Patents

Literature

133 results about "Yttrium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yttrium(III) chloride is an inorganic compound of yttrium and chloride. It exists in two forms, the hydrate (YCl3(H2O)6) and an anhydrous form (YCl3). Both are colourless solids that are highly soluble in water, and deliquescent.

Method for preparing fluorescent nano material converted on NaYF4

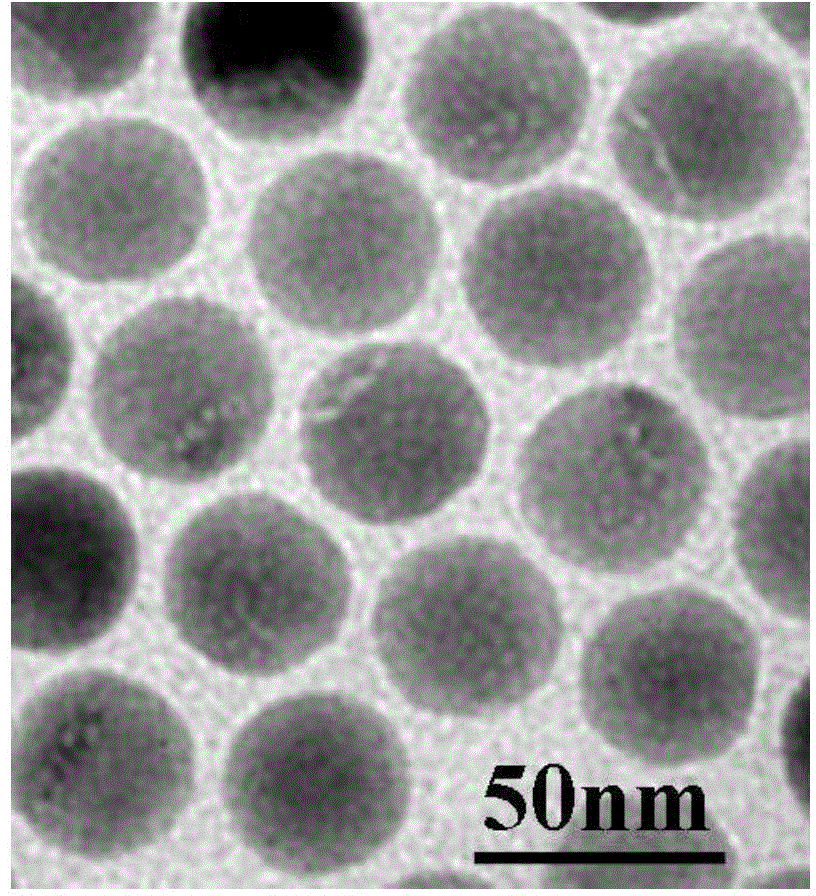

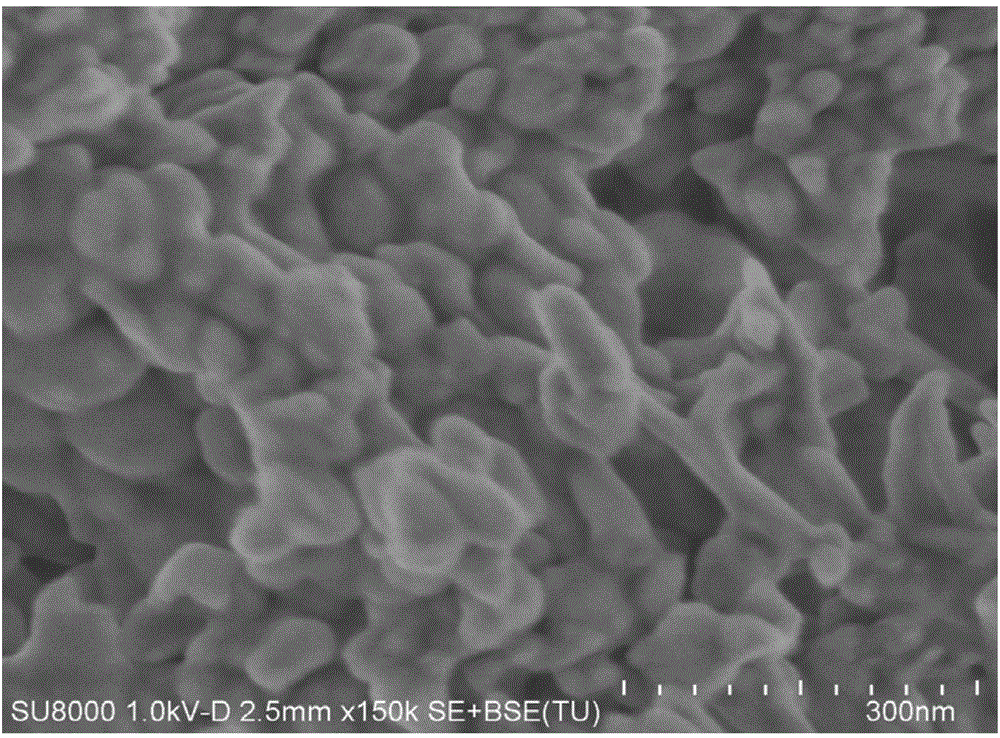

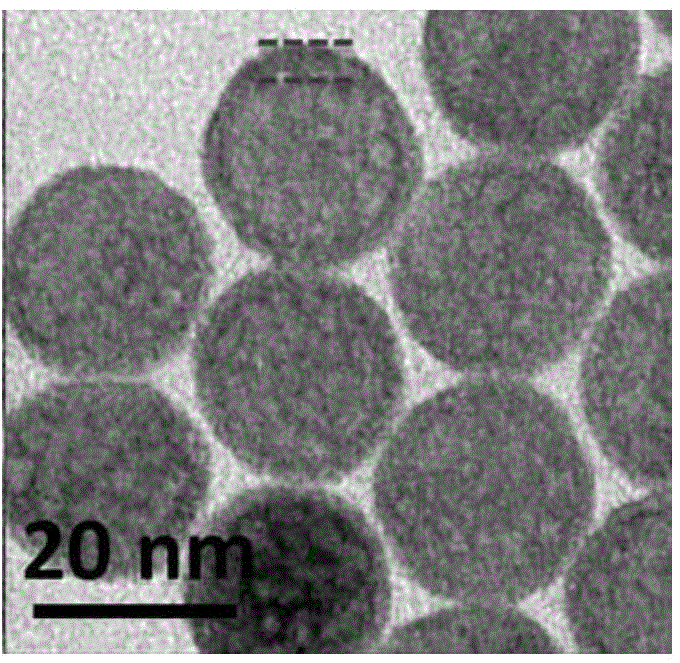

InactiveCN101525540ASmall sizeGood dispersionPolycrystalline material growthFrom normal temperature solutionsSolubilityFluorescence

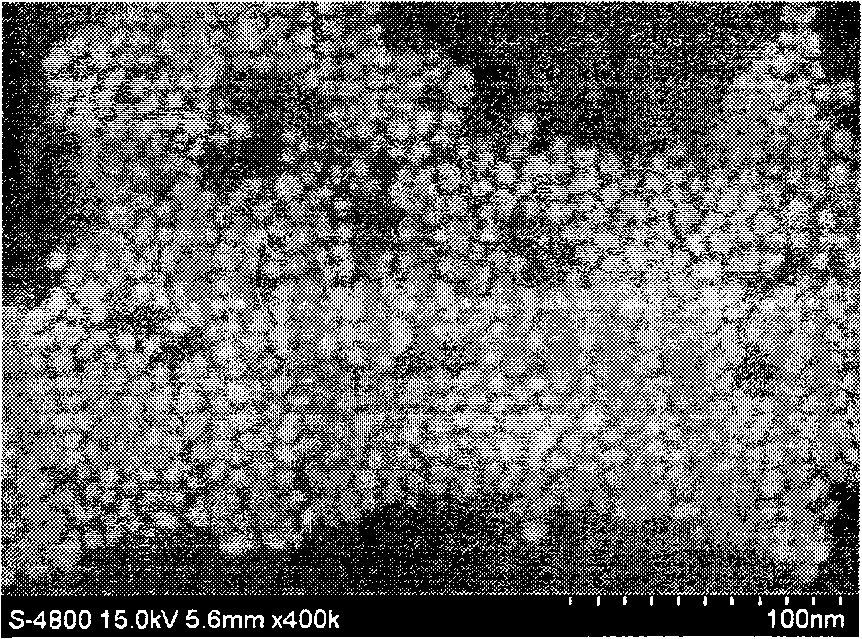

The invention relates to a method for preparing fluorescent nano material converted on NaYF4, comprising the steps: yttrium nitrate, ytterbium nitrate and erbium nitrate or yttrium chloride, ytterbium chloride, erbium chloride and thulium chloride are dissolved in de-ionized water according to the mixture radio that the mol ratio of rare earth ions which are yttrium ion, ytterbium ion and erbium ion is equal to (70-95): (1-25): (0.5-10), so that the mixed solution is prepared; water soluble polymer having the ligand radical with the rare earth ions is added into the mixed solution for stirring reaction to form complex compound; the pH value of the mixed solution is adjusted to be 2-6; sodium fluoride, ammonium fluoride or hydrofluoric acid can be added into the mixed solution and stirred until colloid solution that is approximately transparent is obtained; then, the colloid solution is put into a high pressure closed reactor and heated at the temperature of 140-200 DEG C; after that the obtained product is cooled to be the room temperature, centrifugated, separated, washed and dried, finally, the fluorescent nano material converted on NaYF4 is obtained. The method can be used for preparing the converted material at lower temperature, the particle size and the appearance can be controlled, and the water-solubility is good.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

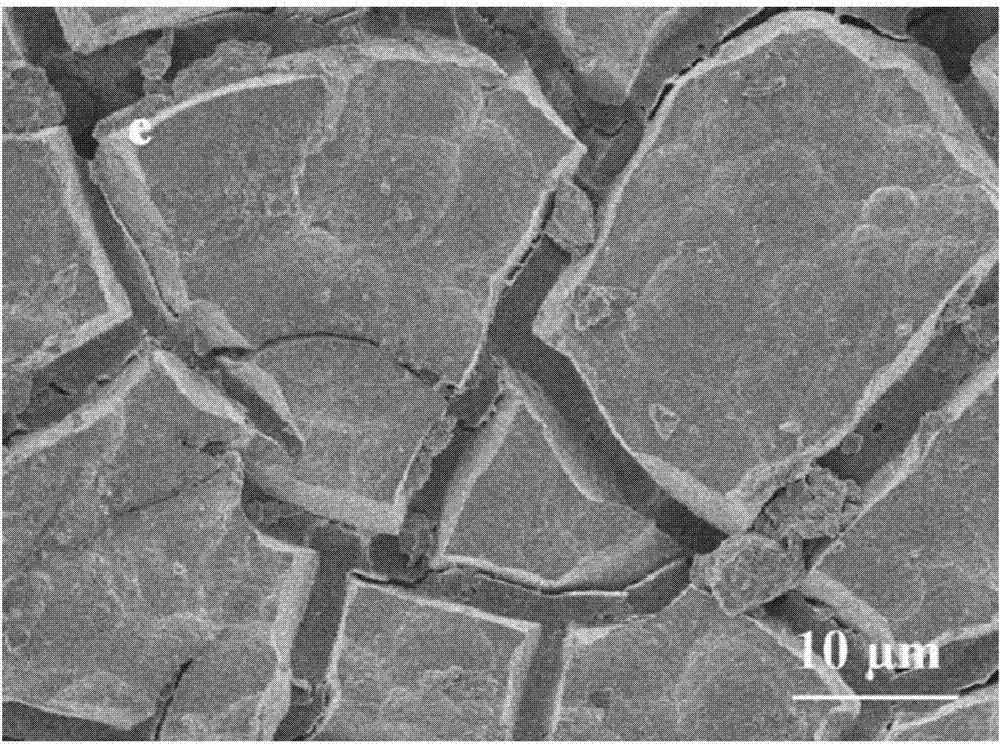

Method for preparing zirconium oxide refractory fibre

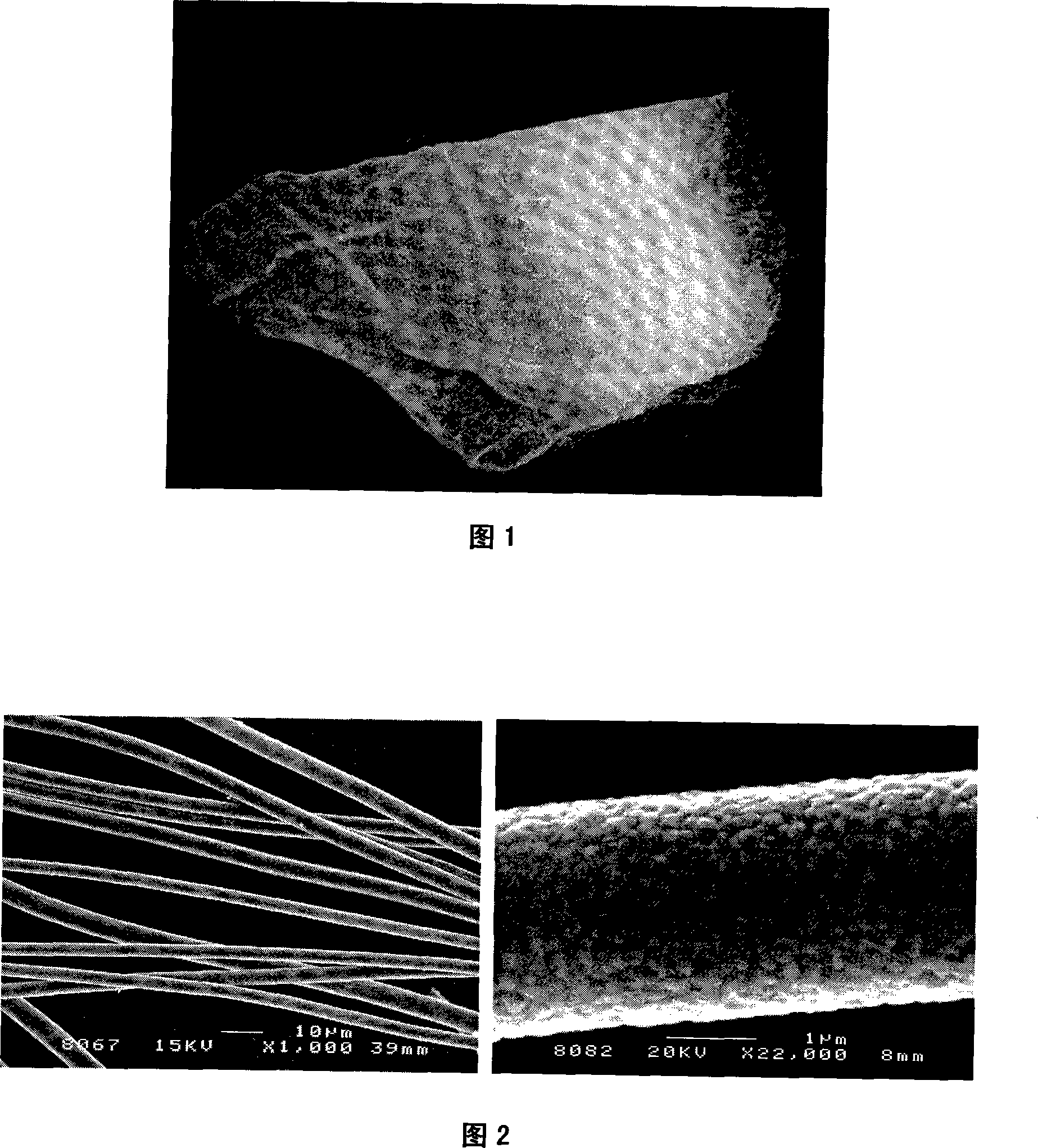

The present invention provides a method for preparing a zirconium oxide refractory fiber. The method adopts zirconium oxychloride, aqueous hydrogen peroxide solution, yttrium chloride or yttrium nitrate as raw material, the inorganic zirconium spinnable glue solution is made by reaction and compression, the gelatinous fiber can be obtained by centrifugal fiber forming, and after heat treating sintering the zirconium oxide refractory fiber which has the following advantages can be obtained: crystal phase composition with square phase and / or cubic phase zirconium oxide, purity up to 99.5% above, diameter around 5 mu m, length approximate continuous, soft and flexible property and without slag including sphere. The using temperature of the fiber is above 1600 DEG C, the material can be used as extreme temperature refractory, heat insulation material, protecting material, ablative material, satellite battery separator material and the like, used for the fields of aerospace, war industry and national defense, atomic energy and the like; the fiber can also be used as the flame-proof heat-insulating material of the extraordinary high-temperature electric furnace with temperature 1600 DEG C to 2200 DEG C, the oil or gas burning furnace and other extraordinary high-temperature heating mechanism, and is used for the fields of ceramic sintering, crystal growth, metal smelting, petroleum cracking, scientific researching and the like. The invention totally adopts the inorganic raw material, has the advantages of low cost, no pollution, simple technique and excellent effect.

