Patents

Literature

108results about How to "Evenly sintered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sliver electrode slurry for back electric field of silicon solar cell and preparation method thereof

ActiveCN102354545AImprove wettabilityImprove solder resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver electrodePhysical chemistry

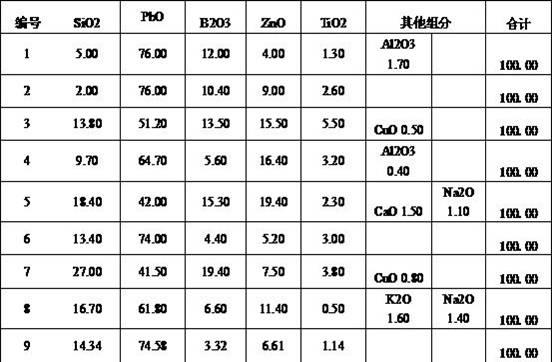

The invention discloses sliver electrode slurry for a back electric field of a silicon solar cell and a preparation method thereof, and the silver electrode slurry for the back electric field of the silicon solar cell comprises the following components by weight percent: 60-70% of spherical silver powder, 0-5% of flaky silver powder, 2-6% of glass powder with a high-temperature softening point, 1-3% of glass powder with a low-temperature softening point and 20-30% of organic bonding agent. The particle size of the spherical silver powder is 0.5-2.5 mu m, and the tap density is above 4.5g / ml; the particle size of the flaky silver powder is below 5 mu m, and the tap density is above 4.0g / ml; and the glass powder with the high-temperature softening point is a PbO3-B2O3-SiO2-ZnO glass system, and the glass powder with the low-temperature softening point is a Bi2O3-B2O3-SiO2 glass system. The slurry is applied to a sliver electrode of the back electric field of the silicon solar cell; furthermore, after fast high-temperature sintering by a chained belt furnace, the adhesive capability is strong, the soldering resistance is good and the photoelectric conversion efficiency of a product is high.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

