Patents

Literature

102results about How to "Serial mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

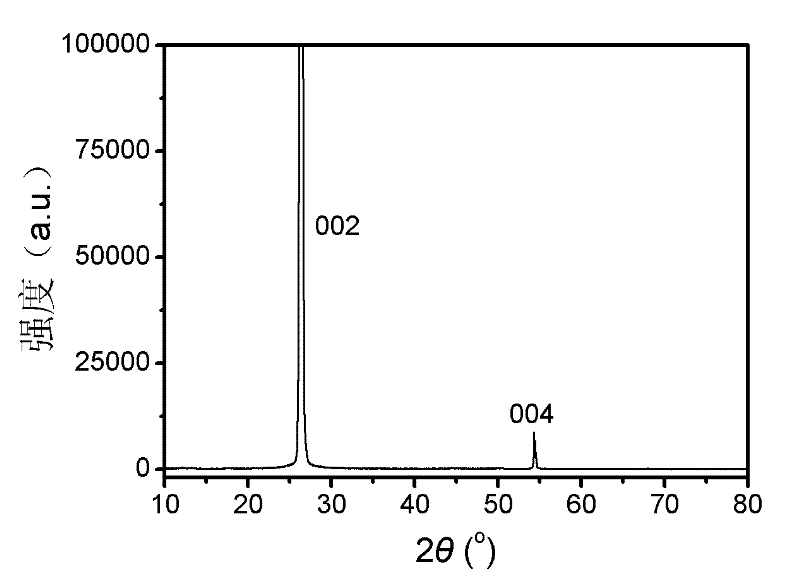

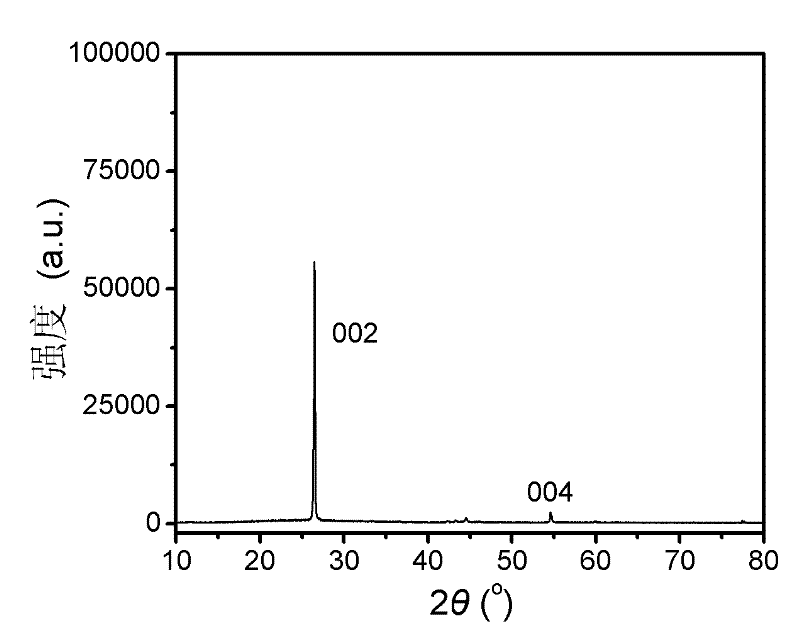

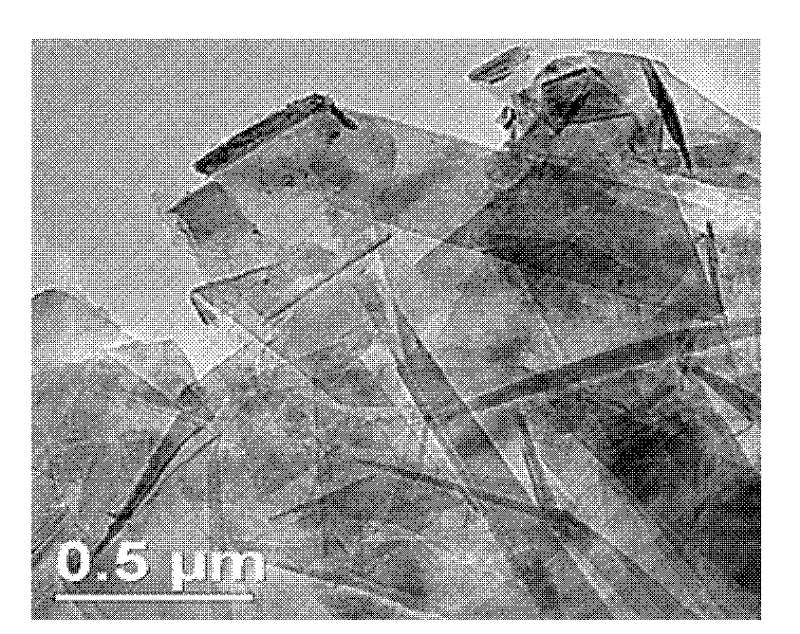

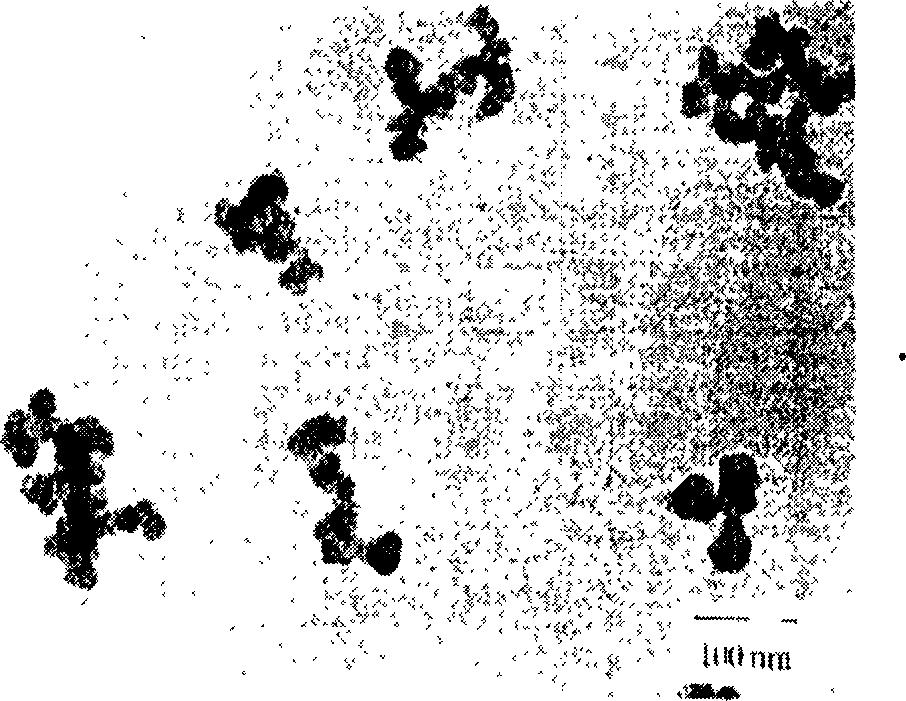

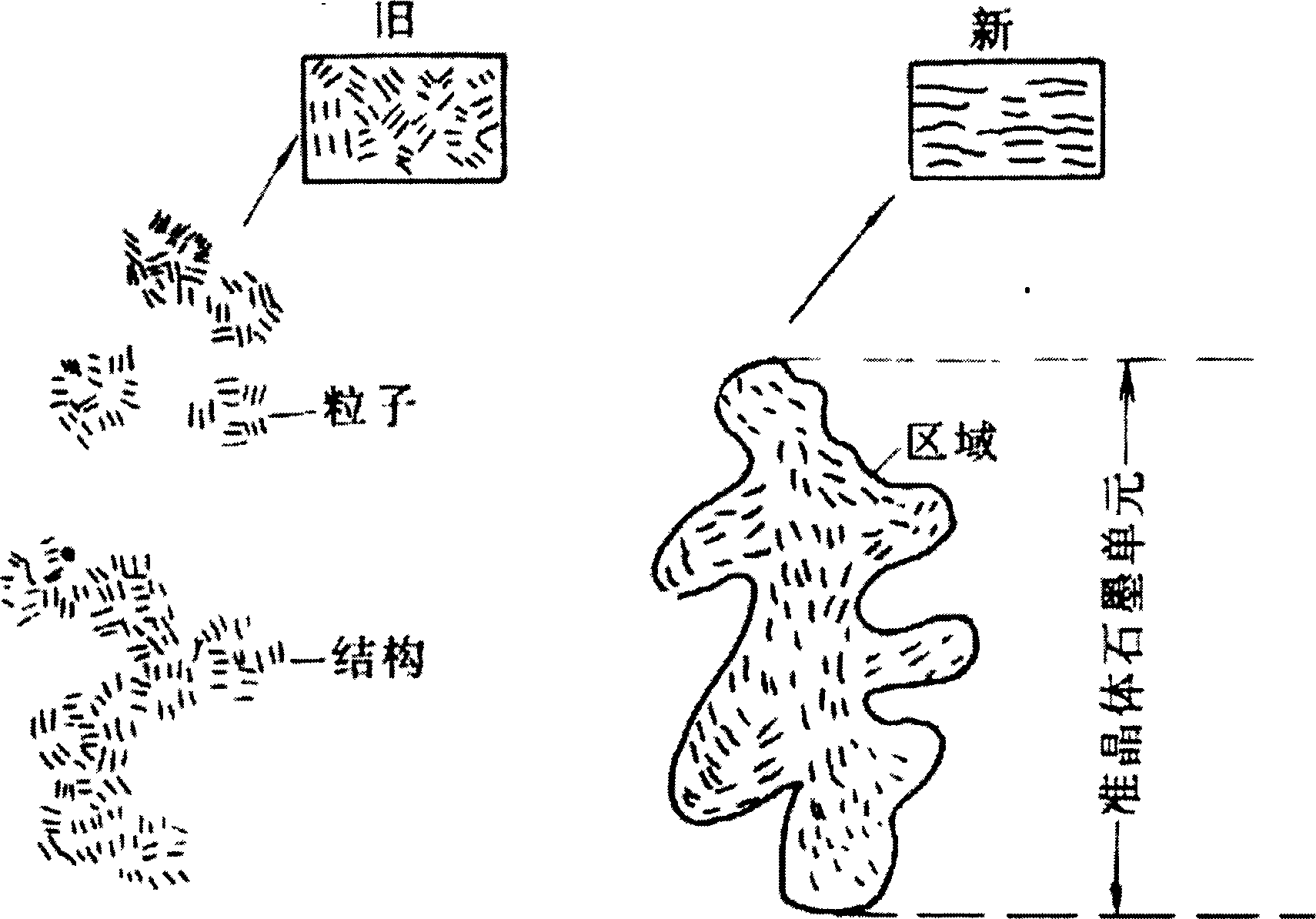

Preparation method of graphene uniform dispersion

The invention relates to a preparation method of graphene uniform dispersion, belonging to the technical field of new nano materials. The preparation method comprises the following steps of: (1) preparing aqueous surfactant solution with the concentration of 0.2-20g / L; (2) mixing raw graphite powder with the aqueous surfactant solution according to the concentration of 1-100g / L, forming suspension and adding the suspension into a high-pressure reactor with strirring; (3) adjusting the rotating speed of the high-pressure reactor to be 50-300rpm and the temperature in the reactor to be 100-300 DEG C, carrying out heat preservation treatment on the raw graphite powder for 5-24 hours and then taking out paste; (4) carrying out 1000-2000rpm centrifugation on the paste for 15-45 minutes, and obtaining supernatant solution which is the dispersion with one-layer and multilayer graphene. The preparation method has the advantages that the aqueous surfactant solution used in the preparation process can be recycled without exhaust emission; the used materials are non-corrosive, non-toxic, non-flammable and non-explosive products; the process can not cause large damage to the protogenic conjugated structure of the graphene; and the low cost can be realized, and the graphene dispersion with excellent dispersity and stability can be prepared.

Owner:常熟三爱富氟源新材料有限公司

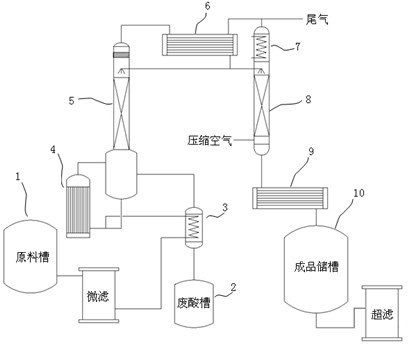

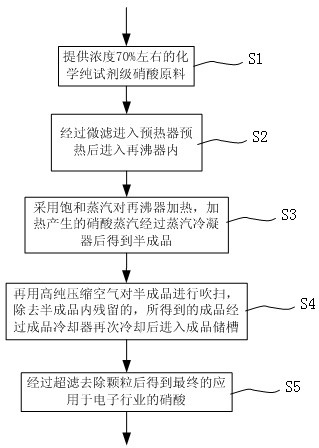

Method for producing electronic-grade nitric acid

The invention discloses a method for producing electronic-grade nitric acid. The method sequentially comprises the following steps of: a) providing a chemically pure reagent-grade nitric acid raw material of which the concentration is about 70 percent; b) performing microfiltration on the nitric acid raw material, adding the nitric acid raw material into a pre-heater for preheating, and adding into a reboiler; c) heating the reboiler with saturated vapor, and making nitric acid vapor generated by heating pass through a vapor condenser to obtain a semi-finished product; d) blowing the semi-finished product with high-purity compressed air to remove residual vapor in the semi-finished product, cooling the obtained finished product again with a finished product cooler, and adding the finishedproduct into a finished product storage tank; and e) performing ultrafiltration on the finished product to remove particles so as to finally obtain the nitric acid applied in the electronic industry.In the method for producing the electronic-grade nitric acid, the normal chemically pure reagent-grade nitric acid raw material of which the concentration is about 70 percent is directly rectified and then the rectified product is blown with the high-purity compressed air. The used raw material is safe; the pressure for the subsequent tail gas treatment is greatly reduced; and the production costis reduced.

Owner:SHANGHAI ZHENGFAN TECH

Nano carbon black with in-situ grafted organic compound and its producing method

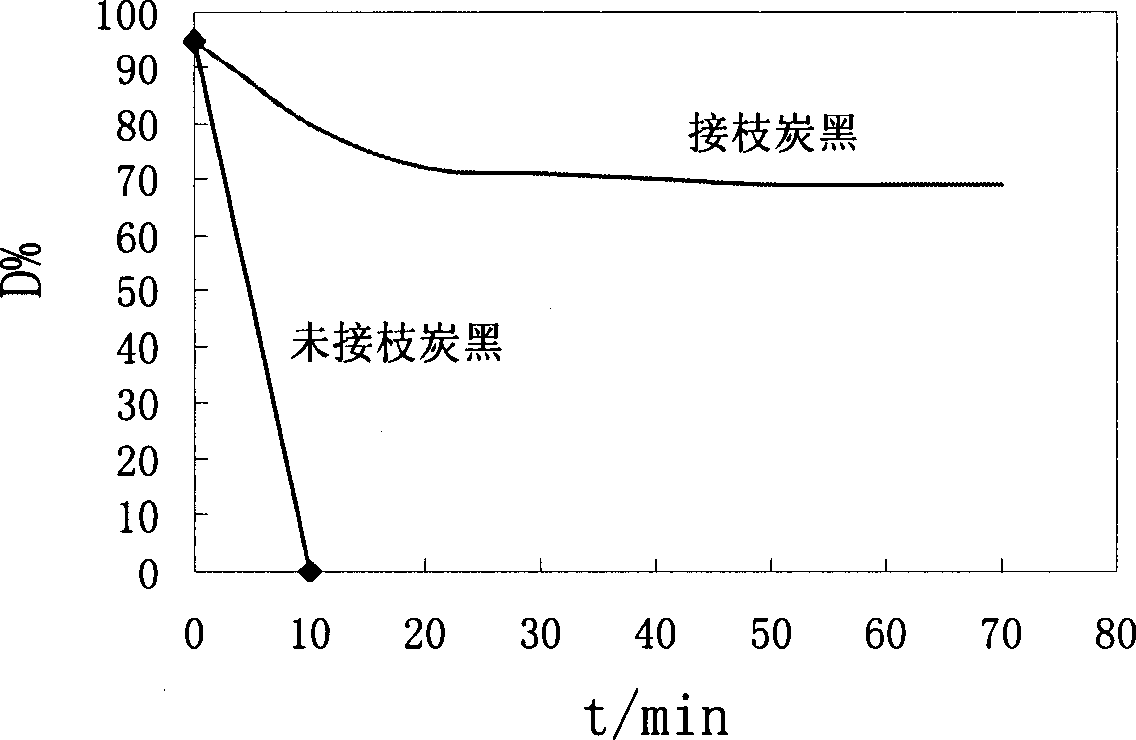

InactiveCN1781999ASimple processLow costPigment treatment with non-polymer organic compoundsModified carbonSolvent

The present invention relates to a kind of nano carbon black with in-situ grafted organic compound and its preparation process. Under the action of mechanical shearing force field, carbon black and organic compound possessing or capable of producing active free radical are made to produce direct grafting reaction at the temperature over the smelting point forming the grafted carbon black. The obtained grafted carbon black has high dispersivity and compatibility, as well as nano effect common modified carbon black does not have. In addition, the said carbon black modifying process needs no solvent, has no pollution, simple procedure and low cost, and is suitable for continuous production.

