Patents

Literature

97 results about "Rotational viscometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

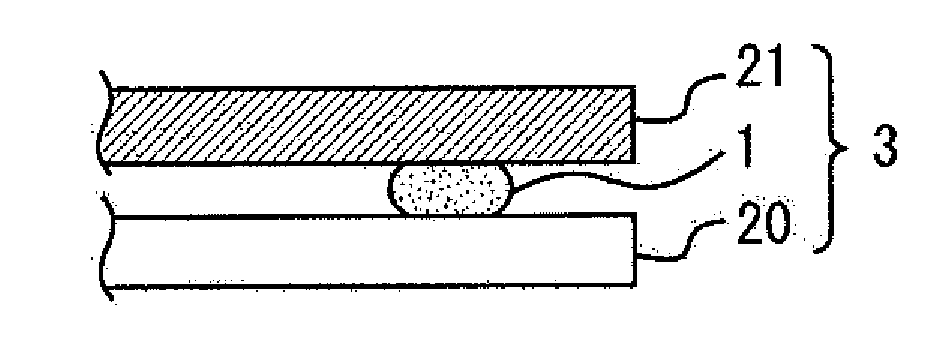

Support material for three-dimensional laminating molding

InactiveUS20050053798A1Increasing of electric power consumptionIncreasing start-up timeAdditive manufacturing apparatusAuxillary shaping apparatusVolumetric Mass DensityDensity difference

A three-dimensional laminated mold is formed by ejecting a mold material into a groove formed in a support. The support is formed from a support material ejected from an inkjet head. The support material has a ratio of density difference of equal to or less than 13.5%. The ratio of density difference is calculated from an equation: ratio of density difference=((D1-D2) / D1)×100 wherein D1 indicates the density of the support material at 20° C., and D2 indicates the density of the support material at a temperature at which a viscosity of the support material measured using a rotational viscometer falls within the range of 10±1 mPa·s.

Owner:RICOH PRINTING SYST

Engine oil compositions and preparation thereof

A multi-grade engine oil composition meeting required specifications of manufacturers is provided. In one embodiment, the engine oil composition contains a sufficient amount of a Pour Point Reducing Blend Component for the engine oil to have cold crank simulator viscosity at −20° C. of less than have a cold crank simulator viscosity at −20° C. of less than 9000 cP and a mini rotary viscometer (MRV) viscosity at −20° C. of less than 60,000 cP. The Pour Point Reducing Blend Component is selected from 1) an isomerized Fischer-Tropsch derived bottoms product; 2) a bottoms product prepared from an isomerized highly waxy mineral oil, or 3) an isomerized oil having a kinematic viscosity at 100° C. of at least about 8 mm2 / s made from polyethylene plastic.

Owner:CHEVROU USA INC

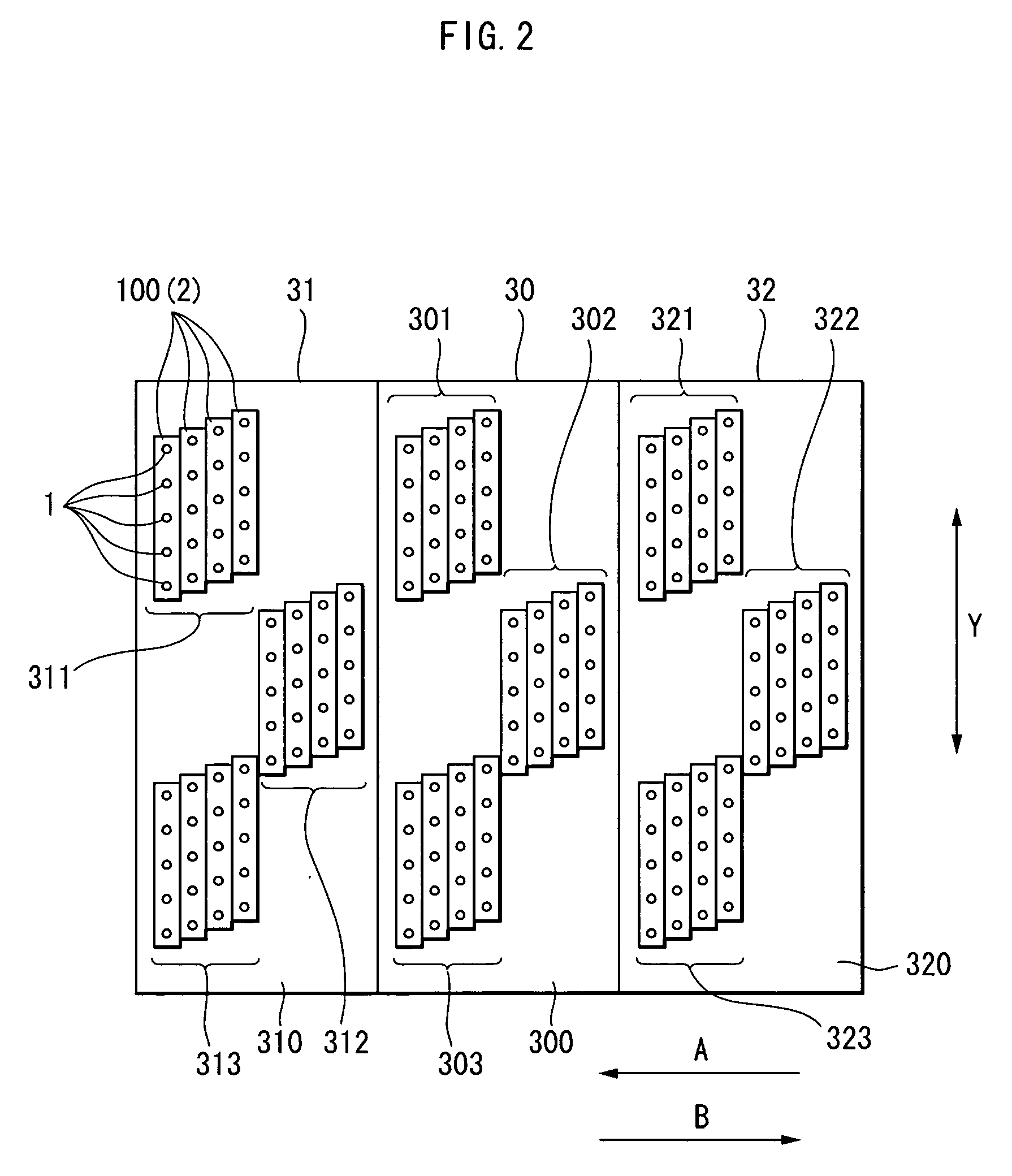

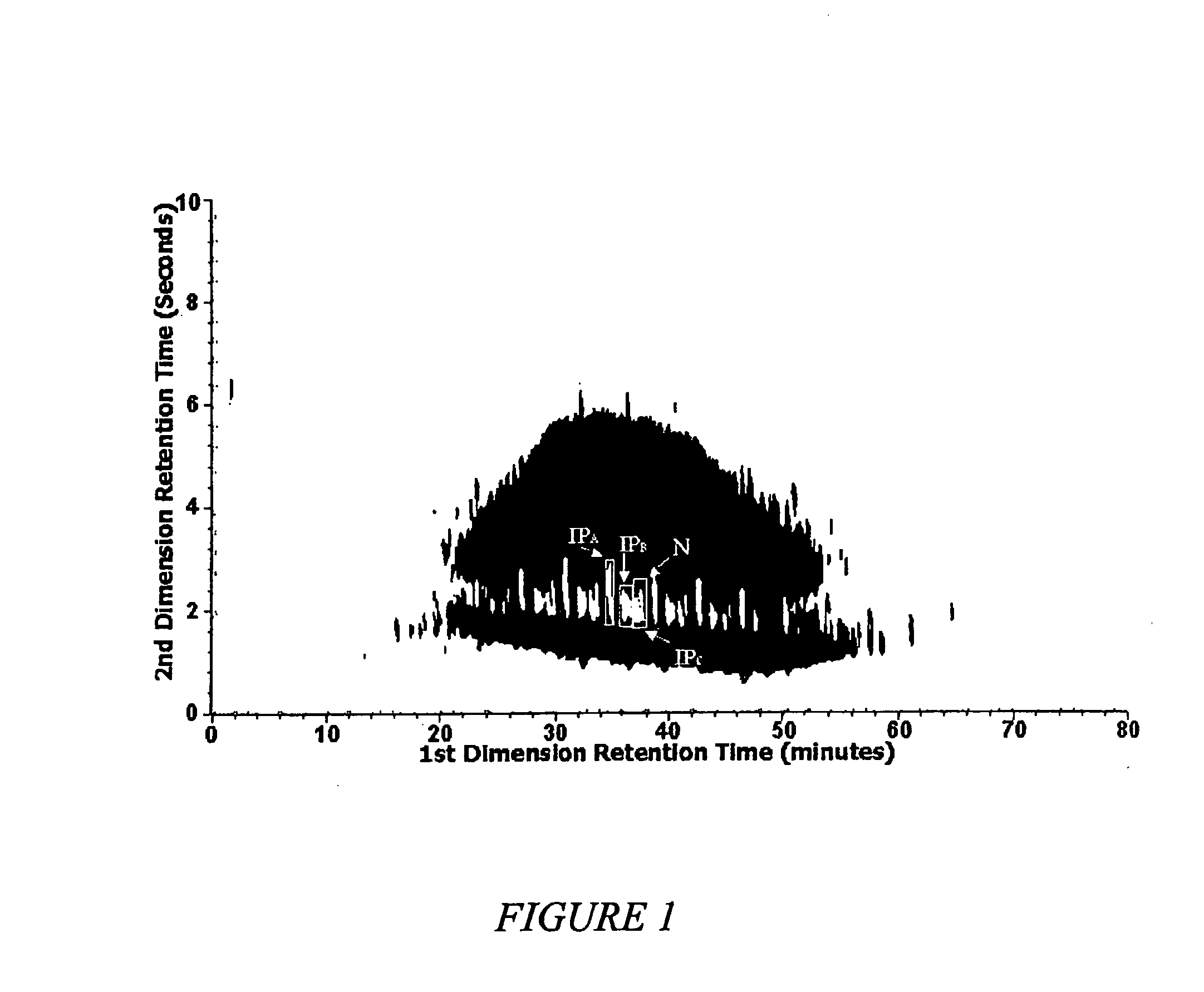

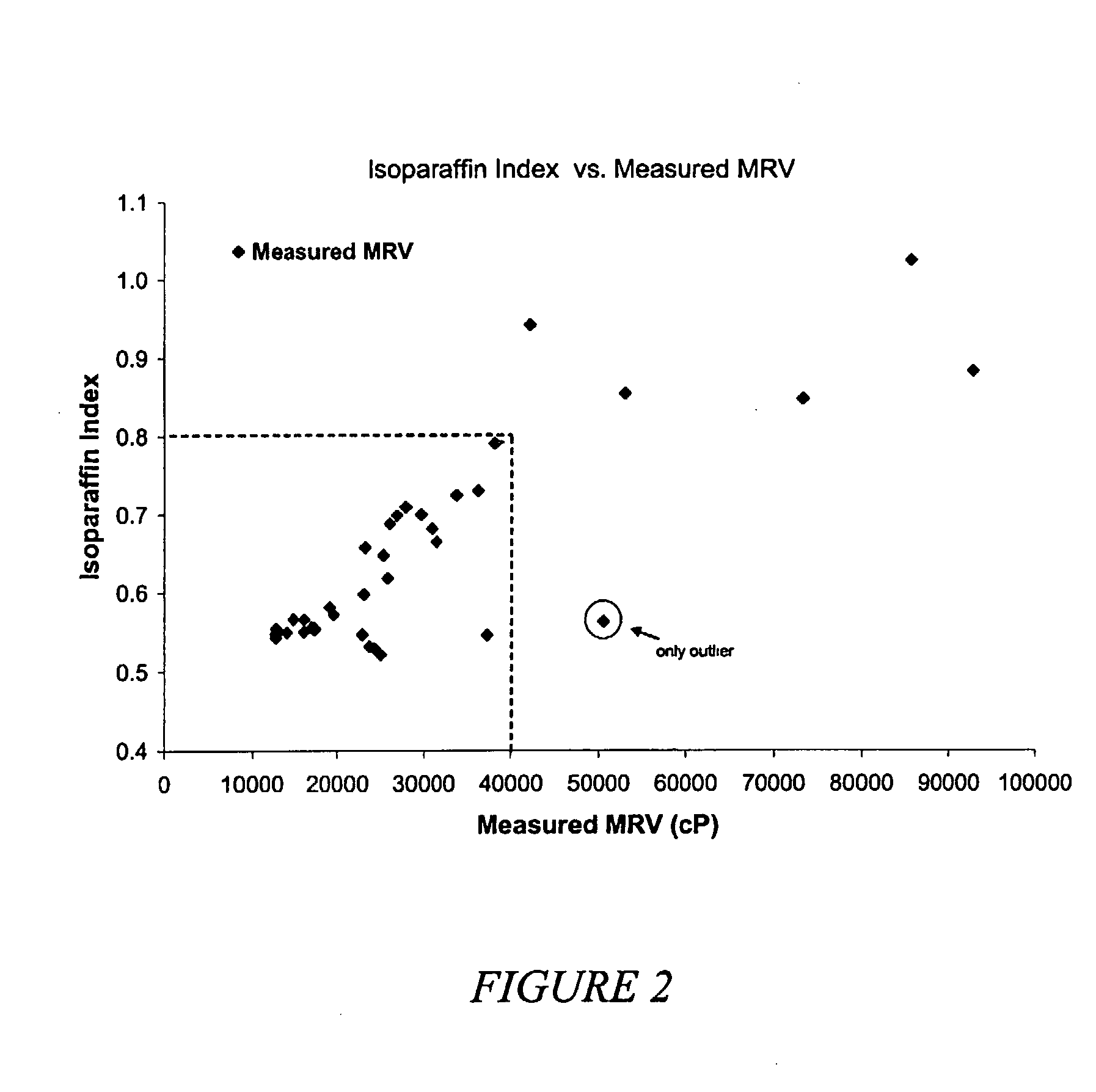

Method of Analyzing Basestocks for Low Temperature Properties

The invention relates to a method for analyzing a lubricating oil for low temperature properties. The method utilizes 2-dimensional gas chromatography (2D GC) to determine the amounts of paraffins and isoparaffins in the oil. In particular, the method analyzes for a particular isoparaffin fraction which is correlated to low temperature performance. The compositional information thus obtained is correlated with formulated oil Mini Rotary Viscometer (MRV) properties.

Owner:EXXON RES & ENG CO

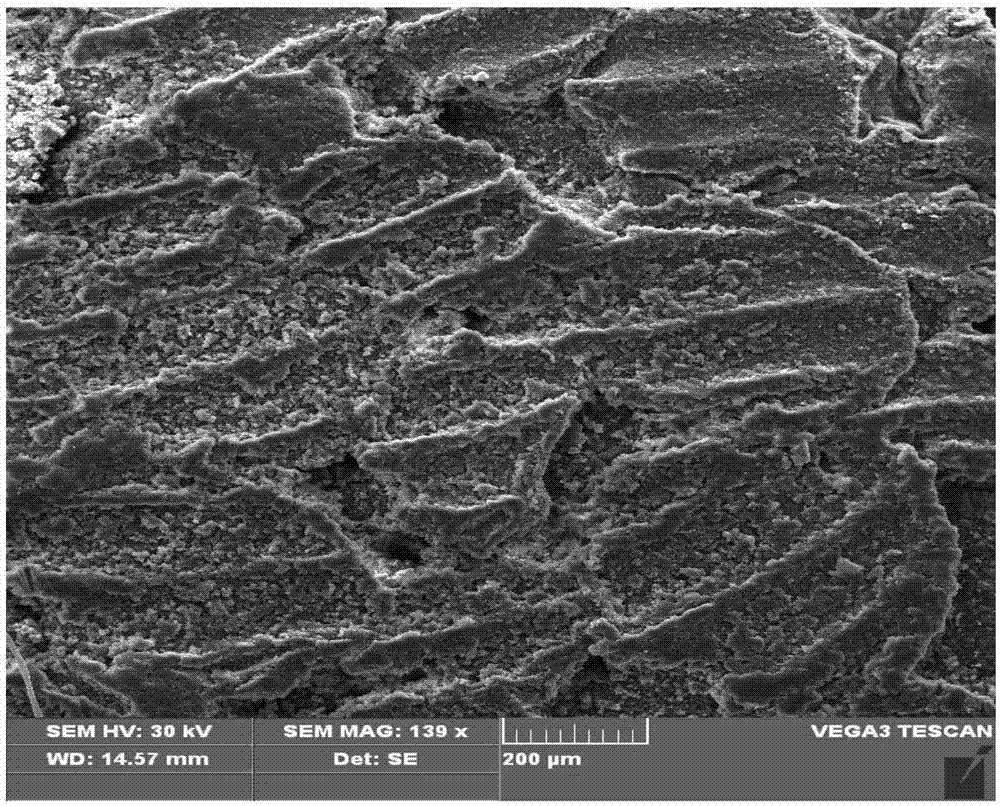

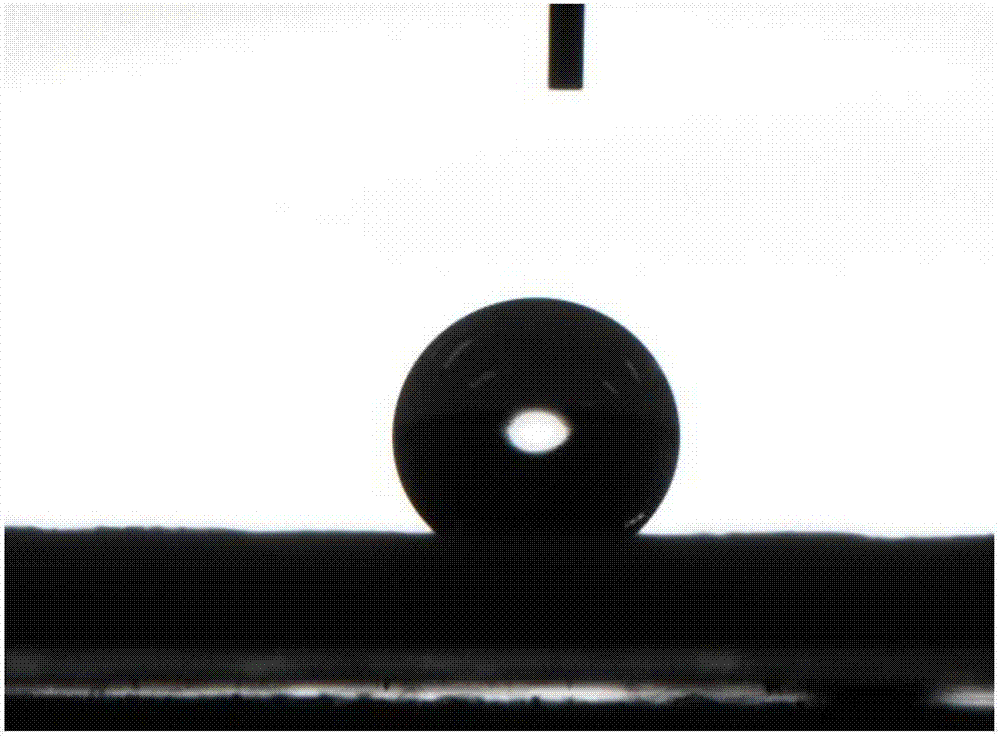

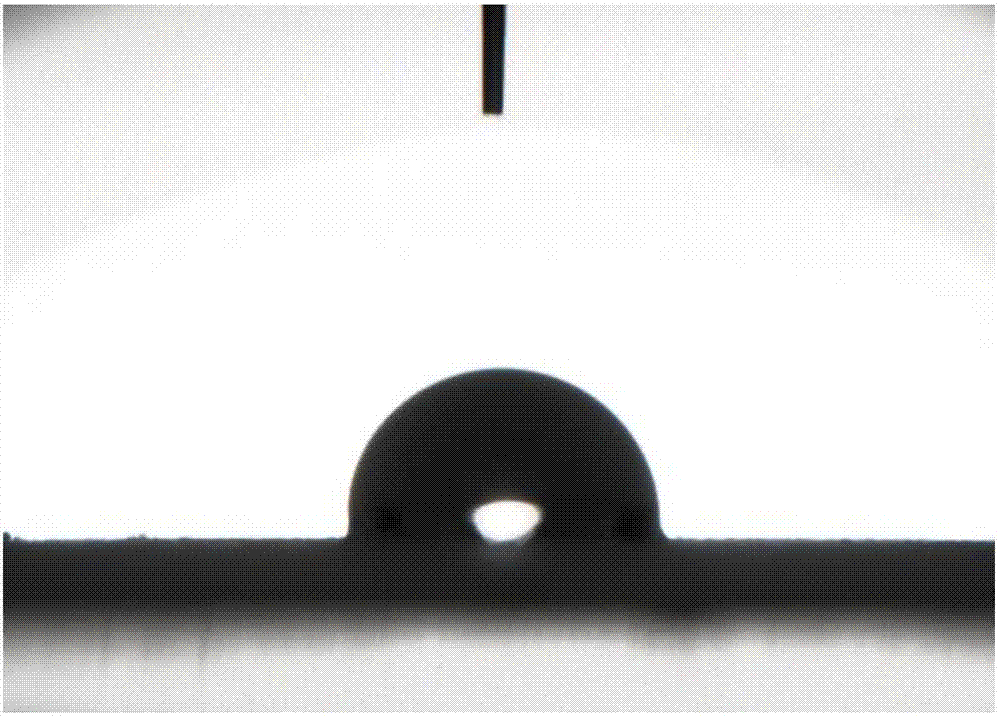

Self-repairing super-hydrophobic anti-drag elastomer thin film and preparation method thereof

ActiveCN107459668AHas super hydrophobic effectSelf-healing superhydrophobic propertiesMicro nanoElastomer

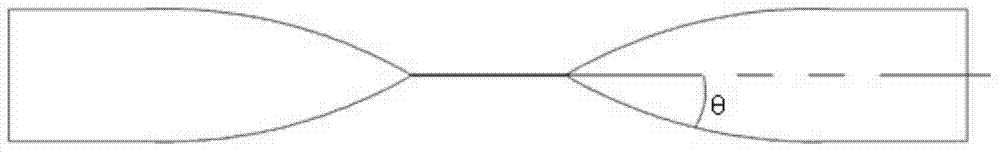

The invention relates to a self-repairing super-hydrophobic anti-drag elastomer thin film and a preparation method thereof. A sharkskin V-shaped groove structure is copied on the surface of an elastomer, and a polyarcylamide-polyfluoroalkyl acrylate segmented copolymer capable of self assembling and forming a micro-nano structure is further grafted on the surface of the elastomer; thus, the thin film has self-repair super-hydrophobic performance, a static water contact angle can reach 150 degrees or more, and a rolling angle is smaller than 10 degrees. When the anti-drag film is attached to a rotational viscometer rotor to perform an anti-drag performance test, drag reducing efficiency can reach 20%. The self-repairing super-hydrophobic anti-drag elastomer thin film disclosed by the invention has the advantages that 1, a super-hydrophobic anti-drag method and a bionic anti-drag method are combined together, so that the anti-drag film can have a better anti-drag effect under a laminar condition and a turbulent condition; 2, after surface chemical components of polyfluoroalkyl acrylate grated to the surface of the super-hydrophobic film are damaged, the polyfluoroalkyl acrylate can be self repaired after being soaked by a solvent or being heated under high temperature, so that the film can have a super-hydrophobic effect again.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

