Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Full utilization of resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

InactiveCN102350214ARealize reburning and denitrificationFull joint removalDispersed particle separationResource utilizationCoal dust

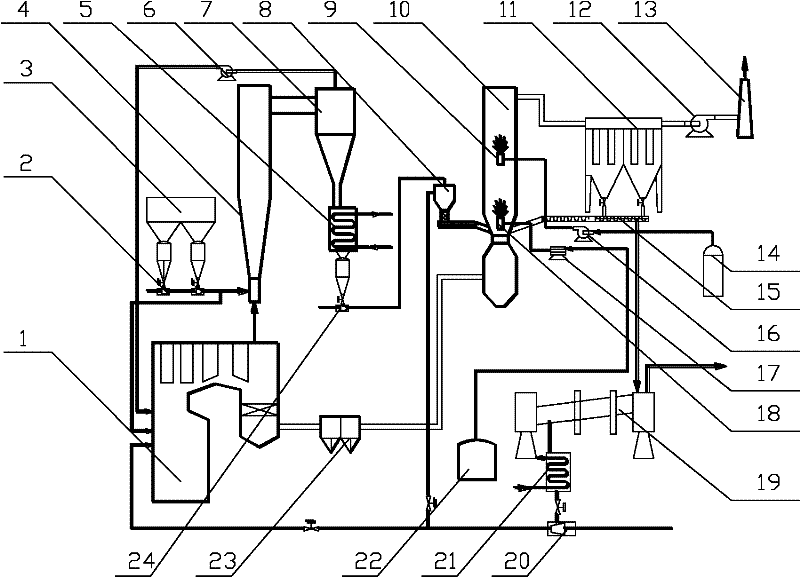

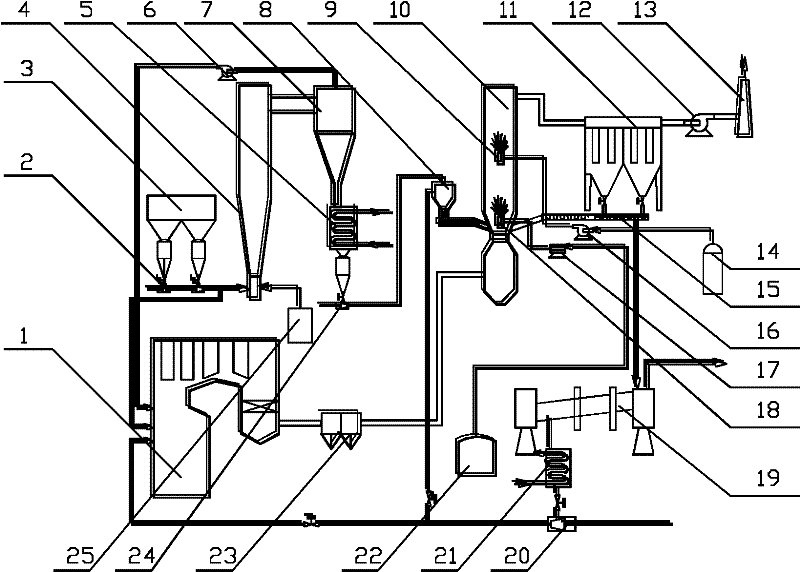

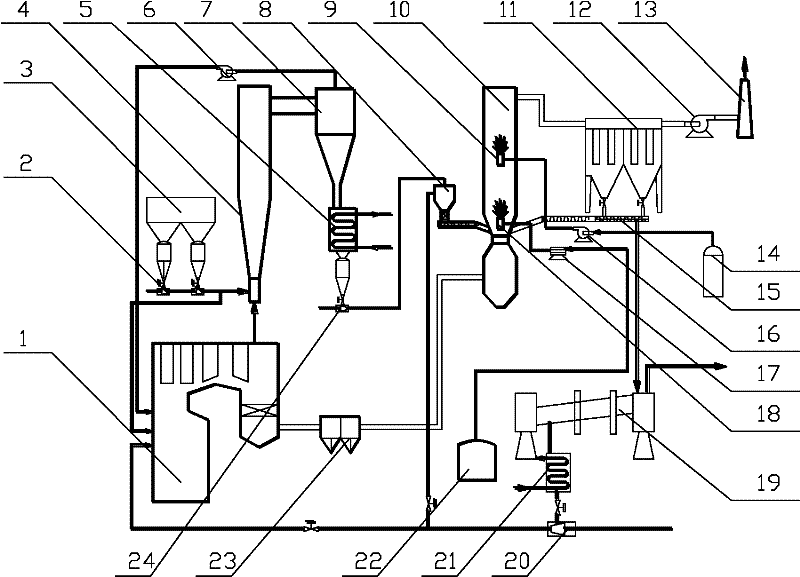

The invention relates to a coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and a technology. The technology provided by the invention comprises the following steps of: using coal dust in a coal-fired power plant as a raw material, simultaneously carrying out carbonization and activation on coal dust in an activated coke preparation reactor to obtain powdered activated coke, using pyrolysis gas obtained during the preparation process as reburning fuel and sending it into a boiler so as to remove part of NOx; sending the powdered activated coke into a flue gas adsorption tower, adsorbing pollutants such as sulfur dioxide, mercury and the like at an appropriate temperature, injecting ammonia gas and nitrogen oxide to perform a catalytic reduction reaction so as to remove nitrogen oxide; reusing the adsorbed activated coke after regeneration; sending the activated coke into the boiler for combustion after multiple adsorption / regeneration; regenerating the activated coke after adsorbing sulfur dioxide to obtain high-density sulfur dioxide gas to realize resource utilization. By the utilization of coal resources in a coal-fired power plant, the comprehensive purification of flue gas and the resource utilization of sulfur dioxide are realized without discharge of waste water, exhaust gas and solid waste.

Owner:SHANDONG UNIV

Method for producing microbial ecological agent by using kitchen garbage

InactiveCN102051335AFull utilization of resourcesFungiBio-organic fraction processingBiotechnologyFungicide

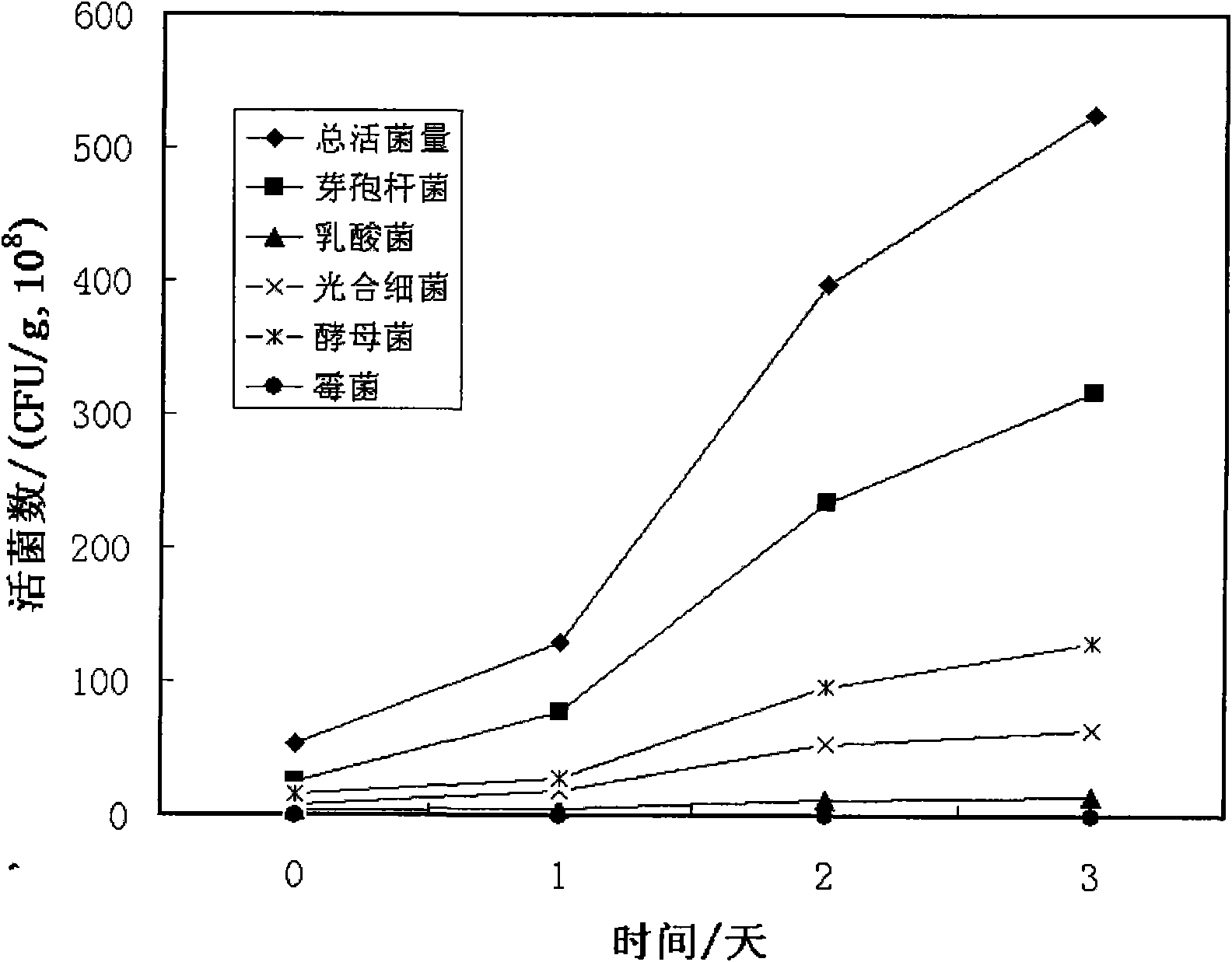

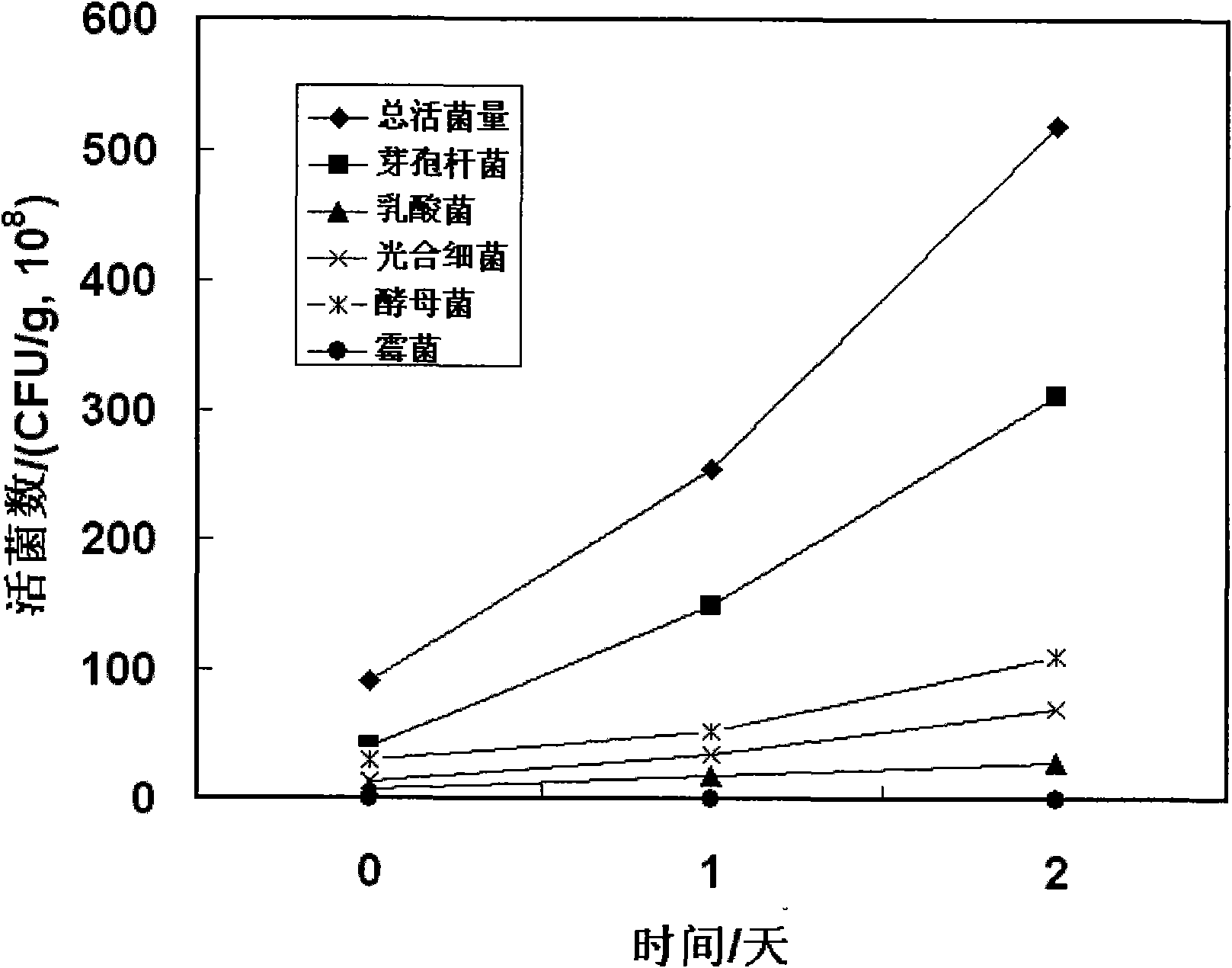

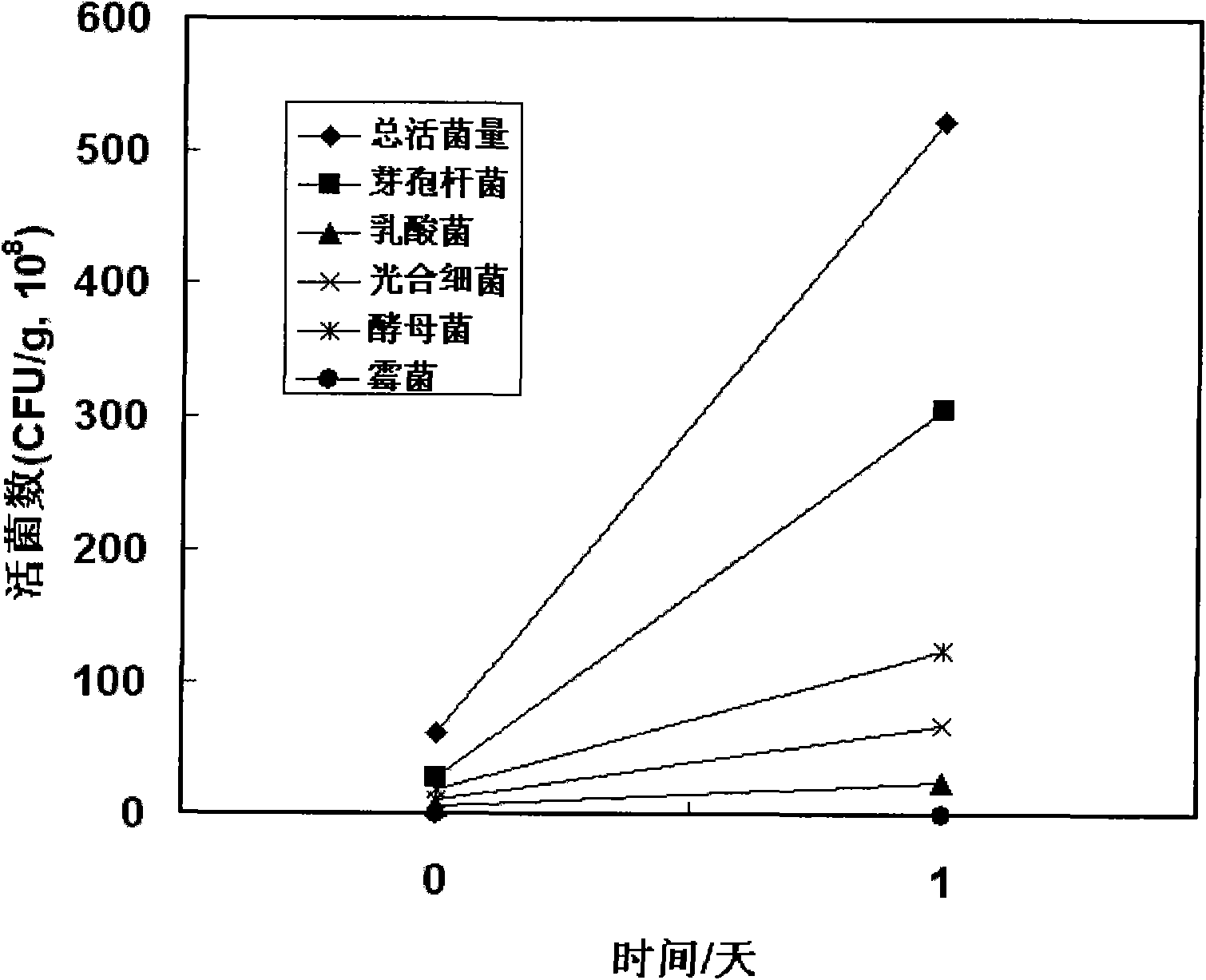

The invention relates to a method for producing a microbial ecological agent consisting of bacillus, yeast, lactobacillus, photosynthetic bacteria and mycete by using kitchen garbage, belonging to the field of biotechnology. The method comprises the following steps of: grinding the kitchen garbage containing rice, flour, vegetables, animal and vegetable oil, fruits, meat, bones and the like, and sterilizing the garbage at high temperature; fully mixing the sterilized garbage with carriers and fungicide formed by multiple probiotic bacteria; carrying out anaerobic solid fermentation for one tothree days at 25-40 DEG C, and then airing to obtain high-value microbial ecological agent with the viable bacteria content as high as 50 billion / g. The method provided by the invention has the advantages that different nutrient constituents in the kitchen garbage are fully recycled, the kitchen garbage is efficiently and biologically processed and the high-value microbial ecological agent formedby multiple probiotic bacteria is produced. Besides, the kitchen garbage is fully recycled in the whole process of producing the microbial ecological agent by using the kitchen garbage and any other pollutants requiring further treatment are not generated any more.