Owner:EAST CHINA UNIV OF SCI & TECH

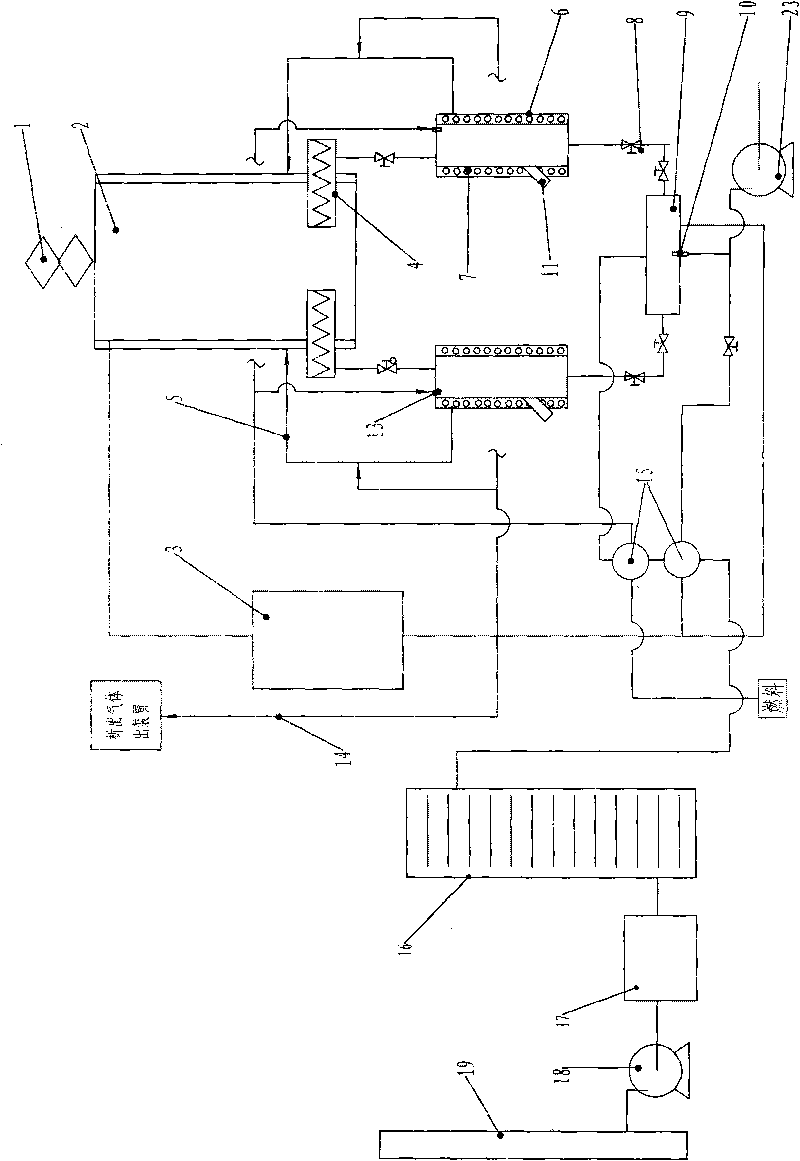

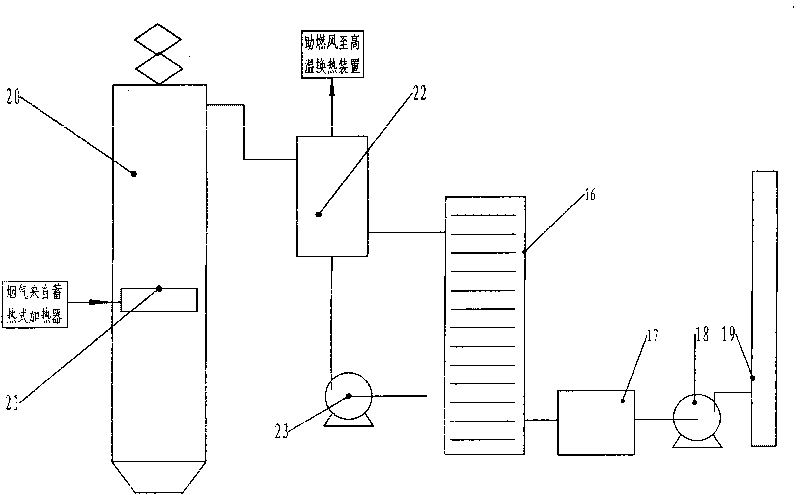

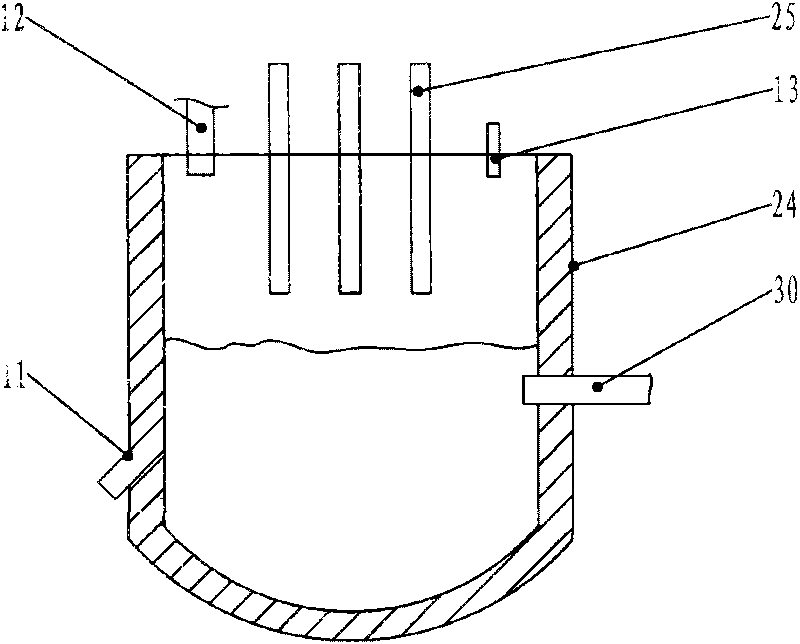

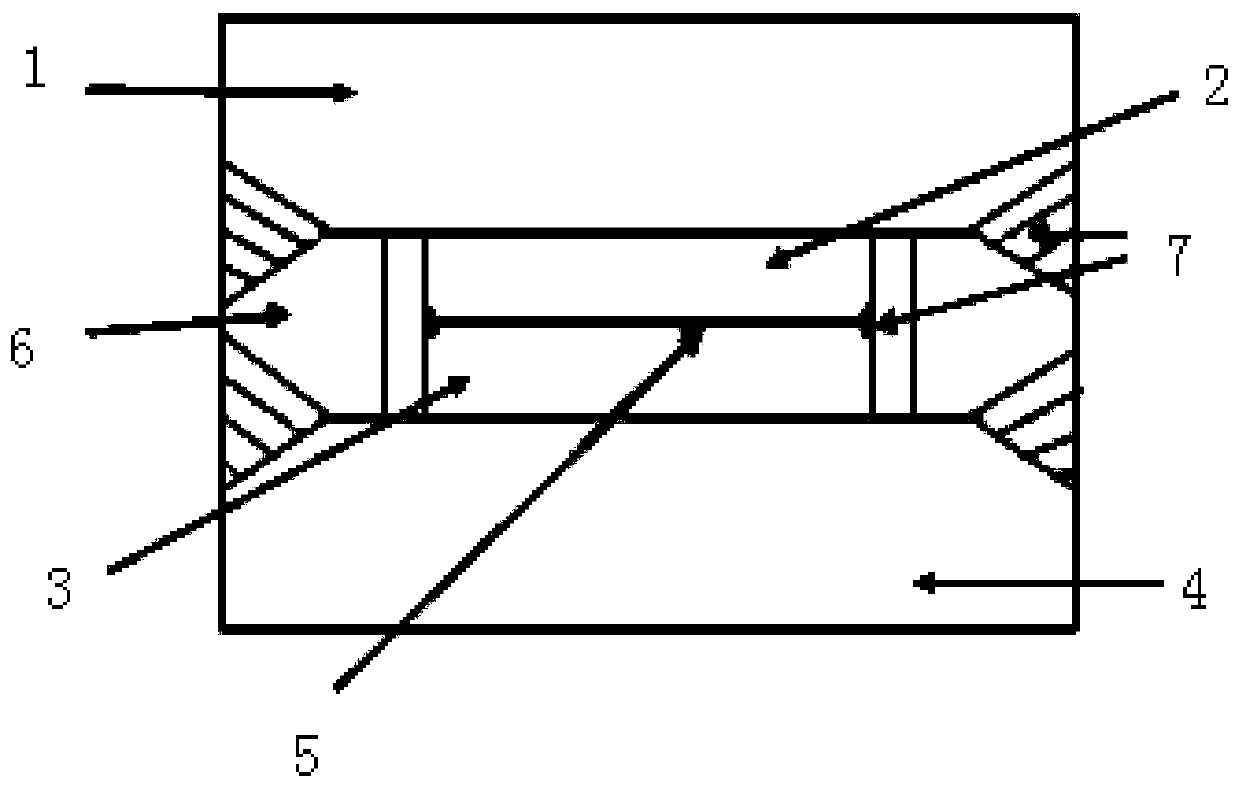

Method and device for ironmaking by smelting

The invention relates to a method and a device for ironmaking by smelting reduction. Natural lump ore or artificial lump ore is taken as a raw material, coal gas produced during reduction is taken as a reducer and a heat carrier, and the raw material reacts through a pre-reduction furnace and then enters final reduction furnaces for a final reduction reaction. Liberated gas which comes out of the upper part of the pre-reduction furnace is treated through a gas processing device and is heated by a high-temperature heat exchange device and then enters the final reduction furnaces. The device for ironmaking by smelting reduction comprises the pre-reduction furnace, the gas processing device and at least one final reduction furnace. The method and the device have reasonable operation flow, fully utilize afterheat, and save energy sources; the method and the device use the two final reduction furnaces for alternate operation, have high production efficiency, and can perform continuous and mass production; and coal gas saved during production provides a raw material to other processes using the coal gas.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

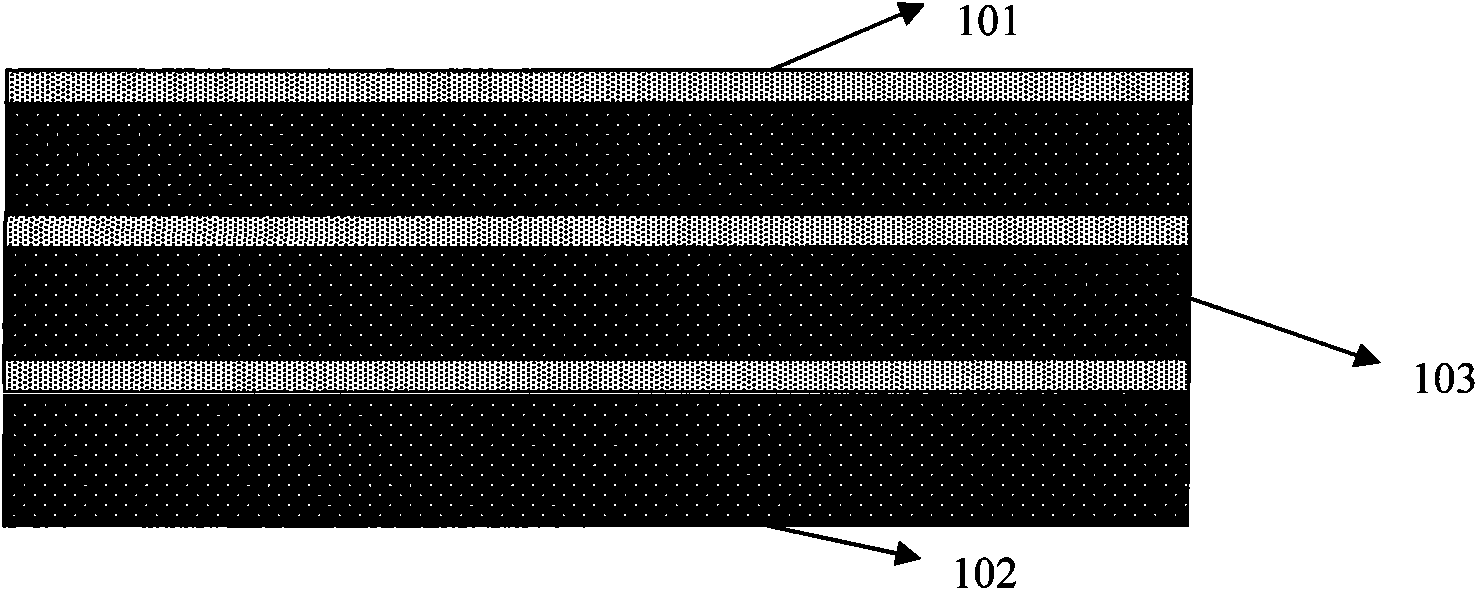

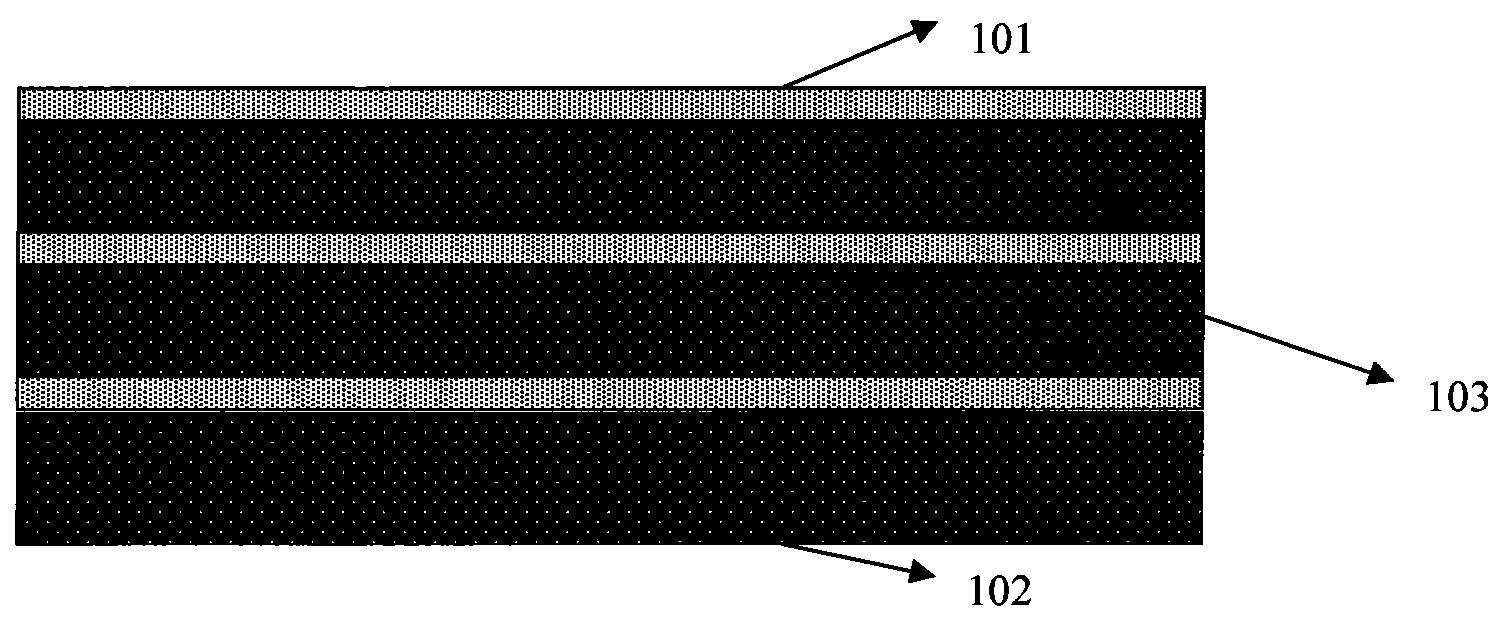

Process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic wafer material by tape casting

InactiveCN101844925AImprove fracture toughnessGive full play to antioxidantCeramic layered productsMultilayer membraneFlexural strength

The invention relates to ZrB2-SiC complex phase ultrahigh temperature ceramic, in particular to a process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic material by tape casting. The process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic material by tape casting is realized by the following steps: preparation of SiC ceramic biological membrane, preparation of ZrB2-SiC complex phase ceramic biological membrane, multilayer membrane stacking and laminating, binder removing and sintering; fracture toughness of the acquired multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic material reaches 7-12Mpa.m1 / 2, flexural strength is 600-800MPa. The two indexes are obviously higher than those of ZrB2-SiC complex phase ceramic prepared by conventional method.

