Patents

Literature

280results about How to "Fall off quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food purification apparatus

ActiveCN101336809AFall off quicklyFood Safety GuaranteeClimate change adaptationKitchen equipmentWater savingUltrasonic sensor

A food cleaning device comprises a cleaning water tank, a water pump and an electrolyzed water generator all provided with water inlets and water outlets and connected to form a closed circulation loop by pipelines. An ultrasonic transducer is provided in the water tank. Food can be cleaned safely and effectively by the inventive device with disinfection and pesticide residue removing functions. The invention is provided with advantages of time saving, labor saving, water saving, high cleaning ratio, and body health benefiting, thereby the invention is capable of being widely used by household, school, mess hall, catering industry and vegetable cleaning industry.

Owner:CHINA NAT FOOD PURIFICATION TECH BEIJING CO LTD

Comprehensive maintaining method for submerged plants

ActiveCN105417713AReduce turbidityPromote growthBiological water/sewage treatmentMicrobial agentNutrition

The invention discloses a comprehensive maintaining method for submerged plants. The comprehensive maintaining method comprises the following steps that firstly, a flocculating agent is added into a water body with the quantity of 1-20 mg / l to reduce the turbidity of the water body; secondly, according to the specific circumstance of dirt attached to the submerged plants, a disinfecting agent or organic acid or pesticide or algicide or surfactant or a substrate modifying agent or a microbial agent or microorganism growth promoting liquid is added into the water body with the amount of 0.1-1 mg / l, and flow disturbance is artificially made; thirdly, a nutrition regulator or a heavy metal complex is applied in the growing stage of the submerged plants with the quantity of 0.2-1 mg / l; fourthly, plagiognathops microlepis or barbels are introduced into the water body with the quantity of 50-100 pieces per 666.7 m<2> to eat fixation algae, and chub or bighead carp are introduced with the quantity of 10-30 g / m<3> to eat planktonic single-spore algae. By means of the comprehensive treatment method, the ecology of the water body is balanced, the transparency of the water body is quickly increased so as to promote the growth of aquatic plants in the water body, dirt attached to the stems and leaves of the aquatic plants is quickly removed, and finally the purpose of long-acting cleaning of the stems and leaves of the aquatic plants and the effect of enhancing water ecological restoration are achieved.

Owner:HANGZHOU ENJOY ENVIRONMENTAL PROTECTION TECH

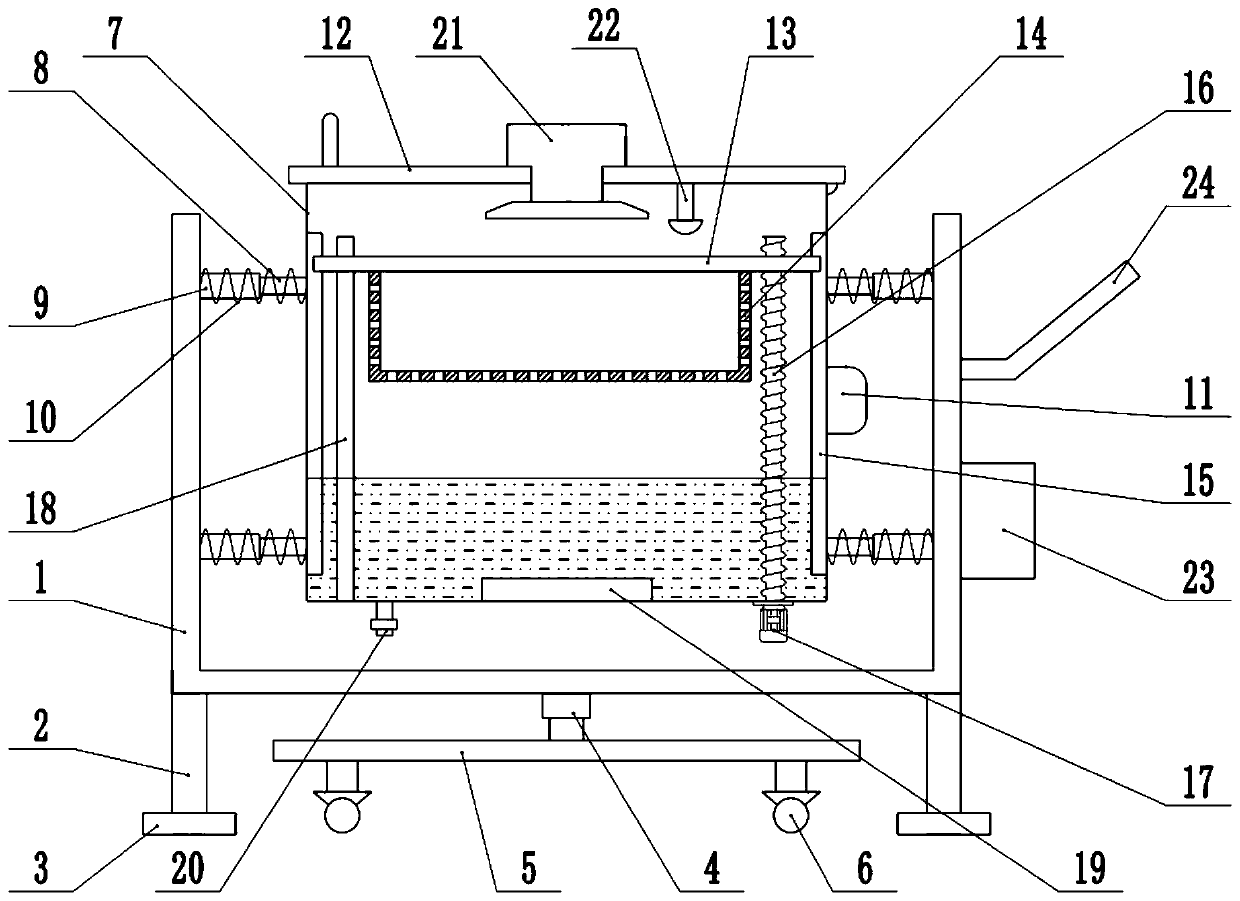

Movable type medical cabinet special for anesthesiology department

InactiveCN110368104AFall off quicklyImprove cleaning efficiencyDiagnosticsSurgeryFixed frameMovable type

The invention relates to the technical field of medical supplies, in particular to a movable type medical cabinet special for an anesthesiology department. The medical cabinet comprises a fixing frame, a cabinet body and a cover plate. The cabinet body is installed inside the fixing frame, a lifting frame is installed inside the cabinet body, a placement basket is fixedly connected to the lower surface of the lifting frame, a lead screw is installed at the right end of the lifting frame, a motor is fixedly connected to the lower surface of the cabinet body, a guiding rod is installed at the left end of the lifting frame, an ultrasonic cleaner is installed at the bottom of the cabinet body, a movable mechanism is installed at the lower surface of the fixing frame, when a medical instrumentneeds to be cleaned, the ultrasonic cleaner is used for cleaning the medical instrument, a vibration motor is used for driving the cabinet body to shake left and right, dirt on the medical instrumentcan be more rapidly disengaged, the cleaning efficiency is improved, the medical instrument can be dried by means of a dryer, the medical instrument can be further disinfected by means of an ultraviolet lamp, and the medical cabinet can be conveniently pushed by the movable mechanism to move.

Owner:赵涛

Environment modifier for disinfection with dry powder

InactiveCN101703072AInhibition of reproductionEliminate odorBiocideDigestive systemDiarrheaDisinfectant

The invention relates to an environment modifier for disinfection with dry powder. The modifier is prepared from adsorbent, disinfectant and environment modifier and has multifunctional dry powder formula for disinfecting the piggery, removing peculiar smell in the piggery, preventing neonate pigs from infecting diseases, reducing the humidity in the piggery, drying the neonate pigs rapidly so as to eat colostrums quickly to obtain immunity, preventing endometritis of sow, treating wound, preventing piglet from fighting as a result of ablactation and reducing the diarrhea. The environment modifier for disinfection with dry powder is simple to use, has high efficiency and little use amount, is environment-friendly, has no residual toxicity, remarkably improves the weight and the survival rate of piglet, greatly reduces the working capacity and labour cost and provides guarantee for environment disinfection and epidemic prevention.

