Self-cleaning concrete stirring device

A technology of mixing device and concrete, which is applied to cement mixing device, clay preparation device, mixer accessories, etc., can solve the problem of inability to clean the mixing rod, and achieve the effect of improving efficiency, improving cleaning efficiency and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

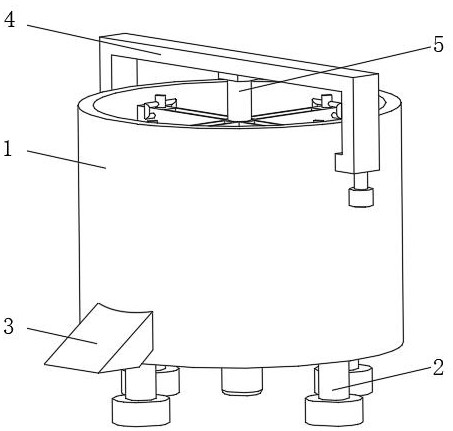

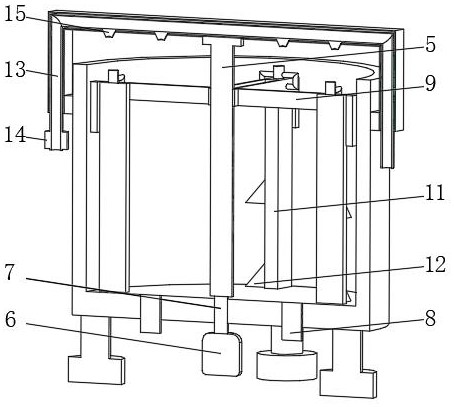

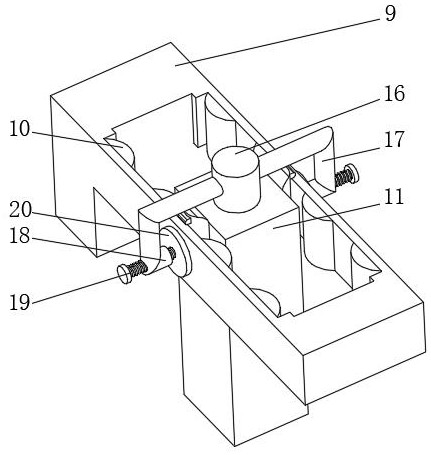

[0030] see Figure 1-4 , the present invention provides a technical solution: a self-cleaning concrete mixing device, including a mixing bucket 1, a support base 2 is evenly installed on the bottom of the mixing bucket 1, a discharge bin 3 is connected to the outside of the mixing bucket 1, and the bottom of the mixing bucket 1 The position away from the discharge bin 3 on the outside is fixedly connected with a fixed frame 4, the bottom of the fixed frame 4 is rotatably connected with a rotating roller 5 through a rotating seat, the bottom of the mixing bucket 1 is fixedly connected with a drive motor 6, and the output end of the drive motor 6 is rotatably connected There is a rotating rod 7, and one end of the rotating rod 7 runs through the mixing tank 1 and is fixedly connected with the rotating roller 5. The bottom of the mixing tank 1 is symmetrically connected with a water outlet pipe 8, and the outer side of the rotating roller 5 is evenly set with a limit frame 9, a li...

Embodiment 2

[0038] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a rectangular groove 22 is provided on one side of the stirring rod 11, the inner wall of the rectangular groove 22 is evenly installed with a limit shaft 23, and the outer side of the limit shaft 23 is sleeved with Rotating plate 24, rotating plate 24 is rotationally connected with limit shaft 23, one side of rotating plate 24 is provided with sawtooth groove 25 symmetrically, one side of rotating plate 24 is fixedly connected with return spring 26, and returning spring 26 is away from one end of rotating plate 24 It is fixedly connected with the rectangular groove 22.

[0039] Stirring bar 11 is equipped with folding plate 27 near the side of rectangular groove 22, and the top of folding plate 27 is evenly equipped with brush head 28, and the top of brush head 28 is evenly equipped with bristle.

[0040] During use, the driving motor 6 drives the stirring rod 11 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com