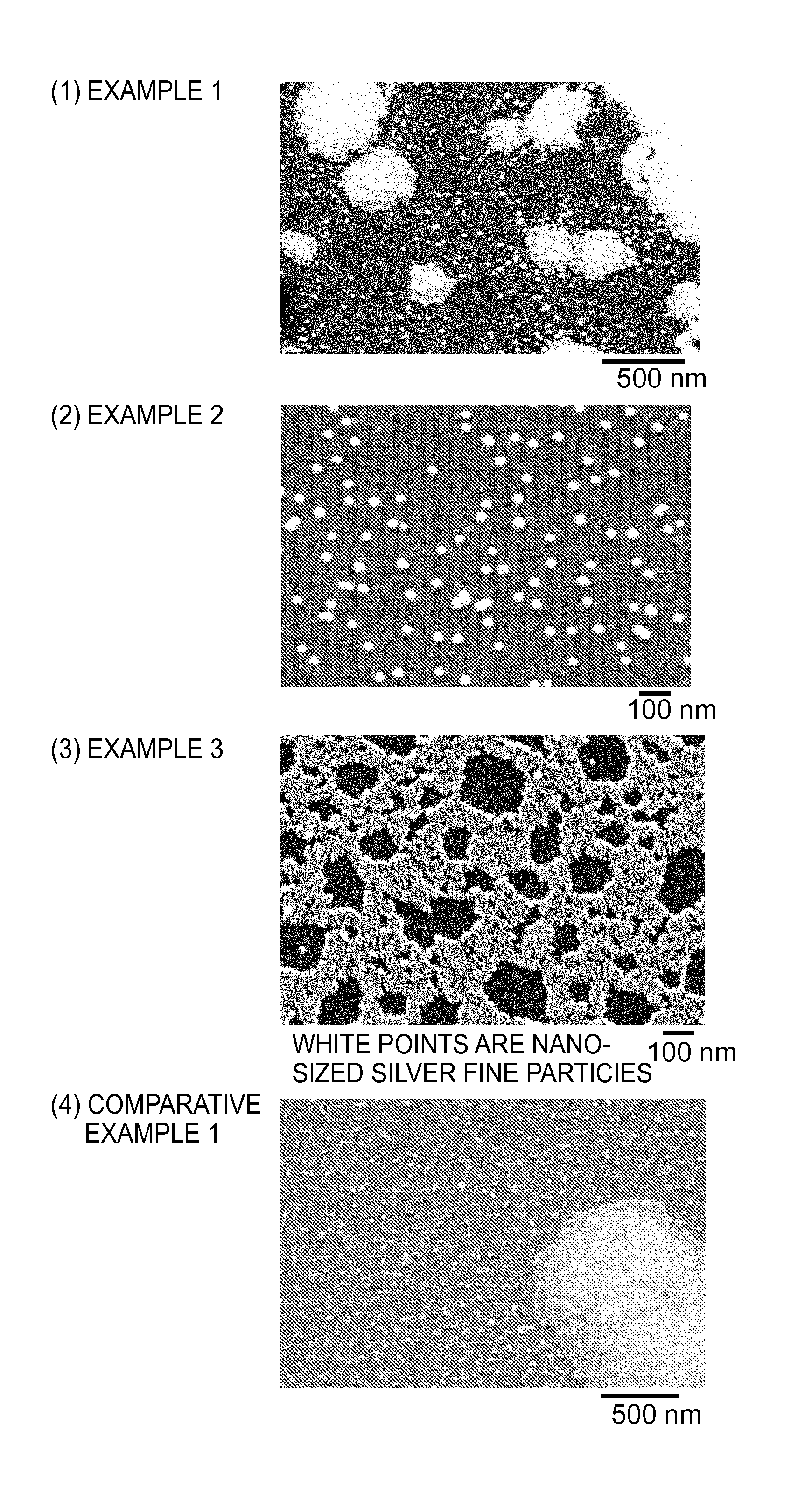

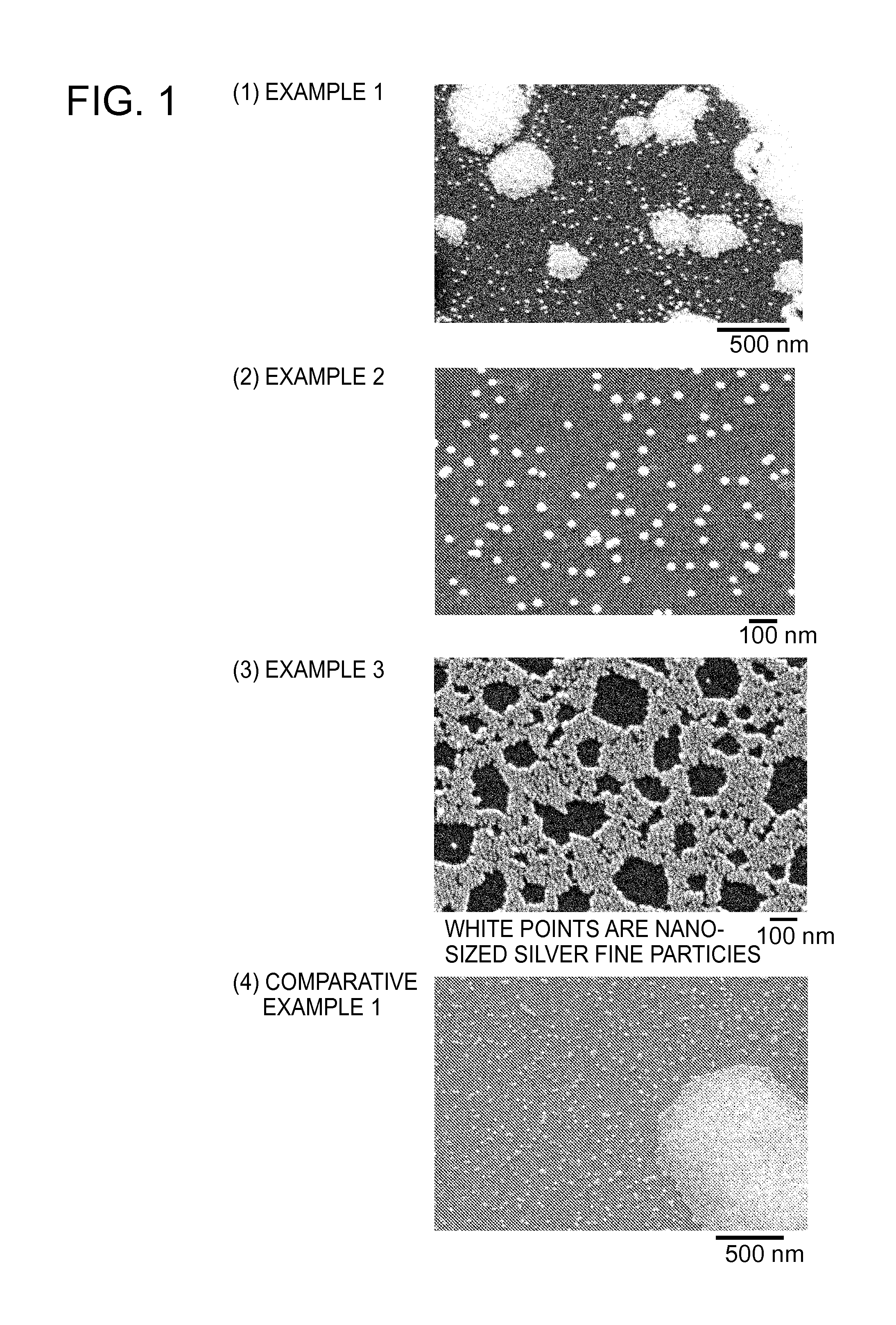

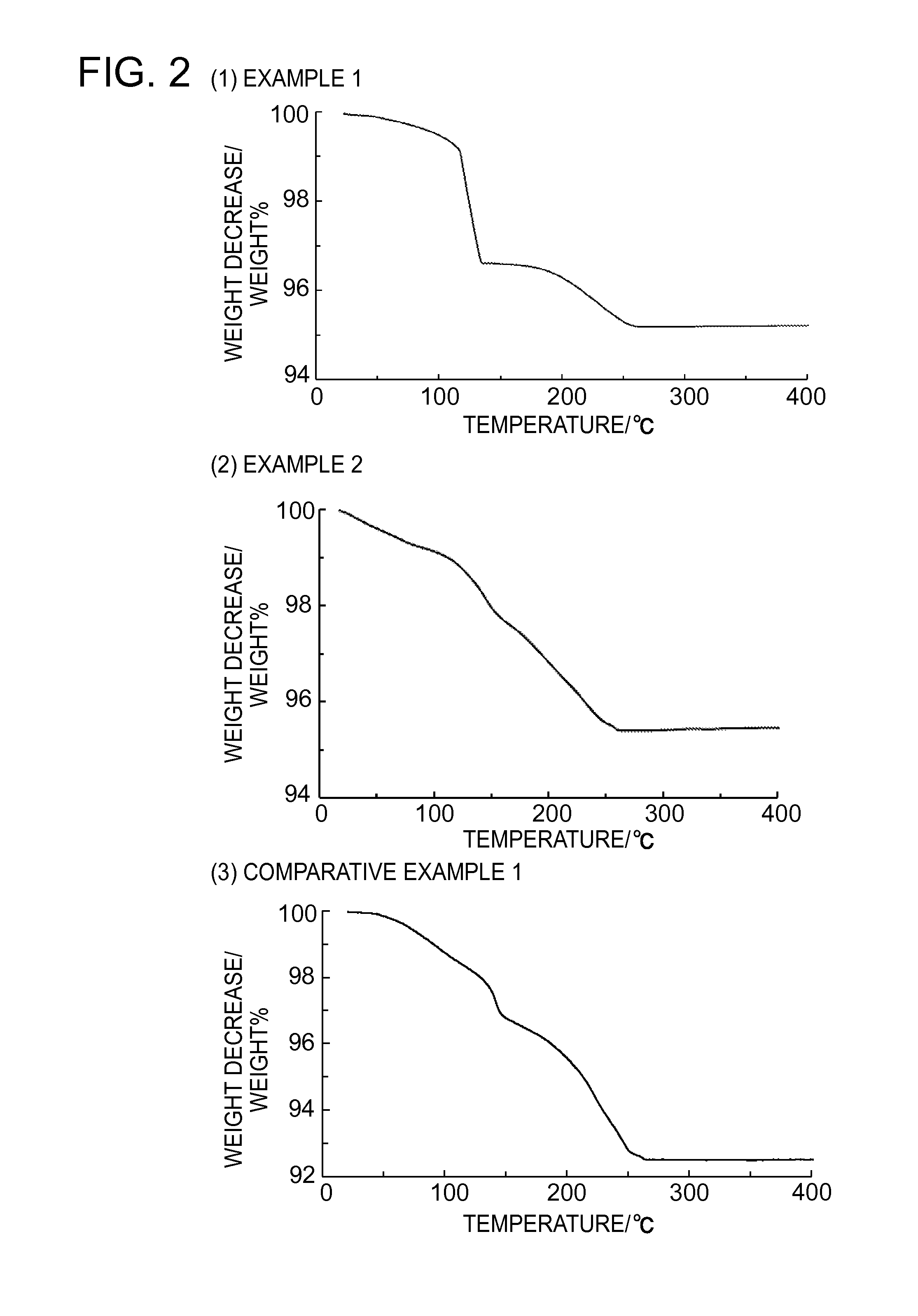

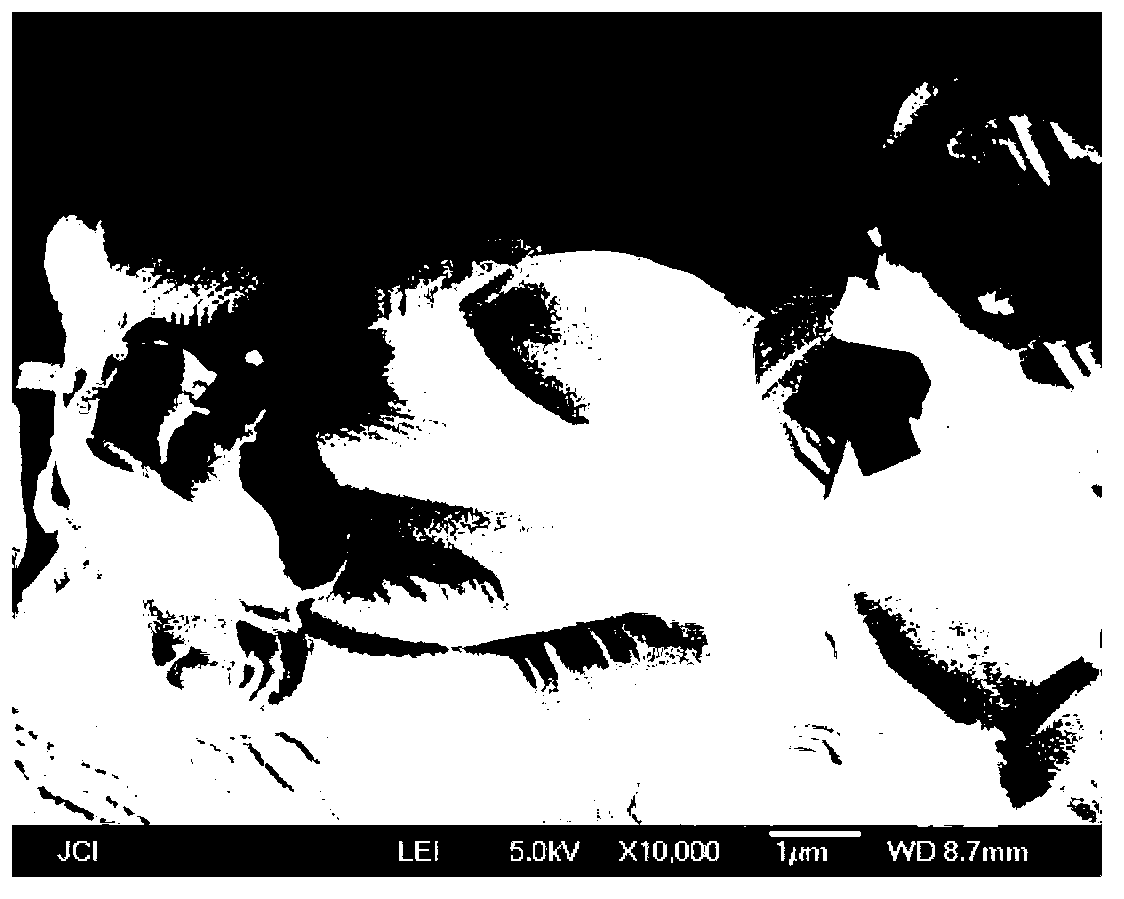

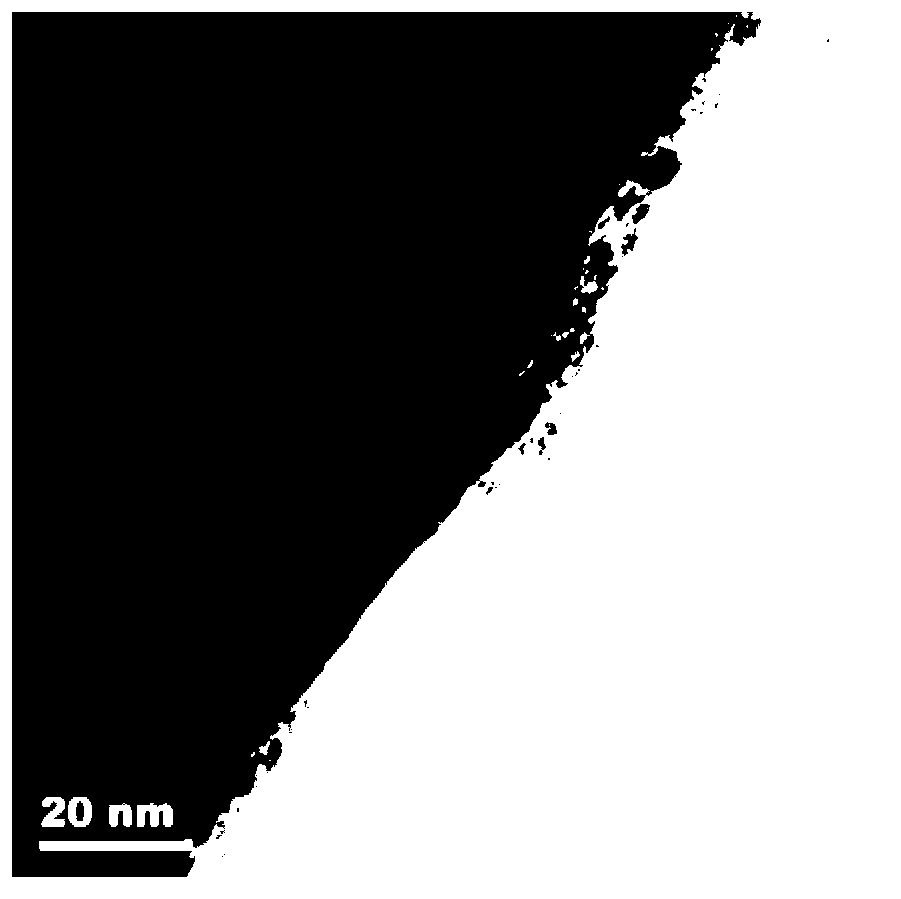

Coated metal fine particle and manufacturing method thereof

ActiveUS20130334470A1Smoothly generatedEvenly sinteredTransportation and packagingConductive materialMetalMaterials science

Objects of the invention are to provide a method in which coated metal fine particles are smoothly manufactured when the coated metal fine particles are manufactured using a metal amine complex decomposition method, and, particularly, to provide coated metal fine particles that can be smoothly sintered even at a low temperature. The manufacturing method of coated metal fine particles includes a first step of mixing an amine liquid mixture of an alylamine having 6 or more carbon atoms and an alkylamine having 5 or less carbon atoms with a metal compound including one or more metal atoms, thereby generating a complex compound including the metal compound and amines; and a second step of heating and decomposing the complex compound, thereby generating coated metal fine particles.

Owner:YAMAGATA UNIVERSITY

Composite filter and manufacturing method thereof

InactiveCN101590345AGood acid and alkali resistanceImprove corrosion resistanceFiltration separationGlass fiberYarn

The invention discloses a manufacturing method of composite filter, comprising the steps: firstly, combining PTFE resin solution to glass fiber fabrics; sintering the glass fiber fabrics which are combined with the PTFE resin; coating one compact PTFE (polytetrafluoroethylene) protection layer on the surface of each yarn of the glass fiber filter cloth; and then, coating a PTFE film on the surface of the filter. The high temperature resistance, the corrosion resistance, the hydrolyzation resistance, the flexility, the wear resistance, the breaking resistance, and the like of the manufactured filter are greatly improved, the dust stripping property of the filter is good, and the dust of the filter is easy to clear. Compared with the prior art, the service life of the filters can be prolonged by over one time.

Owner:厦门美达斯环保工业有限公司

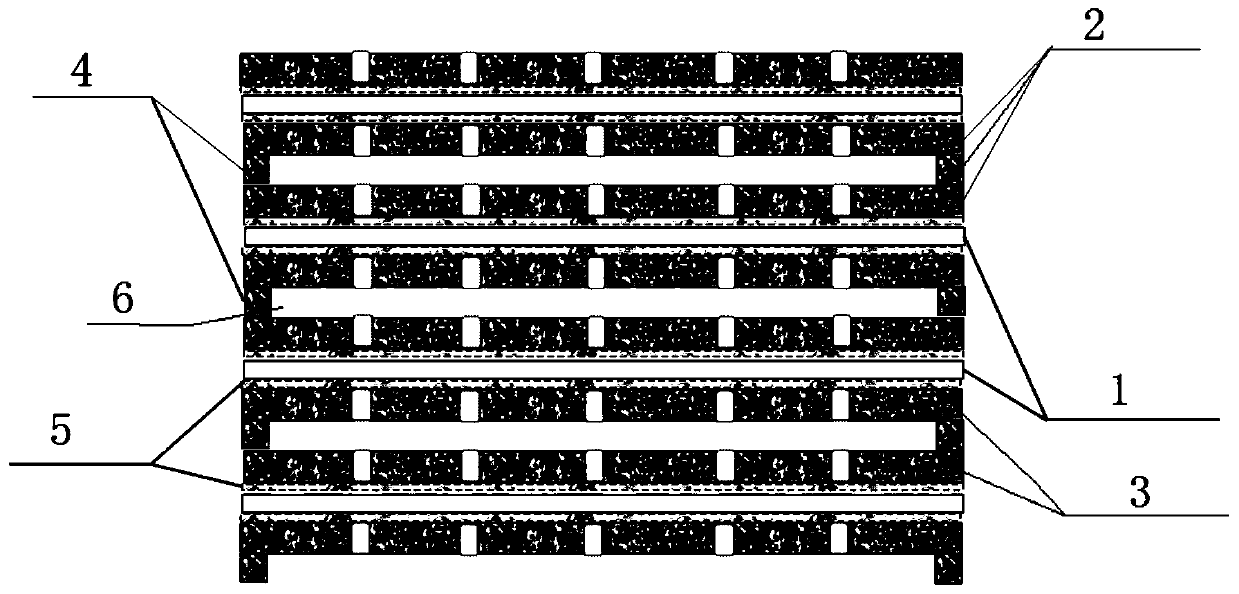

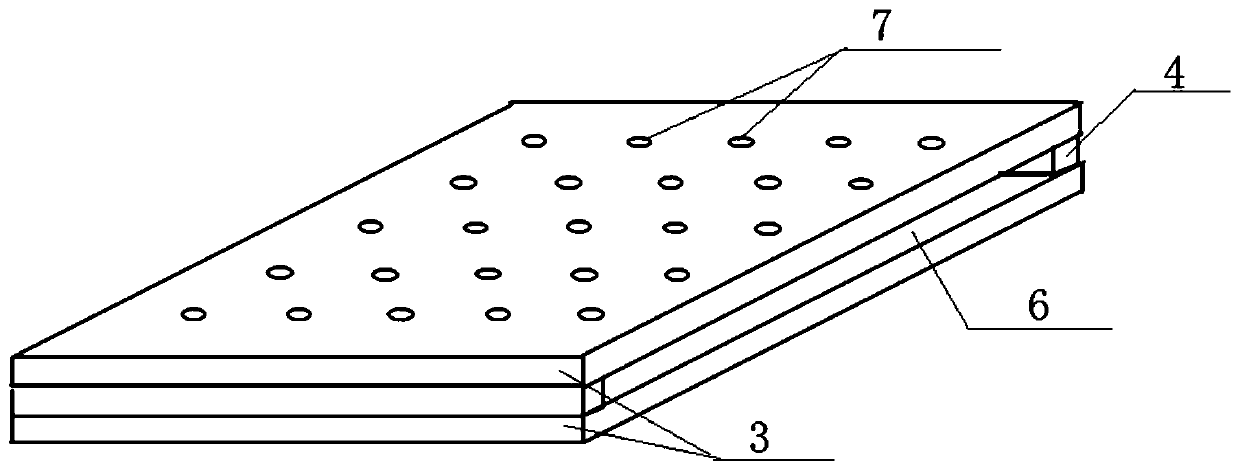

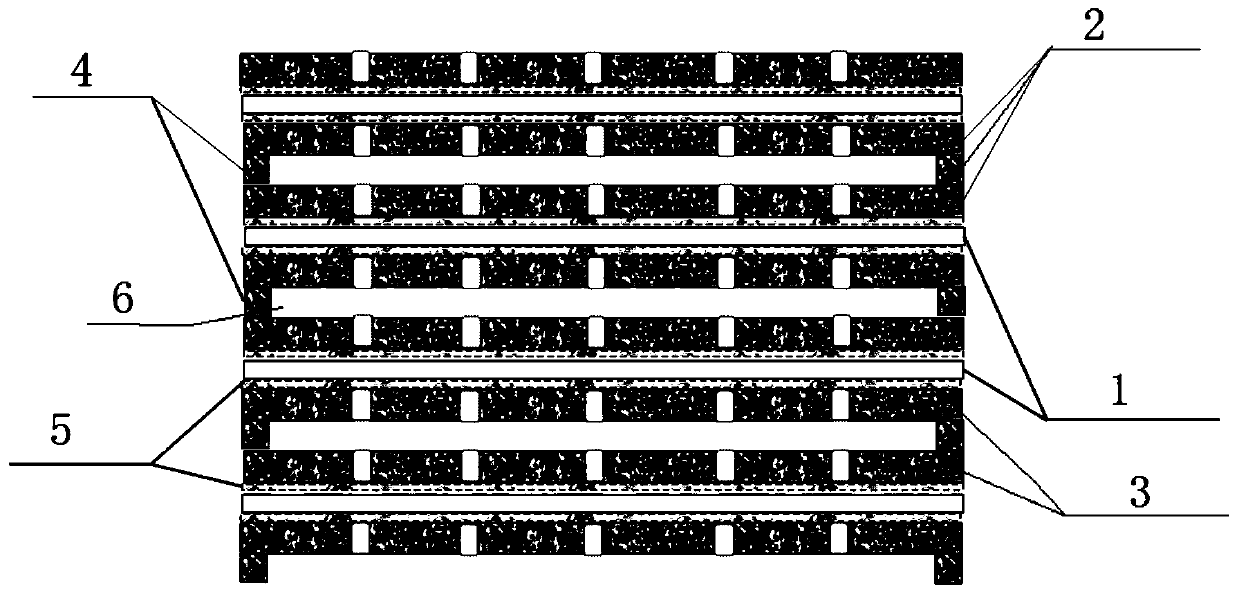

High-thermal-conductivity silicon nitride ceramic substrate and preparation method thereof

ActiveCN109987944AReduce grain boundary phase contentImprove thermal conductivityGraphiteMechanical property

The invention belongs to the technical field of high-thermal-conductivity silicon nitride ceramic substrates, and particularly relates to a high-thermal-conductivity silicon nitride ceramic substrateand a preparation method thereof. The high-thermal-conductivity silicon nitride ceramic substrate is formed by stacking a plurality of silicon nitride tape casting biscuits layer by layer, a middle layer is arranged between every two adjacent silicon nitride tape casting biscuits, each middle layer is composed of two graphite plates and two graphite strips which are located between two ends of thetwo graphite plates respectively to form a cavity, the graphite plates are provided with a plurality of holes communicating with the cavities, and slurry separation layers are arranged between the graphite plates and the corresponding silicon nitride tape casting biscuits. The silicon nitride ceramic substrate prepared by the preparation method disclosed by the invention is relatively good in purity and performance, and particularly has relatively high heat conductivity and excellent mechanical properties.

Owner:TSINGHUA UNIV +1

Porous heat-insulation material prepared utilizing iron ore surrounding rock and iron tailings and preparation method thereof

InactiveCN102515828AEmission reduction benefits are obviousImprove absorbencySolid waste managementCeramicwareMineralogyMining engineering

The invention relates to a porous heat-insulation material prepared utilizing iron ore surrounding rock and iron tailings and a preparation method of the porous heat-insulation material. The porous heat-insulation material prepared utilizing the iron ore surrounding rock and iron tailings is characterized by being prepared from the following components in percentage by weight: 30-60% of iron tailing powder, 20-50% of iron ore surrounding rock powder, 0.5-10% of foaming agent, 0-1% of cosolvent and 0.1-9% of foam stabilizer by uniformly mixing, then adding water, mixing and pulping, carrying out microwave calcining and cooling. The preparation method of the porous heat-insulation material prepared utilizing the iron ore surrounding rock and iron tailings has high utilization rates of iron ore surrounding rock and iron tailings; and the prepared porous heat-insulation material has low density and excellent heat-insulation performance.

Owner:WUHAN UNIV OF TECH

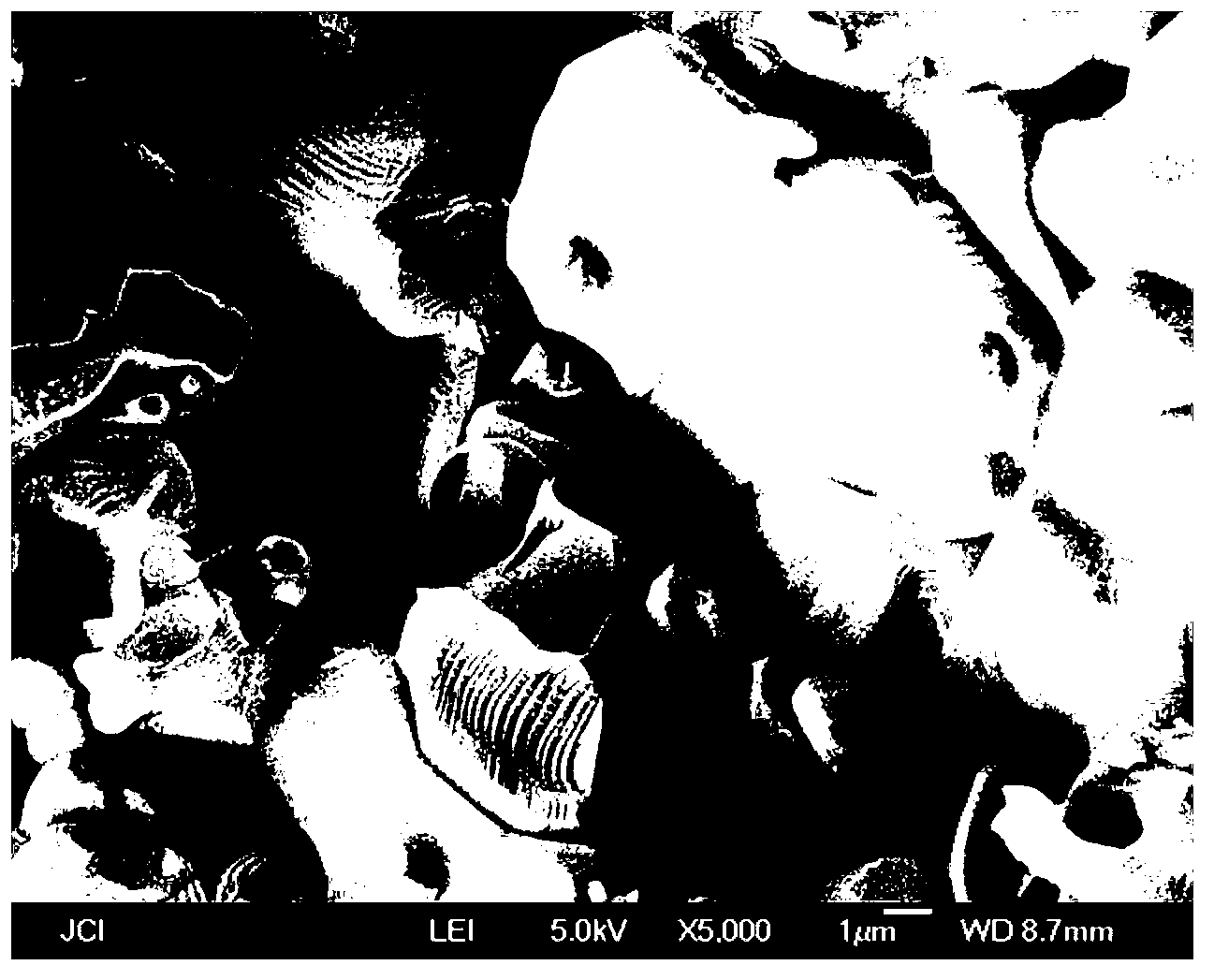

Preparation method of high-purity aluminum oxide ceramic

The invention discloses a preparation method of a high-purity aluminum oxide ceramic. According to the preparation method, a nano Al2O3 coating formed on the surfaces of aluminum oxide particles is used as a sintering aid to ensure that a small amount of the sintering aid can be uniformly dispersed in a main phase, so that uniform adding of a small dose of the sintering aid is realized. The preparation method not only ensures the purity and performance of the high-purity aluminum oxide ceramic and meets process requirements for preparation of the aluminum oxide ceramic, but also effectively solves the problem that when the particle size difference of main phase powder and the sintering aid is large, particles of a nano auxiliary agent are gathered in a main phase powder particle gap; and moreover, partial over-firing is avoided, so that the uniformity of sintering of the main phase powder particles and the sintering assisting effect of the sintering aid are effectively improved.

