Sintering device for soft magnetic ferrite powder

A soft ferrite and sintering device technology, applied in waste heat treatment, charge composition/state, charge processing type, etc., can solve the problems of uneven sintering, long sintering time, poor sintering effect, etc. The effect of quality, improving sintering efficiency and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

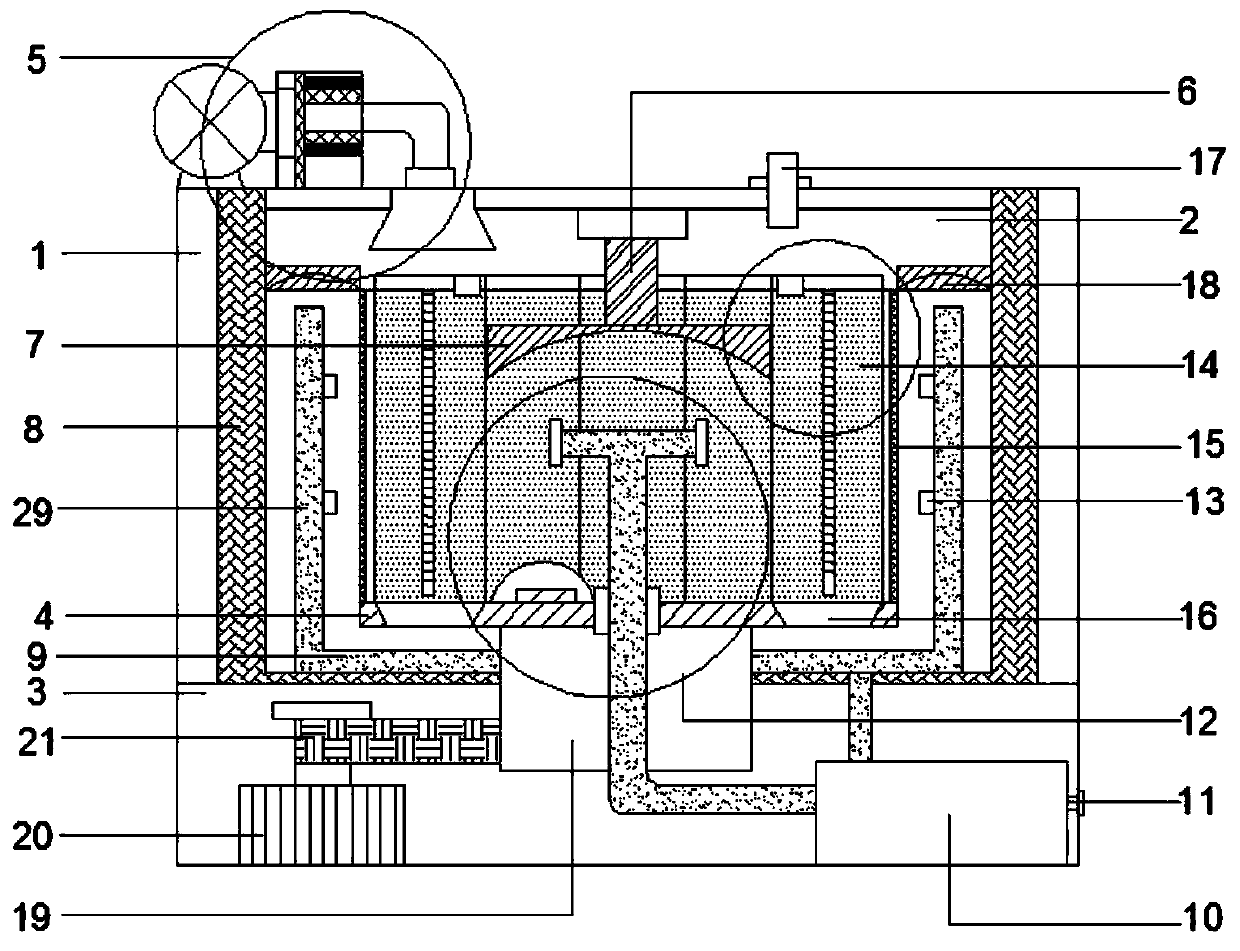

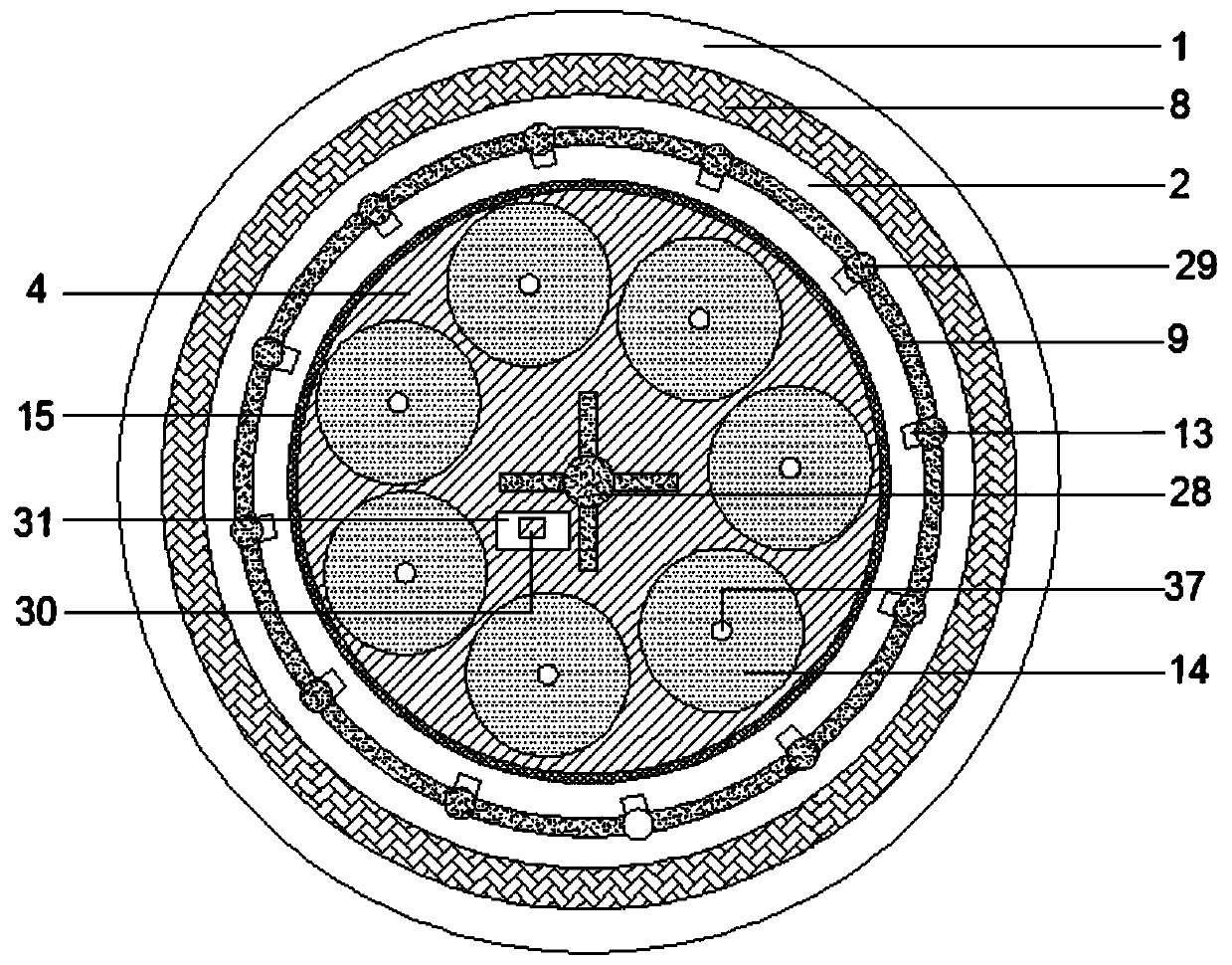

[0030] refer to Figure 1-6 , a soft ferrite powder sintering device, comprising an outer box 1, a sintered inner box 2 inside the outer box 1 and a base 3 at the bottom of the outer box 1, the base 3 is a hollow structure, and a rotating motor is arranged on one side of the inner side of the base 3 20. The other side is provided with a gas bin 10, and the gas bin 10 is connected to an external gas source through an air inlet pipe 11, the outer box 1 and the sintered inner box 2 are connected through an insulation layer 8, and the top of the outer box 1 is An air extraction mechanism 5 is arranged on the side, and the air extraction mechanism 5 is connected with the sintering inner box 2. The bottom of the sintering inner box 2 is provided with a central rotating shaft 19, and a circular turntable 4 is fixed on the upper end of the central rotating shaft 19. The upper end of the turntable 4 is surrounded by a layer of fixed mesh layer 15, the fixed mesh layer 15 is a hollow st...

Embodiment 2

[0032] Such as Figure 1-6As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top of the discharge bin 14 is sealed, and a material inlet 36 is provided on one side of the seal, and a heating rod 37 is provided inside the discharge bin 14. One end of the heating rod 37 is connected and fixed with the center of the top of the discharge bin 14 . The sintering efficiency of raw materials inside the discharge bin 14 is effectively improved, and the uniformity of sintering is enhanced at the same time.

