Patents

Literature

177 results about "Ultrahigh temperature ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

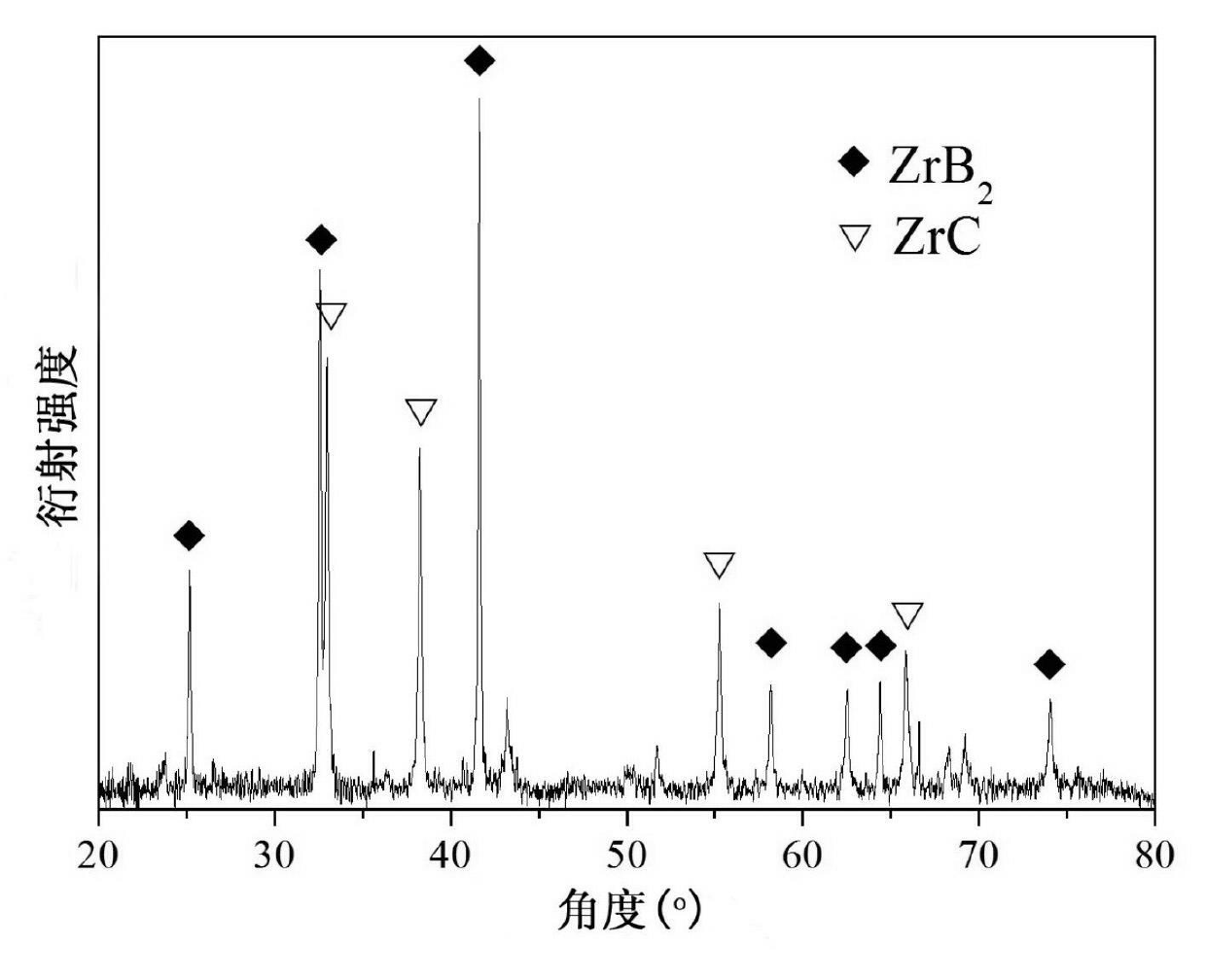

Preparation method of C/SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material

ActiveCN102515870AGuaranteed mechanical propertiesHigh volume contentVacuum pressureUltrahigh temperature ceramics

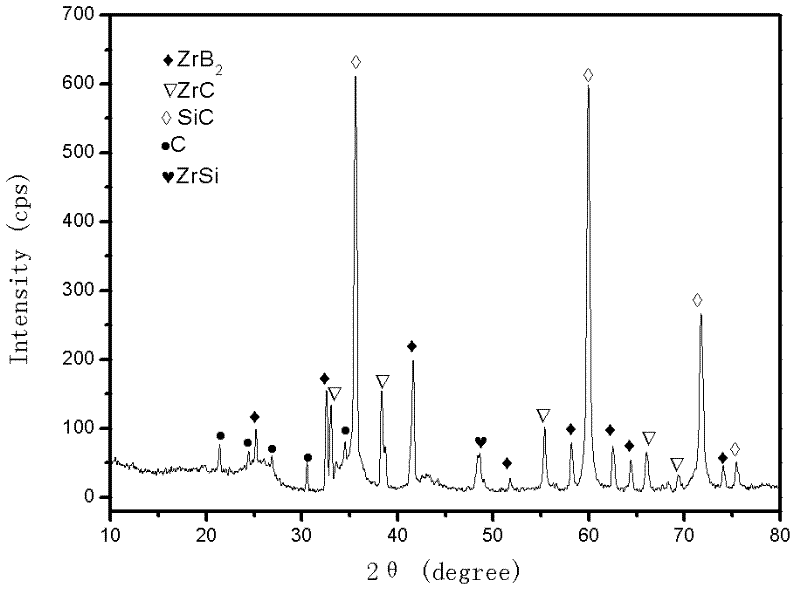

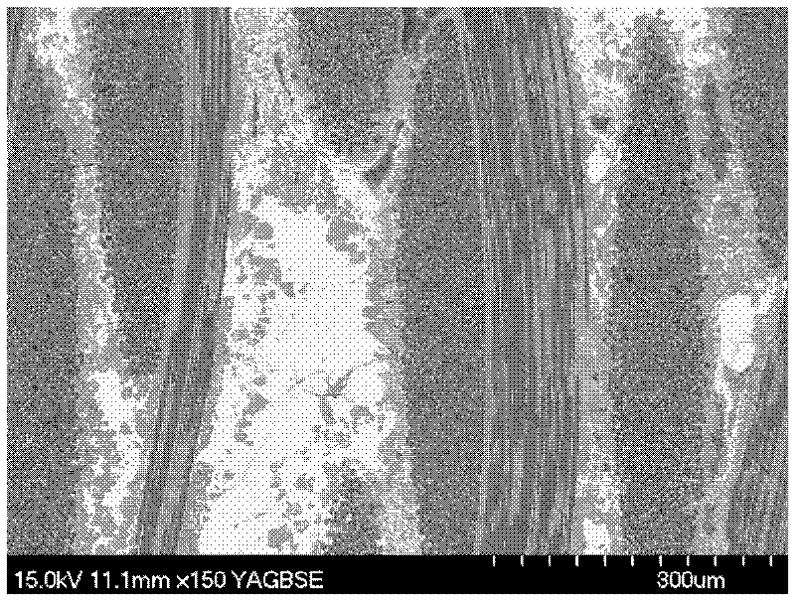

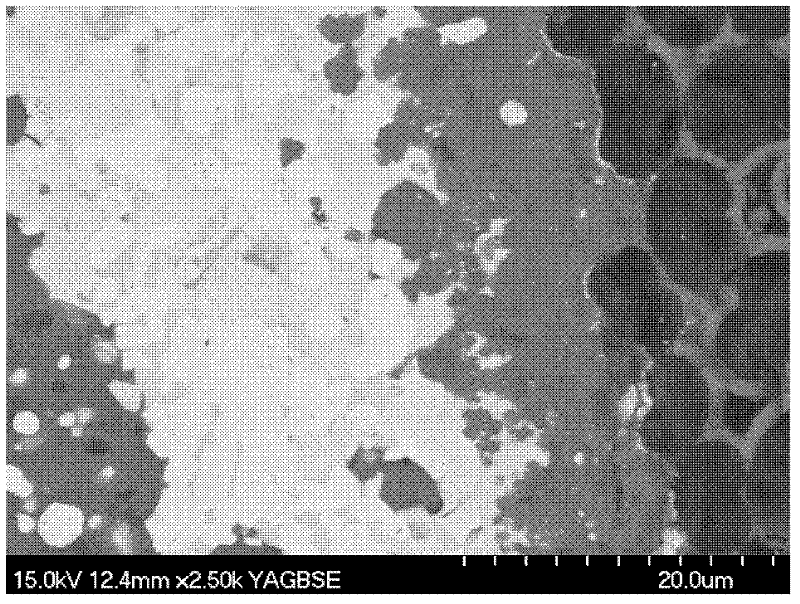

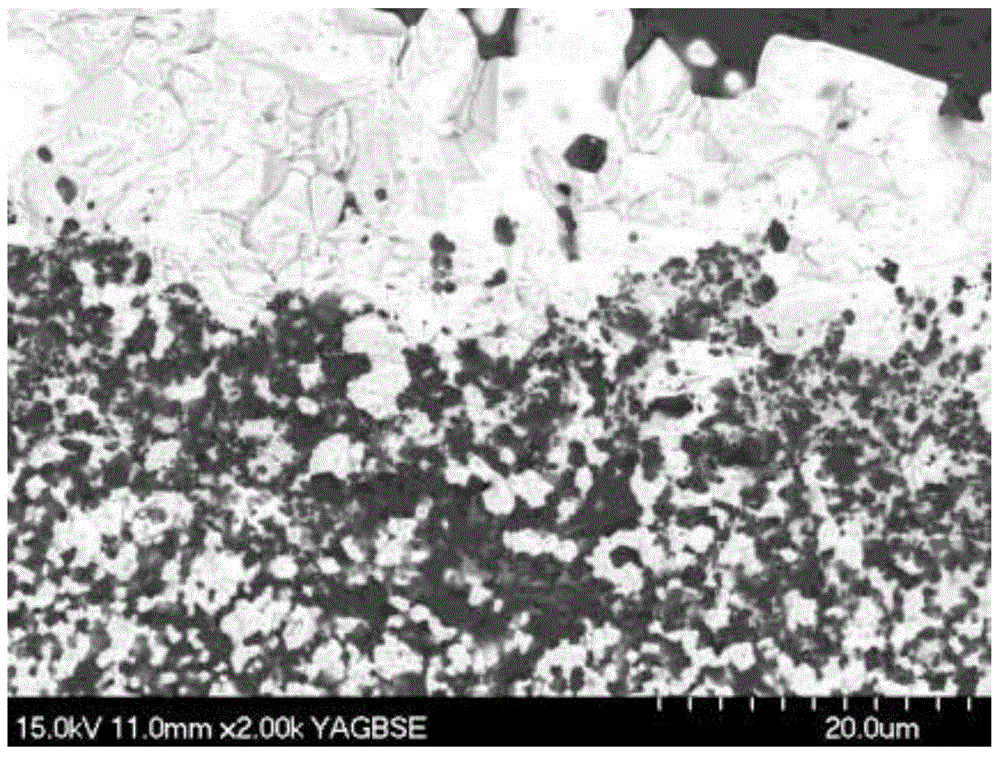

The invention relates to a preparation method of a C / SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material. According to the invention, B4C and a C organic precursor are introduced into a C / SiC composite material with a vacuum pressure impregnation method; the obtained material is cured and is subject to a heat treatment, such that the C organic precursor is cracked, and pores sealed by the C organic precursor are opened; with a reactive melt infiltration method, under a condition that a temperature is higher than that of silicozirconium alloy, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized, and the C / SiC-ZrB2-ZrC composite material is prepared. According to the invention, with the vacuum pressure impregnation method, B4C and the C organic precursor are introduced into the C / SiC composite material; with the reactive melt infiltration method, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized. The produced ZrB2 and ZrC are advantaged in fine grains and high volume content. The ablation resistance and mechanical properties of the composite material are effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

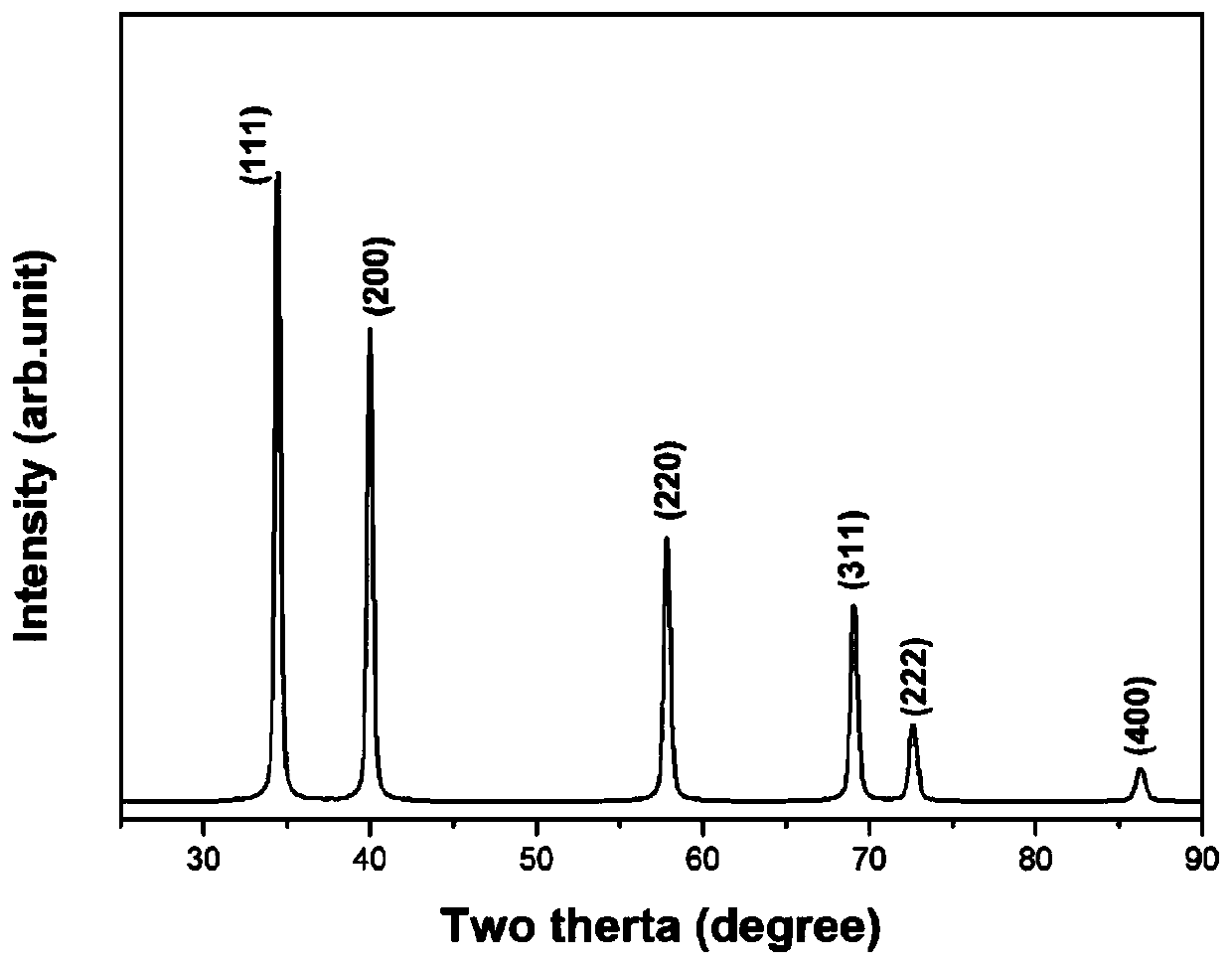

Ultrahigh-temperature high-entropy carbide powder and preparation method thereof

The invention relates to the technical field of ultrahigh-temperature ceramic powder, in particular to ultrahigh-temperature high-entropy carbide powder and a preparation method thereof. The ultrahigh-temperature high-entropy carbide powder adopts a chemical formula as follows: (Ti0.2Zr0.2Hf0.2Nb0.1W0.1Ta0.2) C, and is prepared from TiO2, ZrO2, HfO2, Nb2O5, WO3, Ta2O5 and carbon black as raw materials through wet mixing and a high-temperature carbothermal reduction reaction. The ultrahigh-temperature high-entropy carbide powder is small in grain size, low in heat conductivity and good in hightemperature stability, and is suitable to be used as a base material of an ultrahigh-temperature heat-resistant coating material, an ultrahigh-temperature heat-insulating material and an ultrahigh-temperature composite material; by the preparation method, a technology is simple, the raw material cost is low, and the high-purity ultrahigh-temperature high-entropy carbide powder can be obtained through once heating at relatively low temperature.

Owner:淄博星澳新材料研究院有限公司

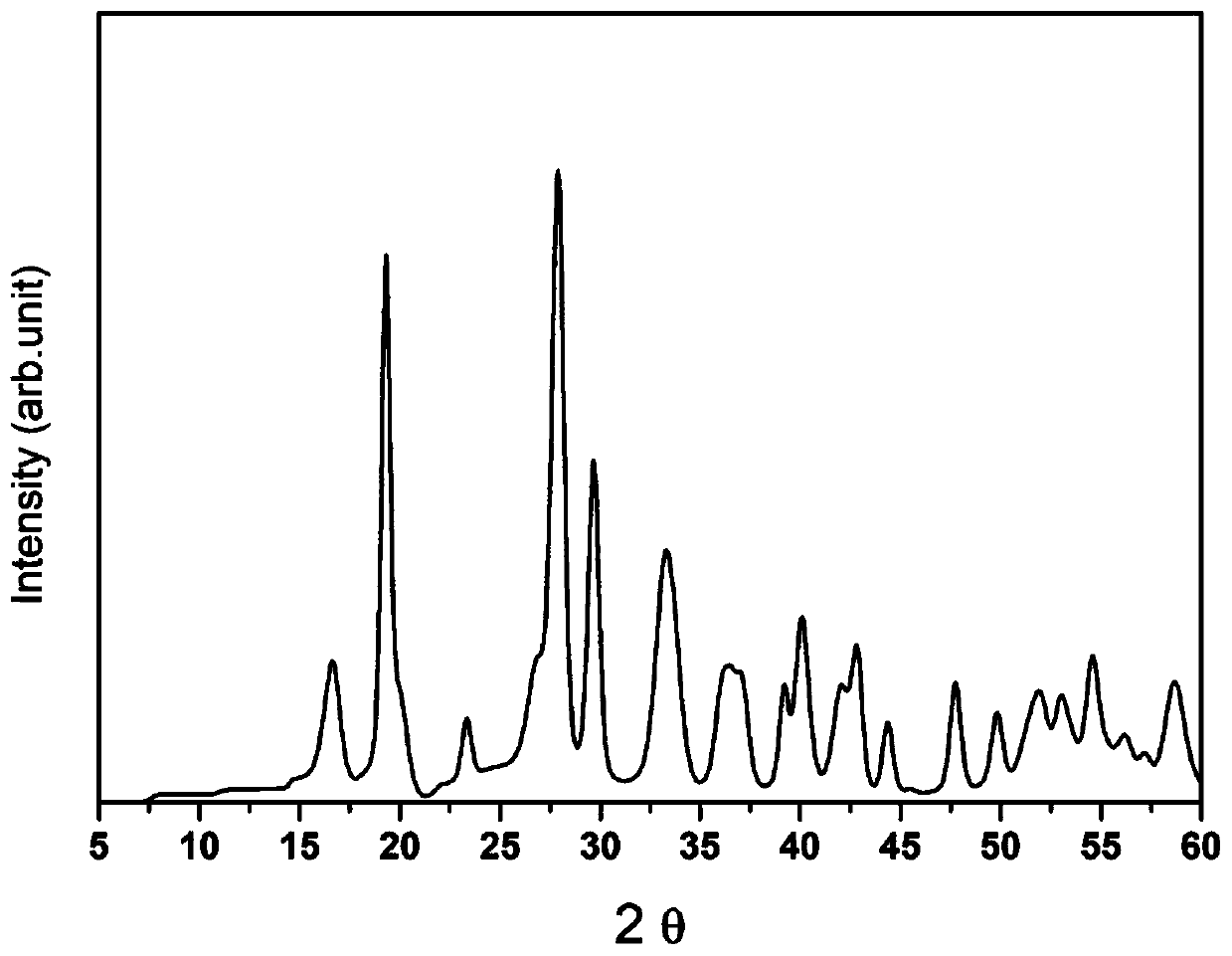

Novel polycarbosilane and preparation method thereof

The invention relates to novel polycarbosilane and a preparation method thereof. A polycarbosilane ceramic precursor is prepared by adopting a Grignard reagent coupling method; a molecular structure contains unsaturated groups such as a Si-H bond, C=C and the like; the precursor can be crosslinked and cured at a certain temperature, and has low curing weight loss and high manufacturability; the Si / C ratio in the precursor and the process performance of a precursor product can be adjusted effectively by adjusting the functionality and feed ratio of a chlorosilane monomer serving as a reactant and optimizing reaction conditions; and the obtained product has excellent heat resistance, high ceramic yield, low free carbon content in ceramic and high SiC ceramic phase purity, is suitable for serving as a high-performance SiC ceramic precursor, and can be used for preparing an ultrahigh-temperature ceramic-based composite material submerged substrate as well as high-performance materials such as SiC ceramic coatings, fibers and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

