Patents

Literature

81results about How to "Don't burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

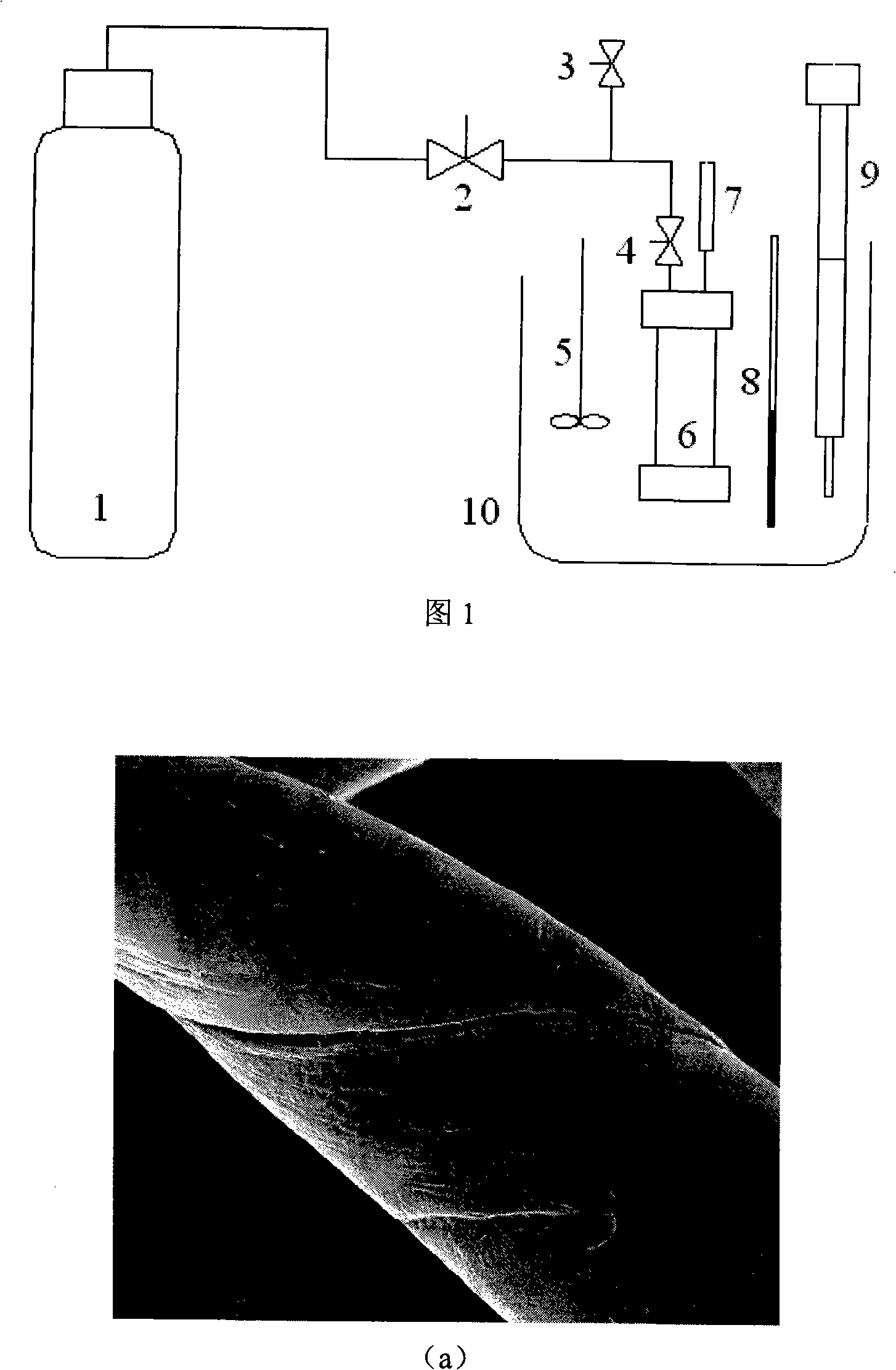

Method for preparing organic or inorganic composite fiber material with supercritical carbonic anhydride

The invention belongs to the technical field of organic and inorganic composite materials, in particular to a preparation method of organic and inorganic composite fibrous materials with supercritical carbon dioxide. The method includes pre-treatment and activation treatment of cellulose, doping of inorganic sol to the cellulose, etc. The invention makes use of the strong permeability of the carbon dioxide under supercritical conditions, can activate the cellulose with cosolvent, or lead nano particles in the inorganic sol to be absorbed and settled on the surface of the cellulose to form an even, continuous and stable coating layer; meanwhile, some sol particles penetrate into the fiber, so as to dope plenty of cellulose. The supercritical carbon dioxide adopted by the invention is safe, reliable, non-toxic, no pollutant and recyclable, and is environment friendly green solvent. The method of the invention is simple and easy to be operated, and the hybrid material has broad application prospect.

Owner:FUDAN UNIV

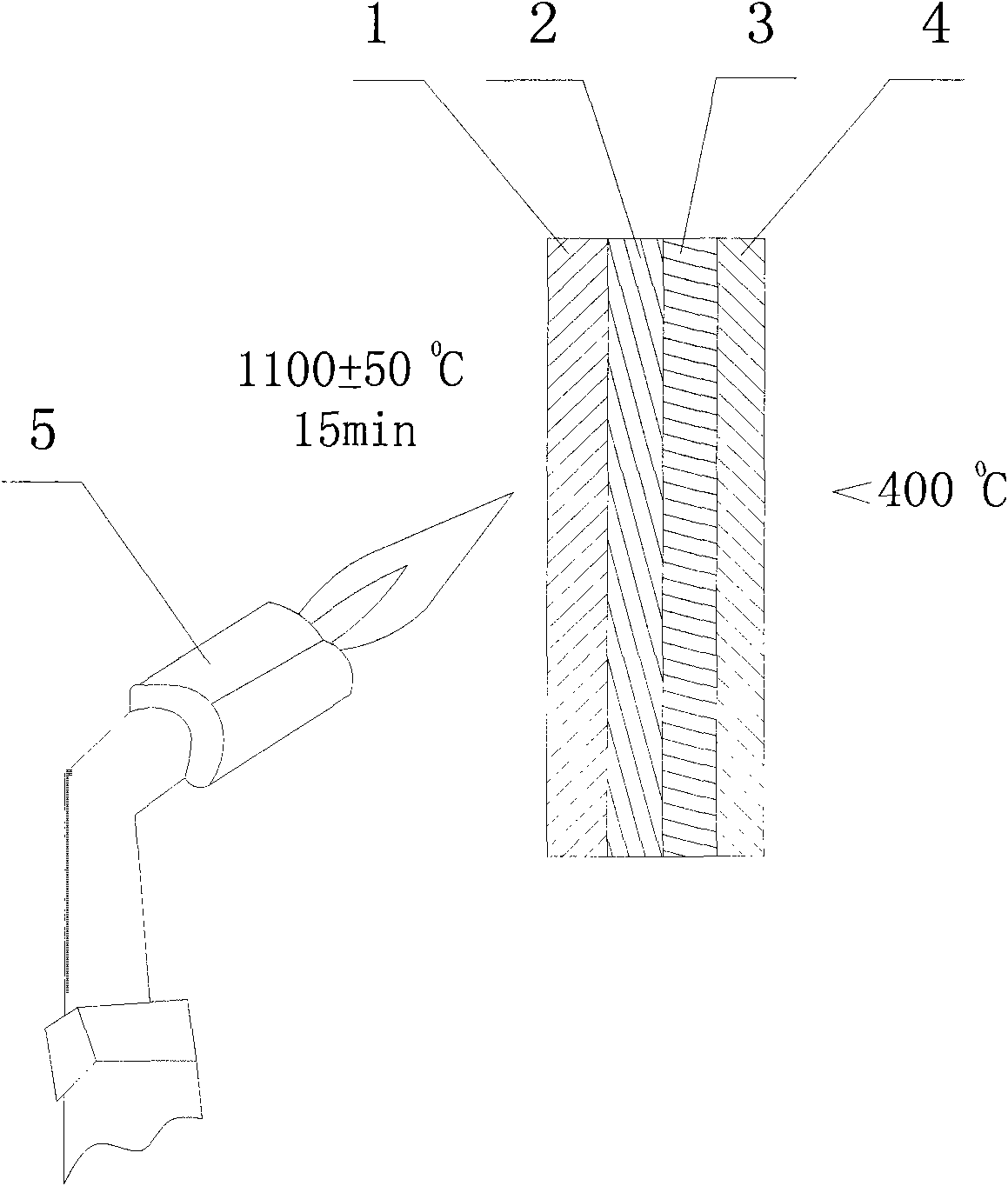

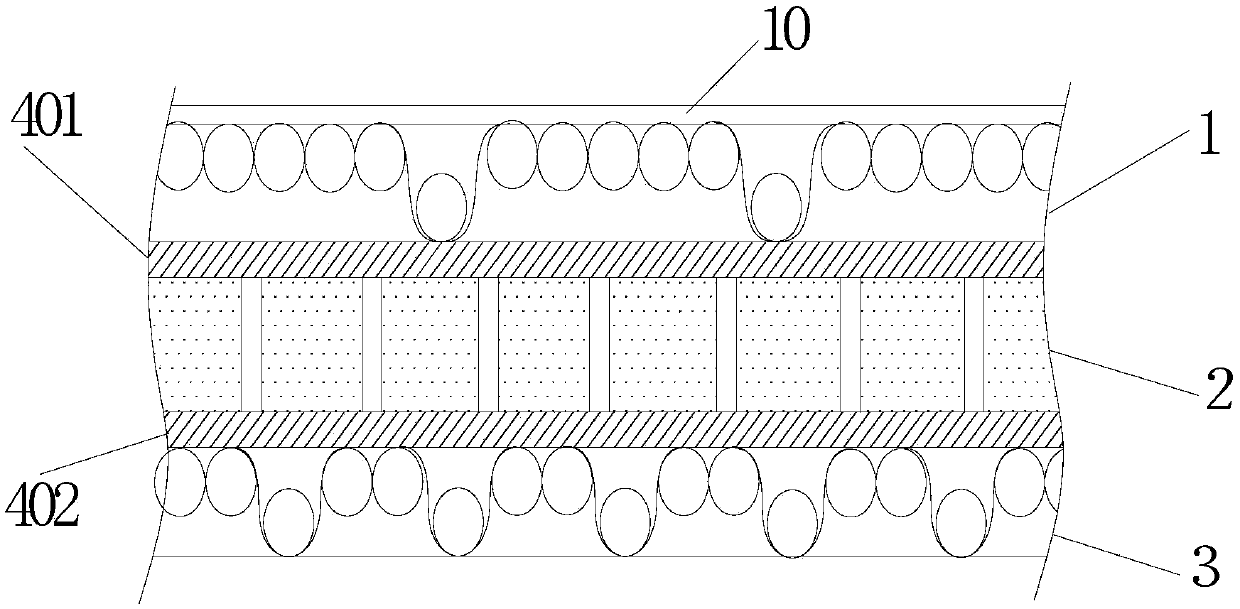

Fireproof silicone rubber composite material and preparation method thereof

InactiveCN101564923AHas smoke suppressant propertiesDon't burnLaminationLamination apparatusAirplaneHot pressing

