Patents

Literature

278 results about "CHLORIDE HEXAHYDRATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

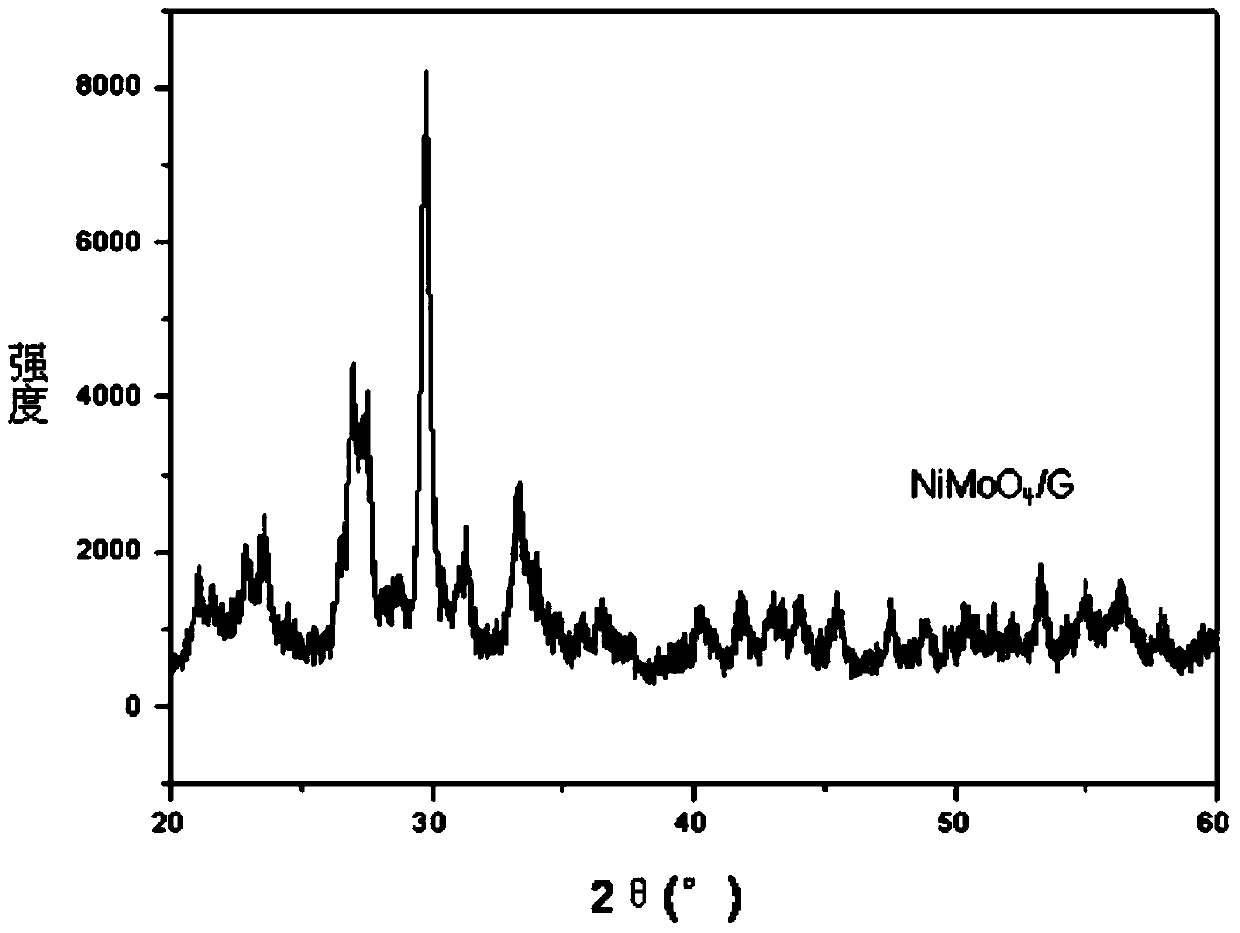

Method for preparing nickel molybdate and graphene nanocomposite

InactiveCN103779105AInhibition of agglomerationImprove poor cycle stabilityHybrid capacitor electrodesNanotechnologySodium molybdateGraphene nanocomposites

The invention relates to a method for preparing nickel molybdate and graphene nanocomposite. The method includes the first step of dispersing oxidized graphene into deionized water and then carrying out ultrasonic processing, the second step of adding Nickel(II) chloride hexahydrate and the deionized water into oxidized graphene solution subjected to ultrasonic processing and stirring the solution, the third step of adding sodium molybdate dehydrate into the oxidized graphene solution subjected to ultrasonic processing, continuing stirring the solution and then adding the solution into a reaction still to carry out reaction for eight hours to fifteen hours at the temperature ranging from 120 DEG C to 180 DEG C, and the fourth step of carrying out cooling to the normal temperature and carrying out centrifugal processing after reaction is completed, utilizing the deionized water and ethanol solvents to wash products obtained through centrifugal processing and then drying the products to obtain the nickel molybdate and graphene nanocomposite. The method has the advantages of being easy to operate, friendly to environment, low in cost and applicable to large-scale industrial production.

Owner:DONGHUA UNIV

Anhydrous aluminum chloride production method

InactiveCN104773746ASolve the problem that the purity is also very low and it is difficult to meet the industrial requirementsAluminium chloridesAluminium chlorideCalcium Chloride Hexahydrate

The invention relates to an anhydrous aluminum chloride production method. In the prior art, the aluminum chloride product produced by using the hydrochloric acid dissolution method has disadvantages of fine particle, large specific surface area and high impurity content, does not meet metallurgical grade alumina requirements, and is difficultly be subjected to direct use, and the prepared aluminum chloride purity is low and difficultly meets the industrial requirements even the aluminum chloride product is utilized. With the production method of the present invention, the problems in the prior art are solved. The production method comprises: immersing an aluminum production raw material into hydrochloric acid to obtain an aluminum chloride solution; directly carrying out concentration crystallization on the prepared aluminum chloride solution to obtain an aluminum chloride hexahydrate crystal; calcining the aluminum chloride hexahydrate crystal to obtain primary alumina; and mixing the primary alumina and carbon, adding to a chlorination furnace, introducing chlorine gas, heating, carrying out a reaction of the alumina and the chlorine gas to generate gaseous aluminum chloride, and carrying out refining impurity removing to obtain the pure anhydrous aluminum chloride. The production method of the present invention is used for industrial production of the anhydrous aluminum chloride.

Owner:GUIYANG AL-MG DESIGN & RES INST

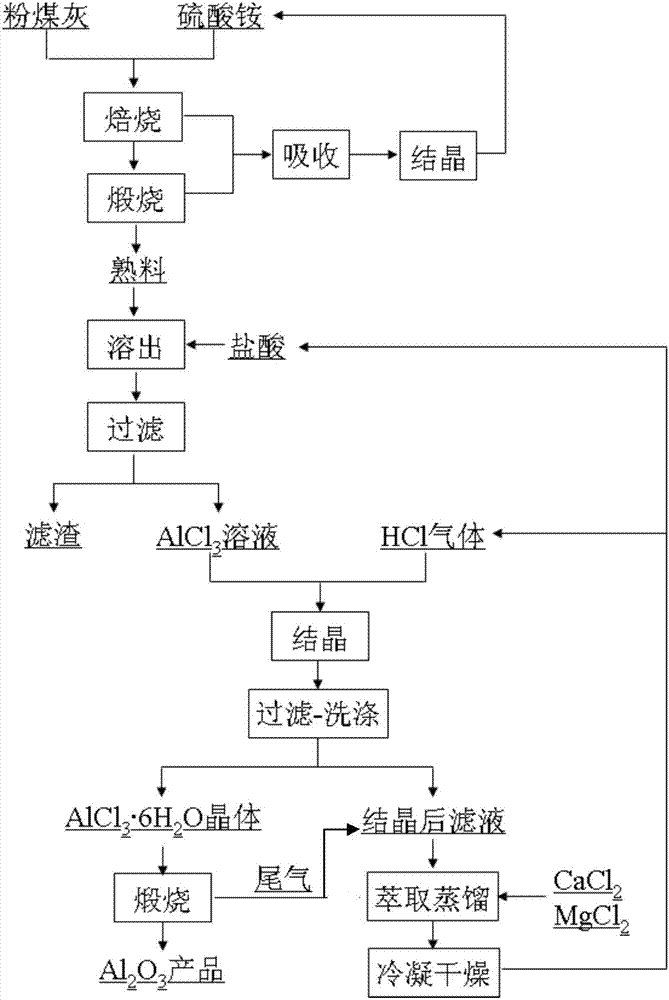

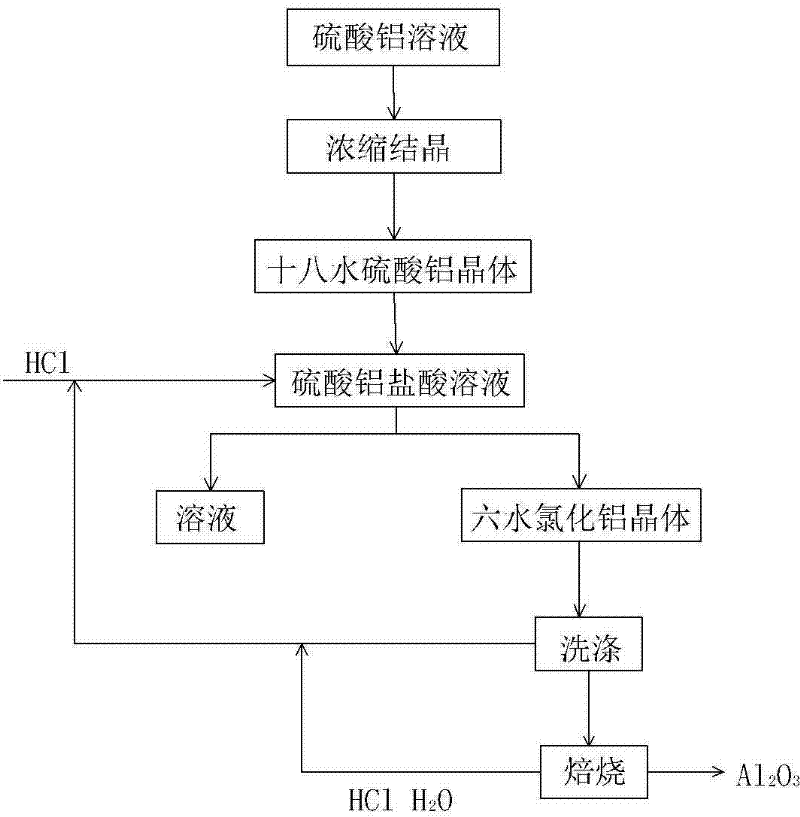

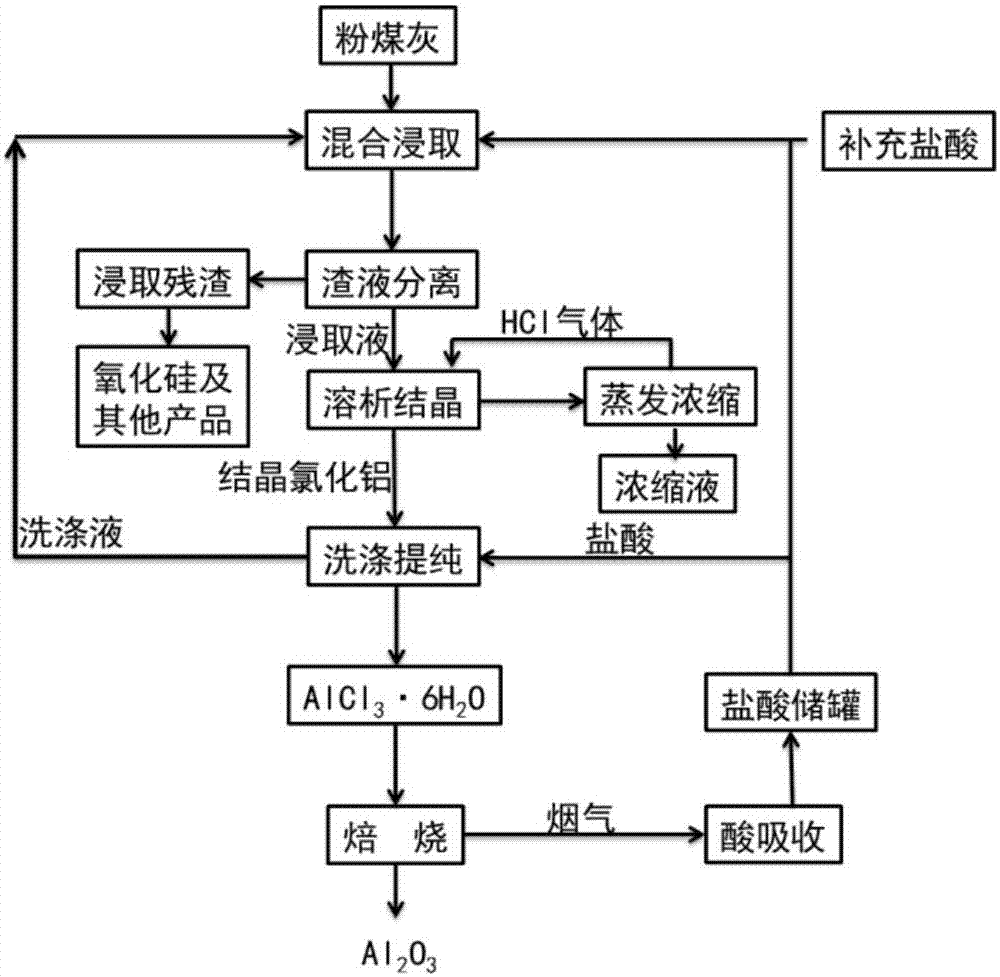

Process method for extracting aluminum oxide in coal ash of pulverized coal furnace by using acid method

InactiveCN106966415ARealize direct recyclingEasy roasting operationAluminium oxides/hydroxidesExtractive distillationBiological activation

The invention relates to a process method for extracting aluminum oxide in coal ash of a pulverized coal furnace by using an acid method. The process method comprises the following steps; adding ammonium sulfate into the coal ash of the pulverized coal furnace for activating, and performing the high-temperature calcination to obtain activated coal ash clinker, adding hydrochloric acid, heating and dissolving out, to obtain aluminum chloride digesting liquor; pumping hydrogen chloride gas into the digesting liquor for crystallizing, performing the solid-liquid separation and washing to obtain high-purity aluminum chloride hexahydrate crystal and waste acid solution, calcining the crystal to generate metallurgy-level aluminum oxide; adding inorganic salt chloride, such as calcium chloride or magnesium chloride, into the waste acid, heating, extractive-distilling and recycling the hydrochloric acid and the hydrogen chloride gas for the dissolving out and crystallization working procedures, performing the absorption-crystallization to tail gas generated in the roasting-calcining activation to generate ammonium sulfate, and realizing the cyclic utilization of materials, wherein the obtained solid residue with abundant silicon dioxide can be used for generating white carbon black or the materials for building. The process method is capable of realizing the reduced recycling of the coal ash of the pulverized coal furnace, and realizing the full cyclic utilization of the materials. The purity of the obtained aluminum oxide product is the first level, the quality of the metallurgy-level aluminum oxide is standard, and the extraction efficiency is up to 84.6%-90.4%.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Anhydrous antiperspirant composition

InactiveUS20060099163A1Cosmetic preparationsBiocideLocalized hyperhidrosisAluminium chloride hexahydrate

An anhydrous composition of dry aluminum chloride hexahydrate in Castor Oil CP or in Dehydrated Castor Oil particularly suitable for the treatment of localized hyperhidrosis.

Owner:HURLEY HARRY J +1

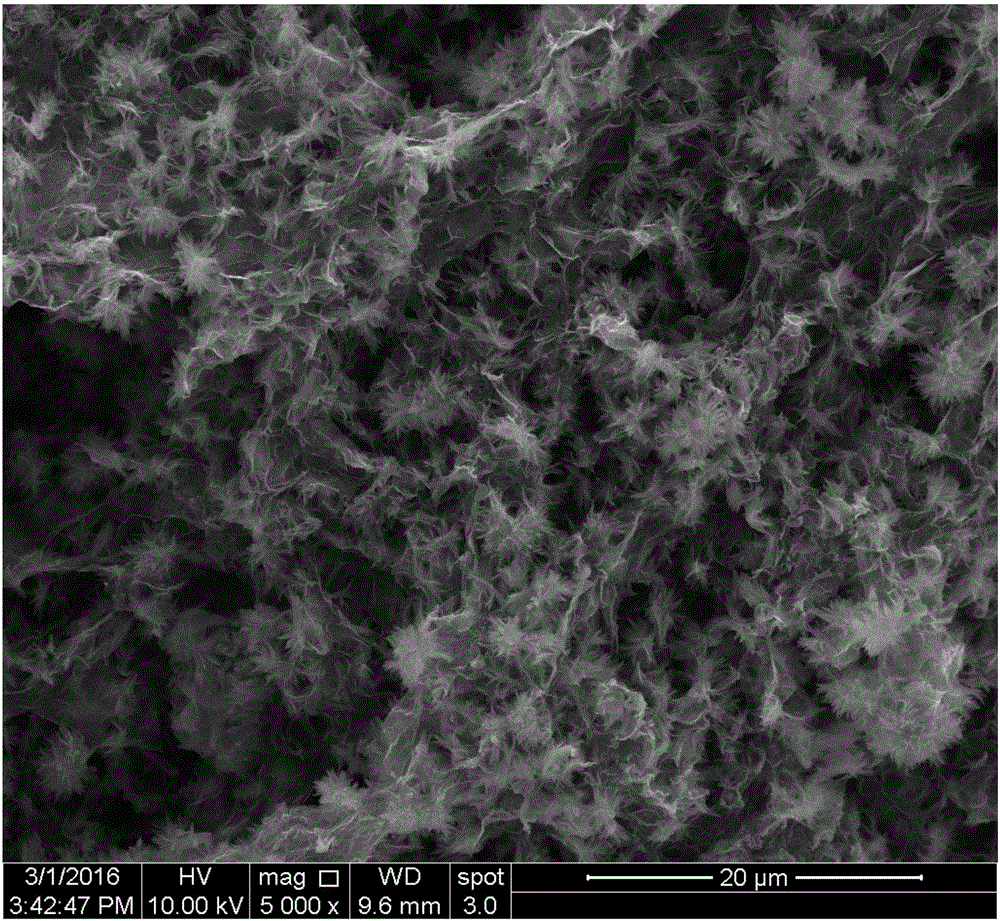

Method for preparing graphene oxide-alumina composite aerogel

ActiveCN105964193AGood dispersionRich pore structureAerogel preparationColloidal chemistry detailsAlumina compositeSolvent

The invention discloses a method for preparing a graphene oxide-alumina composite aerogel, wherein the method comprises the following steps: taking graphene oxide, adding the graphene oxide into a dispersing solvent, carrying out ultrasonic treatment for 1 h in an ultrasonic cleaning instrument, separating with a low speed centrifuge, filtering out a lower precipitate, and taking an upper solution; taking the solution, adjusting the pH of the solution with dilute ammonia water and dilute hydrochloric acid, then adding aluminum chloride hexahydrate, and carrying out a reaction; and after the reaction in the second step is finished, cooling to room temperature, carrying out magnetic stirring for 0.5 h, then transferring the mixed solution into a polytetrafluoroethylene hydrothermal kettle, keeping for 12 h at the temperature of 180 DEG C, after the reaction kettle is cooled to room temperature, taking out a cylindrical product, washing the cylindrical product with alcohol and water for two to three times respectively, and drying the product for 12 h in a freeze dryer, to obtain the graphene oxide-alumina aerogel composite material. The ultra-light composite material prepared by the method has rich pore passage structure, can give full play to the excellent electrical conductivity of graphene, and has wide application prospect.