Owner:张同兵

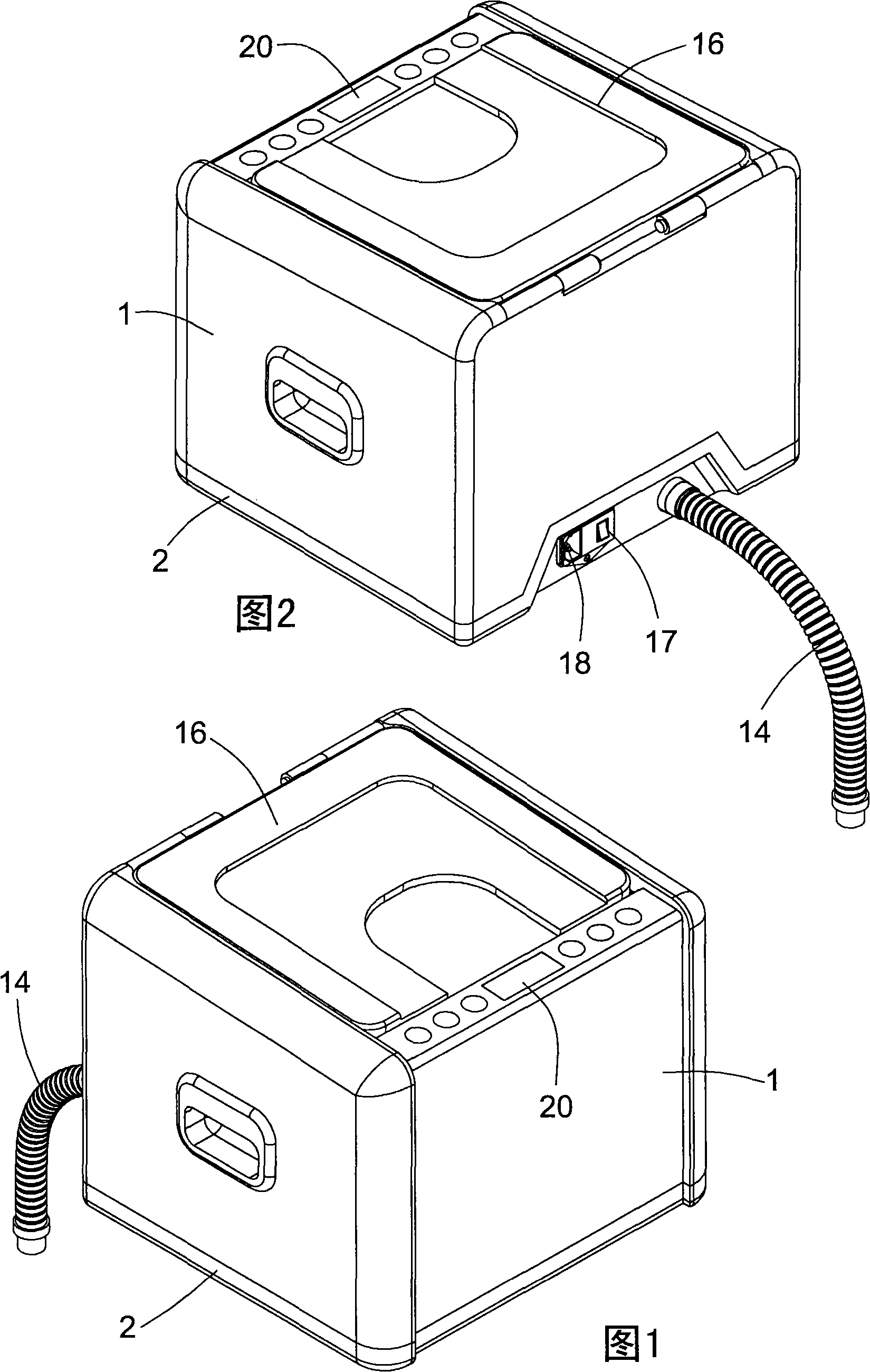

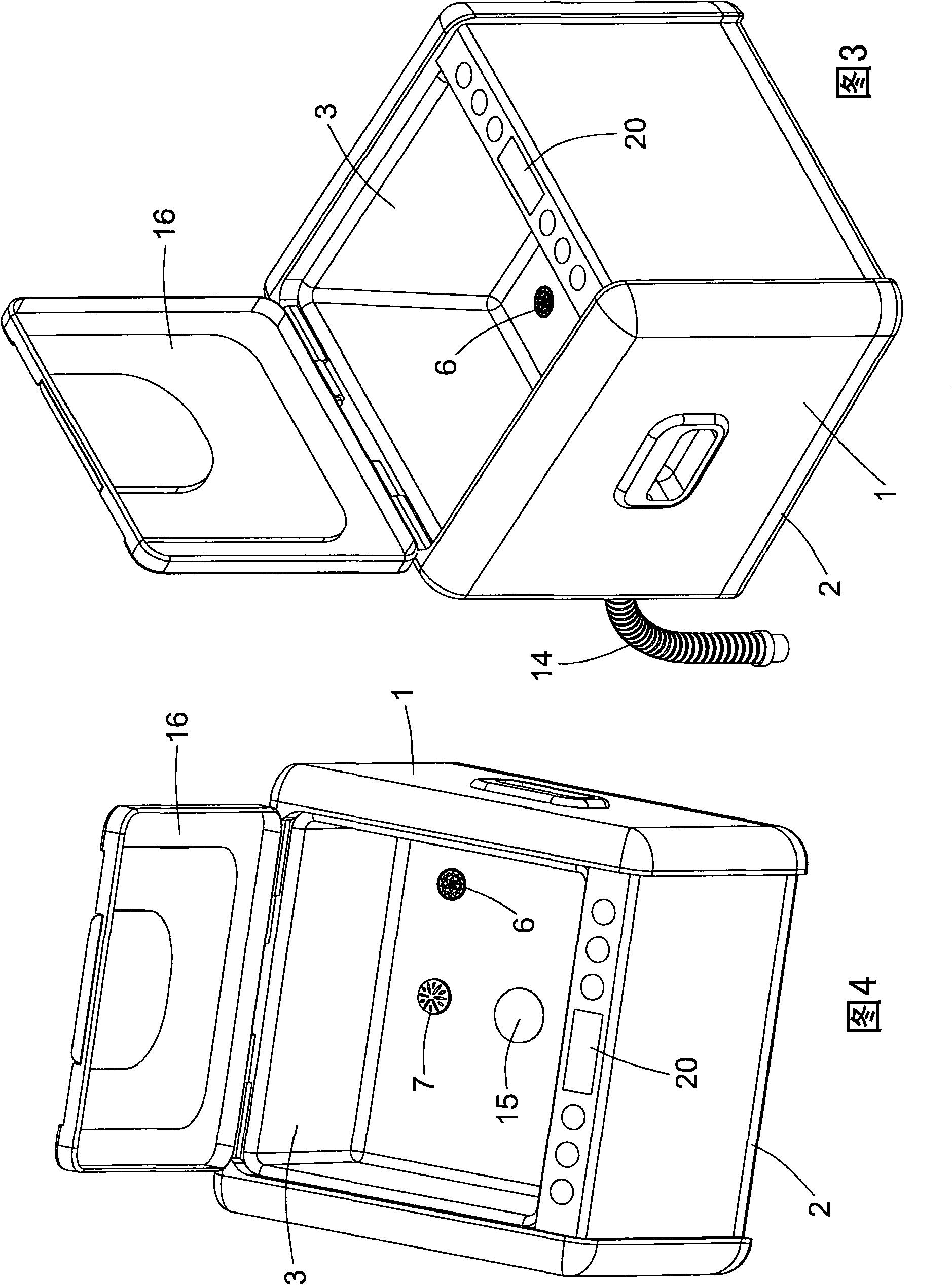

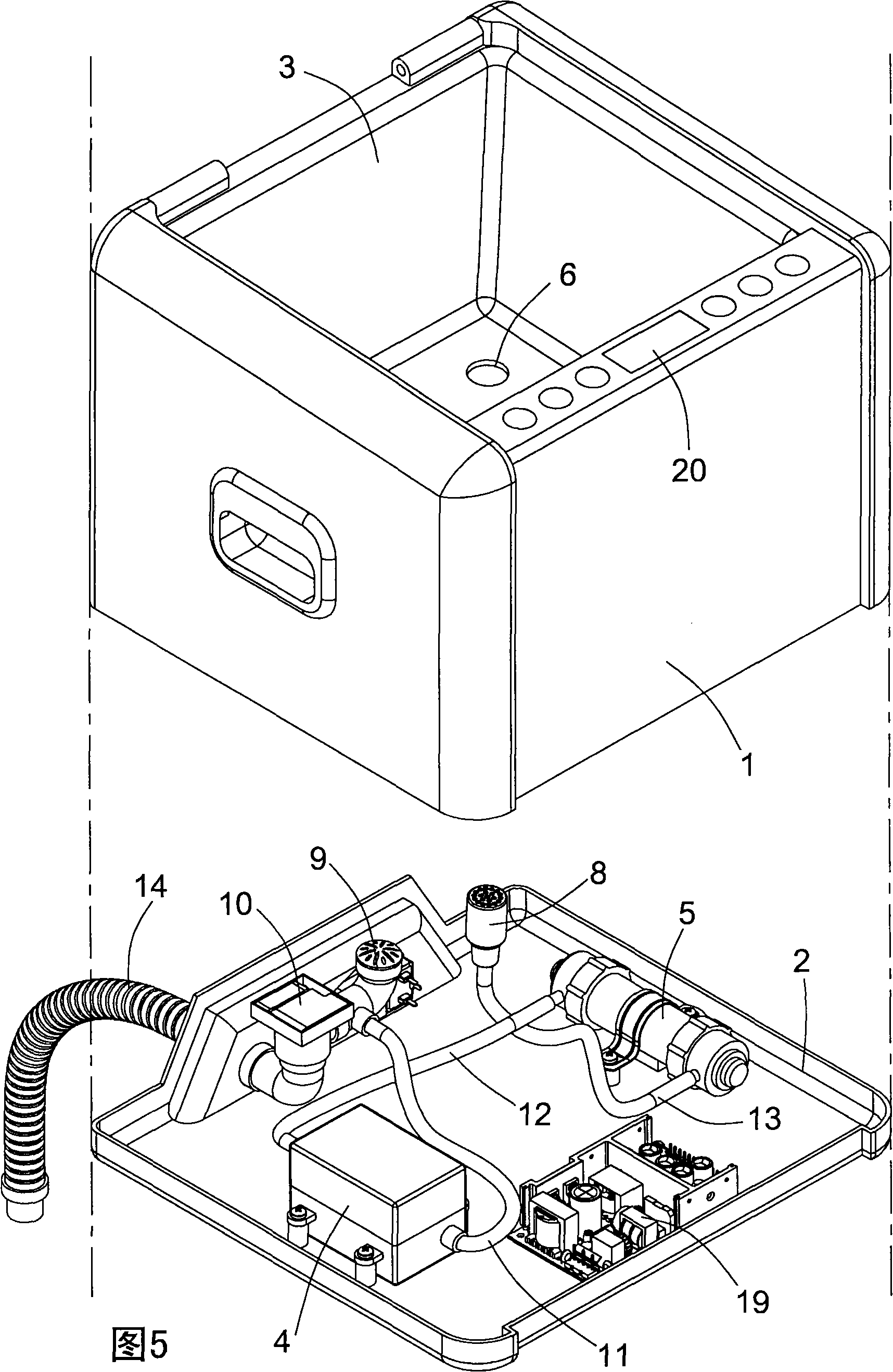

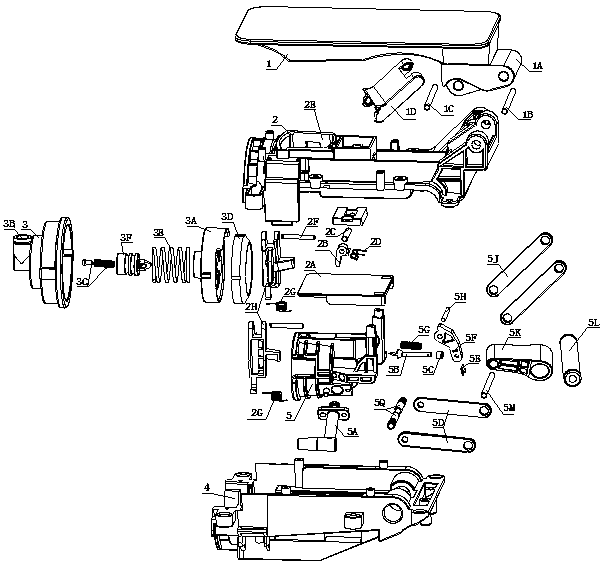

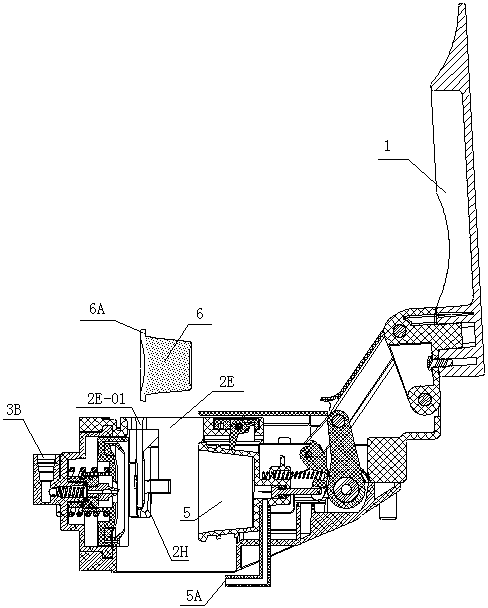

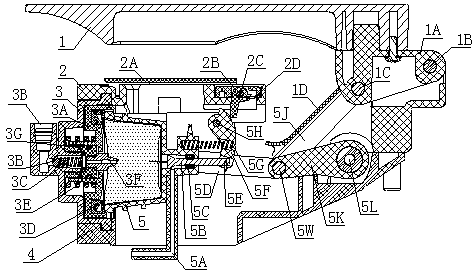

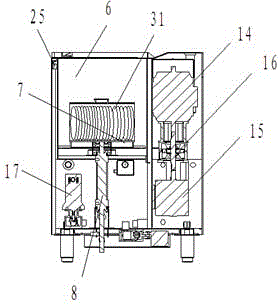

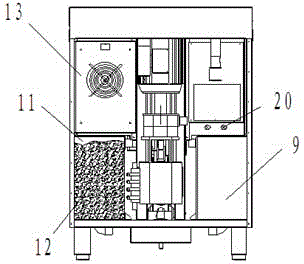

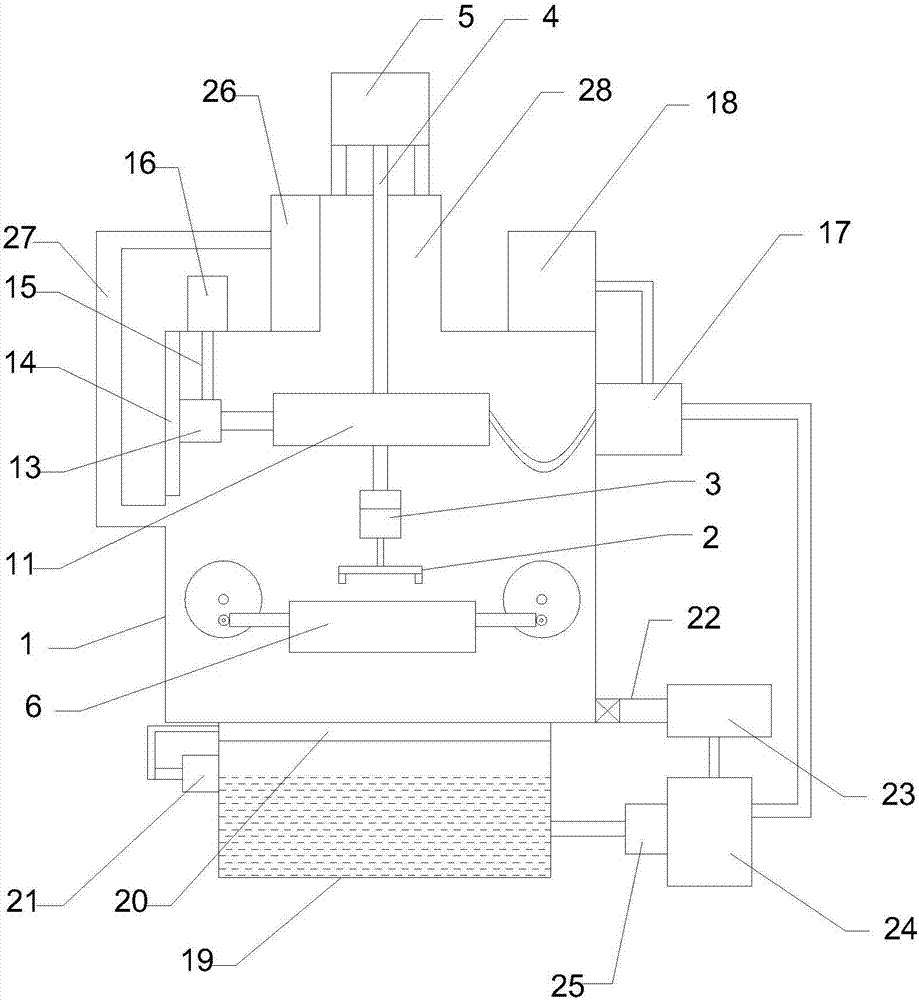

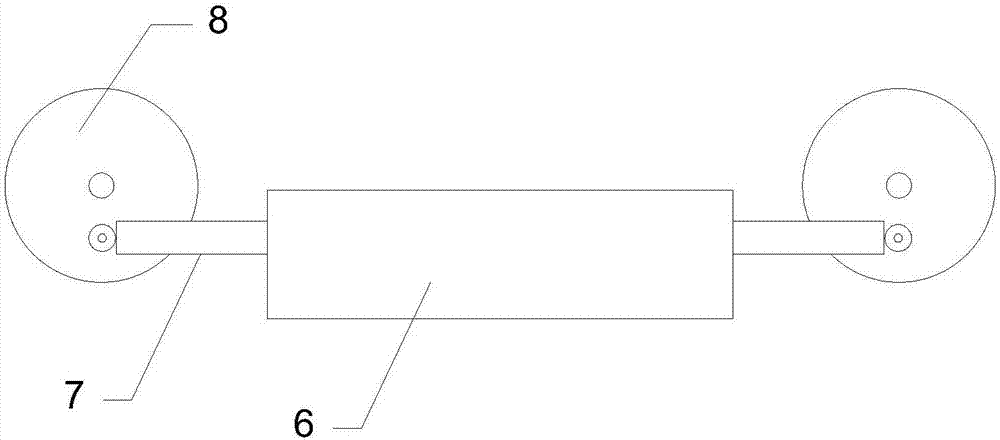

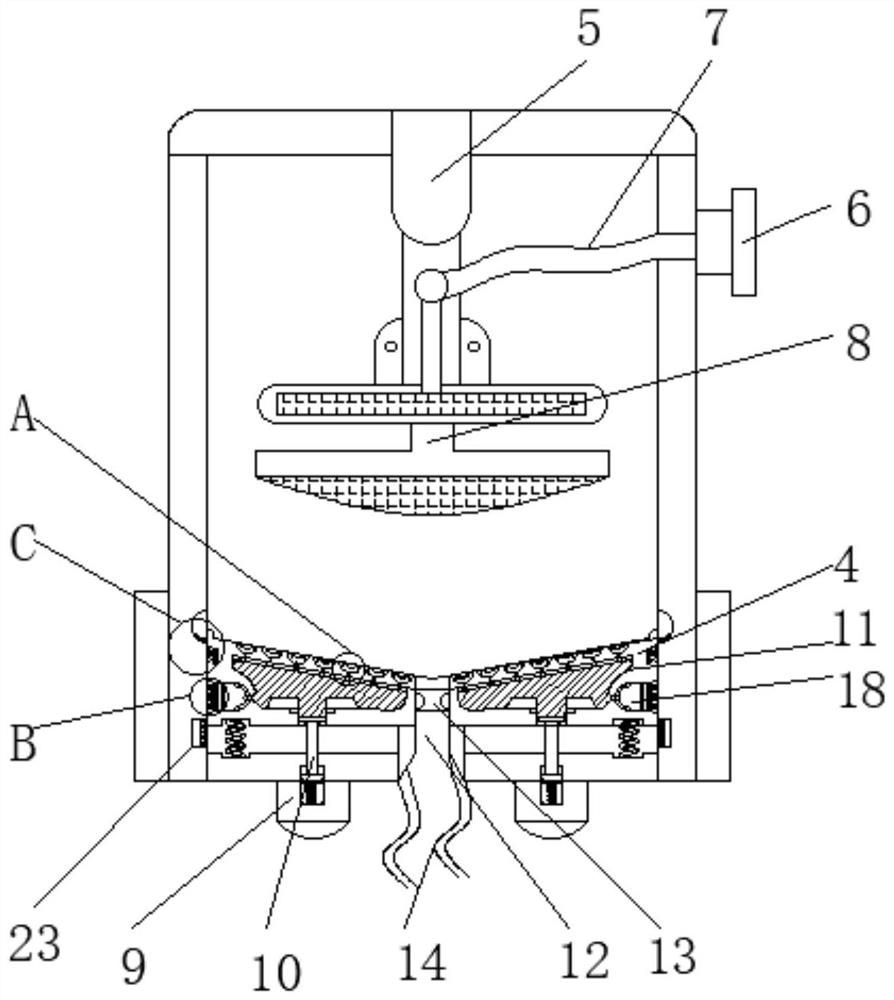

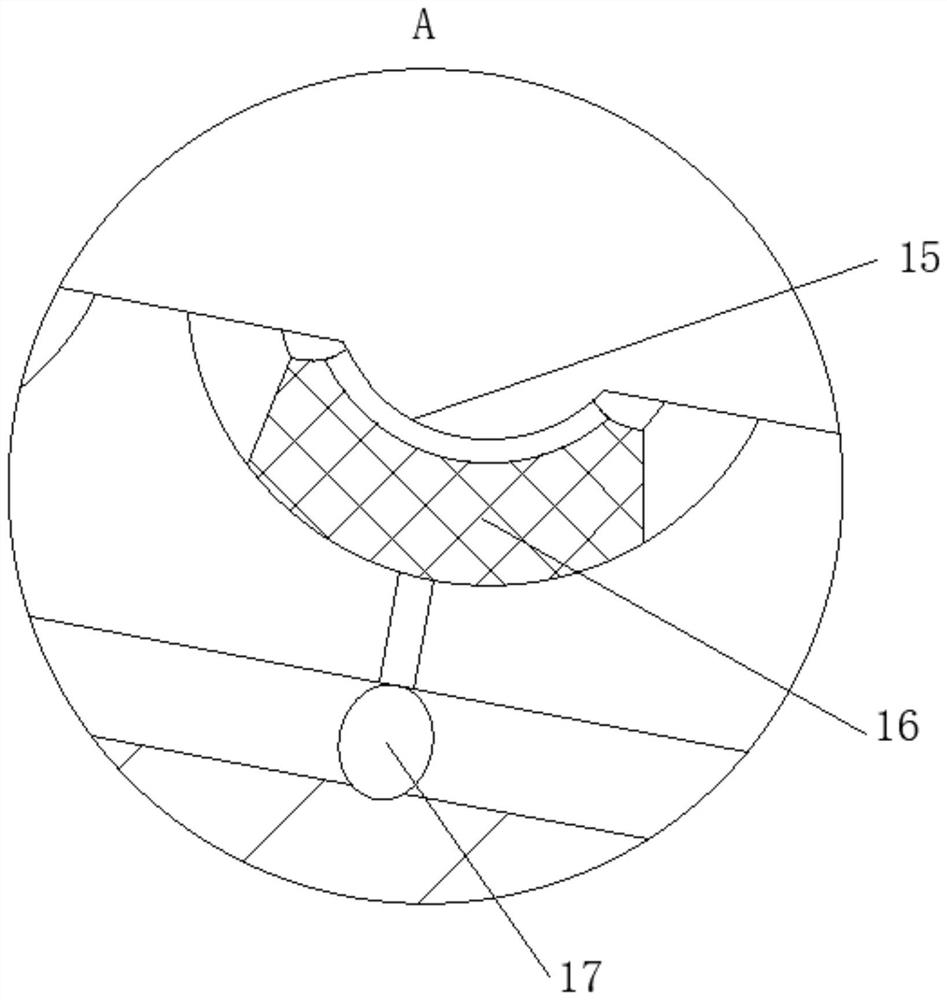

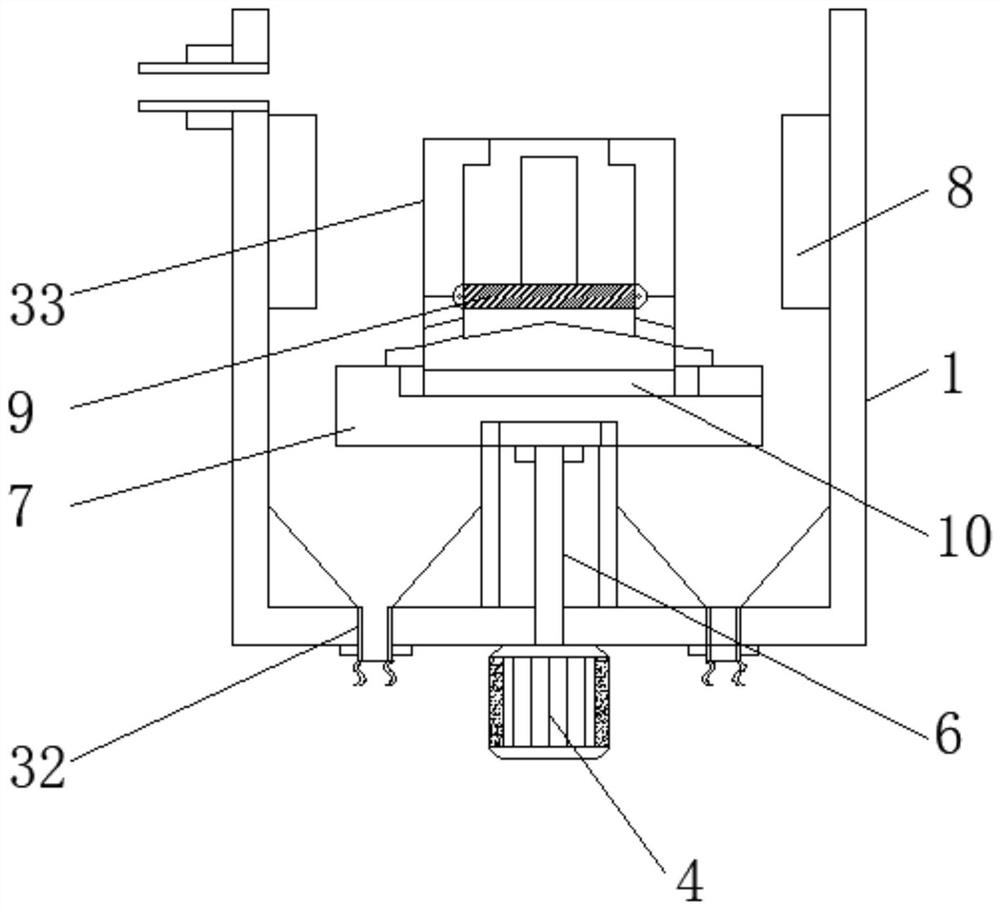

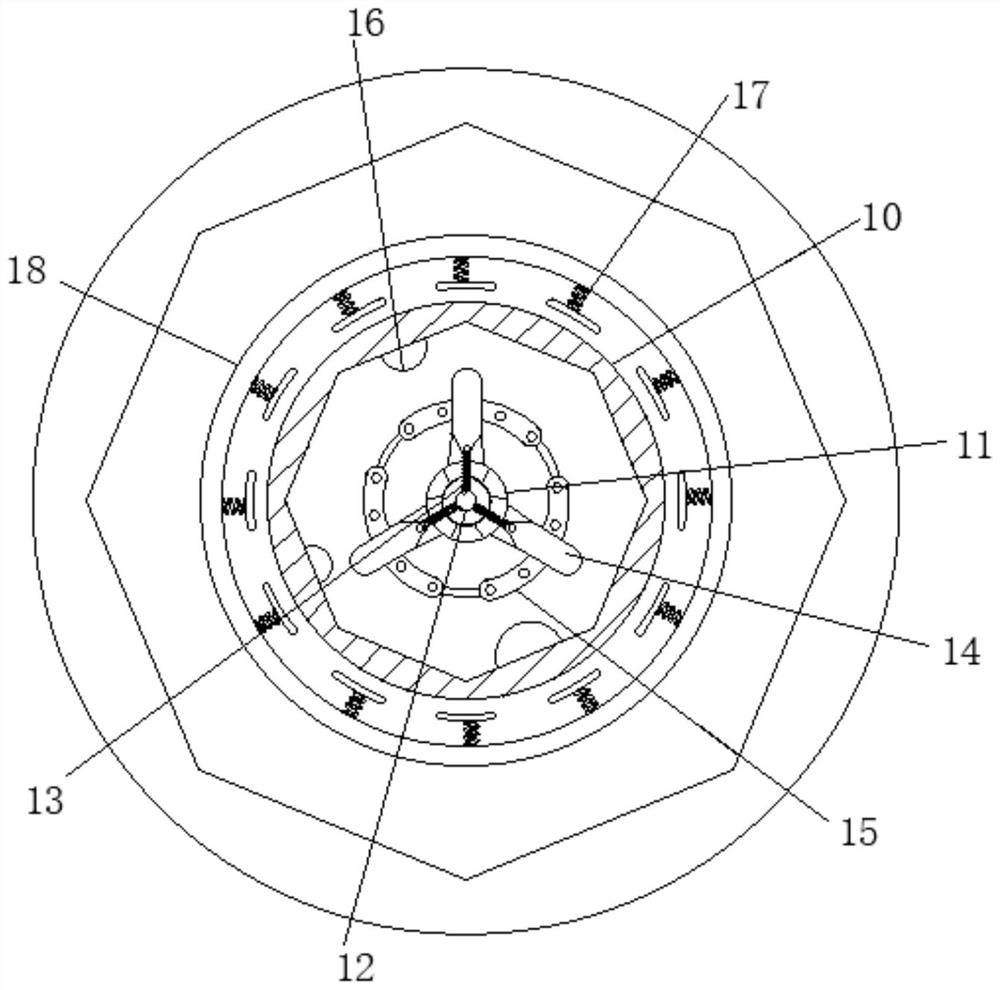

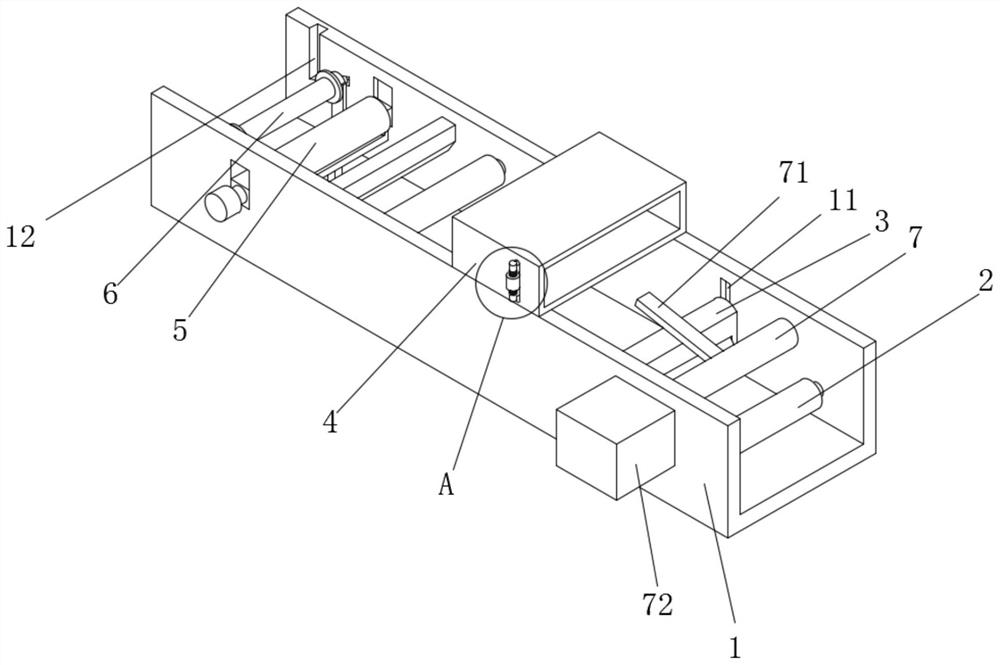

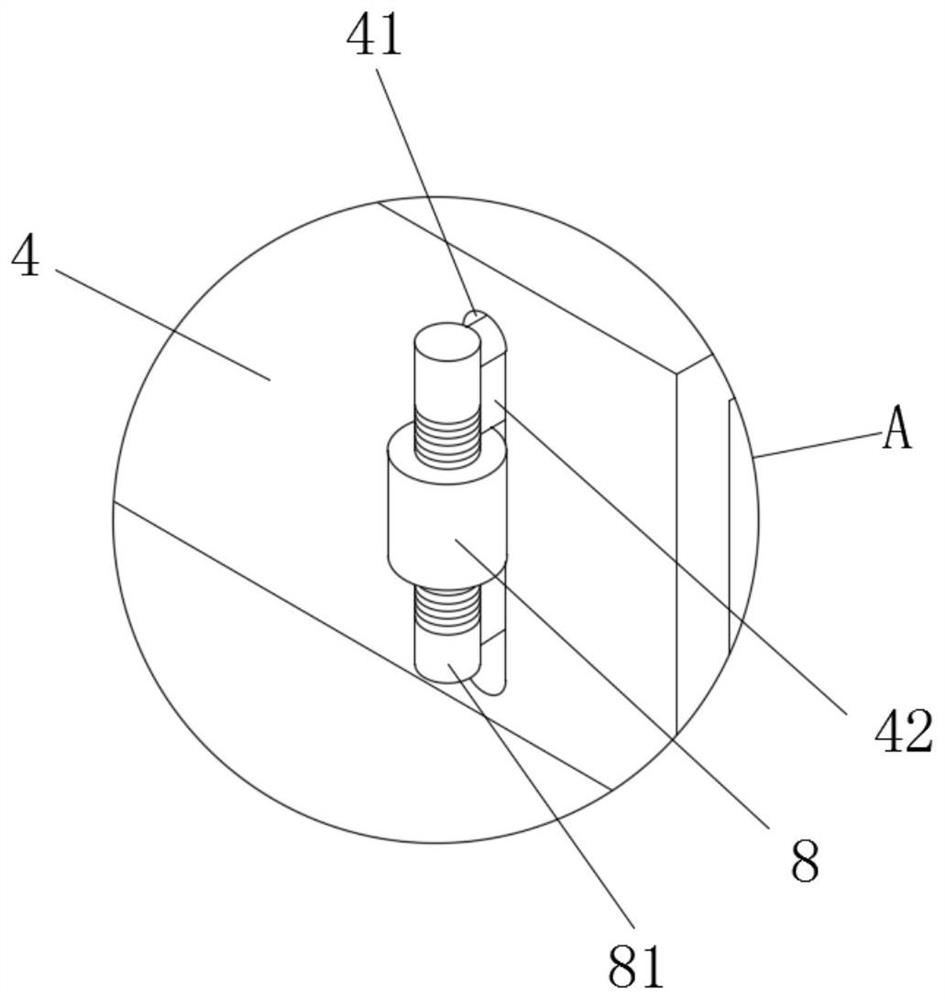

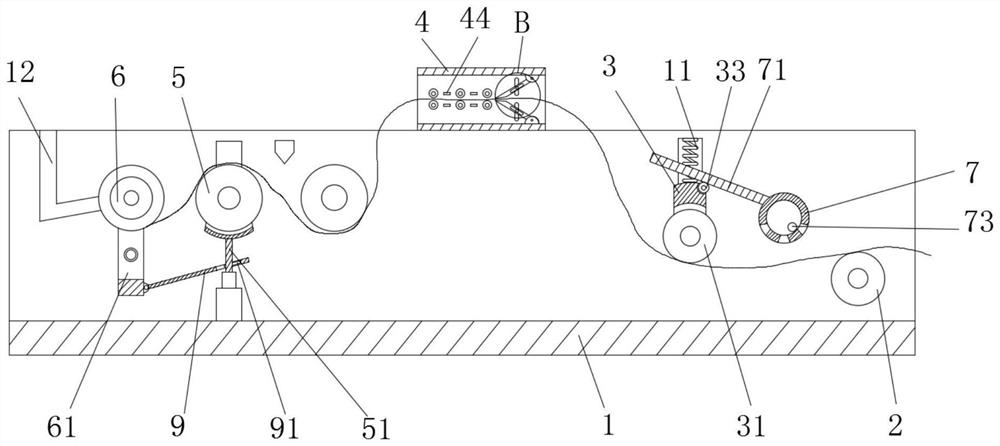

Brewing device for office machines

The invention discloses a brewing device for office machines. The brewing device can be well positioned when capsules are fed, the capsules can drop fast by the aid of gravity after coffee brewing, and the brewing device is convenient to operate and high in reliability. A closed space is provided during the brewing process, and coffee quality is ensured; a good passage is provided for coffee liquid to flow out, and outflowing is smooth. The brewing device comprises a housing, a drive mechanism and a brewing mechanism disposed inside the housing. The brewing mechanism comprises a front brewing chamber and a rear brewing chamber. The front brewing chamber is fixed to the housing. The rear brewing chamber is driven by the drive mechanism to move horizontally. The front brewing chamber is connected with a capsule push plate through an elastic part. A feed hole is provided with a guide channel in the same shape as the edge of a capsule upper cover. Two sides of the housing are provided with capsule positioning blocks facing to each other. Opposing faces of the two capsule positioning blocks are provided with arc rail grooves in the vertical direction and arc guide faces in the horizontal direction. One side, close to the front brewing chamber, of each arc rail groove is also provided with a projection.