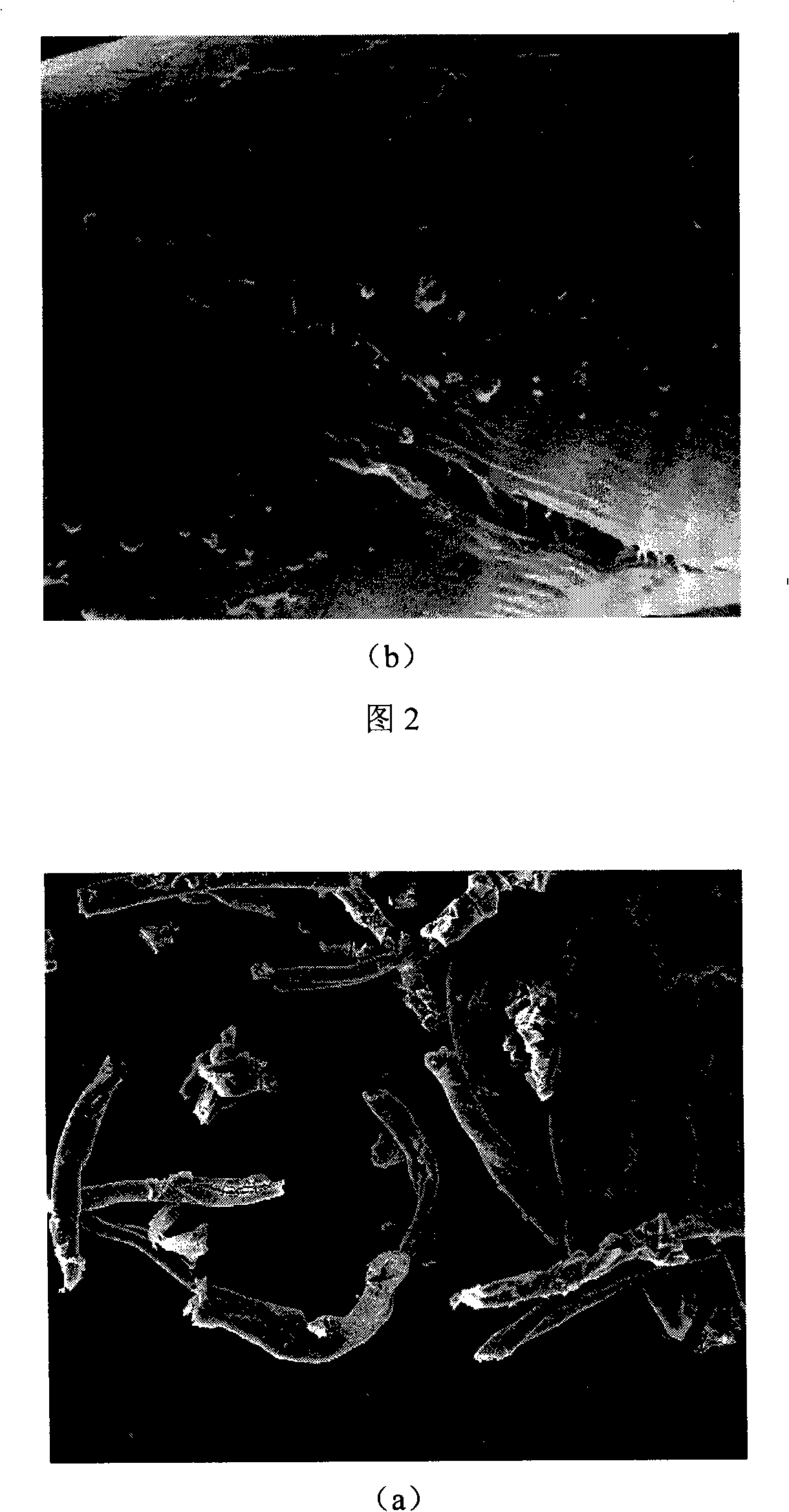

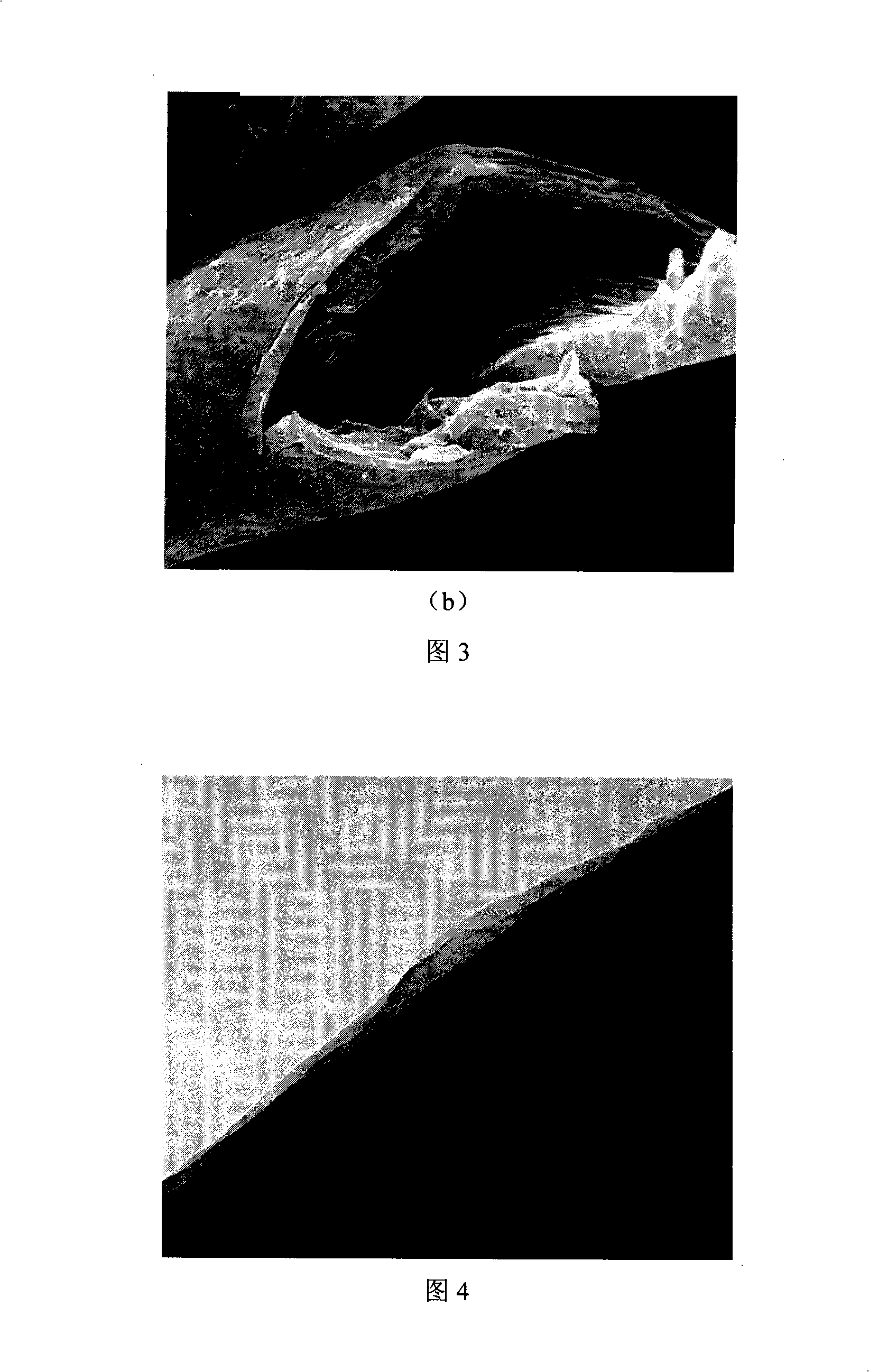

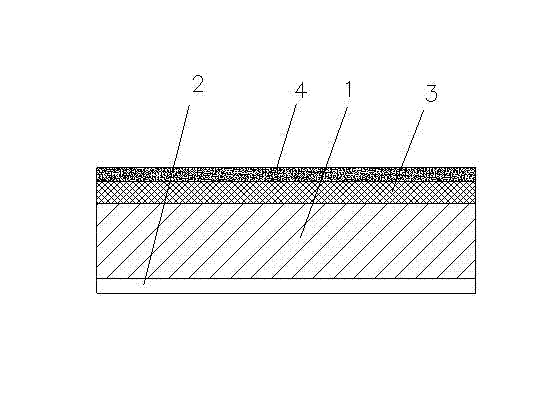

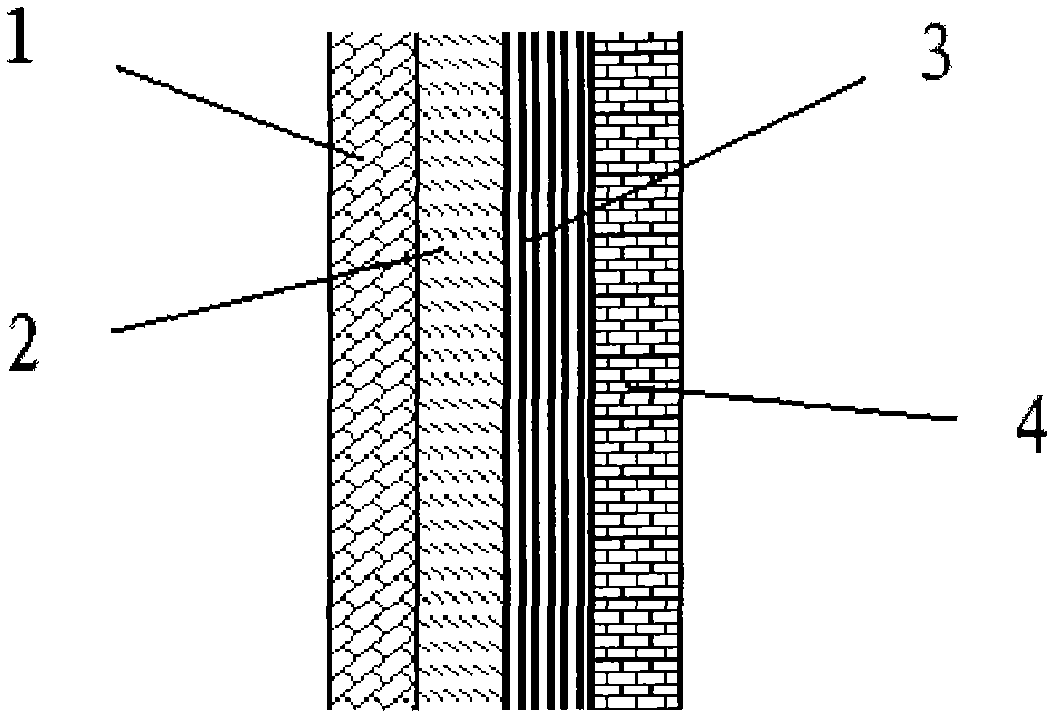

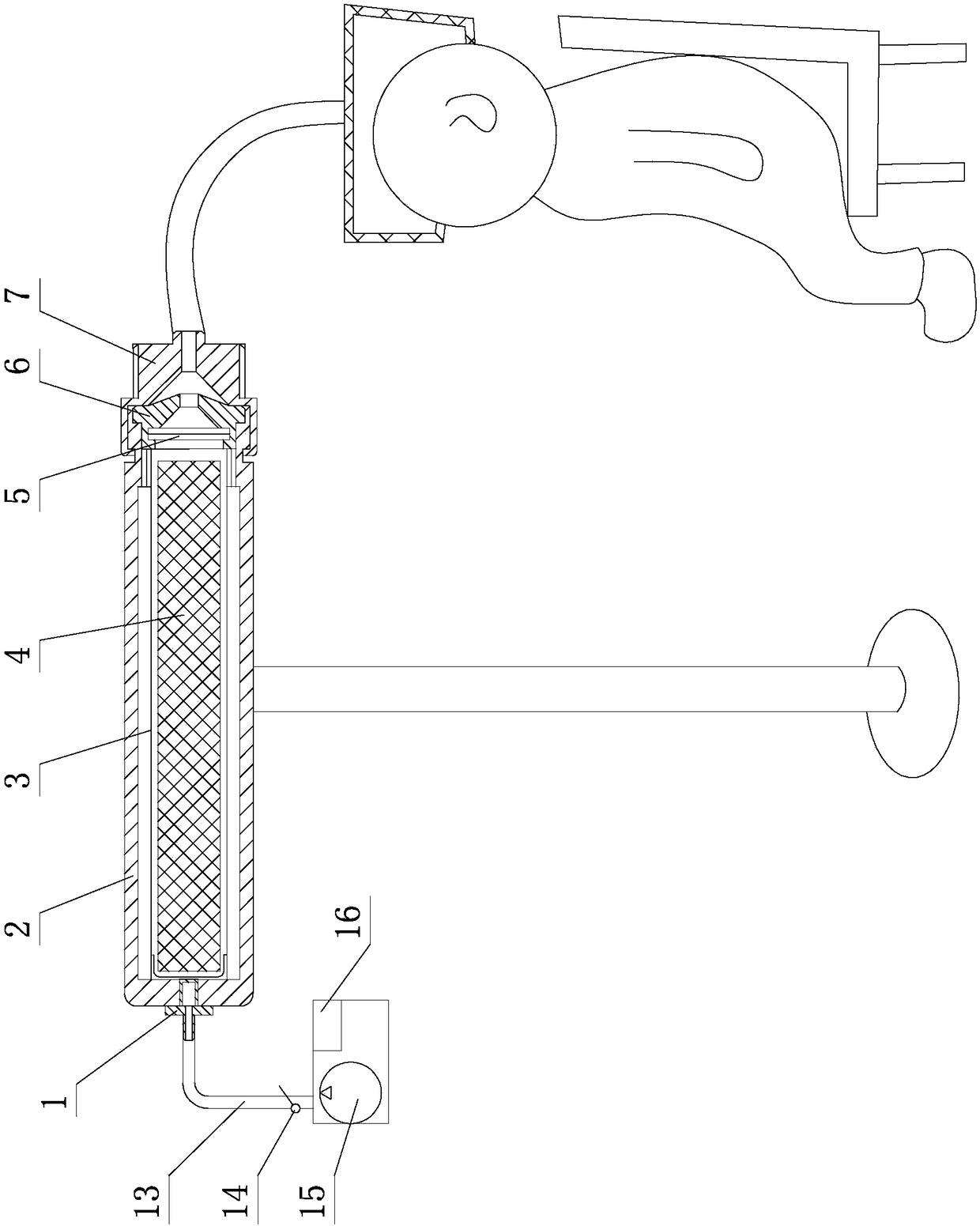

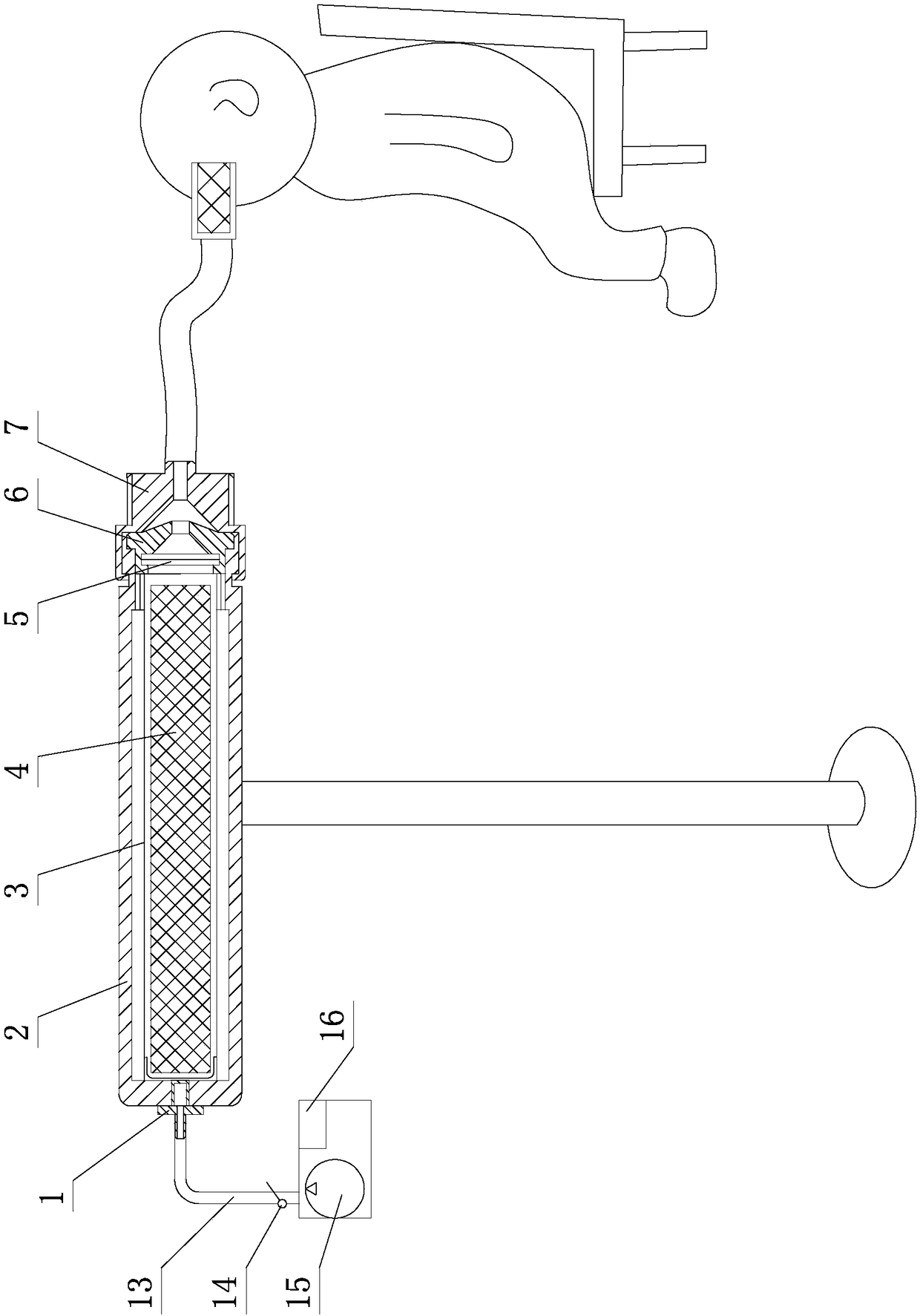

The invention relates to a fireproof silicone rubber composite material and a preparation method thereof and is applicable to the firewall of an airplane, the internal fire prevention equipment of other high-speed transport vehicles, military related equipment and the like. The fireproof silicone rubber composite material is characterized in that: the fireproof silicone rubber composite material is obtained by the hot-pressing and composition of a silicone rubber fireproof isolation layer (1), a silicone rubber flame-retardant cooling layer (2), a silicone rubber ablation-resistant layer (3) and a silicone rubber substance layer (4); and the silicone rubber fireproof isolation layer, the silicone rubber flame-retardant cooling layer, the silicone rubber ablation-resistant layer and the silicone rubber substance layer are arranged from outside to inside in sequence. The fireproof silicone rubber composite material has the advantages of good fireproof effect and good heat insulation effect.