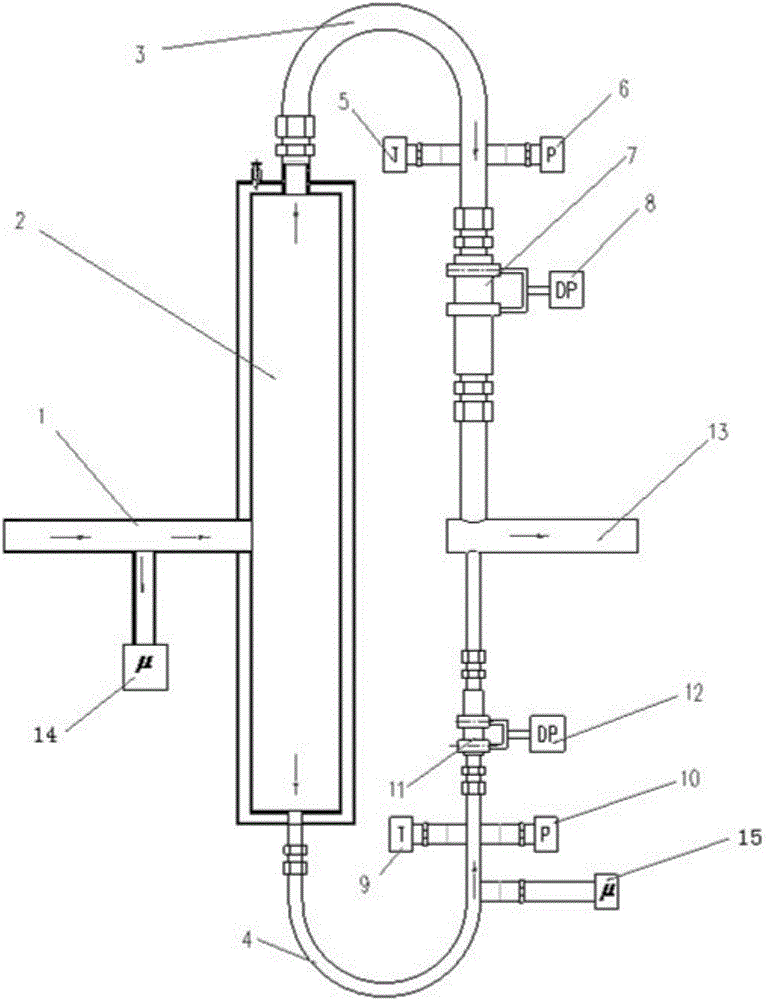

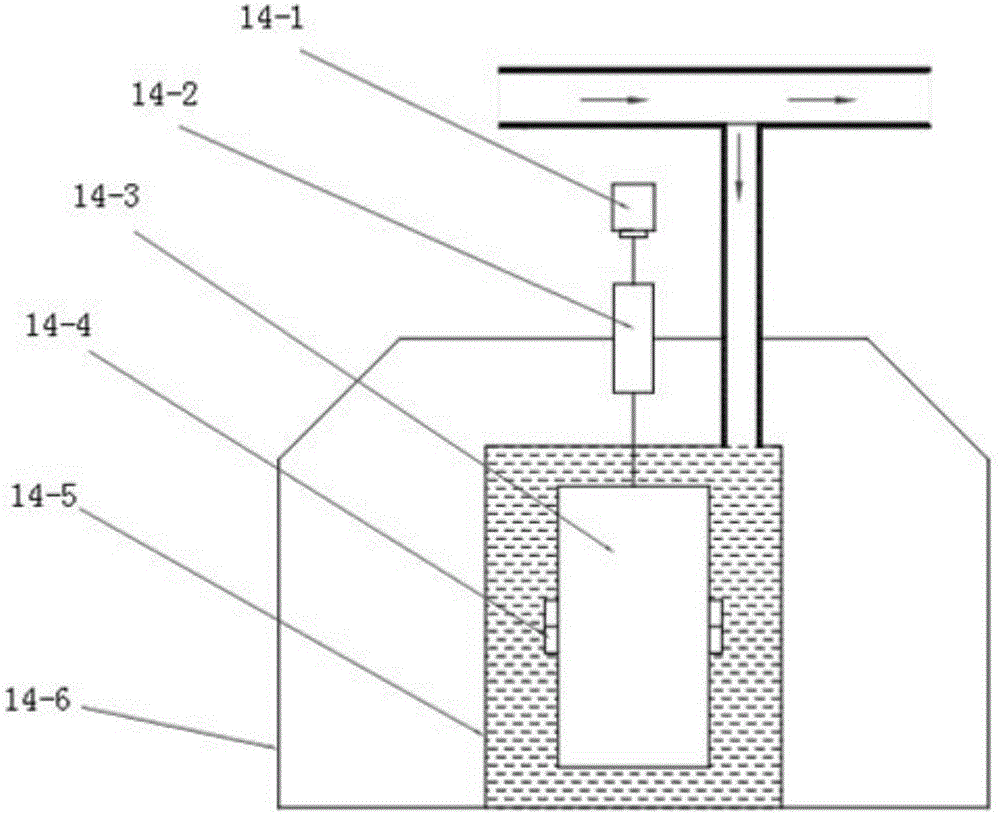

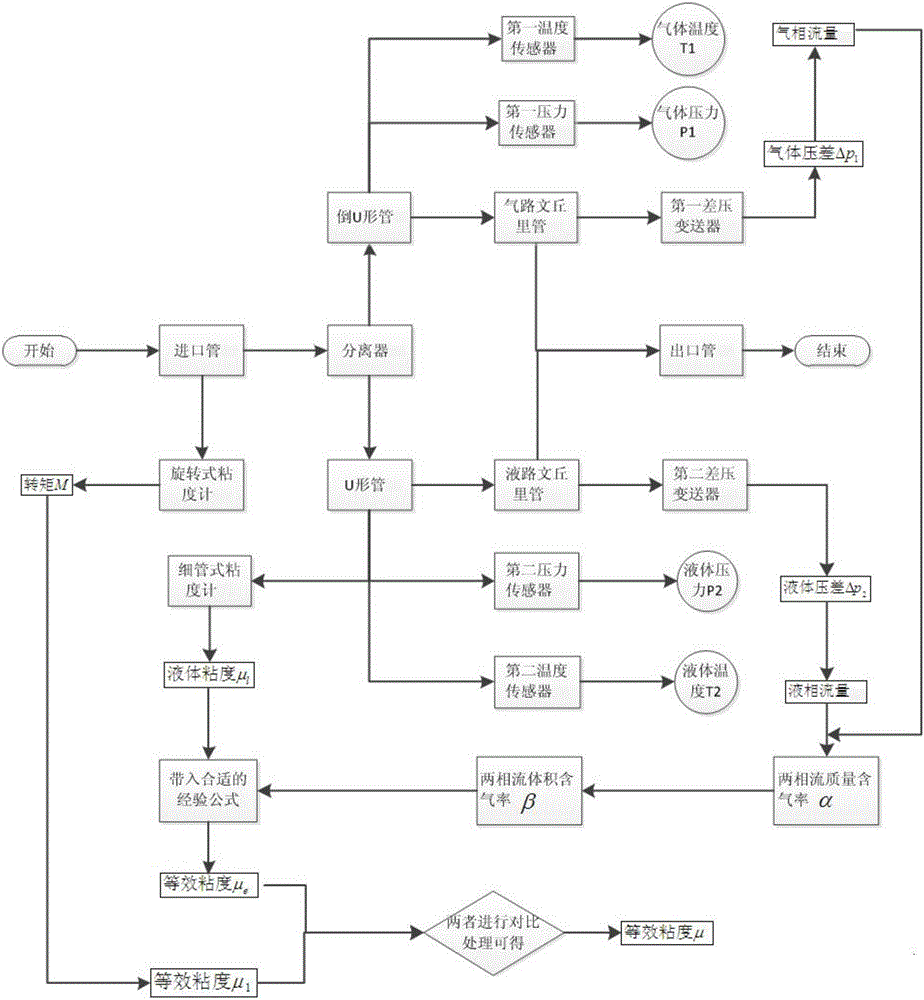

Homogeneous gas-liquid mixed dielectric viscosity measuring device and method

The invention provides a homogeneous gas-liquid mixed dielectric viscosity measuring device and method. An inlet tube of the device is connected with a separator, a gas outlet of the separator is connected with an inverted U tube, the inverted U tube is connected with the upper end of a gas path Venturi tube, and the lower end of the gas path Venturi tube is connected with the outlet tube; the inverted U tube is connected with a first temperature sensor and a first pressure sensor; a liquid outlet of the separator is connected with a U tube, the U tube is connected with the lower end of a liquid path Venturi tube, and the upper end of the liquid path Venturi tube is connected with the outlet tube; the U tube is connected with a second temperature sensor and a second pressure sensor; the gas path Venturi tube and liquid path Venturi tube are respectively connected with a differential pressure transmitter; and the inlet tube is also connected with a rotational viscometer, and the U tube is also connected with a tubule viscometer. The homogeneous gas-liquid mixed dielectric viscosity measuring device and method have important meanings for developing the experiment testing technique and enhancing the measurement accuracy in the engineering field.

Owner:XIDIAN UNIV

Damping glue for vibration reducing plate and preparation method thereof

ActiveCN102115647AHigh dampingGood damping propertiesConjugated diene hydrocarbon adhesivesEpoxyMixed materials

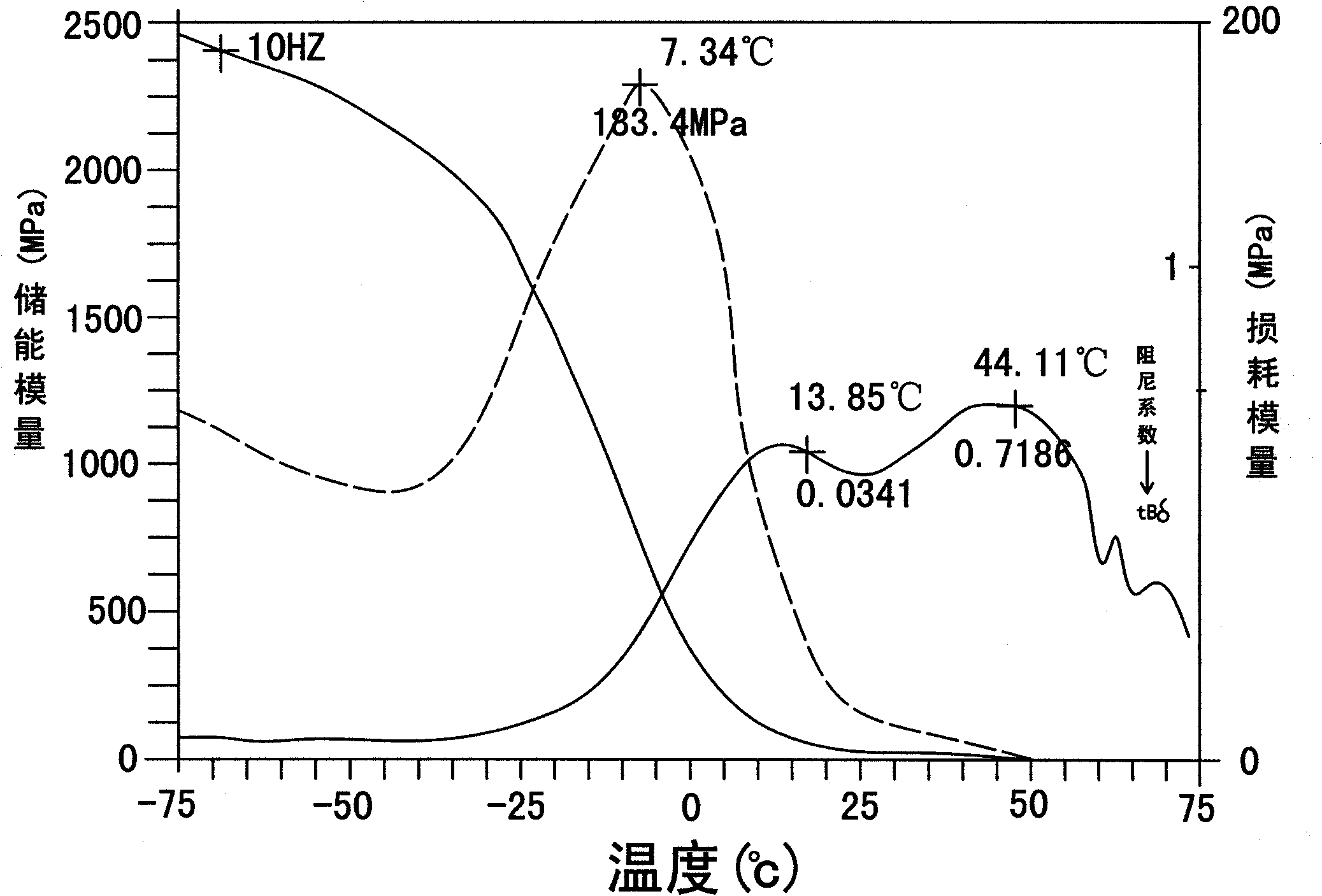

The invention discloses damping glue for a vibration reducing plate and a preparation method thereof. The component formula of the damping glue is as follows: 3 to 10 parts of nitrile-butadiene rubber 26 (NBR 26), 5 to 7 parts of nitrile-butadiene rubber 40 (NBR 40), 2 to 4 parts of additive, 2 to 12 parts of epoxy resin (EP), 1 to 5 parts of phenol formaldehyde resin (PF), 1 to 2 parts of curingagent, 0.3 to 0.5 part of peroxide, 0.5 to 1 part of zinc oxide, and 65 to 75 parts of solvent. The preparation process of the damping glue is as follows: the NBR 26 is firstly plasticated on a double-roll machine for 5 to 10 minutes, and then the zinc oxide is added and mixed with the NBR26 until the Williams plasticity is between 0.2 and 0.3; then the NBR40 is plasticated on the double-roll machine until the Williams plasticity is between 0.3 and 0.4; the mixed material is added to the solvent being stirred and stirred until being completely dissolved; and afterwards, the PF, the additive, the EP or a compound thereof, the curing agent and the peroxide are stirred until being completely dissolved into an evenly thick liquid, and then the normal-temperature damping glue for the vibrationreducing plate can be acquired. The main performances of the manufactured damping glue are as follows: the solid content is 25 to 35 percent; the glue solution viscosity (measured by a rotational viscometer) is 3.5 to 7 Pa.S (25 DEG C); the T-peel strength is larger than 20N / cm; the tensile shear strength is larger than 7MPa; tangent Delta is larger than or equal to 0.20; and the temperature range is minus 10 DEG C to 75 DEG C.

Owner:SHANGHAI PLASTICS RES INST CO LTD

Rotational viscometer based on velocity attenuation

InactiveCN102023124AWide speed rangeWide measurement rangeFlow propertiesUltrasound attenuationAir bearing

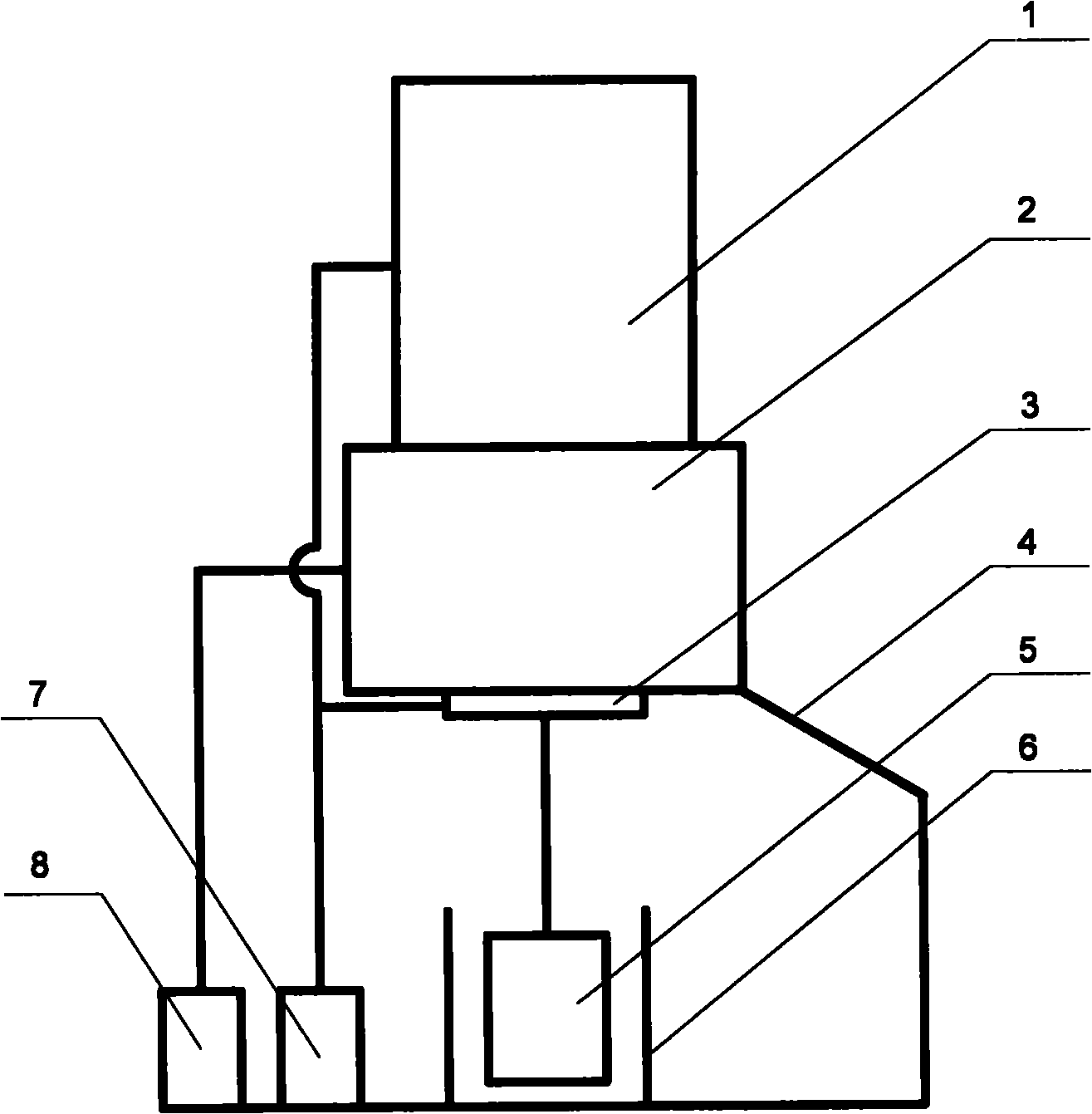

The invention relates to a fluid viscosity (rheological property) measuring instrument which comprises a cascading motor (1), an air bearing (2), a velocity sensor (3), a support (4), a measuring head rotor (5), an outer cylinder (6), a calculation and display unit (7) and a gas source (8). The velocity attenuation of the measuring head rotor (5) in the fluid to be measured has the corresponding relation with the viscosity of the fluid to be measured, and the viscosity of the fluid to be measured can be worked out according to the corresponding relation by detecting the rotating speed of the measuring head rotor (5) at any two corresponding moments. The fluid viscosity (rheological property) measuring instrument has the characteristics of wide measurement range, high measurement accuracy, good measurement repeatability, high measurement speed and the like.

Owner:HARBIN INST OF TECH

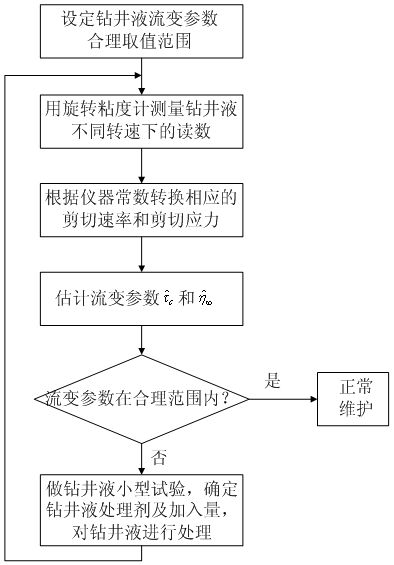

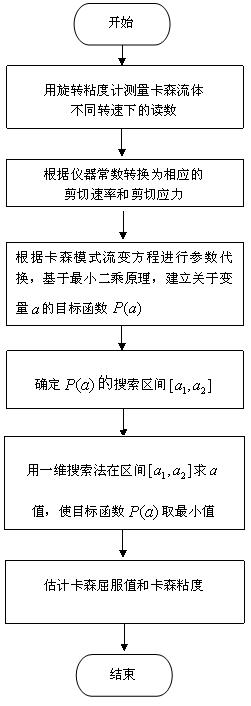

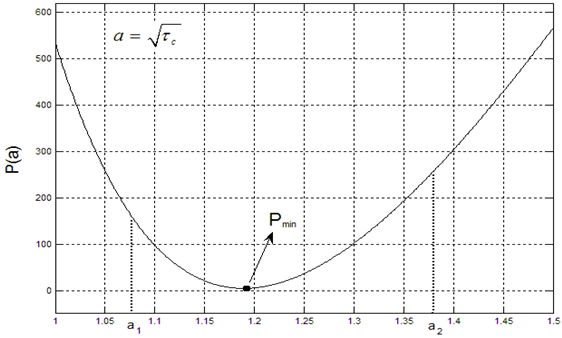

Control method of Casson model drilling fluid rheological parameters

The invention relates to a control method of Casson model drilling fluid rheological parameters, which comprises the following steps: firstly determining a reasonable value range of the rheological parameters, measuring read values of drilling fluid at different rotational speeds through a rotational viscometer, converting to corresponding shearing rates and shearing stresses, estimating the rheological parameters, performing a field small-scale test according to the result of judging whether the estimated value is in the set value range or not and determining the adjustment treatment measures of the drilling fluid, wherein the estimation of the rheological parameters is based on a least square method, a unitary target function P (a) about a is established through mathematical manipulation, and a one-dimensional search method is utilized for solving the value of a so as to enable the P (a) to take the minimum value and further determine a Casson yield value and a Casson viscosity estimated value. The method considers various factors to set the reasonable value range of the rheological parameters, the reasonable judgment is made against adjustment of the drilling fluid by improving the estimation precision of the rheological parameters, and the field small-scale test is utilized for determining the maintenance treatment measures of the drilling fluid, thereby saving the using quantity of a treating agent and reducing the well drilling cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

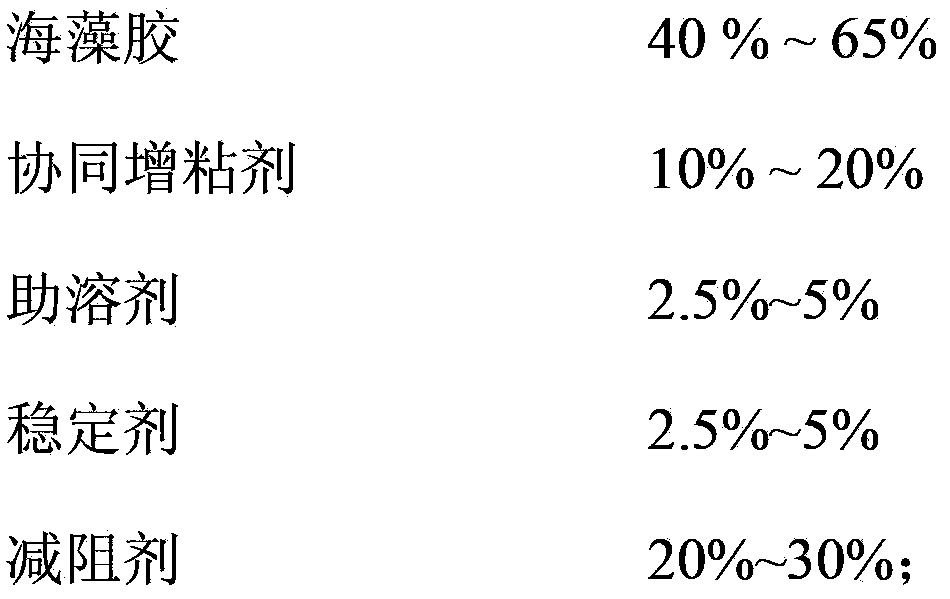

Fracturing composite thickener

The invention relates to a fracturing composite thickener comprising 50-70% of seaweed glue, 10-20% of a collaborative tackifier, 10-20% of a cosolvent and 5-10% of a drag reducer, the fracturing composite thickener has good water solubility, the swelling time is 10 to 45 minutes, the viscosity value of a fracturing fluid base liquid prepared according to the dosage of 0.3% is measured at room temperature, under the conditions of 170S-1 by use of a six-speed rotational viscometer, and the viscosity value is 15-33mPa.s, the drag reduction rate is 59-68%, the proppant static sedimentation rate is 0.5-3.5cm / s, the technical requirements of the mixed water fracturing can be met, to be more important, raw materials of the fracturing composite thickener are all domestic, yield and price are stable, in the case of sharp fluctuation in the price of guanidine gum, cost reduction and inhibitory effects are obvious.