Owner:UNIV OF SCI & TECH BEIJING +1

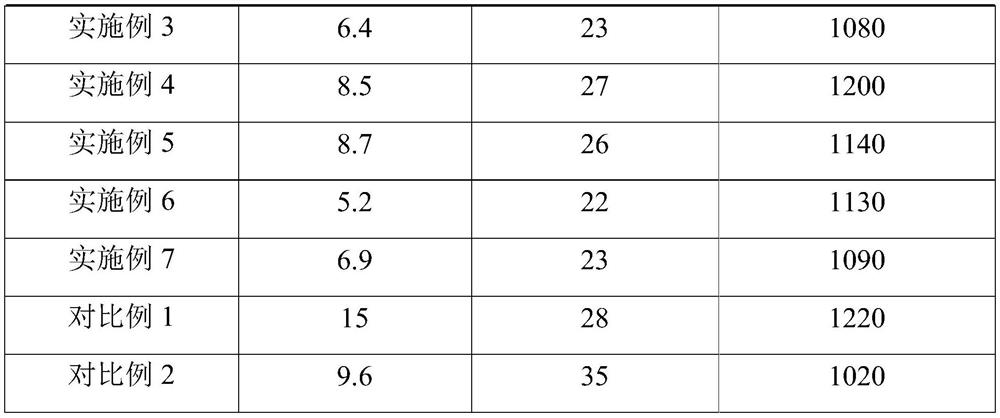

Resource utilization method of Fenton iron sludge

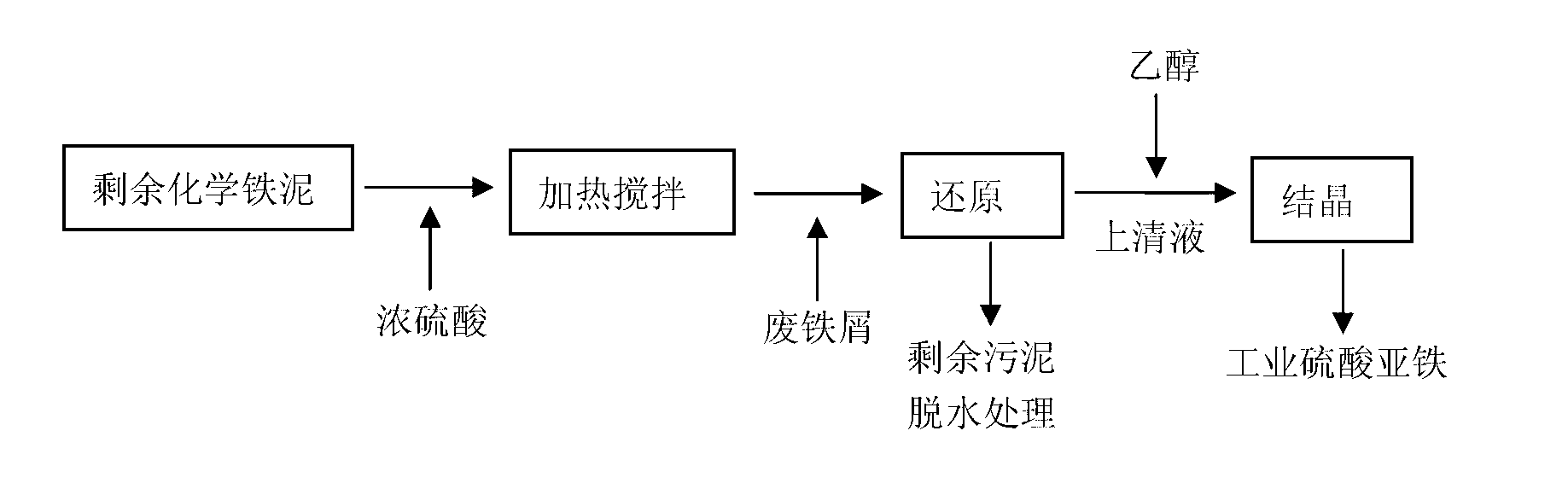

The invention discloses a resource utilization method of Fenton iron sludge. The method comprises the following steps of: (1) treating Fenton; adding the rest of ferrum into concentrated sulfuric acid; and controlling the temperature to be between 70 and 75 DEG C to stir for 30 minutes; (2) adding excessive quantities of scrap iron chips into an iron sludge solution obtained in the step (1) to reduce; detecting Fe3<+> by using a phenol solution until Fe<3+> is totally reduced into Fe<2+>; and (3) after the reduction is finished, standing for precipitating for 30 minutes; extracting supernate; adding ethanol according to the proportion that V(supernate) / V(ethanol) is equal to 10 to 1 and shortening the crystallizing time of ferrous sulfate; and after the crystallization is finished, obtaining an industrial FeSO4.7H2O finished product. According to the method, the bottle neck problem of Fenton technology promotion can be solved, the resource utilization of solid wastes is realized, and Fenton iron sludge is turned from waste into treasure, so that sustainable development of human society is facilitated.

Owner:GUANGXI UNIV

Baked brick of riverslakes sludge and municipal sludge and production method thereof

ActiveCN101672085AImprove performanceLow costConstruction materialCeramic shaping apparatusBrickSludge

The invention discloses baked bricks of riverslakes sludge and municipal sludge and a production method thereof. The baked brick comprises a brick body and a cavity, and the brick body is prepared bythe following raw materials in weight percent: 40-70% of riverslakes sludge, 10-35% of municipal sludge and 13-30% of internal fuel. The production method comprises the following steps of collecting raw materials, batching, blending internal fuel, extruding, molding, drying, roasting and obtaining the products. The baked bricks in the invention have the advantages of energy conservation, heat preservation, superior performance and low cost, and can be widely used in wall body construction in building industry. The production method in the invention has advanced processing steps, economy, reasonability, high cost-performance ratio, and especially low energy consumption of the manufacturing process, thus conforming to the national requirements of environment protection and energy conservation and enabling riverslakes sludge to be in full resource utilization.

Owner:江苏建科土木工程技术有限公司

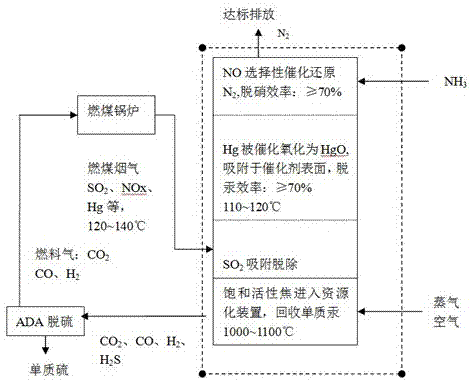

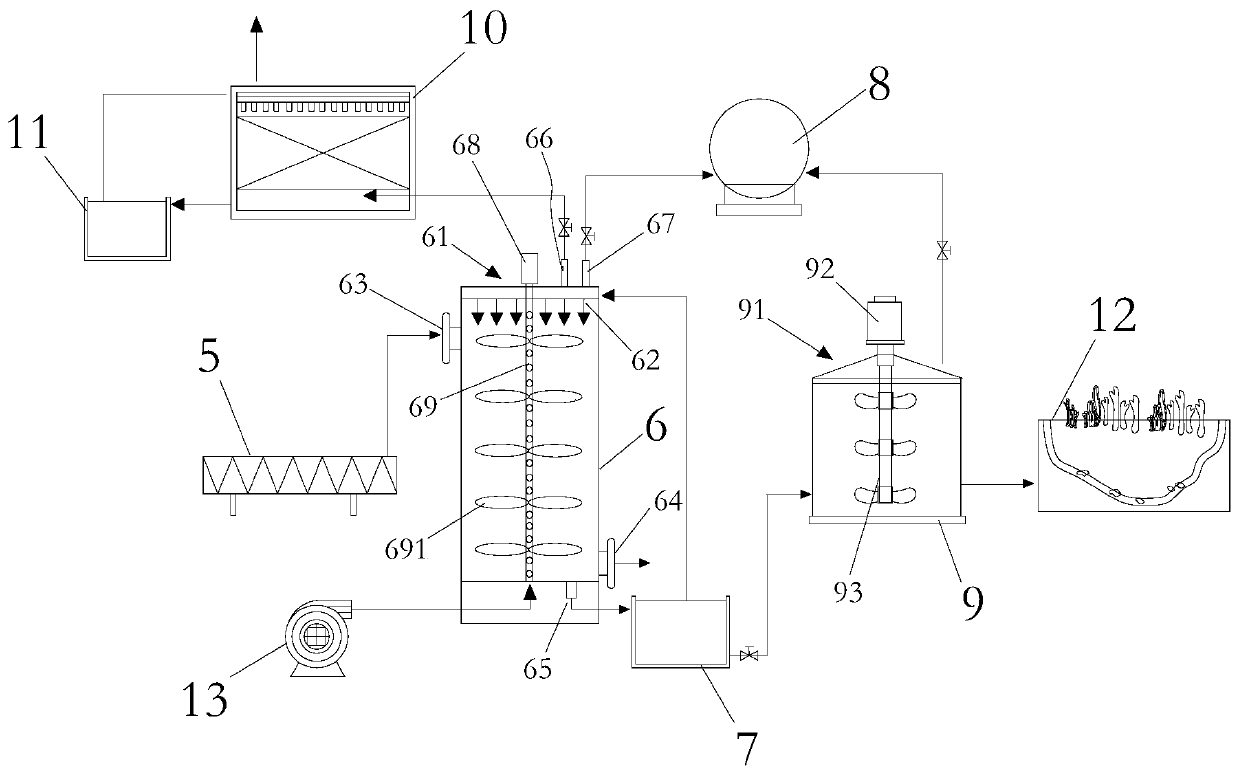

Dry-method flue gas purification method and dry-method flue gas purification device of simultaneously desulfurizing, denitrating and removing mercury

InactiveCN103657368ASimple processSmall footprintLighting and heating apparatusDispersed particle separationPtru catalystPurification methods

The invention discloses a dry-method flue gas purification method of simultaneously desulfurizing, denitrating and removing mercury, and belongs to the field of atmospheric pollution purification technologies. The dry-method flue gas purification method comprises the following steps of firstly, absorbing and removing SO2 in flue gas; secondly, carrying out catalytic oxidation on Hg<0> to obtain HgO by utilizing trace O2 in the flue gas and complementary air, absorbing on the surface of a catalyst, and meanwhile, spraying NH3 and converting NOx to N2 to discharge; lastly, causing commercially available active carbon, which has saturated absorption in the two processes, to enter into a recycling device, generating gases such as CO, H2 and H2S under the conditions that steam is introduced and the temperature is at 1000-1100 DEG C, causing the gases to enter into a wet oxidation process desulfurizing tower (ADA) method operating unit to recycle elemental sulfur, taking the CO and the H2 as fuel gas and returning to a boiler. The process belongs to a tower type fixed bed dry-method united purification process, and the process is simple and convenient for operation and can continuously run.

Owner:KUNMING UNIV OF SCI & TECH

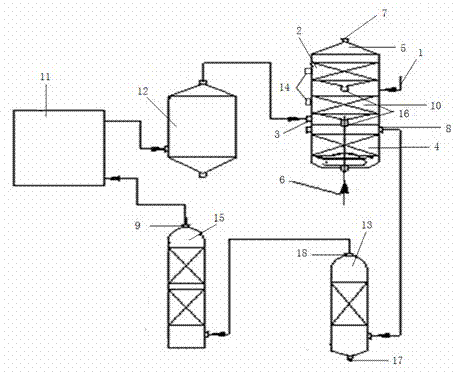

Exhuast gas desulfurization, recycle and treatment method and apparatus

InactiveCN101342459AReduce manual operationStable processing capacityCalcium/strontium/barium sulfatesDispersed particle separationGypsumExhaust gas

The invention relates to a smoke gas desulfurization and recycling method; the smoke gas is processed in an smoke desulfurization and recycling integrated device; the smoke gas desulfurization and recycling technology has three stages: a first stage is an exhaust gas dedusting technology, by which particulate matter in the smoke gas is removed; a second stage is an exhaust gas desulfuration technology, by which SO<2> / SO<3> is removed; a third stage is a post-processing technology, by which the exhaust gas is dried and purified and manufactured into a product; and waste seriflux is made into gypsum after being oxidized; the smoke gas desulfurization and recycling method and the device of the invention are suitable for processing the smoke gas containing the SO<2> / SO<3> produced in various industrial production processes and recycling a material, thereby taking full advantage of a resource, decreasing pollutant emission and having the advantages of high processing efficiency, high coefficient of recovery, wide adaptability and smaller investment.