Owner:山东红阳高温节能材料股份有限公司

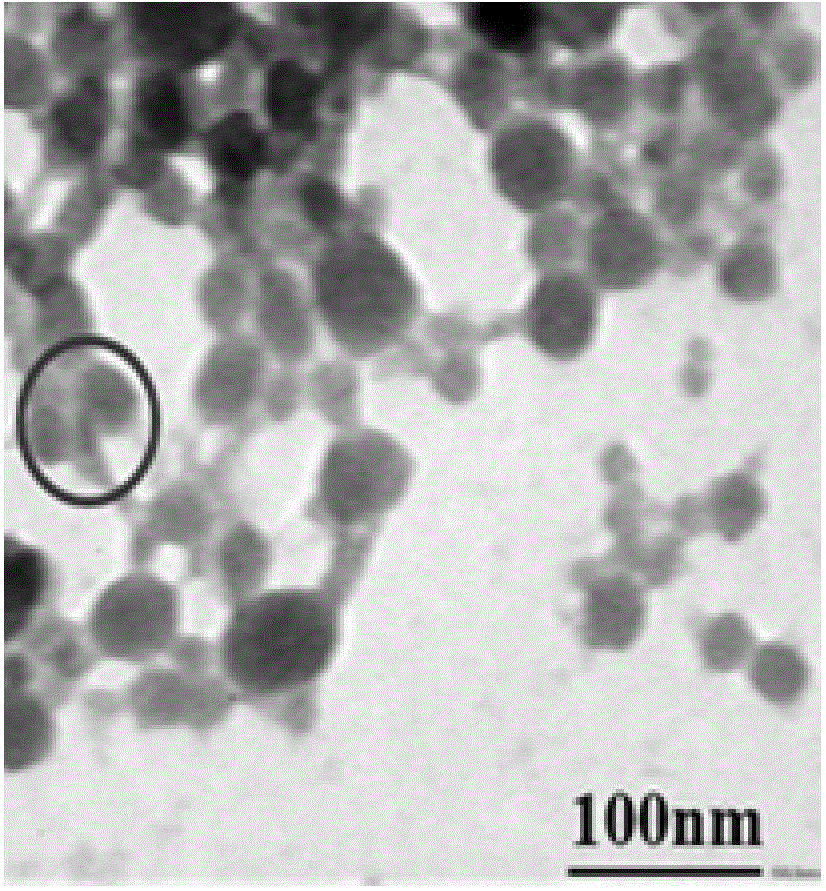

Method for preparing up-conversion fluorescent matrix material NaYF4 nano crystal

InactiveCN1935938ASimple processSimple equipmentLuminescent compositionsRare earth ionsSodium fluoride

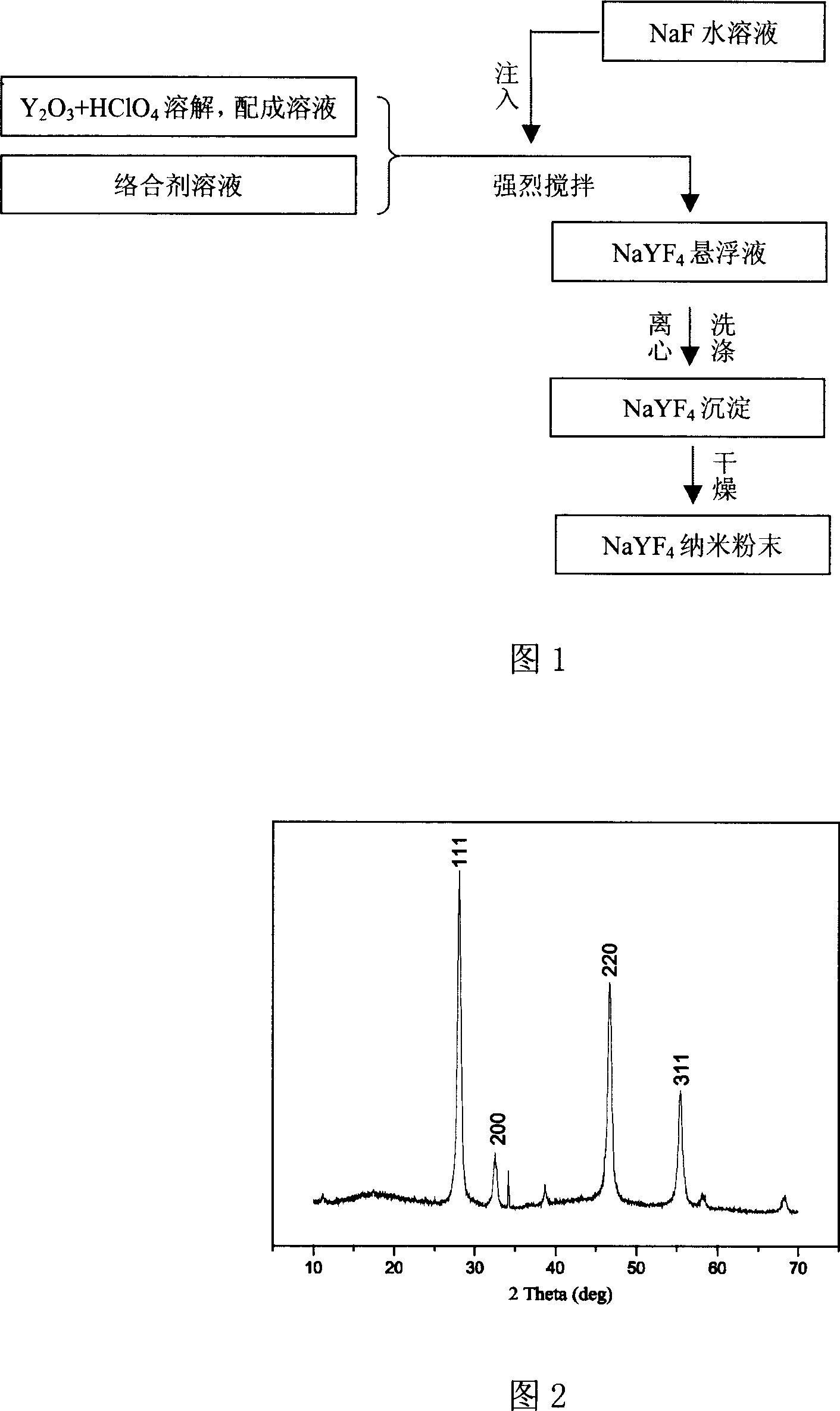

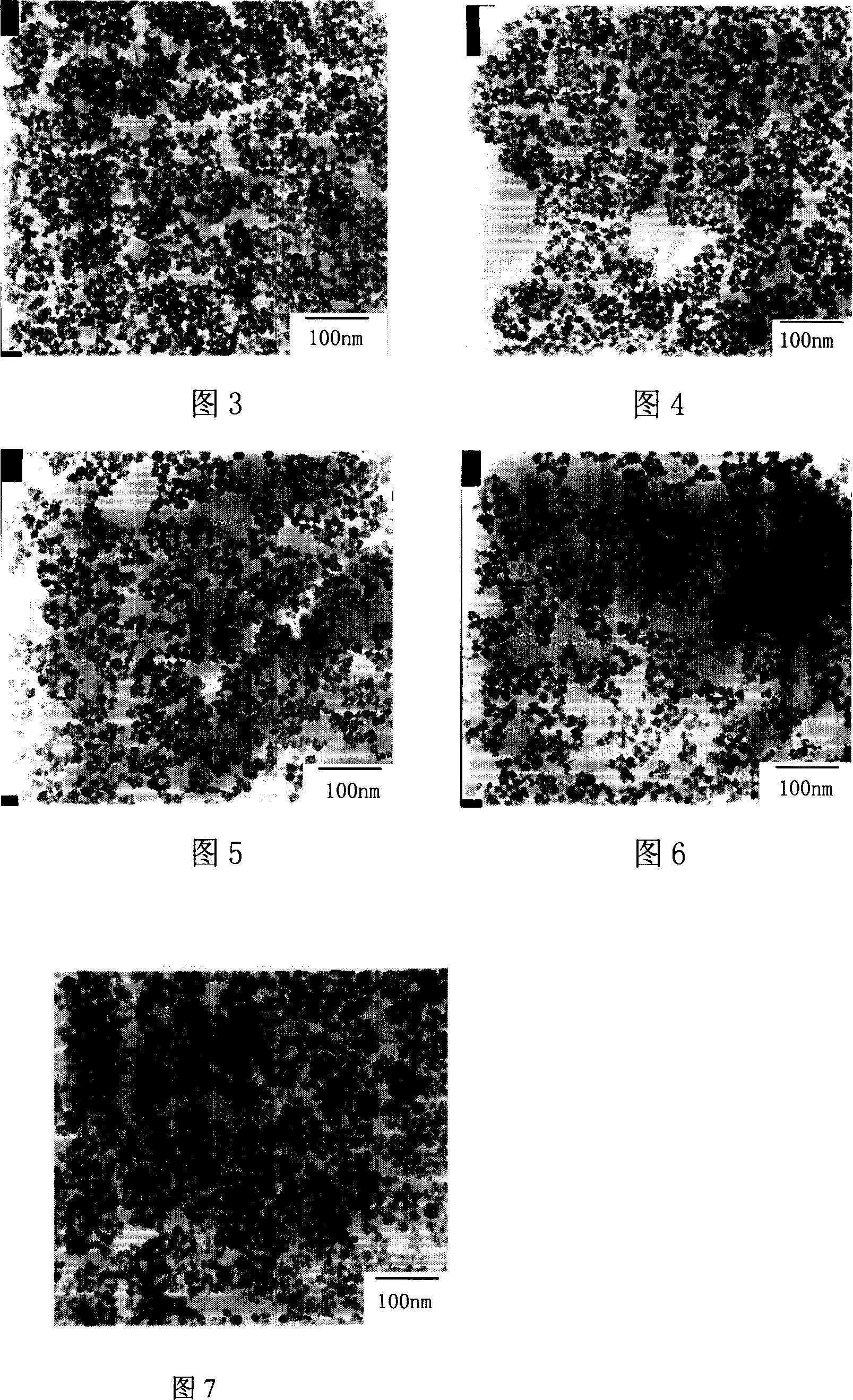

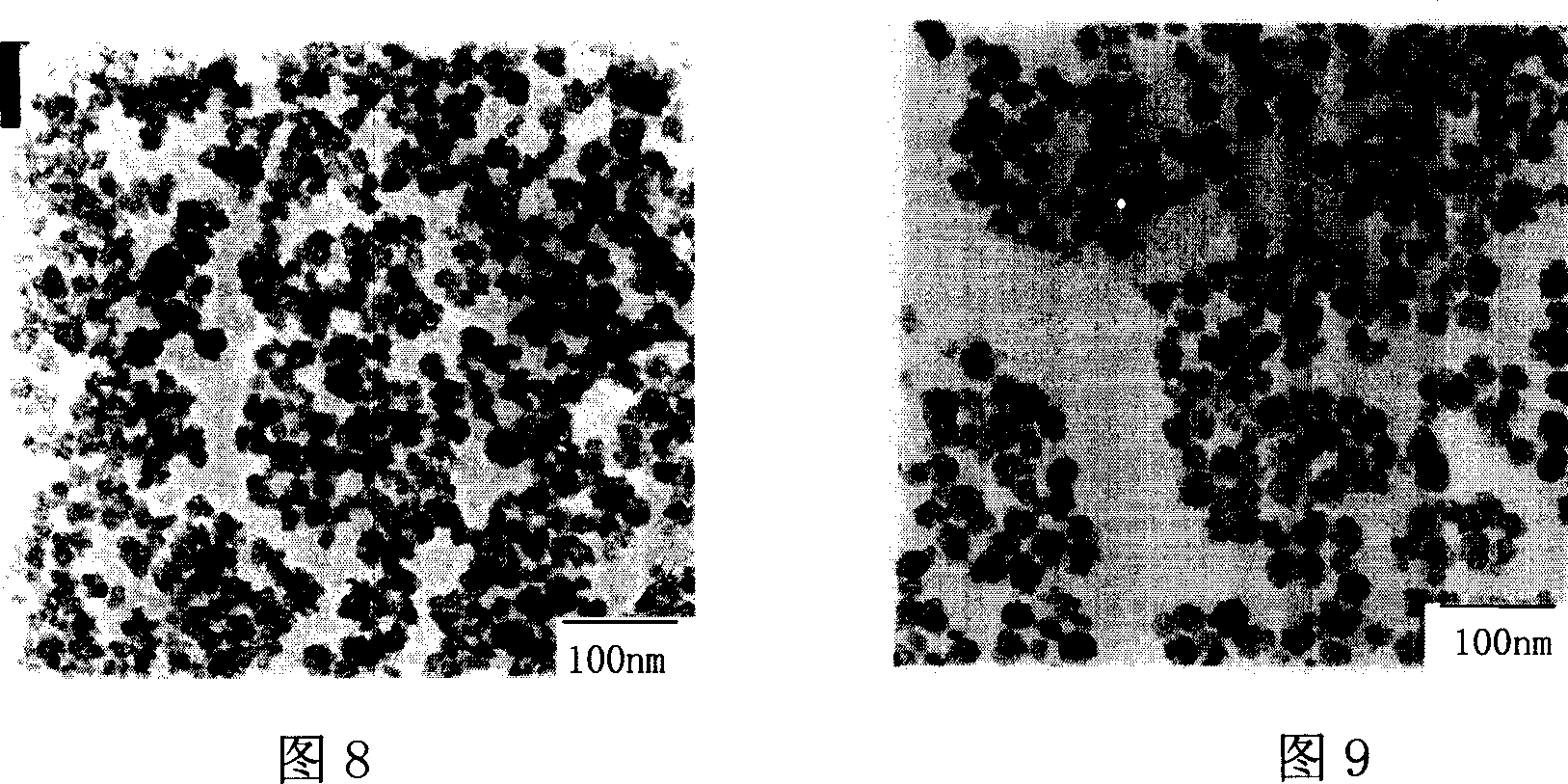

The invention discloses supra transition luminescence substrate material NaYF4 nanometer crystal preparing method. It includes the following steps: (1) dissolving rare earth yttrium oxide in perchloric acid or hydrochloric acid with 0.1-0.5mol / l density and 0-6 pH to produce perchloric acid yttrium or yttrium chloride solution; (2) preparing hydroxyl carboxyl series complexing agent with 0.2-1.0mol / l density, mixing it with the (1) solution, adjusting the pH at 0-6; the mol ratio of the perchlorate or hydrochloride and hydroxyl carboxyl series complexing agent is 1:1-5; (3) preparing sodium fluoride aqueous solution with 0.02-1mol / l density and 10 pH, adding the (2) solution at 0-45 degree centigrade, aging for 1-5h; the mol ratio of the sodium fluoride and the total rare earth ion is 1:1.2-30; (4) separating precipitate, washing, drying to gain nanometer NaYF4 particle. The produced NaYF4 particle has the advantages of controllable size with 10-25 nanometer, simple technology and device, good product quality and repeatability.

