reducing unnecessary loss in the production process. The inorganic materials used in the production are environment-friendly, and low-cost; and the ZSM-23 zeolite molecular sieve synthesized by the invention maintains good crystallinity and purity, and has favorable catalytic reaction activity.

Owner:ZHEJIANG UNIV

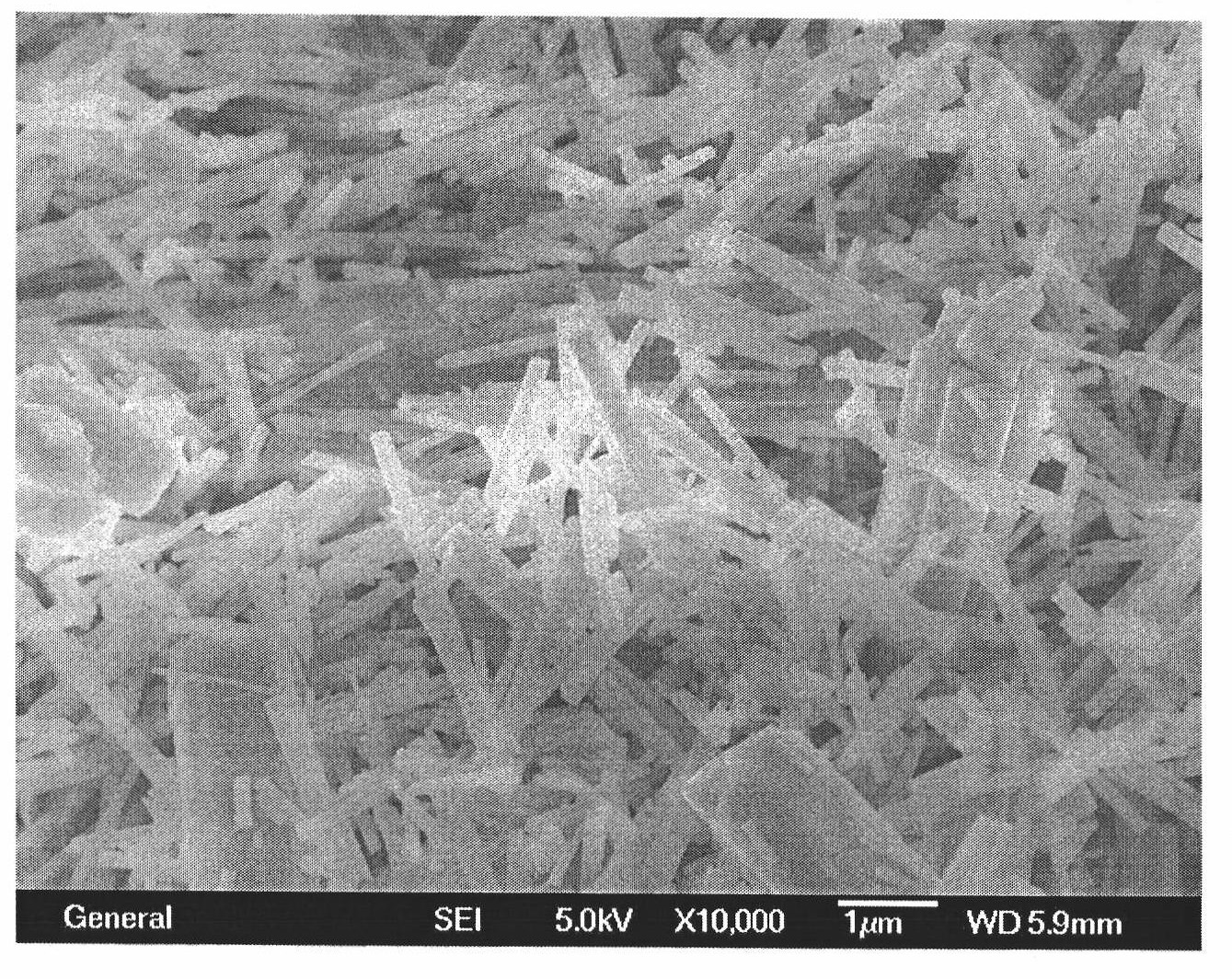

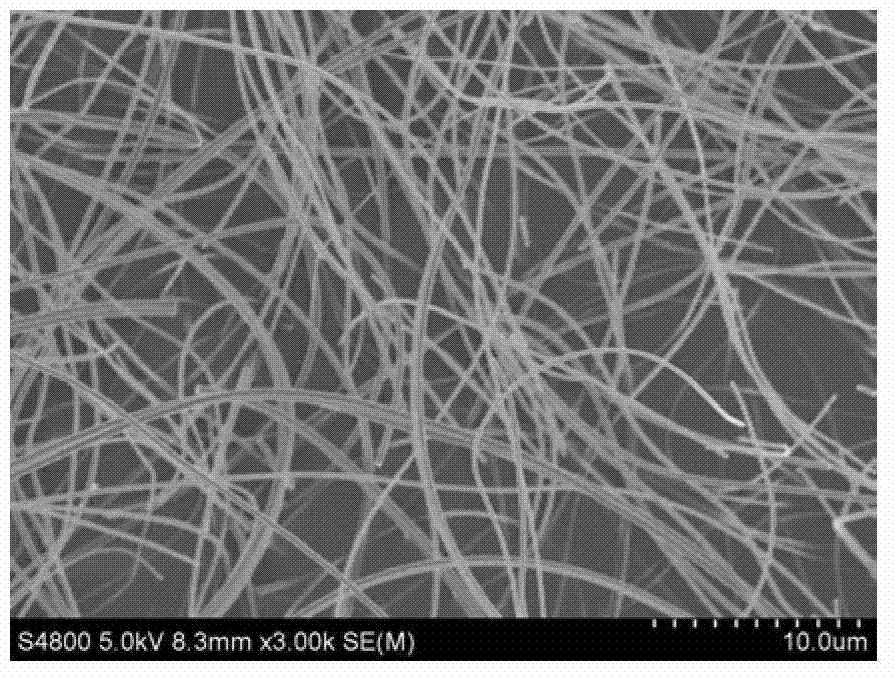

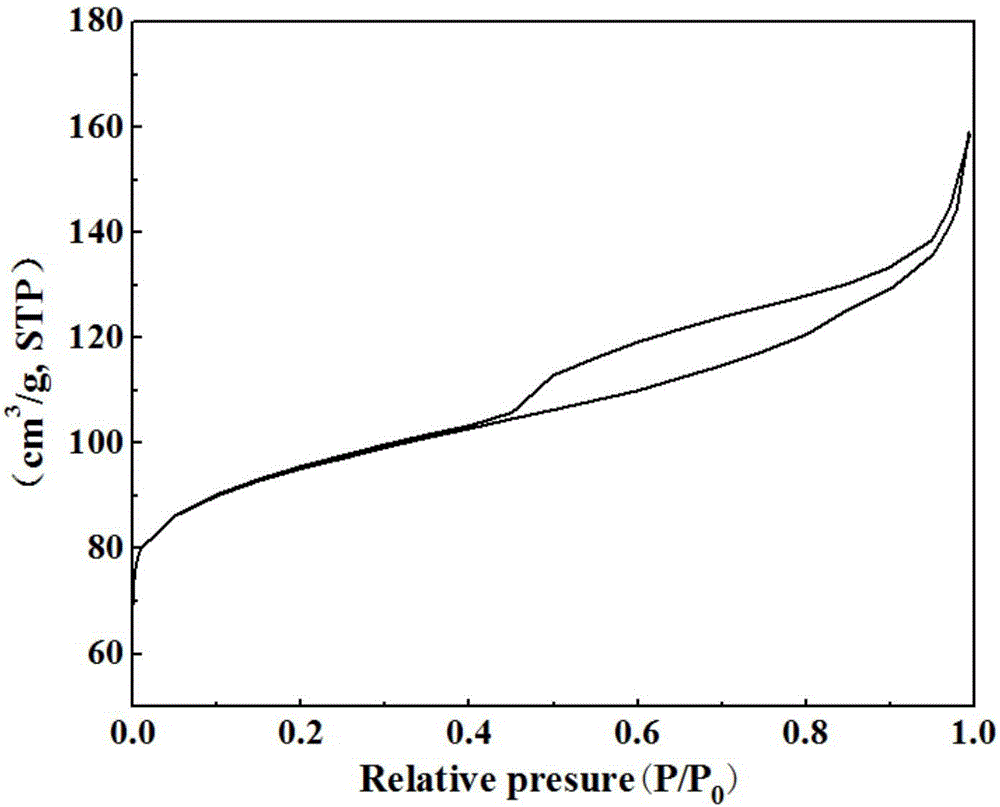

Flexible gamma-Al2O3 fiber membrane and preparing method thereof

The invention relates to a flexible gamma-Al2O3 fiber membrane and a preparing method thereof. The flexible gamma-Al2O3 fiber membrane is formed by gamma-Al2O3 fibers and has the thickness ranging from 10 to 100 micros, the diameter of the fibers forming the fiber membrane ranges from 70 to 400 nanometers, and the particle size of the Al2O3 particles forming the fibers ranges from 8 to 40 nanometers. Aluminium chloride, aluminum isopropoxide, anhydrous ethanol, tartaric acid and polyvinyl pyrrolidone are prepared into sol spinning solution through the combination of the sol-gel method and the electrospinning technique, so as to make aluminium chloride gel fiber membrane and then make the gamma-Al2O3 fiber membrane by calcining the gel fiber membrane. The aluminium chloride fiber membrane has high flexibility, little possibility of being broken, excellent mechanical property and strong machinability, and can serve as the high-temperature catalyst material, the high-temperature thermal insulation material as well as the high-temperature filtering material. The flexible gamma-Al2O3 fiber membrane has simple process equipment and strong machinability, and is suitable for large-scale production.