Owner:WUHAN UNIV OF TECH

Silicone rubber fireproof sealing material and preparation method thereof

InactiveCN101565625AHas smoke suppressant propertiesDon't burnFireproof paintsPolymer scienceAdhesive

The invention relates to a silicone rubber fireproof sealing material and a preparation method thereof. The silicone rubber fireproof sealing material is characterized by consisting of a component A and a component B; when in use, the component A is mixed with the component B according to a weight ratio of 1:1 so as to obtain the silicone rubber fireproof sealing material; the component A is made from raw materials including a substrate, fireproof fillings, reinforced materials, a crosslinking agent and an adhesive; the portions by weight of each raw material of the component A are as follows: 100 portions of the substrate, 100 to 300 portions of the fireproof fillings, 50 to 100 portions of the reinforced materials, 3 to 8 portions of the crosslinking agent and 1 to 100 portions of the adhesive; the component B is made from raw materials including a substrate, fireproof fillings, reinforced materials, a catalyst and an adhesive; the portions by weight of each raw material of the component B are as follows: 100 portions of the substrate, 100 to 300 portions of the fireproof fillings, 50 to 100 portions of the reinforced materials, 0.2 to 0.4 portion of the catalyst and 1 to 100 portions of the adhesive; and the substrate is polydimethylsiloxane. The silicone rubber fireproof sealing material has good flame-retardant and fireproof effects.

Owner:WUHAN UNIV OF TECH

Single-component waterproof coating material and method of preparing the same

InactiveCN101343446ASimple construction processConstruction safetyAntifouling/underwater paintsPaints with biocidesLatex particleSolvent

The invention discloses single component waterproof coating and the preparation method. 50 percent to 80 percent of emulsion, latent solvent, dispersing agent and wetting agent are mixed with 40 percent to 60 percent of anti-foaming agent and are stirred at the rotating speed of 300 rpm to 700 rpm, pigment and filler are added during the stirring process, then the dispersing operation is performed at the rotating speed of 2000 rpm to 4000 rpm, slurry with the fineness lesser 50 um is obtained, and the residual anti-foaming agent is added. After the anti-foaming operation is performed, anticorrosion agent, film forming auxiliary agent, residual emulsion, thickening agent and water are added and evenly stirred at the rotational speed of 300rpm to 700 rpm, and the single component waterproof coating is obtained. The method has the advantages that the construction technology of the coating is simple and convenient, the film-forming process is finished mainly depending on the volatilization of the water and the interfusion of the latex particles, no VOC is discharged, no organic solvent is effused, the single component waterproof coating has no environmental pollution and combustion, the construction is safe, and the coating is an environmental protective-type single component waterproof coating.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

Agent for dirt-removing and antifogging

InactiveCN1418787ANo pollution in the processNo pollutionOther chemical processesVehicle cleaningSolventSURFACTANT BLEND

The detersive antifogging agent for glass is made of (wt%) 10-20% of anhydrous ethanol as solvent, 5-15% of propylene glycol 5-15% of isopropanol as dispersing agent, 5-20% of cocoanut oil fatty acid diethanol acylamide as non-ionic surfactant, 1-1.5% of essence and 40-60% of pure clean water as raw material through the processes of uniformly stirring them and filling. It is simple in productionprocess and is obvious in detersive antifogging effect, and has extensive application.

Owner:崔长安

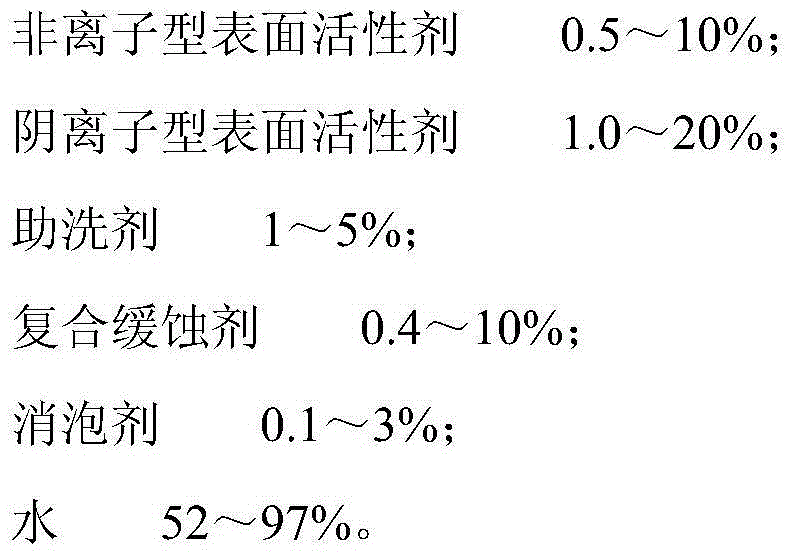

Metallic slag oil-water base cleaning agent

The invention provides a metallic slag oil-water base cleaning agent. The cleaning agent uses water as a solvent, and is characterized by comprising the following components by weight percent: 0.5-10% of a nonionic surfactant, 1.0-2.0% of an anionic surfactant, 1-5% of a dispersant, 0.4-10% of a compound corrosion inhibitor, 0.1-3% of a defoaming agent, and 52-97% of water. Under the normal temperature condition, the metallic slag oil-water base cleaning agent has high cleaning rate, and is capable of well replacing an organic solvent type cleaning agent, is free from corrosion to the metal, easy to prepare in use, simple in operation, free from combustion and explosion, safe and non-toxic.

Owner:HAO YU ADDITION AGENT

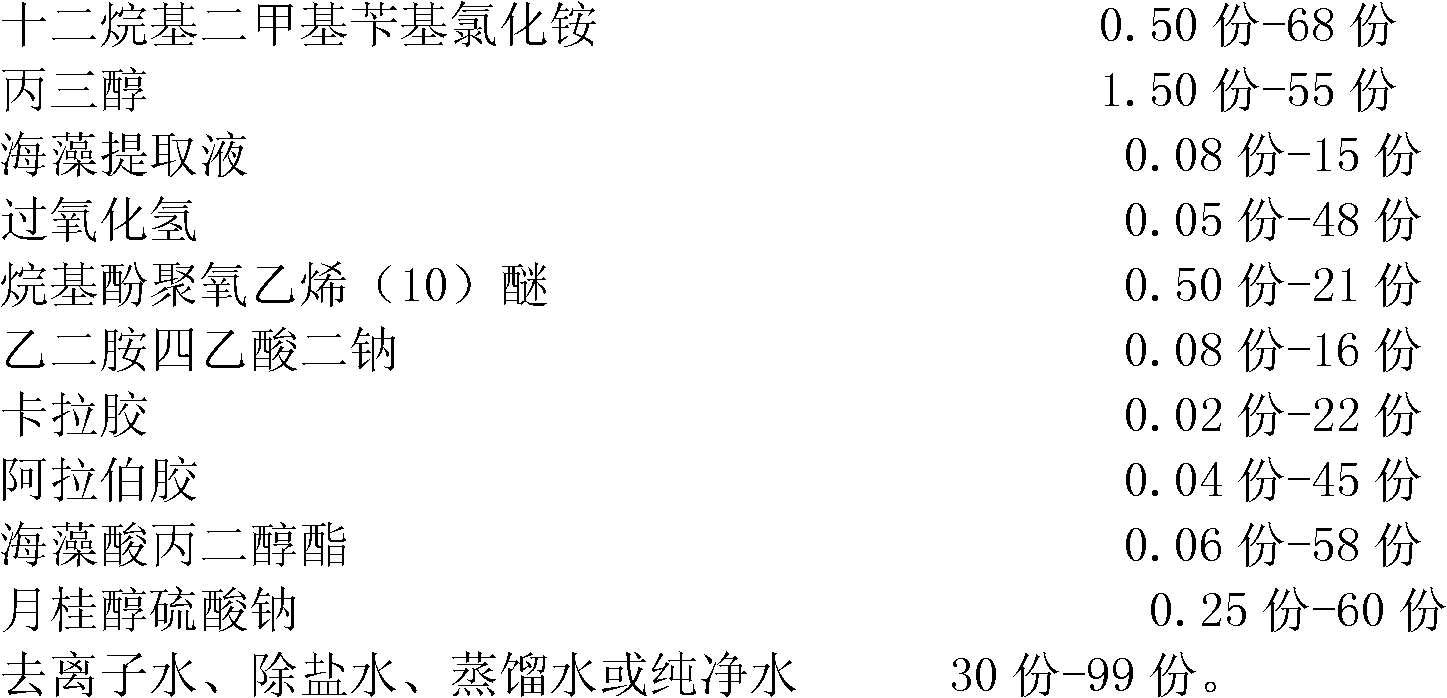

A green efficient sterilizing disinfectant

InactiveCN105581930ALow costStable sterilizationCosmetic preparationsToilet preparationsCarrageenanDisinfectant

A green efficient sterilizing disinfectant is disclosed. The sterilizing disinfectant includes benzyldimethyldodecylammonium chloride, sodium laureth sulfate, coconut oil diethanolamide, glycerin, sodium chloride, a seaweed extract liquid, hydrogen peroxide, citric acid, alkylphenol polyoxyethylene, fatty acid polyoxyethylene ether, fatty acid alkanolamide, disodium ethylenediamintetraacetate, carrageenan, gum Arabic, propylene glycol alginate, sodium laurylsulfate, deionized water, demineralized water, distilled water or purified water according to a weight ratio. According to the sterilizing disinfectant, an accommodating medium is utilized to collect and gather extremely active nascent oxygen with extremely unstable chemical properties, and to store the nascent oxygen in the medium, and the nascent oxygen instantly kills bacteria when being in contact with hand skin. The cost of raw materials of the sterilizing disinfectant is low. The sterilizing disinfectant is free of pollution to the environment after the sterilizing disinfectant is used and is a purely green product.

Owner:邵杰

Efficient flame-retardant heat insulation composite fabric and application

ActiveCN109664582AImprove insulation effectNo pollution in the processPhysical treatmentSynthetic resin layered productsAdhesiveCeramic coating

The invention provides an efficient flame-retardant heat insulation composite fabric and an application. The efficient flame-retardant heat insulation composite fabric comprises a surface fabric, a middle layer and a lining fabric, modacrylic and Lenzing flame-retardant viscose fiber blended yarns serve as warp yarns of the surface fabric, aramid fiber 1313, aramid fiber 1414 and conductive fiberblended yarns are weft yarns, a surface layer is further provided with a nano-ceramic coating, the middle layer is mixture of aerogel and polyurethane, one or two of silicon-nitrogen flame-retardant viscose fibers, aramid fibers 1313, polysulfonamide and polyimide fibers are blended to form the lining fabric, and the middle layer is arranged between the surface layer and a lining layer and fittedwith the surface layer and the lining layer through flame-retardant adhesives. The efficient flame-retardant heat insulation composite fabric is used for manufacturing a flame-retardant heat insulation garment. The efficient flame-retardant heat insulation composite fabric is high in washing fastness by the aid of plasma treatment, the nano-ceramic coating and the middle layer of aerogel and shapememory polyurethane mixture are arranged, flame-retardant heat insulation effects are long and high, and the efficient flame-retardant heat insulation composite fabric has antibacterial health care functions and is widely applied.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

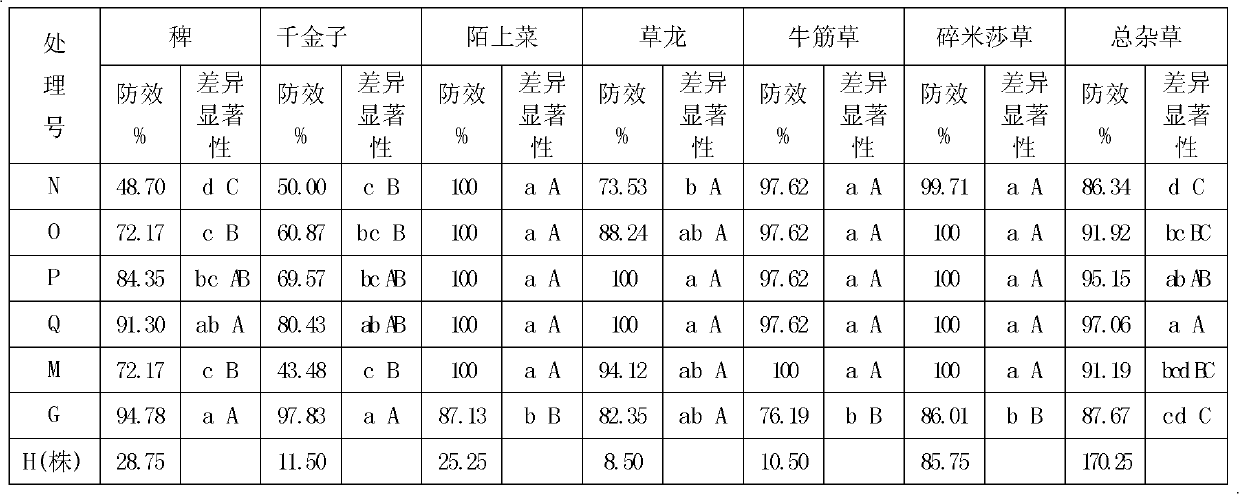

Oxadiargyl and butachlor aqueous emulsion and preparation method thereof

The invention discloses an oxadiargyl and butachlor aqueous emulsion and a preparation method thereof. The aqueous emulsion comprises the following components in percentage by weight: 1%-40% of oxadiargyl, 1%-60% of butachlor, 1%-40% of solvent, 1%-40% of emulsifying agent, 0.1%-10% of thickening agent, 1%-5% of antifreezing agent, 0.1%-1.0% of defoamer, 0.1-1% of preservative agent and the balance of de-ionized water. The preparation method comprises the following steps: dissolving oxadiargyl in the solvent and adding a butachlor pharmacological agent, the emulsifying agent and the thickening agent, thus obtaining an oil phase; mixing the antifreezing agent with the de-ionized water to obtain a water phase; and under a high shear condition, slowly adding the oil phase into the water phase or adding the water phase into the oil phase, thus obtaining the oxadiargyl and butachlor aqueous emulsion. In the field experiment, the oxadiargyl and butachlor aqueous emulsion can achieve a better effect of preventing weeds in a paddy field. The oxadiargyl and butachlor aqueous emulsion has the advantages of high efficiency, low toxicity, environmental friendliness and safety for human and livestock.

Owner:ANHUI KELIHUA CHEM +1

Wearable hot roll

InactiveCN102847713AGood lubrication effectImprove mechanical and chemical propertiesRollsMetal rolling arrangementsNanometreCeramic coating

The invention discloses a wearable hot roll which comprises a hot roll body, wherein a water cooling layer is arranged on the internal wall of the body; and a tungsten carbide hard alloy layer coated with a nanometer ceramic coating outside is coated on the external wall of the body. According to the wearable hot roll, the tungsten carbide hard alloy layer is coated on the surface of the body, and the nanometer ceramic coating is coated outside the tungsten carbide hard alloy layer, so the wearable hot roll has the effect of heat insulating, has no falling and no burning, is waterproof and moisture-proof, and is good in effect of lubricating; the mechanical performance and the chemical performance of the hot roll are greatly improved; and meanwhile, good effect of cooling can be achieved via the water cooling layer, therefore, the longer service life can be ensured.