Owner:DONGHUA UNIV

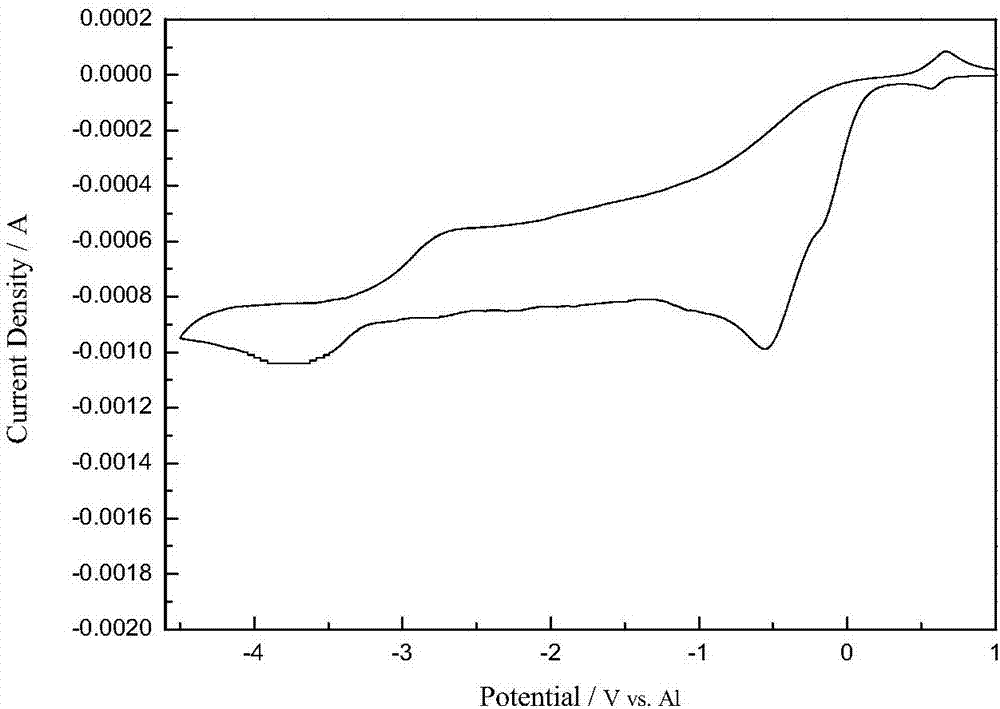

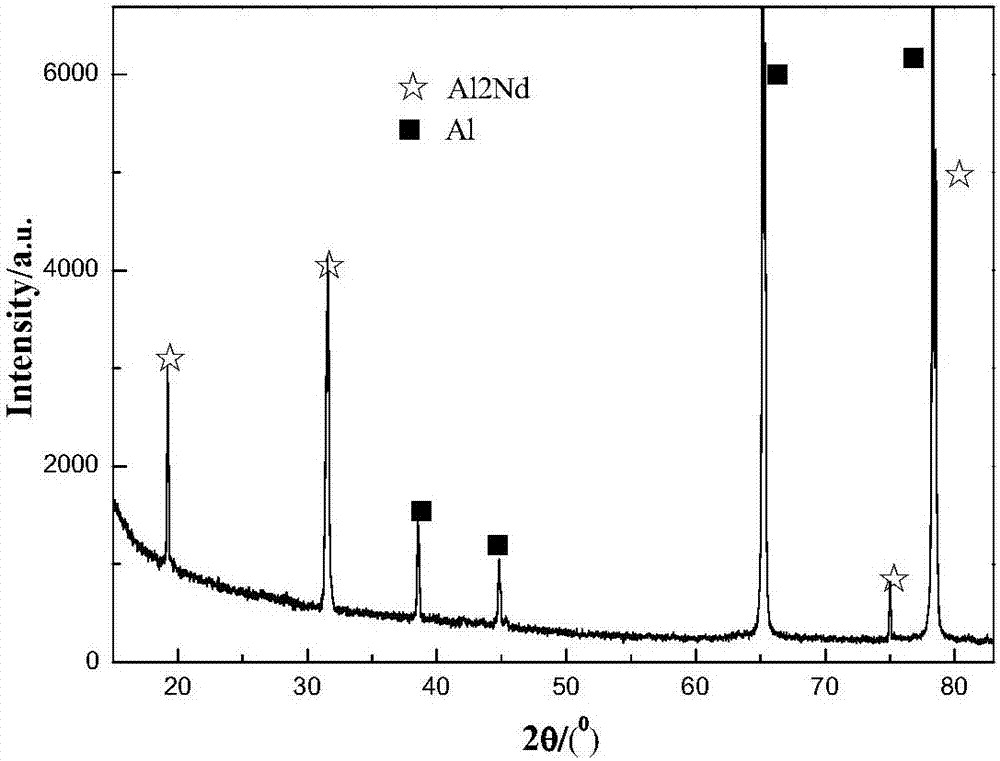

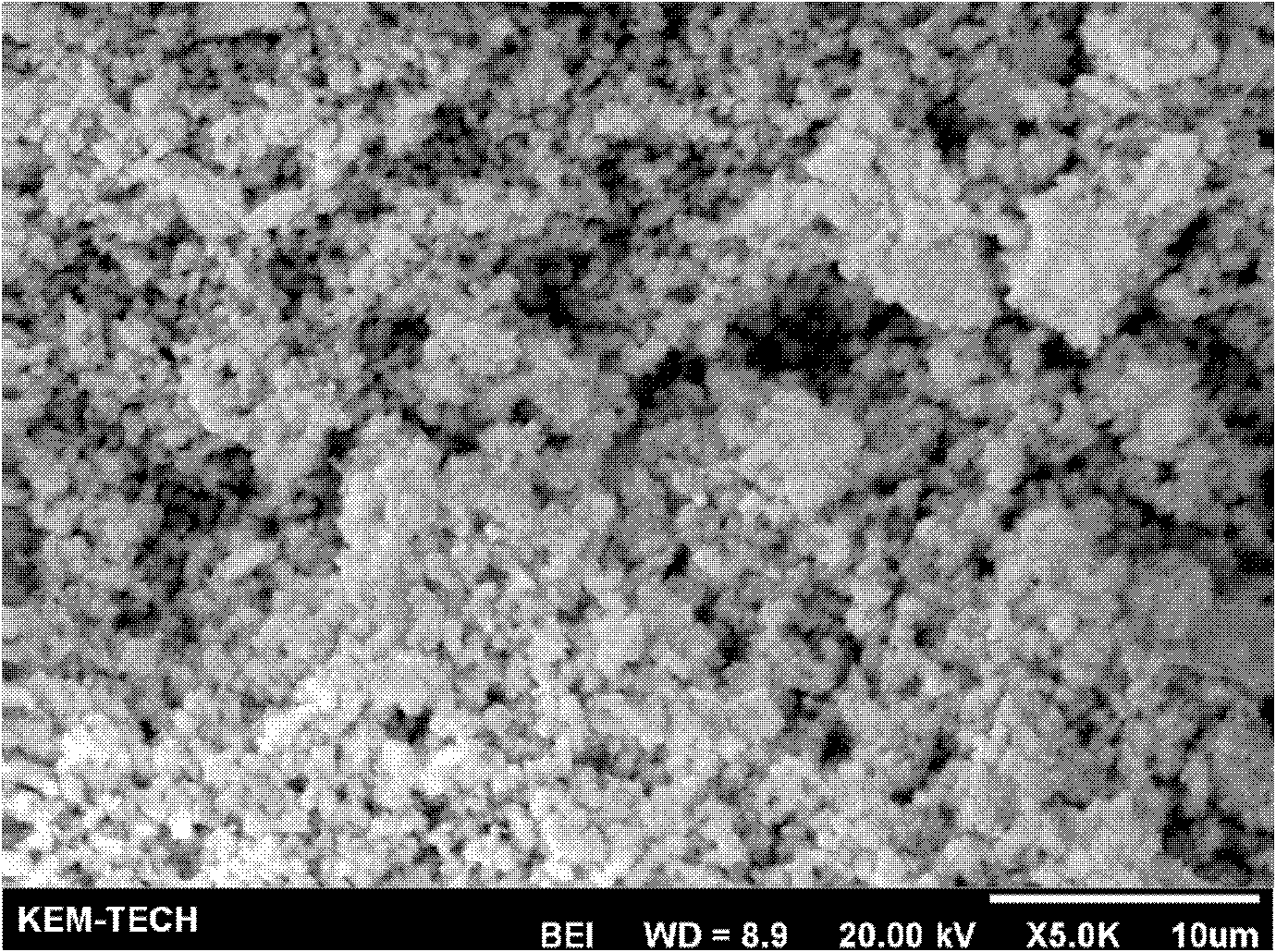

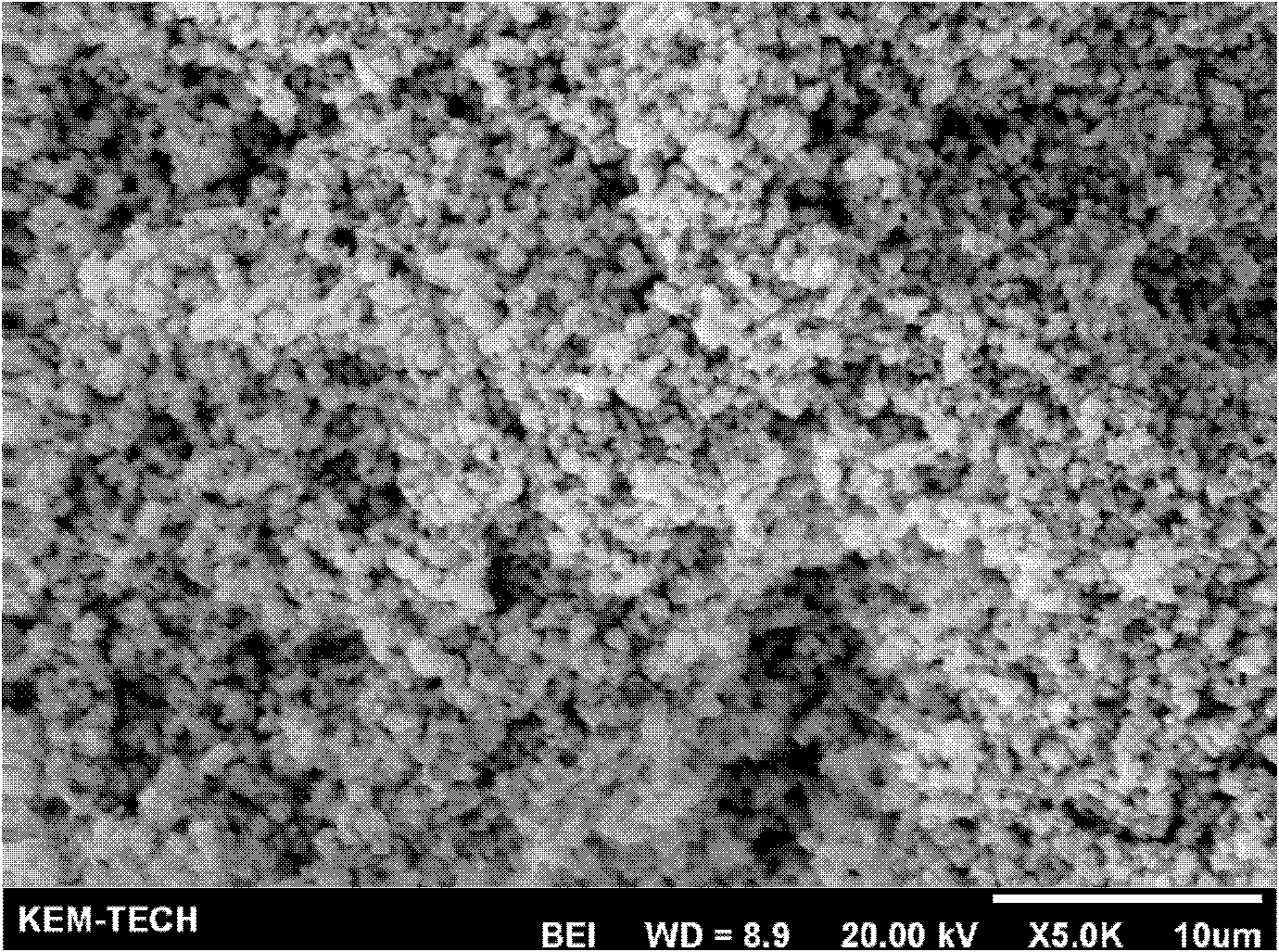

Method for preparing aluminum-based rare earth alloy through near-room-temperature electrolysis

The invention belongs to the field of low-temperature electrochemical extraction and particularly relates to a method for preparing an aluminum-based rare earth alloy through near-room-temperature electrolysis. The method for preparing the aluminum-based rare earth alloy through near-room-temperature electrolysis is an electrolytic method, and a electrolyte adopted by the electrolytic method is formed by rare earth chloride and ionic liquid, wherein the ionic liquid accounts for 96-98% of the total mass of the electrolyte, the rare earth chloride accounts for 2-4% of the total mass, and the rare earth chloride is one of neodymium chloride, lanthanum chloride, cerium chloride, scandium chloride, yttrium chloride, praseodymium chloride, samarium chloride, europium chloride, gadolinium chloride and terbium chloride. According to the technological for preparing the aluminum-based rare earth alloy through near-room-temperature electrolysis, operation is easy, and cost is low; and the technological reserve and theoretical support are provided for green extraction of the low-cost aluminum-based rare earth alloy.

