Patents

Literature

57results about How to "Toughened" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

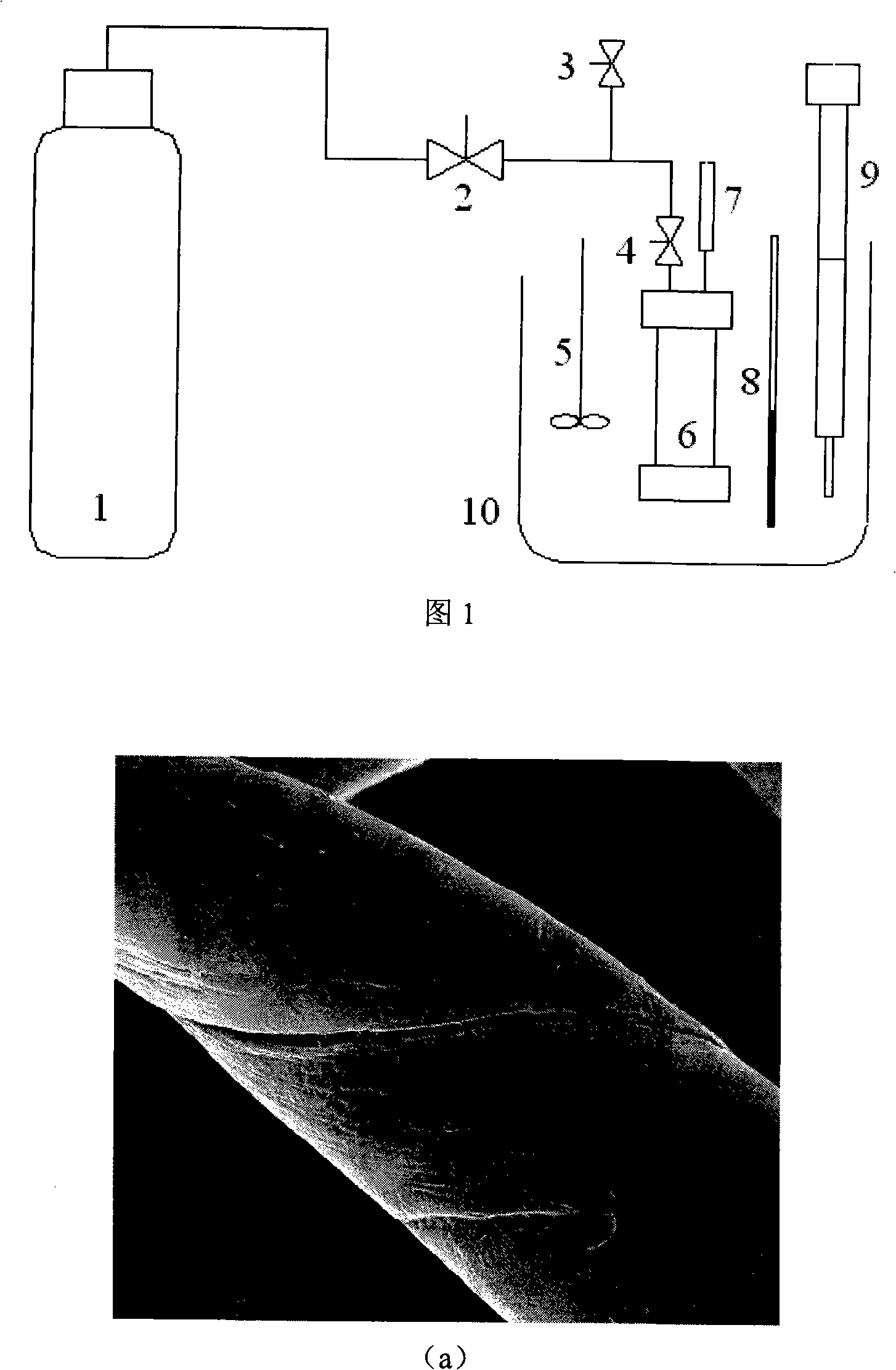

Method for preparing organic or inorganic composite fiber material with supercritical carbonic anhydride

The invention belongs to the technical field of organic and inorganic composite materials, in particular to a preparation method of organic and inorganic composite fibrous materials with supercritical carbon dioxide. The method includes pre-treatment and activation treatment of cellulose, doping of inorganic sol to the cellulose, etc. The invention makes use of the strong permeability of the carbon dioxide under supercritical conditions, can activate the cellulose with cosolvent, or lead nano particles in the inorganic sol to be absorbed and settled on the surface of the cellulose to form an even, continuous and stable coating layer; meanwhile, some sol particles penetrate into the fiber, so as to dope plenty of cellulose. The supercritical carbon dioxide adopted by the invention is safe, reliable, non-toxic, no pollutant and recyclable, and is environment friendly green solvent. The method of the invention is simple and easy to be operated, and the hybrid material has broad application prospect.