Owner:SOUTHEAST UNIV

Method for preparing rare earth europium ternary complex

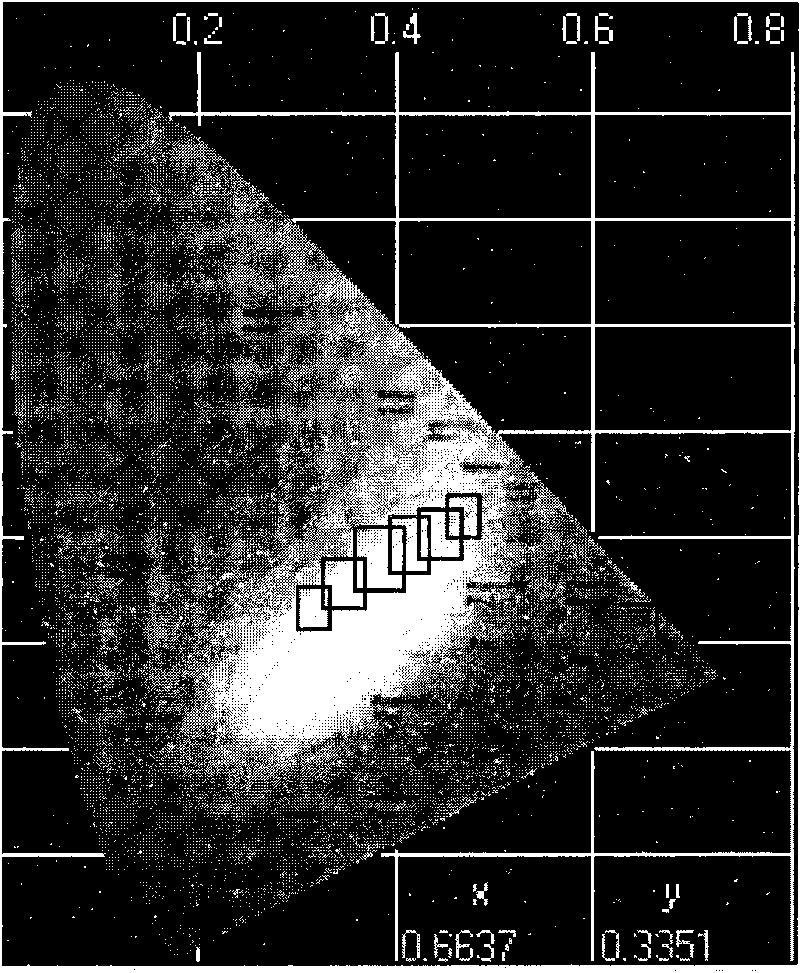

InactiveCN101704829AImprove luminosityHigh color purityGroup 3/13 element organic compoundsChemical reactionFiltration

The invention relates to a method for preparing a rare earth europium ternary complex, which comprises the following steps of: using europium chloride hexahydrate, benzoyl acetone and triphenylphosphine oxide as raw materials, using absolute ethyl alcohol as a solvent and a detergent, using deionized water as a solvent and a cleaning agent, and using sodium hydrate as an acidity-basicity pH value conditioning agent; preparing a solution added with the benzoyl acetone, the triphenylphosphine oxide and ethanol first, and then preparing an europium chloride hexahydrate ethanol solution and a sodium hydrate aqueous solution; dropping the europium chloride hexahydrate ethanol solution and the sodium hydrate aqueous solution into a four-hole boiling flask under a condition with heating, stirring and water circulation condensation to perform chemical reactions so as to prepare a ternary mixed solution; performing vacuum suction filtration, washing, recrystallization purification and vacuum drying on the ternary mixed solution to prepare white powder of the rare earth europium ternary complex, wherein the chromaticity coordinates are that X is equal to 0.6637 and Y is equal to 0.3351, and the rare earth europium ternary complex glows. The preparation method has the advantages of short process flow, fewer used devices, high yield up to 90 percent, good product purity up to 98 percent, good luminous performance and high luminous efficiency.

Owner:TAIYUAN UNIV OF TECH

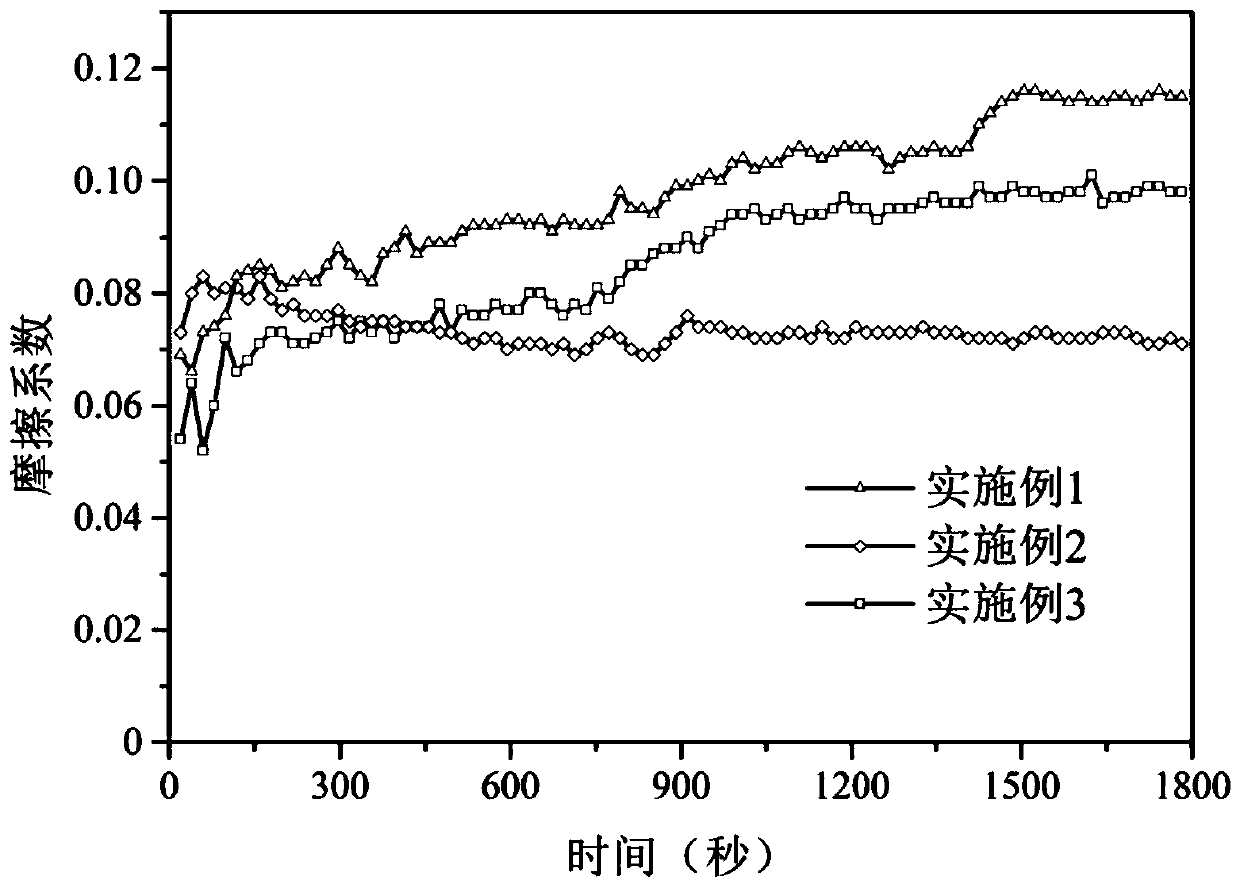

Method for preparing nano-MoS2-Al2O3 composite rolling lubricant by utilizing dopamine polymerization

ActiveCN111117746AMeet friendly requestEasy to save energyLubricant compositionSodium acetateSODIUM METAPHOSPHATE

A method for preparing a nano-MoS2-Al2O3 composite rolling lubricant by utilizing dopamine polymerization belongs to the technical field of lubrication. The method comprises the following steps: auto-polymerizing dopamine to form polydopamine, modifying the surface of a molybdenum disulfide nanosheet with the polydopamine to obtain a polydopamine-modified molybdenum disulfide nanosheet; then adding aluminum chloride hexahydrate, polyethylene glycol 200 and sodium acetate, centrifuging the obtained obtained solution, and washing and drying the obtained material to obtain nano-MoS2-Al2O3 composite powder; and finally, dispersing the prepared composite nano-powder into deionized water, and adding glycerol, triethanolamine, sodium hexametaphosphate, sodium dodecyl benzene sulfonate, water-based borate and a trace amount of a defoaming agent to obtain the required composite rolling lubricant. The composite lubricating oil is simple in preparation process, good in reproducibility, low in cost, high in efficiency and beneficial to batch production, can replace traditional rolling lubricating oil severely polluting the environment to a certain extent, is used for technological lubricationin the plate and strip steel hot rolling process, and promotes energy conservation, emission reduction and environment-friendly production in the plate and strip steel rolling process.

Owner:UNIV OF SCI & TECH BEIJING

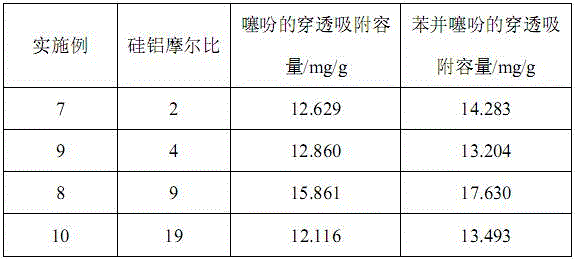

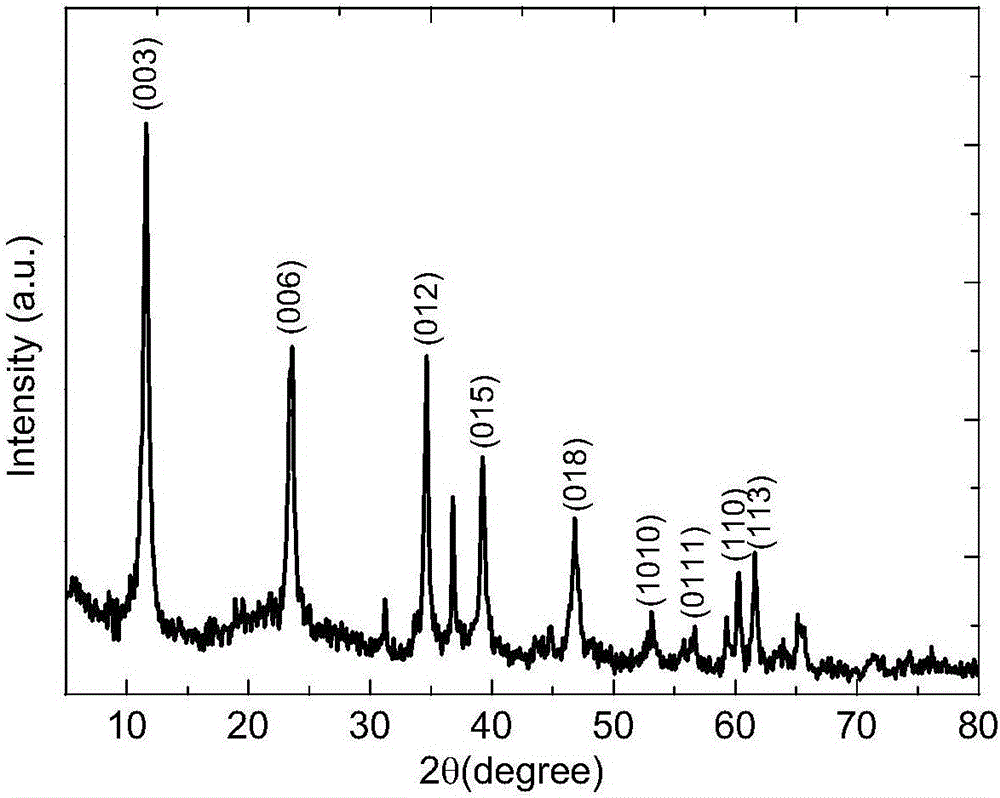

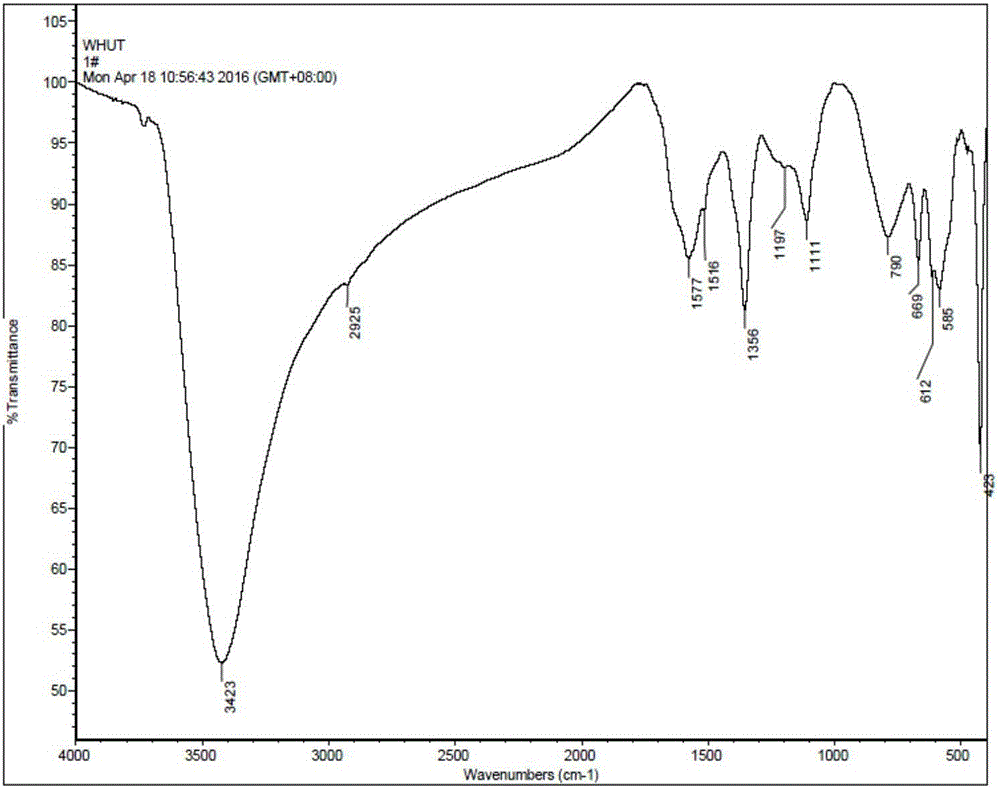

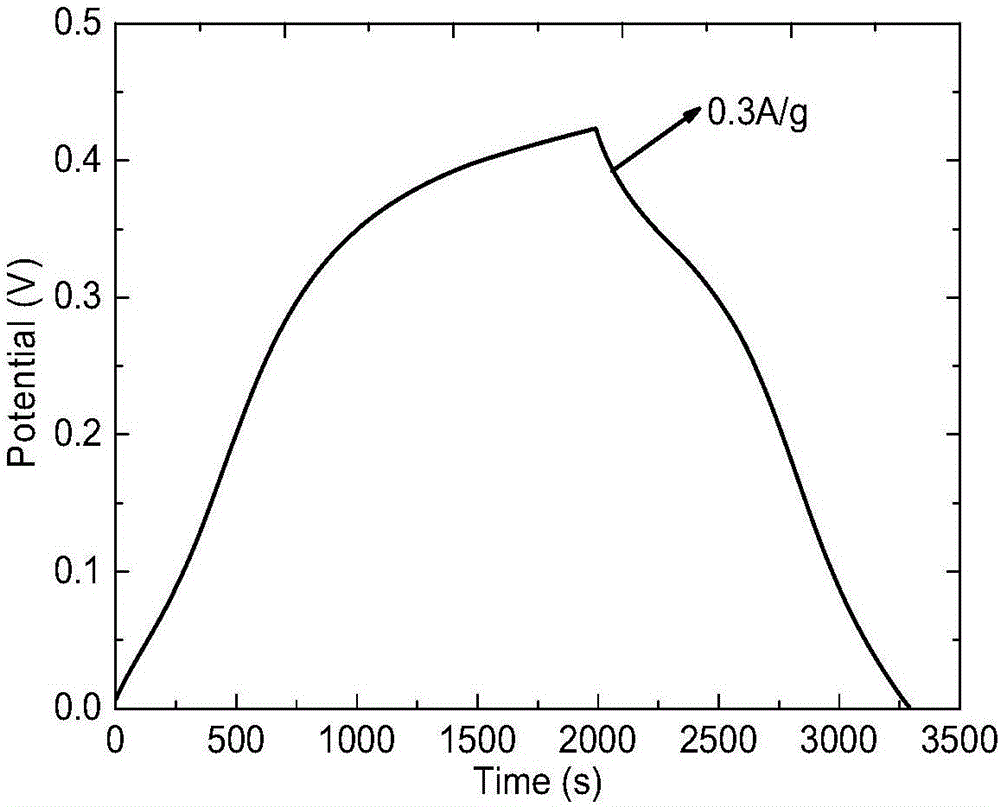

Method or removing thiophenic sulfur from fuel oil by taking Cu2O/SiO2-Al2O3 composite aerogel as adsorbent

ActiveCN106590728AHigh porosityLarge specific surface areaOther chemical processesHydrocarbon oils refiningSorbentFixed bed

The invention discloses a method for removing thiophenic sulfur from fuel oil by taking Cu2O / SiO2-Al2O3 composite aerogel as an adsorbent, and belongs to the technical field of fuel oil processing. The method comprises the following steps: preparing the Cu2O / SiO2-Al2O3 composite aerogel by adopting a sol-gel normal-pressure drying method and taking ethyl orthosilicate as a silicon source, aluminum chloride hexahydrate as an aluminum source and copper acetate as a copper source; and then filling the Cu2O / SiO2-Al2O3 composite aerogel into a fixed-bed adsorption device, and injecting model gasoline at a certain temperature and flow. The model gasoline after adsorption is collected at a lower end outlet of a reaction device to perform gas chromatographic analysis, and the result shows that the Cu2O / SiO2-Al2O3 composite aerogel has good adsorptive property for thiophene and benzothiophene. The Cu2O / SiO2-Al2O3 composite aerogel adsorbent used in the method provided by the invention has a simple preparation method, is low in cost, can be used repeatedly for multiple times, and is high in economic benefit, mild in adsorption condition, and low in requirement on adsorption equipment.