Owner:NINGBO MEROL COFFEE MACHINE

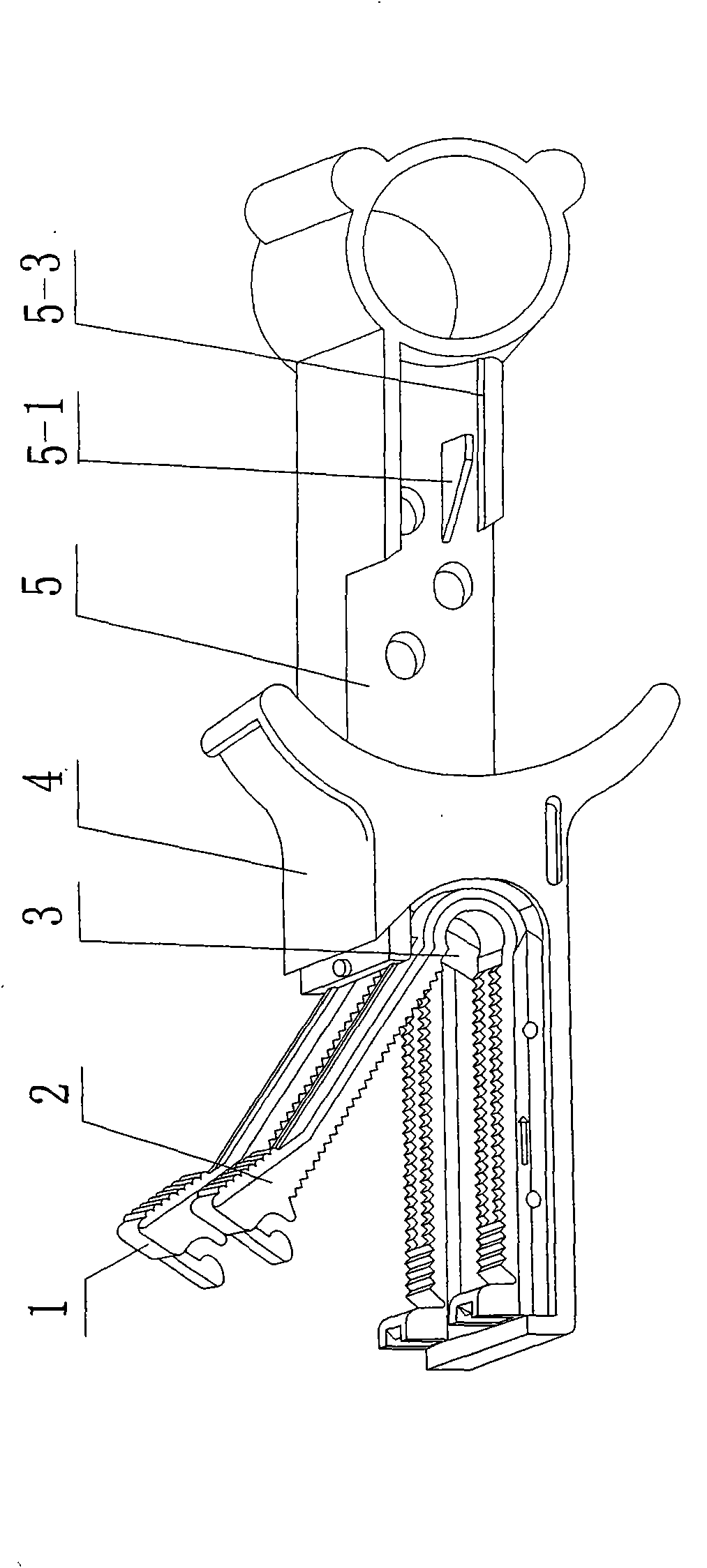

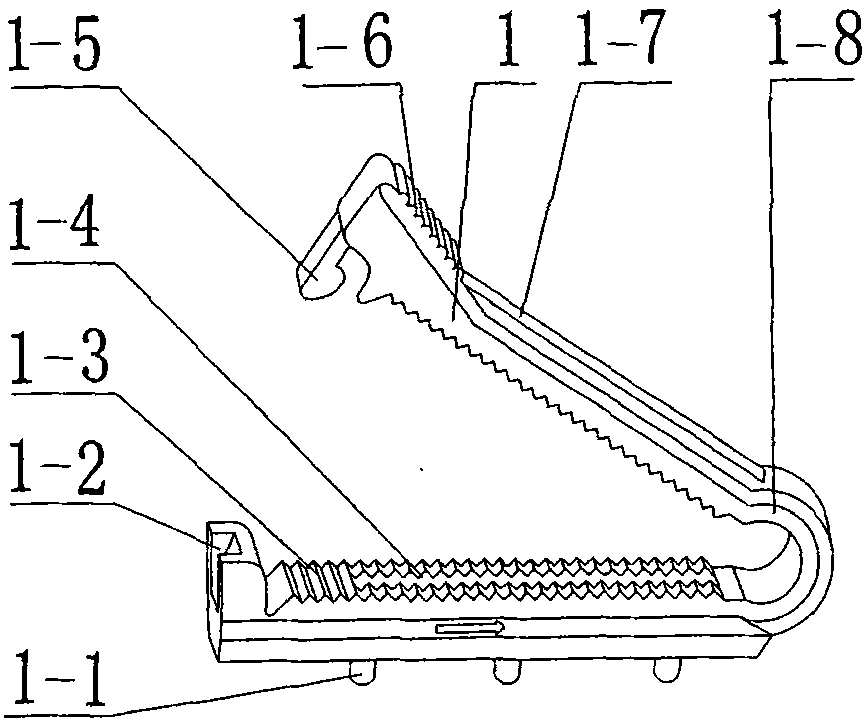

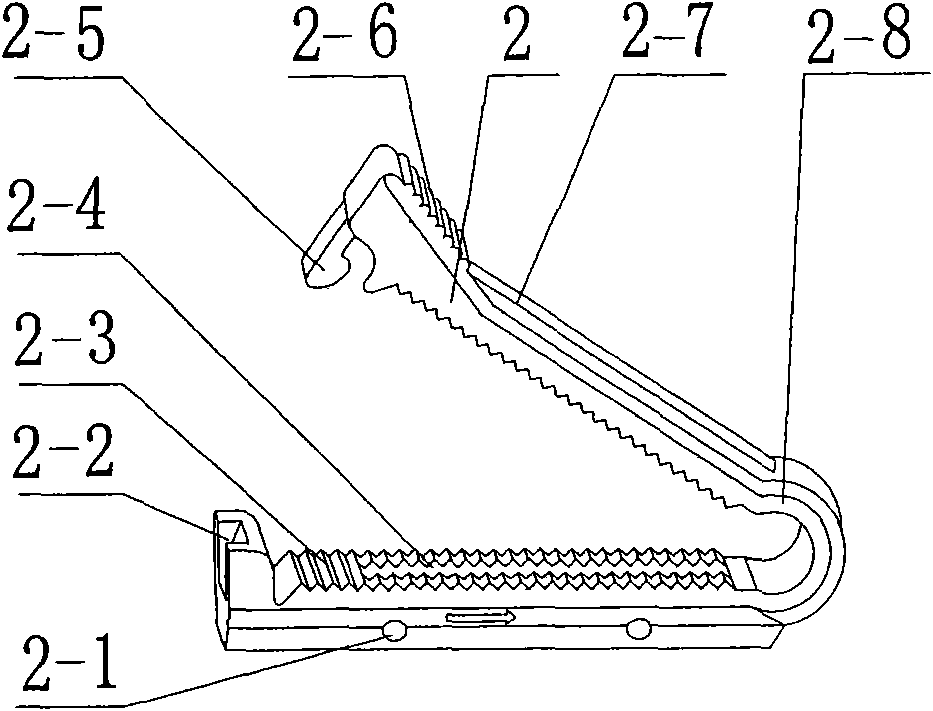

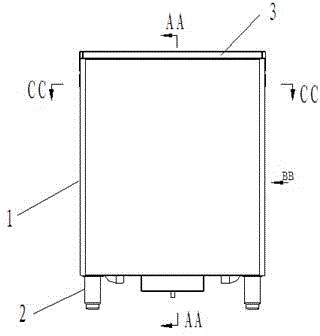

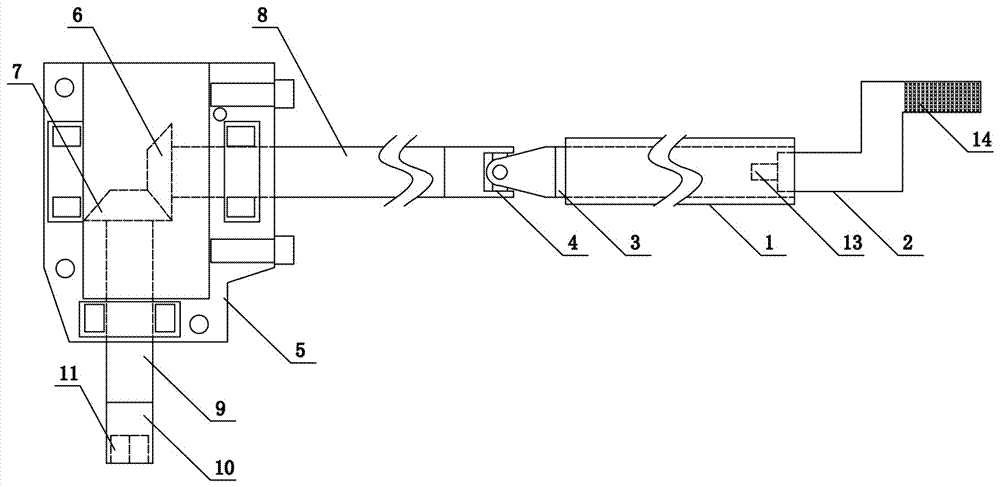

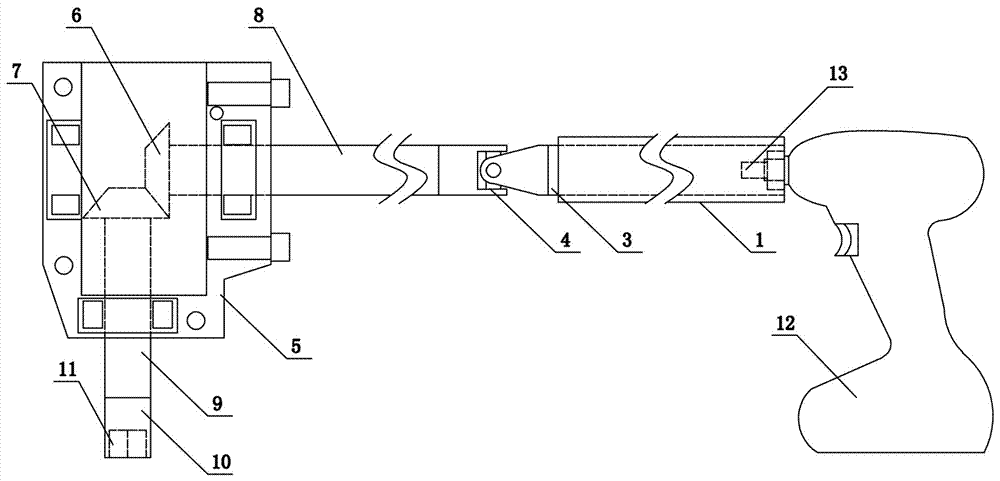

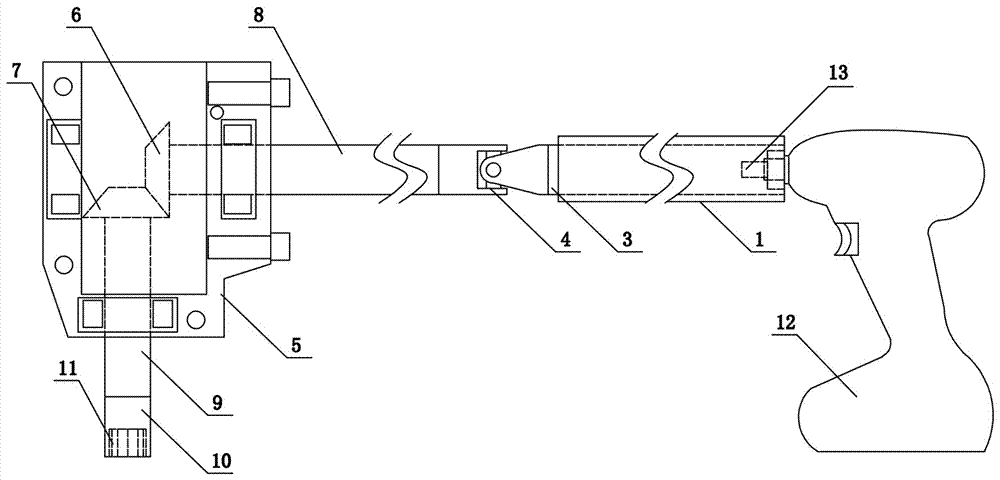

Umbilic clamping cutter

The invention provides an umbilic clamping cutter, comprising a pushing and cutting rod, a mother clamp, an infant clamp and a clamp holder, wherein one end of the pushing and cutting rod is provided with a blade while the other end is a cartoon; one surface of the pushing and cutting rod is fixed with a pick matched with the infant clamp; and one end of the clamp holder is connected with the mother clamp and the infant clamp while an inwall chute at the other end thereof is matched with the pushing and cutting rod. As one end of the clamp holder is manufactured into a big opening, only one end of the clamp holder operates by fingers, the whole operation process can be seen clearly from the big opening; the umbilical cord is clamped by two clamps in advance so as to facilitate the blade to cut; when in operation, the pushing and cutting rod is driven by hands to cut the umbilical cord actively like an injector, thus having easy cut-off and good cutting effect, saving labor, and avoiding blood from sputtering, thereby ensuring physical and psychological health of medical care personnel. The umbilical cord is clamped at first and then the blade is moved to cut, so the length of the reserved umbilical head can be short so as to shorten the drying time thereof, accelerate drop of umbilical head and avoid infection risk induced by the overlong reserved umbilical head.

Owner:宁波菲特医疗器械有限公司

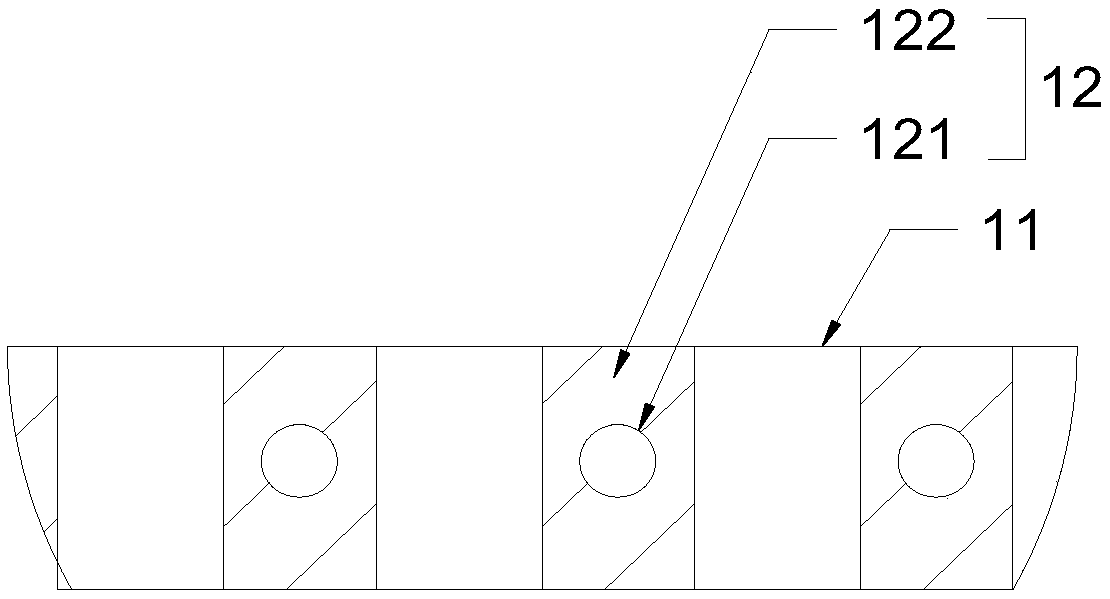

Intelligent dish washing machine and washing method thereof

PendingCN105455754AFall off quicklyImprove solubilityTableware washing/rinsing machine detailsWater useMicrocomputer

The invention discloses an intelligent dish washing machine and a washing method thereof. To-be-washed tableware is cleaned through the steps of high-pressure water flushing, residue smashing machine cleaning, heating, friction particle dry cleaning and washing, ending processing and the like. The intelligent dish washing machine has the advantages of being simple in structure, safe and reliable and is ingenious in design and low in device cost, all work is controlled through a microcomputer, the process is fed back through a sensor, one-key automatic and intelligent washing can be achieved, and manual labor is thoroughly liberated. According to the intelligent dish washing machine , at the high-pressure water flushing stage, a high-pressure pump pumps clean water from a clean water tank and flushes tableware through a nozzle, residues are smashed in a concentrated mode and discharged, water used at the stage of washing tableware through friction particles is high-temperature water with the temperature of 80 DEG C, the water can conduct disinfection and sterilization and can also soften greasy dirt, dissolution of greasy dirt in water is accelerated, the water can even be recycled, and water and energy are saved.

Owner:郑桂成

Method for separating solder and detaching electronic elements from waste circuit boards

InactiveCN101590555AAvoid wastingAvoid pollutionSolid waste disposalSolid separationElectronic componentPrinted circuit board

The invention relates to a method for separating solder and detaching electronic elements from waste circuit boards, which comprises the following steps: in an enclosed device, firstly conveying the waste circuit boards to an appointed position; then starting a heating device, heating the circuit boards in a hot air heating mode of a warm-air pipe with annular pinholes, melting soldering tin on welding spots to remove the soldering tin; at the time of starting the heating device, starting a vibration device to make the electronic elements vibrate, fall off from the circuit boards and fall into a collection box; and finally, withdrawing the circuit boards and recovering the electronic elements. The method can make the electronic elements on the circuit boards quickly and integrally separated from the circuit boards and fall off; and then the electronic elements are screened and detected, and perfect and effective electronic elements and partial noble metal materials are obtained; therefore, the invention not only finds a way for recycling the large quantity of waste circuit boards in China to avoid resource waste and change waste into treasure, but also finds a good method for processing the waste circuit boards to solve the problems of troubles and environmental pollution caused by destroying the waste circuit boards.

Owner:杨继荣

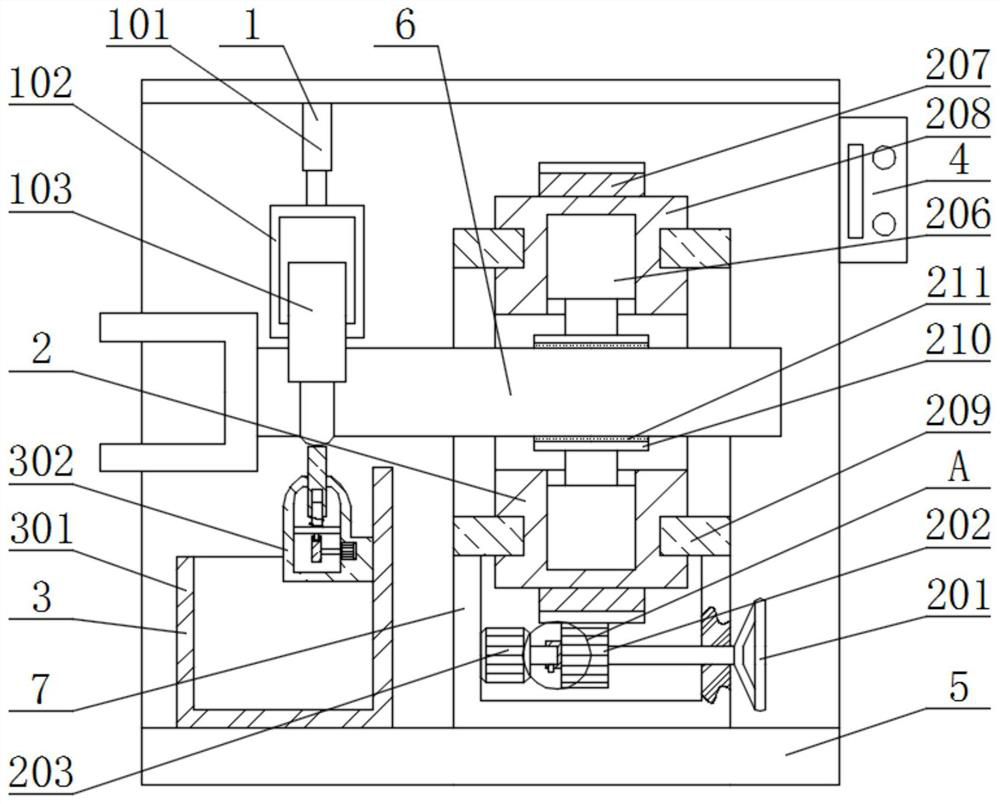

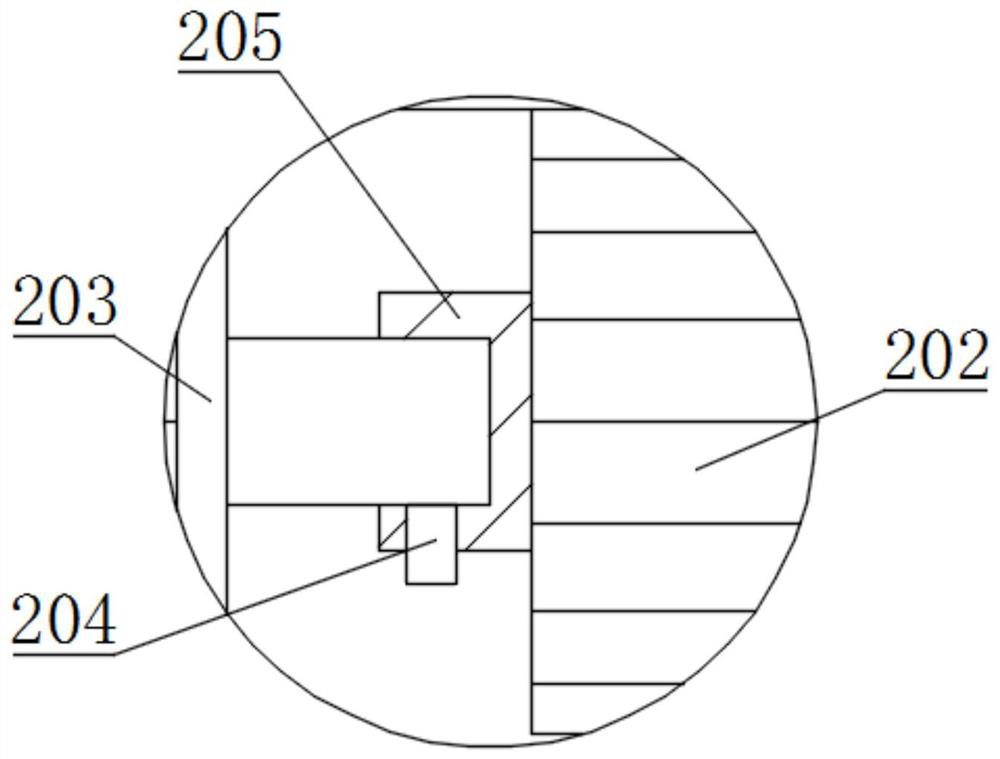

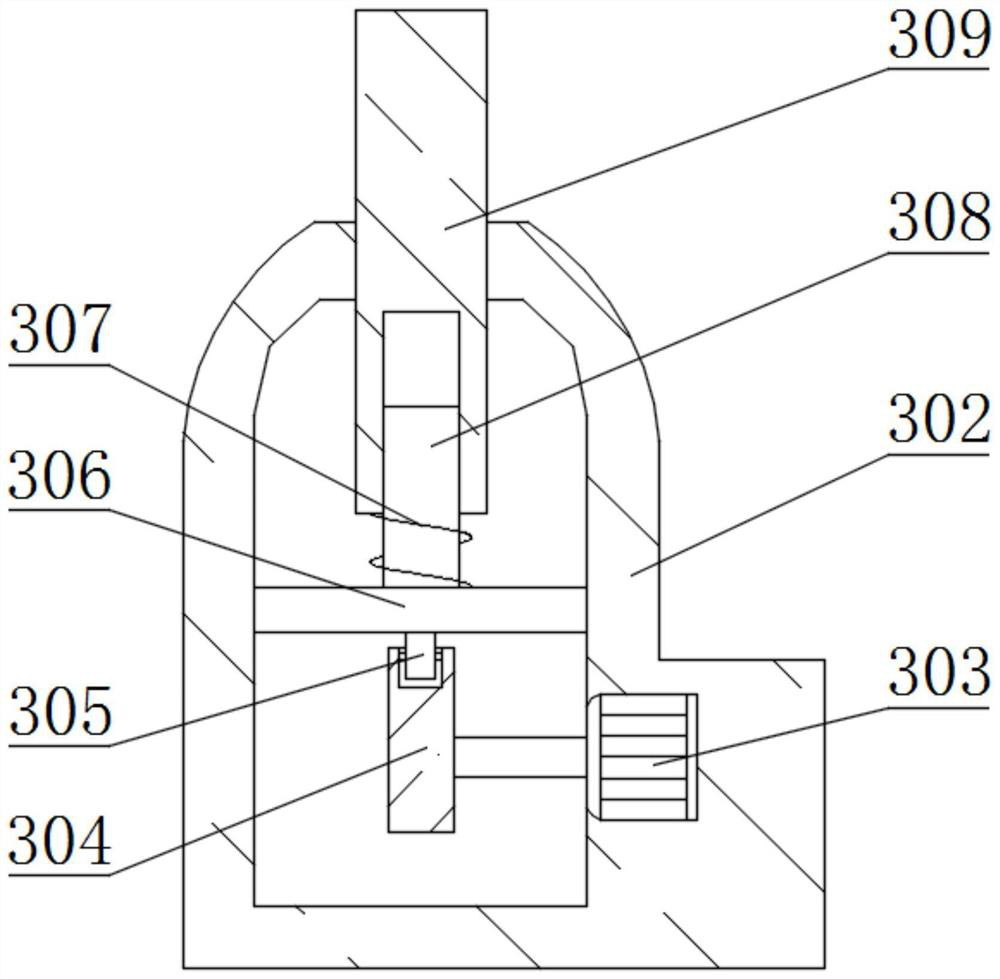

High-efficiency cleaning device for mechanical parts

InactiveCN107020259AFall off quicklyImprove scrubbing effectDrying gas arrangementsCleaning using toolsBristleBrush device

The invention discloses a high-efficiency cleaning device for mechanical parts. The high-efficiency cleaning device comprises a machine body, a clamping device and a rotating motor, wherein the clamping device is arranged in the machine body; a brushing device is arranged in the machine body; a crank is fixedly connected to the brushing device; a cam is rotationally connected to the crank; and a water spraying ring is arranged above the brushing device. According to the high-efficiency cleaning device disclosed by the invention, the brushing device which is provided with hard brush hairs and does circular motion is arranged for brushing the parts without dead angle, so that a better brushing effect is realized; the high-efficiency cleaning device disclosed by the invention is provided with a water spraying head flushing device with different angles; the water spraying head flushing device is used for thoroughly flushing the parts, so that dirt quickly falls off, and the better flushing effect is realized; a cycle hot air drying device is arranged for quickly drying the parts; and the high-efficiency cleaning device is provided with a filtering and separating device for recycling waste liquid, so that resources are saved.

