Perforated film capable of being biodegraded completely and preparation process, application and preparation device thereof

A technology for preparing devices and biodegradable resins, applied in applications, other household appliances, household appliances, etc., can solve the problems of poor toughness and tensile properties, poor hole shape and three-dimensionality, and easy reverse osmosis, etc., to achieve good Good toughness and tensile properties, improved quality, and good three-dimensionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

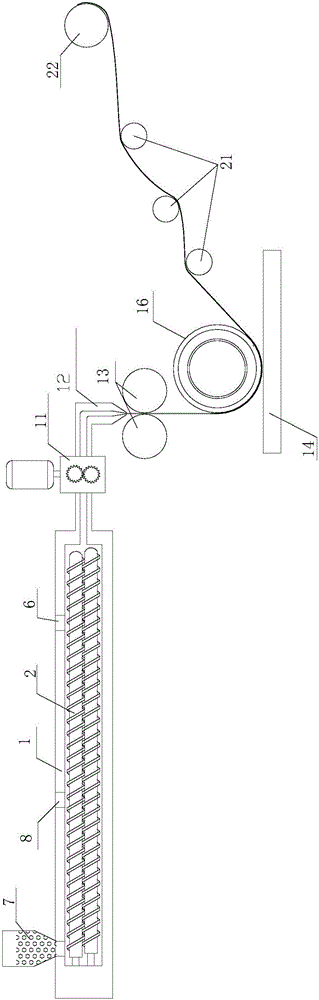

[0030] A preparation process of fully biodegradable perforated film, which comprises the following process steps:

[0031] 1) Material configuration: In terms of weight ratio, 100 parts of tapioca modified starch, 100 parts of polybutylene terephthalate-adipate, 30 parts of polybutylene succinate, 20 parts of polylactic acid, zirconium phosphate Add 2 parts of silver-loaded antibacterial powder, 16 parts of glycerin, 3 parts of ethylene ethyl acrylate, and 4 parts of glyceryl monostearate into a low-speed mixer and mix until uniform. The mixing temperature is 110°C, and the mixing time is 35 minutes. The mixing speed of the mixer is 800 rpm;