Owner:ZHEJIANG UNIV

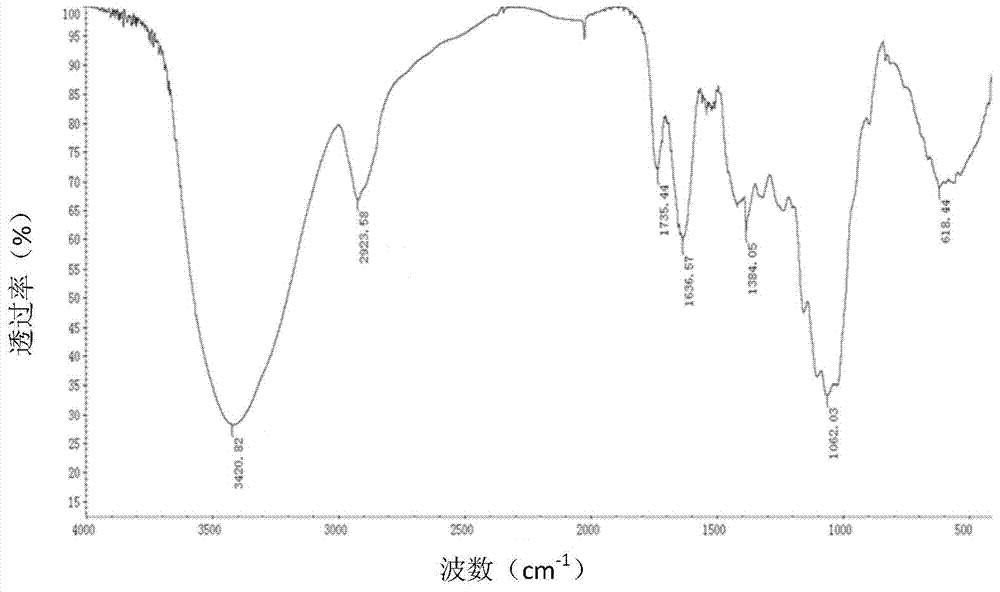

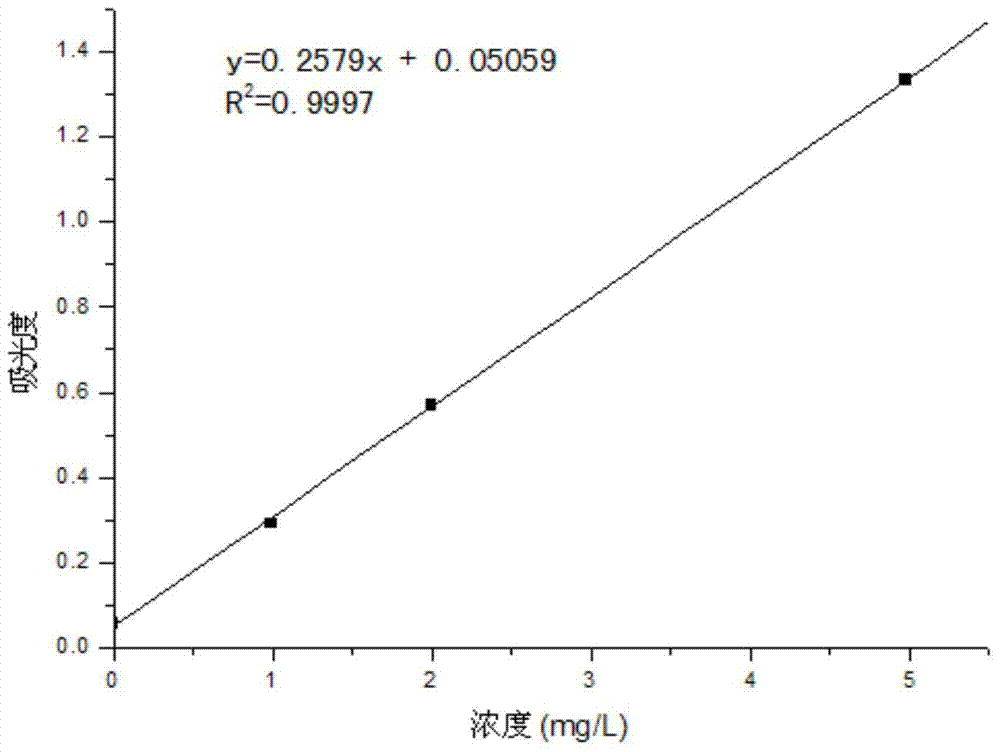

Comprehensive utilization method for pomelo peels

InactiveCN103484257AImprove use valueFull utilization of resourcesOther chemical processesSolid waste disposalFiltrationSorbent

The invention discloses a comprehensive utilization method for pomelo peels, relating to a resource treatment method for agricultural product wastes. The method comprises the steps of separating a pomelo peel into a yellow outer peel and a white inner peel; drying the white inner peel; grinding the yellow outer peel, heating, and collecting fractions to obtain the mixed liquid of essential oil and water; performing extraction and rotary steaming to obtain pomelo-peel essential oil; mixing the yellow outer peel after collecting the fractions with ethanol, refluxing until yellow peel pigments are completely removed, and drying the remaining yellow outer peel; mixing the dried yellow outer peel and the dried white inner peel, and grinding to obtain mixed powder; adding an ethanol aqueous solution into the mixed powder; stirring in an oil bath, performing suction filtration, and washing; adding deionized water, and adjusting the pH value to 1-2; stirring in the oil bath, and performing suction filtration; concentrating the obtained pectin extraction liquid; adding ethanol to separate out pectin to obtain a pectin product; drying the residue after the suction filtration, and grinding; fetching the residue powder; adding the deionized water, and washing to neutrality; performing suction filtration; drying the solid to obtain a residue adsorbent.

Owner:XIAMEN UNIV

Method for using waste concrete as active admixture in cement production

ActiveCN103396020AReduce heat consumptionDoes not affect normal productionCement productionClinker (waste)Process engineering

The invention relates to a method for using waste concrete as active admixture in cement production, which comprises steps as follows: waste concrete is crushed into a particle material with the particle size of at most 40mm; in a rotary kiln cement production process, high-temperature clinker is added to a section between a clinker cooling zone of the rotary kiln head and the blanking port, or a high-temperature space section with the clinker temperature of at least 550 DEG C in the grate cooler; waste heat of the high-temperature clinker is directly utilized to perform thermal activation treatment on the particle waste concrete, and the waste concrete subjected to clinker waste heat activation treatment is mixed in the clinker to be directly used as the active admixture in the clinker; and the waste concrete accounts for 1-30 wt% of the primary clinker fired in the rotary kiln. The invention is simple and easy to implement, has the advantages of no investment pressure and favorable economical efficiency, can be accepted by people, can solve the problems of shortage and cost of the admixture to some extent, is beneficial to inhibiting abundant utilization of inferior admixtures, especially raw shale, raw dirt, douke and the like, in the cement grinding, and lowers the probability of jerry-built projects.

Owner:长沙紫宸科技开发有限公司

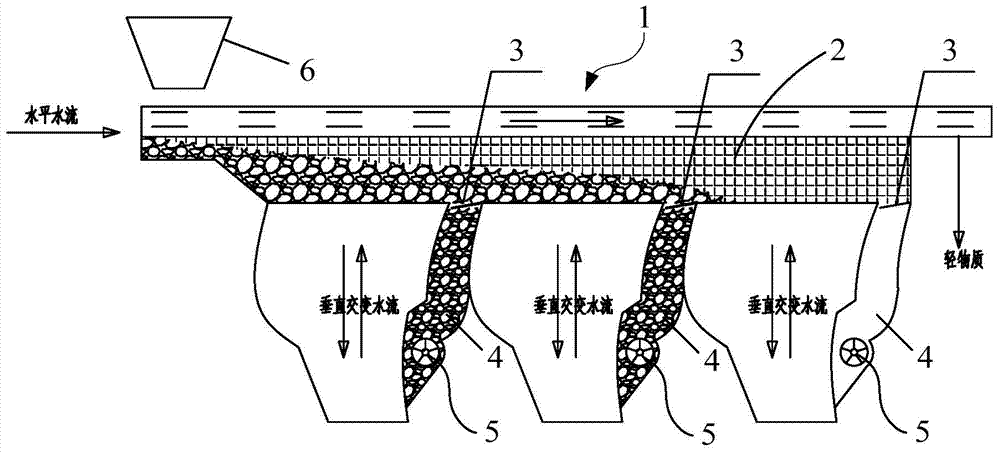

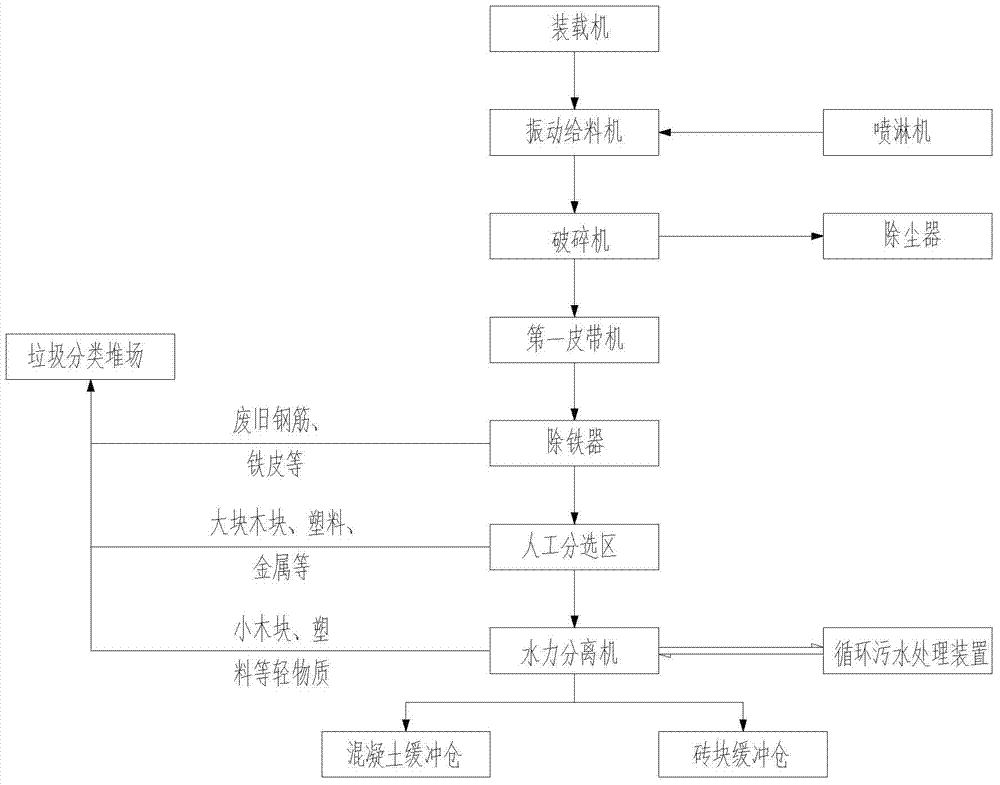

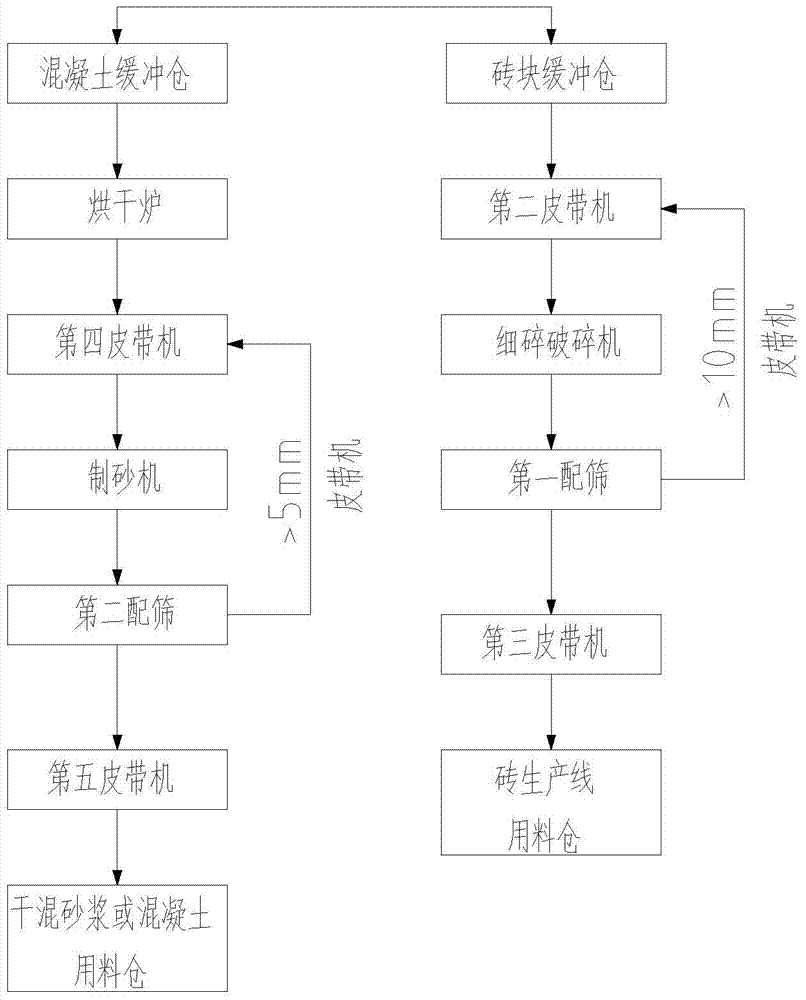

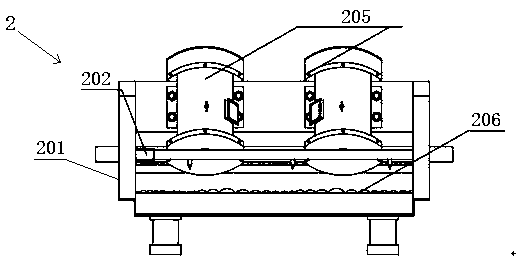

Hydraulic separator and construction waste material resource utilization system

ActiveCN103611721AEfficient separationSimple processConstruction waste recoverySolid waste disposalBrickWater flow

The invention discloses a hydraulic separator and a construction waste material resource utilization system. The hydraulic separator comprises a water tank, a mesh screen, a plurality of gates and a plurality of color sensors, wherein the mesh screen is placed in the water tank and is used for supporting construction waste materials; a plurality of gates are distributed on the bottom of the mesh screen; the plurality of color sensors are distributed in the mesh screen; a horizontal water flow and a vertical water flow are provided for the water tank for separating brick blocks, concrete blocks, and brick and concrete integrated blocks layer by layer. The construction waste material resource utilization system comprises a manual sorting area, a hydraulic separator, a crusher and a dust remover; construction waste material treatment processes in the prior art are simplified; the concrete blocks, the brick blocks, metals, wood blocks and the like in the construction waste materials are effectively separated, and various raw materials in the construction waste materials are fully and reasonably utilized.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Method for producing marsh gas by using entermorpha prolifera as raw material

InactiveCN101418315AFull utilization of resourcesTake advantage ofEnergy inputWaste based fuelWater bathsEnergy products

The invention relates to the field of energy, in particular to a method for producing biogas by taking Entermorpha as a material. The method comprises the following steps: (1) the Entermorpha is rinsed by water; (2) the Entermorpha obtained in step(1) is crushed until the grain size of the Entermorpha is between 0.5 and 2mm; (3) the Entermorpha obtained in step(2) is placed into a fermentation device and added with inoculum, and the weight ratio of the inoculum TS(total solid content) to the Entermorpha TS(total solid content) is between 1 to1 and 1 to 5; (4) the fermentation device is added with fresh water, and the total solid content in the fermentation device is adjusted to between 2.5 and 10 percent; (5) alkali is added into the fermentation device, and the initial pH value of the mixture obtained in step(4) is controlled to between 6.5 and 7.5; and (6) the fermentation device is sealed and placed in the thermostatic water bath, and the fermentation temperature is controlled to between 32 and 38 DEG C. The method has the advantages of realizing the resource utilization of the Entermorpha, having simple process and easy operation, improving the marine environment and producing the energy product of biogas.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

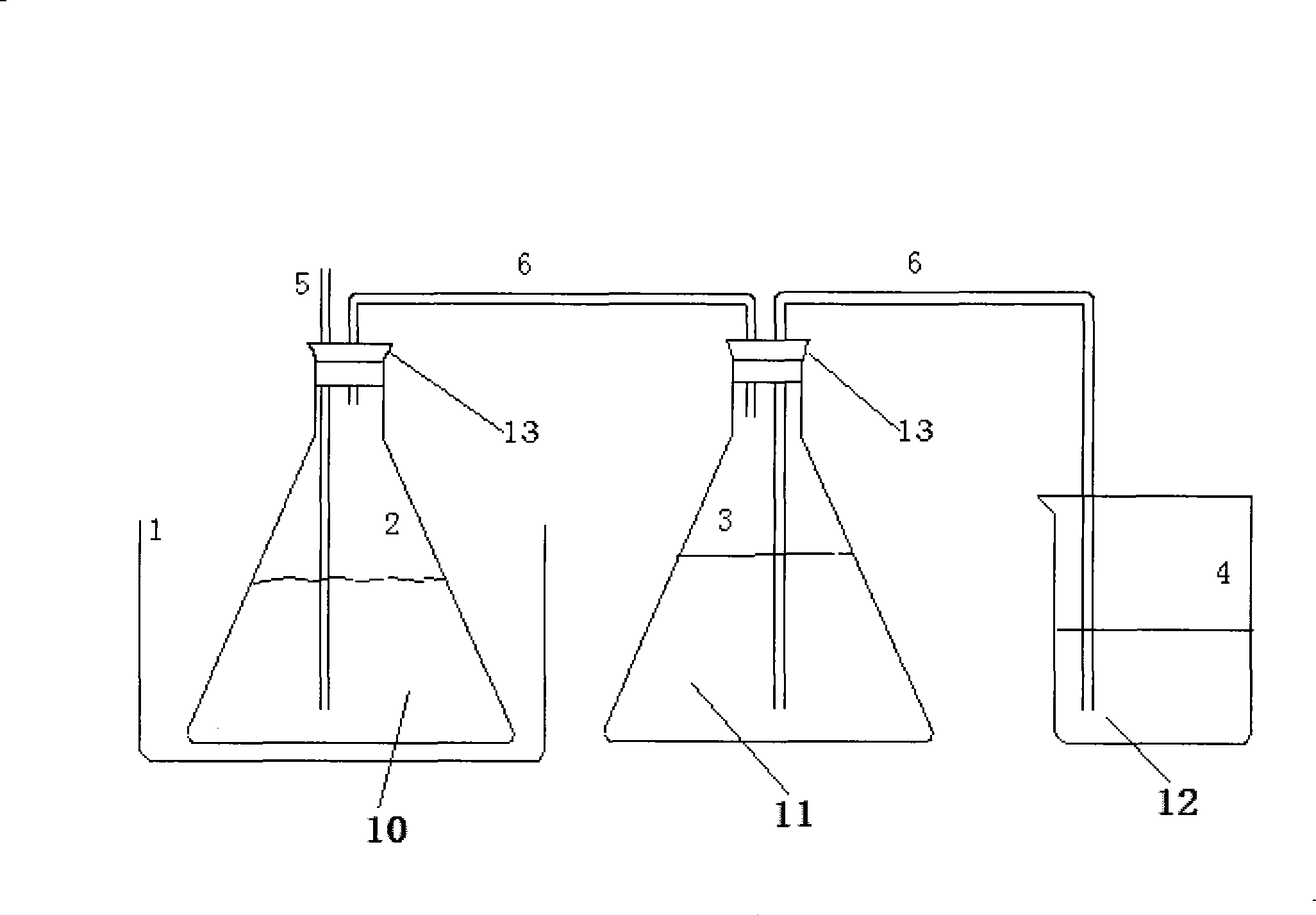

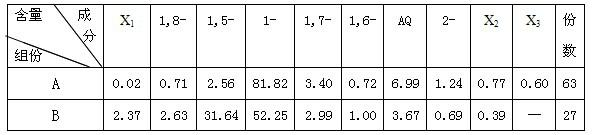

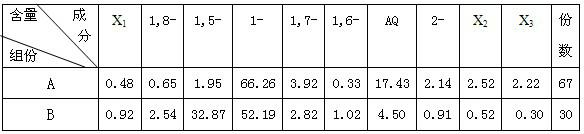

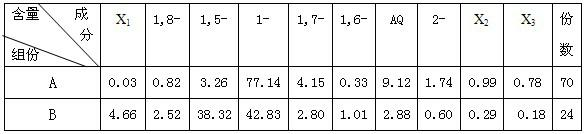

Resource utilization method of waste residues generated by 1-nitroanthraquinone production by solvent method

