Patents

Literature

888 results about "Soft magnet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

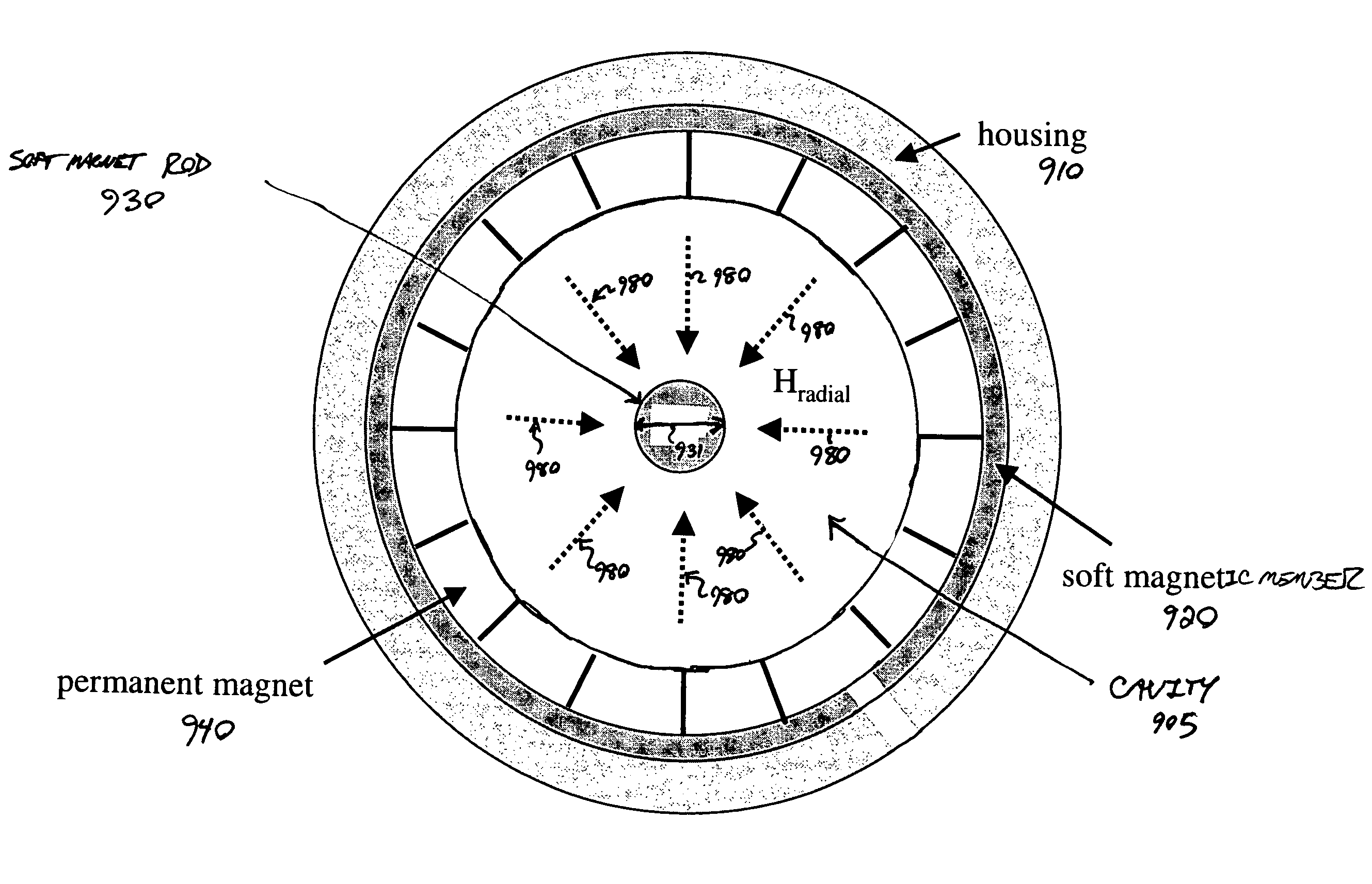

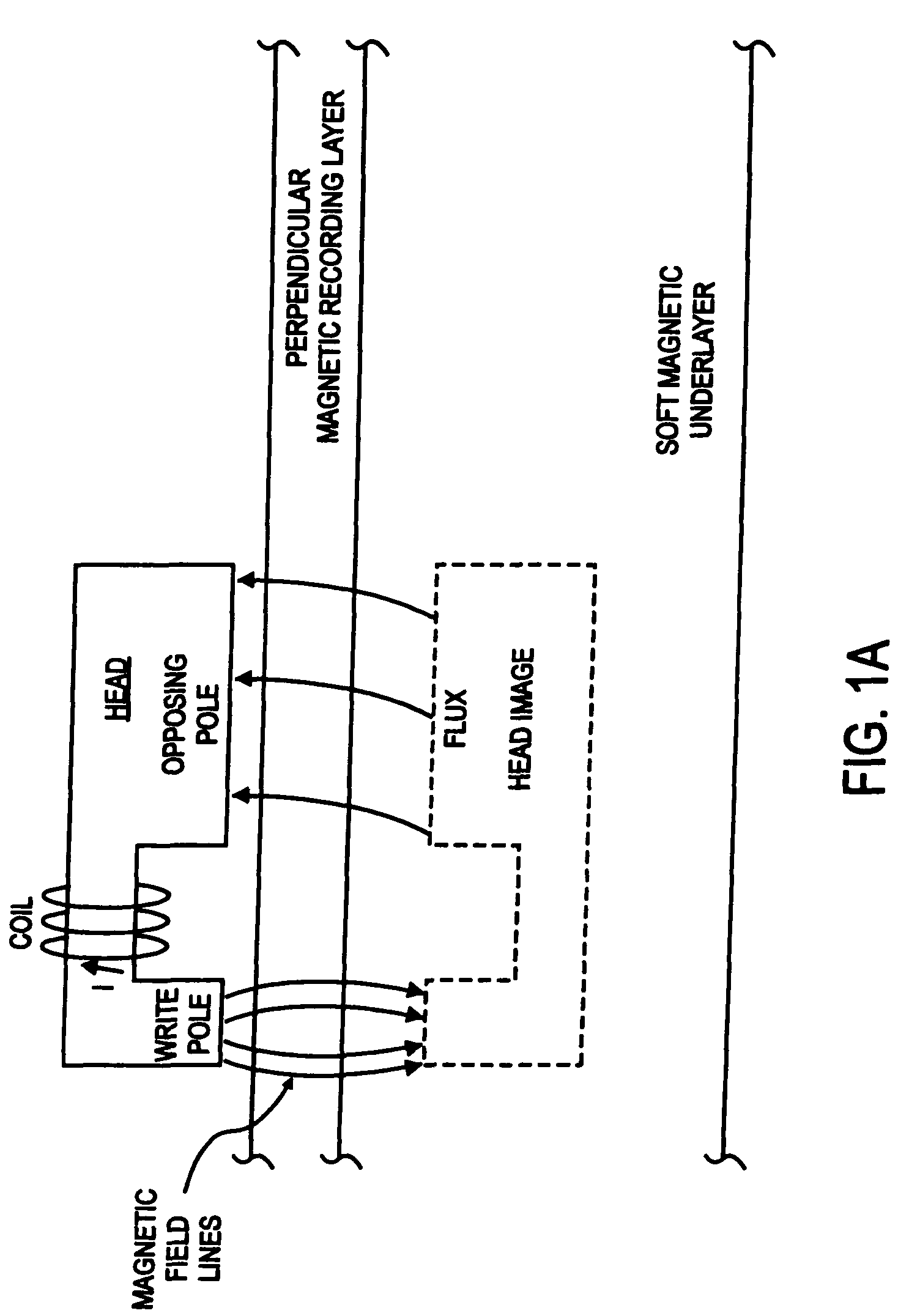

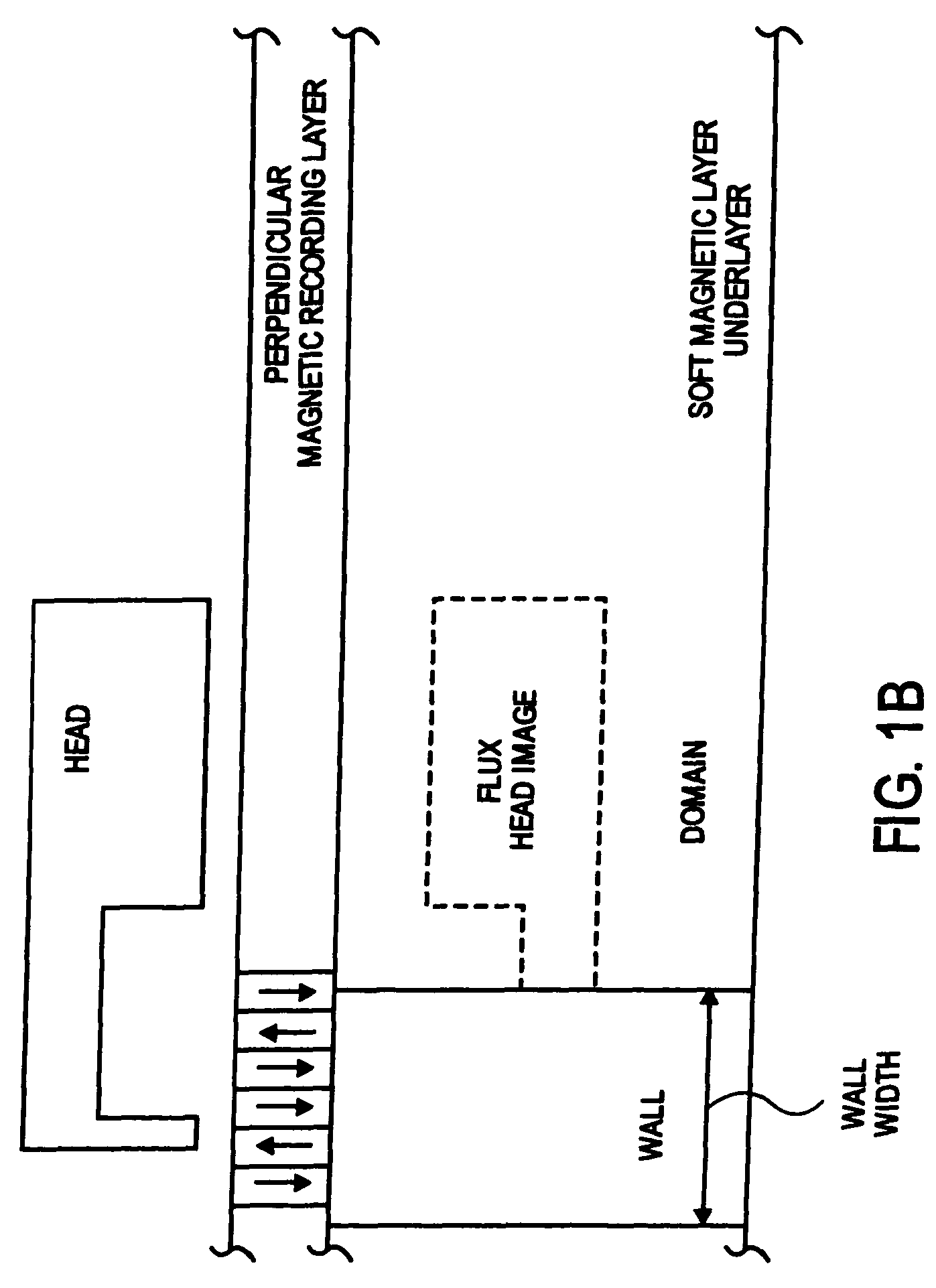

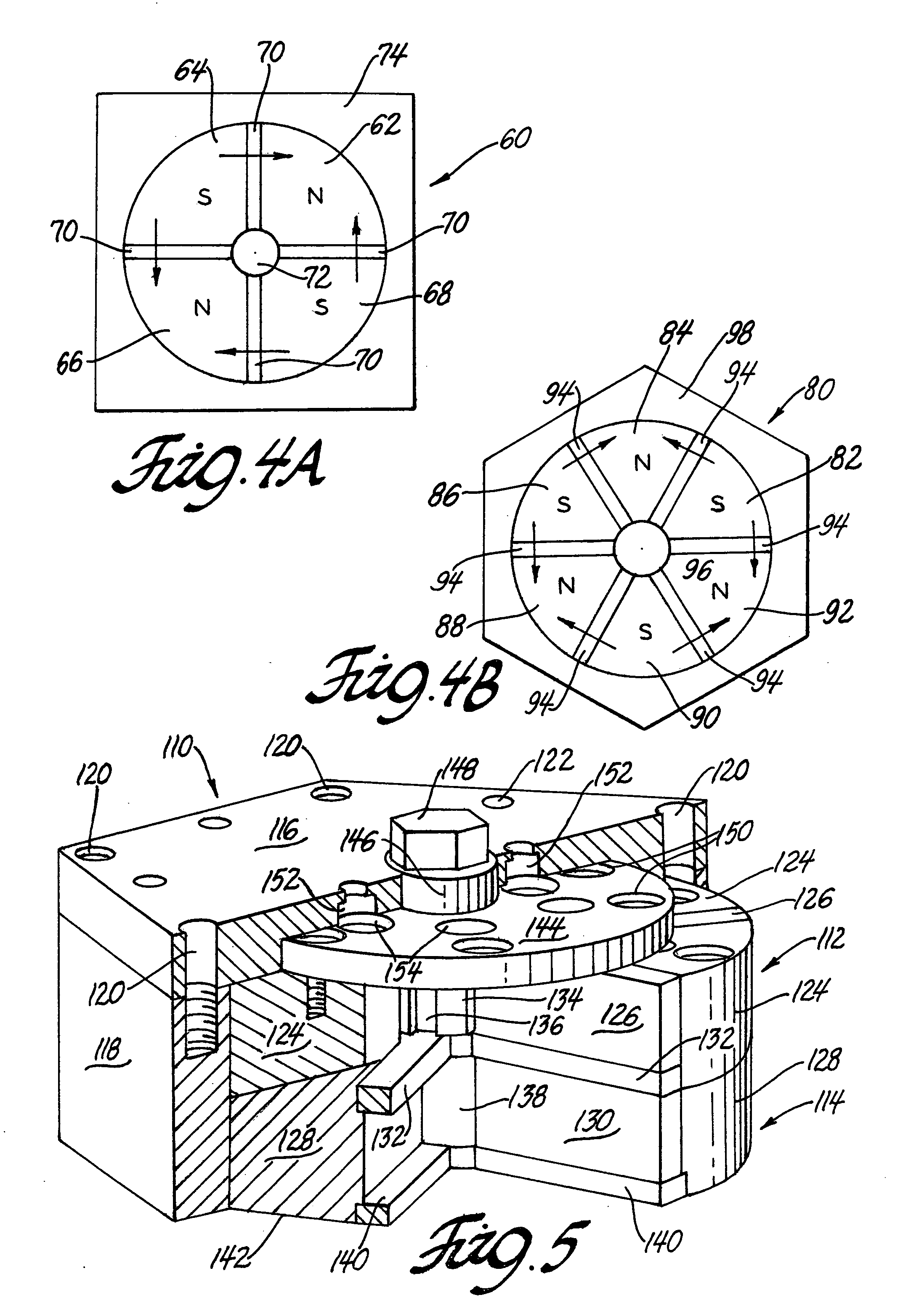

Radial magnetic field reset system for producing single domain soft magnetic underlayer on perpendicular magnetic recording medium

A radial magnetic field reset apparatus including a housing having a cavity with a soft magnet rod disposed at its center and a permanent magnet disposed around the cavity. The cavity and thickness of the soft magnet rod are sized to permit a cassette of disks to be inserted into the housing with the soft magnet rod disposed within the inner diameter holes of the disks contained in the cassette. The soft magnet rod at the center of the housing attracts the magnetic field generated by the permanent magnet, which results in a substantially uniform, radial magnetic field inside the housing.

Owner:WD MEDIA

Nickel-zinc soft magnet ferrite material, inductor product and its producing method

InactiveCN1750182AIncrease inductanceImprove qualityInorganic material magnetismInductances/transformers/magnets manufactureSoft magnetInductor

This invention discloses a Ni-Zn soft magnetic ferrite material including a master composition: Fe2O3, NiO, CuO and ZnO, a first auxiliary composition: CO2O3 and / or MnO2, there is no oxide added with pb and Ge. This invention also discloses an inductor product with said material and a manufacturing method.