Owner:SHANDONG UNIV

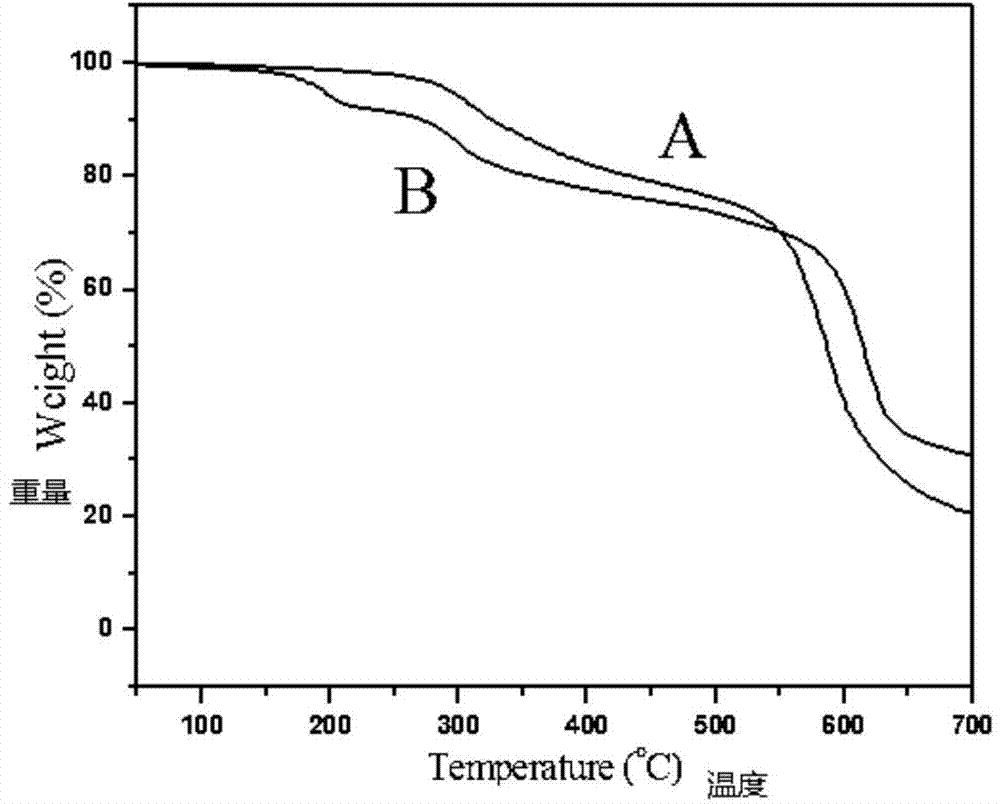

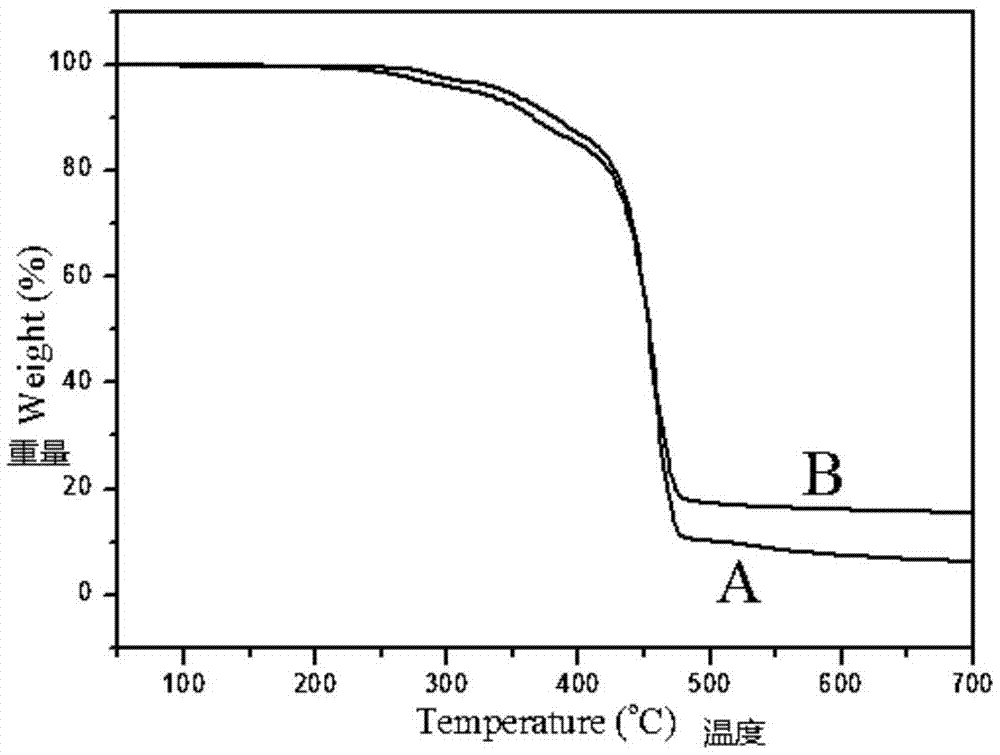

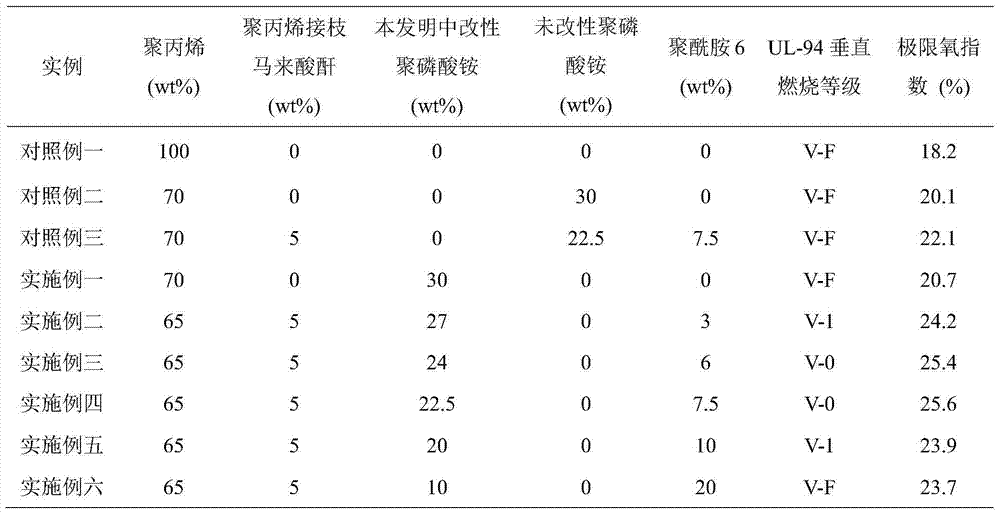

Silica-alumina hydrogel double-coated modified ammonium polyphosphate and application thereof to inflaming retarding polypropylene

ActiveCN104327549AImprove flame retardant performanceImprove heat resistanceInorganic pigment treatmentPolymer scienceCombustion

The invention relates to silica-alumina hydrogel double-coated modified ammonium polyphosphate and an application thereof to inflaming retarding polypropylene. Double-coated modification is carried out on ammonium polyphosphate by silica gel and alumina gel so that the surface performance of ammonium polyphosphate and the inflaming retarding performance of the system are improved. According to the silica-alumina hydrogel double-coated modified ammonium polyphosphate, tetraethoxysilane, aluminum nitride and ammonium polyphosphate are utilized and absolute ethyl alcohol is used as a dispersant, and the materials are reacted to generate the silica-alumina hydrogel double-coated modified ammonium polyphosphate. The heat stability and the inflaming retarding performance of the modified ammonium polyphosphate and the unmodified ammonium polyphosphate are improved. The prepared silica-alumina hydrogel double-coated modified ammonium polyphosphate and polyamide 6 are cooperated to be commonly used as an expansion type fire retardant which is applied to inflaming retarding of a polypropylene material; and the extreme oxygen index, the UL-94 vertical combustion grade, the heat stability, the charcoal forming capability and the like of the obtained composite inflaming retarding polypropylene material are remarkably improved.