Owner:NORTHEASTERN UNIV

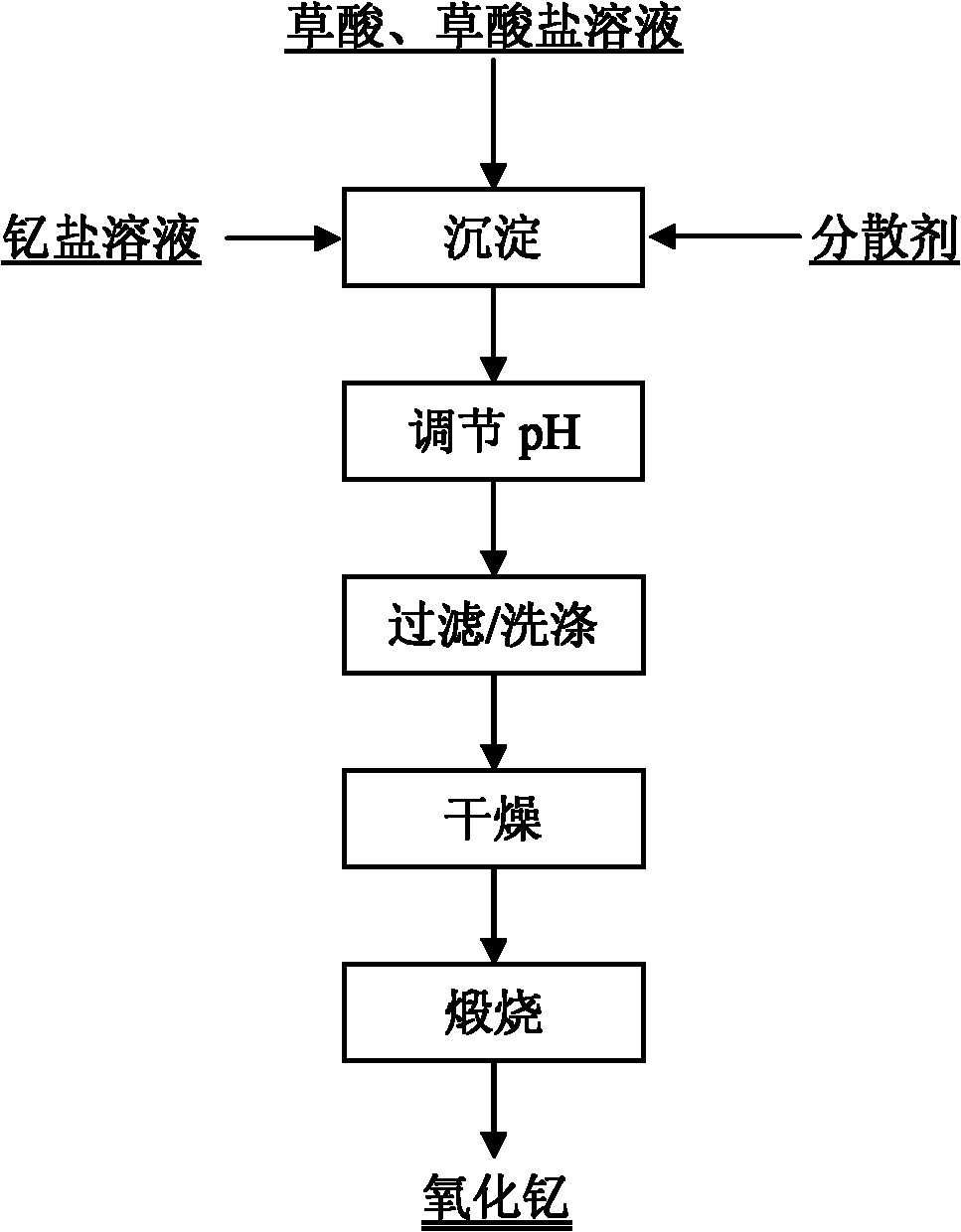

Submicron yttrium oxide and preparation method thereof

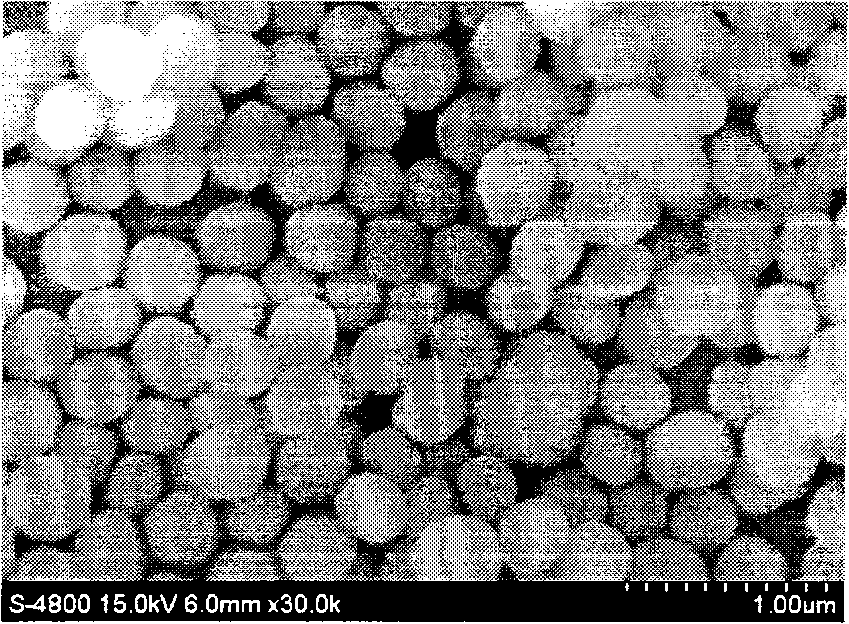

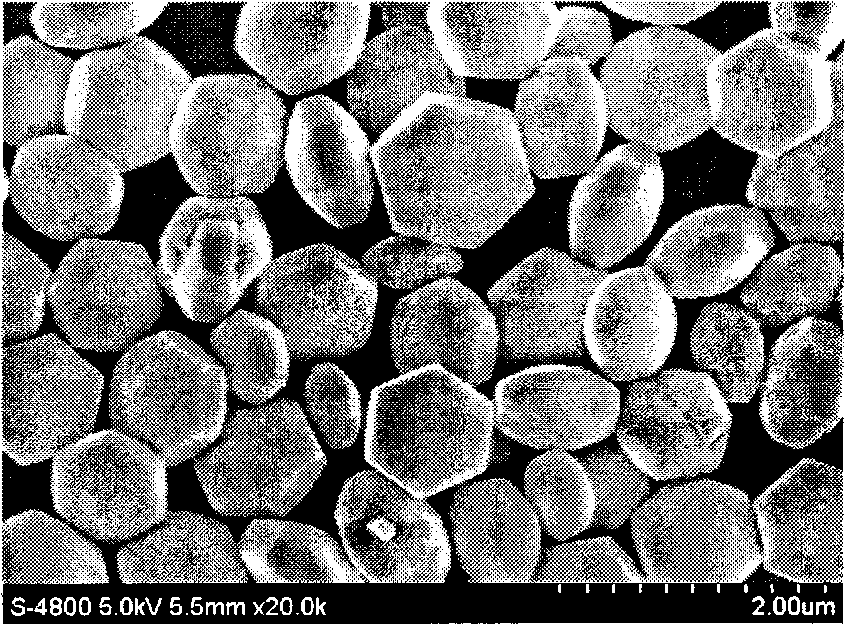

The invention relates to submicron yttrium oxide and a preparation method thereof. The preparation method comprises the following steps of: in the presence of a compound precipitator formed by oxalic acid and one oxalate of ammonium oxalate, ammonium hydrogen oxalate, sodium oxalate, sodium hydrogen oxalate, potassium oxalate and potassium hydrogen oxalate, adding a yttrium nitrate and / or yttrium chloride solution into a base solution under certain reaction conditions, regulating the pH value of precipitation size, filtering and washing precipitate for a plurality of times, drying, and calcining to obtain the submicron yttrium oxide. The yttrium oxide has the physical properties that D50 is less than 1.0Mum and more than 0.1Mum, D90 is less than or equal to 1.0Mum, the particle size distribution coefficient Q is less than or equal to 0.20 and the particles are square or spherical in shapes. The invention has the advantages of simple process, operation easiness, low requirement on equipment, low production cost, convenience in production process control, good precipitate dispersibility and filtering property in a technological process, easiness in implementation of industrialized production and stable quality of the prepared product.

Owner:QIANDONG RARE EARTH GRP

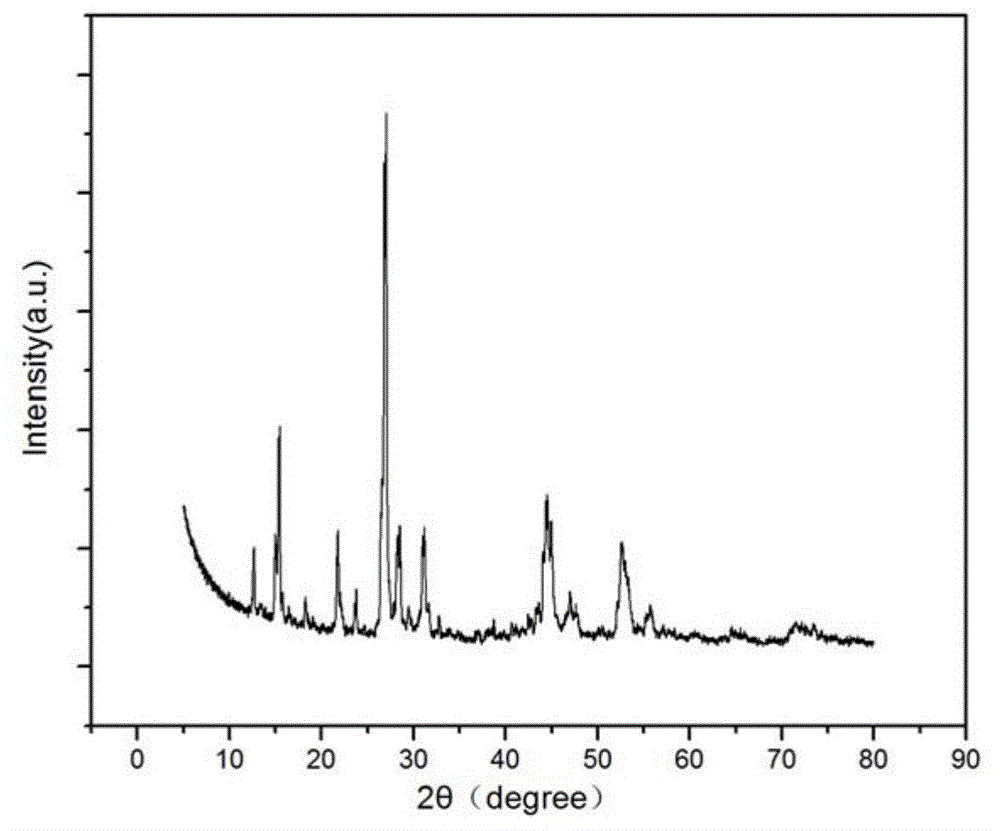

Hydro-thermal synthesis method for nanometer YSZ (Yttria-Stabilized Zirconia) serving as electrolyte material of solid oxide fuel cell

The invention discloses a hydro-thermal synthesis method for nanometer YSZ (Yttria-Stabilized Zirconia, i.e. ZrO2 eutectic containing 8%-10% of Y2O3 in molar fraction) serving as an electrolyte material of a solid oxide fuel cell. The YSZ is a main raw material of the solid oxide fuel cell; and manufacturing the YSZ of high quality is an important approach to increase the performance of the solid oxide fuel cell. The hydro-thermal synthesis method comprises the following steps of: dissolving a certain proportion of zirconium oxychloride and yttrium chloride in water, co-precipitating the mixed liquor by using urea as a precipitating agent in the temperature of more than 70 DEG C, pulping filter cakes by using deionized water after ageing, filtering and washing, carrying out hydro-thermal synthesis on sizing agent under a high temperature and a high voltage to form nanometer crystal products, sanding and carrying out ultrasonication, high-speed centrifugal seperation and spray drying to prepare the nanometer YAZ with good eutectic effect and excellent performance.

Owner:汉高(烟台)新材料股份有限公司

Rare earth compound/titanate coupling agent modified ultrafine calcium carbonate filler

ActiveCN103788410ASimple production processGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsRare earthPolyvinyl chloride

The invention relates to a calcium carbonate filler and in particular relates to a rare earth compound / titanate coupling agent modified ultrafine calcium carbonate filler. The modified calcium carbonate is prepared from the following raw materials in parts by weight: 200 parts of ultrafine calcium carbonate, 1-2 parts of talcum powder, 1-2 parts of homo-polypropylene, 2-4 parts of jade powder, 1-2 parts of zinc sulfate, 1-2 parts of yttrium chloride, 1-2 parts of praseodymium chloride, 1-2 parts of lanthanum nitrate, 1-2 parts of titanate coupling agent TMC-TTS, 1-2 parts of graphene and 4-5 parts of accessory ingredient. According to the modified calcium carbonate powder, composite rare earth compounds such as yttrium chloride, praseodymium chloride, lanthanum nitrate and the like and the titanate coupling agent TMC-TTS are used for modifying the ultrafine calcium carbonate, so that performance indexes such as oil absorption value, viscosity and activating rate are improved; the ultrafine calcium carbonate is more easily dispersed and dissolved in high-molecular polymers; and when the ultrafine calcium carbonate is used for filling a PVC (Polyvinyl Chloride) material, the mechanical property of the PVC material is effectively improved and the good effect of toughening and reinforcing is achieved.

Owner:安徽雪城超细碳酸钙有限公司

Improved yttrium partially stabilized zirconia production process

Disclosed is an improved yttrium partially stabilized zirconia production process which comprises subjecting the mixed water dissolved material of zirconium oxychloride and yttrium chloride for coprecipitation reaction with ammonia, i.e., letting the mixed water dissolved material of zirconium oxychloride and yttrium chloride into 4-6N of ammonia for coprecipitation, terminating the reaction when the pH of the solution reaches 9-10, the concentration of the zirconium oxychloride in the mixed water solution being 280-350g / L if converted to zirconium oxide, the ratio of zirconium oxide and yttrium oxide is 95.2-94 : 4.8-6, then washing the precipitate with deionized water, carrying out centrifugal dehydration, drying, firing and disintegrating to obtain the product.

Owner:宜兴新兴锆业有限公司

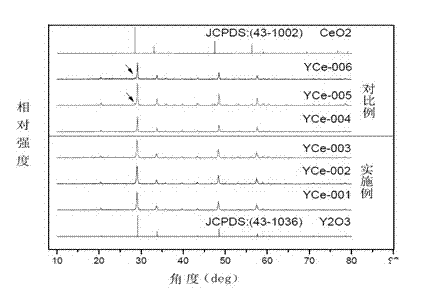

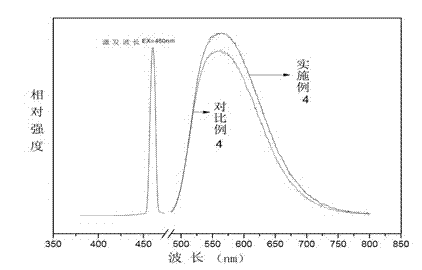

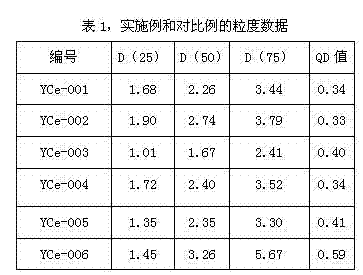

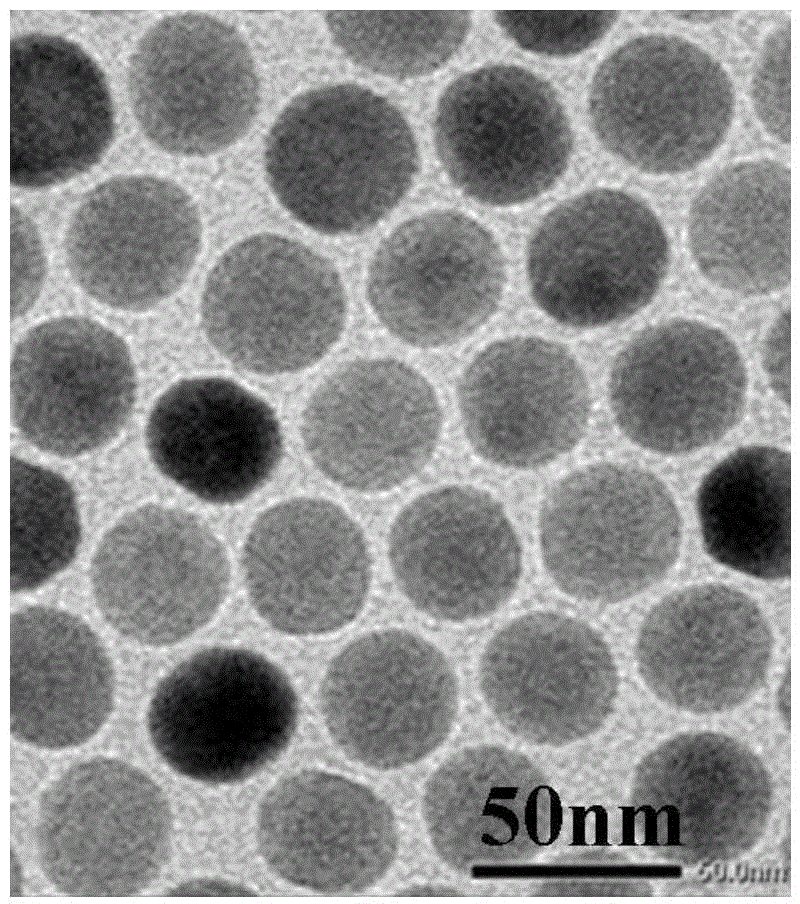

Preparation method of granular yttrium cerium oxide solid solution

The invention discloses a preparation method of a granular yttrium cerium oxide solid solution. A granular (1-3mum) yttrium cerium rare earth oxide is successfully synthesized from yttrium chloride solution and cerium oxide solid powder (Y2O3 / REO>=99.99%, CeO2 / REO>=99.99%) in the presence of oxalic acid serving as a precipitating agent by adopting a liquid phase precipitation method. According to the preparation method, through controlling influence factors such as feed liquid concentration and precipitation water bath temperature in a synthesis process, the yttrium cerium rare earth oxide which is small in particle size D50 of 1.0-3.0mum and uniform in size distribution is synthesized. The preparation method is short in process, low in cost, convenient to operate, and easy to produce in large scale.