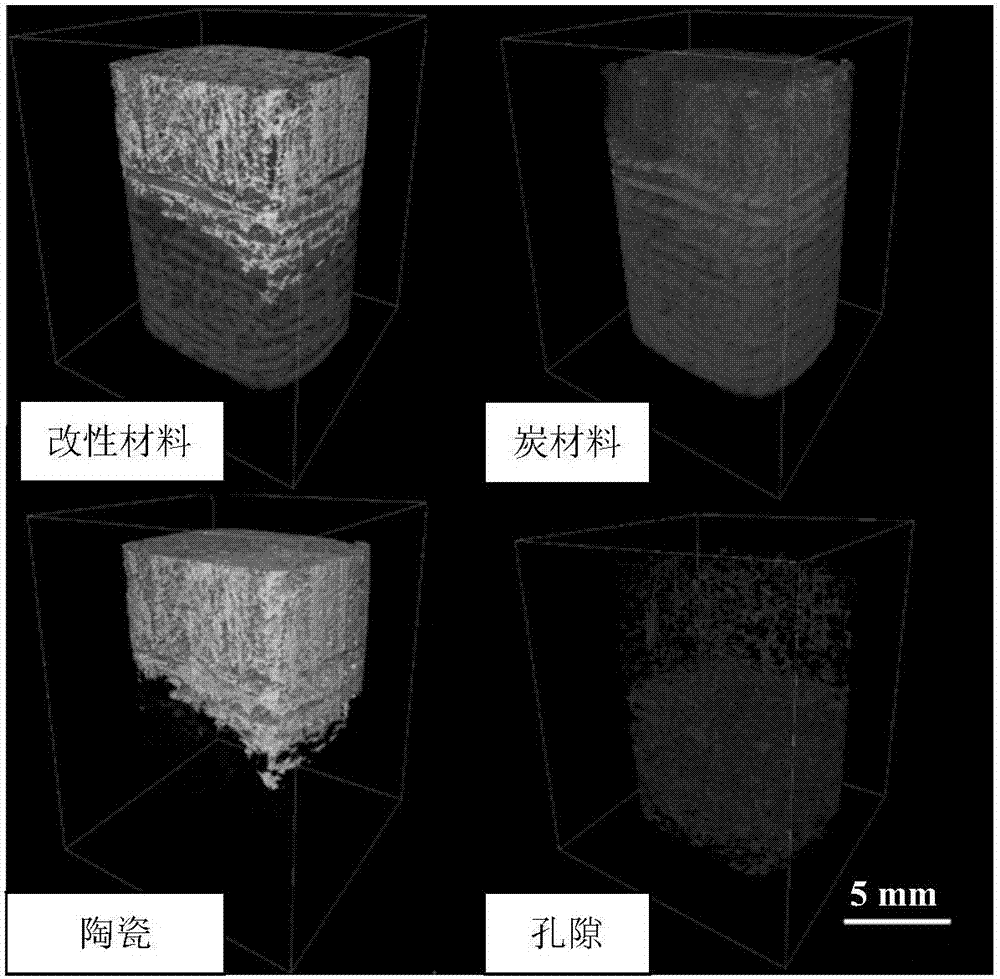

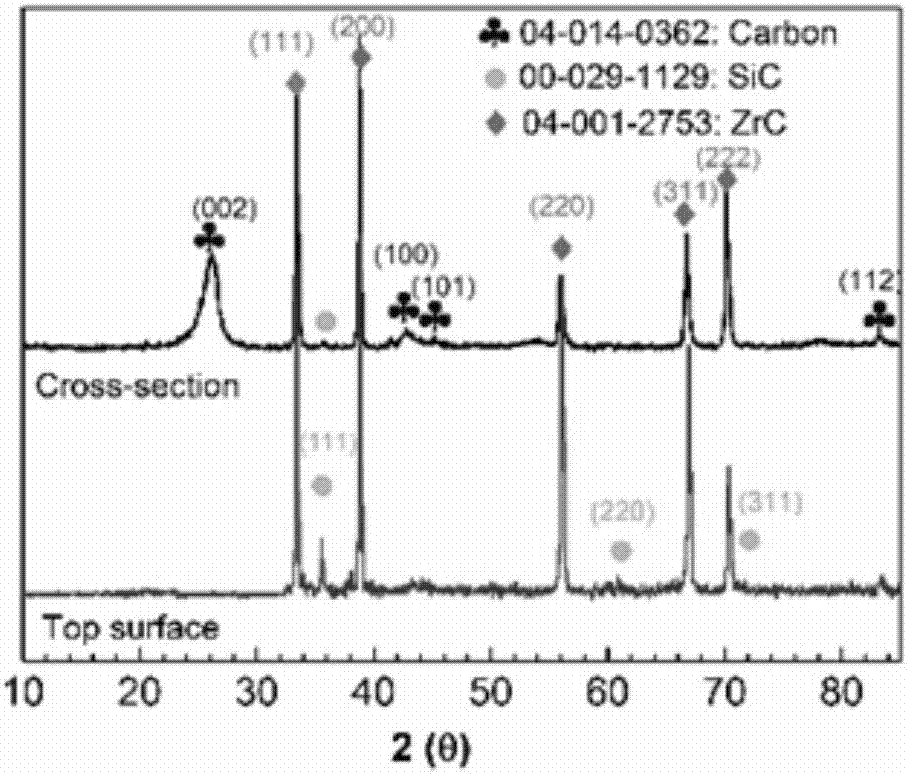

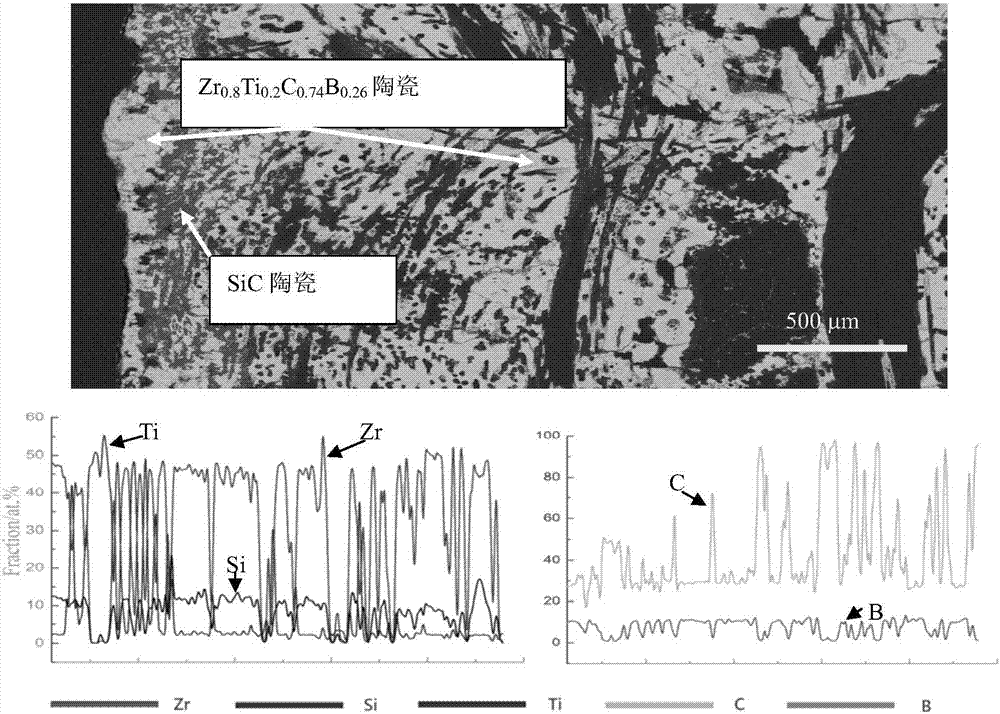

Novel ultrahigh-temperature ceramic integrally-modified anti-ablation carbon/carbon composite material and preparation method thereof

ActiveCN107021773AImprove anti-ablation performanceExhibits high melting point propertiesCarbon compositesCarbon fibers

The invention discloses a novel ultrahigh-temperature ceramic (Zr0.8Ti0.2C0.74B0.26) integrally-modified anti-ablation carbon / carbon composite material and a preparation method thereof. The preparation method comprises the following steps: (1) performing high-temperature thermal treatment on a carbon fiber preform, and depositing pyrolytic carbon in a chemical gas phase permeation furnace to prepare a porous carbon / carbon composite material; (2) placing the carbon / carbon composite material on which the pyrolytic carbon is deposited on zirconium-titanium mixed powder, and preparing a zirconium-titanium carbide modified carbon / carbon composite material in a non-stoichiometric ratio through a high-temperature infiltration reaction method; (3) placing the composite material in mixed powder of C, B4C, SiC, Si and a penetration enhancer, and forming an integral ultrahigh-temperature ceramic modified carbon / carbon composite material by adopting an embedding method. The method is simple, is convenient to operate, can be used for preparing large-sized components, and is suitable for integrally modifying substrates and coatings of anti-ablation carbon / carbon composite materials in heat-resistant components of hypersonic aircrafts.

Owner:CENT SOUTH UNIV

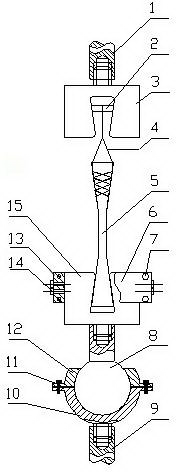

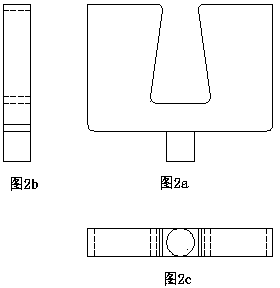

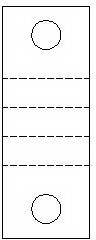

Clamping mechanism for device for testing high-temperature direct tensile strength of ultrahigh-temperature ceramics

InactiveCN104330314AEven by forceExact tensile strengthMaterial strength using tensile/compressive forcesSpherical bearingEngineering

The invention discloses a clamping mechanism for a device for testing the high-temperature direct tensile strength of ultrahigh-temperature ceramics. The clamping mechanism is structurally characterized in that an upper wedge clamp (3) is connected with an upper pull rod (1) of a tester, a circular supporting beam (2) is transversely clamped in a wedge groove of the upper wedge clamp (3), a flexible cable (4) for fixing a test piece (5) by being wound around the upper end of the test piece (5) is wound and fixed together with the circular supporting beam (2), a lower wedge clamp (15) for clamping the lower end of the test piece (5) is connected with a bulb rod (8), a bulb of the bulb rod (8) is mounted in a ball bowl composed of an upper spherical bearing (12) and a lower spherical bearing (10), and the upper spherical bearing (12) and the lower spherical bearing (10) are connected with each other by use of a bolt (11). The clamping mechanism for the device for testing the high-temperature direct tensile strength of the ultrahigh-temperature ceramics has the beneficial effects that the center line of the test piece is located in the same straight line with the straight line of pull under the action of the pull, the test piece is prevented from being bent and distorted, the stress on the test piece in the center line is even, a test result is kept accurate and reliable, and the repeatability is good.

Owner:CHONGQING UNIV

A kind of zr-c-si polymer ceramic precursor and its preparation method and application

ActiveCN102268135AImprove high temperature resistanceThe synthesis process is simplePolymer scienceFlight vehicle

The invention discloses a Zr-C-Si polymer ceramic precursor and a preparation method and application thereof. The Zr-C-Si polymer ceramic precursor is prepared by performing graft copolymerization on a double-bond organic metal zirconium monomer and polycarbosilane (PCS). The Zr-C-Si polymer ceramic precursor is used for preparing Zr-C-Si ceramic, the yield of ceramic is up to 50-65 percent, the content of ZrC and the content of SiC in a prepared ceramic material are higher than 70 percent by weight, and high high-temperature resistance is achieved. The Zr-C-Si polymer ceramic precursor can meet the requirement on temperature over 2,000 DEG C which is needed by ultrahigh-temperature ceramic, and has wide application prospect in the fields of aero-space, supersonic aircrafts, reentrant aircrafts and the like, a simple synthesis process and low energy consumption.

Owner:NAT UNIV OF DEFENSE TECH

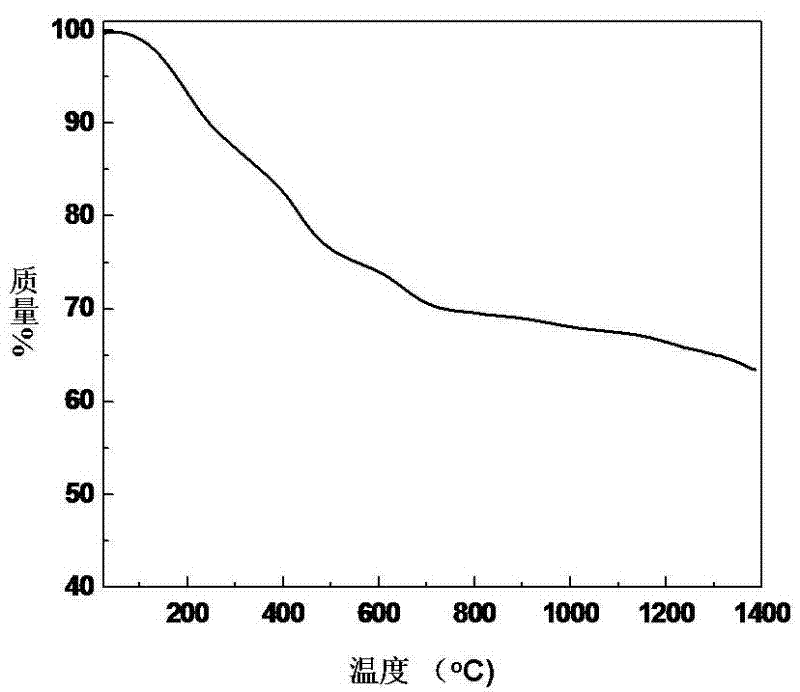

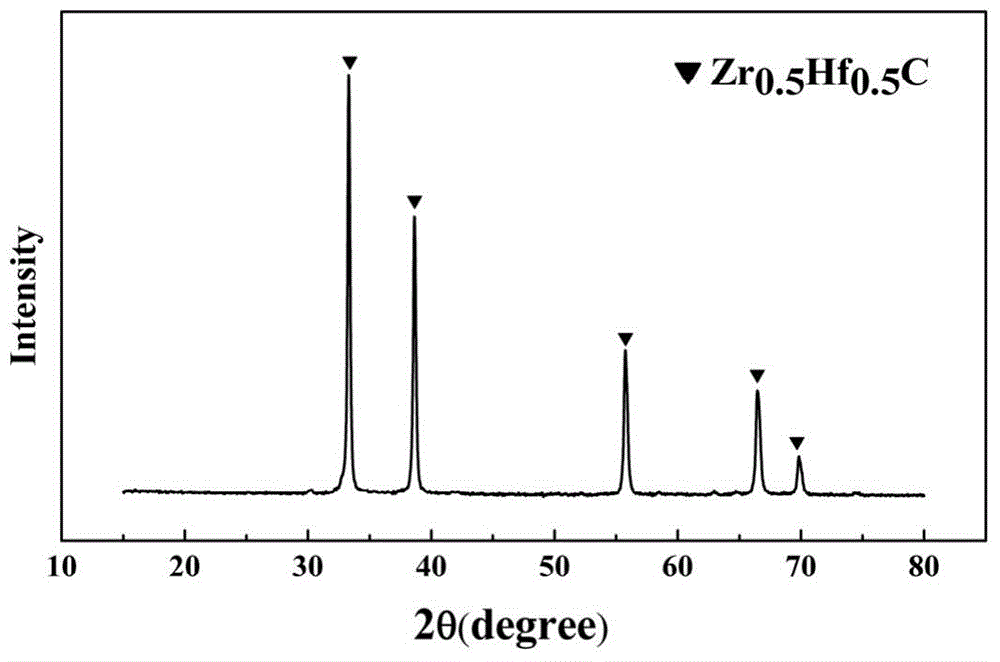

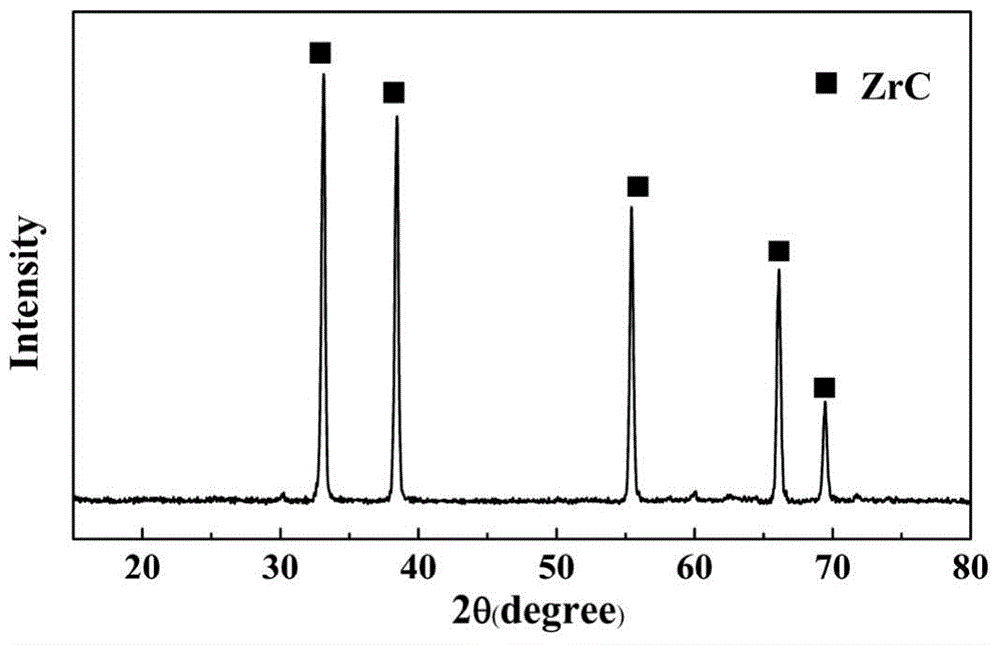

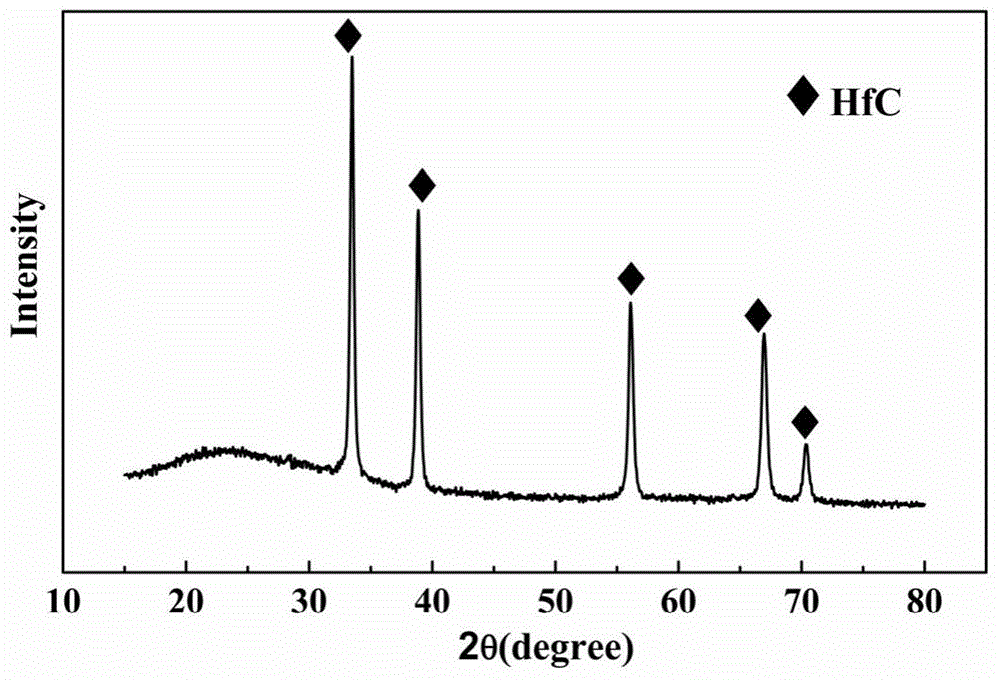

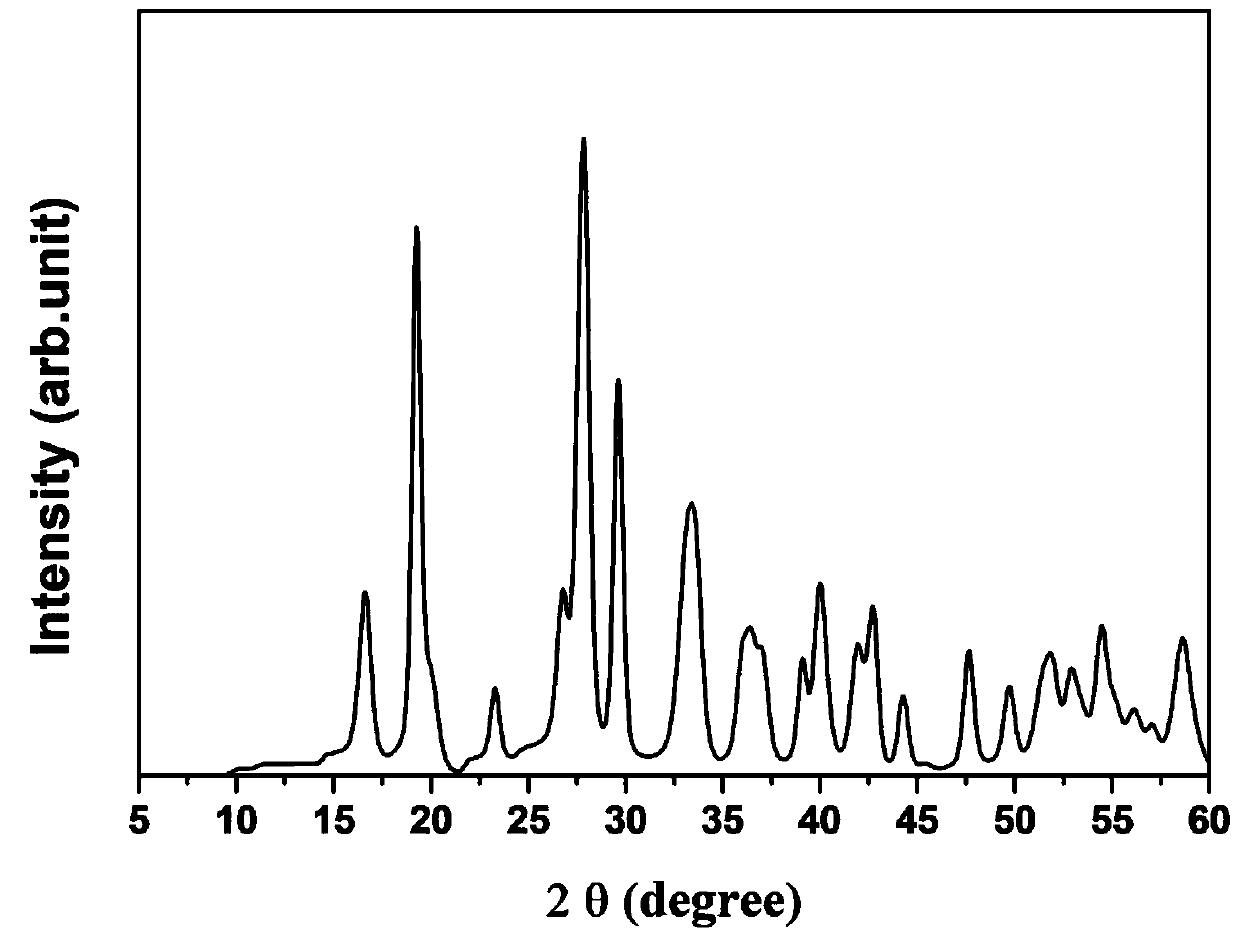

Preparation method and application of carbide ceramic precursor

The invention provides a preparation method and application of a zirconium (Zr) or hafnium (Hf) carbide ultrahigh-temperature ceramic liquid-phase precursor. The method comprises the following steps: by using a water-soluble zirconium (Zr) or hafnium (Hf) inorganic salt as a metal element source in the corresponding ceramic, a water-soluble hydroxycarboxylic acid / water-soluble polyalcohol mixture as a carbon source and distilled water as a solvent, preparing the carbide ceramic precursor, and crosslinking and cracking to prepare the corresponding carbide ceramic powder. The ceramic precursor provided by the invention has the advantages of low cost, low toxicity, environmental protection, simple preparation process, high stability in air, and can be stored for a long time. The prepared carbide ceramic powder has the advantages of higher purity, favorable crystallinity and small particle size. The precursor preparation method is hopeful to be applied in the aspects of synthesis and preparation of an ultrahigh-temperature ceramic precursor, preparation of ceramic fibers and composite materials by precursor conversion, preparation of ultrafine ultrahigh-temperature ceramic powder, and the like.