Owner:虞伯林

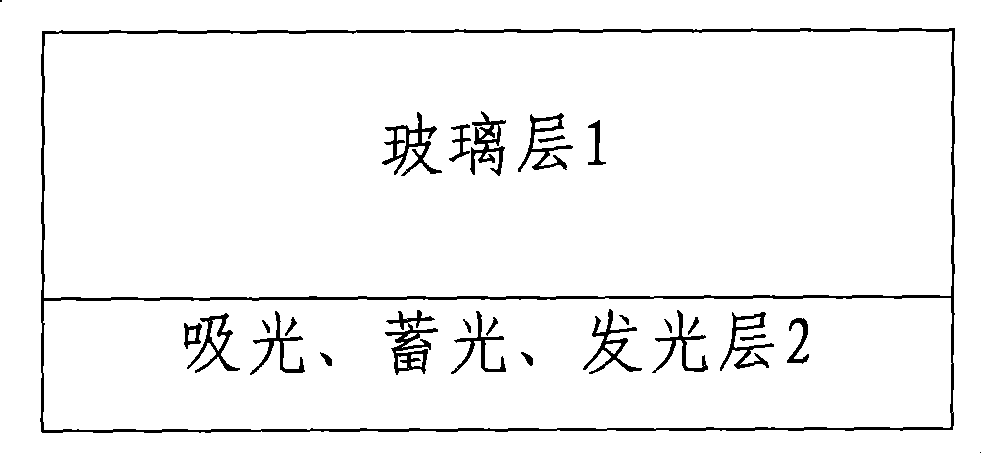

High-brightness extinction, light-storing, luminescent glass and method of producing the same

The invention discloses high-brightness light absorbent, storage and luminescent glass and a manufacture method thereof, which belongs to the technical field of glass manufacture. The glass is designed for solving the problems of low lightness and short time of persistence of the luminescent glass in the prior art. The high-brightness light absorbent, storage and luminescent glass comprises a glass layer and a light absorbent, storage and luminescent layer, wherein the glass layer accounts for 60 to 80 percent of gross weight, and is made of glass powder; and the light absorbent, storage and luminescent layer accounts for 20 to 40 percent of the gross weight, and is made of light absorbent, storage and luminescent powder and the glass powder. The manufacture method comprises the following steps: evenly mixing the glass powder with the light absorbent, storage and luminescent powder; placing the mixed powder on a tray according to certain thickness; covering the glass powder with certain thickness on the tray; and putting the tray in a heating furnace to be baked into the high-brightness light absorbent, storage and luminescent glass. The method is applicable to manufacture luminescent glass.

Owner:葛利民

Ferrous metal corrosion prevention rust preventer and production method thereof

InactiveCN101629044AExtended service lifeNo pollution in the processAnti-corrosive paintsAluminium powderRust converter

The invention relates a ferrous metal corrosion prevention rust preventer and a production method thereof; and the rust preventer comprises the following raw materials according to the parts by weight: 35-40 parts of thermosetting phenolic resin, 10-15 parts of naphthenic acid, 7-10 parts of aluminium oxide, 8-10 parts of clay, 10-15 parts of gypsum powder and talcum powder, 10-12 parts of aluminum naphthenate, 15-18 parts of aluminium powder and 5-10 parts of additive. The production method comprises the following steps: grinding aluminium oxide, talcum powder and clay to powders; mixing naphthenic acid, additive and aluminum naphthenate with aluminium oxide powder, talcum powder and clay powder to react, obtaining a complex compound; dripping thermosetting phenolic resin to react, obtaining a semifinished product; and finally obtaining the finished product by grinding the semifinished product with a ball grinding mill. The ferrous metal coated by the rust preventer of the invention can prevent rust for 20 years in the air, in the rain and in the sun and can prevent rust for 10 years in the water or a well; the ferrous metal can not get rusty and burn, can not be corroded and oxidized, and has no environmental pollution, so that the product of the invention has extremely wide application.

Owner:邵阳市创捷化工有限公司

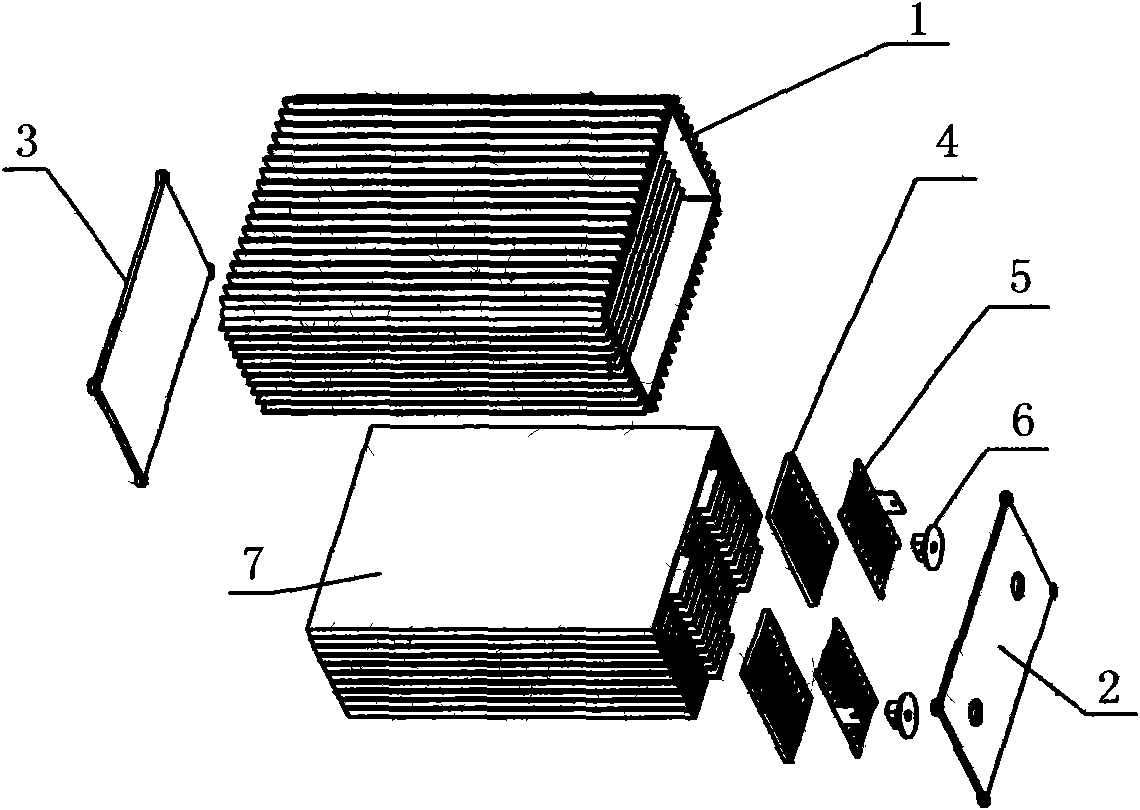

Electric vehicle battery

InactiveCN101630754AImprove securityDon't burnSecondary cellsCell component detailsLithium vanadium phosphate batteryLithium iron phosphate

The invention discloses an electric vehicle battery which is characterized by comprising an aluminum shell internally provided with soft bag lithium iron phosphate batteries. The interior of the aluminum shell has an aluminum bracket structure and is divided into ten cells, and each cell is internally provided with ten flaky soft bag lithium iron phosphate batteries. Insulating reinforced paper is wrapped outside each lithium iron phosphate battery, and the upper ends and the lower ends of the lithium iron phosphate batteries are fixed in each cell in the aluminum shell. The positive pole and the negative pole of each lithium iron phosphate battery collect current by a copper billet and output the current through a connection column, wherein an insulator on the periphery of the connection column is fixed on an upper cover of the aluminum shell, and the periphery of the connection column is provided with an inner nut convenient for the parallel connection and the series connection of battery units. The soft bag lithium iron phosphate battery is a battery unit of 3.2V and 200AH, which is assembled by parallel connection of ten single lithium iron phosphate batteries of 3.2V and 200AH. The invention has the advantages of high efficiency, good performance, long service life, low cost and no environmental pollution.

Owner:SHENZHEN MOTTCELL NEW ENERGY TECH CO LTD

Automobile glass anti-fog frost-prevention agent

The invention provides an antifogging and antifrost agent for car glass. It essentially comprises sodium dodecyl sulfate, alkylsulfo sodium succinate, propanediol, isopropanol, dodecanol, ethylene glycol alcohol, tri hydroxyethyl methyl ammonium methyl sulfate,sodium benzoate,essence and pure water. It can be prepared through a special process. The invention is characterized by low cost and convenient utilization.

Owner:TIANJIN SHIXIONG TECH DEV

Nano magnesium-aluminum anti-corrosion coating and preparation method thereof

ActiveCN104673054ALow dielectric lossGood material uniformityAntifouling/underwater paintsPaints with biocidesDiethylenetriamineDipropylene glycol

The invention discloses a nano magnesium-aluminum anti-corrosion coating. The coating comprises a first component and a second component, wherein the second component is formed by mixing a component A with a component B; the first component comprises components as follows: epoxy resin, hydroxyl acrylic resin and ammonium dihydrogen phosphate; the component A comprises components as follows: nano magnesium oxide, nano aluminum oxide, nano titanium dioxide, nano zirconium dioxide, nano rare earth oxide and deionized water; the component B comprises components as follows: butanol, filler, barium sulfate, diethylenetriamine and dipropylene glycol butyl ether. The invention further discloses a preparation method of the nano magnesium-aluminum anti-corrosion coating. The coating is high in mechanical strength and excellent in wear resistance, hardness, compressive strength and impact resistance, meanwhile, the preparation technology is simple and easy to operate, the cost is lower, the production process is safe and environment-friendly, and no pollutant is produced.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Method for processing silicon rubber composite material

InactiveCN102152553AHas smoke suppressant propertiesDon't burnLaminationLamination apparatusWork in processSilicon

The invention relates to a method for processing a silicon rubber composite material, which is characterized in that semi-finished products of a silicon rubber fireproof isolating layer (1), a silicon rubber flame-retardant cooling layer (2), a silicon rubber ablation-resistant layer (3) and a silicon rubber body layer (4) are respectively prepared in the method firstly, and then the semi-finished products are laminated in a mould of a laminating machine in turn to process the composite material in a molding way under certain conditions. The silicon rubber composite material has better flame-retardant and fireproof effects, and is suitable for serving as a fireproof silicon rubber material for manufacturing fire division walls required in special environments of aircrafts, as well as interior fireproof materials of high-speed vehicles and buildings, military equipment, fire-fighting equipment and the like.

Owner:WUJIANG LANGKE CHEM FIBER

Special-purpose organic silicon rubber waterproof paint for external wall and preparing method thereof

InactiveCN101148563ANon-volatileDon't burnAntifouling/underwater paintsPaints with biocidesWeather resistanceEmulsion

Owner:青州市利达防水材料有限公司

Mixed ion-electron conductor with garnet structure and application thereof in energy storage device