Owner:重庆兀盾纳米科技有限公司

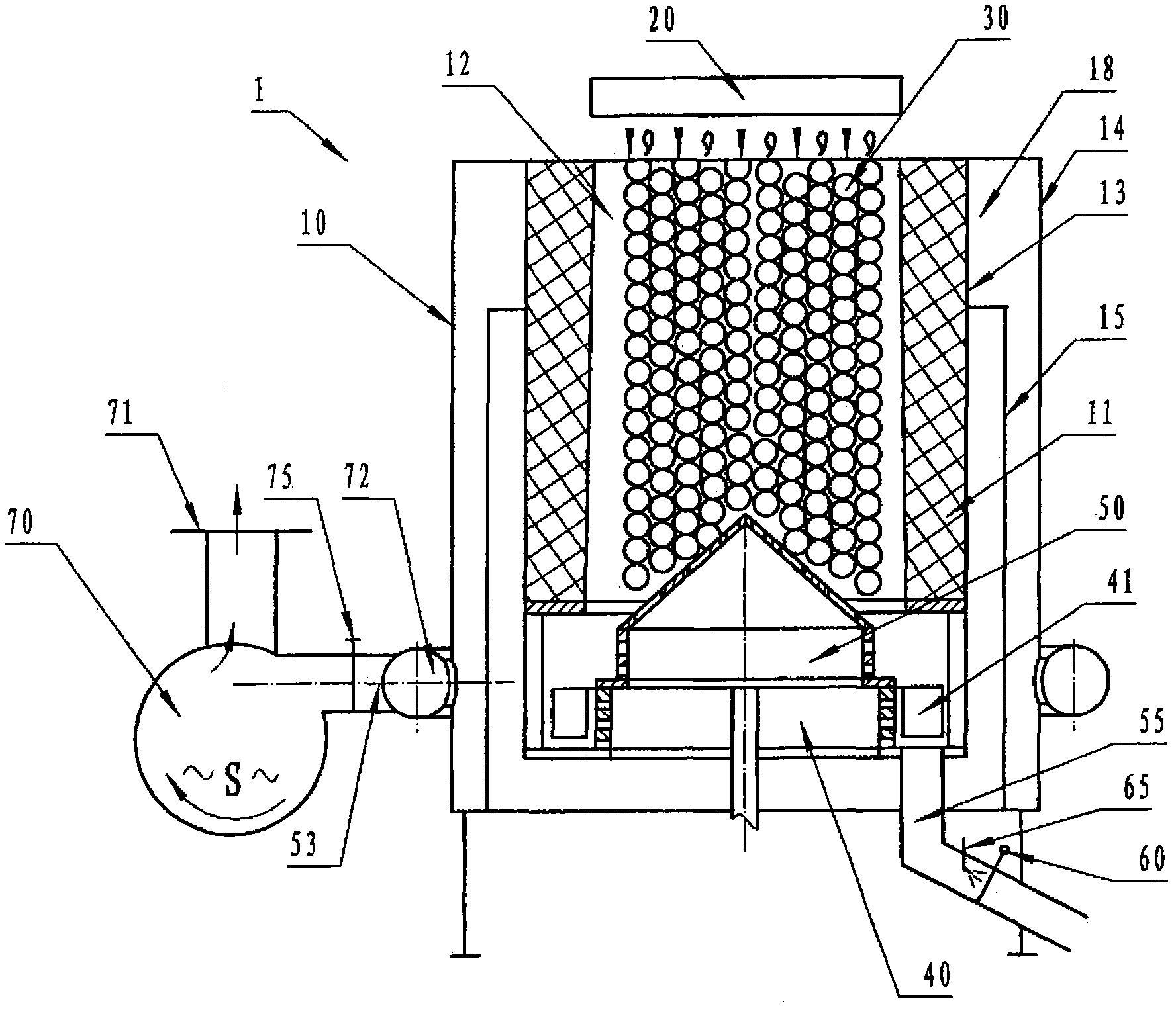

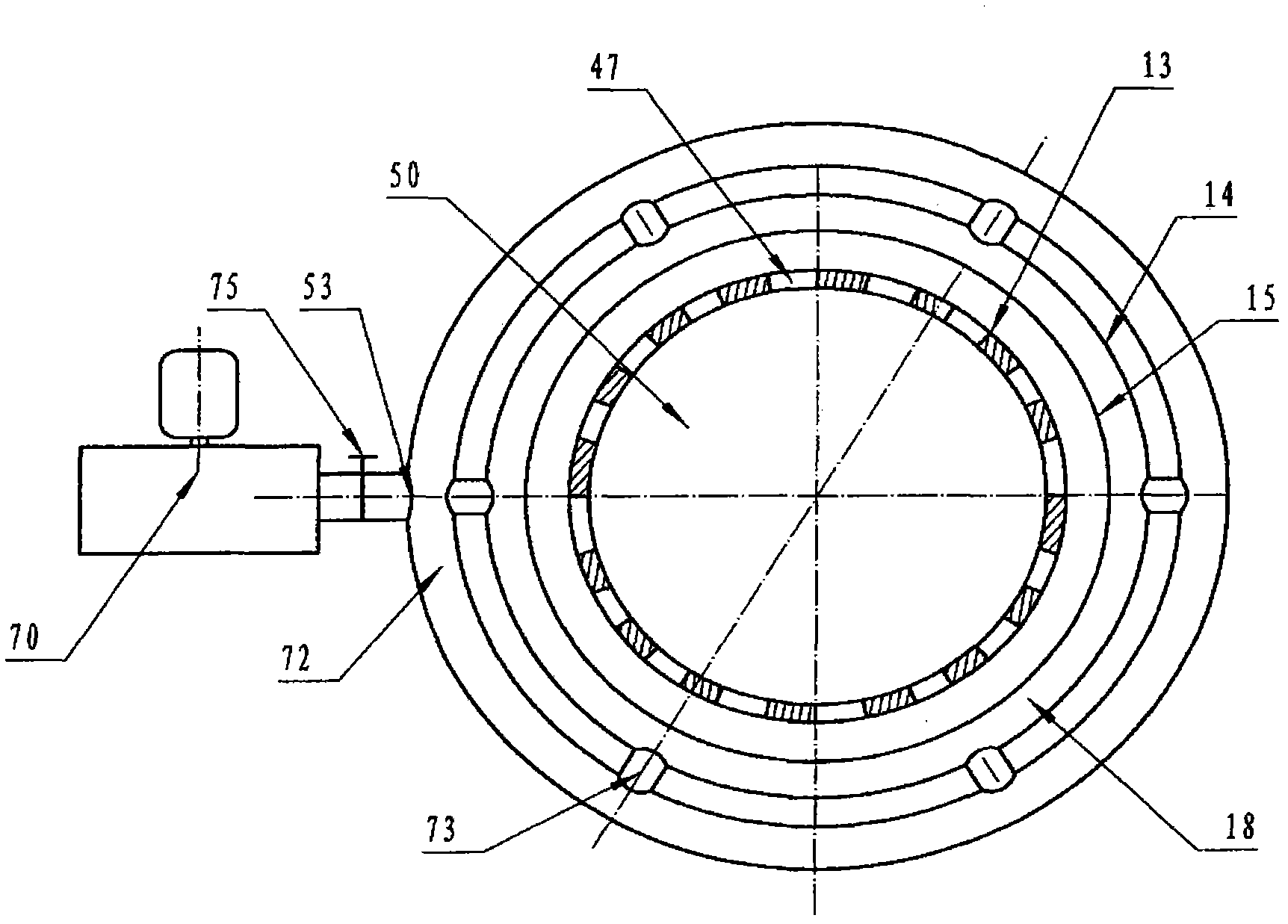

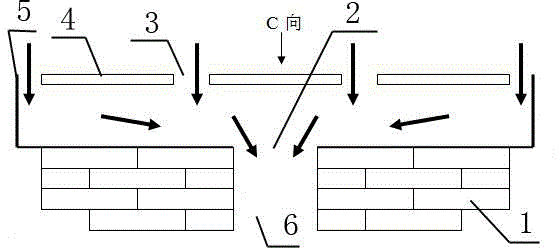

Fly ash product sintering furnace and method and formula thereof

The invention discloses a fly ash product sintering furnace, which comprises a furnace body, a tower grate type discharge ventilation device, a diversion ring, an annular air pipe and an air induction apparatus, wherein the furnace body is provided with a furnace inner shell and a furnace outer shell; a furnace chamber for containing a material is formed in the furnace inner shell; the upper end of the furnace chamber is an ignition end, and the lower end of the furnace chamber is an air induction end; the tower grate type discharge ventilation device is rotatably arranged at the bottom end of the furnace chamber and supports the material in the furnace chamber; the diversion ring is of cylindrical shape and arranged between the furnace inner shell and the furnace outer shell; the annular air pipe is arranged around the outside of the furnace body and provided with an air induction port and multiple ventilation pipelines connected with the furnace outer shell; the air induction apparatus is connected with the air induction port; the diversion ring and the furnace inner shell form a passage; and the high-temperature air in the furnace chamber flows in the passage along the outer side of the furnace inner shell and is used for secondarily heating the furnace chamber. The invention also discloses a sintering method applicable to the sintering furnace. The invention also provides a formula of the fly ash ceramsites applicable to the sintering furnace and the sintering method.

Owner:北京建邦伟业机械制造有限公司

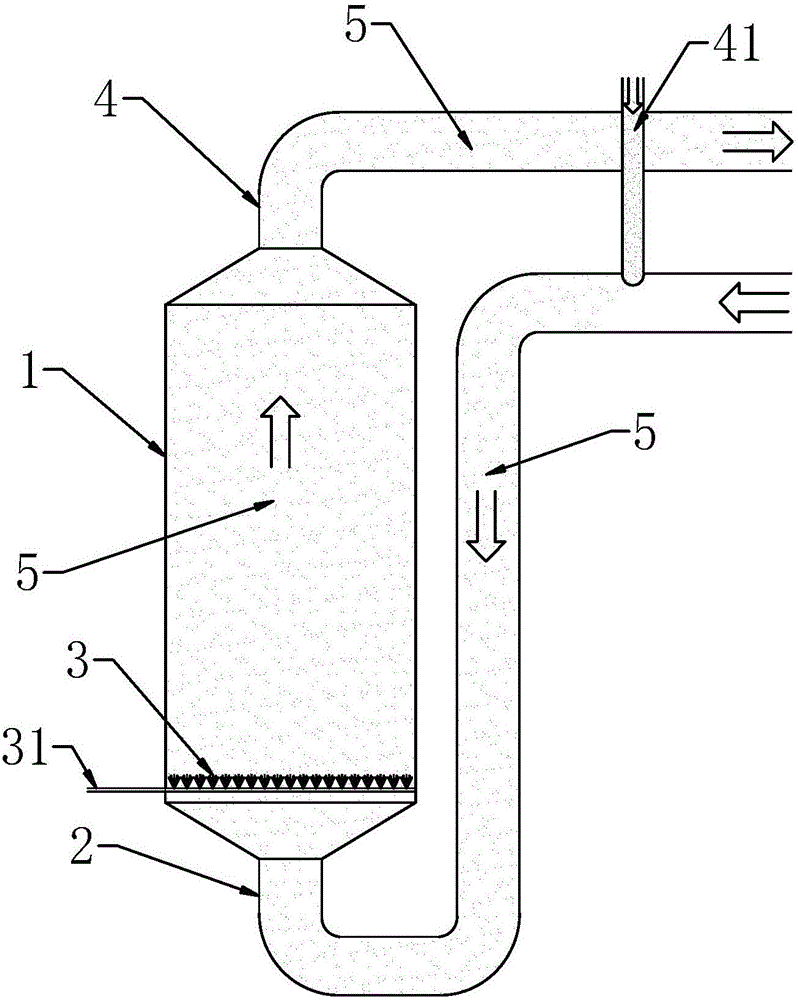

Light calcined magnesia calcinator suspension calcination device

The invention discloses a light calcined magnesia calcinator suspension calcination device. The device comprises a kiln body, the bottom of the kiln body is provided with a gas material inlet pipe, the top of the kiln body is provided with a gas material outlet pipe, the side wall of the kiln body is provided with a fuel inlet, the fuel inlet is communicated with a fuel nozzle in the kiln body, a magnesite ore powder and an air preheating device are arranged in front of the gas material inlet pipe and a gas material separation device is arranged in rear of the gas material outlet pipe. The light calcined magnesia calcinator suspension calcination device solves the problem of blocky material solid-gas phase counter-current movement of the existing light calcined magnesia calcination reverberatory kiln. Reaction products and waste gas go through the gas material outlet pipe on the top, are discharged and then enter the gas material separation device. The materials are in a suspension state, rise along with hot gas, fast react and can be uniformly sintered so that the product has high activity and good quality. The light calcined magnesia calcinator suspension calcination device realizes large scale, continuous and fast production of light calcined magnesia, has a simple structure, is convenient for operation, can be controlled flexibly and realizes uniform sintering. The product has high activity and good quality.

Owner:UNIV OF SCI & TECH LIAONING +3

Ceramic micro-particles for laser sintering ceramic 3D printing, and preparation method thereof

InactiveCN106830901AAdapt to requirementsImprove performanceAdditive manufacturing apparatusMixed materialsSolvent

The invention relates to ceramic micro-particles for laser sintering ceramic 3D printing, and a preparation method thereof. The ceramic micro-particles comprise a ceramic powder raw material, a binder and a defoaming agent, wherein a mass ratio of the ceramic powder raw material to the binder is 7-9:3-1, and the adding mass of the defoaming agent is 0.2-0.35% (total mass). During the preparation, the binder is prepared into a glue, the nano-scale ceramic powder raw material and the defoaming agent are added to the solvent according to a certain ratio, complete mixing is performed, the mixed material is added to a spraying granulator, and spraying granulation is performed to process the ceramic micro-particles. According to the present invention, the size of the ceramic micro-particles is controlled by using the spraying granulation so as to meet the requirements of the selective laser printer on the material; and the prepared material has the stable performance during the printing, is uniform during the sintering, and further has characteristics of good use effect, high strength, and easy popularization.