Owner:广东风华高新科技集团有限公司

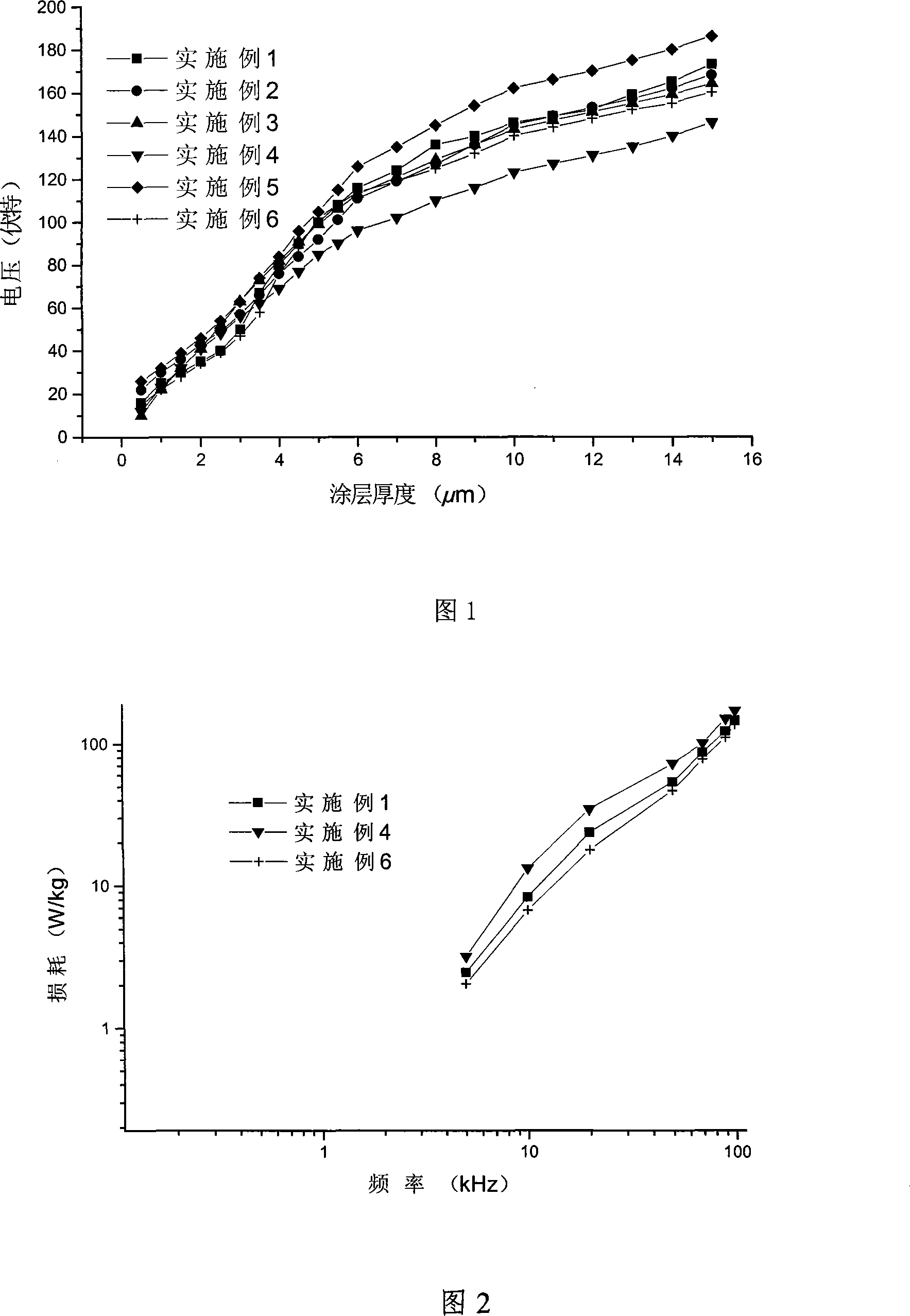

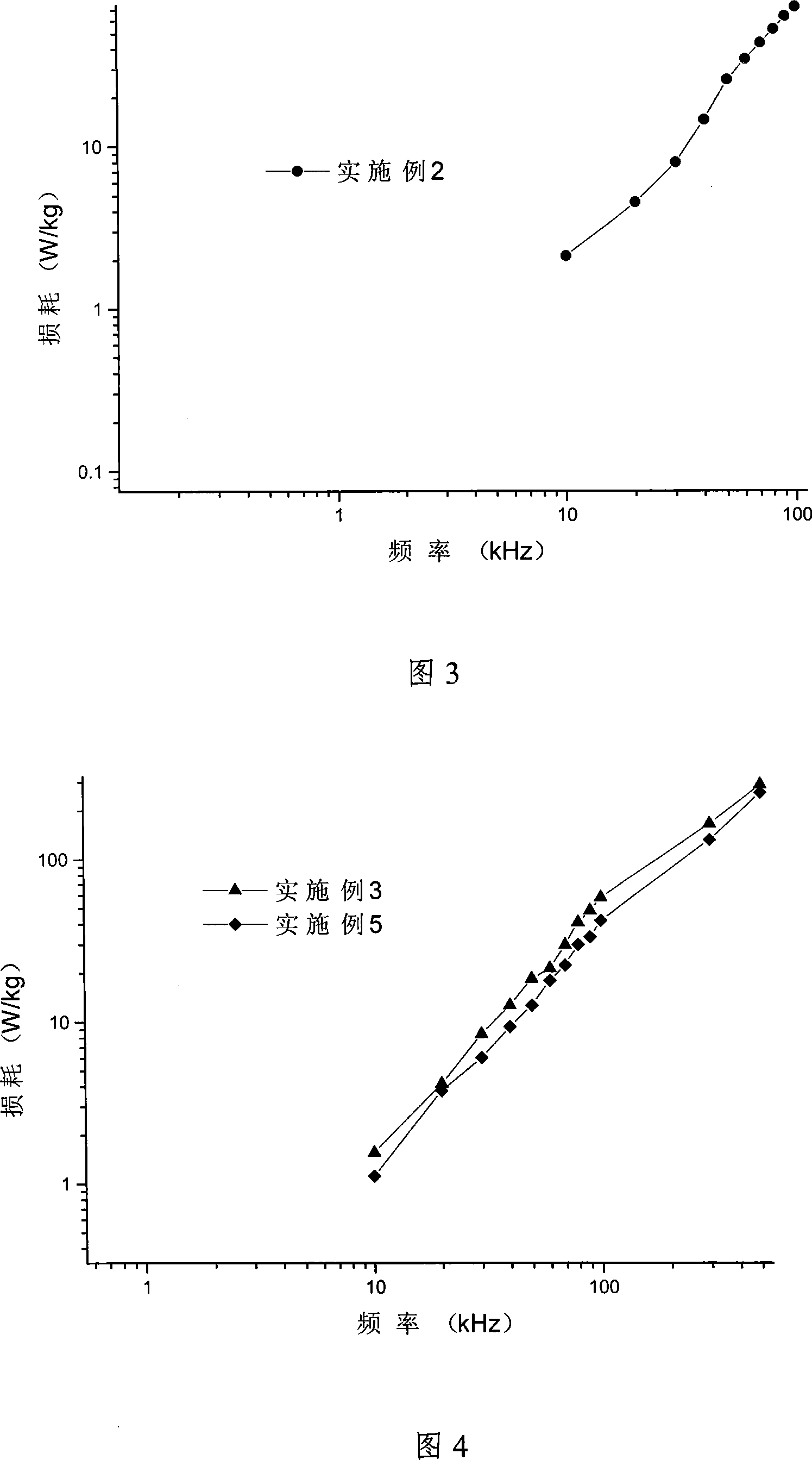

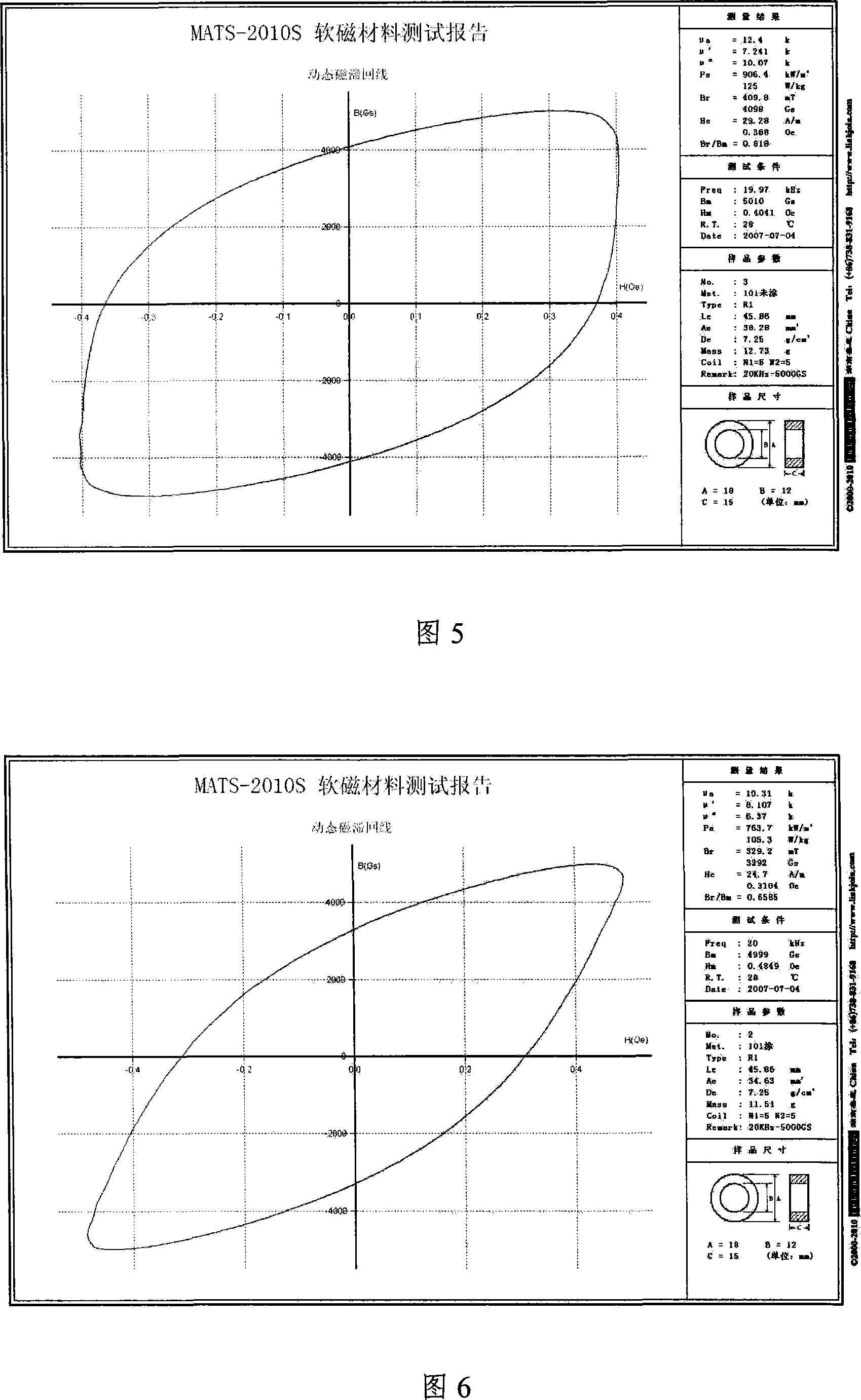

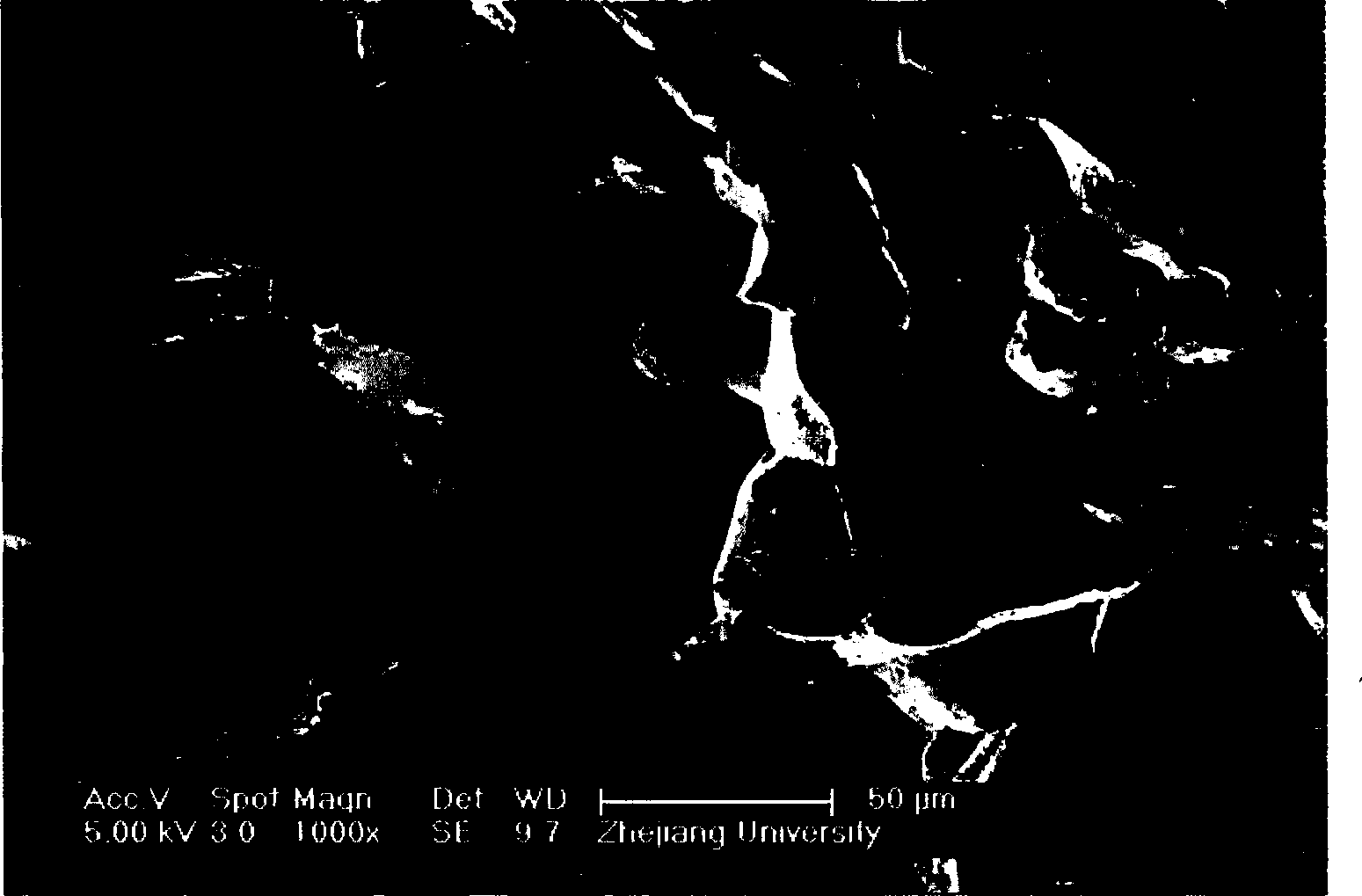

Amorphous nano crystal soft magnet alloy strip with surface insulation coating and its preparation method

InactiveCN101127267AReduce lossPretreated surfacesInorganic material magnetismElectricityInsulation layer

The utility model puts forward a soft magnetic alloy belt material and production method; wherein, the surface of the belt material has a coating layer with good electrical insulation properties. The soft magnetic alloy belt material is dip-coated in the treating liquid confected through the selection of at least one type of the inorganic matter suspension, the inorganic solution and organic solution with the soft magnetic alloy belt material being dip-coated for 60 to 600 seconds in the treating liquid; then the soft magnetic alloy belt material is baked under the temperature of 90 to 250 DEG C for 60 to 1200 seconds, which makes the thickness of the coating layer up to 0.5 to 15 Mum; the soft magnetic alloy belt material is wound to a magnetic core of corresponding size and then processed by annealing heat treatment to become a soft magnetic alloy belt material with an electrical insulation coated layer. The utility model has the outstanding advantages that the breakdown voltages of the electrical insulation layer per Mum of the soft magnetic alloy belt material are all above 20V and the loss is reduced about 25%; the electrical insulation layer can guarantee the outstanding insulation between the belt material layers; meanwhile, the belt material has the excellent medium high frequency soft magnetism, and the coating material can endure the high temperature above 500 DEG C; thus, the outstanding electric insulation properties and performance can be achieved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