Owner:甘肃稀土新材料股份有限公司

Preparation method of NaYF4:Er<3+>@NaYF4@TiO2 nanocrystalline dye-sensitized solar cell photo-anode material

ActiveCN104974758AQuick conversionFully adsorbedLight-sensitive devicesPhotovoltaic energy generationHigh pressureOleylamine

The invention relates to a preparation method of a NaYF4:Er<3+>@NaYF4@TiO2 nanocrystalline dye-sensitized solar cell photo-anode material, relating to a preparation method of a dye-sensitized solar cell photo-anode material, and aiming to solve the technical problem that dye-sensitized solar cells prepared in the prior art have low photoelectric conversion efficiency. The method comprises the following steps: firstly preparing nanocrystalline with the characteristic of spectrum conversion with yttrium chloride, erbium chloride, sodium hydroxide and ammonium fluoride and then adding nanocrystalline to a reaction liquid of yttrium chloride, sodium hydroxide and ammonium fluoride to prepare nanocrystalline NaYF4:Er<3+>@NaYF4 with a core-shell structure; then adding nanocrystalline with the core-shell structure to a mixed liquid of oleylamine and oleic acid, then adding ethanol, water and tetrabutyl titanate, reacting in a high pressure reactor, and washing and drying to obtain nanocrystalline NaYF4:Er<3+>@NaYF4@TiO2. Nanocrystalline can be mixed in the photo-anode material to prepare dye-sensitized solar cells.

Owner:HARBIN HUIGONG TECH CO LTD

Mg-Gd-Y-Zr magnesium alloy refining flux and producing method thereof

The invention provides an Mg-Gd-Y-Zr magnesium alloy refining flux and a production method thereof. The chemical components of the flux are mixed according to the following mass percentages: potassium chloride of ranging from 30 to 50 percent, barium chloride of ranging from 5 to 20 percent, sodium chloride of ranging from 2 to 10 percent, calcium chloride of ranging from 10 to 20 percent, calcium fluoride of ranging from 2 to 8 percent, cryolite of ranging from 1 to 5 percent, gadolinium compound of ranging from 3 to 8 percent, yttrium compound of ranging from 3 to 8 percent, and zirconium compound of ranging from 2 to 8 percent, wherein, the gadolinium compound is gadolinium chloride, gadolinium carbonate or gadolinium fluoride, the yttrium compound is yttrium chloride, yttrium carbonate or yttrium fluoride, the zirconium compound is zirconium tetrachloride or potassium zirconium fluoride. The flux has good melting point, viscosity, wettability and the slag removing performance which is improved greatly. Because the flux does not contain magnesium chloride or react with the lanthanon such as gadolinium and yttrium, the chemical reaction loss of the lanthanon in the refining process is not caused, thereby being particularly suitable for the refining purifying process of the Mg-Gd-Y-Zr magnesium alloy and improving the refining effect of the magnesium fused mass.

Owner:SHANGHAI JIAO TONG UNIV

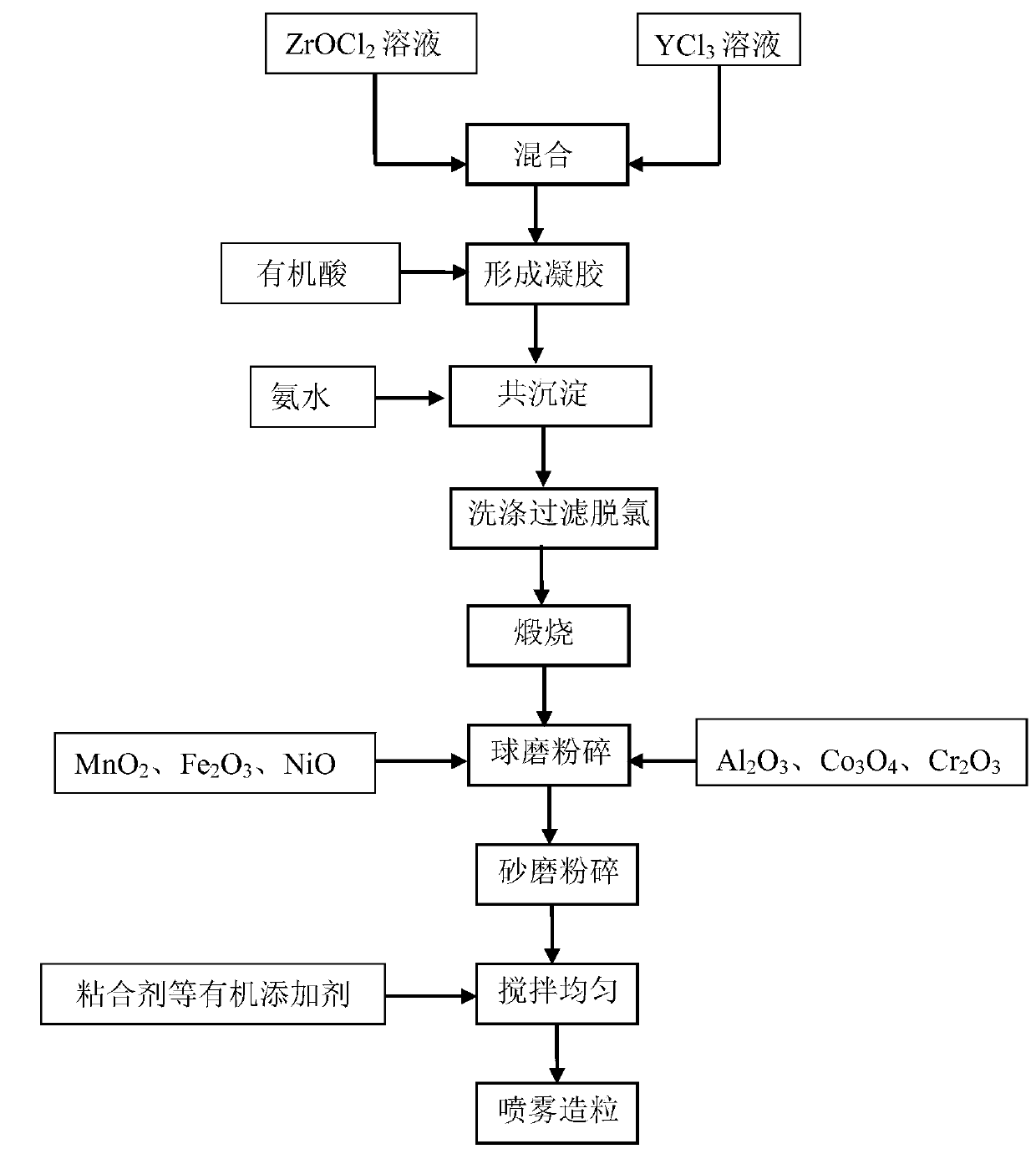

Preparation method of black yttrium-stabilized zirconium oxide powder

ActiveCN111204802AImprove stabilityUniform particle size distributionZirconium oxidesAdhesiveZirconium oxychloride

The invention belongs to the technical field of inorganic new materials, and particularly relates to a preparation method of black yttrium-stabilized zirconium oxide powder. The preparation method comprises the steps: mixing a zirconium oxychloride solution and a yttrium trichloride solution in a proportion; adding an organic acid to generate a gel, adding an ammonia water solution to neutralize and precipitate, washing, filtering and dechlorinating, calcining an obtained filter cake to obtain a precursor powder, adding a coloring agent and a binding agent, ball-milling, sanding and crushing,adding an adhesive and a release agent, uniformly mixing, spraying, granulating and drying to obtain the yttrium-stabilized zirconium oxide powder. The invention relates to the preparation method of black yttrium-stabilized zirconium oxide powder. The process is simple, the yield is high, the produced powder is good in stability, uniform in particle size distribution, good in flowability and stable in shrinkage rate; the sintering temperature is 1350 DEG C, which is 100 DEG C lower than the temperature of common zirconium oxide ceramic production, moulding is convenient, the blank strength ishigh, the processability is good, and black ceramic products prepared from the powder has the advantages of high strength, good toughness, good stability and the like.

Owner:长裕控股集团股份有限公司

Method for preparing narrow-distributed ultra-fine yttrium oxide by sodium carbonate precipitation

ActiveCN108910932AEradicate pollutionEasy to upgradeRare earth metal oxides/hydroxidesMaterial nanotechnologyRare earthUltra fine

The invention discloses a method for preparing narrow-distributed ultra-fine yttrium oxide by sodium carbonate precipitation. The method utilizes sodium carbonate as a precipitating agent and yttriumchloride as a material liquid and a parallel feeding method, strictly controls the conditions in seed crystal preparation, precipitation aging and staged roasting, especially controls the temperate and pH in the seed crystal preparation and precipitation aging and the temperature in the staged roasting, and prepares the narrow-distributed yttrium oxide powder with the primary particle sizes of less than or equal to 100nm, the secondary particle size D50 of less than or equal to 4 micrometers and (D90-D10) / (2D50) of less than 1.0. The method has the advantages of low cost, easy industrialization and removal of ammonia nitrogen pollution, can transform the advantages of China's plutonium resources into economic advantages and plays an important role in promoting the upgrading of the China'srare earth industry.

Owner:GANZHOU ZHANHAI IND & TRADING

Preparation method of nano zirconia coated alumina powder

The invention discloses a preparation method of nano zirconia coated alumina powder. The preparation method comprises the steps of by taking alumina as a main material, preparing zirconium oxychloride and yttrium chloride into a mixed solution; by taking urea or hexamethylenetetramine as a homogenous precipitation agent, carrying out temperature regulation to form a zirconium hydroxide coating layer on the surface of the alumina; and carrying out spray drying on the obtained object so as to obtain precursor powder, and calcining the precursor powder to obtain the nano zirconia coated alumina powder.

Owner:江苏金石研磨有限公司

Method for preparing rare-earth fluorescent up-conversion material by use of waste fluorescent powder

InactiveCN104388087ANo secondary pollutionRealize the comprehensive utilization of green high-value resourcesRecycling and recovery technologiesLuminescent compositionsRare-earth elementFiltration

The invention relates to a method for preparing a rare-earth fluorescent up-conversion material by use of waste fluorescent powder. The method comprises the following steps: weighing process waste fluorescent powder, and leaching the fluorescent powder in a sulfuric acid solution to obtain a solution; performing solid-liquid separation, regulating the pH by use of ammonia water, and then performing primary sedimentation, secondary sedimentation, third sedimentation, fourth sedimentation, aging and filtering to obtain filter residue; firing at a high temperature, cooling until the temperature drops to a room temperature, and then adding MOH solution and performing suction filtration to obtain white powder; adding a hydrochloric acid solution, and drying by distillation to obtain the mixture of anhydrous yttrium chloride and anhydrous europium chloride, MOH solid and MHF2 fine powder and RmF3 or RmCl3 solid, and homogenizing; adding a high boiling point solvent, heating and stirring; centrifuging, performing centrifugal washing on the obtained solid powder by use of normal hexane or acetone, drying and then washing by use of boiling water a plurality of times and drying, thereby obtaining the rare-earth fluorescent up-conversion material. The method for preparing the rare-earth fluorescent up-conversion material by use of the waste fluorescent powder has the advantage and the characteristic that green high-value recycling comprehensive utilization of rare earth elements in rare-earth trichromatic phosphor waste can be realized.

Owner:WUHAN UNIV OF TECH

Method for improving high temperature mechanical properties of hollow turbine blade ceramic mold

ActiveCN103193508AImprove high temperature mechanical propertiesExcellent high temperature mechanical propertiesPotassiumAlloy

The invention discloses a method for improving high temperature mechanical properties of a hollow turbine blade ceramic mold. According to the invention, a yttrium-aluminum garnet high temperature strengthening phase is synthesized from yttrium oxide and alumina through high temperature sintering, magnesium oxide is utilized at the same time for inhibiting growth of an alumina crystal grain under the condition of high temperature sintering, and titanium oxide is used for solution strengthening of alumina so as to improve high temperature strength of an alumina-based ceramic mold; finally, an yttrium chloride ion solution is used for dipping of the alumina-based ceramic mold to allow yttrium ions to be uniformly distributed in the alumina-based ceramic mold with a complex structure, so on the one hand, chloride ions are enabled to react with impurity Na and K ions in an alumina ceramic material to form sodium chloride and potassium chloride under high temperature sintering, thereby removing the Na element and the K element, and on the other hand, the yttrium ions are enabled to react with alumina under high temperature sintering for secondary formation of the yttrium-aluminum garnet high temperature strengthening phase. The method provided by the invention can be used for improving high temperature mechanical properties of a core-shell integrated alumina-based ceramic mold for a hollow turbine blade and improves a qualified rate of a directionally solidified high temperature alloy blade.

