reactor

A reactor and reaction zone technology, applied in the field of reactors, can solve the problems of low product conversion rate, uneven mixing of mixed fluids, and different residence times, achieve continuous and efficient mixing, ensure consistency, and avoid product selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

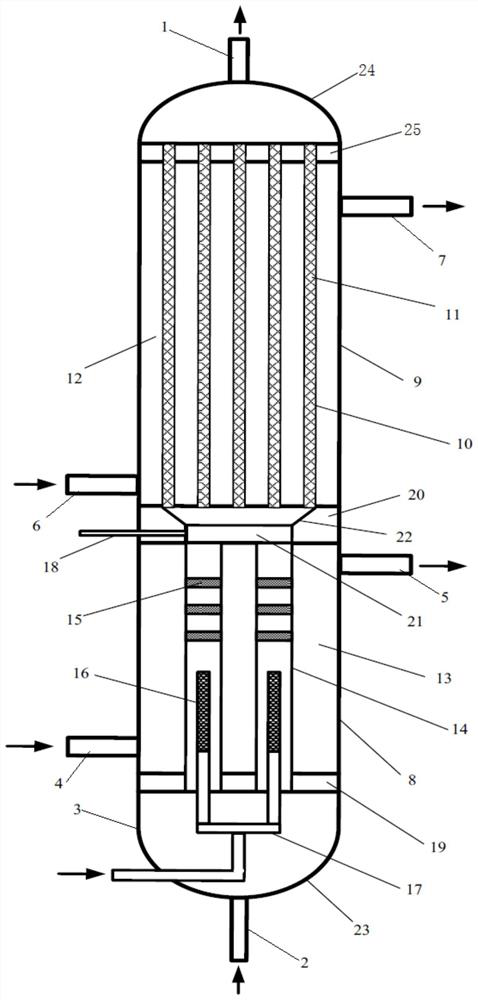

[0095] Use as attached figure 1 The reactor shown.