ActiveCN102320979AFull utilization of resourcesFull recoveryOrganic compound preparationNitro compound preparationSolventChemistry

The invention relates to a resource utilization method of waste residues generated by 1-nitroanthraquinone production by a solvent method, which comprises the steps that: the waste residues are added with water and are crushed, sulphite or hydrosulphite is added for taking reaction for 2 to 5 hours at 96 to 105 DEG C, the mass ratio of the waste residues to the water is 1 / 3 to 10, the mass ratio of the waste residues to the sulphite (or the hydrosulphite) is 1 / 0.3 to 0.7, the temperature reduction and the filtration are carried out after the reaction completion, filter cake is washed by hot water, beta-bit nitroanthraquinone isomers are removed, the filter cake is dried to obtain mixed nitroanthraquinone (mixed nitro, for short), the dried mixed nitro and solvents are heated to 90 to 160 DEG C, the ratio of the mass to the solvent volume of the mixed nitro is 1kg / 7 to 15L, the heat is preserved for about 1 hour, the mixed materials are filtered in the hot state, the filter cake is a component B, methanol is used for washing away the solvents, the drying is carried out, the main ingredients of the component B are 1,5-dinitroanthraquinone, 1,8-dinitroanthraquinone and anthraquinone, the filter liquid solvents are added with water again, after the solvents are recovered by a water vapor distillation method, a component A is filtered out, and the main ingredient of the component A is 1-nitroanthraquinone.

Owner:YANCHENG OUHUA CHEM IND

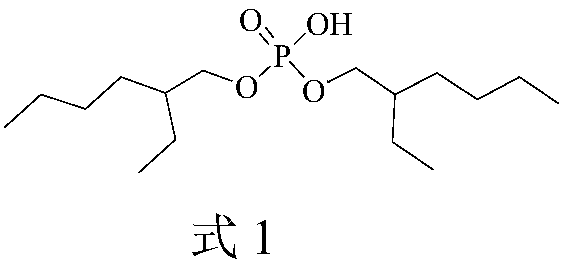

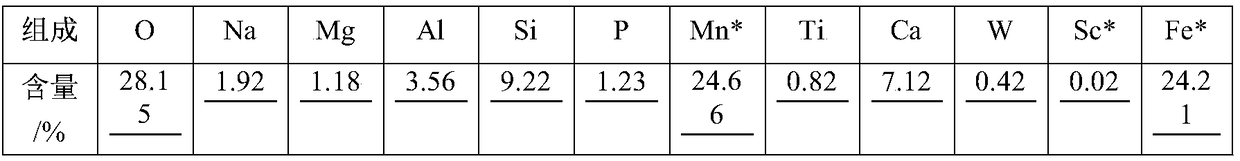

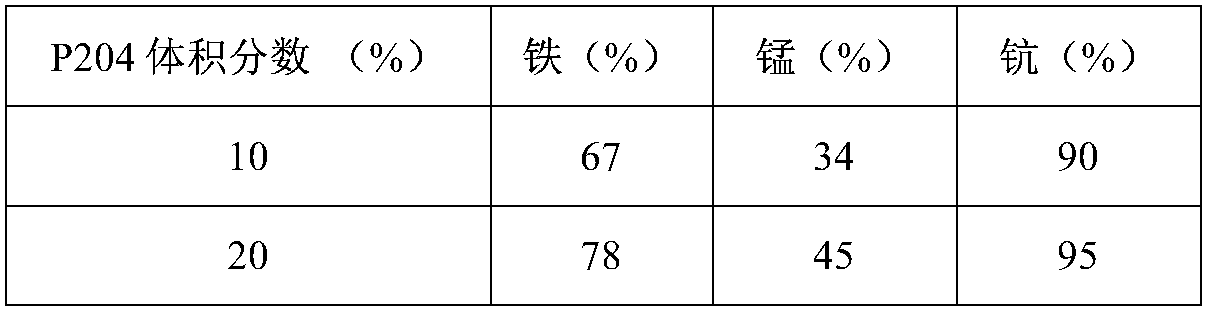

Method for separating and recovering valuable metal iron, manganese and scandium from tungsten slag

ActiveCN109022810AGood for the environmentImprove leaching efficiencyProcess efficiency improvementSlagKerosene

The invention discloses a method for separating and recovering valuable metal iron, manganese and scandium from tungsten slag. The method includes the steps that the tungsten slag is leached with sulfuric acid; valuable metals such as the iron, the manganese and the scandium exist in a leaching solution as Fe<3+>, Mn<2+> and Sc<3+> correspondingly; the Fe<3+>, the Mn<2+> and the Sc<3+> are simultaneously extracted by a P204+ sulfonated kerosene organic phase, the extraction rates are 97%, 95% and 99% correspondingly, and then the manganese, the iron and the scandium in a loaded organic phase are separated and recovered by selective reverse extraction in sequence by using different reverse extraction agents. According to the method, the process is simple, the recovery rate of the valuable metals is high, and the defects such as big acid mist and bad environment in the process of hydrochloric acid leaching are overcome.

Owner:肇庆市珈旺环境技术研究院

Gangue ready mixed mortar and preparation method thereof

InactiveCN102815909AReduced activityHigh strengthSolid waste managementAggregate (composite)Clinker (cement)

The invention discloses gangue ready mixed mortar and a preparation method of the gangue ready mixed mortar. The gangue ready mixed mortar is formed by mixing gangue fine powder, silicate cement clinker, silica fume, a composite fine aggregate, a composite exciter, an inner curing agent and gypsum mixing control agent according to proper mass percentages through a certain process, wherein the content of the gangue fine powder is 5 to 20 percent; and the content of the gangue fine aggregate is 15 to 60 percent. The physical performance indexes such as strength, viscosity, water-retaining property, condensation time and stretching adhesive strength of the gangue ready mixed mortar can meet the standard requirements in a building material industry, and demands for masonry and wall surface plastering can be met. With the adoption of the gangue ready mixed mortar, the problems of long-time accumulation of gangue and environment pollution are solved, and the gangue is turned into wealth; the industrial policies in energy conservation, emission reduction and environment protection in China are met; and the gangue ready mixed mortar is favorable for popularization and application.

Owner:HENAN UNIV OF URBAN CONSTR

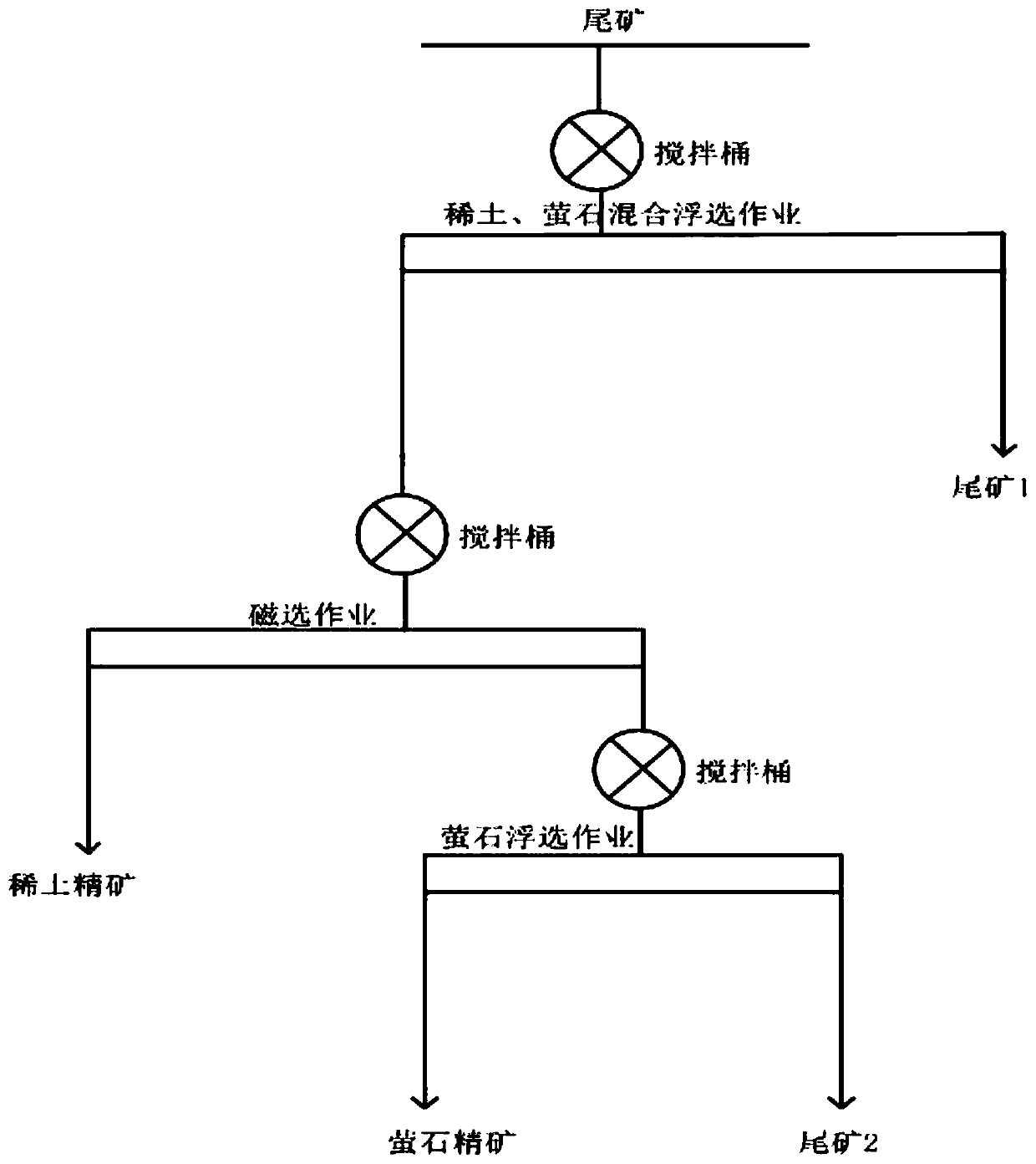

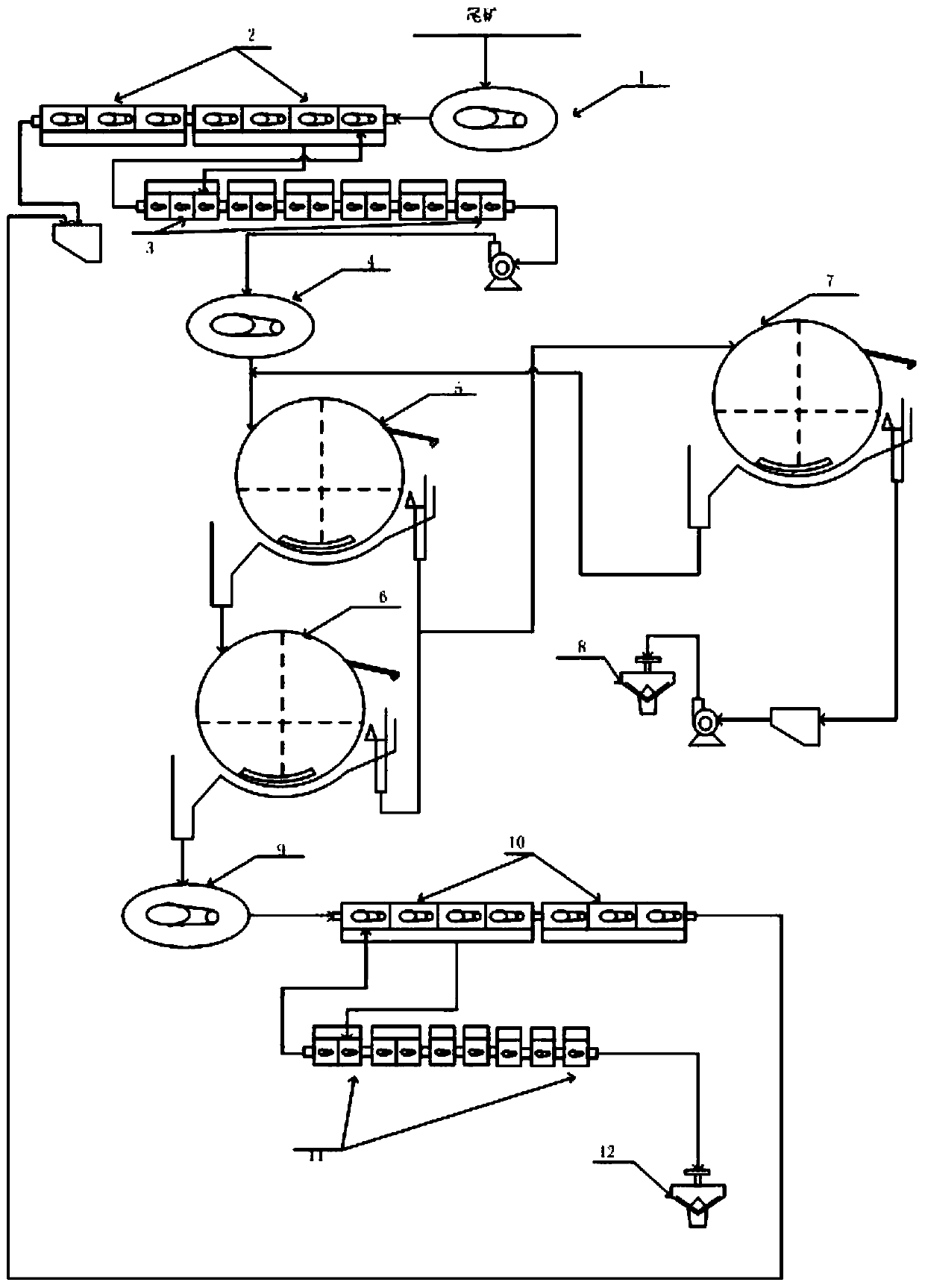

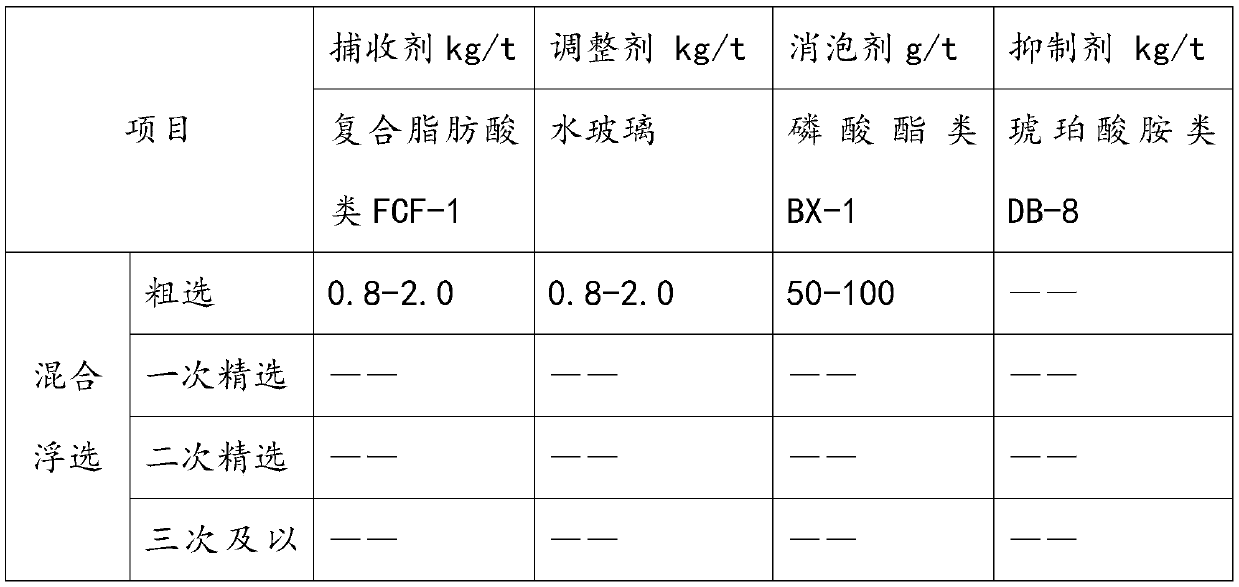

Beneficiation method for recovering ultra-low-grade rare earth and fluorite from rare earth tailings

