Preparation method of C/SiC-HfB2-HfC ultrahigh-temperature ceramic-based composite material

A technology of sic-hfb2-hfc and ultra-high temperature ceramics, which is applied in the field of preparation of C/SiC-HfB2-HfC ultra-high temperature ceramic matrix composites, can solve problems such as poor mechanical properties and poor thermal shock resistance of ceramics, and achieve Improve the effect of anti-ablation performance, good mechanical properties and high volume content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

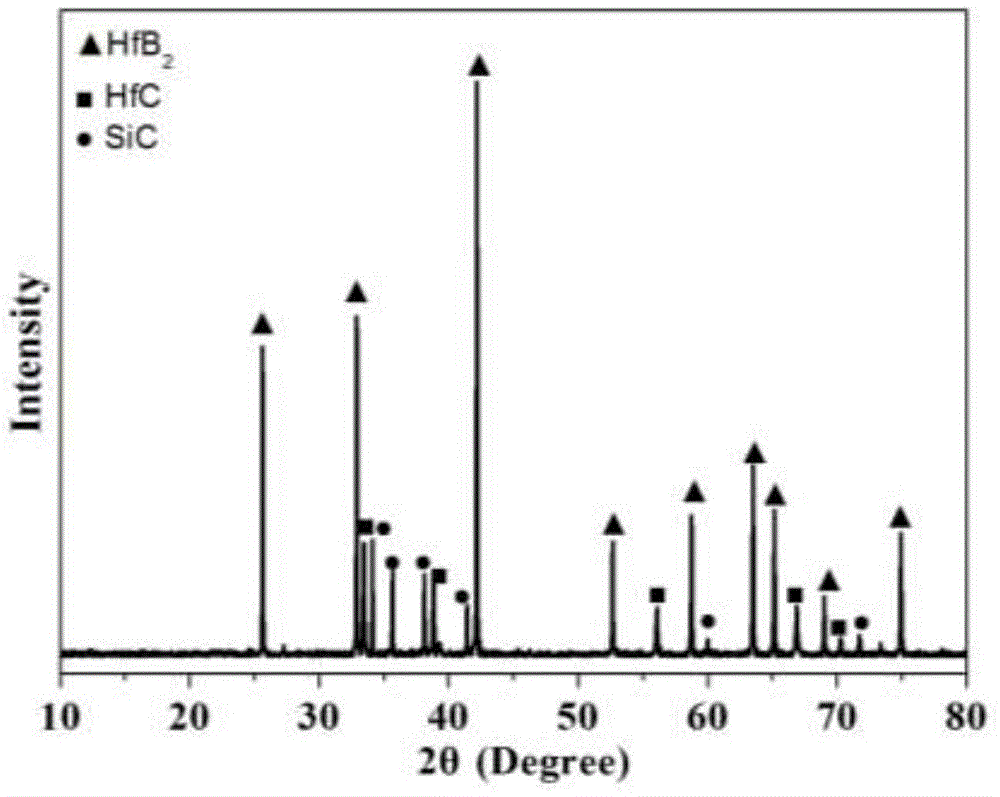

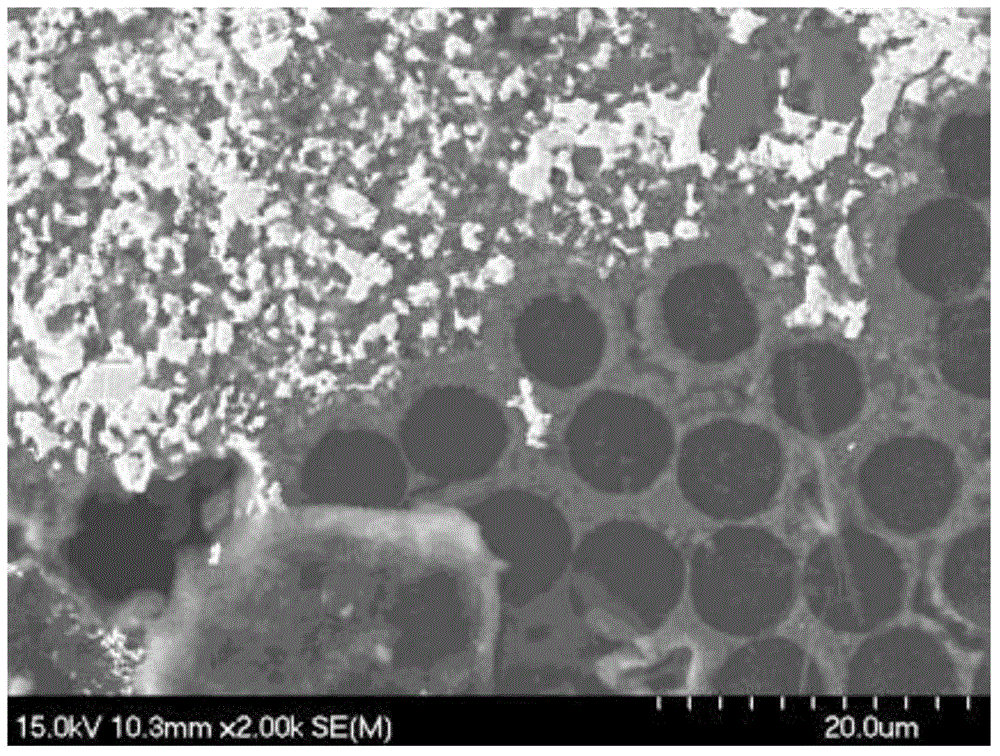

[0027] Example 1: Preparation of C / SiC-HfB using C / SiC preform 2 -HfC ultra-high temperature ceramic matrix composites

[0028] Concrete preparation steps are as follows:

[0029] 1. Preparation of composite material preform: The three-dimensional needle-punched C / SiC composite material preform with an open porosity of 35vol% was cleaned by ultrasonic waves for 1 hour, and dried in an oven at 100°C for 2 hours to obtain a C / SiC preform.