Owner:NAT UNIV OF DEFENSE TECH

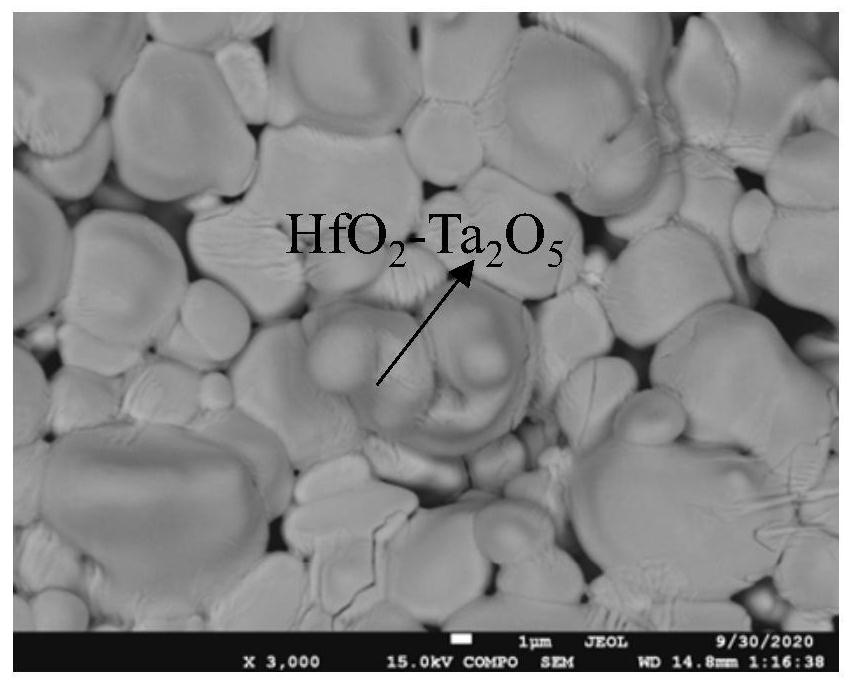

High purity zirconium boride / hafnium boride and preparation of superhigh temperature ceramic target material

The invention discloses a method for preparing a high-purity ultrahigh-temperature ceramic target material which belongs to the technical field of ceramic target materials, and in particular provides a method for preparing high-purity zirconium / hafnium boride powder and a ceramic target material thereof. The method comprises the steps of taking high-purity Zr powder, Hf powder and high-purity B powder as raw materials, adopting a self-propagating method to prepare high-purity ZrB2 and HfB2 powder respectively and then adopting a high-temperature high-pressure hot-pressing molding process to prepare a high-purity dense zirconium / hafnium boride ultrahigh-temperature ceramic target material, wherein the relative density of the target material reaches 95 to 99 percent. Relative to the prior art, metal powder in the method is slightly excessive when the materials are mixed, so as to make up for the metal loss during self-propagating reaction and further guarantee the component unicity of products. Relative to pressureless sintering, the sintering temperature needed in the method is greatly lowered; in addition, as the hot-pressing process adopts two-stage temperature, blank is uniform in temperature field, so as to ensure that the target material with uniform density can be obtained in the late hot-pressing process.

Owner:有研资源环境技术研究院(北京)有限公司

Polybasic solid solution rare earth silicate ceramic powder and preparation method thereof

The invention relates to the technical field of ultrahigh temperature ceramic powder, in particular to polybasic solid solution rare earth silicate ceramic powder and a preparation method thereof. Thechemical formula of the polybasic solid solution rare earth silicate ceramic powder is (Y0.2Yb0.2Re'0.2Re'0.2La0.2)2Si2O7, wherein Re' and Re' are selected from any two of Nd, Ce, Sm, Er and Eu. Thepreparation method comprises the following steps: mixing raw materials by adopting a wet-mixing method, and drying; then placing the mixture in a high-temperature reaction furnace for reacting; performing wet milling and spray drying granulation to obtain the polybasic solid solution rare earth silicate ceramic powder. The polybasic solid solution rare earth silicate ceramic powder has high solidsolubility, excellent high temperature resistance, no decomposition at a high temperature and low thermal conductivity. The preparation method is simple and feasible.

Owner:淄博星澳新材料研究院有限公司

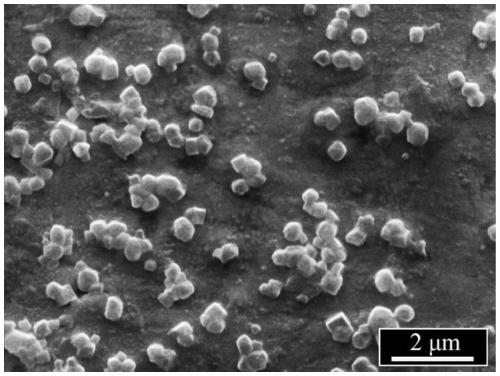

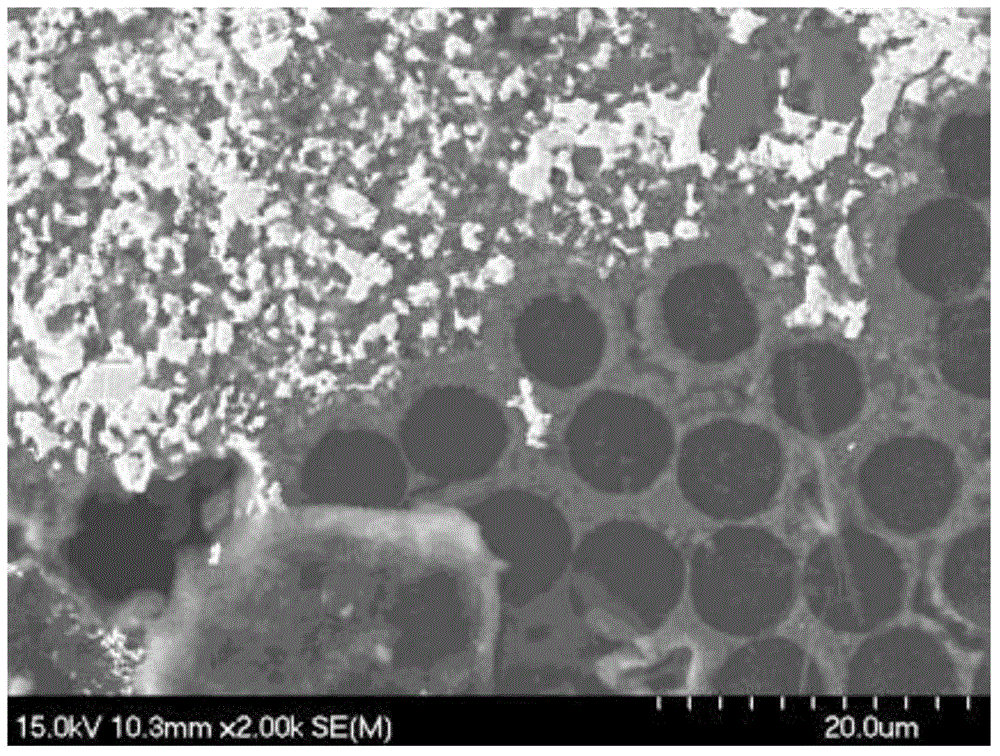

Method for preparing C/SiC-HfC carbon fiber reinforced ultrahigh-temperature ceramic matrix composite

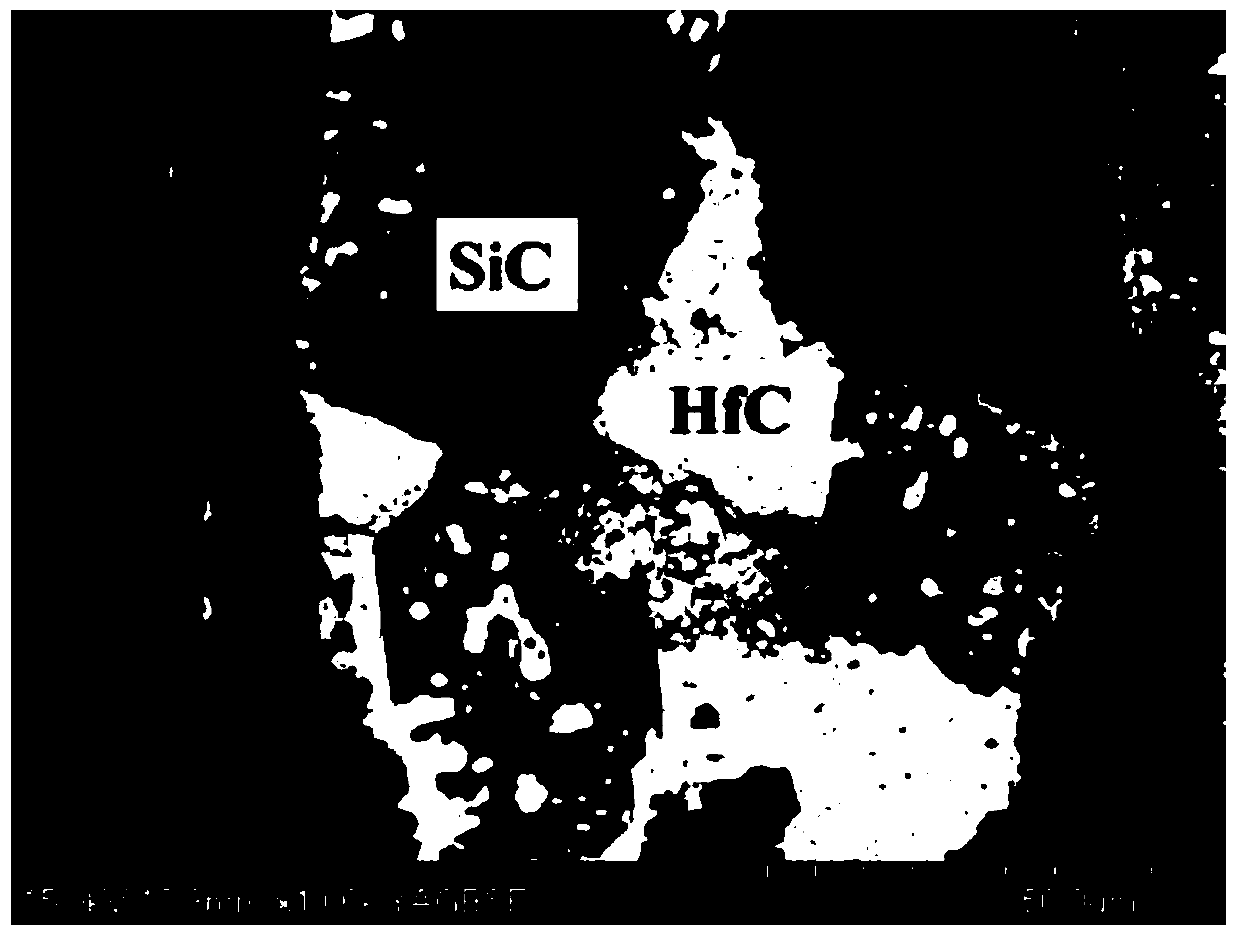

The invention relates to a method for preparing C / SiC-HfC carbon fiber reinforced ultrahigh-temperature ceramic matrix composite, which comprises the following steps: introducing C organic precursor in C / SiC preform by vacuum pressure impregnation method or directly using C / C perform; combining with reaction melt impregnation method; and reacting silicon hafnium alloy with C to in-situ generate HfC-SiC. The obtained composite has high volume fraction of HfC; generated SiC and HfC have small grains to effectively improve the erosion resistance capability of materials. The method is applicable for composite, in site generates HfC phase in the process of preparing material and increases the volume fraction of hafnium compounds to enhance the erosion resistance capability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

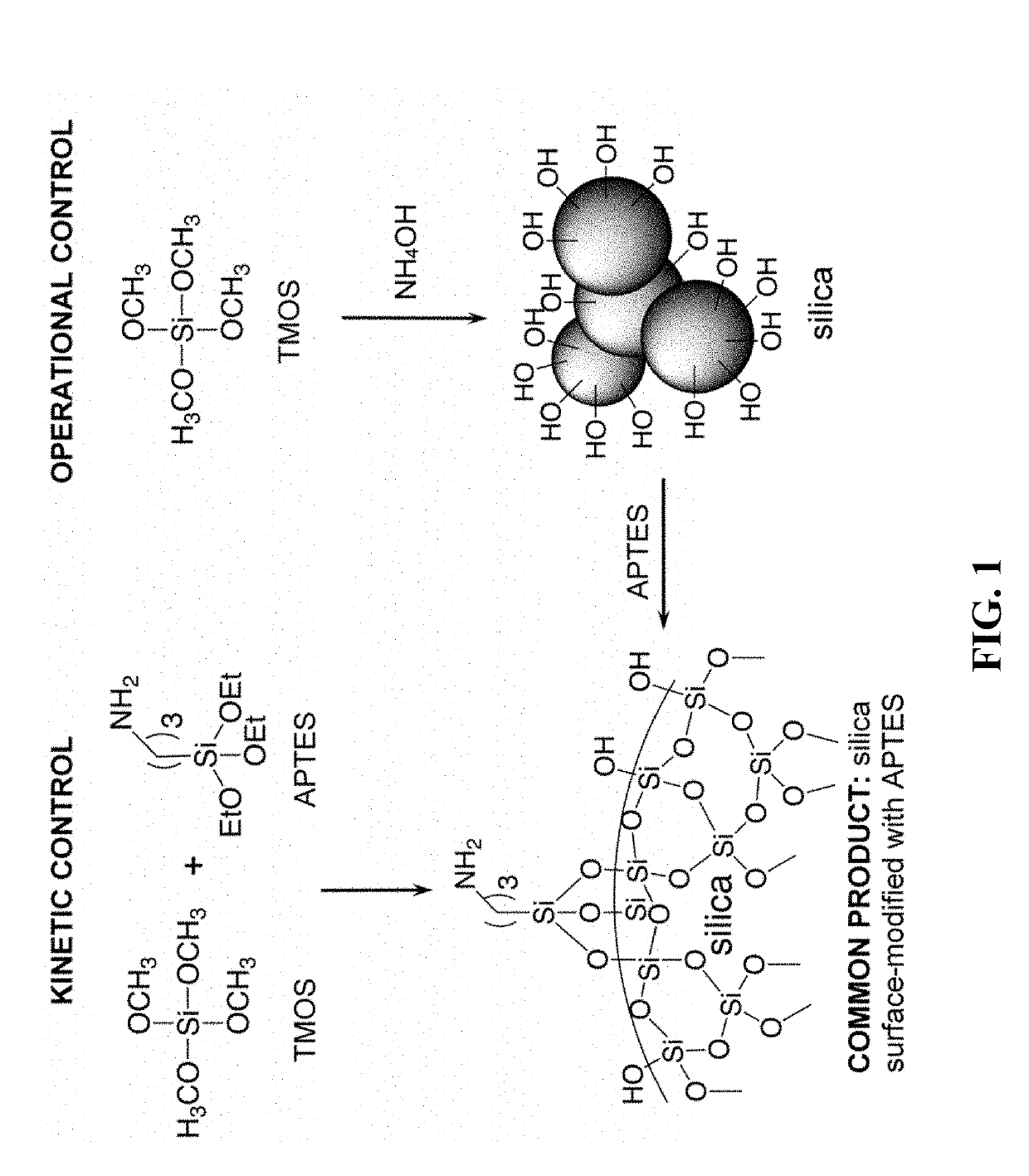

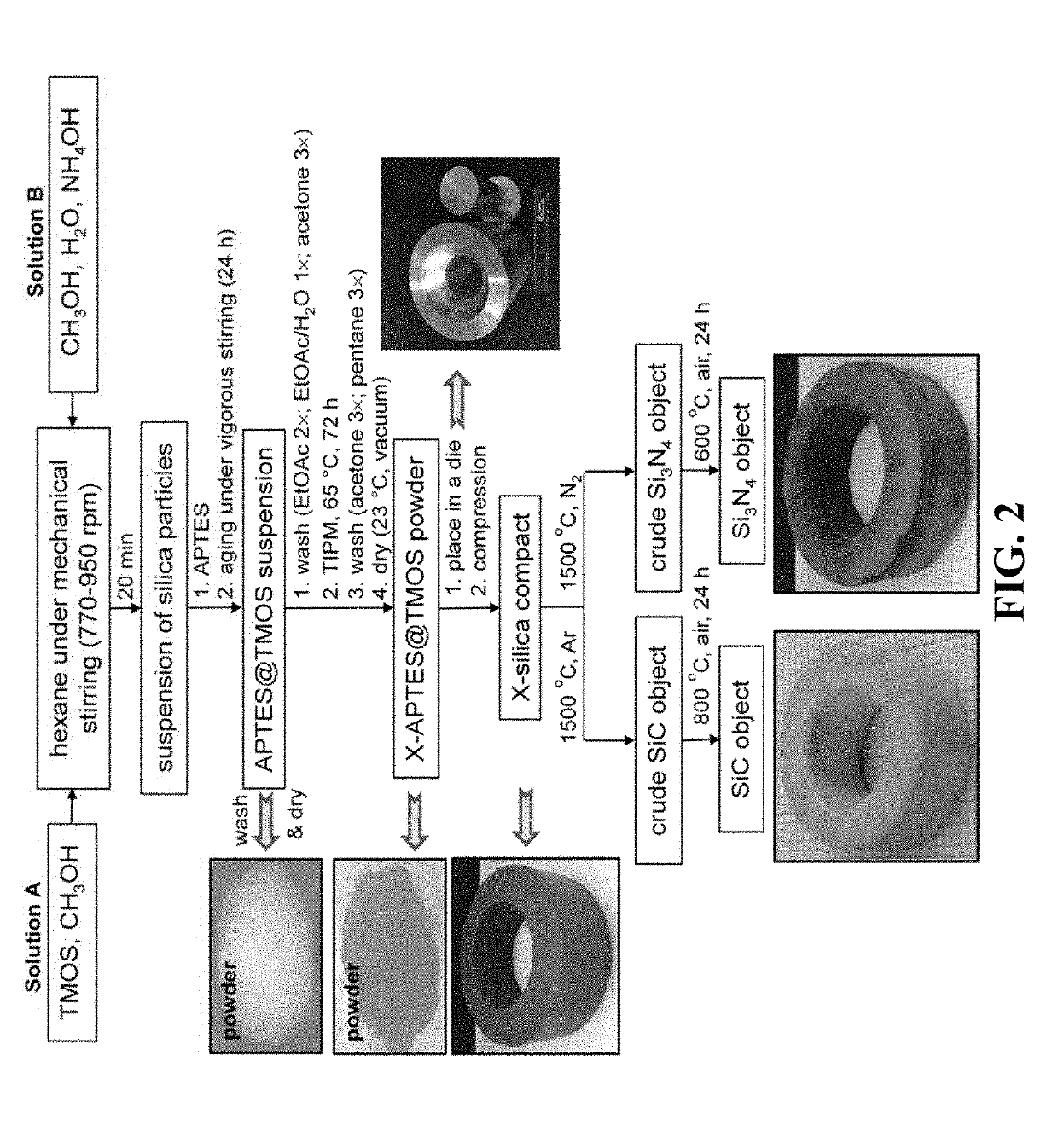

Novel highly porous ceramic and metal aerogels from xerogel powder precursors, and methods for their production and use

ActiveUS20190308912A1Speed up the processReduce lossesTransportation and packagingMetal-working apparatusConvertersBoride

The present invention discloses novel methods for producing highly porous ceramic and / or metal aerogel monolithic objects that are hard, sturdy, and resistant to high temperatures. These methods comprise preparing nanoparticulate oxides of metals and / or metalloids via a step of vigorous stirring to prevent gelation, preparing polymer-modified xerogel powder compositions by reacting said nanoparticulate oxides with one or more polyfunctional monomers, compressing said polymer-modified xerogel powder compositions into shaped compacts, and carbothermal conversion of the shaped xerogel compacts via pyrolysis to provide the highly porous ceramic and / or metal aerogel monolithic objects that have the same shapes as to their corresponding xerogel compact precursors. Representative of the highly porous ceramic and / or metal aerogel monolithic objects of the invention are ceramic and / or metal aerogels of Si, Zr, Hf, Ti, Cr, Fe, Co, Ni, Cu, Ru, Au, and the like. Examples include sturdy, shaped, highly porous silicon carbide (SiC), silicon nitride (Si3N4), zirconium carbide (ZrC), hafnium carbide (HfC), chromium carbide (Cr3C2), titanium carbide (TiC), zirconium boride (ZrB2), hafnium boride (HfB2), and metallic aerogels of iron (Fe), nickel (Ni), cobalt (Co), copper (Cu), ruthenium (Ru), gold (Au), and the like. Said aerogel monolithic objects have utility in various applications such as, illustratively, in abrasives, in cutting tools, as catalyst support materials such as in reformers and converters, as filters such as for molten metals and hot gasses, in bio-medical tissue engineering such as bone replacement materials, in applications requiring strong lightweight materials such as in automotive and aircraft structural components, in ultra-high temperature ceramics, and the like.

Owner:UNIVERSITY OF MISSOURI

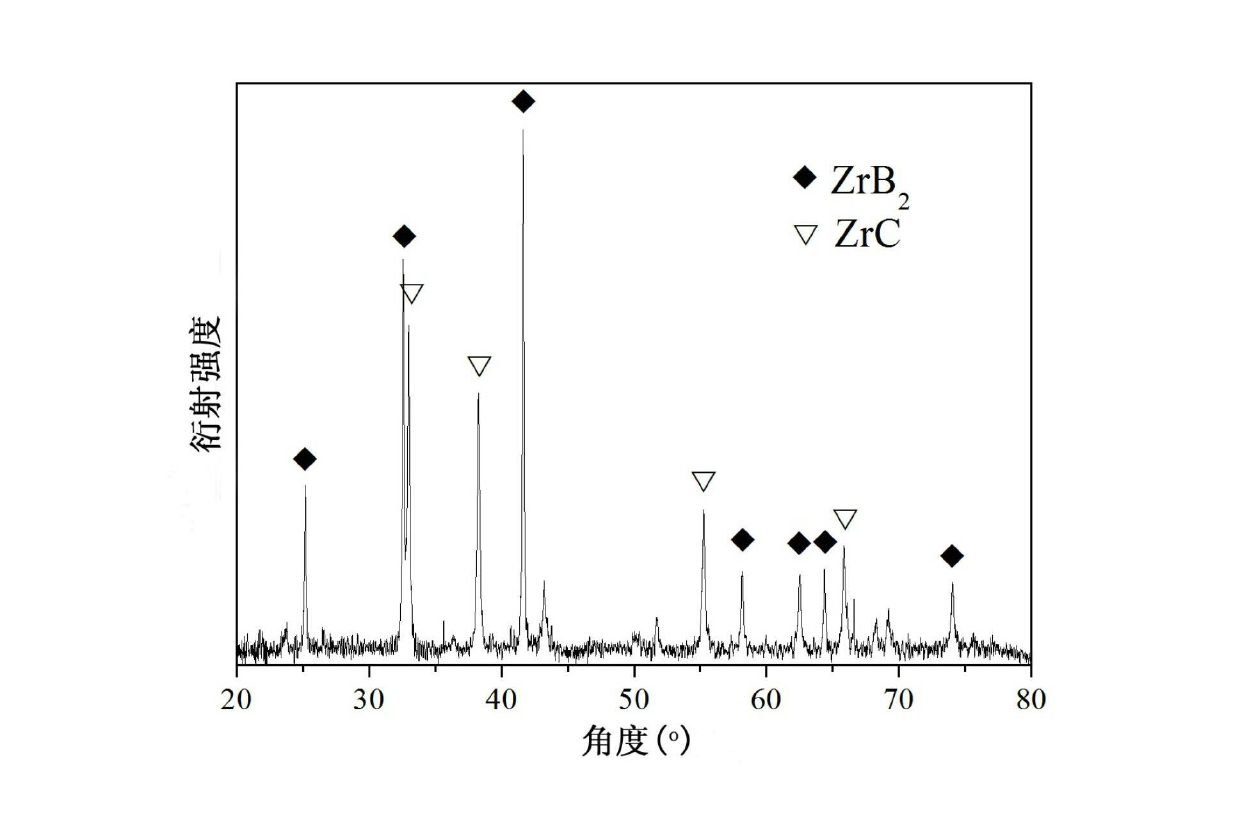

Preparation method of ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic

The invention discloses a preparation method of ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic. The preparation method comprises the following process steps of: weighing raw materials, mixing by ball milling, and performing die pressing or crosslinking molding to obtain a green body; performing high-temperature cracking and heat preserving on the green body to obtain a porous rigid prefabricated body; undergoing an infiltration reaction by taking the porous rigid prefabricated body as a substrate and taking a zirconium-containing alloy as an infiltration agent to obtain semi-finished ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic; and embedding the semi-finished ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic with B4C powder or SiC powder and performing high-temperature treatment to obtain the ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic. The process of the invention has the advantages of low preparation temperature and low cost. By adopting the preparation method, a ceramic product with high density, high mechanical property and high temperature resistance can be obtained.

