Method for preparing graphene by using waste lithium ion power battery

A lithium-ion battery and power battery technology, which is applied in the new technology field of solid waste recycling, can solve the problems of ecological environment impact, poor controllability, graphene integrity damage, etc., and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

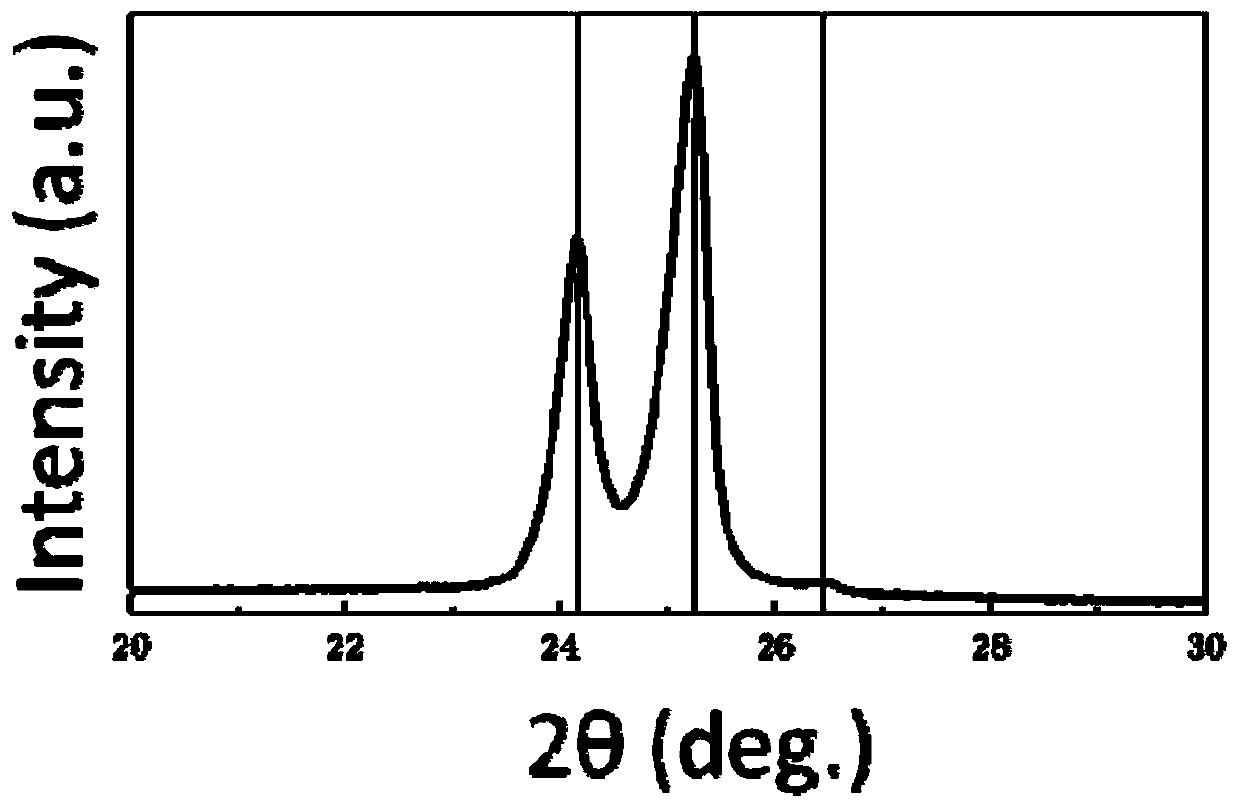

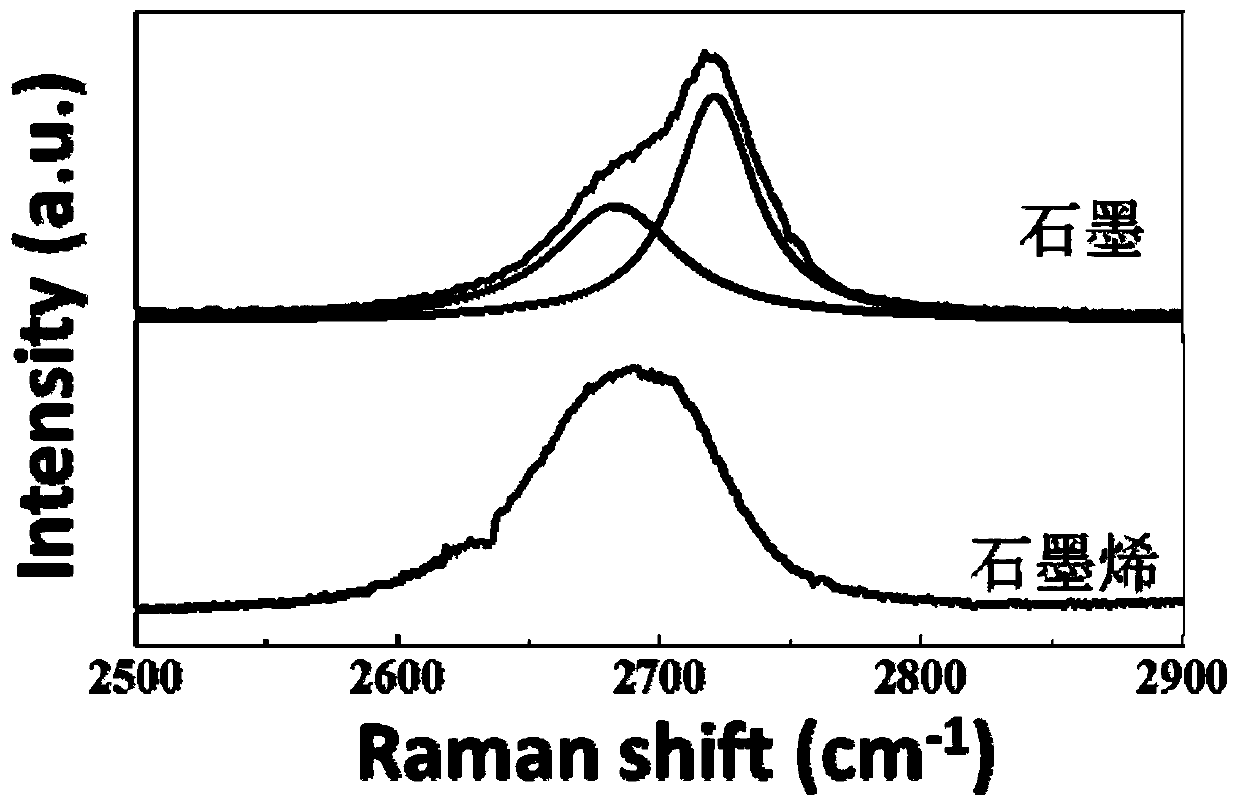

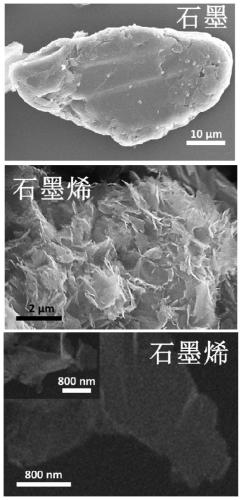

Embodiment 1

[0018] Sorting the battery cells with a battery capacity greater than 60% of the nominal capacity from the decommissioned lithium-ion batteries, charging the sorted battery cells to a state of charge of 90%, and disassembling the charged battery cells And isolate the negative electrode sheet, and obtain the negative electrode powder after ball milling the negative electrode sheet for 15 minutes, sieve the negative electrode powder with an 80-mesh sieve, collect the sieve and the sieve, the sieve is copper, and the The undersize was added to an organic solvent and sonicated for 3 hours with stirring. After the ultrasonic treatment, the organic solvent was filtered under reduced pressure, washed with deionized water and vacuum-dried to obtain graphene powder, the graphene exfoliation rate was 98%, the number of graphene layers was less than 10, and the graphene size was 500nm to 1 μm , the ratio I of the D peak and the G peak peak intensity in the obtained powder Raman spectrum ...

Embodiment 2

[0020] Sorting the battery cells with a battery capacity greater than 70% of the nominal capacity from the decommissioned lithium-ion batteries, charging the sorted battery cells to a state of charge of 0.6, disassembling the charged battery cells and Separate the negative