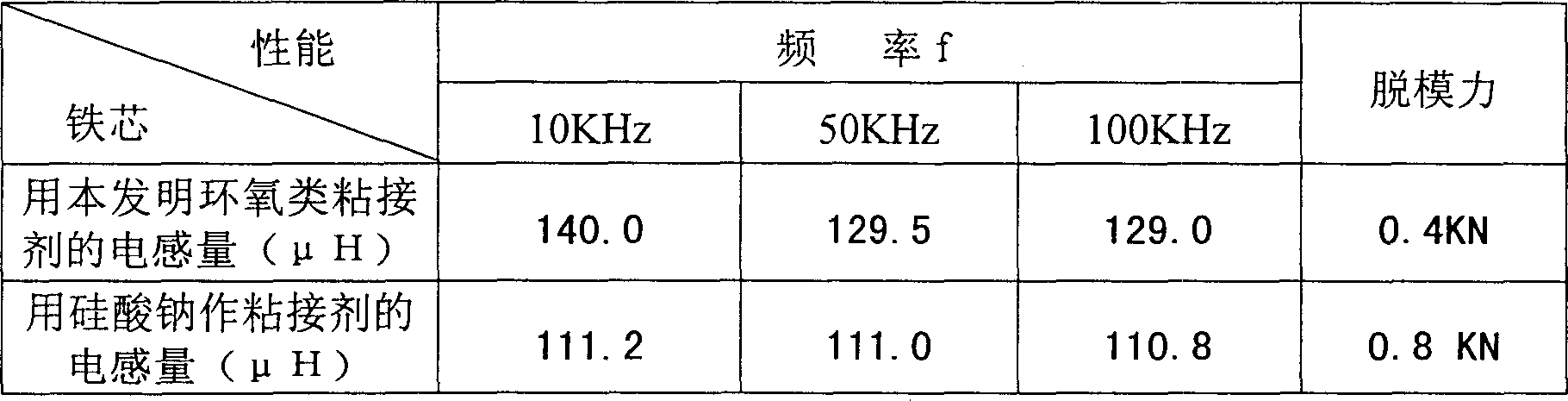

Method for making soft magnet silicon aluminium alloy powder core

InactiveCN1516204AHigh mechanical strengthImprove securityInorganic material magnetismSoft magnetIngot

The invention provides method to make a soft-magnetic inductance iron core by Fe-Si-Al alloy powder, including the steps: smelting Fe-Si-Al alloy - roughly crushing the cast ingot - heat treating - finely crushing into powder - annealing - grain mixing - passivating - adding insulating, binder, and mould-release agent - die forming - heat treating -coating surface. Its character: the binder is an epoxy one; the tempering after die forming is preserving the heat of the formed alloy powder at least 30 min on the condition of 600-800 deg.C nitrogen gas, argon gas or vacuum.

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

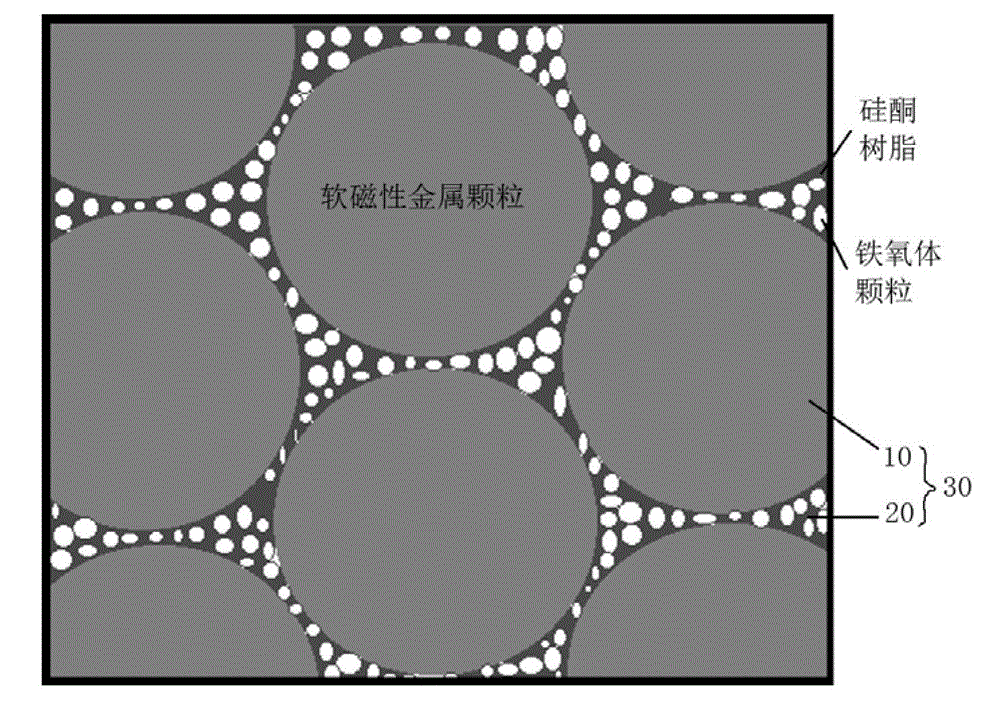

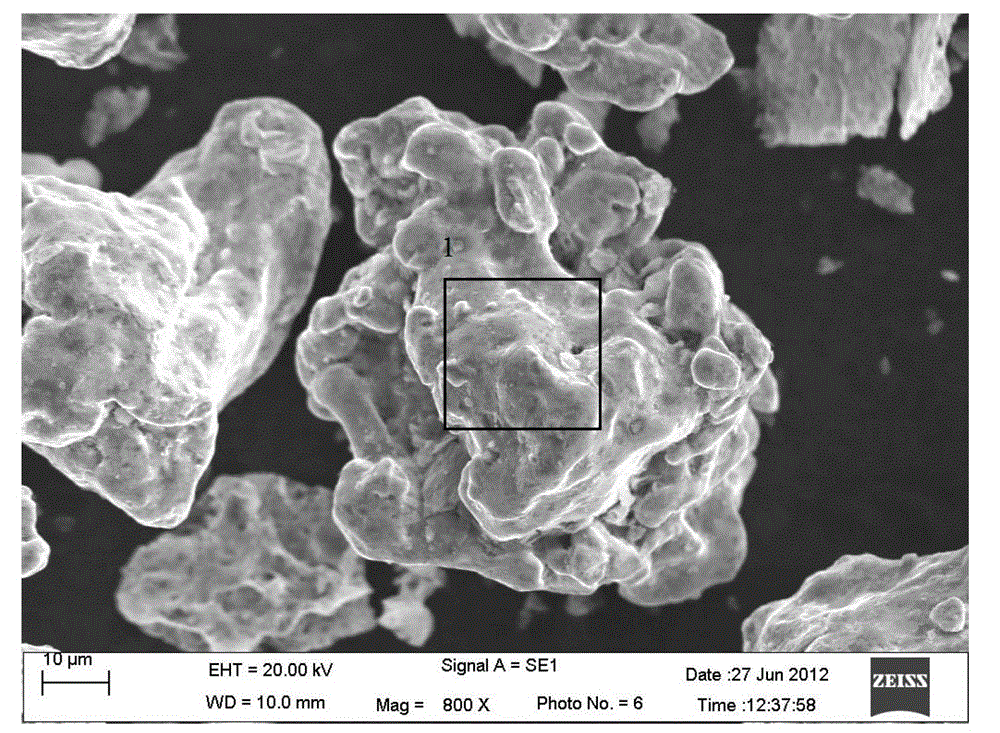

Composite silicone rein-ferrite-coating soft magnetic powder core and preparation method thereof

InactiveCN103151134AImprove adhesionHigh resistivityInorganic material magnetismInsulation layerVolumetric Mass Density

The invention discloses a composite silicone rein-ferrite-coating soft magnetic powder core and a preparation method thereof, and belongs to the metallurgical industry of magnetic functional material and powder. The soft magnetic powder core is formed by pressing and forming composite magnetic particles, wherein each composite magnetic particle comprises a soft magnetic metal particle and a composite insulation film, and each composite insulation film is coated on the surface of each soft magnetic metal particle. The preparation method of the soft magnetic powder core comprises the following steps of surface modification and coupling treatment of the soft magnetic metal particles, forming of the composite insulation coating around each soft magnetic metal particle, pressing and forming, and high-temperature heat treatment at 300 DEG C to 650 DEG C. Compared with the prior art, the soft magnetic powder core and the preparation method have the advantages that the adopted organic resin can resist the high temperature of 600 DEG C; since the soft magnetic ferrite power is added into the composite coating agent, the damage of the insulation layer to the magnetic performance of a substrate is reduced; and the magnetic conductivity is high, the density is high, the rapture strength is high, the loss is low, and the industrial production is easy.

Owner:UNIV OF SCI & TECH BEIJING

Material powder of manganese-zinc power soft magnet ferrite and its preparation method

InactiveCN1447356AExcellent physical and chemical propertiesReduce power consumptionInorganic material magnetismSpray GranulationSoft magnet

Manganese-zinc soft magnetic ferrite material powder is made through five working procedures: admixture, preburning, coarse cracking, sand mill and spraying-granulation by using Fe2O3, Mn3O4, and ZnOas main materials. The produced material powder has advantages of lower power consumption, high saturation induction density Bs, low cost and superior performances.

