Patents

Literature

87 results about "Modacrylic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A modacrylic is a synthetic copolymer. Modacrylics are soft, strong, resilient and dimensionally stable. They can be easily dyed, show good press and shape retention, and are quick to dry. They have outstanding resistance to chemicals and solvents, are not attacked by moths or mildew, and are nonallergenic. Among their uses are in apparel linings, furlike outerwear, paint-roller covers, scatter rugs, carpets, and work clothing and as hair in wigs.

Polymeric fibers and articles made therefrom

InactiveUS20120244333A1Electric discharge heatingMonocomponent cellulose artificial filamentPolyesterYarn

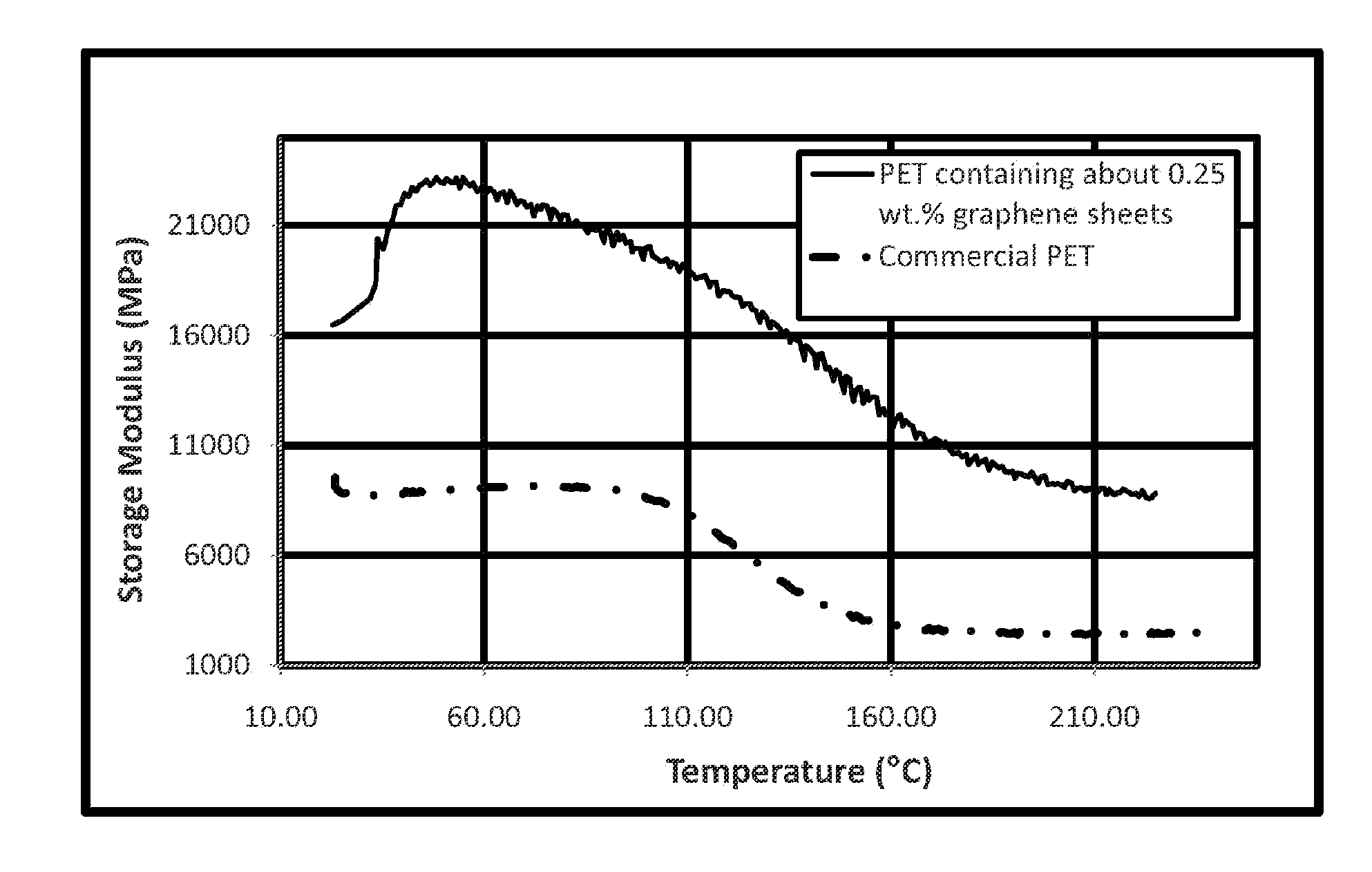

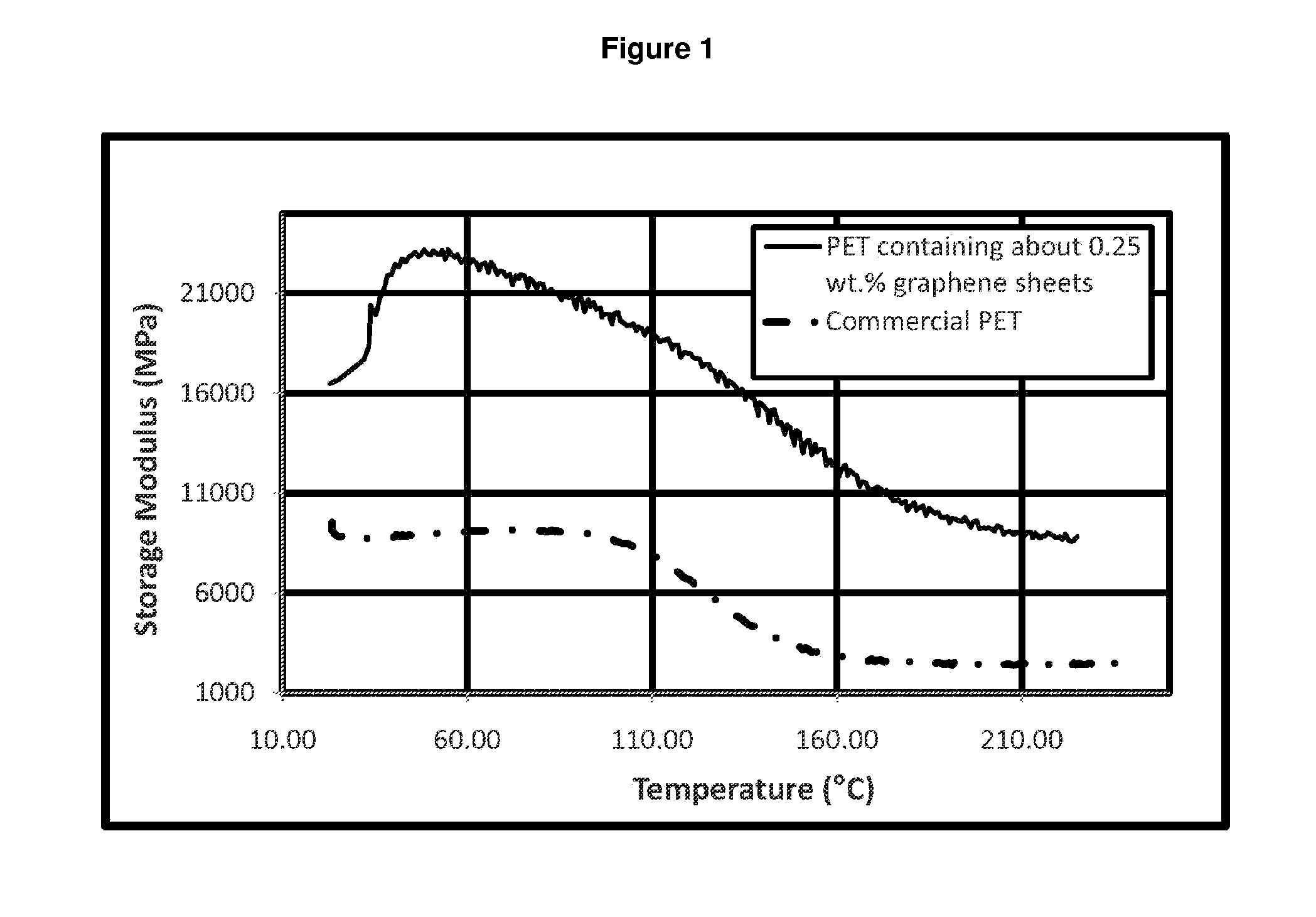

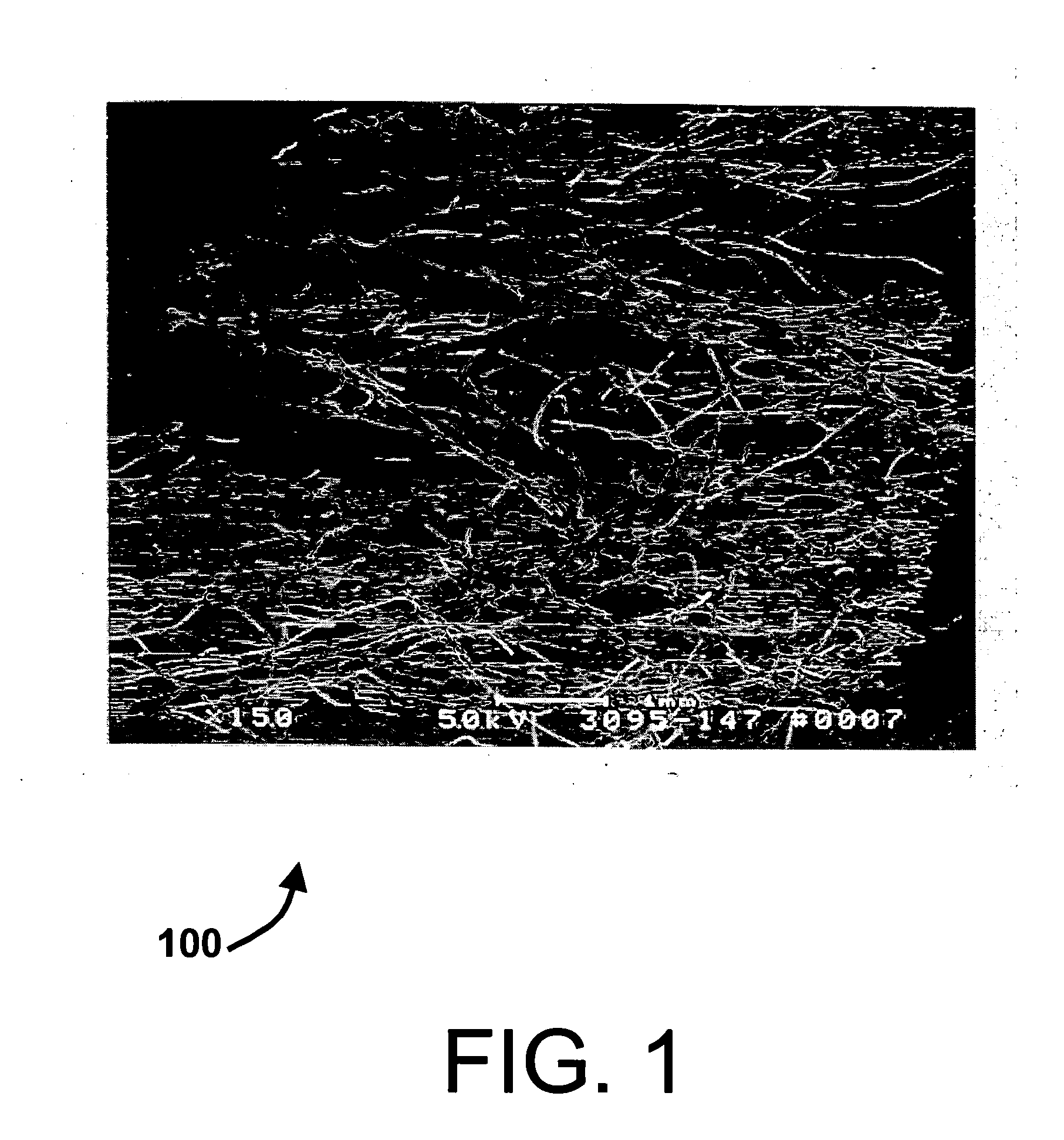

Fibers described herein comprise a composition including a polymer and graphene sheets. The fibers can be further formed into yarns, cords, and fabrics. The fibers can be in the form of polyamide, polyester, acrylic, acetate, modacrylic, spandex, lyocell fibers, and the like. Such fibers can take on a variety of forms, including, staple fibers, spun fibers, monofilaments, multifilaments, and the like.

Owner:VORBECK MATERIALS CORP +1

Modacrylic/aramid fiber blends for arc and flame protection

A yarn, fabric and garment suitable for use in arc and flame protection contains modacrylic, p-aramid and m-aramid fibers.

Owner:DUPONT SAFETY & CONSTR INC

Modacrylic/aramid fiber blends for arc and flame protection and reduced shrinkage

ActiveUS7348059B2Resistance to break open and abrasionReduce Shrinkage ProblemsSynthetic resin layered productsNatural mineral layered productsYarnPolymer science

Owner:DUPONT SAFETY & CONSTR INC

Modacrylic Shrinkable Fiber and Method for Manufacturing The Same

A modacrylic shrinkable fiber according to the present invention is containing a polymer composition obtained by mixing 50 to 99 parts by weight of a polymer (A) containing 40 wt % to 80 wt % of acrylonitrile, 20 wt % to 60 wt % of a halogen-ontaining monomer and 0 wt % to 5 wt % of a sulfonic-acid-containing monomer, and 1 to 50 parts by weight of a polymer (B) containing 5 wt % to 70 wt % of acrylonitrile, 20 wt % to 94 wt % of an acrylic ester and 1 wt % to 40 wt % of a sulfonic-acid-containing monomer containing a methallylsulfonic acid or metal salts thereof or amine salts thereof, in which a total amount of the polymer (A) and the polymer (B) is 100 parts by weight. In this way, a modacrylic shrinkable fiber that has a favorable color development property after dyeing and a high shrinkage ratio even after dyeing is obtained.

Owner:KANEKA CORP

Flame-resistant, high visibility, anti-static fabric and apparel formed therefrom

InactiveUS20060068664A1Optimal static dissipationBig contrastWarp knittingCircular knitting machinesPolyesterYarn

A fabric is provided for use in safety apparel, including a first yarn type comprising at least about 60 percent modacylic fibers and a second yarn type comprising an intimate blend of anti-static fibers and other fibers selected from the group of fibers consisting of polyester, nylon, rayon, modacrylic, cotton, wool, and combinations thereof. The fabric meets the American Society for Testing and Materials standard ASTM F-1506 for flame resistance, Federal Test Method Standard 191A, Method 5931 for electrostatic decay, and the Electrostatic Discharge Association Advisory ADV11.2-1995 voltage potential.

