Process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic wafer material by tape casting

An ultra-high temperature ceramic, zrb2-sic technology, applied in ceramic layered products, layered products, chemical instruments and methods, etc., can solve the problems of insufficient material toughness, and the anti-oxidation performance needs to be further improved, so as to improve the fracture toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

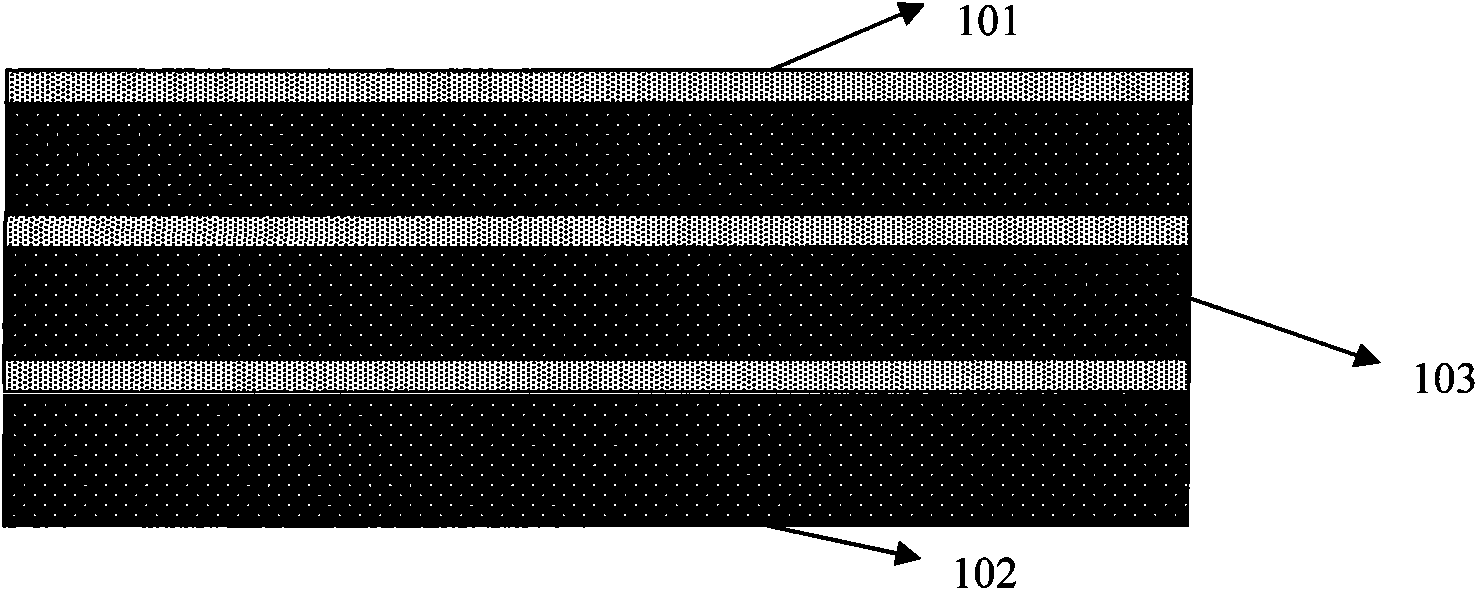

[0026] Preparation of multilayer ZrB by a casting method 2 -The process of SiC composite ultra-high temperature ceramic material is realized by the following steps:

[0027] 1. Preparation of SiC ceramic green film

[0028] After mixing 50kg of SiC powder with a particle size of 1-10μm, 40kg of xylene and alcohol mixed liquid with a volume ratio of 1:1, and 0.5kg of dispersant, stir and ball mill for about 24 hours, and then add 1.5kg of plasticizer and 4kg of The binder continues to be mixed by ball milling for about 24 hours; the resulting slurry is filtered and then vacuum degassed using an air pump to obtain a slurry with a viscosity of 50-200cps, and finally cast the slurry on a commercial casting machine to obtain a 2μm thick SiC ceramic raw film;

[0029] 2. Preparation of ZrB 2 -SiC composite ceramic green film

[0030] 60kg of ZrB with a particle size of 1-10μm 2 Mix with SiC powder with a particle size of 1-10μm, 40kg of xylene and alcohol mixed liquid with a vo...

