Efficient flame-retardant heat insulation composite fabric and application

A composite fabric and high-efficiency technology, applied in the field of fabrics, can solve problems such as failure to meet the requirements of use, and achieve the effect of prolonging service life, improving service life and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

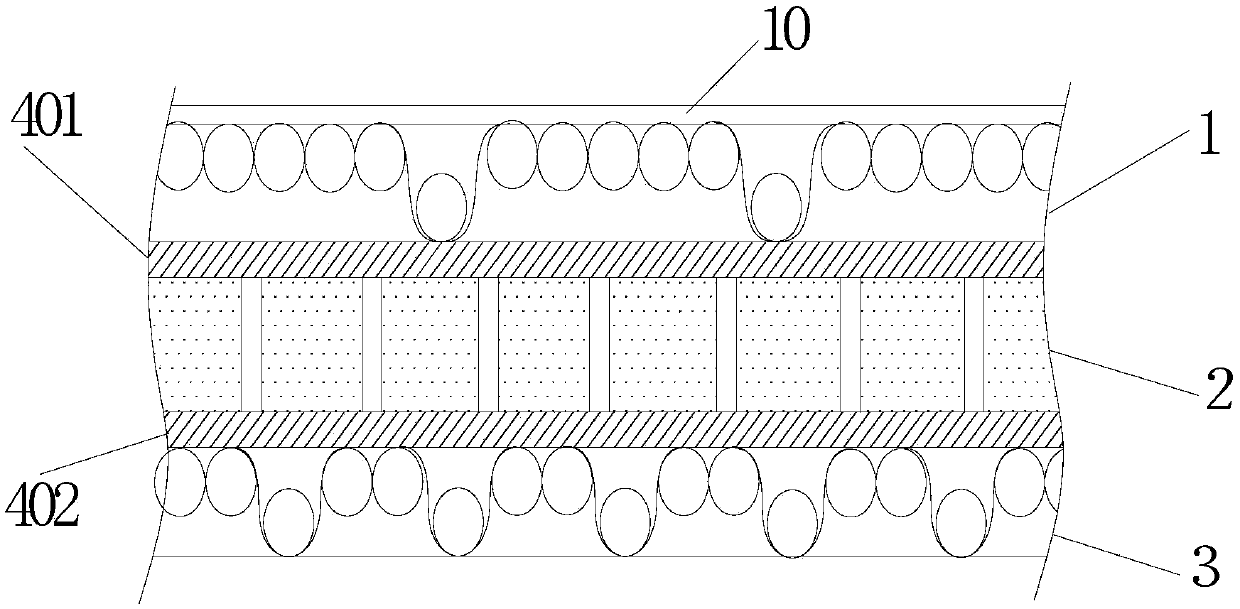

[0045] This embodiment one provides a kind of high-efficiency flame-retardant and heat-insulating composite fabric, please refer to figure 1 , this high-efficiency flame-retardant and heat-insulating composite fabric includes:

[0046] Surface layer 1, with acrylic and Lenzing flame-retardant viscose fiber blended yarns as warp yarns, aramid 1313, aramid 1414, conductive fiber blended yarns as weft yarns, woven herringbone twill weave fabric with 5 up and 1 down methods , the control weight is 160g / m 2 ; Use plasma treatment after weaving, and then set nano-ceramic coating 10 on the surface through a coating machine;

[0047] The middle layer 2, the middle layer is a mixture of airgel and shape memory polyurethane; and

[0048] Inner layer 3, the inner layer fabric is made of silicon nitrogen flame retardant viscose fiber and aramid 1313 blended knitting twill fabric, the control weight is 50g / m 2 ;Plasma treatment after weaving;

[0049] The middle layer 2 is arranged bet...

Embodiment 2

[0051] In an alternative embodiment, the structure still refers to figure 1 , this high-efficiency flame-retardant and heat-insulating composite fabric includes:

[0052]Surface layer 1, with acrylic and Lenzing flame-retardant viscose fiber blended yarns as warp yarns, aramid 1313, aramid 1414, conductive fiber blended yarns as weft yarns, woven herringbone twill weave fabric with 5 up and 1 down methods , the control weight is 400g / m 2 , use plasma treatment after weaving, and then set nano-ceramic coating 10 on the surface through a coating machine; the blending ratio can be selected according to the routine;

[0053] middle layer 2, the middle layer is a mixture of airgel and shape memory polyurethane; and

[0054] Inner layer 3, the inner layer fabric is made of silicon nitrogen flame retardant viscose fiber blended with aramid 1313 and sulfonamide to obtain a plain weave fabric, and the control weight is 200g / m 2 ;Plasma treatment after weaving;

[0055] The middle l...

Embodiment 3

[0057] In another optional embodiment, this high-efficiency flame-retardant and heat-insulating composite fabric includes:

[0058] Surface layer 1, with acrylic and Lenzing flame-retardant viscose fiber blended yarns as warp yarns, aramid 1313, aramid 1414, conductive fiber blended yarns as weft yarns, woven herringbone twill weave fabric with 5 up and 1 down methods , the control weight is 300g / m 2 , use plasma treatment after weaving, and then set nano-ceramic coating 10 on the surface through a coating machine; the blending ratio can be selected according to the routine;

[0059] middle layer 2, the middle layer is a mixture of airgel and shape memory polyurethane; and

[0060] Inner layer 3, the inner layer fabric is made of silicon nitrogen flame retardant viscose fiber mixed with aramid 1313 and polyimide fiber to obtain a twill fabric, and the control weight is 150g / m 2 ;Plasma treatment after weaving;

[0061] The middle layer 2 is set between the surface layer 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com