Owner:NAT UNIV OF DEFENSE TECH

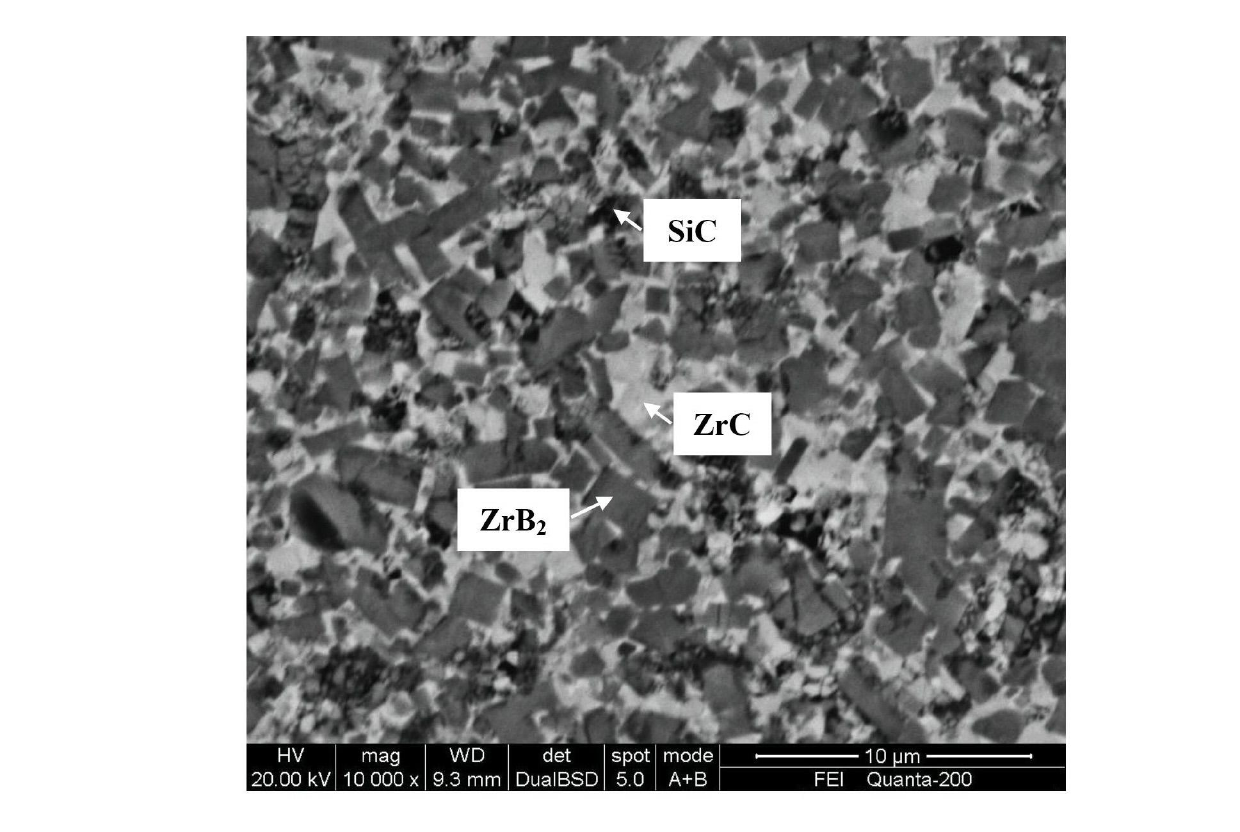

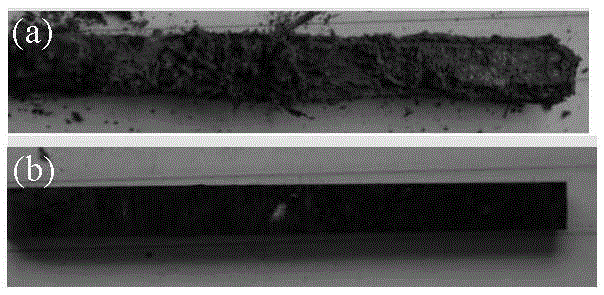

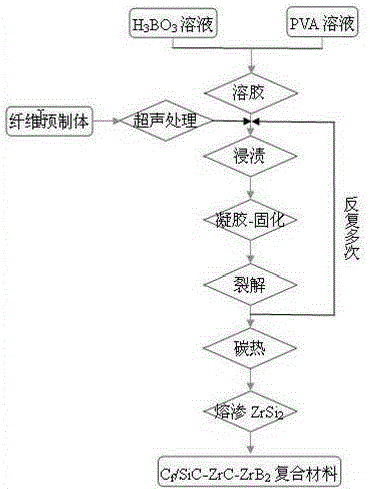

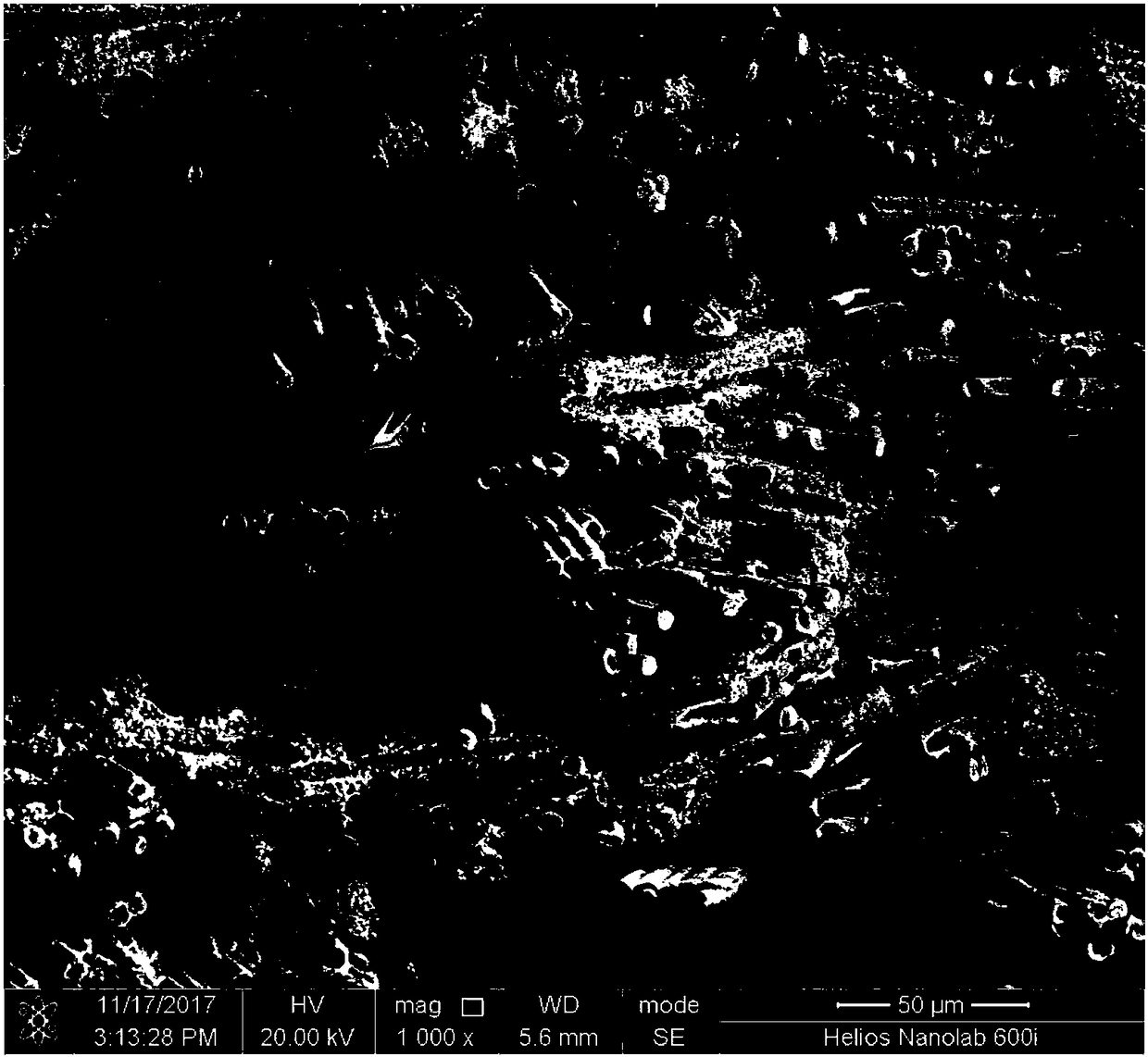

Preparation method of Cf/SiC-ZrC-ZrB2 ultrahigh-temperature ceramic-based composite material

The invention relates to a preparation method of a Cf / SiC-ZrC-ZrB2 ultrahigh-temperature ceramic-based composite material. The preparation method comprises the following steps: (1) preparing a sol solution containing H3BO3 and polyvinyl alcohol; (2) introducing the sol solution into a carbon fiber preform by utilizing vacuum impregnation, and performing gelatinization to obtain Cf / polyethyl borate; (3) cracking the Cf / polyethyl borate in the presence of an inert gas to obtain Cf / B2O3-C; (4) performing a carbothermal reduction reaction on the obtained Cf / B2O3-C in the presence of the inert gas to obtain Cf / B4C-C; and (5) infiltrating fused ZrSi2 into the Cf / B4C-C to perform an infiltration reaction to generate SiC, ZrC, ZrB2 in situ, thereby obtaining the Cf / SiC-ZrC-ZrB2 ultrahigh-temperature ceramic-based composite material. The method provided by the invention is simple and feasible, the prepared Cf / SiC-ZrC-ZrB2 has high contents of ultrahigh-temperature phases (ZrC and ZrB2) and is uniformly distributed, and the method significantly improves ablation resistance, oxidation resistance and mechanical properties of the material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

High-strength high-toughness zirconium diboride-silicon carbide-zirconia ceramic-based composite material and preparation method thereof

The invention relates to a high-strength high-toughness zirconium diboride-silicon carbide-zirconia ceramic-based composite material and a preparation method thereof, which relate to a ceramic-based composite material and a preparation method thereof and solve the problems of low fracture toughness and sintering difficulty of a ZrB2 ceramic-based composite material prepared by a traditional method. The material is made of zirconium diboride powder, silicon carbide powder and zirconium diboride fibers. The method comprises the following steps of: 1. weighing and wetly mixing raw materials to obtain slurry; 2. drying the slurry and then grinding to obtain a mixed powdery material; 3. sintering, cooling and taking out the mixed powdery material to obtain the ceramic-based composite material. In the invention, the ZrO2 fibers are introduced into a zirconium diboride-silicon carbide ultrahigh-temperature ceramic-material system to improve the brittleness and the thermal-shock resisting performance of an ultrahigh-temperature ceramic material and improve the use reliability of the material. The ceramic composite material prepared by the method provided by the invention is easy to sinter, the fracture toughness of the ceramic composite material is 5.69-6.82MPa.m1 / 2, and the bending strength is 700.86-723.15MPa.