Owner:GLEN RAVEN INC

Modacrylic/aramid fiber blends for arc and flame protection and reduced shrinkage

ActiveUS20050287364A1Resistance to break open and abrasionReduce Shrinkage ProblemsSynthetic resin layered productsNatural mineral layered productsYarnPolymer science

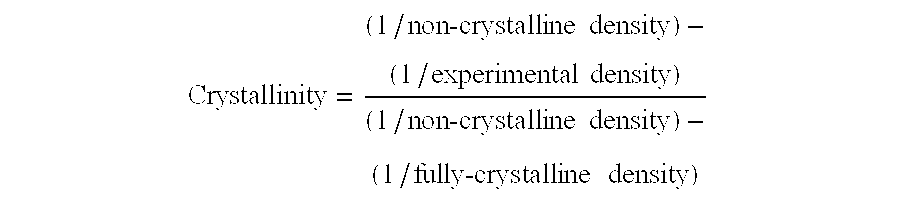

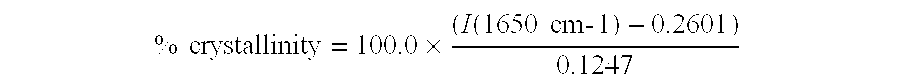

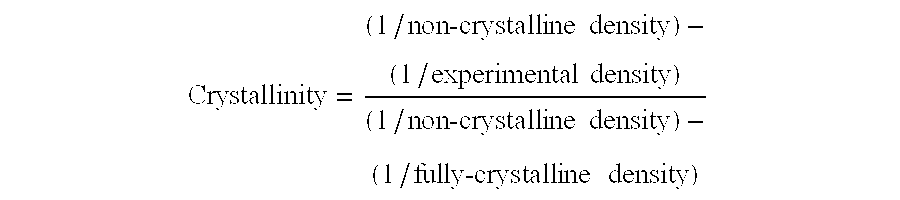

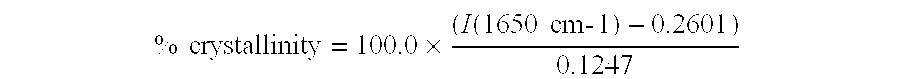

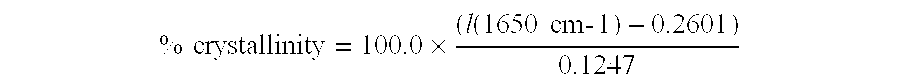

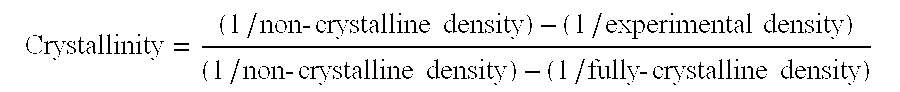

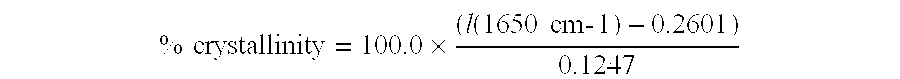

A yarn, fabric and garment suitable for use in arc and flame protection contains modacrylic, p-aramid and m-aramid fibers wherein the m-aramid fibers have a degree of crystallinity of at least 20%.