Owner:SOUTHWEST JIAOTONG UNIV

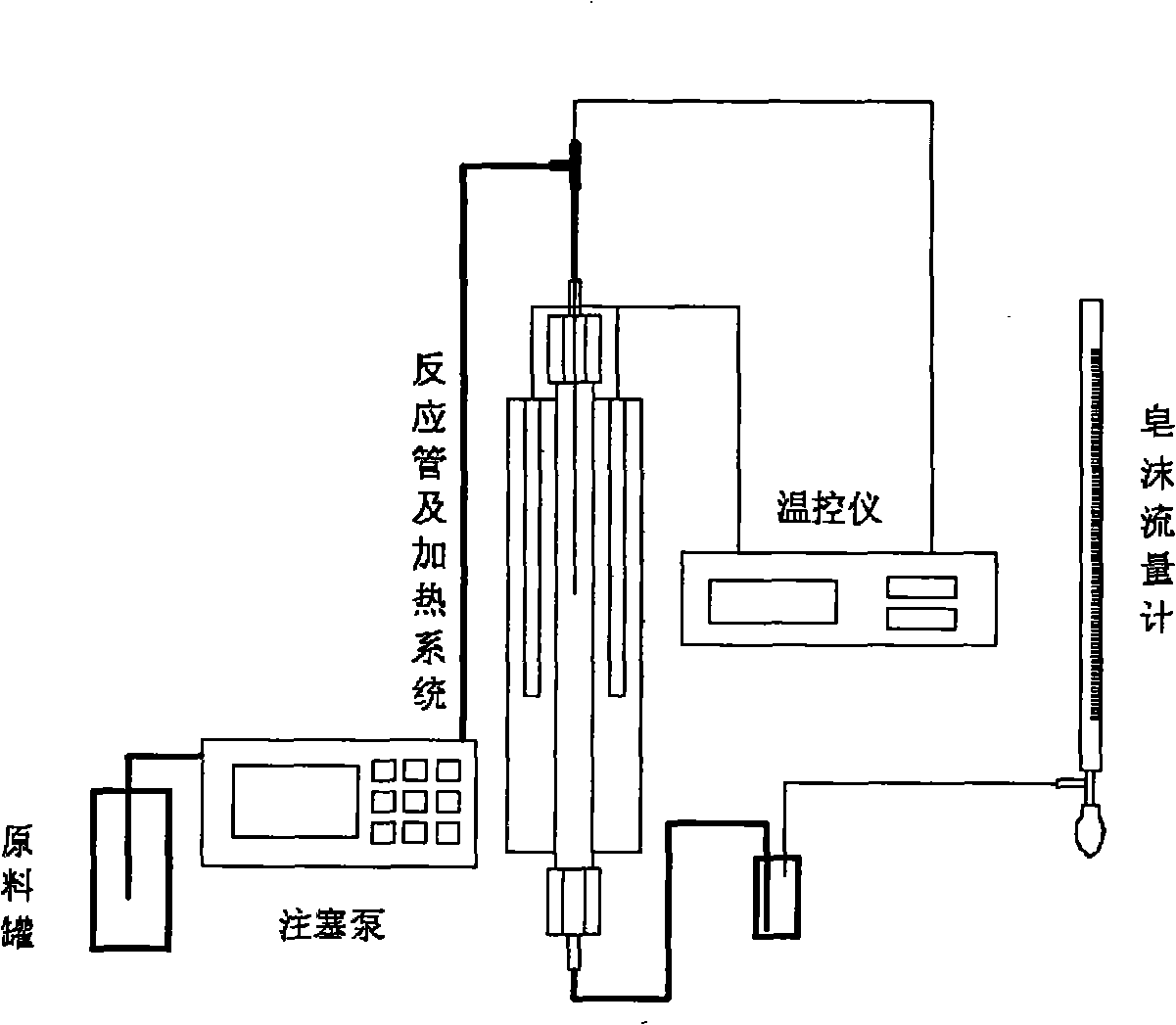

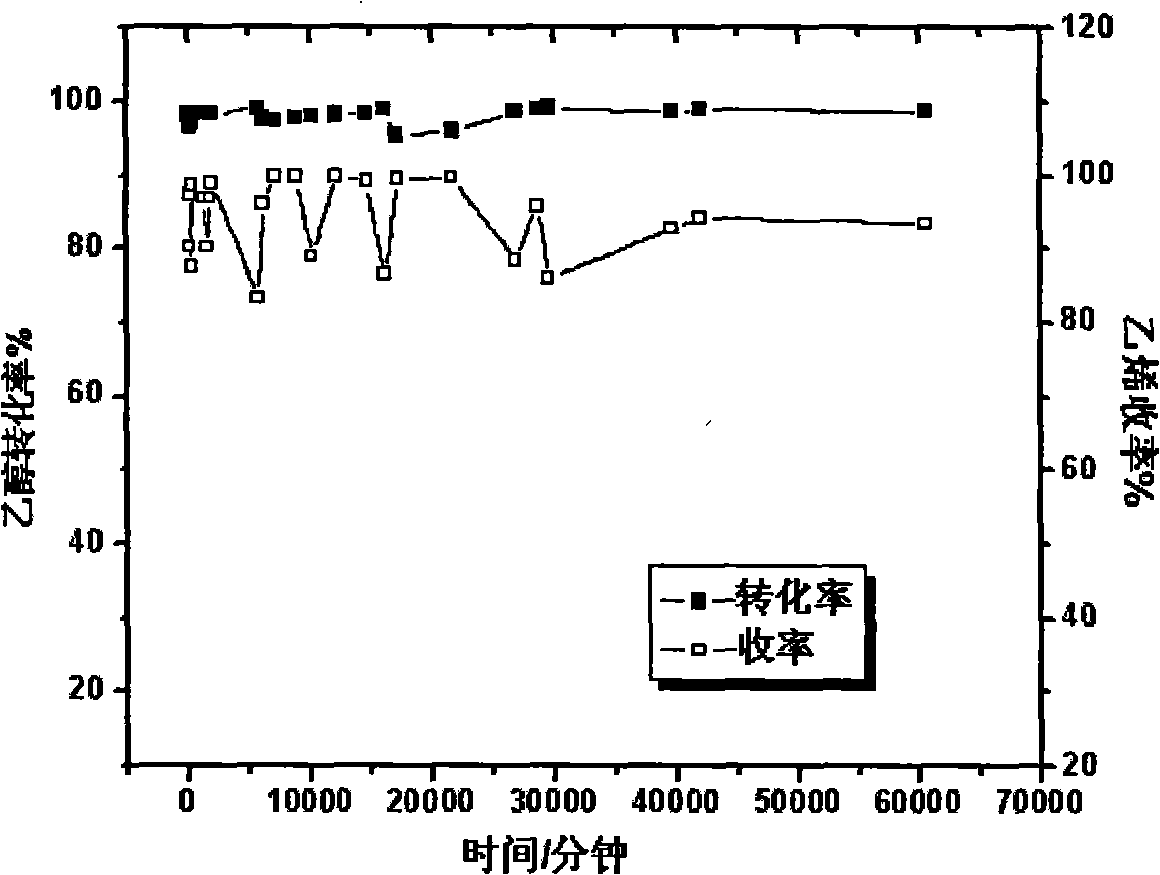

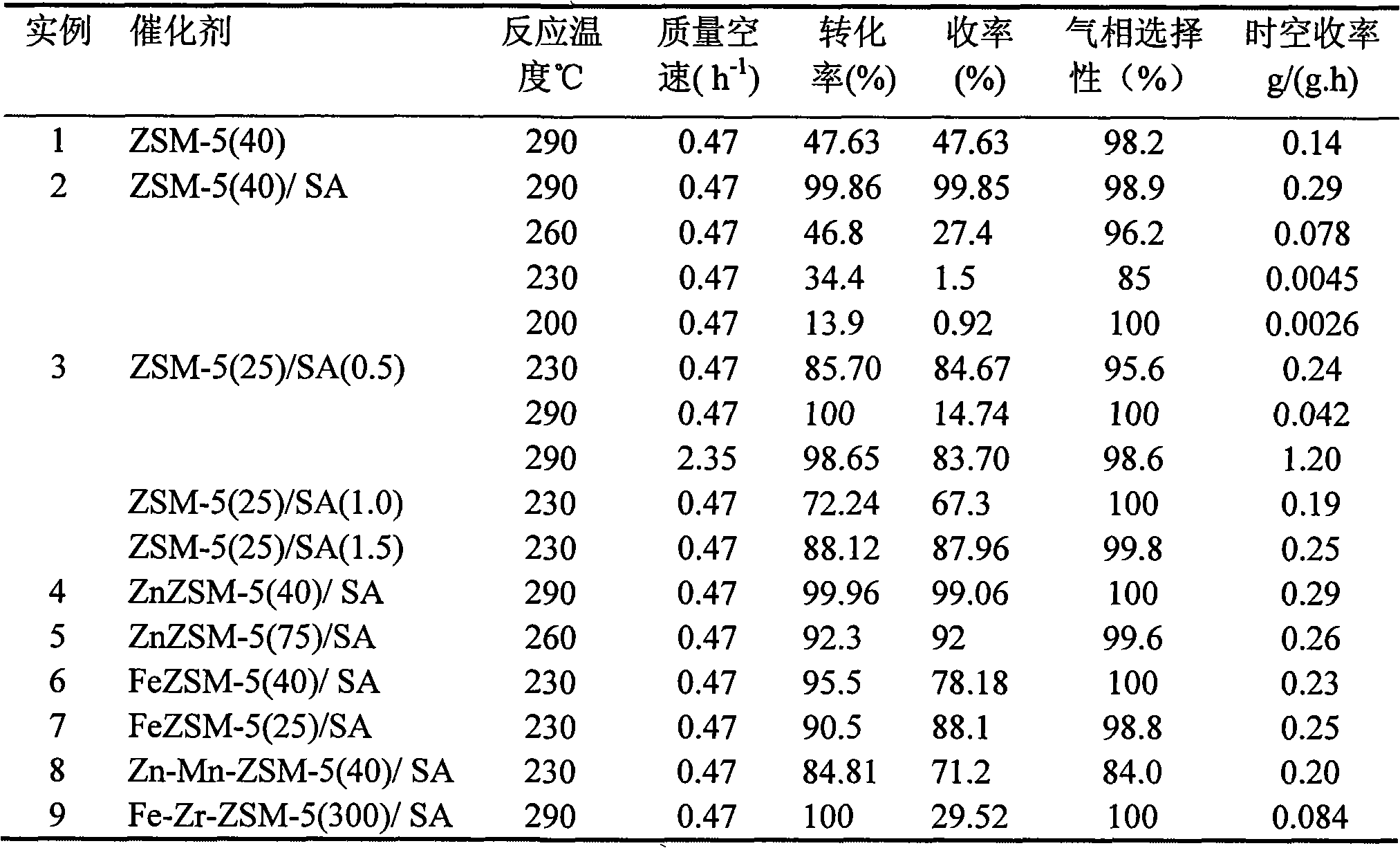

Catalyst used in reaction process of producing ethylene from dehydration of ethanol

InactiveCN101274286AReduced tendency to coke inactivationIncrease one-way productionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureFixed bed

The invention relates to a catalyst used in a reaction for producing ethylene by ethanol dehydration, which is characterized in that the catalyst of the invention consists of HZSM-5, in which the ratio of the 0.5 to 7 percent of one or a plurality of kinds of active metallic components by weight to the 5 to 30 percent of amorphous silica-alumina gel and skeleton silica-alumina by weight is 5 to 300. In the reaction implemented in a fixed bed fluid reactor, the catalyst of the invention can achieve high conversion rate and high selectivity for converting ethanol to ethylene under the conditions of normal pressure, reaction temperature of 200 to 290 DEG C and reactant airspeed of 0.1-10h<-1>, and with 10 to 100 percent of the ethanol water solution as raw reaction materials. Under optimized conditions, the ethanol conversion rate, the vapor ethylene selectivity and the overall ethylene yield all approximate 100 percent. The catalyst of the invention is used for the reaction for producing ethylene by ethanol dehydration, and has the outstanding features of wide concentration range of the raw reaction material solution, lower reaction temperature and wider airspeed range, does not need the preliminary gasification of the raw reaction material solution, does not use the inert diluent gas, and has high catalyst activity and selectivity as well as long catalytic life.

Owner:HUNAN UNIV

Method for preparing nano flyash zeolite

InactiveCN101993089ASmall particle sizeIncrease profitSolid waste disposalCrystalline aluminosilicate zeolitesIon exchangeSolvent

The invention relates to a method for preparing nano flyash zeolite. Flyash is used as a raw material in the method, and the method comprises the following steps of: firstly melting the flyash and sodium hydroxide at high temperature; mixing the molten flyash with concentrated seawater used as a solvent, stirring and aging to obtain silica-alumina gel; crystallizing the silica-alumina gel hydrothermally, and then washing with water to be neutral; and finally drying to obtain a powdery product. Based on the special aperture structure of zeolite, the synthesized zeolite can be applied to catalysis, adsorption, ion exchange and soil improvement. By using the flyash and the concentrated seawater which are both wastes, the method realizes the recycling of the flyash and the concentrated seawater and is a new environment-friendly production method which meets the requirement of sustainable development.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Synthesis method of beta/Y composite molecular sieve

ActiveCN103058215AOdds of Avoiding Standalone Y Molecular SievesFaujasite aluminosilicate zeoliteMolecular sieveSynthesis methods

The invention discloses a synthesis method of a beta / Y composite molecular sieve, which comprises the following steps: mixing a beta molecular sieve and a Y-structure guide agent, standing for some time, mixing with a silica-alumina gel, and carrying out crystallization reaction. By using such treatment, the Y-structure guide agent can be firmly anchored on the surface of the beta molecular sieve to form crystal nucleus for growing the Y-type molecular sieve, thereby being beneficial to growing the Y-type molecular sieve on the surface of the beta molecular sieve, preventing the Y-type molecular sieve from forming an independent Y-type molecular sieve in the reaction solution system, and finally forming the highly-composite beta / Y composite molecular sieve with core-shell structure.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of methane synthetic catalyst carrier

ActiveCN102350375AGood hydrothermal stabilityImprove heat stabilityCatalyst carriersHydrocarbon from carbon oxidesMagnesiumAlumina gel