Owner:XI AN JIAOTONG UNIV +1

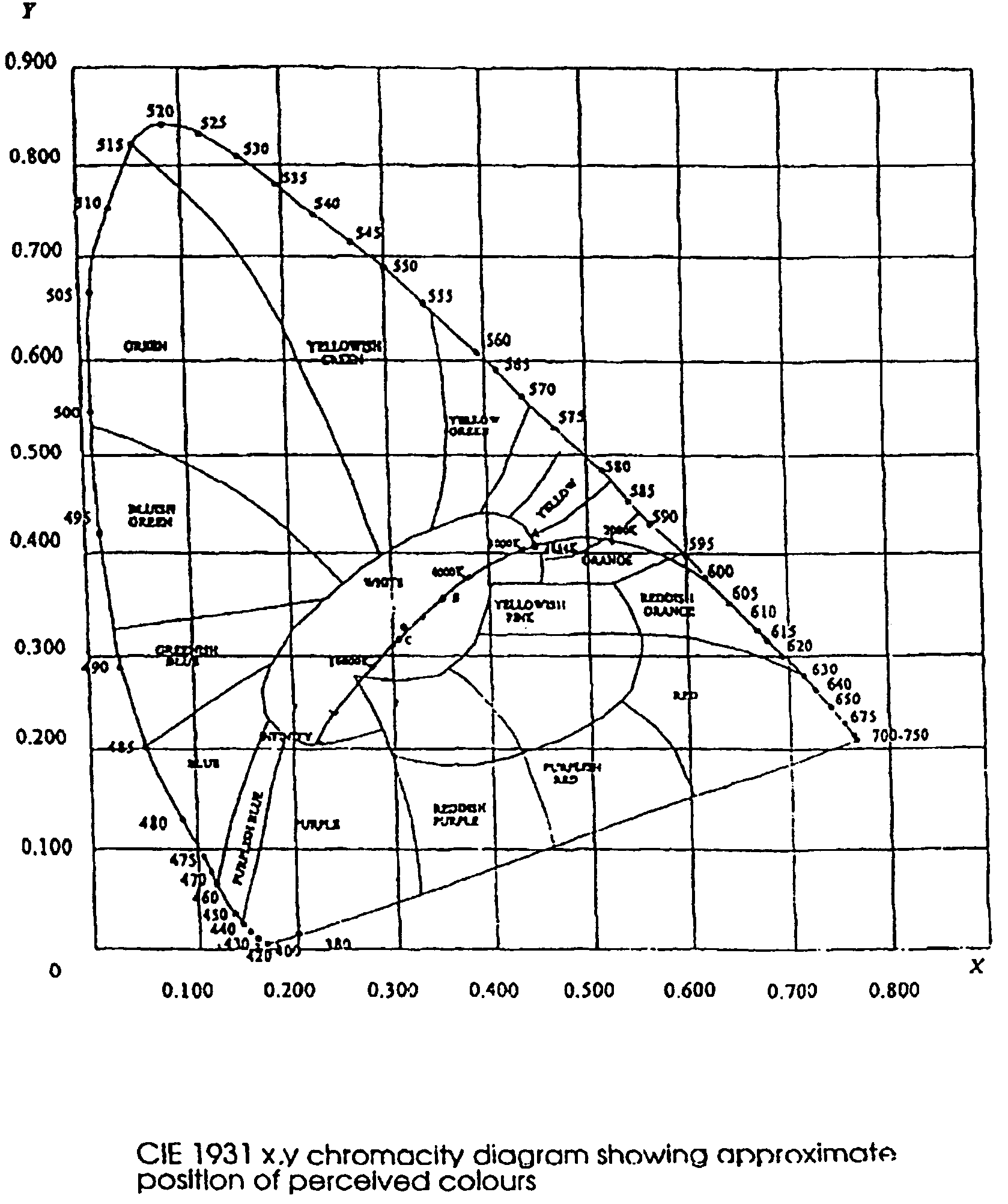

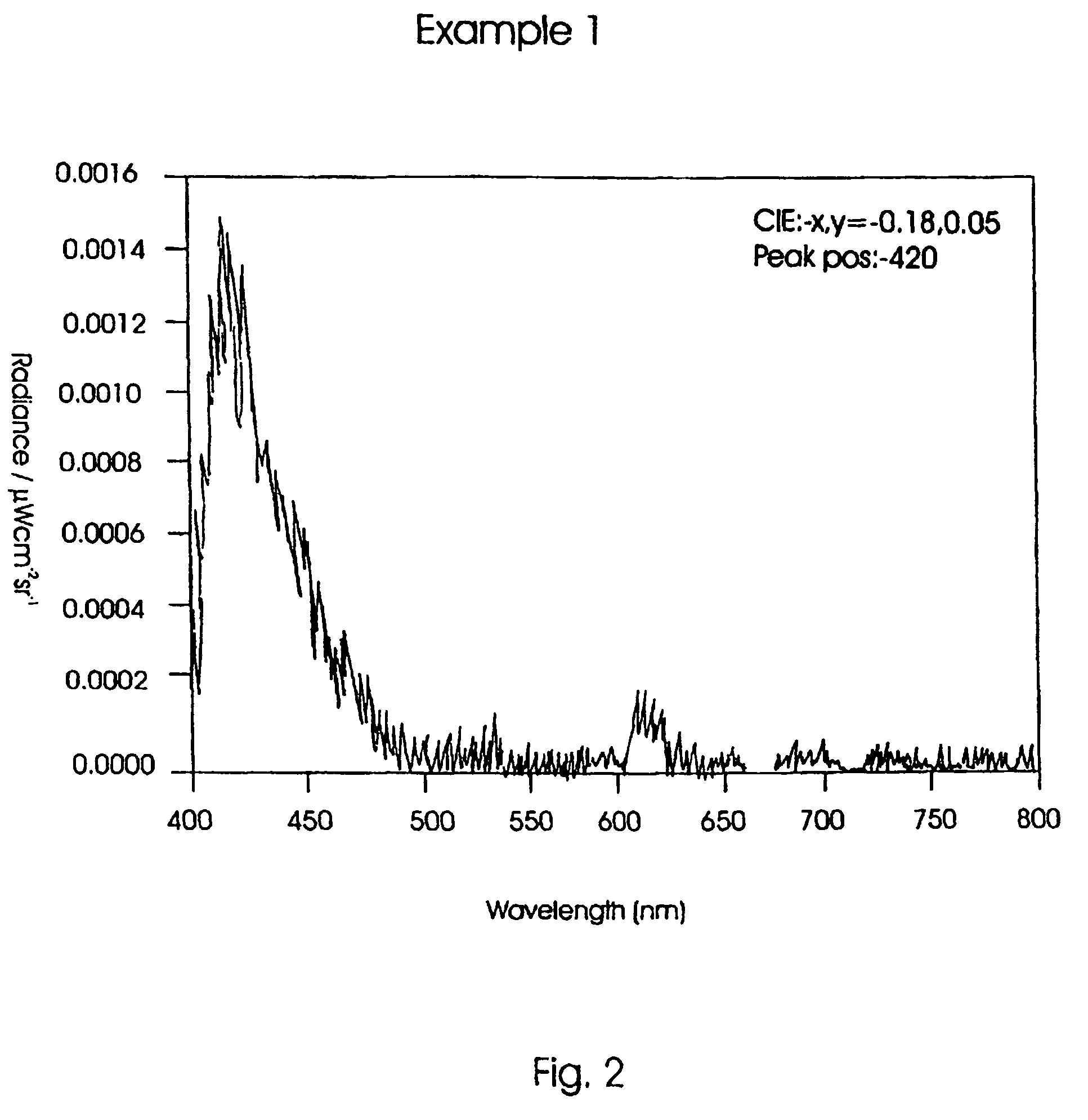

Electroluminescent materials

InactiveUS7183008B1Discharge tube luminescnet screensElectroluminescent light sourcesLanthanideChloride

A novel electroluminescent compound which emits blue or blueish purple light is a complex of a lanthanide or actinide and an organic complex e.g. mono(bathophenanthroline) thoriumIV chloride or mono(tripyridyl)yttrium chloride.

Owner:MERCK PATENT GMBH

Preparation method of graphene/zirconium dioxide hollow sphere/sulfur composite material

InactiveCN105720250AImprove conductivityInhibition of dissolutionCell electrodesSecondary cellsWater bathsElectrochemistry

The invention provides a preparation method of a graphene / zirconium dioxide hollow sphere / sulfur composite material. The preparation method comprises the following steps of (1) weighing and adding nano calcium carbonate to absolute ethyl alcohol, carrying out ultrasound to form a suspension liquid; (2) weighing and dissolving zirconyl chloride and yttrium chloride in deionized water, and preparing to an aqueous solution; (3) adding the aqueous solution obtained in the step (2) into the suspension liquid in water bath, and adding an ammonia water adjustment value to obtain a white solid; (4) placing the white solid in a muffle, cooling the white solid, placing the white solid in an acetate solution, stirring the mixture solution and removing calcium carbonate to obtain hollow zirconium dioxide; and (5) adding the obtained hollow zirconium dioxide, elemental sulfur and graphene into carbon disulfide to obtain the composite material. A sulfur-based material is coated with zirconium dioxide hollow spheres in the graphene / zirconium dioxide hollow sphere / sulfur composite material, the dissolving of a discharging product polysulfide can be prevented, volume expansion can be reduced, and the electrochemical performance of the graphene / zirconium dioxide hollow sphere / sulfur composite material is improved.

Owner:钟玲珑

Chestnut shell active carbon and preparation method thereof

InactiveCN103551109AWell-developed pore structureWell-developed structureOther chemical processesCerium nitrateHazardous substance

Chestnut shell active carbon is prepared by the following raw materials by weight: 120-140 parts of chestnut shell, 3-5 parts of zinc chloride, 4-6 parts of Arabic gum, 4-6 parts of periston, 25-30 parts of bentonite, 10-15 parts of alumina, 20-25 parts of pumice, 2-4 parts of lanthanum chloride, 2-4 parts of cerium chloride, 2-4 parts of scandium chloride, 2-4 parts of yttrium chloride, 2-4 parts of praseodymium chloride, 1-3 parts of lanthanum nitrate, 1-3 parts of cerium nitrate, 1-2 parts of scandium nitrate, 1-2 parts of yttrium nitrate, 1-2 parts of praseodymium nitrate, 4-5 parts of modified diatomite, and a proper amount of water. Chestnut shell is used as a raw material, so as that the active carbon has advantages of developed aperture structure, big specific surface area, high adsorption speed, and good adsorption capability on various solutes and dissociation gases; lanthanum chloride is used for activation so as to form active carbon, which has big gaps and strong adsorption capability, is suitable for absorbing organic matters in air and water and removing harmful substances like formaldehyde, is low in cost, and is suitable for industrialization production.

Owner:BENGBU PIONEER FILTER

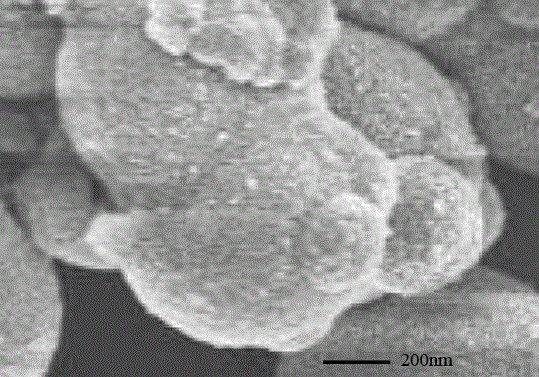

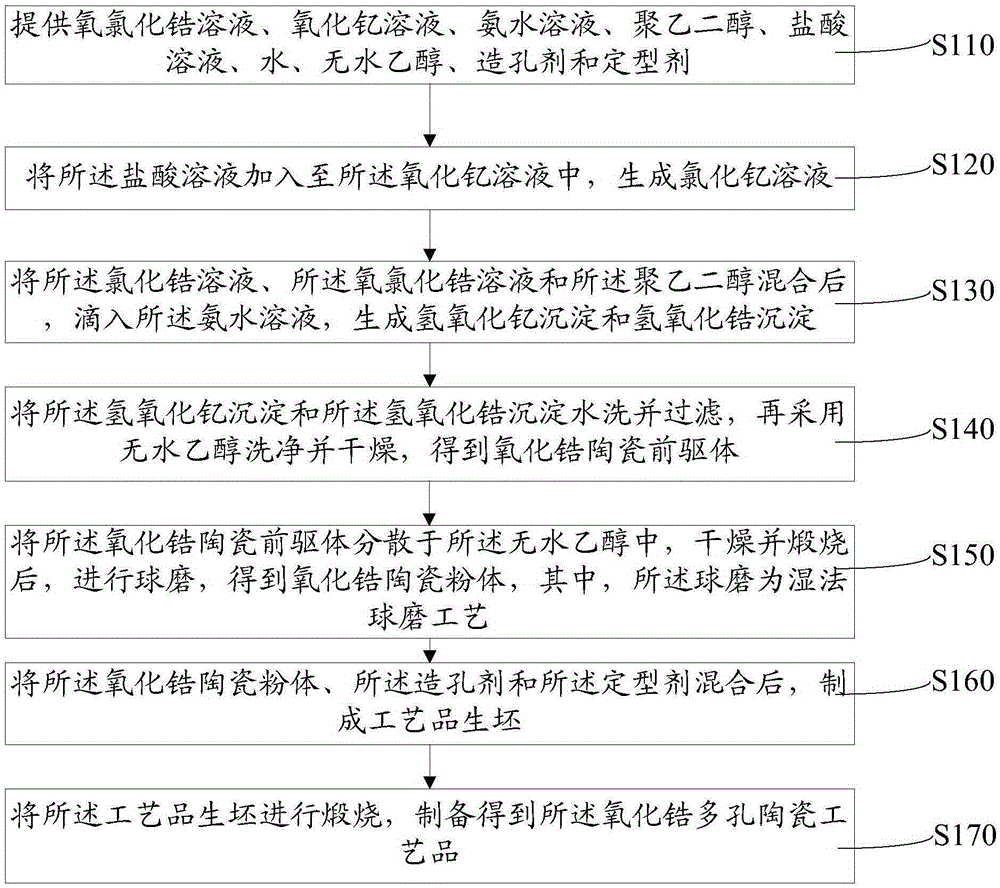

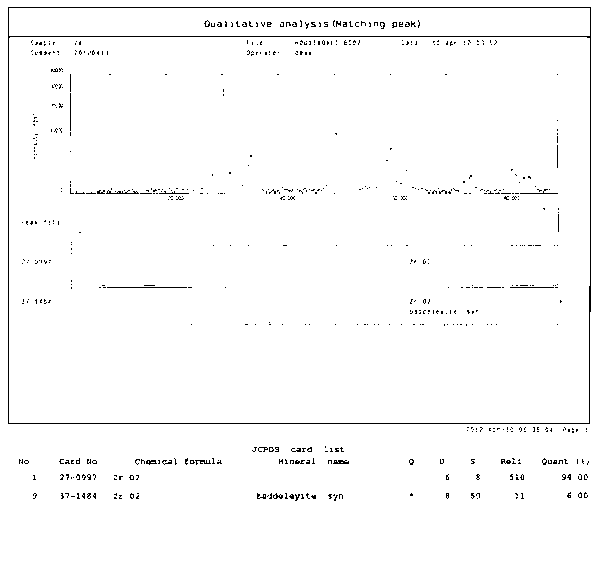

Preparation method for zirconium oxide porous ceramic artwork

The invention discloses a preparation method for a zirconium oxide porous ceramic artwork. The preparation method comprises the following steps: adding a hydrochloric acid solution in a yttrium oxide solution to generate a yttrium chloride solution; mixing the yttrium chloride solution, a zirconium oxychloride solution and polyethylene glycol, and dropwise adding an aqueous ammonia solution to generate yttrium hydroxide precipitate and zirconium hydroxide precipitate; washing the yttrium hydroxide precipitate and the zirconium hydroxide precipitate with water, filtering, then cleaning with absolute ethyl alcohol and drying to obtain a zirconium oxide ceramic precursor; dispersing the obtained zirconium oxide ceramic precursor in the absolute ethyl alcohol, drying and calcining, and then carrying out ball milling to obtain zirconium oxide ceramic powder; mixing the zirconium oxide ceramic powder, a pore former and a tackifier, and then preparing to obtain an artwork green body; and calcining the artwork green body, and preparing to obtain the zirconium oxide porous ceramic artwork. According to the preparation method for the zirconium oxide porous ceramic artwork, through the pore former and the tackifier, the green body is prepared, and is calcined again to obtain the zirconium oxide porous ceramic artwork with relatively high mechanical performance.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

Preparation method for yttrium oxide with different specific surface area

InactiveCN102205985ASimple processShort preparation timeRare earth metal compoundsOxalateReaction temperature

Disclosed is a preparation method for yttrium oxide with different specific surface areas, which is characterized by, at a temperature of 30 to 90 DEG C, adding 4 to 6 M of ammoniacal liquor into 0.4 to 0.6 M of a yttrium chloride solution until the solution reaches a pH value of 7 to 8, stirring the solution for 5 to 10 min, adding an oxalic acid solution with a mass concentration of 15 to 25% until a complete deposition is obtained, stirring the mixture for 15 to 20 min, filtering and carrying out calcination at a temperature of 800 DEG C. The invention has the advantages of a simple process, a short preparation time, low cost and capacity of preparing yttrium oxide with different specific surface areas at various reaction temperatures.