InactiveCN110860369AEfficient recyclingShort processSolid separationMechanical material recoveryMineralogyMagnetic separation

The invention discloses a beneficiation method for recovering ultra-low-grade rare earth and fluorite from rare earth tailings. The beneficiation method includes the following steps of 1, performing rare earth and fluorite mixed flotation on the rare earth tailings to obtain mixed floatation concentrates with the qualified grade; 2, performing wet magnetic separation on the mixed flotation concentrates obtained in the step 1 to obtain magnetic separation concentrates and magnetic separation tailings; and 3, performing fluorite flotation on the magnetic separation tailings obtained in the step2 to obtain high-grade fluorite concentrates. By means of the beneficiation method, the unified technological process that mixed flotation is preferentially performed on the rare earth and the fluorite to obtain the fluorite and rare earth mixed concentrates, the fluorite and rare earth mixed concentrates are then subjected to magnetic separation to separate the rare earth, and the fluorite is separated from the magnetic separation tailings is adopted, when the high-grade fluorite concentrates and the rare earth concentrates are separated from the ultra-low-grade rare earth and fluorite tailings and the fluorite is separated from the magnetic separation tailings, the flotation concentration is 5%-25%, the process adaptability is relatively good, and the defects that an existing separationprocess is high in process cost, poor in sorting effect, low in economic benefit and the like are overcome.

Owner:中稀(凉山)稀土有限公司

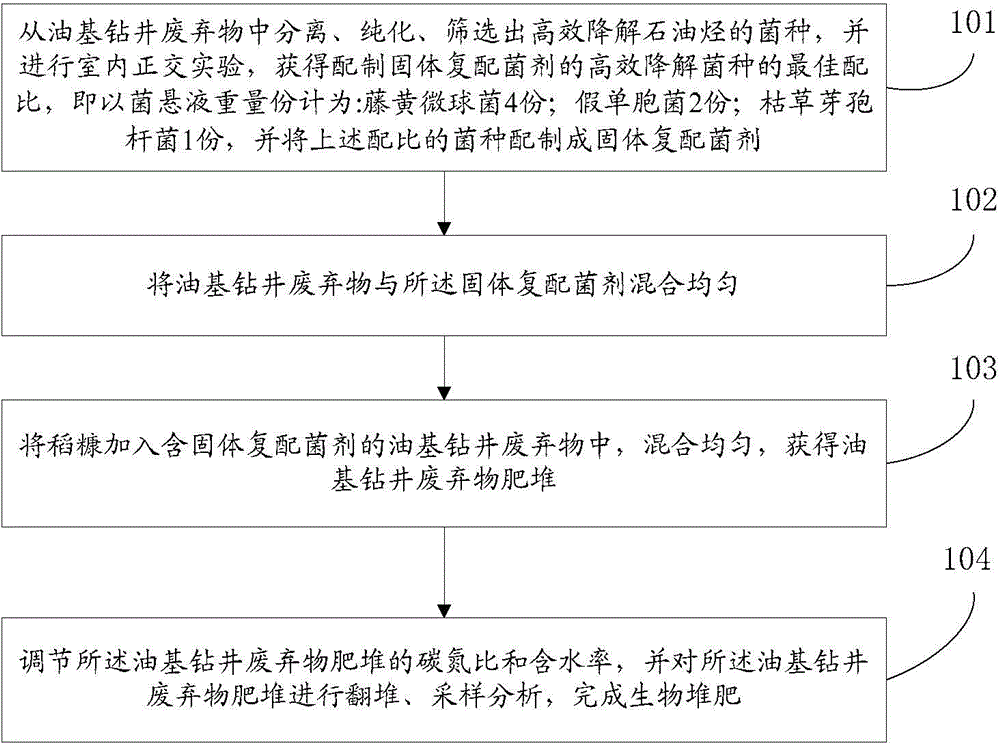

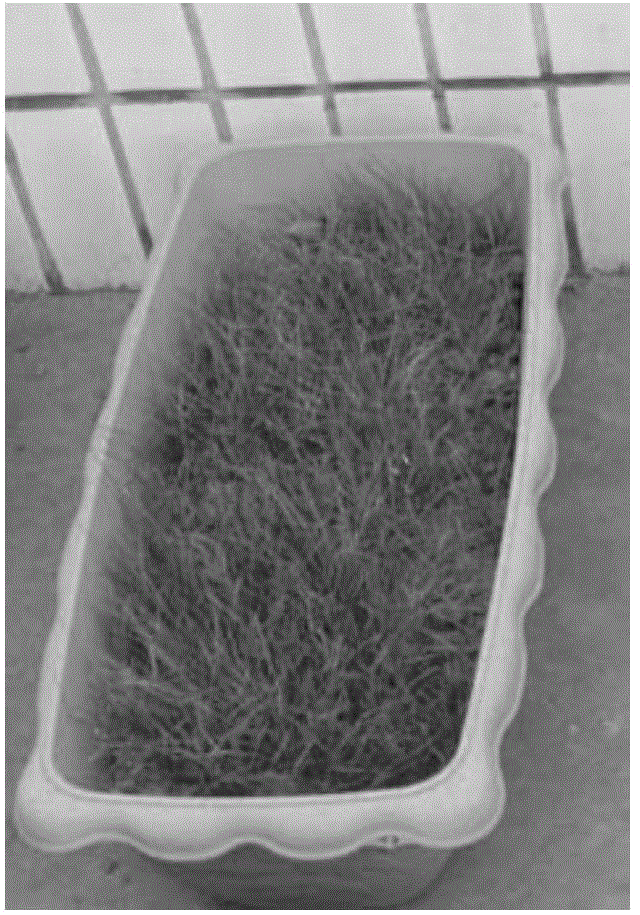

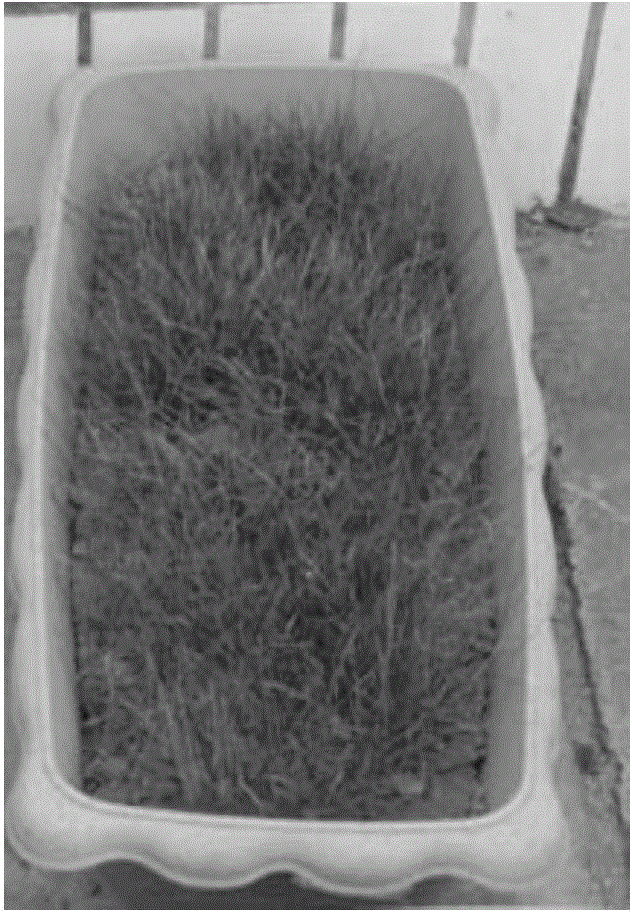

Biological composting processing method of oil-based drilling wastes

ActiveCN104803721AImprove degradation efficiencySmall footprintBio-organic fraction processingClimate change adaptationWell drillingNitrogen

The invention discloses a biological compost processing method of oil-based drilling wastes. The method comprises the following steps: screening strains capable of efficiently degrading petroleum hydrocarbons from the oil-based drilling wastes, and carrying out orthogonal experiment to prepare a solid compounded inoculant; adding the solid compounded inoculant into the oil-based drilling wastes, adding rice chaff as a supporter, and uniformly mixing to obtain compost of the oil-based drilling wastes; and adjusting the carbon / nitrogen ratio and the water content of the compost, turning, and carrying out sampling analysis to complete onsite composting. The degradation rate of total petroleum hydrocarbons in the oil-based drilling wastes reaches above 80% 1 month after the method is used to process the oil-based drilling wastes; and compost obtained in the invention can be used for planting plants, and the growth vigor of the plants is good within 3 months. The method has the advantages of simple process, simple required capital construction facility, handy enforcement surrounding a well site, short cycle, easy control, high degradation efficiency of the oil-based drilling wastes, low processing cost, and solving of troubles in economy and environmental protection for efficient exploitation of oil and gas fields.

Owner:PETROCHINA CO LTD

Sodium chloride and sodium sulfate mixed waste salt resource reutilization method

PendingCN113371736AAvoid pollutionImprove separation efficiencySemi-permeable membranesAlkali metal sulfite/sulfate purificationFlue gasEnvironmental engineering

The invention relates to the field of waste treatment, and discloses a sodium chloride and sodium sulfate mixed waste salt resource reutilization method which comprises the steps of co-treatment, dissolution treatment, nanofiltration membrane filtration, evaporative crystallization and the like. According to the method, the sodium sulfate body can be recycled, and organic matters contained in the waste salt can be fully utilized to burn to produce heat to supply energy to the cement kiln so that the aim of full resource utilization is fulfilled; according to the invention, the use amount of water in the process can be reduced, the energy consumption in the evaporative crystallization process is reduced, and the treatment cost is saved; according to the method, the organic matters in the waste salt are decomposed by fully utilizing heat generated by the cement kiln, then volatile organic matters generated by the decomposed organic matters are mixed with air along with flue gas and then enter the cement kiln to be fully combusted, heat is provided for the cement kiln, combustion is complete, harmless emission is achieved, and the purpose of green treatment is achieved.

Owner:浙江红狮环保股份有限公司

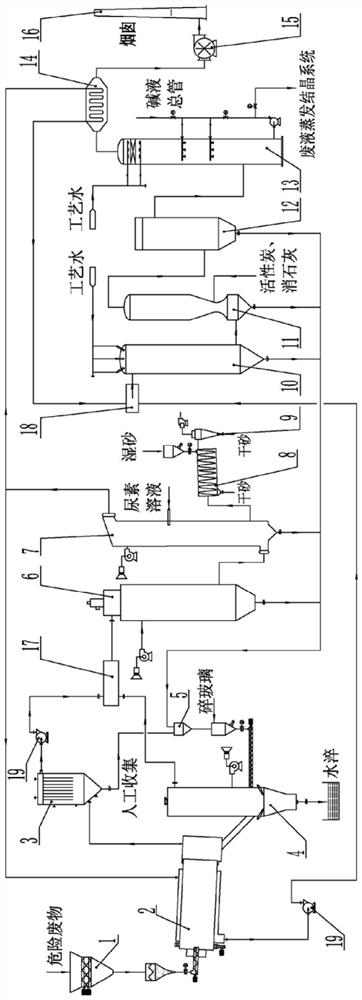

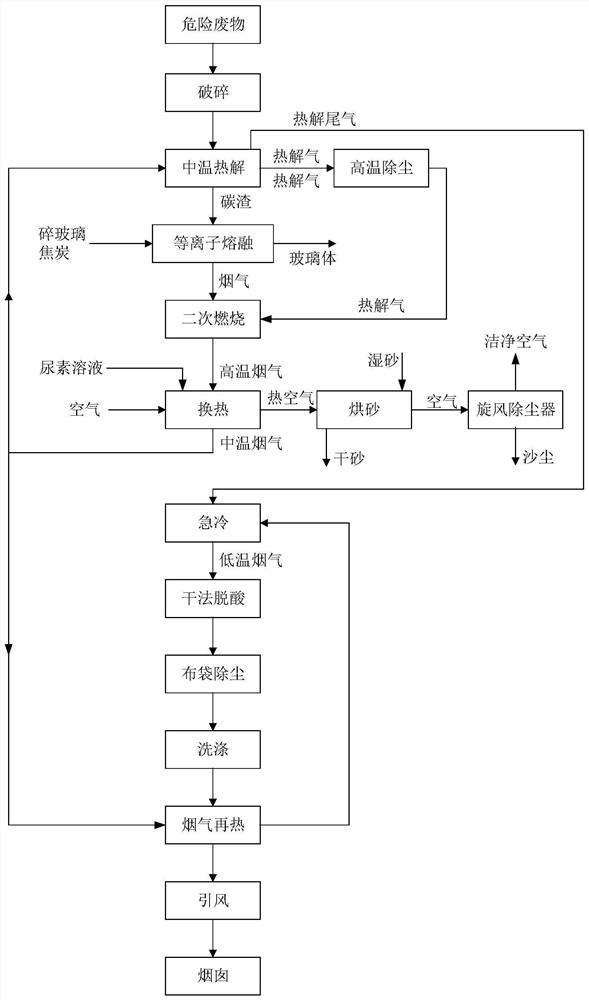

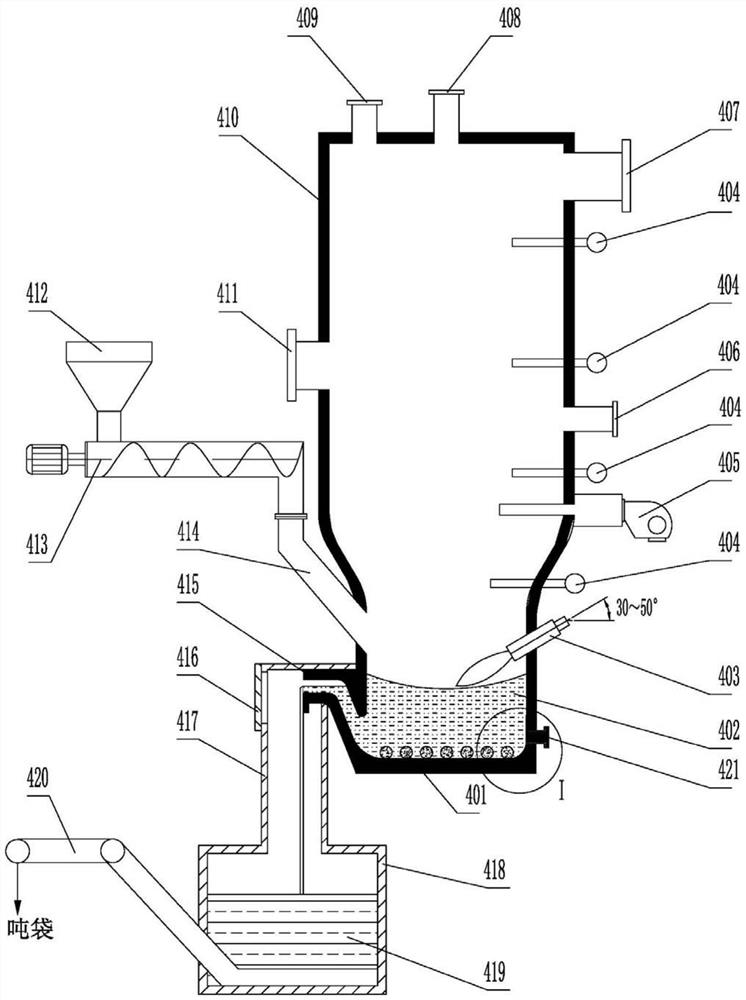

Hazardous waste treatment system and method based on medium-temperature pyrolysis and plasma high-temperature melting

ActiveCN113182311AHigh degree of harmlessnessHarmlessSolid waste disposalTransportation and packagingCombustion chamberDust control

The invention provides a hazardous waste treatment system and method based on medium-temperature pyrolysis and plasma high-temperature melting. The problems that existing hazardous waste incineration treatment is low in harmless degree, pyrolysis treatment is not thorough, and plasma melting treatment cost is high are solved. According to the system and method, hazardous waste is broken and then subjected to medium-temperature pyrolysis in an oxygen-deficient environment, pyrolytic carbon residues form harmless glass bodies through a plasma melting furnace, pyrolysis gas and smoke generated by plasma melting enter a combustion chamber to be subjected to secondary combustion, high-temperature smoke obtained after secondary combustion exchanges heat with air and then is cooled into medium-temperature smoke, the medium-temperature smoke is divided into two parts, one path enters a pyrolyzing furnace to heat materials, the other path enters a flue gas reheater to exchange heat, pyrolysis tail gas obtained after the materials in the pyrolyzing furnace are heated is mixed with flue gas obtained after heat exchange of the flue gas reheater, and after mixing, quenching cooling, dry-process deacidification, cloth bag dust removal, washing and reheating are conducted in sequence, and then a mixture is sent to a chimney to be discharged through an induced draft fan; and air is heated after heat exchange, is used as a heat source of a sand dryer, and is discharged after sand drying and cyclone dust removal.

