Method for preparing organic or inorganic composite fiber material with supercritical carbonic anhydride

A carbon dioxide and inorganic composite technology, which is applied in the production of bulk chemicals, etc., can solve the problems of the expensive precursor isopropyl titanate, unsuitable control of the ratio and rate, and achieve simple and easy-to-operate preparation methods, improved reactivity, The effect of high doping content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Put 4 grams of cotton linters in a fat extractor, extract with 50 milliliters of acetone for 4 hours to remove wax and grease components in the linters, and then put them into a vacuum oven to dry for later use.

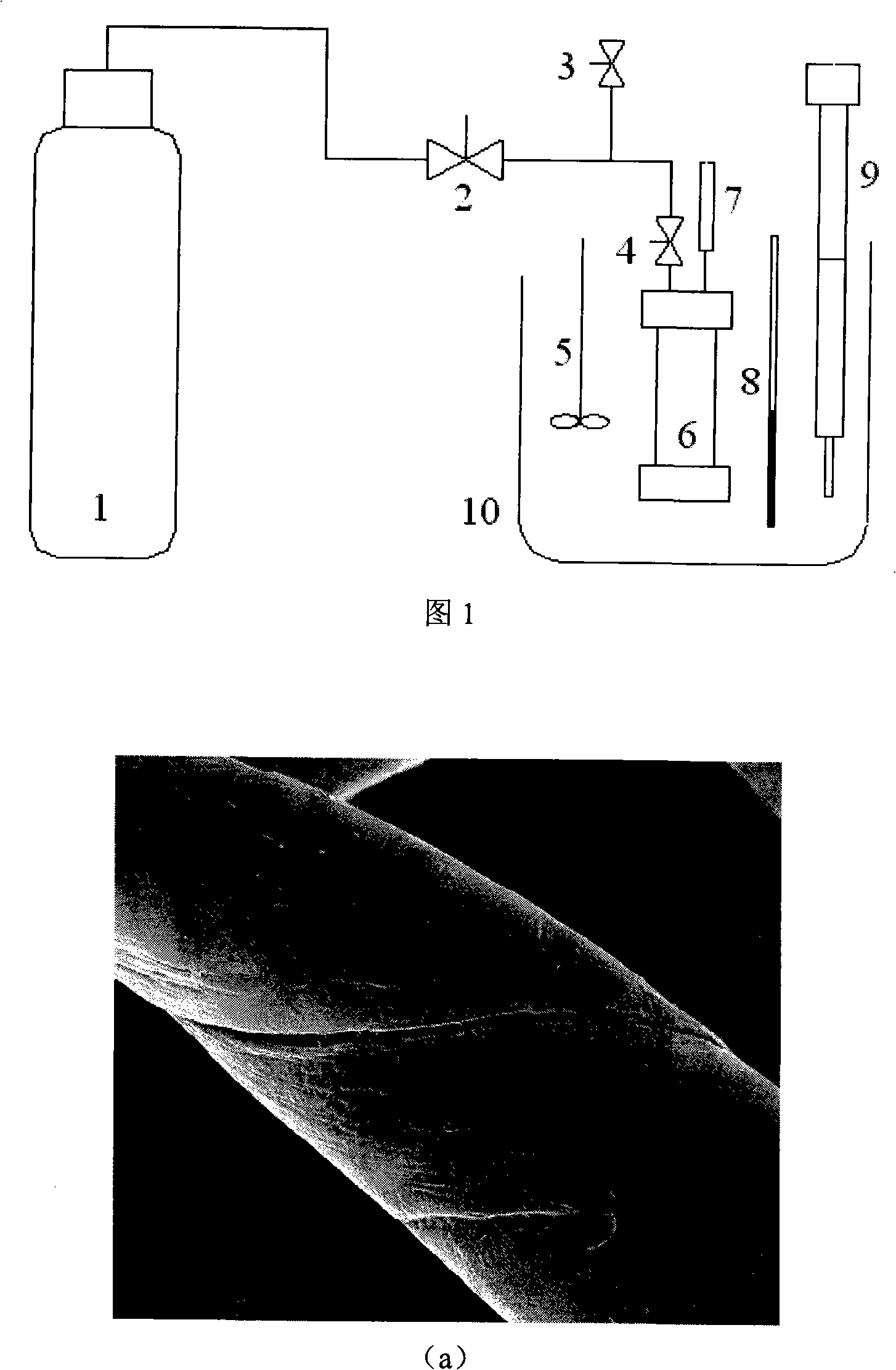

[0039] Use the device shown in Figure 1. 0.3 grams of cotton linters and 3 milliliters of ethanol after the above-mentioned extraction treatment were added in a stainless steel autoclave, and the temperature of the oil bath in the thermostatic tank was controlled to be 40 ° C, and a small amount of carbon dioxide was introduced to exhaust the air in the reaction device. Carbon dioxide is injected through a high-pressure pump, and the pressure inside the control device is 15 MPa. Close the inlet valve, and place the reactor at a constant temperature in an oil bath for 2 hours. Then remove the constant temperature tank, and discharge the carbon dioxide in the reaction kettle within 5 minutes after the temperature drops to room temperature. After the pressure is...

Embodiment 2

[0041] Use the device shown in Figure 1. Add 1 gram of ash-free filter paper and 10 milliliters of ethanol into a stainless steel high-pressure reaction kettle, control the temperature of the oil bath in the constant temperature tank to 50°C, and feed a small amount of carbon dioxide to exhaust the air in the reaction device, then inject carbon dioxide through a high-pressure pump to control The pressure inside the device was 20 MPa. Close the inlet valve, and place the reactor at a constant temperature in an oil bath for 5 hours. Then remove the constant temperature tank, discharge the carbon dioxide in the reaction kettle within 3 minutes after the temperature drops to room temperature, take out the sample after the pressure is released to normal pressure, and obtain supercritical carbon dioxide and ethanol-treated ash-free filter paper for activation after vacuum drying Fiber samples.

Embodiment 3

[0043] Put 10 grams of cotton in a fat extractor, extract with 100 milliliters of toluene for 8 hours, remove the impurity components in the cotton, and then put it in a vacuum oven to dry for use.

[0044] Use the device shown in Figure 1. Add 3 grams of cotton after the above-mentioned extraction treatment, 10 milliliters of titanium dioxide sol and 3 milliliters of ethanol into a stainless steel autoclave, control the temperature of the oil bath in the constant temperature tank to be 60 ° C, and feed a small amount of carbon dioxide to exhaust the air in the reaction device. After cleaning, carbon dioxide is injected through a high-pressure pump, and the pressure in the control device is 18 MPa. Close the inlet valve, and place the reactor at a constant temperature in an oil bath for 4 hours. Then remove the constant temperature tank, and discharge the carbon dioxide in the reaction kettle within 5 minutes after the temperature drops to room temperature. After the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com