Owner:PETROCHINA CO LTD

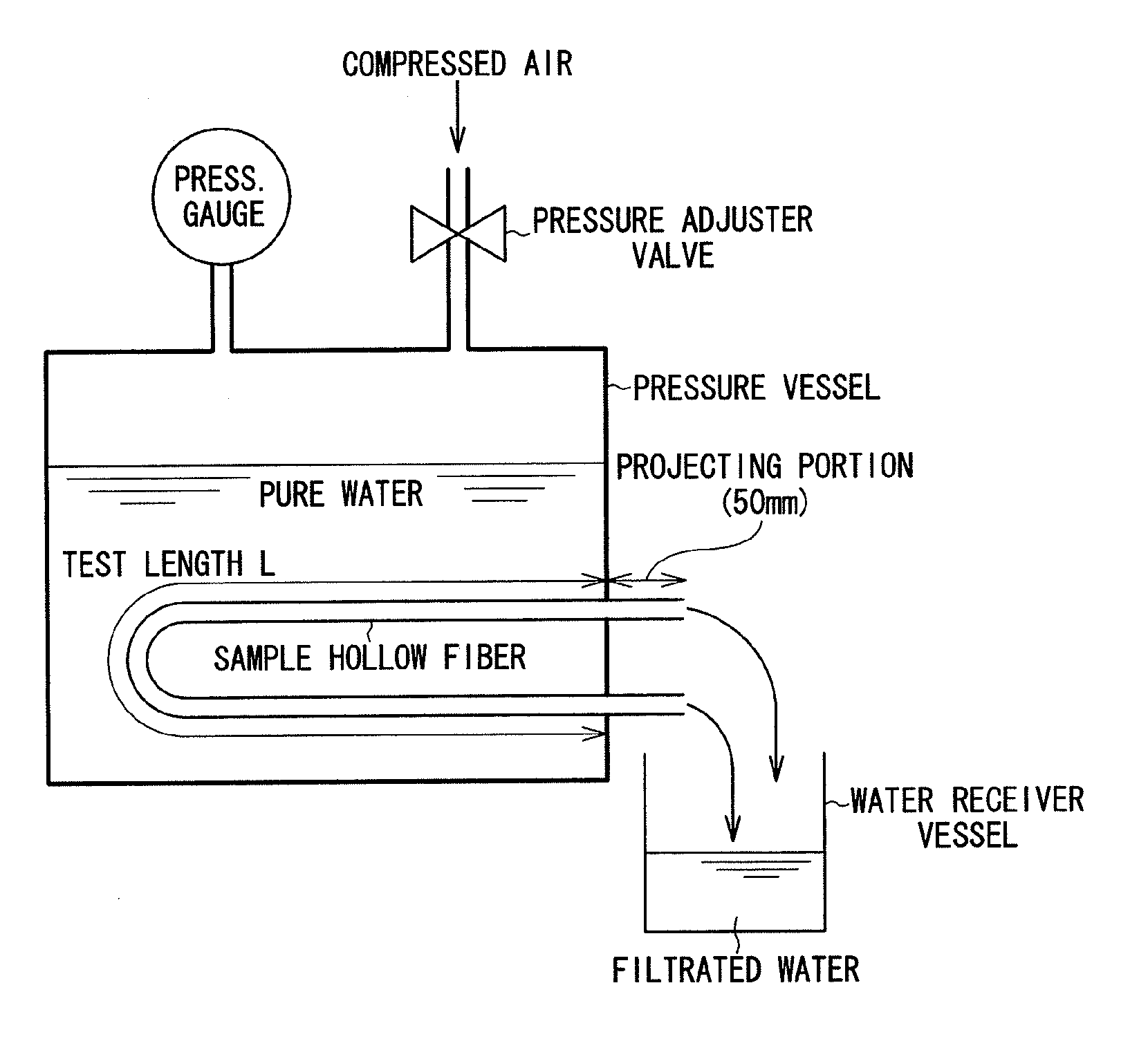

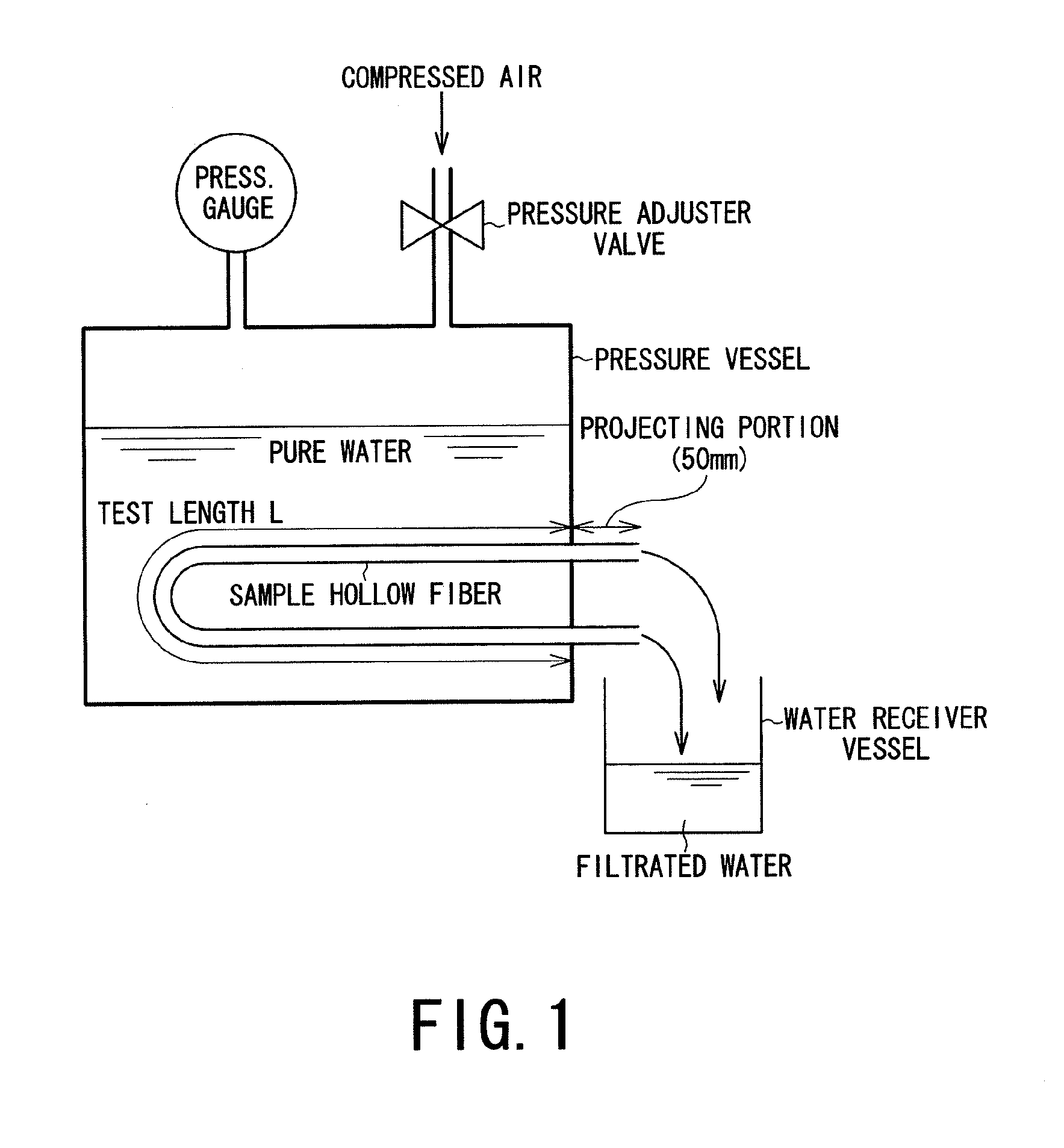

Porous vinylidene fluoride resin membrane and process for producing same

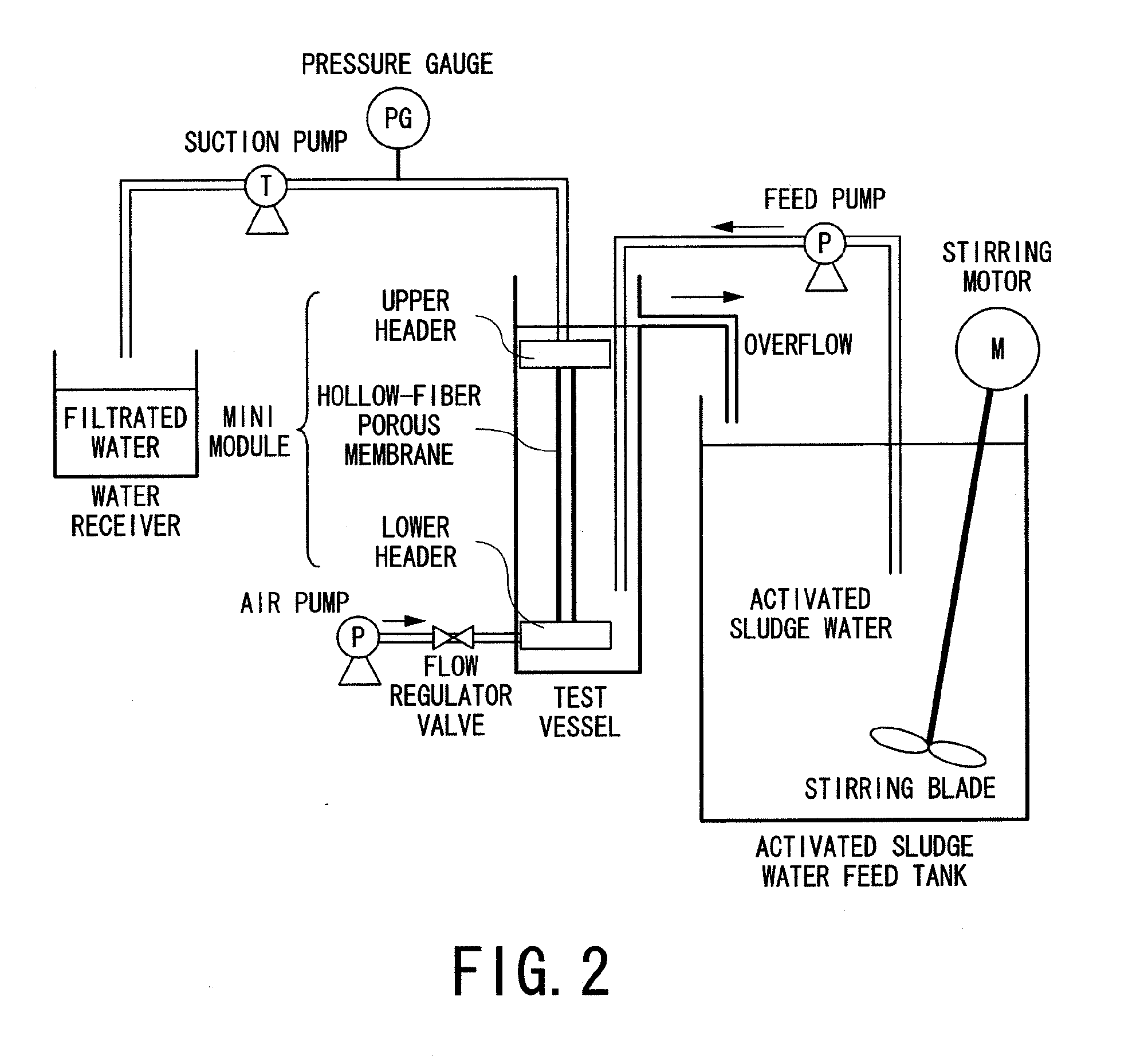

InactiveUS20120160764A1Good water-permeation-rate maintenance performanceMembranesSemi-permeable membranesFiltrationPressure difference

A porous membrane of vinylidene fluoride resin, comprising a substantially single layer membrane of vinylidene fluoride resin having two major surfaces sandwiching a certain thickness, including a dense layer that has a small pore size and governs a filtration performance on one major surface side thereof, having an asymmetrical gradient network structure wherein pore sizes continuously increase from the one major surface side to the other opposite major surface side, and satisfying conditions: (a) the dense layer includes a 5 μm-thick portion contiguous to the one major surface showing a porosity A1 of at least 60%, (b) the one major surface shows a pore size P1 of at most 0.30 μm, and (c) the porous membrane shows a ratio Q / P14 of at least 5×104 (m / day·μm4), wherein the ratio Q / P14 denotes a ratio between Q (m / day) which is a value normalized to a whole layer porosity A2=80% of a water permeation rate measured at a test length L=200 mm under the conditions of a pressure difference of 100 kPa and a water temperature of 25° C., and a fourth power P14 of the pore size P1 on the one major surface. The porous membrane is produced through a process including: extruding a melt-kneaded mixture of a vinylidene fluoride resin and a plasticizer through a die into a form of a film, followed by cooling, to form a solidified film; and extracting the plasticizer to recover a porous membrane; wherein the plasticizer is mutually soluble with the vinylidene fluoride resin at a temperature forming the melt-kneaded mixture and further satisfies properties: (i) giving the melt-kneaded mixture with the vinylidene fluoride resin with a crystallization temperature Tc′ (° C.) which is lower by at least 6° C. than a crystallization temperature Tc of the vinylidene fluoride alone, (ii) giving the cooled and solidified product of the melt-kneaded mixture a crystal melting enthalpy ΔH′ (J / g) of at least 53 J / g per weight of the vinylidene fluoride resin as measured by a differential scanning calorimeter (DSC), and (iii) the plasticizer alone showing a viscosity of 200 mPa-s-1000 Pa-s at a temperature of 25° C. as measured according to JIS K7117-2 (using a cone-plate-type rotational viscometer).

Owner:KUREHA KAGAKU KOGYO KK

Ink for mirror surface printing and mirror surface printed matter using the same

The invention provides an ink for printing, which is characterized in that the ink contains more than 80 percent of aluminum foil with a thickness under 0.03 mu m and a foil area 1.5 mu m2 to 2000 mu m2 in a datum of accumulated area. The aluminum foil is used as paint. The ink contains adhesive polymer 3 to 200 parts by weight and solvent 500 to 2500 parts by weight relative to the aluminum foil 100 parts by weight, and the viscosity determined by a BM type rotational viscometer is 3500 to 5500 cps in the temperature of 20 DEG C, so that the deformation in a datum of 0.1mm blank thin wire clearance maintenance can be prevented. The invention also provides a printing material using the ink.

Owner:TEIKOKU INK MFG CO LTD

Double-layer cosmetics, its use, and cosmetics box containing the same

InactiveCN1535673AEasy to useIncrease coverageCosmetic preparationsBody powdersPolymer chemistryPolymer

A cosmetic makeup product comprising at least two compositions, the first composition comprising a physiologically acceptable medium and the second composition comprising a mixture of at least one high molecular weight polymer having a weight-average molecular mass of greater than or equal to 200,000 g / mol and at least one low molecular weight non-volatile liquid silicone compound having a weight-average molecular mass of less than 200,000 g / mol, wherein the at least one high molecular weight polymer and the at least one low molecular weight non-volatile liquid silicone compound are present in a proportion such that the dynamic viscosity of the mixture at 25 DEG C., measured with a Mettler RM 180 rotational viscometer, ranges from 0.1 to 120 Pa.s; a makeup method and a makeup kit comprising the cosmetic makeup product. The cosmetic makeup product may, for example, be a lipstick.

Owner:LOREAL SA

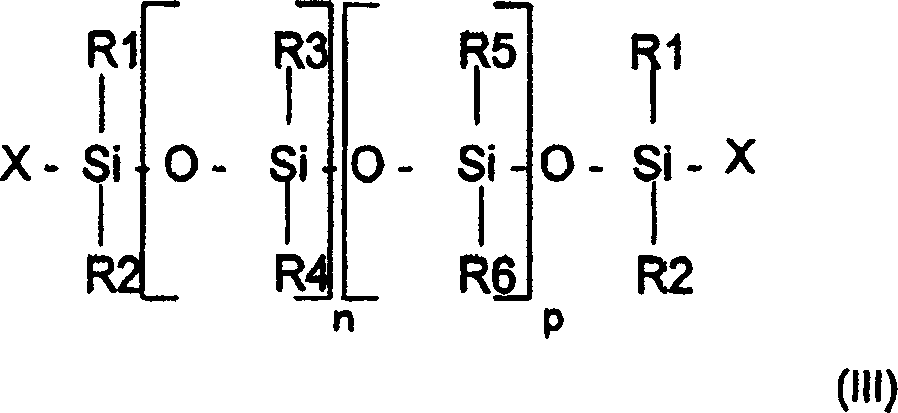

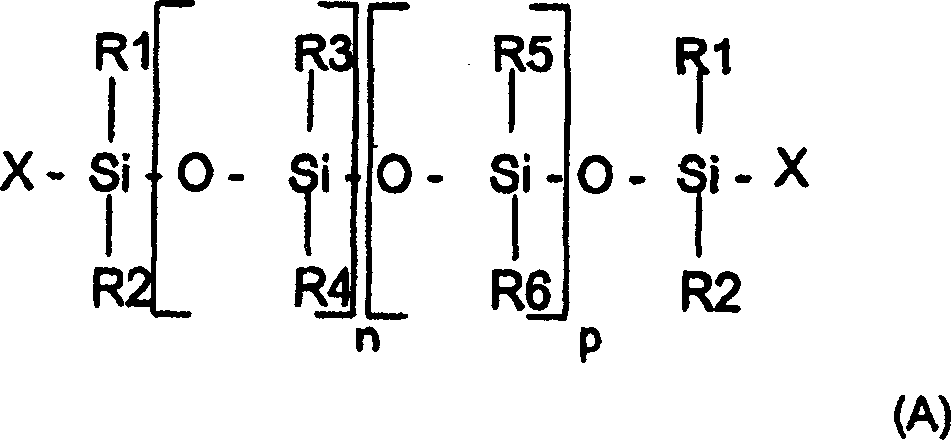

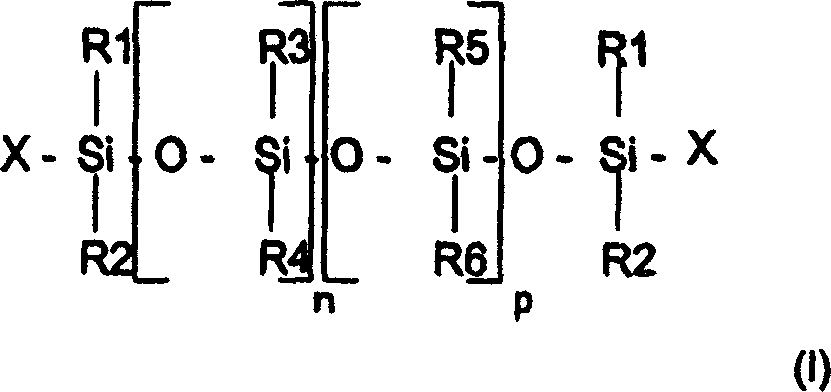

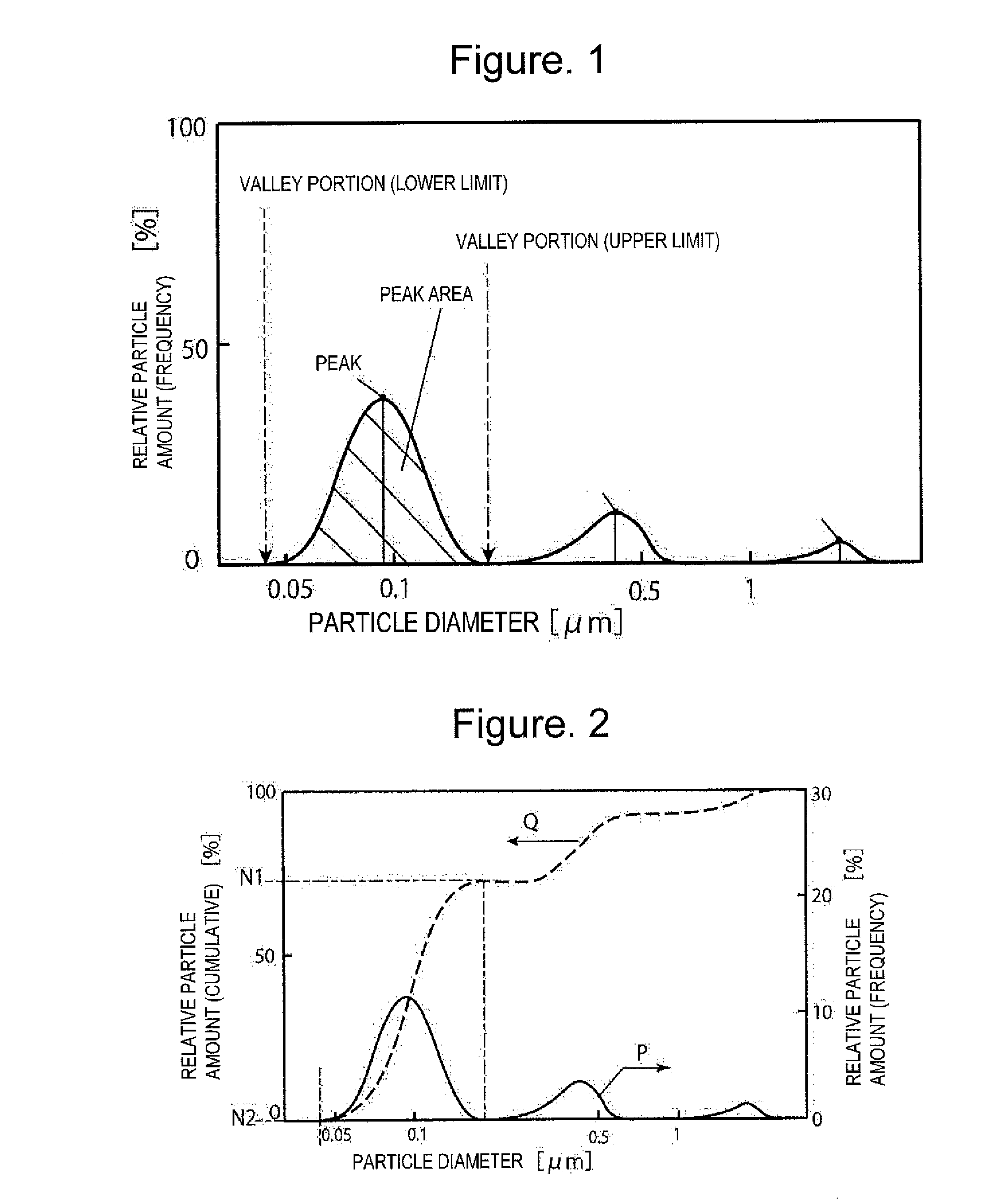

Active Energy Ray-Curable Resin Composition, Method for Producing the Same, and Seal Material Using the Same

InactiveUS20150175861A1Improve discharge performanceHigh in shape retention propertyEngine sealsNon-macromolecular adhesive additivesPolymer scienceApparent viscosity

Provided is an active energy ray-curable resin composition for seal materials, suitable as a bead-shaped seal material high in shape dimensional precision and excellent in productivity. An active energy ray-curable resin composition for seal materials including at least a thixotropy imparting agent (B) in an amount of 0.1 to 25 parts by weight dispersed in 100 parts by weight of an active energy ray-curable resin (A), wherein the active energy ray-curable resin composition has an apparent viscosity in an uncured state (according to JIS Z8803, cone and plate rotation viscometer, 40° C.) of 50 to 5000 Pa·s in a shearing speed range from 0.1 to 10 / sec and has a thixotropic coefficient, determined from the apparent viscosity in the shearing speed range, of 1.1 to 10, the thixotropy imparting agent (B) is made of silica fine particles, and the silica fine particles in the active energy ray-curable resin (A) has a particle size distribution having a plurality of peaks.

