Hydraulic separator and construction waste material resource utilization system

A hydraulic separation and recycling technology, applied in the field of construction waste material treatment, can solve the problems of difficult separation and sorting of bricks and concrete blocks, and achieve the effect of reducing waste of resources, reducing pollution, and simplifying the system process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the present invention will be described in detail with reference to the drawings and specific embodiments.

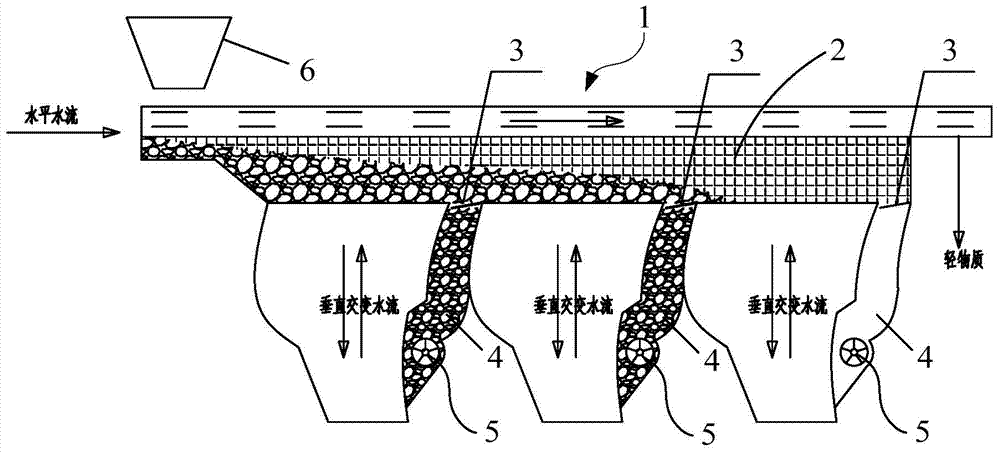

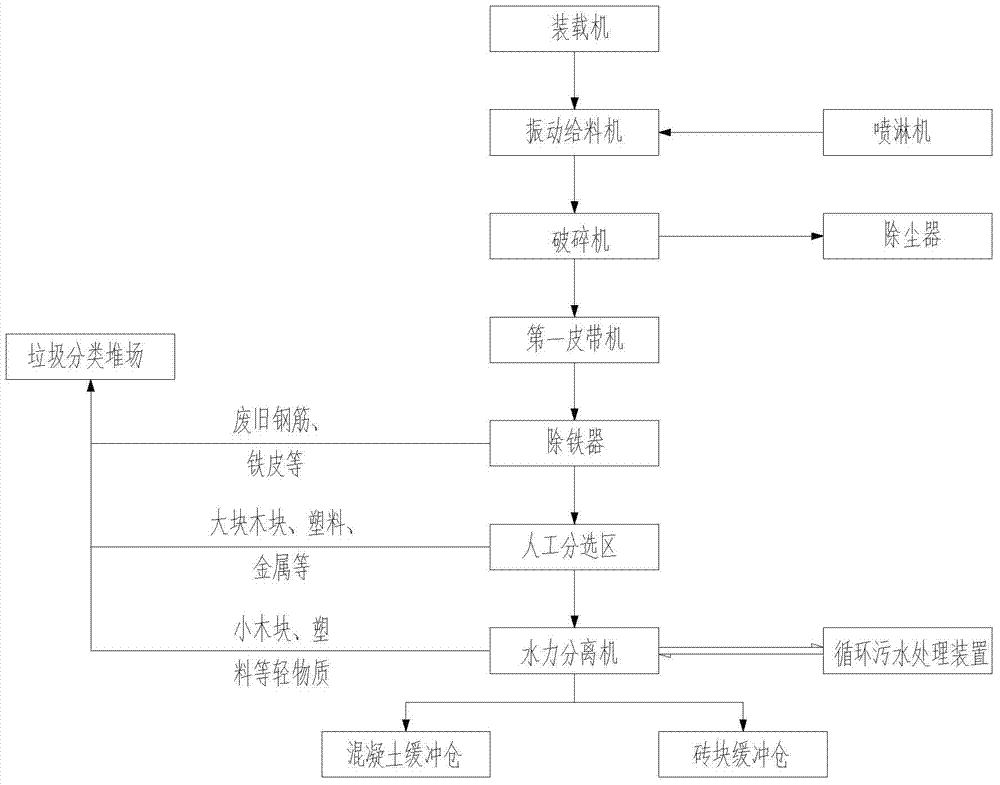

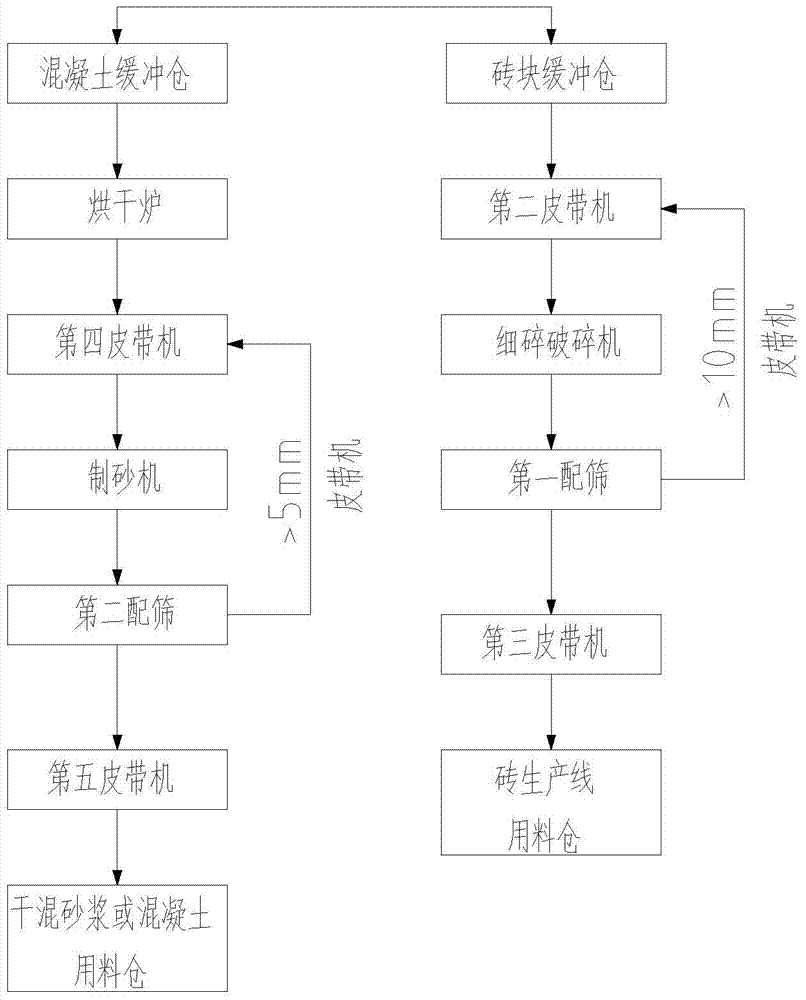

[0020] see figure 1 , figure 1 It is a working principle diagram of a preferred embodiment of the hydraulic separator of the present invention. The hydraulic separator in this embodiment includes a water tank 1, a mesh screen 2, a plurality of color sensors (not shown in the figure), a plurality of gates 3, a plurality of row Material channel 4 and multiple discharge valves 5.

[0021] The water tank 1 is divided into upper and lower parts, and the upper part is provided with a mesh screen 2, which is used to support the construction waste materials to be separated entering from the feed port 6. At the same time, the upper part of the water tank 1 is connected with flowing water in the horizontal direction, and the water flow will be The separated construction waste material is dispersed and moved along the water flow direction, and at the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com