[0030] 2. Slurry preparation: Dissolve phenolic resin and hexamethylenetetramine in absolute ethanol, then add B 4 C powder and ball milled on a roller ball mill for 36 hours to obtain slurry; phenolic resin and B 4 The mass ratio of C powder is 2:1, the quality of hexamethylenetetramine is 10% of the phenolic resin quality; the viscosity of the slurry is controlled by the content of absolute ethanol to be 125mPa.s; the pH value is adjusted to 10 to control the dispersion .

[0031] 3. Vacuum pressure impregnation: Vacuum pressure impregn...

Embodiment 2

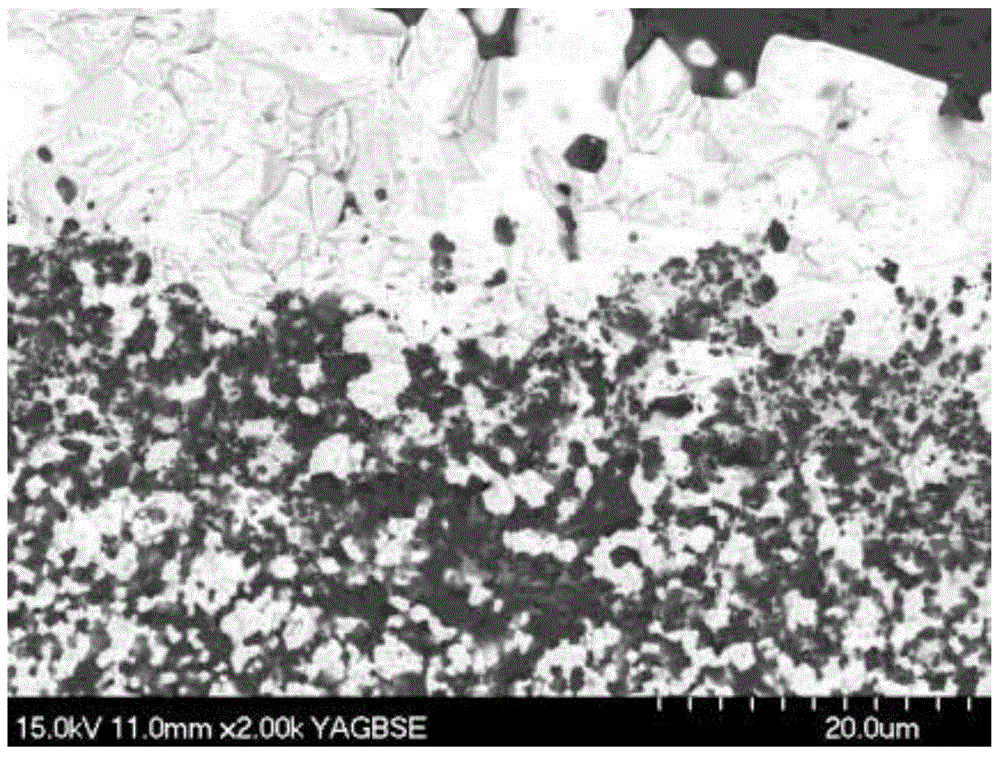

[0034] Example 2: Preparation of C / SiC-HfB using C / C preform 2 -HfC ultra-high temperature ceramic matrix composites

[0035] Concrete preparation steps are as follows:

[0036] 1. Preparation of composite material preform: The two-dimensional laminated C / C composite material preform with an open porosity of 25vol% was cleaned by ultrasonic waves for 1 hour, and dried in an oven at 120°C for 1 hour to obtain a C / C preform.

[0037] 2. Slurry preparation: Dissolve phenolic resin in absolute ethanol, then add B 4 C powder and ball milled on a roller ball mill for 48 hours to obtain slurry; phenolic resin and B 4 The mass ratio of C powder is 1:1, the quality of hexamethylenetetramine is 10% of the phenolic resin quality; the viscosity of the slurry is controlled by the content of absolute ethanol to be 150mPa.s; the pH value is adjusted to 10 to control the dispersion .

[0038] 3. Vacuum pressure impregnation: Vacuum pressure impregnation of the C / C preform in the slurry, t...

Embodiment 3

[0041] Example 3: Preparation of C / SiC-HfB using C / SiC preform 2 -HfC ultra-high temperature ceramic matrix composites

[0042] Concrete preparation steps are as follows:

[0043] 1. Preform preparation: The three-dimensional needle-punched C / SiC composite material preform with an open porosity of 30vol% was cleaned by ultrasonic waves for 1 hour, and dried in an oven at 120° C. for 1 hour to obtain a C / SiC preform.

[0044] 2. Slurry preparation: Dissolve furan resin in absolute ethanol, then add B 4 C and ball milled on a drum type ball mill for 48 hours to obtain slurry; phenolic resin and B 4 The mass ratio of C powder is 2:1, and the quality of hexamethylenetetramine is 10% of the furan resin quality; The viscosity of the slurry is controlled by the content of dehydrated alcohol to be 100mPa.s and measure the viscosity with a rotational viscometer, and adjust the pH A value of 9 controls dispersion.

[0045] 3. Vacuum pressure impregnation: vacuum pressure impregnate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com