Owner:NANCHANG UNIV

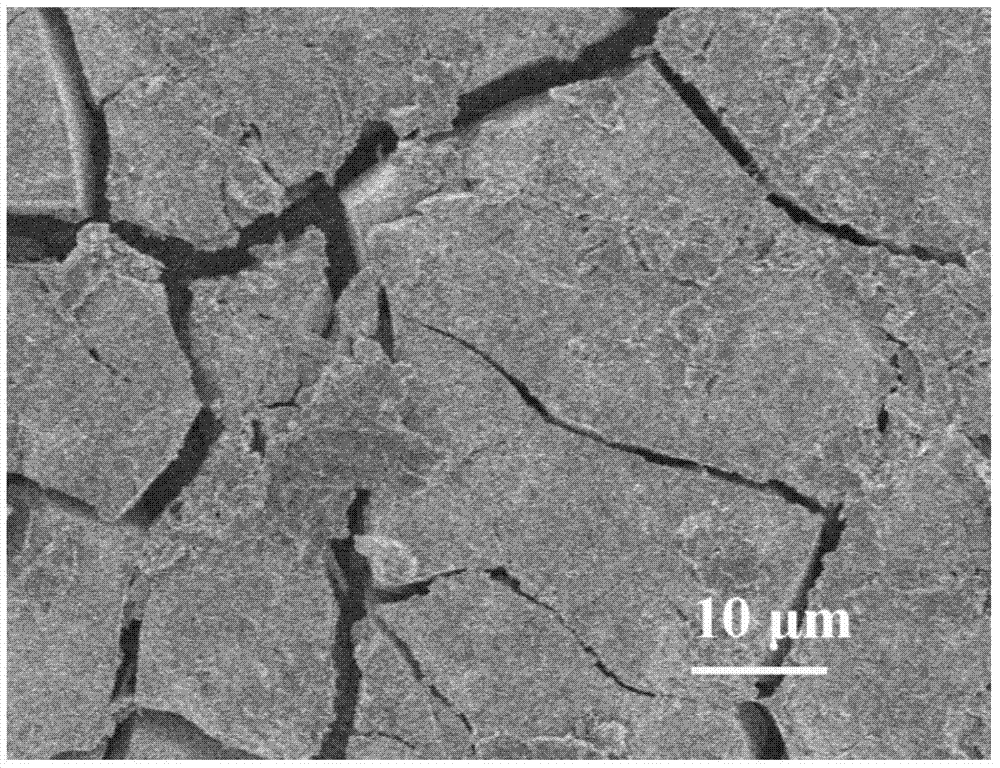

Preparation method of yttrium stabilized zirconium oxide powder with low monoclinic phase and high activity

ActiveCN103288131AUniform particle sizeReduce reunionZirconium oxidesCombined methodZirconium oxychloride

The invention discloses a preparation method of yttrium stabilized zirconium oxide powder with low monoclinic phase and high activity. The preparation method comprises the following steps of: reacting zirconium oxychloride serving as a raw material with concentrated sulfuric acid at a high temperature to produce zirconium basic sulfate; performing precipitation reaction on the zirconium basic sulfate serving as a carrier, yttrium chloride and ammonia water in an aqueous solution to finally produce a zirconium stabilized precursor; and mechanically diffusing, drying, sintering and introducing gas flow to finally obtain the yttrium stabilized zirconium oxide powder. The yttrium stabilized zirconium oxide powder is prepared by a chemical and mechanical combined method; and the prepared powder has low monoclinic phase content, less agglomerates and high sintering activity.

Owner:西安迈克森新材料有限公司

Preparation method of rare earth-doped fluoride up-conversion luminescent nano dispersion

InactiveCN107556998AHigh puritySmall particle sizeMaterial nanotechnologyLuminescent compositionsPhotonicsUp conversion

The invention discloses a preparation method of a rare earth-doped fluoride up-conversion luminescent nano dispersion, belongs to the cross fields of chemical engineering, materials and photonics, andrelates to a method for preparing the rare earth-doped fluoride up-conversion luminescent nano dispersion by utilizing a super-gravity reaction intensifying technology, i.e. a rotating packed bed reactor. Raw materials and reagents required for realizing the synthetic method of the rare earth-doped fluoride up-conversion luminescent nano dispersion comprise rare earth chlorate, sodium hydroxide,ammonium fluoride, a surfactant, deionized water and absolute ethanol, wherein the rare earth chlorate comprises yttrium chloride, ytterbium chloride and erbium chloride; the surfactant is respectively prepared from oleic acid, oleylamine and sodium citrate; a dispersion solvent is prepared from ethanol, tetrahydrofuran, cyclohexane, chloroform and toluene. According to the preparation method disclosed by the invention, the rotating packed bed reactor is introduced for premixing a reaction precursor solution, and molecular uniform mixing is realized, so that the rare earth-doped fluoride up-conversion luminescent nano dispersion which is small in particle size and narrow in particle size distribution is synthesized.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of high-purity yttrium oxide

ActiveCN103466679AEfficient removalEmbody recyclingRare earth metal compoundsProcess efficiency improvementTunnel kilnPhase splitting

The invention relates to a preparation method of high-purity yttrium oxide, belonging to the field of rare earth separation technologies. The preparation method comprises the following steps: putting a rare earth chloride solution containing Ho, Er, Tm, Yb, Lu and Y enrichments and tertiary amine into a vessel with a stirring device, and stirring; putting a first extraction agent and the pre-treated rare earth chloride solution into a vessel with a stirring device, and standing until phase splitting, thus obtaining a pre-equilibration solution; adding pure water into the pre-equilibration solution, evenly stirring to obtain an yttrium-enriched material, and controlling the mol concentration of the yttrium-enriched material; taking the yttrium-enriched material as a raw material, and performing continuous extraction separation by using a second extraction agent and adding a washing solution, a reverse extraction solution and liquid alkali, thus obtaining a crude yttrium chloride solution; taking the crude yttrium chloride solution as a raw material, performing successive extraction separation by using a third extraction agent and adding a washing solution and a reverse extraction solution, thus obtaining a high-purity yttrium chloride solution; introducing the high-purity yttrium chloride solution into a precipitation tank; and introducing solid yttrium oxalate into a roller type tunnel kiln, and firing to obtain the finished product. The preparation method embodies cyclic utilization of waste water and environment protection.