Owner:DUPONT SAFETY & CONSTR INC

Modacrylic/cotton/aramid fiber blends for arc and flame protection

Owner:EI DU PONT DE NEMOURS & CO

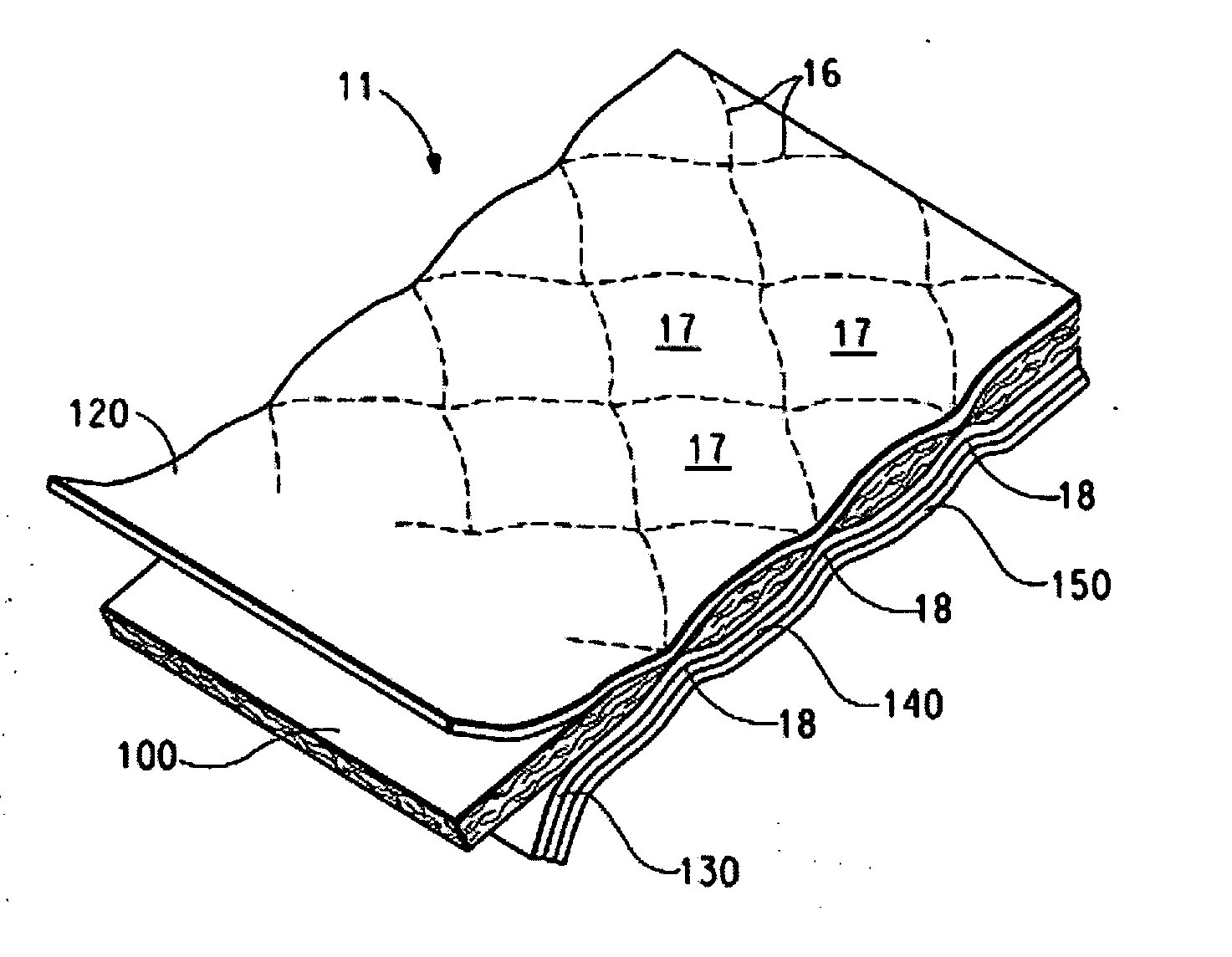

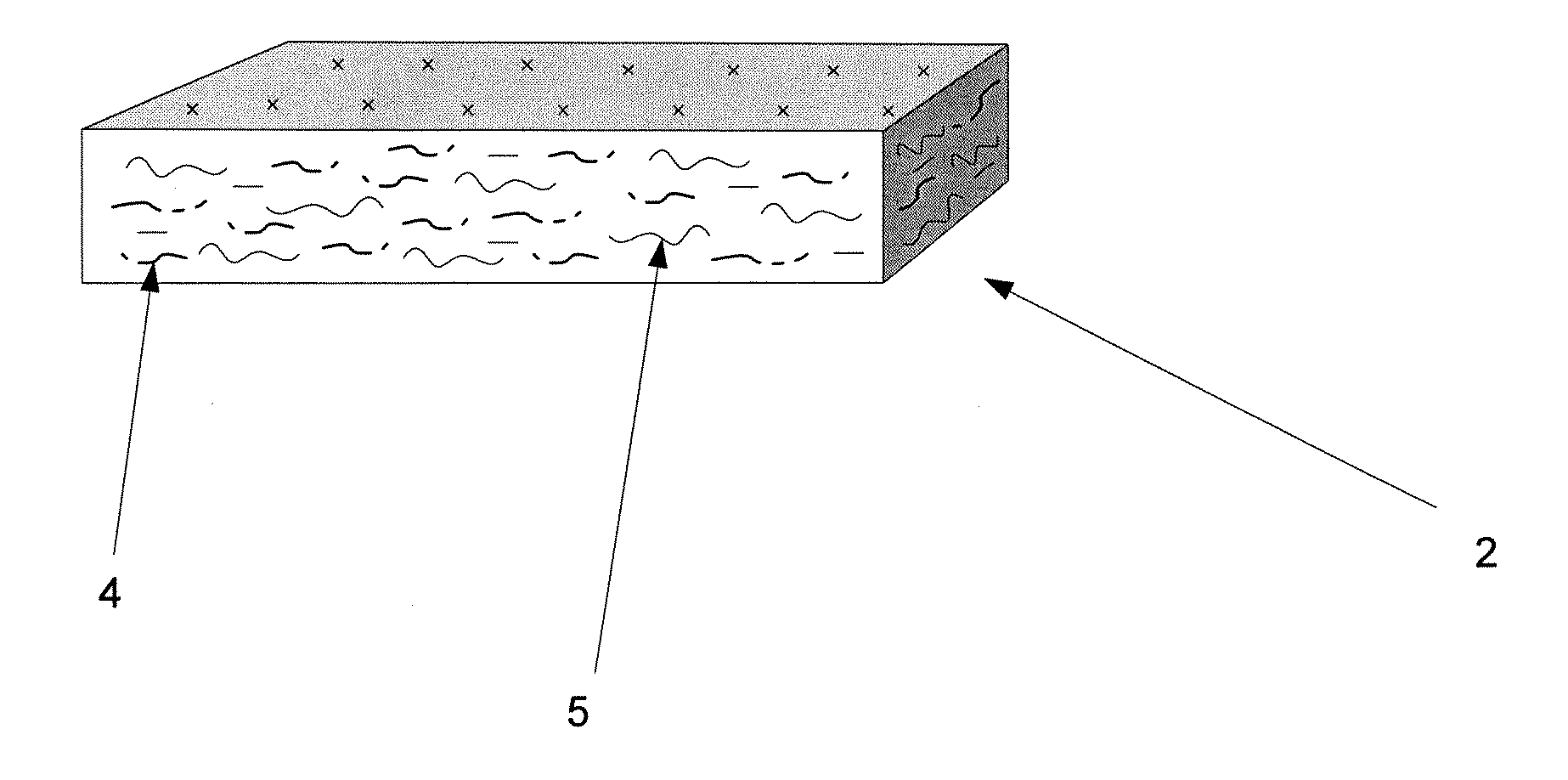

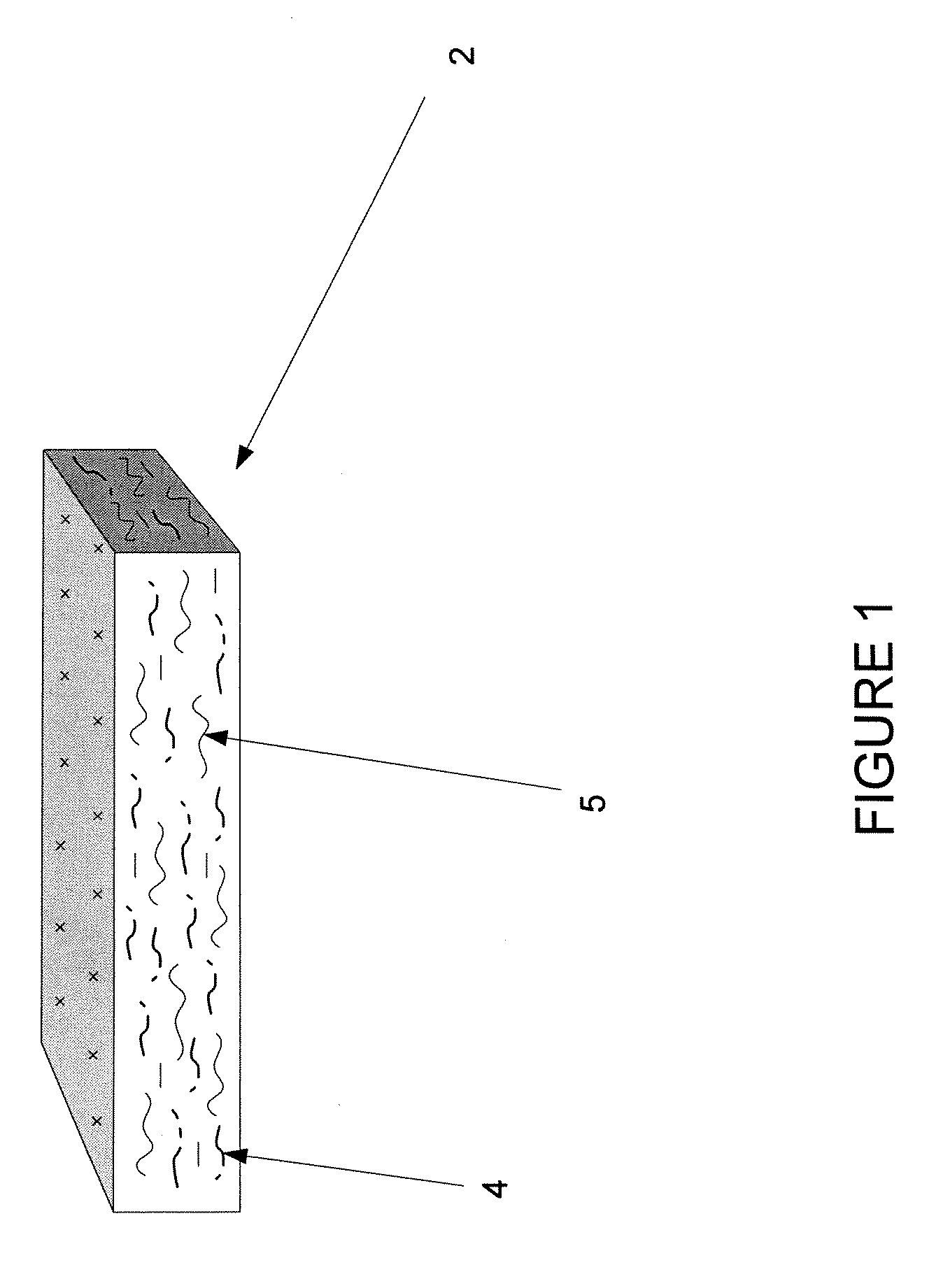

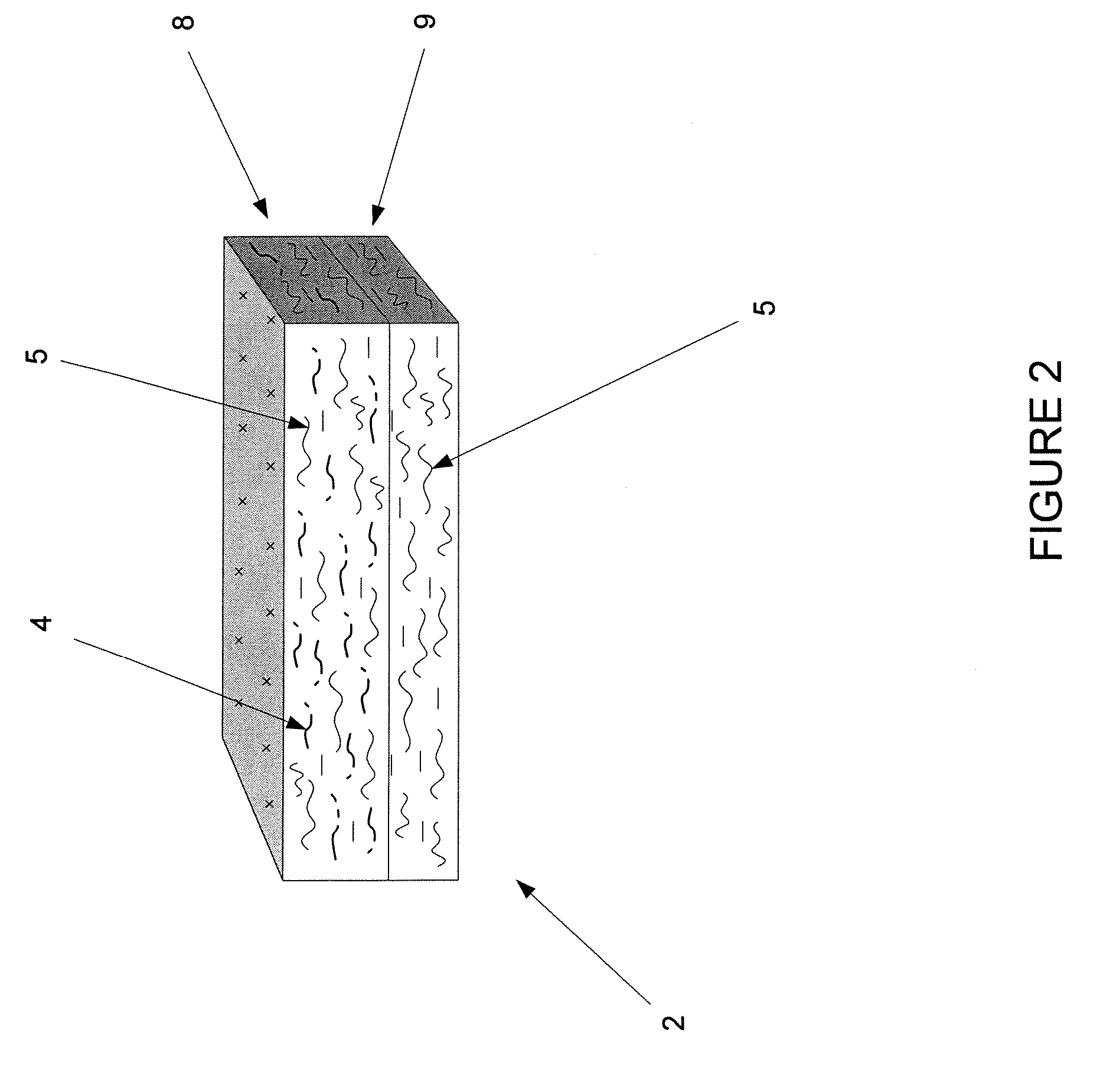

Fire blocker fiber composition, high loft web structures, and articles made therefrom

The present invention is directed to a fiber composition useful for fire blocking; a high loft web structure made from such fiber composition and a process for making such web structure; and a fire blocked article such as a mattress or furniture incorporating such high loft web structure and a method for fireblocking said articles; the fiber composition comprising (a) 1 to 20 parts by weight p-aramid fiber, (b) 5 to 30 parts by weight regenerated cellulose fiber containing silicic acid, and (c) 10 to 40 parts by weight modacrylic fiber, (d) 10 to 60 parts by weight polyester fiber, (e) up to 20 parts by weight binder material wherein the total of (a), (b), (c), (d) and (e) is on a basis of 100 parts by weight.

Owner:EI DU PONT DE NEMOURS & CO

Flame-resistant high visibility textile fabric for use in safety apparel

ActiveUS20080227352A1Improve visibilityFlame resistanceOrnamental textile articlesFire rescueYarnVisibility

A knitted textile fabric for use in safety apparel, comprising a first yarn containing modacrylic fibers and a second yarn containing cellulosic fibers. The first and second yarns are intimately interknitted with one another in plated relationship with the modacrylic yarn disposed predominantly at an outer face of the fabric for imparting flame resistant properties and an affinity for high visibility dyes and with the cellulosic yarn disposed predominantly at the opposite face of the fabric for imparting a hand suitable for comfortable body contact with a user's skin.

Owner:INNOVATIVE TEXTILES LLC

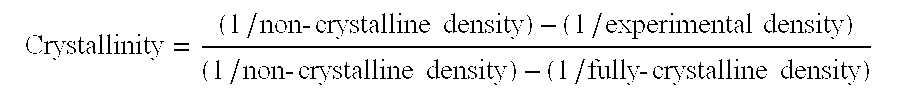

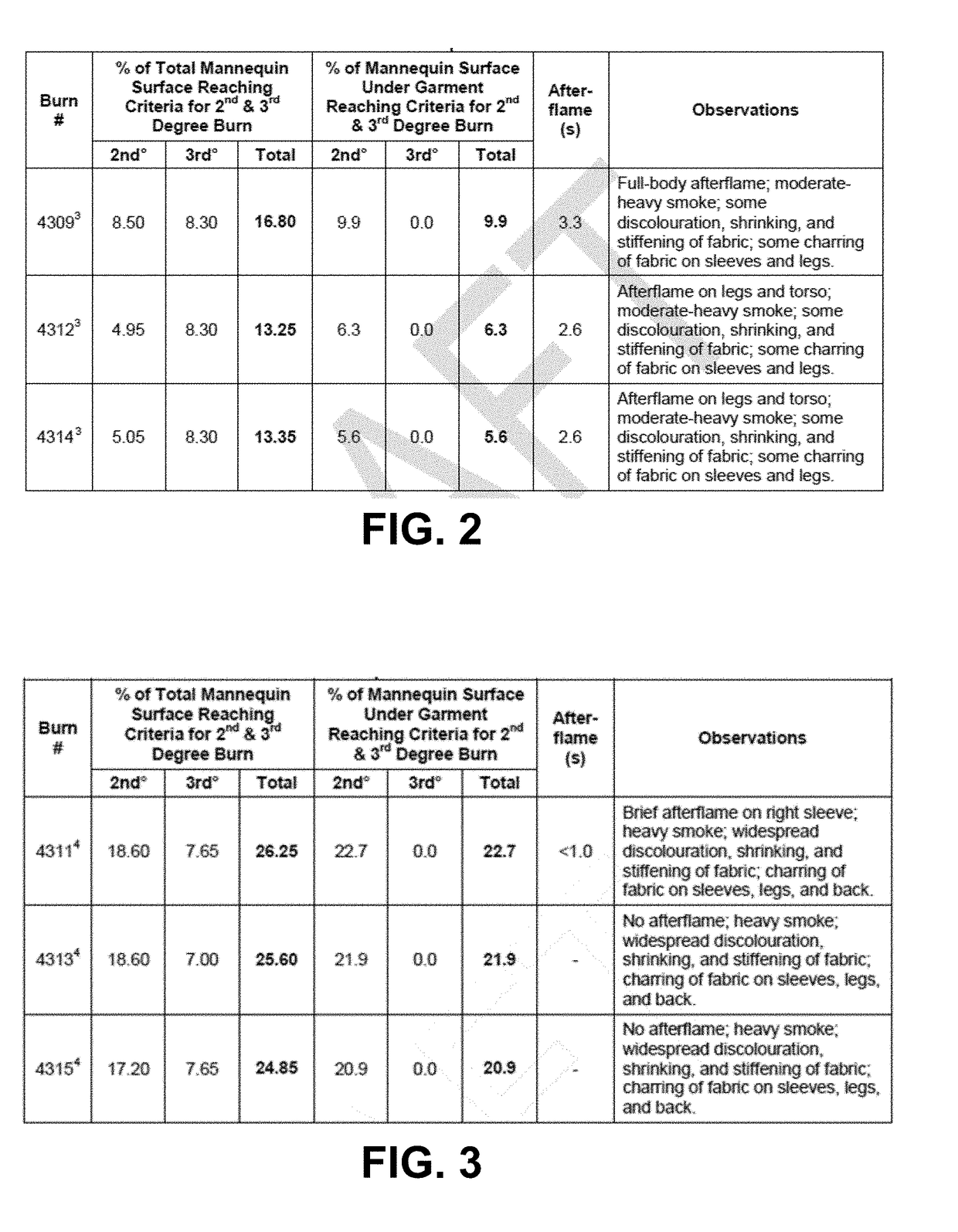

Limited-antimony-content and antimony-free modacrylic / aramid blends for improved flash fire and arc protection

A yarn, fabric, and garment suitable for use in arc and flame protection comprising aramid fiber and modacrylic fiber wherein the modacrylic fiber has less than 1.5 percent antimony and is preferably antimony-free. In one embodiment, the yarn, fabric, and / or garments consist essentially of (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 40 weight percent modacrylic fiber that is antimony-free, (c) 5 to 20 weight percent para-aramid fiber, and (d) 1 to 3 weight percent antistatic fiber, based on the total weight of components (a), (b), (c) and (d). In some embodiments, garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

Modacrylic/aramid fiber blends for arc and flame protection

ActiveUS20050204718A1Resistance to break abrasionResistance to break openWoven fabricsYarnYarnModacrylic

A yarn, fabric and garment suitable for use in arc and flame protection contains modacrylic, p-aramid and m-aramid fibers.

Owner:DUPONT SAFETY & CONSTR INC

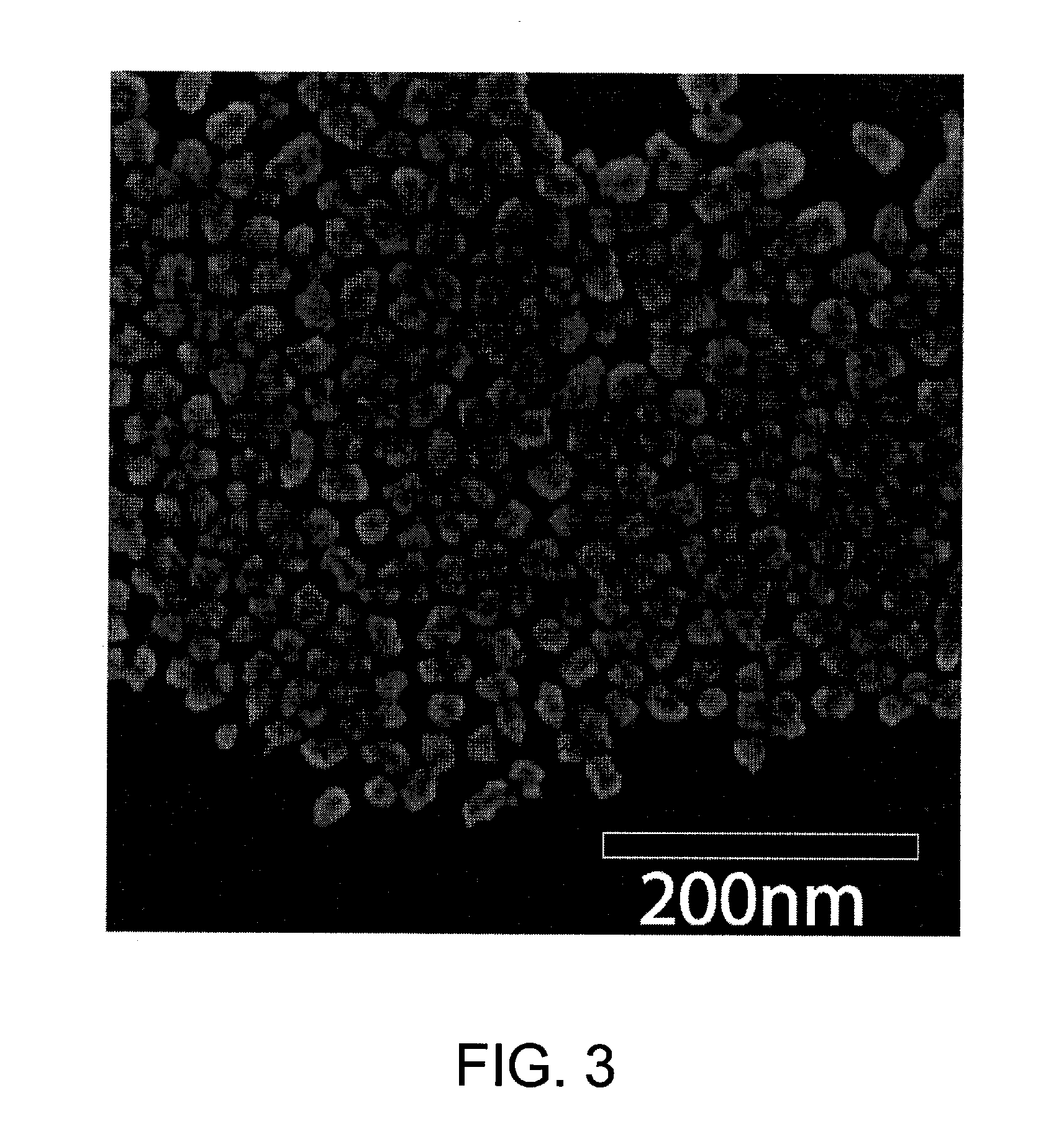

Polymeric materials incorporating core-shell silica nanoparticles

InactiveUS20110263037A1VersatileAnalysis using chemical indicatorsChemical analysis using titrationPolyesterCellulose acetate

Fibers, fabrics and textiles in which core-shell silica nanoparticles are incorporated are provided. The fibers, fabrics and textiles can be polymeric materials or natural cellulose-based or protein-based materials in which core-shell silica nanoparticles are incorporated. A variety of polymeric and natural materials can be employed, such as cellulose acetate, nylon, rayon, modacrylic, olefin, acrylic, polyester, polylactic acid, polylactic-co-glycolic acid (PLGA), polyurethane, aramid, wool, cotton, ramie, milk protein, soy protein, bamboo, etc. The core-shell silica nanoparticles can incorporate sensing, magnetic, thermal, electrical, chemical or RFID properties that can be imparted to the materials and that allow the materials to sense one or more conditions of interest, making them ideal for in situ sensing, treatment, or security applications.

Owner:CORNELL UNIVERSITY

Multifunctional protective fabric

The present invention is directed toward a multifunctional protective fabric and yarn. The fabric has a double knit interlock material of the yarns. The yarns include: a first filament being a liquid crystal polymer filament; and a second filament being selected from the group consisting of: modacrylic, polyacrylonitrile, nylon, glass, aramid, olefins, and combinations thereof. The weight ratio of the first filament to the second filament ranges from 20:80 to 99:1.

Owner:NEPTUNIC TECH INC

Flame-resistant, high visibility, anti-static fabric and apparel formed therefrom

InactiveUS7419922B2Big contrastImprove visibilityWarp knittingCircular knitting machinesYarnPolyester

A fabric is provided for use in safety apparel, including a first yarn type comprising at least about 60 percent modacylic fibers and a second yarn type comprising an intimate blend of anti-static fibers and other fibers selected from the group of fibers consisting of polyester, nylon, rayon, modacrylic, cotton, wool, and combinations thereof. The fabric meets the American Society for Testing and Materials standard ASTM F-1506 for flame resistance, Federal Test Method Standard 191A, Method 5931 for electrostatic decay, and the Electrostatic Discharge Association Advisory ADV11.2-1995 voltage potential.