Owner:TAICA

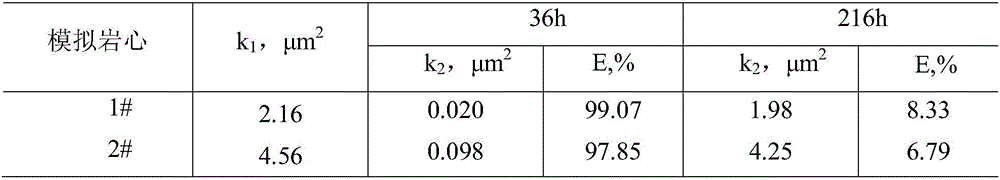

Gel temporary plugging agent

InactiveCN106590560AAvoid toxicityAvoid irritationDrilling compositionAntioxidantHexamethylenetetramine

The invention discloses a gel temporary plugging agent. The gel temporary plugging agent is prepared from, by mass, 0.3-0.4% of partially hydrolyzed polyacrylamide, 0.03-0.08% of phenol crosslinking agent, 0.03-0.08% of aldehyde crosslinking agent, 0.05-0.2% of water soluble polyvinyl alcohol, 0.05-0.5% of hydrochloric acid or acetic acid, 0.2-0.5% of antioxidant and the balance water, and the sum of the mass percents of all the components is 100%, wherein the phenol crosslinking agent is one of combination of resorcinol and hydroquinone, the aldehyde crosslinking agent is urotropin, and the antioxidant is one or combination of diphenylamine, p-phenylenediamine and sodium fluoborate. The gelling time of the gel temporary plugging agent is adjustable in the range of 5-50 h, the gel breaking time is adjustable in the range of 120-240 h, after gel breaking, the viscosity is measured by a rotational viscometer at the shear rate of 70 / s to be 5-10 mPa.s, which indicates thorough gel breakage, and therefore the gel temporary plugging agent can be suitable for most conventional oil deposit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

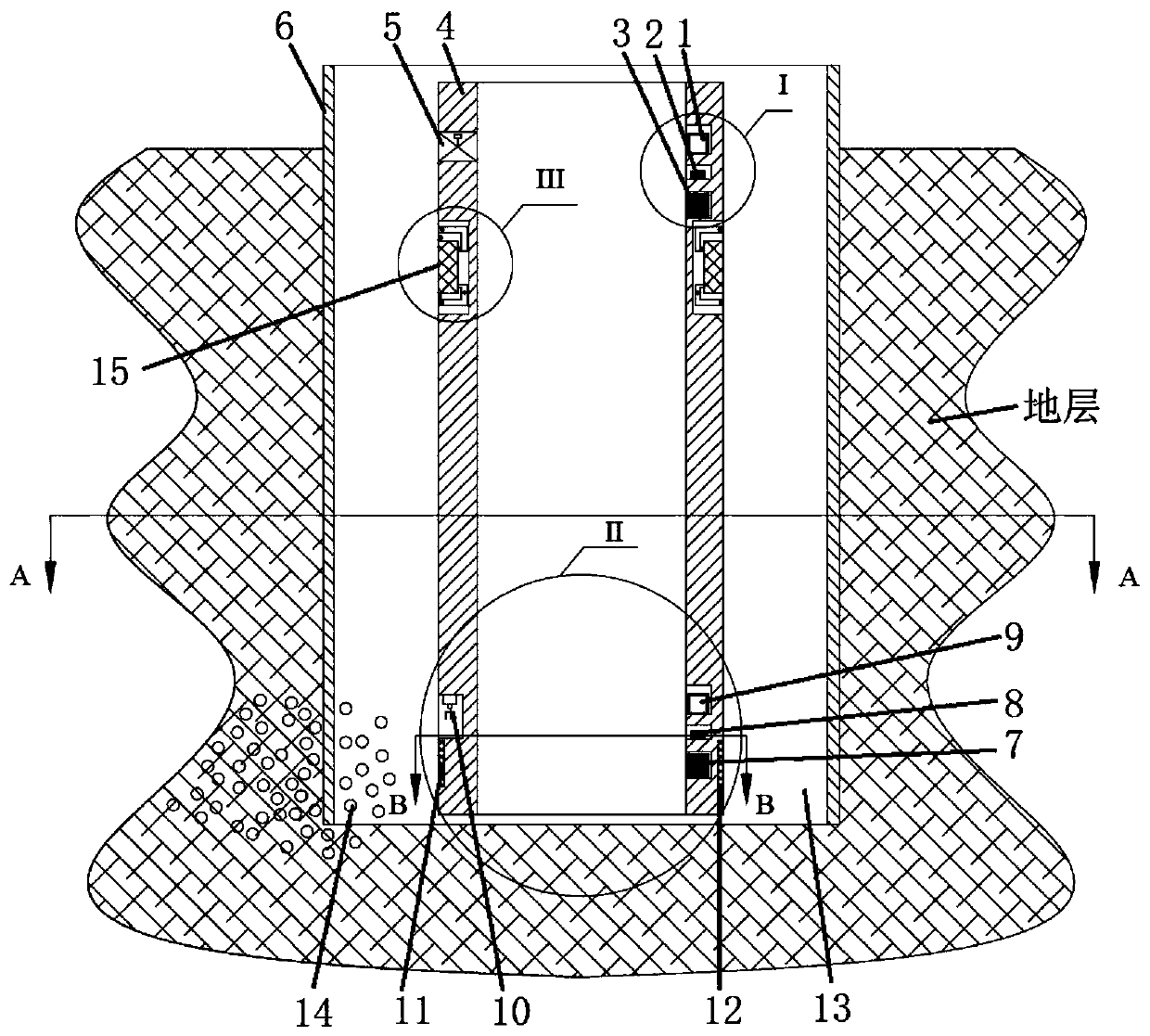

Underground gas cut intelligent control system

ActiveCN111255443AHarm reduction buys timeHigh precisionSurveyFlushingMechanical engineeringElectromagnetic valve

The invention relates to the field of underground gas cut monitoring and control, in particular to an underground gas cut intelligent control system which comprises a control assembly microcomputer, acontrol assembly storage battery, a signal receiver, a bypass electromagnetic valve, a signal projector, a monitoring assembly storage battery, a monitoring assembly microcomputer, a rotational viscometer, an electrical resistivity measuring positive electrode, an electrical resistivity measuring negative electrode, a packer and the like, wherein the control assembly microcomputer, the control assembly storage battery, the signal receiver, the signal projector, the monitoring assembly storage battery and the monitoring assembly microcomputer are mounted in mounting holes of a well drilling shaft bottom pipe column; the rotational viscometer, the electrical resistivity measuring positive electrode, the electrical resistivity measuring negative electrode and the packer are mounted in a dedicated mounting space of the outer wall of the well drilling shaft bottom pipe column; variation of viscosity and electrical resistivity of the drilling fluid are detected to judge whether the gas cutoccurs or not; the packer is utilized to temporarily seal and separate gas cut drilling fluid; and the bypass electromagnetic valve is utilized to reach communication between the well drilling shaft bottom pipe column and the annular space to conveniently replace the drilling fluid so as to avoid the blowout accident.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

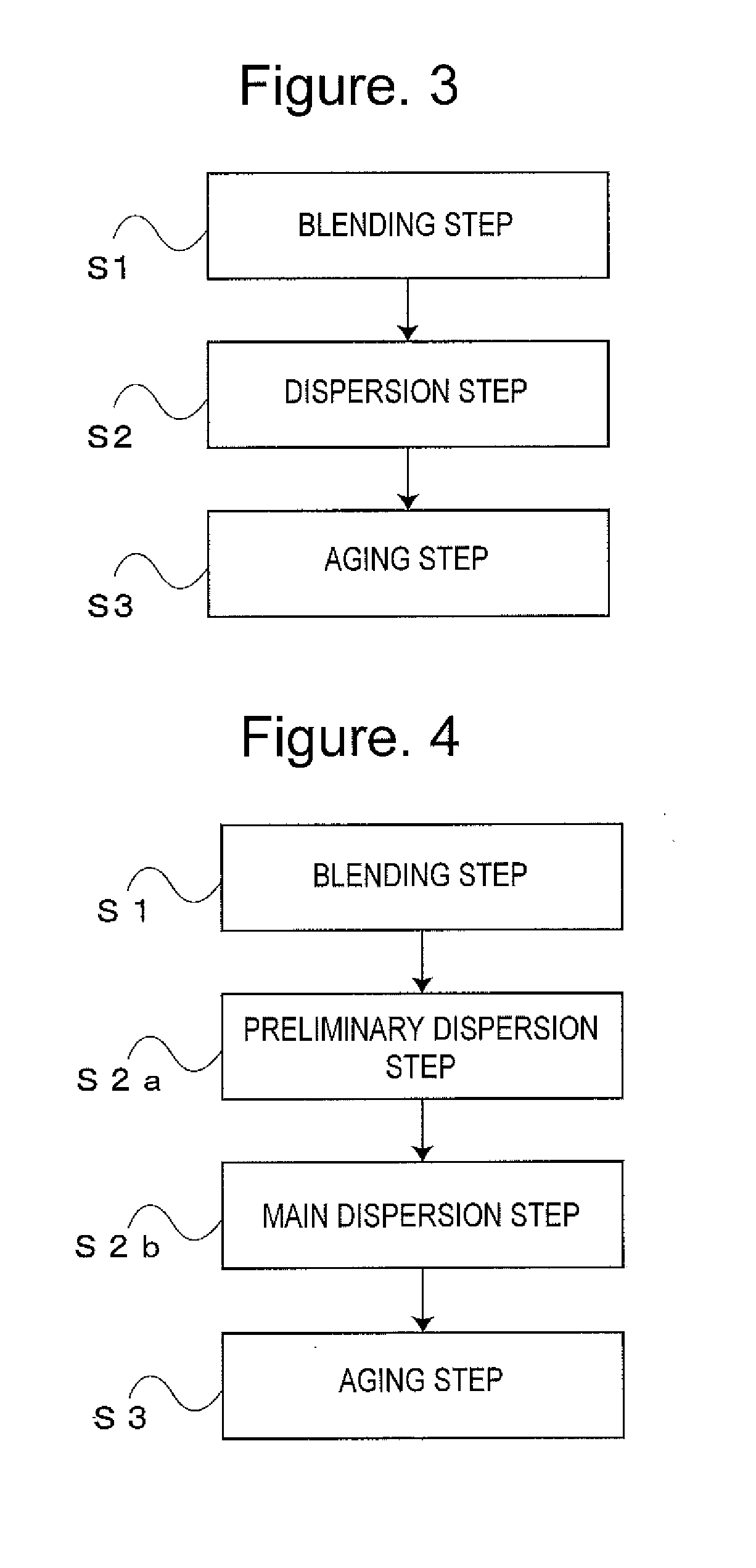

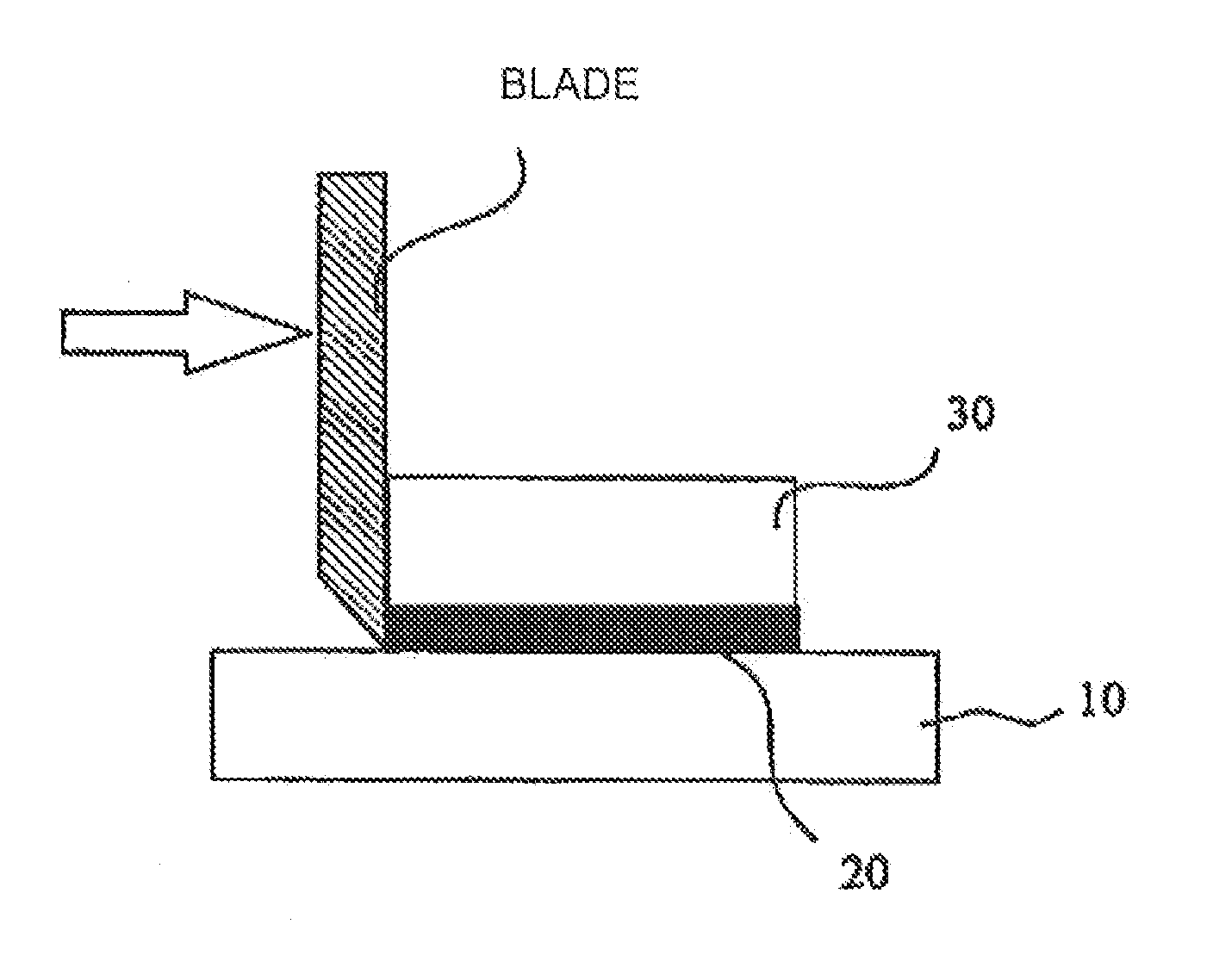

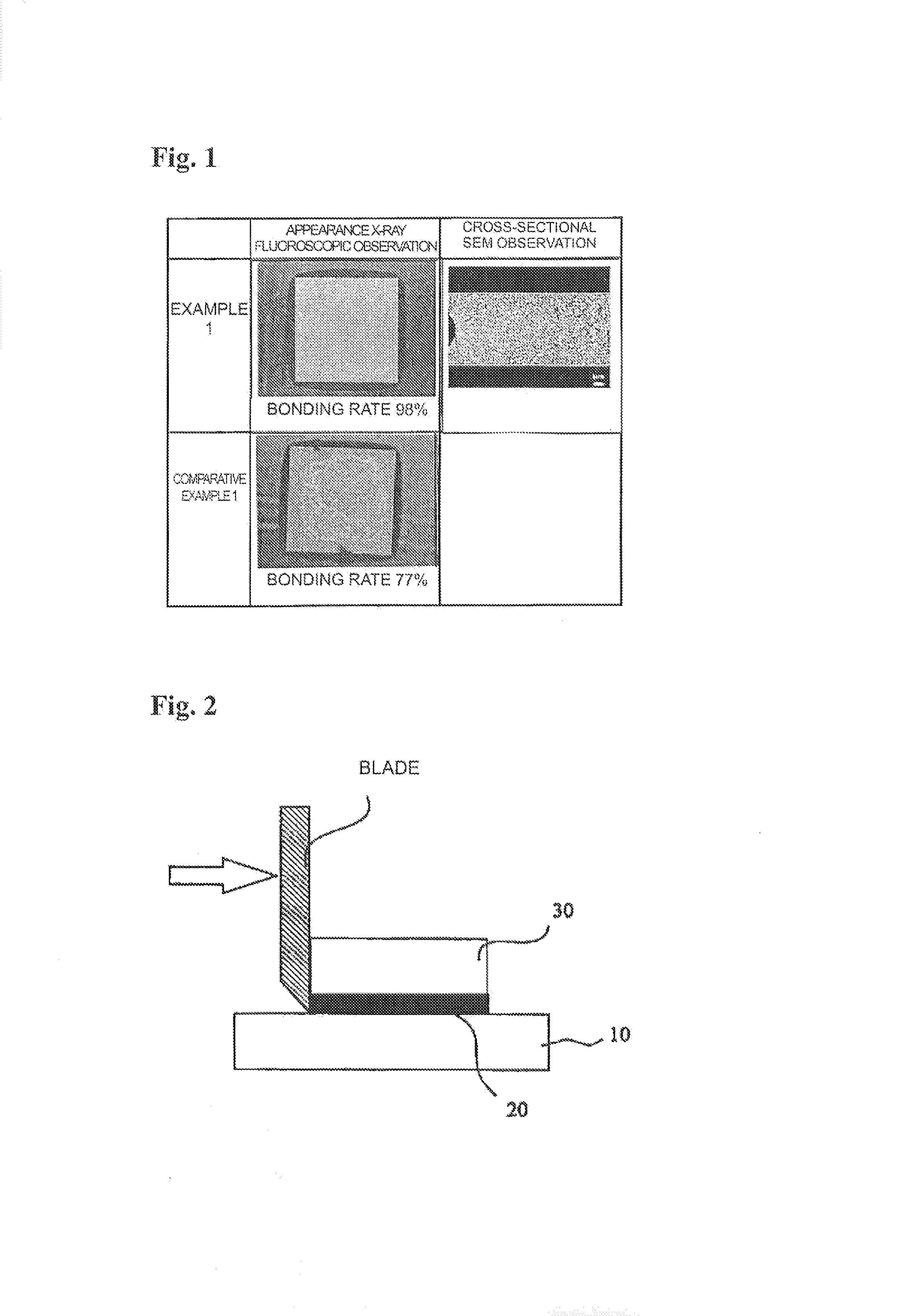

Noble metal paste for bonding of semiconductor element

ActiveUS20130168437A1Evenly sinteredCooking-vessel materialsSolid-state devicesOrganic solventMetallurgy

A precious metal paste which does not cause contamination of a member, which can be uniformly coated to a member to be bonded, and which is in good condition after bonding is provided. The present invention relates to a precious metal paste for bonding a semiconductor element, of the paste including a precious metal powder and an organic solvent, in which the precious metal powder has a purity of 99.9 mass % or more and an average particle diameter of 0.1 to 0.5 μm, the organic solvent has a boiling point of 200 to 350° C., and a thixotropy index (TI) value calculated from a measurement value of a viscosity at a shear rate of 4 / s with respect to a viscosity at a shear rate of 40 / s at 23° C. by means of a rotational viscometer is 6.0 or more.