Owner:南通市通州区益君劳务有限公司

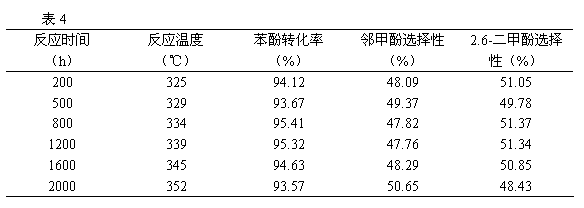

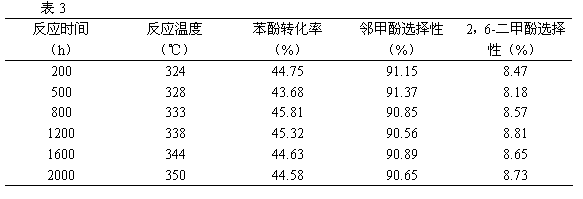

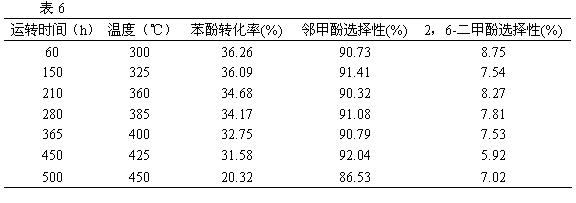

Method for preparing ortho-cresol and 2,6-dimethylphenol

InactiveCN102826960AAdjustable pHHigh activityOrganic chemistryOrganic compound preparationPtru catalystOrtho position

The invention discloses a method for preparing ortho-cresol and 2,6-dimethylphenol and is characterized in that a reaction mixed liquid at the mole ratio of phenol to methanol to water being 1: (2-5): (1-3) is pumped the into a reactor by the use of a pump at the feeding space velocity of 0.5-2 hr<-1>; N2 with the flow velocity of 10-25 mL / min is used as a carrier gas; and a vapor-phase alkylation reaction is carried out at the reaction pressure of normal pressure to 0.5 MPa at the reaction temperature of 320-380 DEG C and under the condition of an alkaline Fe / Mg / Sb composite oxide used as a catalyst. The method provided by the invention has advantages as follows: high average conversion rate of phenol, long one-way service life of the catalyst, high ortho-selectivity, and no generation of impurities m.p-cresol and anisole. In addition, the process is simple, and the method is suitable for continuous large-scale production of ortho-cresol, or reallocation of 2,6-dimethylphenol, or co-production of ortho-cresol and 2,6-dimethylphenol.

Owner:HUNAN XINLING CHEM CO LTD

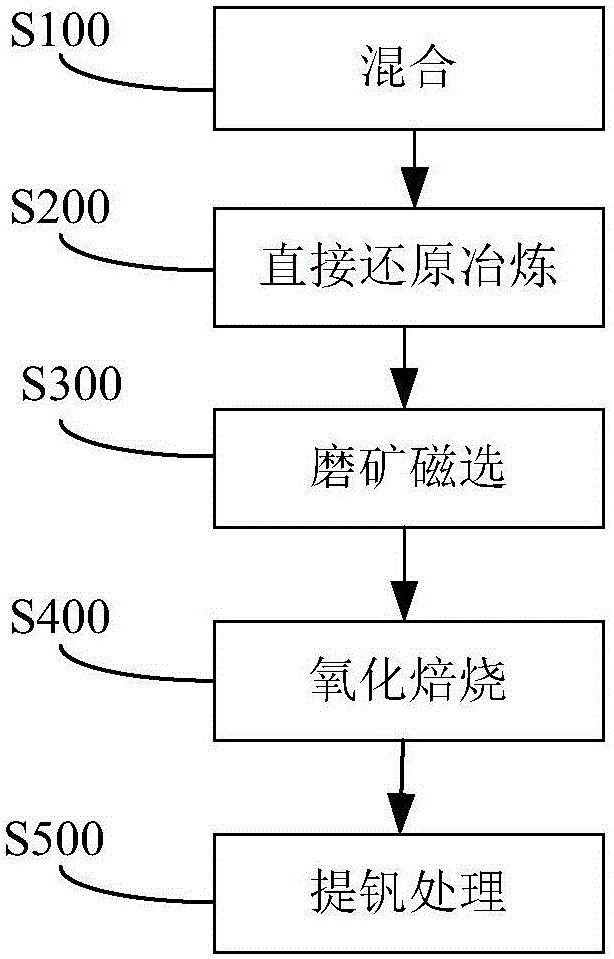

Method for comprehensively utilizing vanadium slag

ActiveCN105907984AImplement step-by-step extractionHigh recovery rateProcess efficiency improvementIron powderSlag

The invention provides a method for comprehensively utilizing vanadium slag. The method comprises the following steps: mixing the vanadium slag, calcium salt and a reducing agent to obtain a mixed material; directly reducing and smelting the mixed material to obtain a metallized pellet; performing grinding and magnetic separation for the metallized pellet to obtain reduced iron powder and vanadium-rich slag; performing oxidizing roasting for the vanadium-rich slag to obtain a calcium vanadate clinker; extracting vanadium from the calcium vanadate clinker to obtain vanadium pentoxide. With the adoption of the method, an iron resource in the vanadium slag can be recovered; the iron is recovered by calcifying, reducing and magnetic separation, and then the vanadium-rich slag is directly oxidized and roasted to obtain a high-valence calcium vanadate clinker; vanadium pentoxide can be produced by a currently-mature acid leaching-vanadium precipitating-roasting process.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

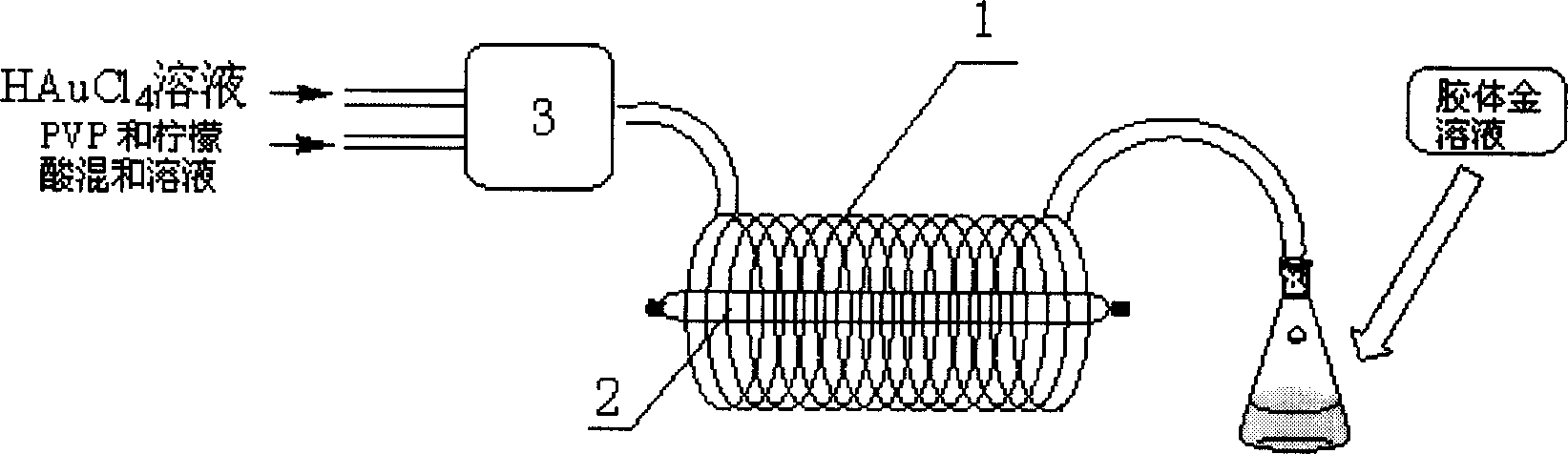

Method for preparing gold colloidal nanaparticles

The invention relates the method for preparation of nanometer gold particle, comprising the following step: making the mixture solution of PVP and citric acid, adding chlorauric acid solution, and injecting the mixture solution into quartz coiled pipe which is irradiated by ultraviolet lamp, the radiated wave length of ultraviolet lamp being 253.7-300nm, and the power of ultraviolet lamp being 14-2000W. Using the method, the grain-size distribution of nanometer gold particle is homogeneous, the particle sizes are easy to control, the least mean particle diameter is 1.5nm, and no poison material and the polluted material are produced.

Owner:XI AN JIAOTONG UNIV

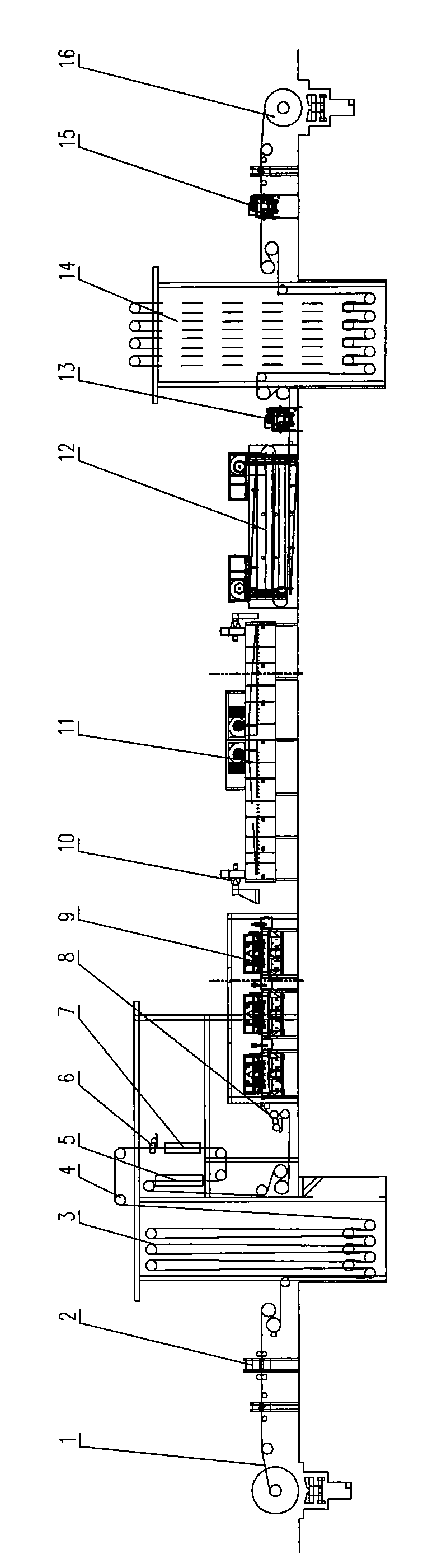

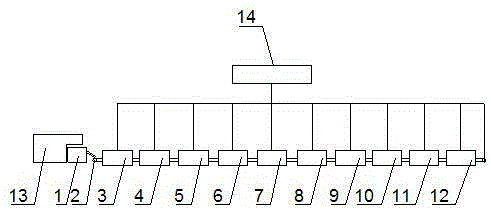

Continuous production process and production equipment for flocking steel belts and steel plates

InactiveCN101612613ASerial mass productionIncrease productivityPretreated surfacesCoatingsHigh volume manufacturingSheet steel

The invention relates to a continuous production process and production equipment for flocking steel belts and steel plates. The production process comprises the following steps of: rewinding; forward storing materials and correcting deviation; pre-treating materials; gluing; flocking; drying, cooling and brushing; and backward storing materials and rolling. The production equipment comprises a rewinding device, a forward material storing device, a double-roll deviation correcting device, a passivating device, a passivation drying device, a cooling box, a roller spreading machine, an electrostatic flocking machine, a drying room, an air cooling room, a first brushing box, a backward material storing device, and a rolling device which are connected in turn. The process and the equipment can realize continuous and mass production of the flocking steel belts or the steel plates, the production efficiency is high, and the quality of the products is reliable. The forward material storing step, the forward material storing device, the backward material storing step and the backward material storing device ensures the continuous production when rolls are changed.

Owner:无锡市鹏程植绒机械有限公司

Glass fiber reinforced polystyrene micro-foam double-layer co-extrusion section and its making method

ActiveCN103213366AWon't breakEvenly dispersedSynthetic resin layered productsGlass fiberSurface layer

The invention aims to provide a glass fiber reinforced polystyrene micro-foam double-layer co-extrusion section. The core layer of the section contains 3-8% of a uniform-distribution glass fiber (by polystyrene) having a length-diameter ratio of 10-20. The surface of the core layer is coated with a layer of high-impact-resistance polystyrene, and the mass fraction ratio of the material of the core layer to the material of the surface layer is 100:5-25. The density of the section reaches 0.40g / cm<3>, so the tensile strength and the charpy impact strength of the section can reach 12MPa and 4.5kJ / m<2> respectively, and are 31% and 23% higher than that of a same micro-foam material not added with the glass fiber respectively. In the invention, a polystyrene raw material is substantially saved, and the production cost is reduced.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

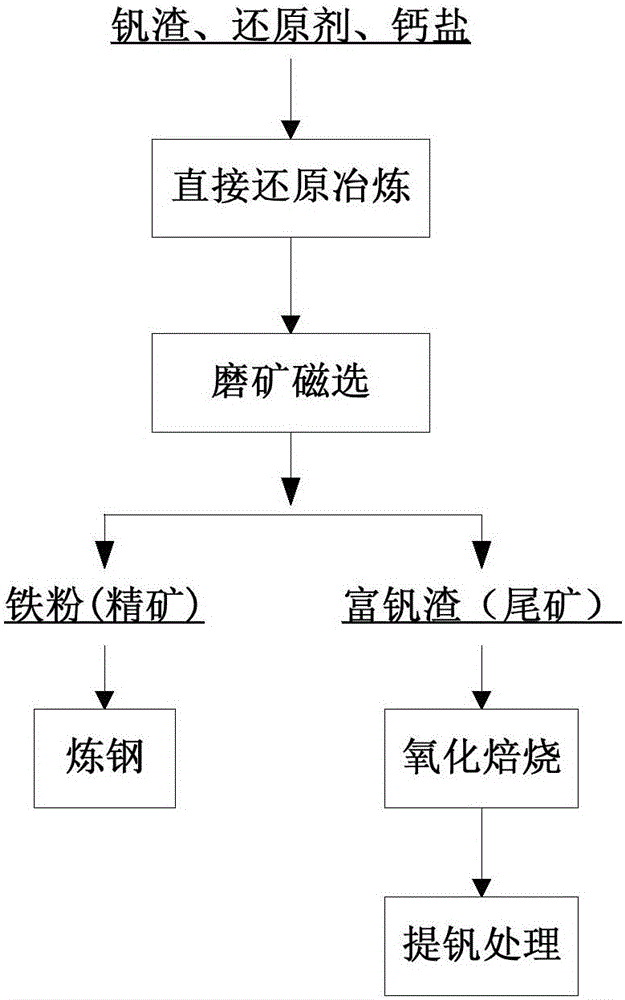

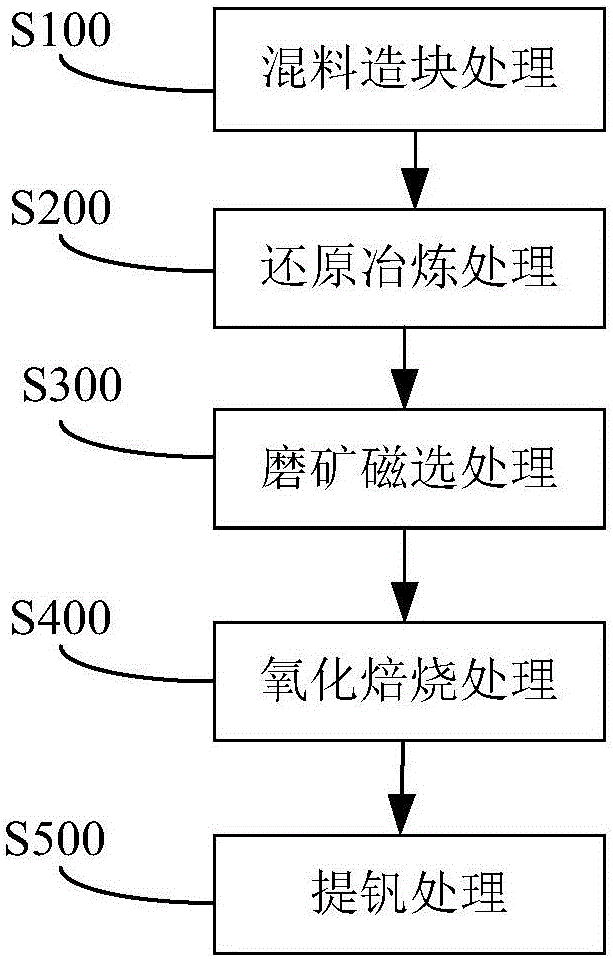

Comprehensive treatment method for vanadium slag and application thereof

PendingCN106086431AIncrease metallization rateHigh recovery rateProcess efficiency improvementSlagMixed materials