Owner:ZHEJIANG UNIV OF TECH

Cobalt aluminum hydrotalcite/fluorinated graphene composite material, and preparation method thereof

ActiveCN106206056AImprove electrochemical performanceImprove stabilityHybrid capacitor electrodesCobalt compoundsHigh pressureCrusher

This invention relates to a cobalt aluminum hydrotalcite / fluorinated graphene composite material, and a preparation method thereof. The composite material is prepared by the steps of: 1) preparing graphite oxide powder by a Hummers method; 2) dispersing the graphite oxide powder in deionized water; stripping by an ultrasonic cell crusher; centrifuging by a centrifuge; obtaining supernatant liquor; adding hydrofluoric acid solution in the supernatant liquor to stir and react; putting the solution into a high-pressure reactor to perform constant-temperature fluoridation; cooling to room temperature; filtering and washing till the solution is neutral, so as to obtain the fluorinated graphene; 3) dispersing the fluorinated graphene in ethanol solution; stripping by the ultrasonic cell crusher to obtain fluorinated graphene suspension; 4) adding cobalt sulfate heptahydrate, aluminum chloride hexahydrate and urea into the fluorinated graphene suspension to stir and react; putting the solution into the high-pressure reactor to perform hydrothermal reaction; then cooling to the room temperature; and obtaining the cobalt aluminum hydrotalcite / fluorinated graphene composite material after post-processing.

Owner:WUHAN UNIV OF TECH

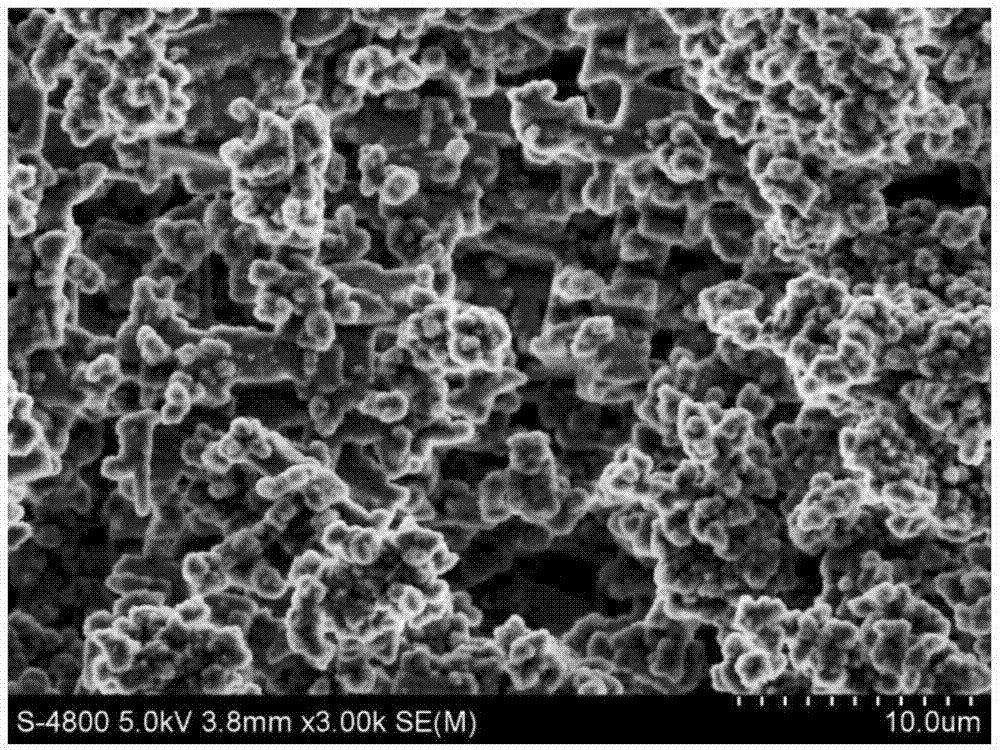

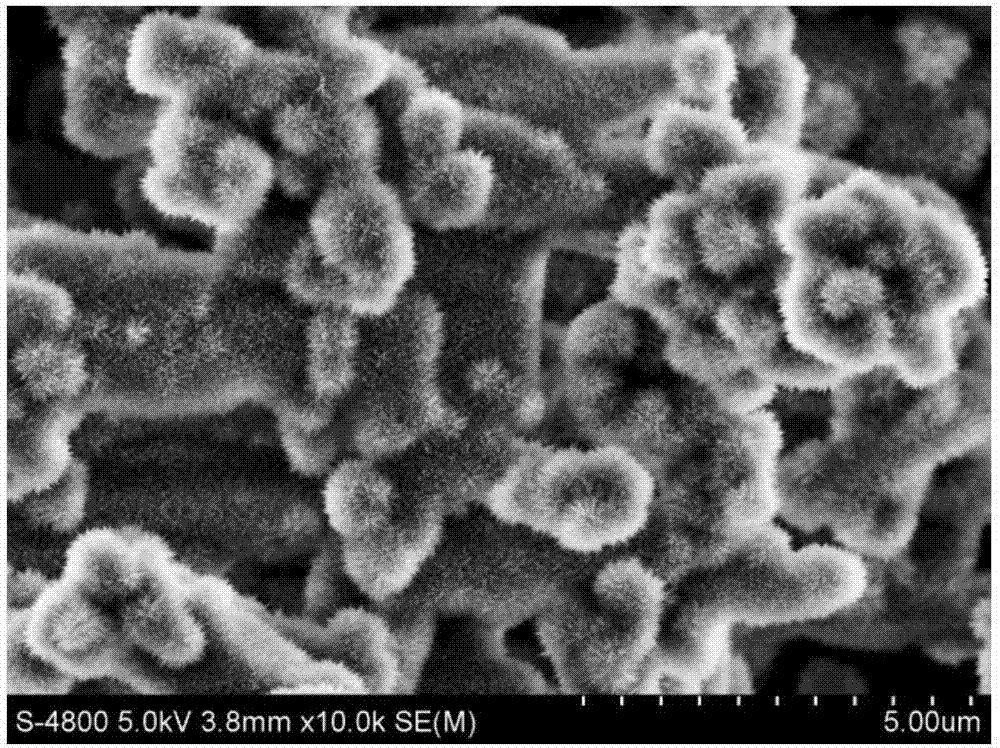

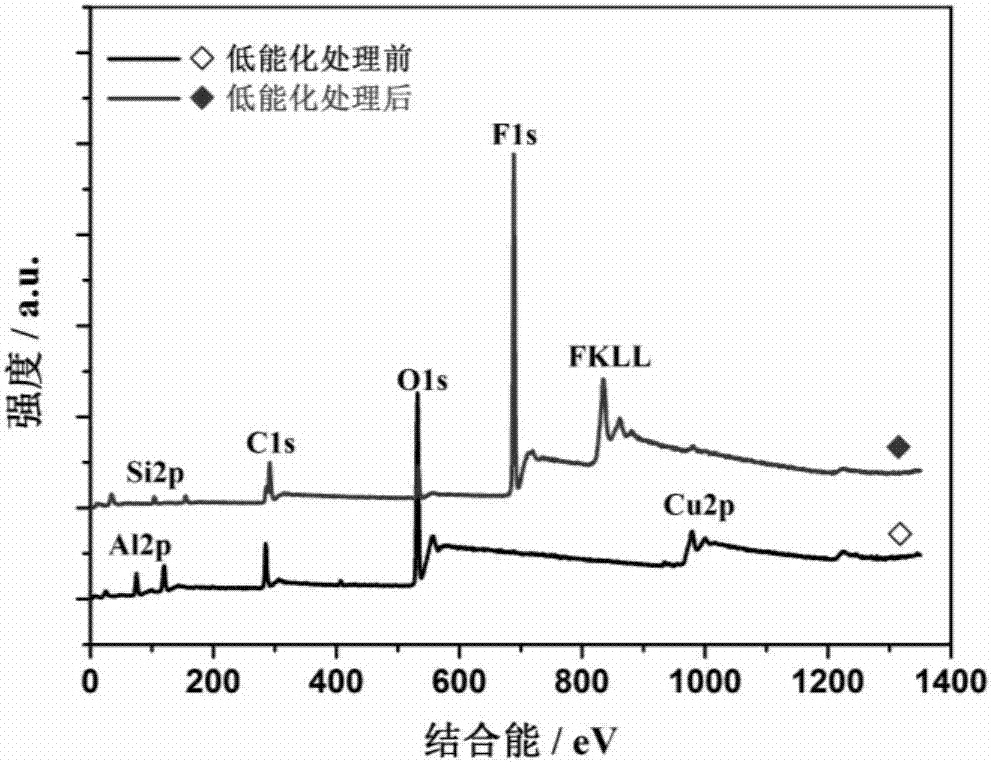

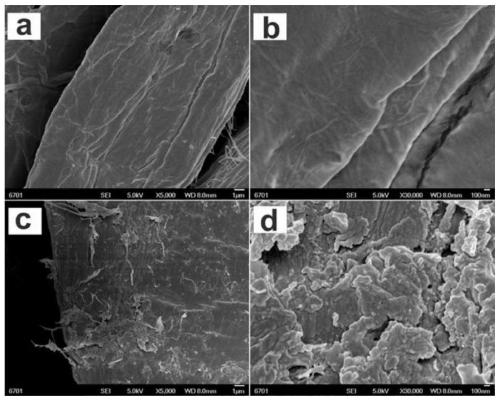

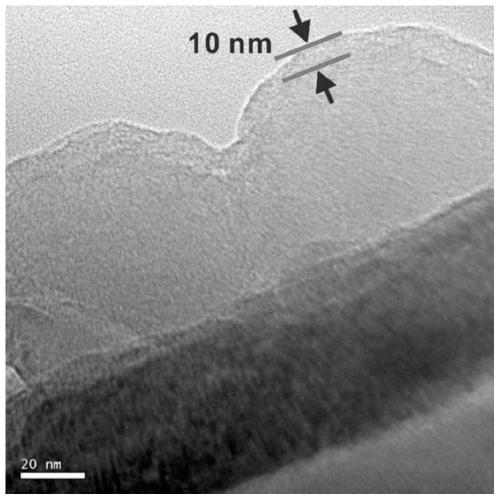

In-situ construction method and application of super-hydrophobic surface adopting micro/nano hierarchical structure

ActiveCN107321583ASuper Hydrophobic PropertiesHigh roughness factorPretreated surfacesCoatingsAluminium chlorideElectrolytic agent

The invention discloses an in-situ construction method and an application of a super-hydrophobic surface adopting a micro / nano hierarchical structure. Pure aluminum or an aluminum alloy is used as a matrix material, a micron-sized rough structure is firstly constructed on the metal matrix with a NaCl solution used as an electrolyte with an electrochemical etching method, then a nano-sized structure adopting a needle-ball-shaped structure is continuously etched on the surface of the existing micron-sized structure with an aluminum chloride hexahydrate and triethanolamine solution having certain concentration used as an etching solution with a hydrothermal method, then low-energy treatment is performed with heptadeca-fluoro silane, and the super-hydrophobic surface adopting the micro / nano hierarchical structure is obtained finally and has the surface contact angles larger than 155 degrees and the rolling angle smaller than 5 degrees. According to the method, the prepared super-hydrophobic surface adopting the micro / nano hierarchical structure has the great practical significance in promotion of morphology construction and industrial application of the super-hydrophobic surface, particularly in the anti-icing application field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Production process for preparing aluminium fluoride by using ammonium bicarbonate

InactiveCN101654273AReduce utilizationEfficient use ofAluminium fluoridesAluminium chlorideO-Phosphoric Acid

The invention relates to a production process for preparing aluminium fluoride by using ammonium bicarbonate, which solves the problem that the prior wet-method aluminium fluoride production process adopts more expensive aluminium hydroxide as a raw material, reduces production cost and is easy to carry out industrial production. The process is characterized in that fluosilicic acid reacts with ammonium bicarbonate to generate ammonium fluoride solution and silicon dioxide deposition; then, the filtered and separated ammonium fluoride solution reacts with aluminum chloride hexahydrate to prepare soluble Beta-AlF3.3H2O and ammonium chloride solution; soluble Alpha-AlF3.3H2O is converted into insoluble Beta-AlF3.3H2O through crystallization; and the finished product of aluminium fluoride isobtained through separation, washing, drying and calcination. The process is the most economical process for producing aluminium fluoride from a by product fluosilicic acid of enterprises for producing phosphoric acid and calcium superphosphate by a wet-method.

Owner:HUBEI YUANDA FUCHI PHARMA CHEM

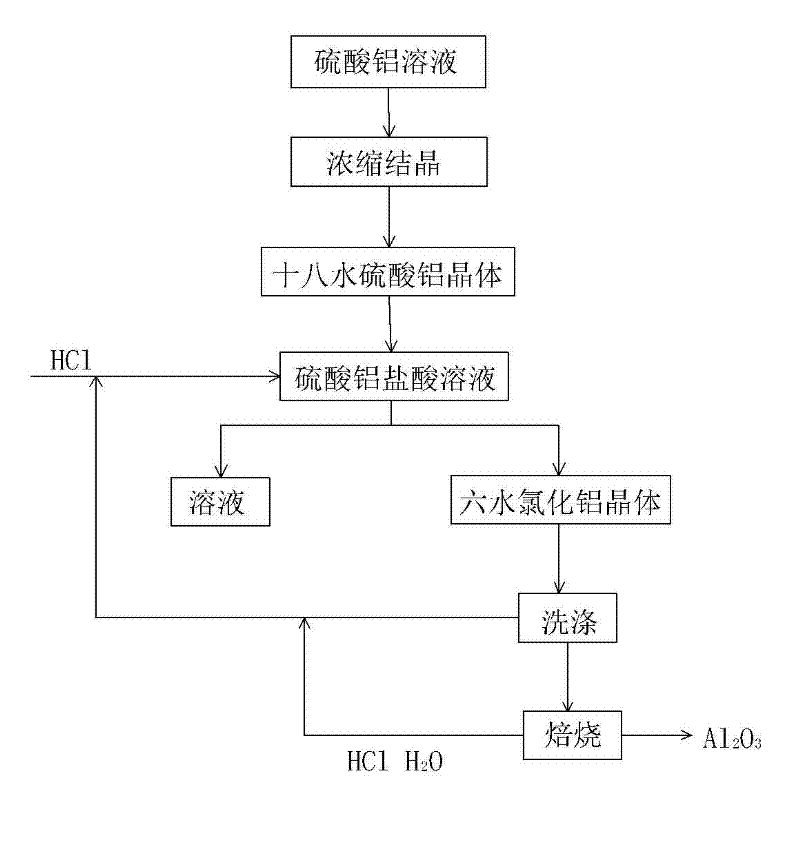

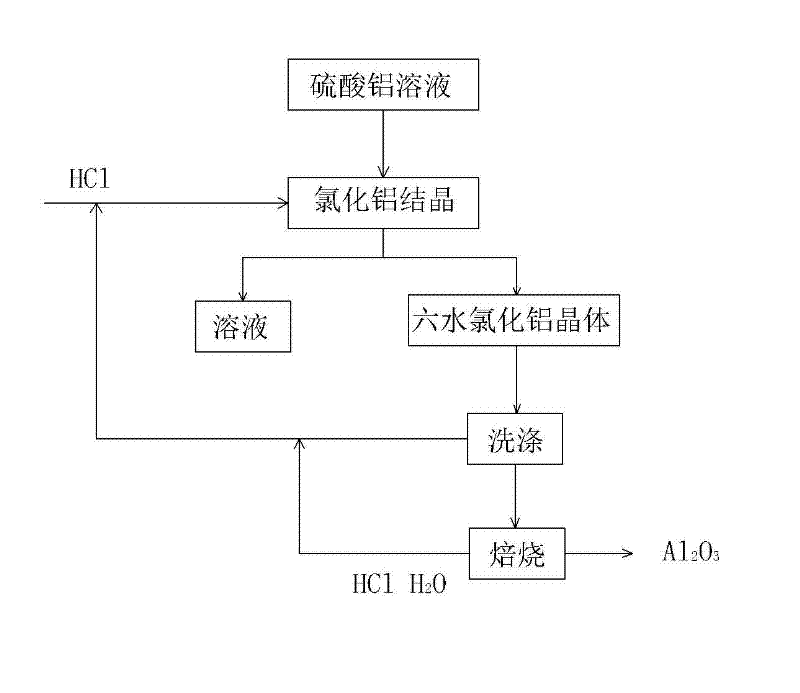

Method for subsequent treatment of aluminum sulfate generated in technical process of extracting alumina from fly ash

InactiveCN102557091AOvercome the problems of difficulty in realizing continuous production and high investment costsOvercome the problem of high investment costAluminium oxides/hydroxidesAluminium chlorideAluminum sulphate

The invention relates to a method for the subsequent treatment of aluminum sulfate generated in the technical process of extracting alumina from fly ash. According to a process for extracting the alumina from the fly ash, when hydrochloric acid is used for dissolving out, the corrosion of equipment is serious, and the continuous production is difficult to realize; and when sulfuric acid is used for dissolving out, the content of crystal water in prepared aluminum salt crystals is high, and the thermal loss of roasting decomposition is relatively high. The method comprises the following steps of: adding a subsequent aluminum chloride lotion or a solution of hydrochloric acid into a solution of aluminum sulfate generated in the technical process or aluminum sulfate crystals obtained after crystallization, diluting, introducing HCl gas into the mixed solution at the temperature of between 30 and 85 DEG C to ensure that the solution is saturated, and precipitating aluminum chloride hexahydrate crystals; and roasting to obtain the alumina. By the method, the problems about equipment corrosion caused by using the hydrochloric acid for dissolving out in the process for extracting the alumina from the fly ash, and overhigh energy consumption caused by roasting aluminum sulfate salt crystals after the sulfuric acid is used for dissolving out are solved; and the HCl gas which is brought into the production process can be obtained from smoke produced by roasting aluminum chloride hexahydrate, and can be recycled without any conversion, so that the cost is effectively reduced.