Owner:TANAKA PRECIOUS METAL IND

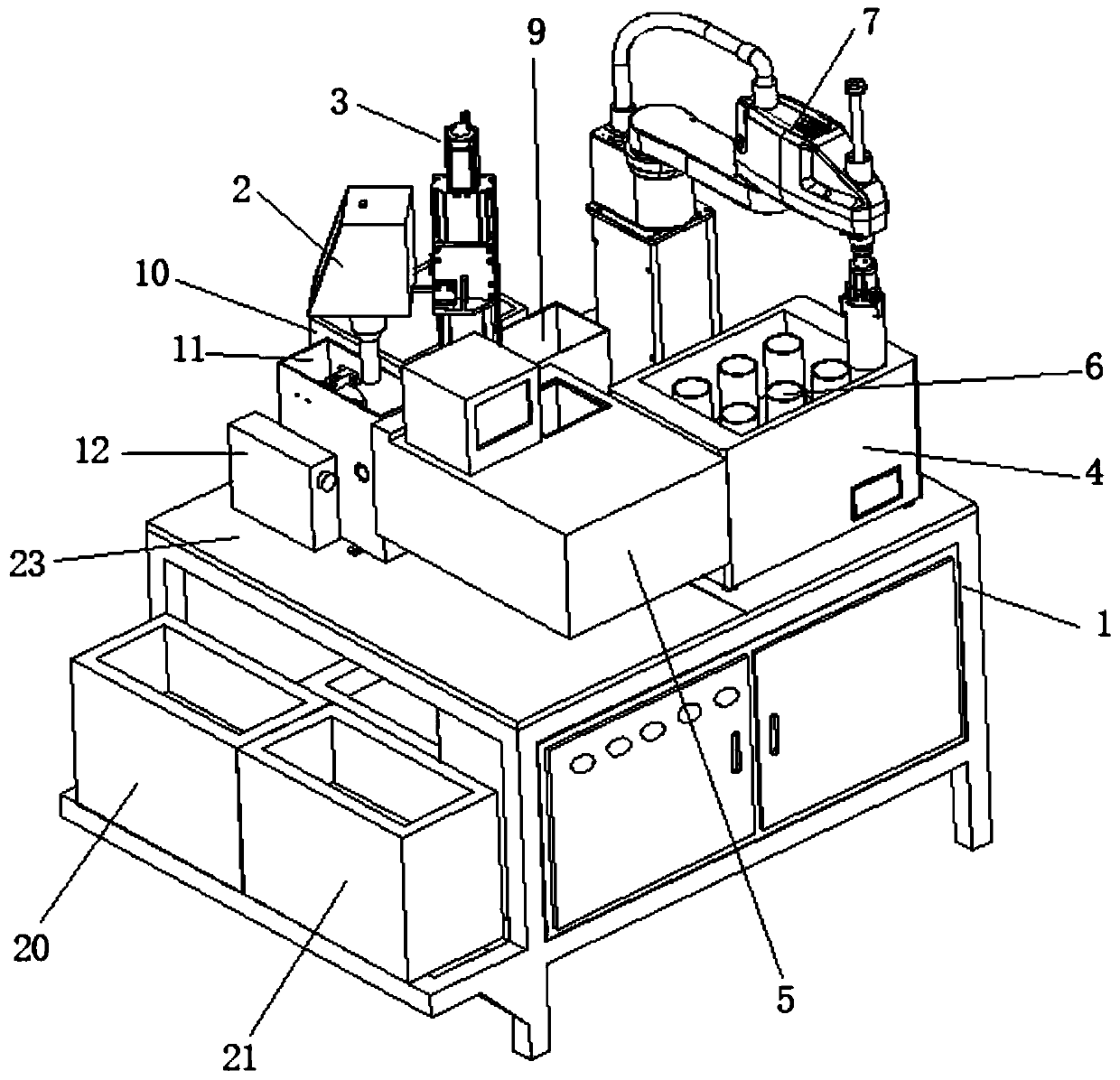

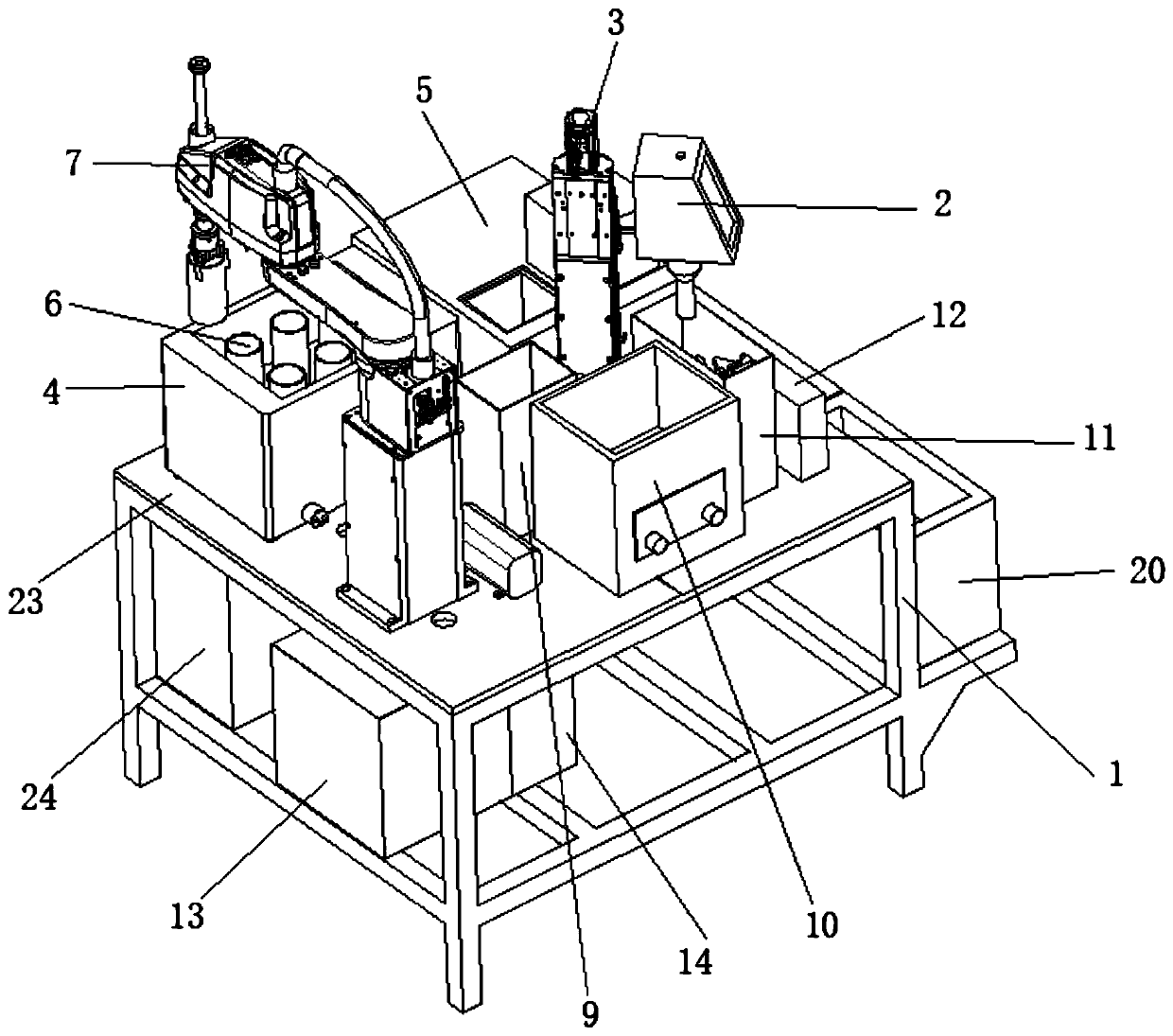

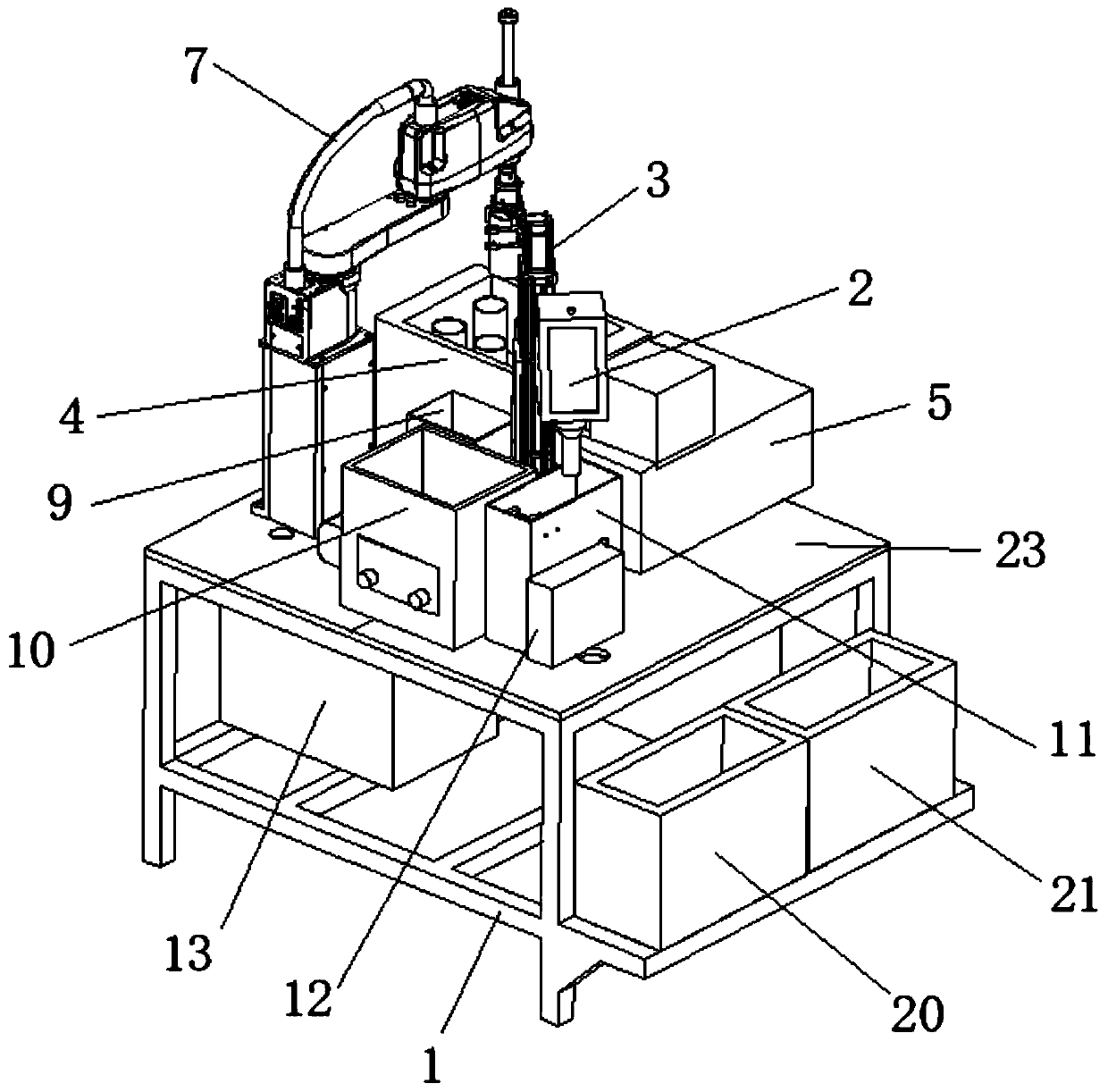

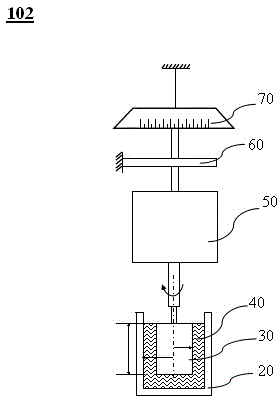

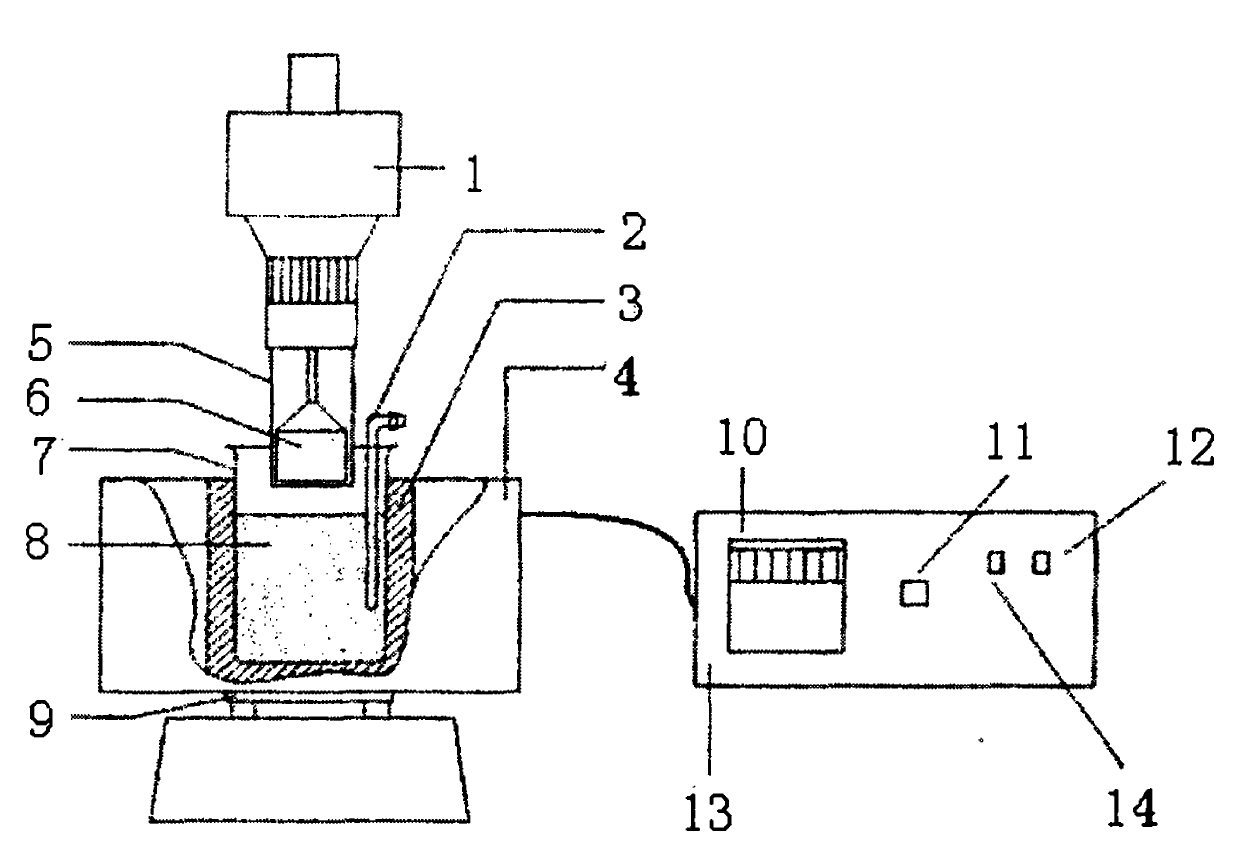

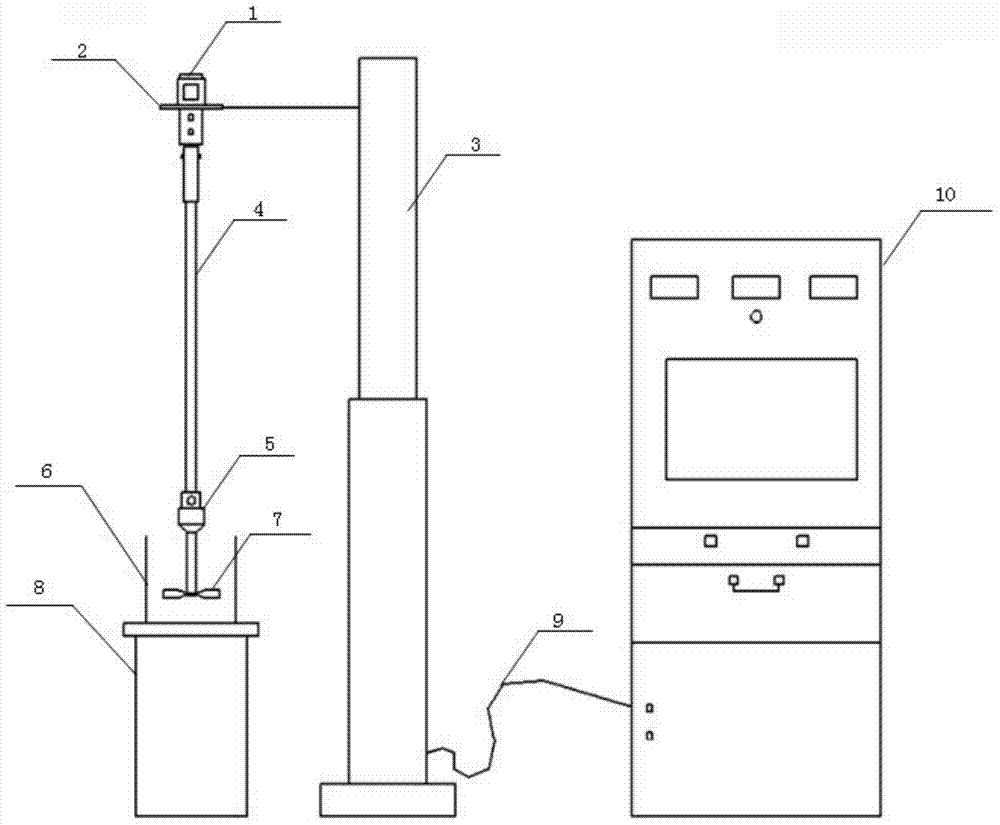

Full-automatic intelligent hydrodynamic viscosity measurement device and method

The invention provides a full-automatic intelligent liquid dynamic viscosity measurement device and method, and belongs to the field of experimental instruments. The full-automatic intelligent liquiddynamic viscosity measurement device comprises a viscosity measurement unit which comprises a rotary viscometer and a viscometer adjusting frame, wherein the rotary viscometer is used for measurementthe viscosity value of the measured liquid, and the viscometer adjusting frame drives the rotary viscometer to lift, translate and rotate; a constant-temperature water bath unit which comprises a preheating constant-temperature water bath kettle and a measurement constant-temperature water bath kettle, wherein the two water bath kettles are used for controlling the temperature of the measured liquid; a sample receiving and sending unit which is used for clamping and releasing a sample cup filled with the measured liquid between the two water bath kettles in a reciprocating manner; a cleaning unit which is used for cleaning a rotor of the rotary viscometer; a drying unit which is used for drying the cleaned rotor; a control unit which is used for controlling the operation of each unit; anda data acquisition and analysis unit which is used for acquiring the viscosity data measured by the rotary viscometer and acquiring and analyzing the viscosity data. The device integrates the artificial intelligence and the automation as one, and is high in measurement precision and efficiency.

Owner:YANCHANG OIL FIELD

Soft capsule shell and soft capsule

PendingCN113398088AMeet the requirements of industrial productionPharmaceutical non-active ingredientsCapsule deliveryGellan gumPolymer science

The invention relates to a soft capsule shell and a soft capsule. The invention provides the soft capsule shell. The soft capsule shell is prepared from a film-forming composition comprising 1.5-5 wt% of a first gelling agent, 30-40 wt% of starch, 10-25 wt% of a plasticizer, and 35-55 wt% of water, where the first gelling agent is gellan gum having the following properties that when measured by a rotational viscometer, the gellan gum solution obtained by dissolving 1.5 wt% of gellan gum in water at 90 DEG C for 30 minutes has a viscosity in range of 10-60 mPa.s, the soft capsule shell contains 0-3 wt% of starch particles, and the starch particles are starch particles with an average particle size of 10-50 microns. The soft capsule shell has an enteric effect, and disintegration time limit of the soft capsule shell conforms to regulations of pharmacopoeia at home and abroad.

Owner:SIRIO PHARMA CO LTD

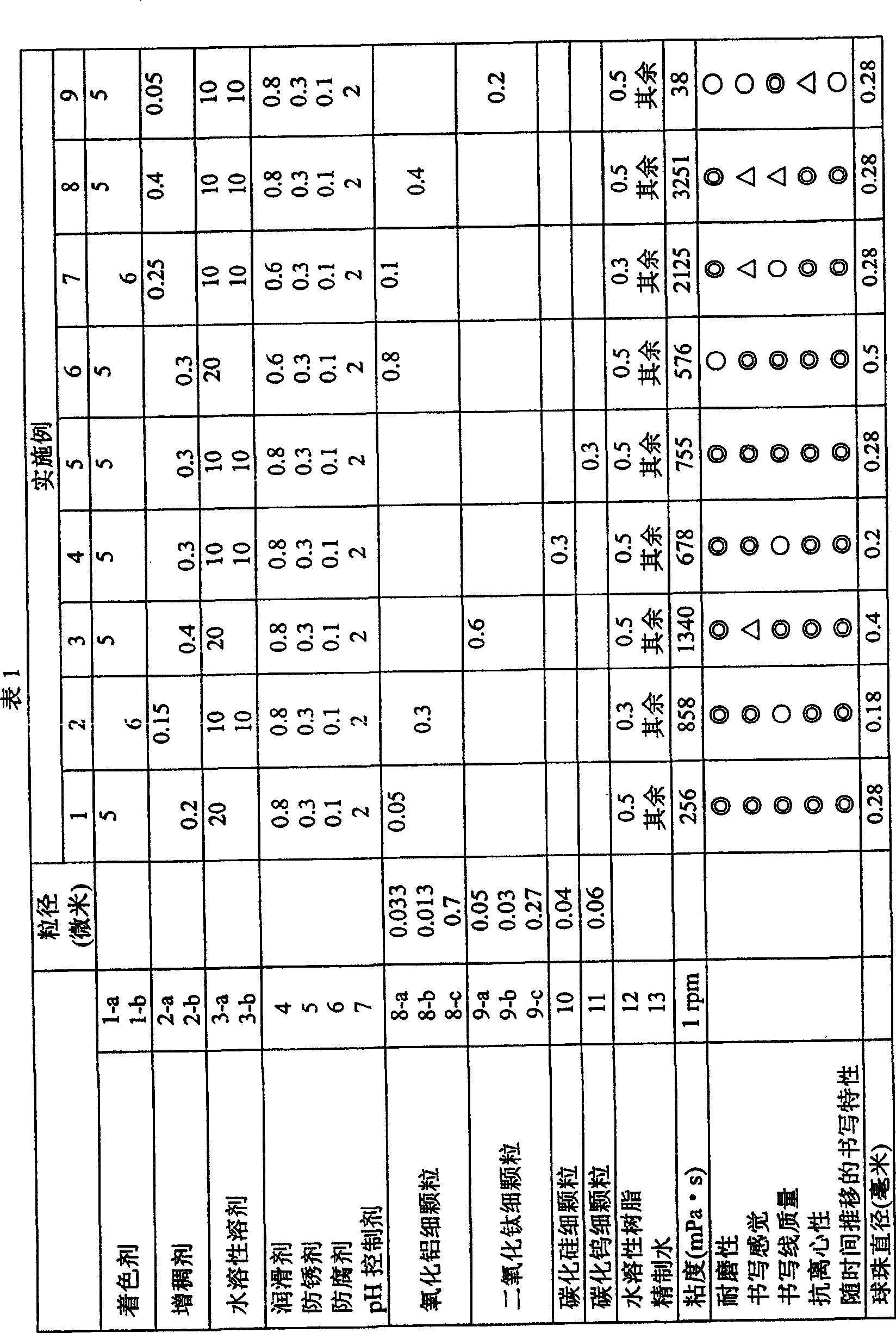

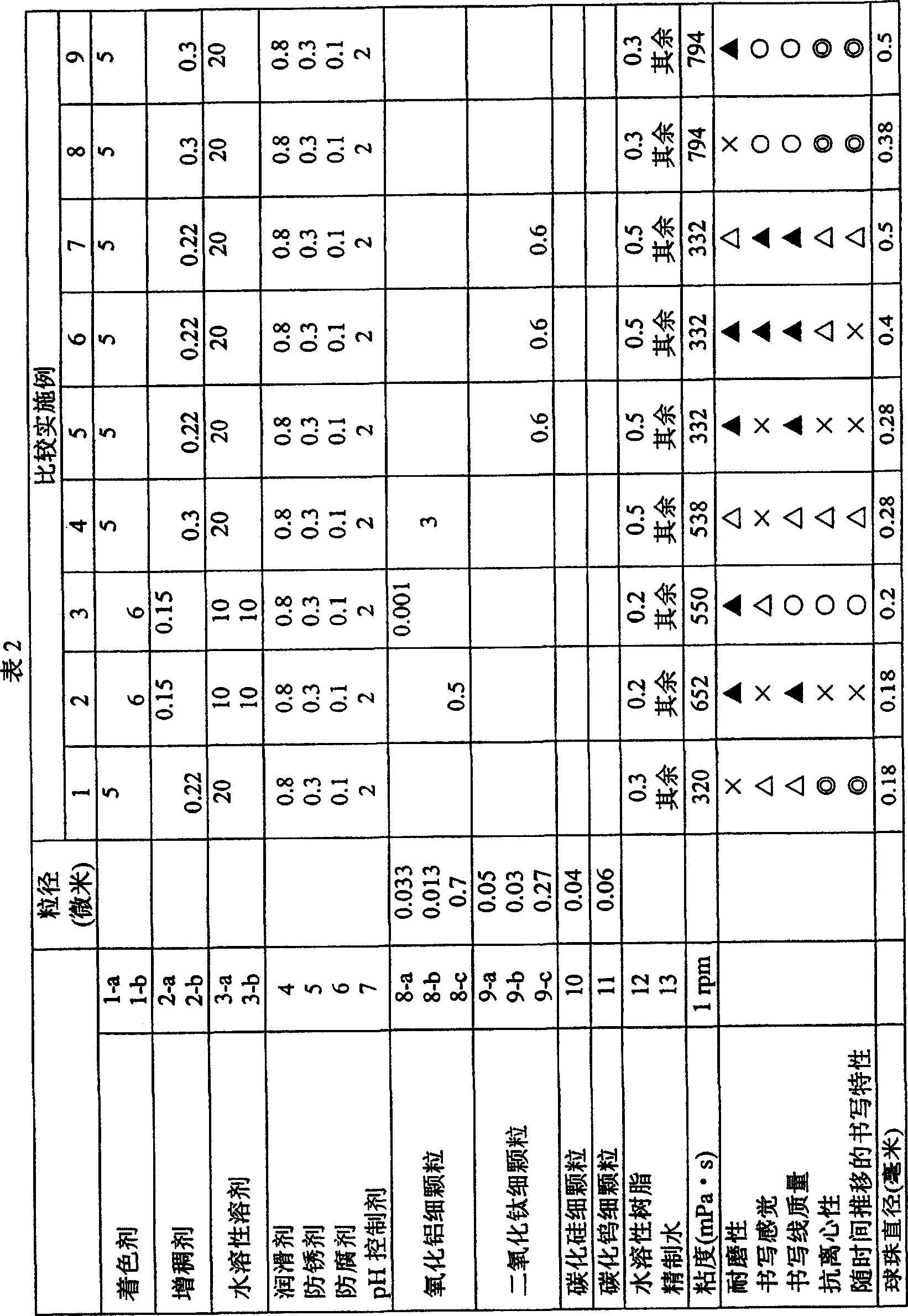

Water-based ink composition for fine pointed ballpoint pen and fine pointed ballpoint pen

Provided is a water-based ink composition for a fine pointed ballpoint pen characterized by blending an ink composition comprising at least water, a colorant and a water soluble solvent with at least one kind of ultra fine particles selected from the group consisting of alumina, titanium oxide, silica, silicon carbide and tungsten carbide each having an average particle diameter of less than 0.1 [mu]m, wherein a blending amount of the ultra fine particles is 0.002 to 2 % by weight based on the ink composition, particularly preferably an ink composition having a viscosity of 50 to 2000 mPa.s (25 DEG C) which is measured at 1 rpm by means of a corn and plate type rotational viscometer (1 DEG 34'R24 corn). Further, provided is a fine pointed ballpoint pen having a ball of a diameter of 0.4 mm or less, filled with the water-based ink composition described above.