Owner:ACADEMY OF AEROSPACE PROPULSION TECH +1

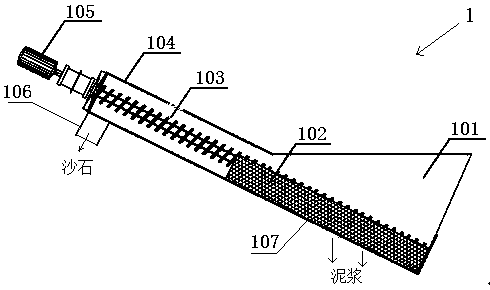

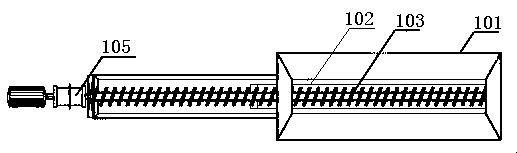

Shield muck treatment method and equipment

PendingCN109761396ASave water for cleaningAvoid pollutionMultistage water/sewage treatmentFlocculationBelt filter

The invention discloses a shield muck treatment method and equipment. The method comprises the steps that stones, sand and mud in the muck transported out in the shield construction process are subjected to vibrate separation under impact of water, the separated big sand is accumulated concentratedly through conveying equipment, meanwhile the separated thin sand and mud mixture is subjected to twisting separation, the thin sand is discharged, the separated mud is subjected to one flocculation treatment through a flow guiding tank or pipe, the mud subjected to flocculation treatment settles ina mud pool so as to separate mud and clear water, the clear water is drained into a clear water pool to serve as construction recycling water, the mud is pumped into a con ave-convex mud conveying pipe to be subjected to second flocculation treatment, and the mud subjected to second flocculation treatment is sent into a belt filter press to obtain dry mud cakes. The solid-liquid separation effectof the equipment is good, the automation degree is high, shield construction water is recycled, cleaning water for externally transported mud is greatly reduced, water is saved by50% or above in the whole construction process, and city pollution brought by external transportation of shield muck is thoroughly solved.

Owner:邓为成

Garden planting soil prepared from construction waste and its application

InactiveCN107673814AImprove physical structureImprove permeabilityGrowth substratesCulture mediaGrowth plantSites treatment

Owner:南昌理工学院

Efficient low-consumption red mud comprehensive utilization method

The invention discloses an efficient low-consumption red mud comprehensive utilization method. The method comprises the following steps that red mud and water are stirred for slurry mixing, then filter pressing is performed to obtain red mud with alkali removed in advance; the red mud with the alkali removed in advance is mixed with a reducing agent and a calcium-containing additive for pellet pressing manufacturing, a pellet material undergoes preheating and high-temperature melting, the molten product undergoes crushing and magnetic separation to obtain reduced iron and furnace slag which can be used as a compound fertilizer raw material. According to the method, the comprehensive utilization of the red mud can be realized, the reduced iron and compound fertilizer raw materials with relatively high additional value can be obtained, moreover, the red mud treatment process is simple, the raw materials are easy to obtain, the operability is high, the energy utilization rate is high, thecost is low, and relatively good economic and social benefits can be generated.

Owner:深圳前海中能再生资源有限公司

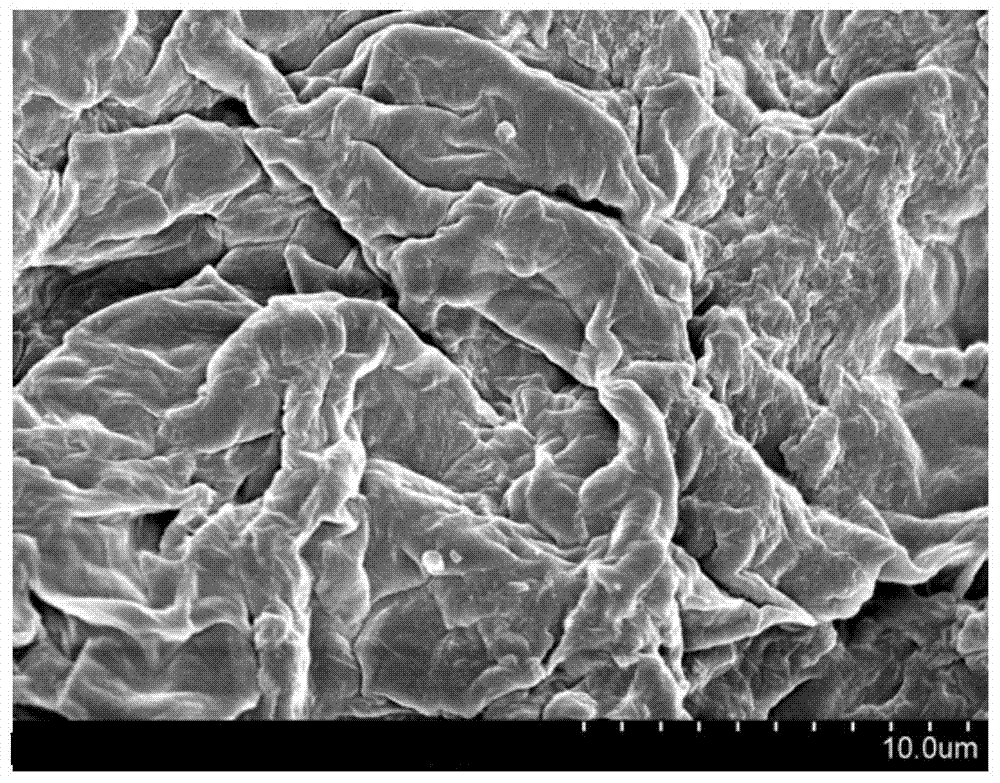

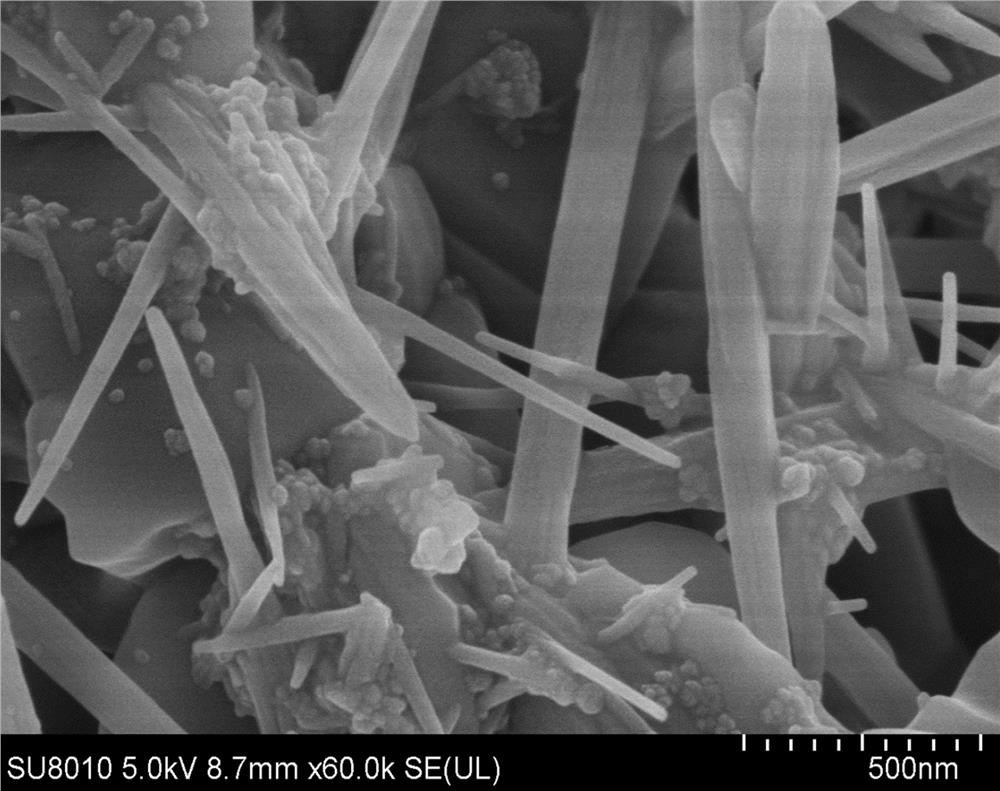

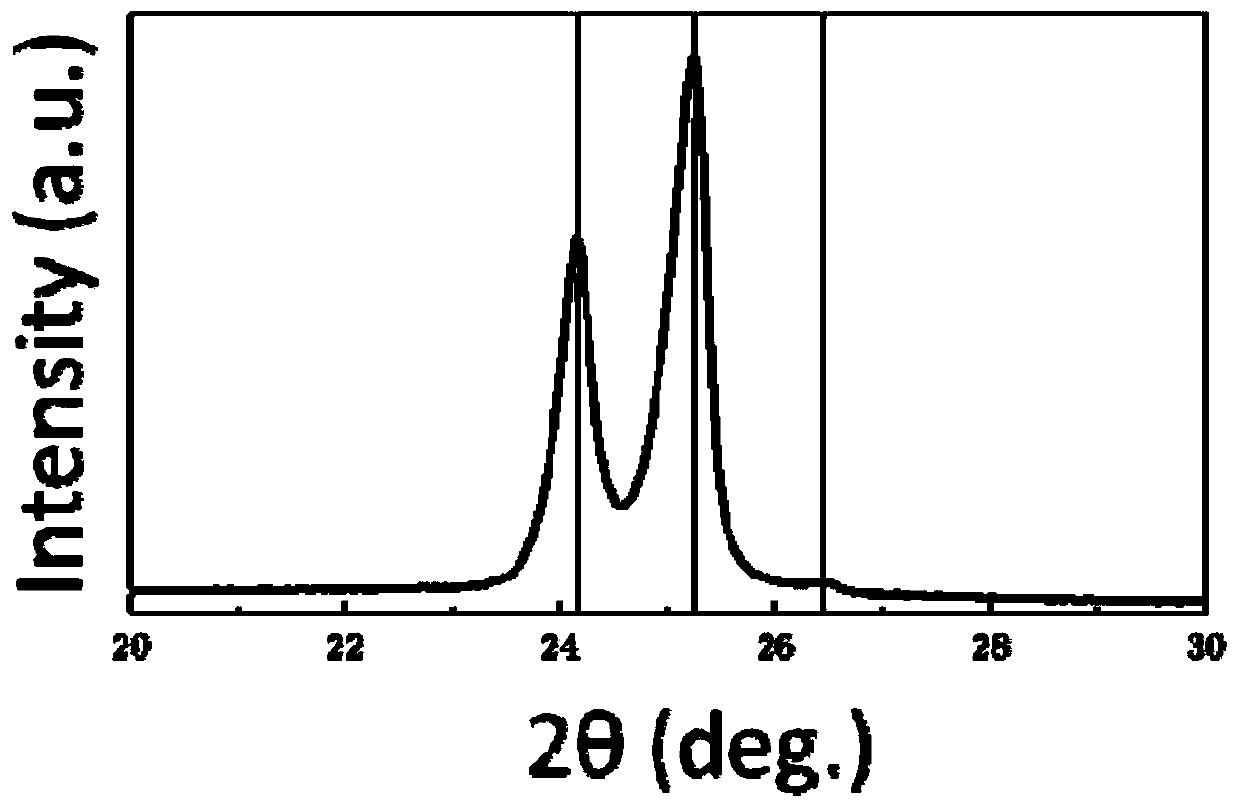

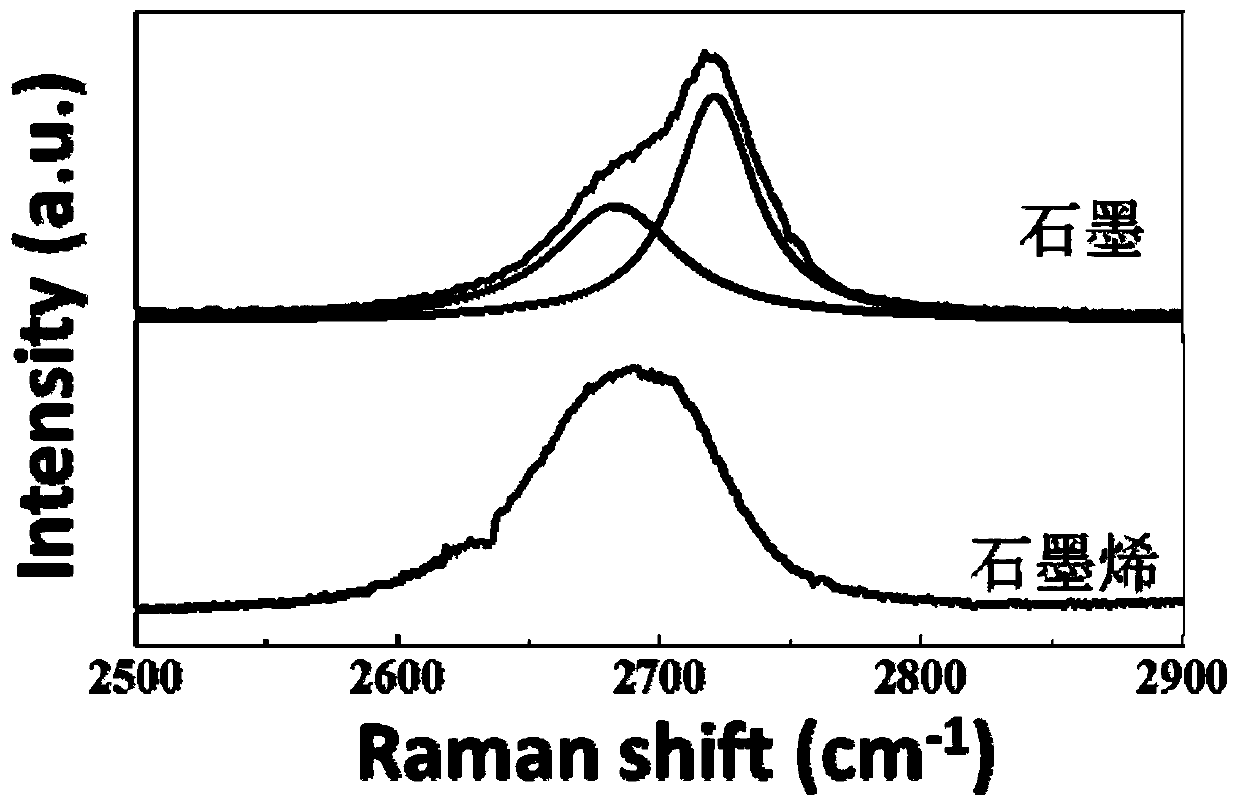

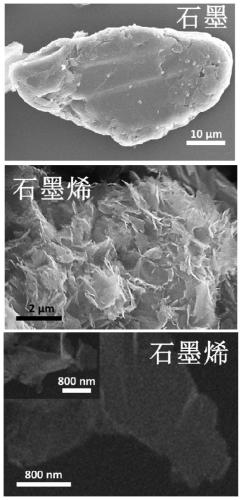

Method for preparing graphene by using waste lithium ion power battery

InactiveCN111252757AEmission reductionAchieve reductionGrapheneWaste accumulators reclaimingPower batteryPhysical chemistry