Owner:西安航天科技工业有限公司

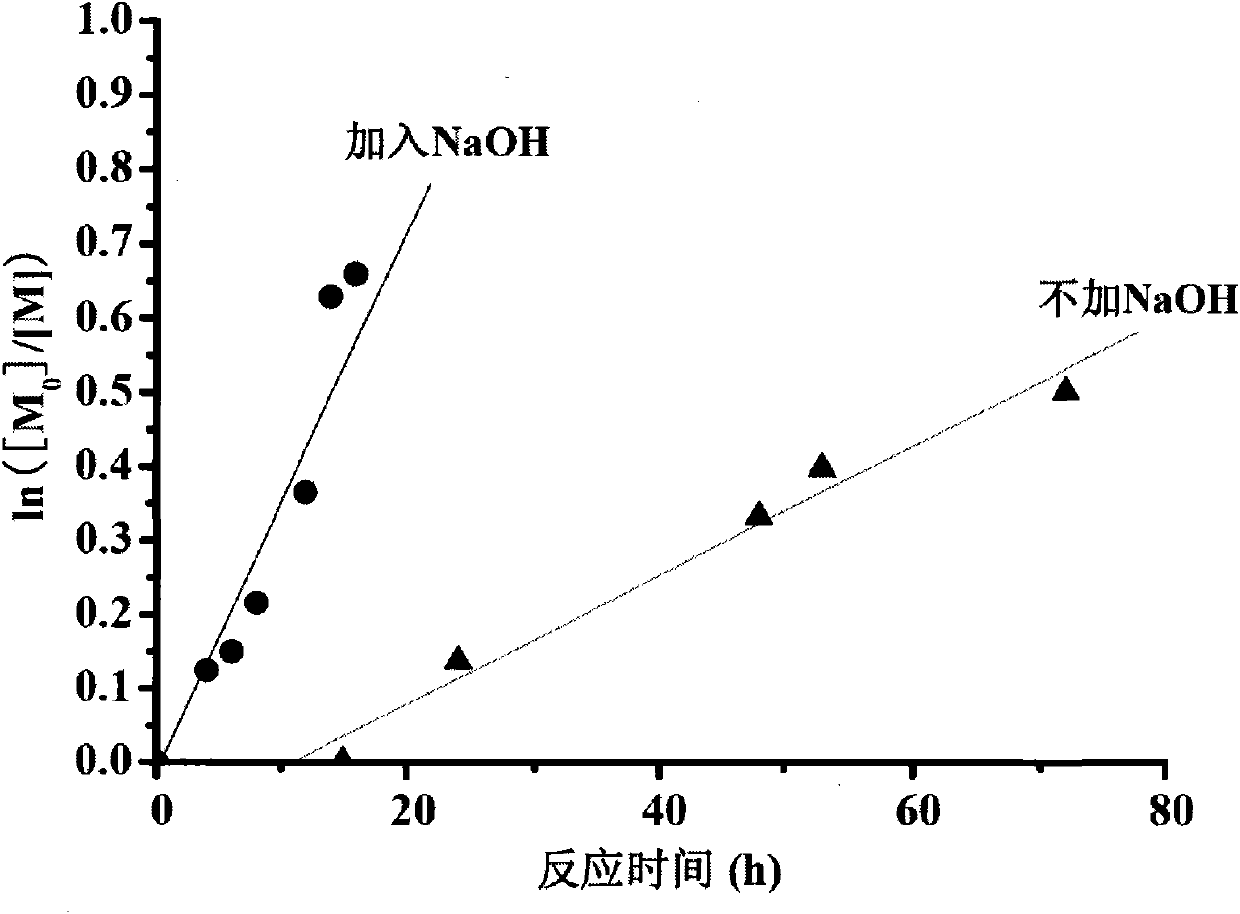

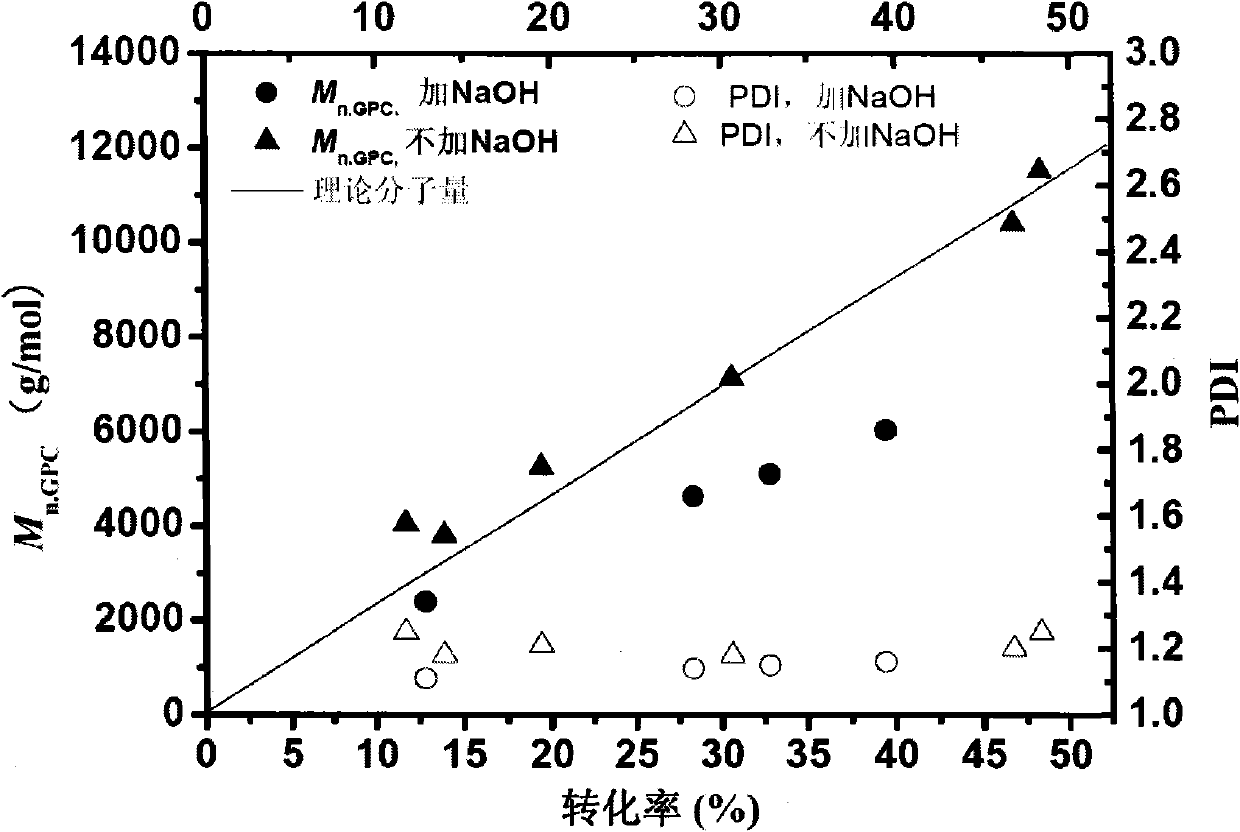

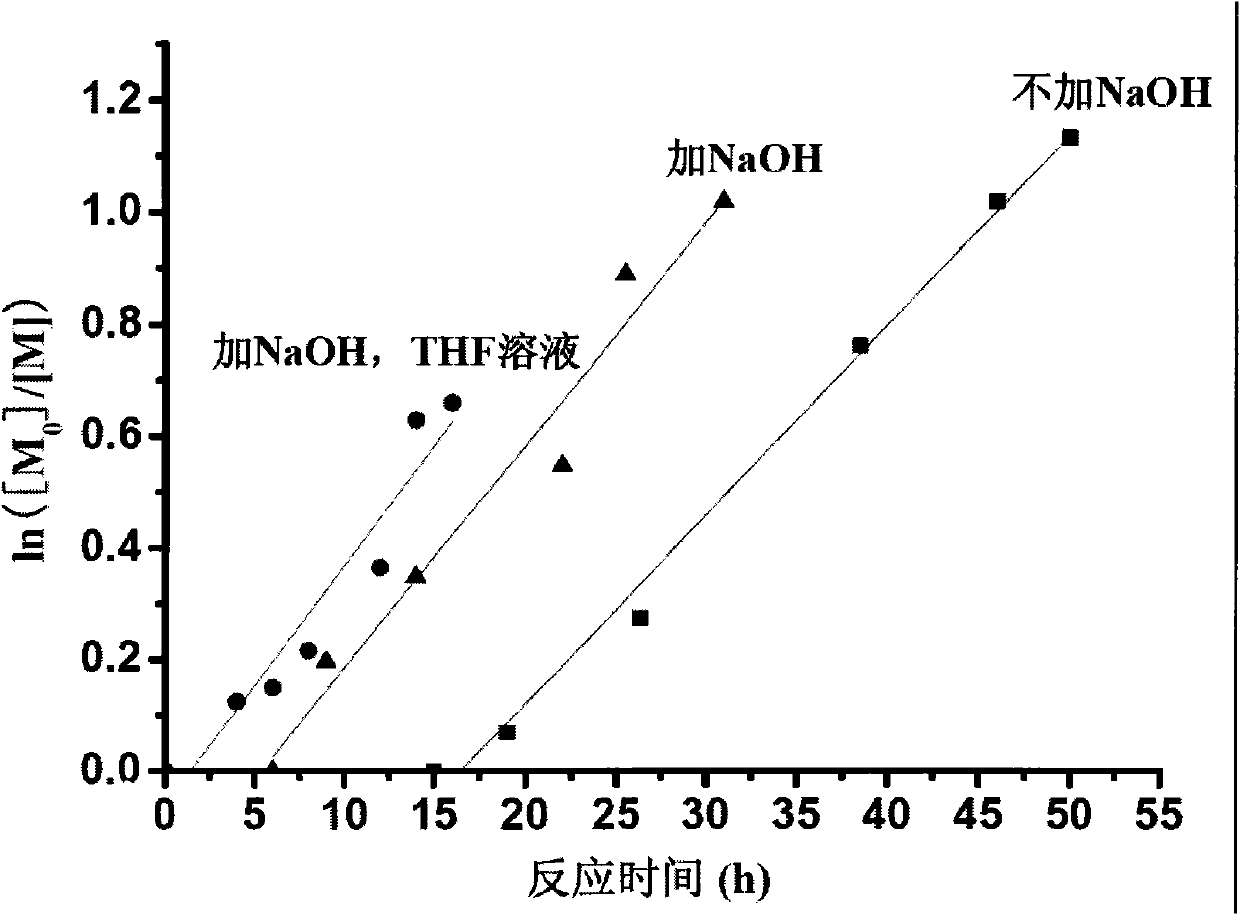

Polymerization system for atom transfer radical polymerization (ATRP) using activators generated by electron transfer (AGET)

The invention discloses a polymerization system for atom transfer radical polymerization (ATRP) using activators generated by electron transfer (AGET), comprising radical polymerization monomers, initiator, coordination agent, catalyst and reducer. The invention is characterized in that the polymerization system still comprises alkaline; the components are proportioned in mol as that monomers: initiator: alkaline equals to 100-1000: 1: 1-5; the catalyst is selected from Iron(III) chloride hexahydrate or iron bromide; and the alkaline is selected from one of sodium hydroxide (NaOH), sodium bicarbonate and ferric hydroxide (Fe (OH) 3). Because the alkaline with the same dose of the catalyst is added into the AGET ATRP polymerization system, the polymerization reaction rate is improved, a polymer with high percent conversion can be generated in a short time and the control performance of polymerization reaction is improved.

Owner:SUZHOU UNIV

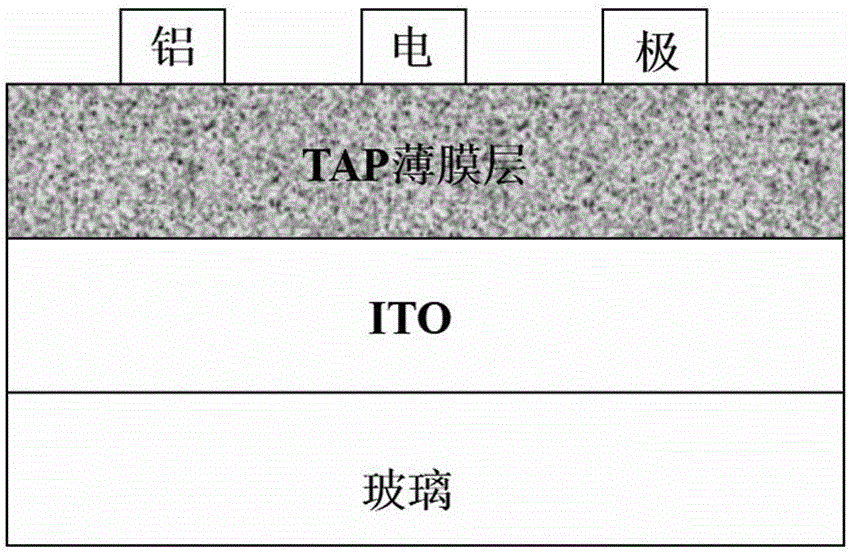

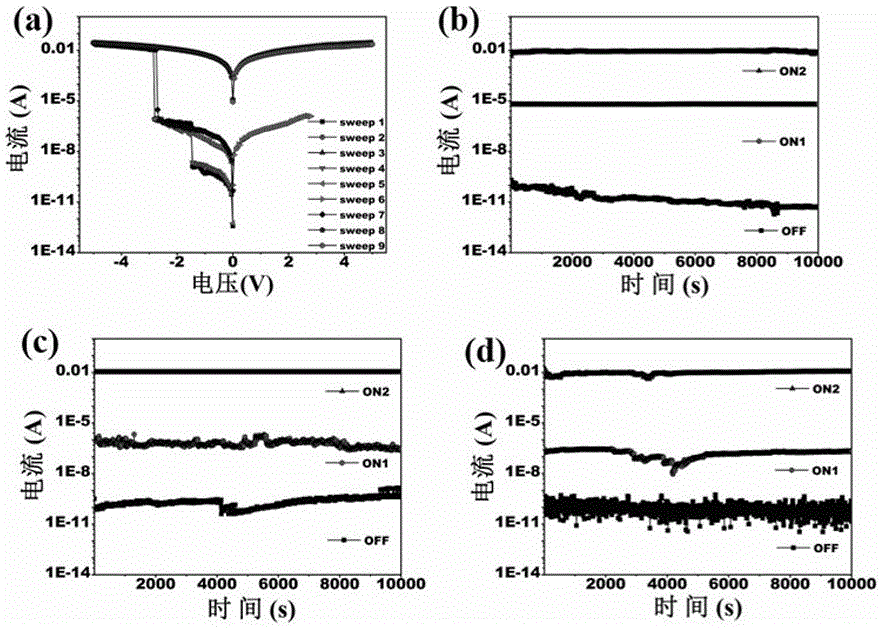

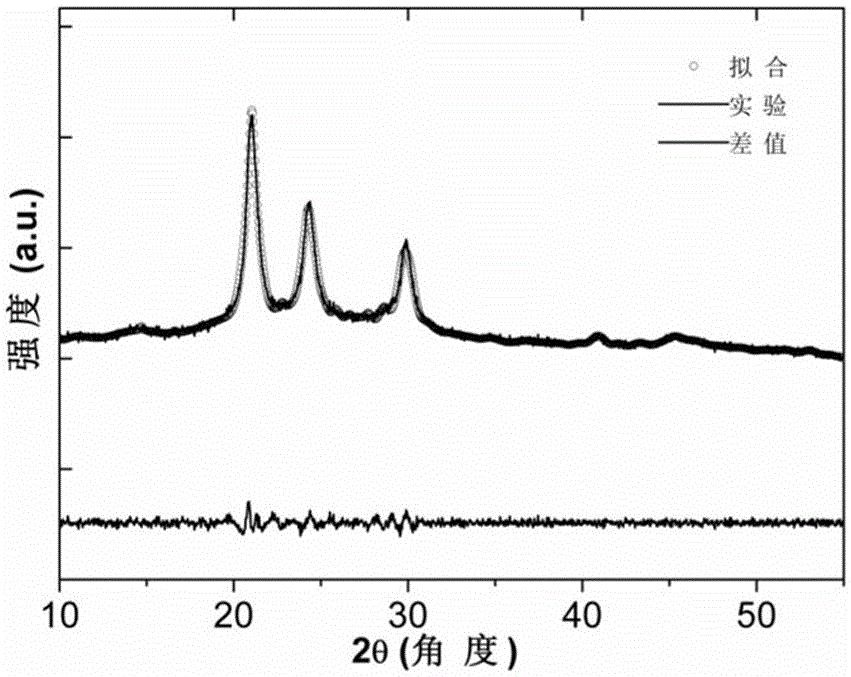

Electric memory device based on one-dimensional organic/inorganic hybridized polymer chain and preparation method thereof

ActiveCN106684245AReasonable thicknessImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmElectricity

The invention discloses an electric memory device based on a one-dimensional organic / inorganic hybridized polymer chain and a preparation method thereof. The preparation method comprises the steps of dripping nickel (II) chloride hexahydrate aqueous solution in amine salt organic solution and adjusting a system pH value to 7; stirring and reacting for 6 hours to prepare organic / inorganic hybridized polymer; coating organic / inorganic hybridized polymer saturated solution on a substrate to prepare an organic film layer; and preparing an electrode on the organic film layer, thereby obtaining the electric memory device based on the one-dimensional organic / inorganic hybridized polymer chain. According to the device and the method, through coordination of small organic molecules and inorganic metal compound, the one-dimensional organic / inorganic hybridized polymer is formed; the organic electric memory device with a sandwich structure is prepared; an organic electric storage behavior is successfully realized; a preparation process is simple; and the device environment and high temperature stability are good. The invention also discloses an application of the organic / inorganic hybridized polymer in electric memory device preparation.

