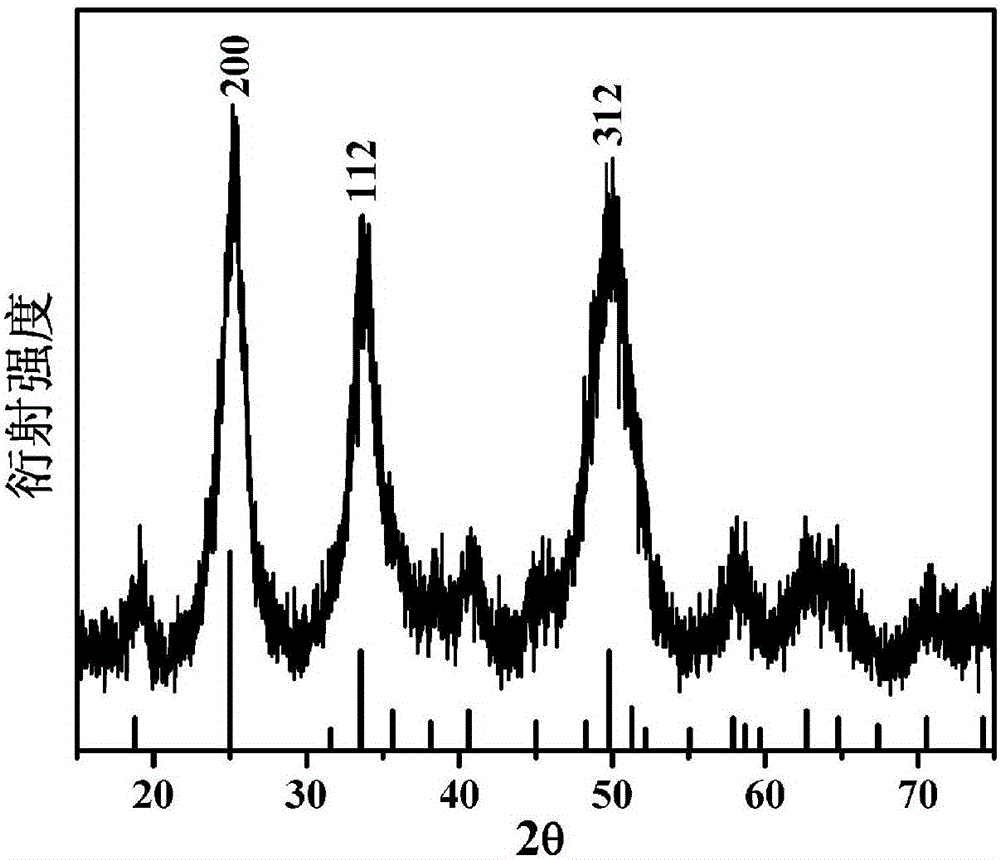

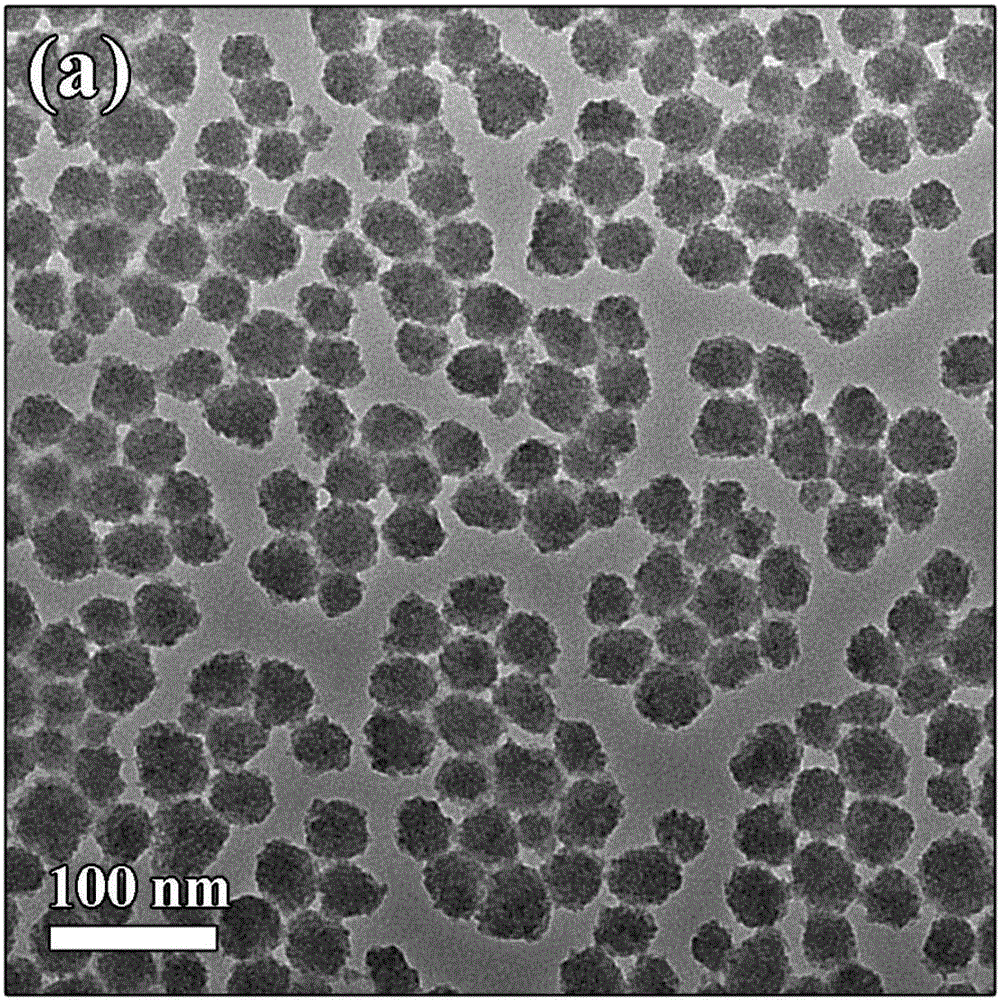

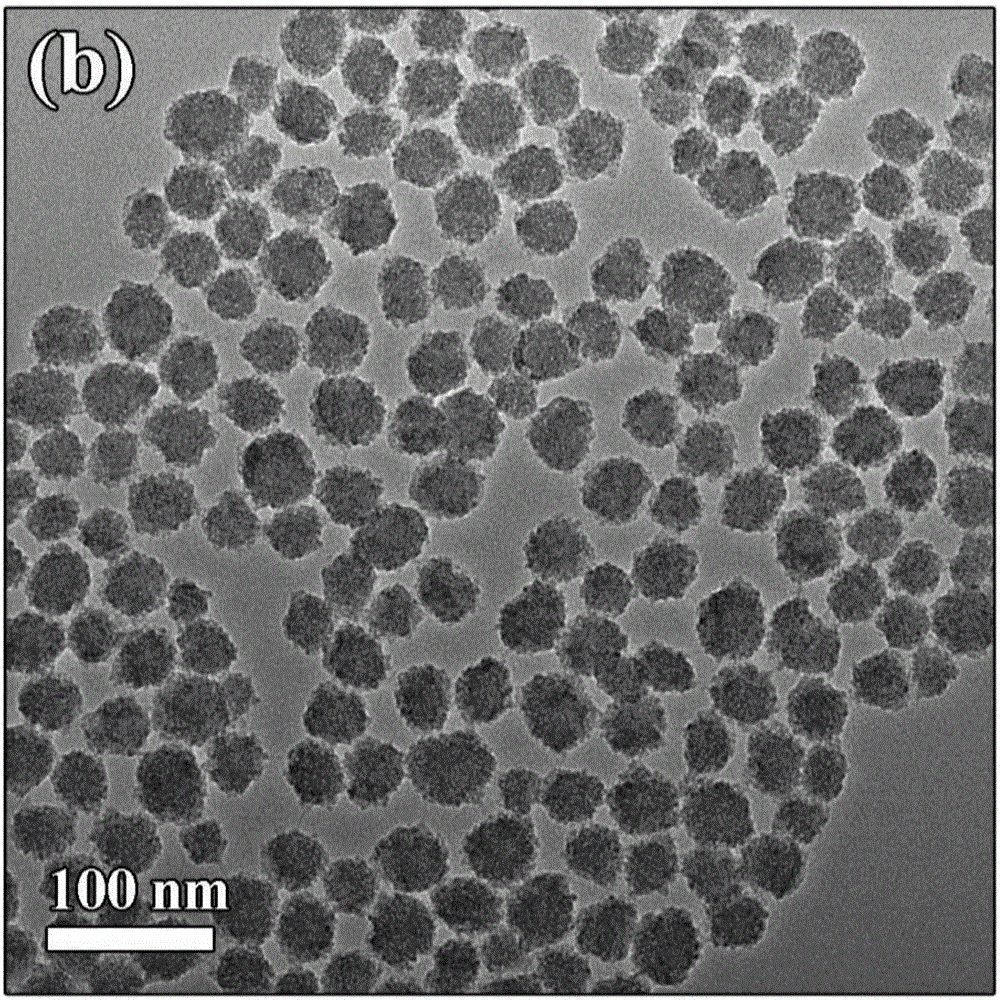

Yttrium vanadate nanoparticles, rare earth ion-doped yttrium vanadate nanoparticles and preparation method of yttrium vanadate nanoparticles and rare earth ion-doped yttrium vanadate nanoparticles

A technology of nano-particles and rare earth ions, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problems of poor particle shape, complex process, poor water solubility, etc., and achieve good process repeatability, size The effect of uniform distribution and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (a) Mix 0.6 mmol sodium orthovanadate dodecahydrate and 6 mL water in a weighing bottle, stir at room temperature until uniform, and obtain an aqueous solution of sodium orthovanadate.

[0038] (b) First weigh 0.2594g of polyacrylic acid into another weighing bottle, then add 0.6mmol of yttrium chloride hexahydrate, and then add 9mL of water. Mix evenly to obtain a reaction mixture solution.

[0039] (c) Inject the prepared aqueous solution of sodium orthovanadate into the reaction mixture solution, stir until uniform, and use the prepared concentration of 1mol L -1 sodium hydroxide solution to adjust the pH of the reaction mixture to 12, and continued to stir for 30 hours.