The invention belongs to the technical field of catalysis, and relates to a preparation method of a methane synthetic catalyst carrier, particularly a preparation method of a methane synthetic catalyst carrier existing in the form of magnesia alumina spinel. The method comprises the following steps: independently neutralizing a magnesium soluble salt solution with alkali, washing the obtained precipitate until the precipitate is qualified, mixing with alumina gel and a rare earth metal salt solution to react, drying, pulverizing, roasting, granulating, tabletting to form, and roasting to obtain the methane synthetic catalyst carrier. The carrier prepared by the method provided by the invention has high hydrothermal stability; and the methane synthetic catalyst prepared by using the carrier has the characteristics of high thermal stability, wide temperature range applicability and the like, and can not easily deposit carbon under the conditions of high CO content.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation of composite double microporous material

ActiveCN101376505AMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveReaction temperature

The invention discloses composite dual-microporous material and a preparation method. A guiding agent gel of a Y molecular-sieve is confected first, and then a silica-alumina gel is confected; the guiding agent gel is added in the silica-alumina gel and mixed evenly, and a molecular-sieve seed crystal is added finally; the mixed materials are processed through crystallization for a period of time at low temperature and then are processed through crystallization for a period of time at high temperature after the temperature is raised, and a Y / Beta composite molecular-sieve is obtained through cooling and separation finally. The composite molecular-sieve which is prepared by adopting the preparation method has the high composite advantage of the two types of molecular-sieves, can remarkably increase the medium oil selectivity of the hydrocracking reaction, and can reduce the reaction temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silica-alumina catalyst support with bimodal pore distribution, catalysts, methods of making and using same

ActiveUS7186757B2Dispersion of catalytic metal and product diffusion can be optimizedMolecular sieve catalystsOrganic compound preparationPore distributionSilicon dioxide

An effective catalyst includes an amorphous silica-alumina support having a bimodal pore size-distribution. The support may be prepared by a method that includes the physical mixing of two silica-alumina gels prepared so as to have two different average pore sizes. The catalyst has the advantage that both metal dispersion on the support and product diffusion in the pores are optimized. Further, the catalyst has improved performance in the production of hydrocarbons from synthesis gas.

Owner:CLARIANT INT LTD

Synthesis method of NaY molecular sieve

ActiveCN103449468AShorten crystallization timeHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteSynthesis methodsSodium aluminate

The invention relates to a synthesis method of an NaY molecular sieve. The method includes: mixing water glass, sodium metaaluminate and deionized water, conducting aging at 15-70DEG C for 0.5-48h to obtain a crystallization guiding agent; mixing the crystallization guiding agent, water glass, an acidic aluminum salt and a sodium aluminate solution uniformly to obtain a silica-alumina gel; crystallizing the silicon-aluminum gel at 80-140DEG C for 0.1- 80h; adding a peroxide into the crystallized silicon-aluminum gel, making molar ratio of the 02<2-> in the peroxide to the Al2O3 in the gel at 0.05-20, then further conducting crystallization for 5-20h, thus obtaining the NaY molecular sieve. Without adding any organic or inorganic template and being free of multiple after-treatment modification processes, the method can directly prepare the Y type molecular sieve with a high silicon-aluminum ratio. The obtained molecular sieve has crystallinity up to over 80%, a silicon-aluminum ratio of not less than 5.8, and an average grain size of 200-300.