Owner:GLEN RAVEN INC

Mixed printing method for metal flat plate

ActiveCN101973170AIncrease the scope of applicationAvoid insufficient phenomenonOther printing apparatusUV curingAcrylic resin

The invention discloses a mixed printing method for a metal flat plate, and in particular relates to a method for printing on a metal flat plate, such as tinplate, an aluminum sheet, and the like, by using metal oily ink and ultraviolet curing ink respectively. The metal oil ink and the ultraviolet curing ink are used in the mixed printing method for the metal flat plate respectively, and the method is characterized by comprising the following steps of: firstly carrying out base coating on the metal flat plate by using a denatured polyester resin coating as a base coating material; carrying out metal oily ink printing after the base coating is cured; and then carrying out ultraviolet curing ink printing after the metal oily ink coating is cured; and finally glazing after the ultraviolet curing ink coating is cured, wherein denatured acrylic resin is used as a glazing coating. The invention has the advantages of simple production process, low production cost and high printing quality.

Owner:HANGZHOU CPMC +1

Protective flame barrier product

A flame barrier product for use in mattresses, foundations, and upholstered furniture with one or more layers of fibers. A first component scavenges oxygen from a burn site. A second component burns to form an insulating char. The first component may comprise at least one category 2 fiber, which may comprise modacrylic. In one embodiment, the second component is a batting comprising at least one category 4 fiber, which may be cotton. The first component may be treated with a flame-retardant coating. Flame barrier products of the present invention may comprise highloft batting or densified batting. Where cotton is used, it may be treated with flame retardant chemicals, such as boric acid. A method of constructing the invention also is disclosed.

Owner:WOLF STEPHEN +1

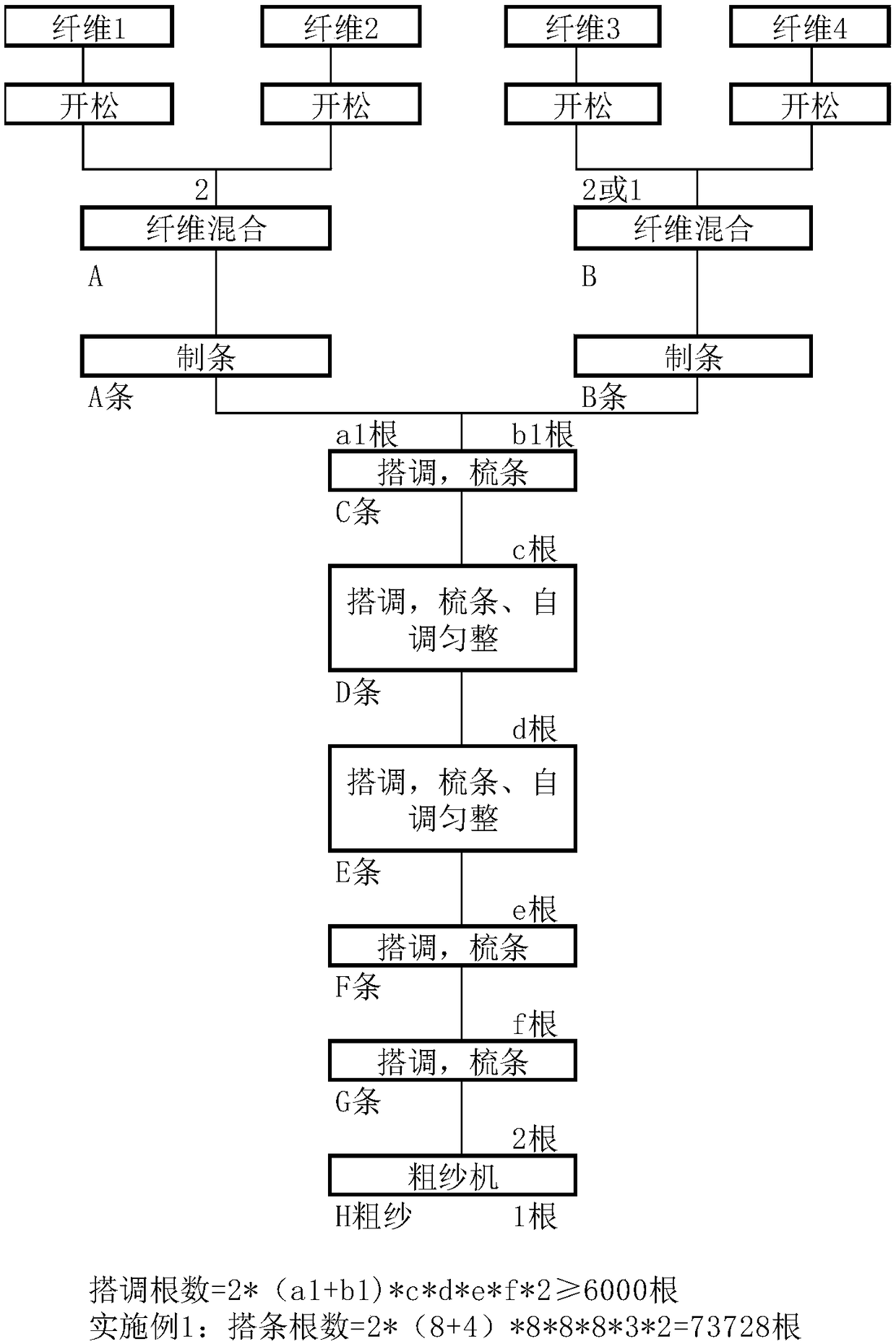

Aramid fiber blended yarn and preparation technology thereof

The invention relates to the field of textile production, in particular to aramid fiber blended yarn and a preparation technology thereof. The aramid fiber blended yarn is characterized in that 1414.Kevlar aramid fiber, 1313.T450 aramid fiber, flame retardant glue, modacrylic, combed cotton, conducting fiber, chinlon and tencel are adopted as raw materials, fineness degrees of the materials are respectively 1.7, 2.2 and 3 deniers, any four materials in the raw materials are selected as main raw materials, the length of the four materials selected as the main materials at will is 48-51 millimeters, the lengths of the remaining auxiliary raw materials are respectively 28 millimeters and 38 millimeters. Compared with the prior art, the processing technology is simple in process, produced products have good performance such as high strength, high modulus, high-temperature resistance, acid resistance, alkali resistance and light weight, are high in strength, and can solve the problem that a machine part is damaged easily. The development of the aramid fiber blended yarn and the success of matched military supplies can bring markets for enterprises and innovation conceptions. Meanwhile, firmness, flame-retarding performance and anti-static electricity capacity of the military supplies are changed in nature compared with prior fiber blended yarn.

Owner:SHANGHAI SHENAN TEXTILE

Fluorescent orange retardant double layer fabrics and weaving, arranging method thereof

InactiveCN105369436ASolve the flame retardant problemHigh color fastnessSynthetic resin layered productsCellulosic plastic layered productsModacrylicViscose

The invention discloses fluorescent orange retardant double layer fabrics and a weaving, arranging method thereof, and the method comprises the steps of taking 150D terylene filament that is dyed into fluorescent orange as an upper level warp yarn and an upper level filling yarn; taking 24S / 2 twin thread retardant modacrylic and aramid fiber yarn as a lower layer warp yarn and a lower layer filling yarn; a twill weave structure comprising an upper layer and a lower layer that are overlapped mutually is formed, wherein the upper level warp yarn and the upper level filling yarn employ a weaving method of two up one down, and the weaved organization is taken as the terylene filament surface layer; the lower layer warp yarn and the lower layer filling yarn employ a weaving method of two down one up, and the weaved organization is taken as the retardant modacrylic aramid fiber yarn inner layer; the retardant modacrylic aramid fiber yarn is formed by twisting the single thread of modacrylic 40-60%, 1414 aramid fiber 10-18%, retardant viscose glue 25-45%, and antistatic conductive filament 0.5-3% in weight percentage. The fabrics meet the fluorescence standard and has a very high retardant effect; no droplet is generated in the process of combustion, nor did a fusion hole; and the flame retardation problem of the fluorescent orange products is solved.

Owner:SHAOXING FAMOUS TEXTILE CO LTD

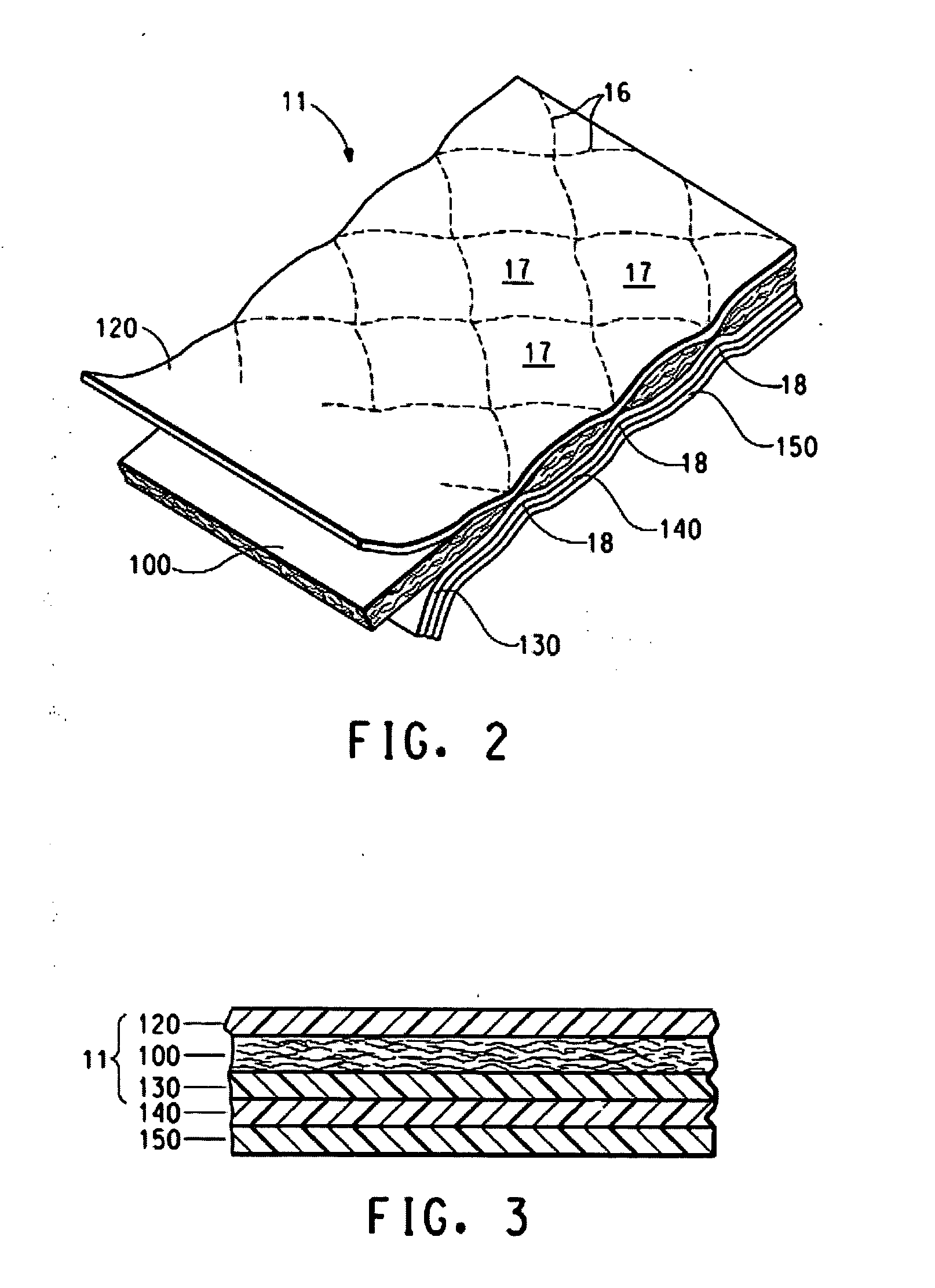

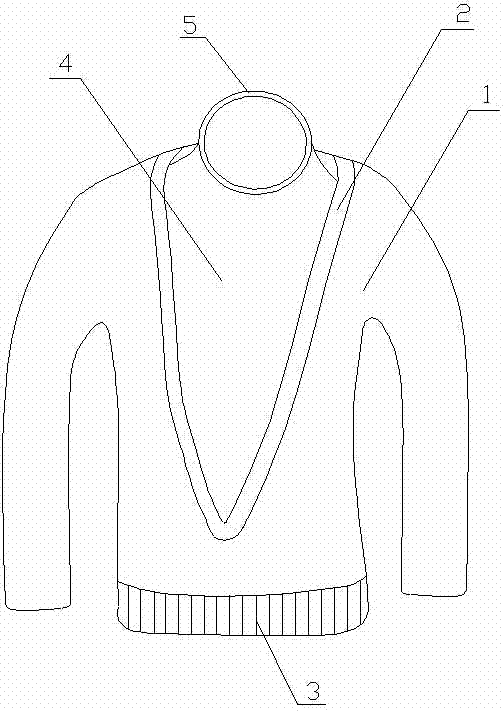

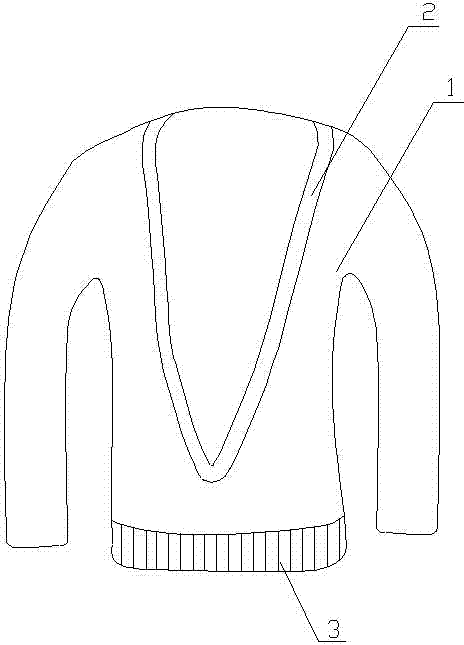

Efficient flame-retardant heat insulation composite fabric and application

ActiveCN109664582AImprove insulation effectNo pollution in the processPhysical treatmentSynthetic resin layered productsAdhesiveCeramic coating

The invention provides an efficient flame-retardant heat insulation composite fabric and an application. The efficient flame-retardant heat insulation composite fabric comprises a surface fabric, a middle layer and a lining fabric, modacrylic and Lenzing flame-retardant viscose fiber blended yarns serve as warp yarns of the surface fabric, aramid fiber 1313, aramid fiber 1414 and conductive fiberblended yarns are weft yarns, a surface layer is further provided with a nano-ceramic coating, the middle layer is mixture of aerogel and polyurethane, one or two of silicon-nitrogen flame-retardant viscose fibers, aramid fibers 1313, polysulfonamide and polyimide fibers are blended to form the lining fabric, and the middle layer is arranged between the surface layer and a lining layer and fittedwith the surface layer and the lining layer through flame-retardant adhesives. The efficient flame-retardant heat insulation composite fabric is used for manufacturing a flame-retardant heat insulation garment. The efficient flame-retardant heat insulation composite fabric is high in washing fastness by the aid of plasma treatment, the nano-ceramic coating and the middle layer of aerogel and shapememory polyurethane mixture are arranged, flame-retardant heat insulation effects are long and high, and the efficient flame-retardant heat insulation composite fabric has antibacterial health care functions and is widely applied.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