[0040] (d) Add ethanol precipitation and centrifugation to the reaction product, wash the precipitate repeatedly with water and ethanol several times, to remove unreacted excess substances in the reaction, and then disperse in 3ml of water to prepare a water-soluble product with good dispersibility....

Embodiment 2

[0043] (a) Mix 0.6 mmol sodium orthovanadate dodecahydrate and 6 mL water in a weighing bottle, stir at room temperature until uniform, and obtain an aqueous solution of sodium orthovanadate.

[0044] (b) First weigh 0.2594g of polyacrylic acid into another weighing bottle, then add 0.6mmol of yttrium chloride hexahydrate, and then add 9mL of water. Mix evenly to obtain a reaction mixture solution.

[0045] (c) Inject the prepared aqueous solution of sodium orthovanadate into the reaction mixture solution, stir until uniform, and use the prepared concentration of 1mol L -1 The sodium hydroxide solution adjusted the pH of the reaction mixture to 12, transferred the reaction solution into a three-necked bottle, reacted at 80° C. for 30 minutes, and cooled to room temperature.

[0046] (d) The reaction product is added to ethanol precipitation, centrifugation, and the precipitate is repeatedly washed with water and ethanol several times to remove unreacted excess substances in t...

Embodiment 3

[0049] (a) Mix 0.6 mmol sodium orthovanadate dodecahydrate and 6 mL water in a weighing bottle, stir at room temperature until uniform, and obtain an aqueous solution of sodium orthovanadate.

[0050] (b) First weigh 0.2594g polyacrylic acid into another weighing bottle, then add 0.51-0.57mmol yttrium chloride hexahydrate, 0.03-0.09mmol europium chloride hexahydrate, samarium chloride hexahydrate or chloride hexahydrate Dysprosium, then add 9mL of water. Mix evenly to obtain a reaction mixture solution.

[0051] (c) Inject the prepared aqueous solution of sodium orthovanadate into the reaction mixture solution, stir until uniform, and use the prepared concentration of 1mol L -1 sodium hydroxide solution to adjust the pH of the reaction mixture to 12, and continued to stir for 30 hours.

[0052] (d) The reaction product is precipitated by adding ethanol, centrifuged, and the precipitate is repeatedly washed with water and ethanol several times to remove unreacted excess subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com