Owner:FUDAN UNIV

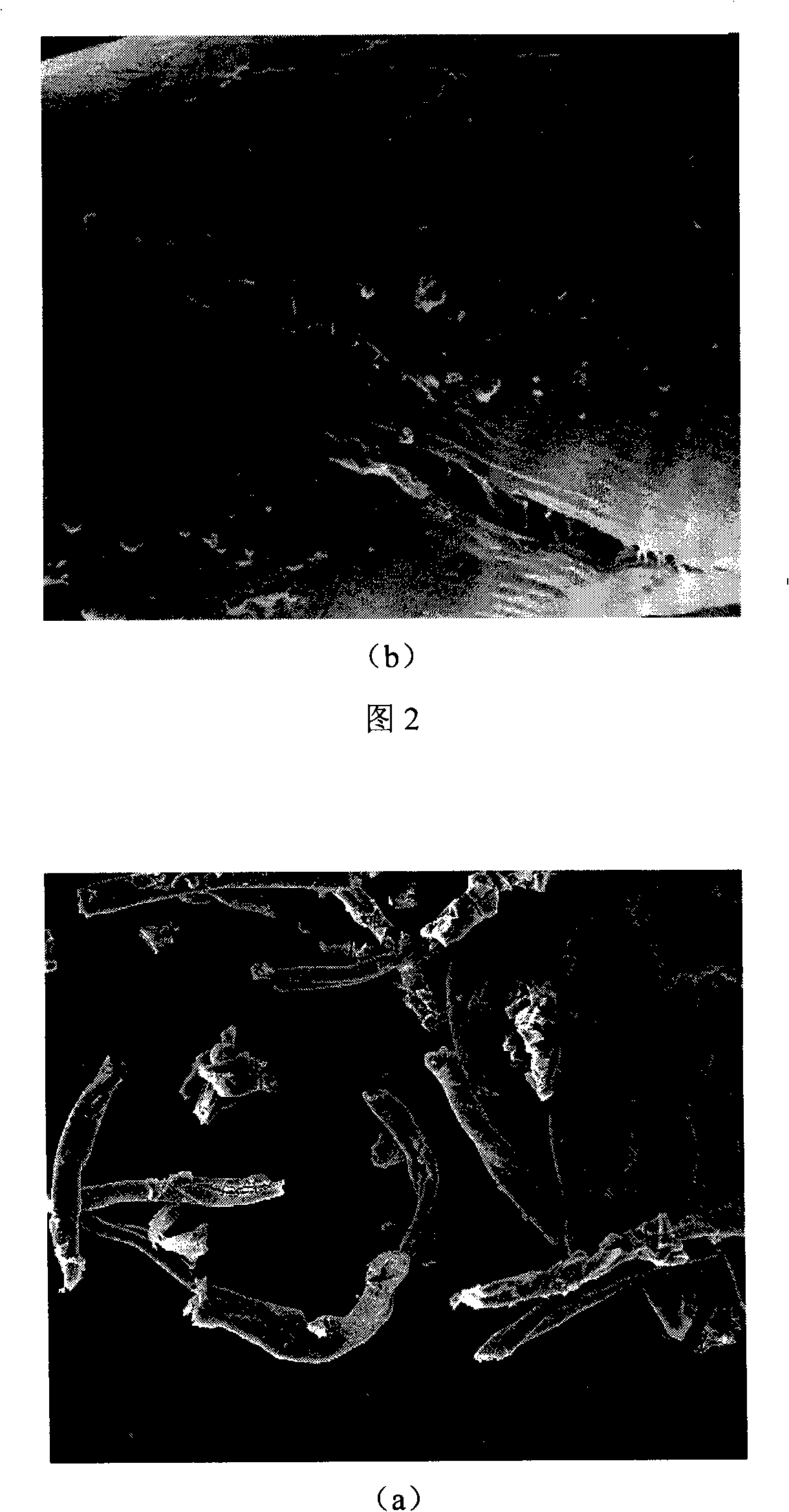

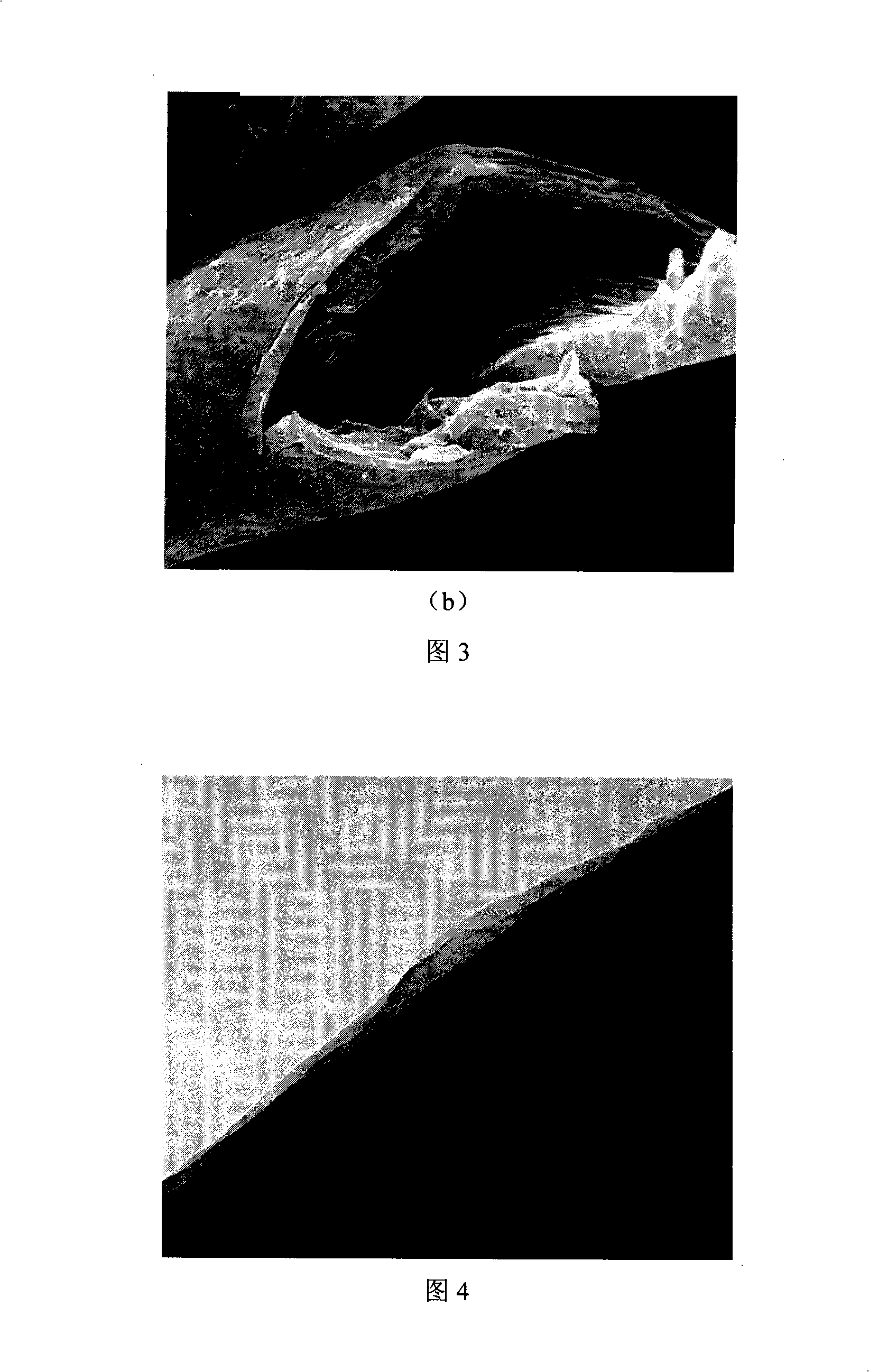

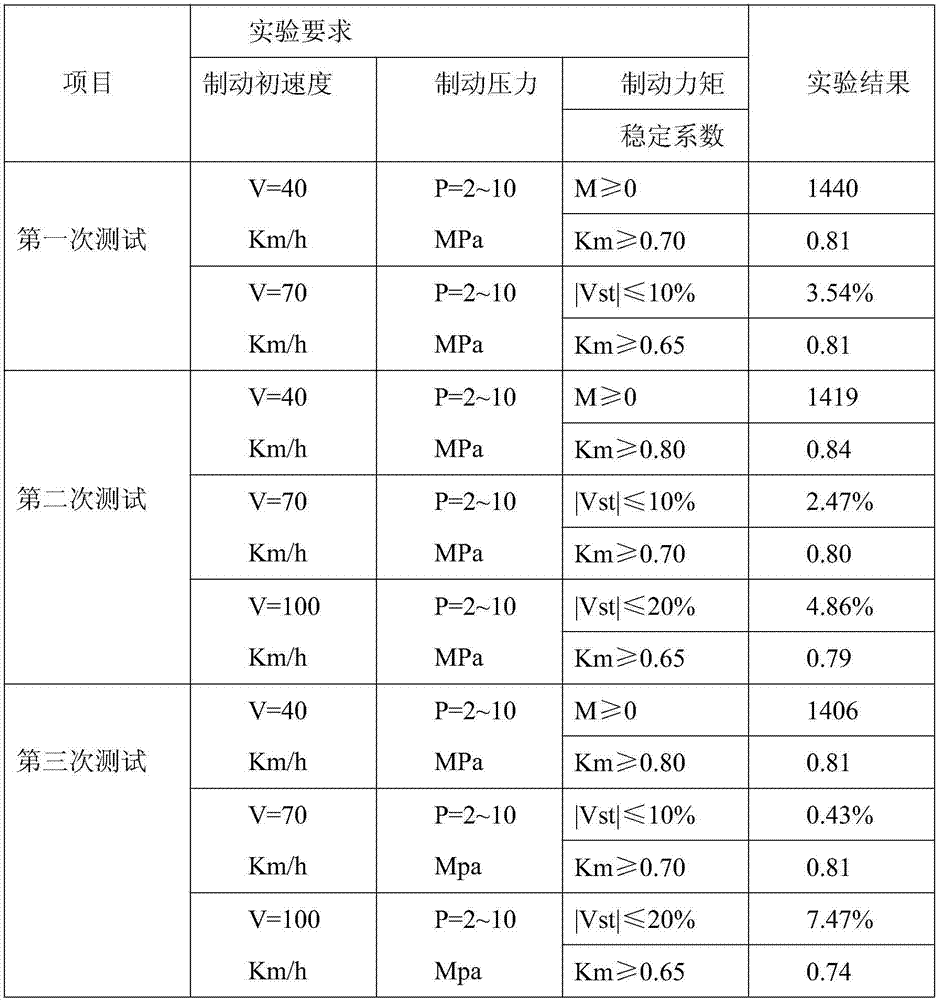

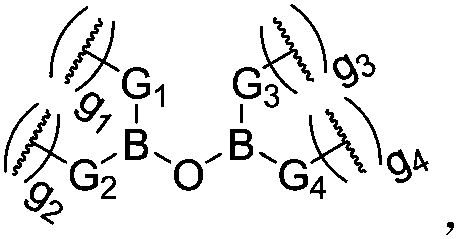

Method of preparing automobile brake pad by adopting basalt fiber

ActiveCN106949179AStable performanceExtended service lifeOther chemical processesFriction liningWollastoniteBasalt fiber

The invention relates to a method of preparing an automobile brake pad by adopting basalt fiber. The method comprises the following steps: butadiene nitrile rubber modified phenolic resin, surface modified basalt superfine fiber, acicular wollastonite fiber and carbon fiber are added to a material mixing machine and are mixed; then crystalline flake graphite, artificial graphite particles, chromite powder, feldspar powder, dolomite powder, fluorite powder, calcium carbonate powder, mica, nano ZnO, butadiene nitrile rubber and wollastonite are sequentially added to the material mixing machine and mix is carried out; a mixture is placed in a brake pad mould, and hot pressing and demoulding are carried out; a hot pressed material after the demoulding is subjected to grading heat treatment; and a discharged brake pad is subjected to follow-up treatment and packing. The automobile brake pad prepared by the method has a stable friction coefficient and a low wear rate, and further has high heat resistance and heat-aging resistance.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

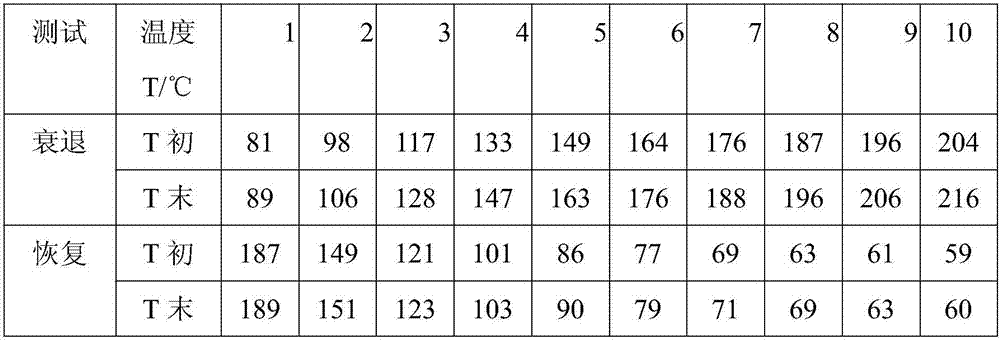

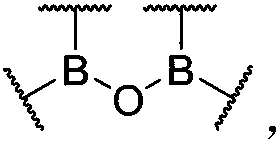

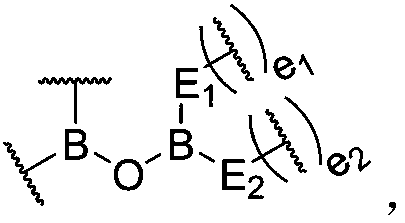

Dynamic polymer and application thereof

The invention discloses a dynamic polymer. The structure of the dynamic polymer contains dynamic covalent bonds and optional hydrogen bonds, wherein the dynamic covalent bonds are boron-oxygen-boron bonds which are composed of organic boron-oxygen-boron bonds, organic-inorganic boron-oxygen-boron bonds and inorganic boron-oxygen-boron bonds, or composed of organic boron-oxygen-boron bonds and organic-inorganic boron-oxygen-boron bonds, or composed of inorganic boron-oxygen-boron bonds and organic-inorganic boron-oxygen-boron bonds, or composed of organic-inorganic boron-oxygen-boron bonds; andall the inorganic boron-oxygen-boron bonds in the structure of the dynamic polymer are connected to the polymer via the organic-inorganic boron-oxygen-boron bonds and / or inorganic boron-oxygen-boronbonds. A plurality of the boron-oxygen-boron bonds and the optional hydrogen bonds in the structure of the dynamic polymer endow the dynamic polymer with good and hierarchical dynamic nature and allowthe dynamic polymer to have good toughness, buffering performance and self-repairing performance; and the dynamic polymer can be applied to fields like damping and buffering products, protection materials, sport protection materials, self-repairing materials, tough materials, stress-sensing materials, adhesives and sealing members.