Owner:醴陵市陶瓷3D打印研究所

Method for preparing foamed ceramic by microwave sintering of cobalt smelting waste slag

InactiveCN109553393AMass consumptionSolve environmental problemsCeramic materials productionCeramicwareHigh energySlag

The invention belongs to the technical field of resource utilization of solid wastes, and particularly relates to a method for resource utilization of cobalt smelting waste slag. The invention provides the method for preparing foamed ceramic by microwave sintering of the cobalt smelting waste slag. The method comprises the following steps: carrying out proportioning by using the cobalt smelting waste slag, filler, a liquid phase agent, a plasticizer and a foaming agent, carrying out grinding, mixing, granulating, and mold pressing or mold powder accumulation to prepare a green body; and carrying out microwave sintering to prepare the foamed ceramic. The microwave heating method is adopted, and compared with a conventional electric heating or fuel heating mode, the microwave heating methodhas the advantages that the foaming temperature is greatly reduced, the foaming time is shortened, and therefore energy consumption is greatly reduced. According to the method, the problems of high energy consumption in existing formed ceramic industry and high additional value comprehensive utilization of the cobalt smelting waste slag are solved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

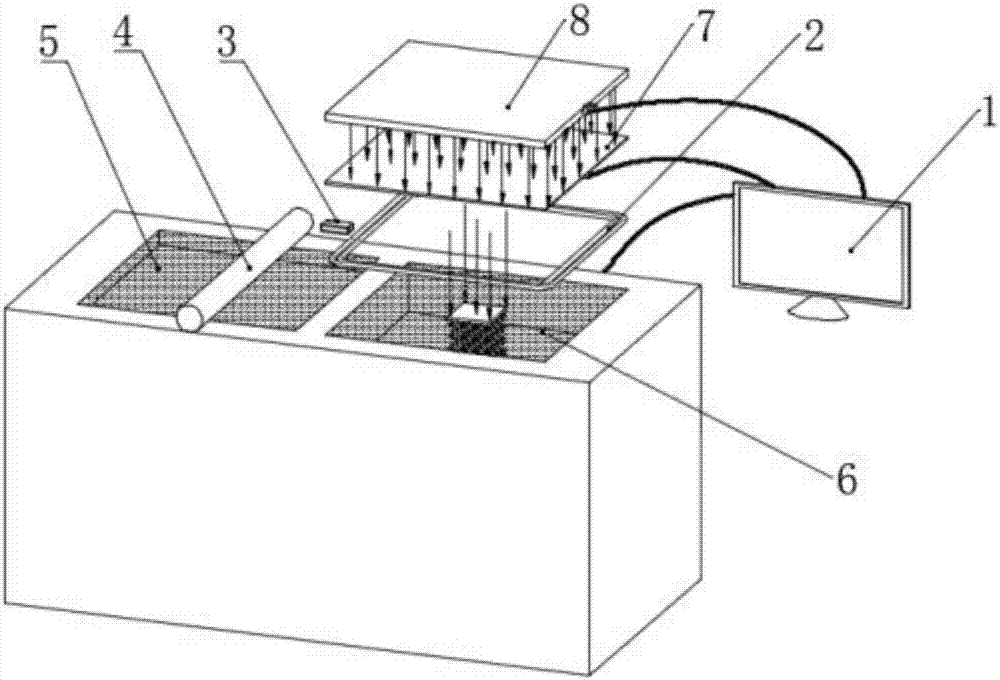

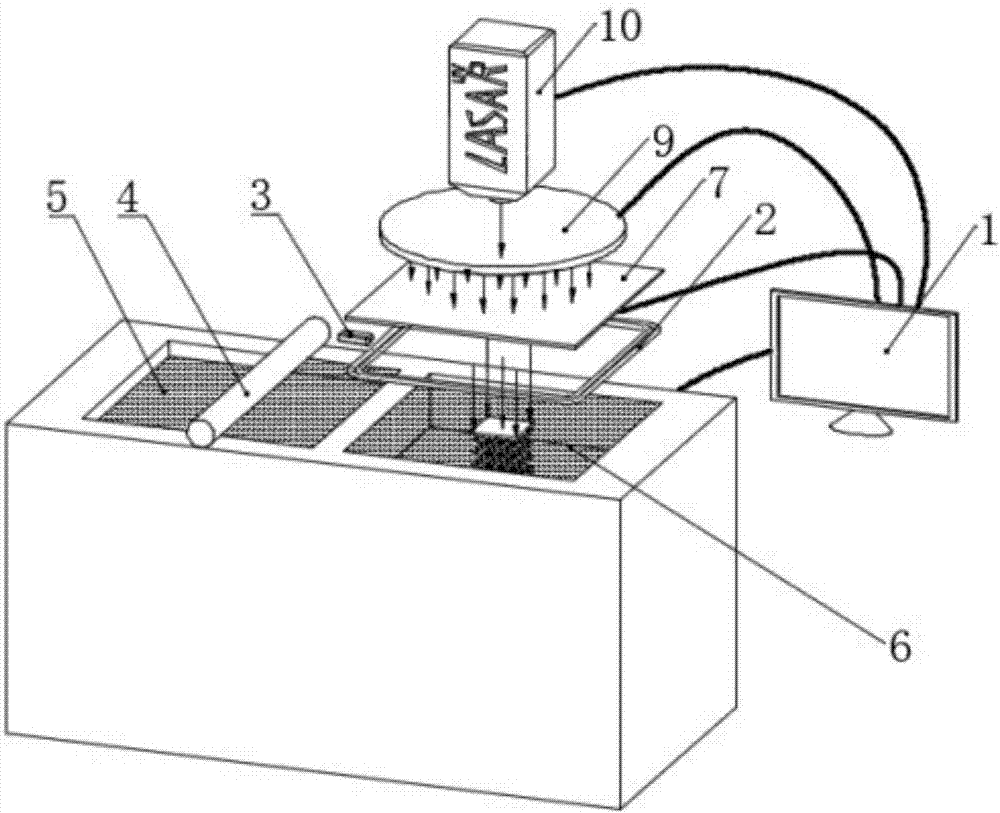

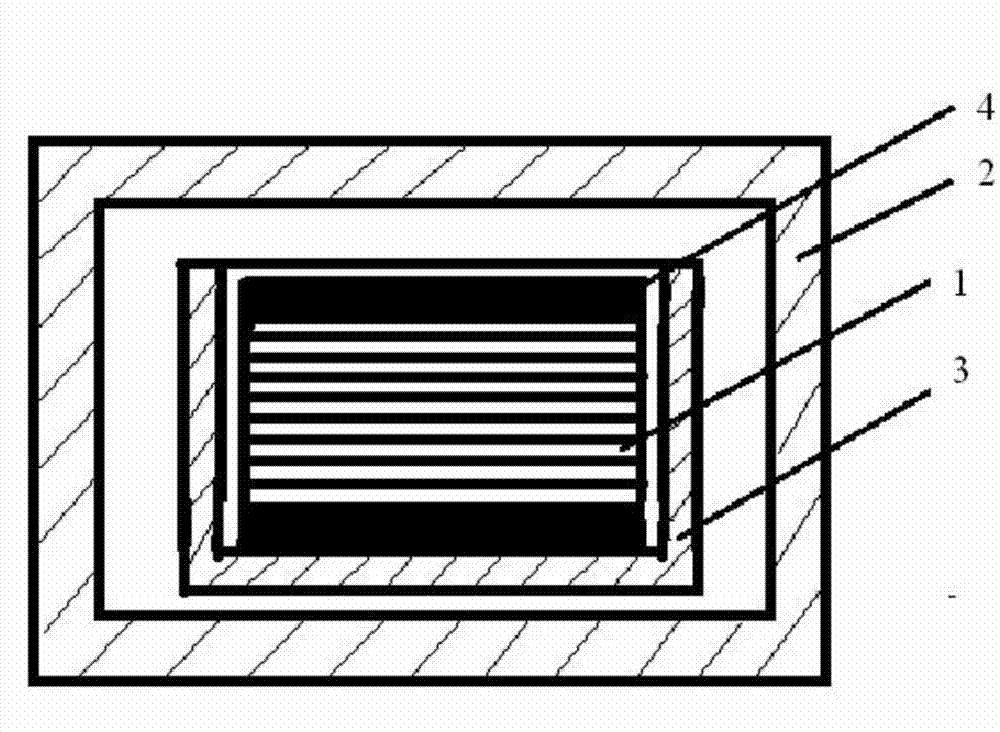

Selective laser sintering method and device based on surface light source

InactiveCN107379526AImprove efficiencyEvenly sinteredIncreasing energy efficiency3D object support structuresTemperature controlSelective laser sintering

The invention discloses a selective laser sintering method and device based on a surface light source. The method comprises the steps of firstly, drawing a three-dimensional solid model in a computer, and carrying out slicing processing on the three-dimensional solid model, so as to acquire information of section layers; converting information of the section layers in the computer into parallel surface light beams of corresponding images through a light source device and a light path system, and irradiating the light beams on powder of a processing layer; after one processing plane is sintered and molded, paving the processing plane with a layer of powder through a roller or scraper, and sintering a new processing layer; and repeating the steps till the entire part is sintered. The device comprises a powder paving system, a temperature control system, the light source device and the light path system which are connected with the computer. According to the selective laser sintering method and device, workpiece selective laser sintering efficiency is improved, molding quality is uniform, and the device is simple in structure, long in service life, and convenient to operate.

Owner:XI AN JIAOTONG UNIV

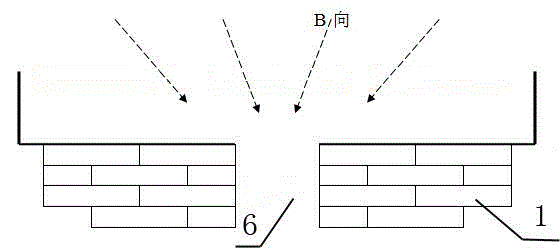

Microwave rapid sintering method for high-quality aluminum nitride ceramic substrates

The invention discloses a microwave rapid sintering method for high-quality aluminum nitride ceramic substrates. The method belongs to microwave firing of ceramic materials and comprises the following steps: after discharging glue, putting aluminum nitride ceramic substrate blanks into an auxiliary heating insulation structure in a microwave sintering cavity, uniformly spraying boron nitride powder among the blanks, wherein the aluminum nitride ceramic substrate blanks are overlapped orderly and the auxiliary heating insulation structure comprises an aluminum nitride fiber plate, a boron nitride sagger and a high-purity graphite plate; sintering in a nitride atmosphere containing 6-10% of hydrogen under the conditions that the microwave sintering frequency is 2.45GHz, the normal-pressure microwave sintering temperature is 1700-1750 DEG C and the heating rate is 8-10 DEG C per minute; preserving the heat for two hours, cooling along with a furnace, opening the furnace and taking out the aluminum nitride ceramic substrate blanks when the temperature is below 400 DEG C, thus obtaining high-quality aluminum nitride ceramic substrate sintering bodies which are small in deformation and has a heat conductivity being greater than 150W / (m K). Different from a conventional methods adopting a convection, conduction or radiation heating manner, the method adopts a heating manner that the microwave with a special waveband is used to be coupled with basic structures of the materials so as to generate heat and the materials are heated completely by adopting medium loss of the materials; and in combination with special microwave sintering structures and sintering process, the method is capable of rapidly and uniformly sintering the materials and has the advantages of low sintering temperature, short time, low energy consumption, high quality and high efficiency.

Owner:XINHUA TIANHE MATERIAL TECH CO LTD

Ceramic 3D printing material based on selective laser sintering and preparation method of ceramic 3D printing material

ActiveCN106810268AHigh densityImprove performanceAdditive manufacturing apparatusSelective laser sinteringFrit

The invention discloses a ceramic 3D printing material based on selective laser sintering and a preparation method of the ceramic 3D printing material. The ceramic 3D printing material comprises the following components in parts by mass: 65-79 parts of ceramic particles, 10-20 parts of thermoplastic resin, 10-20 parts of ceramic frit and 1-10 parts of a coloring material, wherein the resin, the ceramic frit and the coloring material are powdery. During preparation, the ceramic particles and the powdery resin, ceramic frit and the coloring material are added into a stirrer in proportion for stirring, and are mixed uniformly to obtain a needed printing material. According to the preparation method provided by the invention, the ceramic frit is added during preparation to fill pores so as to improve the compactness of a printed product, and the printing material is stable in performance during printing and more uniform during sintering; moreover, the prepared material has simple components, and is convenient to manufacture, good in using effect, high in strength and easy to promote.