Owner:SHANGHAI BAOSTEEL MAGNETICS

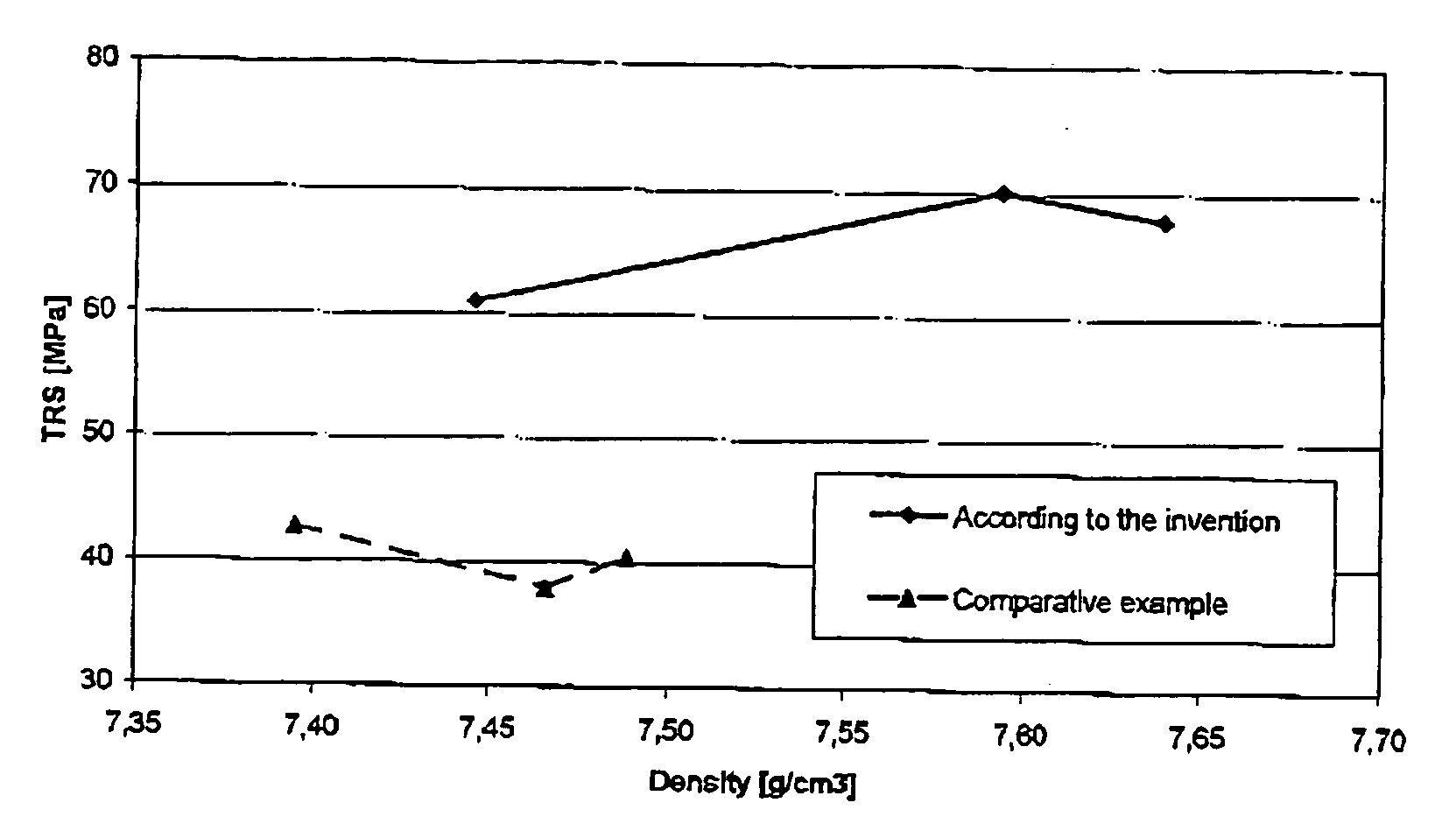

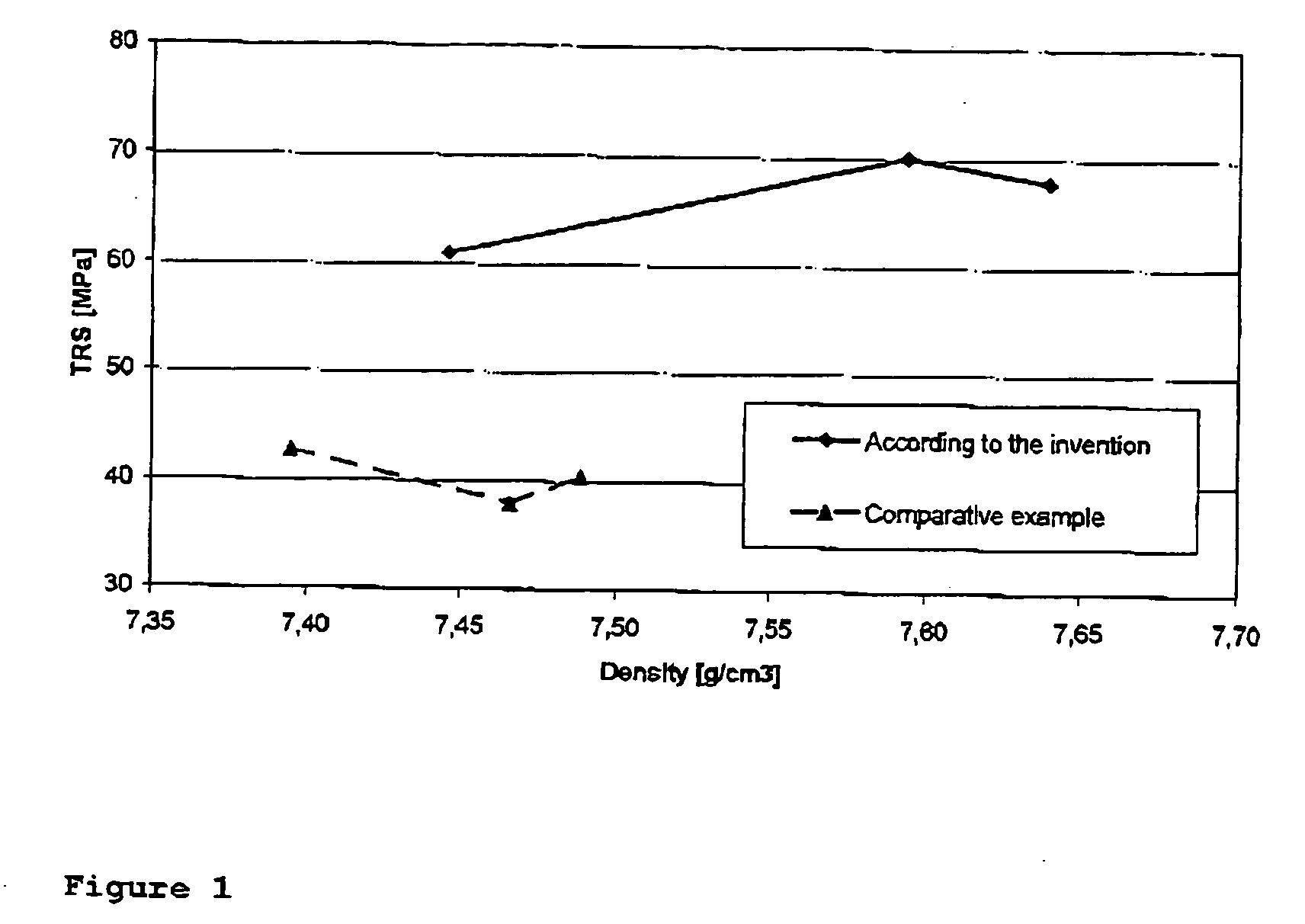

Iron-based powder

ActiveUS20040191519A1High wear of dieLess shiny and deterioratedSynthetic resin layered productsMetal-working apparatusSilanesZirconate

The present invention concerns a new ferromagnetic powder composition comprising soft magnetic iron-based core particles wherein the surface of the core particles are surrounded by an insulating inorganic coating, and a lubricating amount of a compound selected from the group consisting of silanes, titanates, aluminates, zirconates, or mixtures thereof. The invention also concerns a process for the preparation of soft magnetic composite materials using the new powder composition.

Owner:HOGANAS AB

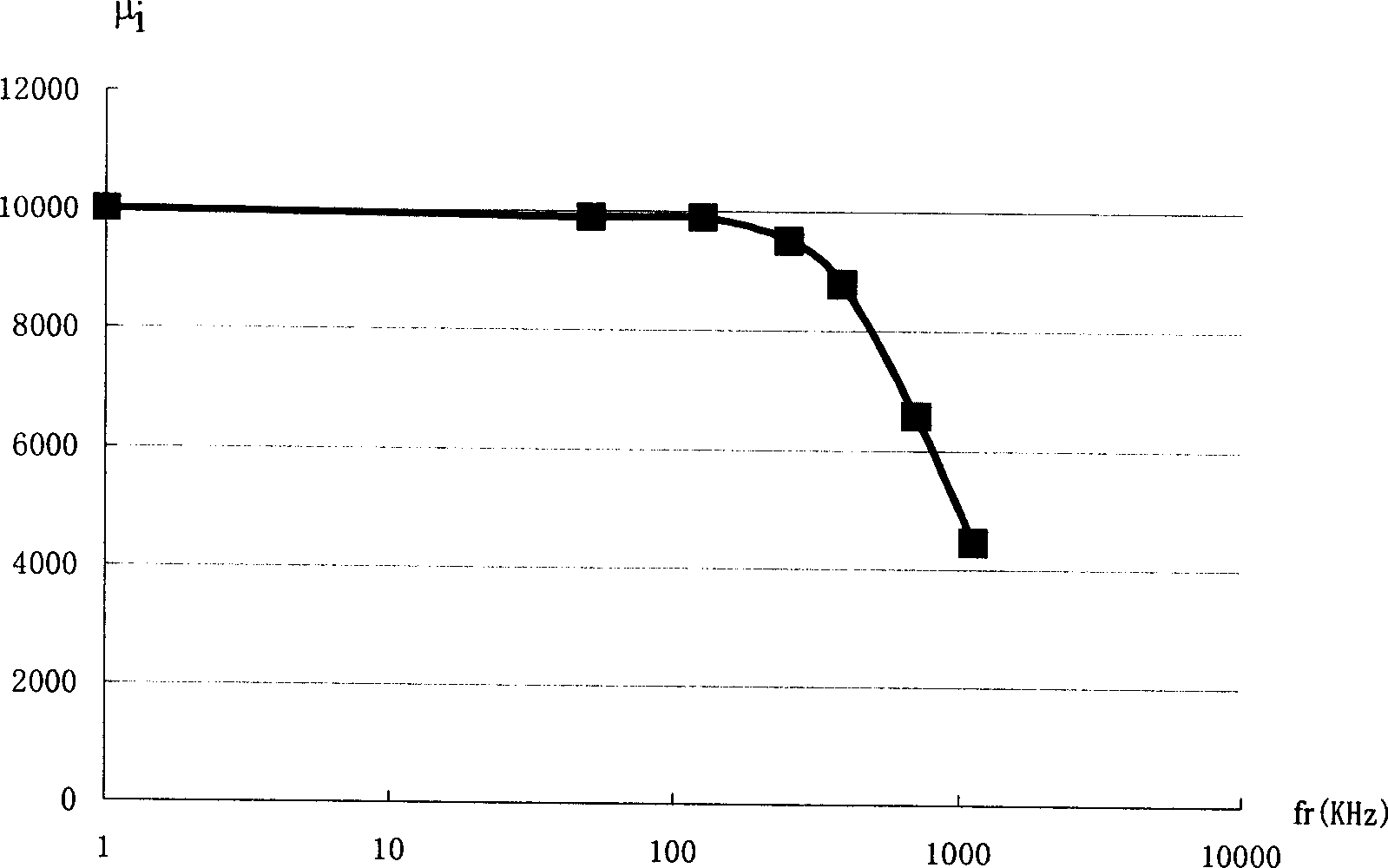

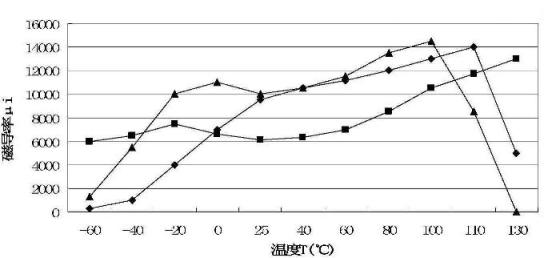

Wide-band manganese-zinc series high-magnetic-conductivity soft magnet oxysome material

ActiveCN1677579AHigh initial permeabilityRaise the cutoff frequencyInorganic material magnetismInitial permeabilitySoft magnet

The material of soft-magnetic ferrite comprises 50 - 55mol% Fe, 20 - 30mol% MnO, and 20 - 30mol% ZnO. initial permeability Mui is greater than or equal to 10000, and cut-off frequency fr is greater than or equal to 400 kHz. Features are low cost and applicable to fabricating filters, inductance transformer, digital transformer, chokes and current transformers etc.

