Solid phase microextraction coating and preparation method thereof

A coating and extraction technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of non-extractable coating, short service life, poor heat resistance, etc., and achieve cheap consumables and short preparation time. , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

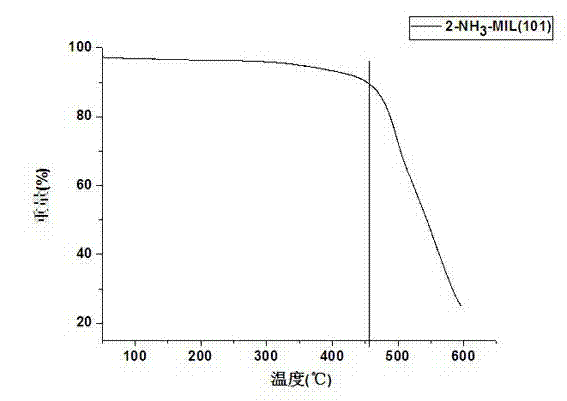

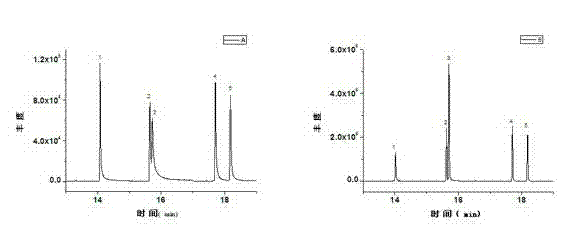

Examples

Embodiment 1

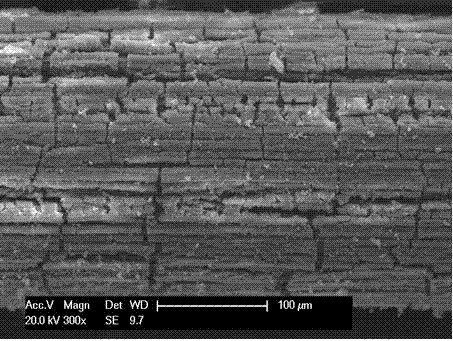

[0022] Immerse 3 cm of the front ends of four 15 cm long stainless steel wires in a hydrofluoric acid solution heated at 80°C and corrode for 10 min to make the stainless steel wires form a rough surface, wash them with secondary water and dry them in an oven at 60°C before use .

[0023] Accurately weigh 1.02 g of aluminum chloride hexahydrate and 1.12 g of 2-aminoterephthalic acid into a beaker, add 60 mL of nitrogen-nitrogen dimethylformamide, and stir in a magnetic stirrer to dissolve it. The dissolved solution was divided into 4 microwave reaction tanks, each 15mL, the corroded stainless steel wire was inserted into the solution, the lid was closed, and the reaction tank was put into the microwave for reaction. The reaction conditions were as follows: the temperature was raised to 130 °C within 2 min, and the power was 600 W; the temperature was kept at 130 °C for 6 h, and the power was 400 W. After the reaction was completed, the stainless steel wire was taken out, rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com