Owner:湖南省陶瓷研究所有限公司

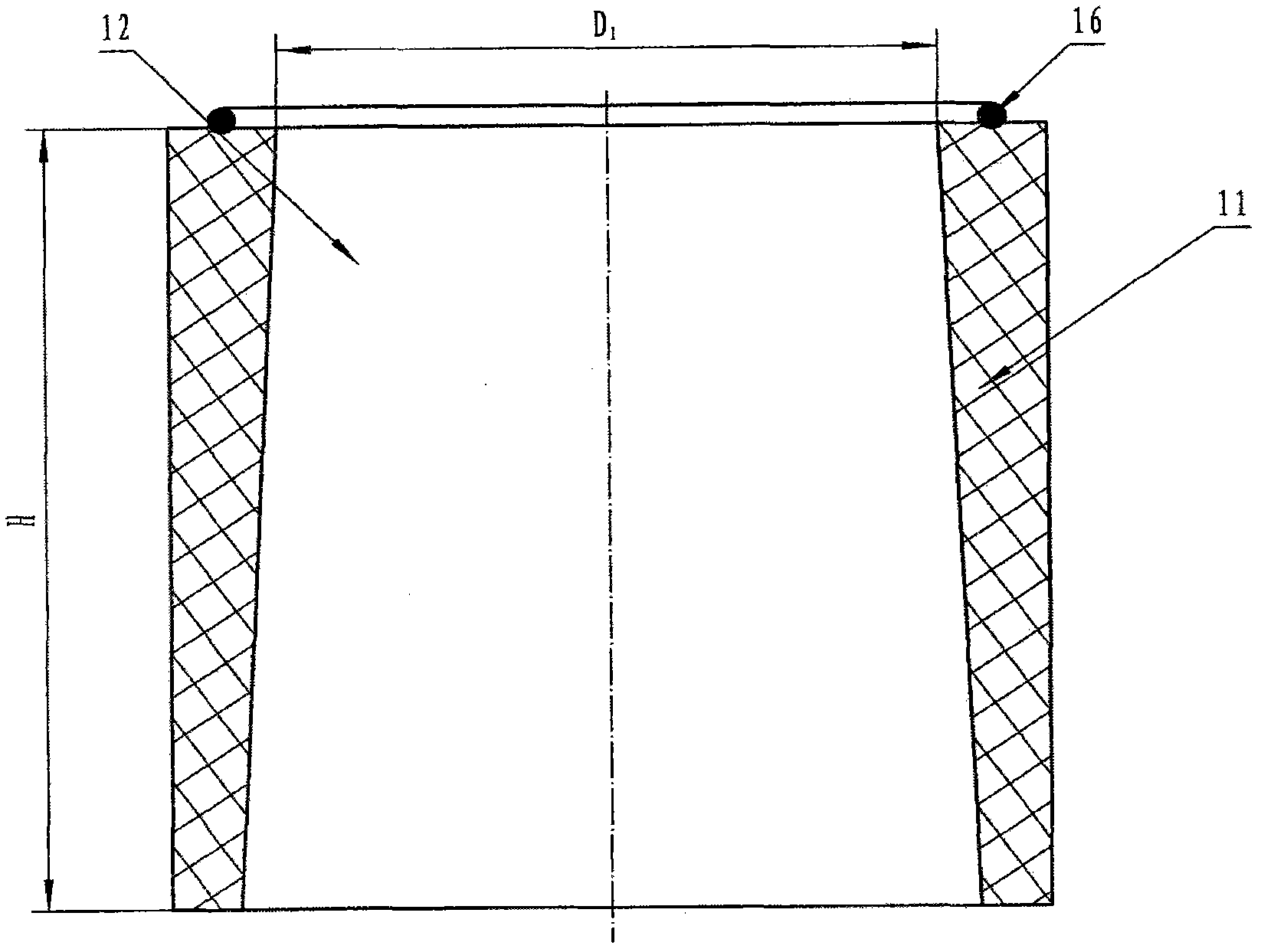

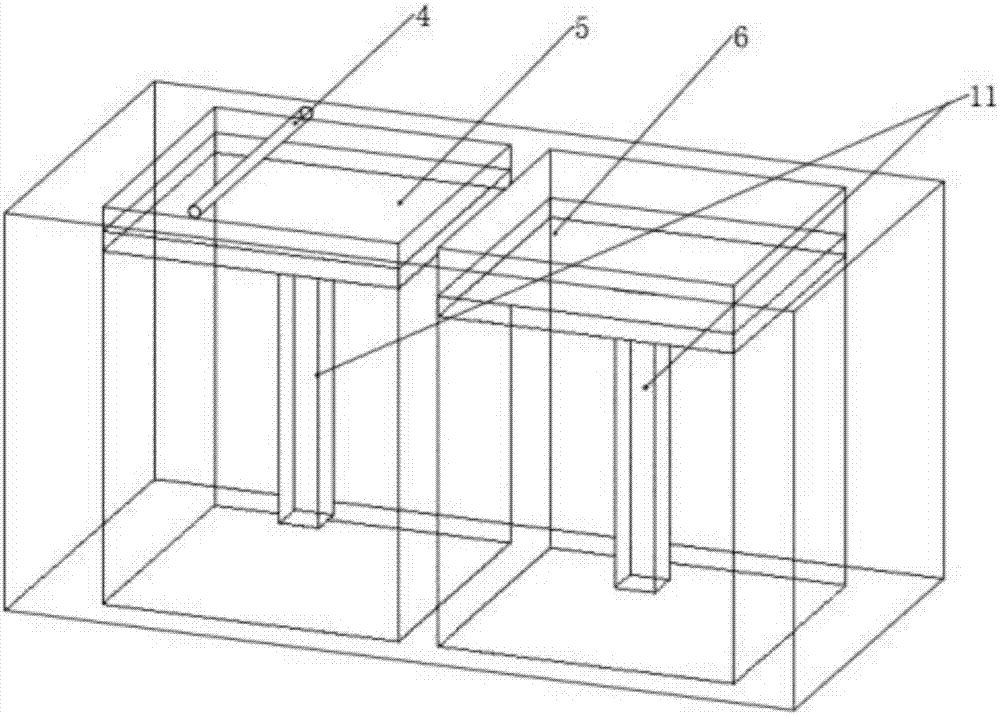

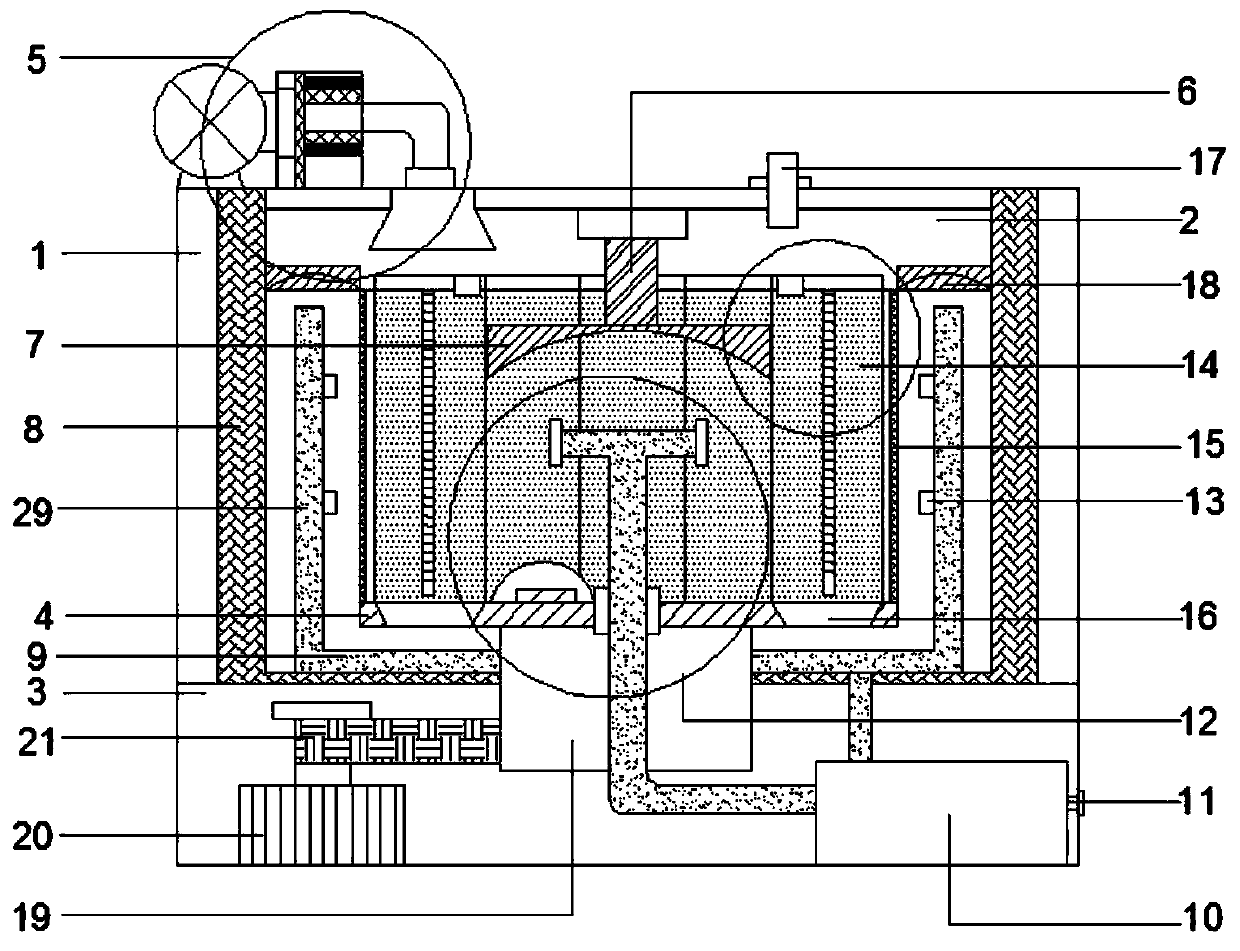

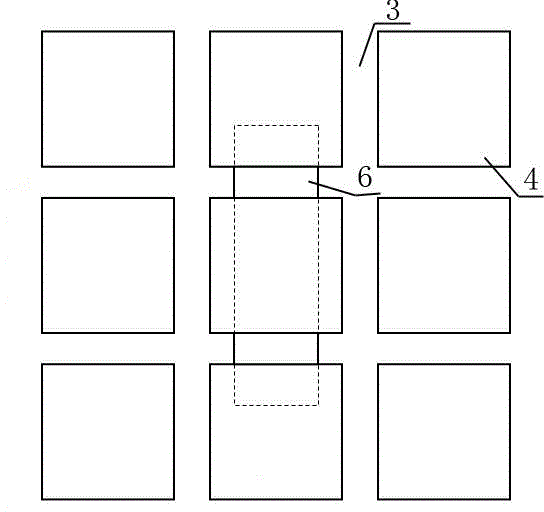

Furnace body of atmosphere protection three-pushed-slab kiln

The invention discloses a furnace body of an atmosphere protection three-pushed-slab kiln. The furnace body comprises a furnace shell, a refractory material brick body and a heating device. The refractory material brick body comprises guide rails and guide blocks, wherein the guide rails and the guide blocks are used for carrying and pushing push plates and saggers. The guide rails and the guide blocks penetrate a kiln cavity and extend out of the kiln cavity. The three rows of pushed slabs located on the same transverse position are spaced through the guide blocks. The furnace body has the beneficial effects of being high in production efficiency, large in yield, even in sintering, stable in pushing, high in energy utilization rate, capable of saving energy, environment-friendly and the like.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

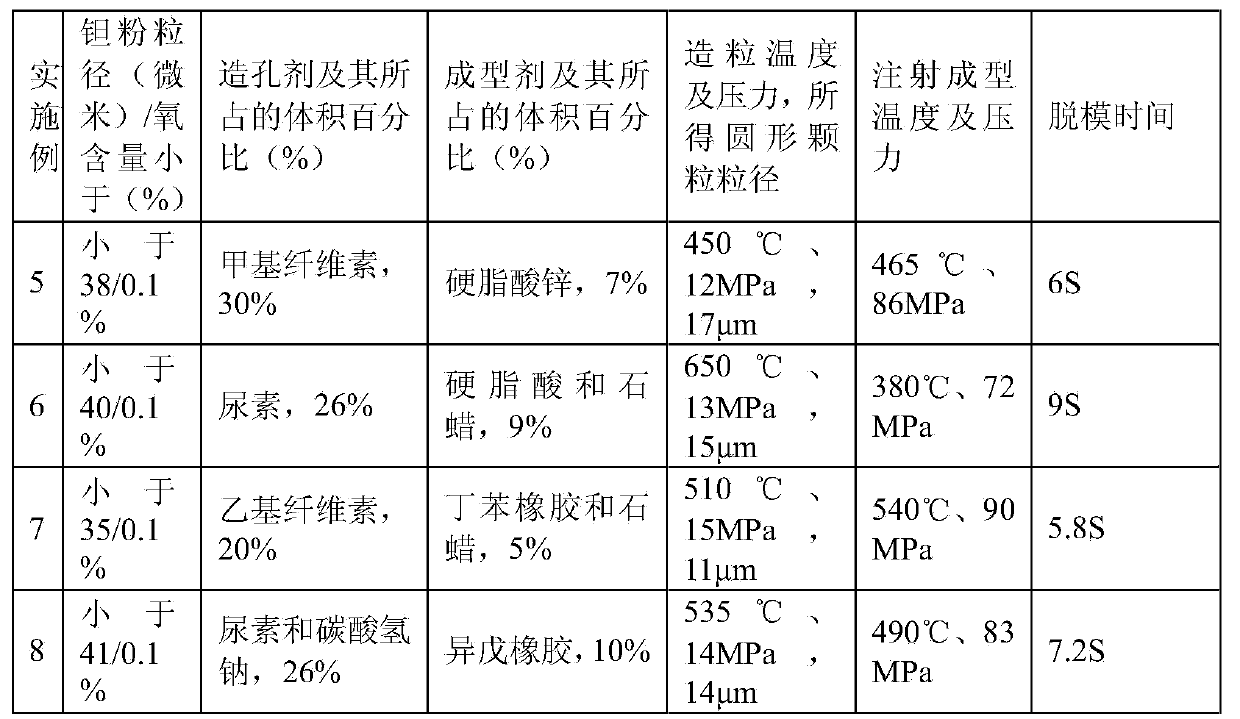

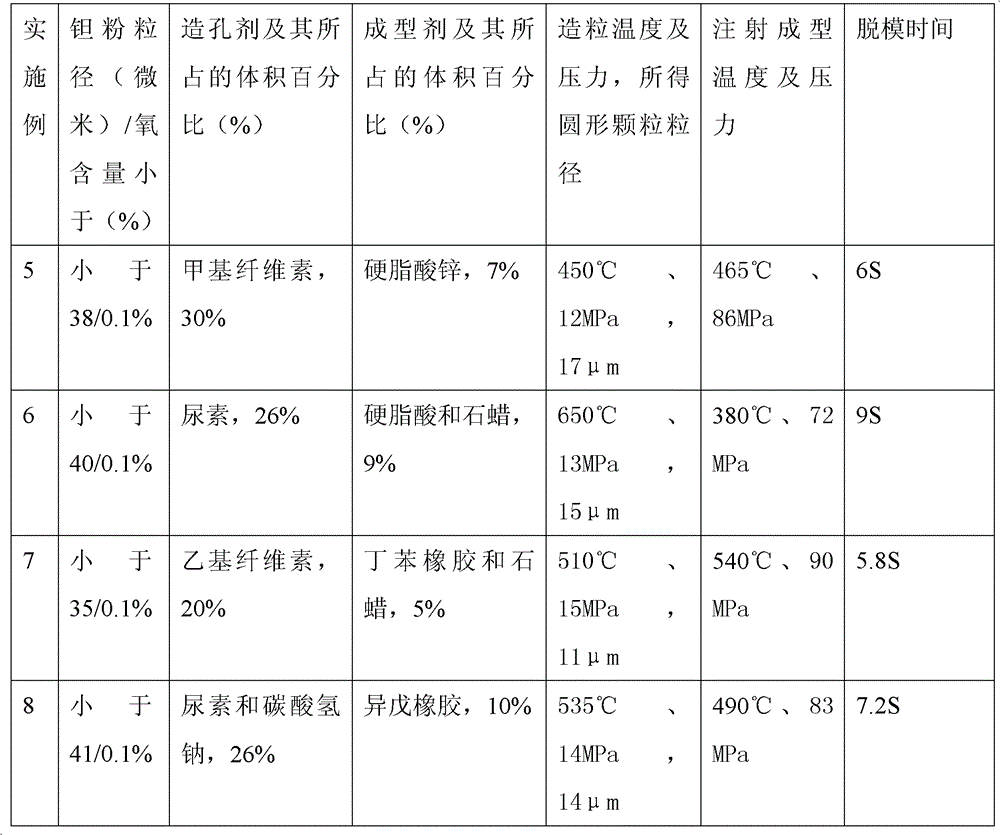

Preparation method of medical porous metal implant material

ActiveCN103740964AImproved biosafety and biocompatibilityOptimizing Process ConditionsProsthesisUreaImplant material

The invention relates to a preparation method of a medical porous metal implant material. The method comprises the following steps: mixing tantalum powder with a pore former and a forming agent so as to form mixed powder; and performing granulation, injection mould forming, demoulding, degreasing, sintering and heat treatment on the mixed powder so as to prepare the medical porous metal implant material capable of replacing a dentale tissue, wherein the pore former is one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethyecellulose; the forming agent is one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin and synthetic rubber; the degreasing process is performed under the conditions of gradually heating to 400 DEG C to 800 DEG C according to the speed rate of 0.5 DEG C / minute to 3 DEG C / minute, forming a protective atmosphere in an argon leading-in mode and carrying out heat preservation for 60 to 240 minutes; the sintering process and the heat treatment process are effectively improved. Thus, the mechanical property of the prepared medical porous metal implant material is greatly improved. As a result, the prepared medical porous metal implant material is very suitable for replacement of the dentale tissue.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical porous metal implanting material

ActiveCN102796899AUniform tissueOrganizational stabilityTransportation and packagingMetal-working apparatusSodium bicarbonatePolyvinyl alcohol

The invention discloses a preparation method of a medical porous metal implanting material. The preparation method comprises the steps of: mixing tantalum powder, pore-forming agent and forming agent to mixed powder; and carrying out granulation, mould-injection forming, demoulding, degreasing, sintering and heat treatment to obtain the medical porous metal implanting material which is used for replacing tooth bone tissues, wherein the pore-forming agent comprises one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethyl cellulose; the forming agent comprises one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin and synthetic rubber; and the degreasing process comprises the steps of: gradually raising the temperature to 400-800 DEG C at a speed of 0.5-3 DEG C / min, introducing in argon to form protection atmosphere and holding the temperature for 60-240min. According to the preparation method provided by the invention, the sintering and heat treatment steps are effectively improved, so that the mechanical property of a prepared porous tantalum material is greatly improved and the porous tantalum material is particularly suitable for serving as a medical implanting material for replacing the tooth bone tissues of human body.