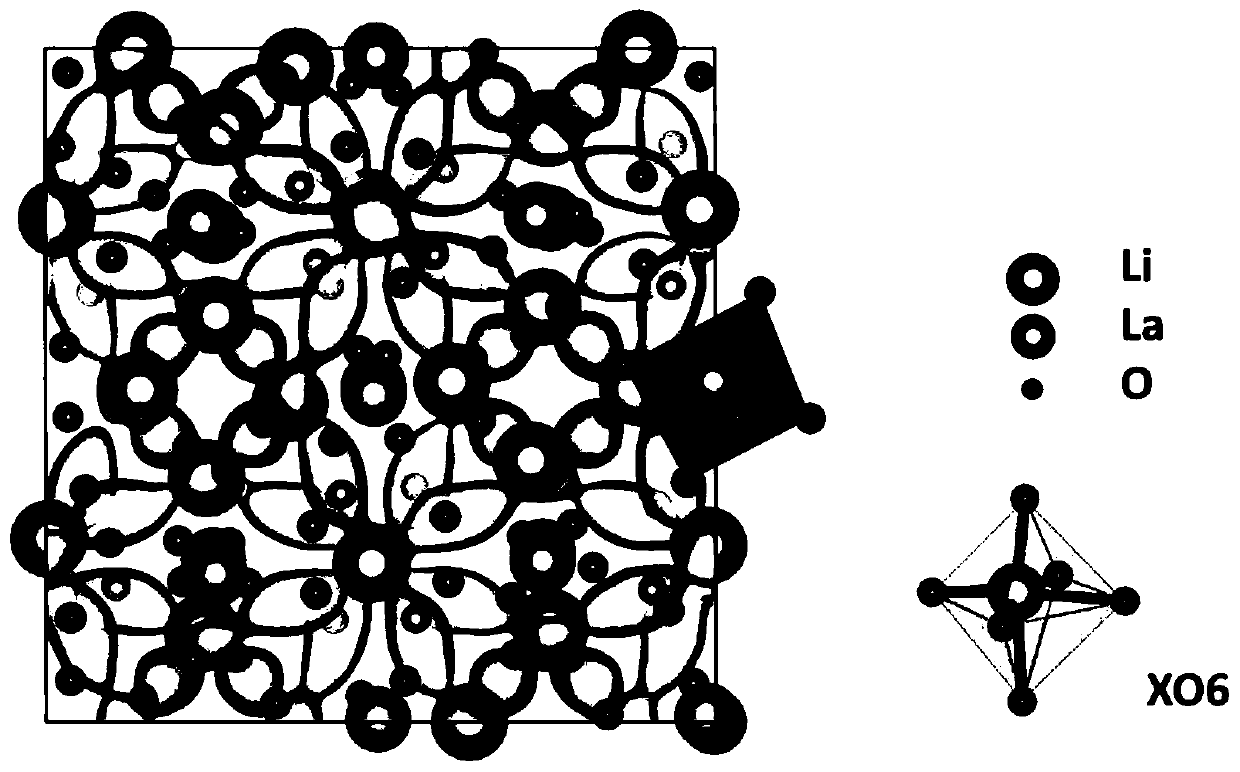

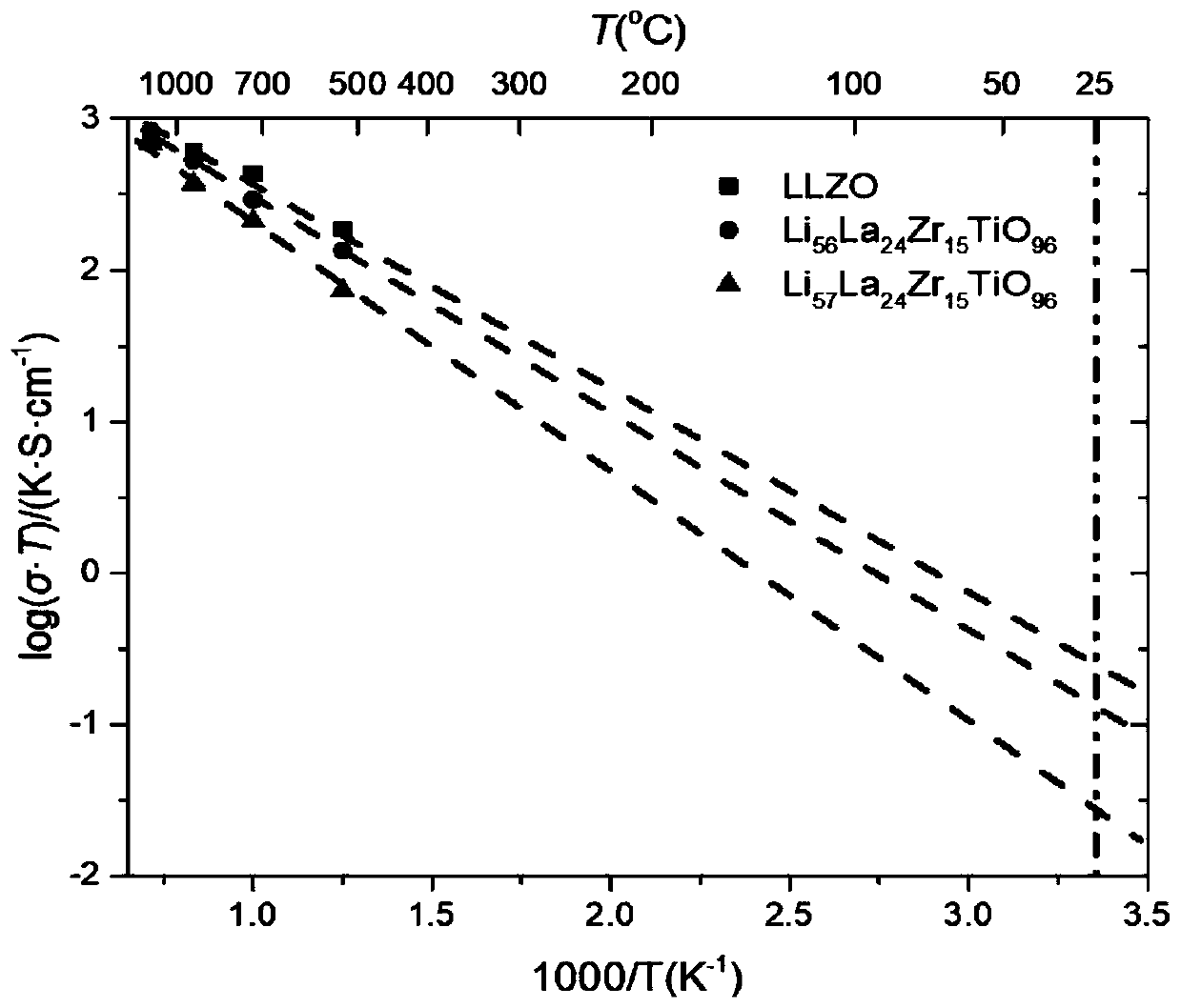

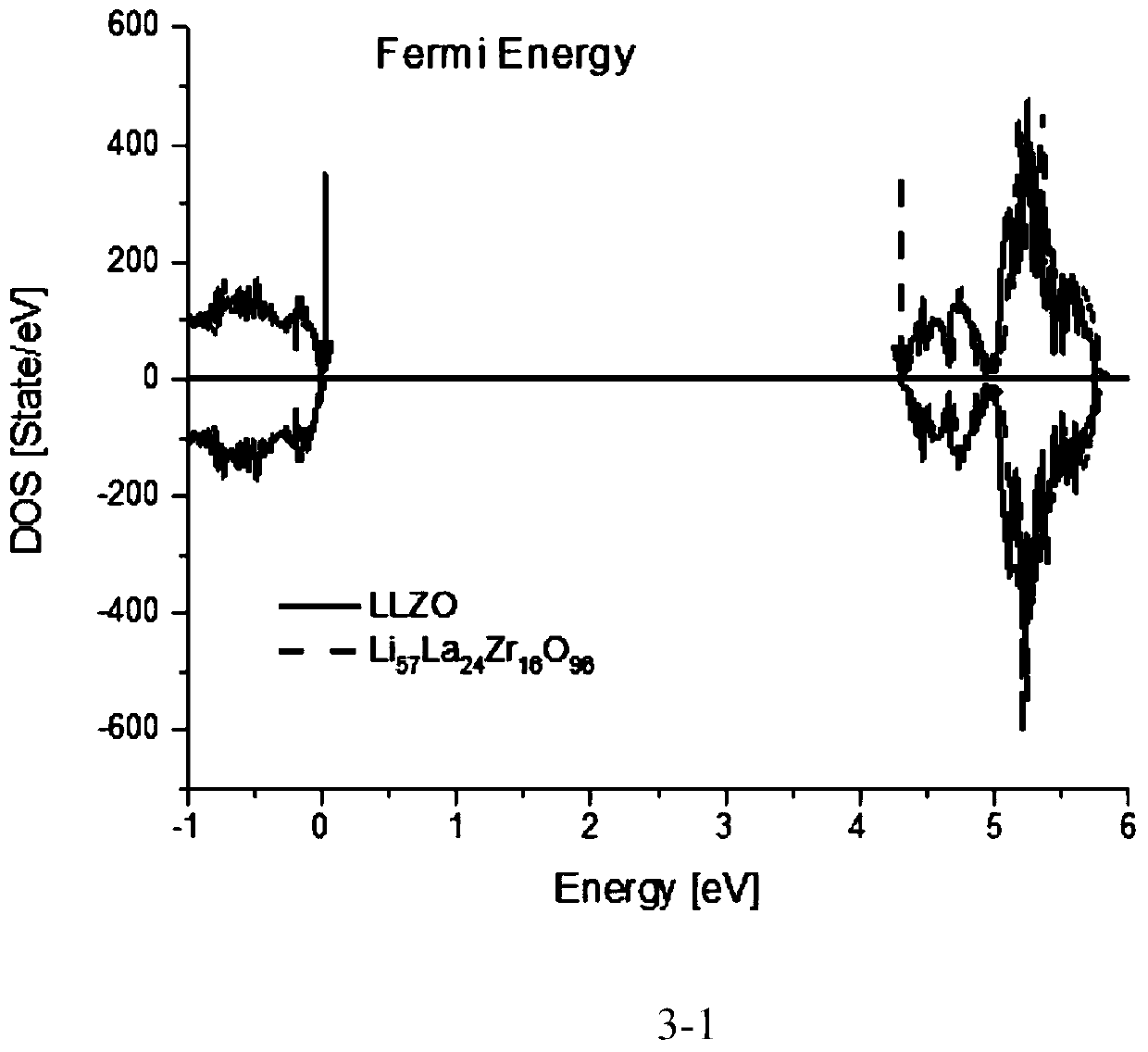

InactiveCN111326787AImprove power densityAdapt to assembly needsHybrid capacitor electrolytesRegenerative fuel cellsMetallic lithiumElectrical conductor

The invention relates to a mixed ion-electron conductor with a garnet structure and application of the mixed ion-electron conductor in an energy storage device. The general formula of the conductor is(LimM)xLa3(Zr<1-a>Xa)2O12, wherein m is greater than 0 and less than or equal to 1, n is greater than or equal to 0 and less than or equal to 0.5, the sum of m and n is less than or equal to 1, and xis greater than or equal to 3 and less than or equal to 7.5; M comprises at least one element selected from H, Na, K, Rb, Mg, Ca, Sr, Ba, Y, La, Ti, Zr, Zn, B, Al, Ga, In, C, Si, Ge, P, S and Se; a is greater than or equal to 0 and less than 1; and X comprises at least one element selected from Ta, Hf, V, Nb, Ta, Cr, Mo, W, Mn, Fe, Co, Ni, Si, Ge, Sn, Pb, As, Sb and Se. The conductor provided bythe invention has high ionic conductivity and electronic conductivity, and can be applied to an electrode / electrolyte interface layer in a battery or a capacitor, a positive electrode layer and a negative electrode layer. The mixed ion-electron conductor can be applied to a lithium ion battery, a rechargeable metal lithium battery, a lithium flow battery and a lithium ion capacitor, and the energystorage devices have wide application.

Owner:BEIJING UNIV OF CHEM TECH

Process for cleaning optical resin lens substrate and forming mould

InactiveCN102601072ALong service lifeImprove cleaning efficiencyCleaning using liquidsCorrosive substanceAqueous solution

The invention discloses a process for cleaning an optical resin lens substrate and a forming mould. The process includes the steps of cleaning liquid preparation, ultrasonic cleaning, ultrasonic rinsing, drying and the like. The cleaning liquid is prepared by adding, in weight percent, 1-10% of alkyl sodium sulfonate, 1-5% of TX-10 and 1-5% of citric acid into sodium hydroxide with the concentration of 1-10% after mixing, neutralizing the mixture to reach the pH (potential of hydrogen) value ranging from 7 to 7.5, and adding water to reach 100%. The cleaning liquid is high in cleaning strength, dirt such as resin, adhesive, fingerprint, grinding residue and the like adhered to the surface of the resin lens substrate or the forming mould can be rapidly removed, the surface of the substrate or the forming mould is not damaged, water solution in the cleaning liquid can be reused, and the cleaning liquid is fine in economical efficiency, safe in use, simple in discharge, environment-friendly, non-corrosive, non-volatile, non-hazardous and non-combustible.

Owner:王家德

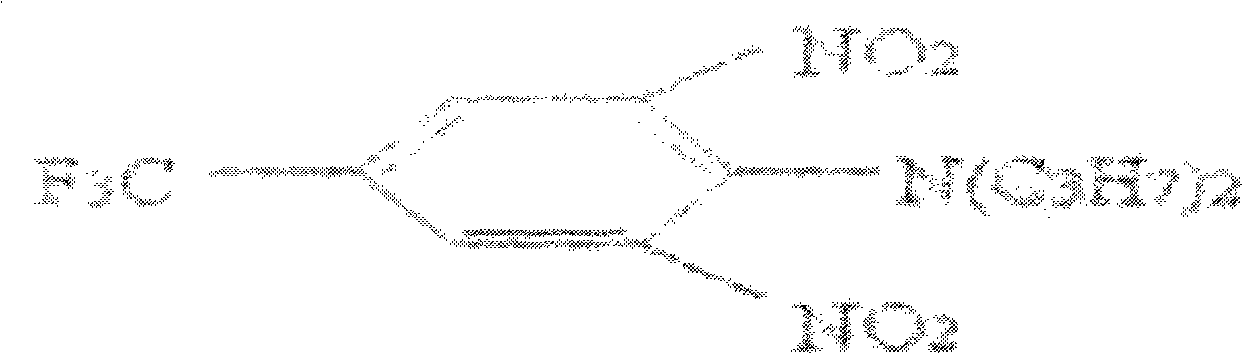

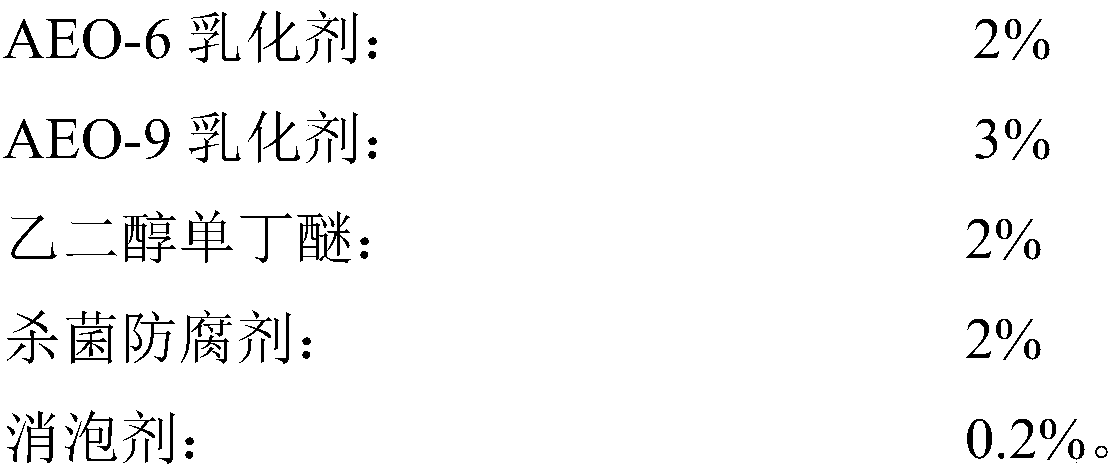

Trifluralin emulsion in water and preparation method thereof

The invention relates to a pesticide preparation and a preparation method thereof, in particular to a trifluralin emulsion in water and a preparation method thereof. The trifluralin emulsion in water comprises the following components in part by mass: 0.5 to 48 parts of trifluralin, 1 to 20 parts of solvent, 1 to 16 parts of emulsifier, 0.1 to 5 parts of thickening agent, 0 to 8 parts of antifreezing agent, 0.1 to 1.6 parts of defoaming agent, 0 to 3 parts of antimicrobial agent, a proper amount of pH value regulator, and the balance of deionized water. The trifluralin emulsion in water is a selective pre-emergence soil treatment agent, and is mainly absorbed through coleoptiles and hypocotyls of weeds. The trifluralin emulsion in water has the effect on gramineous and partial small-seed broadleaf weeds, and is applicable to cotton, soybeans, rape, peanuts, potatoes and the like. The trifluralin emulsion in water does not contain or rarely contains an organic solvent, so the manufacturing cost and use cost are reduced, and the toxicity produced to operators, storers and transporters, and users is reduced in the process of production, storage and transportation; and the trifluralin emulsion in water is a product which is environmental-friendly and has high safety.