The invention discloses a comprehensive treatment method for vanadium slag and application thereof. The comprehensive treatment method for the vanadium slag includes the steps that the vanadium slag, sodium salt and a reducing agent are subjected to mixing and briquetting treatment, so that mixed material briquettes are obtained; the mixed material briquettes are subjected to reducing smelting treatment, so that metalized briquettes are obtained; the metalized briquettes are subjected to grinding magnetic separation treatment, so that reduced iron and vanadium-rich slag are obtained; the vanadium-rich slag is subjected to oxidizing roasting treatment, so that vanadium slag clinker is obtained; and the vanadium slag clinker is subjected to vanadium extraction treatment, so that vanadium pentoxide is obtained. According to the comprehensive treatment method, the vanadium slag, the reducing agent and the sodium salt are mixed, then the iron in the vanadium slag is recovered through reducing smelting, vanadium is enriched after the iron is recovered from the vanadium slag, and the vanadium-rich slag is obtained; and the vanadium-rich slag is subjected to oxidizing roasting to obtain water-soluble sodium vanadate, and the vanadium pentoxide is extracted from the vanadium slag. The comprehensive treatment method for the vanadium slag realizes step-by-step extraction of valuable elements of the iron and the vanadium in the vanadium slag, and the recovery rate of the iron and the vanadium is high.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Preparation method of pectin nutritional jelly having high calcium salt content

The invention relates to a preparation method of a pectin nutritional jelly having a high calcium salt content, which comprises the following steps: mixing 10-25 parts of pectin and a proper amount of buffer salt to obtain a pectin / buffer salt mixture; mixing the pectin / buffer salt mixture and 20-150 parts of sweetening agent, and dissolving with 60-300 parts of hot water of 80-100 DEG C while stirring, thus obtaining a pectin solution; preparing a pectin / syrup mixed solution; preparing a calcium salt suspension; adding the calcium salt suspension into the pectin / syrup mixed solution to prepare a feed solution; casting the prepared feed solution into a mold; arranging the cast jelly in an environment of hot air, drying, and shaping; demolding at 18-26 DEG C; and performing surface treatment on the demolded jelly to obtain the product. The preparation method provided by the invention maximally reduces the influence of the calcium content on the shaping of the pectin jelly; the calcium salt content can be up to 25-350 parts; and the calcium-containing pectin jelly is favorable in temperature tolerance and mouthfeel and stable in calcium content.

Owner:SIRIO PHARMA CO LTD

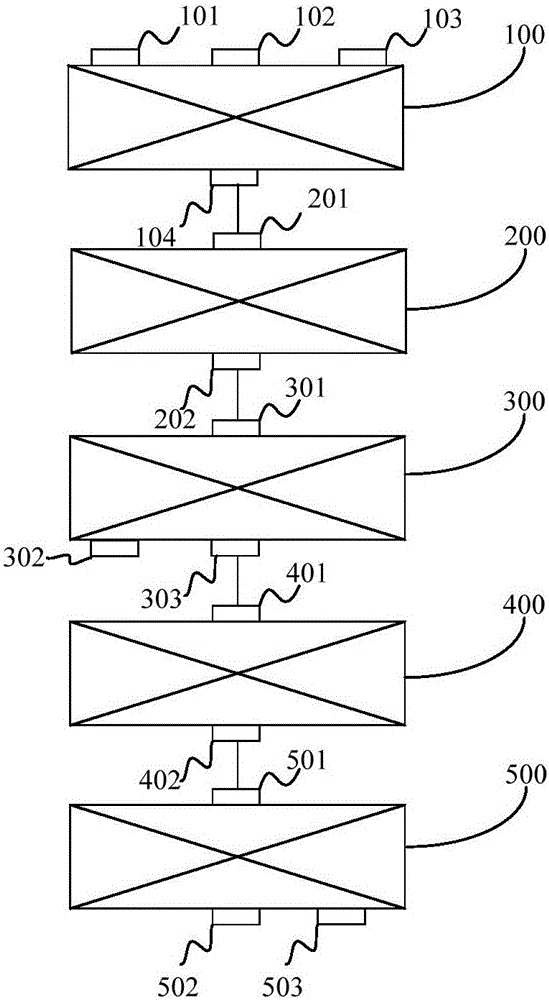

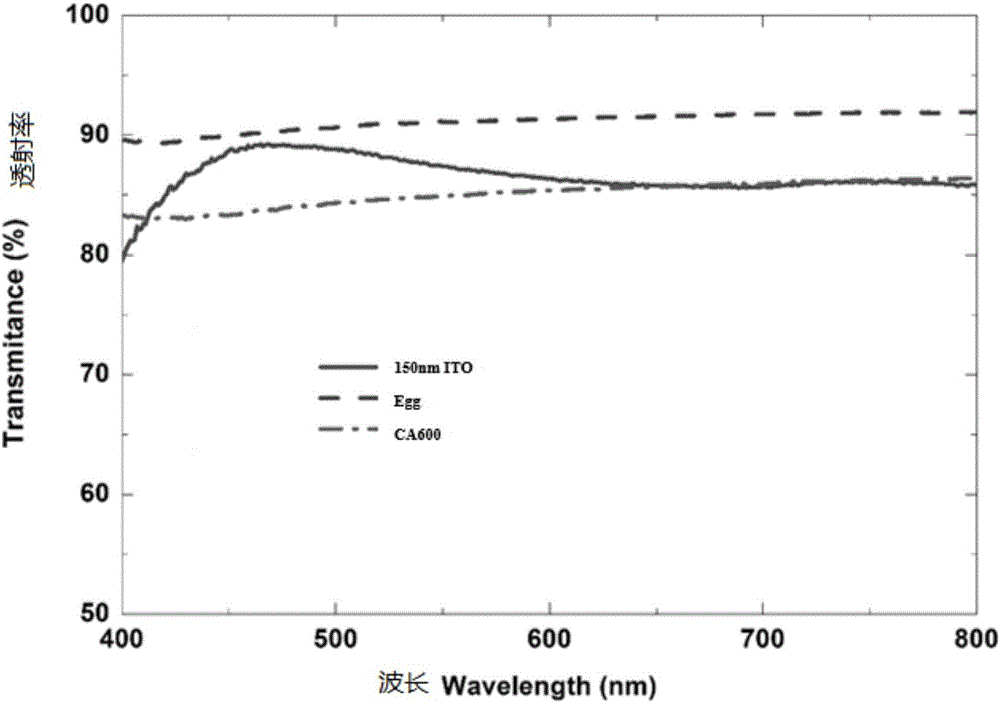

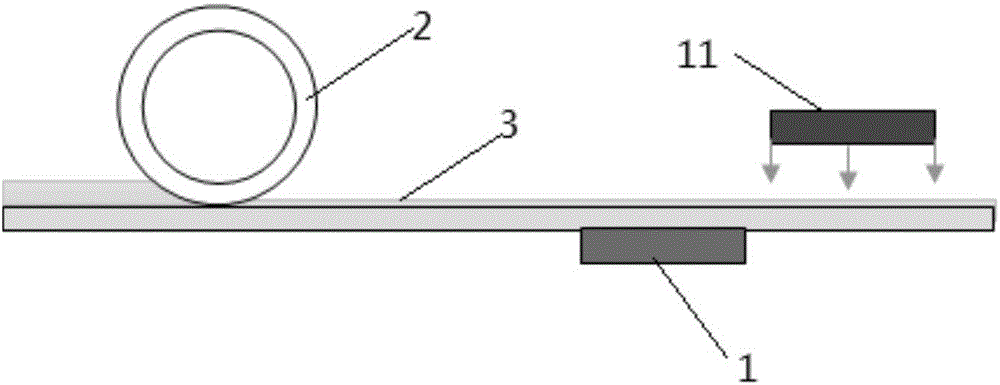

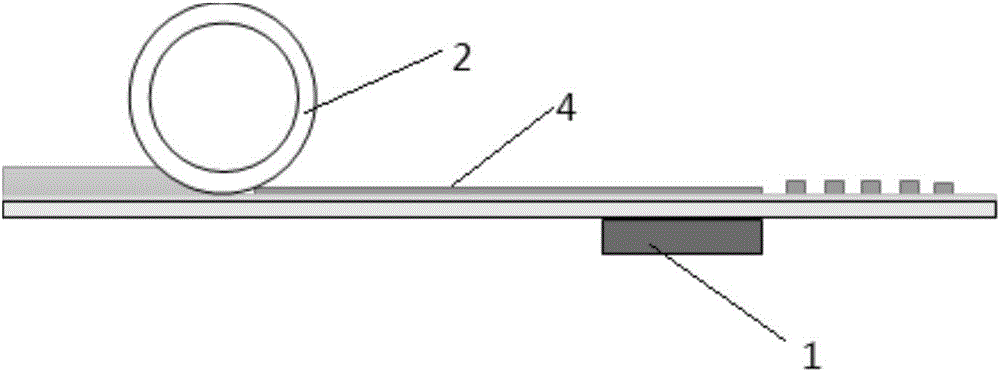

Method for preparing metal network transparent conductive electrode by low-cost plasma bombardment

ActiveCN106782879AGood liquidityEasy to cleanNanotechnologyCable/conductor manufacturePhotoresistLow input

The invention discloses a method for preparing a metal network transparent conductive electrode by low-cost plasma bombardment. The method comprises the following steps of (1) coating a substrate with photoresist; (2) fixing the photoresist; (3) manufacturing a cracked template network; (4) performing plasma bombardment on the photoresist to form a network; (5) forming a nanometer metal network; (6) removing the photoresist; and (7) performing adhesive property treatment. The transparent conductive electrode prepared by the method has the advantages of low input, relatively high yield, simple process, low construction cost, and easy realization of reel-to-reel industrial production and the like; and meanwhile, the electrode is relatively high in conductivity, and high in transparency, and can replace or partially replace ITO conductive glass.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Production equipment and technology for cathode or anode material of converter-type lithium battery

Owner:济宁市无界科技有限公司

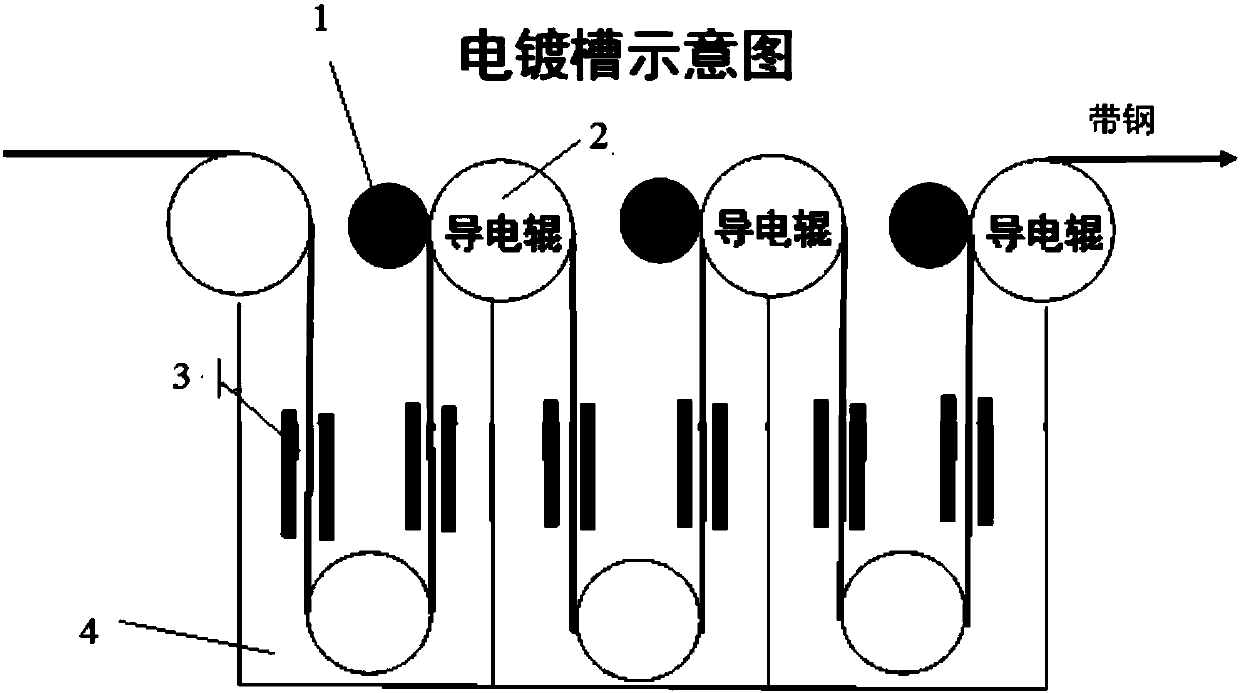

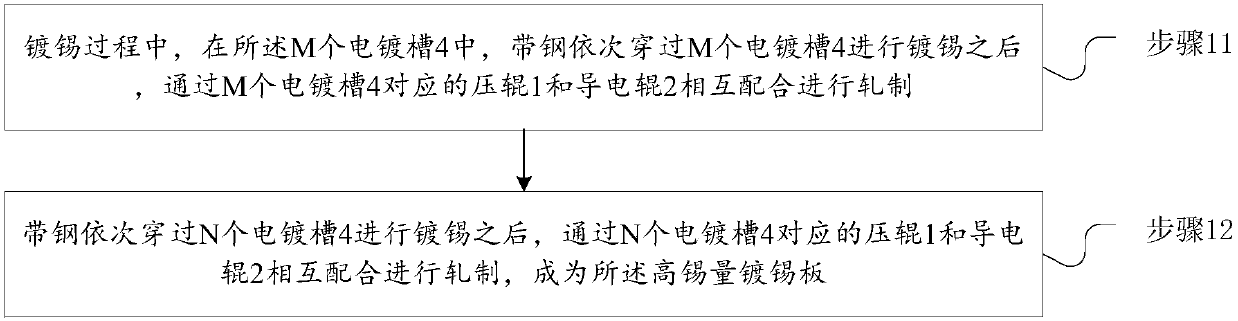

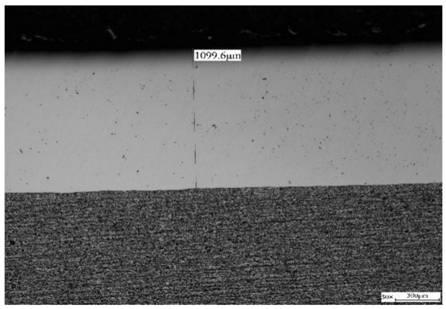

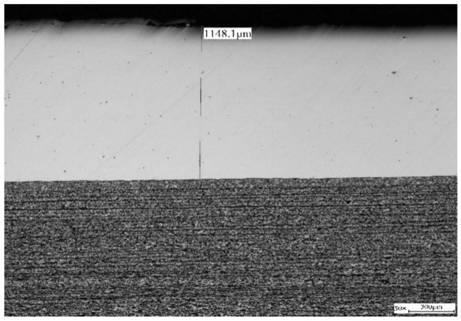

High-tin tinned plate edge quality control method

The invention discloses a high-tin tinned plate edge quality control method. P plating tanks are arranged on a soluble anode tin plating production line. Each plating tank is equipped with a press roll and a conductive roll correspondingly. Each plating tank is equipped with an anode pure tin bar as a tin plating source. The concentration of tin ions in electroplating liquid of each of the P plating tanks is controlled within 19-25 g / L; the current density of M plating tanks among the P plating tanks is controlled within 28-30 A / dm2, and the current density of N plating tanks among the P plating tanks is controlled within 20-28 A / dm2. In the tin plating process, in the M plating tanks, a steel strip passes the M plating tanks in sequence to be subjected to tin plating and then is rolled through cooperation of the corresponding press rolls and the corresponding conductive rolls in the M plating tanks; and then the steel strip passes the N plating tanks and are subjected to tin plating in sequence and then is rolled through cooperation of the corresponding press rolls and the corresponding conductive rolls in the N plating tanks to form a high-tin tinned plate.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Rolling method of stainless steel composite plate

ActiveCN111530927AEasy to shapeQuality improvementTemperature control deviceWork treatment devicesSS - Stainless steelComposite plate

The embodiment of the invention provides a rolling method of a stainless steel composite plate. The rolling method of the stainless steel composite plate comprises the following process steps in sequence: detecting high-temperature mechanical properties of carbon steel and stainless steel, correcting and inputting chemical components, selecting a control model, heating a plate blank, rough rolling, descaling after being discharged from a furnace, finish rolling, finish descaling, finish rolling outlet, layer cooling control and coiling control. The stainless steel composite plate blank consists of four layers of steel plates from top to bottom, and the first layer and the fourth layer are both carbon steel plates with the thickness of 75-80 mm, the second layer and the third layer are bothSUS304 stainless steel plates with the thickness of 12-14 mm, and after rolling, the thickness of a finished product is generally 6-16mm; and through the technical means provided by the invention, continuous and mass production is smoothly realized on a traditional hot continuous rolling unit, and the stainless steel composite plate with good shape and surface quality of a steel strip is prepared.