Owner:厦门天策材料科技有限公司

Epoxy grout and preparation method thereof

ActiveCN105176465AImprove adhesionImprove performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesPolyamideSlurry

The invention discloses epoxy grout, comprising a component A and a component B by weight; the resin component A comprises bisphenol F epoxy resin, epoxy resin octyl group glycidyl ether, bisphenol A type 128 epoxy resin, a reactive diluent AGE, an organic silica coupling reagent, fumed silica, cement C35 type, silica powder, titanium dioxide, talcum powder and epoxy black slurry; the curing agent component B comprises the following components in ratio by weight: a polyamide curing agent, a cashew nut shell oil-modified curing agent, DMP-30 (Tris(dimethylaminomethyl)phenol), organobentonite, silica micropowder and superfine mica powder; a ratio of the resin component A to the curing agent component B is 3-6:1. The invention also discloses a preparation method of the epoxy grout. The compressive resistance and bonding strength of the expoxy grout after long-term curing are higher, and the water resistance is higher than that of expoxy grout on the market, and the expoxy grout is wide in ratio, has no solvent and non-transferability plasticizer and solvent and is excellent in comprehensive performance.

Owner:HUNAN QUANCHEN TECH

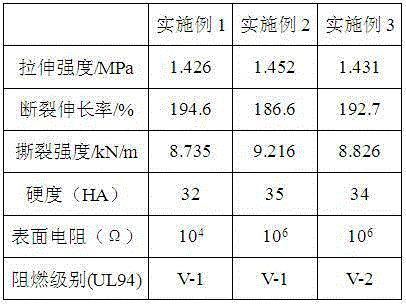

Preparation method of bismaleimide block polymer containing carbon nanotubes

The invention belongs to the technical field of nanomaterials, and in particular relates to a preparation method of a bismaleimide block polymer containing carbon nanotubes. The method of the invention comprises the following steps: after surface quantitative carboxylation and acyl chlorination of purified carbon nanotubes, introducing long-chain diamine or polyamine with characteristic structures into the carbon nanotubes; after the whole carbon nanotubes are changed into the diamine or the polyamine, regarding the aminated carbon nanotubes as high polymer chains; and then, carrying out Michael addition reaction on the aminated carbon nanotubes and bismaleimide to generate a bismaleimide resin linear block polymer containing carbon nanotubes, so that the carbon nanotubes become part of the bismaleimide resin system. The carbon nanotube modified bismaleimide resin can fully use the strength and the toughness of the carbon nanotubes to strengthen and toughen the bismaleimide and also increase the heat resistance and wear resistance of the bismaleimide, thereby providing a foundation for the application of bismaleimide resin in the fields of high-performance composite materials in space flight, aviation and the like.

Owner:TONGJI UNIV

Epoxy resin curing agent and preparation method thereof

The invention relates to an epoxy resin curing agent and a preparation method thereof. The epoxy resin curing agent comprises the following raw materials in parts by weight: 30-60 parts of methacrylic acid dimethylamine ethyl ester, 20-30 parts of methyl methacrylate, 10-20 parts of isoamyl methacrylate, 10-20 parts of hydroxyethyl methacrylate, 0.5-3 parts of an initiating agent, and 50-100 parts of solvent. According to the invention, the methacrylic acid dimethylamine ethyl ester with unsaturated bond is adopted as a main comonomer, and tertiary amine which can be used for performing cross-linking and solidification reaction with the epoxy resin is directly inserted into a macromolecular chain, so that the epoxy resin can be solidified, the toughening modification effect is achieved, and a curing agent and a flexibilizer are not required at one time; therefore the cost is saved and the technology is simplified.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

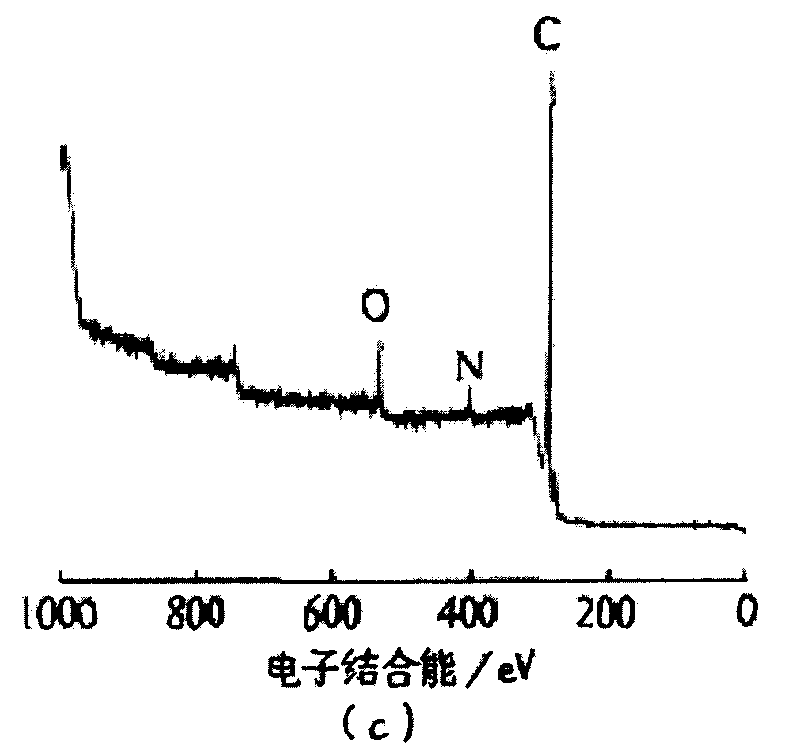

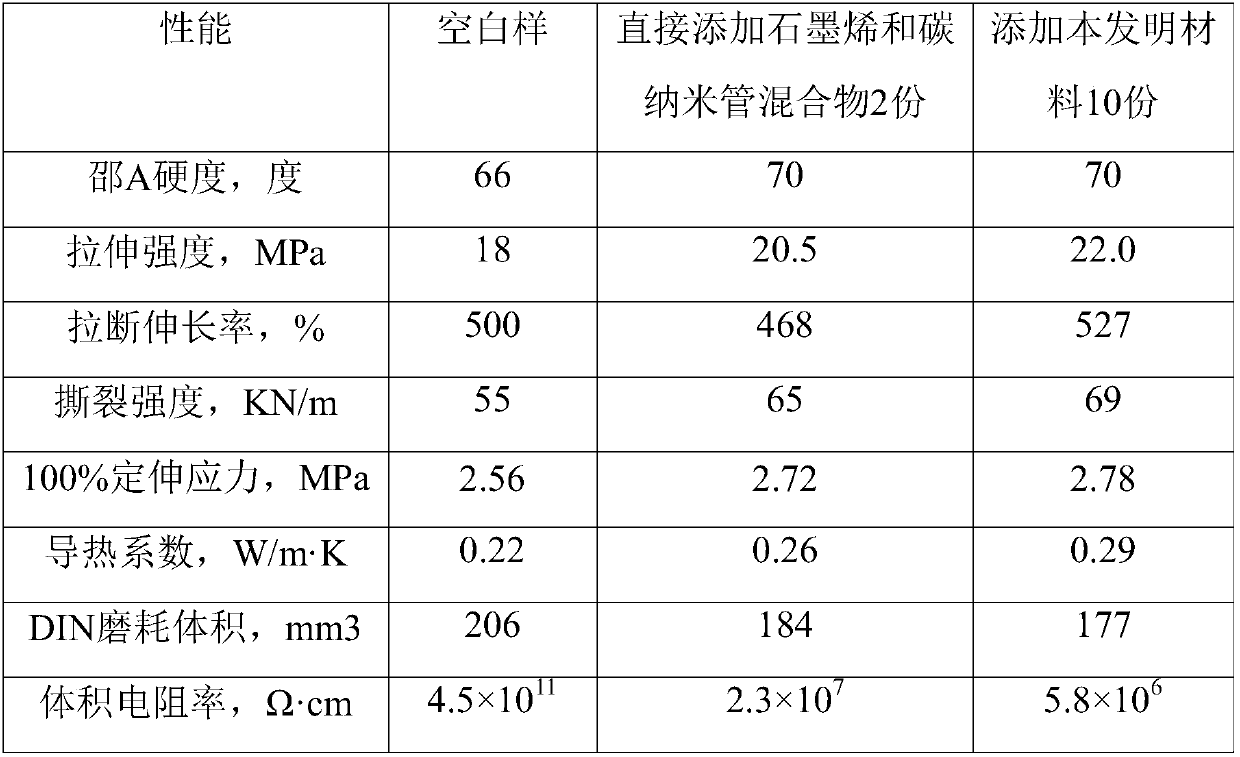

Modified composite material using carbon nanotubes and graphene and preparation method thereof

The invention discloses a modified composite material using carbon nanotubes and graphene and a preparation method thereof, and belongs to the technical field of a rubber product. In the formula, methacrylic acid is firstly added into the graphene and the carbon nanotubes for acidification modification; then, zinc oxide is added for ionization reaction; the in-situ generation of zinc methacrylateis realized; then, liquid rubber and peroxide initiating agents are added; the zinc methacrylate is initiated for performing co-crosslinking with the liquid rubber after the copolymerization; the surface adsorption wrapping modification and the surface chemical modification on the graphene and the carbon nanotubes are realized, so that the carbon nanomaterial surface has high chemical activity; good bonding force between a carbon nanomaterial and a polymer base body is ensured; the dispersion degree of the carbon nanomaterial in the polymer base body is improved; further, after the composite material is formed, the load can be smoothly transferred onto the carbon nanomaterial; the carbon nanomaterial achieves the enhancing and toughening effects; the heat conduction and electric conductionperformance of the modified composite material are obviously improved.