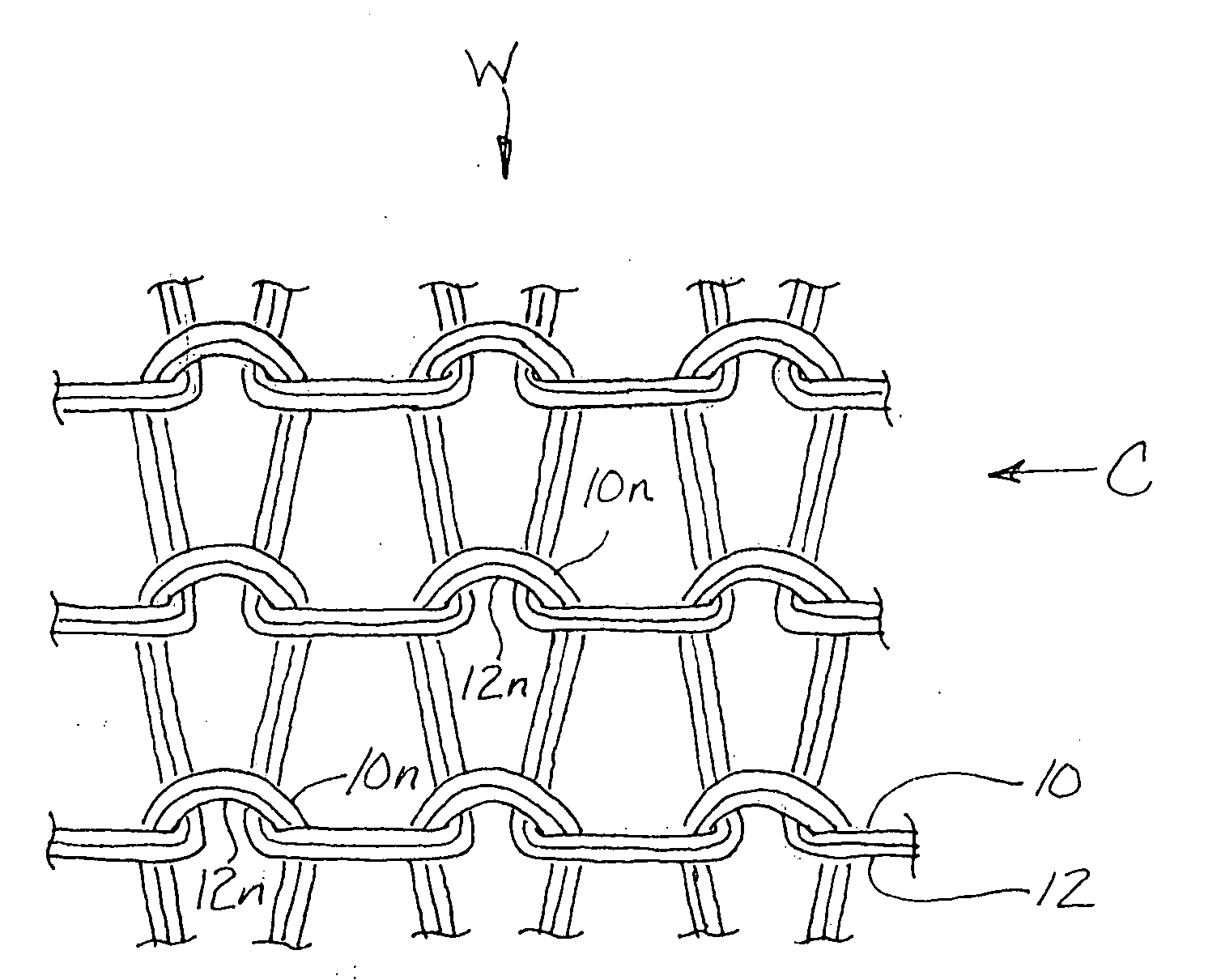

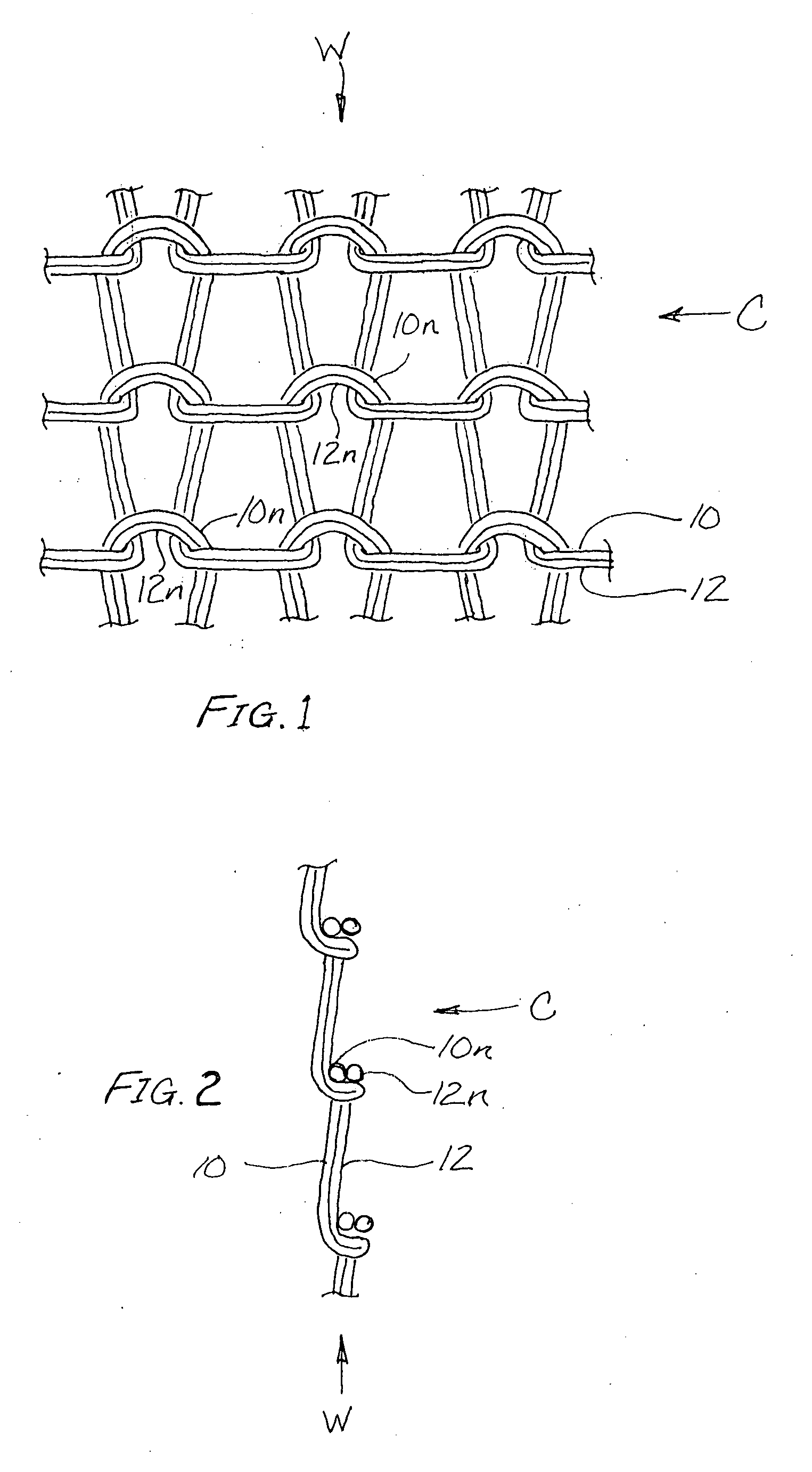

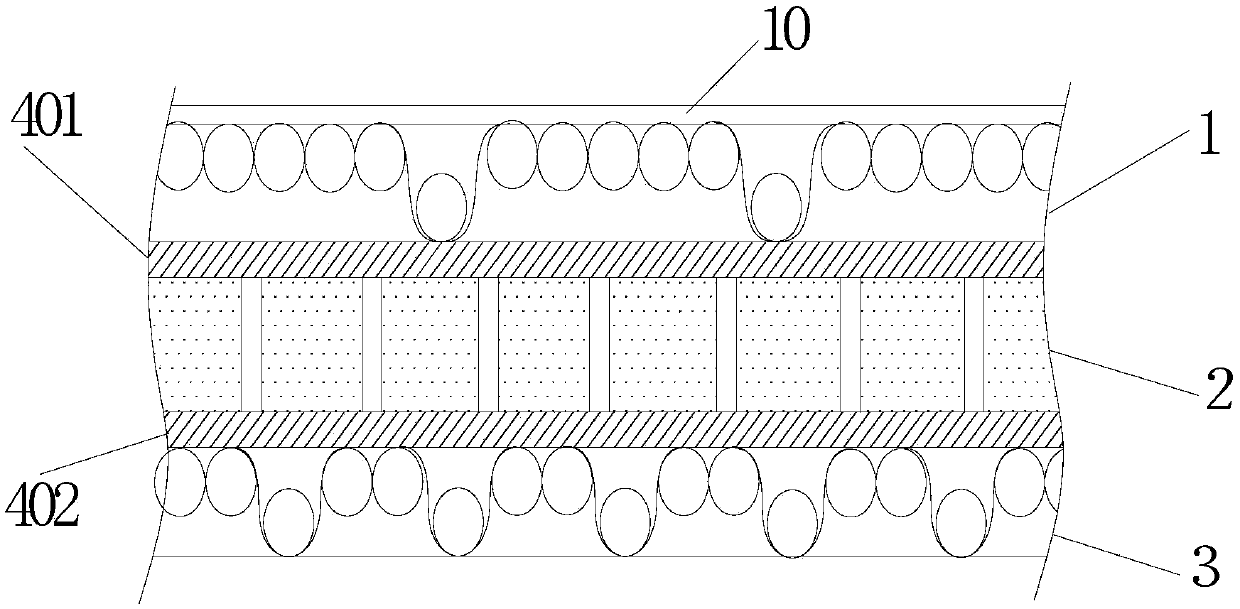

Flame-retardant anti-static two-faced plush cloth

ActiveCN105019119APermanent Flame RetardancyImprove thermal protection performanceWeft knittingYarnModacrylic

The invention discloses flame-retardant anti-static two-faced plush cloth which is formed by blending the following components in parts by weight: 50-60 parts of modacrylic, 30-40 parts of cotton, 5-15 parts of nylon and 1-3 parts of conductive wires. The two-faced plush cloth includes a first surface and a second surface, wherein both the first surface and the second surface are formed by blending and weaving modacrylic fibers and cotton fibers; the first surface and the second surface are connected with each other through polyamide yarns and the conductive wires; the polyamide yarns are arranged parallel to the conductive wires, the distance between adjacent polyamide yarns is 0.08-0.15 cm, and the distance between adjacent conductive wires is 0.8-1.2 cm. The two-faced plush cloth is knitted fabric and has the characteristics that the cloth is resistant to high temperature, non-combustible, free of molten drops, soft, comfortable and good in heat retention property, and does not lose plush.

Owner:上海俊首安防科技有限公司 +1

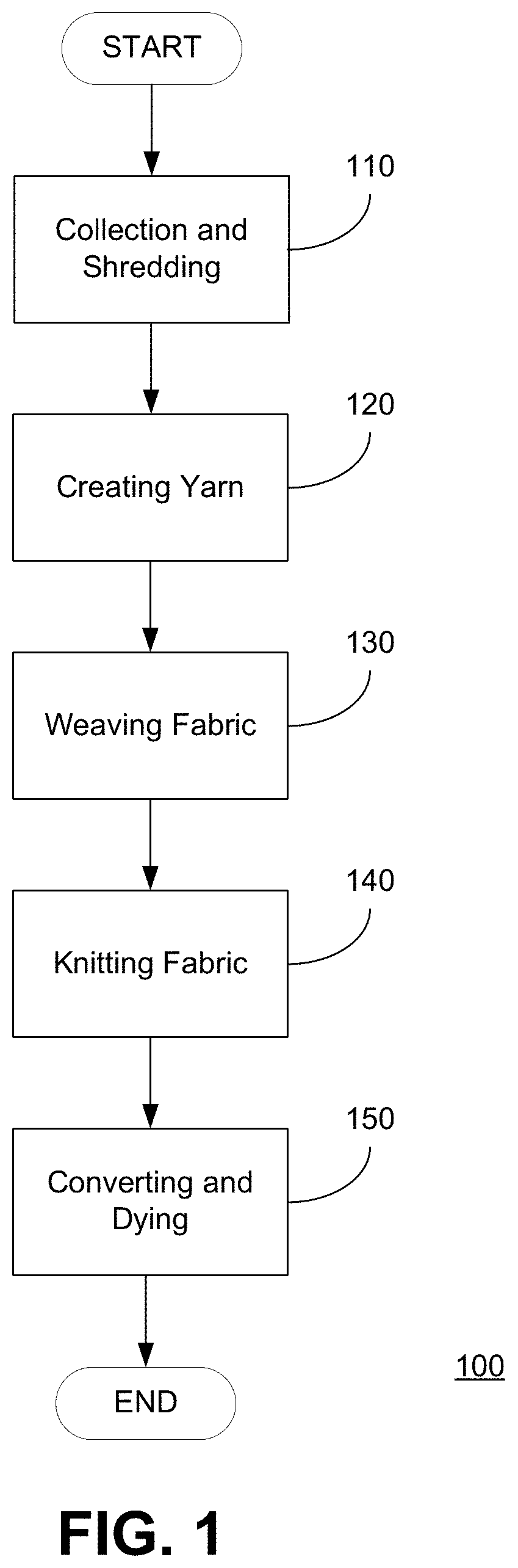

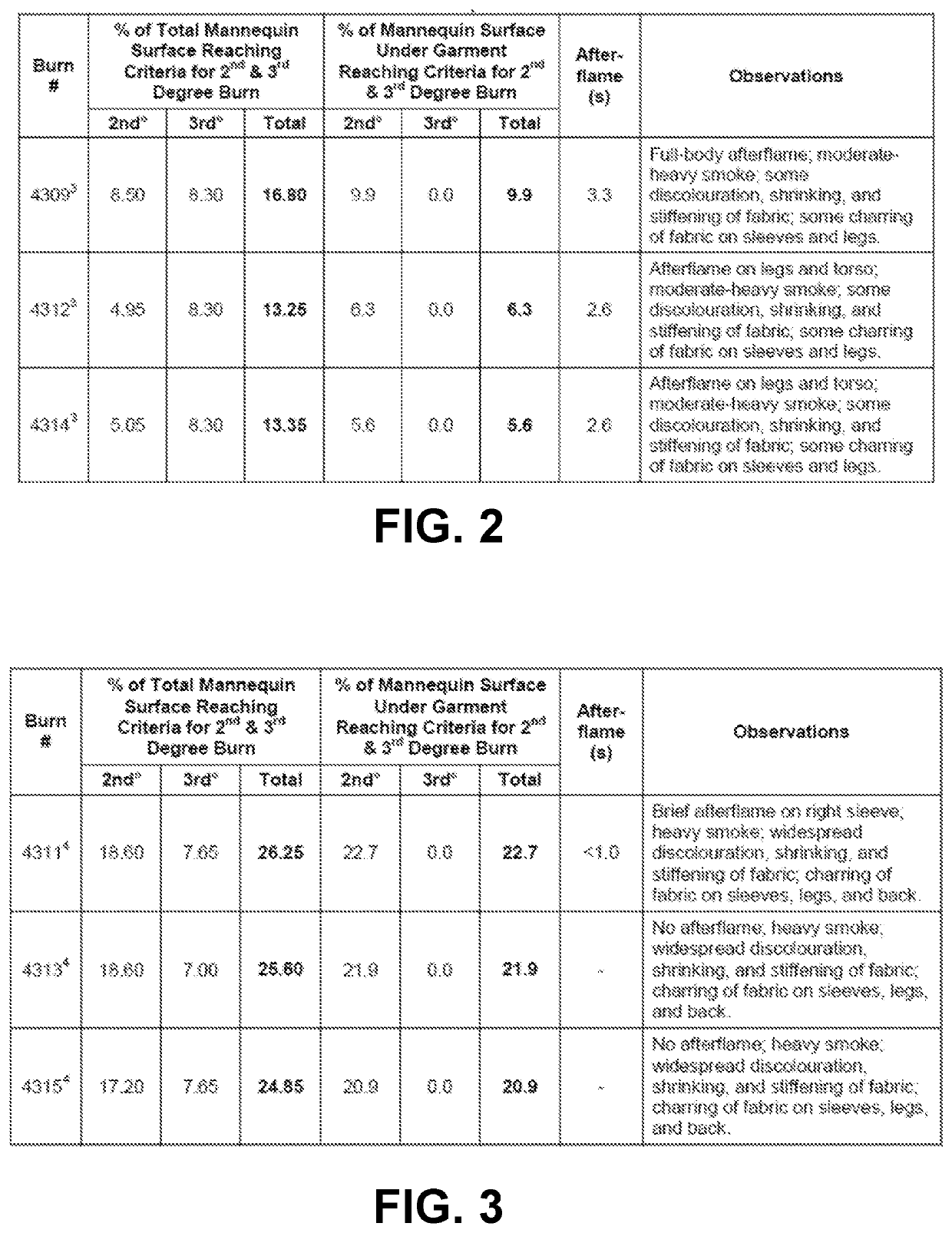

Limited-antimony-content and antimony-free modacrylic / aramid blends for improved flash fire and arc protection