Embodiment 3

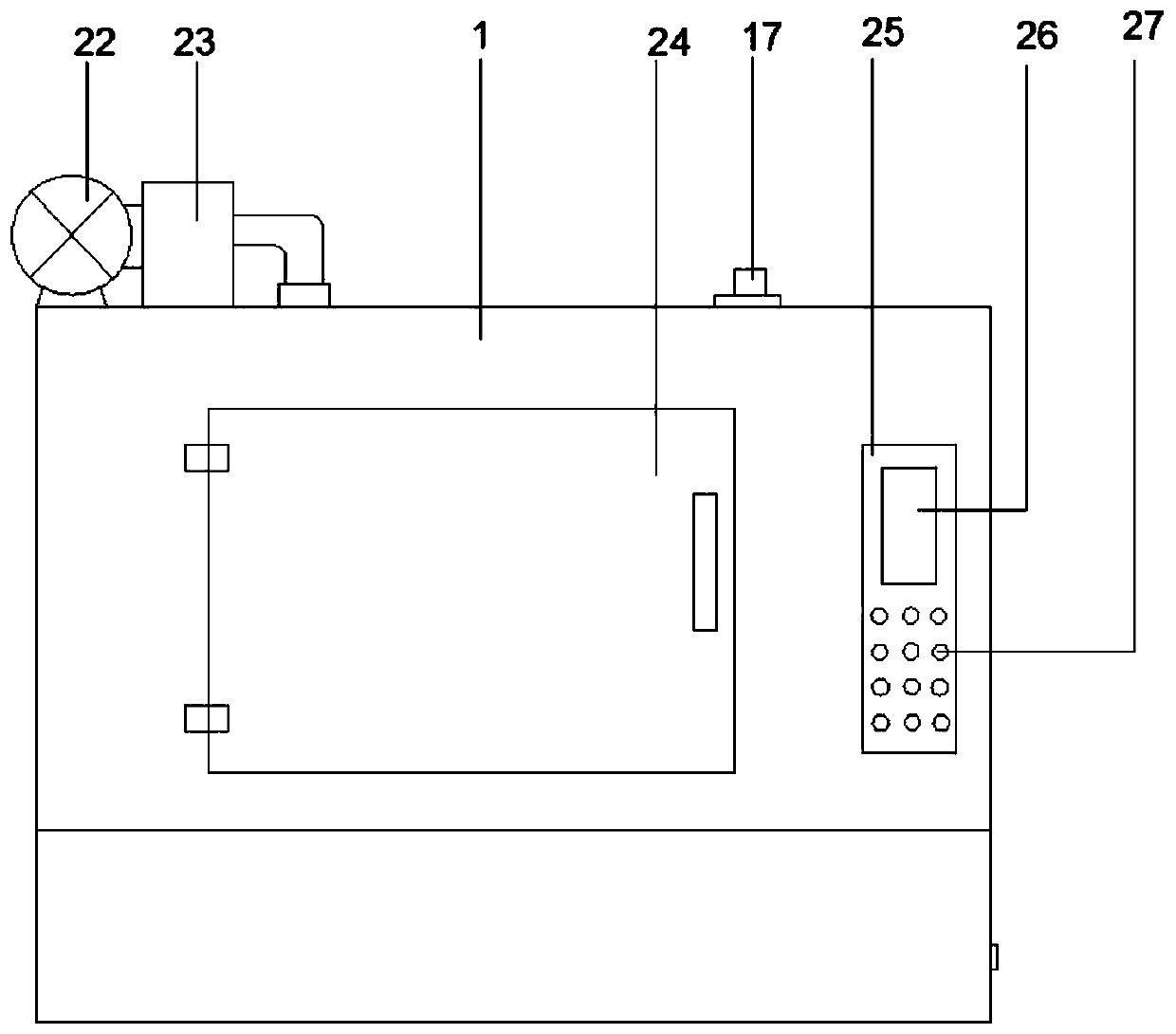

[0034] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1-2. Preferably, a temperature sensor 30 is provided at the bottom of the circular turntable 4, and a protective cover 31 is provided outside the temperature sensor 30, and the outside of the outer box 1 One side is provided with a control panel 25, the control panel 25 is provided with a temperature display screen 26 and a control button 27, the temperature display screen 26 is connected with the temperature sensor 30 signal, the control button 27 is respectively connected with the valve at the combustion port 13, the air pump 22. The heating rod 37, the rotating motor 20, the electronic igniter at the combustion port 13 are electrically connected with the valve at 10 places of the gas storehouse.

[0035] It is convenient for users to observe the temperature inside the device and to regulate the components inside the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com