electrode sheet, ball mill the isolated negative electrode sheet for 20 minutes to obtain negative electrode powder, sieve the negative electrode powder with an 80-mesh sieve, collect the sieve and the sieve, the sieve is copper, and the The undersize was added to the organic solvent and sonicated for 1 hour with stirring. After the ultrasonic treatment, the organic solvent was centrifuged and the suspension was collected, the suspension was filtered under reduced pressure, cleaned with deionized water and vacuum-dried to obtain graphene powder with a graphene exfoliation rate of 80%, graphite The number of ene layers is 4 to 10, and the graphene size is 1 μm to 2 μm. The ratio of the D peak to the G peak pe...

Embodiment 3

[0022] Sorting battery cells with a battery capacity greater than 50% of the nominal capacity from retired lithium-ion batteries, charging the sorted battery cells to a state of charge of 100%, and disassembling the charged battery cells And isolate the negative electrode sheet, and obtain the negative electrode powder after ball milling the negative electrode sheet for 15 minutes, sieve the negative electrode powder with an 80-mesh sieve, collect the sieve and the sieve, the sieve is copper, and the The undersize was added to the organic solvent and sonicated for 1 hour with stirring. After the ultrasonic treatment, the organic solvent was centrifuged and the suspension was collected, the suspension was filtered under reduced pressure, cleaned with deionized water and vacuum-dried to obtain graphene powder with a graphene exfoliation rate of 92%, graphite The number of ene layers is less than 10, and the graphene size is 1 μm to 5 μm. The ratio of the peak intensity of the D ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com