ActiveUS8069643B2Electroconductive/antistatic filament manufactureFlame-proof filament manufactureYarnBody burning

A yarn, fabric, and garment suitable for use in arc and flame protection comprising aramid fiber and modacrylic fiber wherein the modacrylic fiber has less than 1.5 percent antimony and is preferably antimony-free. In one embodiment, the yarn, fabric, and / or garments consist essentially of (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 40 weight percent modacrylic fiber that is antimony-free, (c) 5 to 20 weight percent para-aramid fiber, and (d) 1 to 3 weight percent antistatic fiber, based on the total weight of components (a), (b), (c) and (d). In some embodiments, garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

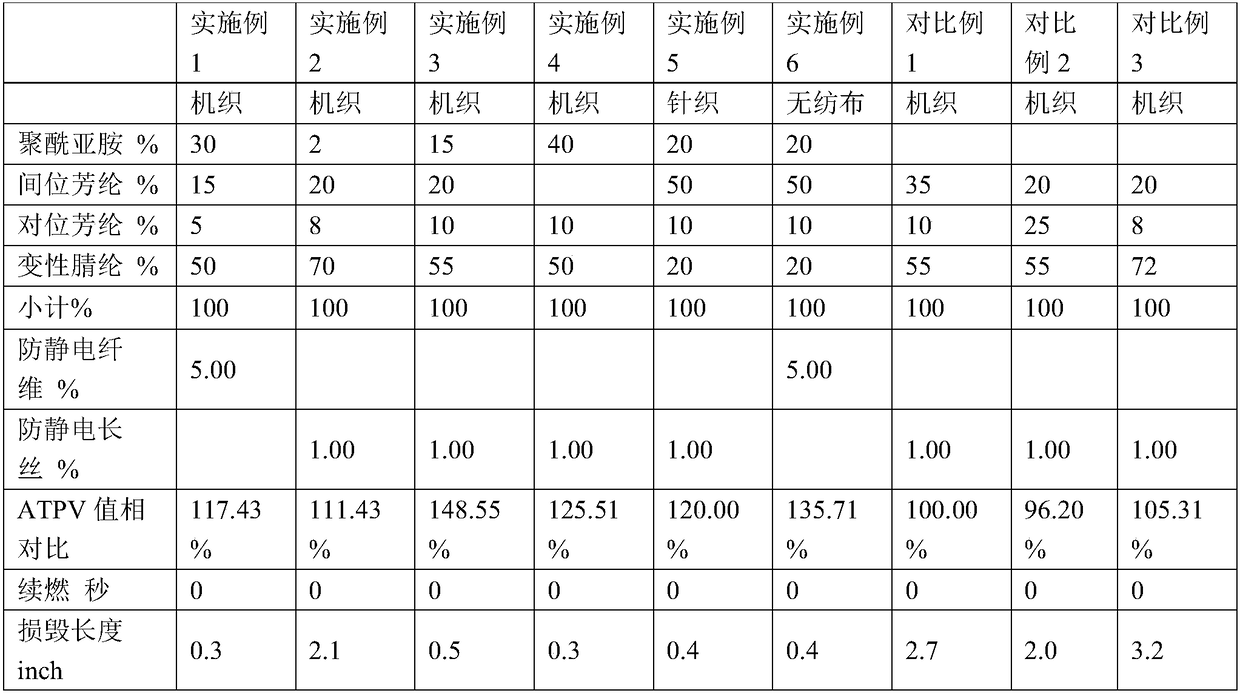

Anti-electric-arc flame-retardant mixture and manufacturing method thereof

The invention discloses an anti-electric-arc flame-retardant mixture and a manufacturing method thereof. The anti-electric-arc flame-retardant mixture comprises polyimide, aramid and modacrylic; the aramid is meta-aramid, para-aramid or a mixture of the meta-aramid and the para-aramid; the mass percentage of the polyimide, the aramid and the modacrylic in the total amount of the three materials isas follows: the polyimide: 2 to 40 percent, the aramid: 10 to 60 percent and the modacrylic: 20 to 70 percent. The existing form of the mixture is one or any combination of a fiber mixture, yarns, fabric, non-woven or clothing. Vertical combustion test is conducted by ASTM D6413-1999, the continuous combustion time is less than 2 seconds and the damaged length does not exceed 6 inches.

Owner:南通谐好安全科技有限公司 +2

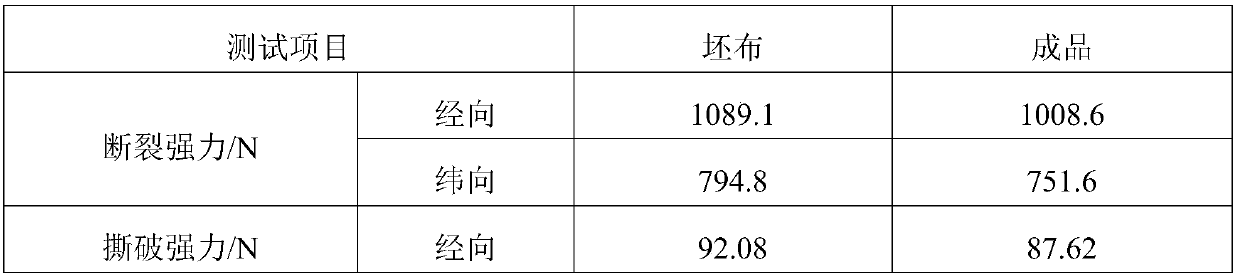

Pad dyeing process for flame-retardant polyester/modacrylic blended fabric

InactiveCN109680519ASerial mass productionIncrease productivityDry-cleaning apparatus for textilesDyeing processPolyesterAfter treatment

The invention discloses a pad dyeing process for a flame-retardant polyester / modacrylic blended fabric. The process specifically comprises the following steps: 1, desizing and scouring the flame-retardant polyester / modacrylic blended fabric; 2, pre-setting the fabric subjected to desizing and scouring in the step 1; 3, dyeing the pre-set fabric in the step 2; and 4, performing after-treatment on the fabric dyed in the step 3. According to the pad dyeing process for the flame-retardant polyester / modacrylic blended fabric disclosed by the invention, continuous large-scale production can be realized, the production efficiency is improved, and the service requirements of the flame-retardant fabric are met.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