Owner:CHONGQING RUNZE PHARM CO LTD

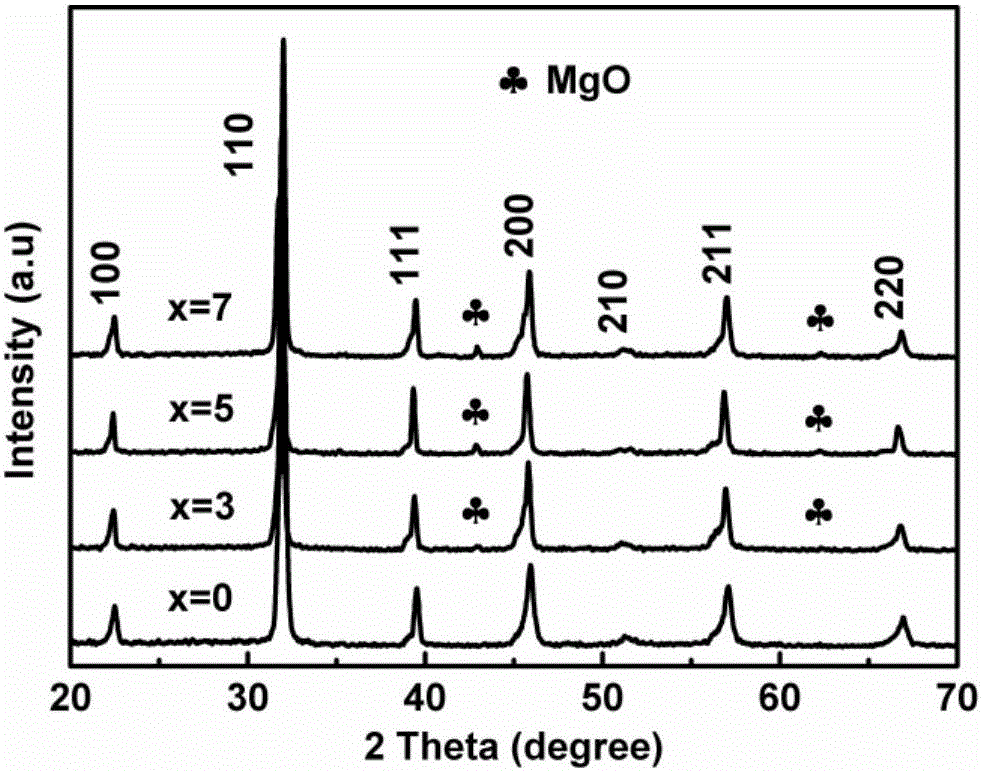

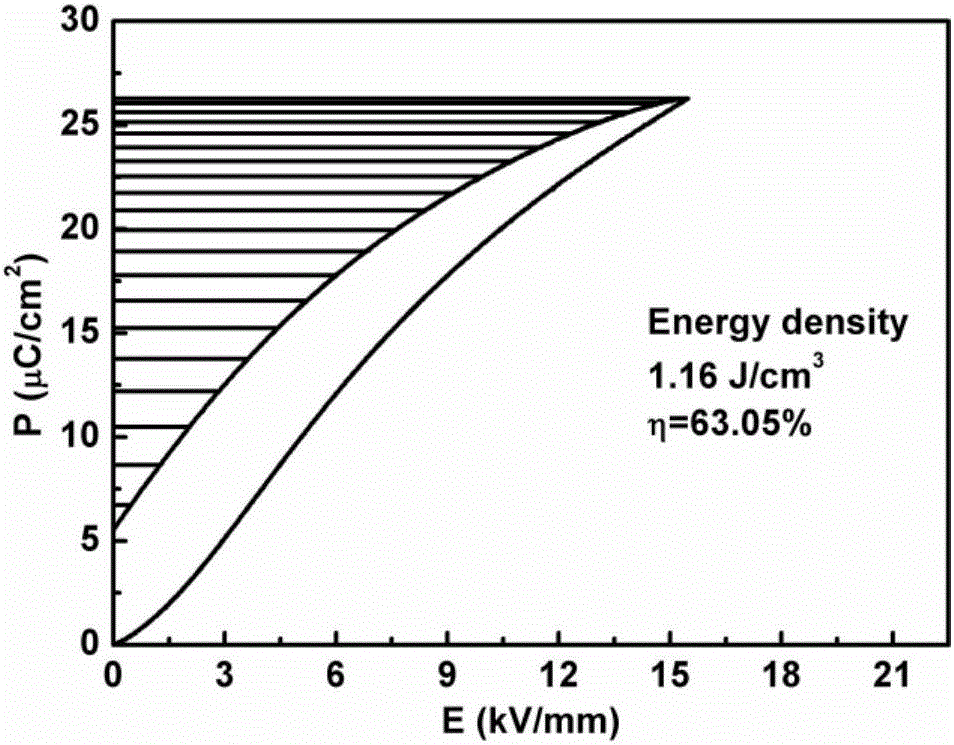

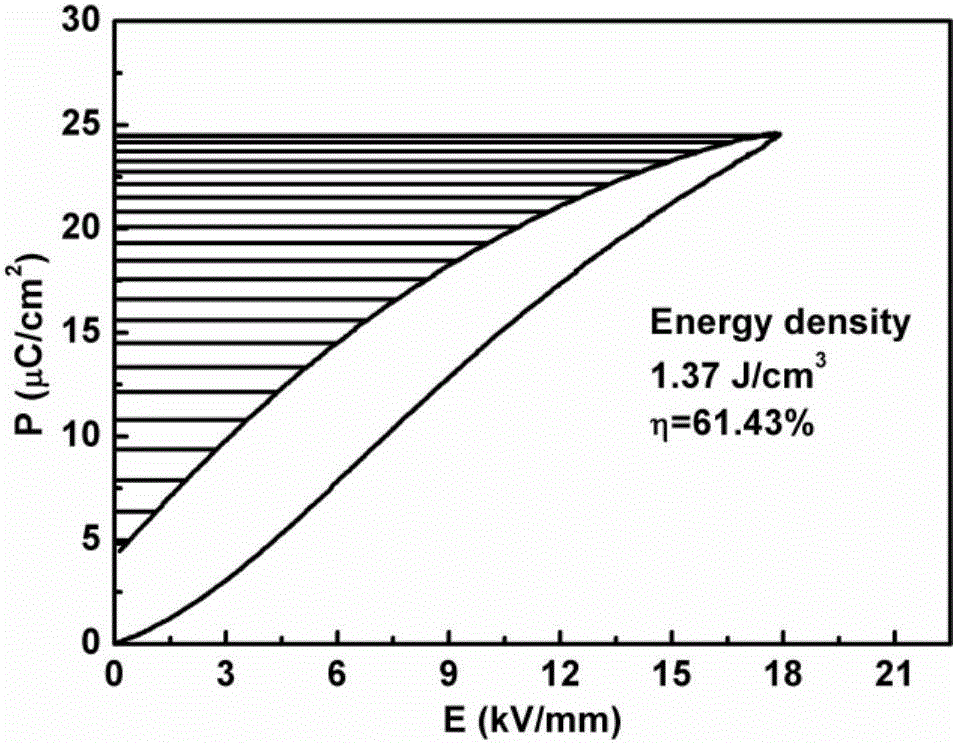

0.5NBT-0.5BCTZ-xwt%MgO high-storage-energy-density ceramic material prepared by microwave sintering and method

The invention relates to a 0.5NBT-0.5BCTZ-xwt%MgO high-storage-energy-density ceramic material prepared by microwave sintering and a method. The method comprises the following steps: firstly, proportioning BCTZ ceramic powder, NBT ceramic powder and magnesium oxide powder according to a stoichiometric ratio of a chemical formula 0.5NBT-0.5BCTZ-xwt%MgO, uniformly mixing, pelletizing and forming; and sintering and forming ceramics by preserving heat for 4 to 20 minutes at a temperature ranging from 900 DEG C to 1100 DEG C in a microwave sintering mode, thereby obtaining the high-storage-energy-density ceramic material, wherein x ranges from 3 to 7. Through microwave sintering, the method has the advantages of high heating speed, uniform heating and the like; reaction of MgO and a matrix material can be effectively restrained at a relatively low sintering temperature within relatively short sintering time, and the microstructure of the material can be optimized to improve the compactness of the material, so that breakdown strength of the material is effectively improved, and the high-storage-energy-density ceramic material is prepared.

Owner:SHAANXI UNIV OF SCI & TECH

Micro-wave sintering method for foam glass

InactiveCN101265018AEvenly sinteredReduce the temperature difference between inside and outsideGlass shaping apparatusGlass productionNeutral atmosphereRoom temperature

A microwave sintering method of foam glass comprises the following steps of: placing a foam glass blank into a microwave sintering device with oxidizing atmosphere or neutral atmosphere and microwave frequency of 300MHz-300GHz, heating up to 300-350 DEG C in 5 min, keeping at the temperature for 10 min, heating up to 750-820 DEG C in 20-45 min, keeping at the temperature for 15-40 min, turning off microwave source, rapidly cooling to 600 DEC G in 5 min, keeping at the temperature for 20 min, cooling to room temperature, and taking out. In the inventive method, the heat for microwave sintering is originated from inside, the foam glass blank is self-sintered by absorbing microwave, the internal and external temperature difference of the foam glass blank is small during sintering process, so as to uniformly sinter the foam glass blank, reduce sintering temperature, shorten sintering time, and improve sintering quality. The used temperature is 5-150 DEG C lower than conventional sintering temperature.

Owner:SHAANXI UNIV OF SCI & TECH

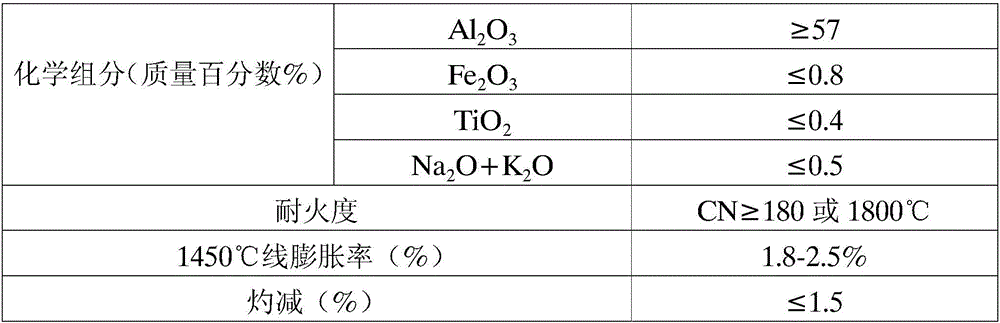

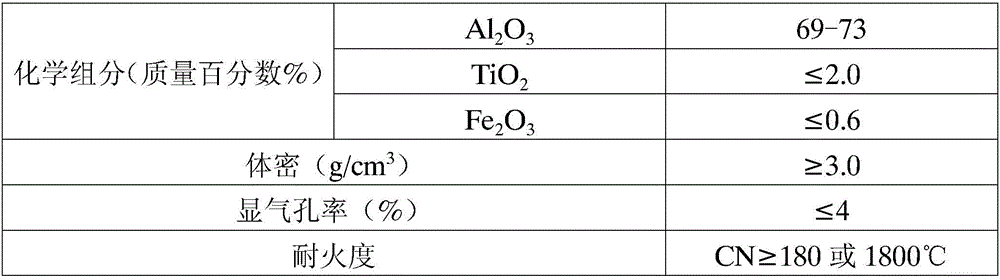

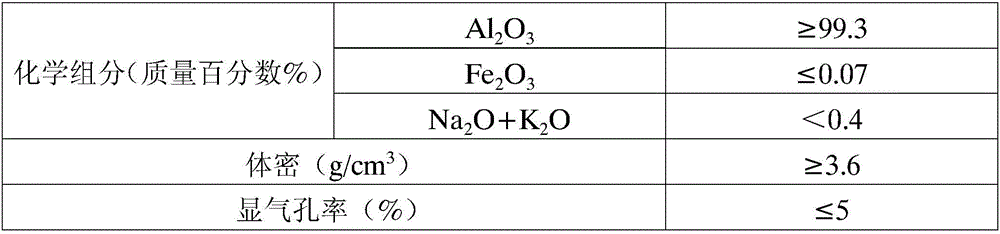

Preparation method of dry quenching furnace chute corbel brick

The invention discloses a preparation method of a dry quenching furnace chute corbel brick. The method comprises the following steps: S1. uniformly mixing materials; S2. mulling; S3. compression moulding; S4. firing; and S5. inspecting and packaging. Andalusite is adopted to enhance the frame strength, thereby effectively enhancing the thermal shock resistance. High-purity electrofused mullite has the needle-shaped crystal structure, and is capable of absorbing the andalusite expansion in the transformation stage and enhancing the thermal shock and folding strength. Slaty corundum can enhance the wear resistance, and can substitute the original silicon carbide powder component to effectively enhance the oxidation resistance. The nano alpha-Al2O3 material is a high-temperature liquid phase, and the high-temperature liquid phase sintering mechanism can be enhanced and the stable crystal lattice can be produced.

Owner:MAANSHAN IRON & STEEL CO LTD

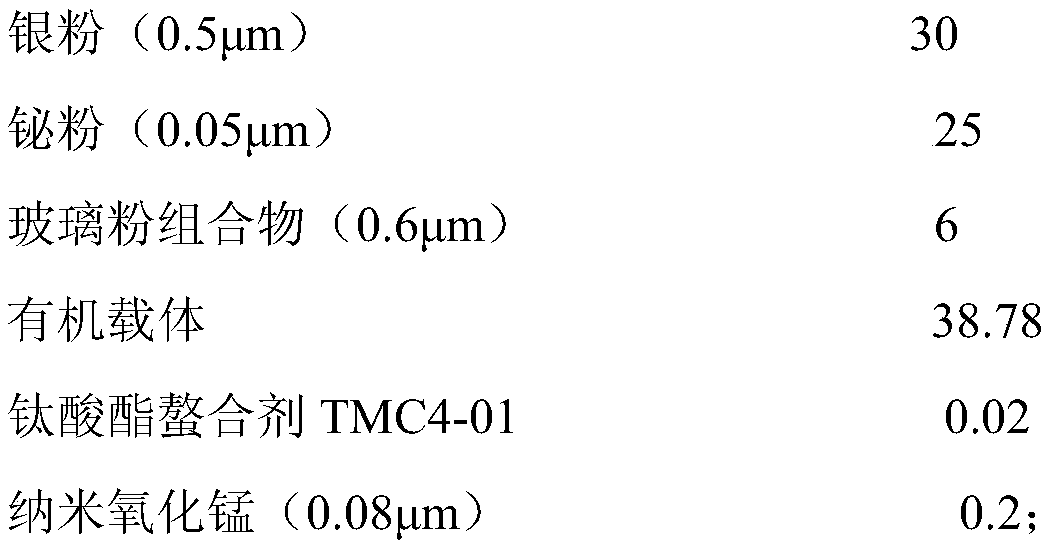

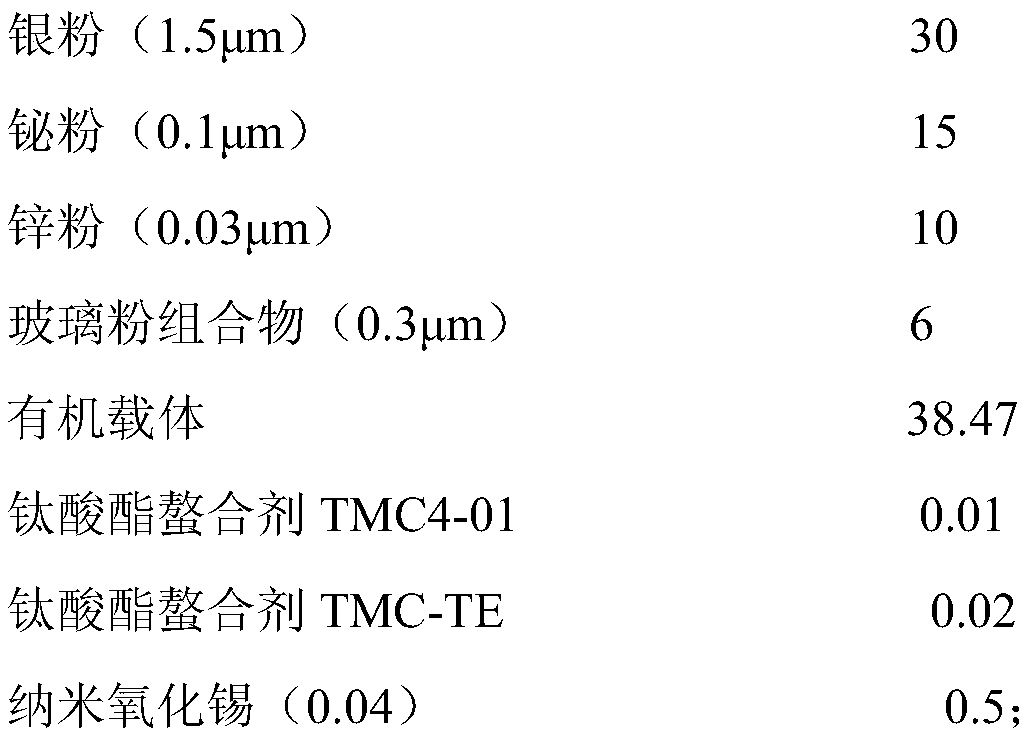

All-aluminum BSF (back surface field) back electrode slurry and preparation method and application thereof

ActiveCN110120274AEvenly sinteredUniform and dense sinteringNon-conductive material with dispersed conductive materialPhotovoltaic energy generationBack surface fieldSlurry

The invention provides all-aluminum BSF (back surface field) back electrode slurry and a preparation method and application thereof. The raw material of the back electrode slurry comprise 20%-60% of back electrode slurry, 1%-40% of nano metal powder, 0.5%-6% of a glass powder composition, 10%-50% of an organic vehicle, 0.01%-0.1% of a dispersant, and 0%-5% of an additive, wherein the total mass ofthe components of the back electrode paste is 100%, and the average particle size of the silver powder is 0.1-3 microns. The invention also provides the preparation method of the back electrode slurry. The back electrode slurry can be fully sintered in an aluminum slurry layer, and the photoelectric conversion efficiency of a solar cell is improved.