Owner:广东肇庆微硕电子有限公司 +1

Soft-magnetic powder core and method of preparing the same

ActiveCN101226802AReduce permeabilityReduce AC lossInorganic material magnetismSoft magnetAmorphous phase

The invention relates to magnetic powder cores of soft magnet and a process of preparation thereof, belonging to the technical field of magnetic material. The magnetic powder cores of soft magnet is made from the following magnetic powders, a principal phase formed by one or a plurality of Fe based, Fe-Si based, Fe-B based, Fe-Si-B based and Fe-Al-B based and an amorphous phase which is inlaid in the principal phase and formed by one or plurality of Fe, C, Cu, Nb, Zr and Hf form nanocrystalline powders, wherein the principal phase is amorphous or in nanocrystalline state with average grain size of 3-100 nm. The prepared magnetic powder has the advantages of low eddy current loss, perfect direct current superposition property, suitable for higher frequency and the like.

Owner:CHINA JILIANG UNIV +1

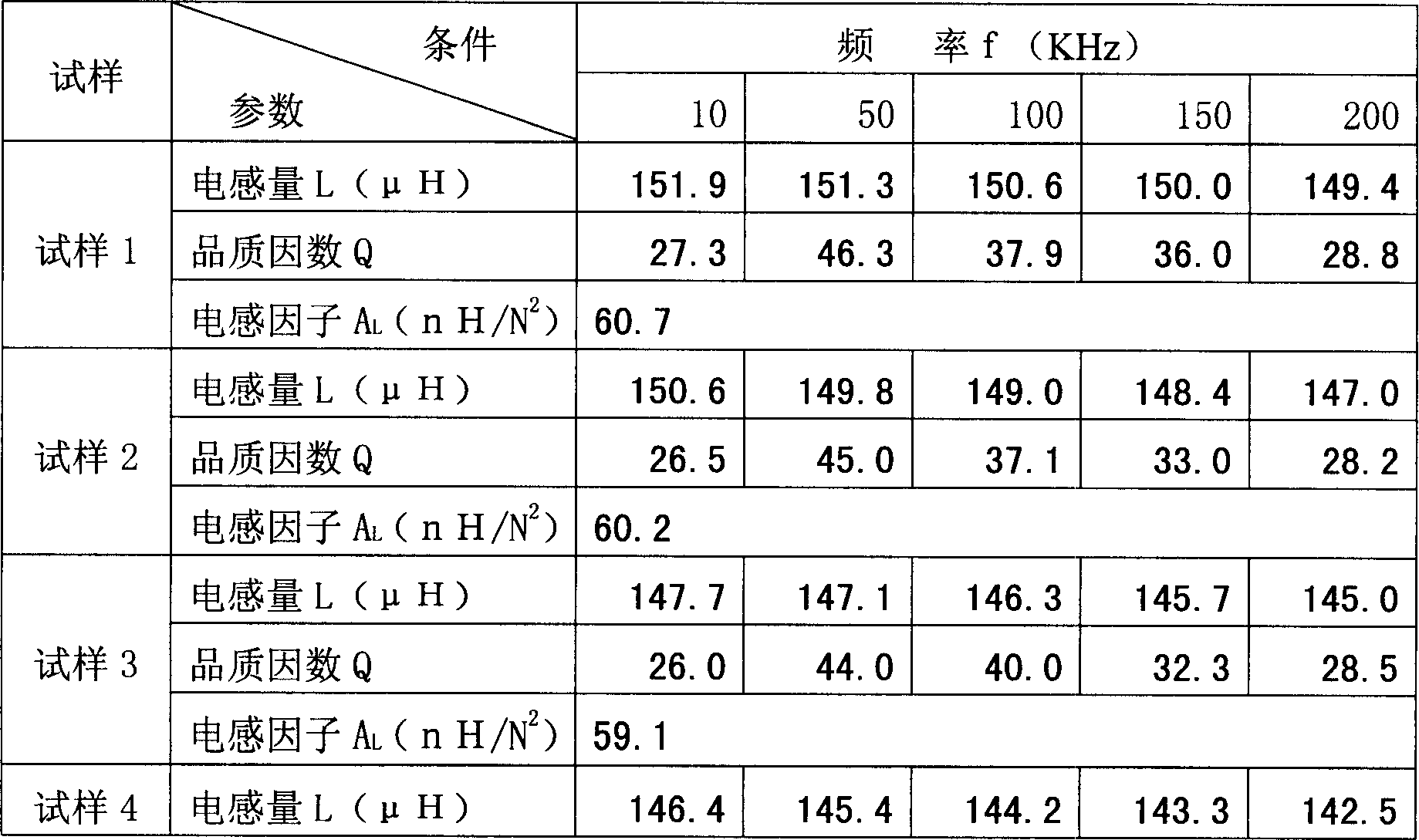

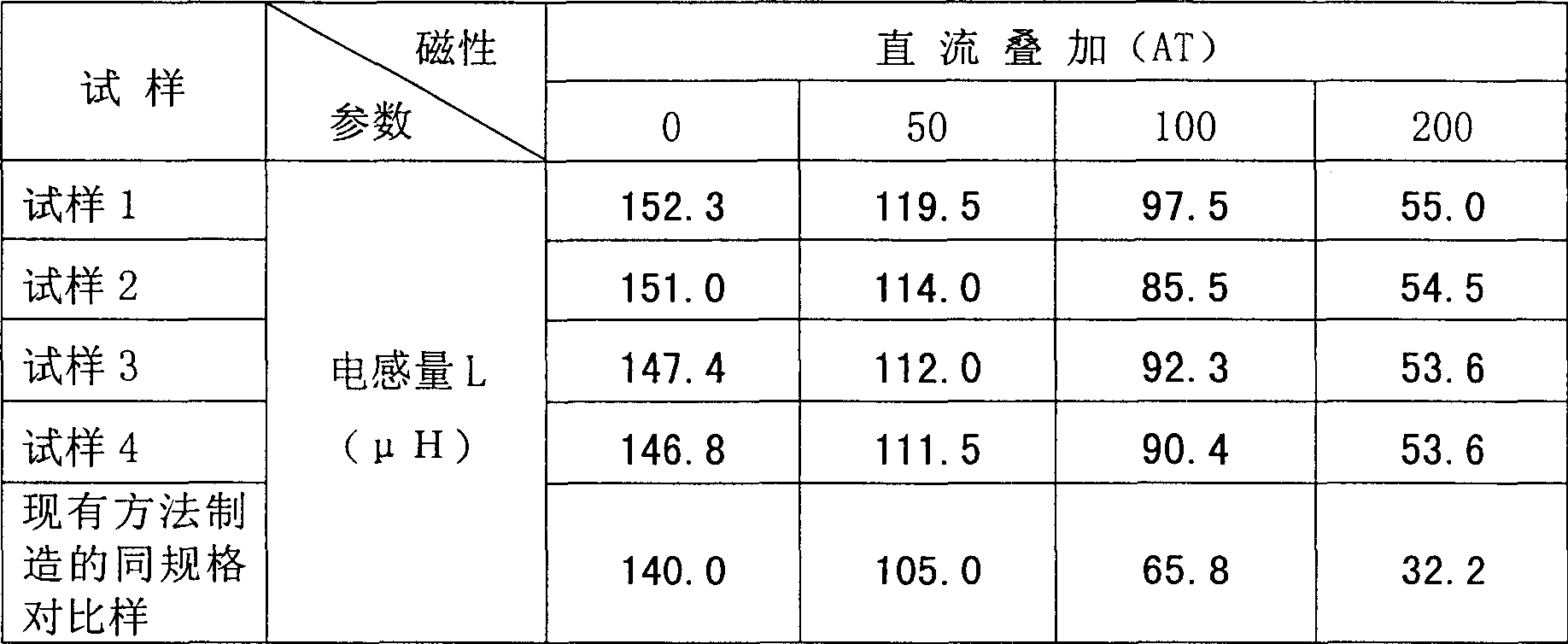

Method for manufacturing soft magnet silicon-aluminium magnetic powder core

InactiveCN1622236ADoes not affect electromagnetic performanceReduce curing stressInorganic material magnetismInductances/transformers/magnets manufactureAl powderBreaking strength

The production process of soft magnetic Fe-Si-Al powder core includes the steps of compounding magnetic powder in different sizes, surface treatment, mixing magnetic powder, insulating agent, adhesive and demolding agent, molding, curing, magnetic heat treatment, soaking and surface coating. The present invention has the advantages of: breaking strength after curing in radial direction of 7-12 kg, less surface stripping, small demolding force, final breaking strength in radial direction of 17-24 kg, no influence of the insulating lacquer on electromagnetic performance and capability of realizing automatic production.