Owner:PETROCHINA CO LTD +1

SCR-based NO oxidation catalyst and preparation method thereof

ActiveCN104190413AImprove stabilityIncrease oxidation rateCatalyst carriersMolecular sieve catalystsAdhesiveCordierite

The invention relates to a SCR-based NO oxidation catalyst and a preparation method thereof. The preparation method of the SCR-based NO oxidation catalyst comprises the following steps: firstly coating the surface of a catalyst carrier with coating slurry containing noble metal Pt by taking cordierite honeycomb ceramic as the catalyst carrier, drying and roasting; and subsequently fixing a certain amount of noble metal Pd solution at one end of the catalyst by using an impregnation method, wherein the amount of the impregnated noble metal Pd solution accounts for 1 / 3 of the total water absorption amount of the catalyst; the coating slurry is prepared by taking a molecular sieve as an HC adsorption material, taking SiO2 as a dispersing agent, taking zirconium acetate as a thermal stability additive, taking noble metal Pt as an active component and adding an alumina gel adhesive. The preparation method of the SCR-based NO oxidation catalyst is simple in processing steps; the noble metal Pt or Pd is impregnated in the air inlet direction of the prepared catalyst; by virtue of the improved catalyst, the oxidation rate of the NO at the low temperature can be improved, so that the and the temperature window is relatively wide when the NO is oxidized to between 40%-70% in the process of oxidizing NO into NO2; the catalyst is relatively high in stability.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Method for preparing ZSM-5 zeolite catalyst

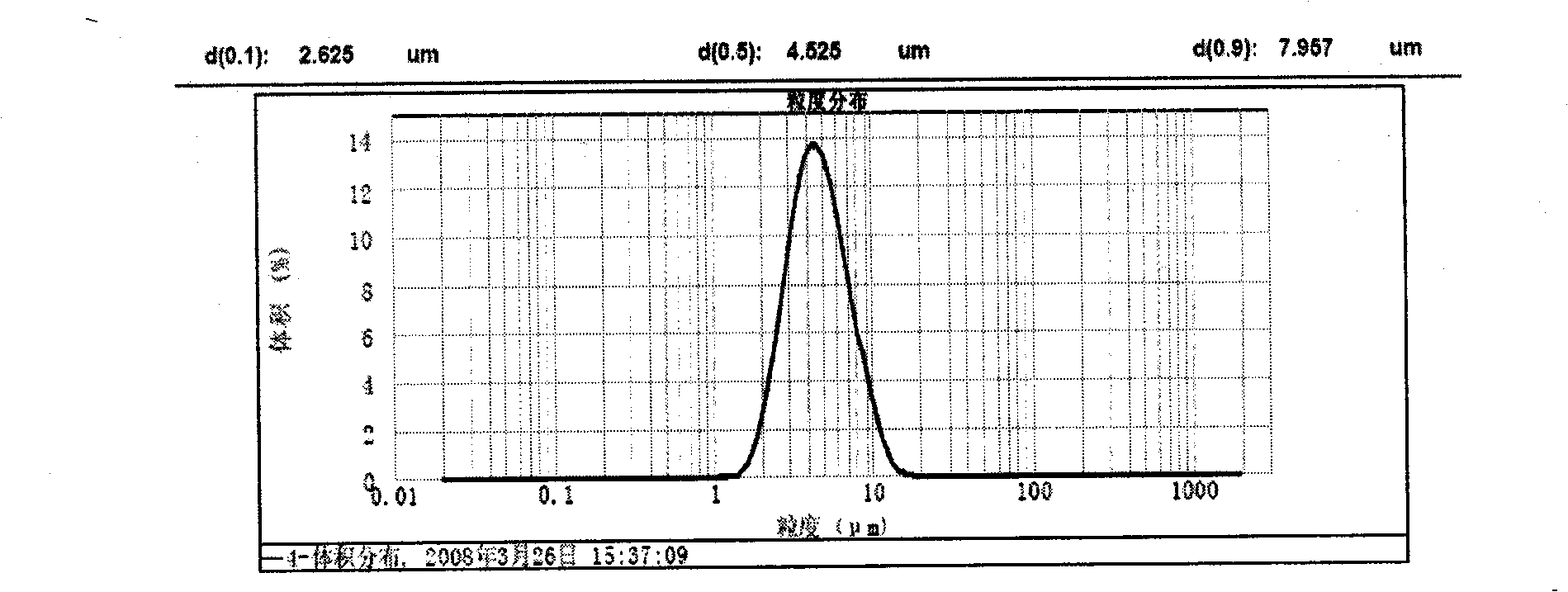

InactiveCN101538051ASolve the problem that the particle size is difficult to control in the preparationSolve the problem of difficult particle size controlMolecular sieve catalystsPreparation by hydroxy group additionCyclohexeneHigh pressure

The invention discloses a method for preparing a ZSM-5 zeolite catalyst. The method comprises the following steps: mixing mixed salt solution of a silicon source and a sodium source with aluminum salt solution according to a proportion to form silica-alumina gel, adding the silica-alumina gel and a template agent into a high-temperature high-pressure reaction kettle, and carrying out hydrothermal crystallization for the mixture under set conditions to form the ZSM-5 catalyst. The method is characterized in that during the hydrothermal crystallization, CO2 gas is introduced above the liquid level at proper time to further adjust and control the pH value of a system; during synthesis, the raw material mixing rate, crystallization temperature and crystallization time are controlled so as to effectively solve the problem of grain size control during the preparation of the ZSM-5 zeolite catalyst; and the mean grain size of the prepared zeolite catalyst is 3 to 7mu m, and the range of the grain size is 2.5 to 8mu m. The ZSM-5 zeolite catalyst prepared by the method can be used for the test of preparing cyclohexanol by cyclohexene hydration.