Owner:青岛泰歌新材料科技有限公司

Nano polyethylene composite material and preparation method thereof

The invention discloses a nano polyethylene composite material and a preparation method thereof. The nano polyethylene composite material comprises the following components in percentage by mass: 60-75% of polyethylene resin, 5-15% of nano particles, 18-25% of halogen-free flame retardant, 0.1-0.3% of surface treating agent, 0.2-1.5% of lubricant, 0.1-1% of antioxidant, and 0-0.5% of pigment. The nano polyethylene composite material disclosed by the invention has the beneficial effects that the nano particles and the polyethylene resin are blended together, and a proper amount of halogen-free flame retardant, surface treating agent and the like are added, so that the rigidity, heat resistance and stability of the material are greatly improved, and the effects of increasing the flexibility, increasing the strength and keeping relatively good strength can be achieved; moreover, the halogen-free flame retardant has smoke-suppressing, nontoxic and environment-friendly high flame retarding efficiency, and is excellent in comprehensive performance, good in processing performance and low in cost.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

EVA composite material applied to high jump mat and preparation method thereof

The invention discloses an EVA composite material applied to a high jump mat and a preparation method thereof. The EVA composite material is prepared from the following components in parts by weight: 40-60 parts of a base material, 5-10 parts of masterbatches serving as a foaming agent, 0.5-1 part of a cross-linking agent, 10-20 parts of elastomers, 1-3 parts of an antibacterial agent, 10-25 parts of carbon black, 10-20 parts of a filler and 0.5-1 part of compound additives, wherein the base material is prepared by mixing an ethylene-vinyl acetate copolymer and polyethylene according to a weight ratio of (70-90) to (10-30); the carbon black is prepared by mixing special conductive carbon black and acetylene carbon black according to a weight ratio of (2-5) to 1; the filler is prepared by mixing organic modified montmorillonite and calcium carbonate according to a weight ratio of 1 to (2-3). The preparation method is simple and is convenient to operate. The invention provides a light, antibacterial and environment-friendly high jump mat; a compound system has the characteristics of static electricity resistance, flame retardance, abrasion resistance, flexibilization and shock absorption, can highly meet requirements of the high jump sport and simultaneously responds to the healthy and safe sport concept.

Owner:XUCHANG UNIV

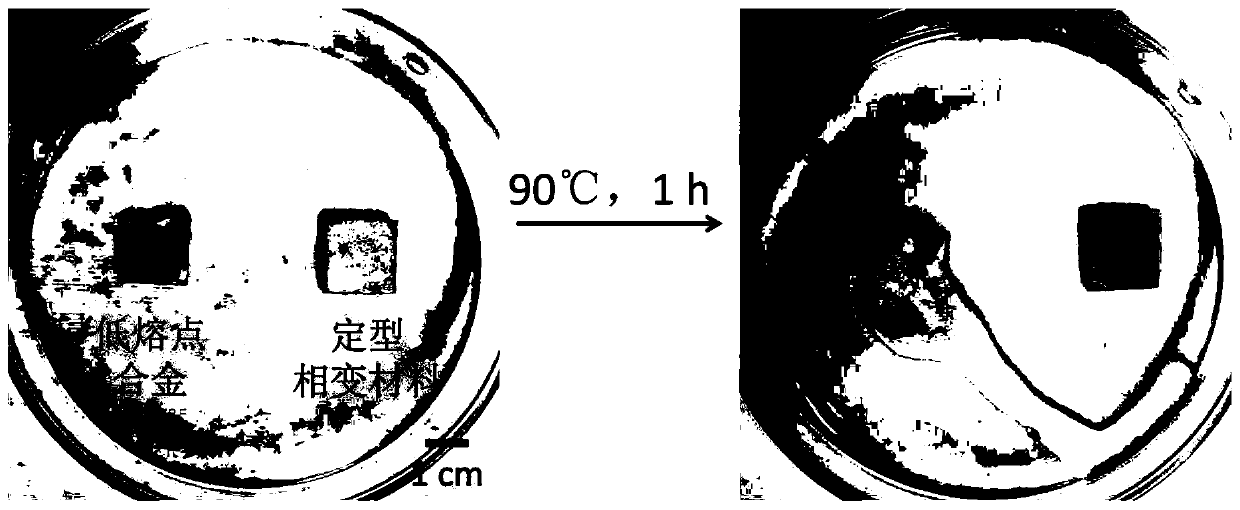

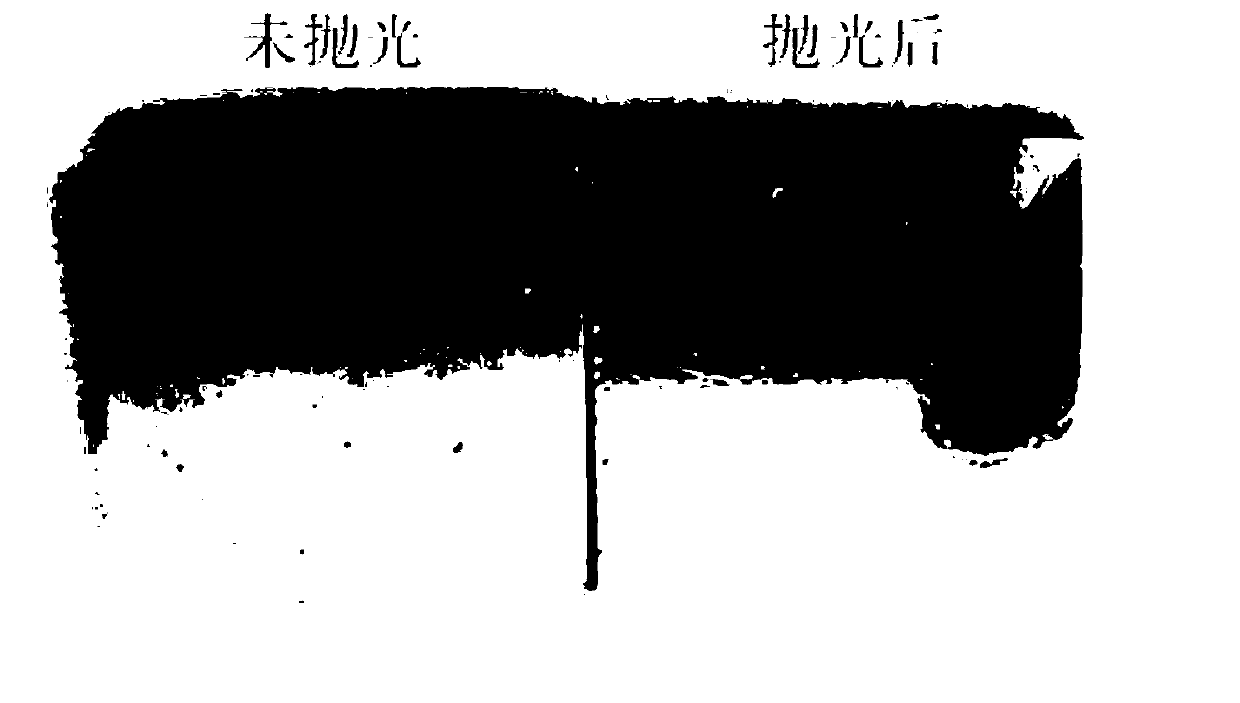

Low-melting-point metal shaped phase-change material and preparation method thereof

ActiveCN111040736AImprove heat storage performanceEasy to processHeat-exchange elementsPhase-change materialMacromolecule

The embodiment of the invention relates to a low-melting-point metal shaped phase-change material and a preparation method thereof. The preparation method comprises the following steps: dispersing a heat-conducting material in a solvent to form a dispersion, soaking polymer foam in the dispersion, and taking out and drying the soamed polymer foam to obtain composite foam; and soaking the compositefoam into molten low-melting-point metal, and taking out and cooling the soaked composite foam to obtain the low-melting-point metal shaped phase-change material. The low-melting-point metal shaped phase-change material obtained by the preparation method is easy to process, good in heat storage performance and good in interface affinity.

Owner:TIANJIN POLYTECHNIC UNIV

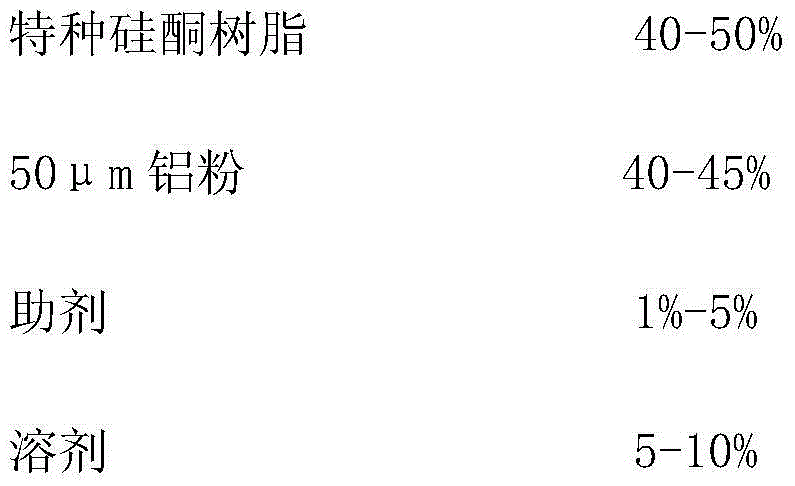

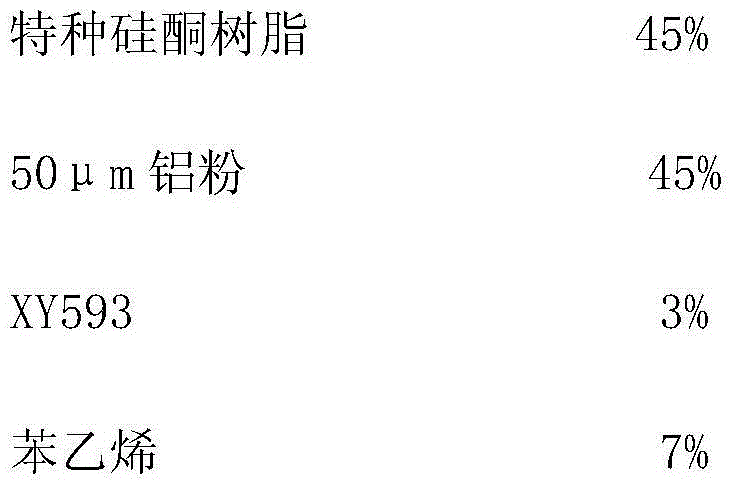

Silicone coating capable of resisting high temperature of 800 DEG C and preparation method thereof