Embodiment 2

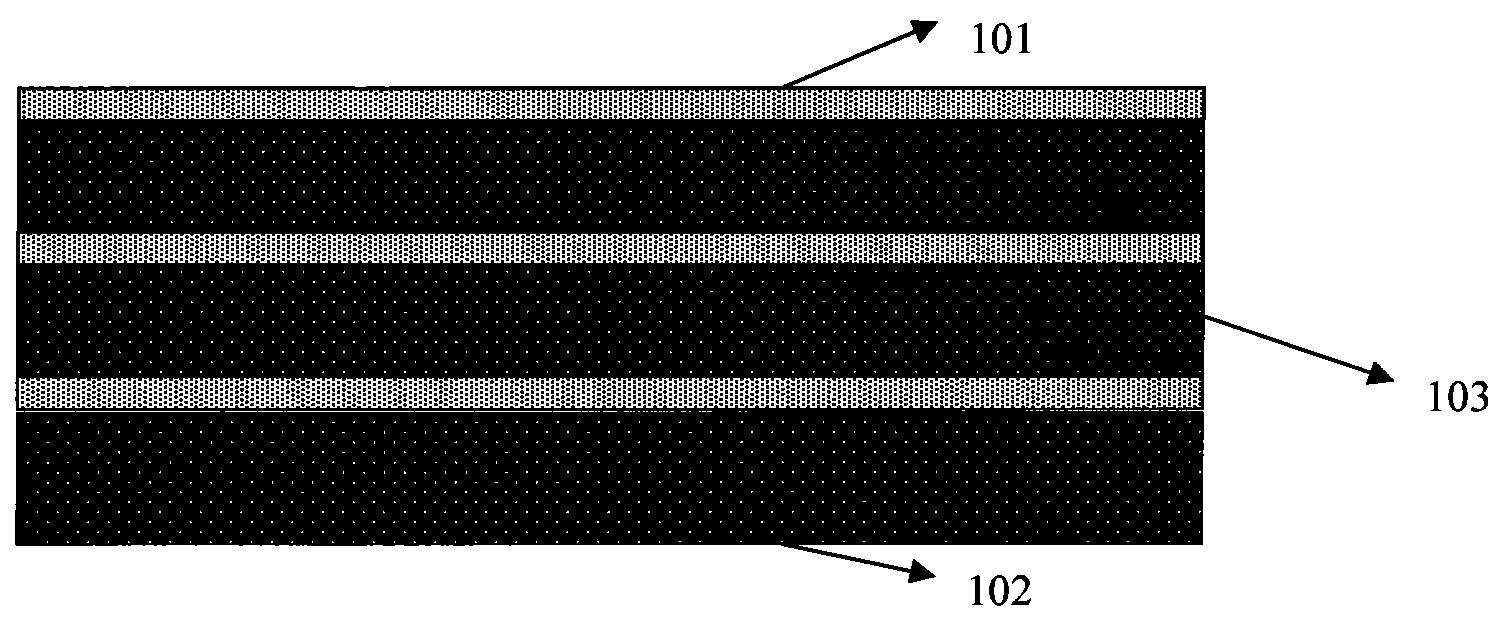

[0042]Preparation of multilayer ZrB by a casting method 2 -The process of SiC composite ultra-high temperature ceramic material is realized by the following steps:

[0043] 1. Preparation of SiC ceramic green film

[0044] After mixing 50kg of SiC powder with a particle size of 1-10μm, 80kg of xylene and alcohol mixed liquid with a volume ratio of 1:1, and 1kg of dispersant, stir and ball mill for about 24 hours, and then add 2.5kg of plasticizer and 4- 6kg of binder continued to be mixed by ball milling for about 24 hours; the resulting slurry was filtered and then vacuum degassed with an air pump to obtain a slurry with a viscosity of 50-200cps, and finally cast the slurry on a commercial casting machine to obtain 20-200 cps 500μm thick SiC ceramic raw film;

[0045] 2. Preparation of ZrB 2 -SiC composite ceramic green film

[0046] 60kg of ZrB with a particle size of 1-10μm 2 Mix with SiC powder with a particle size of 1-10μm, 80kg of xylene and alcohol mixed liquid wi...

Embodiment 3

[0058] A kind of multi-layer ZrB prepared by casting method 2 -The process of SiC composite ultra-high temperature ceramic material is realized by the following steps:

[0059] 1. Preparation of SiC ceramic green film

[0060] After mixing 50kg of SiC powder with a particle size of 1-10μm, 60kg of xylene and alcohol mixed liquid with a volume ratio of 1:1, and 0.8kg of dispersant, stir and ball mill for about 24 hours, and then add 2kg of plasticizer and 5kg of viscose respectively. The binder continues to be mixed by ball milling for about 24 hours; the resulting slurry is filtered and then vacuum degassed with an air pump to obtain a slurry with a viscosity of 50-200cps, and finally cast the slurry on a commercial casting machine to obtain a thickness of 20-500μm SiC ceramic raw film;

[0061] 2. Preparation of ZrB 2 -SiC composite ceramic green film

[0062] 60kg of ZrB with a particle size of 1-10μm 2 Mix with SiC powder with a particle size of 1-10μm, 60kg of xylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com