Owner:BEIJING UNIV OF CHEM TECH

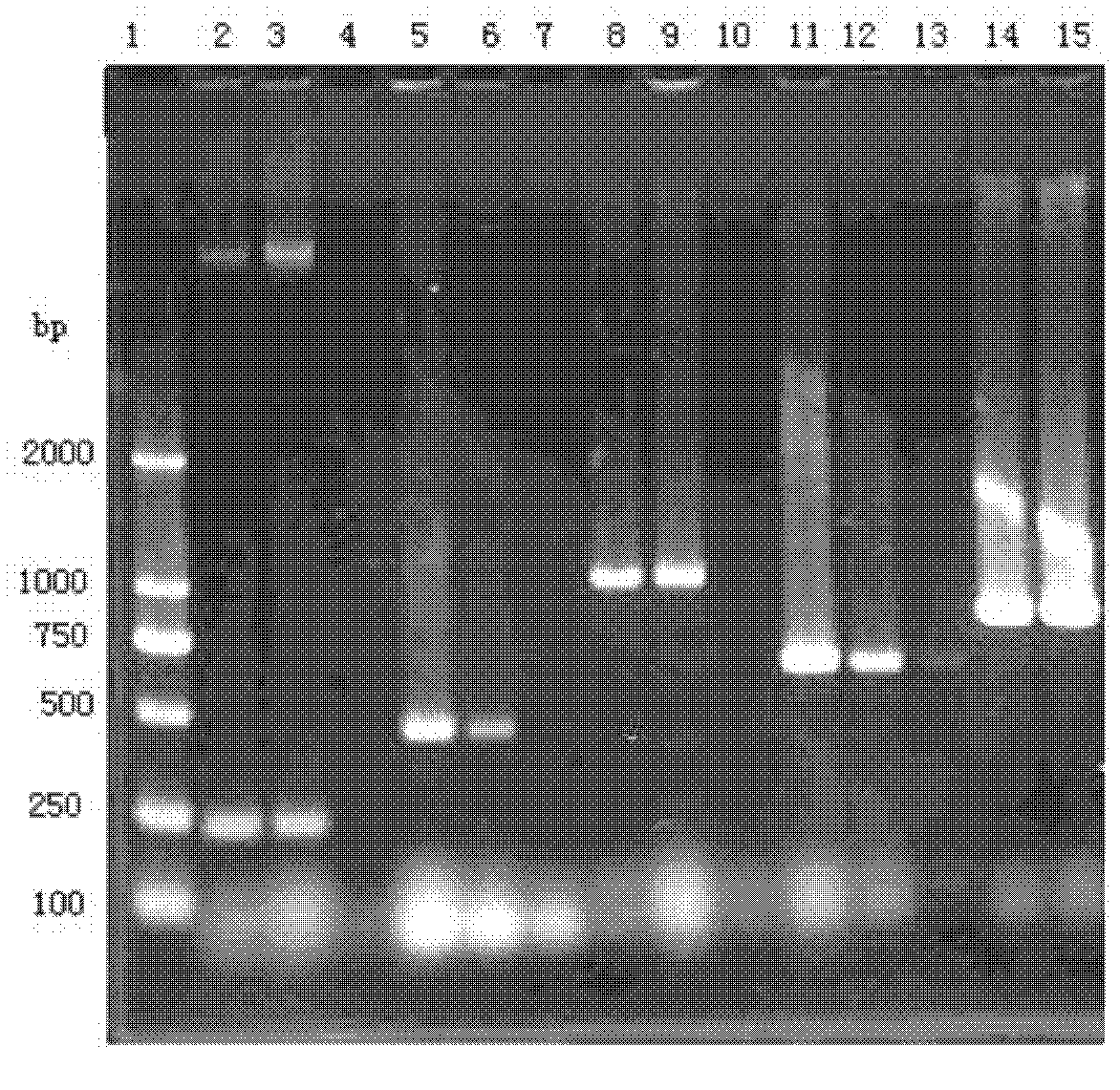

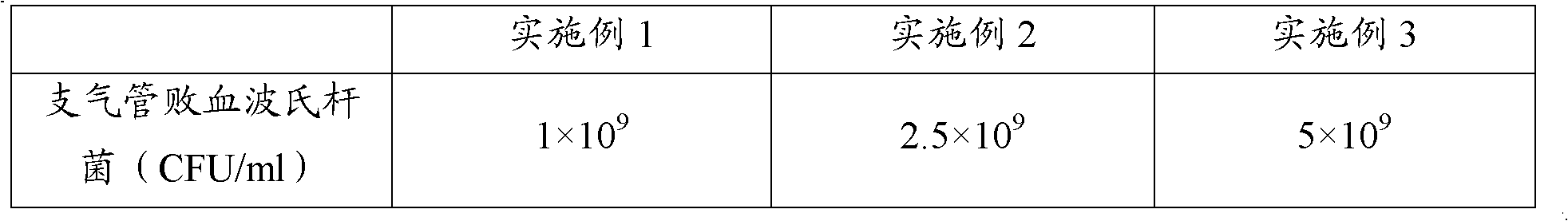

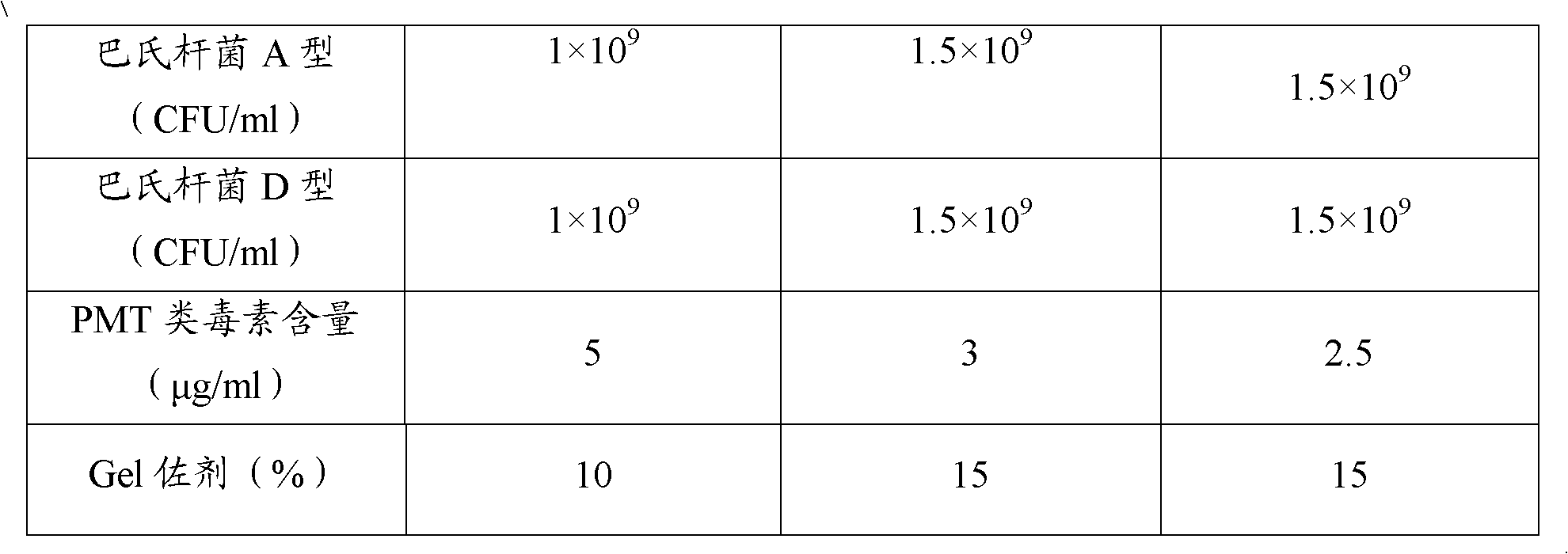

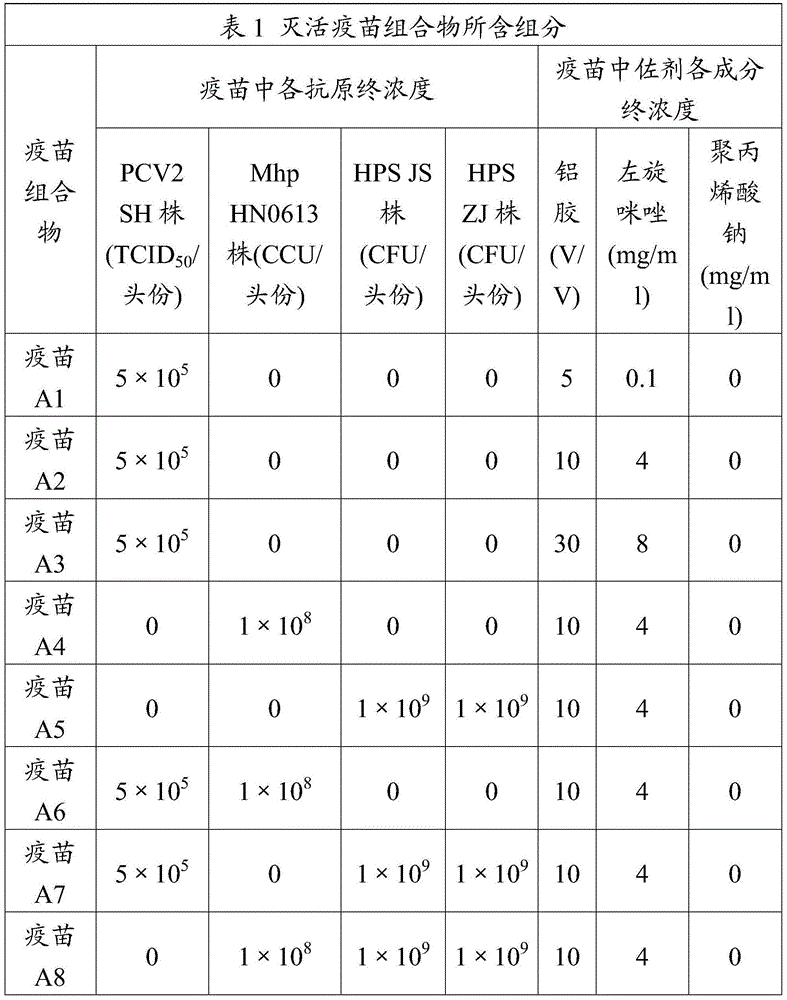

Polyvalent inactivity vaccine for preventing and treating atrophic rhinitis of swine

ActiveCN102302771AEffective therapeuticEffective preventionAntibacterial agentsBacterial antigen ingredientsPasteurella multocida toxinImmune effects

The invention provides a polyvalent inactivity vaccine for preventing and treating atrophic rhinitis of a swine and a preparation method thereof. The polyvalent inactivity vaccine contains inactivated Bordetella bronchiseptica, Pasteurella multocida A, Pasteurella multocida D and PMT (Pasteurella Multocida Toxin) anatoxin. The invention further provides a novel method for culturing and extractingPMT. Compared with the traditional atrophic rhinitis of the swine, the polyvalent inactivity vaccine for the atrophic rhinitis of the swine, provided by the invention, can be used for more generally and effectively treating and preventing the atrophic rhinitis of the swine by comprehensive antigen protection. Finally, in the polyvalent vaccine provided by the invention, the vaccine with a plurality of antigens in a reasonable proportion can be used for solving the problem that the plurality of the antigens interfere each other, thereby improving an immune effect. Furthermore, the inventor provides a water adjuvant by which defects such as incomplete absorption, large side reaction and the like after the traditional alumina gel adjuvant, Freund adjuvant and water-in-oil adjuvant are injected into the water adjuvant can be overcome.