Owner:SUZHOU UNIV

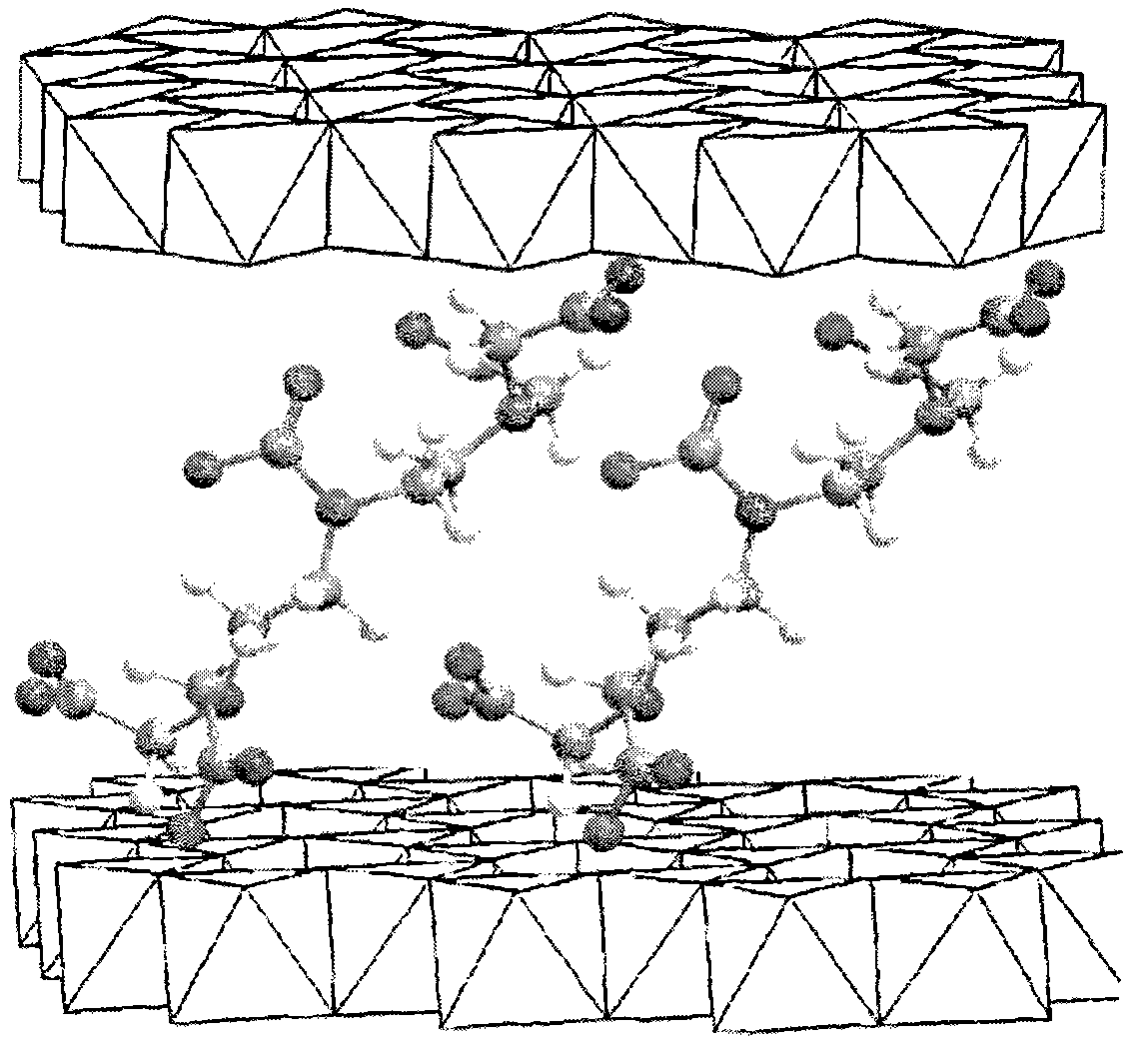

Method for preparing microwave synthesized inorganic-organic compound bentonite and application thereof

PendingCN106311128ASimple preparation processLow costOther chemical processesWater contaminantsAmmonium compoundsAlkyl polyglycoside

The invention discloses a method for preparing microwave synthesized inorganic-organic compound bentonite and application thereof. The compound bentonite mainly comprises a montmorillonite crystal structure and specific exchangeable cations between montmorillonite crystal structural layers. The preparation scheme of the compound bentonite comprises the following steps: weighing prescribed alkyl glucoside quaternary ammonium compound and aluminum chloride hexahydrate, dissolving in an alcohol solution, and stirring for 30 minutes to prepare a solution A; weighing prescribed sodium bentonite, and adding into the solution A to prepare a semi-dry reaction material B; putting the reaction material B in microwave reactor, and performing a radiation heating reaction for a period; and washing the heated product, drying at 105 DEG C, grinding the dried product, and filtering through a 100-mesh screen. The compound bentonite can be applied to removal of ammonia nitrogen, phosphor and algae in a water body.

Owner:GUANGDONG UNIV OF TECH

Porous cordierite block preparation method

The present invention discloses a porous cordierite block preparation method, which sequentially comprises: 1) at a room temperature, dissolving magnesium chloride hexahydrate, aluminum chloride hexahydrate and polyacrylamide in a solvent, adding tetramethyl orthosilicate in a dropwise manner, and continuously carrying out a stirring reaction for 50-70 min at a temperature of 50-70 DEG C; 2) naturally cooling the transparent clear solution obtained in the step 1) to a room temperature, adding propylene oxide, and uniformly stirring; 3) placing the homogeneous solution obtained in the step 2) into a container, sealing, and carrying out gelation for 3-5 min at a temperature of 35-45 DEG C; 4) placing the wet gel obtained in the step 3) in an environment with a temperature of 35-45 DEG C, and aging for 60-80 h; and 5) placing the aged gel obtained in the step 4) in an environment with a temperature of 50-70 DEG C, carrying out normal pressure drying for 72-96 h, and carrying out a heat treatment for 4-6 h at a temperature of 900-1300 DEG C. The porous cordierite block prepared by using the preparation method has characteristics of porous structure, high porosity and the like.

Owner:ZHEJIANG UNIV

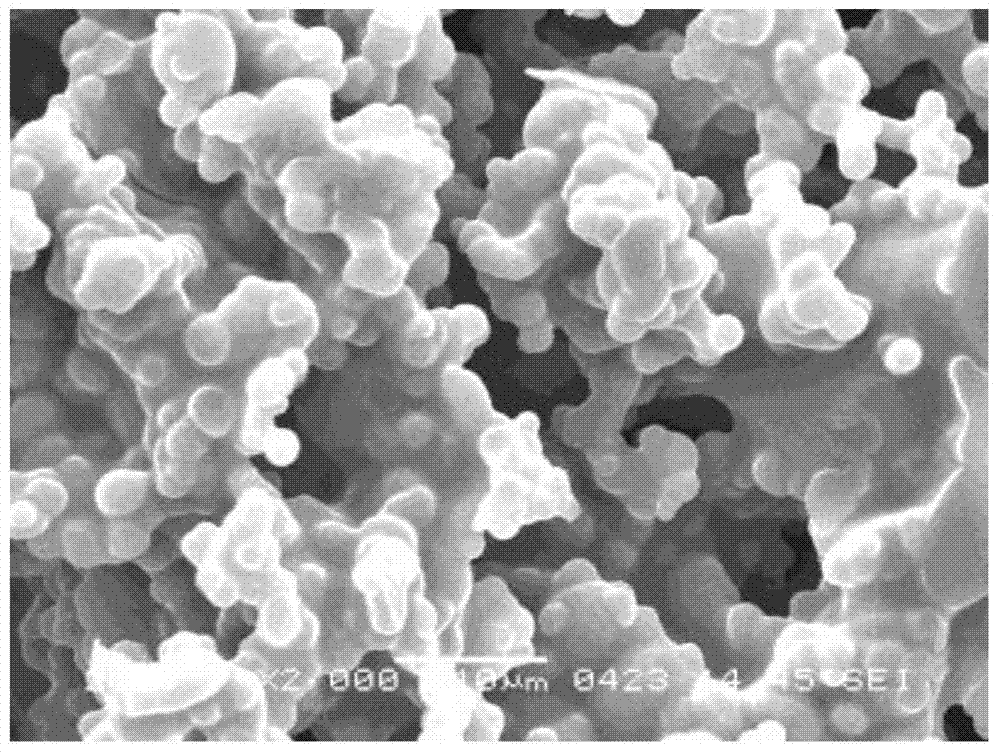

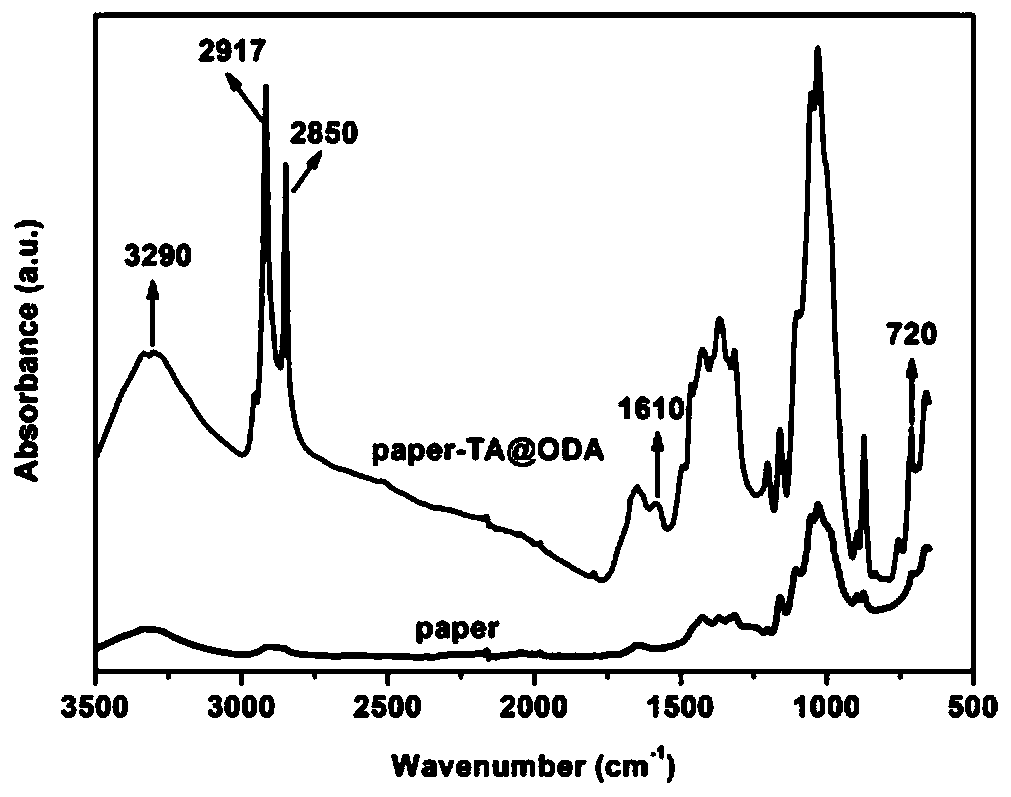

Preparation method of super-hydrophobic paper

ActiveCN111549568AAchieving superhydrophobicityImproves UV resistanceWater-repelling agents additionNon-macromolecular organic additionAluminium chlorideFiber

The invention discloses a preparation method of super-hydrophobic paper, wherein the preparation method comprises the following steps: step 1, carrying out ultrasonic emulsification on octadecylamineto obtain an octadecylamine emulsion; step 2, uniformly mixing the octadecylamine emulsion with paper pulp in proportion to form an octadecylamine-paper pulp mixed solution; step 3, adding tannic acidand aluminum chloride hexahydrate into the octadecylamine-paper pulp mixed solution, adjusting the pH value, and carrying out a stirring reaction to form tannic acid@octadecylamine microcapsule (TA@ODA) modified paper fiber pulp; and step 4, centrifuging, flattening and drying the paper fiber pulp to obtain the super-hydrophobic paper. Compared with a traditional method, the preparation method ofthe super-hydrophobic paper provided by the invention does not need complex instruments and equipment, does not need a complex synthesis process, does not need too long time, and has the advantages of simple operation, convenience, environmental protection and the like, and the prepared super-hydrophobic paper has good super-hydrophobic performance, good durability and self-repairing performance.

Owner:LANZHOU JIAOTONG UNIV

Method of preparing anhydrous aluminium chloride

The present invention is one method of preparing anhydride aluminum chloride with simple technological process, no waste gas exhaust and high purity product. The aluminum chloride hexahydrate material is first compounded into water solution, C1-C4 alcohol is then added into the water solution for separating crystal, and the separated crystal as anhydride aluminum chloride product is finally separated from the solid-liquid mixture. The liquid after solid-liquid separation has main component alcohol and may be reused. The said process can eliminate impurity from aluminum chloride hexahydrateto obtain high purity anhydride aluminum chloride.