Owner:MITSUBISHI PENCIL CO LTD

Curable material and method for molding said thermally curable material

PendingUS20200157257A1Excellent continuous formabilitySuppression of glitchesCoatingsMethacrylatePolymer science

The present invention provides a thermosetting material, which contains the following components (A) to (C) and which, when measured with a rotational viscometer at a constant shear rate (JIS K7117-2:1999), exhibits a viscosity at 25° C. and 10 s1 of 5 Pa·s or more and 200 Pa·s or less and, when measured with a rotational viscometer at a constant shear rate in the same manner as above, exhibits a viscosity at 25° C. and a shear rate of 100 s1 of 0.3 Pa·s or more and 50 Pa·s or less. (A): a (meth) acrylate compound in which a substituted or unsubstituted alicyclic hydrocarbon group having 6 or more carbon atoms is ester-bonded, and which, when measured with a rotational viscometer at a constant shear rate in the same manner as above, exhibits a viscosity of 5 to 300 mPa·s as a viscosity measured at 25° C. and 10 to 100 s−1; (B): spherical silica; and (C): a black pigment.

Owner:IDEMITSU KOSAN CO LTD

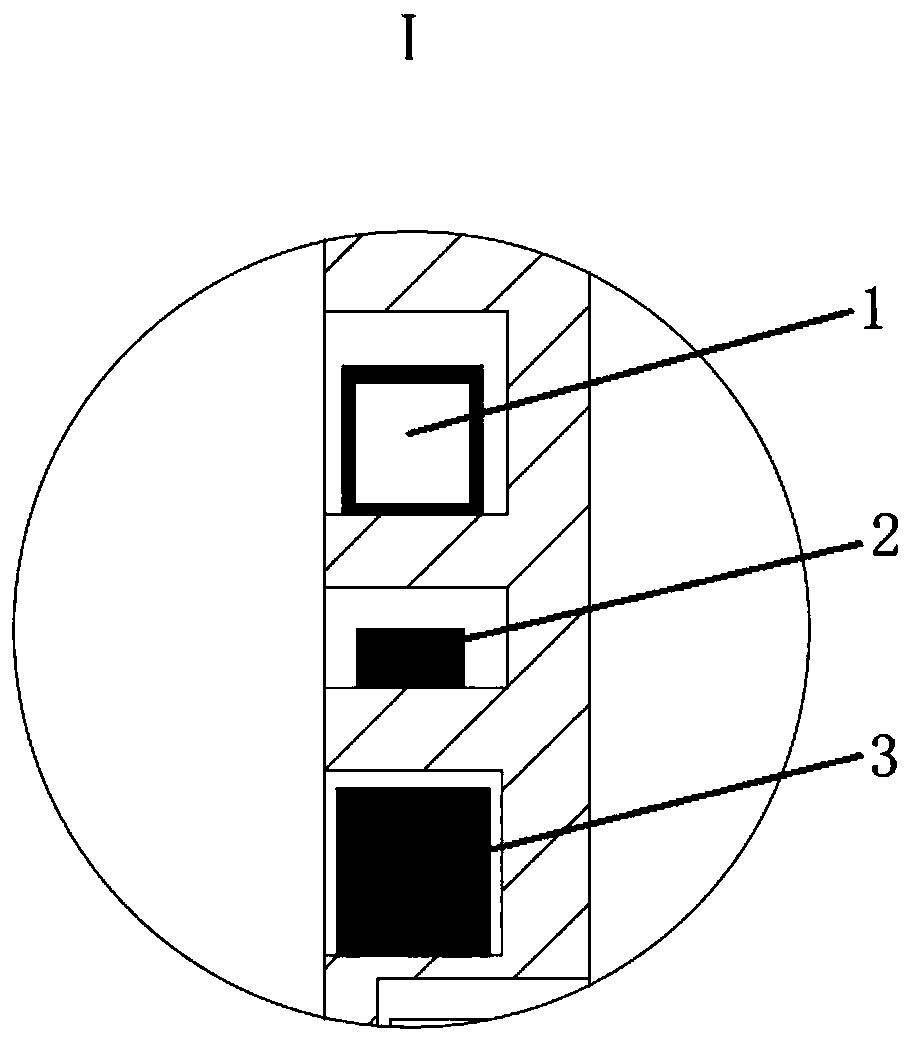

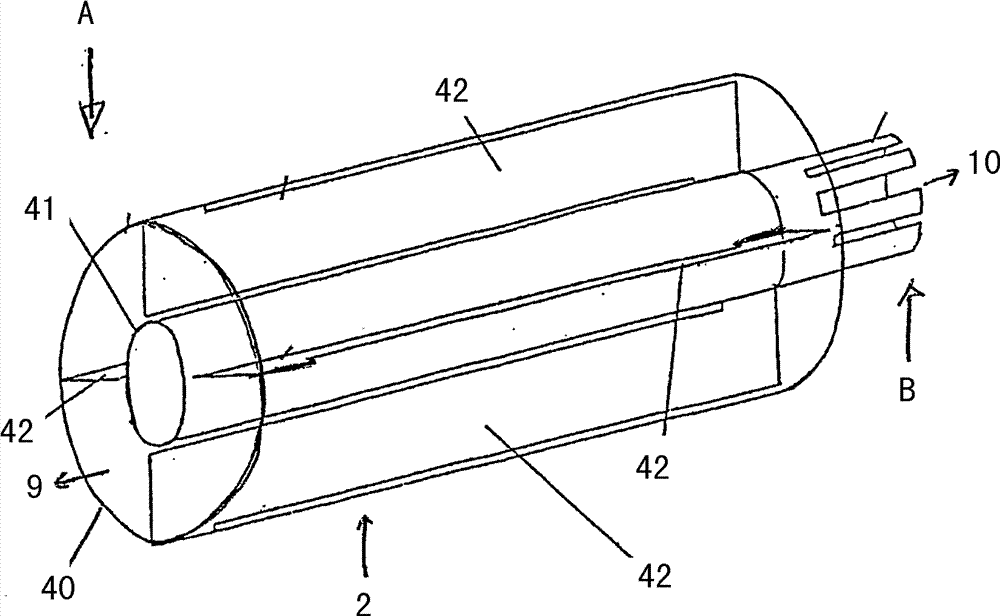

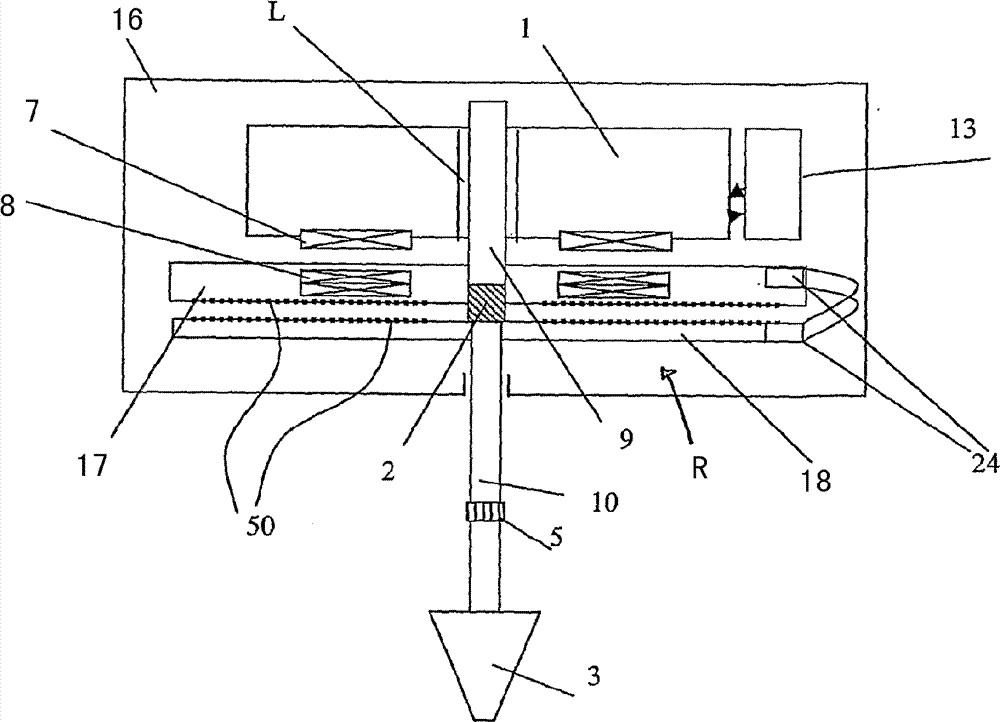

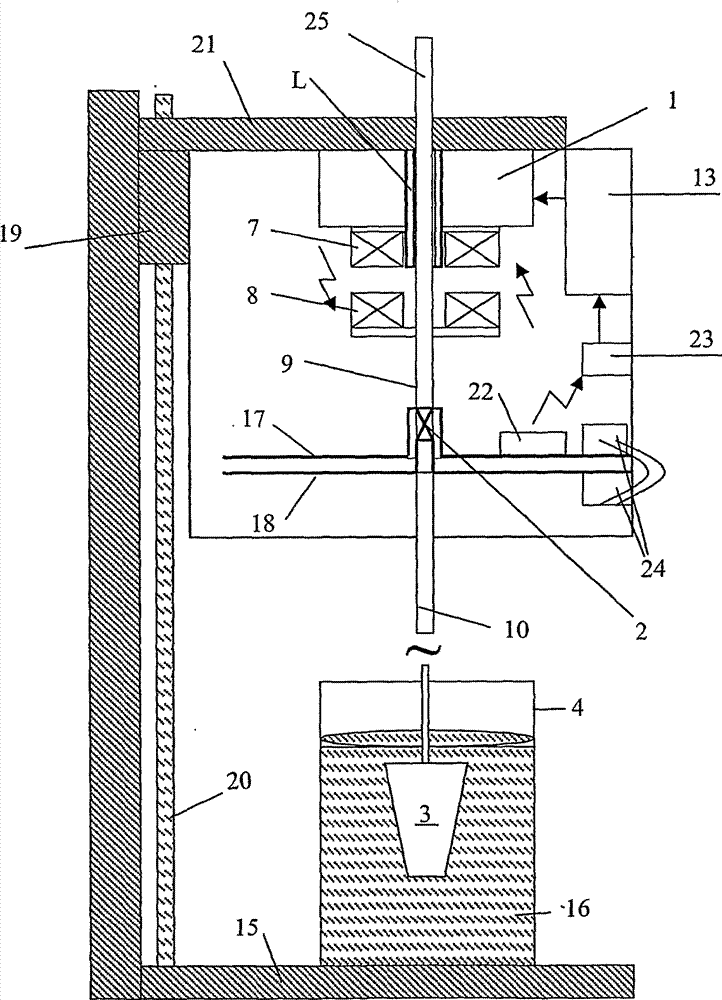

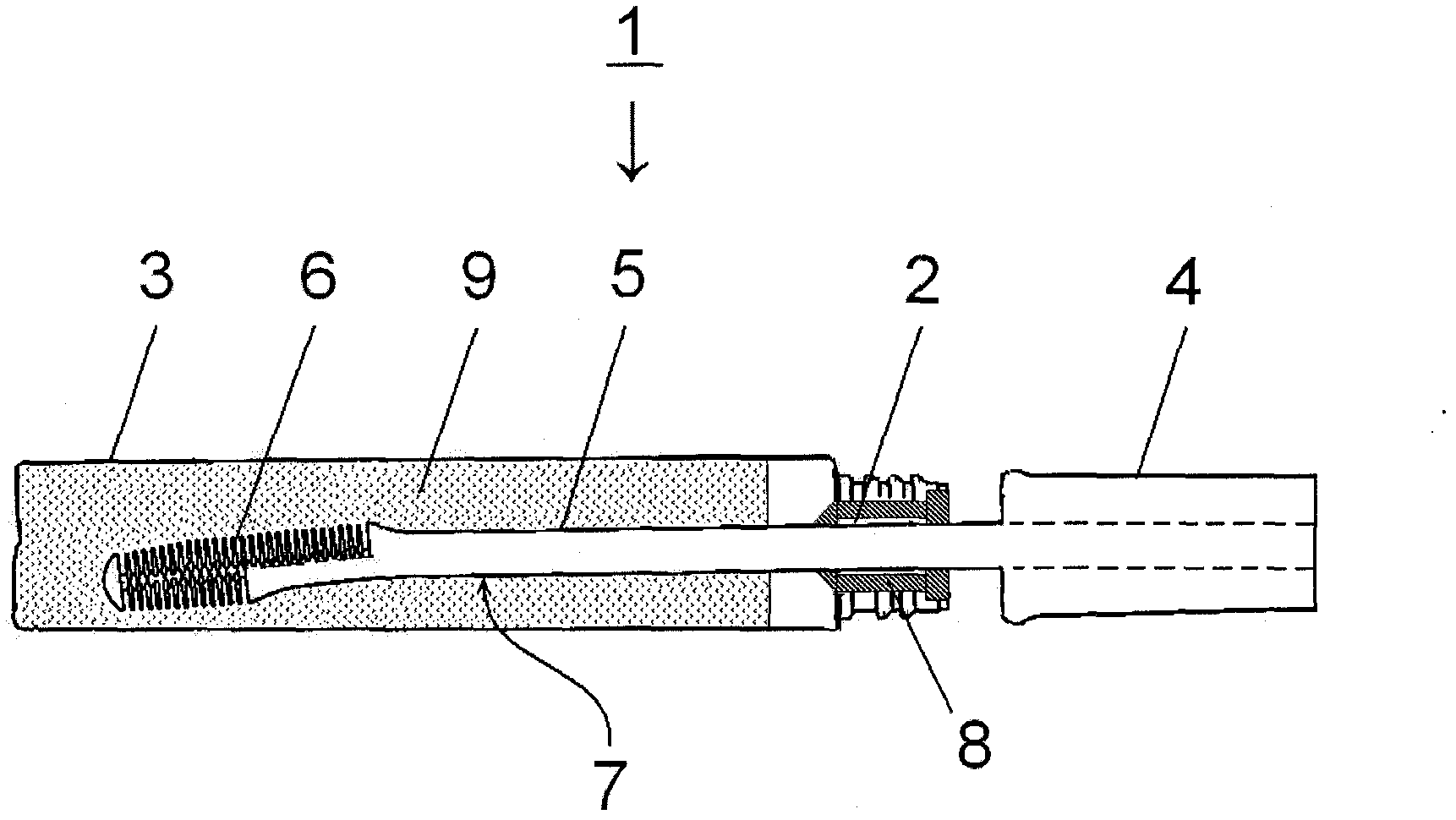

Rotational viscometer

InactiveCN102713561AAccurate measurementExclude distortionFlow propertiesAngular degreesRotational viscometer

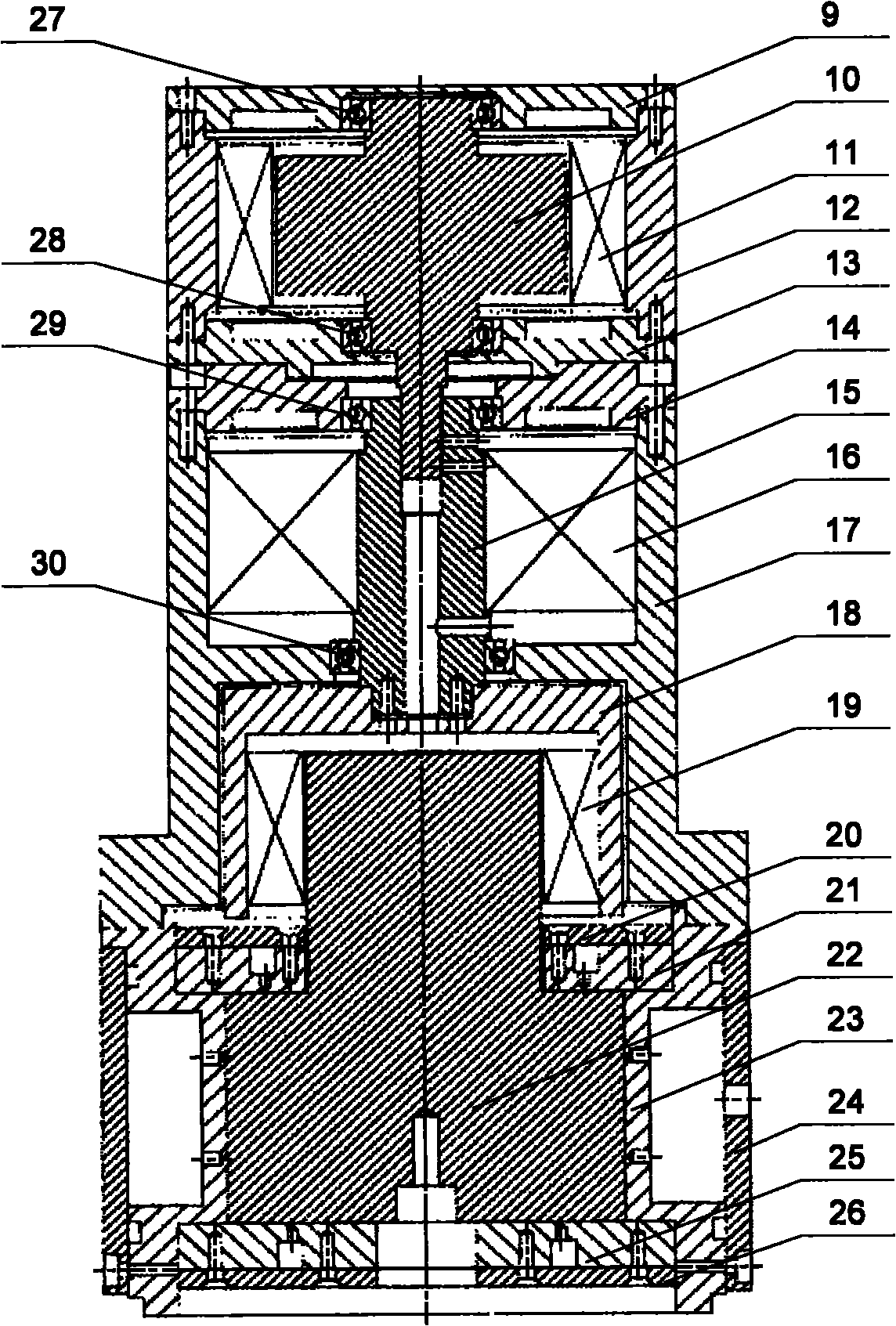

The invention relates to a rotational viscometer, comprising a measuring shaft (25) that can be rotated at a specified rotational speed, a measuring part (3) that is carried by said measuring shaft and that can be lowered into a sample, and a detection unit for determining the angle of twist of the measuring part (3) relative to the driven part of the measuring shaft (25).; According to the invention, a twistable element (2) is inserted into the measuring shaft (25), preferably in the section of the measuring shaft close to the motor, the detection unit (17, 18, 24) is moved along with the shaft and determines the relative twist or the angle of twist between the shaft part (9) located on the motor side relative to the twistable element (2) and the shaft part (10) located on the measuring-part side, and the output signals of the detection unit (17, 18, 24) are fed to an evaluation device (13) as the basis for determining the viscosity of the sample.

Owner:安东帕有限责任公司

Water-based ink composition for fine pointed ballpoint pen and fine pointed ballpoint pen

Provided is a water-based ink composition for a fine pointed ballpoint pen characterized by blending an ink composition comprising at least water, a colorant and a water soluble solvent with at least one kind of ultra fine particles selected from the group consisting of alumina, titanium oxide, silica, silicon carbide and tungsten carbide each having an average particle diameter of less than 0.1 [mu]m, wherein a blending amount of the ultra fine particles is 0.002 to 2 % by weight based on the ink composition, particularly preferably an ink composition having a viscosity of 50 to 2000 mPa.s (25 DEG C) which is measured at 1 rpm by means of a corn and plate type rotational viscometer (1 DEG 34'R24 corn). Further, provided is a fine pointed ballpoint pen having a ball of a diameter of 0.4 mm or less, filled with the water-based ink composition described above.

Owner:MITSUBISHI PENCIL CO LTD

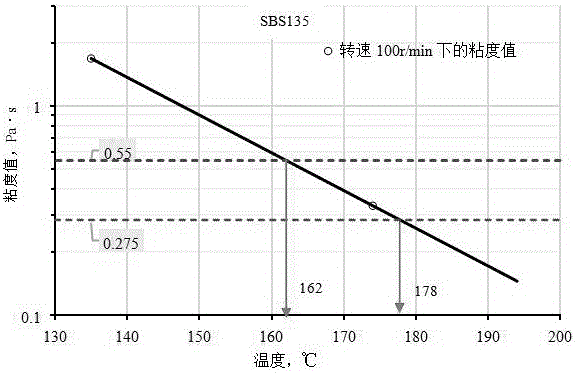

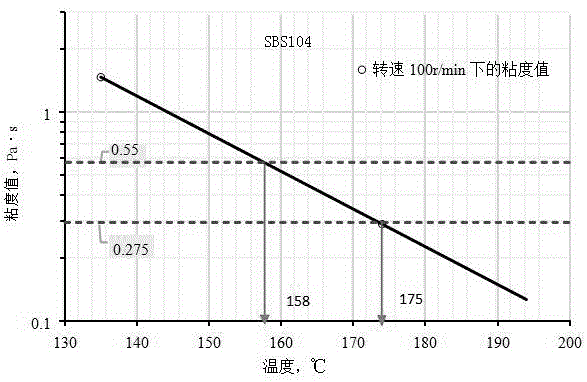

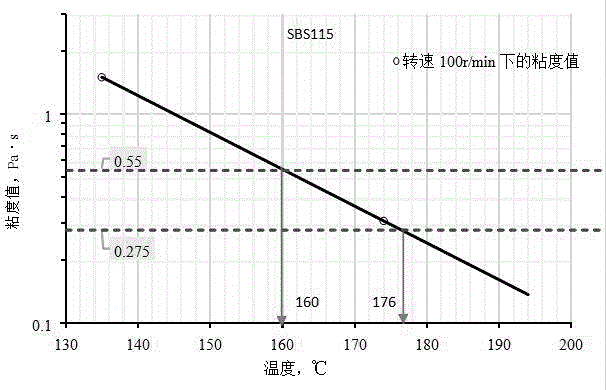

SBS modified asphalt construction temperature determination method

InactiveCN106556554AClear legal meaningThe experimental results are accurateFlow propertiesThermometers using physical/chemical changesRoad engineeringEngineering

The invention discloses a SBS modified asphalt construction temperature determination method and belongs to the field of road engineering. The method comprises the following steps: A, by the utilization of a rotational viscometer, by the adoption of a No. 27 rotor and at the revolving speed of 100 RPM, viscosity number of a SBS modified asphalt sample used in engineering practice is acquired at 135 DEG C and at 174DEG C; B, a relation curve of logarithmic viscosity and temperature is drawn; and C, with the temperature corresponding to 0.275 Pa.s as a mixing temperature and with the temperature corresponding to 0.55 Pa.s as a compaction temperature, corresponding mixing temperature and compaction temperature are calculated by interpolation algorithm. In comparison with existing design methods, the determination method has characteristics of clear physical significance, accurate experimental results and the like, and also has good engineering practice effects.