Owner:中稀(宜兴)稀土新材料有限公司

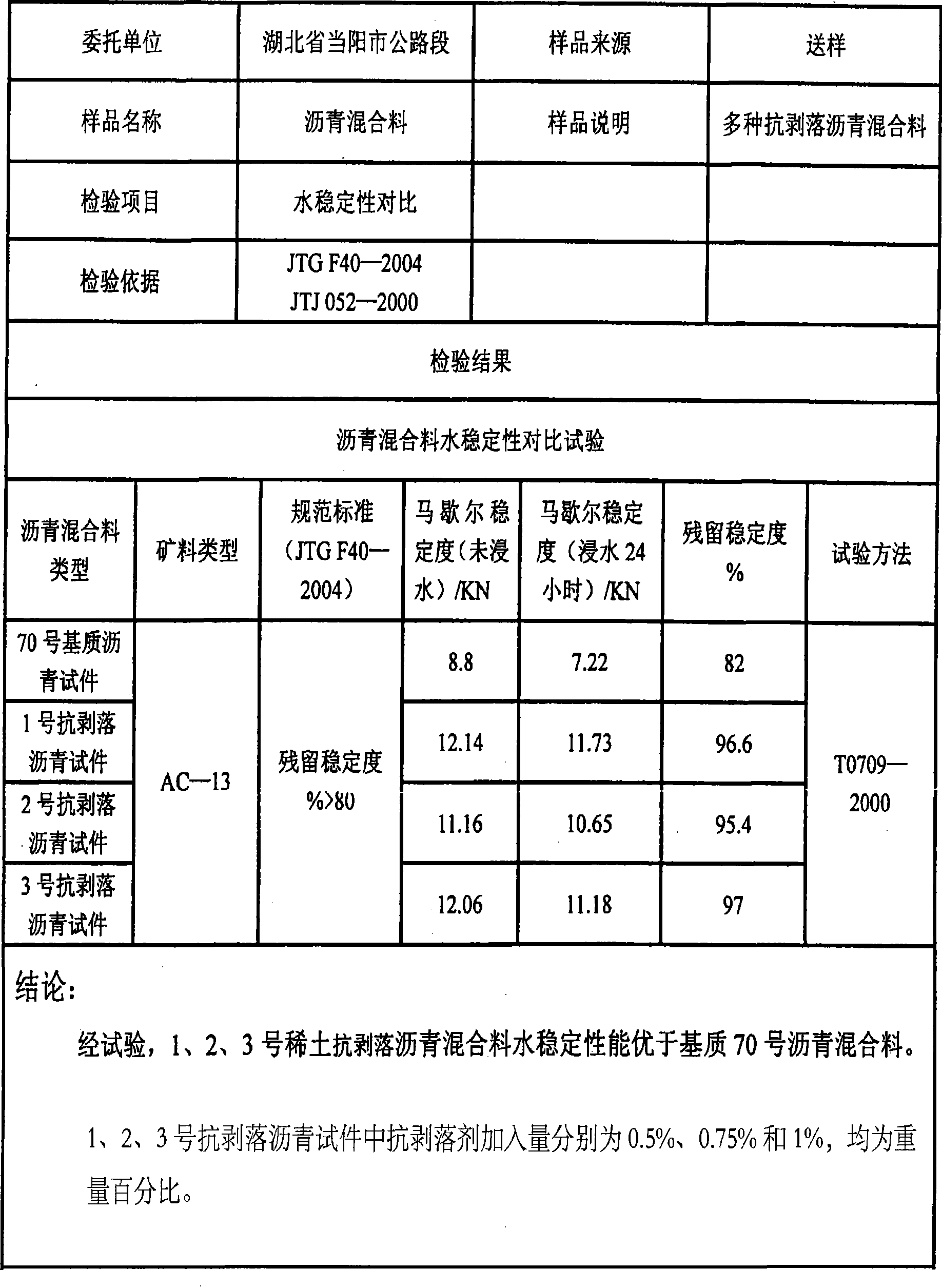

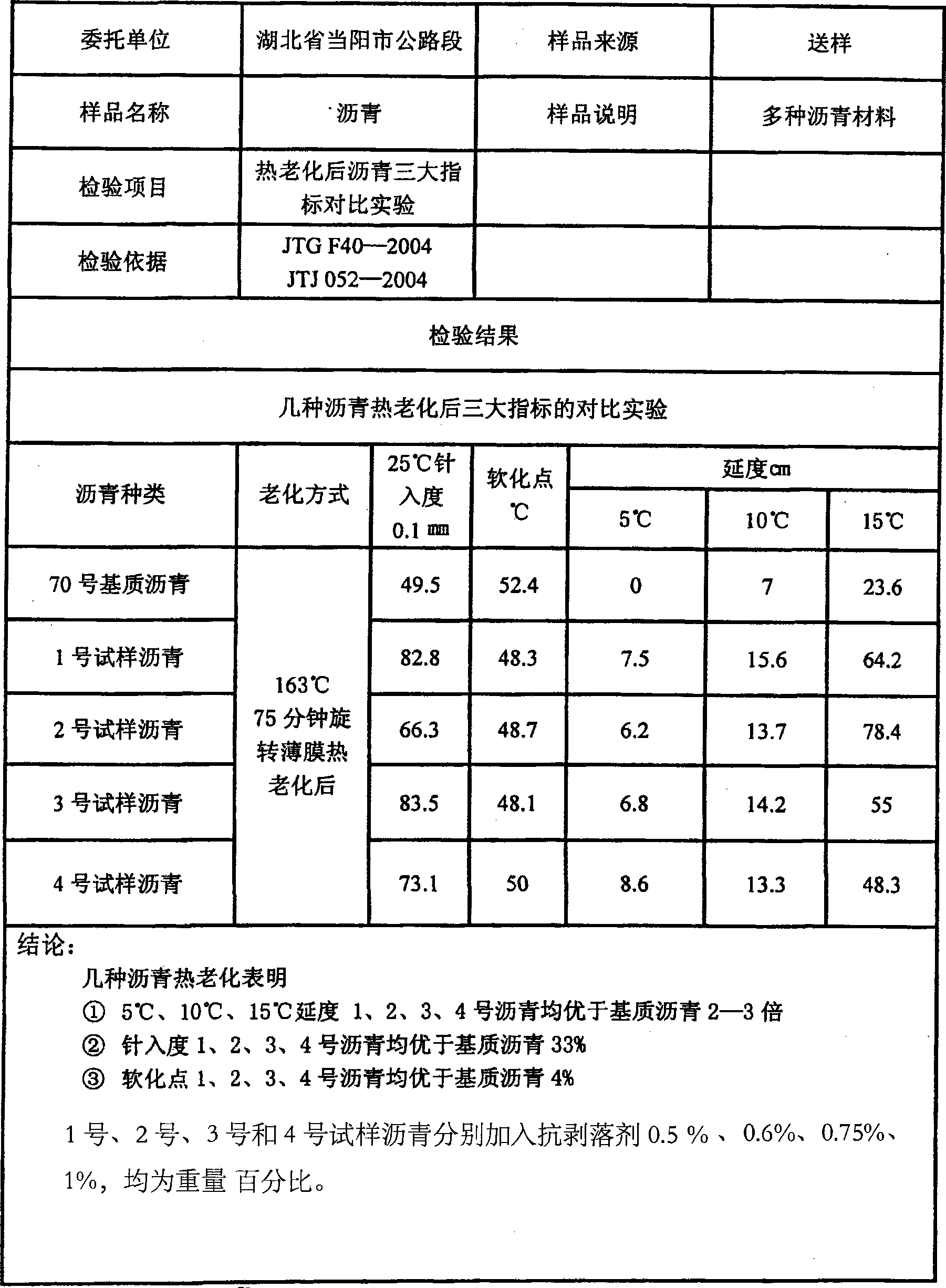

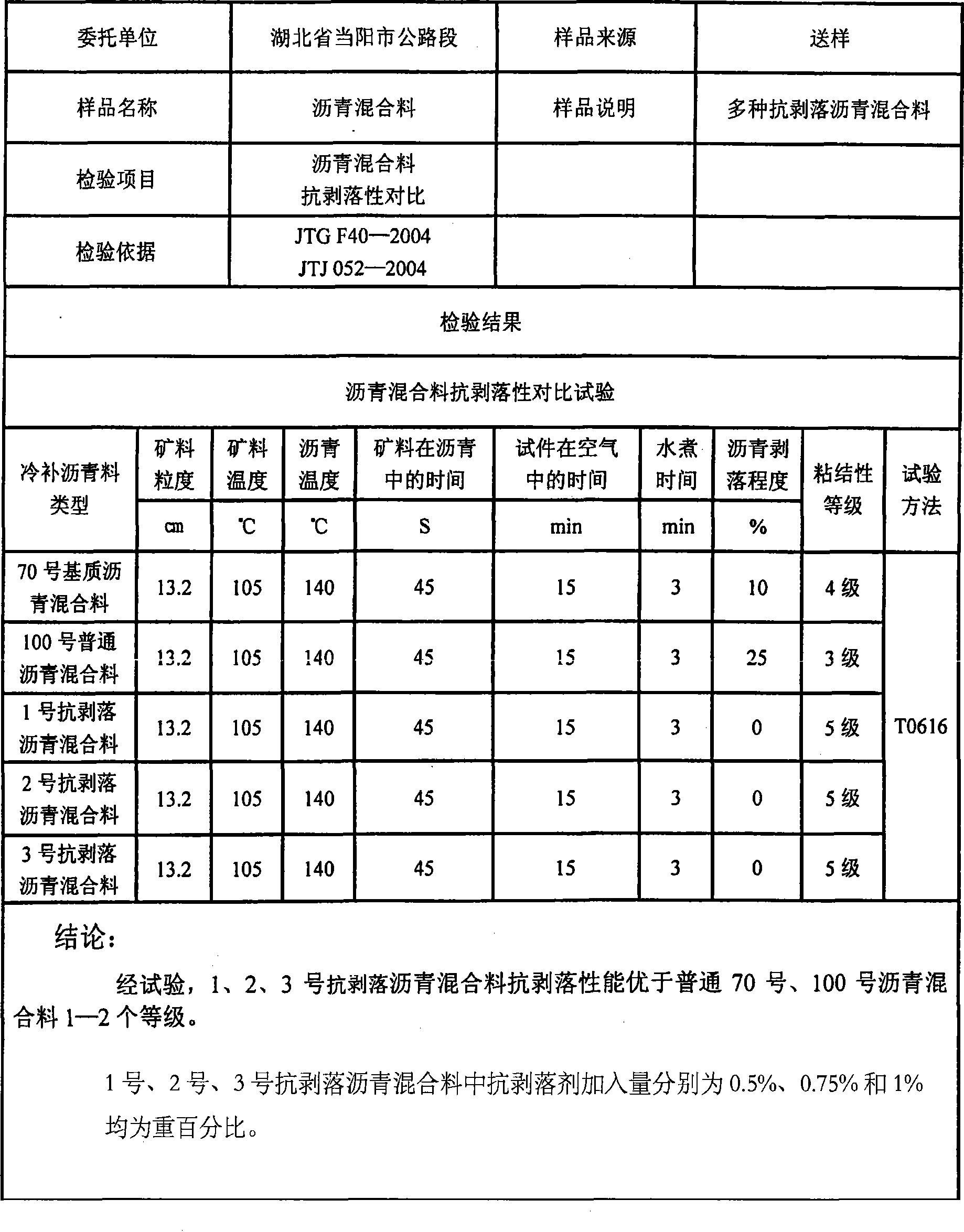

Asphalt antistripping agent

The invention relates to a pitch anti-stripping agent, which is prepared by evenly mixing the following materials in percentage by weight: 45 to 55 percent of nanometer calcium carbonate and 45 to 55 percent of yttrium chloride. When the pitch anti-stripping agent is added to the pitch, the 5 DEG C, the 10 DEG C and the 15 DEG C of the pitch is improved by 2 to 3 times compared with that of the substrate pitch; the penetration degree and the softening point of the pitch are also superior to that of the substrate pitch; the water stability of the pitch is superior to that of the substrate pitch; and the anti-strip performance of the pitch is 1 to 2 grades superior to the common No.70 and No.100 pitch mixtures.

Owner:当阳市公路管理段

Refining flux for smelting of WE43 magnesium alloy, and preparation and usage method thereof

The invention relates to a refining flux for smelting of magnesium alloy, and in particular relates to a refining flux for smelting of WE43 magnesium alloy, and a preparation method and a usage method thereof. The refining flux is characterized by comprising the following raw materials, by weight: 60-62% of potassium chloride, 5-10% of calcium fluoride, 3-5% of yttrium chloride, 8-12% of calcium chloride and 18-20% of barium chloride. The invention has the advantages of easily available raw materials, effectively controlled smelting cost, good refining effect, significantly increased yields of Y and Nd elements, and further saving of rare earth resources; therefore, the invention has a breakthrough significance in the research of the field.

Owner:山东宏泰科技有限公司

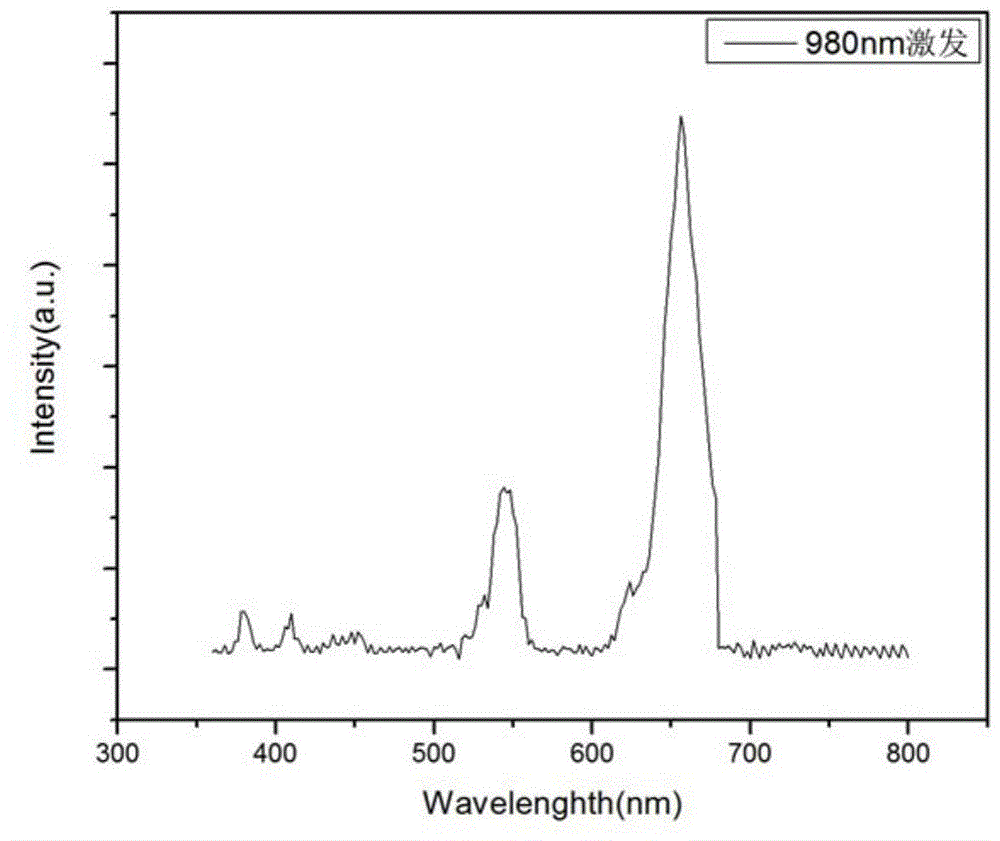

Method of preparing dye-sensitized solar cell photo anode material capable of absorbing near infrared sunlight in multiple bands

ActiveCN104992842APromote absorptionEfficient absorption effectLight-sensitive devicesPhotovoltaic energy generationSensitized cellYtterbium chloride

The invention discloses a method of preparing a dye-sensitized solar cell photo anode material capable of absorbing near infrared sunlight in multiple bands, which relates to the dye-sensitized solar cell photo anode material preparation method and aims at solving the technical problem of low infrared band sunlight utilization by the existing method of enhancing the dye-sensitized cell by an up-conversion material. The method comprises steps: yttrium chloride, ytterbium chloride, erbium chloride and ammonium fluoride are firstly used for preparing nanocrystalline which serves as crystal nucleus; the nanocrystalline is then diffused in a ytterbium chloride and ammonium fluoride raw material solution, and a first-layer core-shell structure nanocrystal is obtained; the first-layer core-shell structure nanocrystal is diffused in a yttrium chloride, holmium chloride and ammonium fluoride raw material solution for reaction, and a two-layer core-shell structure nanocrystal is obtained; and the two-layer core-shell structure nanocrystal is diffused in a raw material solution containing tetrabutyl titanate, and after a hydrothermal reaction, the photo anode material is obtained. The method of the invention can improve the photoelectric conversion efficiency of the solar cell.

Owner:HARBIN HUIGONG TECH CO LTD

Method for industrially producing iron-based dispersion-strengthened material with low cost on large scale

The invention provides a method for industrially producing an iron-based dispersion-strengthened material, belonging to the technical field of oxide dispersion-strengthened materials. The invention provides a powder metallurgy preparation method of an iron-based dispersion-strengthened material with industrial application value and low cost. The method comprises the following steps of: adding yttrium chloride in industrial pickling wastewater, then treating the pickling wastewater by adopting a Ruthner-spray roasting process, atomizing the solution into tiny liquid drops in the spry roasting process, enabling the liquid drops to contact with gases and be dried to form powder, and heating the powder in the air to form a metal oxide; reducing the mixed powder of the obtained metal oxide in a hydrogen flow to obtain yttrium chloride dispersion-strengthened iron powder; and densifying the dispersion-strengthened iron powder to obtain a dispersion-strengthened iron material with high performance. The iron-based dispersion-strengthened material prepared with the method is simple in preparation process, can be prepared by directly adopting a steel mill pickling wastewater process and has low cost. In addition, the prepared iron-based dispersion-strengthened material has excellent performance and is suitable for production on a large scale.

Owner:UNIV OF SCI & TECH BEIJING

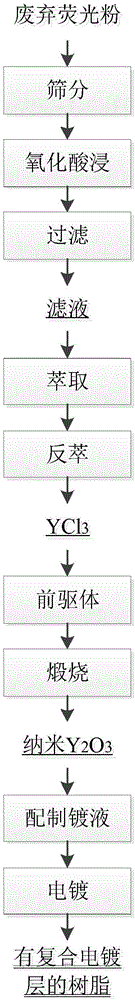

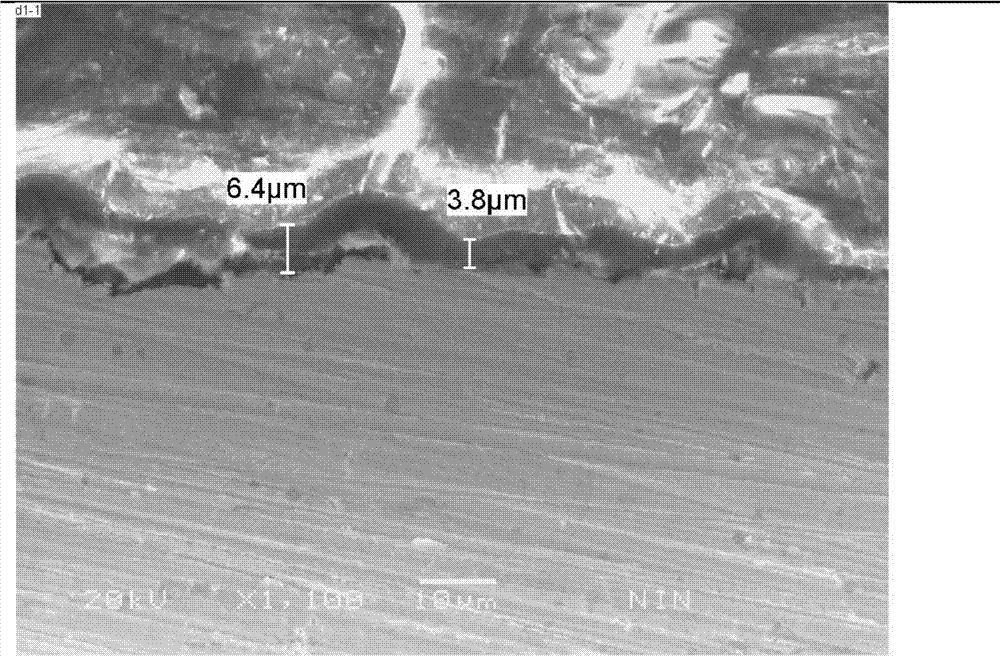

Method for recycling rare earth element yttrium from waste fluorescent powder and preparing resin surface composite coating

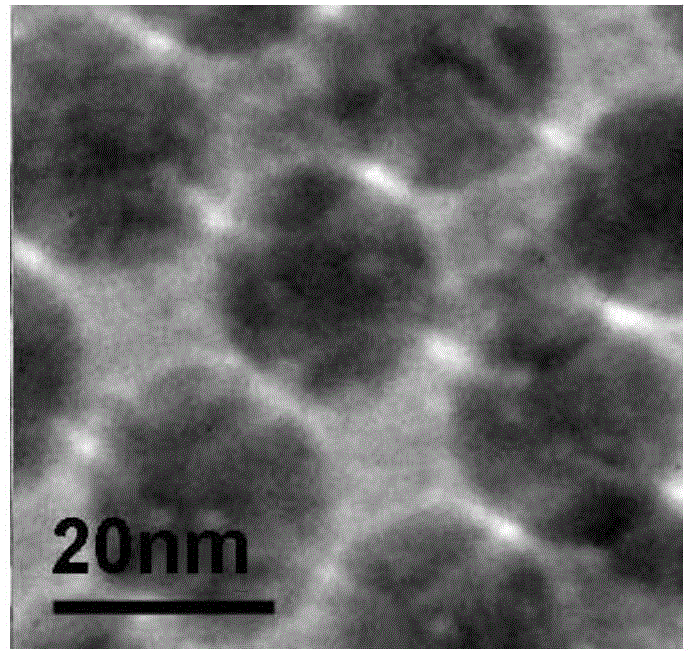

ActiveCN106191446AHigh hardnessImprove wear resistanceElectrolytic coatingsProcess efficiency improvementRare-earth elementElectrical conductor

The invention discloses a method for recycling rare earth element yttrium from waste fluorescent powder and preparing a resin surface composite coating, and belongs to the field of solid waste resource utilization. The method comprises the following steps of: mechanically crushing a waste CRT fluorescent screen and screening the crushed waste CRT fluorescent screen through a screen with certain mesh number to remove impurities such as glass, thereby obtaining fluorescent powder oriented powder; carrying out oxidizing and acid-leaching treatment on the screened fluorescent powder, and leaching out rare earth elements in the fluorescent powder; extracting most of yttrium and a small part of europium through a multi-stage extracting method, reversely extracting to obtain a yttrium chloride solution, and regulating the pH value of the yttrium chloride solution until white precipitates just appear; adding the yttrium chloride solution into an ammonium hydrogen carbonate solution containing a dispersing agent drop by drop to prepare a precursor; drying and roasting the precursor to obtain nano yttrium oxide powder; and finally, adding the nano yttrium oxide powder into a plating solution containing the dispersing agent to prepare a composite electroplating solution, and electroplating the composite electroplating solution to a conductive plastic surface prepared from resin and carbon-series conductors.

Owner:常州厚德再生资源科技有限公司

Method for preparing anti-oxidation coatings on surface of molybdenum and molybdenum alloy

ActiveCN103938190APrevent oxidationGood high temperature oxidation resistanceLiquid/solution decomposition chemical coatingHydrofluoric acidMixed oxide

The invention discloses a method for preparing anti-oxidation coatings on the surfaces of molybdenum and a molybdenum alloy. The method can be used for preparing Hf-Y mixed oxide coatings on the surfaces of the molybdenum and the molybdenum alloy by adopting a stepwise brushing method. The method comprises the following steps: firstly carrying out alkali cleaning degreasing and pickling decontamination on the surfaces of the molybdenum and the molybdenum alloy, washing, and then carrying out hydrofluoric acid surface etching treatment to prepare a substrate; then preparing a normal propyl alcohol solution of hafnium oxychloride and yttrium chloride according to a certain proportion to prepare a needed coating liquid; uniformly brushing the coating liquid to the substrate surfaces of the molybdenum and the molybdenum alloy; and after the coating liquid is brushed every time, firstly drying and then roasting, repeating for 15-30 times, and roasting for 1-2 hours for the last time to prepare the Hf-Y mixed oxide coatings on the surfaces of the molybdenum and the molybdenum alloy. The coatings prepared through the method have the advantages of excellent high temperature oxidation resistance, compact coating material, good compatibility with the substrate and difficulty in dropping and greatly enlarges the usage ranges of the molybdenum and the molybdenum alloy.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com