Shield muck treatment method and equipment

A technology of treatment equipment and treatment methods, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of reducing clean water, increasing mud storage, and solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

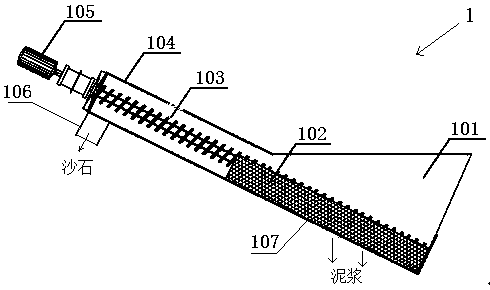

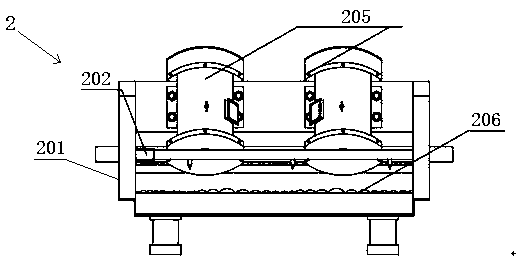

[0036] See figure 1 , the shield dregs processing equipment provided by the present invention includes multiple strong-pressure water flushing vibratory separators 2, a winch cage mud separator 1 connected to the multiple strong pressure flushing vibratory separators 2, and a winch cage mud separator through a mud pump 7. 1 The discharged mud is transported to the diversion tank or pipe 3 of the mud pool 8, the mud pool 8 connected to the diversion tank or pipe 3, and the mud in the mud pool 8 is transported to the concave and convex of the filter press 6 by the mud pump 7' Type mud conveying pipe 5, filter press 6 connected with concave-convex mud conveying pipe 5, the dry mud cake discharged by the filter press 6 is transported to the stockyard through the conveyor belt.

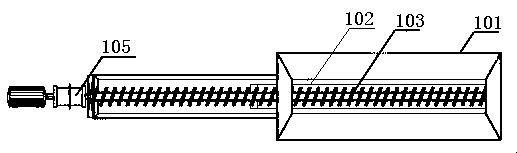

[0037] The cage mud separator 1, such as figure 2 , image 3 Shown, comprise tubular twisted cage body 104, be located at the helical strand 103 in the twisted cage body 104, be located at the hopper 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com