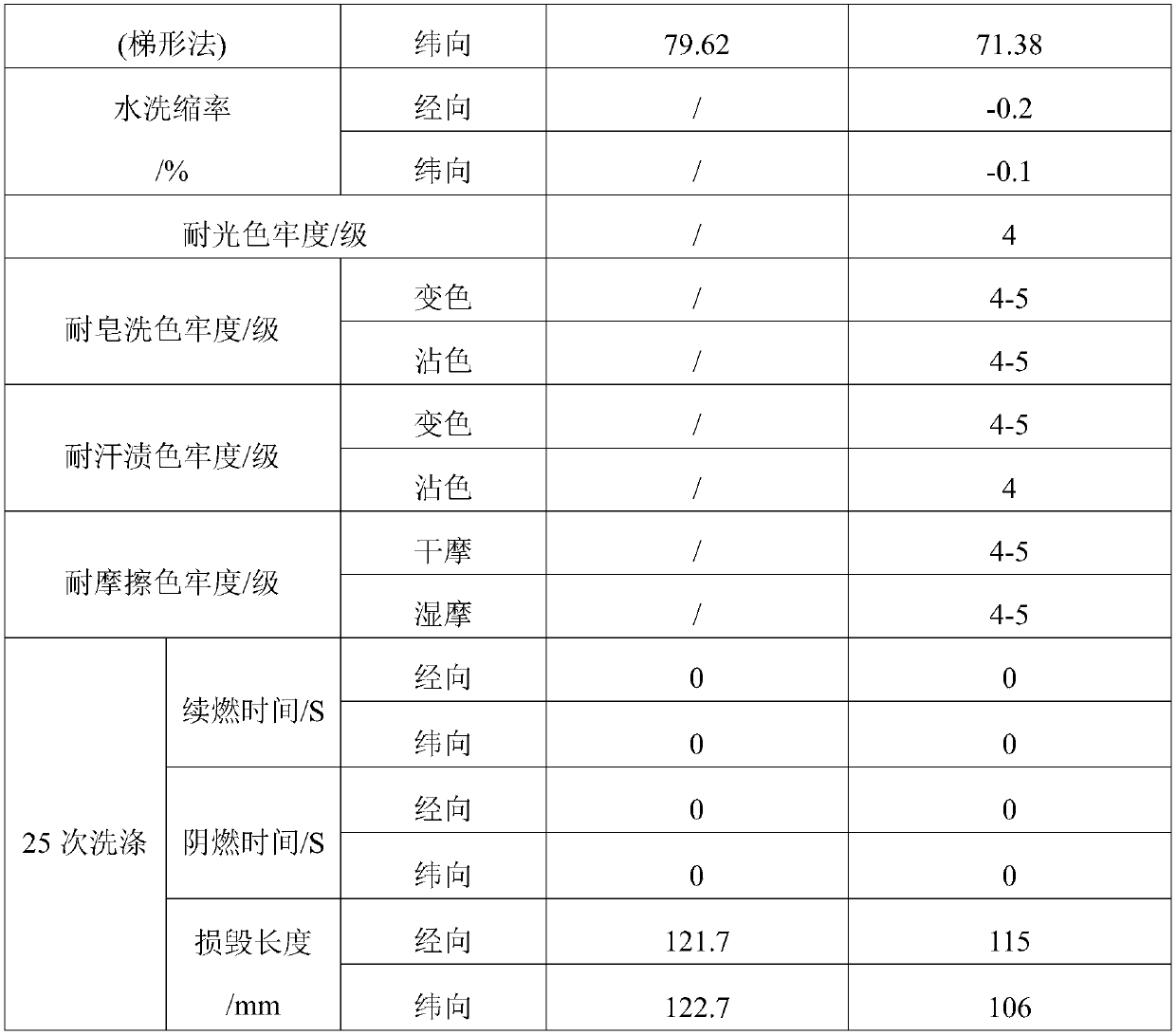

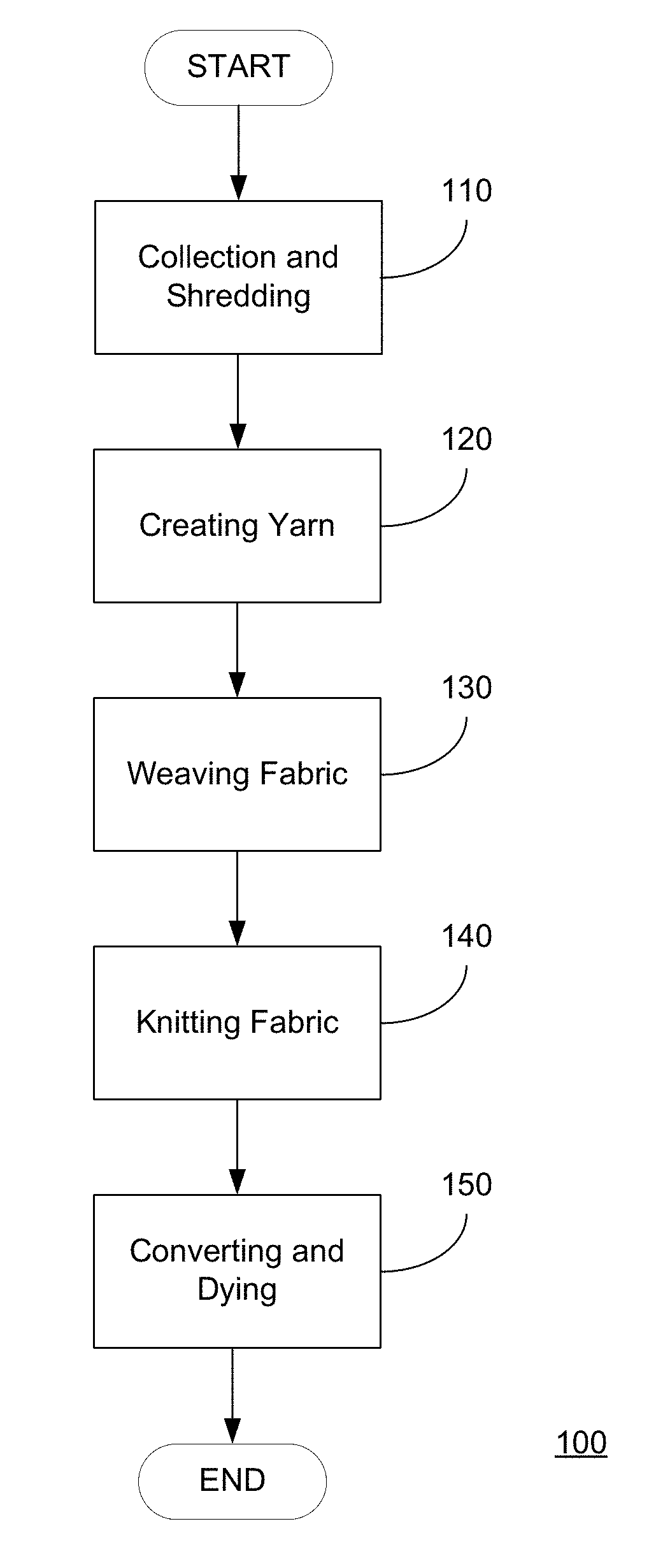

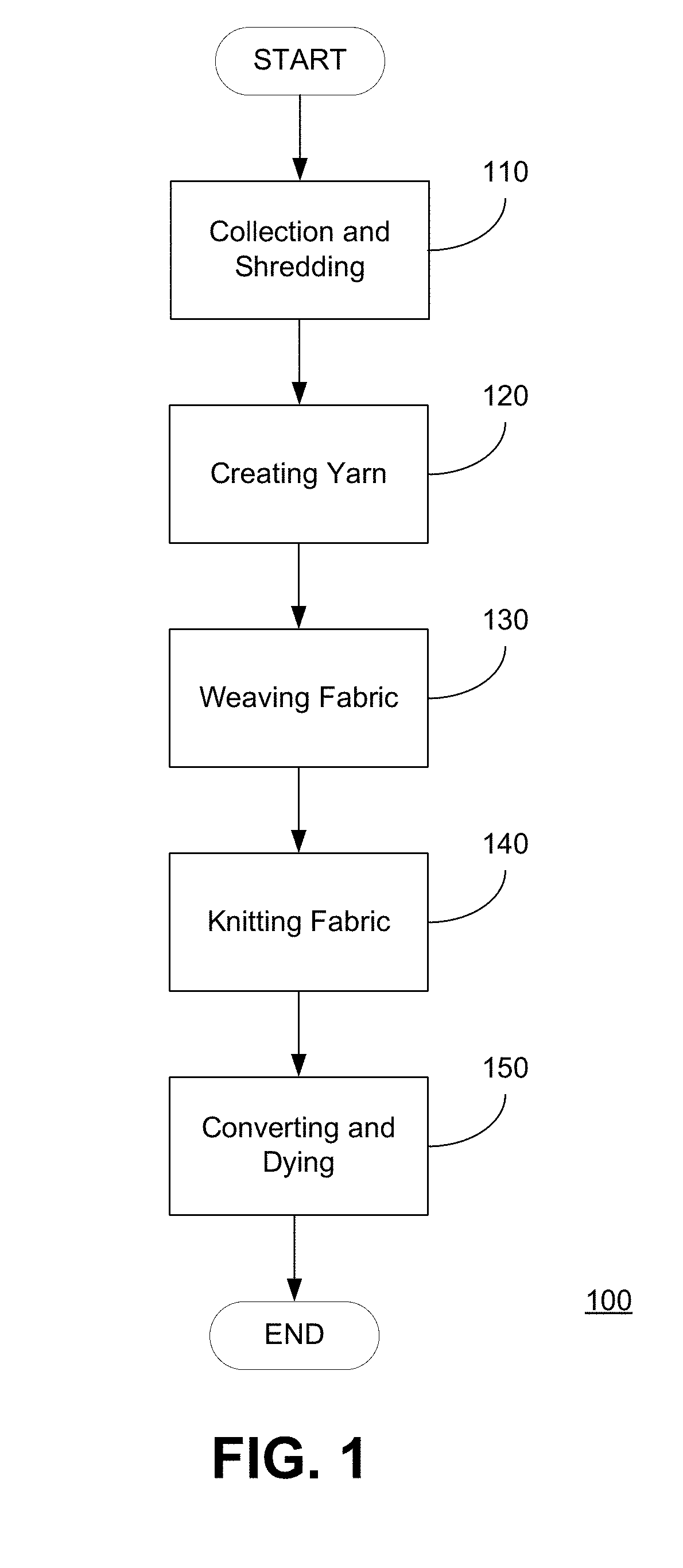

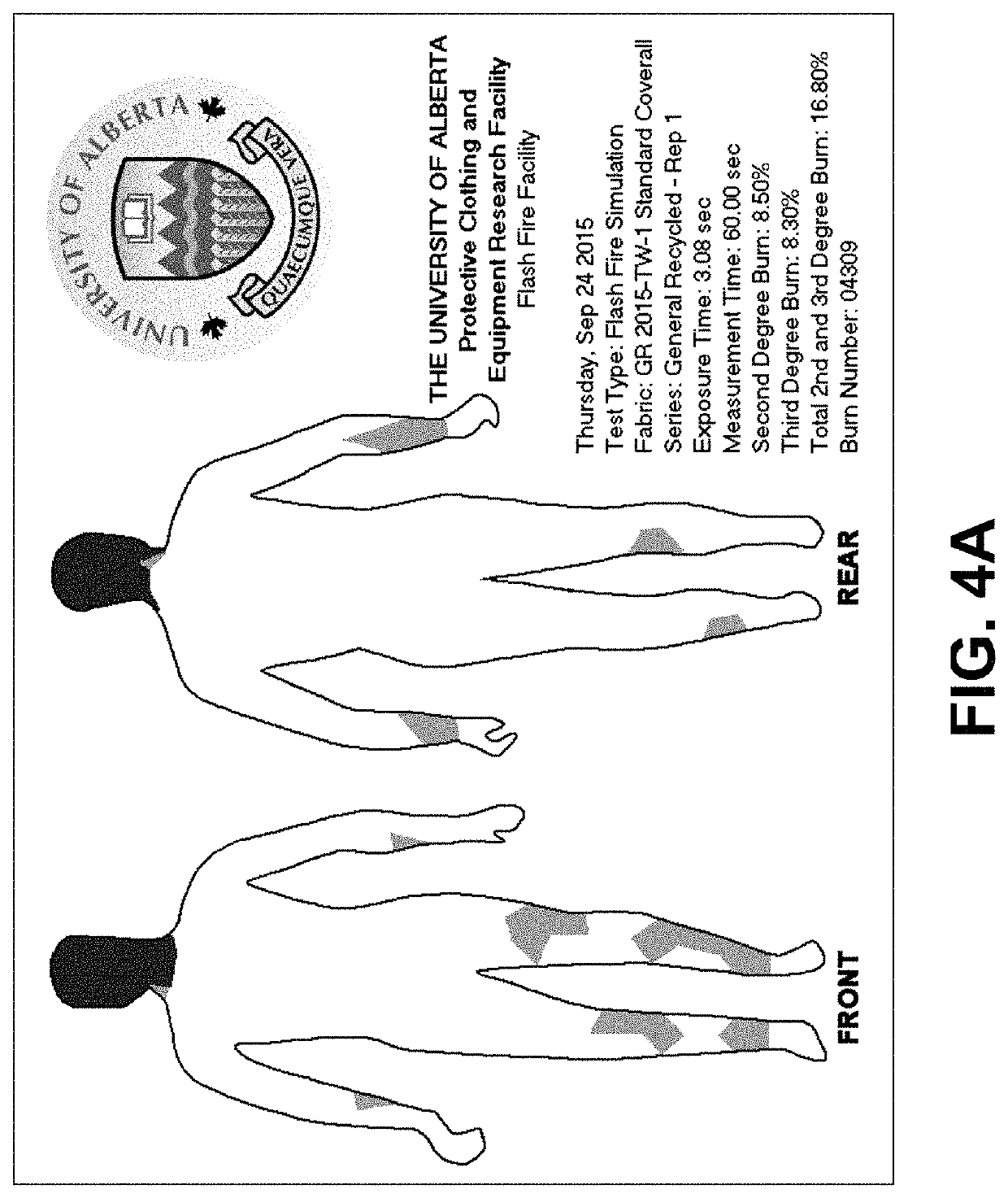

Protective Fabric and Process of Manufacturing Same

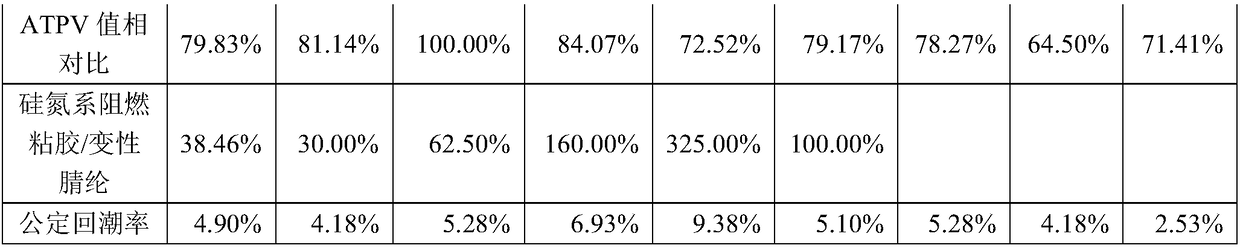

A fabric for use in arc and flame protection, and a process for producing a fire resistant fabric are provided. The fabric is comprised of at least 70 weight percent (wt%) aramid fiber; less than 40 wt% modacrylic; 8 wt% nylon; and 2 wt% anti-static. The process comprises shredding recycled fire resistant garments into fibers; creating yarn from the shredded fibers; weaving the yarn into fabric; and knitting the yarn to produce new garments. The fabric may be used to produce fire-resistant garments worn by workers in many industries such as the oil and gas.

Owner:GENERAL RECYCLED

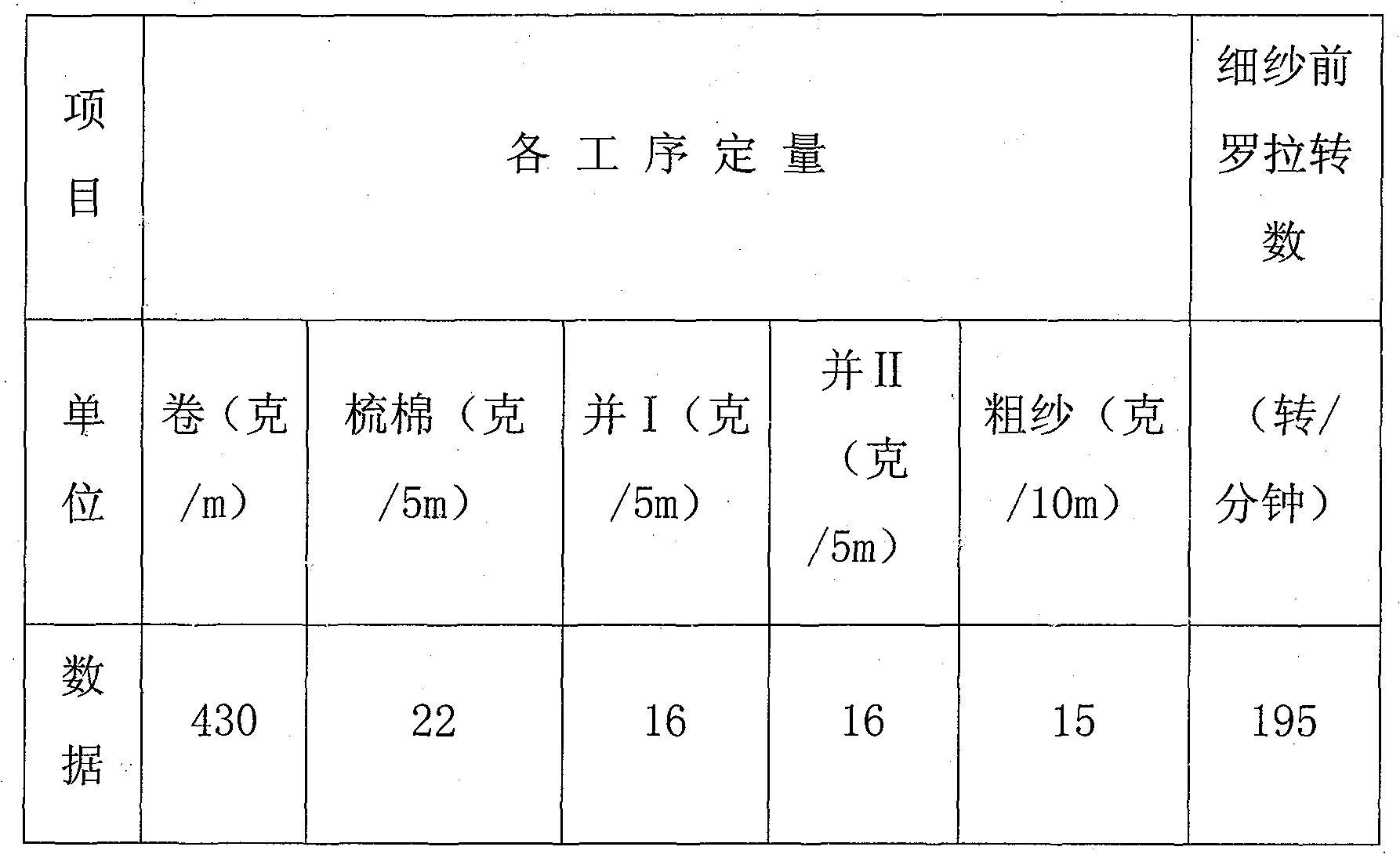

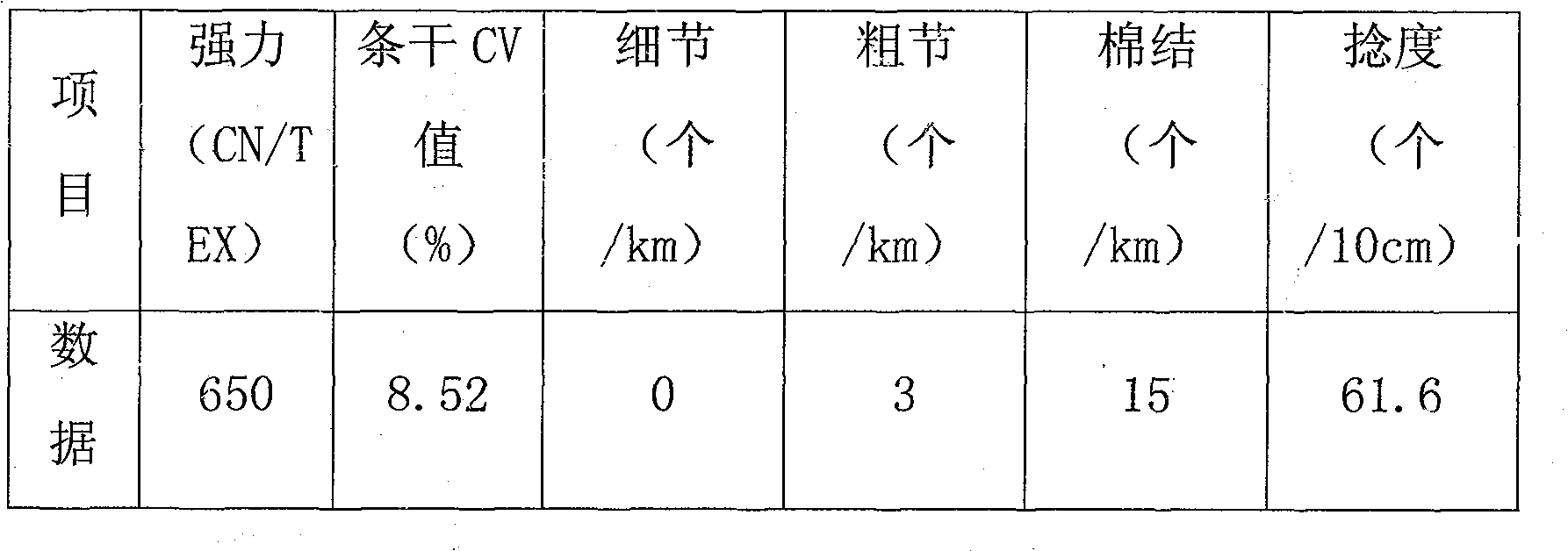

Modacrylic, chinlon and combed cotton blended flame-retardant yarn

The invention discloses a modacrylic, chinlon and combed cotton blended high-tech flame-retardant textile product and a weaving method thereof. The common flame-retardant yarn has the defects of unobvious flame-retardant effect, low wearing comfortableness, massive static electricity generation and the like. The product has the advantages of low melting point, non-flammability close to fire, high comfortableness, no static electricity generation and the like. The manufacturing method for the product is characterized in that modacrylic is subjected to oil spraying treatment before on-production, and parameter quantification is performed in a production process so as to improve the spinning property. The manufacturing performance, the weaving efficiency and the product performance are improved by controlling temperature, humidity and speed of processes of scotching, drawing, roving, spinning, doubling and the like. The product can be widely applied to production of textiles of special protective clothing, aerospace suits, special furniture, automobile ornaments and the like, and has very considerable economic and social benefits.