Owner:王锋 +1

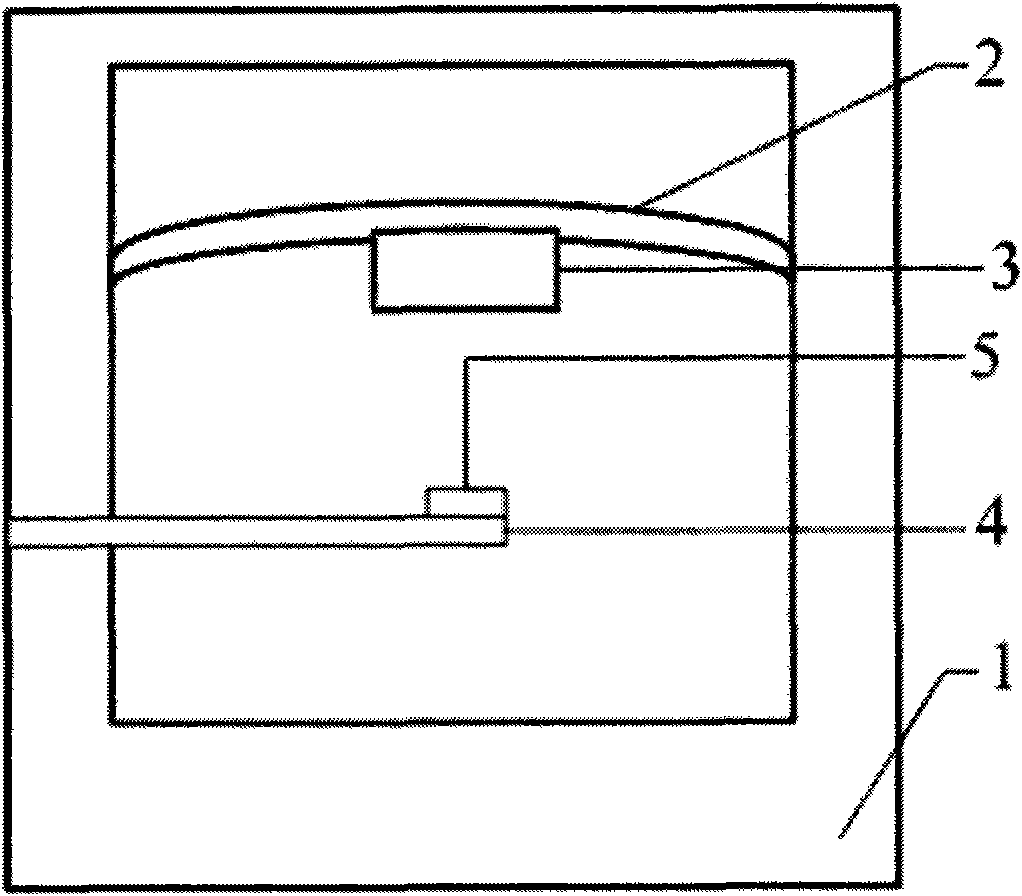

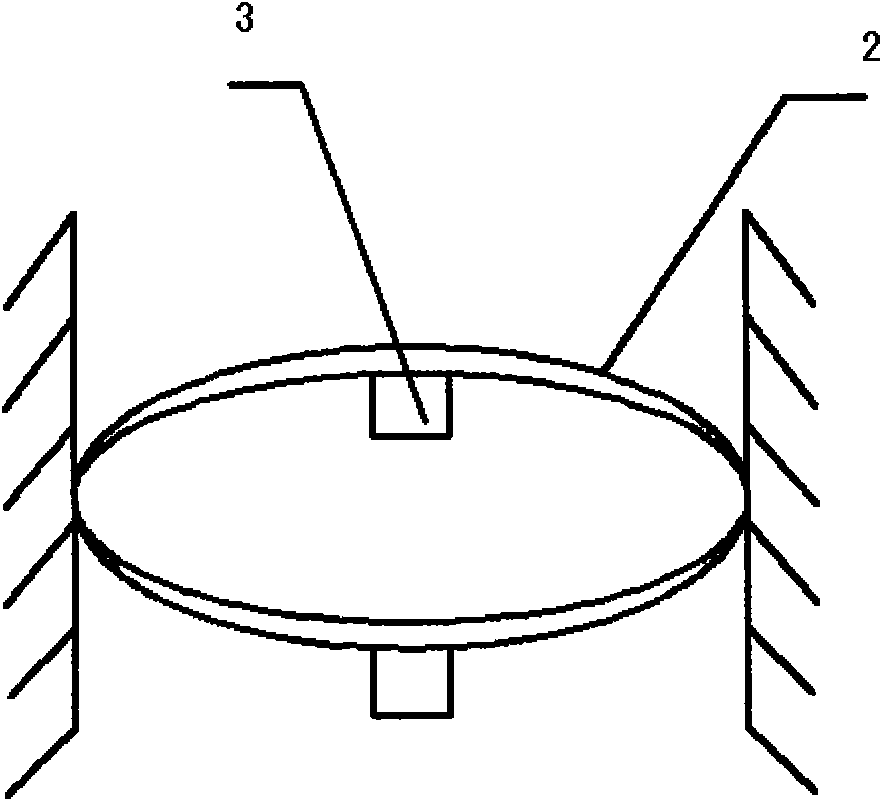

MEMS wideband piezoelectricity energy collector based on bistable state frequency raising structure

InactiveCN101656493ASimple structureEasy to manufacturePiezoelectric/electrostriction/magnetostriction machinesSoft magnetEngineering

The invention relates to an MEMS wideband piezoelectricity energy collector based on a bistable state frequency raising structure in the technical field of electric appliances, which comprises a frame, a bistable state beam arranged in the frame, a piezoelectric over hanging beam, a permanent magnet and a soft magnet. The MEMS wideband piezoelectricity energy collector is characterized in that twoends of the bistable state beam are both fixed on the frame, the permanent magnet is attached to the bistable state beam, on end of the piezoelectric over hanging beam is fixed on the frame, and thesoft magnet is arranged on the piezoelectric over hanging beam. The invention adopts a bistable state frequency raising structure to enable a piezoelectric transduction component to obtain greater output power in a low-frequency vibration environment. Compared with the prior MEMS piezoelectric energy collector, the invention has simple structure, easy manufacture and volume reduction, can be operated in a low-frequency environment, and can output stable frequency within wider environment vibration frequency range.

Owner:SHANGHAI JIAO TONG UNIV

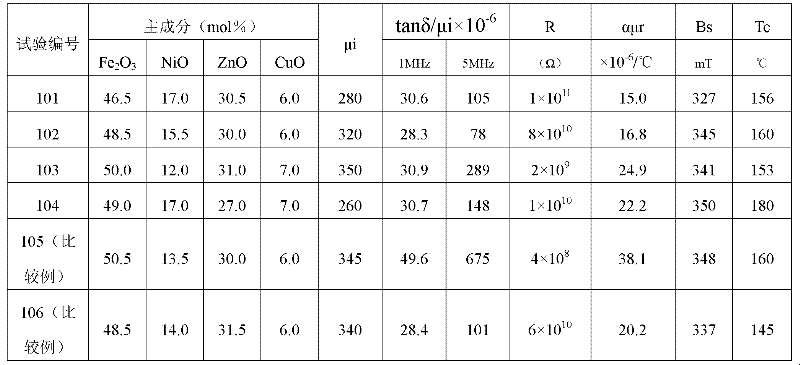

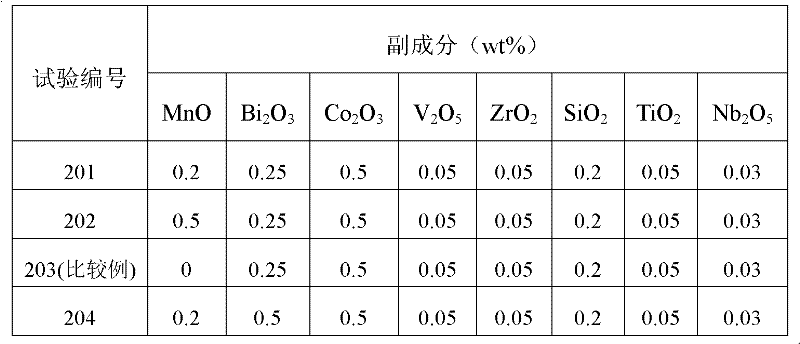

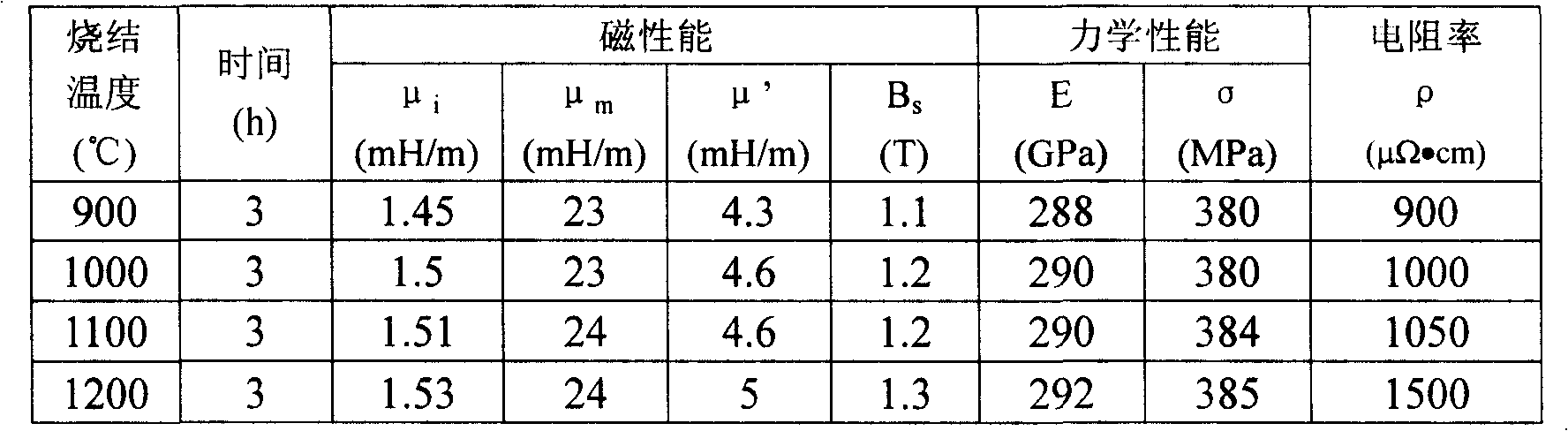

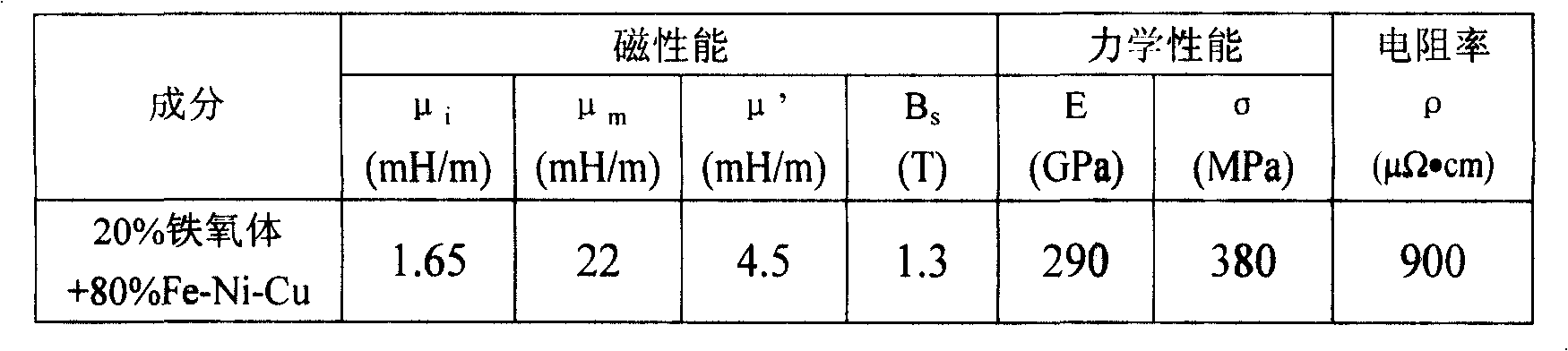

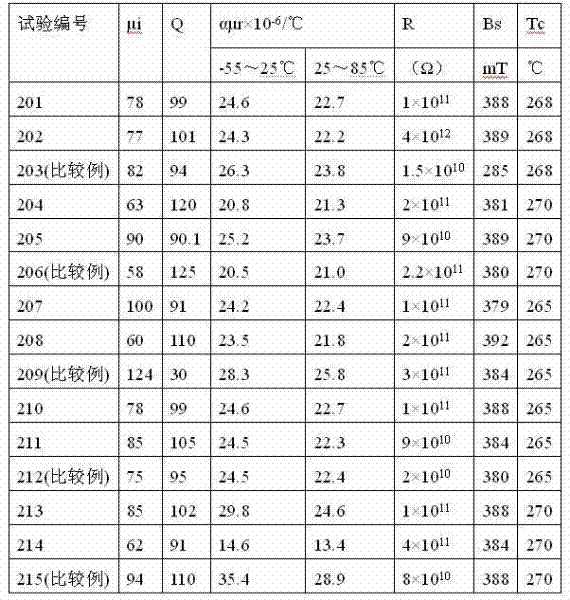

Soft-magnetic nickel-copper-zinc ferrite material and preparation method thereof

The invention belongs to the field of soft magnets, and particularly provides a soft-magnetic nickel-copper-zinc ferrite material which comprises major components and minor components, wherein the major components comprise the following components in percentage by mol: 46.5-50.0 mol% of Fe2O3, 12.0-17.0 mol% of NiO, 27.0-31.0 mol% of ZnO and 4.0-8.0 mol% of CuO; and the minor components comprise manganese oxide and bismuth oxide, wherein on the basis of the total weight of the major components, the total weight percent of the minor components and standard substances thereof MnO and Bi2O3 is 0.1-1.0 wt%. Under the wide frequency of 50 KHz-10 MHz and especially high frequency of 1 MHz-10 MHz, the material provided by the invention has the characteristics of high magnetic conductivity (mu i is approximately equal to 300, and f is equal to 1 MHz), high resistivity, low specific loss, low specific temperature coefficient and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