Owner:PU LIKE BIO ENG

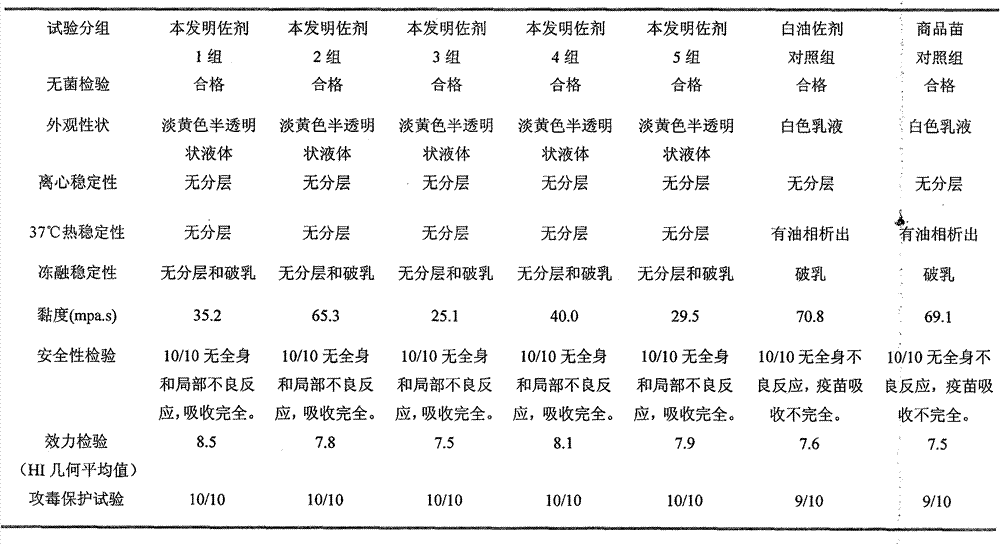

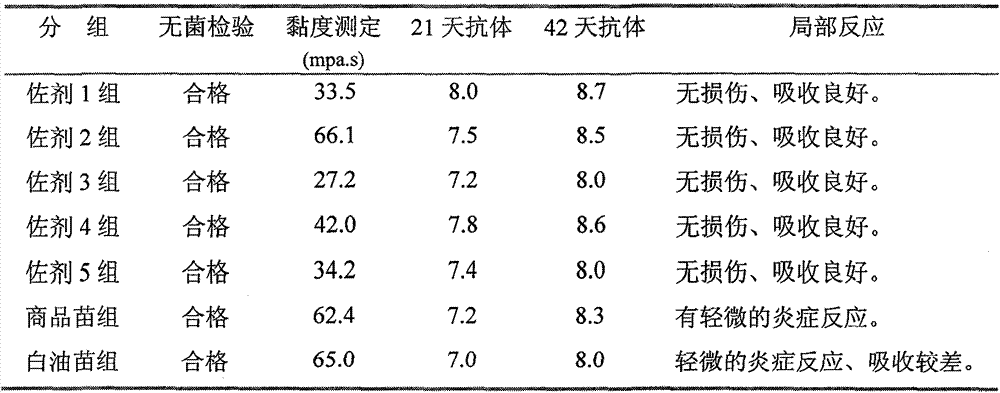

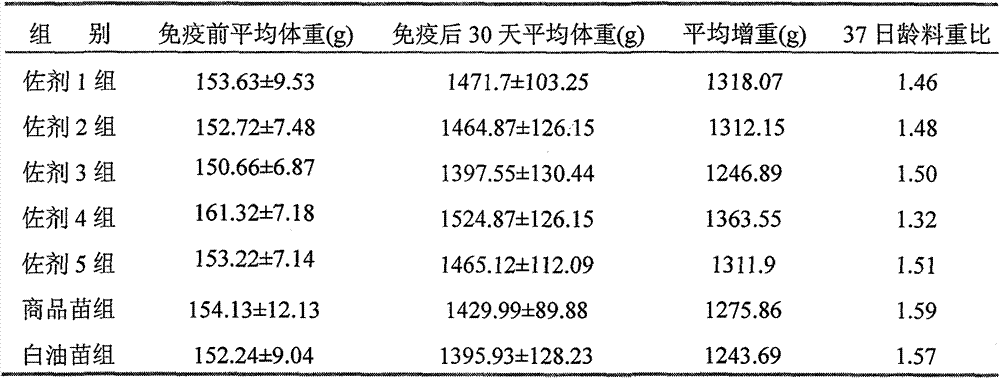

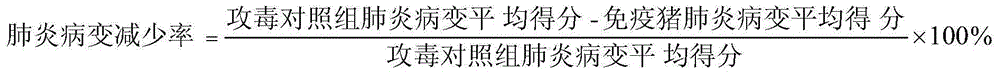

Preparation method and application of novel oil-free adjuvant

ActiveCN103083659AImprove product qualityReduce manufacturing costAntibacterial agentsAntiviralsImmune effectsAdjuvant

The invention relates to a preparation method of a novel oil-free adjuvant (adjuvant 605) compound and an application of the novel oil-free adjuvant in veterinary vaccines. The adjuvant prepared by using the method provided by the invention is capable of completely taking the place of mineral oil adjuvants and alumina gel adjuvants for inactivated vaccine production; the adjuvant can be completely absorbed by organisms within short time without residual; the adjuvant is low in side reaction, and capable of improving the safety of vaccines, and simultaneously simplifying the vaccine production process and reducing the vaccine production cost. The adjuvant prepared by using the method provided by the invention can be also taken as live vaccine diluting protection liquid, and has the characteristics of protecting the biological activity of the vaccine antigen, enhancing the immune effect of the vaccine, prolonging the persistent period of the vaccine antibody and the like.

Owner:BEIJING HUAXIA XINGYANG BIOLOGICAL SCI & TECH

Adjuvant used for vaccine and application thereof

ActiveCN106177939ALow costEasy to usePharmaceutical non-active ingredientsImmunological disordersAdjuvantProtein stabilization

The invention provides an adjuvant used for vaccine. The adjuvant comprises alumina gel, levamisole or its derivative, and also polyacrylate. The invention also discloses a vaccine composition containing the adjuvant and an application thereof. The adjuvant can be used as the adjuvant for inactivated vaccine, and also can be used for preparing protein stabilization liquid. The vaccine composition containing the adjuvant can generate humoral immunity for human body and can generate cellular immunity, and can generate good immune response under condition of low antigen content and single immune, and can stabilize protein, degradation and irreversible change cannot be generated.

Owner:PU LIKE BIO ENG

Synthesis method of lamellar ZSM-5 zeolite

ActiveCN106006668ALarge specific surface areaReduce pollutionPentasil aluminosilicate zeoliteSynthesis methodsCrystallinity

The invention provides a synthesis method of lamellar ZSM-5 zeolite. The synthesis method comprises the following steps: crystal seed pretreatment, silica-alumina gel preparation and the like. The synthesized zeolite is a typical MFI structure, has the advantages of high crystallinity and large specific area, has the lamellar shape with the lamellar thickness of 50nm or so, and has favorable application potential in the aspects of high-molecular reaction and the like by using the unique shape and physical property characteristics. Compared with the prior art, the synthesis method does not need any organic template or surfactant, has the advantages of simple synthesis technique operation, lower cost, no environment pollution and the like, and thus, can be popularized and applied in industry.

