Sensor cleaning method, device, mining unmanned vehicle and readable storage medium

A sensor, unmanned vehicle technology, applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve problems affecting mining unmanned vehicle operations, low cleaning efficiency, etc., to achieve the effect of improving efficiency and saving clean water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

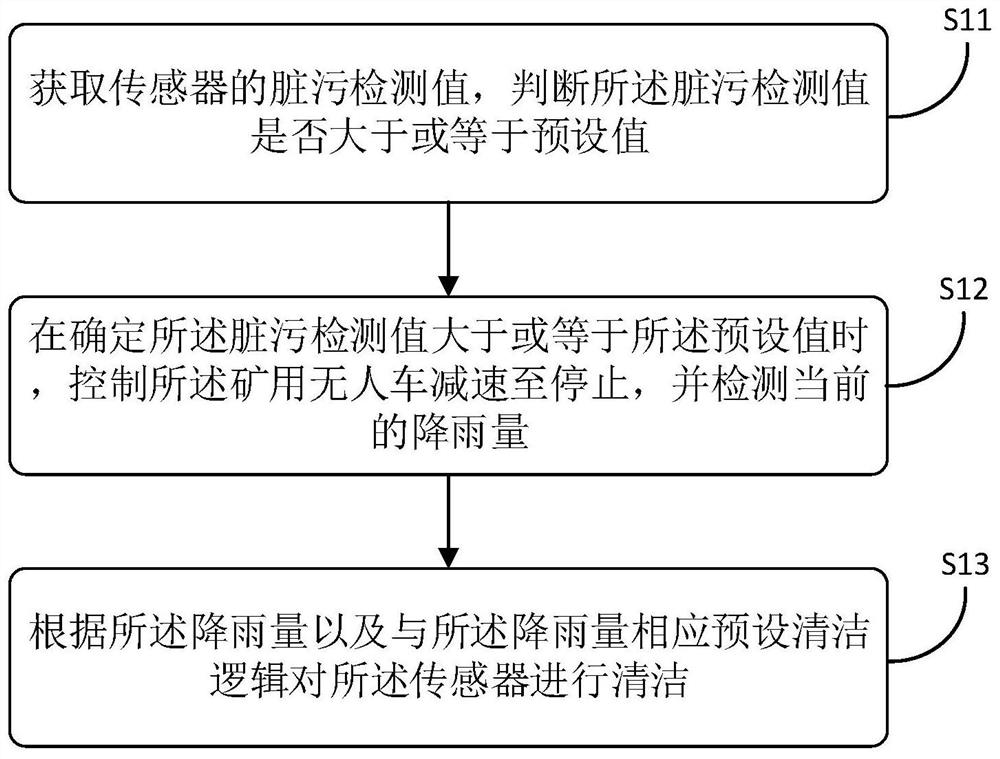

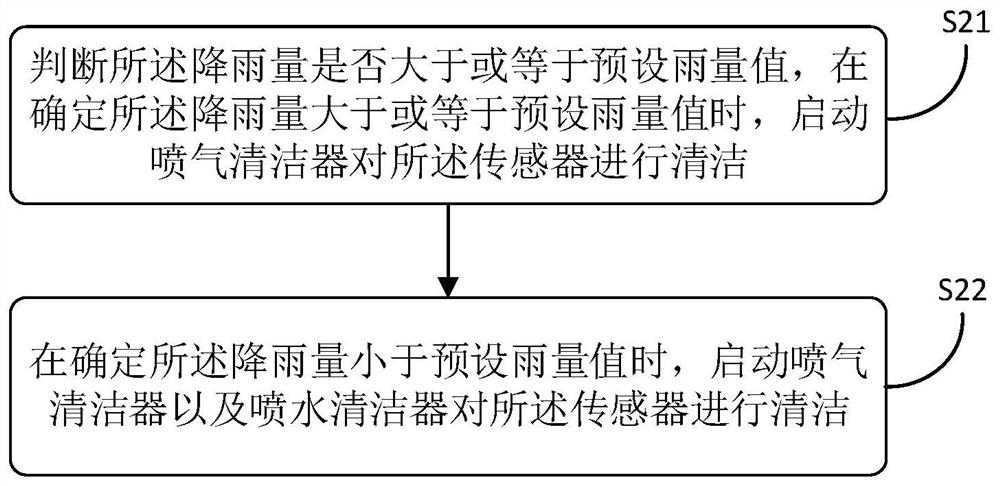

[0046] figure 1 It is a flow chart of a sensor cleaning method provided in Embodiment 1 of the present invention. The method is applied to mine unmanned vehicles and includes the following steps:

[0047] Step S11: Acquiring the dirt detection value of the sensor, and judging whether the dirt detection value is greater than or equal to a preset value.