Owner:LIUZHOU IRON & STEEL

Circulation method for preparing expanded cut tobacco

ActiveCN101617854AHigh energy consumptionReduce energy consumptionTobacco preparationFinal product manufactureVacuum pumpingProcess engineering

The invention discloses a circulation method for preparing expanded cut tobacco, comprising the following steps: (1) putting cut tobacco into a preheated impregnating tank, then carrying out vacuum-pumping; (2) spraying liquid expanding agent to the cut tobacco; (3) filling gas expanding agent to the impregnating tank; (4) impregnating; (5) first, recycling the liquid expanding agent, then recycling the gas expanding agent; and (6) expanding the impregnated cut tobacco, and carrying out operations in step (2) or / and step (3) by the liquid expanding agent and the gas expanding agent recycled in step (5). The method of the invention has mild condition and greatly reduced requirement for devices, by fully recycling the expanding agents, the cost is lowered, the complete set of devices has low energy consumption and high automation, continuous mass production can be carried out, all performance indexes of the obtained expanded cut tobacco are high, the expanded efficiency of the cut tobacco is high, and the recycling rate of the expanding agents is high.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

Preparation method of silicon-carbide square beams through extruding, molding, reacting and sintering

InactiveCN101935218AHigh strengthPrecise DimensionsCeramic shaping apparatusFiberHigh volume manufacturing

The invention provides a preparation method of silicon-carbide square beams through extruding, molding, reacting and sintering. The preparation method comprises the steps of ceramic mud preparation, molding, solidifying and sintering and is characterized by evenly mixing the following raw materials in parts by weight: 65-85 parts of silicon-carbide powder with the granularity d50 smaller than 100microns, 3-10 parts of carbon fiber, 10-20 parts of plastic agent and 2-5 parts of liquid paraffin in a vacuum mud-refining machine to prepare silicon-carbide porcelain plastic mud; and extruding andmolding the silicon-carbide porcelain plastic mud, cutting into silicon-carbide porcelain plastic square beams and solidifying into blanks. The silicon-carbide square beams prepared by extruding, molding, reacting and sintering have high strength and production efficiency and can carry out continuous mass production.

Owner:SHANDONG UNIV OF TECH

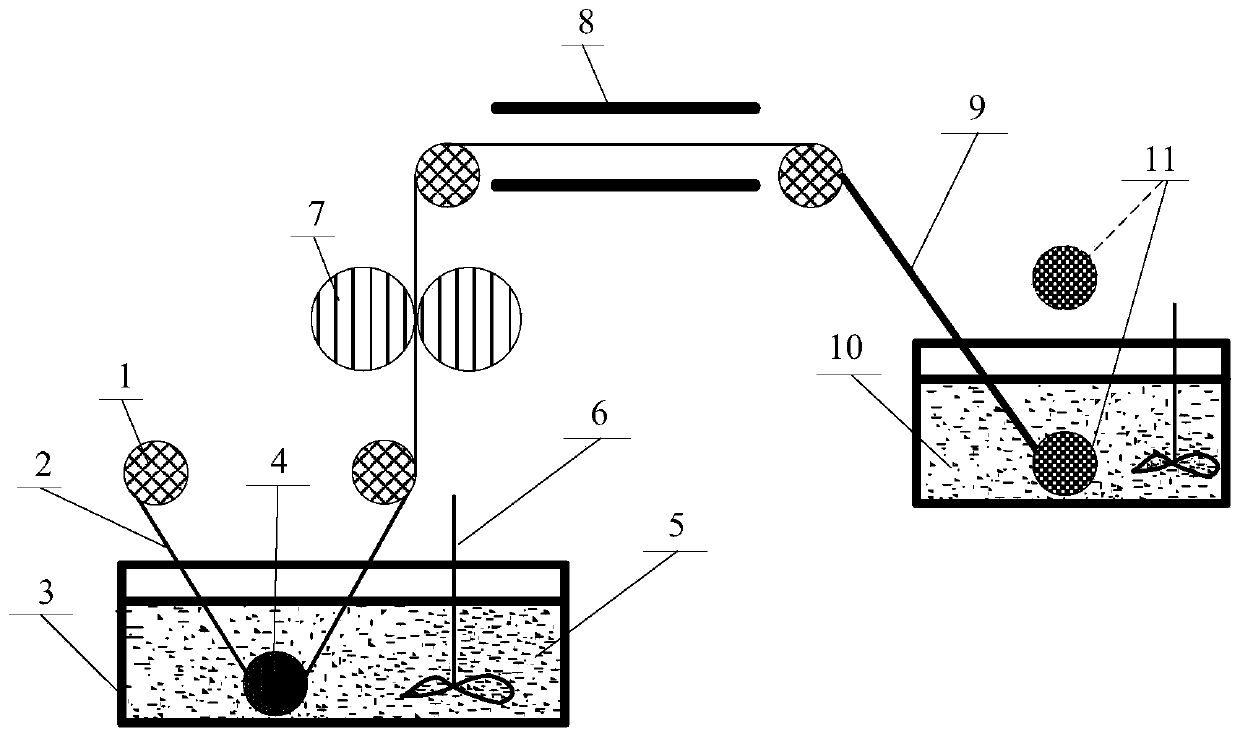

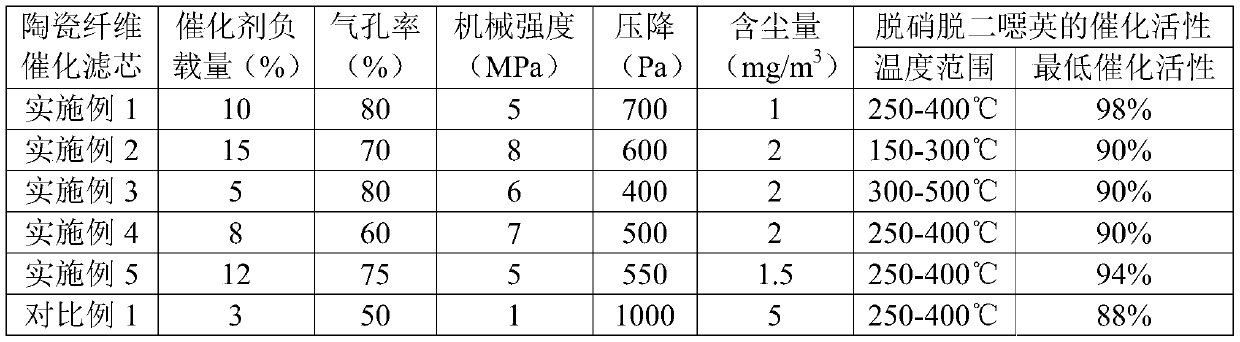

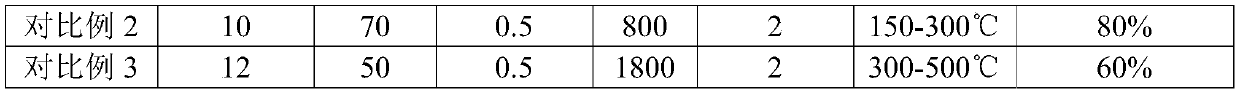

Ceramic fiber catalytic filter element and integrated preparation method thereof

ActiveCN110694353AHigh porosityHigh mechanical strengthGas treatmentDispersed particle filtrationFiberPtru catalyst

The invention relates to a ceramic fiber catalytic filter element and an integrated preparation method thereof. The integrated preparation method includes the following steps: (1) preparing catalyst slurry from a catalyst, and preparing ceramic short fiber slurry from ceramic short fibers; (2) loading an inorganic fiber cloth with the catalyst slurry prepared in the step (1), and performing heat curing to obtain a catalytic filter cloth; and (3) loading the catalytic filter cloth prepared in the step (2) with the ceramic short fiber slurry prepared in the step (1), performing filament windingon a vacuum mold, performing demolding, and performing drying to obtain the ceramic fiber catalytic filter element. The integrated preparation method has the advantages of a simple process, a small occupied space, lower costs, and an adjustable preparation size; and the prepared ceramic fiber catalytic filter element has the characteristics of uniform distribution of the catalyst, high porosity, high mechanical strength, and excellent abrasion resistance.

Owner:NANJING WEIHENG EXPERIMENTAL EQUIP CO LTD

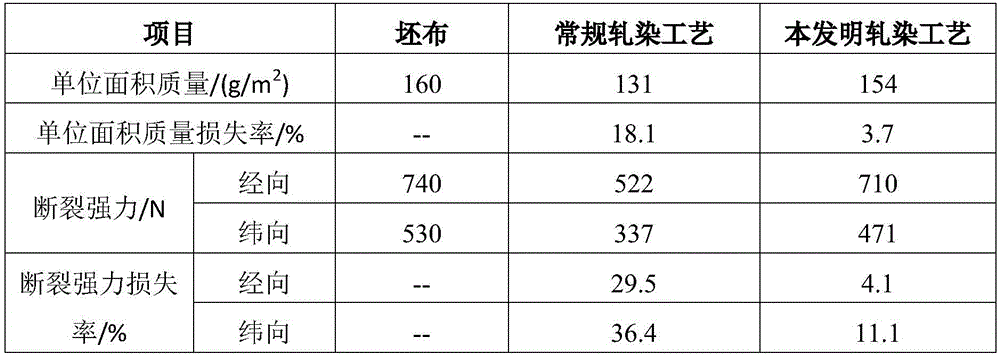

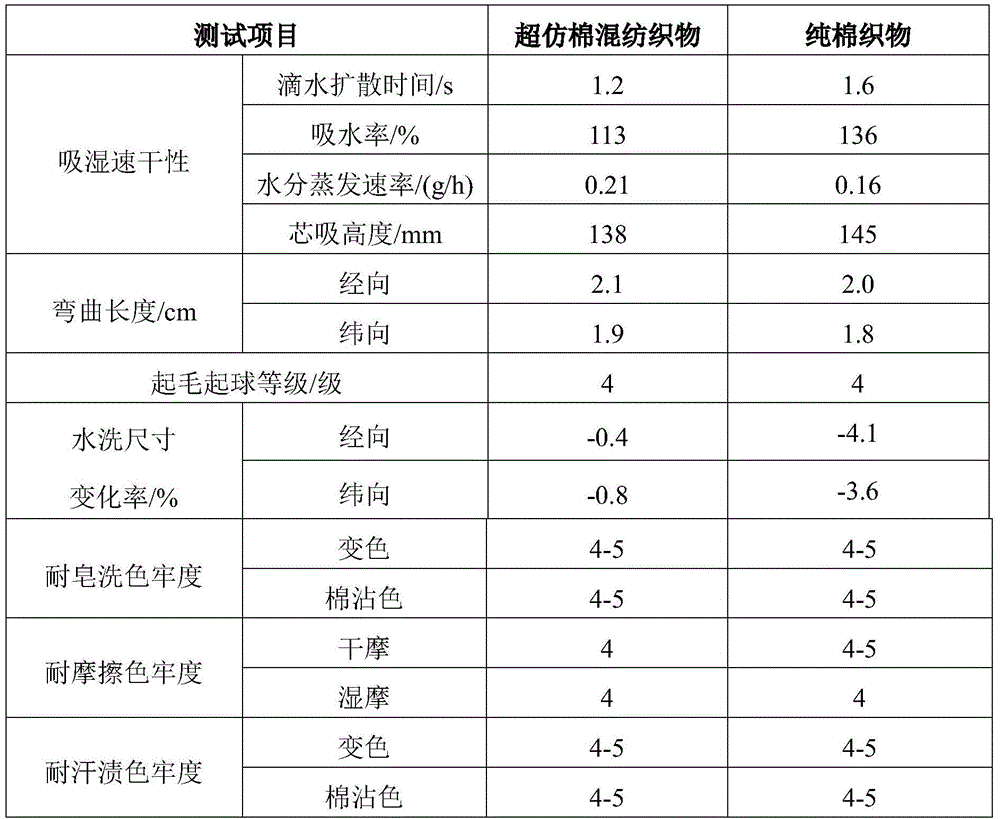

Pad dyeing technology of super-imitated cotton/cotton blended fabric

ActiveCN105463887ABright and plumpHigh color fastnessMercerising of indefinite length fabricsHeating/cooling textile fabricsColour fastnessCotton fibre

The invention discloses a pad dyeing technology of a super-imitated cotton / cotton blended fabric. The pad dyeing technology particularly comprises the following steps: firstly, carrying out light alkali desizing treatment on the super-imitated cotton / cotton blended fabric; and then sequentially carrying out low-alkaline mercerizing, presetting and dyeing, thereby finishing dyeing of the fabric. By a one-bath pad dyeing technology of disperse / reactive dyes, continuous and mass production of a product can be achieved; the problem that a traditional overflow dyeing technology can only be applied to intermittent small-batch production is solved; the production efficiency is improved; and the dyelot chromatism is reduced. Dyeing is carried out by the technology disclosed by the invention, so that the damage to a super-imitated cotton fiber is small; the mass per unit area and the breaking strength loss of a finished fabric product are small; and the processed fabric is bright and full in color, high in color fastness and good in hand feeling and wearing comfort. Compared with a conventional pad dyeing technology, the pad dyeing technology is low in alkali charge, low in dyeing temperature, low in energy consumption, energy-saving and environment-friendly.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