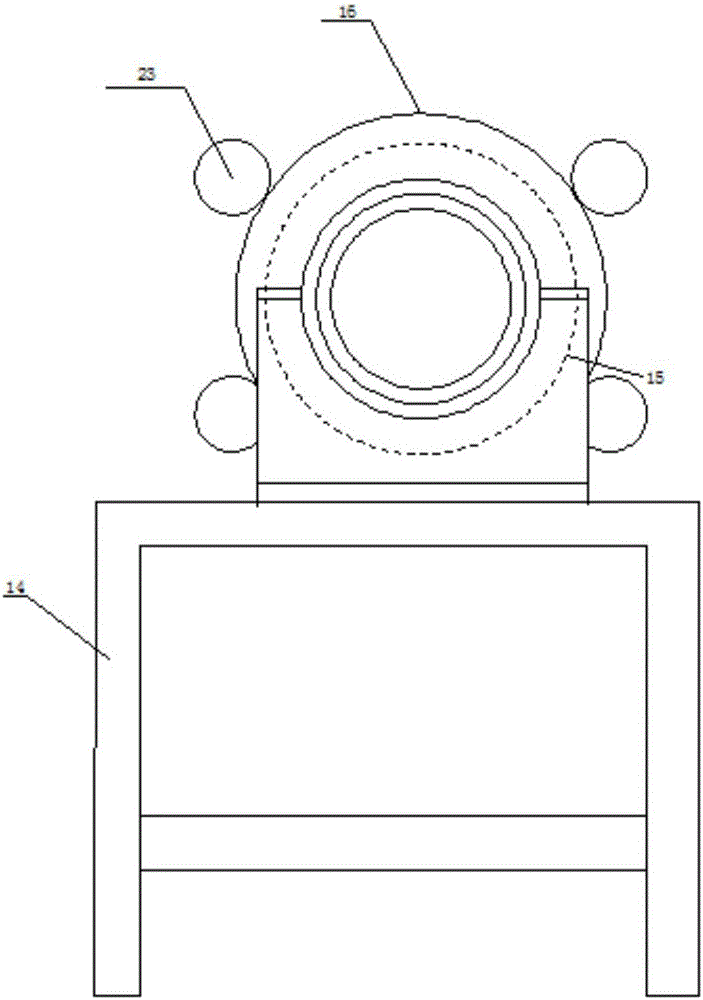

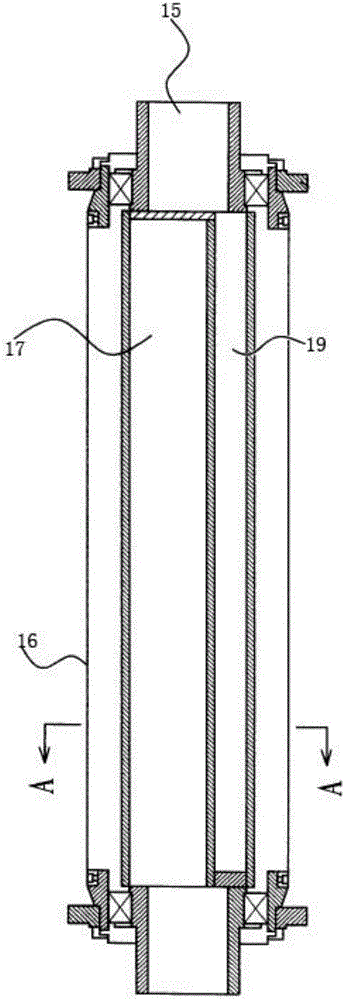

[0032] 2) Compression molding: put the mixed material into the hopper of the screw extruder, shear, knead, plasticize and melt the material through the twin screws of the screw extruder, and generate a crosslinking reaction in the barrel to make The plant modified starch and the biodegradable resin undergo a graft reaction, and at the s...

Embodiment 2

[0036] A preparation process of fully biodegradable perforated film, which comprises the following process steps:

[0037] 1) Material configuration: in terms of weight ratio, 100 parts of modified potato starch, 120 parts of polybutylene succinate-co-butylene terephthalate, 20 parts of polylactic acid, and 2.5 parts of silver-loaded zirconium phosphate antibacterial powder Parts, 12 parts of xylitol, 6 parts of ethylene acrylic acid copolymer, and 8 parts of glyceryl laurate were added to a low-speed mixer and mixed until uniform. The mixing temperature was 115 ° C, the mixing time was 33 minutes, and the stirring speed 900 rpm;

[0038] 2) Compression molding: put the mixed material into the hopper of the screw extruder, shear, knead, plasticize and melt the material through the twin screws of the screw extruder, and generate a crosslinking reaction in the barrel to make The plant modified starch and the biodegradable resin undergo a grafting reaction, and at the same time,...

Embodiment 3

[0042] A preparation process of fully biodegradable perforated film, which comprises the following process steps:

[0043] 1) Material configuration: In terms of weight ratio, 100 parts of sweet potato modified starch, 60 parts of polybutylene succinate, 60 parts of polycaprolactone, 10 parts of polylactic acid, 3 parts of silver-loaded zirconium phosphate antibacterial powder, and Add 18 parts of alcohol, 10 parts of ethylene-vinyl acetate, and 8 parts of monoglyceride succinate into a low-speed mixer and mix until uniform. The mixing temperature is 120°C, the mixing time is 30 minutes, and the stirring speed of the low-speed mixer is 1200 rev / min;

[0044] 2) Compression molding: put the mixed material into the hopper of the screw extruder, shear, knead, plasticize and melt the material through the twin screws of the screw extruder, and generate a crosslinking reaction in the barrel to make The plant modified starch and the biodegradable resin undergo a grafting reaction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com