InactiveCN105017960AChemically stableImprove hydrophobicityFireproof paintsAnti-corrosive paintsPolymer scienceSilicone coating

The invention discloses a silicone coating capable of resisting a high temperature of 800 DEG C and a preparation method thereof. The silicone coating capable of resisting the high temperature of 800 DEG C comprises the following components in percentage by weight: 40-50% of special silicone resin, 40-45% of 50mu m aluminium powder, 1-5% of accessory ingredient and 5-10% of solvent, wherein the special silicone resin is hot setting silicone resin, the accessory ingredient is a modified amine curing agent, and the solvent is selected from one of styrene, tetrachloroethylene, trichloroethylene, ethylene glycol ether and triethanolamine. The silicone coating is stable in chemical property and free from toxicity and stimulation, further has the characteristics of high temperature resistance and high corrosion resistance, is capable of enabling a condensate to have relatively high heat resistance, fire retardance, ablation resistance and favorable electrical properties, and can be widely applied to special devices such as chimney flues, high-temperature stream pipelines, heat exchangers, high-temperature furnaces, high-temperature desulfurization equipment, petroleum and petrifaction cracking equipment, engine components and exhaust pipes.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Production method of modified polystyrene foam plastic plates

The invention provides a production method of modified polystyrene foam plastic plates. The method comprises the following steps: 1, prefoaming: uniformly mixing 80-90 wt% of polystyrene, 5-10 wt% of nano-particles, 5-10 wt% of a pentane foaming agent and 2-4 wt% of calcium carbonate, putting the obtained mixture in a pre-foaming machine, and pre-foaming the mixture; 2, slaking: allowing the foamed mixture to stand in 23 DEG C environment for 10 h; 3, carrying out flame retardation treatment: adding a flame retardant and a smoke suppressant to the slaked mixture, and mixing above materials until the materials are uniform; 4, carrying out extrusion molding: putting the mixture in an extruder, and carrying out extrusion molding; and 5, slaking a product: allowing the product obtained after extrusion molding to stand in a 55 DEG C oven for 10-15 h in order to obtain the modified polystyrene foam plastic plates. The modified polystyrene foam plastic plates produced through the method have the characteristics of good fireproof property, smoke suppression, large strength and large toughness.

Owner:上海轩颂建筑科技股份有限公司

Water-saving permeation tube and manufacture method thereof

The invention provides a water-saving permeation tube and a manufacture method thereof. The permeation tube is prepared from the following ingredients (by weight): 100 parts of polypropylene, 25-30 parts of waste tire rubber powder, 5-8 parts of calcium sulfate whiskers, 4-6 parts of aluminium silicate ceramic fibre, 8-10 parts of calcium carbonate, 2-3 parts of graphite powder, 4-6 parts of 3-(2,3-epoxypropoxy) trimethoxypropylsilane and 2-3 parts of polyethylene wax. The permeation tube has strong impact resistance, aging resistance and long service life, and guarantees infiltrating irrigation requirement in agricultural production.

Owner:ZHANGZHOU LEYNEM IND

Modified nylon material for sealing ring

The invention discloses a modified nylon material for a sealing ring. The modified nylon material is composed of the following raw material components in parts by weight: 100-120 parts of polycaprolactam, 80-90 parts of polyparaphenylene terephthalamide, 80-100 parts of polymethyl methacrylate, 60-80 parts of chloroprene rubber, 65-70 parts of polyamide, 40-50 parts of polyvinylidene fluoride, 50-55 parts of high-density polyethylene, 35-40 parts of polycarbonate, 10-12 parts of disodium hydrogen phosphate, 15-20 parts of viscose fiber, 10-20 parts of polyformaldehyde, 20-30 parts of polyester fiber, 10-15 parts of polyimide, 12-15 parts of polyvinyl chloride, 20-25 parts of polyvinyl acetate, 25-30 parts of polyphenylether, 35-40 parts of lcp engineering plastics, 15-20 parts of nano-zirconia, 10-15 parts of glass fiber powder, 5-10 parts of quartz powder, 10-15 parts of silica, and 10-15 parts of bentonite. The modified nylon material for the sealing ring improves the weather resistance and the wear resistance of the sealing ring, improves the weather resistance of the sealing ring, and improves the toughness, strength and tensile property of the sealing ring.

Owner:李兆源

Polypropylene filling master batch

InactiveCN102675735ASolving Dispersion ProblemsSolve problems such as easy stratificationParaffin waxMasterbatch

The invention discloses a polypropylene filling master batch, which consists of the following raw materials in parts by weight: 12-20 parts of polypropylene, 1 part of stearic acid, 0.3 part of an antioxidant, 1 part of a coupling agent, 3-5 parts of paraffin, 100 parts of stone dust, 2-3 parts of polyethylene wax and 0.1 part of a brightening agent, and is prepared by the following steps of: mixing by using a high-temperature mixing machine for 15 minutes at the temperature of 130 DEG C; and extruding and granulating with a double-screw extruder. The polypropylene filling master batch has a reasonable formula, contributes to solving the problems of difficulty in dispersing an inorganic filler, easiness in dispersing and the like, has the advantages of easiness in dispersing and high efficiency, and plays a role in toughening and enhancing a polypropylene resin, improving size stability and increasing surface gloss.

Owner:青阳县红远塑业有限公司

High-temperature-resistant exhaust pipe coating and preparation method thereof

InactiveCN105504895AImprove high temperature resistanceImprove impact resistanceAnti-corrosive paintsHeat resistanceManganese

The invention discloses a high-temperature-resistant exhaust pipe coating and a preparation method thereof. The coating is prepared from raw materials in parts by weight as follows: 20-30 parts of aluminum powder, 11-22 parts of silica powder, 10-18 parts of manganese, 3-8 parts of carbon, 6-15 parts of zinc oxide powder, 2-4 parts of copper, 3-8 parts of mica powder, 3-7 parts of talc and a solvent. The mica powder and the talc are added to the aluminum powder, the silica powder, the zinc oxide powder and the copper, the high-temperature resistance of the coating is enhanced, the porous state caused by thermal decomposition in the preparation process is improved due to addition of the mica powder and carbon black, the coating is more stable, the added solvent has characteristics of high-temperature resistance and high corrosion resistance, meanwhile, the stability of a coating material can be improved, and the coating is safe and environment-friendly. The coating has multiple functions of curing, toughening, diluting, prolonging the pot life and the like, is used as a curing agent and enables a cured product to have higher heat resistance, flame retardance and ablation resistance and excellent electrical properties.

Owner:WUHU EVERSHINE AUTOMOTIVE COMPONENT

High-performance coating for exhaust pipe and preparation method thereof

InactiveCN105670498AImprove high temperature resistanceStrong corrosion resistanceFireproof paintsAnti-corrosive paintsSolventSilicone resin

The invention discloses a high-performance coating for an exhaust pipe and a preparation method thereof. The coating includes the following raw materials, by weight, 20-25 parts of silicone resin, 15-25 parts of a ferric oxide composite, 8-12 parts of carbon, 10-18 parts of manganese, 3-8 parts of sulfur, 6-15 parts of phthalic acid, 2-4 parts of copper, 3-8 parts of mica powder and 3-7 parts of talcum powder, and additives and solvents. IN the invention, the silicone resin and the ferric oxide composite are mixed with a mixture of the carbon, manganese, sulfur and copper, and then the mica powder and the talcum powder are added to improve the high-temperature resistance of the coating. The porous status due to thermal decomposition during the process is improved due to the mica powder and the talcum powder, so that the coating is more stable. The added solvent is high-temperature-resistant and has strong anti-corrosion property. High-temperature-curing silicone resin is employed and has stable chemical properties, strong hydrophobicity and is free of toxicity and irritation on skin, so that the coating is safe and environment-friendly.

Owner:WUHU EVERSHINE AUTOMOTIVE COMPONENT

Method for preparing modified polyphenylene oxide master batches

The invention discloses a method for preparing modified polyphenylene oxide master batches and belongs to the field of engineering technology. The method comprises the steps of mixing, extruding, cooling, prilling, drying and packaging, wherein the raw materials of the step of mixing comprises 65-80 parts of polyphenyl ether, 0.5-5 parts of filling agents. 12-20 parts of low density polyethylene and 0.1-5 parts of addition agents. The polyphenylene oxide master batches prepared through the method have the advantages that the dimensional stability is good, the performances of corrosion resistance and solvent resistance are good, the application range of polyphenylene oxide materials can be expanded, the production environment is clean, and no harm is caused to the bodies of operators.