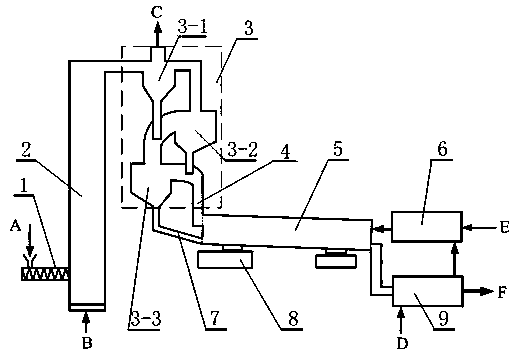

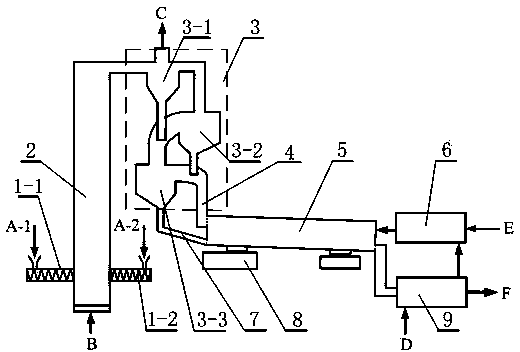

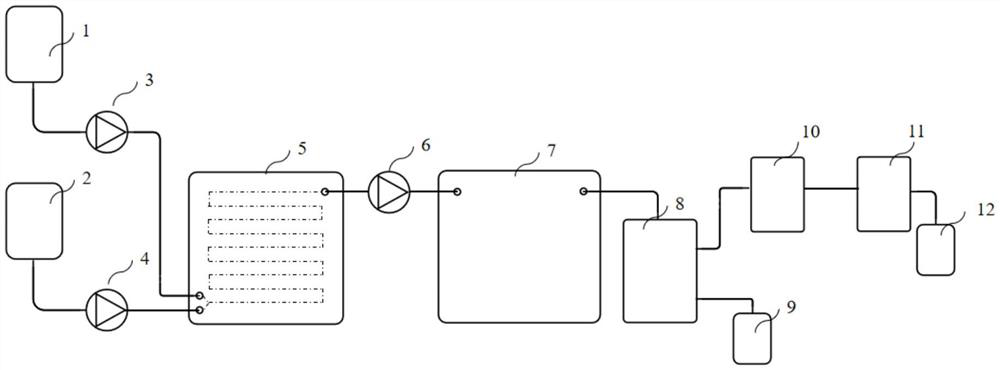

Microfluidic equipment for preparing graphene oxide

PendingCN112774596AWell mixedPrecisely control the degree of oxidationSingle layer grapheneChemical/physical/physico-chemical microreactorsPhysical chemistryEngineering

The invention discloses equipment for preparing graphene oxide through microflow control. The equipment comprises a first raw material tank, a second raw material tank, a micro-mixer, a micro-channel reactor, a separation device, a graphene oxide collection device, an acid liquor collection device and a purification device, wherein the first raw material tank and the second raw material tank are respectively connected with a feed port of the micro-mixer, a discharge port of the micro-mixer is connected with a feed port of the micro-channel reactor, a discharge port of the micro-channel reactor is connected with the separation device, the graphene oxide collection device and the acid liquor collection device are respectively connected with the separation device, and the purification device is connected with the graphene oxide collection device.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA +1

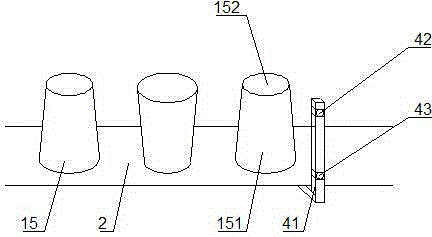

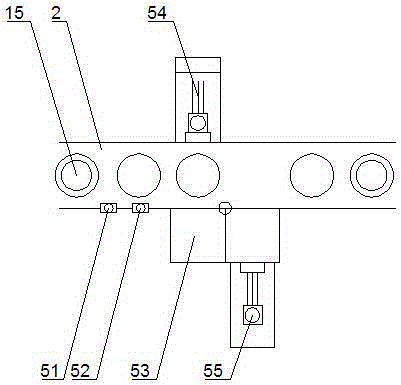

Cone yarn packaging production line and packaging technique thereof

InactiveCN105235944AQuality improvementSave spaceWrappers shrinkagePackaging automatic controlYarnMaterial resources

The invention discloses a cone yarn packaging production line and a packaging technique thereof. The cone yarn packaging production line comprises an alignment device, a big end and small end detecting device, a turning device, a single-yarn cut-sealing machine, a single-yarn heat shrinkage machine, a lining device, a cut-sealing machine for a whole bag of cone yarns, and a heat shrinkage machine for the whole bag of cone yarns, wherein the alignment device, the big end and small end detecting device, the turning device, the single-yarn cut-sealing machine, the single-yarn heat shrinkage machine, the lining device, the cut-sealing machine for the whole bag of cone yarns, and the heat shrinkage machine for the whole bag of cone yarns are installed on a conveying device in sequence. According to the cone yarn packaging production line and the packaging technique thereof, cone yarns are adjusted to be in the vertical state through the alignment device; the big end and small end detecting device is used for detecting the positions of the big end and the small end of each cone yarn; the turning device is used for turning the cone yarns selectively; the single-yarn cut-sealing machine is used for packaging each single cone yarn through a damp-proof plastic film; the single-yarn heat shrinkage machine is used for making the plastic films tightly shrink onto the cone yarns; the lining device is used for lining the cone yarns according to a set number of lines and then packaging the whole bag of cone yarns through damp-proof plastic films. The heat shrinkage machine for the whole bag of cone yarns is used for making the plastic films firmly shrink onto the cone yarns, and then packaging of the whole bag of cone yarns is completed. The cone yarn packaging production line and the packaging technique thereof have the advantages that the automation degree is high, continuous volume production can be achieved, both manpower resources and material resources are saved, and the quality of the whole bag of packaged cone yarns is good.

Owner:TAIAN COMPANION MACHINERY

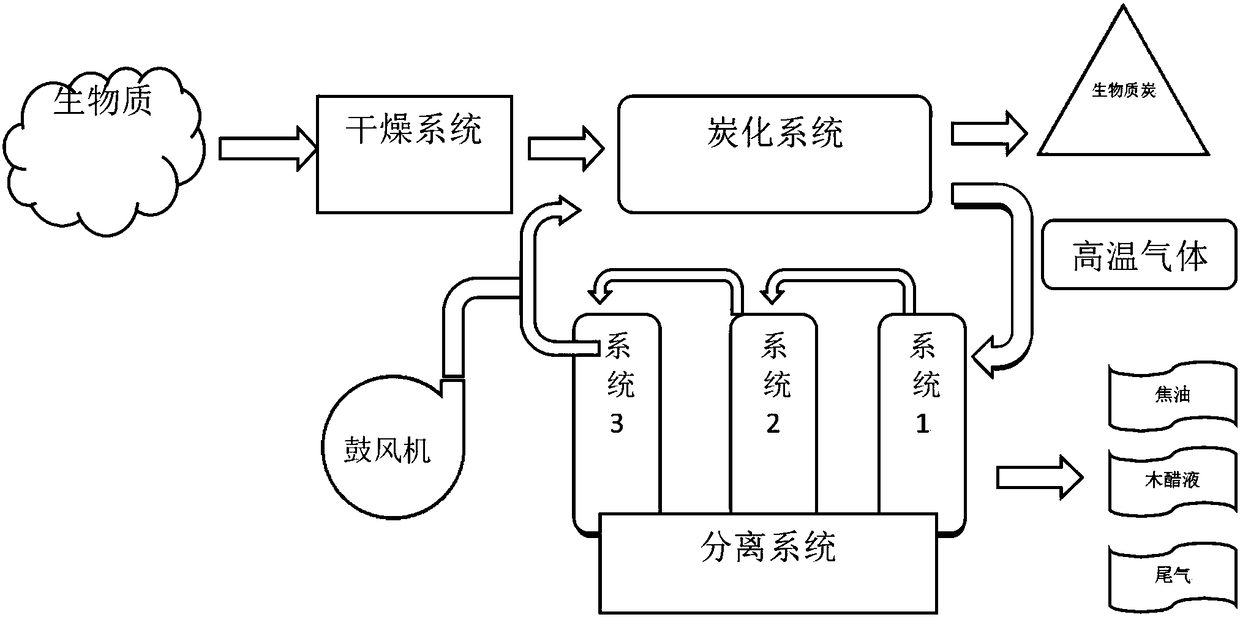

Thermal cracking treatment method for biomass straw

InactiveCN109233879AGuaranteed qualityIncrease productivityChemical industryBiofuelsPositive pressureCarbonization

The invention discloses a thermal cracking treatment method for biomass straw. The method comprises the following steps: step 1, gas with stable chemical properties is introduced into a carbonizationfurnace to ensure that the furnace has oxygen content lower than 1% inside and is in a micro-positive pressure state; step 2, a ring kiln is started, and the carbonization furnace is heated by liquefied gas; step 3, feeding is performed, and biomass particles enter the carbonization furnace through a loading screw and a feeding screw; step 4, a gas separation system is started, and a scrubbing tower is started; step 5, after gas production, cracked gas after scrubbing is introduced into a combustion furnace for combustion, and the liquefied gas is closed; step 6, wood vinegar spraying is started after biochar is discharged from a char discharge system; step 7, parameters are regulated to ensure stable operation of the system. The method has the advantages that quality of the biochar is guaranteed, production efficiency is increased, large-scale continuous production can be realized, liquid-gas separation is relatively perfect, temperature is easy to control, and energy is used circularly.

Owner:南京勤丰秸杆科技有限公司

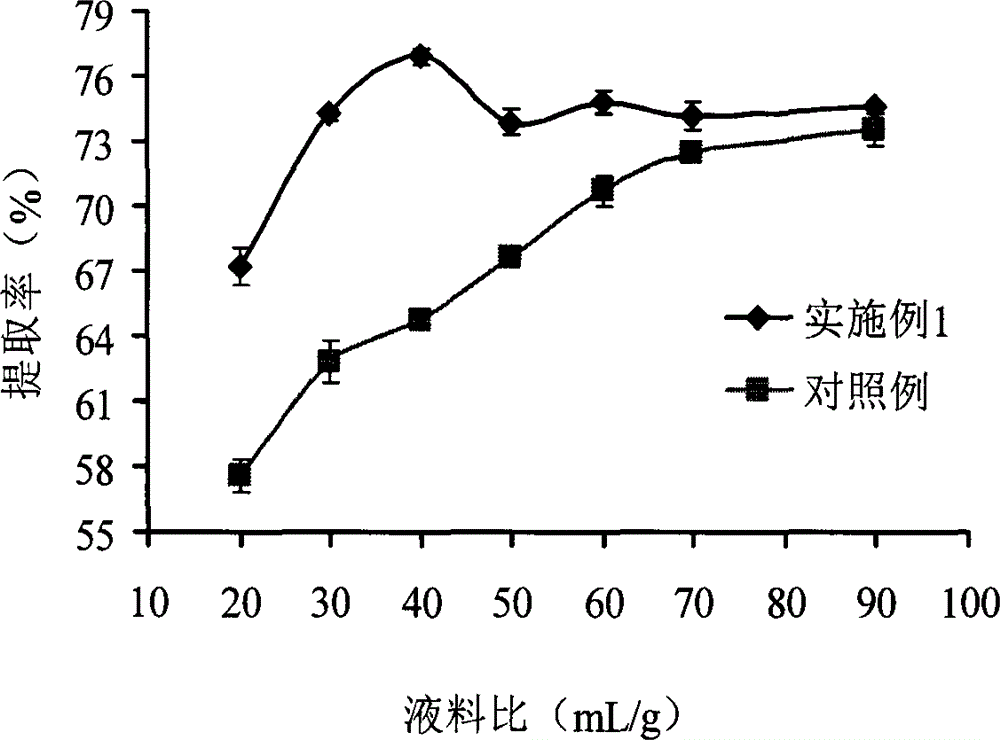

Method for extracting fish scale collagen by using energy-gathered type pulsed ultrasound assistant hot water

InactiveCN104004086AHigh extraction rateReduce manufacturing costConnective tissue peptidesPeptide preparation methodsLiquid temperatureUltrasonic assisted

The invention provides a method for extracting fish scale collagen by using energy-gathered type pulsed ultrasound assistant hot water, and belongs to the field of deep development and utilization of fishery products. The method comprises the steps of weighing 500 g of fish scales; smashing the fish scales; removing impurities preliminarily; removing mineral substances from the fish scales by using hydrochloric acid under the conditions that an acid concentration is 0.2-0.8 mol / L, a removal time is 20-100 min, and a liquid-solid ratio is 10-35 mL / g; adding 30-60 times water to decalcified fish scales to dissolve the fish scales; and extracting the collagen by using energy-gathered type pulsed ultrasound assistant hot water under the extraction conditions that a liquid temperature is 40-80 DEG C; an extraction time is 20-70 min; an extraction pH is 3-8; and ultrasonic parameters are as follows: a frequency is 28 kHz; a power is 150W; a pulse sending time is 4-12 s and a pulse intermittent time is 2-6 s. The method is simple and practicable, is convenient for operation and can be applied in continuously large-scale production.