Owner:HARBIN INST OF TECH

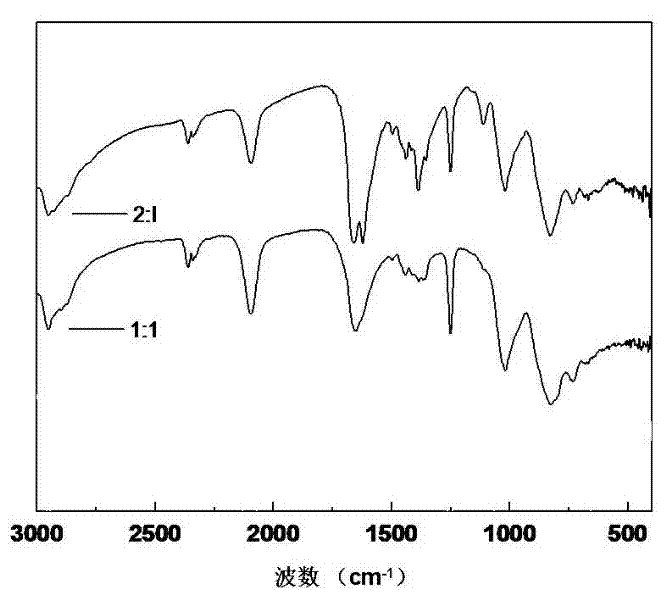

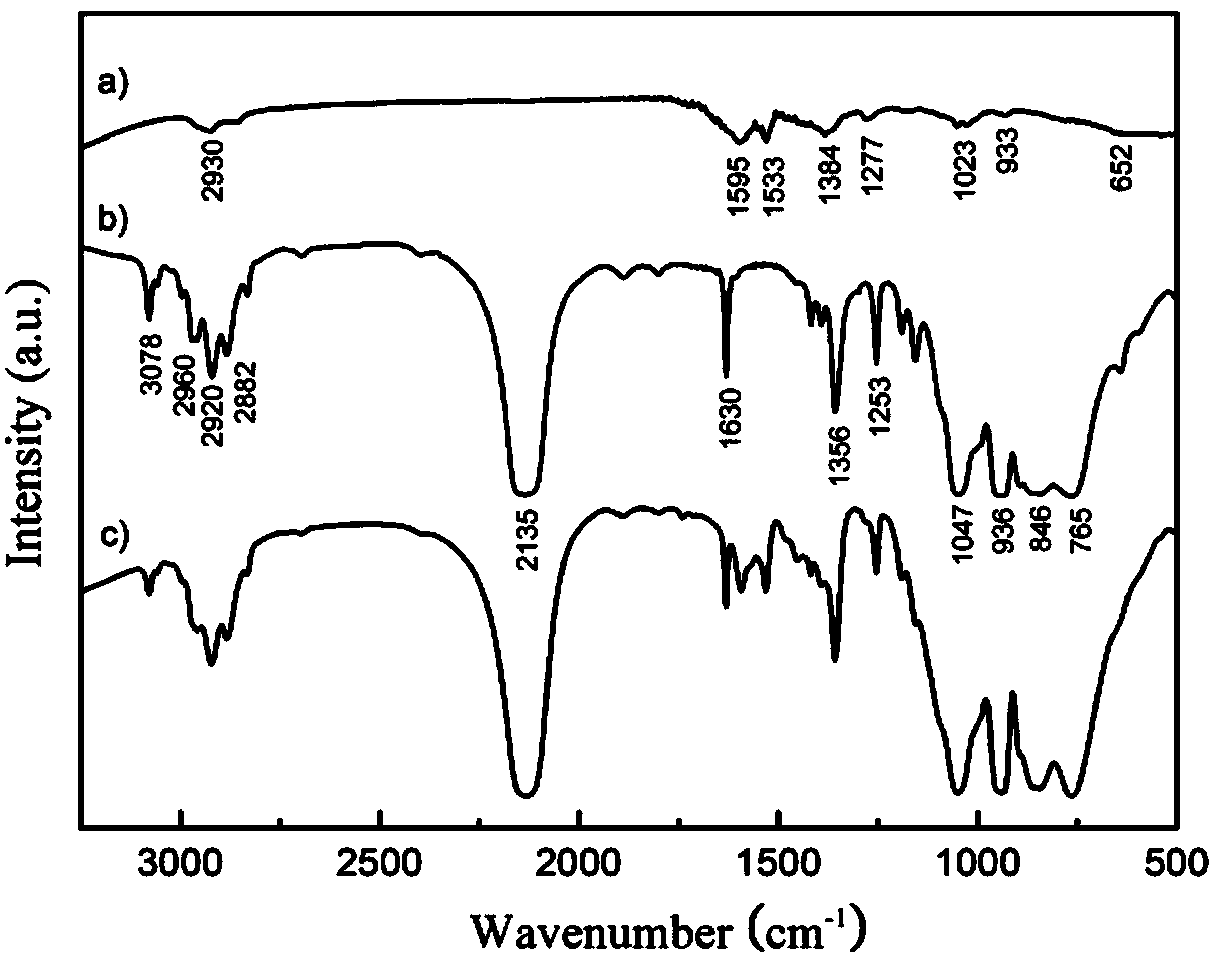

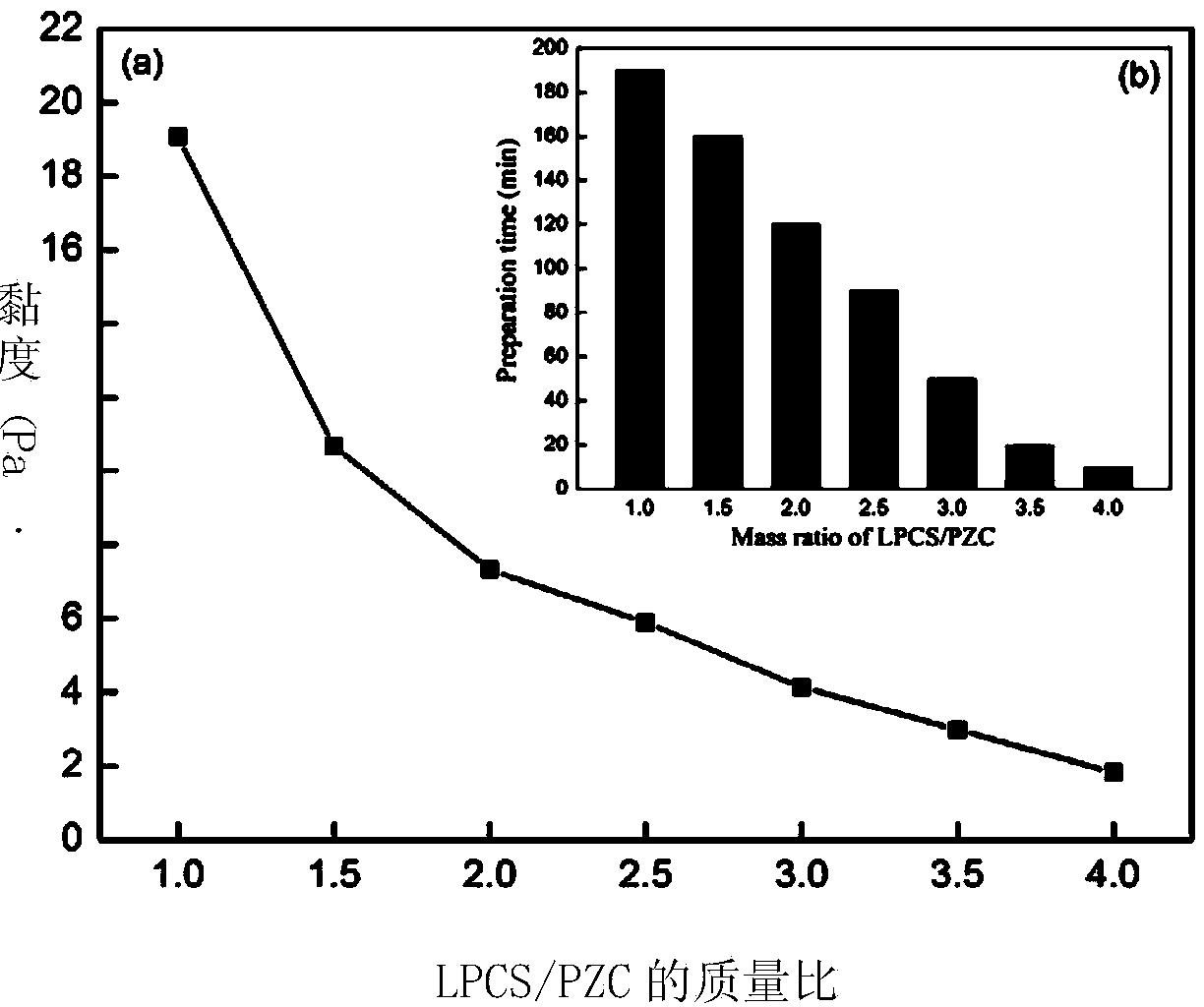

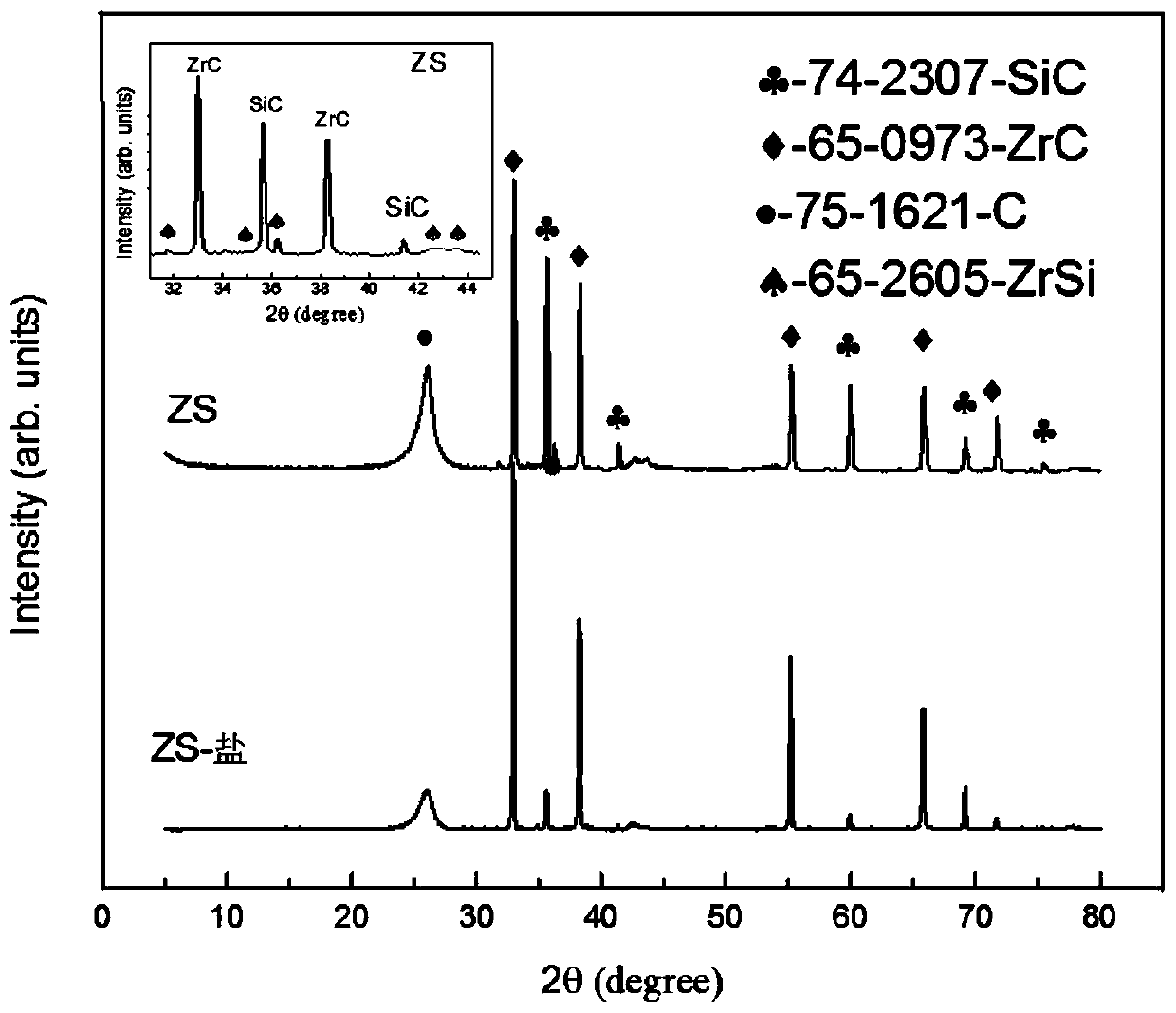

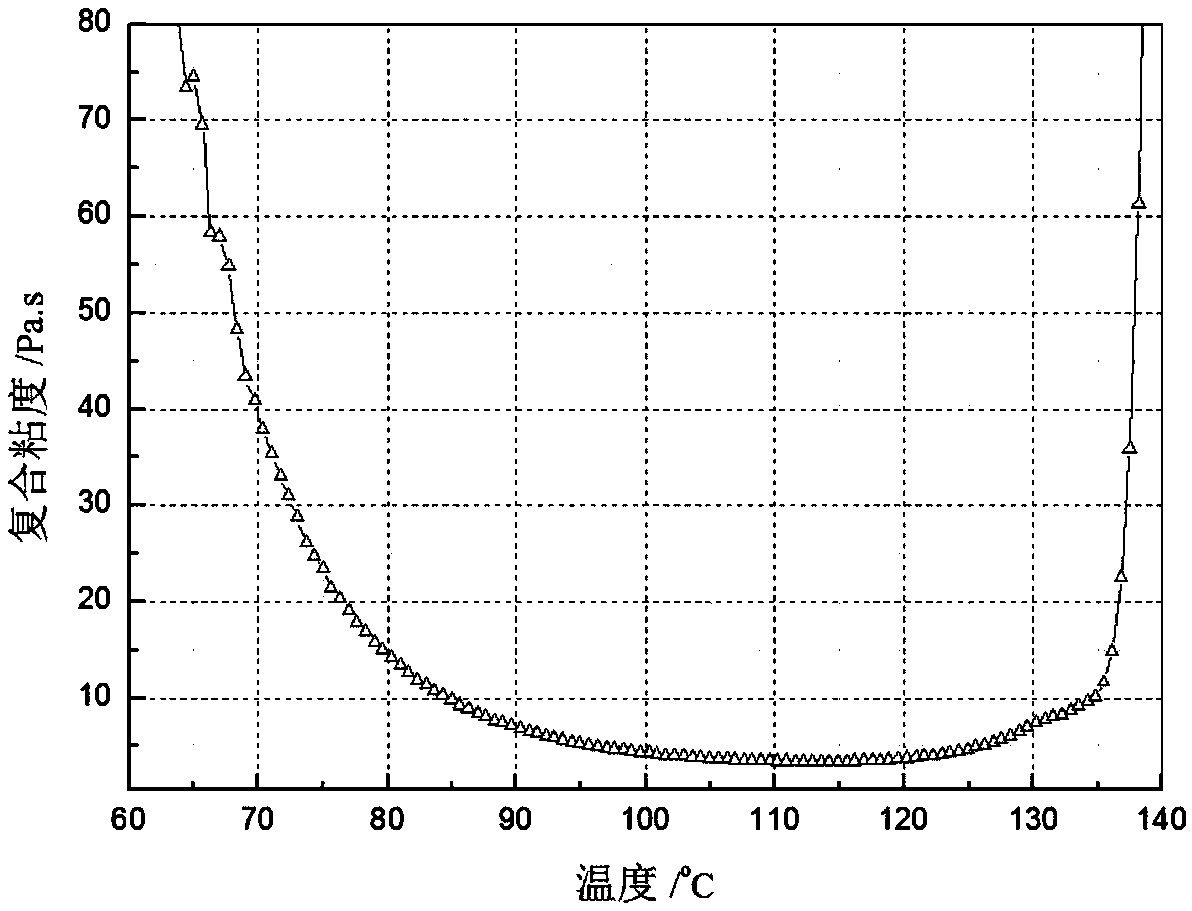

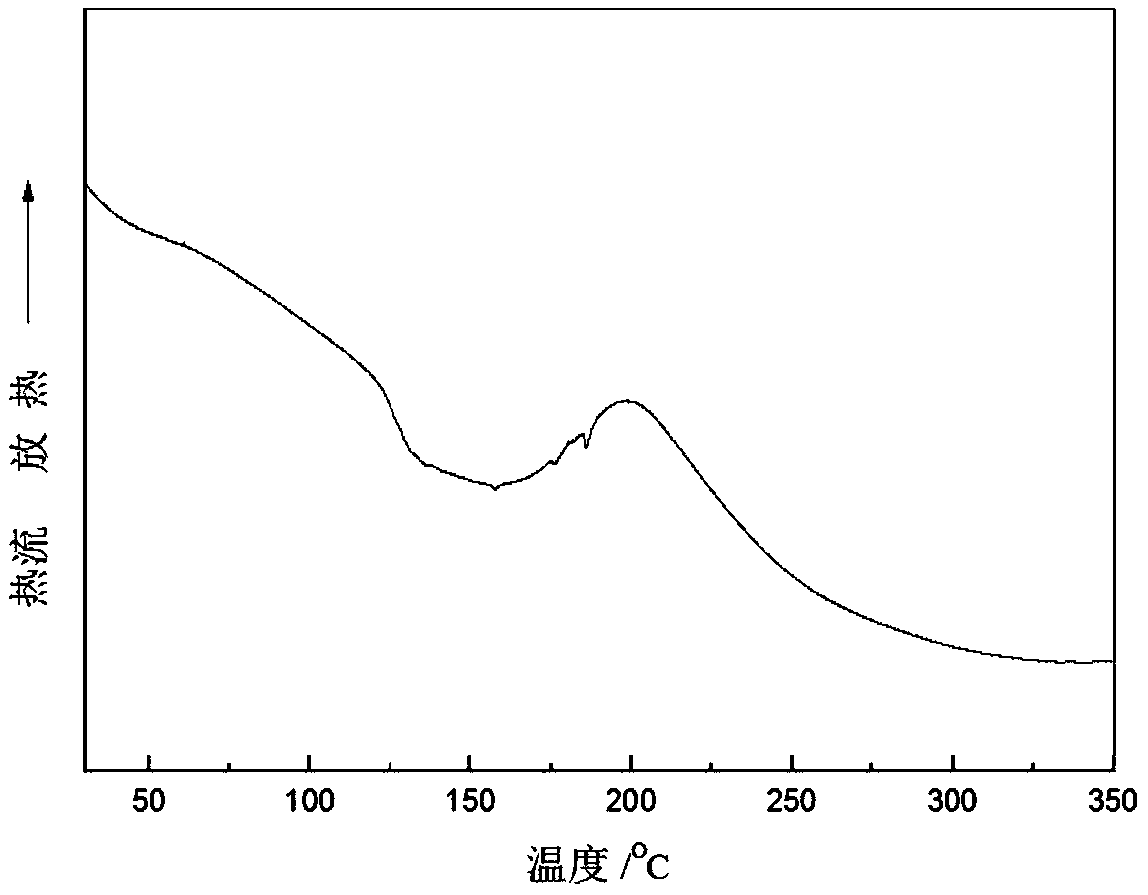

Hybridization liquid precursor, preparing method and method for preparing ZrC-SiC superhigh temperature ceramics and composite materials of ZrC-SiC superhigh temperature ceramics through hybridization liquid precursor

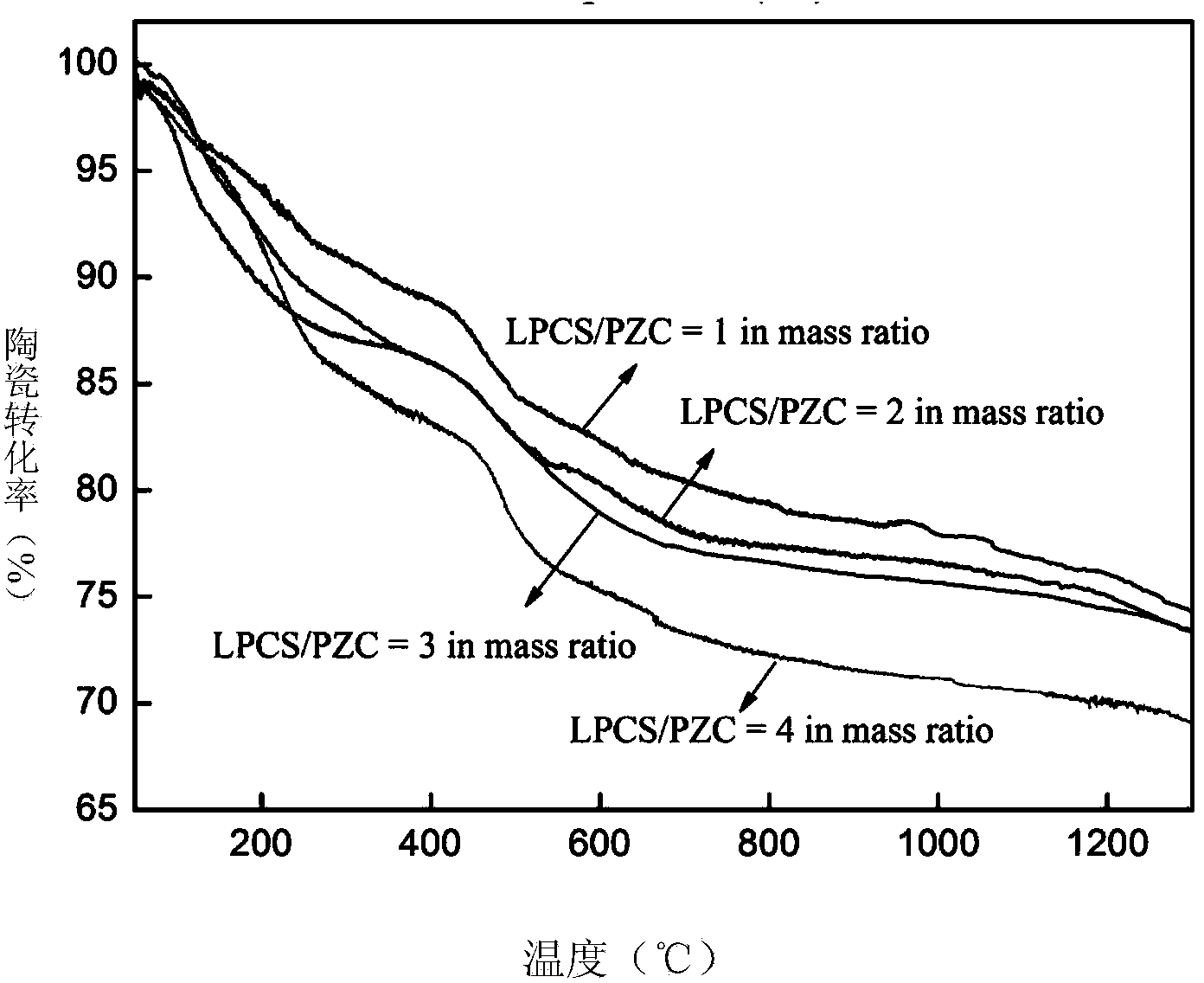

The invention relates to hybridization liquid precursor, a preparing method and a method for preparing ZrC-SiC superhigh temperature ceramics and composite materials of the ZrC-SiC superhigh temperature ceramics through the hybridization liquid precursor. Solid PZC precursor and carbon-rich vinyl adopted to replace liquid polycarbosilane (LPCS) precursor serve as raw materials for the first time and are processed in a hybridization mode to synthesize the brand new hybridization liquid precursor which is low in viscosity, adjustable in component, low in solidifying temperature, good in dipping performance, free of toxicity, harmless and high in productivity, organic solvent does not need to be added to the hybridization liquid precursor, the hybridization liquid precursor can be used for preparing the ZrC-SiC superhigh temperature ceramics and the composite materials of the ZrC-SiC superhigh temperature ceramics, and according to the thermogravimetric analysis, the ceramic productivity of the hybridization liquid LPCS-PZC ceramic precursor is more than 69 percent. The percent conversion of the ZrC-SiC superhigh temperature ceramics or the percent conversion of the fiber-reinforced ZrC-SiC superhigh temperature ceramic composite material ceramic is high, the technology is simple, and the high-temperature oxidation resistance of the obtained materials is good.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

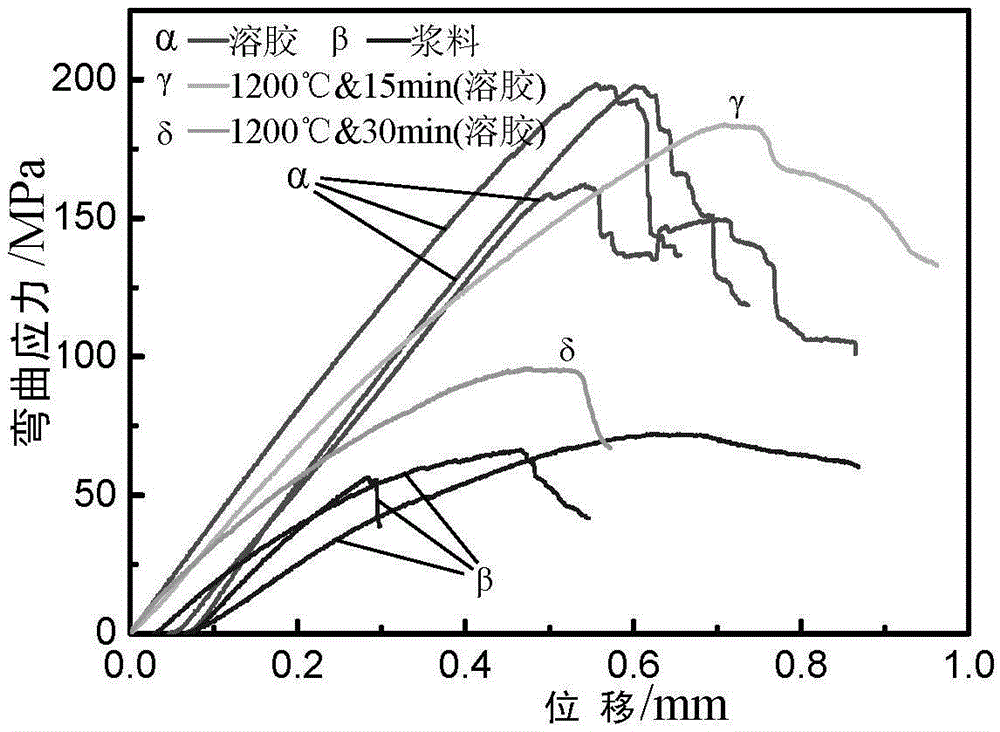

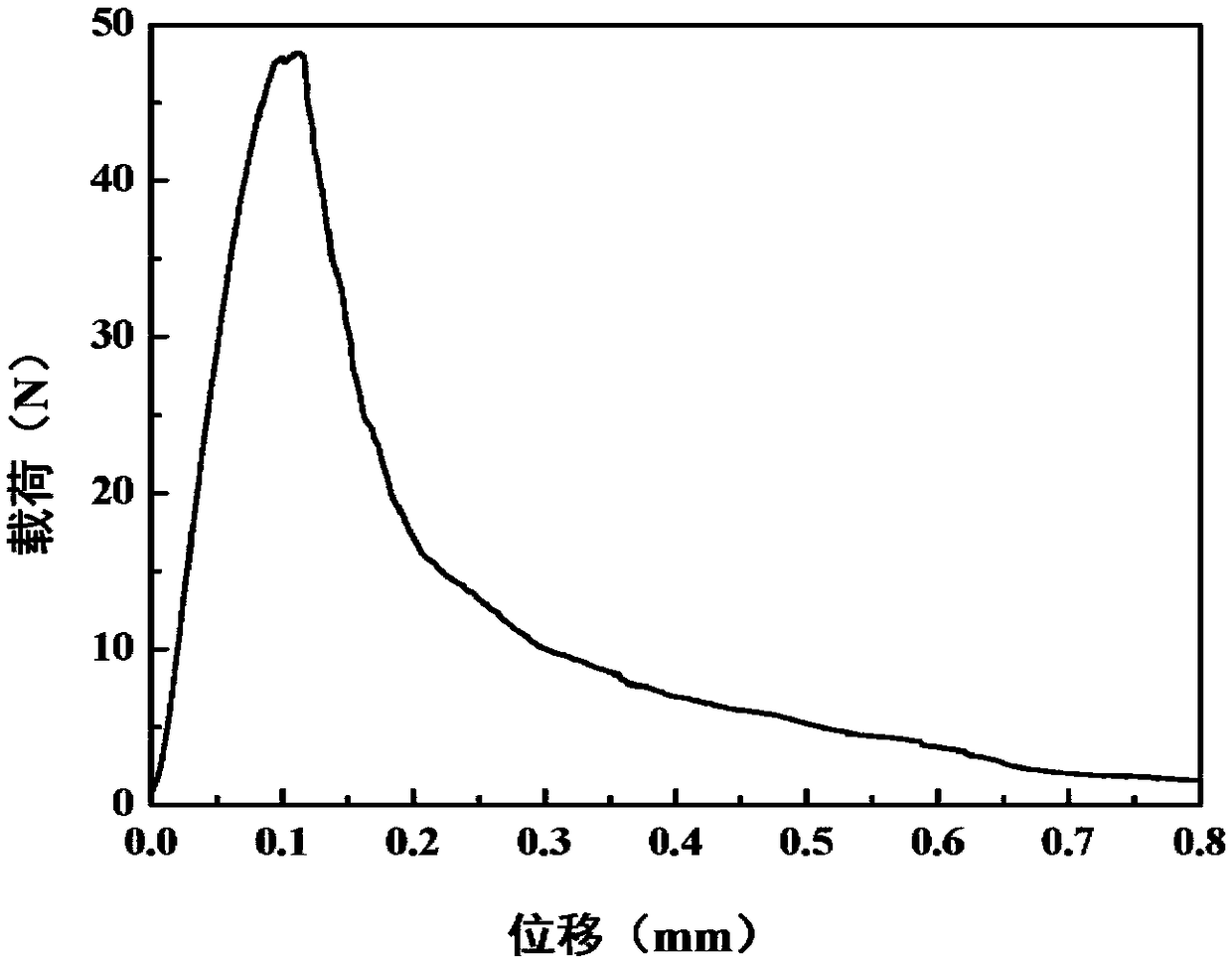

Preparation method of three-dimensional carbon fiber toughened ultrahigh-temperature ceramic-based composite material with high breaking work

The invention relates to a preparation method of three-dimensional carbon fiber toughened ultrahigh-temperature ceramic-based composite material with high breaking work, and belongs to the field of inorganic non-metal materials, and solves the problems of low content of ceramic components and low fracture work of three-dimensional carbon fiber toughened ultra-high temperature ceramic-based composite material obtained by the present preparation methods. The preparation method comprises the following steps of: 1, depositing a cracking carbon coating on the surface of a three-dimensional carbon fiber woven body; 2, mixing the ultra-high temperature ceramic powder with absolute ethyl alcohol and polyacrylic acid to obtain the ultra-high temperature ceramic slurry; 3, injecting the ceramic slurry into the three-dimensional carbon fiber braided body through a grouting device, and applying ultrasonic vibration when the resistance is to be injected and repeating the auxiliary grouting processfor a plurality of times; 4, performing a vibration-assisted vacuum impregnation process for a plurality of times; 5, performing discharge plasma sintering after molding. The intrinsic brittleness ofthe three-dimensional carbon fiber toughened ultrahigh-temperature ceramic-based composite material is obviously optimized, and the fracture power is up to 1,200J / m2.