Owner:张炳强

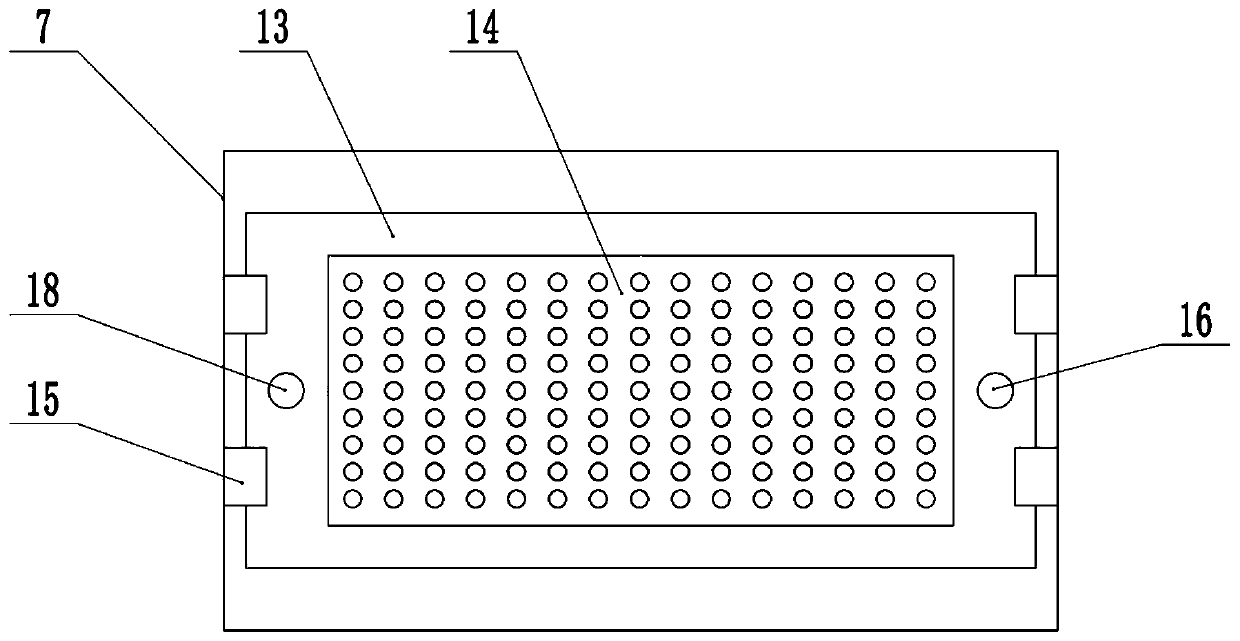

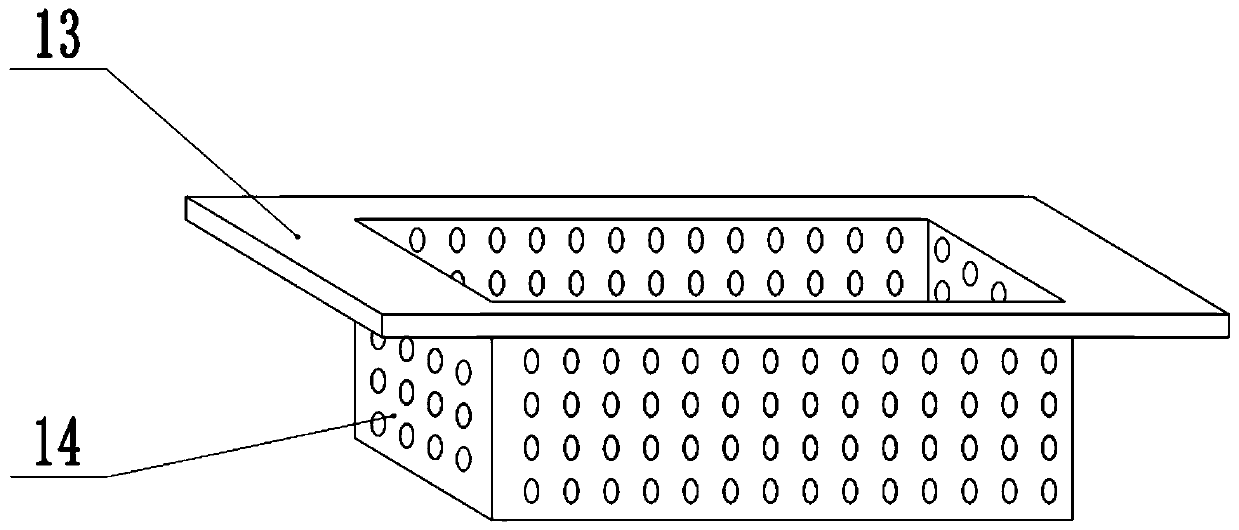

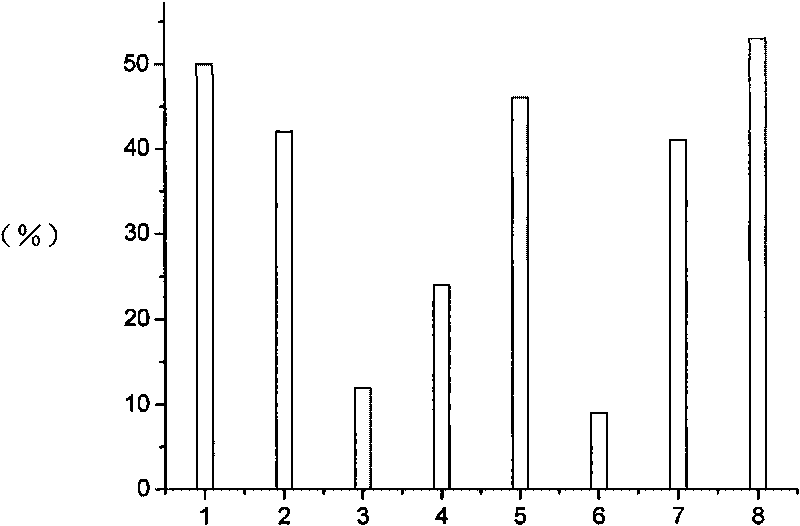

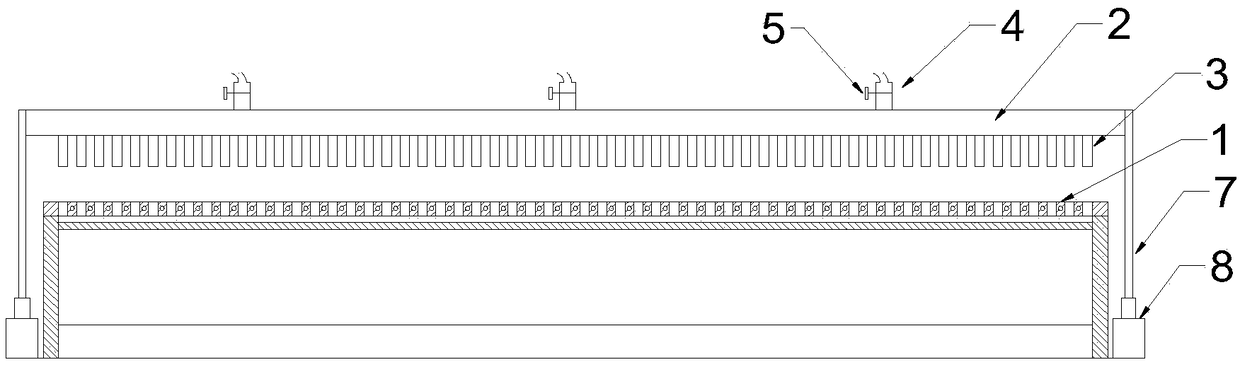

Sieve plate device preventing hole blocking in screening blind area

The invention provides a sieve plate device preventing hole blocking in a screening blind area. The sieve plate device comprises a compressed air system and a sieve body which are arranged sequentially from top to bottom. The sieve body comprises a sieve net provided with a plurality of sieve holes. The compressed air system comprises a flat air bag matched with the sieve net in shape. A pluralityof acicular air pipes corresponding to the sieve holes are arranged at the bottom of the air bag. Each acicular air pipe comprises an upper pipe end communicating with the air bag, and a lower pipe end communicating with the outside air, wherein the pipe hole of the upper pipe end is of a straight cylinder structure, and the pipe hole of the lower pipe end is of a wide-end-up conical structure. Aplurality of compressed air inlet pipes are arranged at the top of the air bag and are connected with outside compressed air pipelines. The compressed air system with the acicular air pipes is arranged above a sieve plate, the acicular air pipes blow air to the sieve holes of the sieve net to blow off viscous matter blocking the sieve holes, blocking prevention efficiency is high, and cost for cleaning the sieve net can be lowered effectively.

Owner:JIANGSU YIYIHEHUA SCREENING EQUIP CO LTD

Wrench

The invention belongs to the technical field of power transmission and transformation overhaul devices and particularly relates to a wrench which comprises a first connecting rod and a steering mechanism. A first rotating shaft is rotatably connected into the first connecting rod; one end of the first rotating shaft is provided with a universal joint; the steering mechanism comprises an outer shell, a first bevel gear and a second bevel gear, wherein the first bevel gear and the second bevel gear are arranged in the outer shell; a second rotating shaft is coaxially fixed to the first bevel gear; one end of the second rotating shaft stretches out of the outer shell and then is fixedly connected with the other end of the universal joint; the first bevel gear and the second bevel gear are connected in engaged and transmission modes; a third rotating shaft is coaxially fixedly connected to the second bevel gear; and one end of the third rotating shaft is provided with a sleeve after stretching out of the outer shell. According to the wrench, a traditional universal joint and the steering mechanism are subjected to matching design, the operating radius of the wrench is about 90-135 degrees, and the disassembling and assembling requirements of all bolts in a power transmission and transformation station are met.

Owner:国网河南省电力公司超高压公司 +1

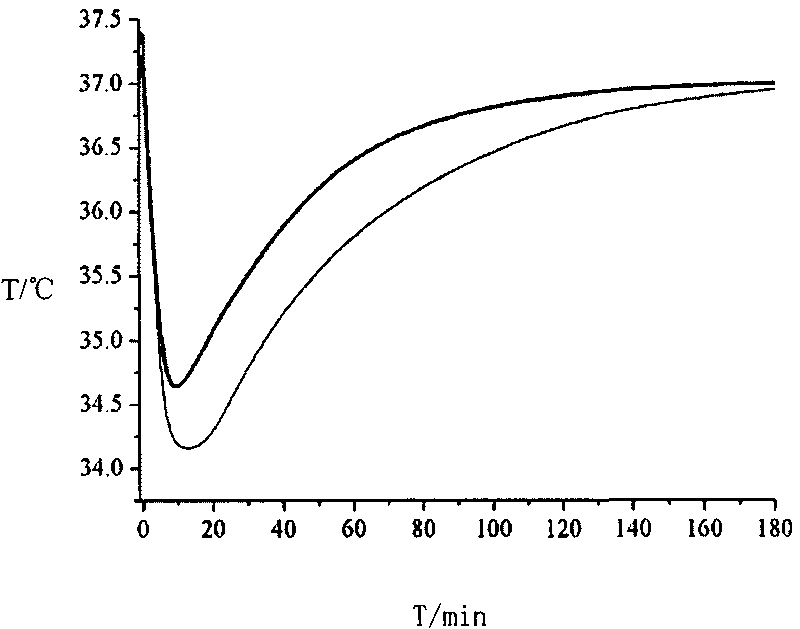

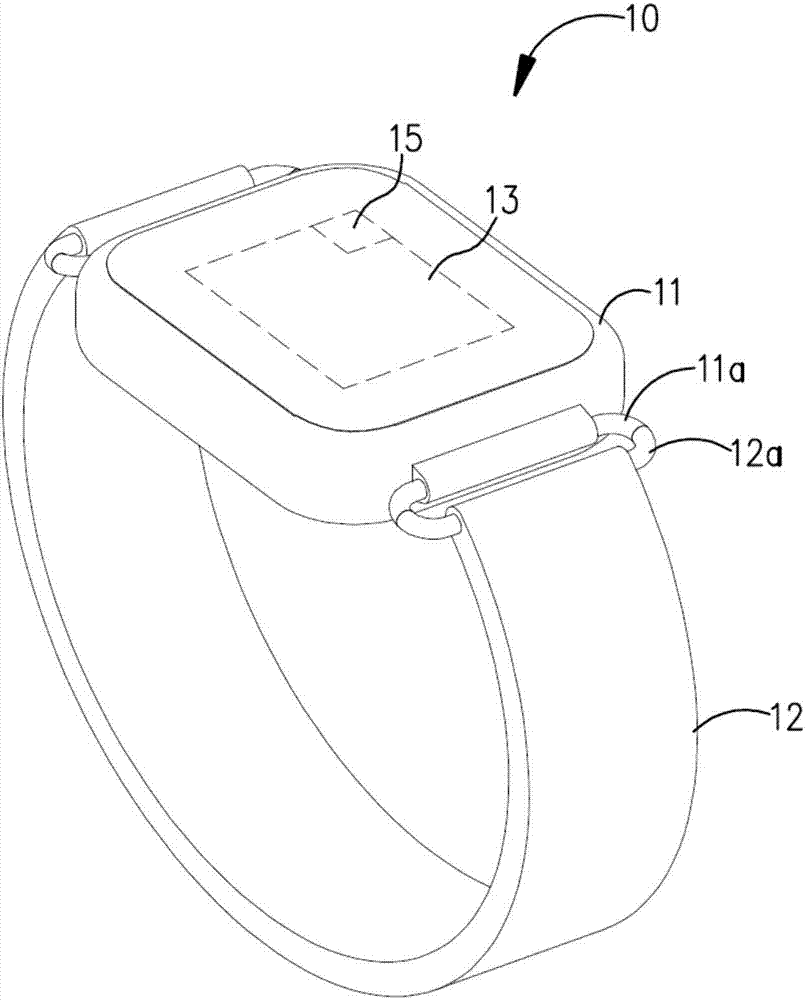

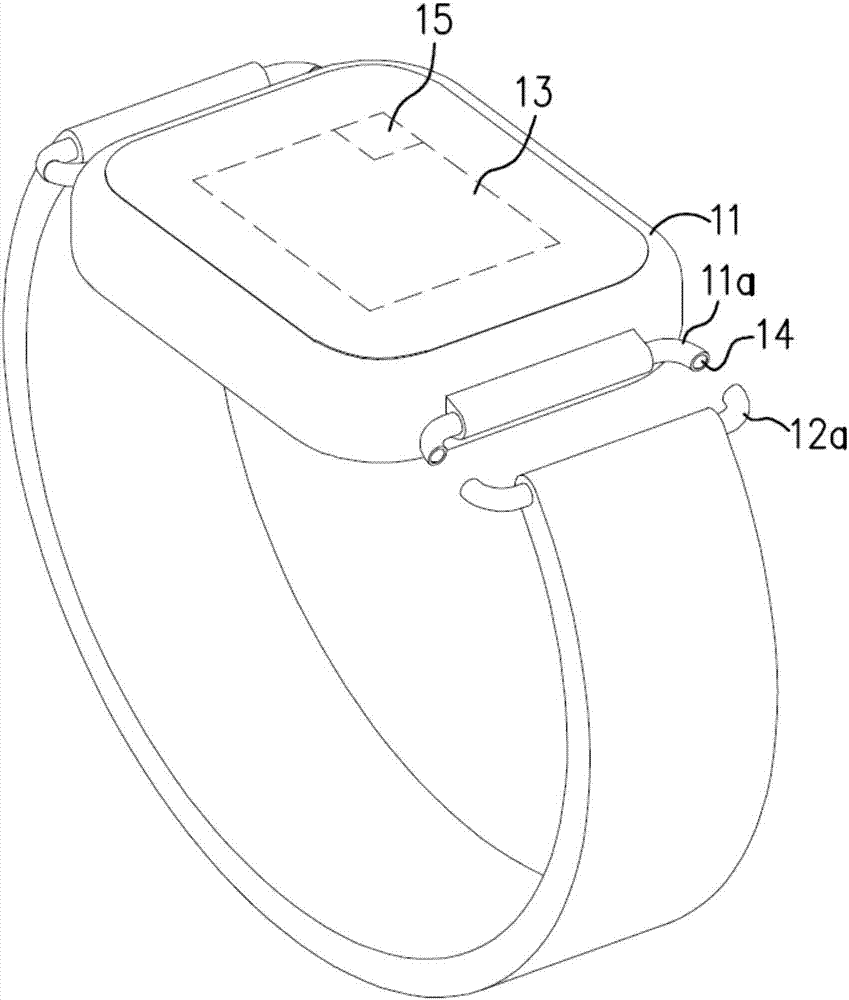

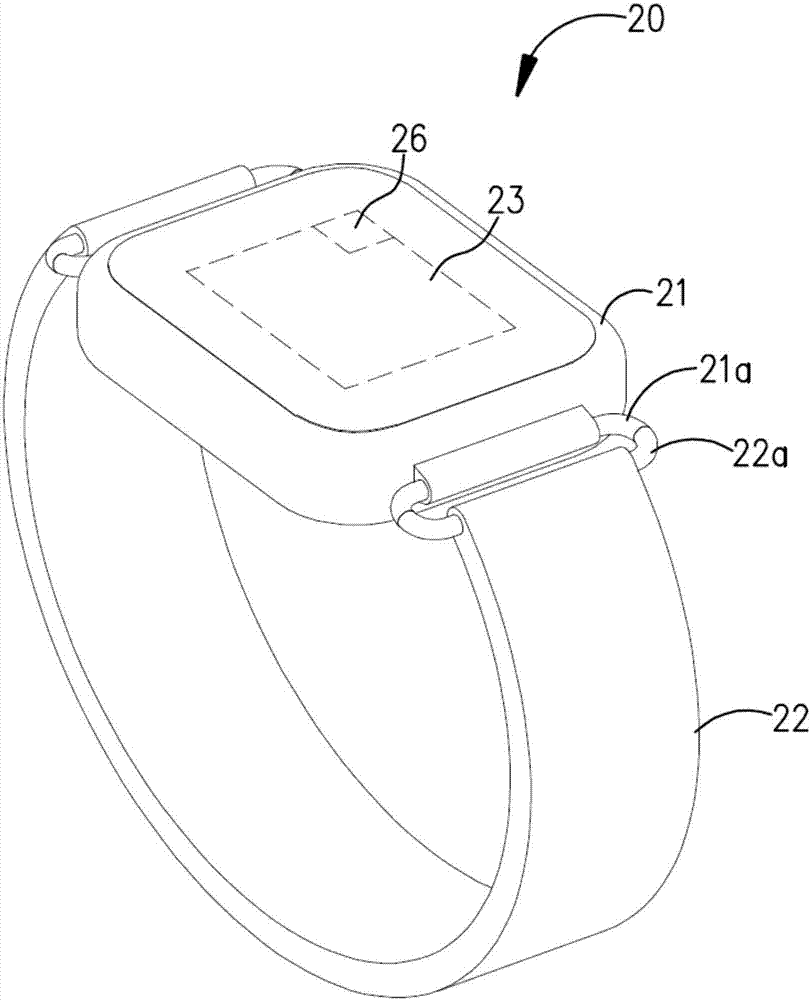

Intelligent wearable device and watchband rapid fall-off method

InactiveCN106990709AFall off quicklyPrevent burnsElectronic time-piece structural detailsTime-pieces with integrated devicesElectricityEngineering

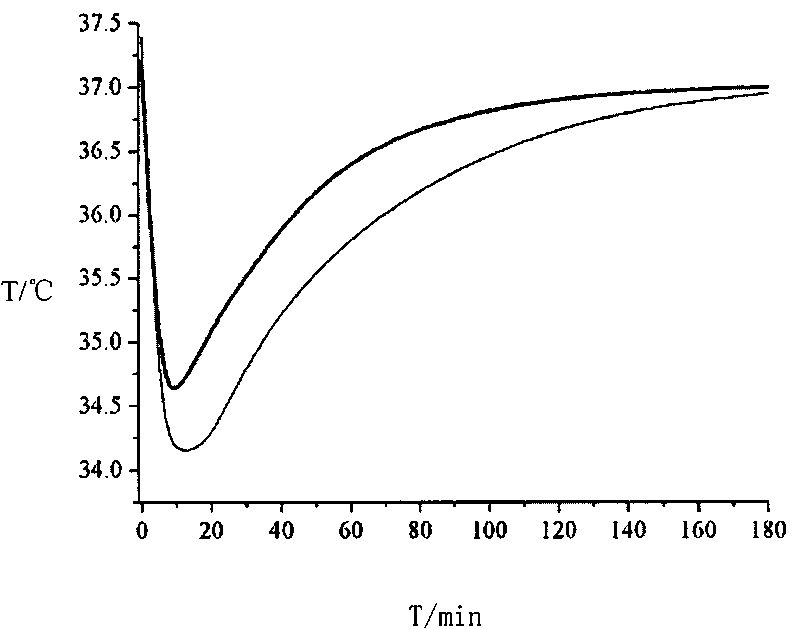

The invention discloses an intelligent wearable device, including a dial, a watchband, a control mainboard and at least one electromagnetic element. The dial is provided with a first metal button, the watchband is provided with a second metal button, the at least one electromagnetic element is electrically connected with the control mainboard, the control mainboard is used for supplying power to the at least one electromagnetic element to enable the second metal button to adhere to the first metal button. The control mainboard is also used for cutting power to the at least one electromagnetic element when receiving a cut-off signal, so as to disconnect the second metal button with the first metal button. The intelligent wearable device and the watchband rapid cut-off method provided by the embodiments of the invention can ensure that the watch can be quickly separated from the dial by controlling the board to power off the electromagnetic element quickly when the dial is used for too long or when the temperature is too high due to abnormal usage, thereby preventing a condition that the user is burned due to contact between the bottom of the dial and the user's skin and ensuring the usage safety of the user. In addition, the invention also discloses an intelligent wearable device and a watchband rapid fall-off method.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

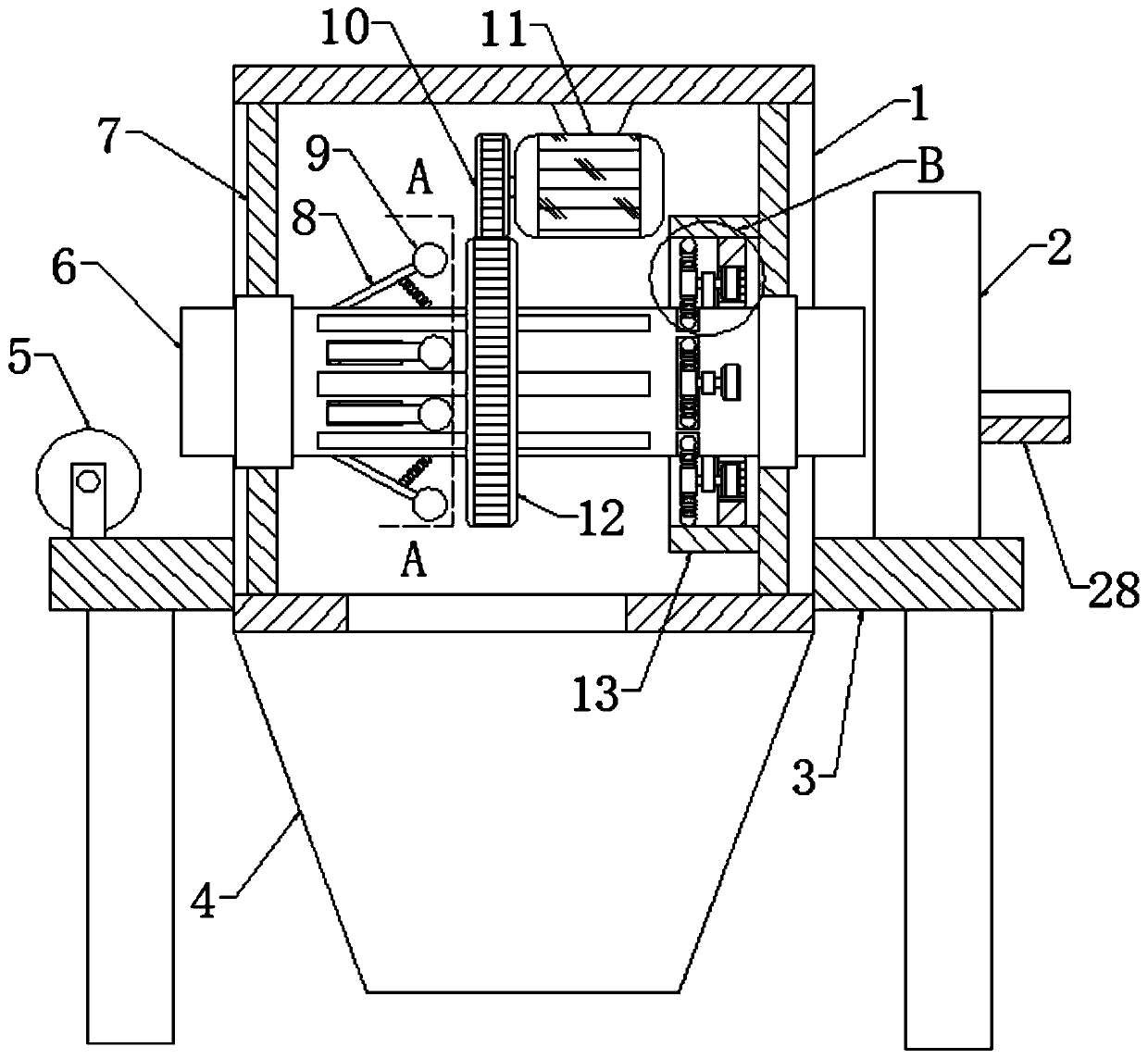

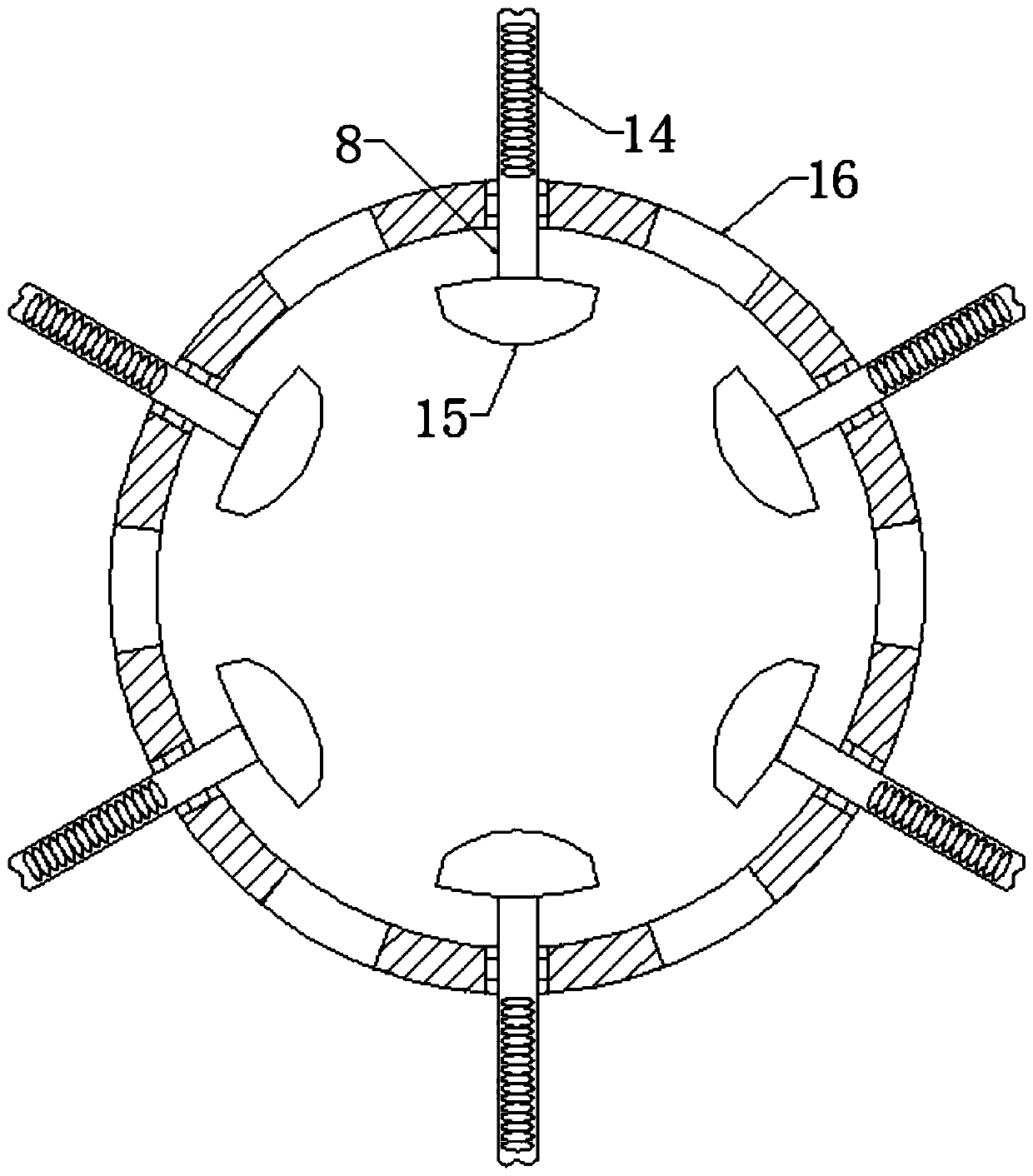

Equipment for removing cement on surfaces of steel pipes of scaffold for building

ActiveCN111515823AImprove work efficiencyImprove cleaning effectGrinding carriagesGrinding drivesSteel tubeArchitectural engineering

The invention relates to the technical field of building equipment, and discloses equipment for removing cement on the surfaces of steel pipes of a scaffold for a building. The equipment comprises a cross plate, the position, between the upper end and the lower end, of the cross plate is fixedly connected with a sleeve through a rectangular opening, and the inner edges of pipe openings in the leftend and the right end of the sleeve are fixedly connected with sealing plates. The opposite sides of the two sealing plates are rotationally connected with a cross pipe through first rolling bearings, and the two ends of the cross pipe penetrate through the first rolling bearings and extend out of the sleeve. An annular block is arranged in the sleeve, the inner side of the annular block is sleeved with the pipe wall of the cross pipe, one side of the annular block is fixedly connected with one side of one sealing plate, and the pipe wall, in the annular block, of the cross pipe is connectedwith a clearing mechanism. According to the equipment for removing the cement on the surfaces of the steel pipes of the scaffold for the building, the work efficiency of manually clearing the steel pipes of the scaffold can be improved, clearing is thorough, and the labor intensity is low; and grinding treatment can be directly carried out when the cement is removed, and subsequent antirust treatment can be directly carried out on the steel pipes.