Owner:威海韩孚生化药业有限公司

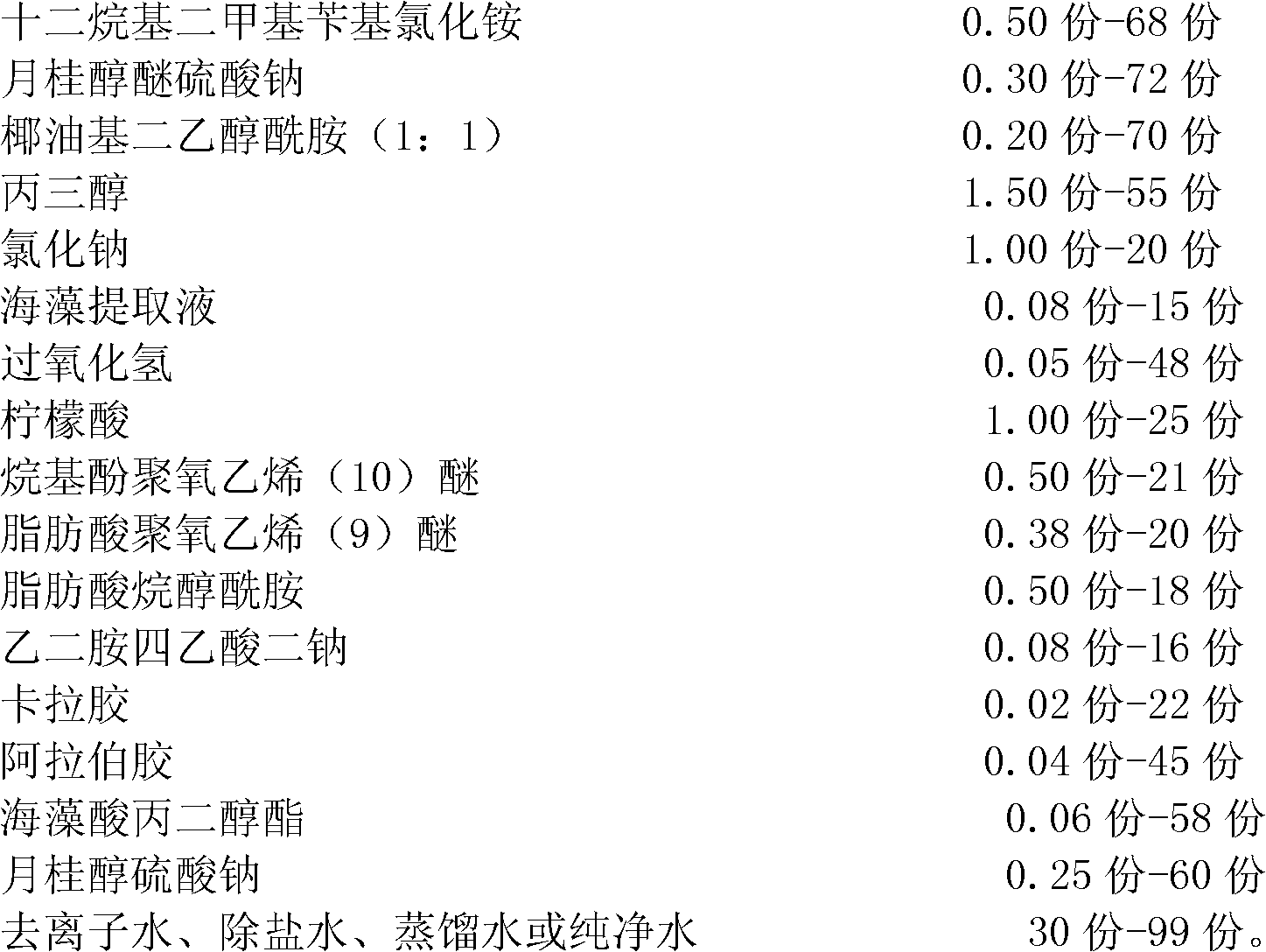

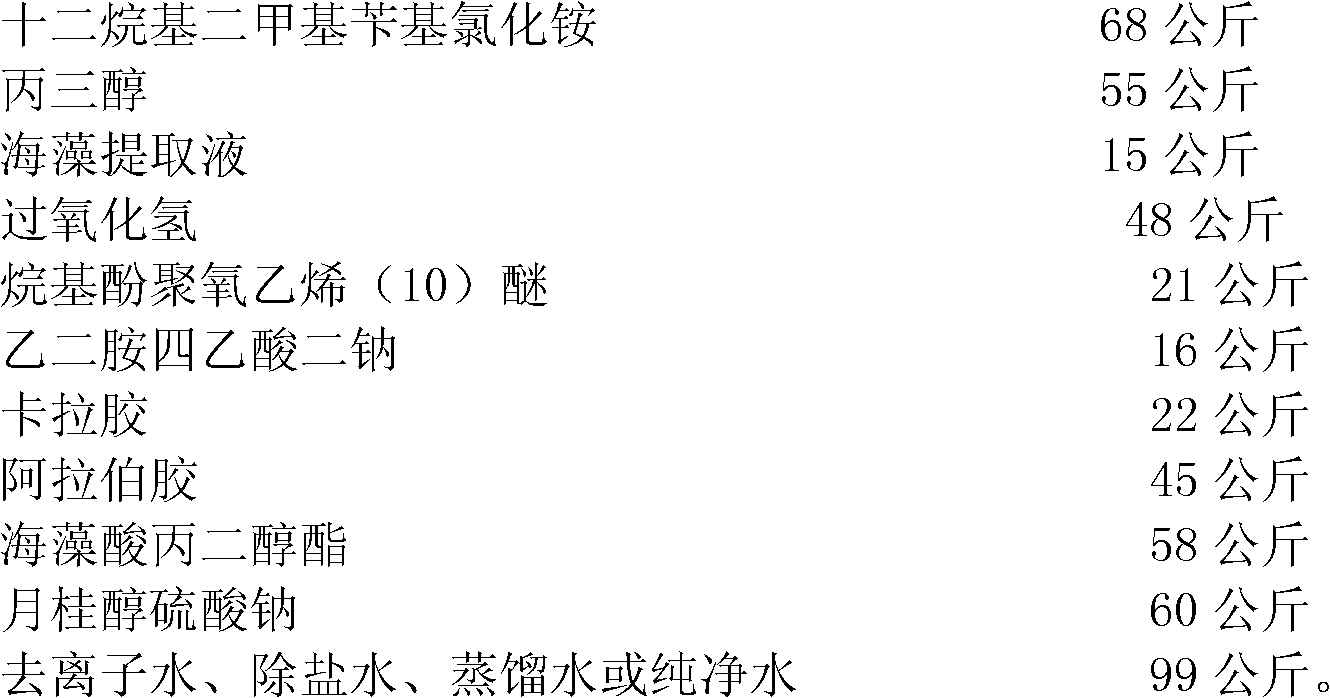

Nascent oxygen high speed specific bactericidal disinfectant

The invention provides a nascent oxygen high speed specific bactericidal disinfectant. The nascent oxygen high speed specific bactericidal disinfectant comprises dodecyl dimethyl benzyl ammonium chloride, sodium laureth sulfate, a coconut diethanol amide, glycerol, sodium chloride, seaweed extract, hydrogen peroxide, citric acid, alkylphenol polyoxyethylene, fatty alcoholpolyoxyethylene ether, fatty acid alkanol amide, ethylene diamine tetraacetic acid, carrageenan, Arabic gum, propylene glycol alginate, sodium lauryl sulfate, deionized water, demineralized water, distilled water or purified water according to a weight ratio. According to the nascent oxygen high speed specific bactericidal disinfectant provided by the invention, the extremely active nascent oxygen with extremely instable chemical property is collected, gathered and stored in the medium by using a wrapping medium; and the nascent oxygen instantaneously kills bacteria while contacting hand skins. The nascent oxygen high speed specific bactericidal disinfectant, which is a purely green and environment friendly product, has the advantages of very low raw material cost and no pollution to the environment after being used.

Owner:唐玉江

Water-based cleaning agent for magnesium aluminum alloy and preparation method of water-based cleaning agent

The invention provides a water-based cleaning agent for magnesium aluminum alloy and a preparation method of the water-based cleaning agent. The cleaning agent comprises stearic acid, phosphatidylcholine, sodium polyacrylate, propanediol butyl ether, sodium xylene sulfonate, dimethyl silicon oil, alkanolamide, sodium metasilicate, benzotriazole, sodium allysulfonate, diacetone acrylamide, dimethylaminoethyl acrylate, a defoaming agent and deionized water. The preparation method comprises the steps of firstly, adding stearic acid, phosphatidylcholine, sodium polyacrylate, propanediol butyl ether and diacetone acrylamide into the deionized water, heating and stirring to obtain a mixture I; then, adding sodium xylene sulfonate, dimethyl silicon oil and alkanolamide into the mixture I, and stirring while adding to obtain a mixture II; next, adding sodium metasilicate, benzotriazole and sodium allysulfonate into the mixture II, and stirring while adding to obtain a mixture III; and finally, adding the left components into the mixture III, heating, stirring, and cooling by standing to obtain the water-based cleaning agent. The cleaning agent is rather high in cleaning rate under the condition of normal temperature, capable of favorably replacing an organic solvent type cleaning agent and free of corrosion to metal.

Owner:南通江海港建设工程有限公司

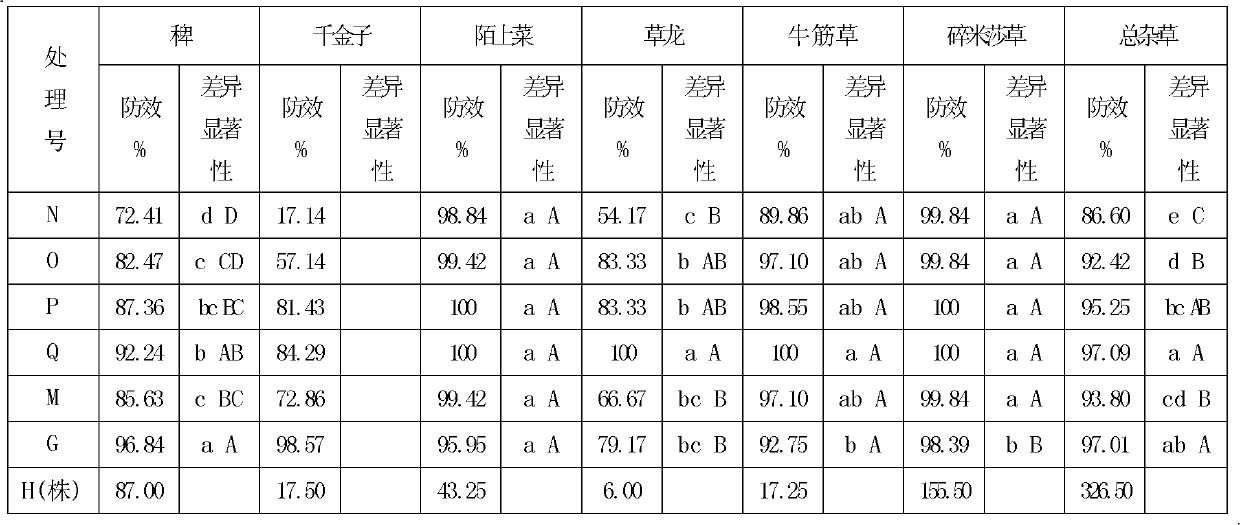

Pendimethalin emulsion in water and preparation method thereof

The invention relates to a pesticide preparation and a preparation method thereof, in particular to a pendimethalin emulsion in water and a preparation method thereof. The pendimethalin emulsion in water comprises the following components in percent by mass: 1-45 parts of pendimethalin, 1-20 parts of solvent, 1-18 parts of emulsifier, 0.1-6 parts of thickening agent, 0-5 parts of antifreeze, 0-3 parts of antimicrobial, 0.1-0.5 portion of defoamer, a proper volume of pH regulator and 100 parts of deionized water. The invention relates to a selective herbicide, which is used for preventing and removing annual Gramineae weeds, and applied after planting grain plants, corns and rice and before seedling, or applied in shallow soil for broad beans, cottons, peanuts and soybeans, and applied before seedling or transplanting in vegetable fields; moreover, the pendimethalin emulsion in water can also be used for preventing and removing tobacco and inhibiting buds. The pendimethalin emulsion in water does not use or uses less organic solvent, which lowers the manufacture cost and use cost, reduces toxicity to operators, storage and transportation personnel, and users during the production, storage, transportation and use processes, and is an environmental protective product with high safety.

Owner:威海韩孚生化药业有限公司

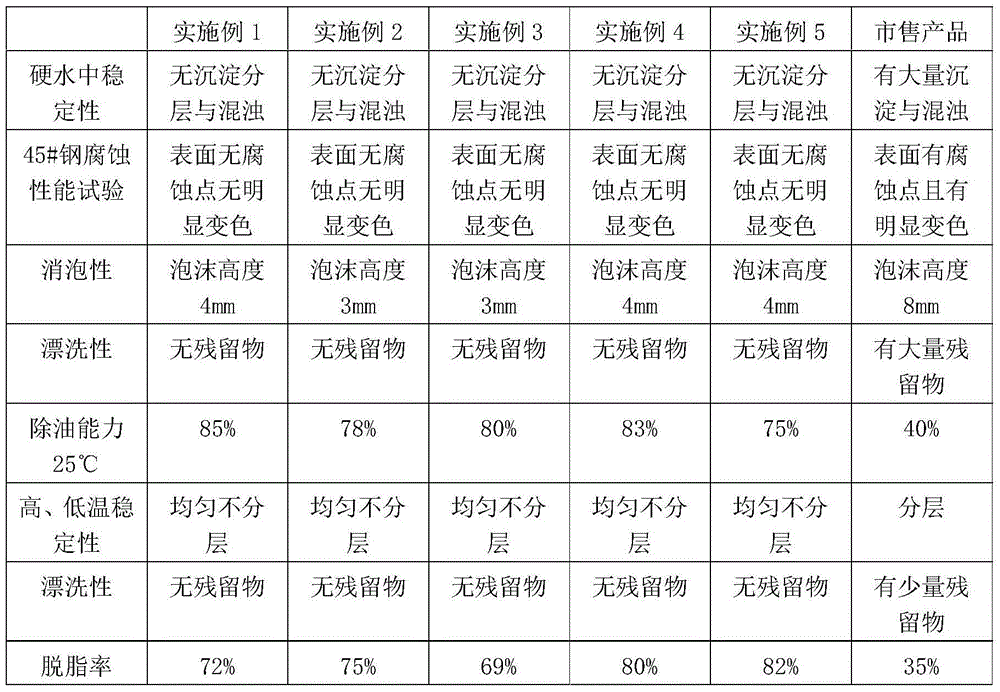

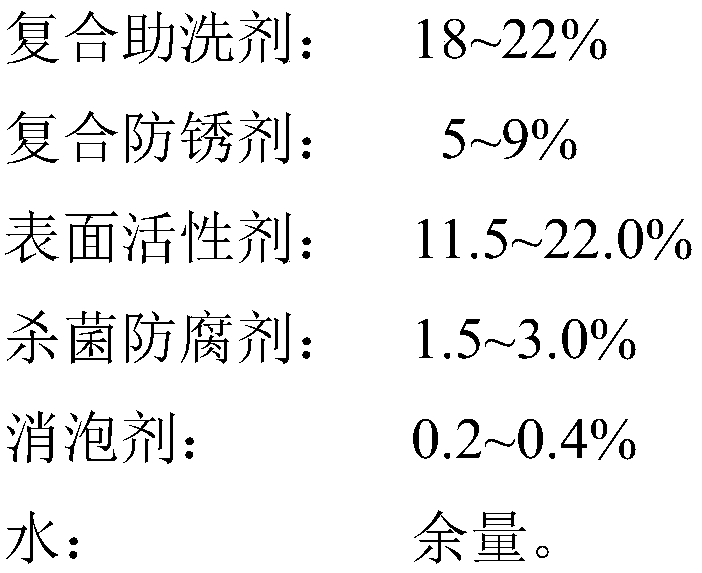

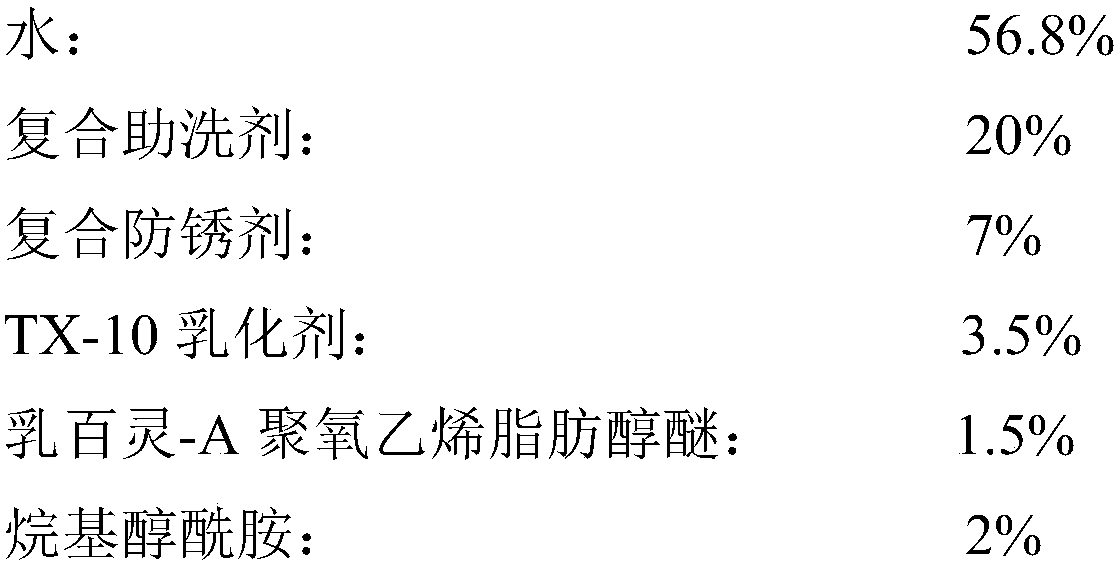

Rust-proof cleaning agent and application thereof to hardware products

InactiveCN109136964AReduce surface tensionGood solubility and dispersibilityPreservativeCleansing Agents

The invention discloses a rust-proof cleaning agent and an application thereof to hardware products. The rust-proof cleaning agent comprises a compound builder, a compound anti-rust agent, a surfactant, a sterilizing preservative, a defoaming agent, water and the like. The rust-proof cleaning agent has good lubricating, permeating, emulsifying and dispersing functions and has a washing performancefor animal and plant oil and mineral oil, the cleaning agent can be blended and diluted by deionized water according to rust-proof cleaning process requirements, and the technical requirement of enterprises for cleanliness quality of various universal mechanical parts and hardware products in the manufacturing process. The rust-proof cleaning agent cannot corrode equipment and workpieces in the use process, cannot foam or combust, is free from unpleasant pungent odor, strong in microbial reproduction resistance, long in use cycle and not easy to stink and deteriorate, and the products cleanedby a joint cleaning device are free from rusting after being suspended and exposed in inter-processes for more than 7 days.