Owner:章浩龙

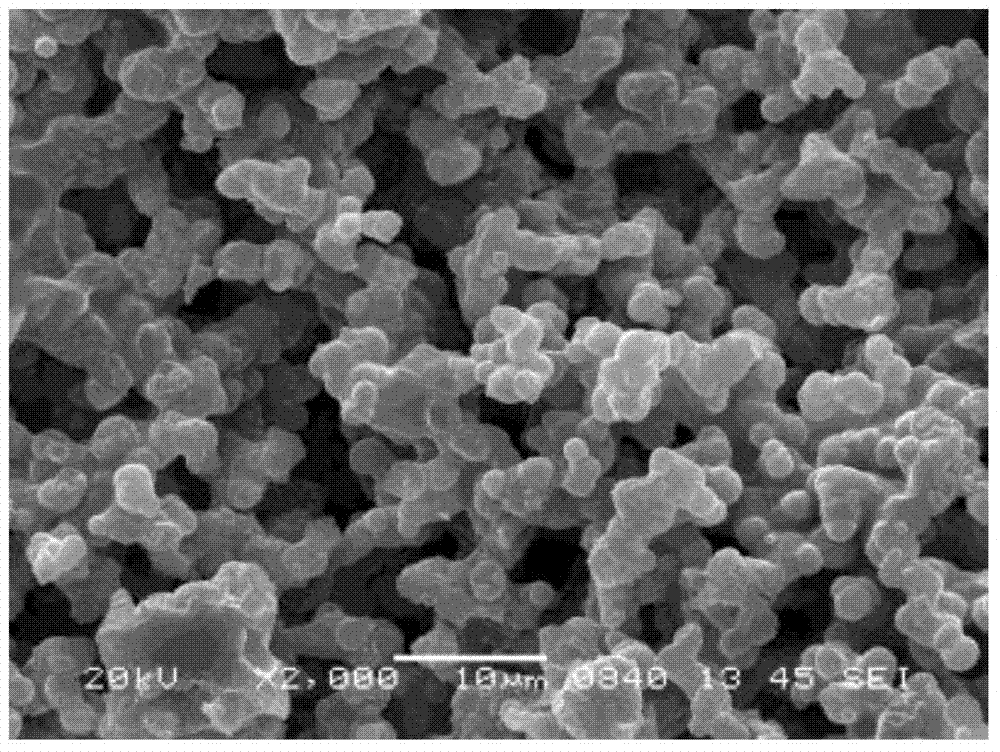

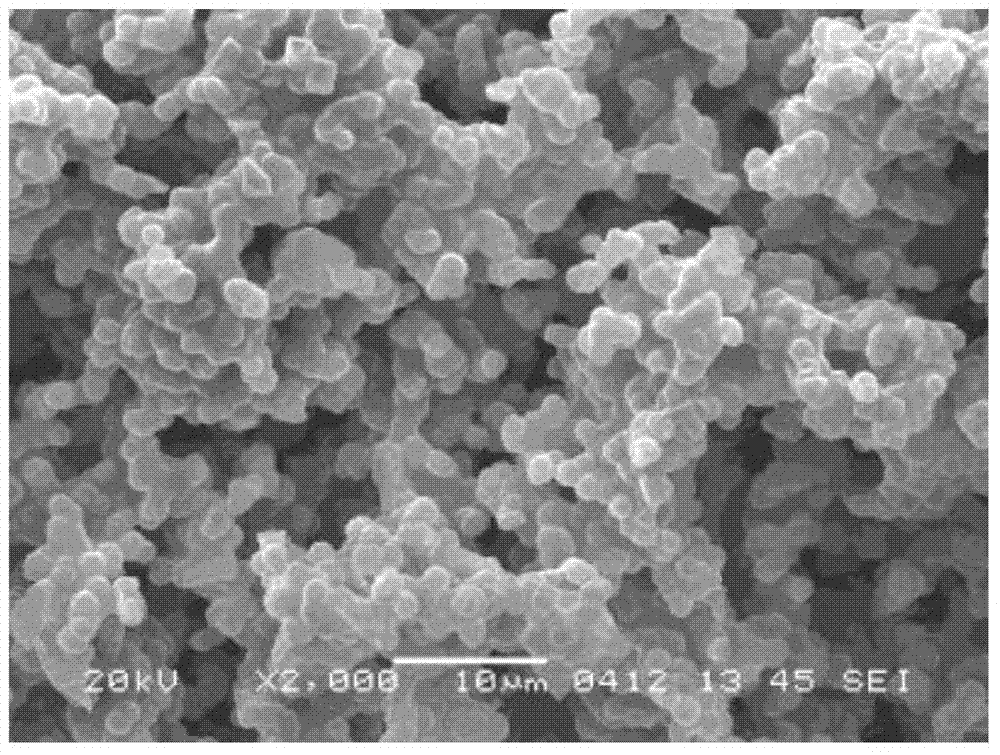

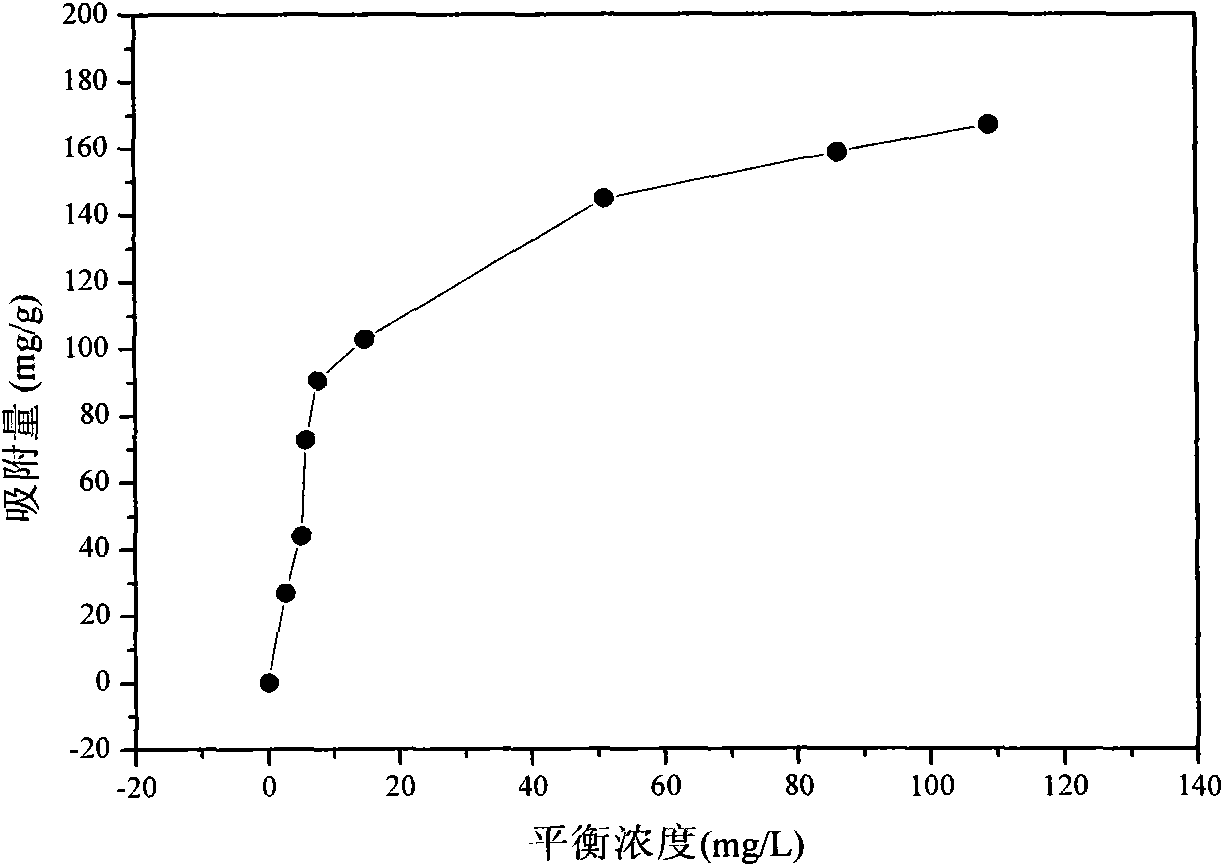

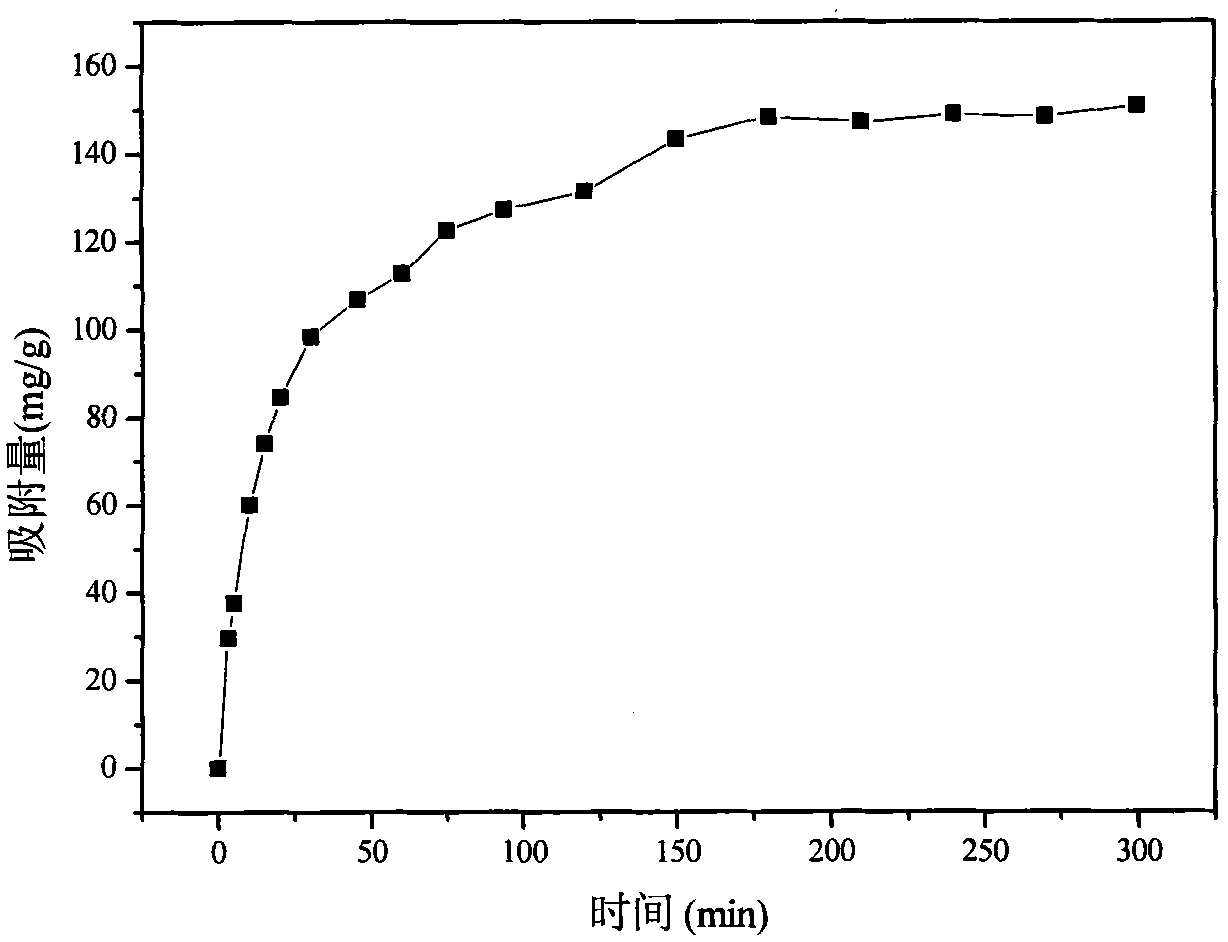

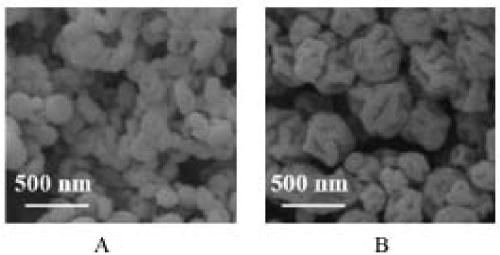

Preparation and application of layered double hydroxides with diethylenetriaminepentaacetic acid intercalation

InactiveCN101993101AImprove adsorption capacityLow costAluminium oxides/hydroxidesCadmium CationLayered double hydroxides

The invention provides a preparation method of layered double hydroxides (LDHs) with diethylenetriaminepentaacetic acid (DTPA) intercalation, wherein, Mg-Al LDH is taken as a matrix, and DTPA is introduced into positive charge of a layer balance Mg-Al LDH laminate panel by a coprecipitation method. The preparation method comprises the following steps: dissolving magnesium chloride hexahydrate and aluminum chloride hexahydrate into water to obtain solution A; dissolving the DTPA into ammonia water to obtain solution B; diluting ammonia water with water to obtain solution C; mixing and stirring the three types of solution, keeping standing and aging; and washing and filtering the obtained mixed solution, collecting a gel filter cake, drying the filter cake at constant temperature, and grinding to obtain the product, wherein, the product can be used as a heavy metal adsorbing material. The invention has the advantages that the adsorbing material contains a large quantity of active functional groups, thus having good adsorbing effect; the adsorbing material can obtain better effect with less consumption when in use and has low cost and no pollution; and the adsorbing material is mainly applied to repairing a heavy metal polluted water body and has obvious effect on combined pollution caused by a plurality of heavy metal elements such as lead, cadmium and the like.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

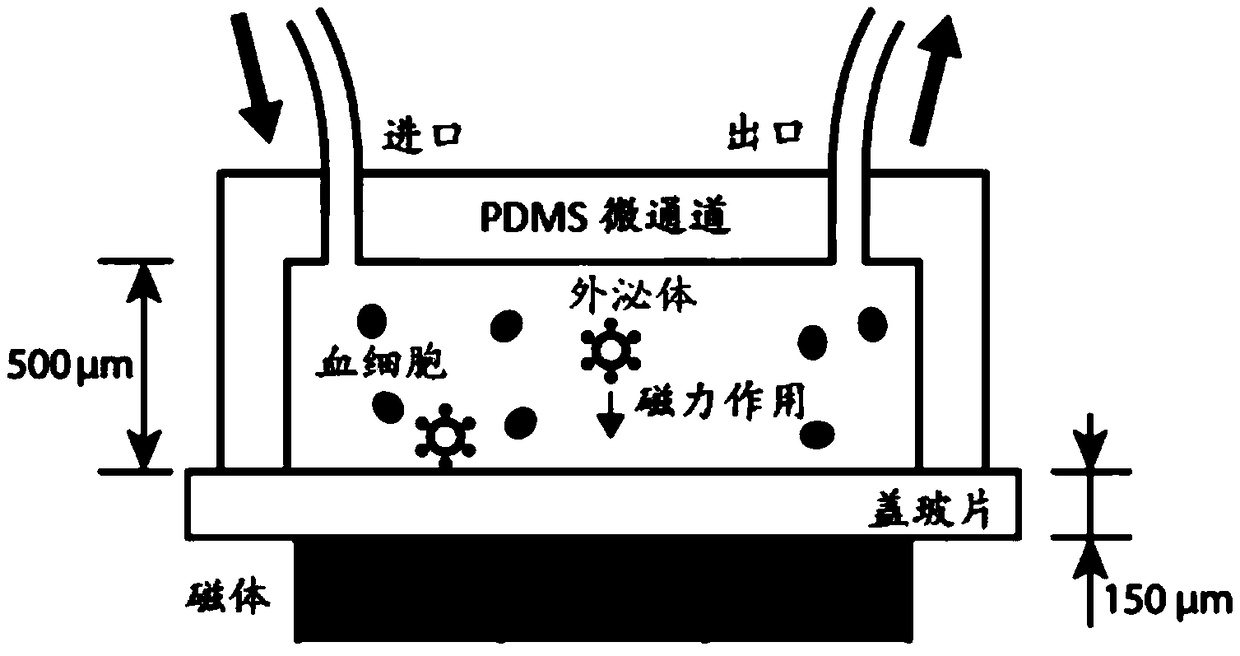

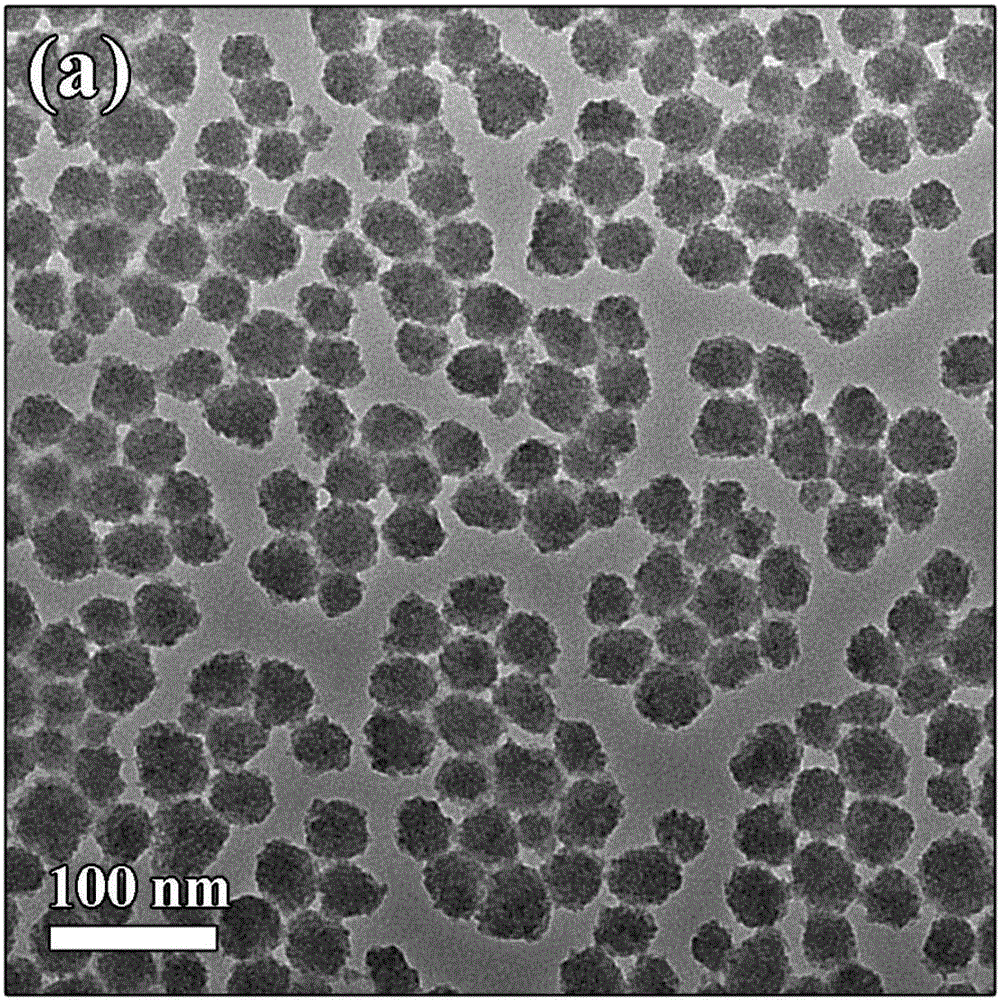

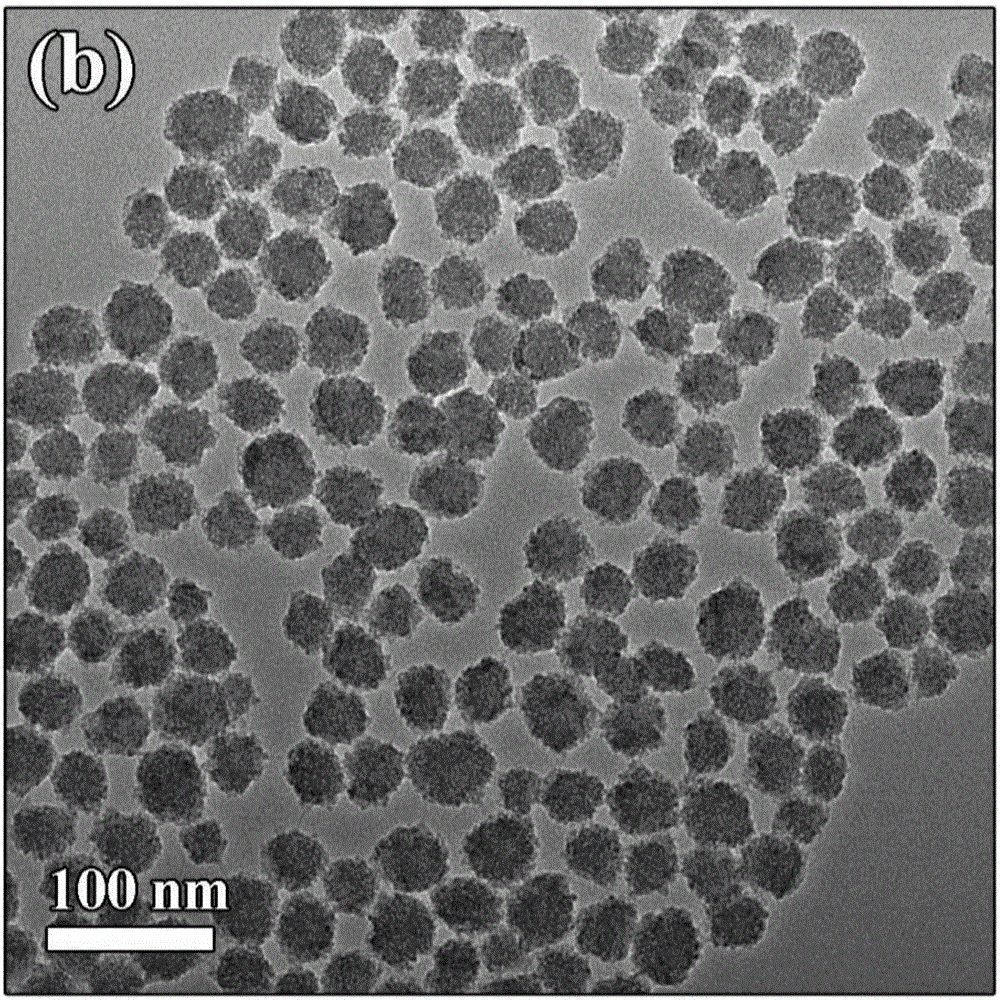

Preparation method and application of magnetic nanoparticles for capturing exosomes in blood

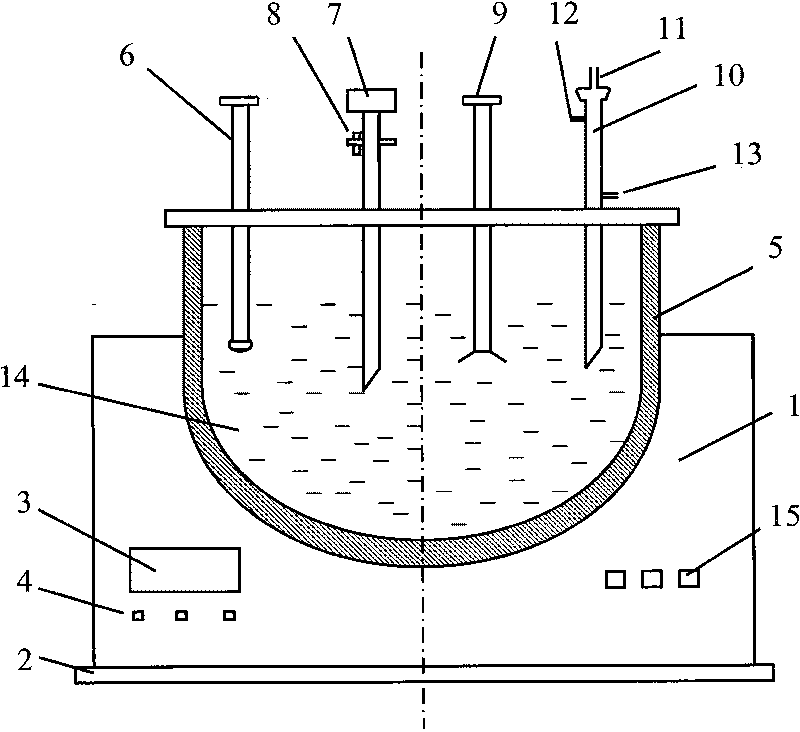

ActiveCN109402052AEfficient sortingFacilitate early diagnosisCell dissociation methodsBlood/immune system cellsWater bathsMagnetite Nanoparticles

The invention discloses a preparation method and application of magnetic nanoparticles for capturing exosomes in blood. The preparation method is characterized by comprising the following steps: (1) after mixing diferric chloride hexahydrate and ferrous chloride tetrahydrate, dissolving a mixture into distilled water; after stirring and uniformly mixing, heating to 70 DEG C; then slowly dropwise adding an ammonia water solution; after hydrolysis is basically finished, slowly adding cetyl trimethyl ammonium bromide into the solution; stirring, centrifuging and collecting a product and washing;taking lower-layer sediment and drying in vacuum to obtain nano Fe3O4 particles; (2) after dispersing the nano Fe3O4 particles into an ethanol water solution and carrying out ultrasonic treatment, adding a tetraethyl orthosilicate solution; gradually adding into an ammonia water bath and reacting for 5 h; centrifuging and collecting a product; washing and drying to obtain the irregular magnetic micro-nanoparticles which are covered with SiO2 and have the surface distributed pore diameter of 40 to 200 nm. The preparation method disclosed by the invention has the advantages that the exosomes arelosslessly combined to the greatest extent, the amount of used samples is small, the treatment time is short and the operation is simple and convenient.