Owner:HARBIN INST OF TECH

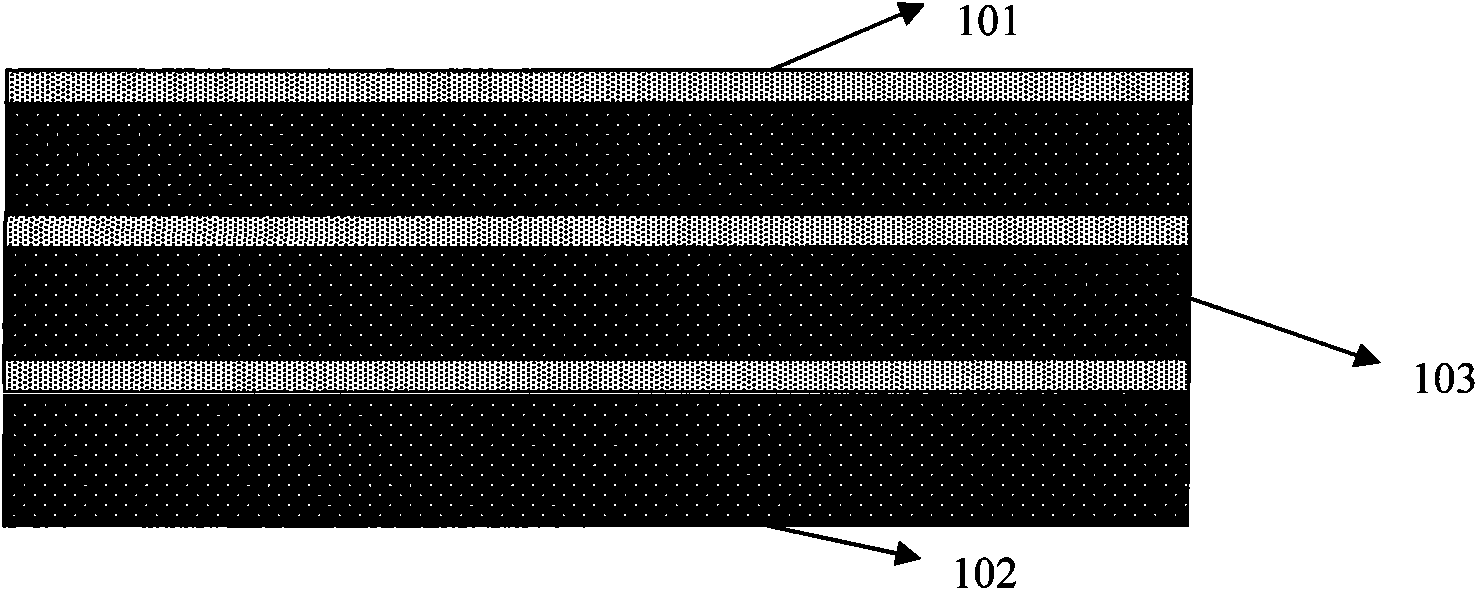

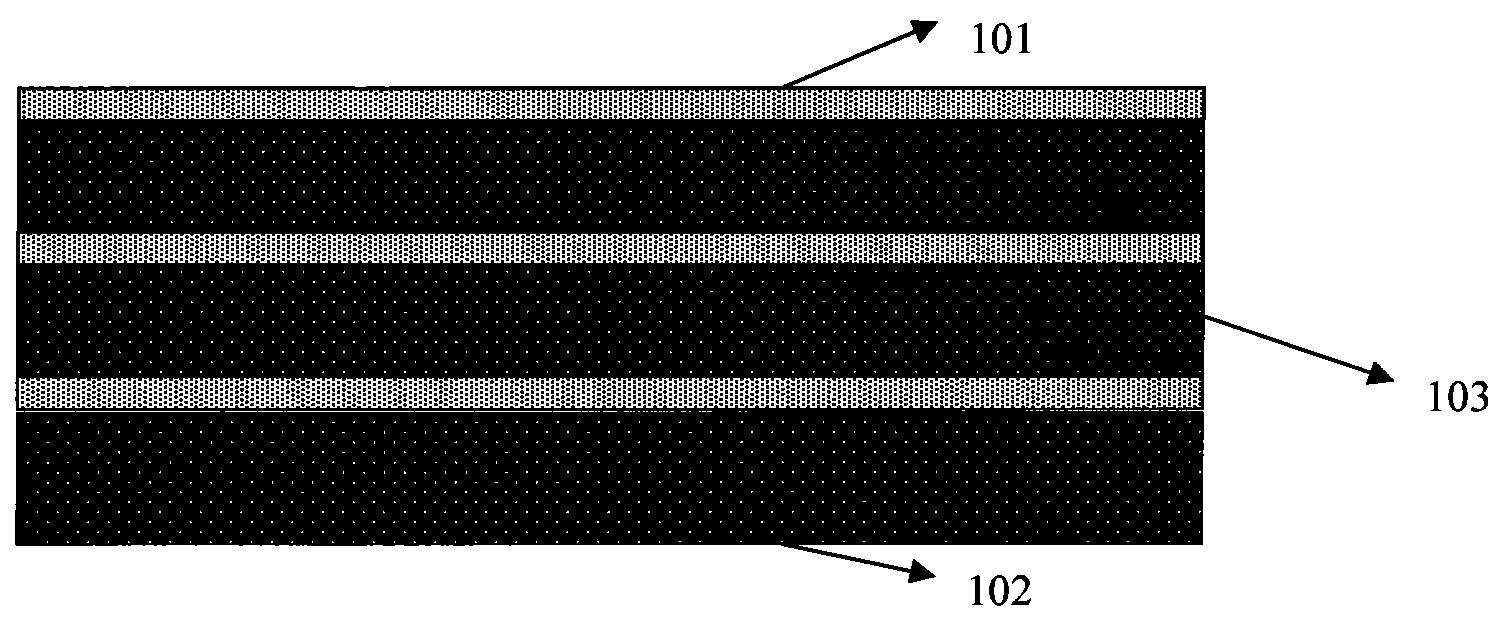

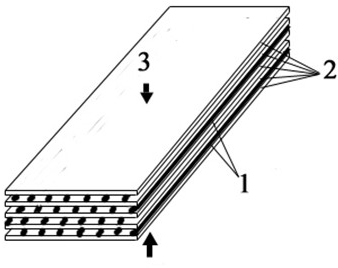

Process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic wafer material by tape casting

InactiveCN101844925AImprove fracture toughnessGive full play to antioxidantCeramic layered productsMultilayer membraneFlexural strength

The invention relates to ZrB2-SiC complex phase ultrahigh temperature ceramic, in particular to a process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic material by tape casting. The process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic material by tape casting is realized by the following steps: preparation of SiC ceramic biological membrane, preparation of ZrB2-SiC complex phase ceramic biological membrane, multilayer membrane stacking and laminating, binder removing and sintering; fracture toughness of the acquired multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic material reaches 7-12Mpa.m1 / 2, flexural strength is 600-800MPa. The two indexes are obviously higher than those of ZrB2-SiC complex phase ceramic prepared by conventional method.

Owner:南通市通州区益君劳务有限公司

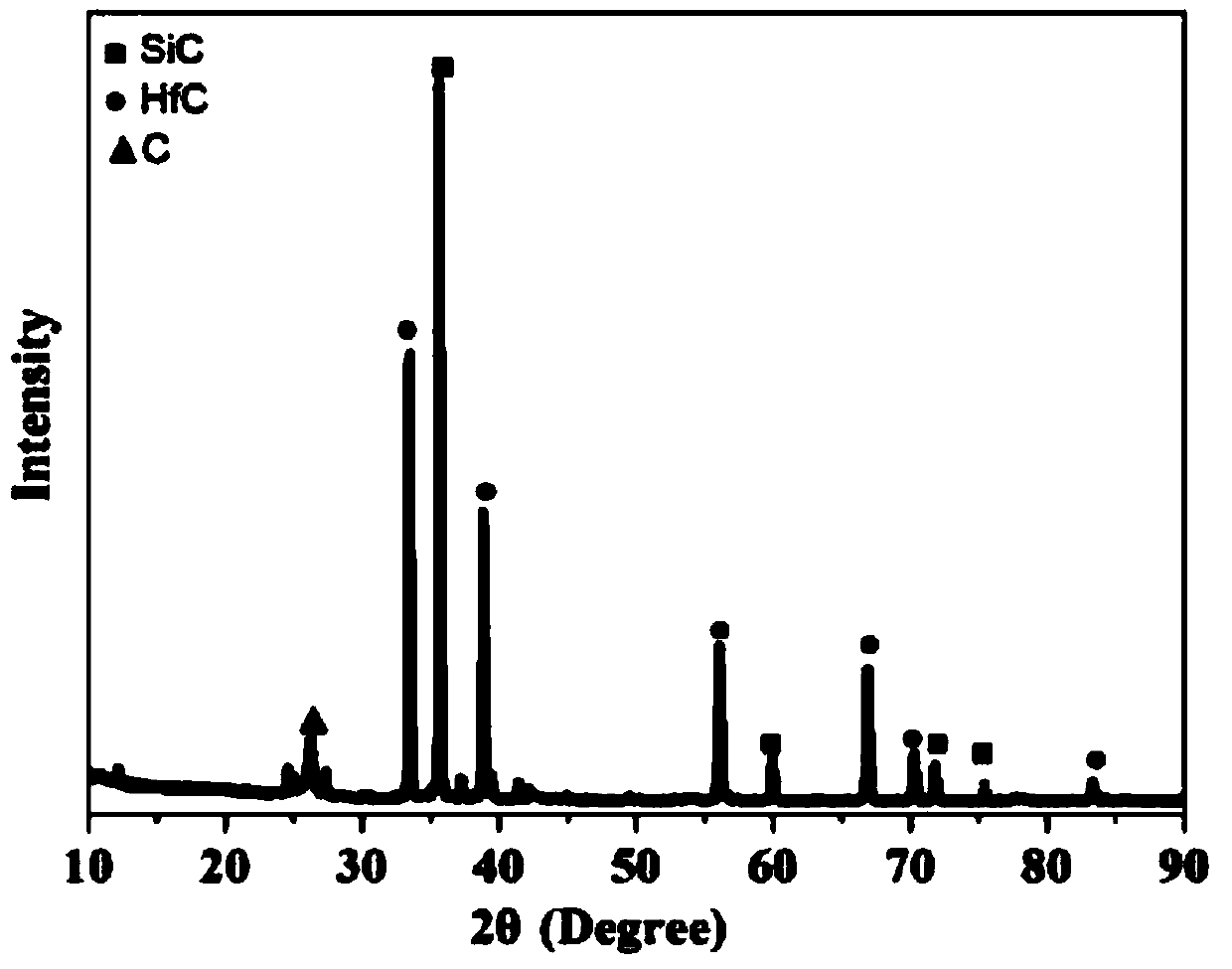

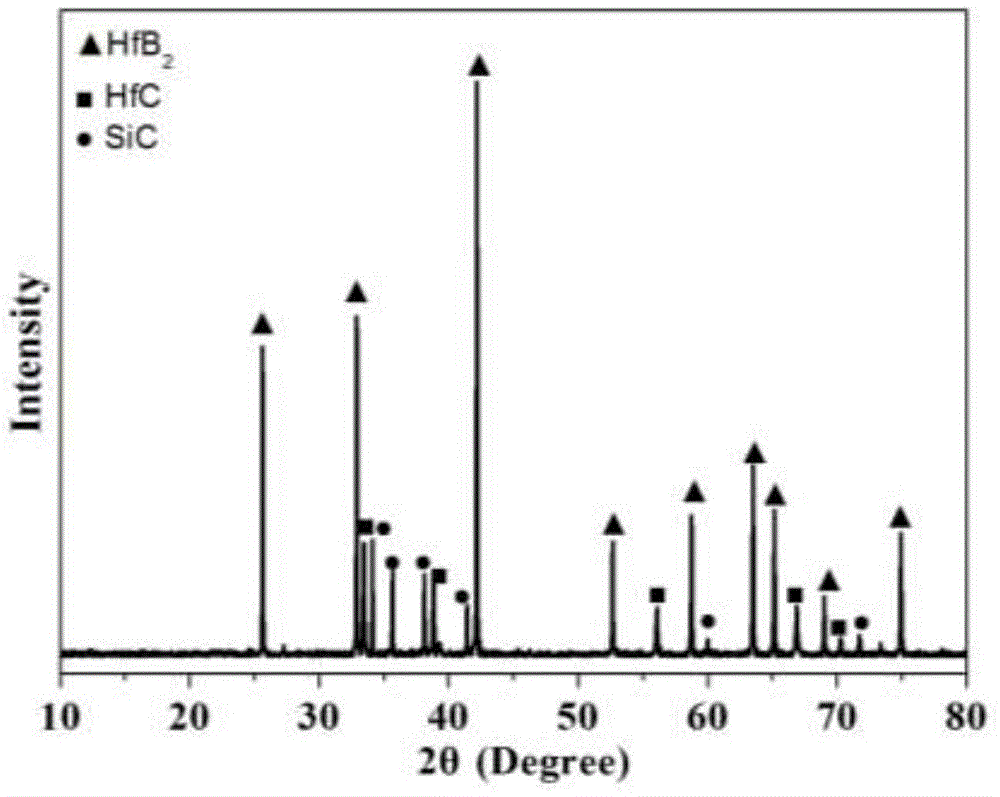

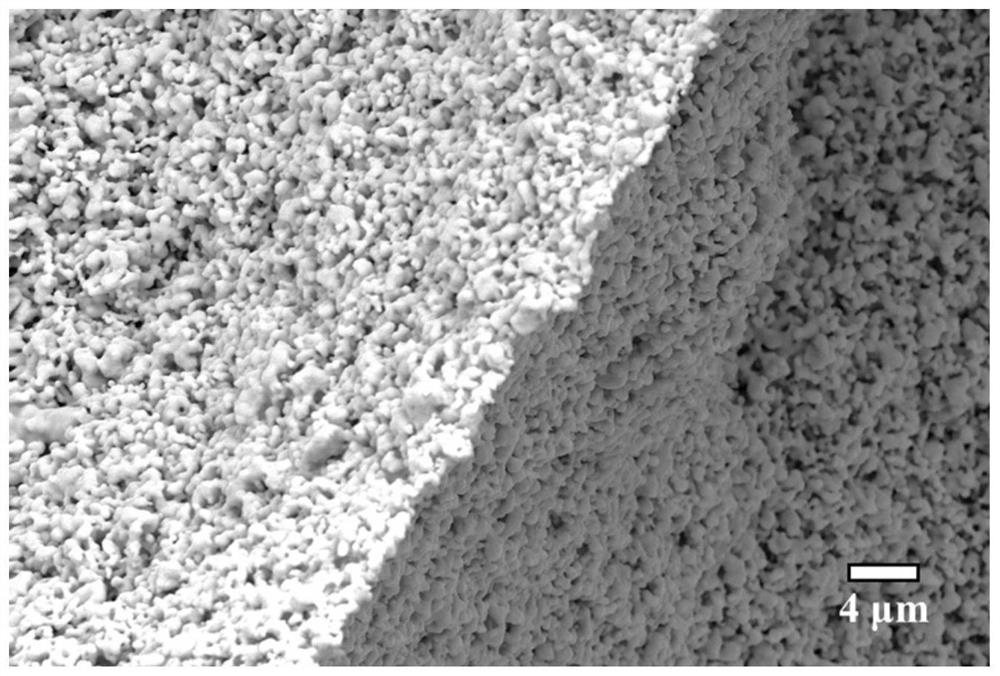

Preparation method of C/SiC-HfB2-HfC ultrahigh-temperature ceramic-based composite material

The invention relates to a preparation method of a C / SiC-HfB2-HfC ultrahigh-temperature ceramics-based composite material. B4C and an organic precursor of C are introduced on a prefabricated body of a fiber reinforced composite material in a manner of vacuum pressure immersion method. A silicon-hafnium alloy is reacted with B4C and C to obtain SiC, HfB2 and HfC in situ with a reaction melt infiltration method. The material has good mechanical properties and contains various anti-ablation components. The obtained HfB2 and HfC are fine in grystal grains, are high in volume content and has effectively-improved anti-ablation performance. The material preparation method of the invention is suitable for a composite material. An HfC phase, a SiC phase and an HfB2 phase can be generated. The volume fraction of hafnium compound phases in a substrate is effectively increased and the anti-ablation performance at an ultrahigh-temperature environment of the material is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of lamellar silicon carbide/zirconium carbide ultrahigh-temperature ceramic

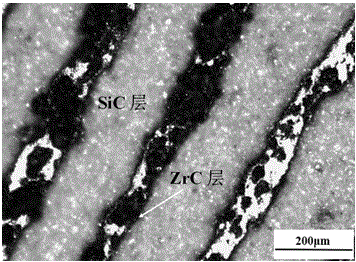

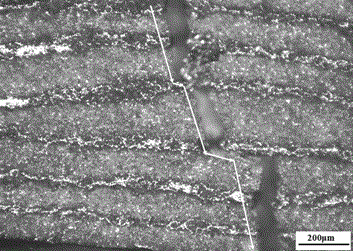

ActiveCN104478436APromote carbonizationGood steric stabilityCeramic layered productsPolymethyl methacrylatePolyethylene glycol

The invention belongs to the technical field of preparation of an ultrahigh-temperature ceramic, and particularly relates to a preparation method of a lamellar silicon carbide / zirconium carbide ultrahigh-temperature ceramic. The preparation method comprises the following steps of: preparing a silicon carbide tape-casting sheet and a zirconium carbide tape-casting sheet by adopting a tape-casting method; then alternately stacking the silicon carbide tape-casting sheet and the zirconium carbide tape-casting sheet; then carrying out glue discharge and vacuum sintering. According to the preparation method, the usage amounts of polymethyl methacrylate, polyethylene glycol, ethanol and n-octyl alcohol are limited, so that a prepared tape-casting sheet is smooth in surface and generates no bubble; the glue discharge, sintering temperature, temperature increase speed and sintering pressure are limited in regulation and control, so that the prepared lamellar ultrahigh-temperature ceramic has the advantages of clearness in interface, moderation in strength and good ceramic compactness and is enhanced in fracture toughness by changing a crack propagation path.

Owner:嘉兴睿创新材料有限公司

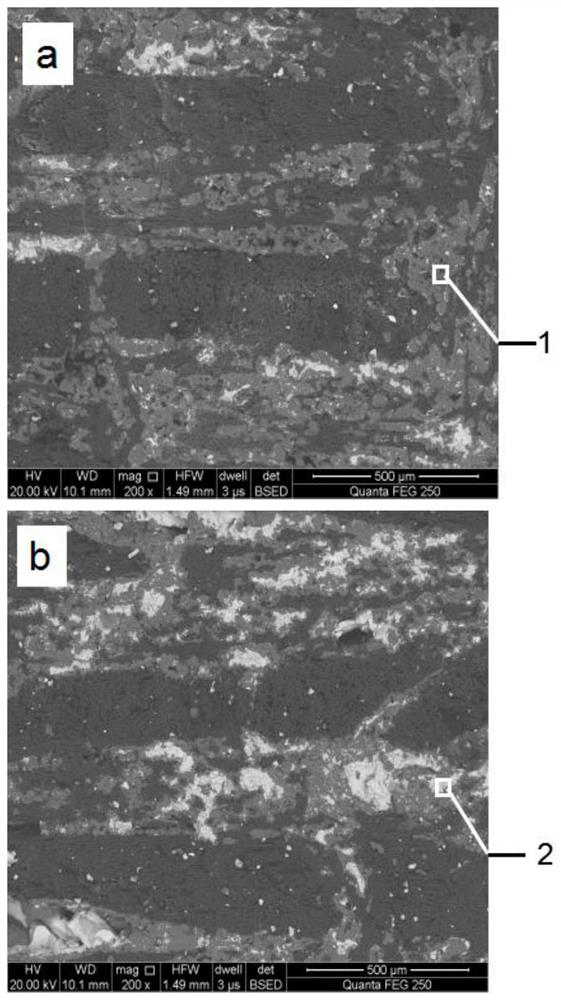

Preparation method of ultrahigh-temperature ceramic modified C/C composite material

ActiveCN110803942AReduce SiC contentSolve the problem of excessive SiC contentMolten saltUltrahigh temperature ceramics

The invention discloses a preparation method of an ultrahigh-temperature ceramic modified C / C composite material, and the method comprises the following steps: carrying out reactive infiltration treatment on a C / C composite material preform to obtain the ultrahigh-temperature ceramic modified C / C composite material; wherein during the reactive infiltration treatment, infiltration powder containinga reactive molten salt is used as an infiltration raw material, and the infiltration powder comprises Zr-Si mixed powder, K2ZrF6 powder and an alkali metal salt; according to the invention, the reactive molten salt is used as the infiltration raw material for the first time, a molten salt method is combined with reaction infiltration to realize two-step infiltration in a C / C matrix, the C / C-UHTCscomposite material with ultrahigh content of ZrC ceramic is formed through reaction, and the content of ZrC in the matrix is greater than or equal to 83%; and the ablation resistance is greatly improved.

Owner:深圳金羽先进材料有限公司

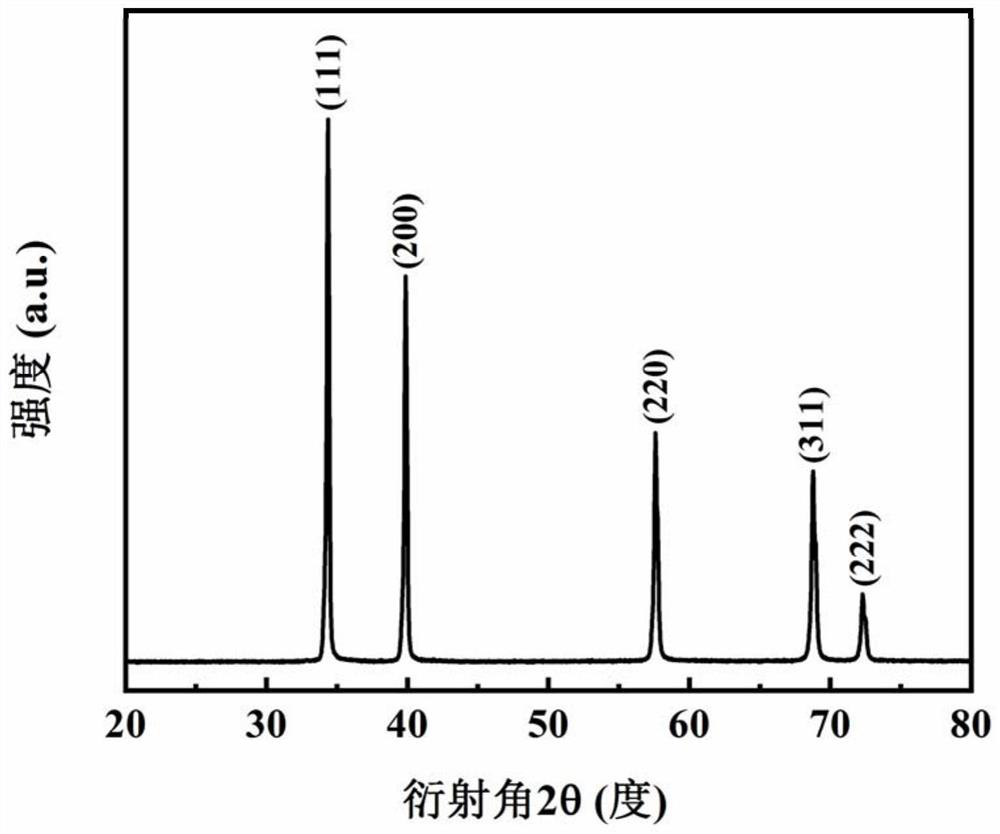

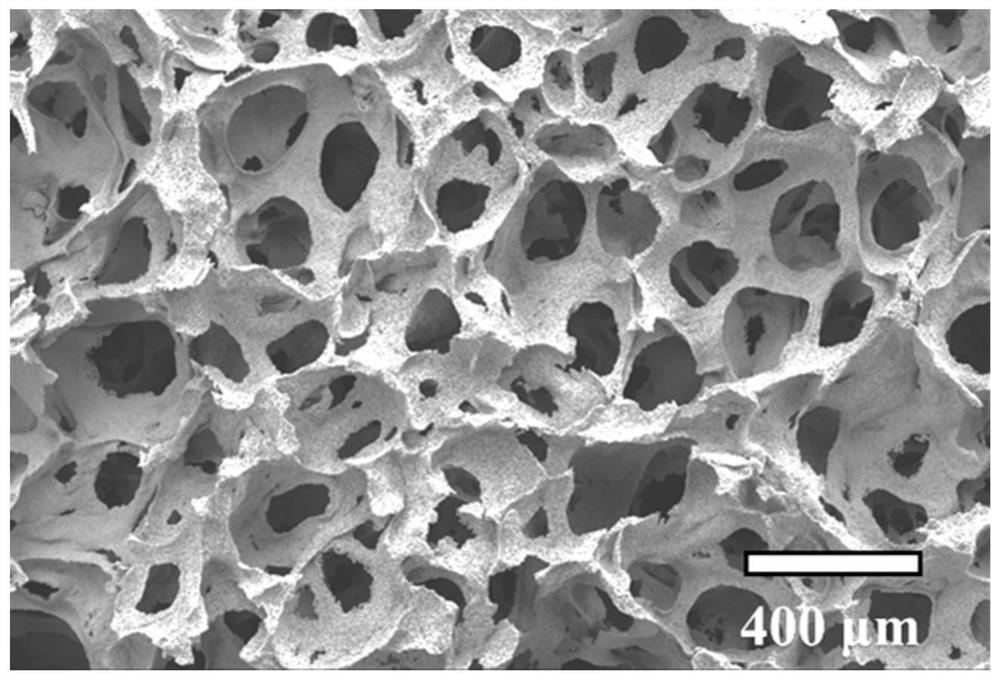

High-entropy carbide ultrahigh-temperature ceramic with ultrahigh porosity and preparation method

The invention relates to the field of porous high-entropy ultrahigh-temperature ceramic thermal insulation materials, in particular to ultrahigh-porosity high-entropy carbide ultrahigh-temperature ceramic and a preparation method thereof, wherein the framework matrix material of the porous (ZraHfbNbcTadXe) C ceramic is a single-phase high-entropy ultrahigh-temperature ceramic with a face-centered cubic structure, calculated as atomic percent, the value range of a, b, c, d and e is 10-35%, a + b + c + d + e is equal to 1, and X is Ti, W, V, Cr or Mo. The preparation method comprises: taking mixture powder of five carbides as a raw material, preparing slurry of the mixture powder, adding a foaming agent, foaming, adding a gel, carrying out injection molding, and freezing and drying; and presintering at a temperature of 1300-1550 DEG C, and carrying out high-temperature non-pressure in-situ reaction sintering at a temperature of 1750-2000 DEG C to prepare the porous high-entropy ultrahigh-temperature ceramic thermal insulation material. The ultrahigh-temperature thermal insulation material synthesized by the invention has the advantages of ultrahigh porosity (83-96%), low density (0.25-1.90 g / cm<3>), high strength (0.21-16.92 MPa), low thermal conductivity (0.10-0.35 W / (m.K)) and ultrahigh temperature (more than 2000 DEG C)resistance, and has a wide application prospect in the field of aerospace thermal protection.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