Owner:GUANGZHOU YUEHUI METAL MACHINERY PROTECTION TECH +2

Phoxim emulsion in water (EW) and preparation method thereof

The invention relates to a pesticide preparation and a preparation method thereof, in particular to a phoxim emulsion in water (EW) and a preparation method thereof. The phoxim EW comprises the following components in parts by weight: 1-40 parts of phoxim, 0-20 parts of solvent, 1-16 parts of emulsifier, 0.1-3 parts of thickener, 0.2-5 parts of antifreeze agent, 0-3 parts of antimicrobial agent, 0.1-1.5 parts of antifoaming agent, a proper amount of pH value modifier and the balance of deionized water. The pesticide preparation is used for preventing and curing soil pests, such as mole crickets, grubs, wireworms, cutworms and the like, can be used for warehouses and sanitary pests, has the advantage of long-lasting efficacy and short efficacy continuing period for foliage application, and can be used for preventing and curing cotton bollworms, armyworms, rice stem borers, ostrinia furnacalis, soybean moth and the like. The pesticide preparation has the advantages that the use amount of organic solvent is reduced or the organic solvent is abandoned, the manufacture cost and use cost are lowered, and the toxicity for operators, storage and transportation personnel and users in the use process is reduced, thereby being an environmentally-friendly product with high safety.

Owner:威海韩孚生化药业有限公司

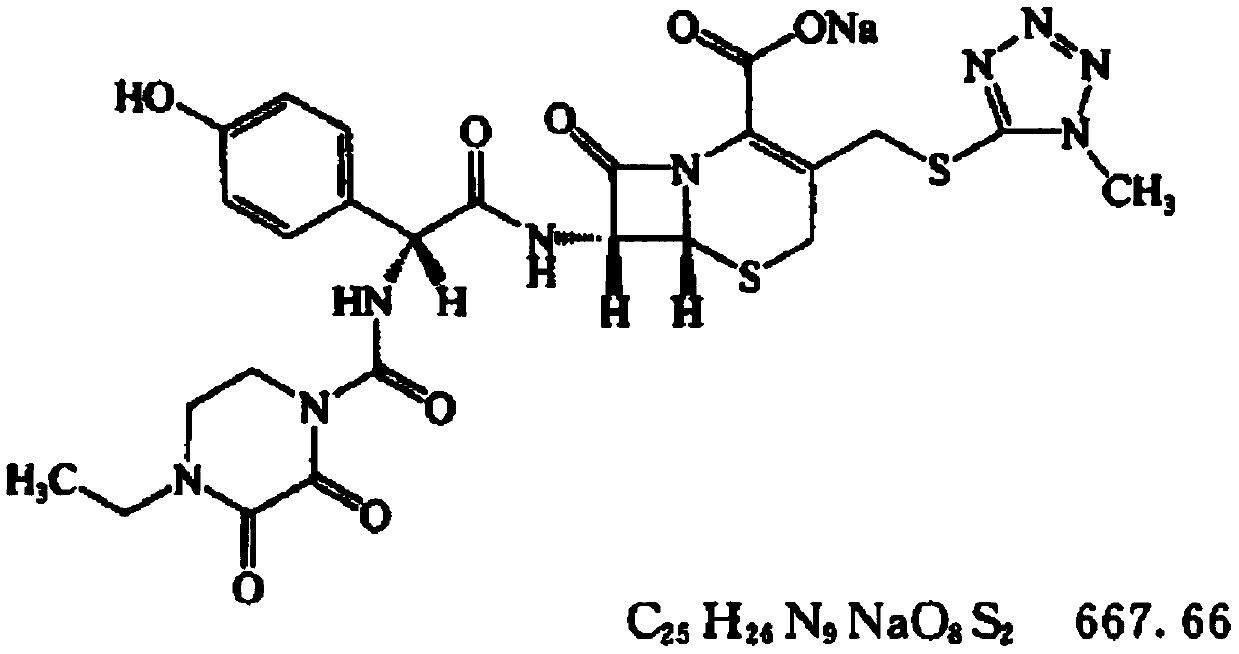

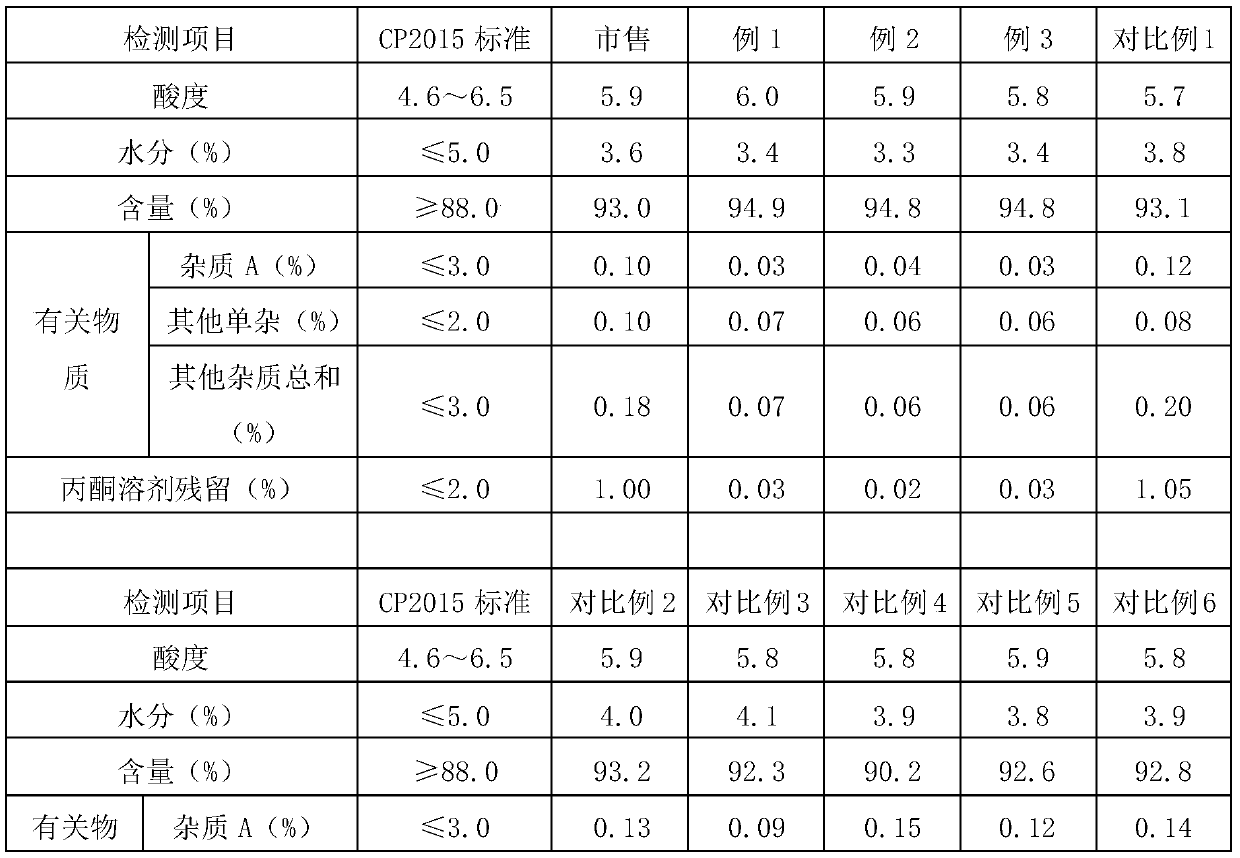

Preparation method of high-purity cefoperazone sodium micro powder

ActiveCN109796470AHigh purityLess impuritiesOrganic chemistryBulk chemical productionImpurityCrystallization

The invention discloses a preparation method of high-purity cefoperazone sodium micro powder, and belongs to the technical field of medicines. Cefoperazone acid is taken as a raw material, a cefoperazone sodium solution is prepared first, decolorizing treatment is then conducted, the decolorized cefoperazone sodium solution is added to a reaction kettle to which a super-critical fluid is added, and the cefoperazone sodium micro powder is obtained through crystallization. The preparation method has the advantages that the process is stable, the micro powder is green and environmentally friendly, the oxidation of a product can be avoided, the prepared cefoperazone sodium micro powder has the advantages of high purity and less impurity, the particle fluidity of the product is good, and the granularity is controllable.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