Owner:江苏江大五棵松生物科技有限公司 +1

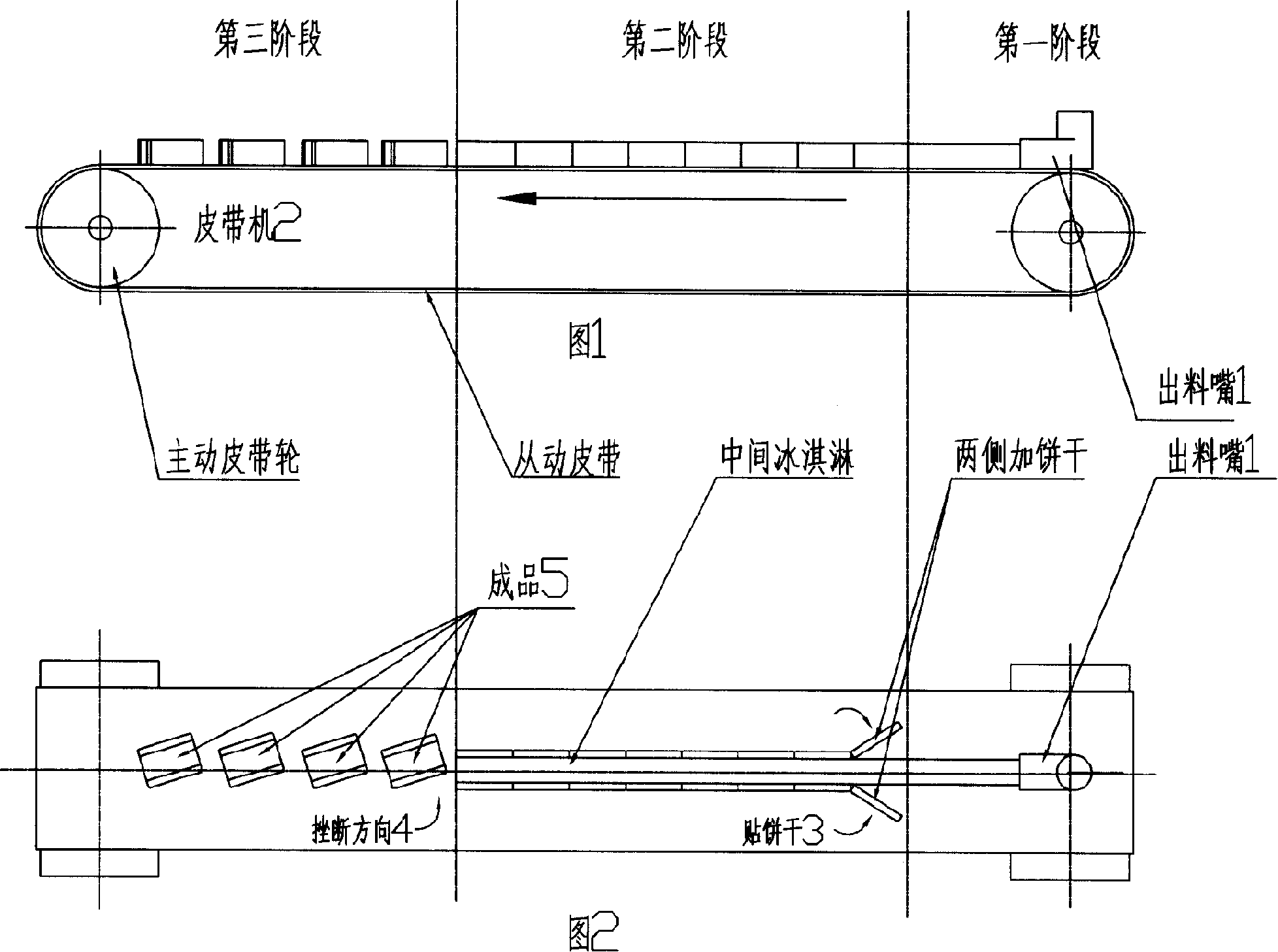

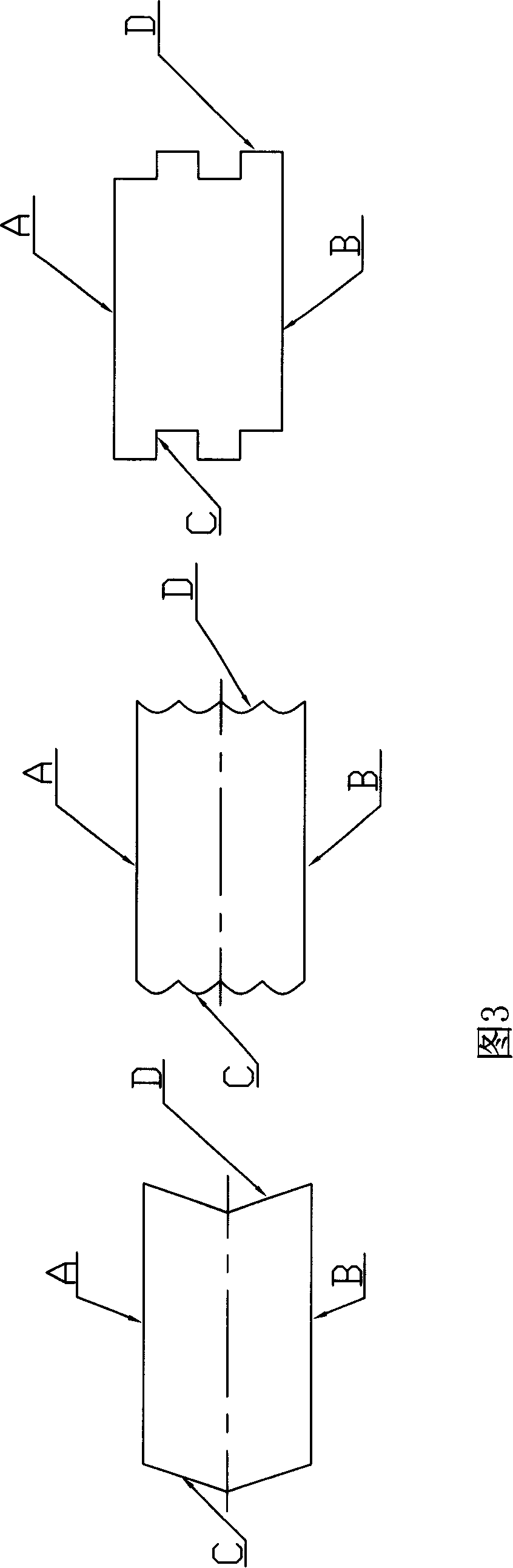

Technique for preparing sandwich ice creams

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

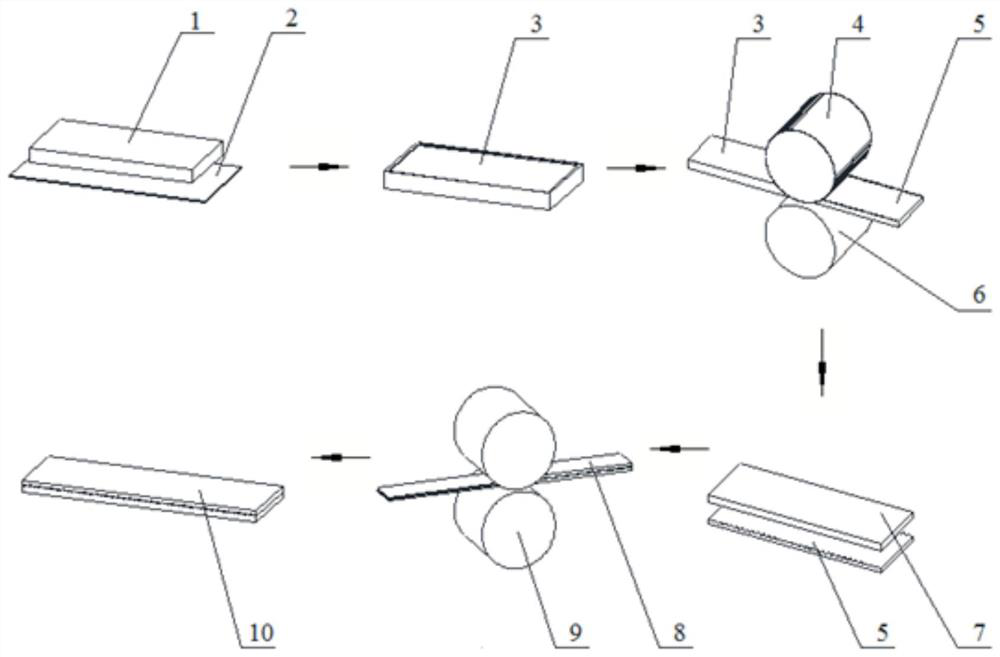

Wave-flat rolling composite method for steel/aluminum/aluminum alloy layered composite plate

ActiveCN111922079AEnhance the bonding strength of the steel-aluminum interfaceEliminate Oxygen ProblemsAuxillary arrangementsMetal rolling arrangementsAlloy surfaceAluminium alloy

The invention discloses a wave-flat rolling composite method for a steel / aluminum / aluminum alloy layered composite plate. The method comprises the following steps that a steel / aluminum layered composite plate with a good plate shape and a firmly combined interface is prepared, cold rolling is carried out by using large-thickness-ratio ripples, deformation of a to-be-composited interface is enhanced, deformation of component metal is coordinated, and the problem of no deformation of a steel-aluminum interface is solved; then aluminum and aluminum alloy surface compounding is achieved through interface wave-flat hot rolling and coordinating component deformation, and the high-performance steel / aluminum / aluminum alloy layered composite plate is prepared; the anti-oxidation problem in the compounding process is eliminated by utilizing the advantage that interfacial oxidation has little influence on combination of aluminum and aluminum alloy; and finally, the problems that in the rolling process of the steel / aluminum / aluminum alloy layered composite plate with the thickness being 4 mm or above, the interface shearing effect is weak due to the fact that the steel-aluminum joint face is close to a neutral layer, and the interface bonding strength is low due to the fact that interface bonding mainly depends on the heat-pressure effect are solved, and the problem of deformation discordance caused by large performance difference of steel, aluminum and aluminum alloy is solved.

Owner:TAIYUAN UNIV OF TECH

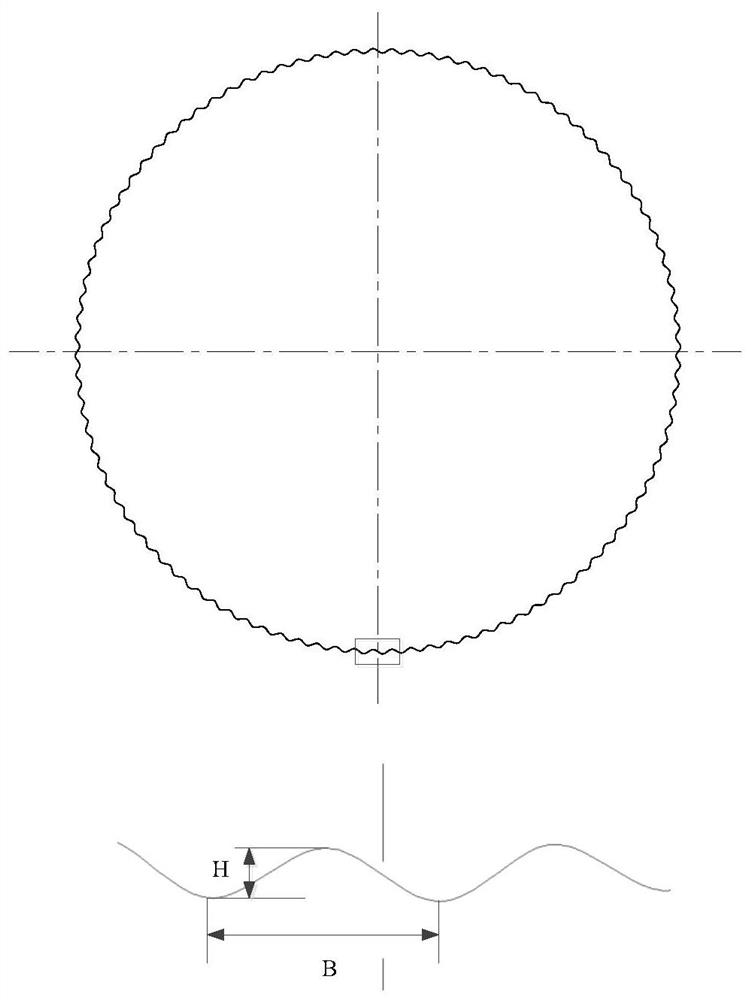

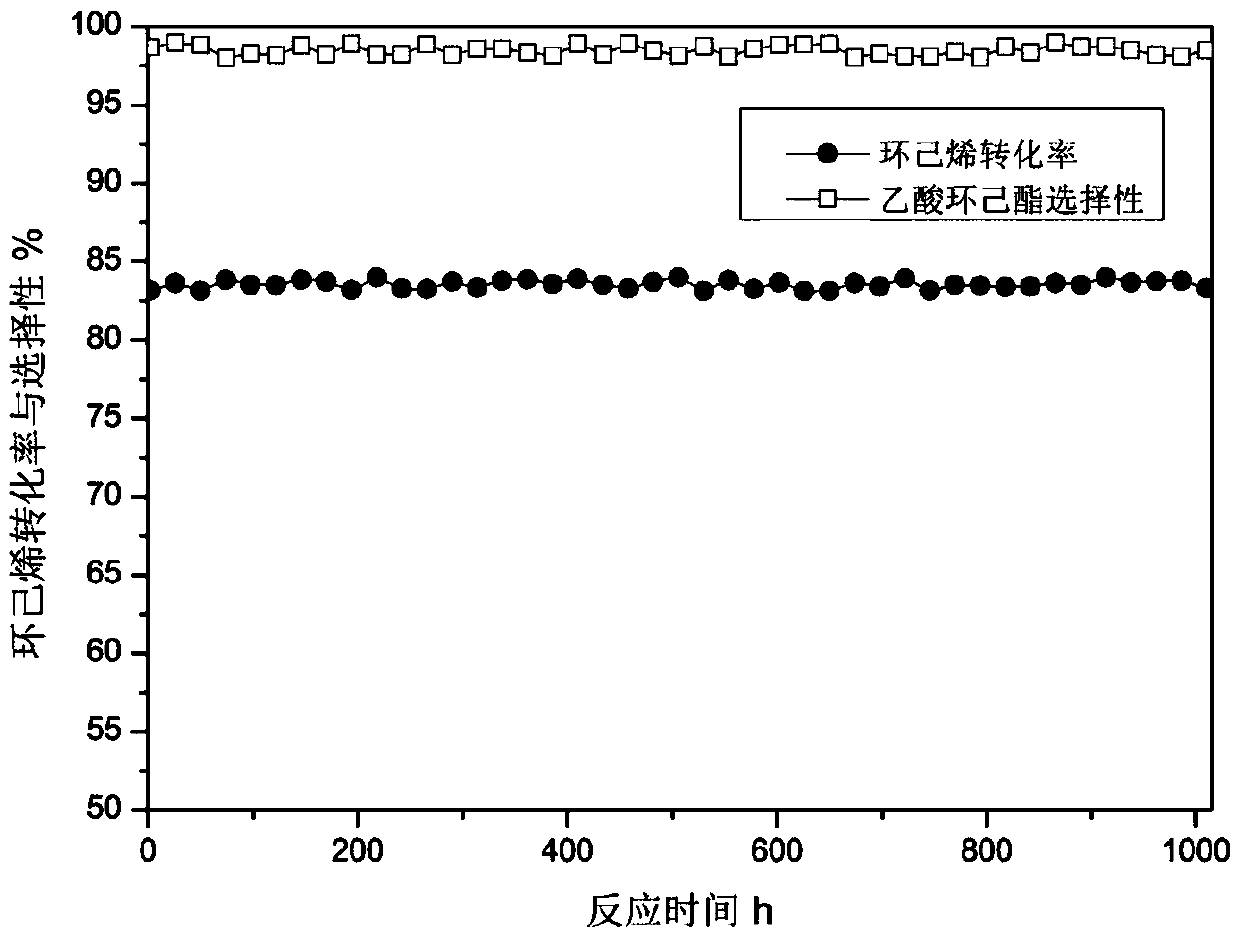

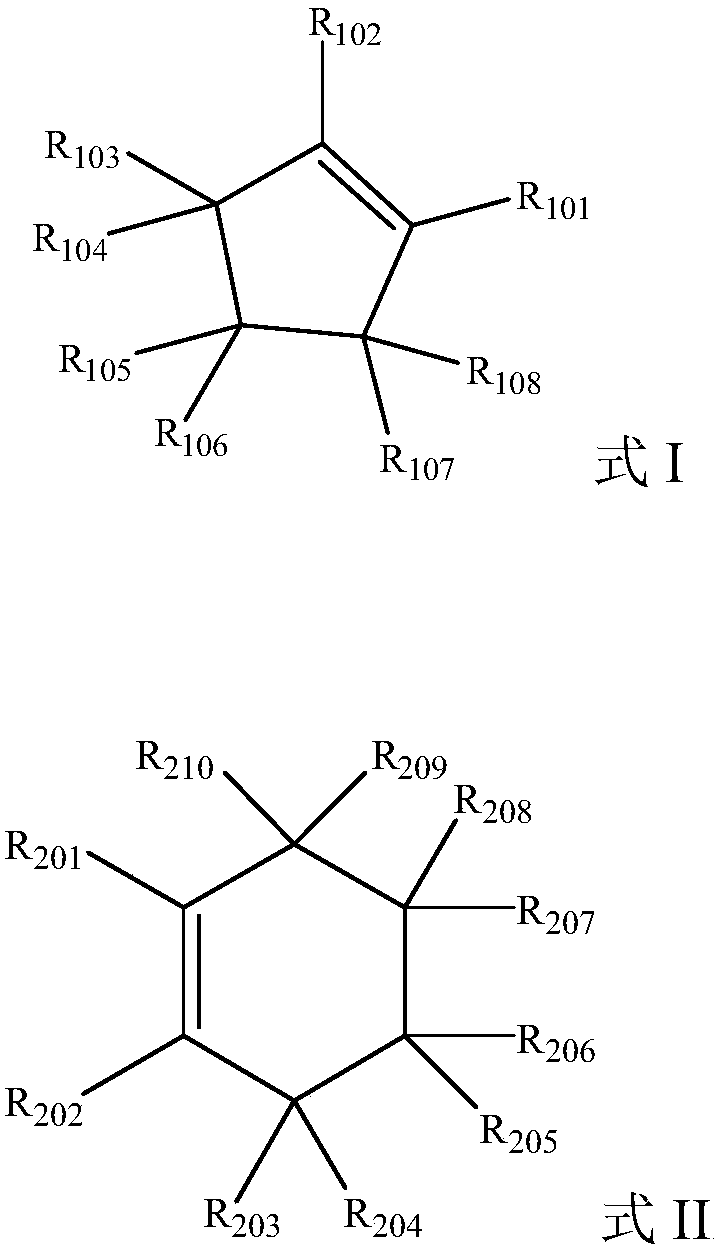

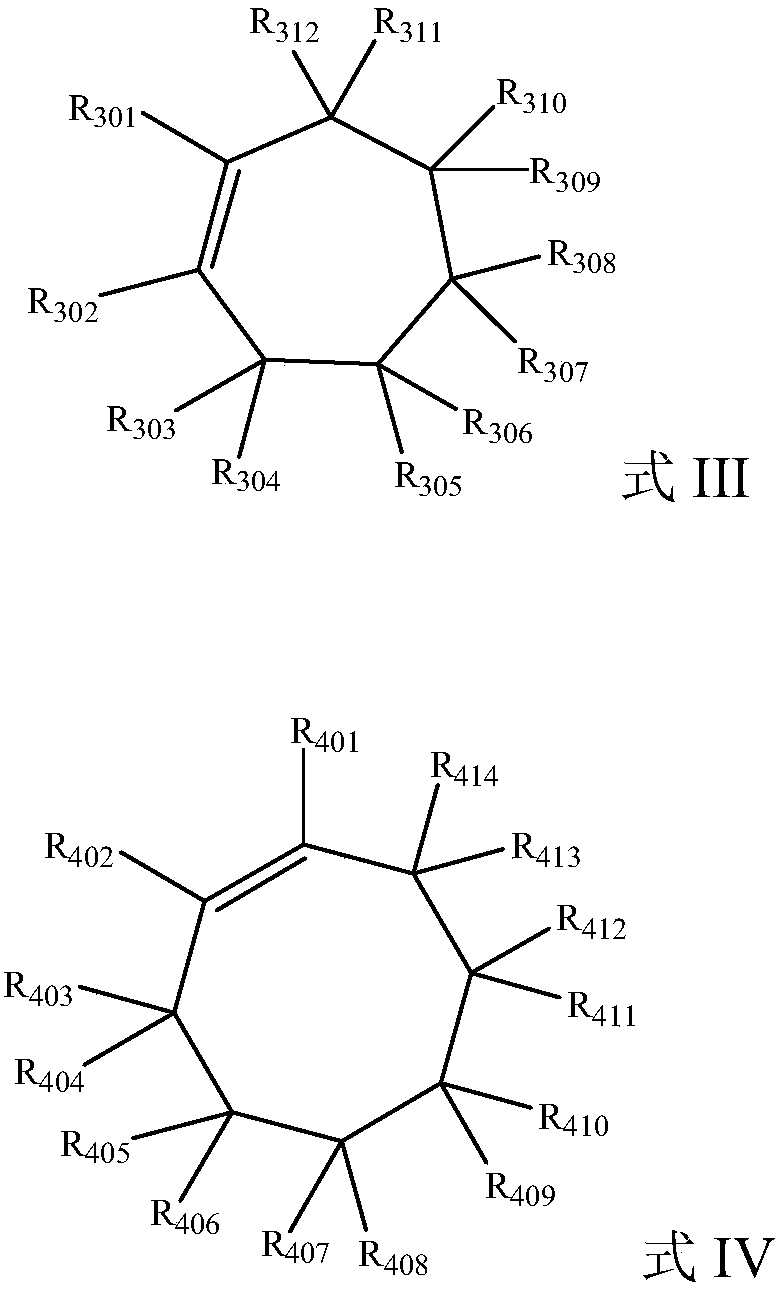

Preparation method of dicarboxylic acid

ActiveCN110615736AImprove contact effectGood miscibilityMolecular sieve catalystsOrganic compound preparationReaction rateCarboxylic acid

