Flexible gamma-Al2O3 fiber membrane and preparing method thereof

A fiber membrane and flexible technology, applied in the field of flexible γ-Al2O3 fiber membrane and its preparation, can solve the problems of poor flexibility, poor processability, brittle alumina fiber membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

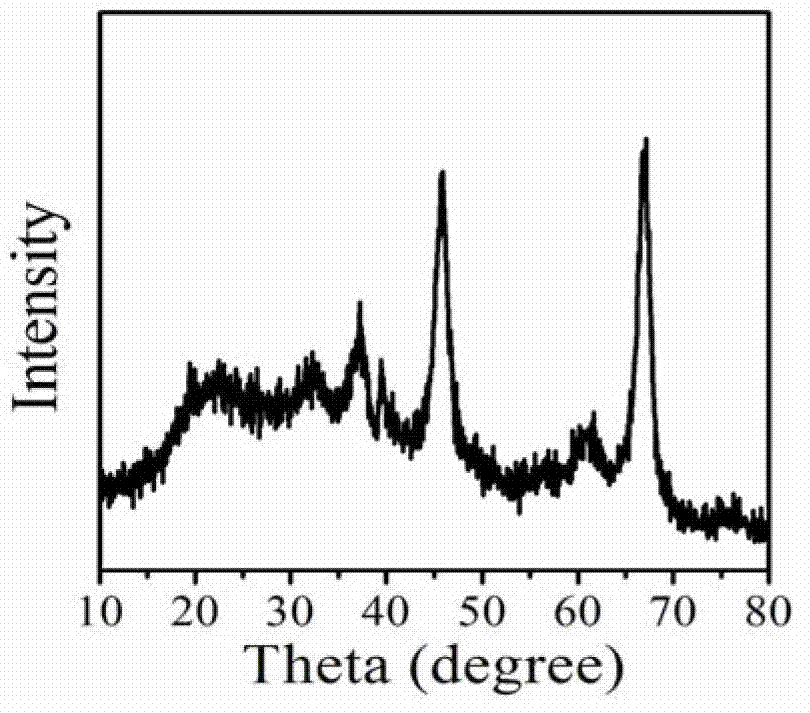

Embodiment 1

[0041] (1) Preparation of sol-spinning solution: Add 1.207g of aluminum chloride hexahydrate into 3.7mL of deionized water, stir until the aluminum chloride is completely dissolved, and slowly add 2.553g of aluminum isopropoxide and 5.0mL of absolute ethanol at the same time, After stirring for 10 minutes, 0.143 g of tartaric acid was added, and then 1.7 mL of concentrated hydrochloric acid was added to adjust the pH value to 2 to promote the hydrolysis of aluminum isopropoxide. Stir for 8 hours. After the aluminum isopropoxide is completely hydrolyzed, add 0.188 g of polyvinylpyrrolidone (PVP), and stir vigorously until the polyvinylpyrrolidone (PVP) is completely dissolved to obtain a spinnable sol spinning solution.

[0042] (2) Electrospinning: inject the sol-spinning solution prepared in step (1) into the electrospinning device, the spraying speed of the sol-spinning solution is 1.9mL / h, the voltage is 20kV, and the spinning receiving distance is 23cm , the spinning humid...

Embodiment 2

[0046] (1) Preparation of sol-spinning solution: as described in Example 1, the difference is that the amount of polyvinylpyrrolidone (PVP) added is 0.242 g.

[0047] (2) Electrospinning: Same as Example 1.

[0048] (3) Calcination of fibers: as described in Example 1, the difference is that the heat preservation time of 800°C is 120min to obtain γ-Al 2 o 3 Fiber membrane.