Owner:SUZHOU ISILVER MATERIALS

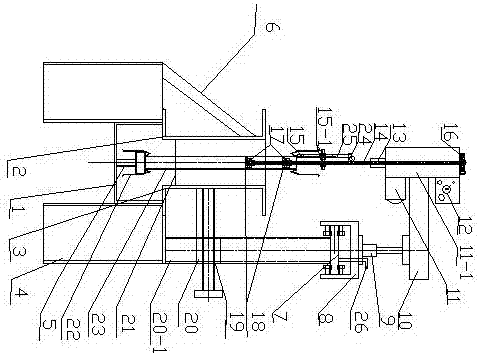

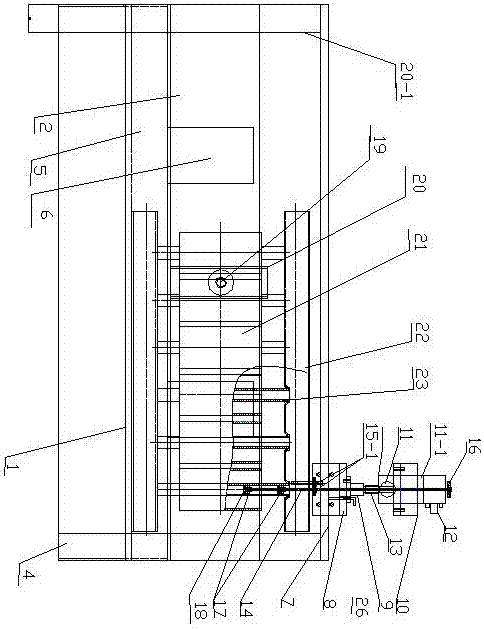

Stainless steel pipe circular automatic welding member of heating radiator and manufacturing method thereof

ActiveCN107234356ASimple structureEasy to replaceWelding/cutting auxillary devicesAuxillary welding devicesCircular discSteam line

The invention provides a stainless steel pipe circular automatic welding member of a heating radiator. In a steel-channel-combined frame structure, a balancing cork base makes contact with a bottom port of a horizontal communicating pipe on the lower side of the heating radiator, an upper port of a horizontal communicating pipe on the upper side of the heating radiator makes contact with a welding gun fixed to a rotating shaft, an air cylinder guiding rod descends, the rotating shaft is inserted into a vertical stand pipe, and the rotating shaft is further provided with the welding gun; the welding gun rotates by a circle with the rotating shaft which is inserted into a polyurethane circular disc of the vertical stand pipe as the circle center, the rotating shaft and a pipe core bearing rotate, and the polyurethane circular disc does not rotate; a coupling is inserted into the upper part of the rotating shaft, and the coupling is connected with a lower main shaft of a reducer; the reducer is connected with a motor, and an upper main shaft of the reducer is connected with a circular disc spring; the main shafts of the reducer and the rotating shaft positively rotate by one circle, simultaneously, the welding gun and a steam line on the welding gun positively rotate by one circle, the circular disc spring is stretched, the main shafts of the reducer are stopped, a control button which electrically arranged is automatically twisted to a neutral position, the circular disc spring retracts, the main shafts of the reducer drive the rotating shaft and the welding gun to oppositely rotate by one circle, and the steam line of the welding gun is restored.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

N-type solar cell front fine grid slurry and preparation method thereof

ActiveCN110491545AReduce manufacturing costImprove electrical performanceOxide conductorsNon-conductive material with dispersed conductive materialElectricitySilver paste

The invention discloses N-type solar cell front fine grid slurry which comprises the following preparation raw materials in parts by weight: 1-5 parts of high-activity glass powder, 1-5 parts of silicon powder, 75-79 parts of aluminum-silicon alloy powder and 15-20 parts of organic components. According to the N-type solar cell front fine grid slurry and the preparation method thereof provided bythe invention, the aluminum paste is used for replacing aluminum-doped silver paste in the prior art; the production cost of the N-type solar cell is reduced, the slotting process before printing is omitted due to the high-activity glass powder contained in the aluminum paste, the process steps are simplified, a passivation layer cannot be damaged, and the electrical performance of the solar cellis improved.

Owner:NANTONG T SUN NEW ENERGY CO LTD

Magnesian hot patching material and preparation process thereof

The invention relates to the technical field of magnesian patching materials, in particular to a magnesian hot patching material and a preparation process thereof. The magnesian hot patching material comprises the following raw materials in parts by mass: 60-80 parts of large-particle magnesia, 7-8 parts of asphalt, 3-4 parts of an organic solvent and 8-30 parts of small-particle magnesia. The preparation process of the magnesian hot patching material comprises the following steps: crushing dead burnt magnesia into the large-particle magnesia and the small-particle magnesia; dissolving the asphalt in the organic solvent; mulling the large-particle magnesia and the asphalt so as to allow the asphalt to fully wrap the surface of the large-particle magnesia; and then adding the small-particle magnesia for mulling, and conveying a formed mixture into a ball press machine to be pressed into balls. The content of magnesium oxide in the magnesia is more than 90%, the content of silicon dioxide is less than 3.5%, the content of calcium oxide is less than 5%, and the volume density of the magnesia is more than 3.4 g / cm<3>.

Owner:初德增

Preparation method of active (Mn, Re, Co)3O4 spinel mixed electrode materials and application thereof in HEMAA

InactiveCN103326036AGood room temperature toughnessGood high temperature oxidation resistanceCell electrodesRare-earth elementDistilled water

The invention discloses a preparation method of active (Mn, Re, Co)3O4 spinel mixed electrode materials, and the preparation method is characterized by comprising the following steps: (1) dissolving soluble salts of Mn, Co and rare earth elements, and a complexing agent in distilled water, and uniformly stirring the obtained mixture at room temperature; (2) carrying out low-temperature drying on a solution obtained in the step (1) for 1-200 hours at a temperature of 60-200 DEG C, and carrying out intermediate-temperate calcinating on the obtained object for 2-48 hours at a temperature of 350-500 DEG C so as to remove organic matters, and in a reducing atmosphere, calcining the obtained product for 1-24 hours in a high-temperature atmosphere furnace at a temperature of 600-900 DEG C so as to obtain superfine active mixed powder with the particle size of 10-1000 nm; (3) placing the superfine MnO, Co and Re2O3 active mixed powder obtained in the step (2) into a die, and in a vacuum or protective atmosphere, carrying out sinter molding on the obtained product at a high temperature of 900-1400 DEG C and at a pressure of 20-60 Mpa. The obtained electrode has good room-temperature toughness and electrical conductivity.

Owner:JIANGSU UNIV OF SCI & TECH

Method for preparing high-entropy boron ceramic surface material by microwave sintering

The invention discloses a method for preparing a high-entropy boron ceramic surface material by microwave sintering, which comprises the following steps of: putting nitride ceramic substrate blanks into an auxiliary heating insulation structure in a microwave sintering cavity, neatly stacking the nitride ceramic substrate blanks, arranging a graphite plate between the nitride ceramic substrate blanks, introducing a nitrogen atmosphere containing 7-10% of hydrogen, carrying out normal-pressure microwave sintering at the frequency of 2.45 GHz and at 500-3000 DEG C at a heating rate of 8-10 DEG C / min, carrying out heat preservation for 2-10 hours, carrying out furnace cooling until the temperature is 400 DEG C or less, opening the furnace, and taking out an obtained material to obtain the compact high-quality nitride ceramic substrate sintered body. The method has the beneficial effects that the reaction sintering process is accelerated, the nitride ceramic material is sintered under normal pressure at a relatively low temperature in a relatively short time, and the method has the characteristics of high temperature rise speed, low sintering temperature, short heat preservation time, relatively good performance, energy conservation and high production efficiency; and the method is suitable for large-scale production.

Owner:ZHAOSHAN TECH BEIJING CO LTD

Preparation method for molybdenum blank

The invention discloses a preparation method for a molybdenum blank. The method comprises the following steps that (1), under the condition of 160-300 MPa, pressing is carried out on the molybdenum powder with the average particle size of 3-4 microns, moreover, the pressure is maintained for 3-20 minutes, and a green body is prepared; (2), low-temperature sintering is carried out; (3), medium-temperature sintering is carried out; and (4), high-temperature sintering is carried out, finally, cooling is carried out until the temperature reaches the room temperature, and the molybdenum blank is obtained. The molybdenum blank prepared by the preparation method is high in purity and uniform in tissue structure, and a prepared molybdenum foil is stable in performance.

Owner:CHENGDU LIANHONG MOLYBDENUM IND CO LTD

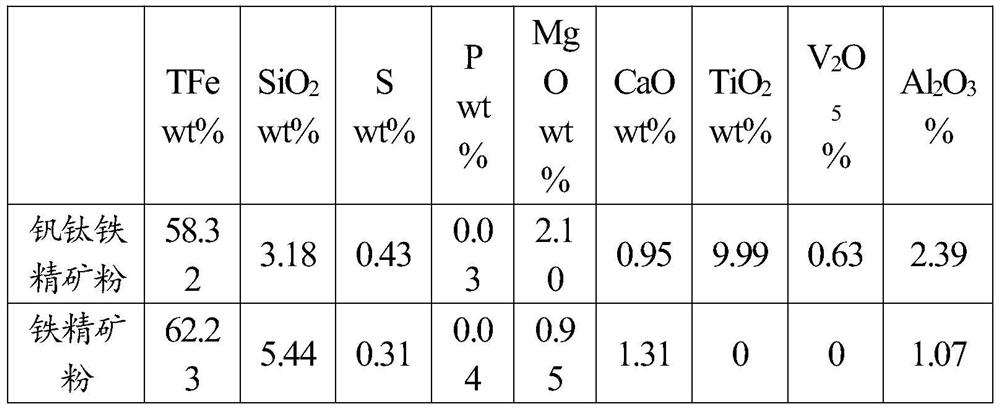

Sintering method of high-grade vanadium-titanium-iron ore concentrates

The invention discloses a sintering method of high-grade vanadium-titanium-iron ore concentrates. The sintering method comprises the following steps that 1), sintering raw materials are mixed evenly and comprise the following components in parts by weight: 50-60 parts of high-grade vanadium-titanium-iron ore concentrate powder, 5-8 parts of iron ore concentrate powder, 10-20 parts of flux and 3-5parts of fuel A; 2), a potassium permanganate solution is sprayed onto the sintering raw materials, water is added to soak the sintering raw materials, and then pelletizing is conducted to obtain pellets B; and 3), the pellets B are distributed to obtain a material layer B, fuel C is distributed on the material layer B to obtain a material layer C, the thickness of the material layer B ranges from650 mm to 700 mm, the thickness of the material layer C ranges from 20 mm to 50 mm, and igniting and sintering in a nitrogen environment are conducted to obtain vanadium-titanium sinter. The sintering performance improvement effect is remarkable, and the sintering utilization coefficient, the yield and the drum index can be improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