The invention relates to a method for preparing graphene by using a retired lithium ion power battery negative electrode material, which belongs to a new solid waste recycling technology in the fieldof comprehensive utilization of waste resources. The method is characterized in that the method is specifically characterized by comprising the steps; according to the characteristics of the waste lithium ion battery; the lithiated graphite can be obtained by recharging the waste lithium ion battery; by utilizing the characteristics that the interlayer spacing of the lithiated graphite is increased and the acting force between graphite layers is greatly weakened, the graphene powder with 1-4 layers is prepared in a manner of externally applying mechanical force, the size of the obtained graphene product is 500 nanometers to 5 microns, only a few defects (ID / IG (0.34) exist, and the application prospect is good.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Tire carbon catalyst capable of activating persulfate and preparation method and use thereof

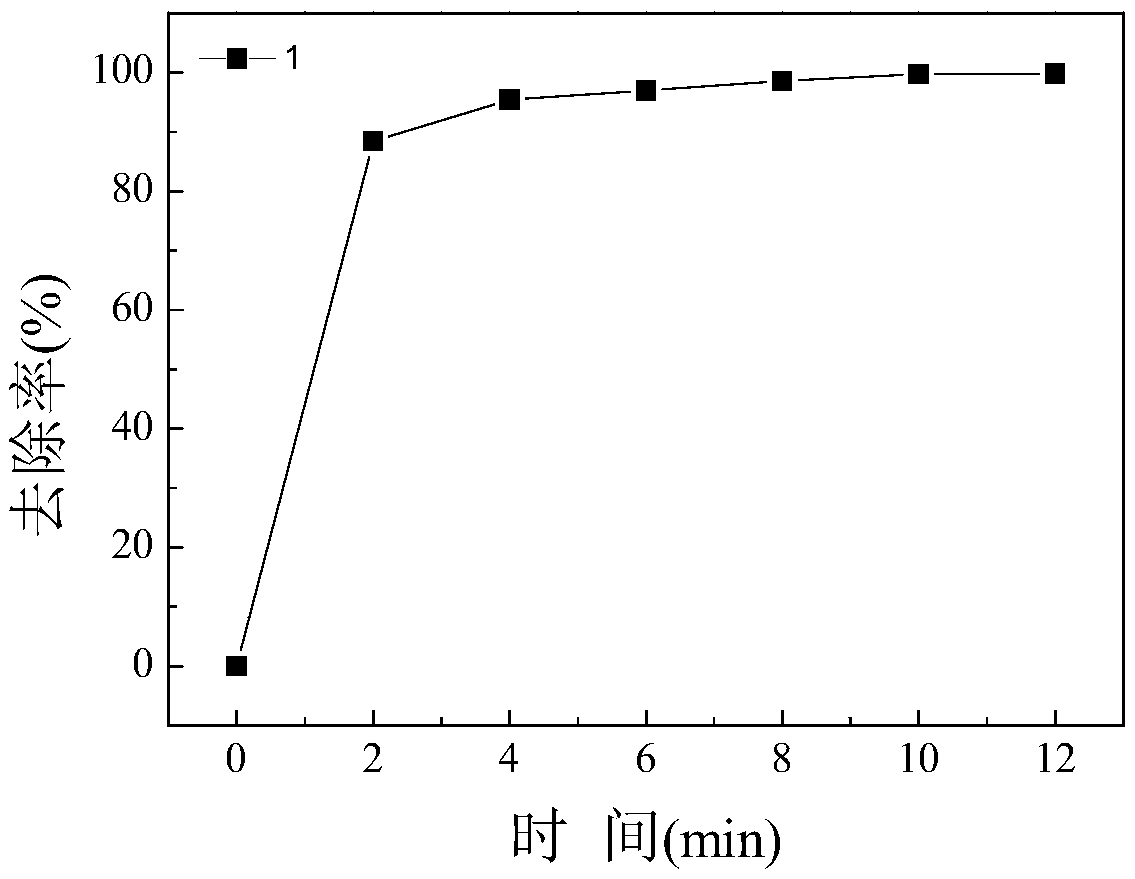

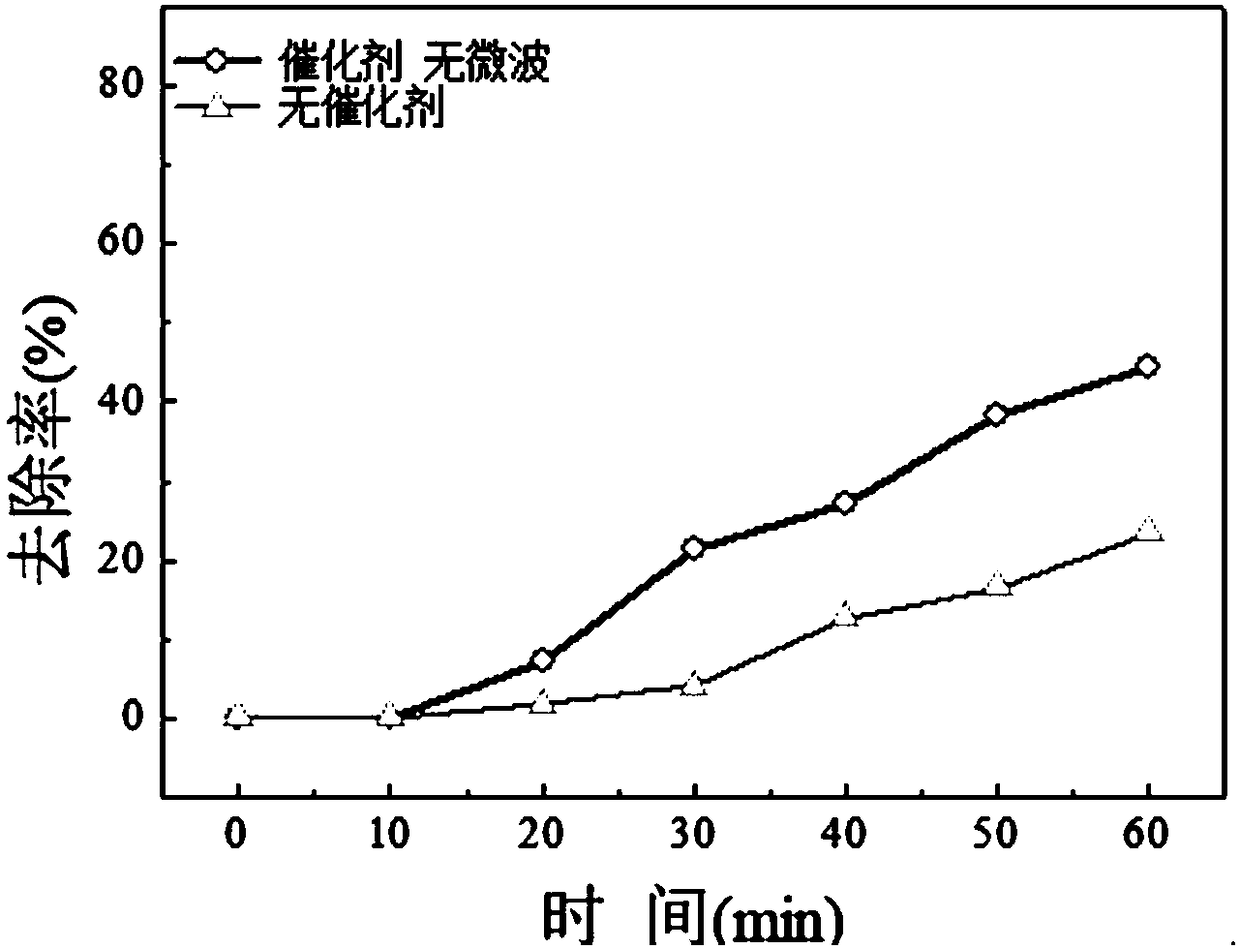

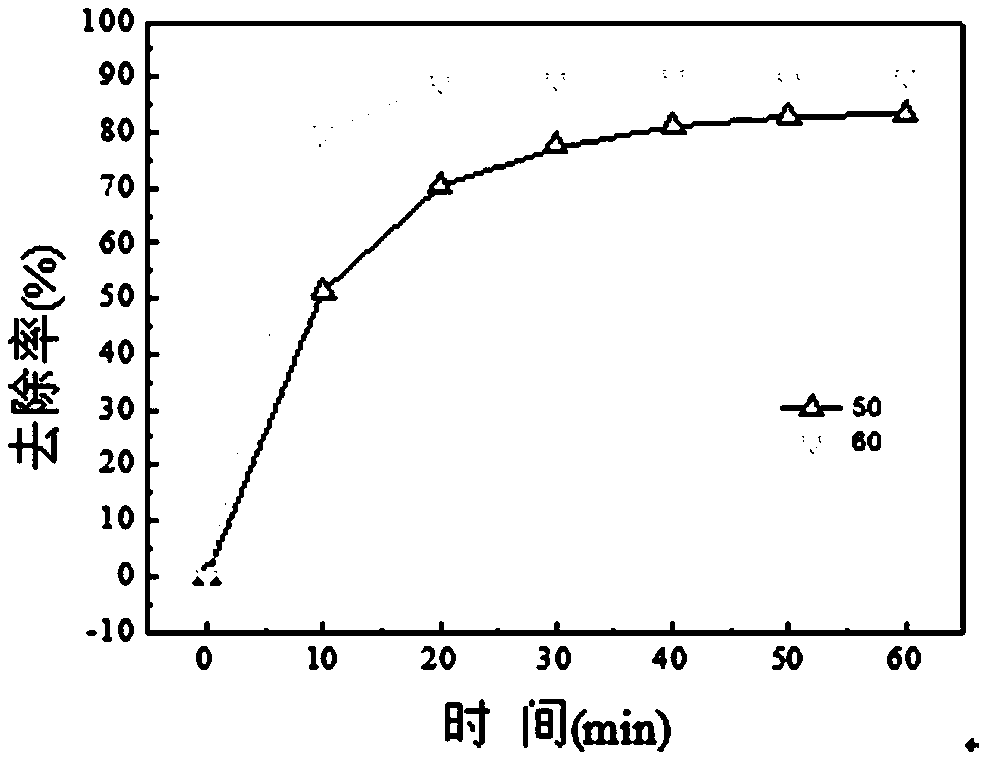

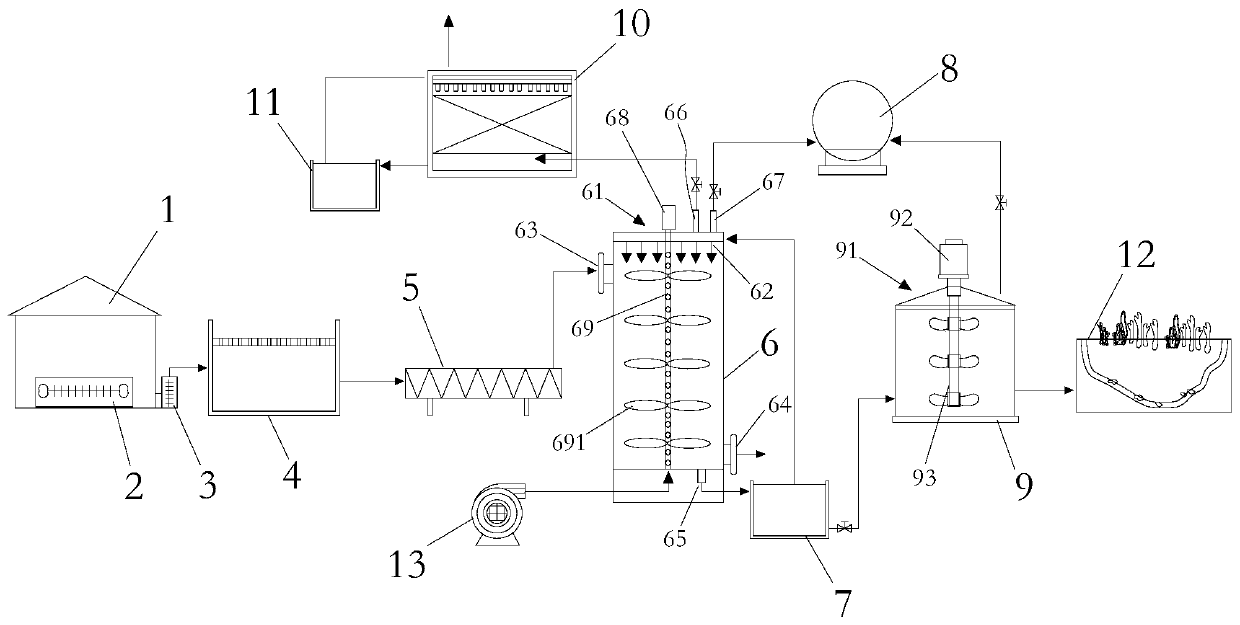

ActiveCN108993510AWide range of sourcesLess impregnationWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsMature technologyHigh activity

The invention discloses a preparation method of a tire carbon catalyst capable of efficiently activating persulfate. The preparation method comprises: carrying out crushing, magnetic separation and low temperature pyrolysis on waste and old tires to obtain catalyst carrier tire carbon, and carrying out impregnation, mixing kneading and pyrolysis on CuO, CeO2, Fe2O3, Bi2O3 and Co2O3 to obtain the novel and efficient catalyst for a persulfate system. The catalyst has the advantages of high activity in the persulfate system, small active component impregnation amount, simple preparation process,mature technology, good stability and low cost and can be used in the fields of sewage treatment and environmental treatment. The catalyst utilizes waste and old tires as raw materials, changes wasteand old tires into valuables, fully utilizes the resources, treats wastes through wastes and has significant economic benefits. The invention also provides a method for decomposing organic wastewaterby the catalyst. The method has an organic wastewater removal rate of 95% or more and satisfies national first-class wastewater discharge standard.

