Production equipment and technology for cathode or anode material of converter-type lithium battery

A negative electrode material, lithium battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low degree of automation and inability to achieve continuous production, and achieve the effect of low degree of automation, automatic control, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

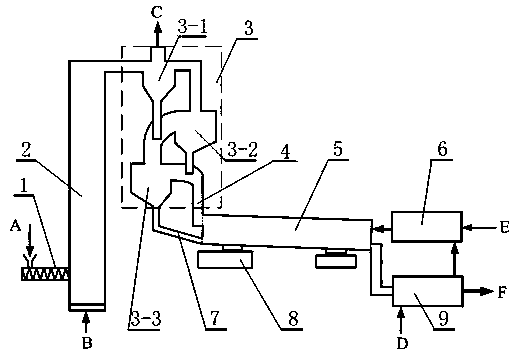

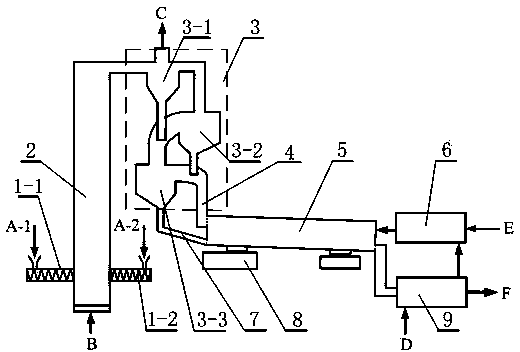

[0036] A kind of production technology of lithium manganate battery cathode material, such as figure 2 As shown, lithium carbonate and manganese dioxide with a particle size of 0.1-100 μm are added to the fluidized bed mixing device 2 from the first feeder 1-1 and the second feeder 1-2, to the fluidized bed inlet B The lithium carbonate and manganese dioxide entering the fluidized bed mixing device 2 are fluidized and fully mixed in the fluidized bed mixing device; lithium carbonate and manganese dioxide enter the gas-solid sedimentation gas-solid separation assembly 3 and then fall Enter the feed pipe 7, and then enter the converter 5; in the converter 5, the mixture of lithium carbonate and manganese dioxide reacts at a temperature of 500-900 ° C for 8-20 hours to generate lithium manganate; the generated lithium manganate enters the particle The cooler 9 is discharged from the discharge port F after cooling; the lithium manganese oxide generated by the particle cooler 9 is...

specific example 2

[0038] A kind of production technology of lithium iron phosphate battery cathode material, such as figure 2 As shown, lithium carbonate with a particle size of 0.1-100 μm, ferric phosphate (or ferrous phosphate), reducing agent, etc. are added to the fluidized bed mixing device 2 from multiple feeders 1-1, 1-2, and fed to the fluidized bed The inlet B is fed with air, and the lithium carbonate, ferric phosphate (or ferrous phosphate), reducing agent, etc. entering the fluidized bed mixing device 2 are fluidized and fully mixed in the fluidized bed mixing device; lithium carbonate, ferric phosphate (or Ferrous phosphate), reducing agent, etc. enter the gas-solid sedimentation gas-solid separation assembly 3 and fall into the feed pipe 7 after sedimentation and capture, and then enter the converter 5; in the converter 5, lithium carbonate, ferric phosphate (or ferrous phosphate), The mixture of reducing agent and the like is reacted at a temperature of 500-900°C for 8-20 hours ...

specific example 3

[0040] A production process of a ternary material lithium battery positive electrode material, such as figure 2 As shown, lithium carbonate with a particle size of 0.1-100 μm, Ni-oxygenate, Co-oxygenate, Mn-oxygenate, etc. are fed into the fluidized bed mixing device from multiple feeders 1-1 and 1-2 2. Air is introduced into the fluidized bed inlet B, and the lithium carbonate, Ni-oxygenate, Co-oxygenate, Mn-oxygenate, etc. entering the fluidized bed mixing device 2 are in the fluidized bed mixing device 2 Medium fluidized and fully mixed; Lithium carbonate, Ni-oxygen compounds, Co-oxygen compounds, Mn-oxygen compounds, etc. enter the gas-solid sedimentation gas-solid separation component 3, settle and collect, fall into the feeding pipe 7, and then enter the converter 5; In the converter 5, the mixture of lithium carbonate, Ni-oxygen compound, Co-oxygen compound, Mn-oxygen compound, etc. is reacted at a temperature of 500-900°C for 8-20 hours to form a ternary lithium batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com