The invention discloses a preparation method of dicarboxylic acid, which comprises the following steps: 1) carrying out an addition reaction on a raw material system containing cyclic olefin and monocarboxylic acid under the action of an addition catalyst to generate an intermediate product system containing carboxylic acid cyclic ester; and 2) carrying out ring-opening oxidation reaction on the intermediate product system under the action of an oxidation catalyst to generate a corresponding dicarboxylic acid product. The addition reaction in the dicarboxylic acid synthesis route provided by the invention is high in one-way conversion rate, and the corresponding carboxylic acid cyclic ester is good in selectivity; in the addition-oxidation synthesis route provided by the invention, the addition reaction rate and the oxidation reaction rate are relatively high, and the yield of the corresponding dicarboxylic acid product is high. The synthetic route based on addition-oxidation providedby the invention is suitable for continuous and stable large-scale production of corresponding dicarboxylic acid products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for hot harvest and continuous freezing of goose and duck livers

InactiveCN102599227AReduce nutrient lossUniform shapePoultry eviscerating devicesGooseContinuous production

The invention discloses a method for hot harvest and continuous freezing of goose and duck livers, which specifically includes the steps: firstly, cutting stunned hairy geese and ducks, and bleeding the geese and the ducks; secondly, placing the cut and bled hair geese and ducks into a scalding tank with water at the temperature ranging from 60 DEG C to 62 DEG C to scald the geese and ducks; thirdly, opening 'T'-cuts on abdomens of the geese and ducks to fully expose viscera, pressing down to strip intestines in the viscera with one hand, and removing the livers; fourthly, removing gallbladders from the livers and placing in the water at 0 DEG C to rinse and cool for 3 minutes, taking out and putting the livers into mould boxes for shaping and protection, and freezing at -48 DEG C for 40 minutes; and fifthly, keeping the quick-frozen livers in cold storage at the temperature of -18 DEG C. The method has the advantages that the time is shortened by 10 times as compared with that in the traditional technique while energy is saved by 40%; large-scale continuous production can be completely achieved; the method is high in food safety and evident in economic benefit and social benefit.

Owner:吉林维迪艾食品有限公司

Seafood powder seasoning and preparation method thereof

InactiveCN104256476AShorten the production cycleImprove yield and qualityFood hydrolysisFood preparationChemistryProtease

The invention discloses a seafood powder seasoning taking marine organisms as the raw materials and a preparation method of the seafood powder seasoning, wherein scallop edges, fresh crabs and fresh shrimp heads are used as the raw materials; and the substances, such as protein of scallop edges, fresh crabs and fresh shrimp heads, are hydrolyzed by an autolytic enzymolysis system in cells of scallop edges, fresh crabs and fresh shrimp heads instead of externally added protease; a production process for producing seafood powder from a nutritional solution prepared by adopting a seafood enzymolysis method comprises the steps of processing raw materials, carrying out directional enzymolysis, inactivating enzyme, carrying out vibration separation, configuring a formula, batching, pulverizing, sterilizing, packaging and the like; and the seafood powder seasoning disclosed by the invention is low in production cost, high in yield, safe, sanitary, abundant in nutrition, delicious in taste and wide in application.

Owner:徐学林

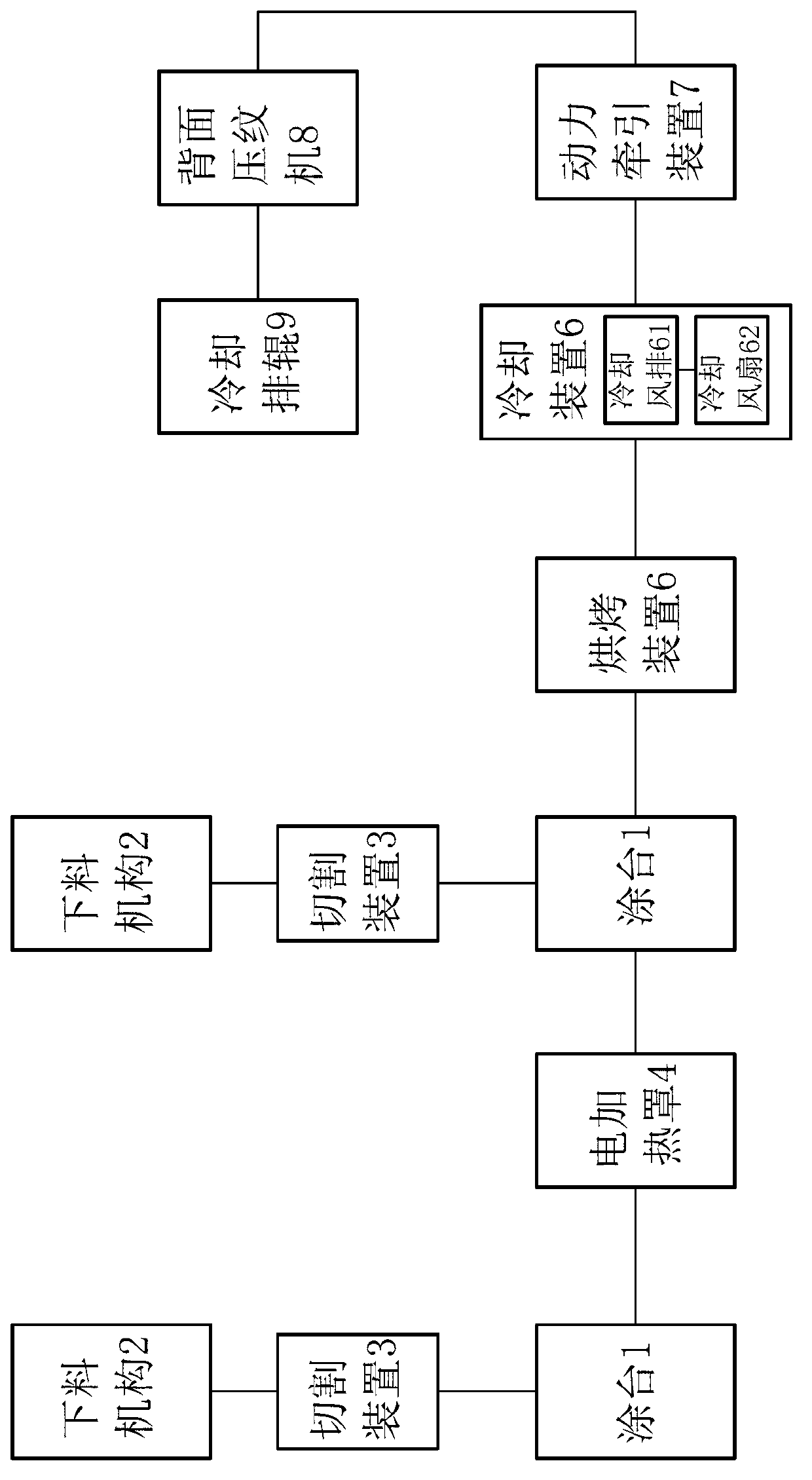

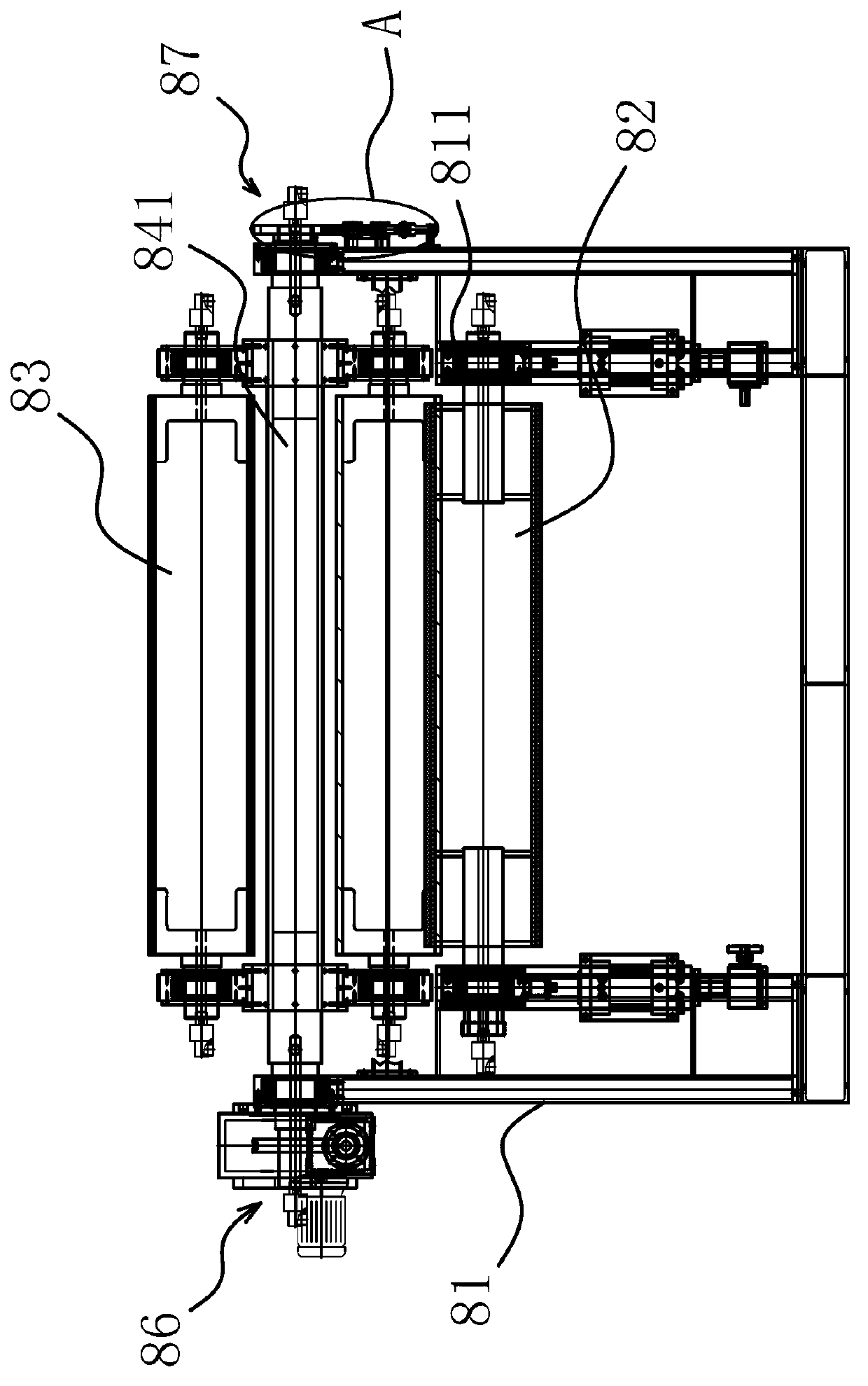

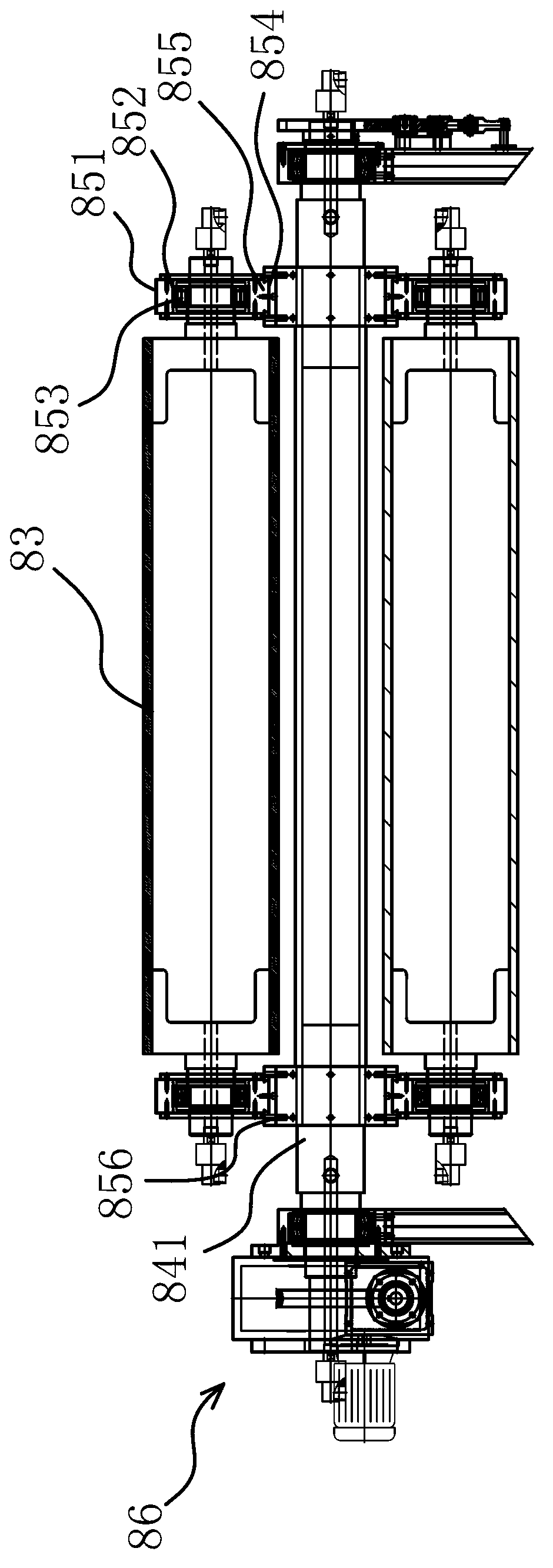

Reciprocating multi-coated foam material production line

The invention belongs to the technical field of industrial manufacture, and relates to a foam material production line, especially to a reciprocating multi-coated foam material production line, solving problems that present technologies are not reasonable. The reciprocating multi-coated foam material production line comprises a plurality of mutually connected coating benches being capable of supporting convey belts, wherein each coating bench is provided with a feed mechanism, a cutting apparatus is arranged at a position where each feed mechanism is contacted with the convey belt, the feed mechanism can drive the cutting apparatus to reciprocally and vertically move, an electrically heating cover being capable of heating the convey belts is arranged between two coating benches, the other end of the coating bench is sequentially connected with a roasting apparatus, a cooling apparatus and a power traction device, and the convey belts are sequentially connected with a back side embossing machine and a cooling row roller through the power traction device. The reciprocating multi-coated foam material production line is advantageous by reasonable design, simple structure, raw material saving, continuous mass production and good product quality.

Owner:江苏谦胜合成材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com