Method for preparing rare-earth fluorescent up-conversion material by use of waste fluorescent powder

A technology of rare earth fluorescent and conversion materials, applied in the field of solid waste resource utilization, to achieve the effects of further market promotion, good luminous efficiency, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

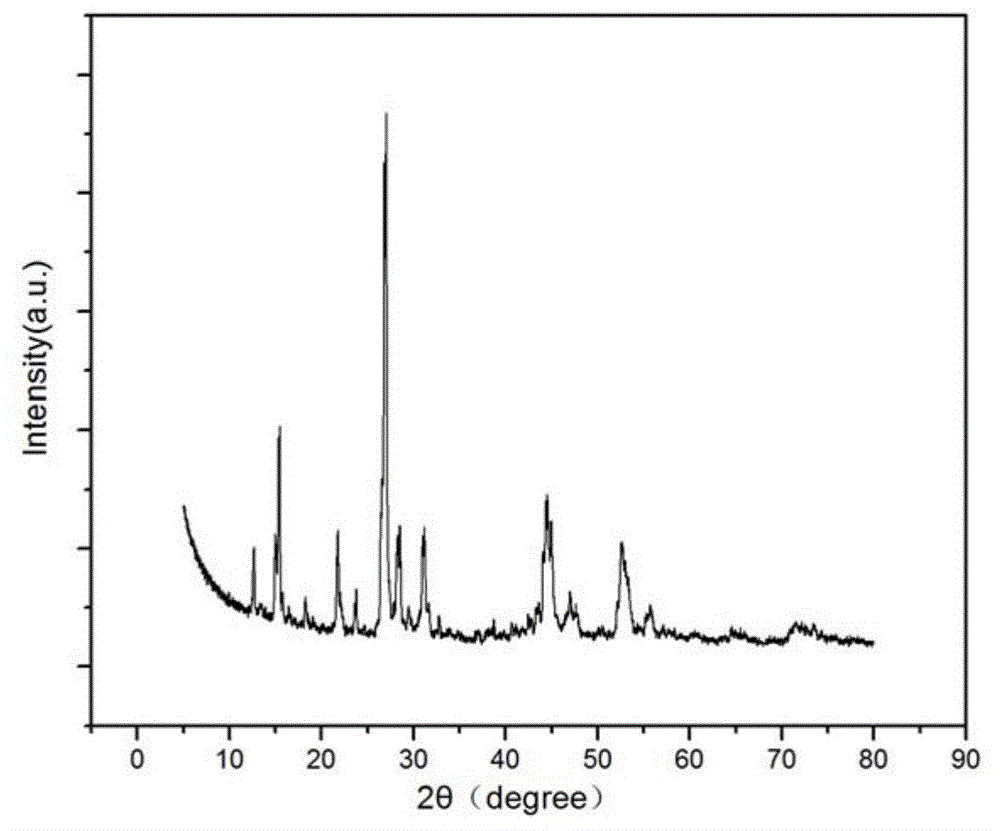

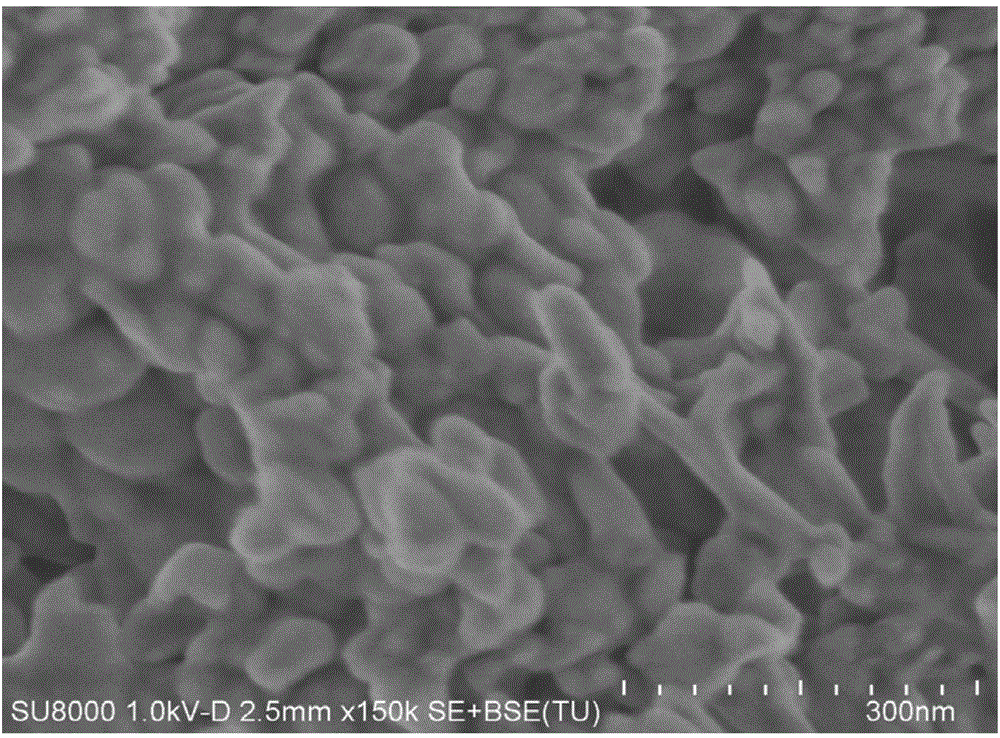

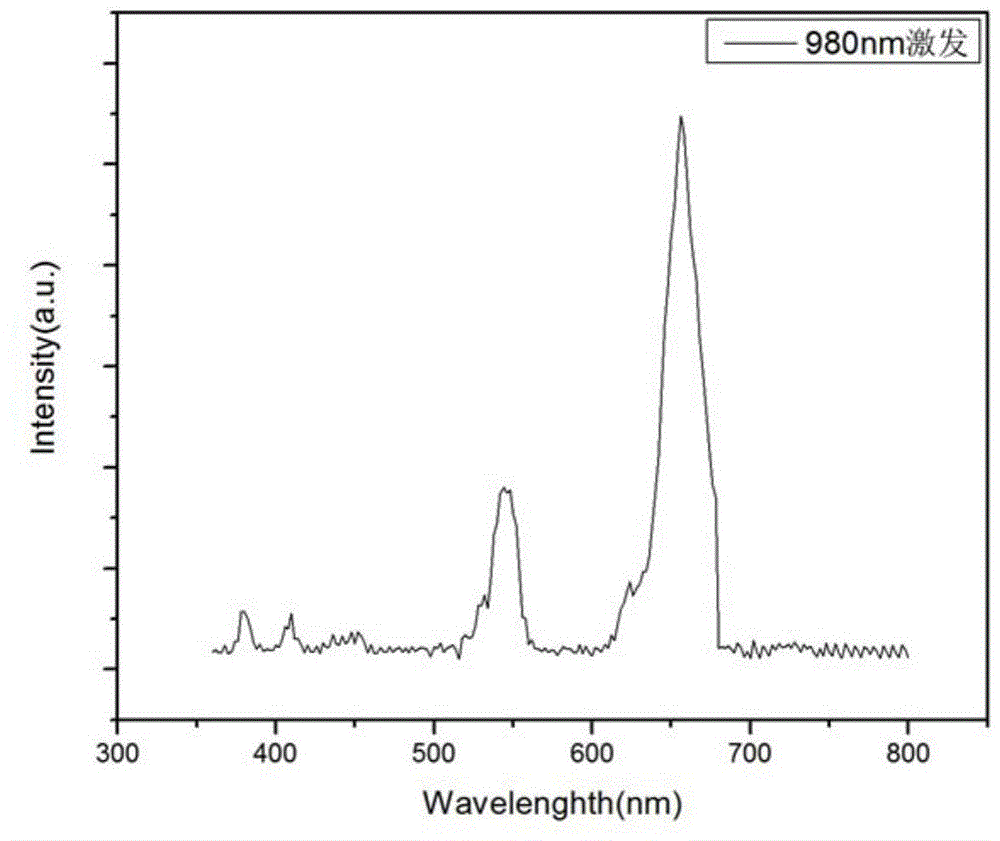

Image

Examples

Embodiment 1

[0033] The specific steps of preparing rare earth fluorescent up-conversion materials with waste phosphor powder are as follows:

[0034](1) Weigh a certain amount of process waste phosphor powder, leach the phosphor powder through a 2mol / L sulfuric acid solution, and add an appropriate amount of hydrogen peroxide as a cosolvent, at a temperature of 70°C, and leach for 4 hours to obtain a solution;

[0035] (2) Put the solution in step (1) into a centrifuge for solid-liquid separation, adjust the pH value of the obtained leachate to 3.5-4 with ammonia water, perform a precipitation, filter, and obtain the filtrate;

[0036] (3) Add ammonia water to the filtrate in step (2), carry out secondary precipitation, adjust the pH value to 7-8, filter to obtain filter residue A and retain the filtrate;

[0037] (4) adding ammonia water to the filtrate in step (3), carrying out three precipitations, adjusting the pH value to 8-9, filtering to obtain filter residue B;

[0038] (5) Disso...

Embodiment 2

[0044] The specific steps of preparing rare earth fluorescent up-conversion materials with waste phosphor powder are as follows:

[0045] (1) Weigh a certain amount of process waste phosphor powder, leach the phosphor powder through a 2mol / L sulfuric acid solution, and add an appropriate amount of hydrogen peroxide as a cosolvent, at a temperature of 70°C, and leach for 4 hours to obtain a solution;

[0046] (2) Put the solution in step (1) into a centrifuge for solid-liquid separation, adjust the pH value of the obtained leachate to 3.5-4 with ammonia water, perform a precipitation, filter, and obtain the filtrate;

[0047] (3) Add ammonia water to the filtrate in step (2), carry out secondary precipitation, adjust the pH value to 7-8, filter to obtain filter residue A and retain the filtrate;

[0048] (4) adding ammonia water to the filtrate in step (3), carrying out three precipitations, adjusting the pH value to 8-9, filtering to obtain filter residue B;

[0049] (5) Diss...

Embodiment 3

[0055] The specific steps of preparing rare earth fluorescent up-conversion materials with waste phosphor powder are as follows:

[0056] (1) Weigh a certain amount of process waste phosphor powder, leach the phosphor powder through a 2mol / L sulfuric acid solution, and add an appropriate amount of hydrogen peroxide as a cosolvent, at a temperature of 70°C, and leach for 4 hours to obtain a solution;

[0057] (2) Put the solution in step (1) into a centrifuge for solid-liquid separation, adjust the pH value of the obtained leachate to 3.5-4 with ammonia water, perform a precipitation, filter, and obtain the filtrate;

[0058] (3) Add ammonia water to the filtrate in step (2), carry out secondary precipitation, adjust the pH value to 7-8, filter to obtain filter residue A and retain the filtrate;

[0059] (4) adding ammonia water to the filtrate in step (3), carrying out three precipitations, adjusting the pH value to 8-9, filtering to obtain filter residue B;

[0060] (5) Diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com