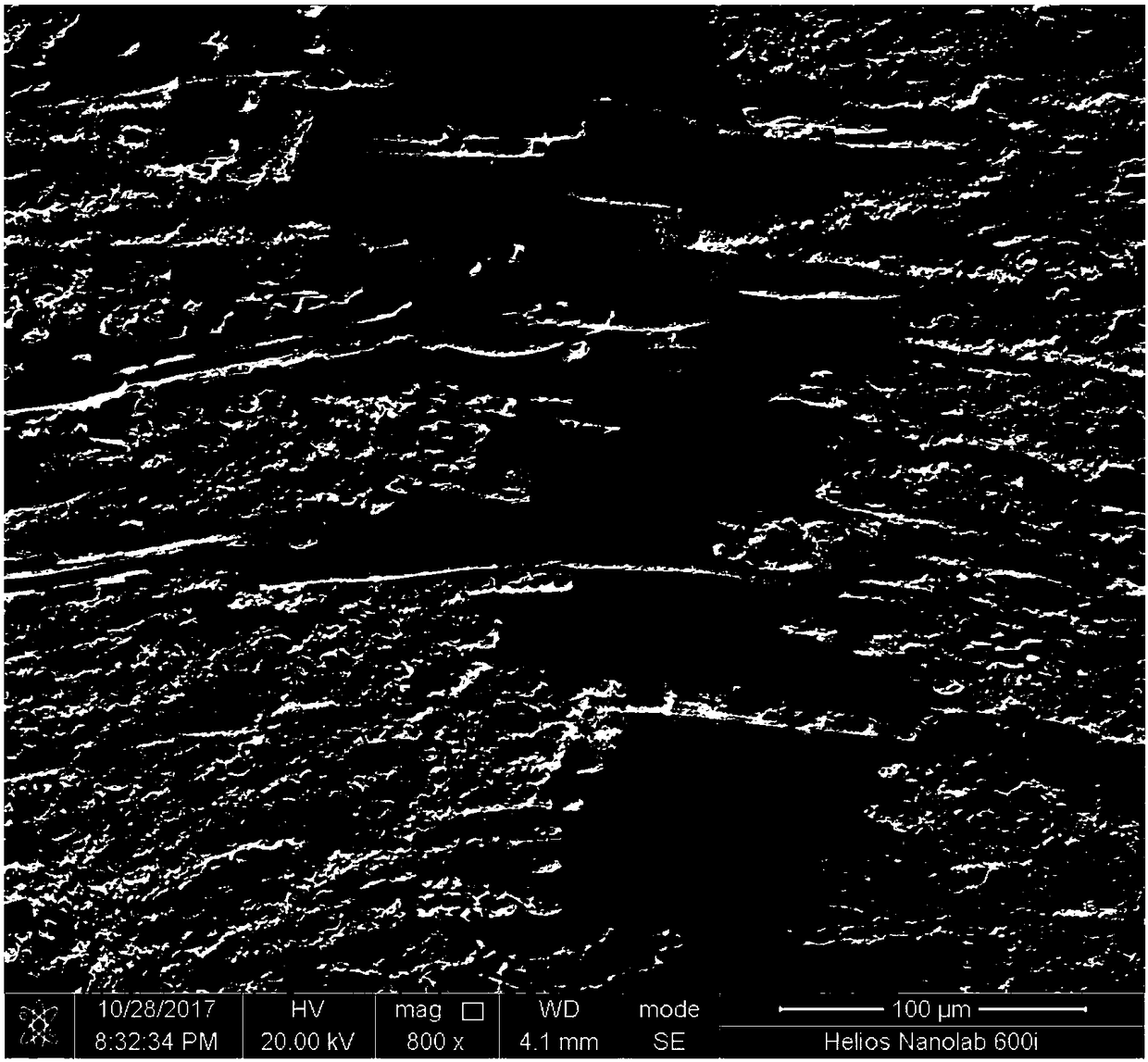

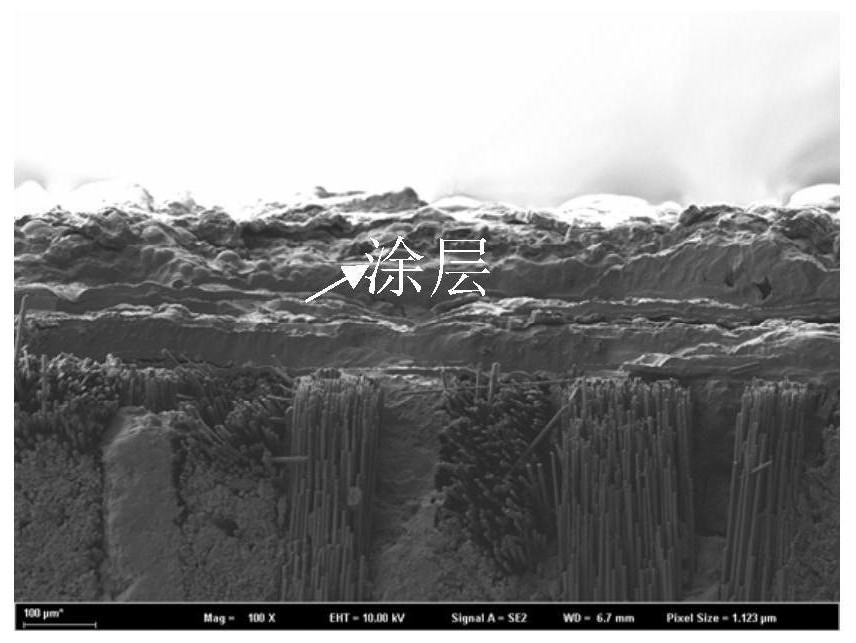

Extremely-high-temperature anti-ablation heat conduction composite material and preparation method thereof

ActiveCN113563091AImprove thermal conductivityImprove anti-ablation performanceCarbon fibersCeramic coating

The invention relates to an extremely-high-temperature anti-ablation heat conduction composite material and a preparation method thereof. The method comprises the following steps of: mixing and weaving high-thermal-conductivity carbon fibers and polyacrylonitrile-based carbon fibers to form a high-thermal-conductivity carbon fiber preform, or weaving high-thermal-conductivity carbon fiber rods to form the high-thermal-conductivity carbon fiber preform; preparing a carbon interface layer on the fiber surface of the high-thermal-conductivity carbon fiber preform by adopting a chemical vapor deposition method and a high-temperature graphitization treatment method in sequence to obtain a heat conduction composite preform; sequentially using a polycarbosilane ceramic precursor and a hafnium tantalum ceramic precursor as impregnation liquid so as to make the heat conduction composite material preform subjected to a PIP process to prepare a heat conduction ultrahigh-temperature ceramic-based composite material; and preparing an anti-ablation ceramic coating on the surface of the heat conduction ultrahigh-temperature ceramic-based composite material to prepare the extremely-high-temperature anti-ablation heat conduction composite material. The extremely-high-temperature anti-ablation heat conduction composite material prepared by the method of the invention has the advantages of high heat conductivity, high density, excellent mechanical properties, excellent high-temperature anti-ablation performance and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

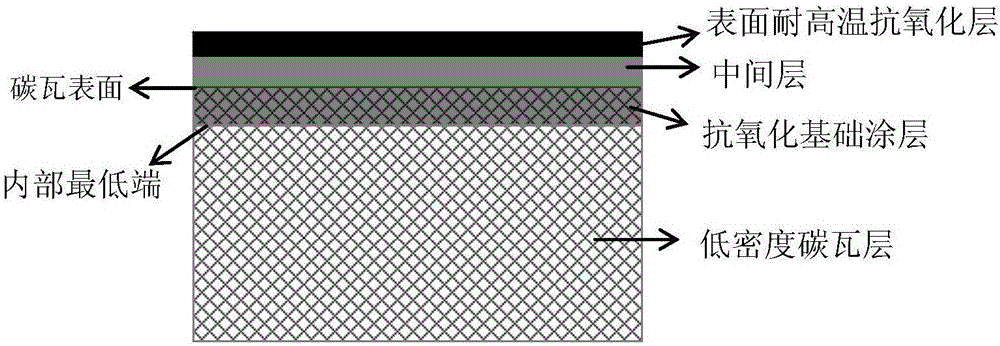

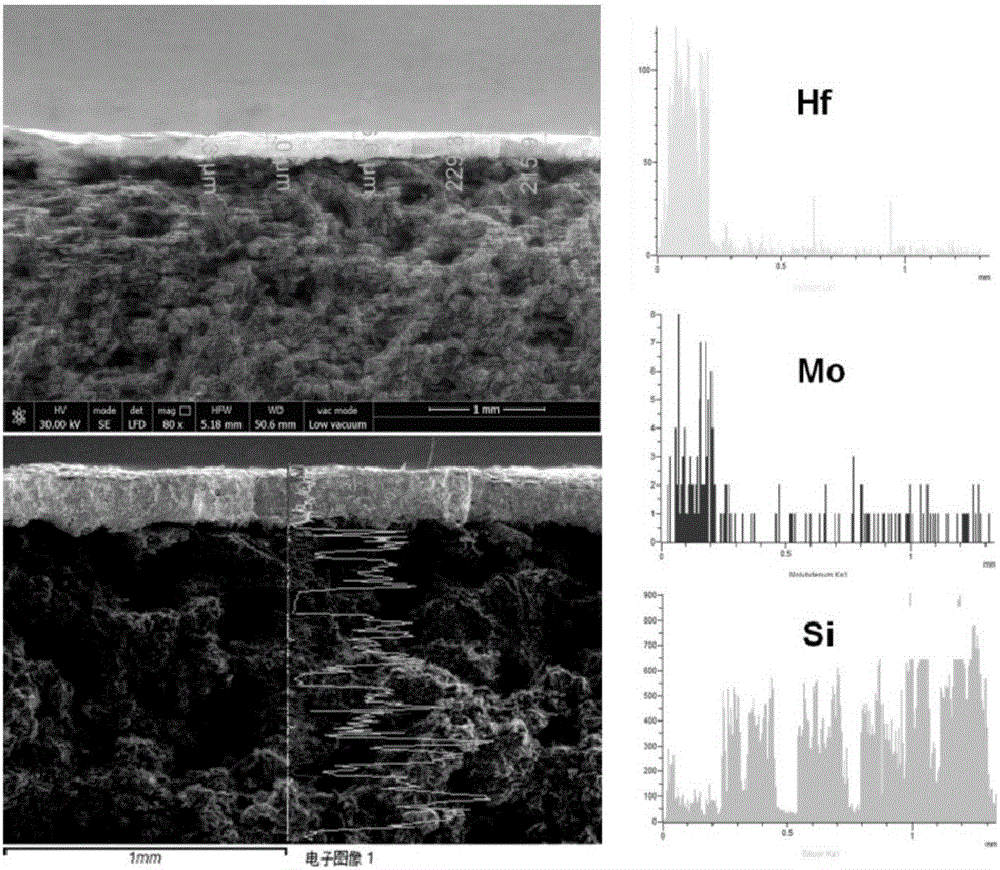

Low-density carbon-tile surface oxidation-resistant coating capable of resisting temperature of 1700 DEG C and preparation method thereof

The invention relates to a low-density carbon-tile surface oxidation-resistant coating capable of resisting the temperature of 1700 DEG C and a preparation method thereof, and belongs to the technical field of heat protective materials. For the requirement of heat protective systems of novel near-space aerocrafts and reusable launch vehicles for the heat protective materials with integrated functions of high-temperature resistance, light weight and heat insulation, the invention provides a low-density carbon-tile surface oxidation-resistant coating system capable of resisting the temperature of 1700 DEG C and a preparation method thereof. The coating is a composite coating with a gradient transition structure. The composite coating comprises an oxidation-resistant layer and a surface high-temperature-resistant oxidation-resistant layer, wherein the oxidation-resistant layer is formed by doping oxidation-resistant components such as Si, B, C and O and the like in a porous carbon-fiber skeleton; and the surface high-temperature-resistant oxidation-resistant layer is composed of compact M(M is Hf, Zr)B2-MoSi2 ultrahigh-temperature ceramic components.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

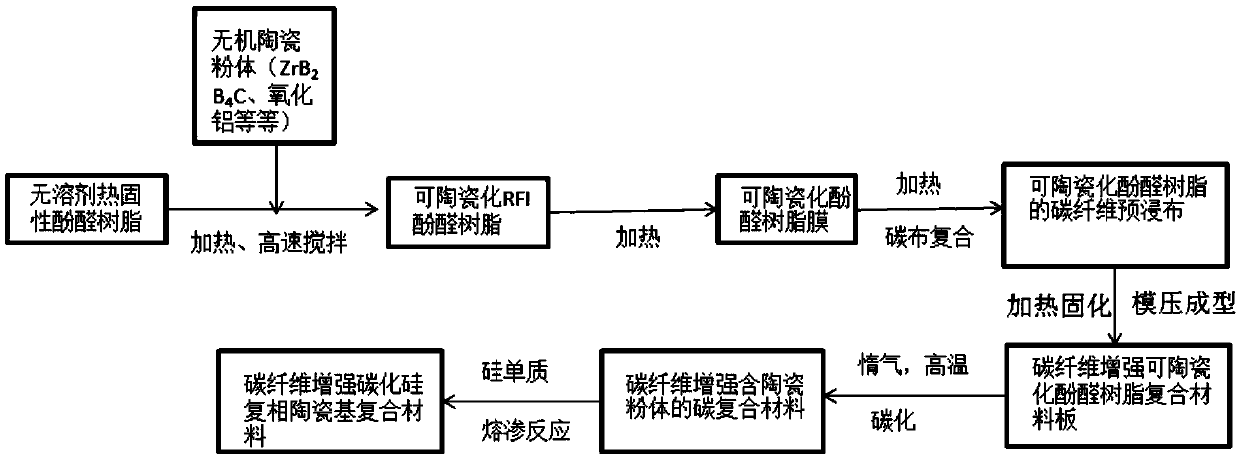

Ceramic-able phenolic resin, and preparation method and application thereof

The invention provides a ceramic-able phenolic resin, and a preparation method and an application thereof; the ceramic-able phenolic resin has effects of high temperature resistance, high carbon residue and anti-oxidization, is excellent in processability, can satisfy technical requirement of RFI, and can be used for preparing a fiber-reinforced silicon carbide ceramic-based composite material athigh efficiency and quality. The ceramic-able phenolic resin is good in designability on formula, wherein according to practical work temperatures, different ultrahigh temperature ceramic powders, such as boron carbide, silicon carbide, zirconium boride, hafnium carbide, tantalum carbide, SiO2, Al2O3, zirconia and the like, can be selected. In the invention, the fiber-reinforced silicon carbide ceramic-based composite material is produced through a reactive infiltration process of silicon simple substance; compared with a conventional precursor impregnation cracking method, the preparation method is low in raw material cost, short in shaping period, simple in processes, strong in operability, low in manufacturing cost and high in shaping quality. The phenolic resin is convenient in industrial large-scale preparation and is easy to promote and apply.

Owner:INST OF CHEM CHINESE ACAD OF SCI

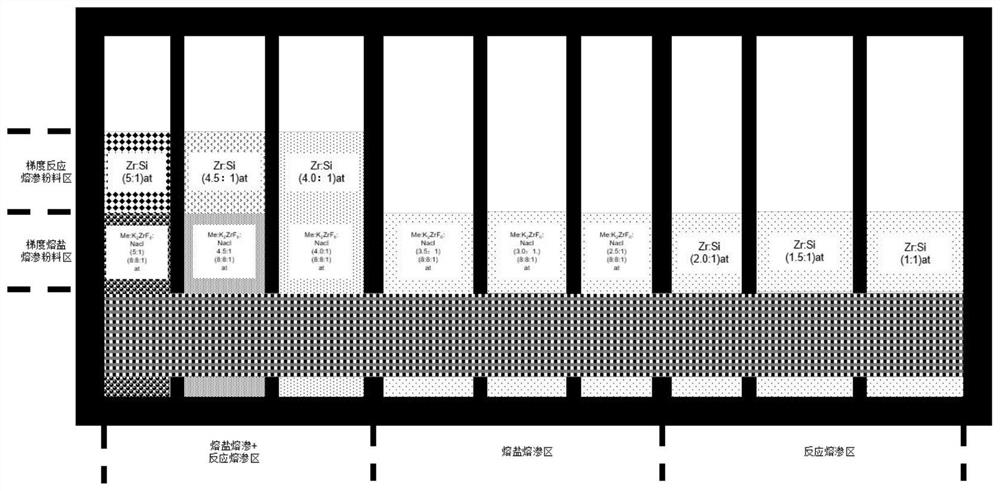

Preparation method of component- gradient -controllable multi-element ultrahigh-temperature ceramic modified C/C composite material

ActiveCN112457056AAvoid stress concentrationImprove anti-ablation performanceCeramicwareMolten saltUltrahigh temperature ceramics

The invention discloses a preparation method of a component-gradient-controllable multi-element ultrahigh-temperature ceramic modified C / C composite material. Through multi-section design of various ultrahigh-temperature ceramics (ZrC, HfC, HfB2 and the like) and high-temperature ceramic (SiC) composite modified C / C composite materials, a ceramic phase forms a continuous component gradient distribution form in a C / C matrix, ablation resistance and oxidation resistance requirements of different temperature range fields are met regionally, and meanwhile the defect that the mechanical property isreduced due to component mutation is overcome. According to the invention, a preparation process of combining molten salt infiltration and common reaction infiltration and gradient infiltration powder configuration are adopted in sections, so that near-ablation-end strong ceramic phase interface design is realized, and ceramic phase distribution realizing that the content of an ultrahigh-temperature ceramic phase is sequentially decreased from the near ablation end to a far ablation end and the high-temperature ceramic phase is sequentially increased is regulated and controlled; finally, thegradient ceramic-based composite material with different ceramic phase components and contents in gradient change and meeting the performance requirements of the material is formed.