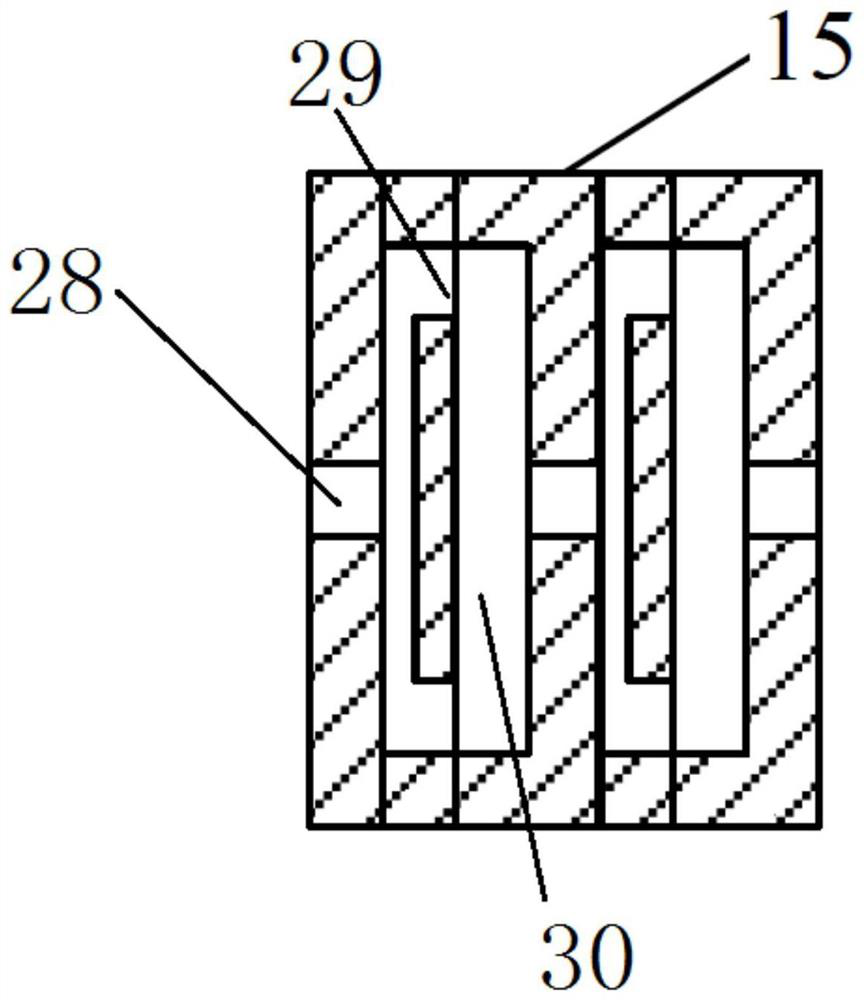

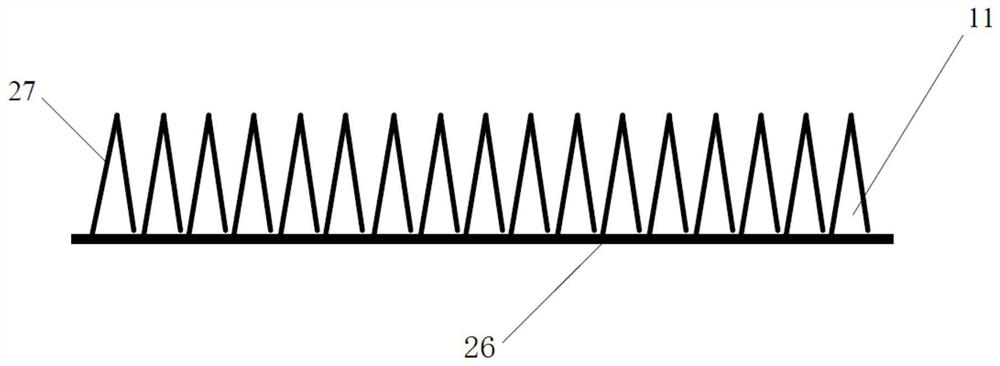

[0096] The reactor comprises 5 reaction channels 10, the cross-section of each reaction channel 10 is rectangular, and the cross-sectional area is 20mm 2 , the length of the reaction channel 10 is 2000mm. The second mixing element 11 in the reaction channel 10 has a triangular tooth portion 27, and the distance between adjacent tooth portions 27 is 5 mm. A total of settings in the reaction channel 10 such as Figure 4 A 4-layer stacked second mixing element 11 is shown. Reactor comprises 2 mixing passages 14, the cross-sectional area of each mixing passage 14 is 10cm 2 , the length is 800mm. The fluid distributor 16 is a metal powder sintered body with an average pore diameter of 5 microns and a cross-sectional area of 8.5 cm 2 , the length is 150mm. Three first mixing elements 15 are arranged in each mixing channel 14 . The reaction temperature is 25° C., and the reaction pressure is 0.6 MPa. The olefin is 1-de...

Embodiment 2

[0098] Use as attached figure 1 The reactor shown.

[0099] The reactor comprises 5 reaction channels 10, the cross-section of each reaction channel 10 is rectangular, and the cross-sectional area is 20mm 2 , the length of the reaction channel 10 is 2000mm. The second mixing element 11 in the reaction channel 10 has a triangular tooth portion 27, and the distance between adjacent tooth portions 27 is 5 mm. A total of settings in the reaction channel 10 such as Figure 4 A 4-layer stacked second mixing element 11 is shown. Reactor comprises 2 mixing passages 14, the cross-sectional area of each mixing passage 14 is 10cm 2 , the length is 800mm. The fluid distributor 16 is a metal powder sintered body with an average pore diameter of 5 microns and a cross-sectional area of 8.5 cm 2 , the length is 150mm. Three first mixing elements 15 are arranged in each mixing channel 14 . The reaction temperature is 25° C., and the reaction pressure is 0.6 MPa. The olefin is 1-de...

Embodiment 3

[0101] Use as attached figure 1 The reactor shown.

[0102] The reactor comprises 5 reaction channels 10, the cross-section of each reaction channel 10 is rectangular, and the cross-sectional area is 20mm 2 , the length of the reaction channel 10 is 2000mm. The second mixing element 11 in the reaction channel 10 has a triangular tooth portion 27, and the distance between adjacent tooth portions 27 is 5 mm. A total of settings in the reaction channel 10 such as image 3 A single-layer second mixing element 11 is shown. Reactor comprises 2 mixing passages 14, the cross-sectional area of each mixing passage 14 is 10cm 2 , the length is 800mm. The fluid distributor 16 is a metal powder sintered body with an average pore diameter of 5 microns and a cross-sectional area of 8.5 cm 2 , the length is 150mm. Three first mixing elements 15 are arranged in each mixing channel 14 . The reaction temperature is 25° C., and the reaction pressure is 0.6 MPa. The olefin is 1-decene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com