Owner:BLUESTAR CHENGDU NEW MATERIALS

High-density polyethylene composition and preparation method thereof

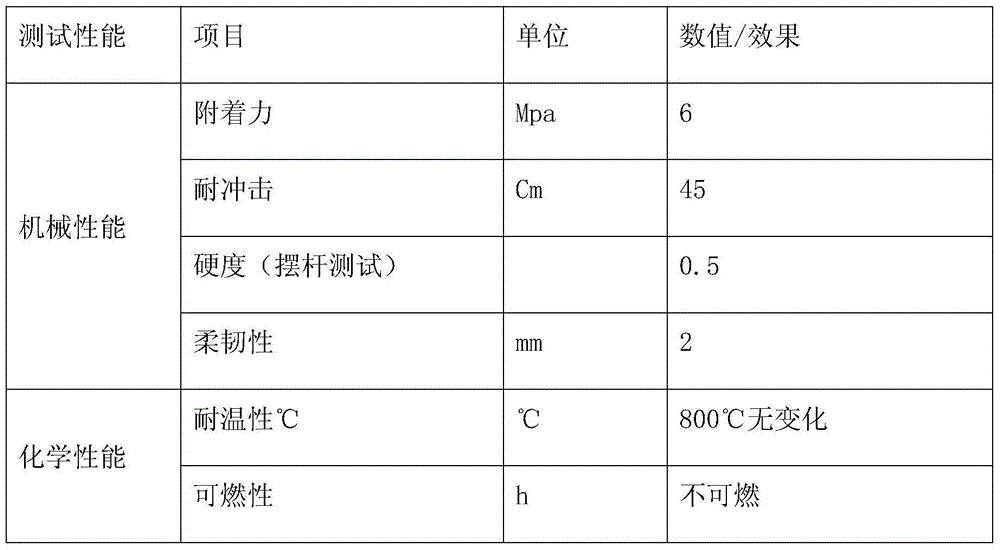

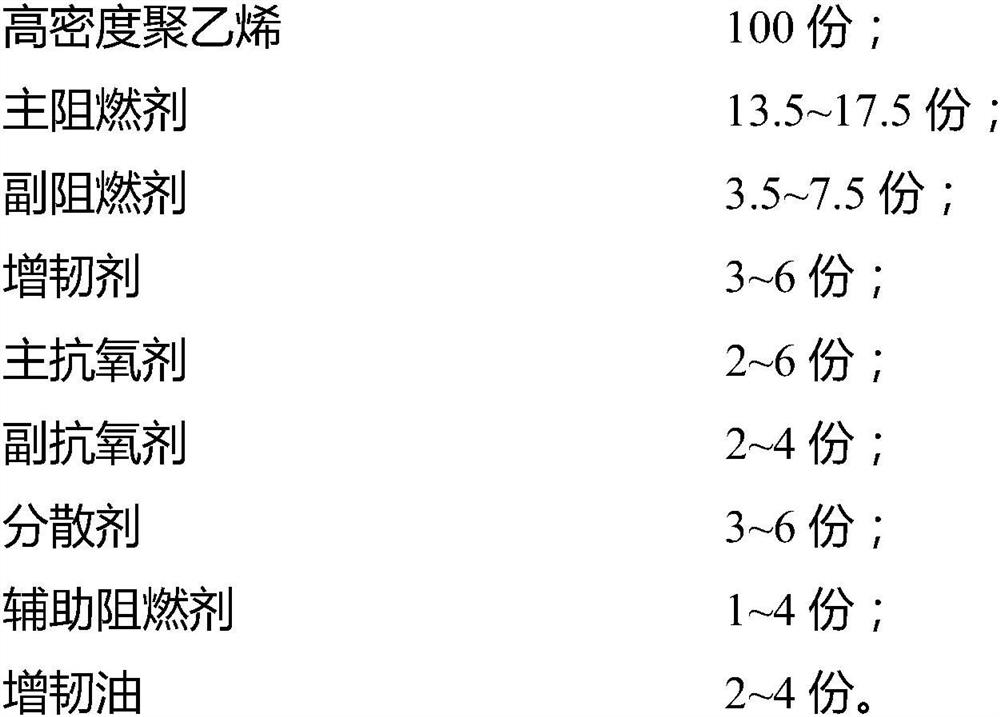

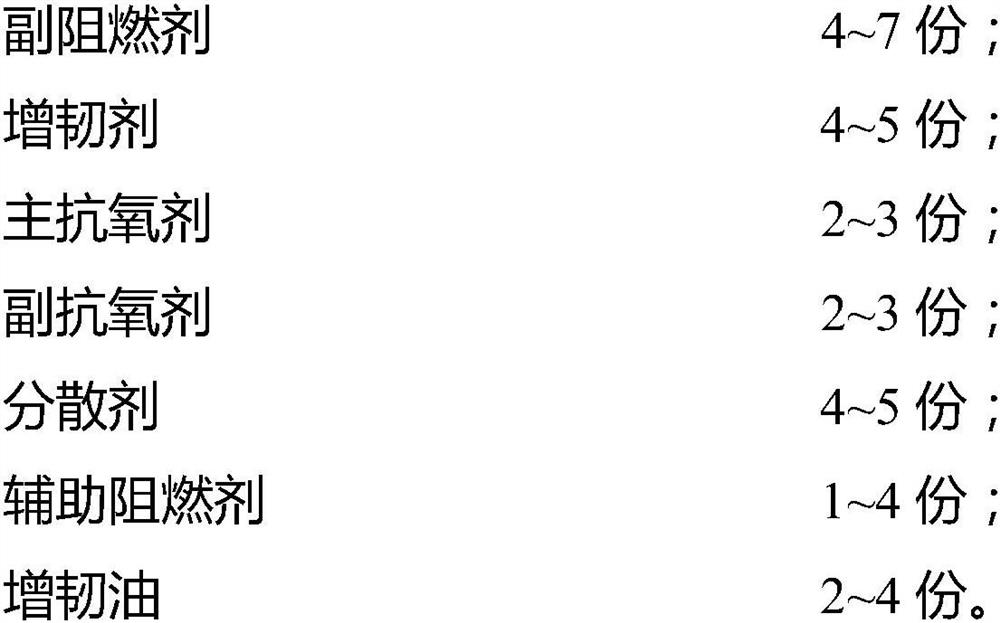

The invention discloses a high-density polyethylene composition and a preparation method thereof. The high-density polyethylene composition comprises the following components in parts by weight: 100 parts of high-density polyethylene; 13.5 to 17.5 parts of a main flame retardant; 3.5 to 7.5 parts of an auxiliary flame retardant; 3-6 parts of a toughening agent; 2-6 parts of a main antioxidant; 2-4parts of an auxiliary antioxidant; 3-6 parts of a dispersant; 1-4 parts of an auxiliary flame retardant; 2-4 parts of a toughening oil. The high-density polyethylene composition is excellent in flameretardant property, the flame retardant property meets the B1 level flame retardant requirement (according to GB / T27904-2011 Testing method for fire characteristics of furniture and subassemblies exposed to flaming ignition source), toughening and environment pressure cracking resistance are achieved, the European Union RoHS instruction standard is met, and the high-density polyethylene composition is particularly suitable for the field of seats. The seats prepared from the composition is successfully applied to many stadiums.

Owner:ZHEJIANG DAFENG SPORTS EQUIP

Silicone coating capable of resisting low temperature of -40DEG C, and preparation method thereof

InactiveCN103992738AChemically stableImprove hydrophobicityAnti-corrosive paintsPolymer scienceAluminium powder

The invention discloses a silicone coating capable of resisting a low temperature of -40DEG C, and a preparation method thereof. The silicone coating comprises, by mass, 40-50% of grafted silicone resin, 40-45% of 50mum aluminum powder, 10-15% of a solvent and 5-8% of an assistant, wherein the grafted silicone resin is moisture-curable silicone resin, and the assistant comprises, by mass, 20-35% of a grafting coupling agent and 65-80% of an orientation agent. The silicone coating has the characteristics of stable chemical properties, no toxicity or irritation, low temperature resistance and strong corrosion resistance, enables cured products to have high freezing, flame and ablation resistances and excellent electric performances, and can be widely used in special apparatuses of liquid nitrogen storage pots, liquid oxygen storage pots and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

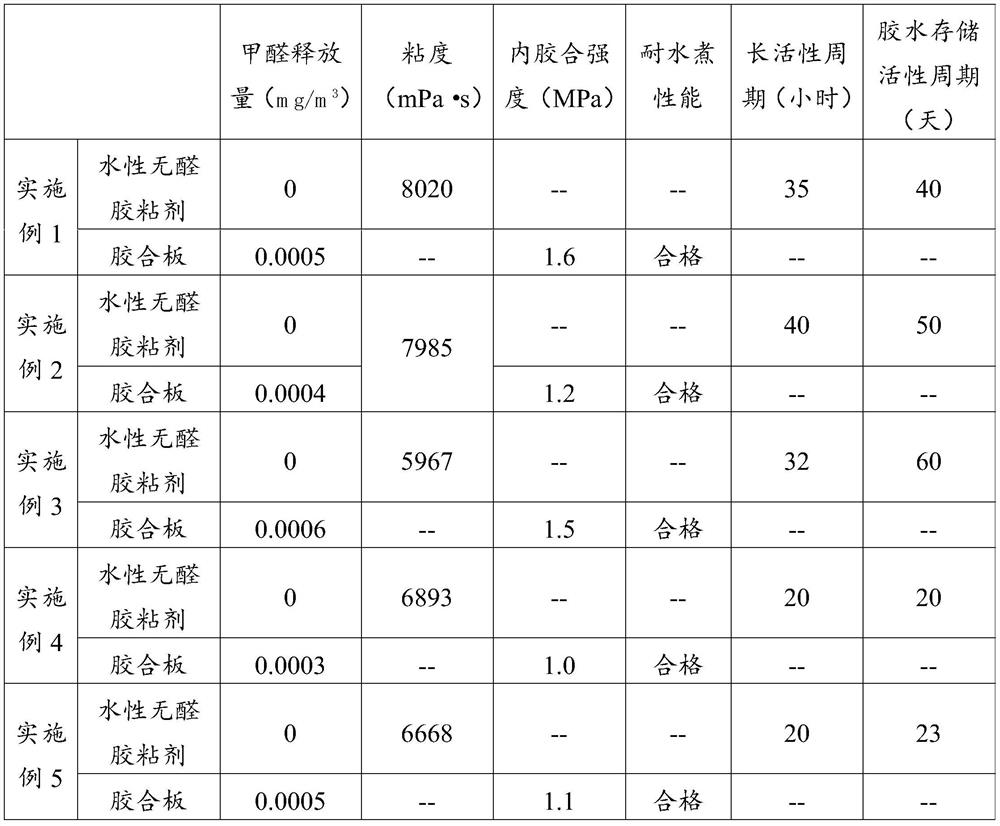

Water-based formaldehyde-free adhesive as well as preparation method and application thereof

InactiveCN113493664AReduce reactivityImprove structural strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesive cementPolymer science

The invention discloses a water-based formaldehyde-free adhesive as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving a water-soluble poly-multistructure compound in water at 0-200 DEG C to obtain a high polymer solution; (2) adjusting the temperature to 0-200 DEG C, adding an active auxiliary agent into the high polymer solution, adjusting the pH value to 2-10, and carrying out a stirring reaction for 1.0-72 h to obtain a hydrogel-like material; (3) reacting the hydrogel-like gel with an emulsion and a surfactant to form an emulsion / composite hydrogel system; and (4) adding a reinforcing material into the emulsion / composite hydrogel system to adjust the pH value to 2-11, and reacting to obtain the water-based formaldehyde-free adhesive. According to the invention, a water molecule, emulsion and hydrogel-like co-embedded film structure is constructed, so that the problem that a water reactive compound and a water-based compound are difficult to coexist is solved. Moreover, the prepared water-based formaldehyde-free adhesive has the effects of high stability, long activity period, toughening, water resistance, high adhesion and no formaldehyde release, and is suitable for artificial boards.