Owner:CENT SOUTH UNIV

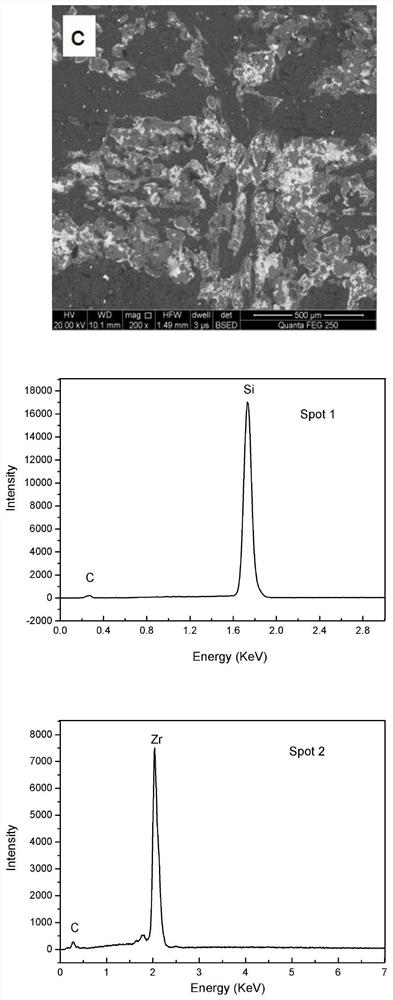

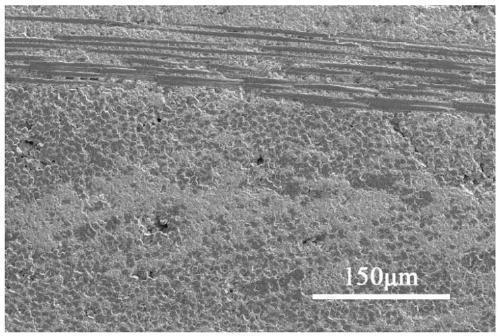

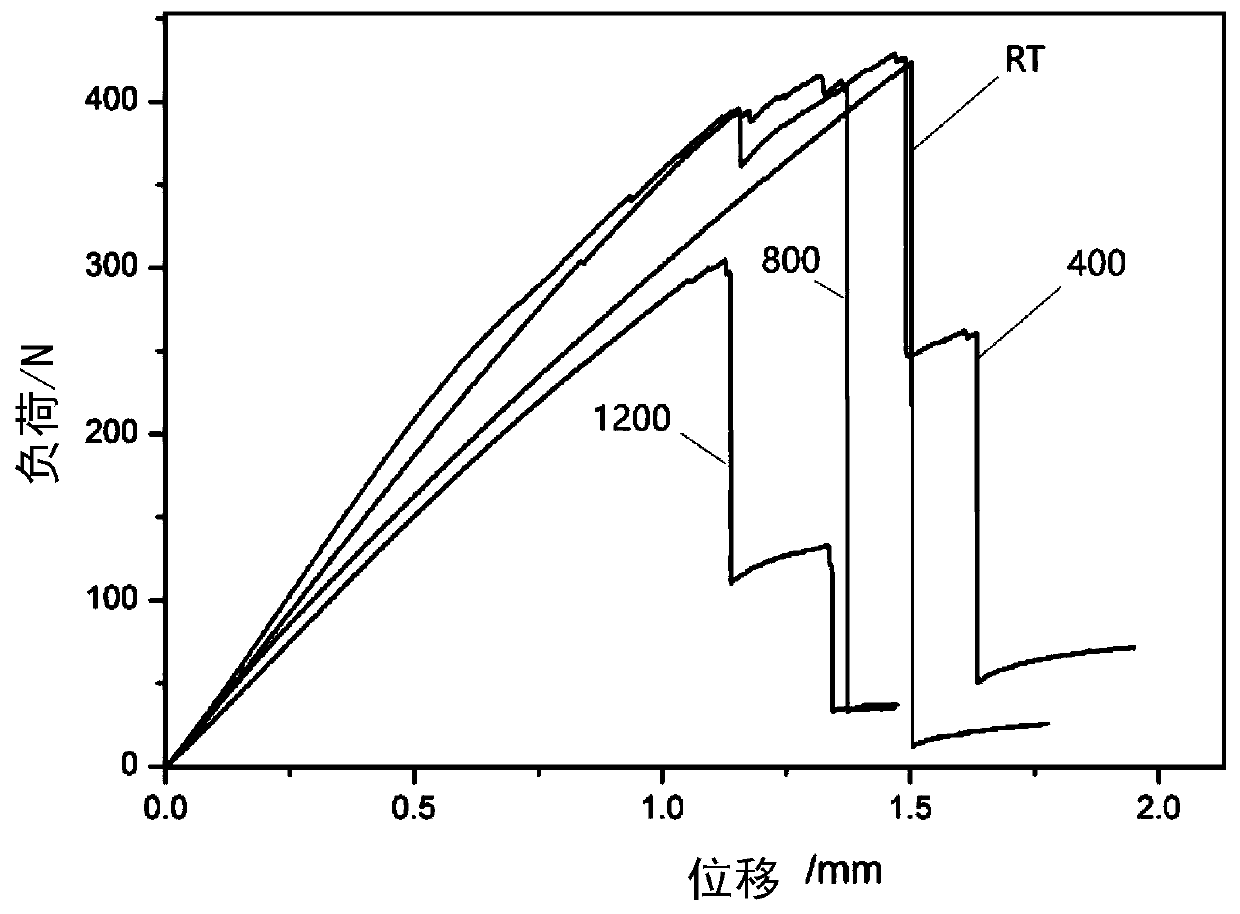

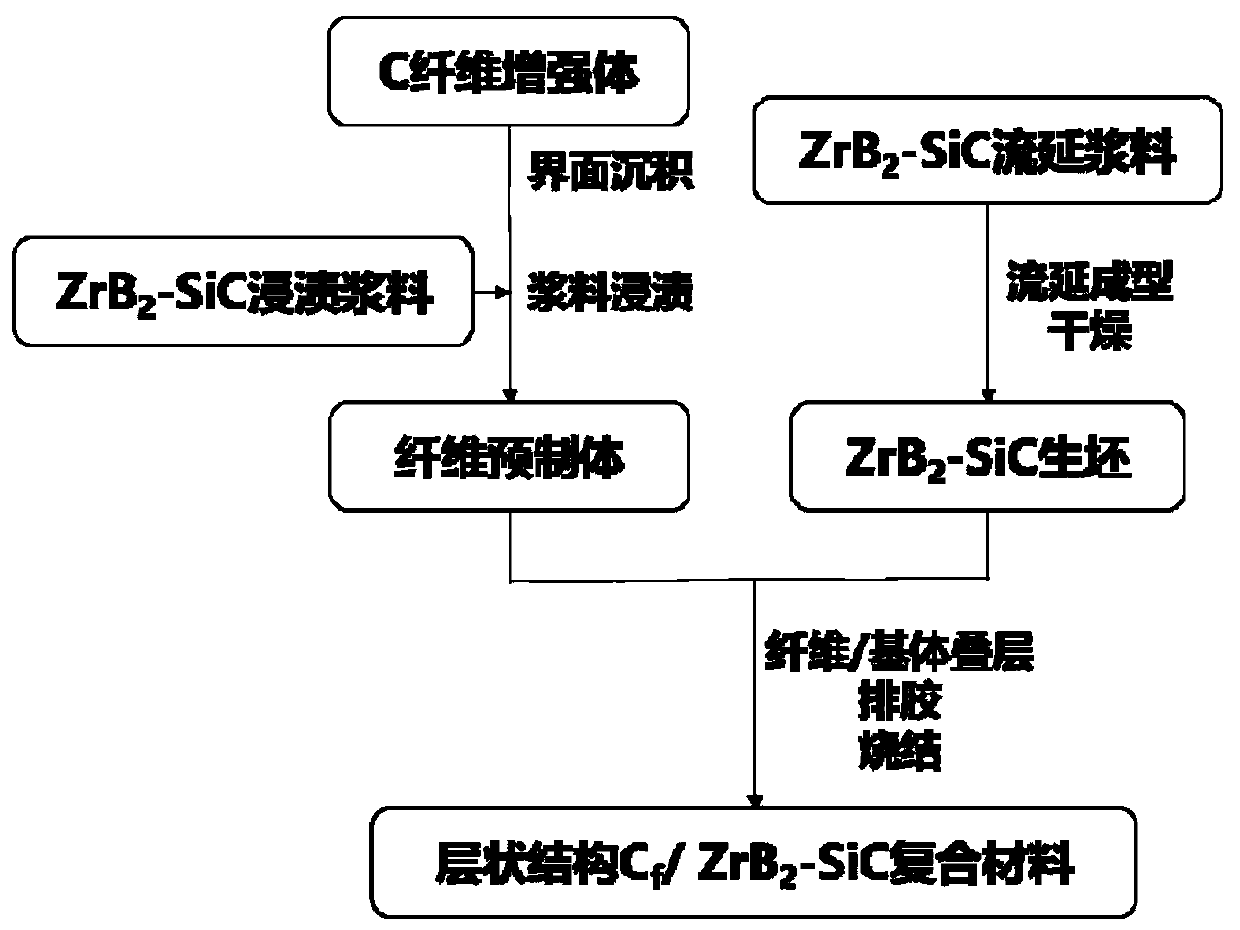

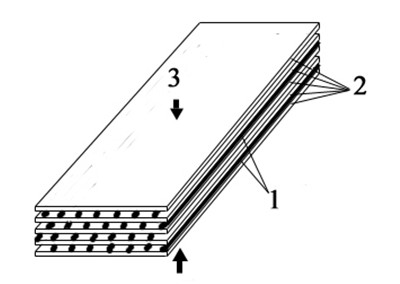

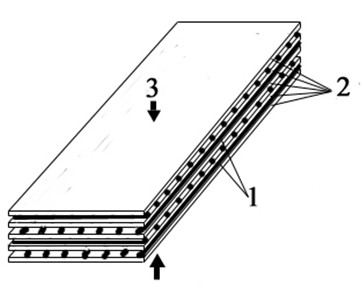

Cf/ZrB2-SiC ultrahigh-temperature ceramic matrix composite material of laminated structure and preparing method thereof

The invention relates to a Cf / ZrB2-SiC ultrahigh-temperature ceramic matrix composite material of a laminated structure and a preparing method thereof. The preparing method comprises the steps of 1, adding ZrB2 powder, SiC powder, a dispersing agent and a binder into a solvent, and mixing the materials to obtain ZrB2-SiC slurry; 2, adopting a casting forming method for preparing the ZrB2-SiC slurry into ZrB2-SiC biscuits; 3, impregnating a carbon fiber fabric body with the ZrB2-SiC slurry to obtain carbon fiber preforms; 4, alternatively laminating the obtained ZrB2-SiC biscuits and the carbonfiber preforms at least once, and then conducting glue discharge and sintering to obtain the Cf / ZrB2-SiC ultrahigh-temperature ceramic matrix composite material of the laminated structure.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

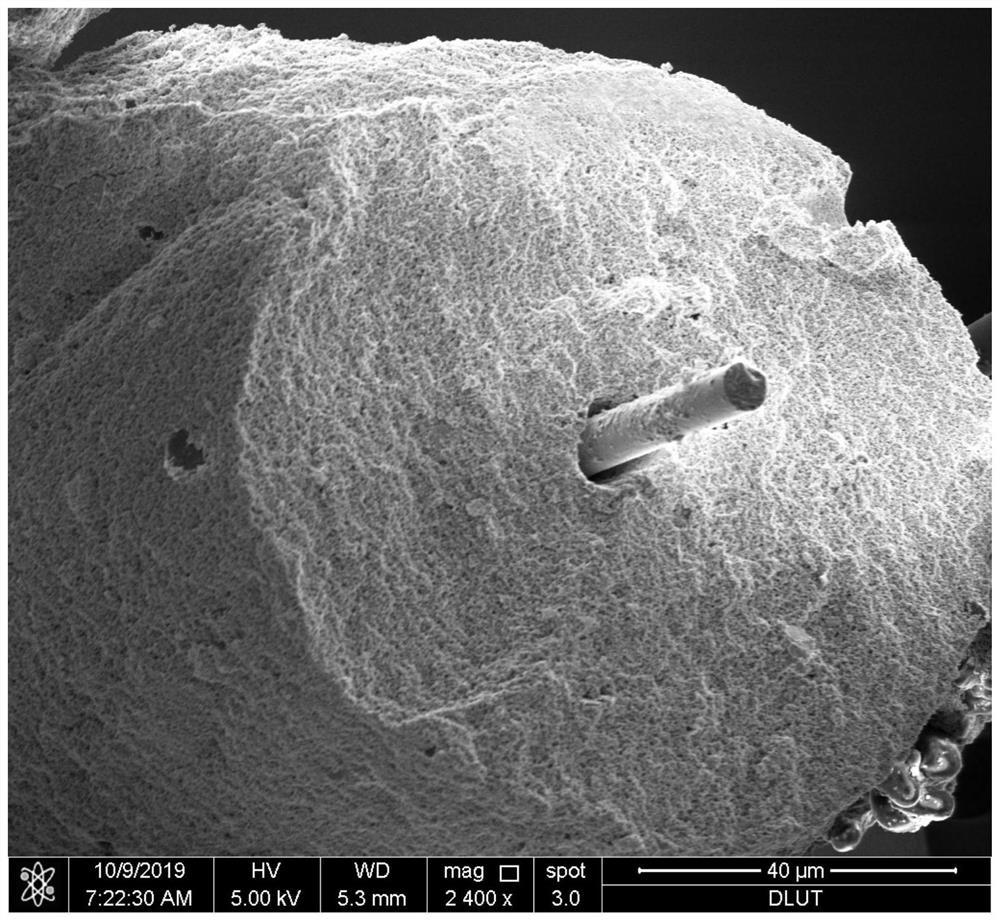

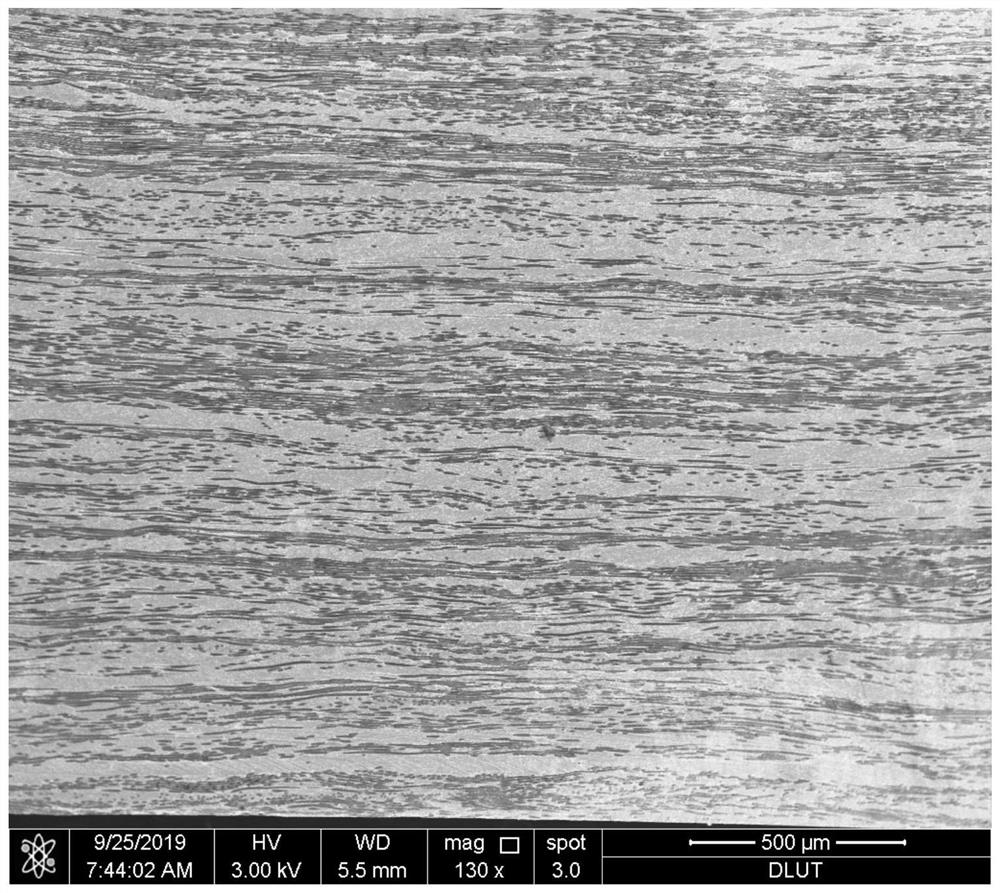

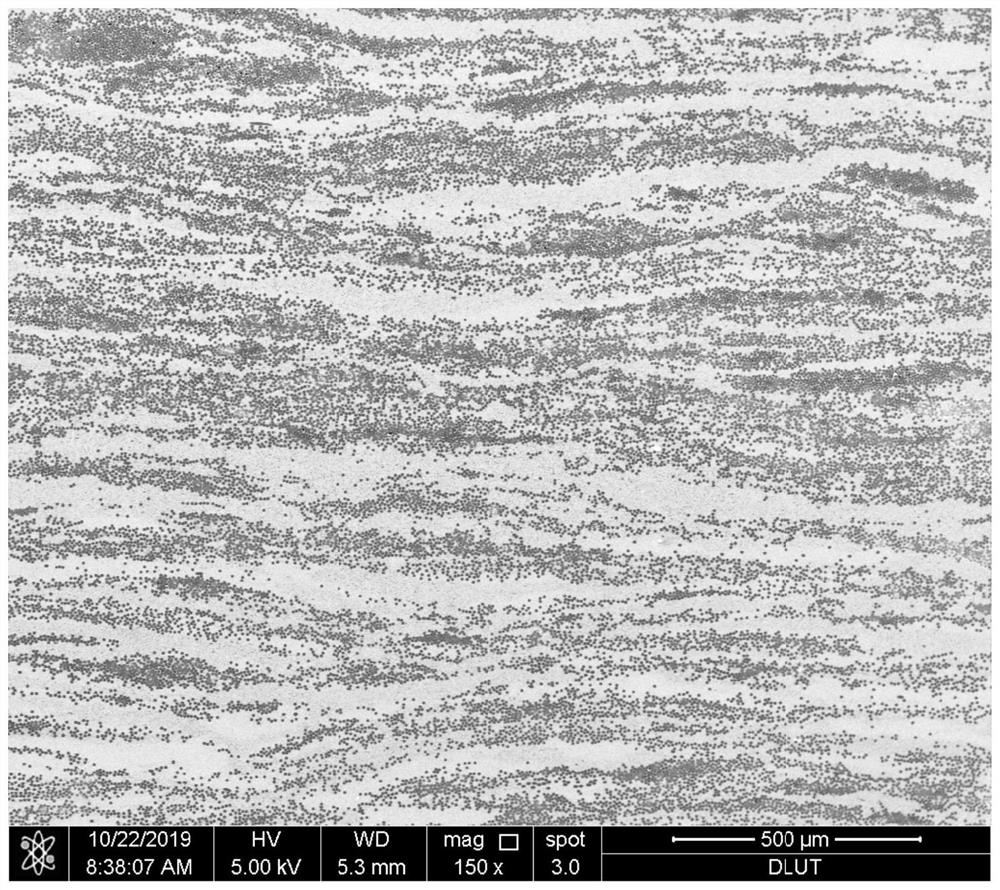

Method for preparing continuous carbon fiber toughened ultrahigh-temperature ceramic-based composite material through electrophoretic deposition

ActiveCN111825471ASolve the problem that the preparation is difficult to densifyAvoid chemical reaction erosion problemsCarbon fibersFiber bundle

The invention belongs to the field of ultrahigh-temperature ceramic matrix composite materials, and particularly relates to a method for preparing a continuous carbon fiber toughened ultrahigh-temperature ceramic matrix composite material by electrophoretic deposition. The method comprises the following steps: preparing a polydopamine coating on carbon fibers; secondly, adsorbing polyethyleneimineon the surface of the ultrahigh-temperature ceramic powder and electrifying the ultrahigh-temperature ceramic powder; then, uniformly depositing charged ultrahigh-temperature ceramic powder on the carbon fiber containing the polydopamine coating through an electrophoretic deposition technology; and finally, carrying out hot pressed sintering to obtain the compact continuous carbon fiber toughenedultrahigh-temperature ceramic-based composite material. The preparation method has the effects and benefits that firstly, the ultrahigh-temperature ceramic powder is effectively introduced into the carbon fiber bundle so that the problem that the continuous carbon fiber toughened ultrahigh-temperature ceramic-based composite material is difficult to densify in preparation is solved; and secondly,chemical corrosion of the carbon fibers is avoided, matrix components are optimized, a good fiber-matrix interface is obtained, and the fracture resistance and the ultra-high temperature resistance of the composite material are improved.

Owner:DALIAN UNIV OF TECH

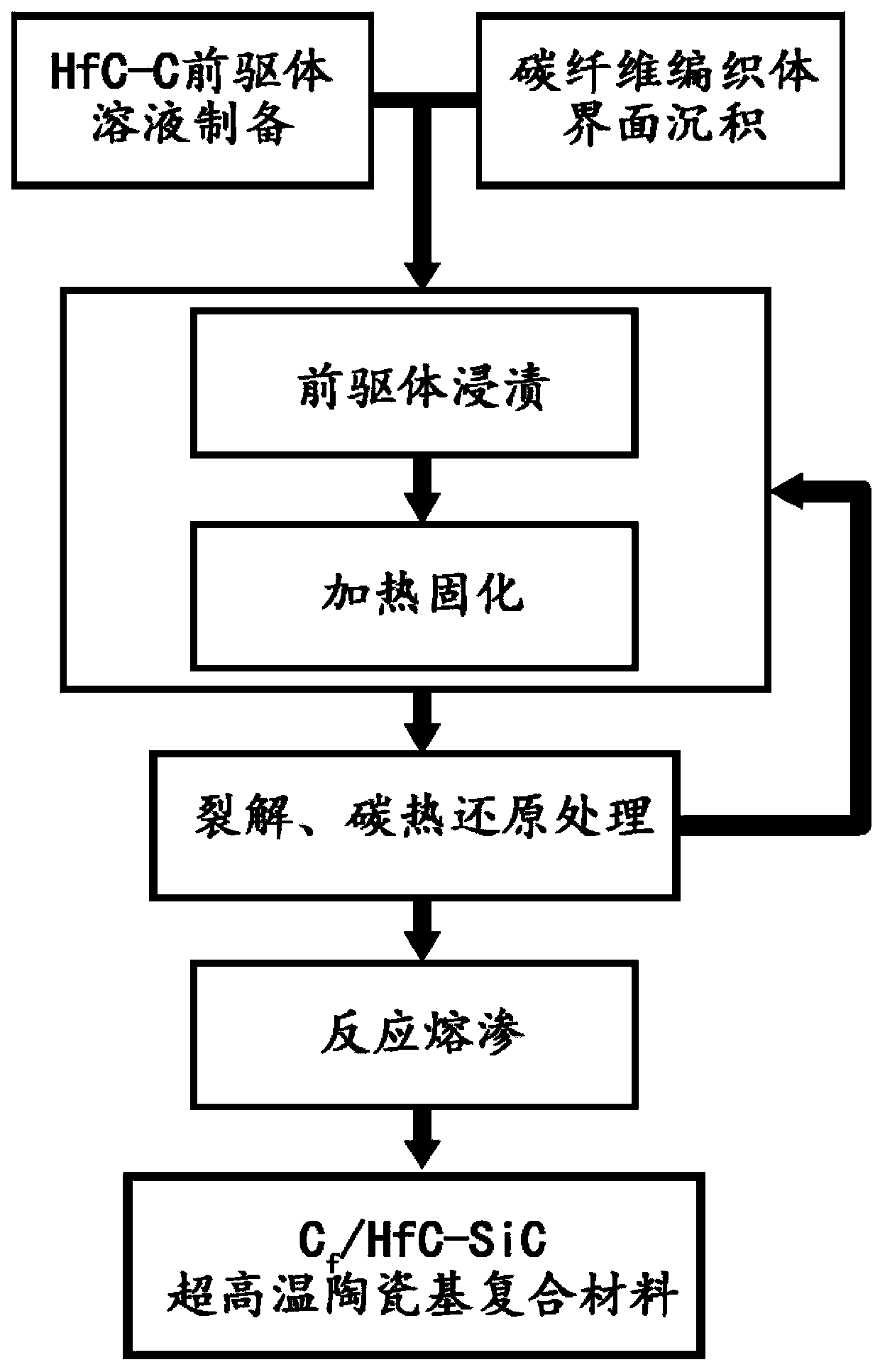

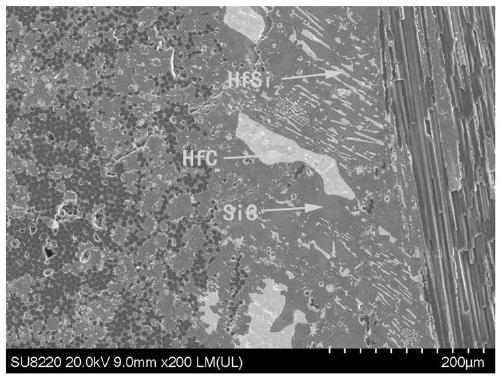

Cf/HfC-SiC ultrahigh temperature ceramic matrix composite material and preparation method thereof

The invention relates to a Cf / HfC-SiC ultrahigh temperature ceramic matrix composite material and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving a hafnium source compound, a carbon source compound and a stabilizer in a solvent to obtain a HfC-C precursor solution, wherein the hafnium source compound is a hafnium salt which can be thermally decomposed to obtain hafnium oxide; (2) introducing the HfC-C precursor solution to a carbon fiber preform by a vacuum impregnation process, and carrying out curing, cracking and carbothermal reduction treatment to obtain a Cf / HfC-C porous preform; and (3) repeating step (2) for at least one time, and carrying out reactive melt infiltration treatment on the Cf / HfC-C porous preform by using Si or HfSi2 to obtain the Cf / HfC-SiC ultrahigh temperature ceramic matrix composite material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Sintering method of ZrB2-SiC superhigh temperature ceramics

The invention discloses a sintering method of ZrB2-SiC superhigh temperature ceramics and relates to a sintering method of superhigh temperature ceramics. The invention aims at solving the problems of high sintering temperature and high energy consumption in the existing process of preparing ZrB2-SiC superhigh temperature ceramics. The method comprises the following steps of: weighing ZrB2 powder, SiC powder and citric acid; ball-milling and mixing to obtain slurry; drying the slurry to obtain composite powder; and performing vacuum sintering at the temperature of 1500 to 1600 DEG C to obtain the ZrB2-SiC superhigh temperature ceramics. According to the sintering method of the ZrB2-SiC superhigh temperature ceramics provided by the invention, the sintering temperature is lowered by about 300 DEG C, thus energy consumption is reduced. The density of the obtained product can achieve 98%, thus the requirement of being used in oxygen-containing atmosphere at the temperature of 1800 DEG C is met. The method is used for preparing the ZrB2-SiC superhigh temperature ceramics.

Owner:HARBIN INST OF TECH

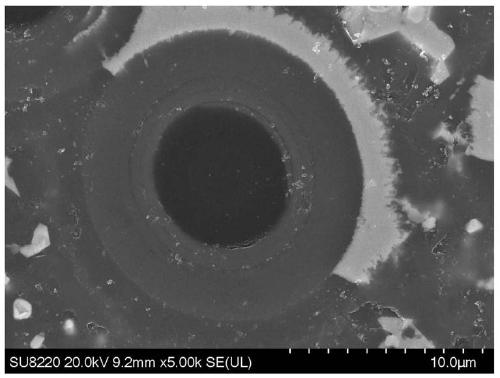

Carbon-core silicon carbide fibre-reinforced boride ultrahigh-temperature ceramic matrix composite and preparation method thereof

ActiveCN102674872AHigh strengthGood high temperature performanceBorideUltrahigh temperature ceramics

The invention discloses a carbon-core silicon carbide fibre-reinforced boride ultrahigh-temperature ceramic matrix composite, characterized by being produced from, in volume fraction, 60-90% of boride powder, 0-30% of silicon carbide particles and 10-40% of carbon-core silicon carbide fibres. The carbon-core silicon carbide fibre-reinforced boride ultrahigh-temperature ceramic matrix composite disclosed by the invention has the advantages of being simple in process and excellent in performance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com