Owner:SHANDONG TRANSPORTATION INST +1

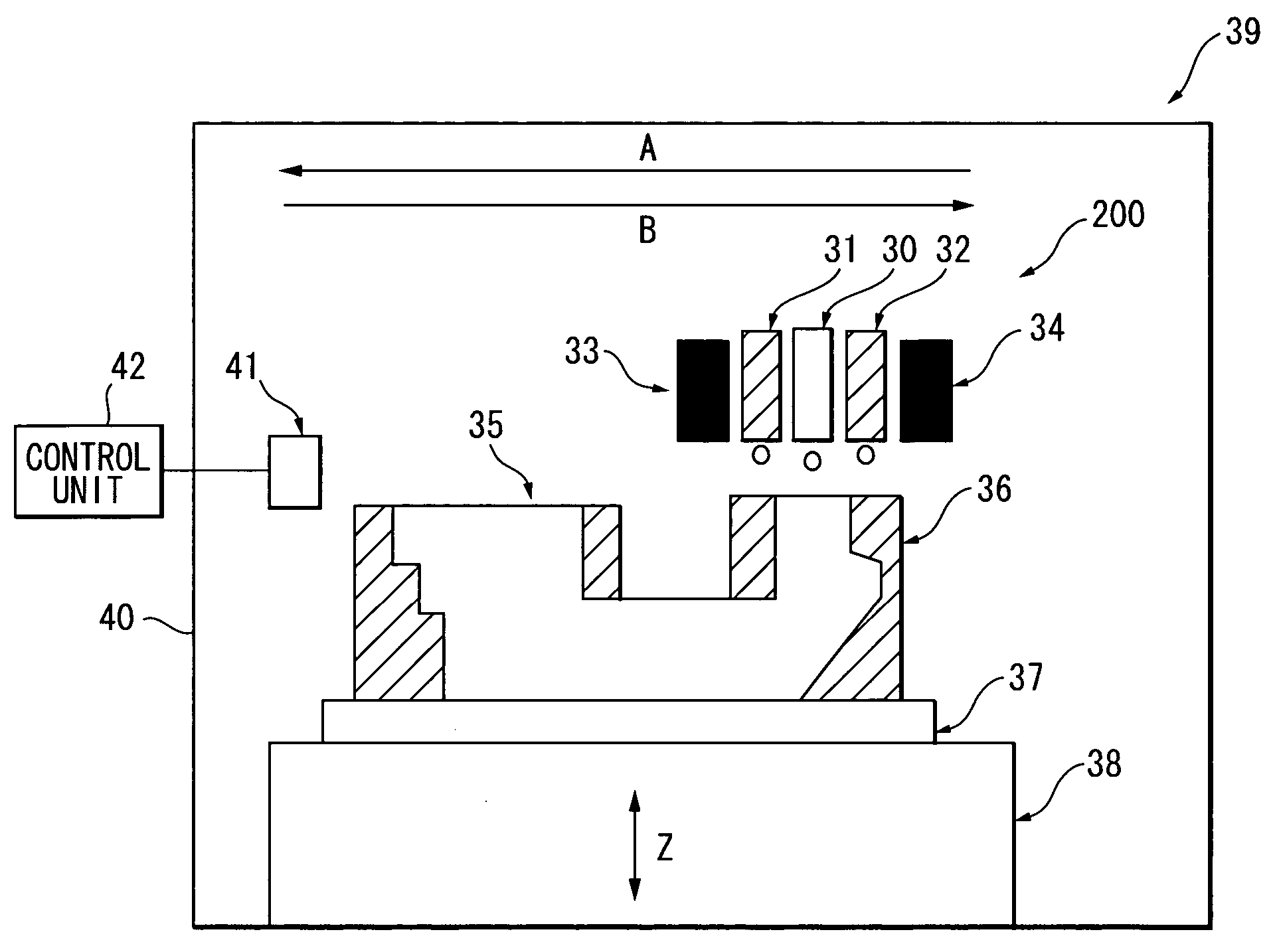

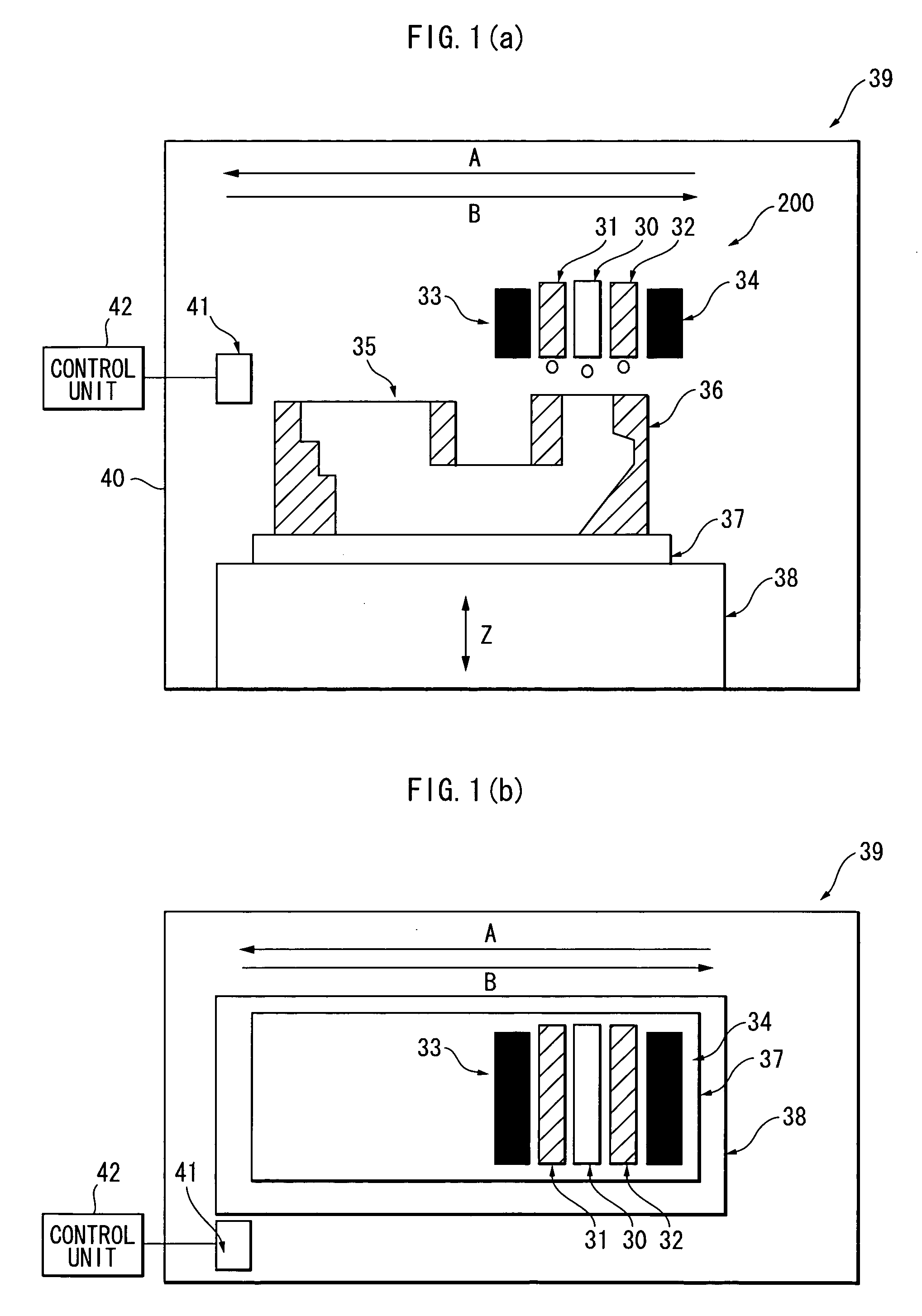

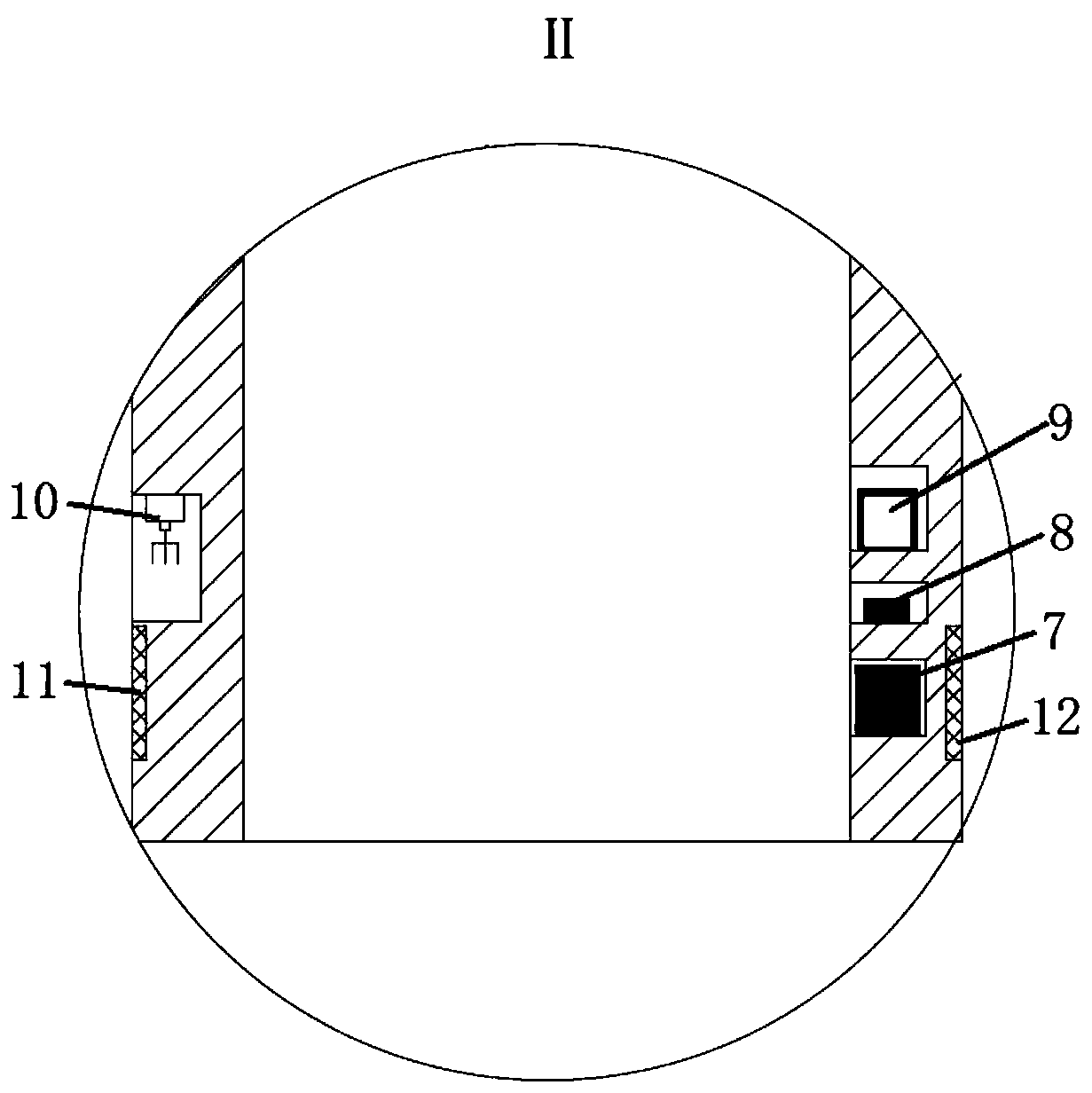

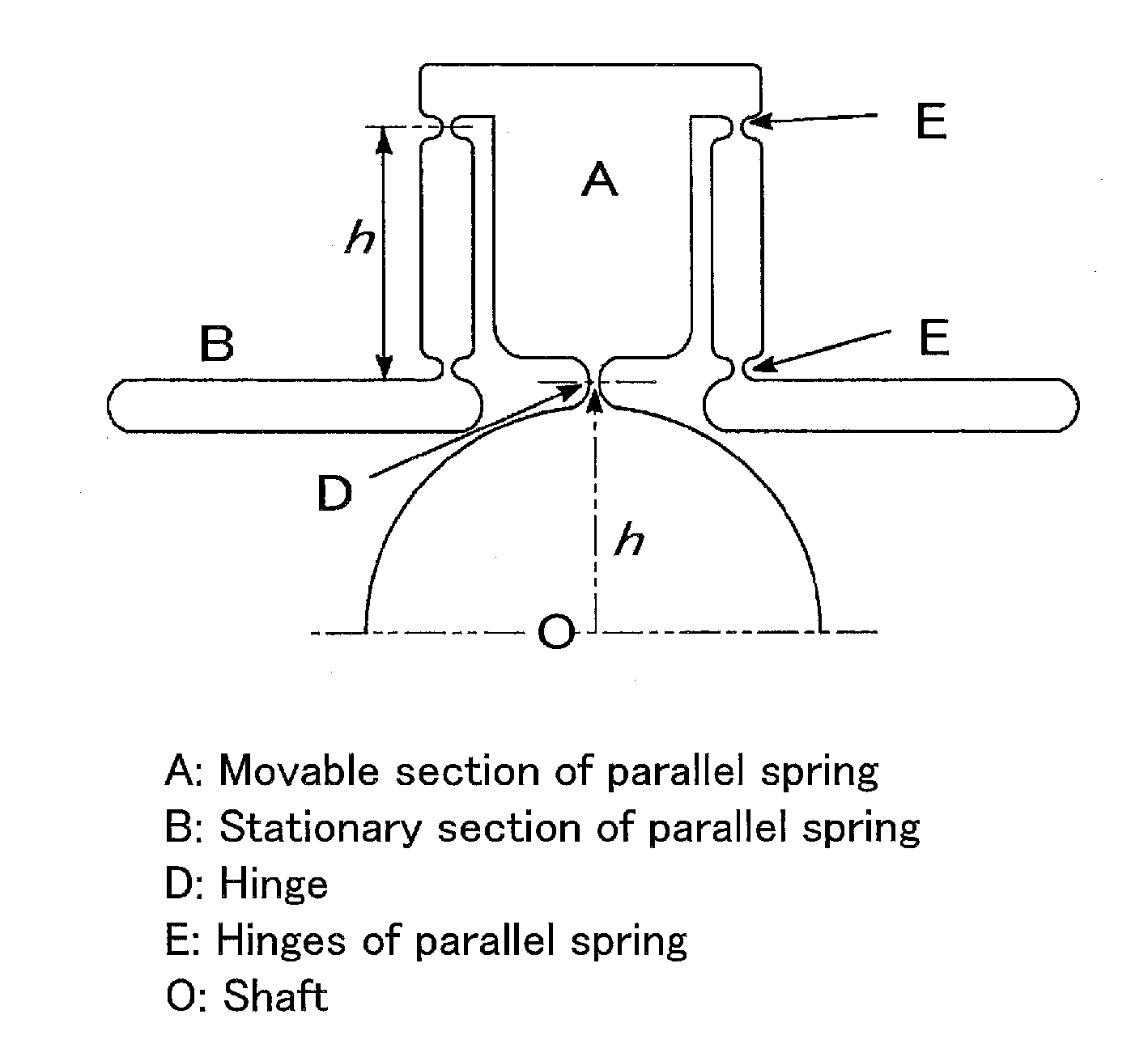

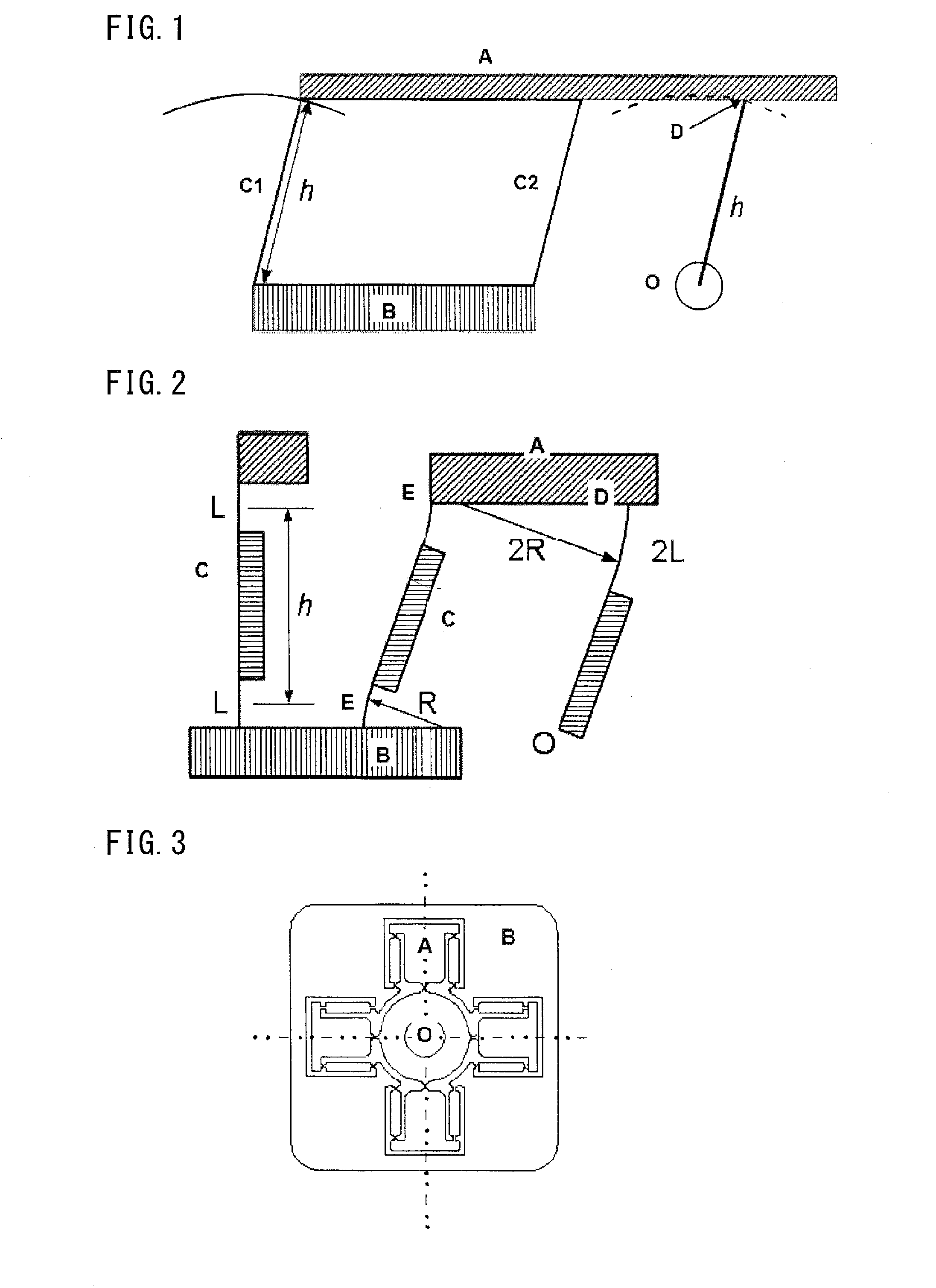

Rotating shaft holding mechanism and rotational viscometer with same

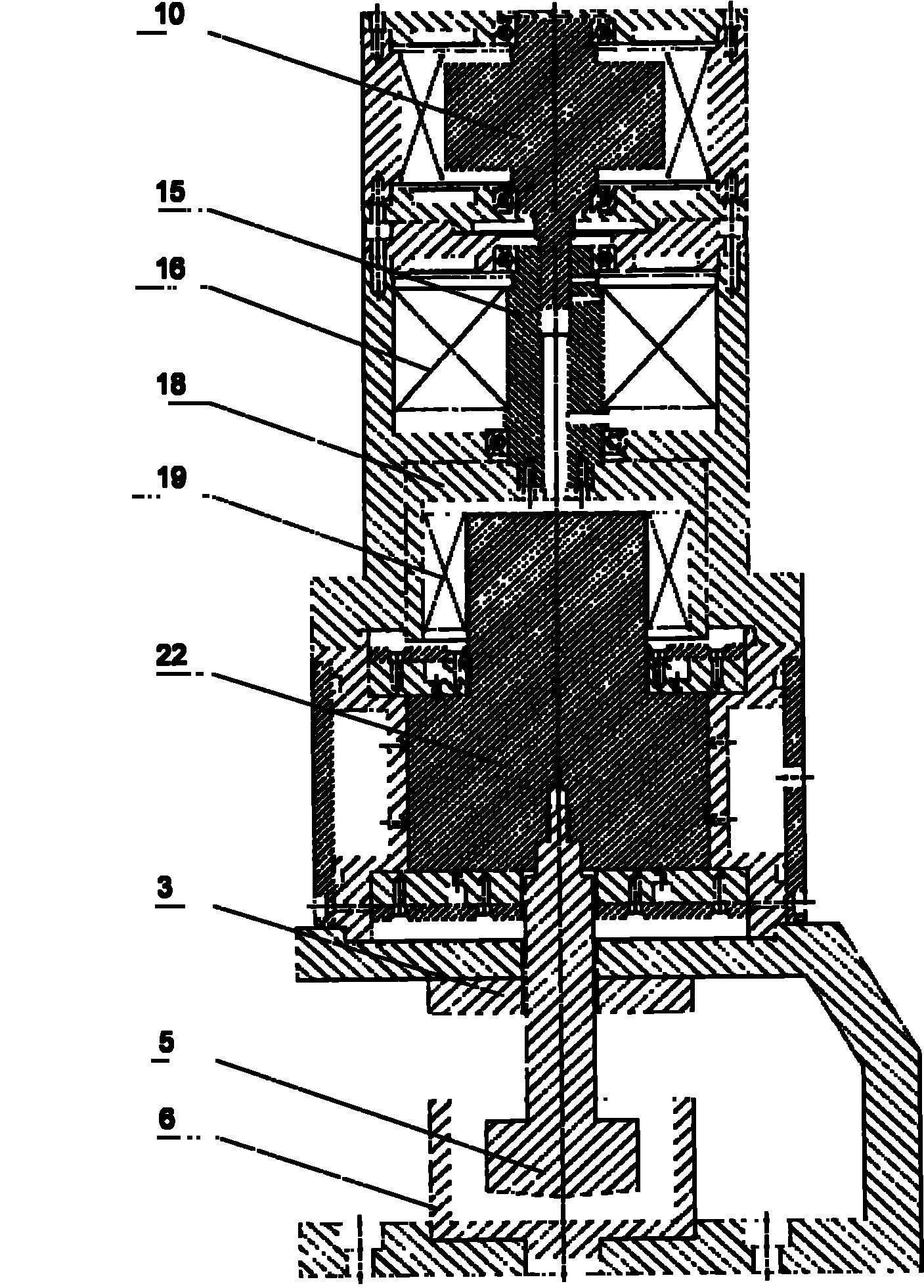

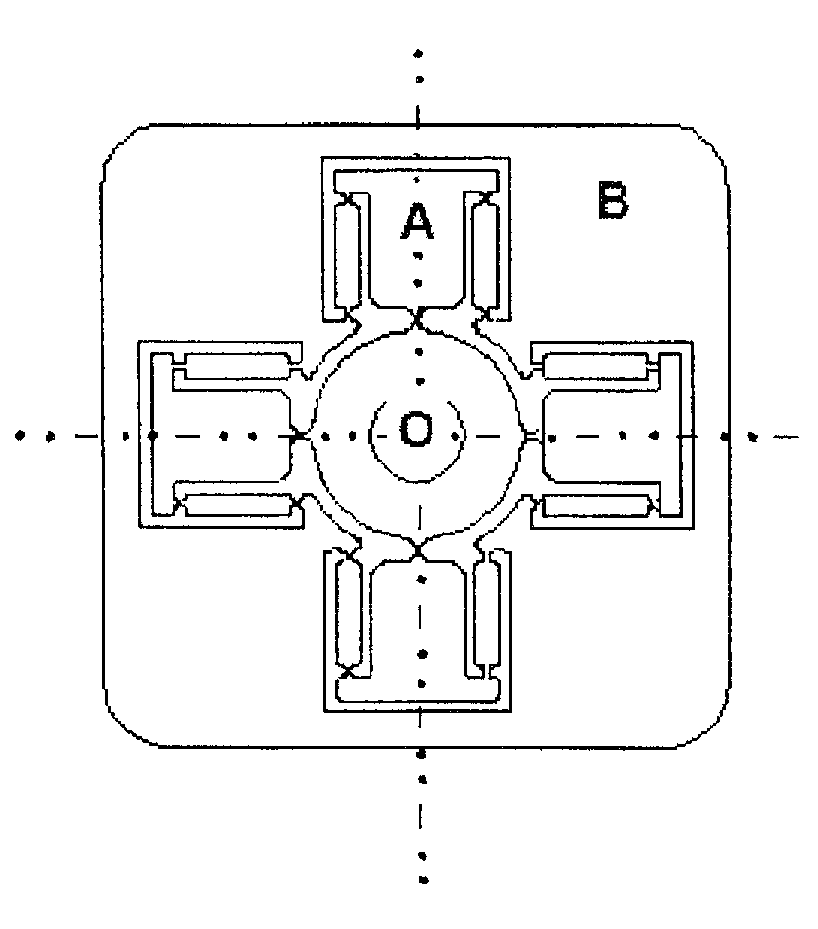

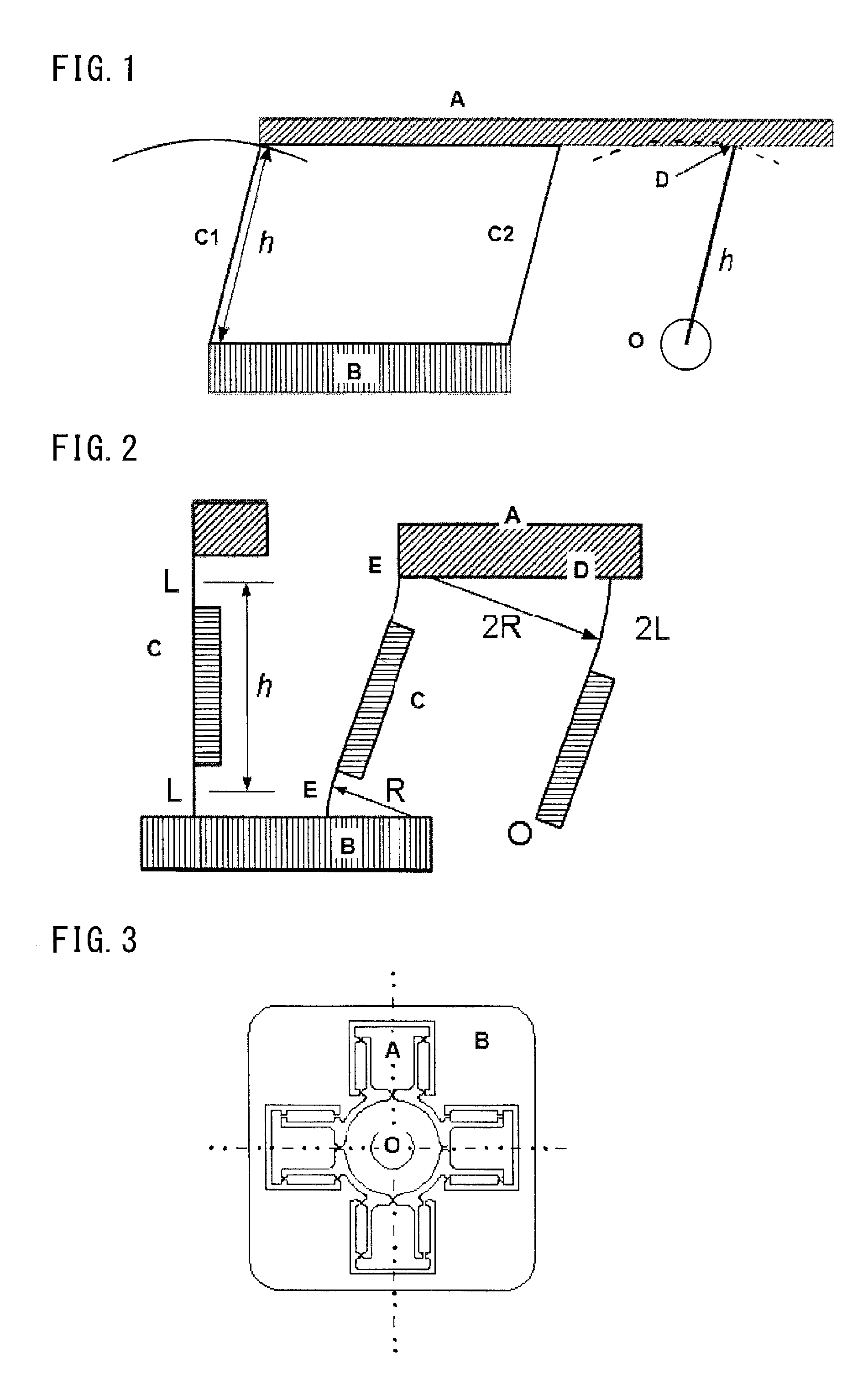

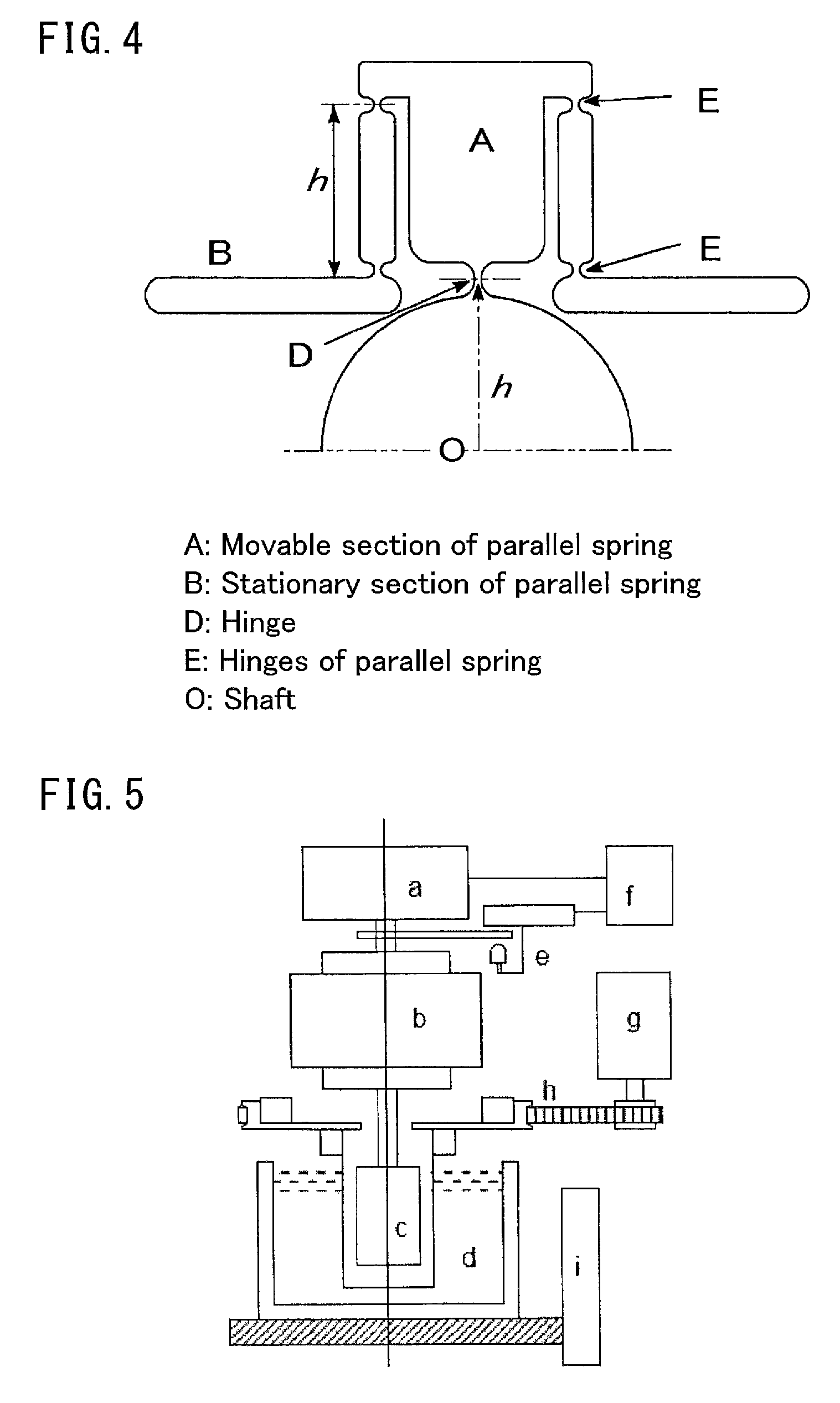

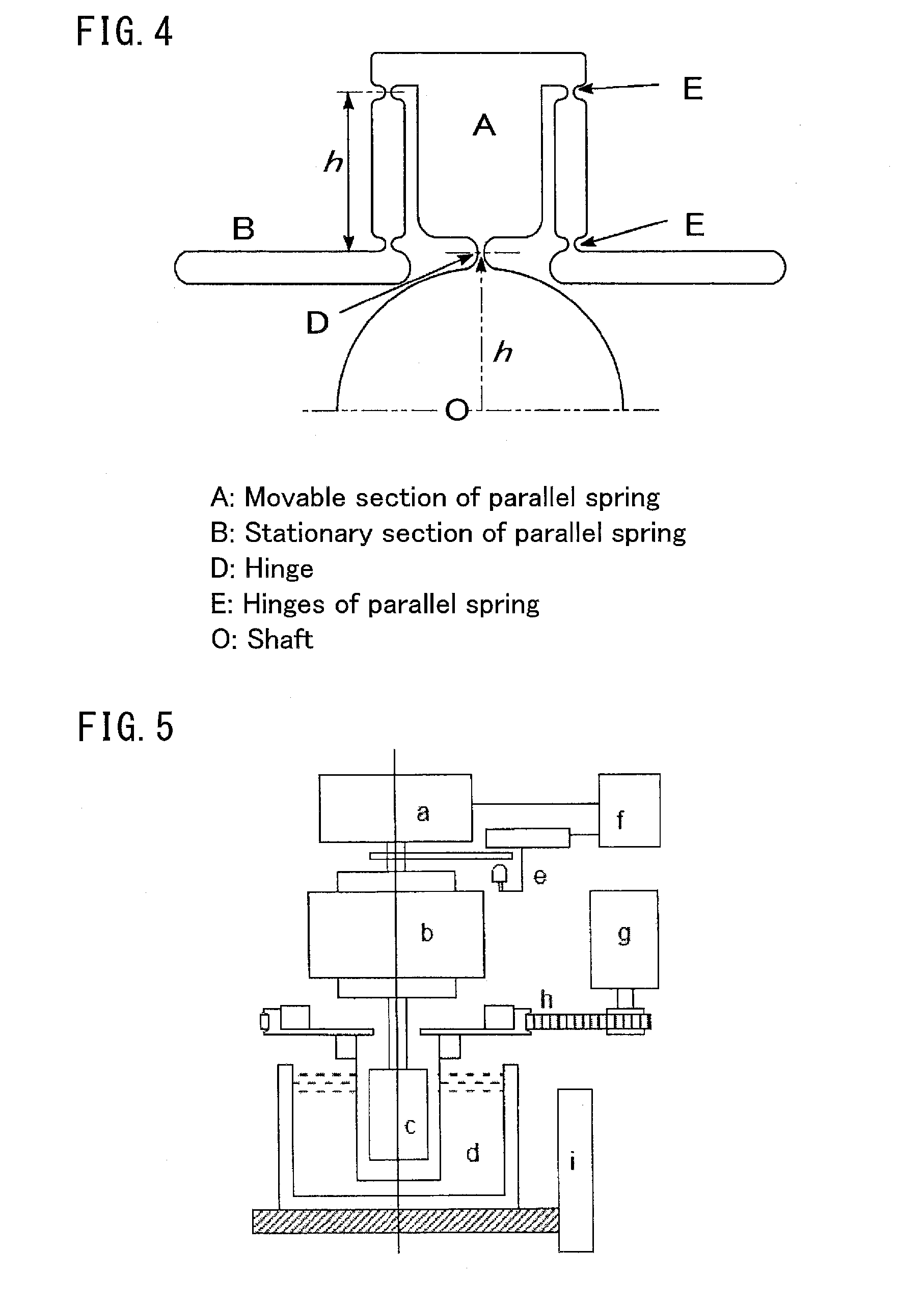

A compact and high-precision rotating shaft holding mechanism is provided which can be utilized for a device that requires a small amount of rotation.A rotating shaft holding mechanism includes a plurality of parallel spring links, each of the plurality of parallel spring links including: a movable side connected to a rotating shaft by a hinge at a connection point at a distance h radially away from a center of rotation of the rotating shaft; a plurality of deformable sides which are parallel to each other; hinges each of which connects one end of a corresponding one of the deformable sides to the movable side; and hinges each of which connects the other end of a corresponding one of the deformable sides to the stationary section, the effective length of each of the deformable sides being set to h to permit the rotating shaft, which is connected to the movable side by the hinge at the connecting point at the distance h radially away from the center of rotation of the rotating shaft, to rotate within a range of finite angles, the plurality of parallel spring links including at least two parallel spring links oriented in different directions. A rotational viscometer uses the rotating shaft holding mechanism.

Owner:NAT INST OF ADVANCED IND SCI & TECH

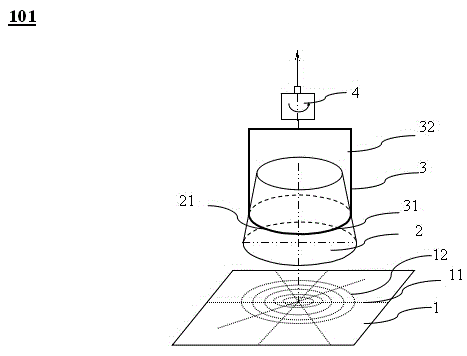

Sludge flowing state measuring device

The invention discloses a sludge flowing state measuring device. The sludge flowing state measuring device comprises a rotary-type rotational viscometer which is used for measuring sludge viscosity properties, and a sludge fluidity measuring device; the sludge fluidity measuring device is composed of a truncated cone circular tube, a base plate, a support, and a lifting motor; the base plate is arranged below the truncated cone circular tube; the area of the base plate is larger than the area of the bottom of the truncated cone circular tube; the support is connected with the truncated cone circular tube; and the truncated cone circular tube is driven by the lifting motor to rise and fall vertically. The sludge flowing state measuring device can be used for measuring both sludge fluidity and sludge glutinousness; the two measuring results are taken into comprehensive consideration; and flowing states of sludge are reflected comprehensively.

Owner:NANJING HYDRAULIC RES INST

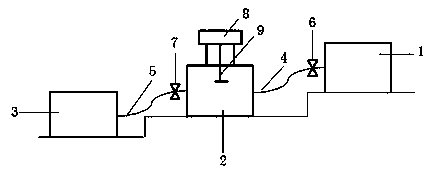

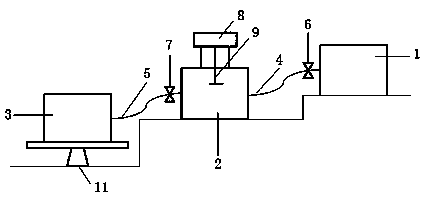

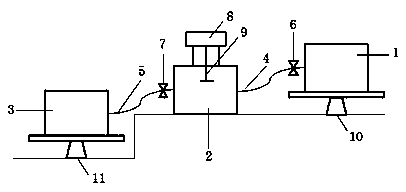

Method for determining gluing viscosity of water-based adhesive and application thereof

ActiveCN103439223ALow equipment requirementsLower requirementFlow propertiesWater basedAdhesive glue

The invention discloses a method for determining gluing viscosity of a water-based adhesive and an application thereof. The method comprises the following steps of arranging a water-based adhesive supplementing unit, a rotational viscometer method measuring unit and a water-based adhesive collecting unit, wherein height differences are sequentially formed between the water-based adhesive supplementing unit, the rotational viscometer method measuring unit and the water-based adhesive collecting unit and the water-based adhesive flows in a flowing pipeline for communicating the water-based adhesive supplementing unit, the rotational viscometer method measuring unit and the water-based adhesive collecting unit, and the rotational viscometer method measuring unit is provided with a rotational viscometer; respectively placing water-based adhesives to be determined in the water-based adhesive supplementing unit and the rotational viscometer method measuring unit, heating the water-based adhesives to be determined to ensure that the temperatures of the water-based adhesives reach a test temperature; and selecting a rotor of a corresponding model for determining the viscosity of the water-based adhesive in the rotational viscometer method measuring unit under the selected rotating speed. The method accords with the actual condition that the water-based adhesive flows when being applied, is simple in process and convenient to operate, is capable of rapidly and directly determining the gluing viscosity of the water-based adhesive, and can be well applied to the pre-judgment on machine applicability on the water-based adhesive before a gluing test is carried out by a water-based adhesive gluing machine.