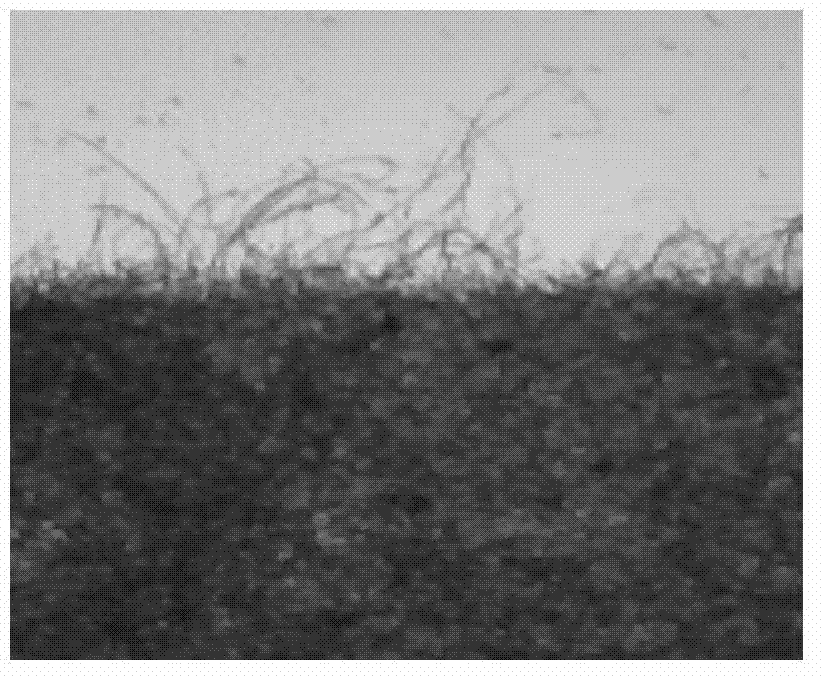

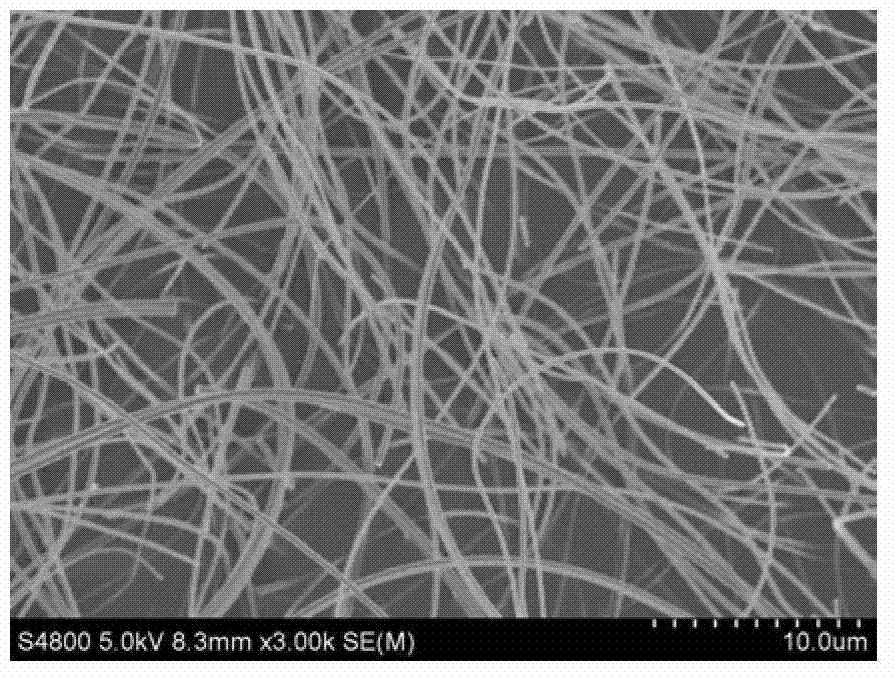

[0049] The resulting flexible γ-Al 2 o 3 The thickness of the fiber film is 10~100μm, the fiber diameter is 170~330nm, the γ-Al of the fiber 2 o 3 The particle size is 8-20nm, the surface of the fiber is smooth and dense, and the fiber membrane shows good flexibility.

Embodiment 3

[0051] (1) Preparation of sol spinning solution: add 0.966g aluminum chloride hexahydrate into 2.8mL deionized water, stir until the aluminum chloride is completely dissolved, and slowly add 0.817g aluminum isopropoxide and 5.0mL absolute ethanol at the same time, After stirring for 10 minutes, 0.143 g of tartaric acid was added, and then 0.5 mL of concentrated hydrochloric acid was added to adjust the pH value to 2 to promote the hydrolysis of aluminum isopropoxide. Stir for 6 hours. After the aluminum isopropoxide is completely hydrolyzed, add 0.168 g of polyvinylpyrrolidone (PVP), and stir vigorously until the polyvinylpyrrolidone (PVP) is completely dissolved to obtain a spinnable sol spinning solution.

[0052] (2) Electrospinning: Same as Example 1.

[0053] (3) Calcination of fibers: same as in Example 1.

[0054] The resulting flexible γ-Al 2 o 3 The thickness of the fiber film is 10~100μm, the fiber diameter is 70~220nm, the γ-Al of the fiber 2 o 3 The particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com