Owner:广东木森态新材料科技有限公司

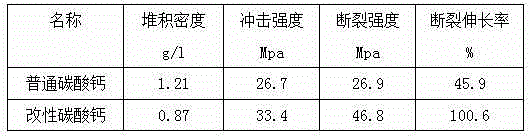

Modified calcium carbonate with good elasticity and preparation method thereof

ActiveCN104130592AImprove rigidityIncrease elasticityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSlagPolyvinyl chloride

Disclosed modified calcium carbonate with good elasticity is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 5.5-7 parts of polyvinyl chloride, 5-7 parts of transparent ABS, 4-6 parts of synthetic rubber, 2-3 parts of calcium carbide slag, 1.5-2.5 parts of crude aggregate, 3-5 parts of teflon, 2-3 parts of cationic starch, 2-3 parts of sulfonated lignin, and 2.5-3.5 parts of modified titanium dioxide. By adding transparent ABS and other macromolecular compounds, synthetic rubber and the like into calcium carbonate, calcium carbonate is substantially improved in rigidity, elasticity and stability, also has the characteristics of toughening, reinforcing and relatively good strength, and also is reduced in cost. The provided preparation method is simple and convenient to operate, and is easy to industrialize. The produced filling material is applicable to coatings, rubber, plastic and the like.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Fungi-proofing pipe and manufacturing method thereof

The invention provides a fungi-proofing pipe and a manufacturing method thereof .The fungi-proofing pipe is prepared from, by weight, 100 parts of polypropylene, 25-30 parts of polyvinyl chloride, 5-8 parts of calcium sulfate whiskers, 4-6 parts of aluminum silicate ceramic fiber, 8-10 parts of calcium carbonate, 2-3 parts of graphite powder, 5-6 parts of copper sulfate, 3-4 parts of palladium sulfate, 4-6 parts of 3-(2,3-epoxypropoxy) propyl tri-methoxysilanesilane and 2-3 parts of polyethylene wax .The fungi-proofing pipe is strong in impact resistance, resistant to aging, good in antibacterial effect and long in service life.

Owner:ZHANGZHOU LEYNEM IND

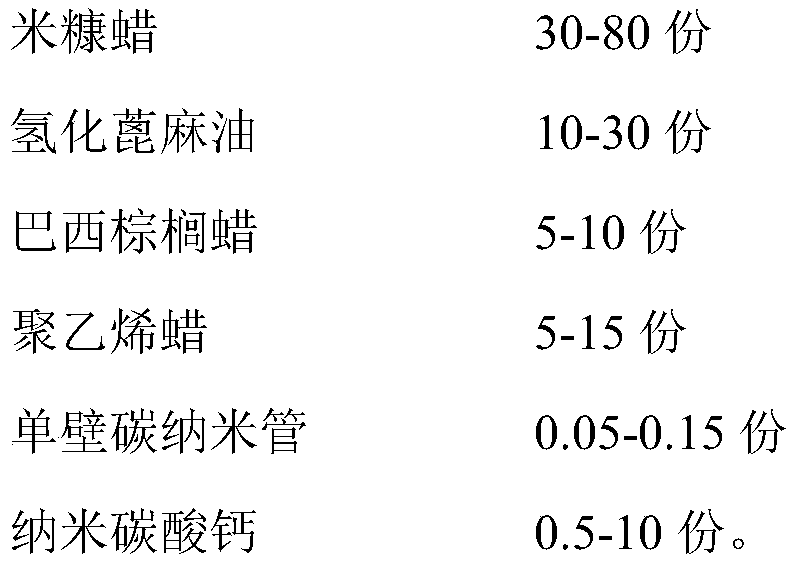

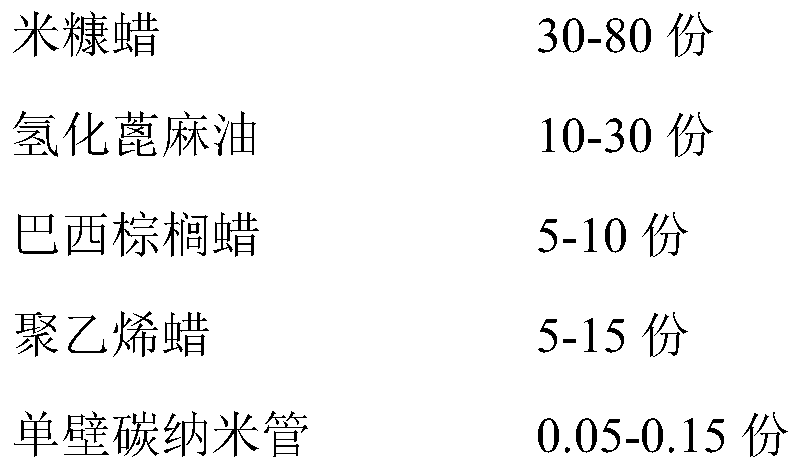

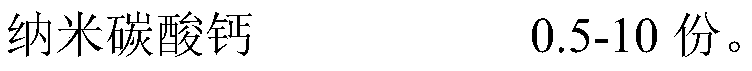

Processing aid containing rice bran wax, and preparation method thereof

The invention discloses a processing aid containing rice bran wax, wherein the processing aid comprises the following components in parts by mass: 30-80 parts of rice bran wax, 10-30 parts of hydrogenated castor oil, 5-10 parts of carnauba wax, 5-15 parts of polyethylene wax, 0.05-0.15 part of single-walled carbon nanotubes and 0.5-10 parts of nano calcium carbonate. The processing aid provided bythe invention is excellent in heat resistance, can be suitable for molding processing of plastics, resins and composite materials with a processing temperature of 125-135 DEG C so as to endow plasticproducts with excellent surface performance and excellent molding processing performance, and has huge commercial prospect.