Owner:CHINA TOBACCO GUANGDONG IND

Rotational viscometer low temperature test device

The invention relates to an on-site drilling fluid viscosity test device under deepwater and low-temperature environment. The device comprises a composite refrigeration system, a heat insulation sleeve, a mud cup, an internal and external temperature sensor. During work, a to-be-tested sample is placed in the mud cup to be loaded into the refrigeration heat insulation sleeve together, the temperature is controlled by a control cabinet, according to the need, the temperature is set arbitrarily ranging from -10DEG C to 100DEG C, the power is switched on, and a refrigeration key is pressed to start work. A thermometer displays the temperature of a refrigeration body, and by pressing an internal and external temperature conversion key, the temperature of the sample in the cup can be observed and displayed, and test can be carried out when the temperature is constant. The device provided by the invention can satisfy drilling fluid low temperature performance test of deepwater drilling on-site operation.

Owner:张玉生

Rotating shaft holding mechanism and rotational viscometer with same

ActiveUS20150159691A1Improve accuracyFlow propertiesWork measurementEffective lengthCentre of rotation

A compact and high-precision rotating shaft holding mechanism is provided which can be utilized for a device that requires a small amount of rotation.A rotating shaft holding mechanism includes a plurality of parallel spring links, each of the plurality of parallel spring links including: a movable side connected to a rotating shaft by a hinge at a connection point at a distance h radially away from a center of rotation of the rotating shaft; a plurality of deformable sides which are parallel to each other; hinges each of which connects one end of a corresponding one of the deformable sides to the movable side; and hinges each of which connects the other end of a corresponding one of the deformable sides to the stationary section, the effective length of each of the deformable sides being set to h to permit the rotating shaft, which is connected to the movable side by the hinge at the connecting point at the distance h radially away from the center of rotation of the rotating shaft, to rotate within a range of finite angles, the plurality of parallel spring links including at least two parallel spring links oriented in different directions. A rotational viscometer uses the rotating shaft holding mechanism.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Rotational viscometer with paddle-type rotor and method for measuring particle fluid viscosity

The invention discloses a rotational viscometer with a blade-shape motor, and a method of measuring particle fluid viscosity by the rotational viscometer. The rotational viscometer comprises a torque transducer, a support, a hoisting mechanism, a rotating rod, a swivel, a sample chamber, a blade-shape rotor, an experiment platform, a signal line and a control mechanism, wherein the blade-shape motor is fixed to the swivel, the swivel is connected to the torque transducer through the rotating rod; the torque transducer is disposed in the support of the hoisting mechanism, and the torque transducer and the hoisting mechanism are controlled by the control mechanism. A using method includes that the torque transducer rotates and drives the blade-shape motor to rotate, the blade-shape motor rotates in a particle fluid and is subjected to shearing stress of the particle fluid, torque changes sensed by the torque transducer are transferred to the control mechanism through electric signals, and the viscosity of the particle fluid can be calculated by the measured torque. The rotational viscometer and the method are advantaged by capability of accurately measuring the viscosity of various fluids at room temperature, high precision, good repeatability, high measuring speed, simple structure, low cost, long service lifetime and high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

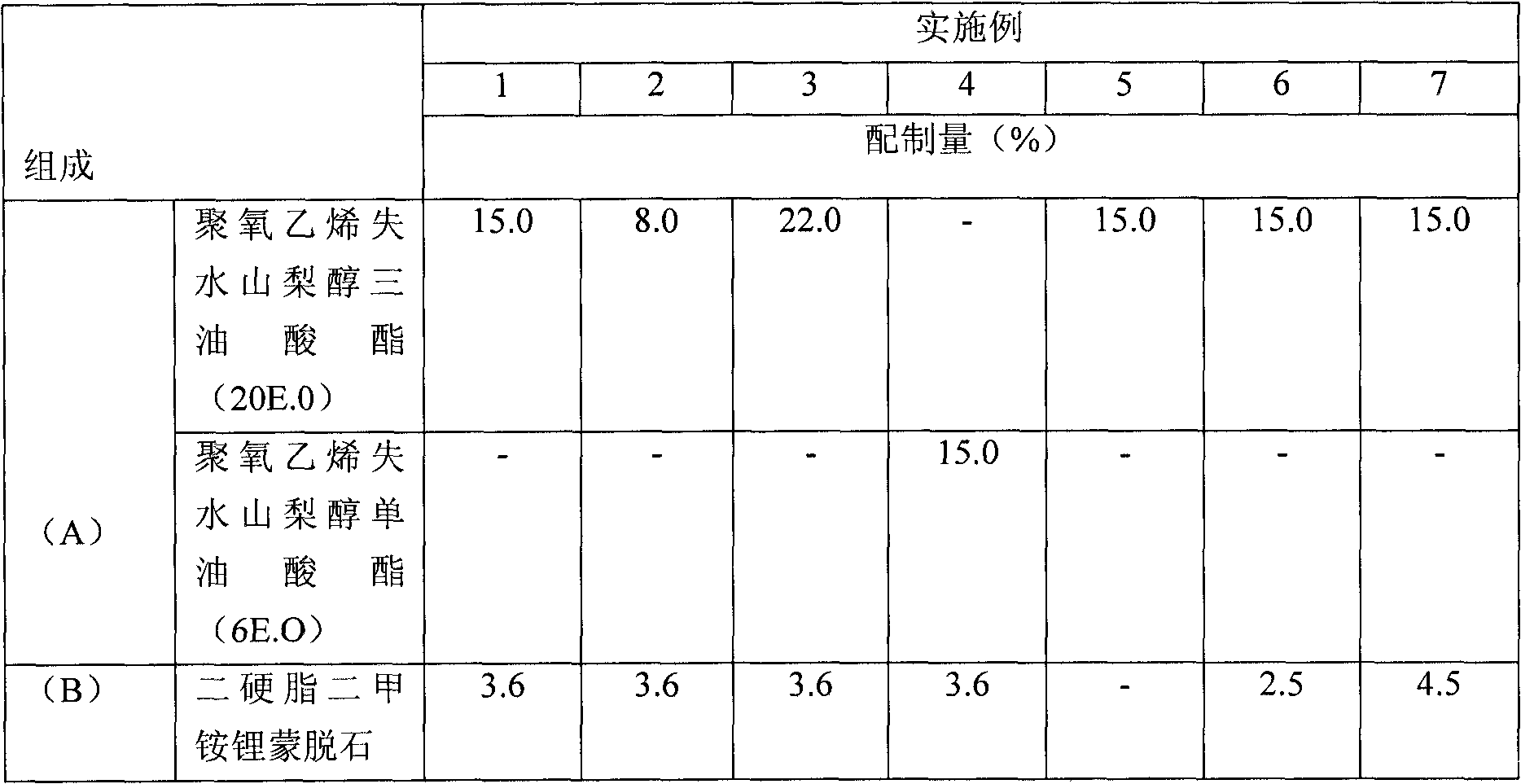

Mascara Remover

ActiveCN102370587AApply evenlyNon-irritatingCosmetic preparationsMake-upClay mineralsSodium Bentonite

The invention provides a mascara remover. The mascara remover at least includes (A) a jydrophilic surface active agent and (B) clay mineral. The jydrophilic surface active agent is polyoxyethylene sorbitan fatty acid ester. The clay mineral is clay mineral of bentonite organically modified. The viscosity is 550 Pa.s-1800m Pa.s measured by a single cylindrical rotational viscometer under a following condition: temperature 20 DEG C, rotor serial number SB3, and rotor speed 30 <-1>minutes.

Owner:株式会社黒龙堂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com