Owner:DALIAN SHUANGLONG TEXTILES

Blended fiber yarns and fabrics including oxidized polymeric fibers

ActiveUS20160053411A1Improve flame resistanceImprove heat resistanceFibre mixingLap-winding devicesYarnPolyester

An article comprising a fabric comprising:(a) a blended yarn comprising:(i) from about 10% to about 85% by weight of at least one biregional fiber comprising an oxidized polymer selected from the group consisting of acrylonitrile based homopolymers, acrylonitrile based copolymers, acrylonitrile based terpolymers, and combinations thereof;(ii) at least one companion fiber selected from the group consisting of FR polyester, FR nylon, FR rayon, FR treated cellulose, m-aramid, p-aramid, modacrylic, novoloid, melamine, wool, nylon, regenerated cellulose, polyvinyl chloride, antistatic fiber, poly(p-phenylene benzobisoxazole) (PBO), polybenzimidazole (PBI), polysulphonamide (PSA), and combinations thereof; and(b) optionally including a companion yarn different from said blended yarn; wherein said companion yarn includes p-aramid in an amount less than 20% of the fabric weight; and wherein the fabric has a weight from about 3 oz / yd2 to about 12 oz / yd2.

Owner:NAT SAFETY APPL INC

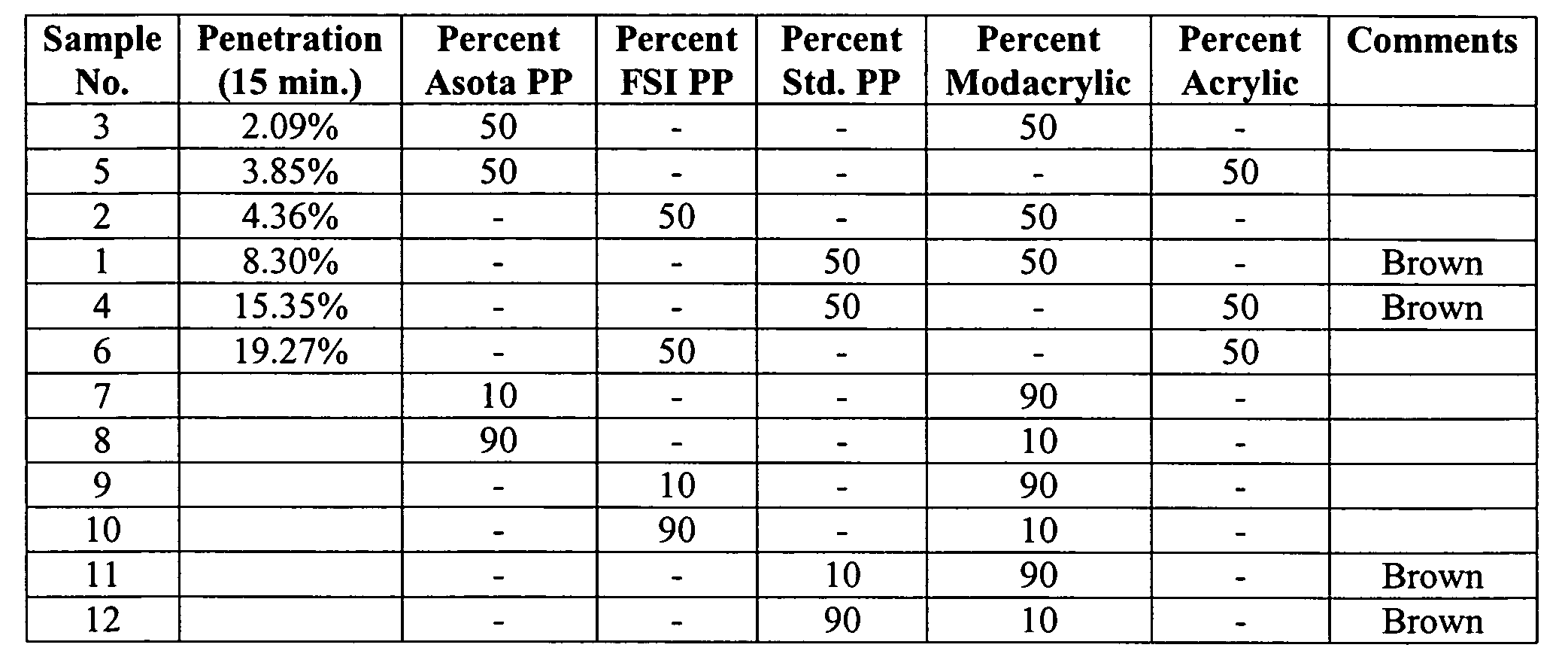

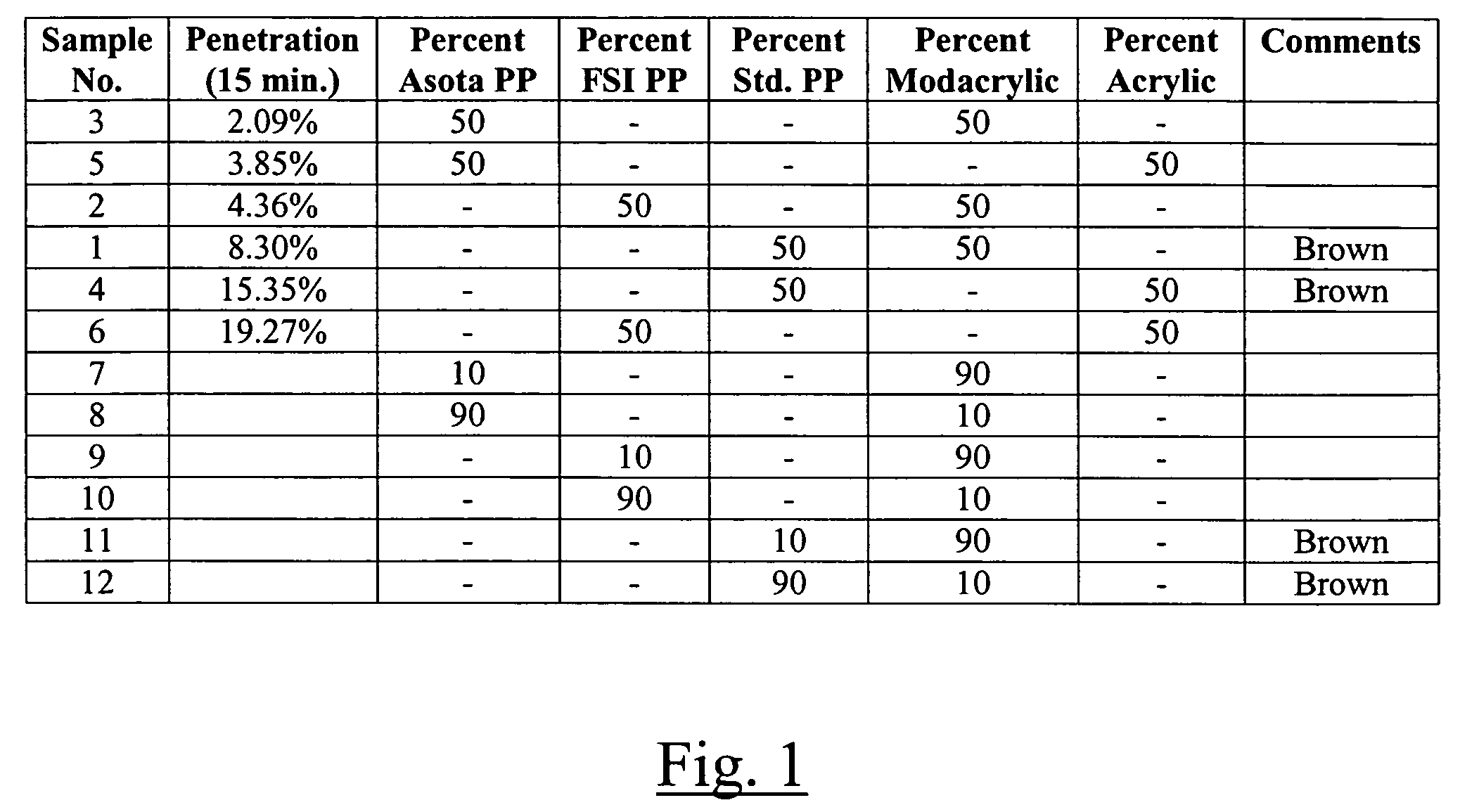

Two fiber filtration material

A filtration material comprising a blend of at least two types of fibers: (a) polypropylene fibers and (b) either acrylic or modacrylic fibers. In a preferred embodiment, the blend contains about 50 weight percent polypropylene fibers and about 50 weight percent modacrylic fibers. In another preferred embodiment, the blend contains about 50 weight percent polypropylene fibers and about 50 weight percent acrylic fibers. The fibers can be blended ranging from 90:10 to 10:90 polypropylene to acrylic or modacrylic. At least one type of fibers includes an extractable agent on the outer surfaces thereof. Performance of the blend is superior to the prior art filtration materials, especially at the preferred compositions.

Owner:AHLSTROM AIR MEDIA

High flame-retardant acrylic-cotton protective suit fabric and clothes made of same

InactiveCN104264320AImprove flame retardant performanceMeets requirementsGarmentsWoven fabricsYarnModacrylic

The invention relates to a high flame-retardant acrylic-cotton protective suit fabric and clothes made of the same. The high flame-retardant acrylic cotton protective suit fabric is characterized by comprising yarns which are used for making the high flame-retardant acrylic cotton protective suit fabric, to be specific, the yarns comprise, by weight, at least 60% of high flame-retardant modacrylic and 40% of combed cotton; or 60% of the high flame-retardant modacrylic, 35% of the combed cotton and 5% of nylon; or 60% of the high flame-retardant modacrylic, 38% of the combed cotton and 2% of antistatic fiber; 60% of the high flame-retardant modacrylic, 33% of the combed cotton, 5% of the nylon and 2% of the antistatic fiber; or 60% of the high flame-retardant modacrylic, 30% of the combed cotton, 5% of the nylon, 3% of aramid fiber and 2% of the antistatic fiber. The high flame-retardant acrylic-cotton protective suit fabric and the clothes made of the same have the advantages that flame-retardant effect is high.

Owner:JIANGSU SUNSHINE GRP CO LTD

Comfortable electric-arc-preventing flame retarding blends

InactiveCN108166119AImprove arc protection performanceGuaranteed StrengthFlame-proof filament manufactureArtificial filaments from viscoseYarnModacrylic

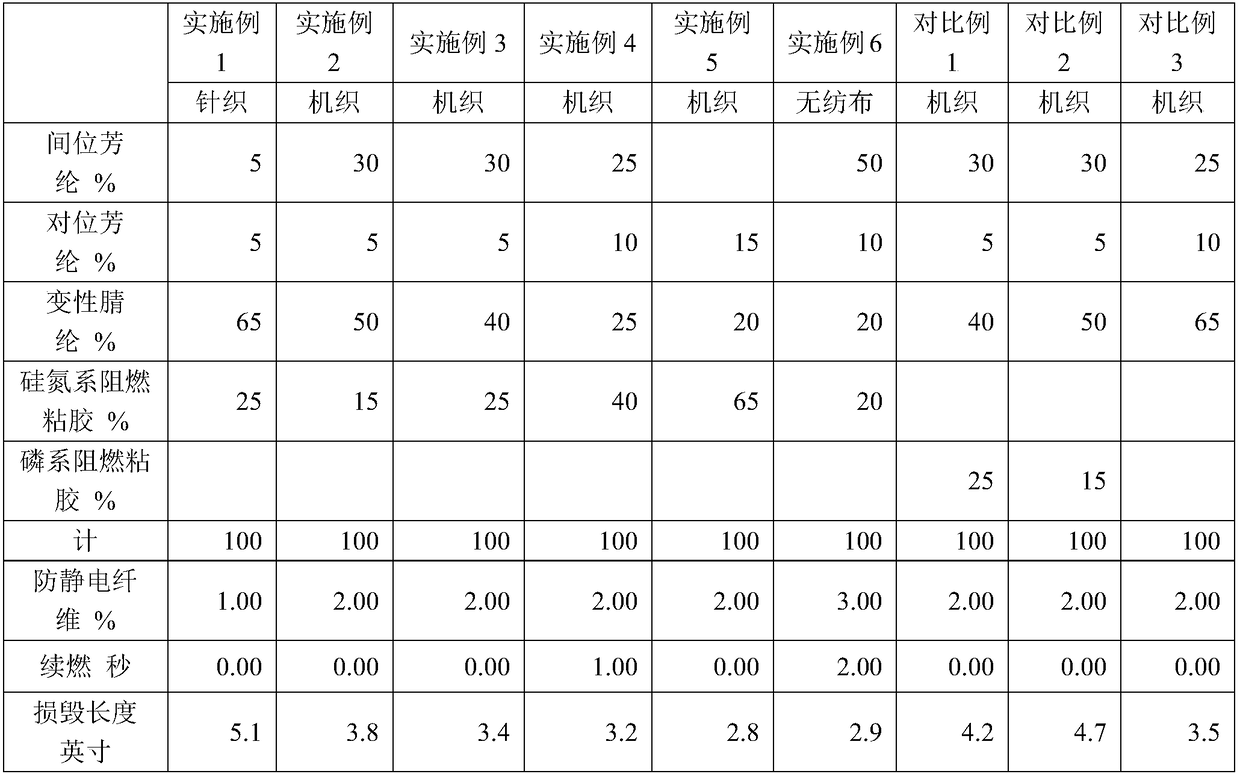

The invention discloses comfortable electric-arc-preventing flame retarding blends comprising aramid, modacrylic, and silicon nitride flame retardant viscose. The percentages of masses of three fibersto the total mass are: aramid fiber 10% to 60%; modacrylic 20% to 65%; silicon nitride flame retardant viscose 15% to 65%. the mass ratio of the silicon nitride flame retardant viscose to the modacrylic is 30% to 325%. Blends exist as fiber blends, yarns, fabrics, nonwovens, garments or the combination of the above. ASTM D6413-1999 is used for vertical burn test: the continued burn time is shorter than 2 seconds and the damaged length is no more than 6 inches.

Owner:南通谐好安全科技有限公司 +1

Protective fabric and process of manufacturing same

ActiveUS10760189B2Textile disintegration and recoveryFibre disintegrationModacrylicMechanical engineering

A fabric for use in arc and flame protection, and a process for producing a fire resistant fabric are provided. The fabric is made from at least 70 weight percent (wt %) aramid fiber; less than 40 wt % modacrylic; 8 wt % nylon; and 2 wt % anti-static. The aramid fiber is made from recycled aramid fiber from recycled fire resistant garments, and virgin aramid fiber. The fabric may be used to produce fire-resistant garments worn by workers in many industries such as the oil and gas.

Owner:GENERAL RECYCLED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com