Owner:枣庄职业学院

Method of removing films on surfaces of waste ring-pull cans

The invention relates to a method of removing films on surfaces of waste ring-pull cans, belonging to the technical field of waste material recycle. The method comprises the following steps: first, uniformly mixing 25-45% of dimethyl sulfoxide and 30-55% of N, N-dimethylformamide in a container, and then adding 5-15% of concentrated sulfuric acid to uniformly mix to obtain a film remover; introducing the film remover to a depainting container, then, introducing pre-crushed aluminous ring-pull can fragments into the depainting container, heating the film remover in the depainting container, and taking out the ring-pull can fragments from the depainting container to be cleaned and dried to obtain crushed ring-pull can fragments without films on the surfaces; and finally, collecting a film material dissolved in the film remover and a film material generated in cleaning in a filtering manner. An organic solvent is combined with an inorganic acid, so that the films on the surfaces quickly fall off and are fully removed, thereby avoiding the secondary pollution, representing the green production and increasing the recovery rate.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Speed-adjustable self-cleaning conveyor

Owner:HUZHOU QIANJIN BAOYUN MACHINERY CASTING

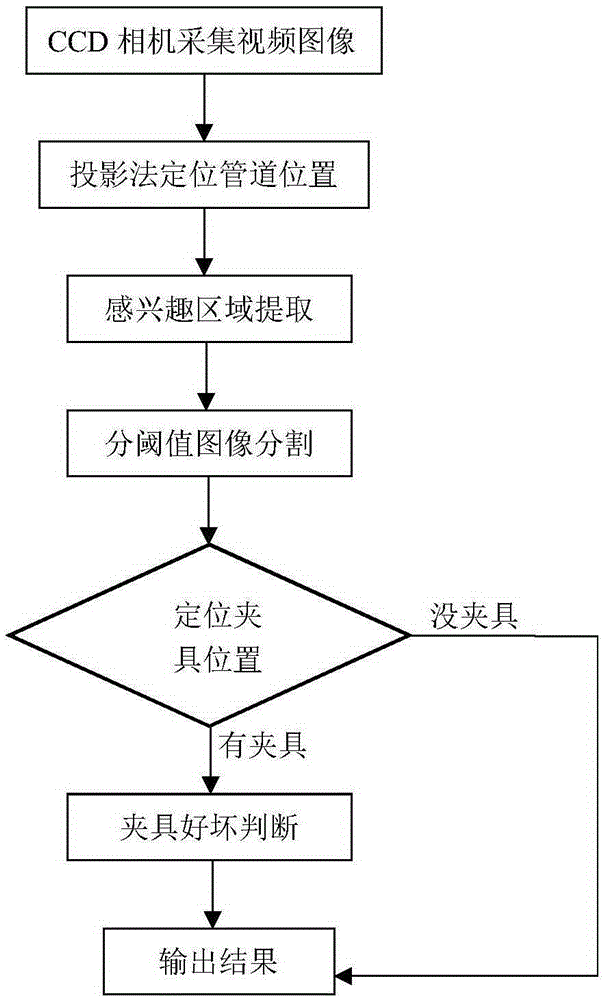

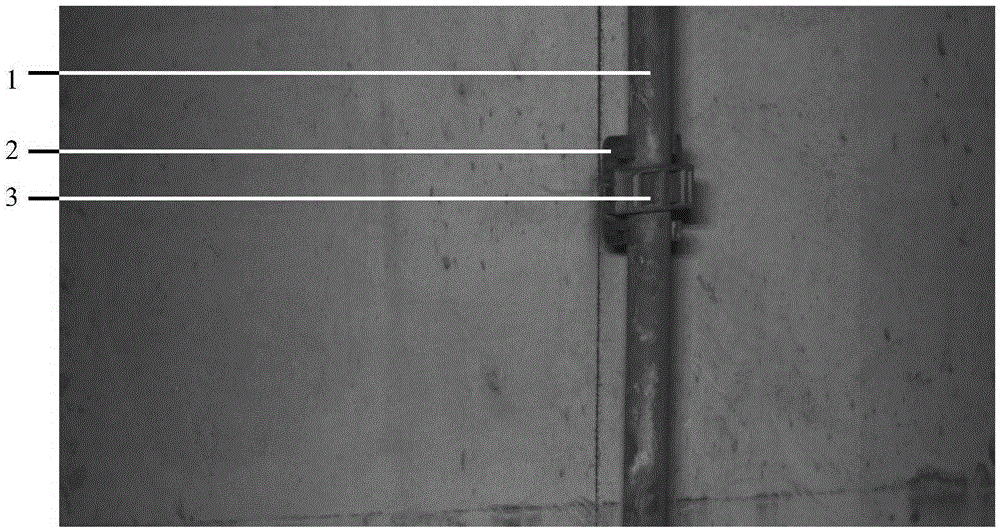

Machine vision based automatic defect detection method for train tunnel cable clamp

The invention discloses a machine vision based automatic defect detection method for a train tunnel cable clamp, and relates to the field of image processing, especially cable clamp image processing in a train tunnel. The method comprises: first, collecting a clamp image; performing a vertical projection on the image, and determining whether a pipe exists in the image according to a protection curve, if yes, determining the location of the pipe and intercepting a pipe image; performing histogram statistics, performing inverting binarization according to a low threshold, and then determining whether a clamp exists on the pipe of the pipe image, if yes, determining a location of the clamp; and performing histogram statistics on the intercepted image, performing inverting binarization according to a high threshold, and then determining whether the clamp on the pipe of the pipe image falls. According to the method, a clamp that falls can be found conveniently, quickly and efficiently, so that the clamp can be replaced timely.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

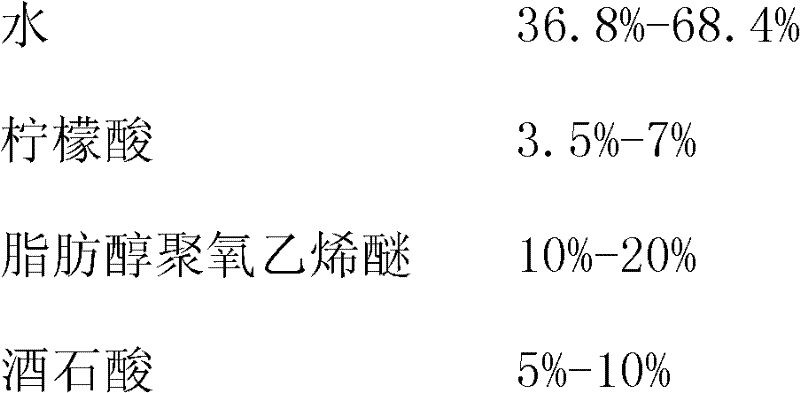

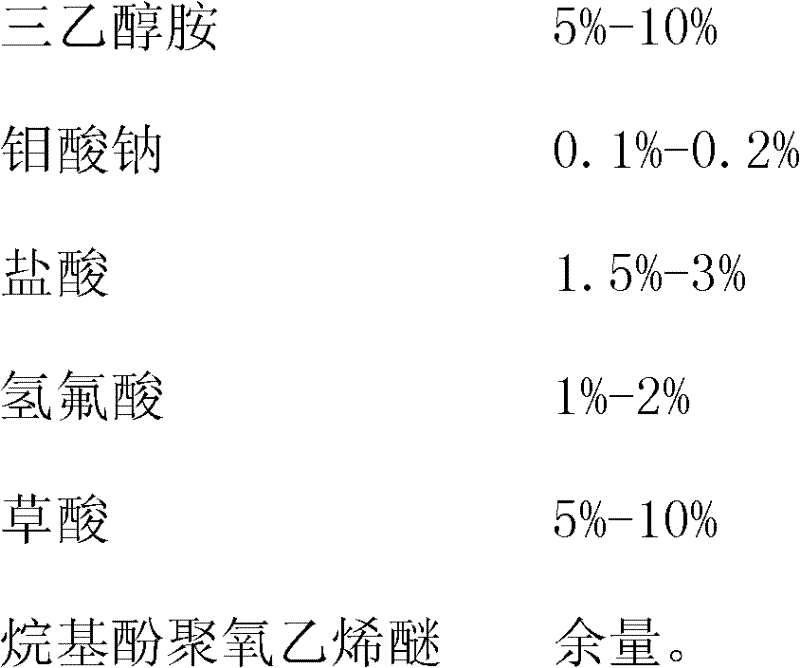

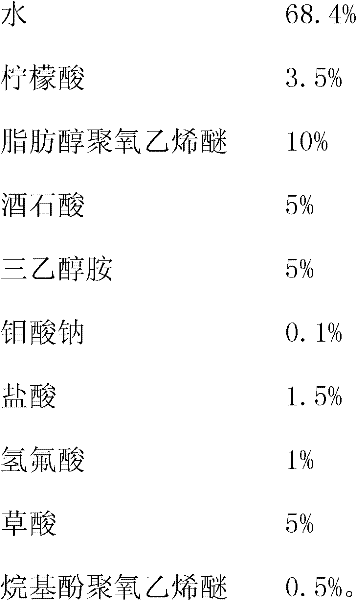

Cleaning agent for stainless steel hot-rolled member and preparation method thereof

The invention relates to the technical field of chemical cleaning, in particular to a cleaning agent applicable to a stainless steel hot-rolled member and a preparation method thereof. The cleaning agent for the stainless steel hot-rolled member is prepared by mixing the following raw materials in percentage by weight at a normal temperature: 36.8%-68.4% of water, 3.5%-7% of citric acid, 10%-20% of fatty alcohol polyoxyethylene ether, 5%-10% of tartaric acid, 5%-10% of triethanolamine, 0.1%-0.2% of sodium molybdate, 1.5%-3% of hydrochloric acid, 1%-2% of hydrofluoric acid, 5%-10% of oxalic acid and the balance of alkylphenol polyoxyethylene. The cleaning agent for the stainless steel hot-rolled member is simple and convenient in operation, novel in process, strong in cleaning capability and harmless in skin contact; the personal safety of an operator is effectively guaranteed; the warming is not needed; the cleaning effect is good; synchronously, the surface of stainless steel is not corroded; the glossiness of the stainless steel is maintained; furthermore, the cleaning agent for the stainless steel hot-rolled member can be used repeatedly and is low-carbon and environment-friendly; and the cost is saved.