[0048] In the embodiment of the present invention, when the mining unmanned vehicle is driving in the mining area, there will generally be large gravels on the road, or artificial obstacles, etc. At this time, the mining unmanned vehicle will detect the surrounding environment through sensors obstacles, so that the obstacles can be avoided in time for driving, wherein the sensor includes at least one sensor among camera, ultrasonic radar, millimeter wave radar and laser radar. Since the loading and unloading of various items is carried out in the mining area with a relatively harsh air environment, the sensor will be dirty due...

Embodiment 2

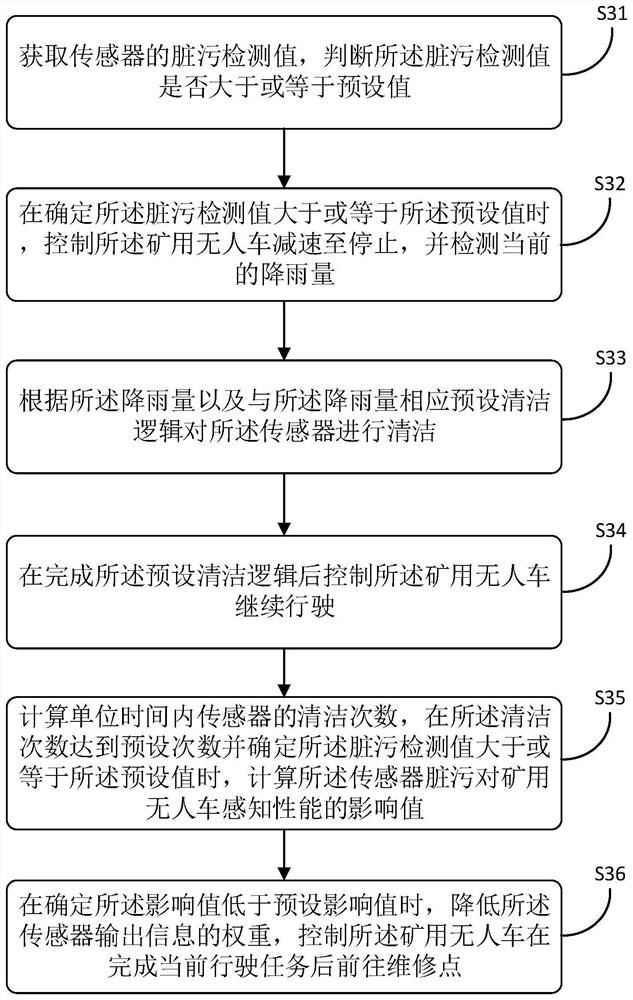

[0062] image 3 It is a flow chart of a sensor cleaning method provided in Embodiment 2 of the present invention. The method is applied to mine unmanned vehicles and includes the following steps:

[0063] Step S31: Acquiring the dirt detection value of the sensor, and judging whether the dirt detection value is greater than or equal to a preset value.

[0064] This step is consistent with the above step S11, and will not be repeated here.

[0065] Step S32: When it is determined that the contamination detection value is greater than or equal to the preset value, control the mining unmanned vehicle to decelerate to a stop, and detect the current rainfall.

[0066] This step is consistent with the above step S12, and will not be repeated here.

[0067] Step S33: cleaning the sensor according to the amount of rainfall and a preset cleaning logic corresponding to the amount of rainfall.

[0068] This step is consistent with the above step S13, and will not be repeated here.

...

Embodiment 3

[0078] Figure 5 It is a schematic structural diagram of a sensor cleaning device provided in Embodiment 3 of the present invention.

[0079] The sensor cleaning device 500 includes:

[0080] A dirt judgment module 510, configured to acquire a dirt detection value of the sensor, and determine whether the dirt detection value is greater than or equal to a preset value;

[0081] The rainfall detection module 520 is used to control the mining unmanned vehicle to decelerate to a stop and detect the current rainfall when it is determined that the dirt detection value is greater than or equal to the preset value;

[0082] A cleaning logic module 530, configured to clean the sensor according to the amount of rainfall and a preset cleaning logic corresponding to the amount of rainfall;

[0083] The driving module 540 is configured to control the mining unmanned vehicle to continue driving after the preset cleaning logic is completed.

[0084] Such as Figure 6 As shown, the cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com