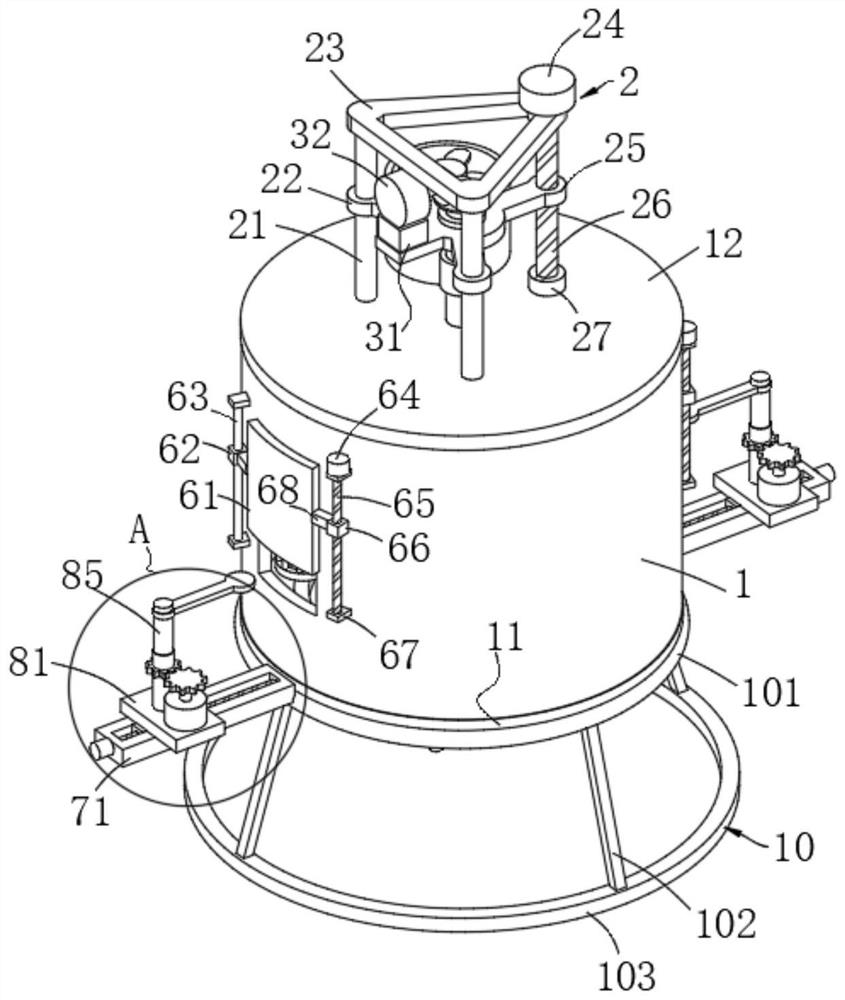

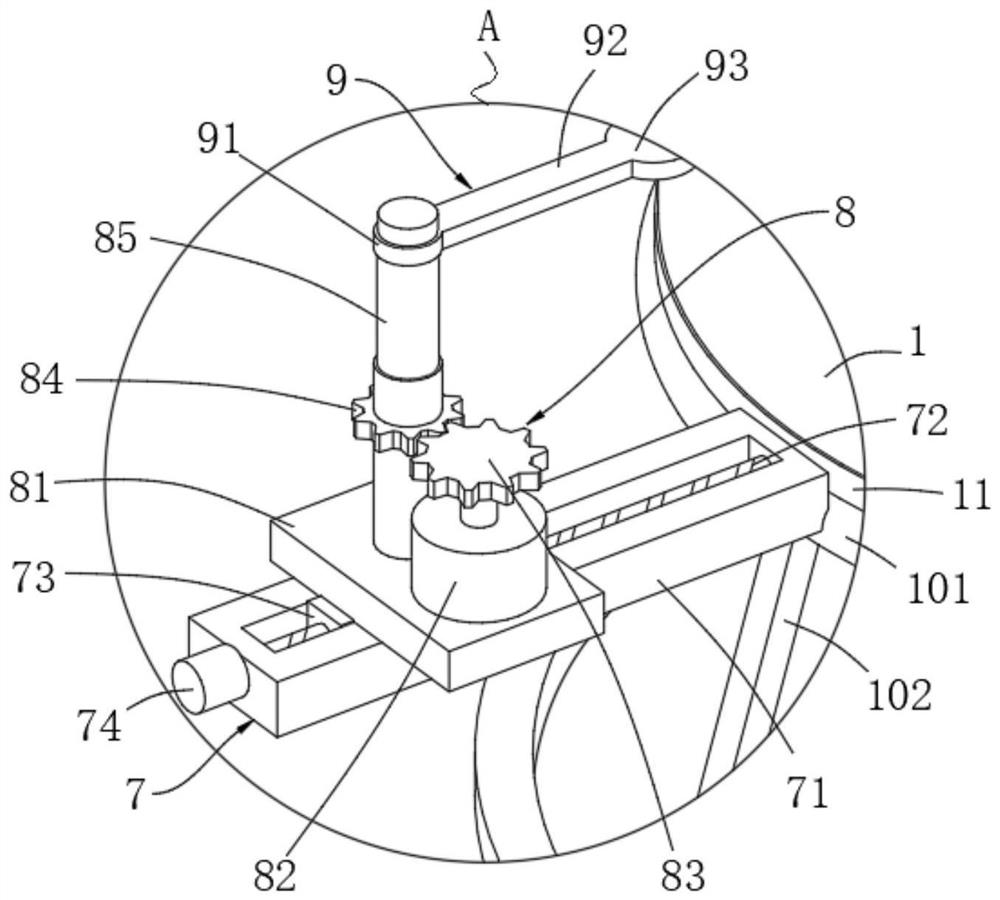

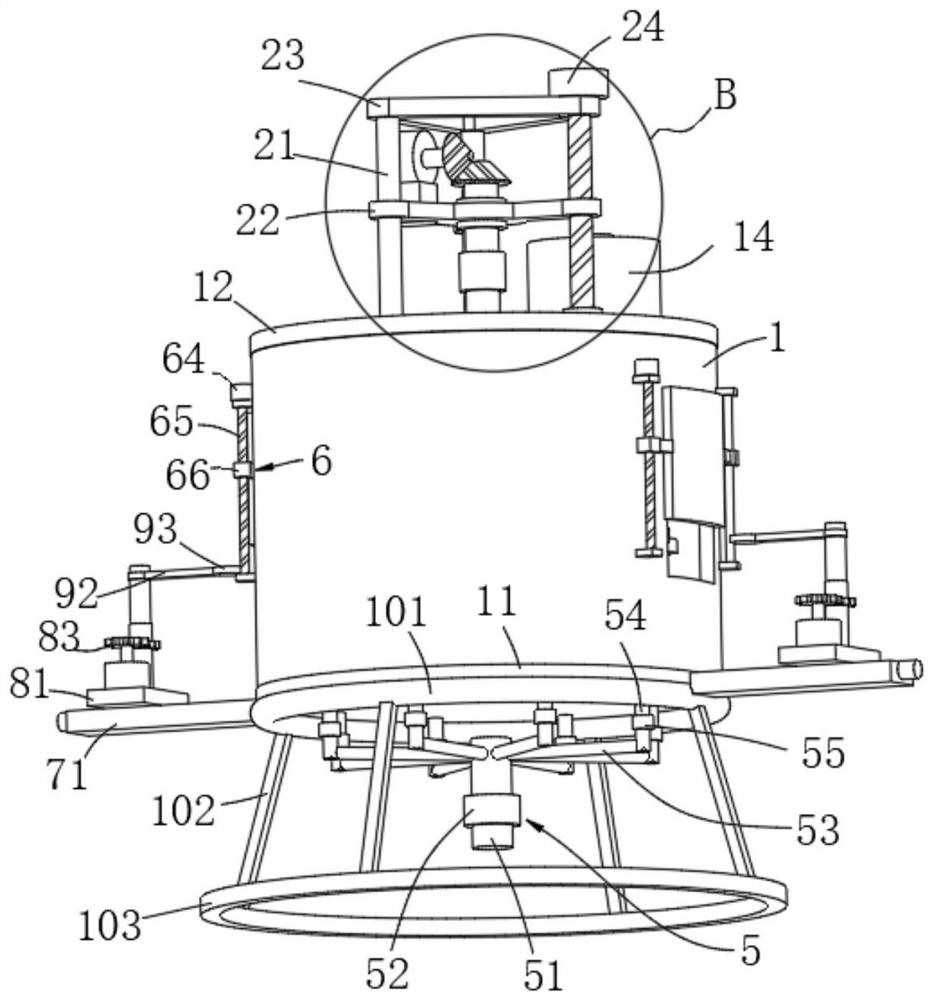

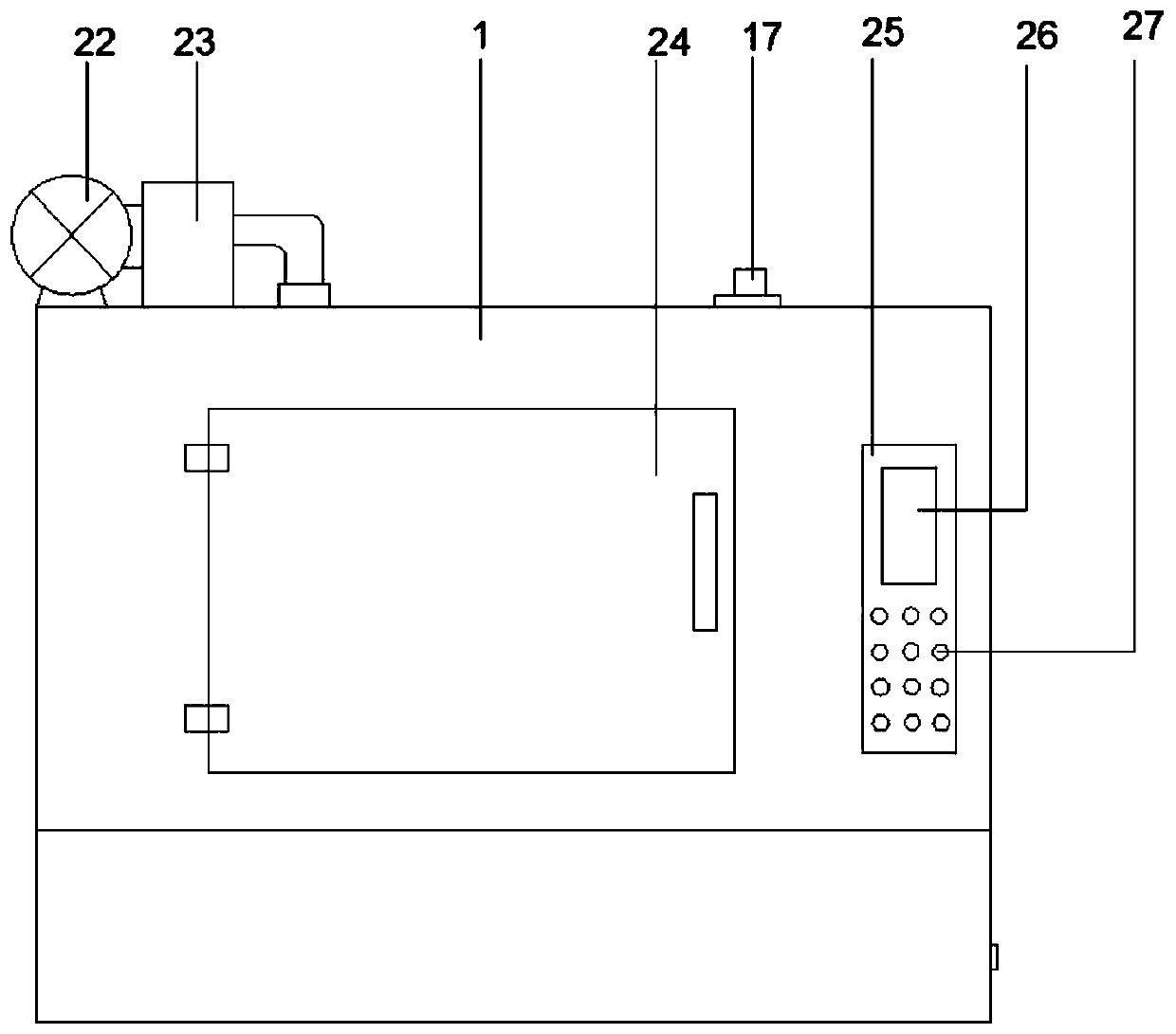

Sintering device of battery positive electrode material for new energy automobile production

InactiveCN113299874AHeating evenlyHigh heating temperatureElectrode thermal treatmentCharge treatment typeMetallurgyElectrical battery

The invention discloses a sintering device of a battery positive electrode material for new energy automobile production, the sintering device comprises a sintering furnace body, the bottom of the sintering furnace body is connected with a furnace body base, the bottom of the furnace body base is supported by a support frame, the top of the sintering furnace body is connected with a furnace body top cover, and two taking and placing through grooves are symmetrically formed in the two sides of the sintering furnace body; the sintering device comprises a sintering frame lifting unit installed on the furnace body top cover, wherein a sintering frame soaking unit is installed on the sintering frame lifting unit, and the bottom end of a soaking shaft of the sintering frame soaking unit penetrates through a round hole in the middle of the furnace body top cover and extends into the sintering furnace body; a sintering frame installed at the end, located in the sintering furnace body, of the soaking shaft; and a sintering heat supply unit mounted on the furnace body base. The device is simple in structure, clean and pollution-free, can fully utilize the temperature of the natural gas side flame, can meet the sintering temperature of a new positive electrode material, is uniform in sintering, can realize automation when the positive electrode material is taken and placed, and can improve the sintering efficiency.

Owner:广州华梁网络科技有限公司

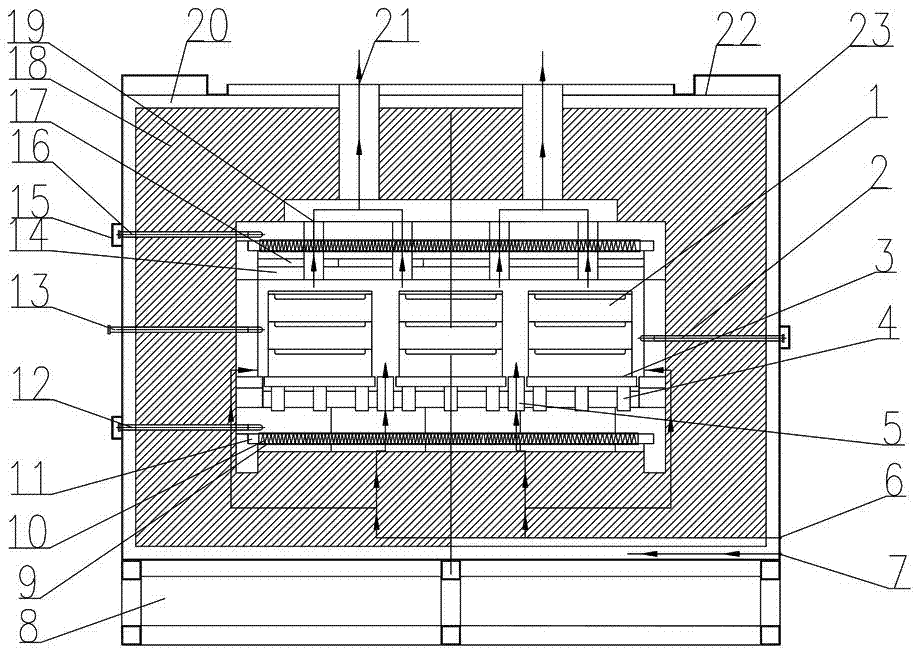

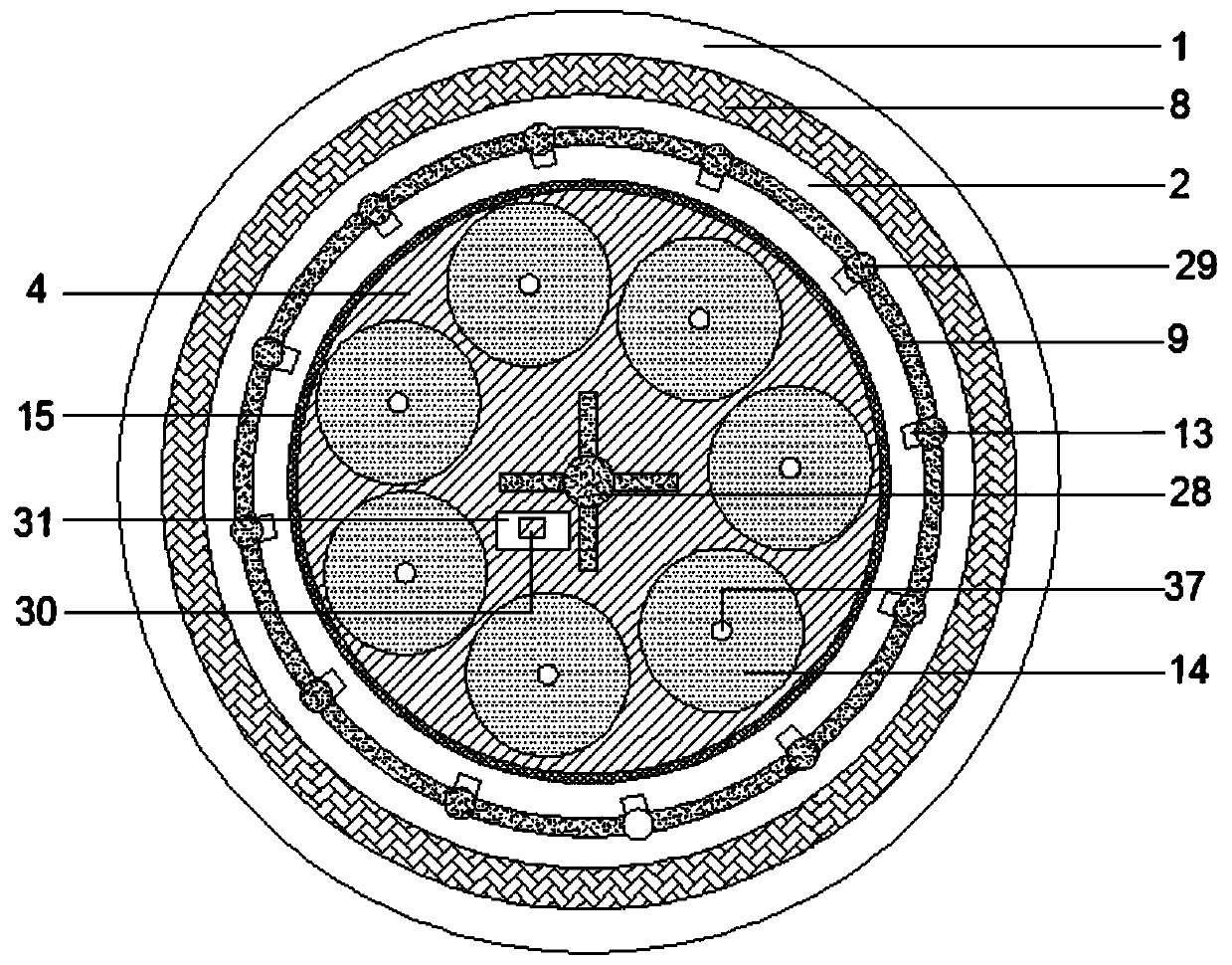

Sintering device for soft magnetic ferrite powder

ActiveCN110986580AImprove efficiencyPromotes grain growthCharge composition/stateCharge treatment typeFerrite powderFuel gas

The invention discloses a sintering device for soft magnetic ferrite powder, and relates to the technical field of soft magnetic ferrite processing. The sintering device comprises an outer box, a sintering inner box and a base, wherein one side of the base is provided with a rotating motor, and the other side of the base is provided with a fuel gas bin; an insulating layer is arranged between theouter box and the sintering inner box, an air pumping mechanism is arranged at the top of the outer box, a central rotating shaft is arranged at the bottom of the sintering inner box, a circular rotating disc is fixed at the upper end of the central rotating shaft, a circle of storage bins are arranged on the circular rotating disc, an internal heating mechanism enters the upper end of the circular rotating disc through the central rotating shaft, the fuel gas bin is connected with a first air duct, a plurality of air outlet pipes are arranged at the upper end of the first air duct, the air outlet pipes are arranged outside a fixed net layer, and one sides, close to the fixed net layer, of the air outlet pipes are provided a plurality of burner ports. The sintering device overcomes the defects of the prior art, has reasonable design and convenient use, effectively improves the sintering efficiency of the remaining ferrite raw materials, improves the uniformity of a sintering process, and strengthens the quality of sintered products.

Owner:天长市华磁磁电有限公司

Smoke discharge method of shuttle kiln

InactiveCN104677119AImprove airflow directionReduce the impactWaste heat treatmentCombustion chamberEngineering

The invention discloses a smoke discharge method of a shuttle kiln, in particular relates to a smoke discharge method for a shuttle kiln. The technical problems to be solved are insufficient combustion of combustion gas, large temperature deviation, easy bending of rollers, low yield of the rollers and low production efficiency in a traditional roller shuttle kiln. At least one spacing plate is laid above a kiln car table board and a smoke flue outlet; and at least one adjusting wind groove is formed between the spacing plates. The smoke discharge method of the shuttle kiln improves the direction of airflows in the kiln, reduces the influence on the rollers, and improves the straightness of the rollers; and meanwhile, the spacing plates enable the kiln pressure and temperature above combustion chamber spacing plates to become more uniform, so that the sintering and size uniformity of the rollers are improved.

Owner:JIYUAN SAFE IND CERAMIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com