Owner:响水德丰金属材料有限公司

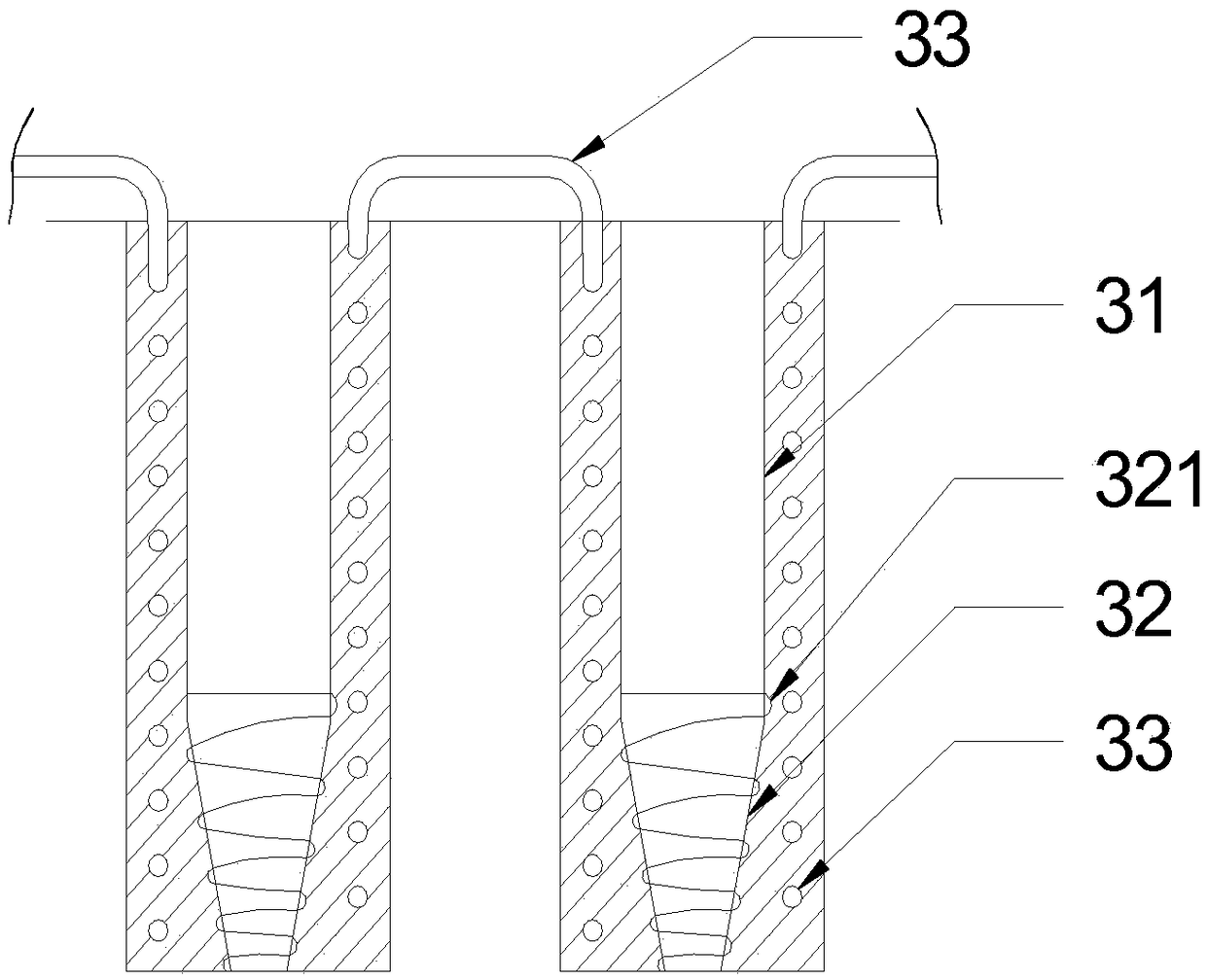

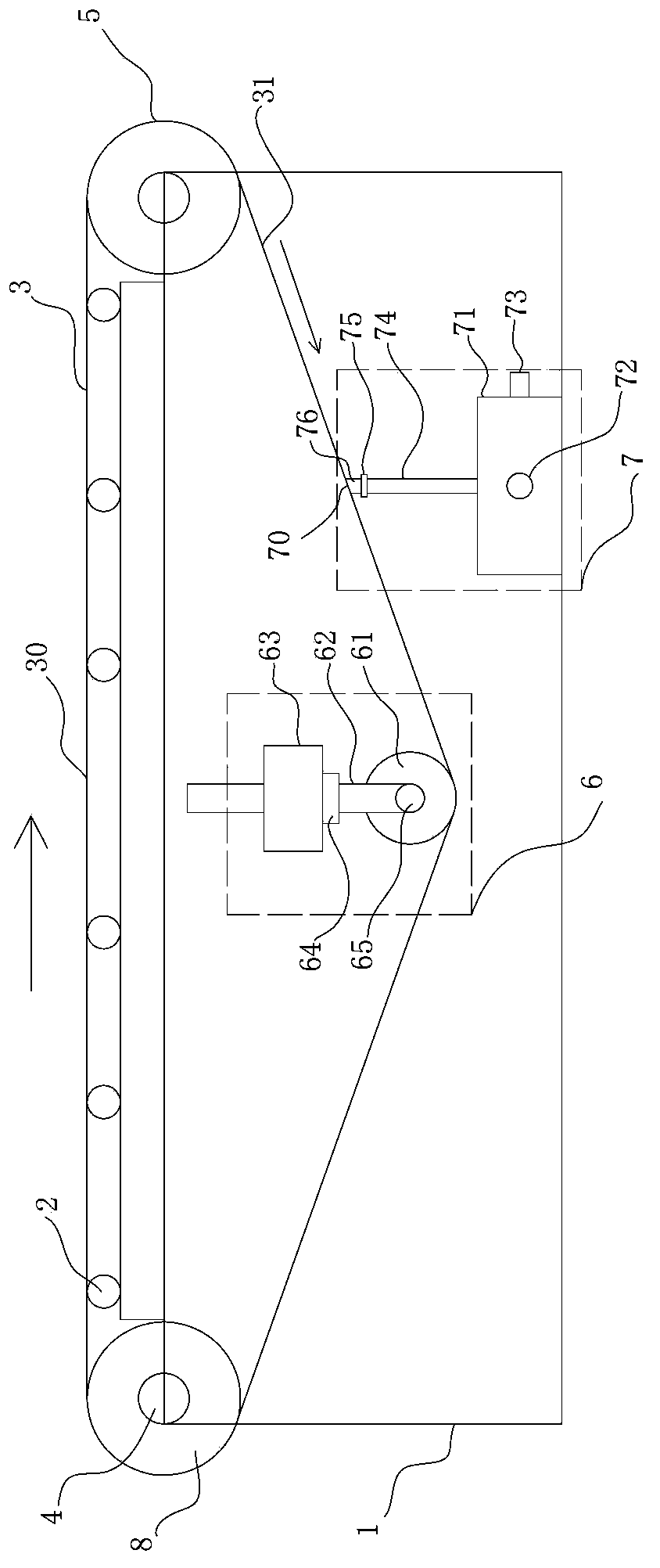

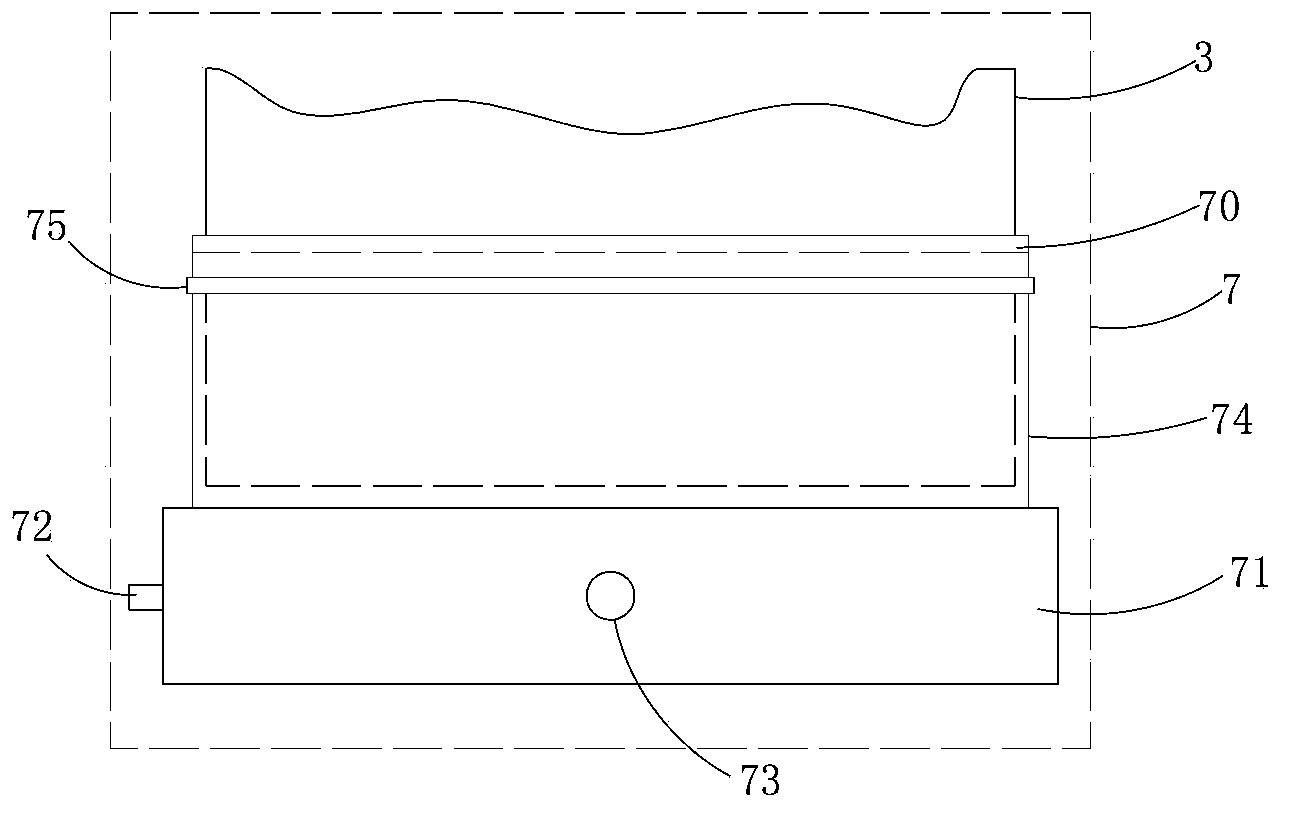

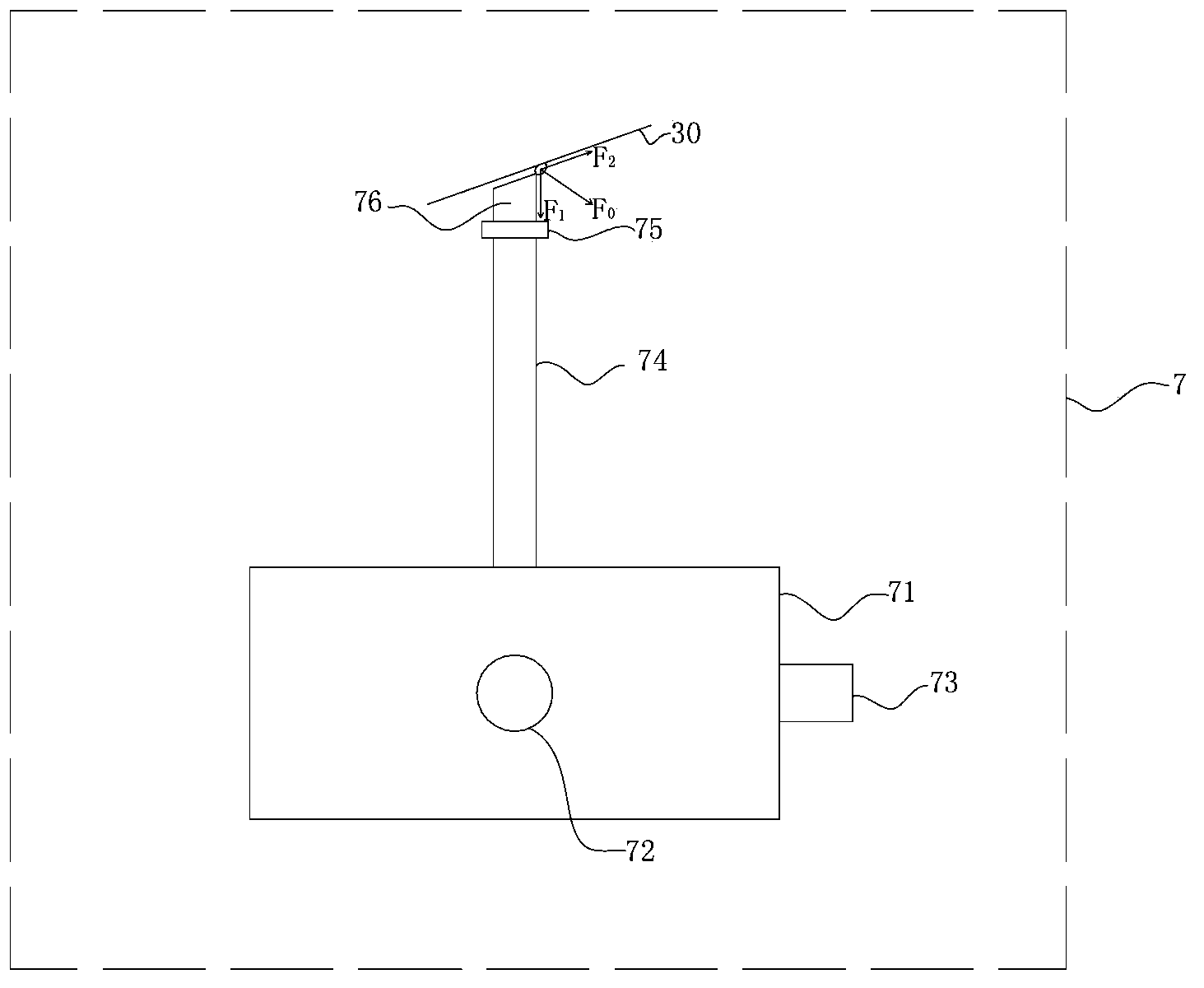

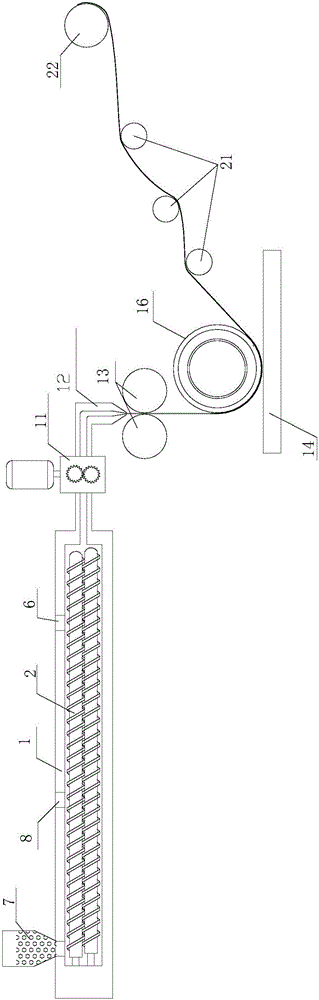

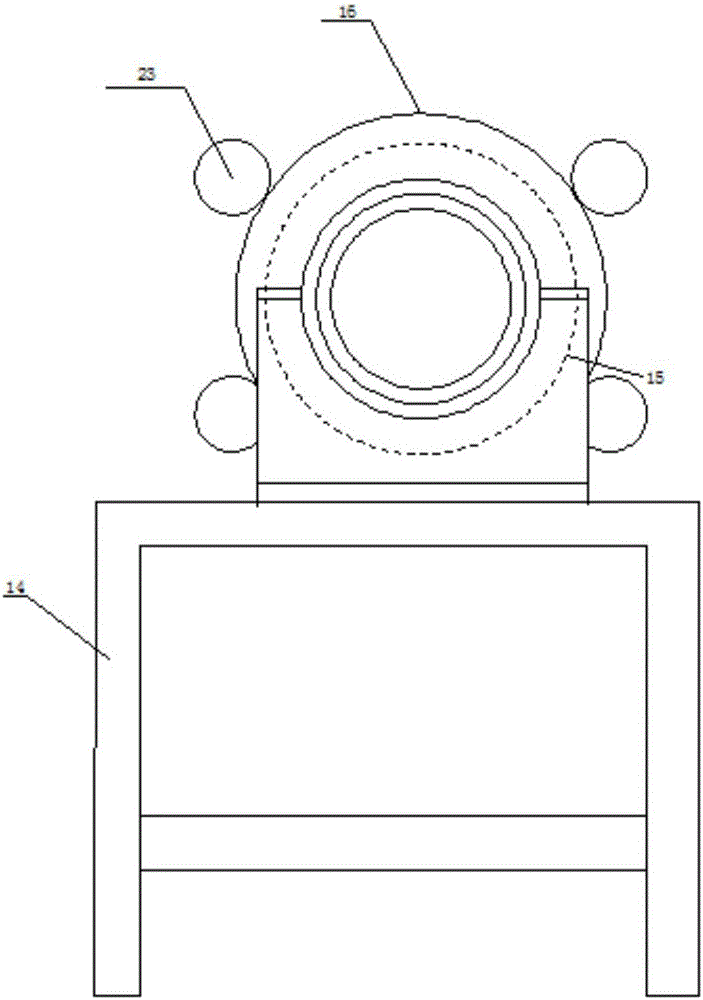

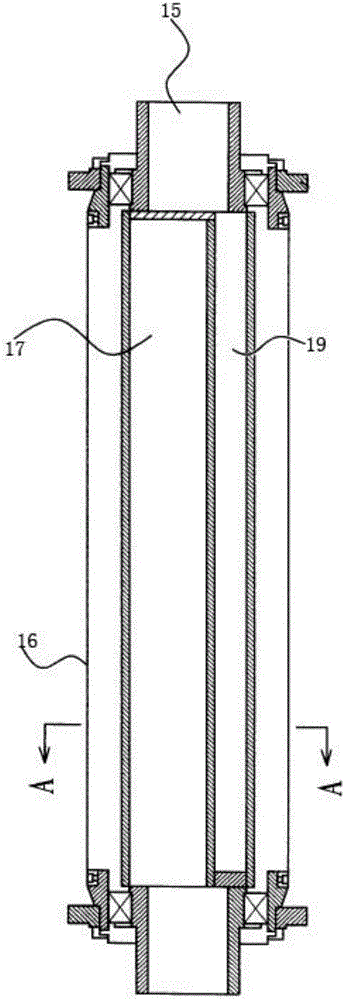

Perforated film capable of being biodegraded completely and preparation process, application and preparation device thereof

InactiveCN105860149AHas antibacterial propertiesSimple preparation processAbsorbent padsFlat articlesMaterials preparationPolyresin

The invention relates to a perforated film capable of being biodegraded completely and a preparation process, application and preparation device thereof. The perforated film capable of being biodegraded completely is prepared from, by weight, 95-100 parts of plant modified starch, 100-150 parts of biodegradable resin, 2-3 parts of zirconium phosphate silver-loaded antimicrobial powder, 0.5-20 parts of pasting agent, 0.3-10 parts of compatibilizer and 0.2-10 parts of dispersant. The preparation device of the perforated film comprises a low-speed mixing machine for raw material mixing, and a film extrusion molding device, a film perforating device and a winding device which are sequentially arranged. The film extrusion molding device comprises a screw extruder, a melt pump and a T-shaped die head which are sequentially connected and communicated. The preparation process of the perforated film comprises material preparation and pressed film molding processes. The prepared perforated film has an antimicrobial effect and can be biodegraded completely, and the preparation efficiency of the perforated film is improved through the preparation device.

Owner:SUZHOU HANFENG NEW MATERIAL +1

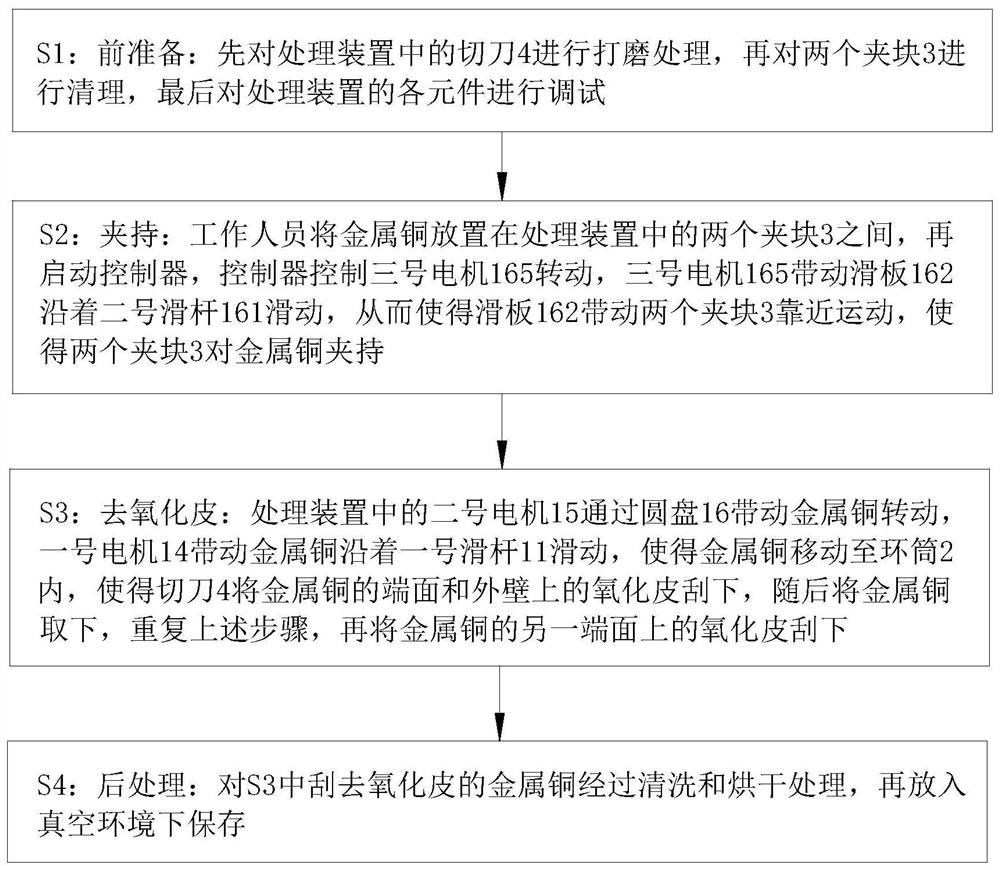

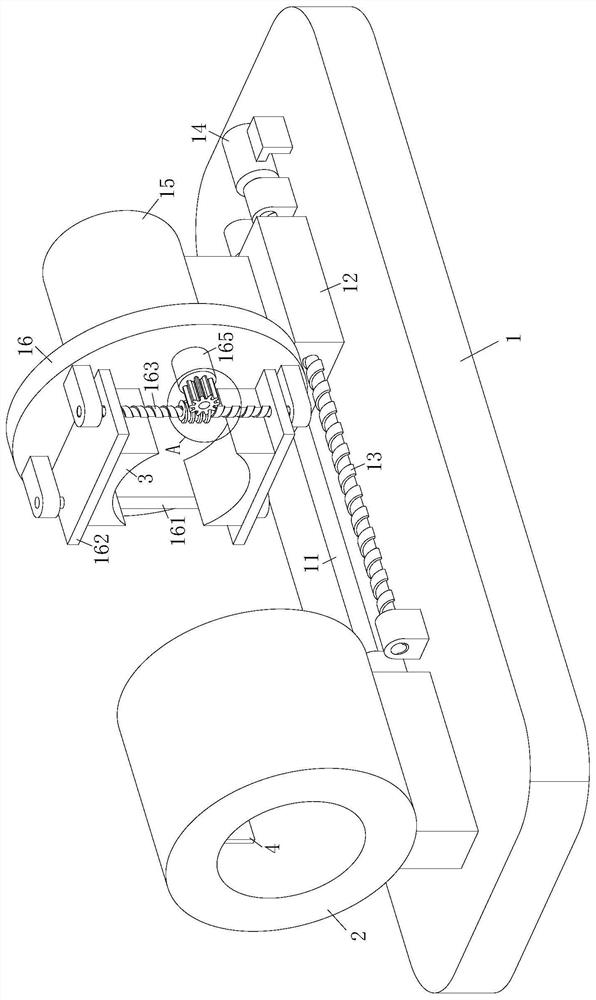

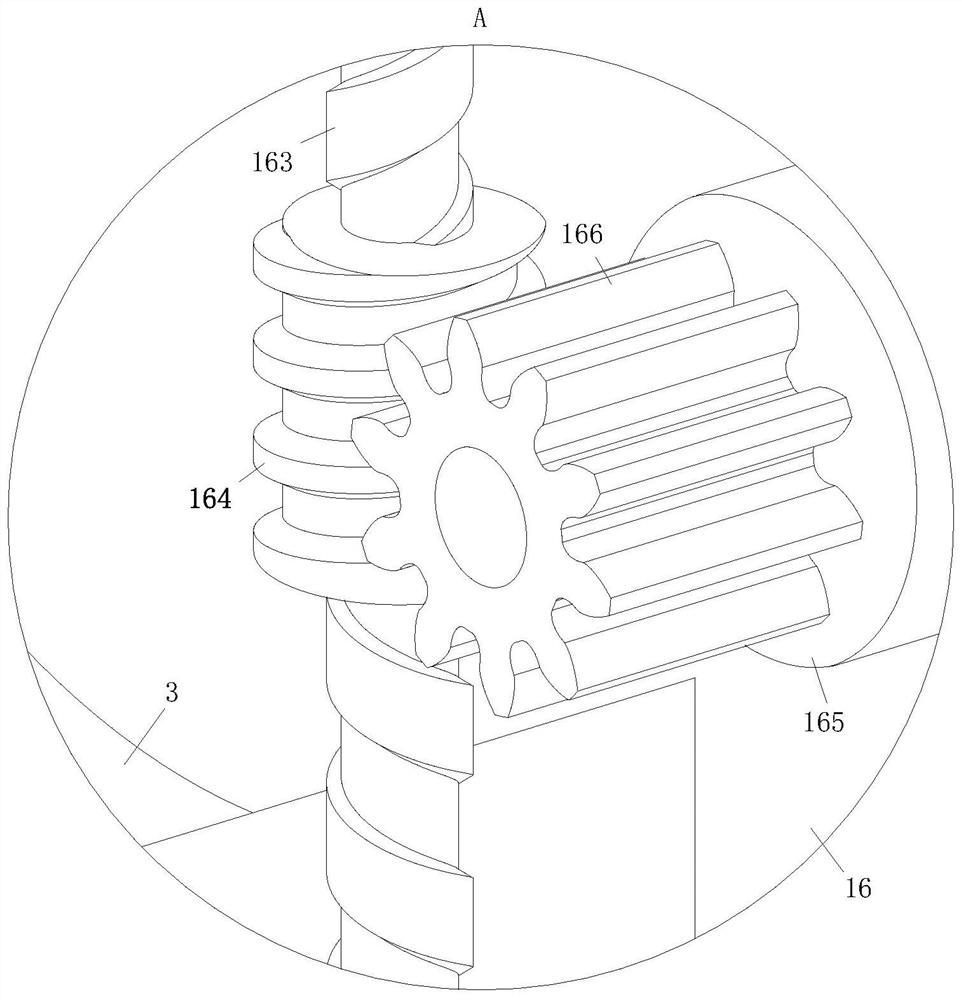

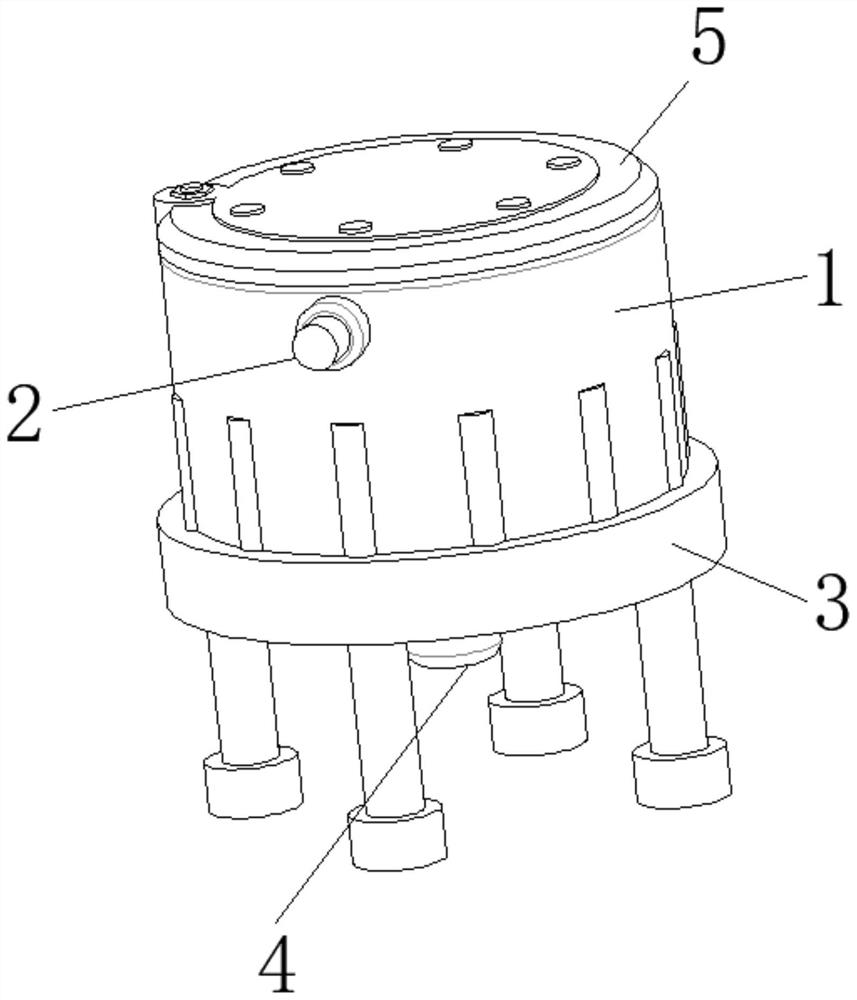

Metal copper surface oxide skin treatment process

PendingCN112475471AImprove qualityFall off quicklyCleaning using toolsOther manufacturing equipments/toolsSkin treatmentsMetallurgy

The invention relates to the technical field of metal surface treatment, in particular to a metal copper surface oxide skin treatment process. A treatment device utilized in the metal copper surface oxide skin treatment process comprises a base, a ring cylinder, a clamping block, a cutter and a controller, wherein the ring cylinder is fixedly connected with the upper end of the base; the axis of the ring cylinder is parallel to the upper end of the base; a strip-shaped groove is formed in the inner wall of the ring cylinder; the cutter is slidably connected into the strip-shaped groove; and No.1 springs are also arranged in the strip-shaped groove. According to the treatment device utilized in the metal copper surface oxide skin treatment process, metal copper is driven by a No.1 motor toslide along a No.1 sliding rod and driven by a No.2 second motor to rotate; through the cooperation between the metal copper sliding and rotating processes, oxide skin on the surface of the metal copper falls off faster and more thoroughly under the scraping action of the cutter; therefore, the metal copper surface oxide skin removing effect is improved, and then the quality of the metal copper isimproved; and meanwhile, the metal copper surface oxide skin treatment process has the advantages of being environmentally friendly and free of pollution.

Owner:王松

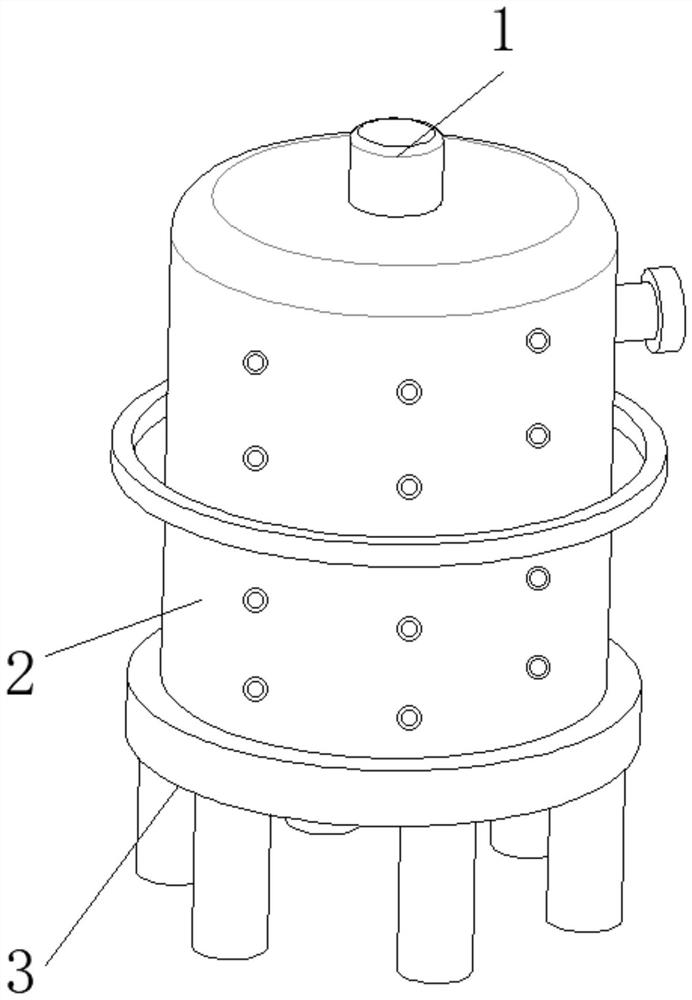

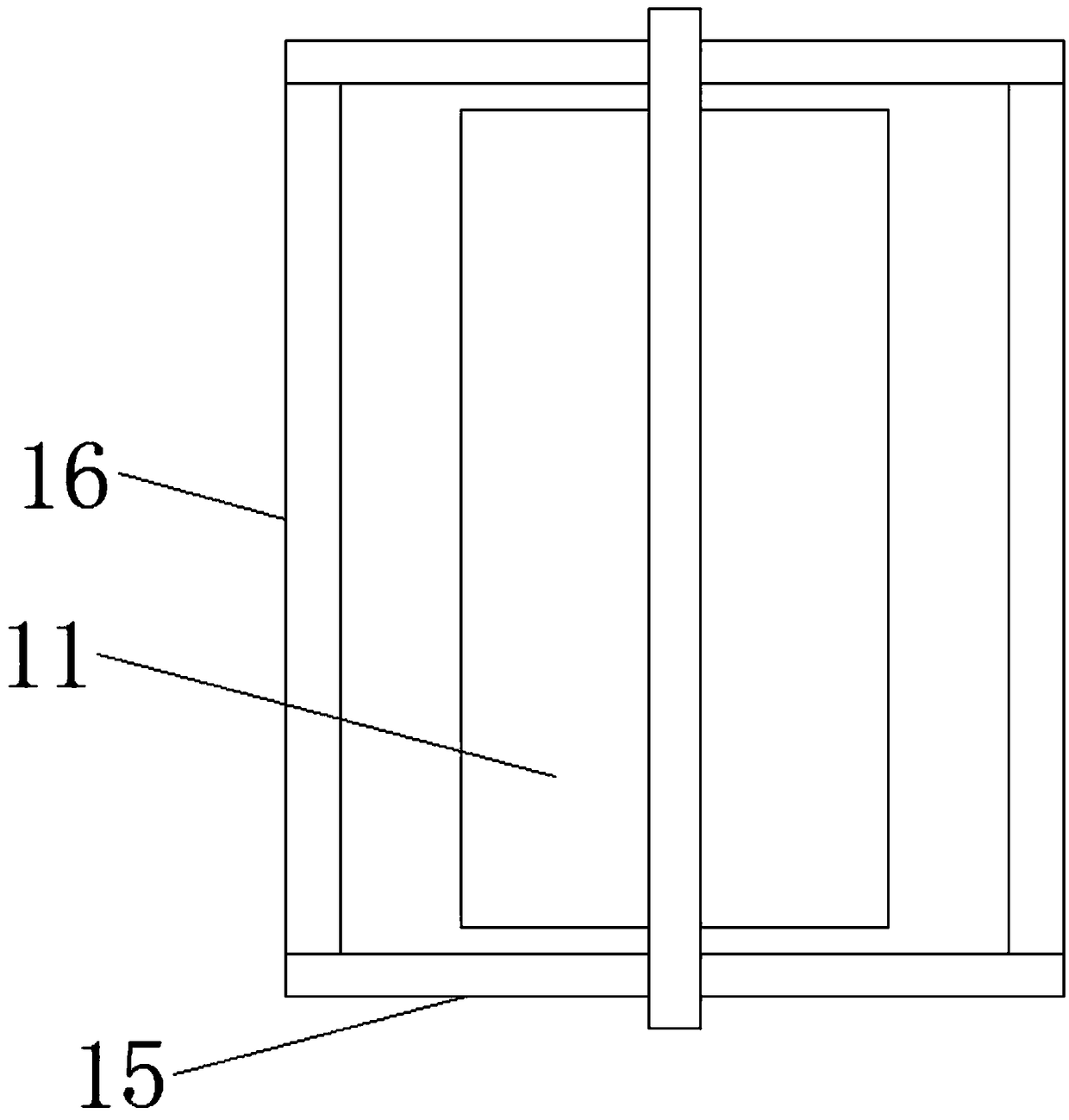

Fermentation tank cleaning device

InactiveCN112958556AEasy to cleanDifficult to clean upHollow article cleaningElectric machineWater flow

The invention provides a fermentation tank cleaning device, and relates to the field of fermentation tank cleaning. The fermentation tank cleaning device comprises a driving motor, a fermentation tank, a mounting frame, a bottom plate and a spraying mechanism; the driving motor is arranged on the outer wall of the top end of the fermentation tank; an output shaft of the driving motor is provided with an electric telescopic rod through a coupler; the mounting frame is arranged on the outer wall of the top end of the fermentation tank; the spraying mechanism comprises a water inlet pipe, a hose and a spray head; one end of the spray head is fixedly connected with the electric telescopic rod, and one end of the hose is connected with the water inlet pipe; and the spray head is communicated with the other end of the hose. According to the fermentation tank cleaning device, the bottom plate can drive impurities to enter a cleaning groove, the problem that impurities at the bottom end of a fermentation tank are not easy to clean is solved, the bottom end can be conveniently cleaned by the spray head, meanwhile, the bottom plate can repeatedly move up and down, caked impurities are crushed and rapidly fall off, and the impurities can conveniently flow out of a liquid outlet cavity along with water flow.