Owner:NINGBO MEIJING MEDICAL TECH

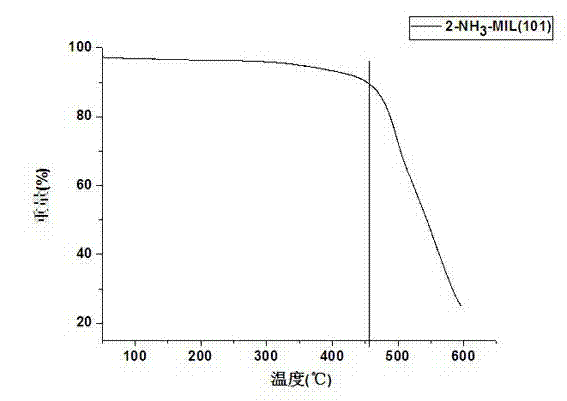

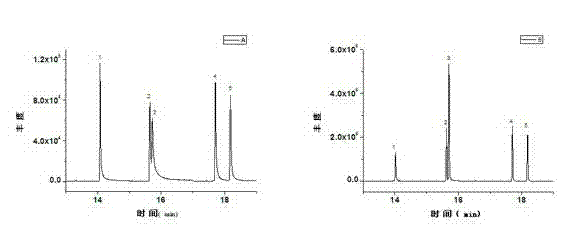

Solid phase microextraction coating and preparation method thereof

InactiveCN103028381AImprove thermal stabilityGood chemical stabilityOther chemical processesN dimethylformamideSolid-phase microextraction

The invention provides a solid phase microextraction coating using NH2-MIL-101(Al) as materials and a preparation method thereof. The method comprises the following steps: putting stainless steel wires in 60-80 EG C of hydrofluoric acid to be corroded to form a rough surface; taking aluminum chloride hexahydrate and 2-aminoterephthalic acid, dissolving with N, N-dimethylformamide, carbinol or chloroform, and then separately putting solutions in a microwave reaction tank; and immersing the corroded stainless steel wires in the microwave reaction tank, reacting for 5-6 hours at 120-130 DEG C, then washing with secondary water, and drying for the night at 80-100 DEG C. The method has simple operation and short preparation time. The prepared coating has the advantages of good resistance to high temperature, high chemical stability, good reproducibility, high enrichment coefficient, low cost and wide application range, and can be used for separation and enrichment of substances such as polycyclic aromatic hydrocarbon, pesticides and the like.

Owner:FUZHOU UNIV

Method and application for extracting iron and aluminum in red mud to prepare absorbent

InactiveCN106111051ADeepen resource utilizationReduce manufacturing costOther chemical processesWater contaminantsSorbentRed mud

The invention relates to a method and application for extracting iron and aluminum in red mud to prepare an absorbent with an aim to solve the problem that low cost and high adsorption capacity cannot be combined with an existing fluorine ion removal method. The method includes 1), acid leaching of the red mud, namely using diluted hydrochloric acid to leach the iron and aluminum from the red mud; 2), subjecting the iron and aluminum to separation and purification, adding sodium hydroxide into a leaching agent, generating sediment and subjecting to solid-liquid separation, adding the diluted hydrochloric acid into the sediment to obtain a ferric chloride solution, and subjecting the ferric chloride solution to evaporation concentration and cooling crystallization to obtain iron chloride hexahydrate; adding the diluted hydrochloric acid in supernate to obtain an aluminum chloride solution, and subjecting the aluminum chloride solution to evaporation concentration and cooling crystallization to obtain aluminum chloride hexahydrate; 3), preparation of the absorbent, namely taking ferric trichloride and aluminum trichloride obtained in the red mud as main materials and adjusting pH (potential of hydrogen) with a coprecipitation method under the room temperature to obtain sediment which is subjected to washing, drying and grinding to obtain the absorbent. The absorbent prepared with the method is applied to removal of fluorinion in water.