Owner:NANJING TECH UNIV

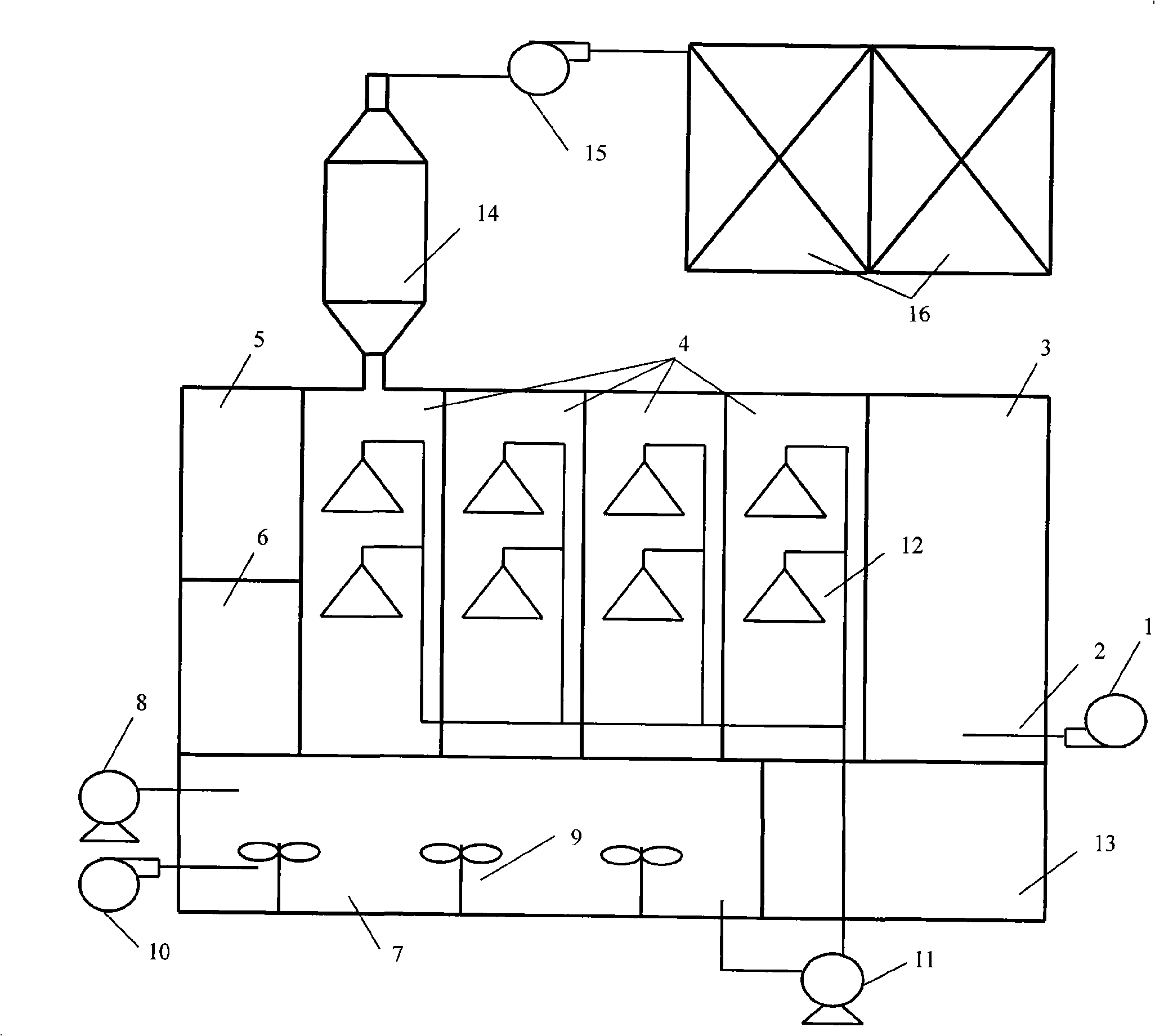

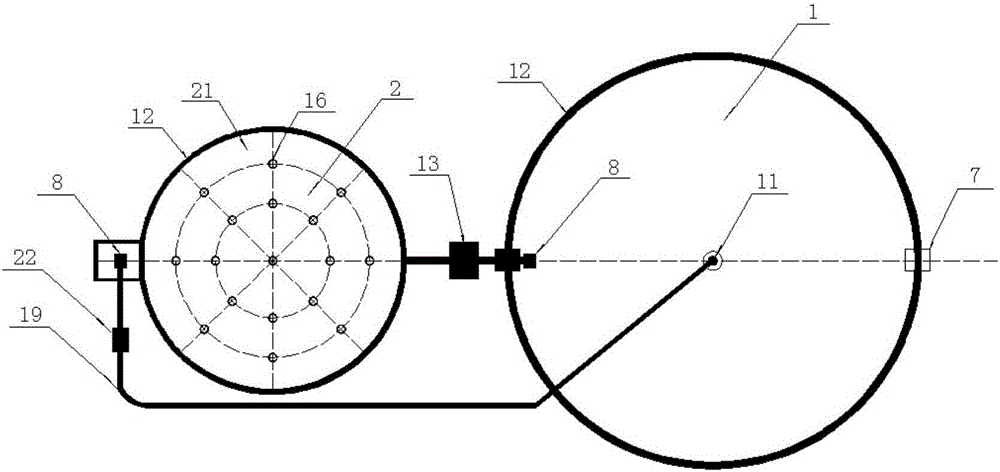

Method and device for comprehensively processing pig dung in large-scale pig farm

PendingCN110127970AGood processing effectSimple process conditionsBio-organic fraction processingSpecific water treatment objectivesScrew conveyorCrop

The invention discloses a method and a device for comprehensively processing pig manure in a large-scale pig farm. The method for comprehensively processing pig dung in the large-scale pig farm comprises the following steps: S1, the pig dung in pig houses is collected by a mechanical dung scraping facility, and is transported into a dung collecting tank; S2, the pig dung in the dung collecting tank is added into a fermentation tower by a screw conveyor, undergoes anaerobic dry fermentation to produce biogas, and then undergoes aerobic composting; S3, the biogas generated in the anaerobic dryfermentation process is introduced into and stored in a gas storage cabinet, odorous gas generated during the aerobic composting is introduced into a biological filter and is processed, the above produced organic fertilizer is transported to a curing workshop and is cured, and generated biogas slurry and leachate enter an anaerobic fermentation reactor by a pump, and are used to produce biogas; and S4, the biogas obtained in step S2 and step S3 is purified, and then used, the produced organic fertilizer is returned to the field, and the generated biogas slurry is used for irrigating crops after being discharged into an oxidation pond and processed. The method and the device have the advantage of good processing effect, simple process conditions, no secondary pollution and high economic benefits.

Owner:广东广垦畜牧工程研究院有限公司

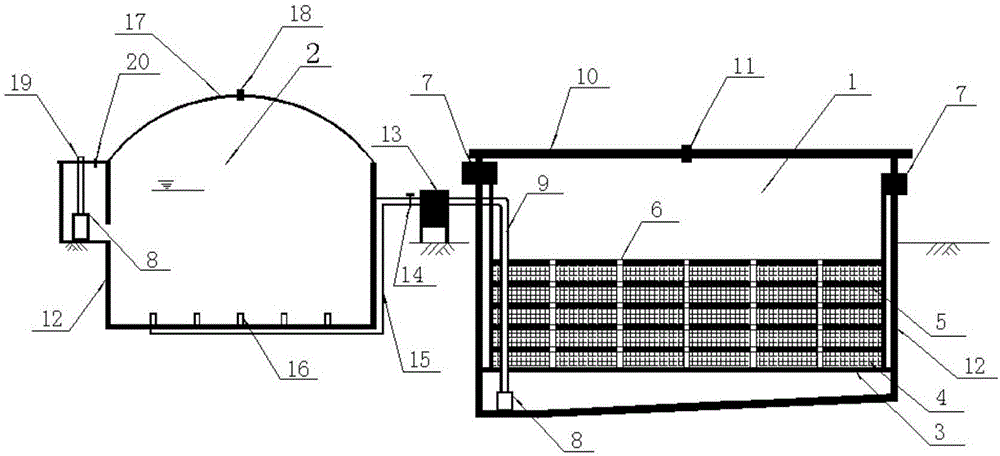

Device for preparing biogas through plant straw degradation and anaerobic fermentation and application method

InactiveCN106148171AEfficient use ofRealize resource utilizationBiological substance pretreatmentsGas production bioreactorsBiotechnologySlag

The invention discloses a device for preparing biogas through plant straw degradation and anaerobic fermentation and an application method. According to the device, an aim of efficiently preparing biogas through anaerobic fermentation of plant straw is achieved by adopting the plant straw (4) as main raw material and mixing with human and animal excreta (5) and a degradation strain. The device comprises a degradation tank (1) and a fermentation tank (2), wherein the human and animal excreta (5) and the plant straw (4) are stacked in layers in the degradation tank (1), and meanwhile, the degradation bacteria are mixed, and the degraded mixture is conveyed into the fermentation tank (2) through a slag discharge pump (13) for anaerobic fermentation to prepare biogas. The biogas slurry in the fermentation tank (2) is pumped and circulated to a ventilation liquid spray port (11) in a top cover plate (10) of the degradation tank (1) and sprayed in; and the humidity of the plant straw (4) and the human and animal excreta (5) is adjusted to increase the degradation speed. Compared with conventional methods, the plant straw (4) does not need to be ground, the cost is low, the biogas yield is high, and the application range is wide.

Owner:NORTHEAST NORMAL UNIVERSITY

Pretreatment method for enzymolysis of wheat straws

InactiveCN107083411AReduce consumptionPromote sustainable developmentFermentationEnzymatic hydrolysisPretreatment method

The invention relates to a pretreatment method for hydrolysis transformation of wheat straws. The method comprises soaking wheat straws in water, adding hydrogen peroxide, sodium hydroxide and distilled water into the wheat straws, carrying out stewing, carrying out extrusion through an extruder, carrying out two-stage grinding disintegrating treatment, carrying out screening, carrying out enzymatic hydrolysis, adding an enzyme solution into the enzymatic hydrolysis product under aseptic conditions, and carrying out enzymatic hydrolysis at a constant temperature to obtain a hydrolysate of wheat straws. The method fully utilizes existing devices in the pulping industry, reduces additional investment, greatly saves an economic cost, has a great significance to the recycling of the existing paper making industry and is conducive to the sustainable development of the pulping and paper making industry.

Owner:QILU UNIV OF TECH

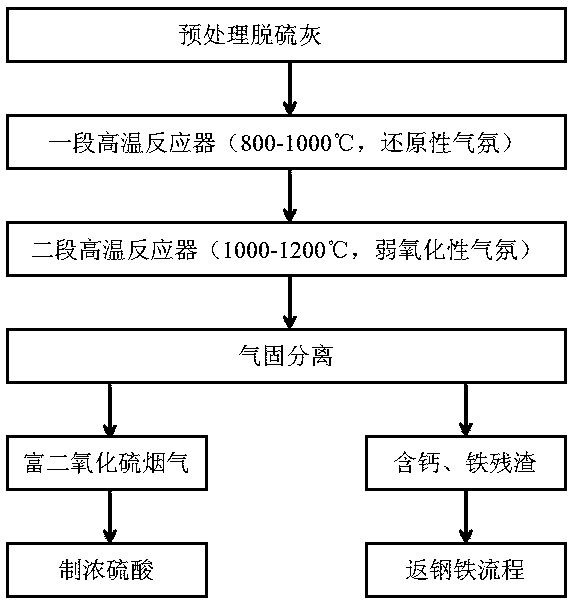

Desulfurized ash reduction-oxidation two-stage treatment method

PendingCN110844888AFull utilization of resourcesMagnesium/calcium/strontium/barium sulfides/polysulfidesProcess efficiency improvementSteelmakingCatalytic oxidation

The invention provides a desulfurized ash reduction-oxidation two-stage treatment method. The desulfurized ash reduction-oxidation two-stage treatment method comprises the following steps: feeding desulfurized ash into a first-stage high-temperature reactor, controlling proper temperature and atmosphere, reducing calcium sulfite and calcium sulfate in the desulfurized ash into calcium sulfide, feeding the calcium sulfide into a second-stage high-temperature reactor, controlling proper temperature and atmosphere, converting the calcium sulfide into sulfur dioxide and calcium oxide, and generating sulfur-containing flue gas and residues. According to the method, the desulfurized ash is converted into SO2-rich flue gas and calcium and iron-containing residues; sulfuric acid can be prepared from the SO2-rich flue gas through dust removal, purification, catalytic oxidation and absorption processes, the residues can be added into iron ore according to a certain proportion to be sintered to replace part of iron-containing raw materials and flux or be used for steelmaking desulfurization, the desulfurized ash is fully recycled, and economic benefits and environmental benefits are remarkable.

Owner:SHAGANG GROUP +1

Process for preparing trisodium phosphate from glyphosate mother liquid

ActiveCN103693631ASimple production processEase of industrial applicationPhosphorus compoundsSodium acid carbonateGlyphosate

The invention provides a process for directly preparing trisodium phosphate from glyphosate mother liquid in order to effectively recover phosphorus resources from the mother liquid for producing trisodium phosphate. The process is characterized by comprising the following steps: oxidizing the glyphosate mother liquid through catalytic air, oxidizing organic phosphine in the mother liquid into orthophosphate ions, adding sodium hydroxide or sodium carbonate into the mother liquid to adjust the pH value to be 9-10, cooling to be -5 DEG C to 8 DEG C while stirring, crystallizing, separating, washing, and drying to obtain trisodium phosphate. The process is simple and easy for industrialization applications, the obtained trisodium phosphate is wide in application range, difficulty in enabling the glyphosate mother liquid subjected to terminal treatment to reach the emission standard is lowered, and treated solid waste is reduced.

Owner:福华通达化学股份公司

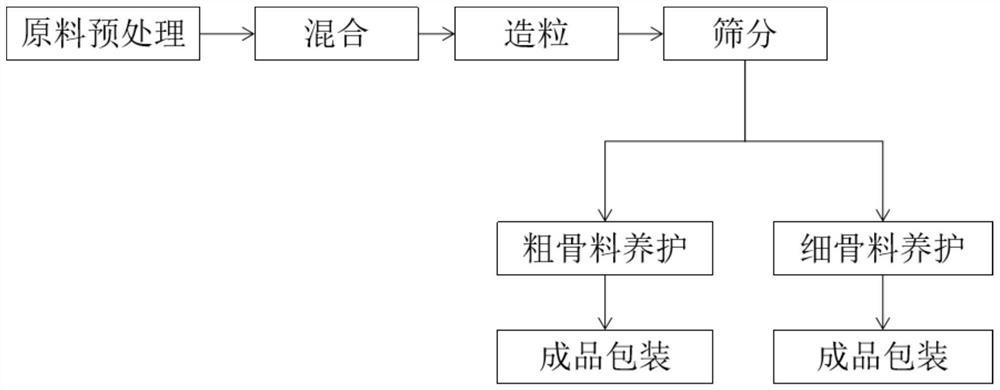

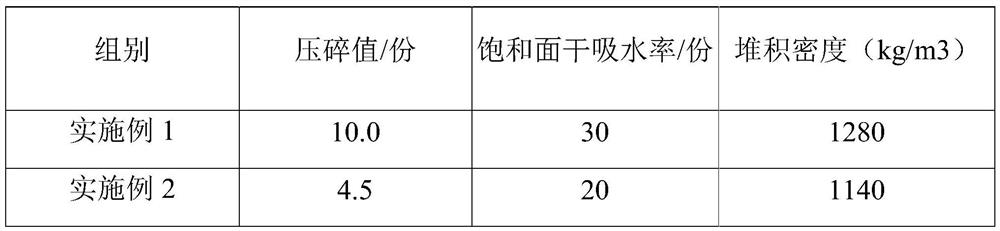

Red mud unfired aggregate

The invention discloses a red mud unfired aggregate, which comprises the following raw materials by mass: 50-80 parts of red mud, 5-30 parts of a reaction auxiliary agent, 3-10 parts of a reinforcing agent, 2-4 parts of an additive, and 10-23 parts of an alkali inhibitor, the reaction auxiliary agent comprises gypsum powder and at least one of mineral powder and steel slag powder, and the reinforcing agent comprises one or two of silica fume and quartz powder; the alkali inhibitor comprises one or two of fly ash and kaolin. Silicon, aluminum and the like with relatively high activity are introduced by utilizing the mineral powder and the steel slag powder, so that the compressive strength of the red mud unfired aggregate is improved. Calcium sulfate and other substances are introduced through gypsum, structures such as ettringite and the like can be generated under the alkaline condition, free calcium is absorbed, gaps of the aggregate are filled, and the water absorption rate of the aggregate is reduced.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Resource utilization method of Fenton iron sludge

The invention discloses a resource utilization method of Fenton iron sludge. The method comprises the following steps of: (1) treating Fenton; adding the rest of ferrum into concentrated sulfuric acid; and controlling the temperature to be between 70 and 75 DEG C to stir for 30 minutes; (2) adding excessive quantities of scrap iron chips into an iron sludge solution obtained in the step (1) to reduce; detecting Fe3<+> by using a phenol solution until Fe<3+> is totally reduced into Fe<2+>; and (3) after the reduction is finished, standing for precipitating for 30 minutes; extracting supernate; adding ethanol according to the proportion that V(supernate) / V(ethanol) is equal to 10 to 1 and shortening the crystallizing time of ferrous sulfate; and after the crystallization is finished, obtaining an industrial FeSO4.7H2O finished product. According to the method, the bottle neck problem of Fenton technology promotion can be solved, the resource utilization of solid wastes is realized, and Fenton iron sludge is turned from waste into treasure, so that sustainable development of human society is facilitated.

Owner:GUANGXI UNIV

Quartz sand tailings treatment and resource utilization process

ActiveCN108620228ADry thoroughlyFull utilization of resourcesWet separationPollutantResource utilization

The invention discloses a quartz sand tailings treatment and resource utilization process, and belongs to the technical field of quartz sand tailings production. The quartz sand tailings treatment andresource utilization process solves the problem that existing quartz sand tailings serve as pollutants to be discharged, and cannot be effectively used. The process comprises the following steps of firstly, quartz sand tailings purification; secondly, quartz sand tailings primary grading; thirdly, quartz sand tailings magnetic separation; fourthly, quartz sand tailings water removal; fifthly, quartz sand tailings drying; sixthly, quartz sand tailings secondary grading; seventhly, quartz sand tailings resource utilization. The process is suitable for quartz sand tailings treatment and resourceutilization.

Owner:SICHUAN NANLIAN MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com