Owner:邵莲侠

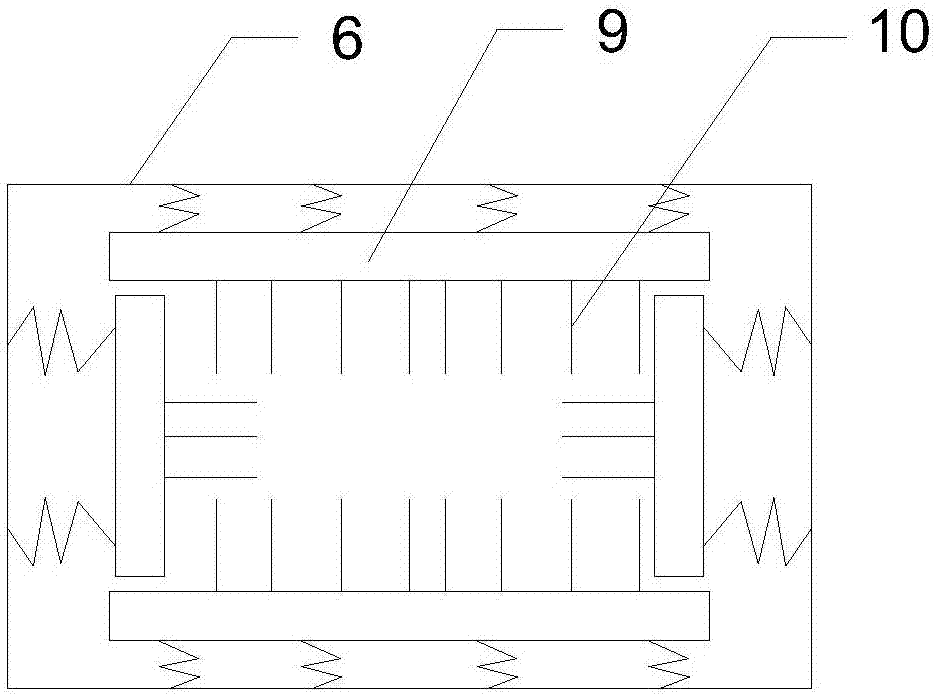

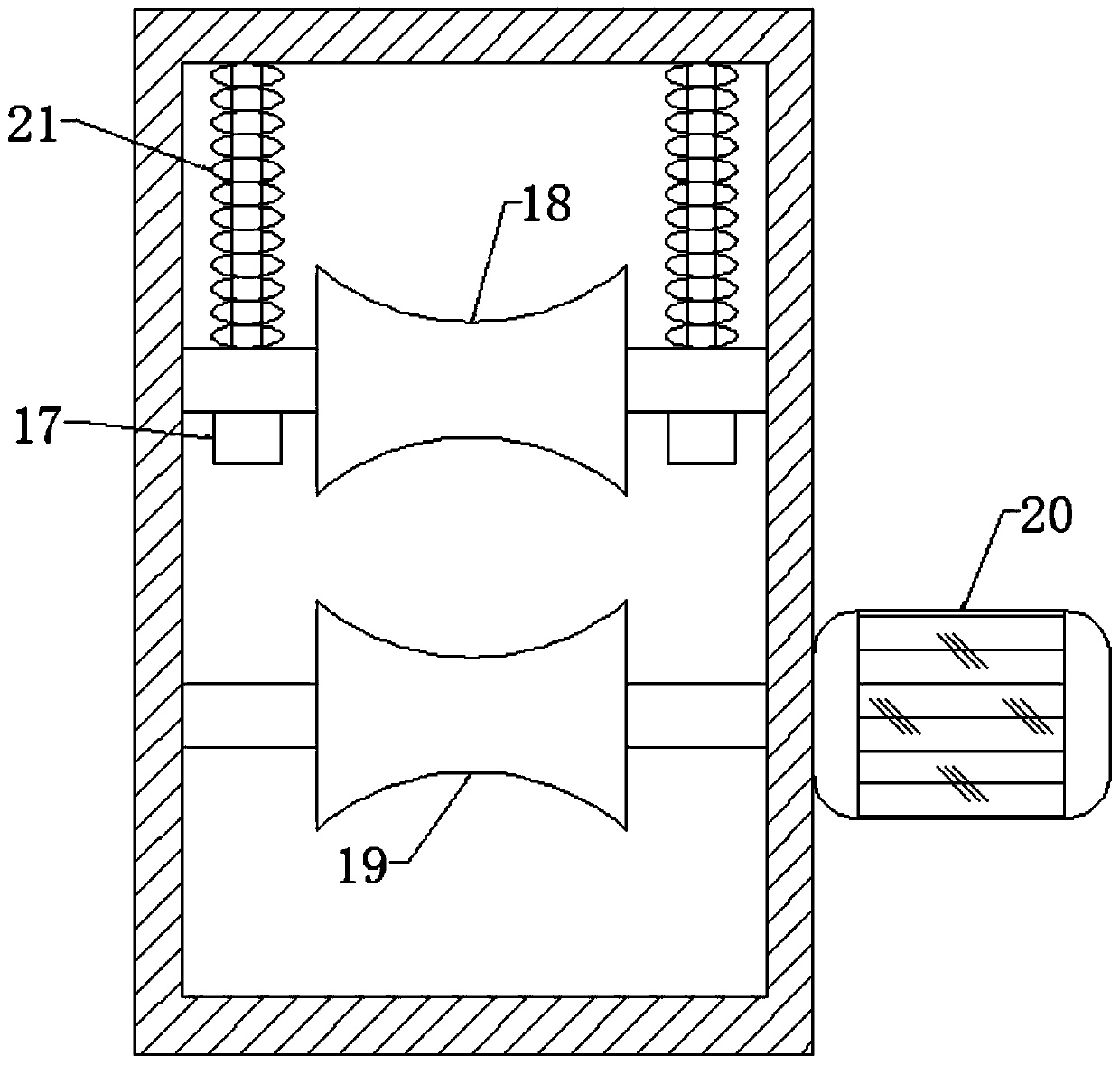

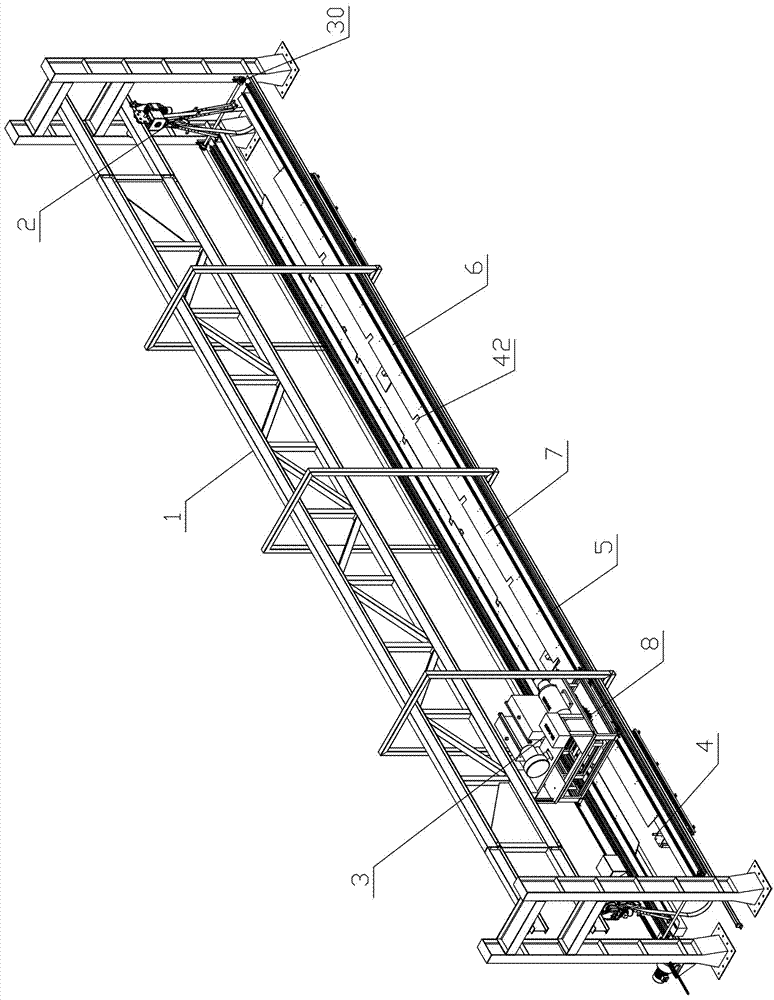

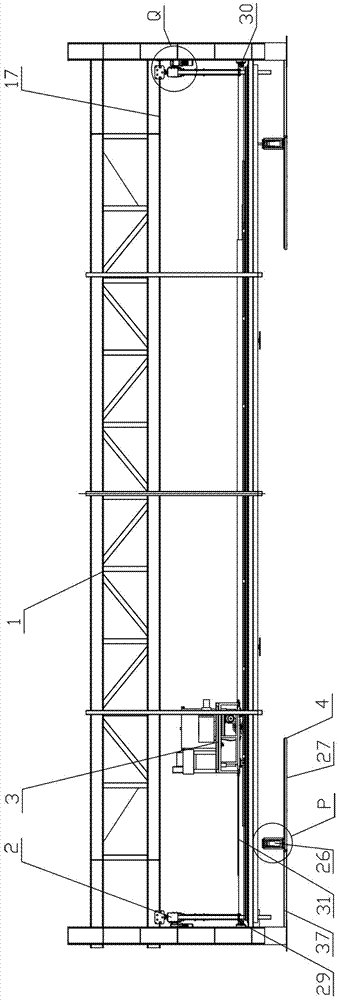

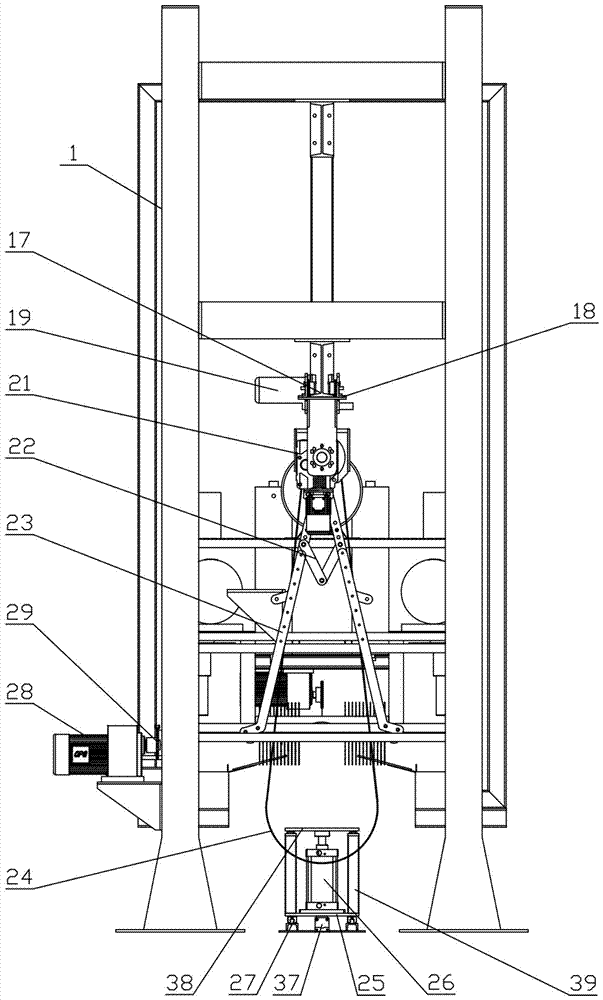

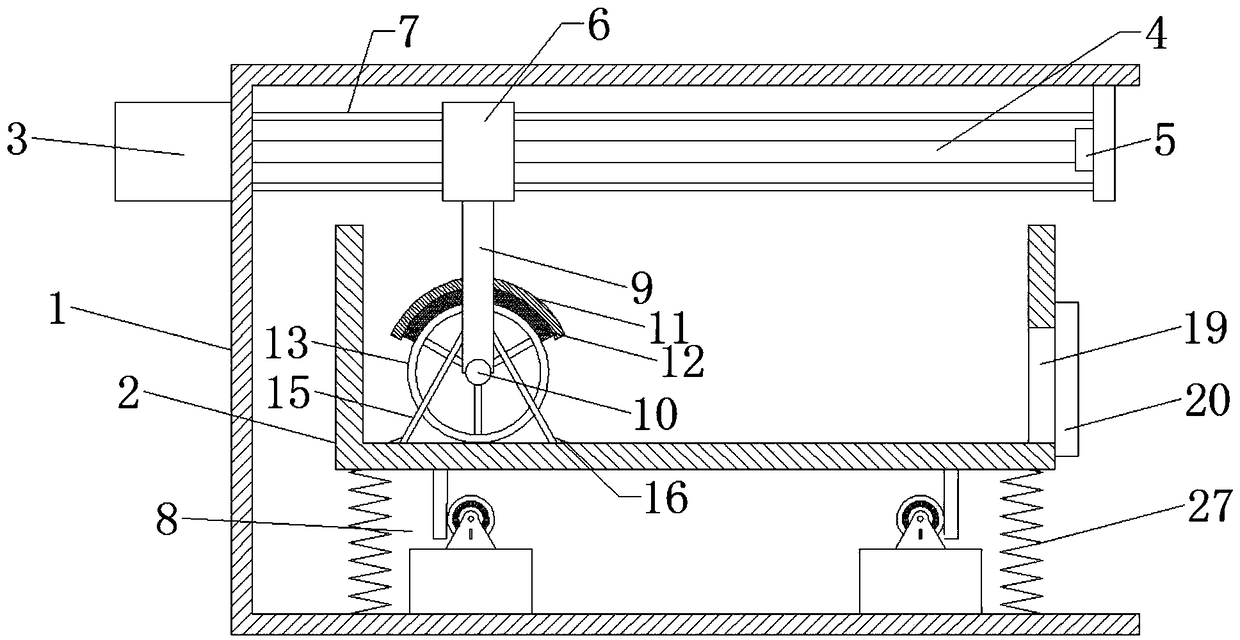

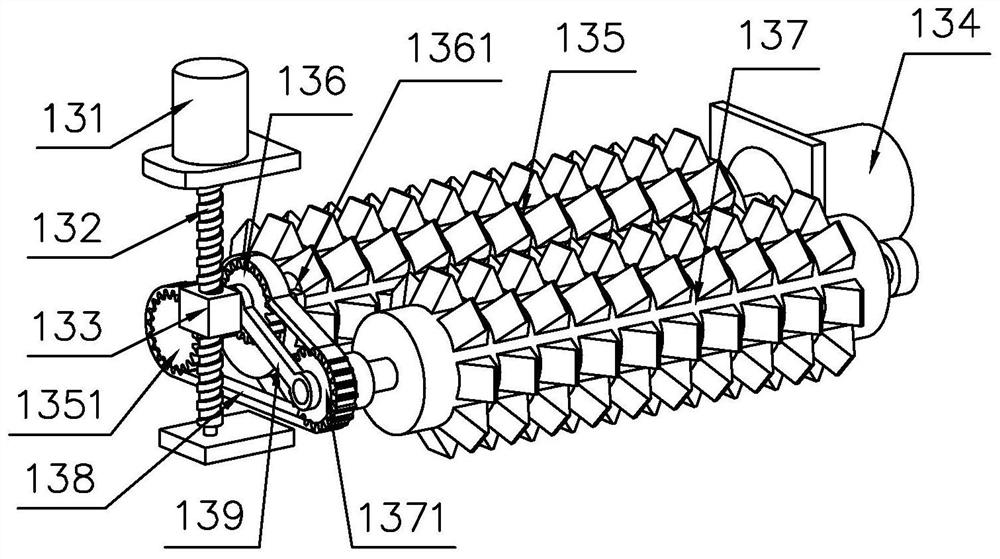

Mould cleaning device of pipe pile production line

PendingCN107971254AFall off quicklyFully cleanedCleaning using toolsCleaning using liquidsProduction lineSteel frame

The invention belongs to the technical field of cleaning devices, in particular to a mould cleaning device of a pipe pile production line. The mould cleaning device comprises a frame-shaped bracket, wherein a pipe mould turnover mechanism, a pipe mould cleaning mechanism and a pipe mould lifting mechanism are arranged on the frame-shaped bracket; the pipe mould cleaning mechanism comprises a sliderail, a water storage slot, a water-resisting rib plate, a movable bracket, a translation drive mechanism, a rolling brush, a tool, a high-pressure spray gun bracket, a high-pressure spray gun, a mould release agent storage box, a high-pressure water pump, a turbofan and a water pump electrical appliance box; the pipe mould turnover mechanism comprises a second slide rail, a travelling bracket, atravelling drive mechanism, a belt wheel drive motor, a belt wheel box, a belt wheel, a scissors type bracket, a supporting arm and a ring-shaped lifting belt; and the pipe mould lifting mechanism comprises a third slide rail, an air cylinder fixing frame, a lifting air cylinder, a tube mould support plate, a n-shaped bracket, a guide post slide sleeve, a guide post and a second air cylinder. According to the mould cleaning device disclosed by the invention, a steel frame structure is matched with the precise rail travelling tool, the rolling brush and the high-pressure spray gun, so that high-speed effective mould cleaning is realized.

Owner:ZHEJIANG JINGDIAN CNC EQUIP CO LTD

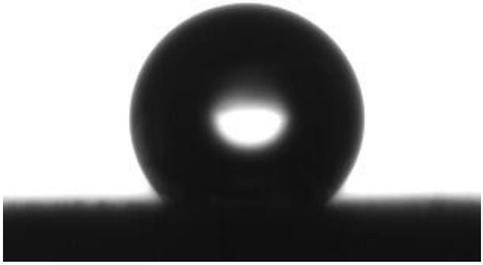

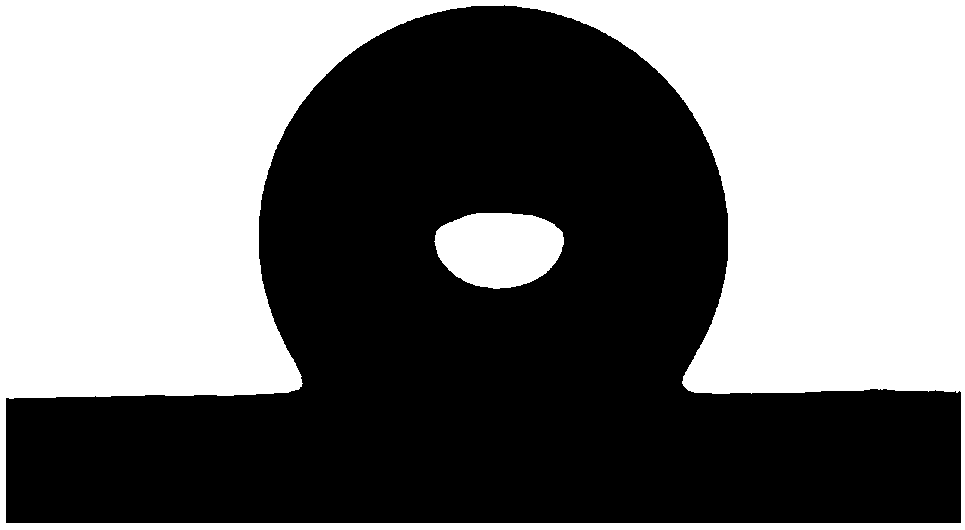

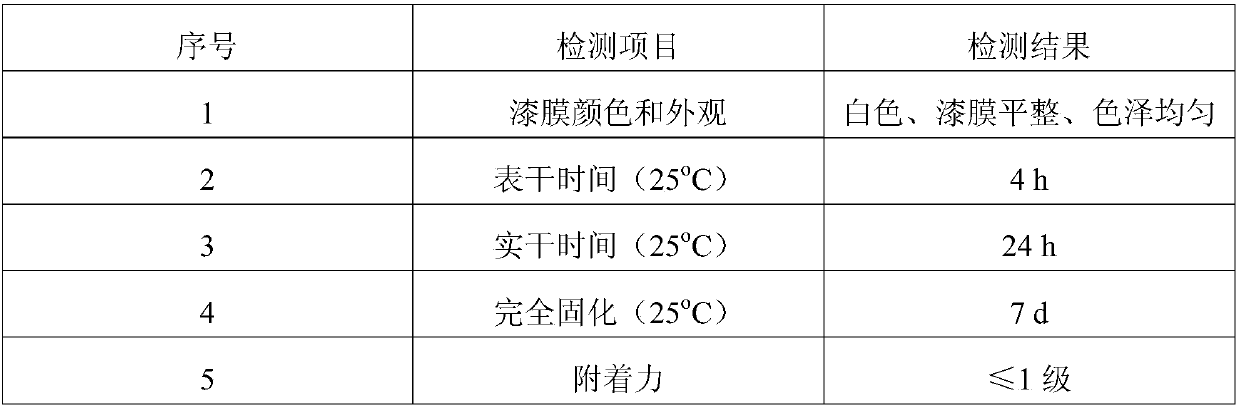

Antibacterial anti-mildew self-cleaning nanometer antifouling coating material, preparation method and applications thereof

ActiveCN109836982AImprove antibacterial propertiesEasy to cleanAntifouling/underwater paintsPaints with biocidesNanoceramicFirming agent

The invention discloses an antibacterial anti-mildew self-cleaning nanometer antifouling coating material, a preparation method and applications thereof, wherein the coating material comprises a component A and a component B, the component A contains an organofluorine resin, an organic-inorganic composite nanometer antibacterial agent, a nanometer ceramic particle, nanometer titanium dioxide, a pigment filler, an anti-precipitating agent, a dispersing agent, a leveling agent and a diluent, and the component B comprises a curing agent. According to the present invention, the coating material has advantages of excellent antibacterial and anti-mildew performance and excellent self-cleaning property; by combining the composite antibacterial agent comprising nanometer silver and a zwitterionicpolymer with nanometer titanium dioxide, the synergistic bactericidal effect can be achieved; by combining a low surface energy organofluorine resin and a nanometer material, the coating has advantages of super-strong hydrophobicity and super-strong oil stain resistance, can greatly reduce the contact area between water stains, dust and microbial bodies and the surface of the matrix, can easily achieve the rapid shedding of surface pollutants, and has excellent self-cleaning property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Rolling type grinding equipment for chemical raw material processing

The invention discloses rolling type grinding equipment for chemical raw material processing. The equipment comprises a shell, a grinding box, a motor, a lead screw, a bearing, a movable base, a guiderod and a supporting spring. The lead screw penetrates through the movable base in a threaded mode, a supporting rod is fixed to the lower end of the movable base, a horizontal supporting shaft is fixed to the lower end of the supporting rod, a rotary hollow squeezing roller is coaxially installed on the supporting shaft, the side wall of the hollow squeezing roller is provided with multiple holes, and a horizontal scraper blade is fixedly connected to the lower ends between supports on the front and rear sides. Raw materials in the grinding box are squeezed through the hollow squeezing roller connected to the movable base, the raw materials are smashed, the holes formed in the hollow squeezing roller enable excess raw materials to enter the hollow squeezing roller, the raw materials between the hollow squeezing roller and the shell are reduced, the load is reduced, the scraper blade can scrape away the raw materials at the bottom of the shell, internal raw materials can be stirred, and the raw materials are ground more evenly.

