Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

A technology for pulverized coal preparation and coal-fired power plants, which is applied in the field of flue gas pollution control, can solve the problems of high price of powdered activated carbon, high system operating costs, and high initial investment, and achieves accelerated adsorption reaction rate and high flue gas purification efficiency. , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

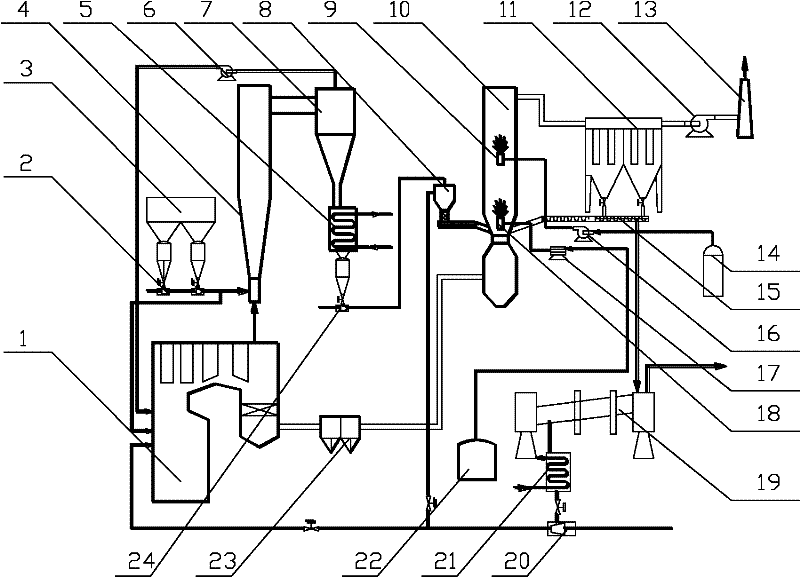

[0028] Such as figure 1 As shown, a coal-fired power plant pulverized coal preparation activated coke flue gas comprehensive purification system, including pulverized coal storage tank 3, pulverized coal storage tank 3 connected to the lower end of the pulverized coal bin pump 2 connected to the carbonization activation furnace 4, the carbonization activation furnace The lower end of 4 is connected with the high-temperature flue gas outlet of boiler 1, the upper end of carbonization activation furnace 4 is connected with separator 7, and the lower end of separator 7 is connected with active coke storage tank 8 through cooler I 5, activated coke bin pump II24, and separator 7 The upper end of the pyrolysis gas conveying fan 6 is connected to the boiler 1, the active coke storage tank 8 is connected to the adsorption tower 10, and the lower part of the adsorption tower 10 is connected to the flue gas outlet of the boiler 1 through the pre-dust collector 23. The adsorption tower 1...

Embodiment 2

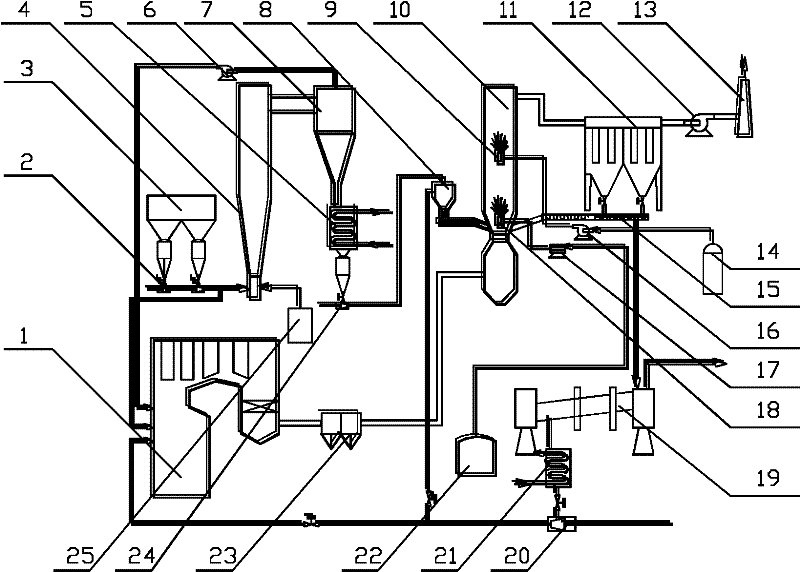

[0039] Such as figure 2 As shown, a coal-fired power plant pulverized coal preparation activated coke flue gas comprehensive purification system, including pulverized coal storage tank 3, pulverized coal storage tank 3 connected to the lower end of the pulverized coal bin pump 2 connected to the carbonization activation furnace 4, the carbonization activation furnace 4. The lower end is connected to the coal-fired flue gas outlet 25 of the power plant. The upper end of the carbonization activation furnace 4 is connected to the separator 7. The lower end of the separator 7 is connected to the active coke storage tank 8 through the cooler I 5 and the activated coke bin pump II24. The separator 7 The upper end of the pyrolysis gas conveying fan 6 is connected to the boiler 1, the active coke storage tank 8 is connected to the adsorption tower 10, and the lower part of the adsorption tower 10 is connected to the flue gas outlet of the boiler 1 through the pre-dust collector 23. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com