Owner:江门市德山复合材料科技有限公司

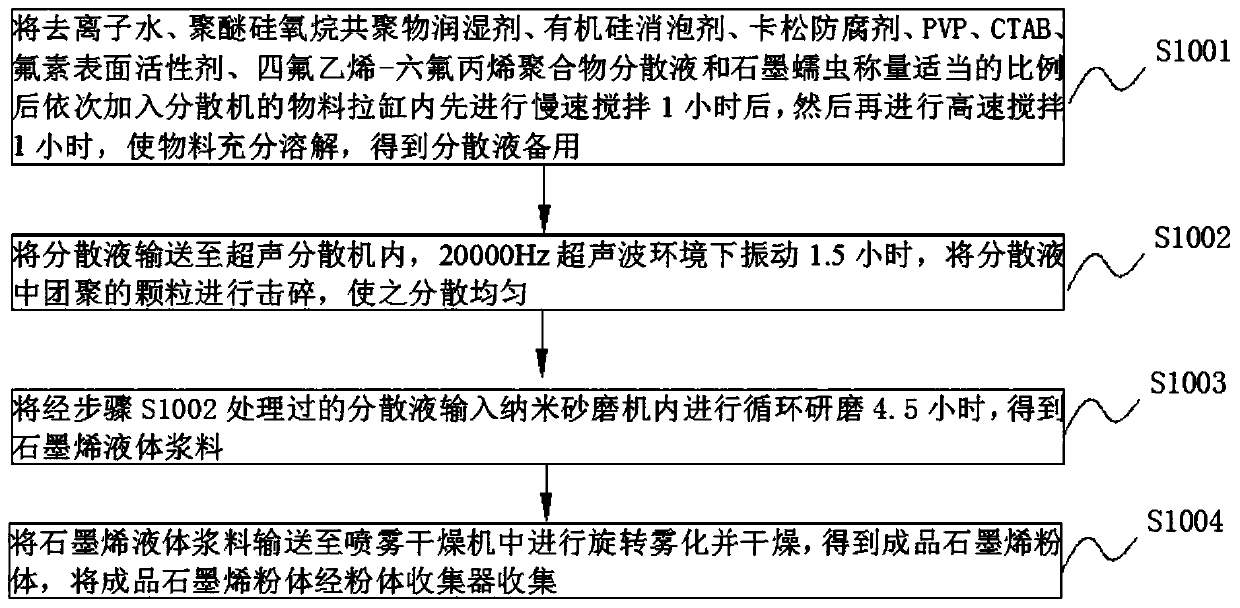

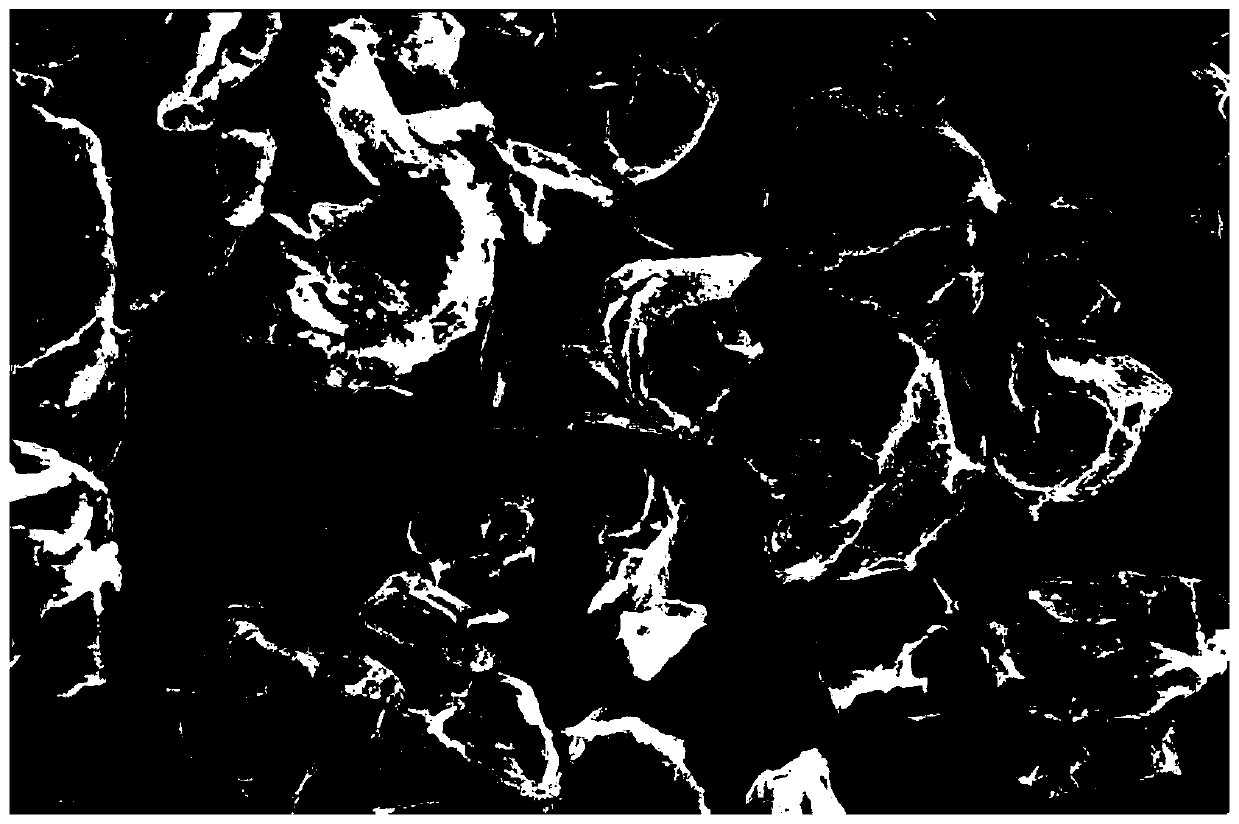

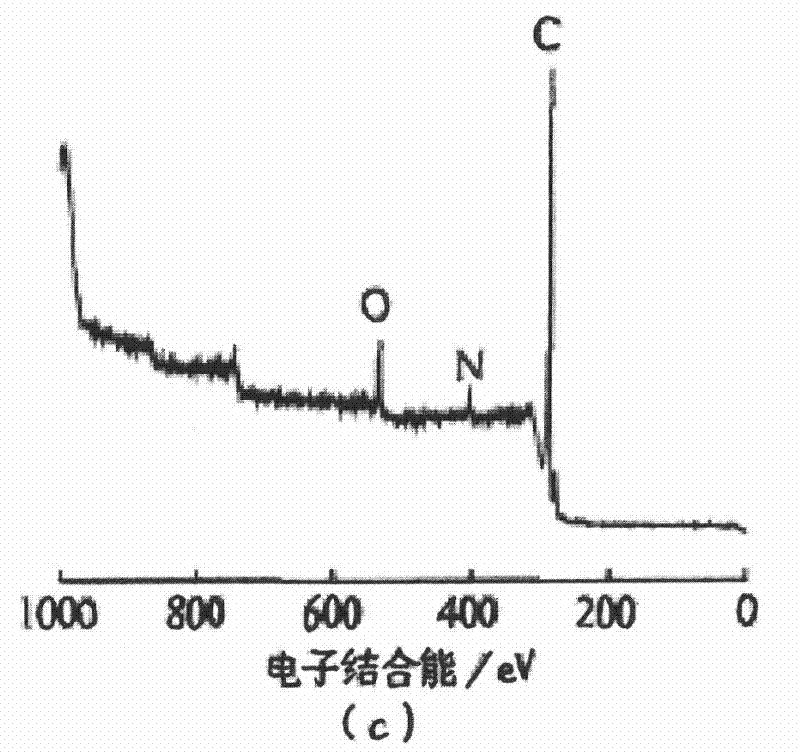

Manufacturing process for graphene powder containing charged tetrafluoroethylene-hexafluoropropylene polymer

The invention belongs to the field of inorganic chemistry, and particularly relates to a manufacturing process for graphene powder containing a charged tetrafluoroethylene-hexafluoropropylene polymer.The manufacturing process comprises the following steps: production of a graphene dispersion liquid; grinding and stripping of the graphene dispersion liquid; and drying and solidifying of the graphene dispersion liquid into powder. A formula for the graphene dispersion liquid is composed of the following components in percentage by mass: 71.8% of deionized water, 0.3% of a polyether siloxane copolymer wetting agent, 0.3% of an organic silicon defoamer, 0.3% of a Kathon preservative, 1% of PVP, 2% of CTAB, 0.3% of a fluorine surfactant, 12% of a tetrafluoroethylene-hexafluoropropylene polymerdispersion liquid and 12% of wormlike graphite. The charged tetrafluoroethylene-hexafluoropropylene polymer dispersion liquid and the fluorine surfactant are added in the manufacturing process of graphene powder, so material composition is optimized, graphene is efficiently stripped, and graphene with relatively high purity, large size and a few-layer structure is finally formed. The process hasthe advantages of simple production process, high production efficiency, short reaction time and the like, optimizes material composition, and reduces production cost.

Owner:汪百战 +1

Building material and preparation method thereof

InactiveCN109180106AGood environmental characteristicsStrong environmental protectionFiberPolyvinyl alcohol

The invention discloses a building material. The building material comprises, by weight, 5-25 parts of triethanolamine, 6-18 parts of silicon oxide, 6-18 parts of heavy calcium carbonate, 2-18 parts of polyvinyl alcohol, 3-13 parts of expanded perlite, 3-15 parts of sodium silicate, 1-17 parts of deionized water, 3-15 parts of Portland cement, 4-18 parts of glass beads, 4-18 parts of fly ash, 4-18parts of polyacrylonitrile fiber, 4-18 parts of modified epoxy resin, 3-13 parts of 2-hydroxy-4-methoxybenzophenone, 6-18 parts of heptyl 4-hydroxybenzoate, 3-17 parts of sulfonated melamine-formaldehyde resin and 3-13 parts of brominated bisphenol A epoxy resin. The building material has the advantages of good fracture resistance, good ultraviolet radiation resistance and long service life.

Owner:孙浩

A kind of preparation method of bismaleimide block polymer containing carbon nanotube

The invention belongs to the technical field of nanometer materials, and in particular relates to a preparation method of a bismaleimide block polymer containing carbon nanotubes. In the present invention, after surface quantitative carboxylation and acid chlorination of the purified carbon nanotubes, long-chain diamines or polyamines with characteristic structures are introduced into the purified carbon nanotubes, and the entire carbon nanotubes become diamines or polyamines. The aminated carbon nanotubes are regarded as polymer chains, and then the aminated carbon nanotubes are used to carry out Michael addition reaction with bismaleimide to generate bismaleimide resin linear blocks containing carbon nanotubes Polymers, carbon nanotubes become part of the bismaleimide resin system. This type of carbon nanotube modified bismaleimide resin can make full use of the strength and toughness of carbon nanotubes to strengthen and toughen bismaleimide, and can also improve its heat resistance and wear resistance. The application of imide resin in the field of high-performance composite materials such as aerospace and aviation has laid a foundation.

Owner:TONGJI UNIV

Modified plastic additive and preparation method thereof

The invention provides a modified plastic additive and a preparation method thereof. The modified plastic additive is prepared from the following components: a thermoplastic elastomer, alumina fiber,magnesium oxide powder, tourmaline powder, titanium dioxide, a compound auxiliary agent, a modified treatment liquid, a coupling agent, an antioxidant and a dispersant. The additive prepared by usingthe preparation method provided by the invention has good compatibility with main plastic, integrates the effects of increasing toughness and whiteness, resisting bacteria and protecting the environment, and can effectively modify the main plastic to enable the main plastic to obtain the above-mentioned effects; meanwhile, the preparation method provided by the invention is simple, has low cost and is applicable to large-scale industrial production.

Owner:ANHUI NINE COWS PLASTIC TECH

Modified PET plastic and preparation method thereof

The invention provides a modified PET plastic and a preparation method thereof, and relates to the technical field of plastic materials. The modified PET plastic provided by the invention comprises the following preparation raw materials in parts by weight: 90-98 parts of PET resin; 0.5 to 5 parts of filler; 0.5 to 3 parts of a toughening agent; and 0.5-2 parts of an additive. According to the invention, the filler can promote crystallization of the material and improve fluidity, and also has the effects of toughening and shrinkage prevention; the toughening agent can obviously improve the impact toughness of the PET resin; the additive can improve the comprehensive use performance of the modified PET plastic. The fluidity, the heat resistance and the impact strength of the PET plastic can be improved through the compounding effect of all the preparation raw materials. The result of the embodiment shows that the HDT B of the modified PET plastic provided by the invention is greater than or equal to 75 DEG C, and the heat resistance is relatively high; the impact strength is greater than or equal to 45kJ / m < 2 >, and the impact strength is high.

Owner:王晖

A kind of high-strength ceramic product and its preparation process

ActiveCN110078528BHigh and fast vacancy diffusion capabilityUnique high-speed vacancy diffusion capabilityFiberUltimate tensile strength

The invention provides a high-strength ceramic product and a preparation process thereof. The specific steps of the preparation process are: S1: preparing fiber ceramic balls; S2: mixing materials: by weight fraction, 40-50 parts of ceramic powder, 5 parts of magnetite ‑10 parts, 6‑12 parts of chromite and 3‑7 parts of phenolic resin, put into a ball mill and grind for 1 hour, then add 30‑40 parts of fiber ceramic balls in step 1, and continue ball milling for 9‑10 hours to make ceramics Blank; S3: mold loading: fill the ceramic blank in step S2 in the mold, after extrusion molding, demoulding into a green body; S4: sintering: the made green body is first dried in a drying room, and then in a sintering furnace Sintered to obtain ceramic products. In the preparation process of the high-strength ceramics of the present invention, fiber ceramic balls are obtained by pre-sintering and decomposing, and then synthetic ceramics are obtained through mixing, molding and sintering, and the dispersion is uniform, and the strength and toughness are also improved.

Owner:FUJIAN WILL CERAMIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com