Owner:HEILONGJIANG UNIV

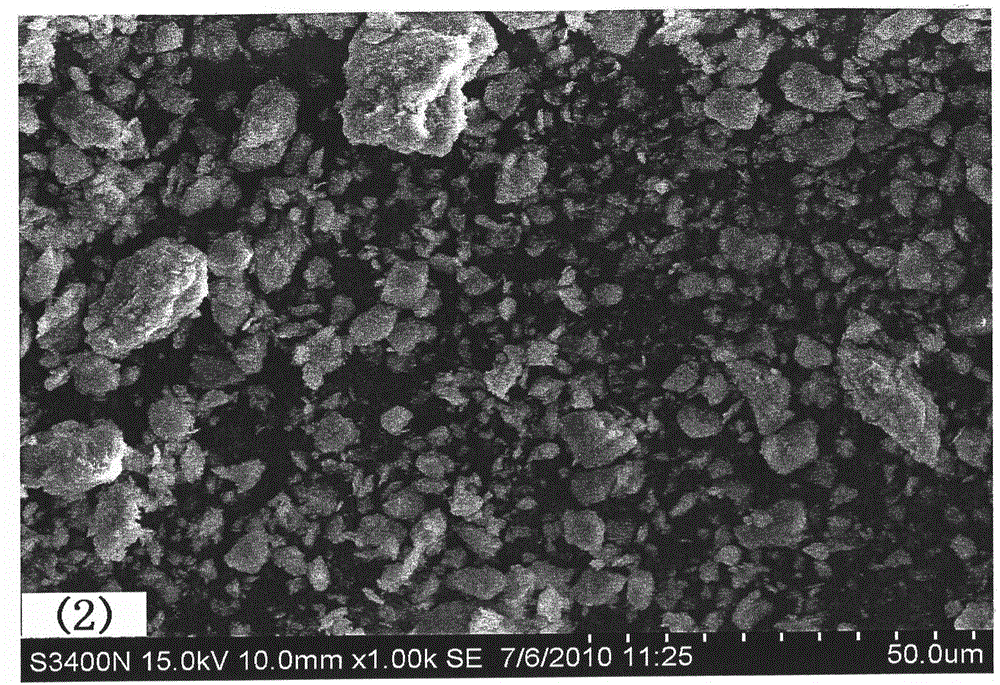

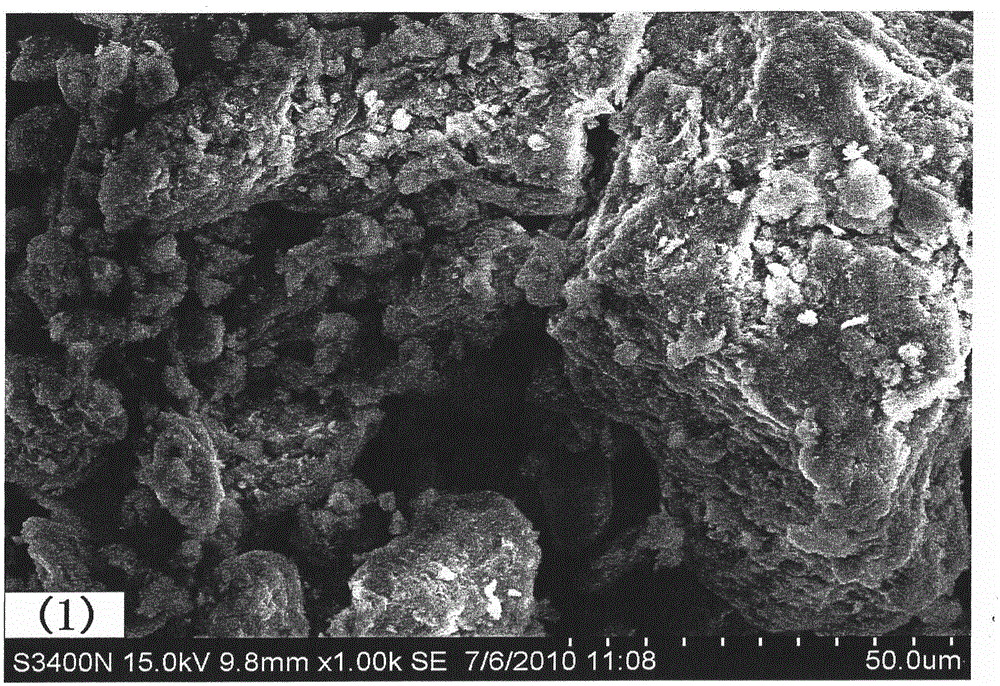

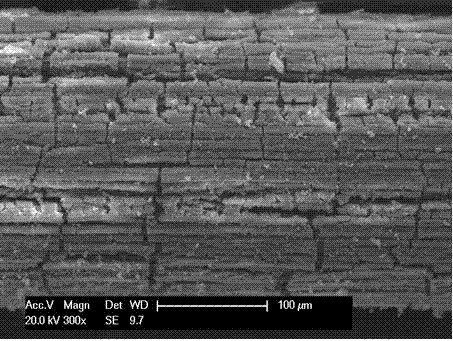

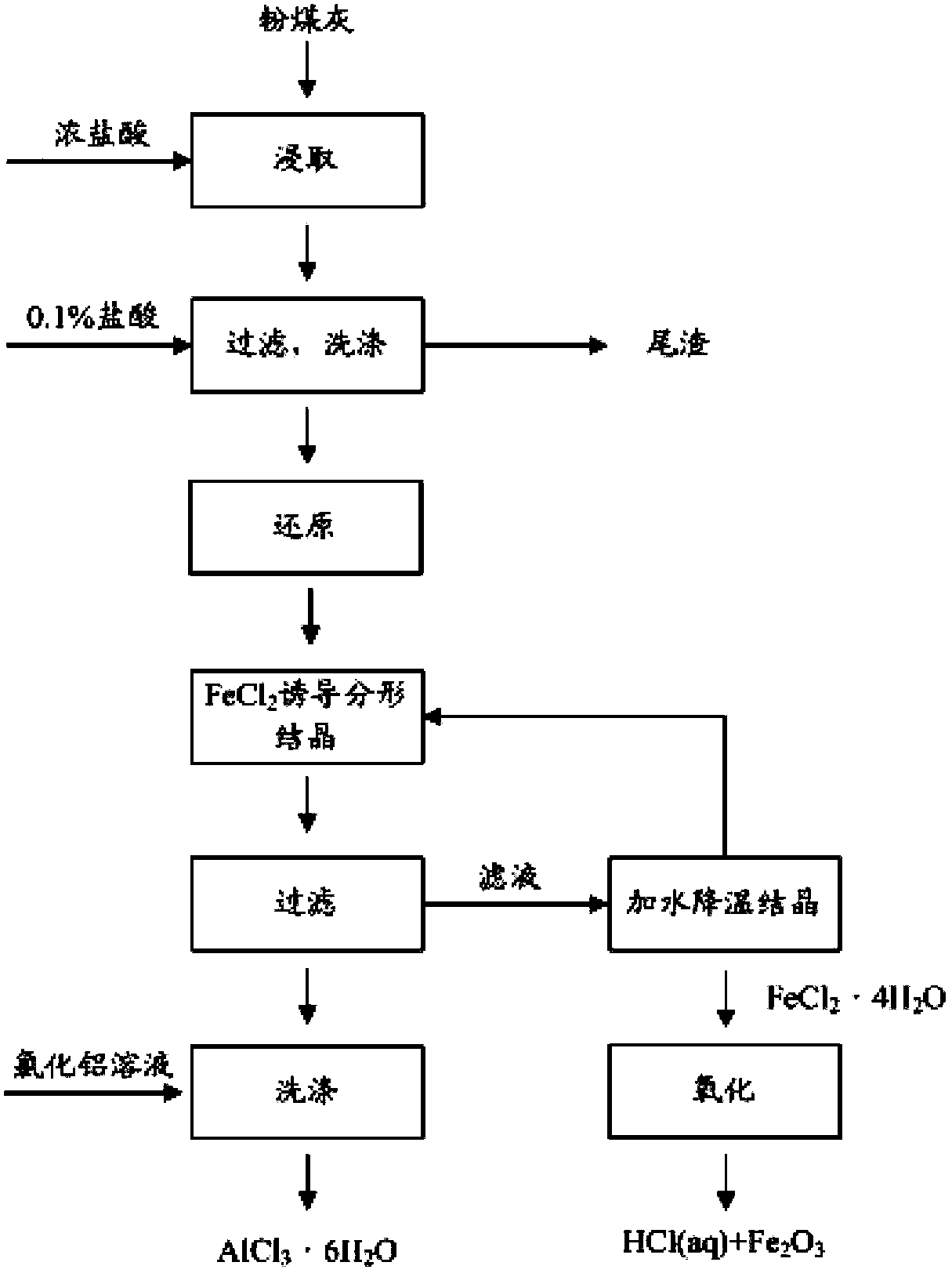

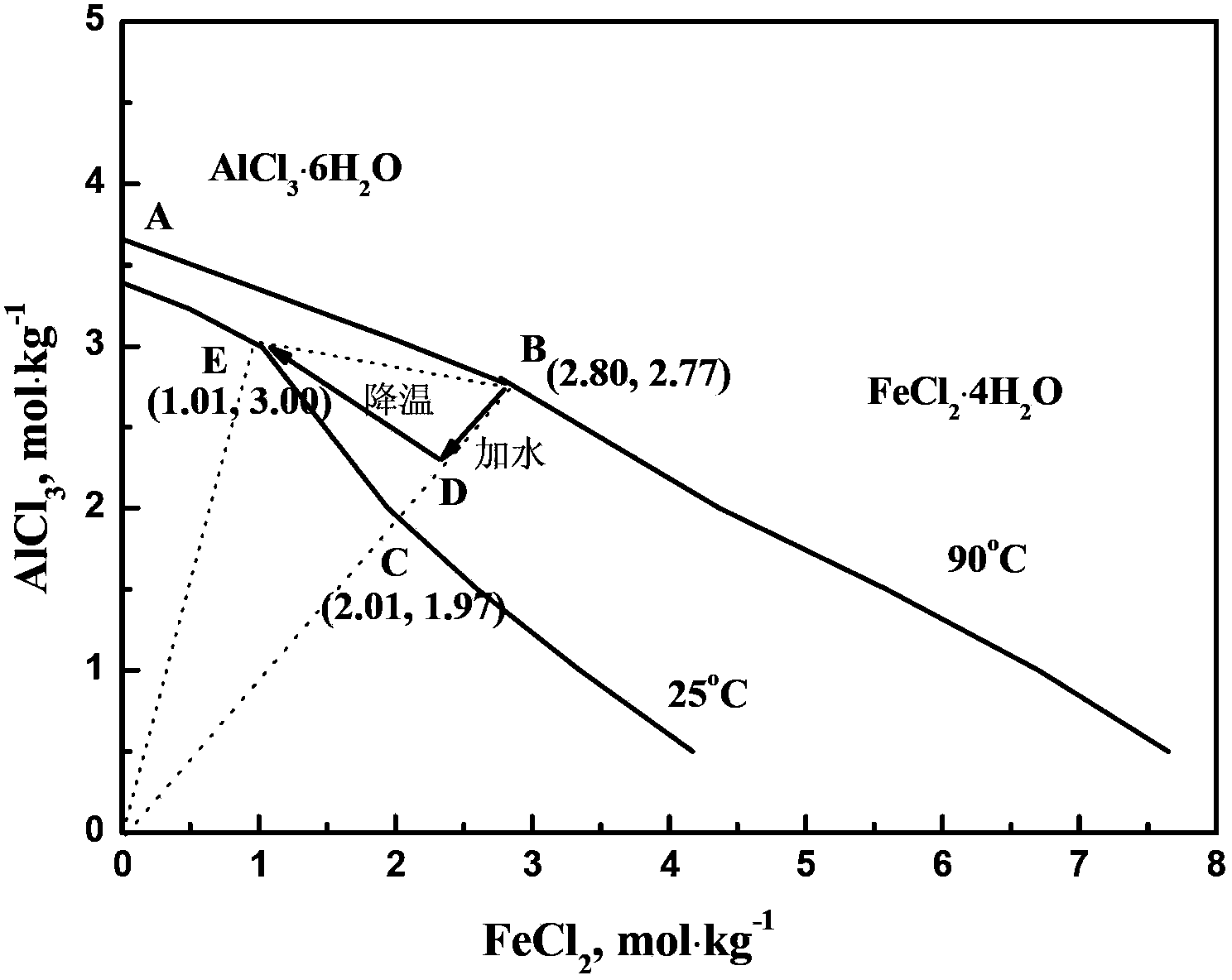

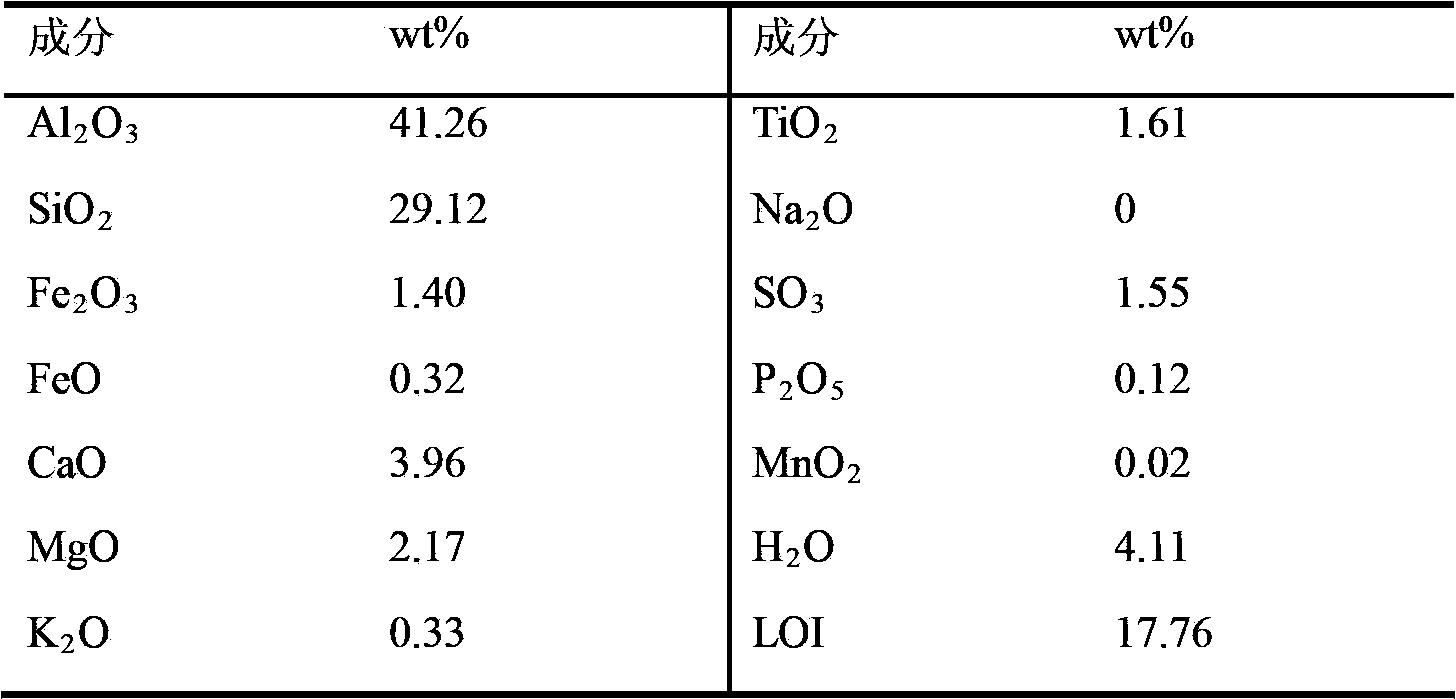

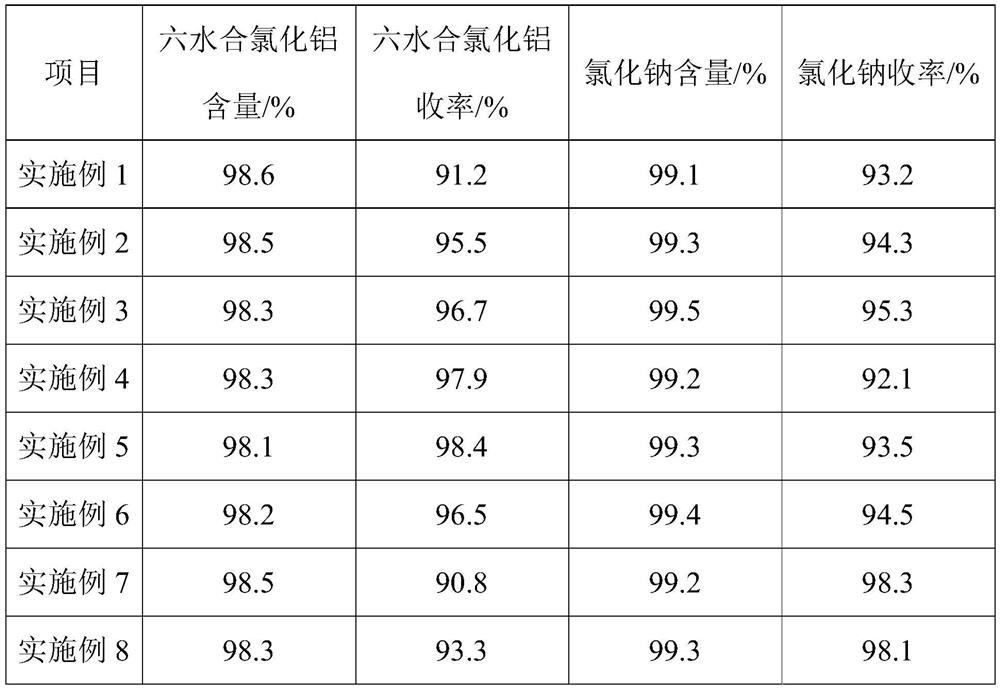

Method for preparing aluminum chloride hexahydrate by using pulverized fuel ash as raw material through ferrous chloride induced crystallization

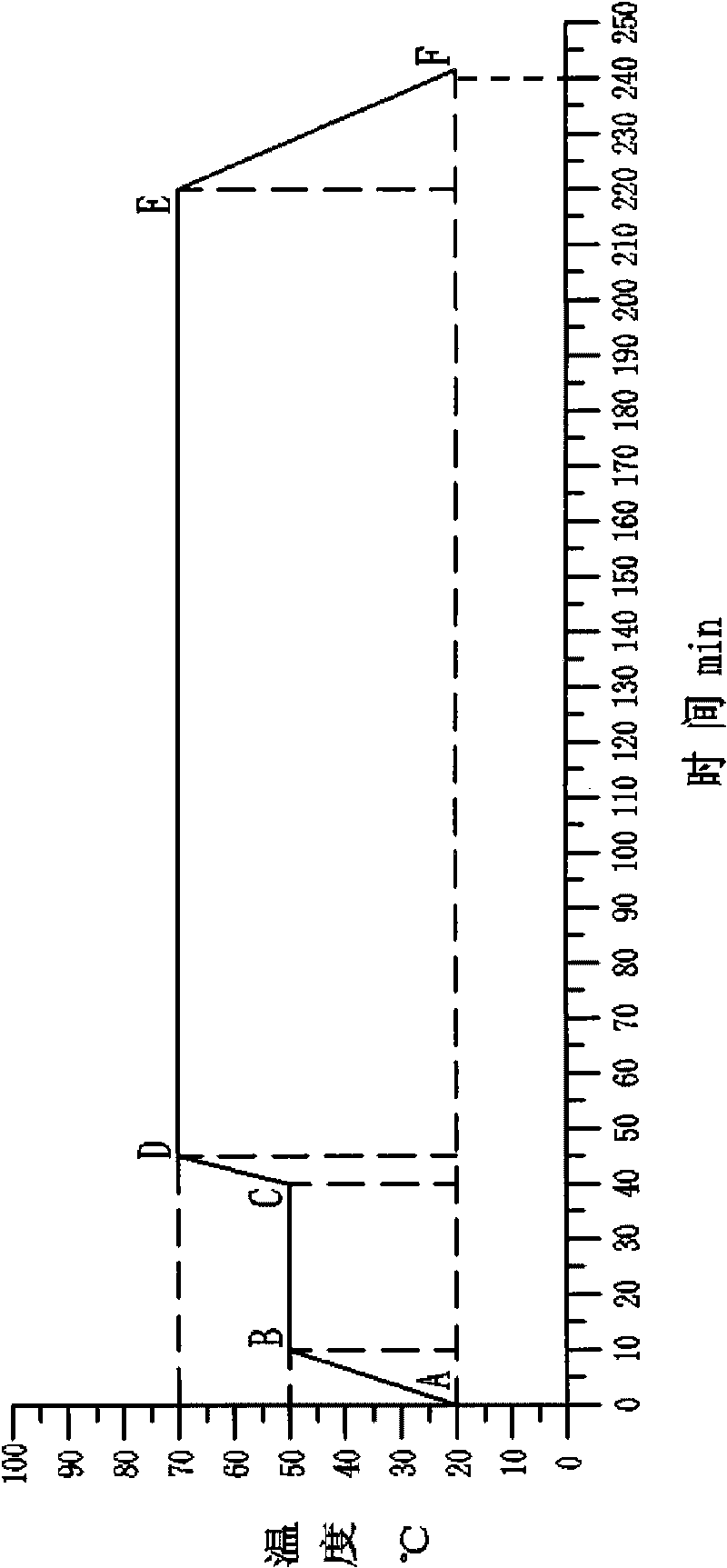

InactiveCN103539182ARealize high-value utilizationThe process is green and environmentally friendlyAluminium chloridesChemical industryElectromotive force

The invention provides a method for preparing aluminum chloride hexahydrate by using pulverized fuel ash as a raw material through ferrous chloride induced crystallization. The method comprises the following steps: (1) batching the pulverized fuel ash and hydrochloric acid in proportions, and reacting for 1-4 hours at the temperature of 80-120 DEG C; (2) filtering leach liquor and solids, and washing more than three times by using diluted hydrochloric acid; (3) adding a reducing agent to a solution till the electromotive force of the solution is about 770mV, so that all Fe<3+> in the solution is reduced to Fe<2+>, and meanwhile, intrinsic Fe<2+> in the solution generates ferric oxide; (4) adding ferrous chloride, carrying out induction fractal crystallization at the temperature of 80-120 DEG C, filtering to obtain aluminum chloride hexahydrate crystals with relatively good crystalline form, or recrystallizing the obtained crystals, then washing by using a high-concentration aluminium chloride solution, and drying to obtain an aluminum chloride hexahydrate product; (5) adding water, cooling and crystallizing so as to respectively remove calcium, magnesium, potassium, sodium and the like in the solution, and separating out ferrous chloride tetrahydrate (FeC12.4H2O); and (6) carrying out a hydrothermal reaction for 4-12 hours at the temperature of 120-200 DEG C by using obtained the ferrous chloride tetrahydrate, and reacting so as to generate ferric oxide and an HCI solution. The method is easy to operate, pollution-free to environments and in line with the requirements of green chemical industries on clean production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Treatment method of sodium tetrachloroaluminate solid residues

ActiveCN111689508ANo cross contaminationLow costGroup 5/15 element organic compoundsAluminium chloridesAluminium chlorideOrganic solvent

The invention relates to a treatment method of sodium tetrachloroaluminate solid residues. The treatment method comprises the following steps: (1) mixing sodium tetrachloroaluminate solid residues with water for dissociation, then adding a separating agent to separate out aluminum chloride hexahydrate, or directly mixing the sodium tetrachloroaluminate solid residues with the separating agent fordissociation, separating out aluminum chloride hexahydrate, and then carrying out primary solid-liquid separation to obtain an aluminum chloride hexahydrate solid and primary filtrate; and (2) carrying out concentration crystallization and secondary solid-liquid separation on the primary filtrate to obtain a sodium chloride solid and a secondary filtrate. According to the treatment method, an organic solvent does not need to be introduced, cross contamination does not exist, and the cost can be reduced; the aluminum chloride and the sodium chloride which are obtained by dissociating the sodiumtetrachloroaluminate solid residues are fully recycled, so that the high resource utilization of the sodium tetrachloroaluminate solid residues is realized, the obtained secondary filtrate can be returned to a solid residue dissociation stage to provide a separating agent, the concept of circular economy is embodied, and the method has the advantages of simple process flow, simplicity and convenience in operation and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Preparation method of porous mullite block

InactiveCN103242027AControl Aperture SizeControl pore volumeAluminium silicatesRoom temperatureMullite

The invention discloses a preparation method of a porous mullite block. The preparation method of the porous mullite block comprises the following steps of: (1) dissolving aluminum chloride hexahydrate and polyoxyethylene in a solvent, dropwise adding tetramethyl orthosilicate, and then stirring continuously and reacting for 50-70minutes; (2) under the room temperature, adding epoxypropane in the mixture obtained in the step (1) and stirring uniformly to obtain a homogeneous solution; (3) sealing the homogeneous solution in a container and then gelling at 35-45 DEG C for 8-12minutes to obtain wet gel; (4) aging the wet gel at 35-45 DEG C for 68-76 hours; and (5) drying the aged gel prepared in the step (4) at 70-80 DEG C for 2-3 days, and then carrying out heat treatment at 800-1400 DEG C for 4-6 hours to obtain the porous mullite block. The porous mullite block prepared by the method has the characteristics that the block has a hierarchical porous structure, the size and amount of apertures are controllable, the frameworks are continuous, the specific surface area is large, and the like.

Owner:ZHEJIANG UNIV

Yttrium vanadate nanoparticles, rare earth ion-doped yttrium vanadate nanoparticles and preparation method of yttrium vanadate nanoparticles and rare earth ion-doped yttrium vanadate nanoparticles

InactiveCN105733584AGood water solubilityControl shapeNanoopticsLuminescent compositionsSolubilityFluorescence

The invention provides yttrium vanadate nanoparticles, rare earth ion-doped yttrium vanadate nanoparticles and a preparation method of the yttrium vanadate nanoparticles and the rare earth ion-doped yttrium vanadate nanoparticles, and belongs to the technical field of fluorescent nanomaterials.The preparation method comprises the steps that sodium orthovanadate dodecahydrate, rare-earth chloride hexahydrate, polyacrylic acid and water are mixed according to a certain proportion, pH is regulated, reacting under stirring is performed at room temperature, or the mixture is transferred into a three-necked bottle to be subjected to a reaction at the temperature of 60 DEG C-90 DEG C, and the water-soluble yttrium vanadate nanoparticles and the water-soluble rare earth ion-doped yttrium vanadate nanoparticles can be obtained.The method is simple in process, convenient and rapid to operate, low in cost, friendly to the environment and good in technological repeatability; the obtained nanoparticles have the good water solubility, are small in particle size and have the huge application potential on medical imaging and fluorescence labeling.

Owner:JILIN UNIV

Method of extracting aluminum oxide by leaching flyash with hydrochloric acid

InactiveCN107285351AOvercome energy consumptionOvercoming demandsAluminium compoundsAluminium chlorideImpurity

The invention discloses a method for extracting alumina by leaching fly ash with hydrochloric acid. By passing hydrogen chloride gas into the leaching solution of fly ash and hydrochloric acid, the aluminum chloride in the leaching solution crystallizes to form aluminum chloride hexahydrate The crystals are precipitated, omitting the complicated iron removal process in the purification process of aluminum chloride and the defects that other impurity ions (sodium, potassium, magnesium, calcium, etc.) cannot be removed, and realize the separation, purification and crystallization of aluminum chloride in one step; at the same time The crystallization process is realized at room temperature, the process is simple, and the energy consumption is low. The impurity metal ions in the residual liquid can be further enriched for recovery. While extracting alumina, other metal salts and silicon oxide in the leaching residue can be recovered. The field of alumina extraction from coal ash has broad application prospects.

Owner:青岛海山环保工程有限公司

Chromium-free photo-sensitive resist for rotary screen printing

The invention relates to chromium-free photo-sensitive resist for rotary screen printing, which comprises the following components: polyvinyl alcohol (30%), gelatin, p-diazodiphenylamine paraformaldehyde condensate, polyisocyanate blocks, silicone modified polyurethane resins, trimethylolethane, 3-6 parts of stilbazole dimethyl sulfate salt, hydroquinone, curing agents, polyethyleneimine, ethylamine boron trifluoride salt, benzyl dimethylamine, aluminum chloride hexahydrate, solvents, aluminum chloride hexahydrate, silicone defoaming agents and vitamin E. The chromium-free photo-sensitive resist has the advantages of strong binding force of the high-precision photo-sensitive resist for a rotary printing screen and the rotary printing screen, excellent chemical resistance and abrasion resistance, and high press run; plate making and developing of the rotary printing screen are clear and mesh holes cannot be stopped; through adding the silicone modified polyurethane resin, the tensile property of the rotary printing screen in a printing process is improved, and the service life of the rotary printing screen is prolonged.

Owner:陈国荣

Method for recycling Al resources in Friedel-Crafts reaction

ActiveCN104803873ANot generatedReduce generationOrganic compound preparationGroup 5/15 element organic compoundsWastewaterSolvent

The invention relates to a method for recycling Al resources in a Friedel-Crafts reaction. The method comprises steps performed after the Friedel-Crafts reaction as follows: (1), a reaction system is concentrated, a reaction solvent is recovered, a replacement solvent is added to disperse concentrated residues when the size of the reaction system is concentrated to 20%-50% of the original size, and concentration is continued until the reaction solvent is completely eliminated; (2), the temperature of the system obtained after the step (1) is controlled to range from subzero 20 DEG C to 100 DEG C, water is added to the system, the mixture is sufficiently mixed and filtered, the replacement solvent is recovered after filtrate is concentrated, meanwhile, a product of the Friedel-Crafts reaction is obtained, aluminum(III) chloride hexahydrate is obtained after a filter cake is dried, and the mole ratio of the added water to aluminum (III) chloride is (1-10):1. According to the method, no wastewater or acid gas is produced, the operation is simple, and environmental protection is facilitated.

Owner:HONGHU YITAI TECH CO LTD

Preparation method of porous aluminum titanate block

The invention discloses a preparation method of a porous aluminum titanate block. The preparation method comprises the following steps: (1) dissolving aluminum chloride hexahydrate, citric acid monohydrate, tetrabutyl titanate and polyoxyethylene in a solvent in sequence at room temperature; (2) cooling a transparent clear solution obtained in the step (1) to -1 DEG C to 1 DEG C, adding formamide, and uniformly stirring; (3) putting a uniform solution obtained in the step (2) into a container, sealing the container, and gelling at 55-70 DEG C for 20-40 minutes; (4) ageing wet gel obtained in the step (3) at 55-70 DEG C for 20-30 hours; (5) performing normal pressure drying on aged gel obtained in the step (4) at 50-70 DEG C for 40-50 hours and performing heat treatment at 1,300-1,350 DEG C for 2-5 hours. The porous aluminum titanate block prepared by the method has the characteristics of continuous macroporous structure, continuous framework, high porosity and the like.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com