Owner:CHINA TIANCHEN ENG +1

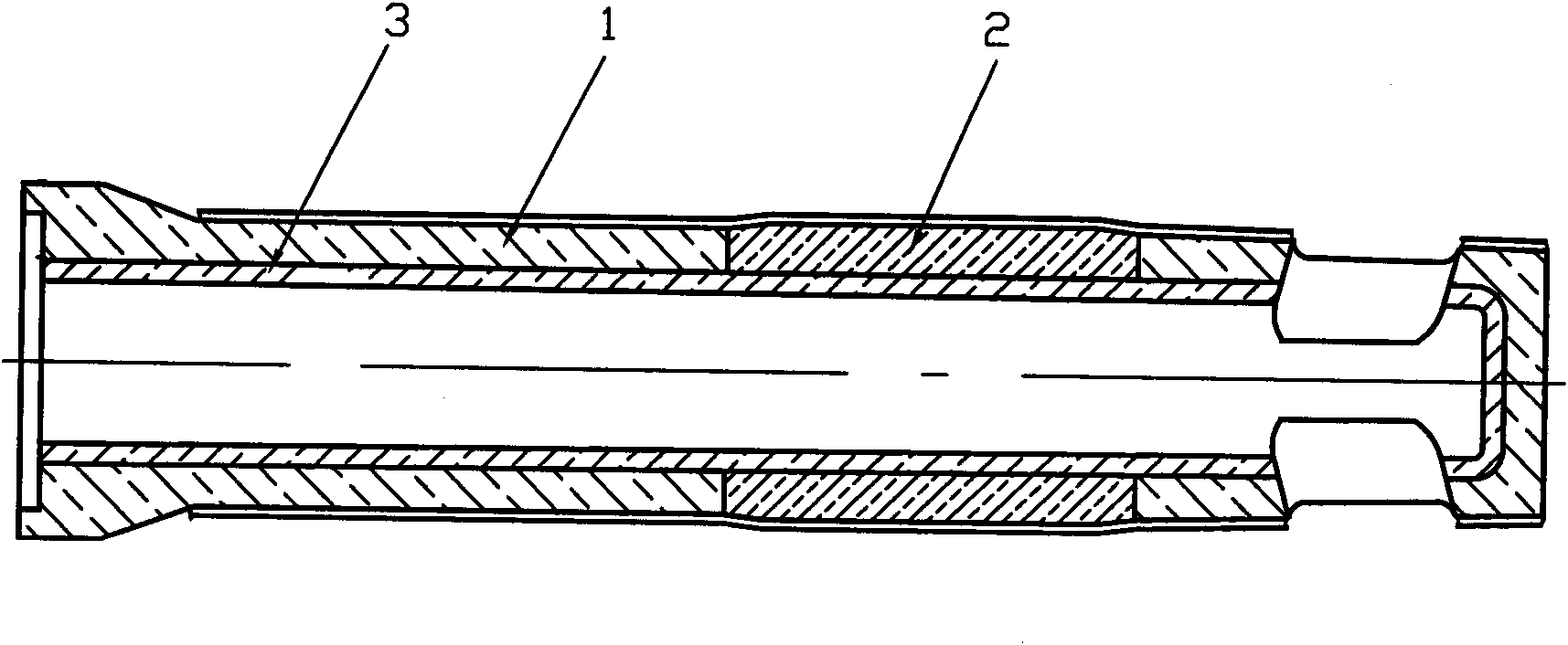

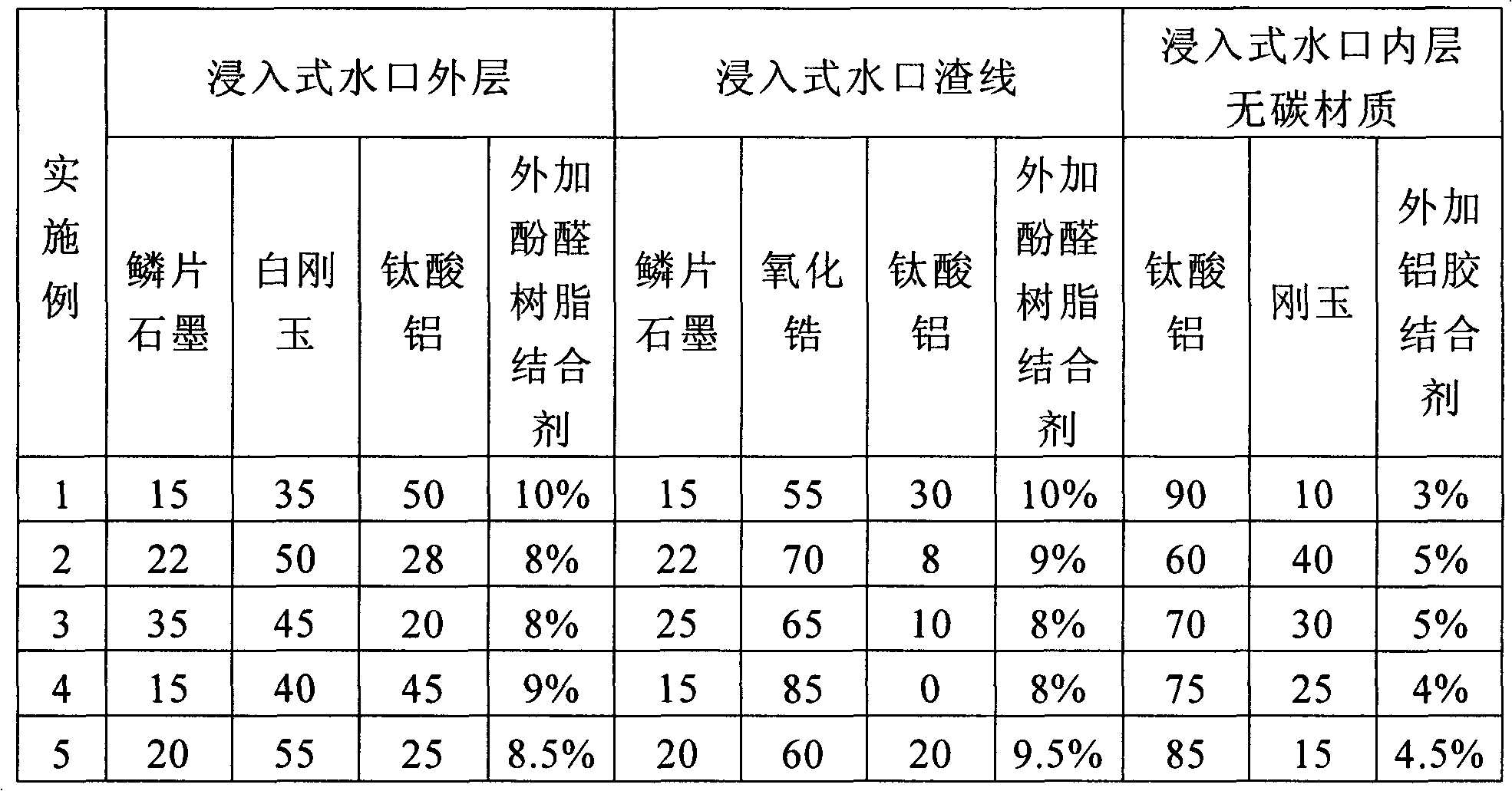

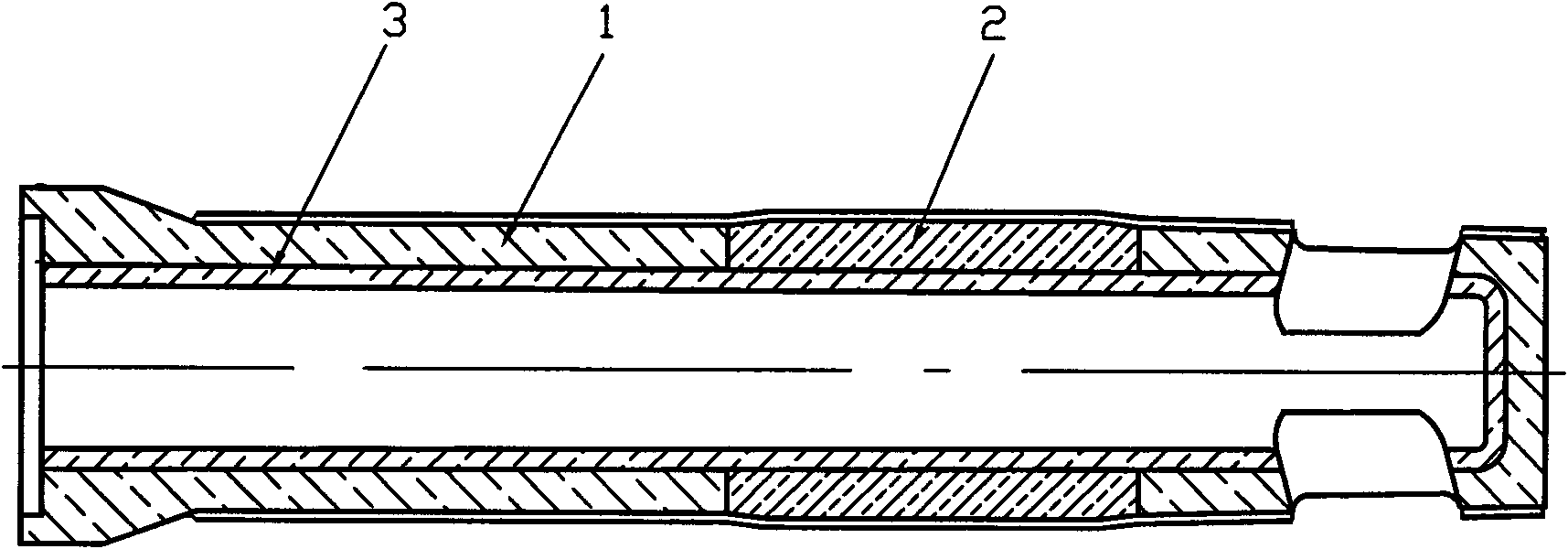

Composite submerged nozzle and manufacturing method thereof

The invention provides a composite submerged nozzle. The composite submerged nozzle comprises an outer layer body, an outer-layer slag line segment and an inner layer, wherein the outer layer body comprises the following components in percentage by weight: 15-35% of crystalline flake graphite, 35-55% of white corundum, 20-50% of aluminum titanate and 8-10% of an external phenolic resin binding agent; the outer-layer slag line segment comprises the following components in percentage by weight: 15-25% of crystalline flake graphite, 45-85% of zirconium oxide, 0-30% of aluminum titanate and 8-10%of an external phenolic resin binding agent; and the inner layer comprises the following components in percentage by weight: 60-90% of aluminum titanate, 10-40% of corundum and 3-5% of an external alumina gel binding agent.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com