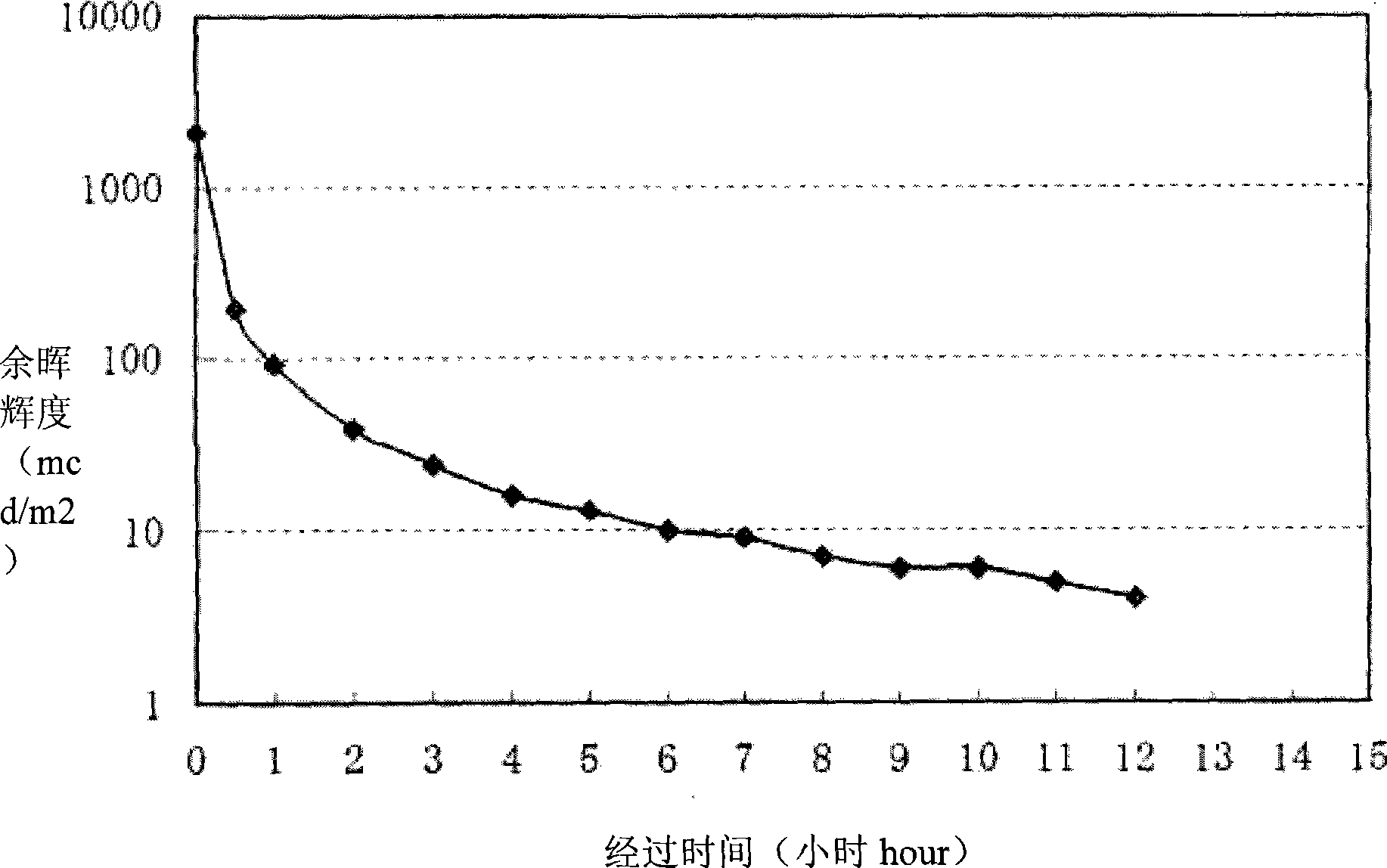

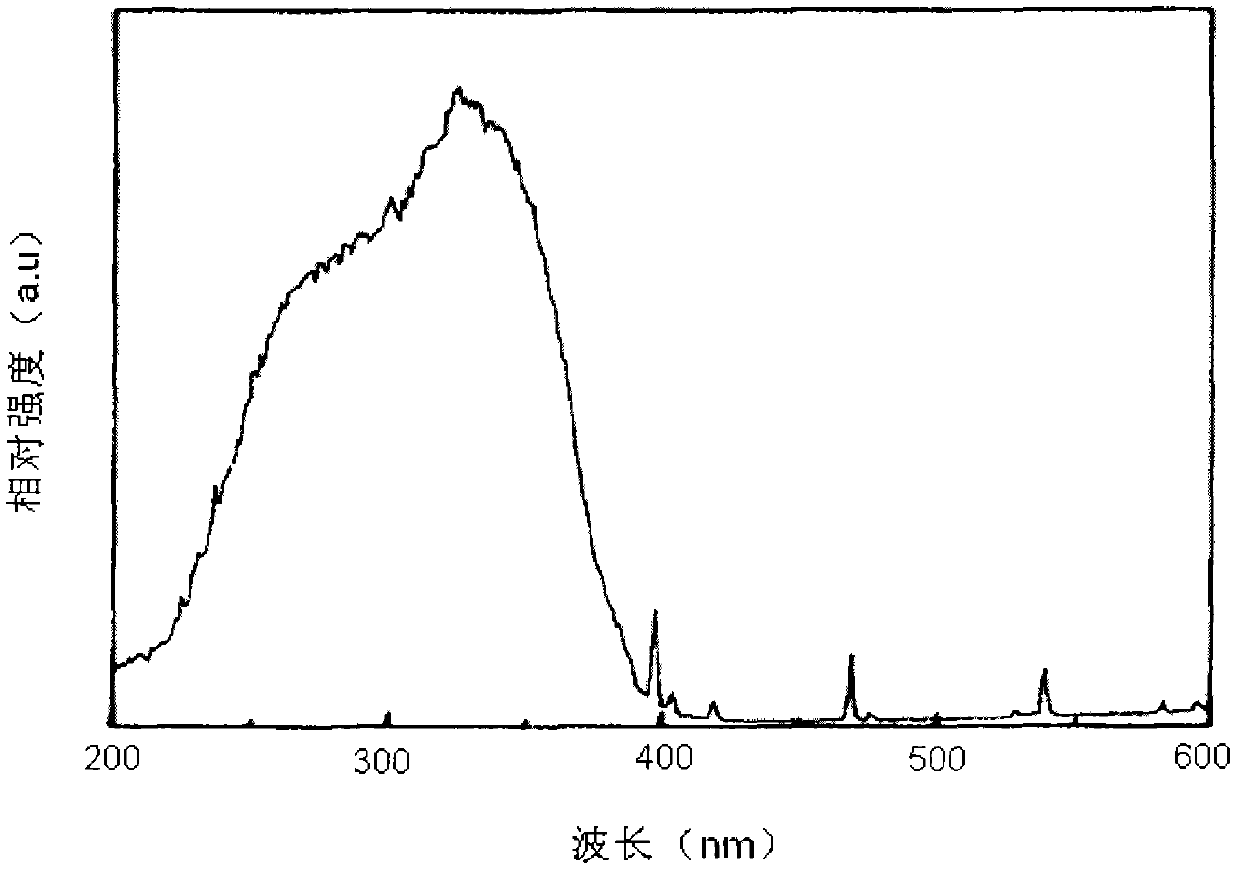

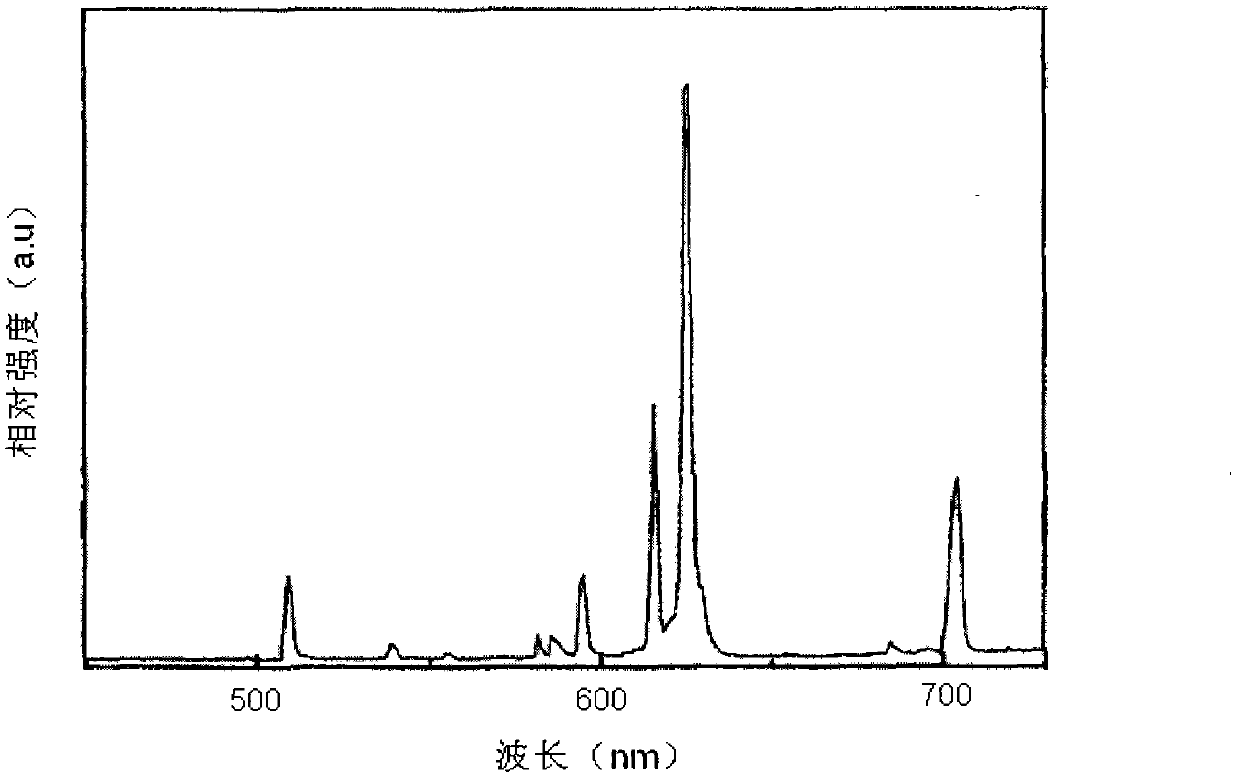

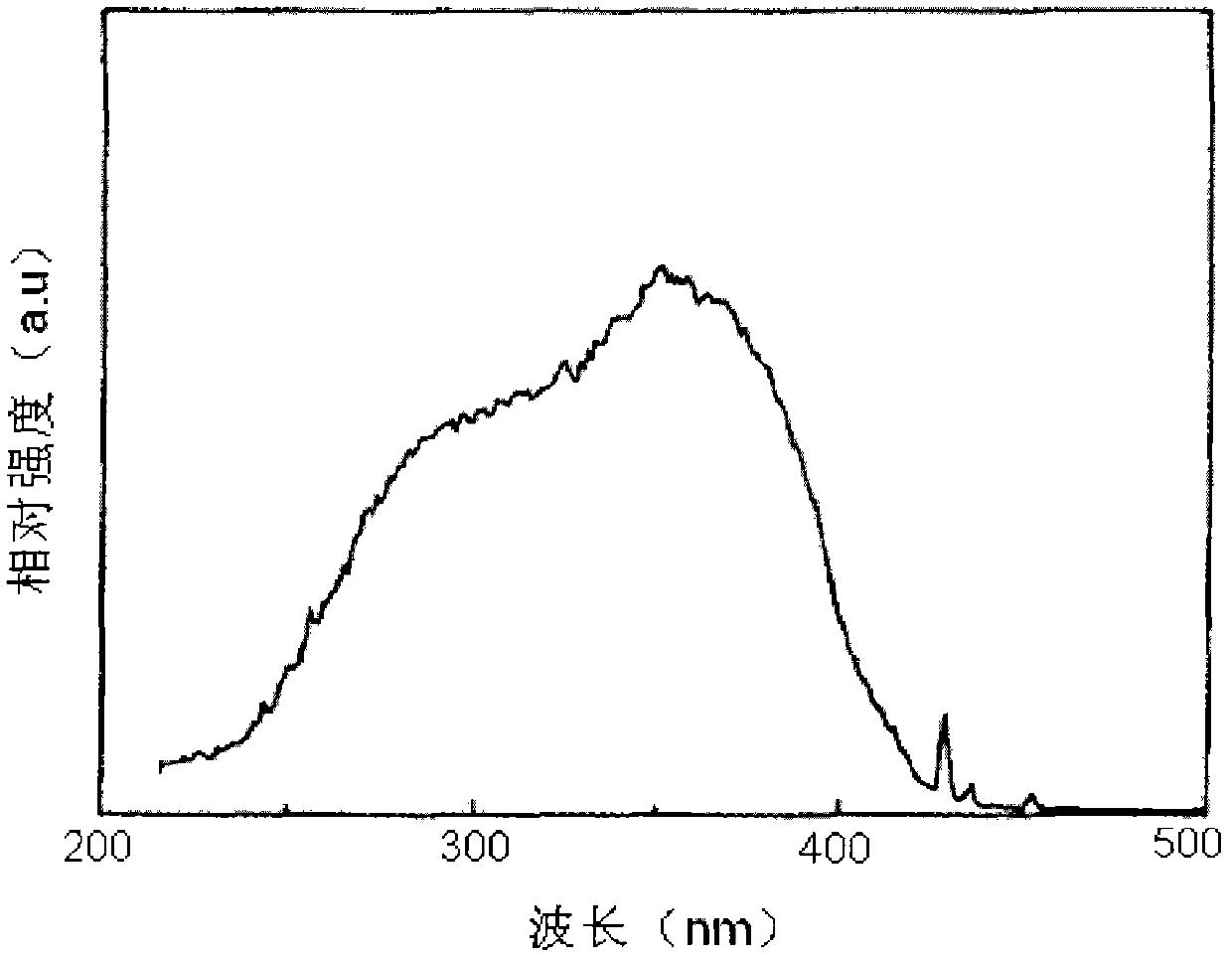

Ultrafine particle energy-storage type long-lasting phosphor material and preparation method thereof

The invention discloses an energy-storage type long-lasting phosphor material and a preparation method thereof. According to the preparation method, after multiple metal oxides are respectively doped with manganese element, multiple oxide superfine particle powder raw materials are prepared; and then the multiple oxide superfine particle powder raw materials are uniformly mixed, and the obtained mixture is roasted so as to obtain an energy-storage type long-lasting phosphor material. The preparation process is low in energy consumption, and the prepared phosphor material is non-toxic, non-radioactive, low in excitation conditions, high in optical storage speed, high in afterglow brightness, long in afterglow time, stable in luminescence property, and wide in application scope.

Owner:梁清源 +1

Production technology for integrated tray type polyurethane heat-insulating heating tile

InactiveCN106273185AKeep warmReduce heat dissipationCovering/liningsFlooring insulationsControllabilitySurface plate

The invention discloses a production technology for an integrated tray type polyurethane heat-insulating heating tile. The production technology comprises the following steps: (1) putting a ceramic panel into a forming mold; (2) putting a tray containing a carbon fiber heating material on the back of the ceramic panel; (3) pouring a polyurethane foaming raw material into the forming mold, closing the mold, polymerizing polyurethane after 8-15min, opening the mold and taking out, thereby acquiring the integrated tray type polyurethane heat-insulating heating tile. The production technology has the advantages of simple process, high controllability and facilitation of large-scale production. The prepared floor heating tile has the advantages of long service life, convenience in mounting, high heating speed, high heat supply efficiency and attractiveness.

Owner:四川省新万兴瓷业有限公司

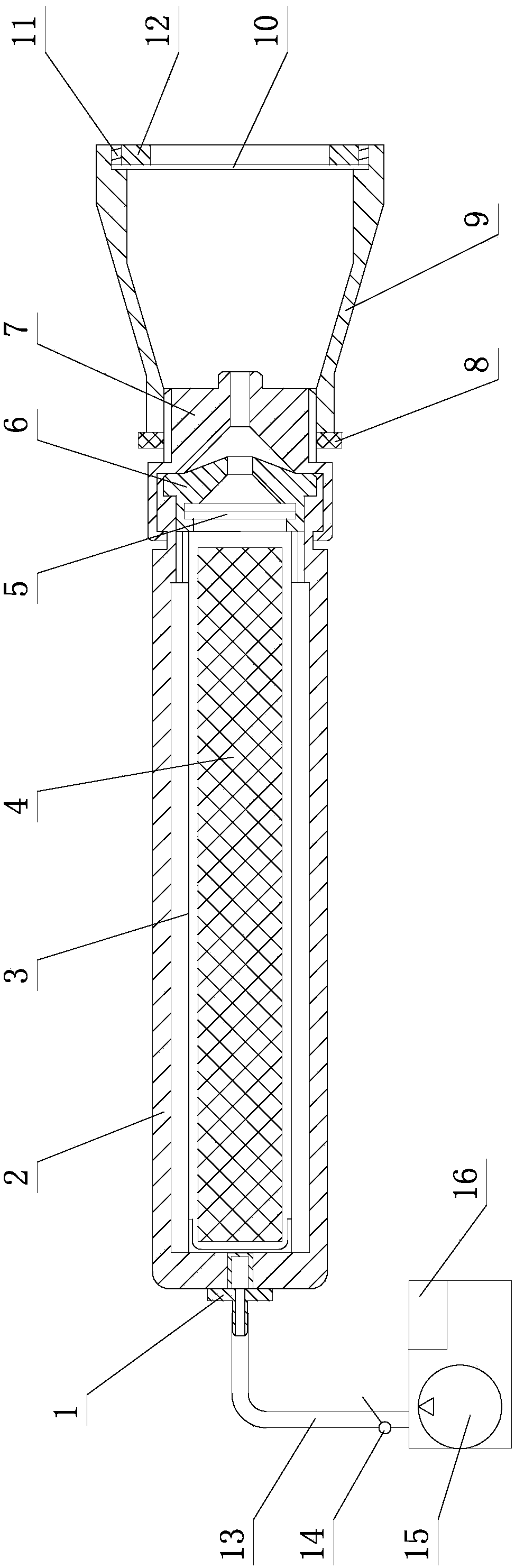

Health maintenance spraying treatment instrument

PendingCN108309779AReduce the impactImprove heat sensitizationDevices for heating/cooling reflex pointsDispersed particle filtrationCombustion chamberEngineering

Owner:赖书

Processing process of waterproof and gas-permeable printing yarn-dyed cloth

InactiveCN107326692AIncrease concentrationImprove cohesionDry-cleaning apparatus for textilesAnti-corrosive paintsYarnHeat setting

The invention relates to a processing process of a waterproof and gas-permeable printing yarn-dyed cloth. The processing process comprises: 1) desizing after weaving, wherein a fabric is subjected to desizing by using sodium bromite, the temperature is 80-100 DEG C, and the pH value is 10; 2) carrying out baking shaping after printing, wherein the baking temperature after printing is 120 DEG C, the steaming temperature is 120-130 DEG C, the steaming time is 5-10 min, then heat shaping is performed, the temperature is 150 DEG C, the heat shaping time is 50 s, and the speed of a heat shaping machine is 40m / min; 3) coating, wherein the fabric is coated with a coating agent; and 4) carrying out water washing, wherein water washing is performed with water having a temperature of 20-30 DEG C and a pH value of 7, and baking is performed for 30 min at a baking temperature of 80 DEG C. According to the present invention, with the processing process, the traditional process is shortened, the production cost is reduced, the obtained product has advantages of water resistance and gas permeation, the disadvantage of the single pattern of the original yarn-dyed cloth is changed through the yarn-dyed cloth printing process, and the obtained pattern has the strong three-dimensional effect.

Owner:WUXI JINSHUANG FABRICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com