Owner:管洪化

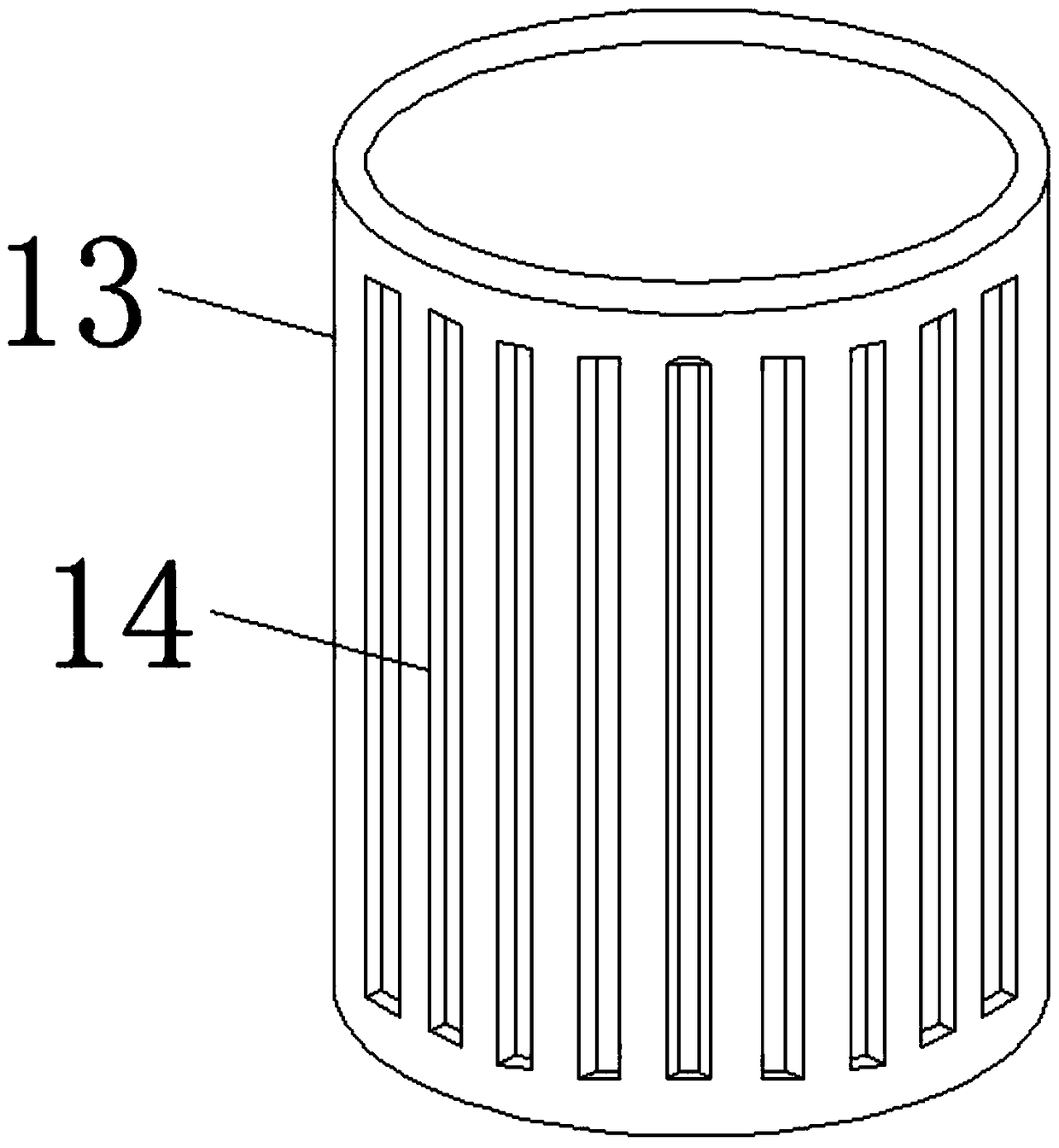

Mechanical part cleaning device

PendingCN113070272AConstantly changing impact forceThe impact force intensifiesCleaning using toolsCleaning using liquidsElectric machineryDrive motor

The invention provides a mechanical part cleaning device, and relates to the field of mechanical part cleaning. The mechanical part cleaning device comprises a cleaning box, a water inlet pipe, a mounting frame, a driving motor and a cover plate, the mounting frame is arranged on the outer wall of one side of the cleaning box, the cover plate is hinged to the outer wall of one side of the cleaning box, the driving motor is arranged on the outer wall of the bottom end of the cleaning box, the output of the driving motor is connected with a rotating shaft through a coupler, a protection plate is arranged on the outer wall of the rotating shaft, a supporting plate is arranged on the outer wall of the top end of the protection plate, a rotating mechanism is arranged outside one end of the rotating shaft, a cleaning cylinder is arranged on the outer wall of one side of the supporting plate, and a polygonal plate is arranged on the inner wall of the cleaning box. According to the mechanical part cleaning device, the impact force of water flow on parts is intensified, so that the cleaning effect is enhanced, impurities on the parts can rapidly fall off, mutual collision between the parts in the cleaning process can be reduced, and the parts are protected in the cleaning process.

Owner:白林

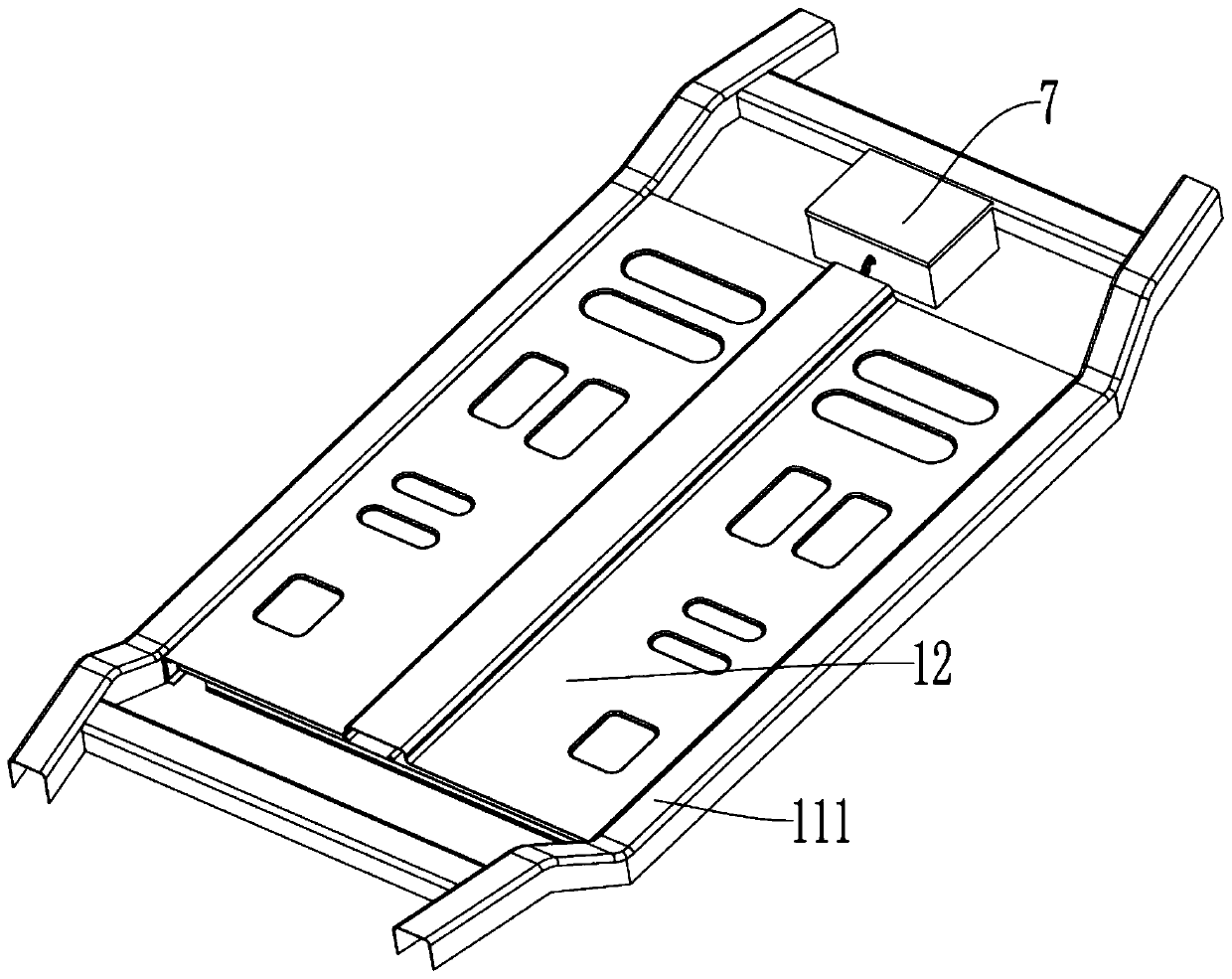

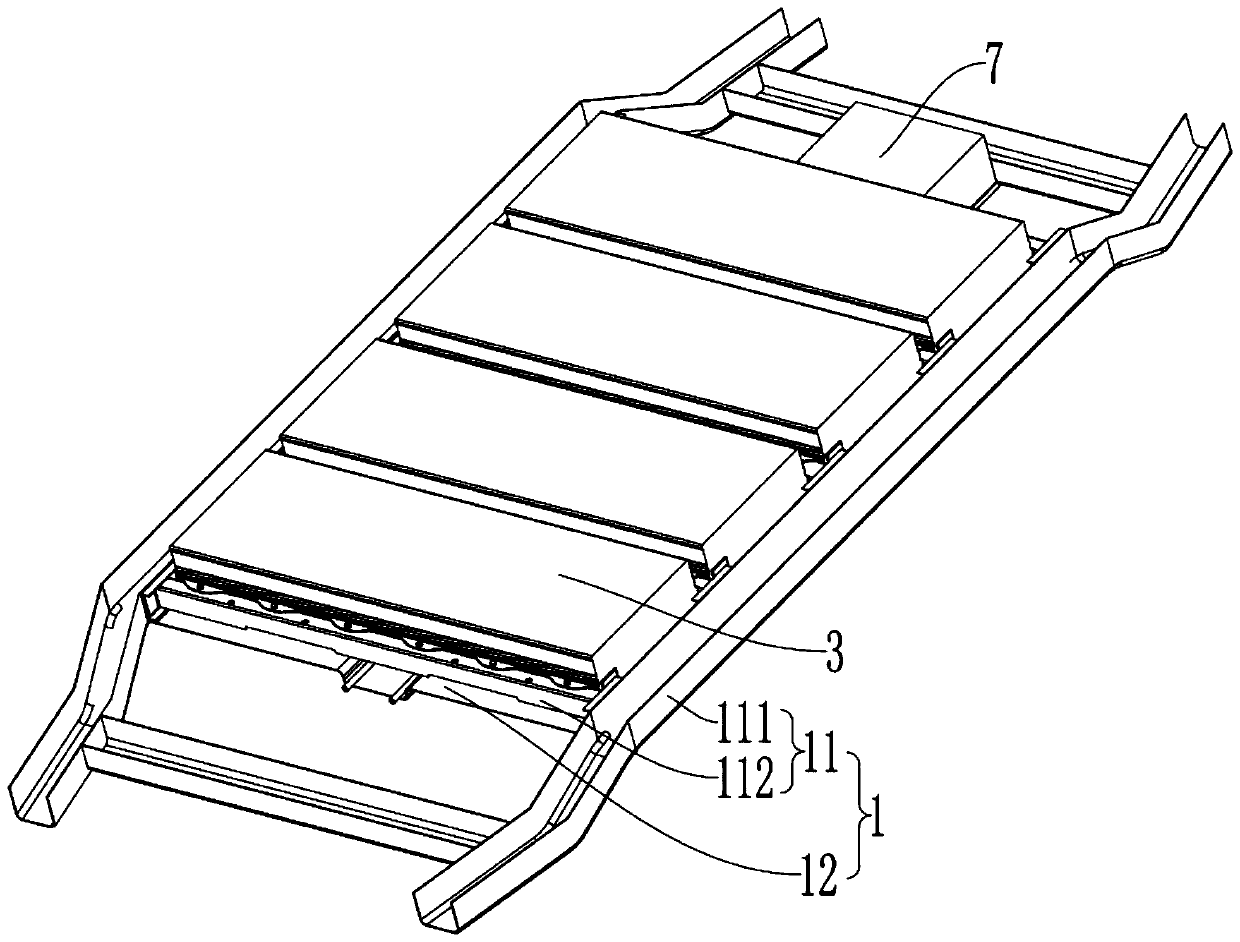

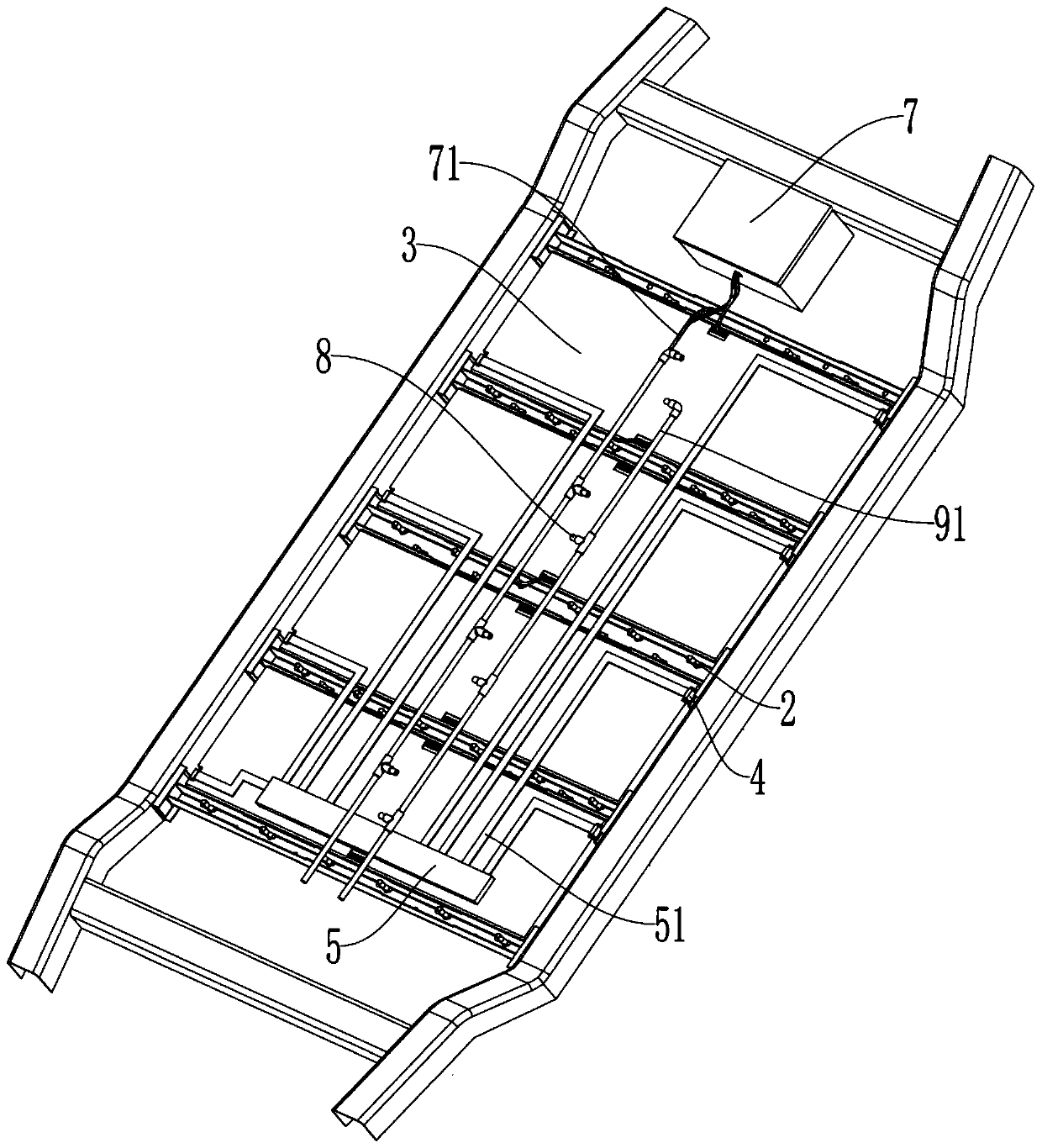

Chassis assembly and vehicle

PendingCN111516476AAvoid vehicle damageAvoid damageElectric devicesElectric propulsion mountingAutomotive engineeringElectrical battery

The invention relates to the technical field of battery modules of vehicles, and discloses a chassis assembly and a vehicle. The chassis assembly comprises a chassis, a quick release device and a voltage electric connection assembly; the chassis is provided with a plurality of installation positions used for installing a battery module; the battery module is mounted on the installation positions through the quick release device; the quick release device is controlled by the control system; and the voltage electric connection assembly is electrically connected with the battery module in a quick-plug manner and is controlled by the control system. When a single module is rapidly disassembled, assembled and maintained, or a vehicle is in a collision process, the battery module may be damagedor even on fire. With the chassis assembly adopted, the above problem can be solved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

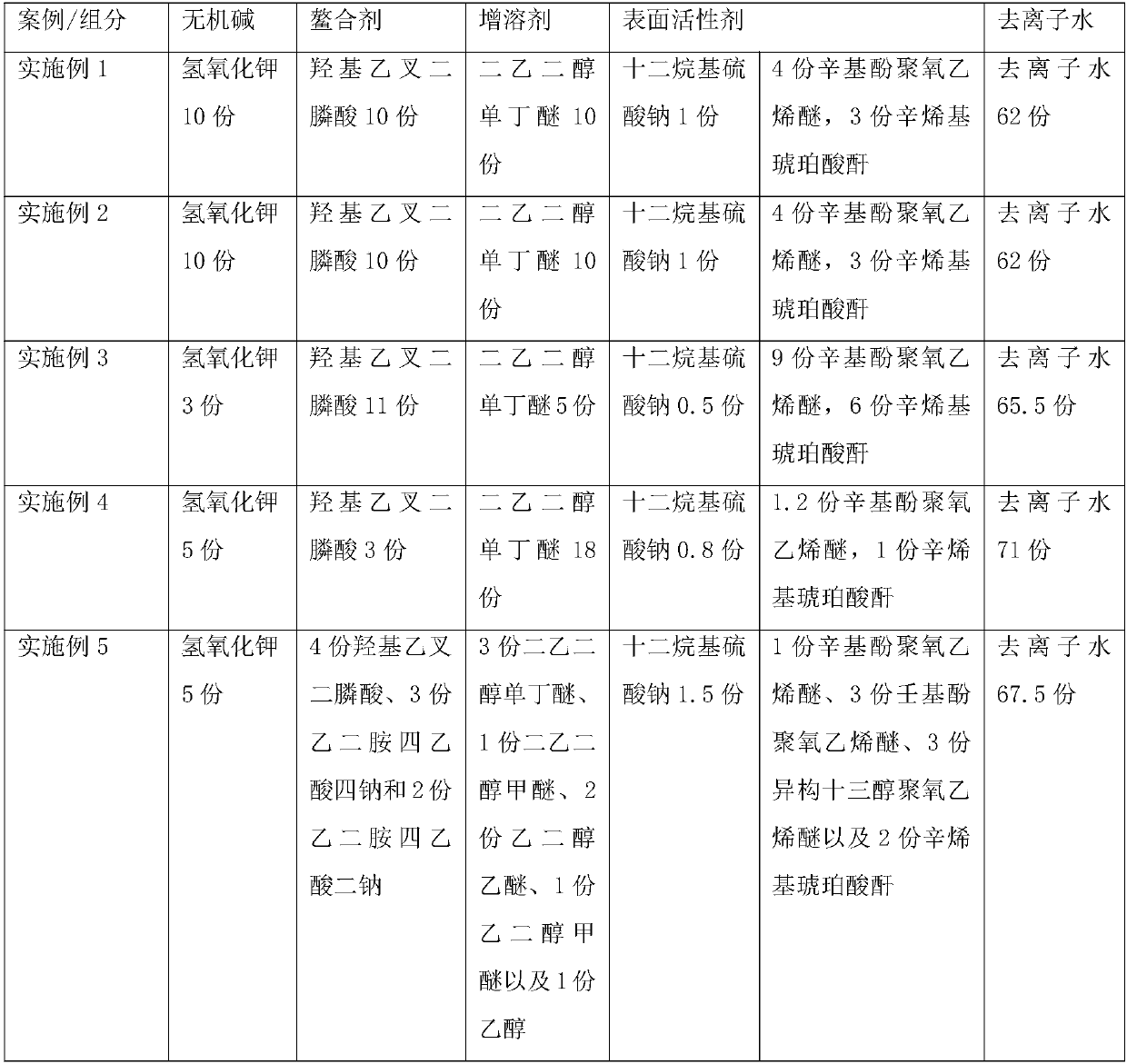

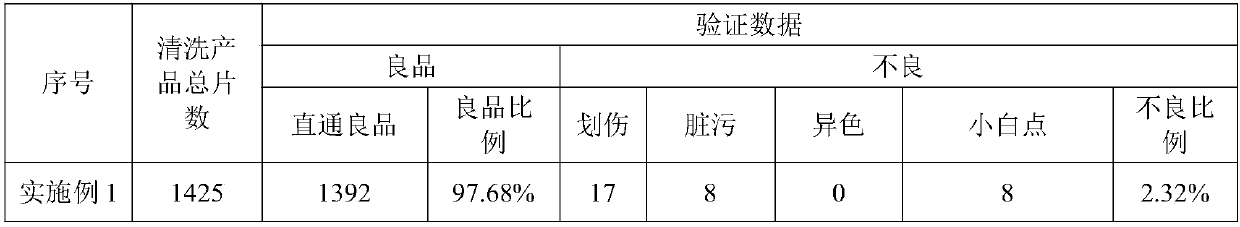

Ceramic cleaning agent and preparation method thereof

ActiveCN109694782ASimple recipeLow costInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityCerium

The invention provides a ceramic cleaning agent, which comprises: 3-10 parts of an inorganic alkali, 3-14 parts of a chelating agent, 5-18 parts of a solubilizing agent, 3.5-17 parts of a surfactant,and the balance of deionized water. According to the preset invention, the ceramic cleaning agent has advantages of simple formulas, easily-available raw materials, moderate cost and reasonable ratioof the raw materials, further has characteristics of weak alkalinity, strong wettability, do corrosion to ceramic substrates, unique penetrating power and the like, can effectively remove the residueof cerium dioxide, silicon dioxide and aluminum oxide auxiliary material particles used in rough polishing and fine polishing, and can achieve the product qualification rate of up to 96%. The invention further provides a preparation method of the ceramic cleaning agent, wherein the preparation process is simple, and the method is suitable for industrial production.

Owner:LENS TECH CHANGSHA

Weld joint grinding device for automobile welding part production and using method thereof

InactiveCN112139928AAchieve tensionStable jobGrinding carriagesGrinding drivesDrive shaftElectric machinery

Owner:HEFEI CHANGQING MACHINERY

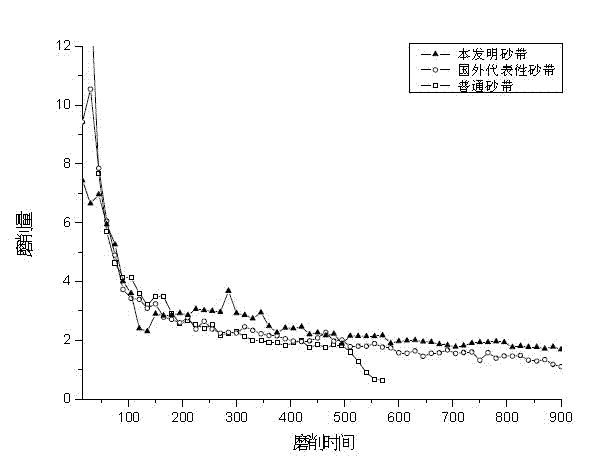

Sintering method of abrasion resisting abrasive particles

The invention relates to a sintering method of abrasion resisting abrasive particles, and belongs to the technical field of preparation of coated abrasive tools. The method comprises the following steps of: mixing 5-15 parts of mineral polymeric material bonder, 1-10 parts of alkali compound, 10-30 parts of stuffing and 60-100 parts of abrasive material; dissolving the components in glycol ether; adding 2-5 parts of catalyst; heating and mixing at a constant temperature within 30-50 DEG C; mixing to a semi-gel state, adding 0.5-1 parts of template to sinter, wherein the sintering temperature is 300-400 DEG C and the sintering time is 6-9 hours, quickly annealing and cooling, smashing, sieving and separating abrasive particles in same size. The abrasive particles prepared by the method provided by the invention are abrasion resistive and anti-blocking, and workpieces are not burned in long time grinding.

Owner:ZIBO RIKEN MT COATED ABRASIVES

Concrete crushing and recycling device

The invention discloses a concrete crushing and recycling device. The concrete crushing and recycling device comprises a crushing mechanism, a dust channel and a mud generating mechanism, wherein thedust channel is formed in one side of the crushing mechanism; and the mud generating mechanism is arranged on one side of the dust channel. According to the concrete crushing and recycling device, a crushing roller adjusting mechanism is additionally arranged, and the distance between crushing rollers can be adjusted in real time according to concrete of different sizes, so that the crushing effect is better, jamming is prevented, and the crushing efficiency is improved; and dust generated in the crushing process is collected and made to form mud under the action of an atomization spraying mechanism, and the mud is discharged under the combined action of a mud settling mechanism and a discharge box, so that the dust is effectively controlled, and the environmental pollution is prevented; and meanwhile, the dust can be reprocessed and reutilized, so that raw materials are saved, and waste is prevented.

Owner:铜仁兴通电杆有限公司

Anti-wrinkle non-woven fabric winding device and using method thereof

PendingCN113307076ASolve the problem of wrinkles in windingWithout compromising integrityCleaning using toolsElectrostatic chargesEngineeringNonwoven fabric

The invention discloses an anti-wrinkle non-woven fabric winding device and a using method thereof, and relates to the field of non-woven fabrics. The anti-wrinkle non-woven fabric winding device comprises a workbench, wherein a conveying roller is rotatably mounted in the workbench, a supporting frame is slidably mounted in the workbench, a pressing roller is rotatably mounted at the bottom of the supporting frame, and a processing box with an opening inside is fixedly mounted in the middle of the upper portion of the workbench; two symmetrical and inclined scraping plates are rotatably mounted inside the processing box; and a plurality of transmission rollers are rotatably mounted inside the processing box. According to the anti-wrinkle non-woven fabric winding device and the using method thereof, the two scraping plates are symmetrically arranged, so that fluff on the surface of a non-woven fabric is scraped away at a time; and then the fluff on the surface of the non-woven fabric is thermalized and ironed in a heating plate ironing mode, so that the the problem that in the prior art, gaps exist in the rolled non-woven fabric due to the fluff in the rolling process, and wrinkles are generated in the rolling process as certain fluff still exists on the surface of the non-woven fabric in the rolling process is solved.

Owner:安徽苏博伦服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com