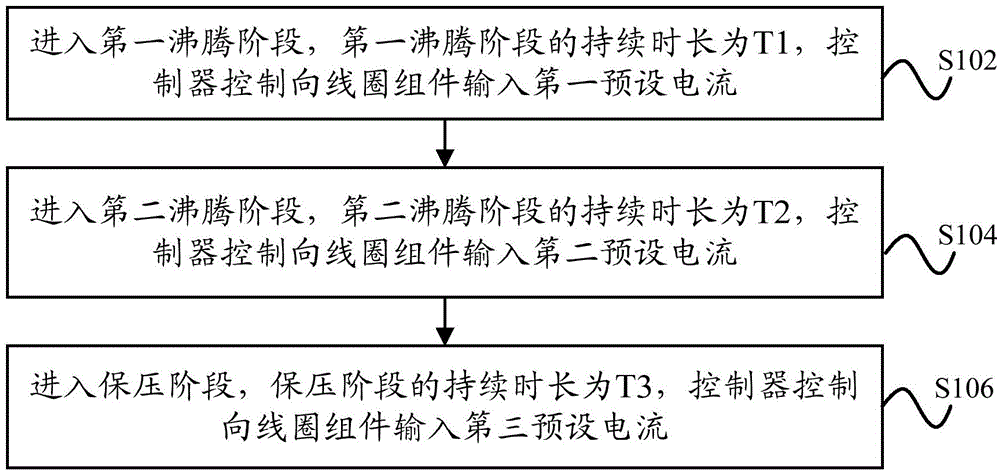

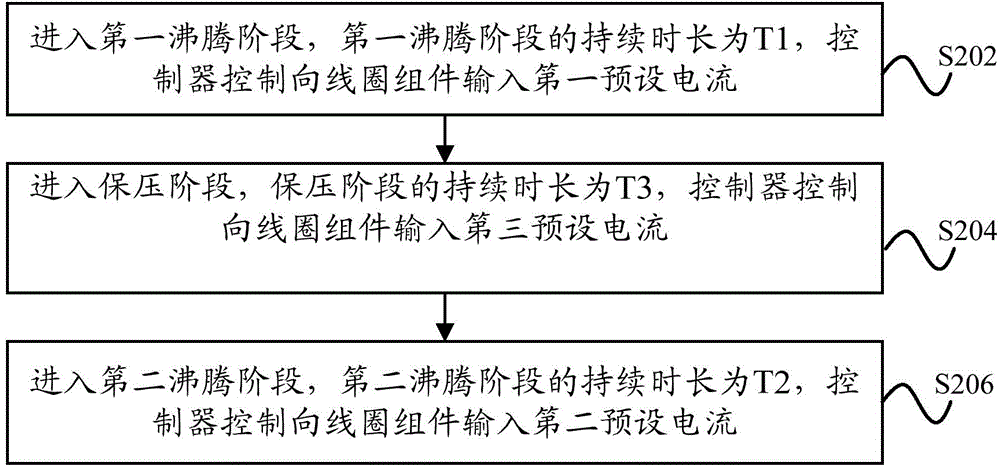

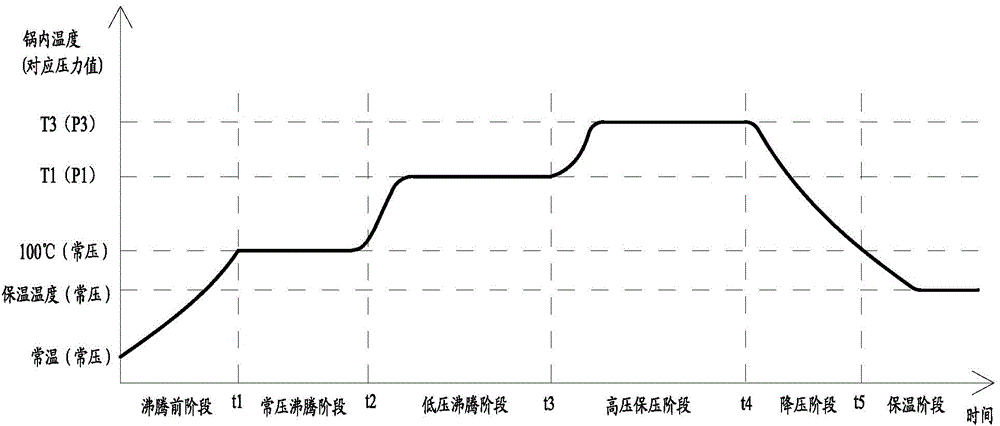

Control method of cooking utensil

The invention provides a control method of a cooking utensil.An upper cover of the cooking utensil is provided with a steam exhaust valve and a coil assembly. The steam exhaust valve is provided with a permanent magnet or a soft magnet and can be affected by active force of a magnetic field generated by electrification of the coil assembly. The control method comprises following steps: a first boiling phase, first pre-set current is input to the coil assembly; a second boiling phase, second pre-set current is input to the coil assembly after the first boiling phase; a pressure maintaining phase, third pre-set current is input to the coil assembly between the first and the second boiling phase or after the second boiling phase.The control method of the cooking utensil has following beneficial effects: due to the fact that different current is input into the coil assembly in different cooking phases, different magnetic field forces can be generated by the steam exhaust valve; the cooking utensil is controlled to be kept in the boiling state in different phases and under different pressure; heat and moisture can be transferred evenly so that thick soup and complete rice can be achieved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

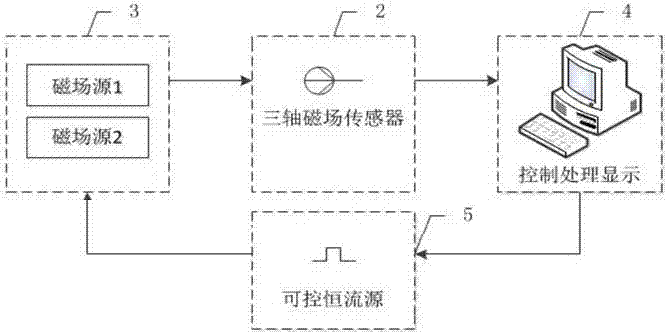

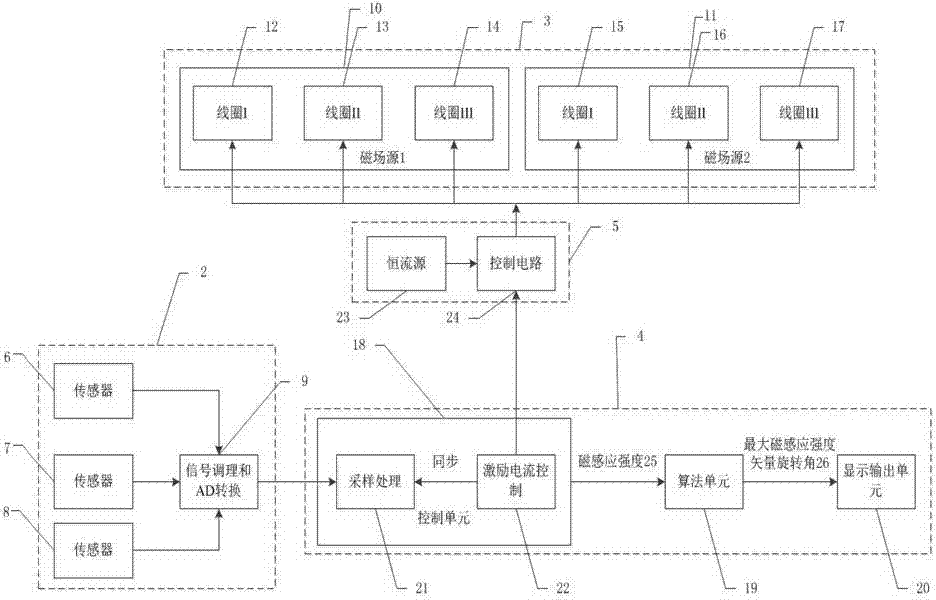

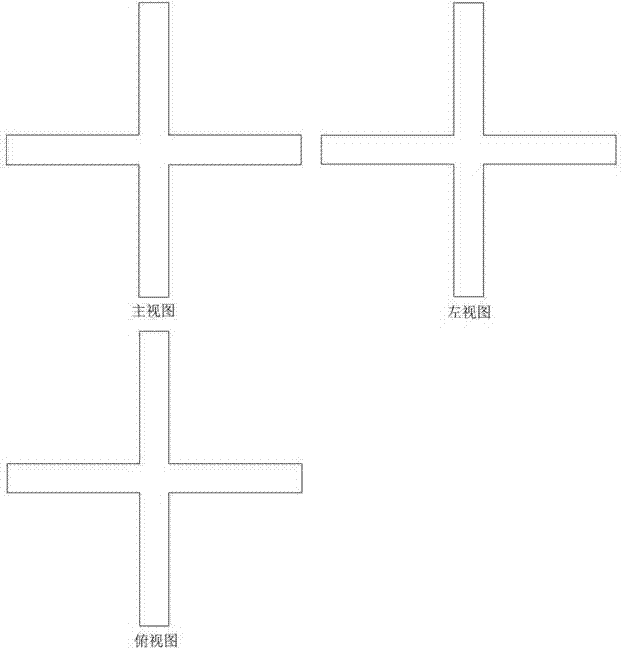

Electromagnetic tracking system and method based on rapid determination of vector rotation angle of maximum magnetic induction intensity

InactiveCN104776865AImprove real-time performanceIncrease flexibilityUsing electrical meansConverting sensor output electrically/magneticallyComputation complexityUltrasonic imaging

The invention belongs to the technical field of electromagnetic tracking, and particularly discloses an electromagnetic tracking system and method based on rapid determination of a vector rotation angle of maximum magnetic induction intensity. The electromagnetic tracking system disclosed by the invention consists of a three-axis magnetic-field sensor device, magnetic-field source devices, a controllable constant-current source device and a control processing display device; the controllable constant-current source device stimulates three coils which are wound on a magnetic core made of soft magnetic ferrite material and are mutually orthometric, and the central points of the coils are overlapped, so that one magnetic-field source device is formed; the three-axis magnetic-field sensor device is used for detecting the magnetic induction intensity of the magnetic-field source devices, and the control processing display device can control the controllable constant-current source device to stimulate the coils and can perform positioning calculation according to the magnetic induction intensity detected by the three-axis magnetic-field sensor device. Due to the adoption of the electromagnetic tracking system disclosed by the invention, positioning can be realized by only stimulating the three coils once, the searching process is avoided, the real-time performance is significantly improved, the stability is high, the calculating complexity is low, and the electromagnetic tracking system can be applied to the navigation of minimally invasive surgery and other fields, such as virtual (enhancing) reality, and three-dimension ultrasonic imaging.

Owner:FUDAN UNIV

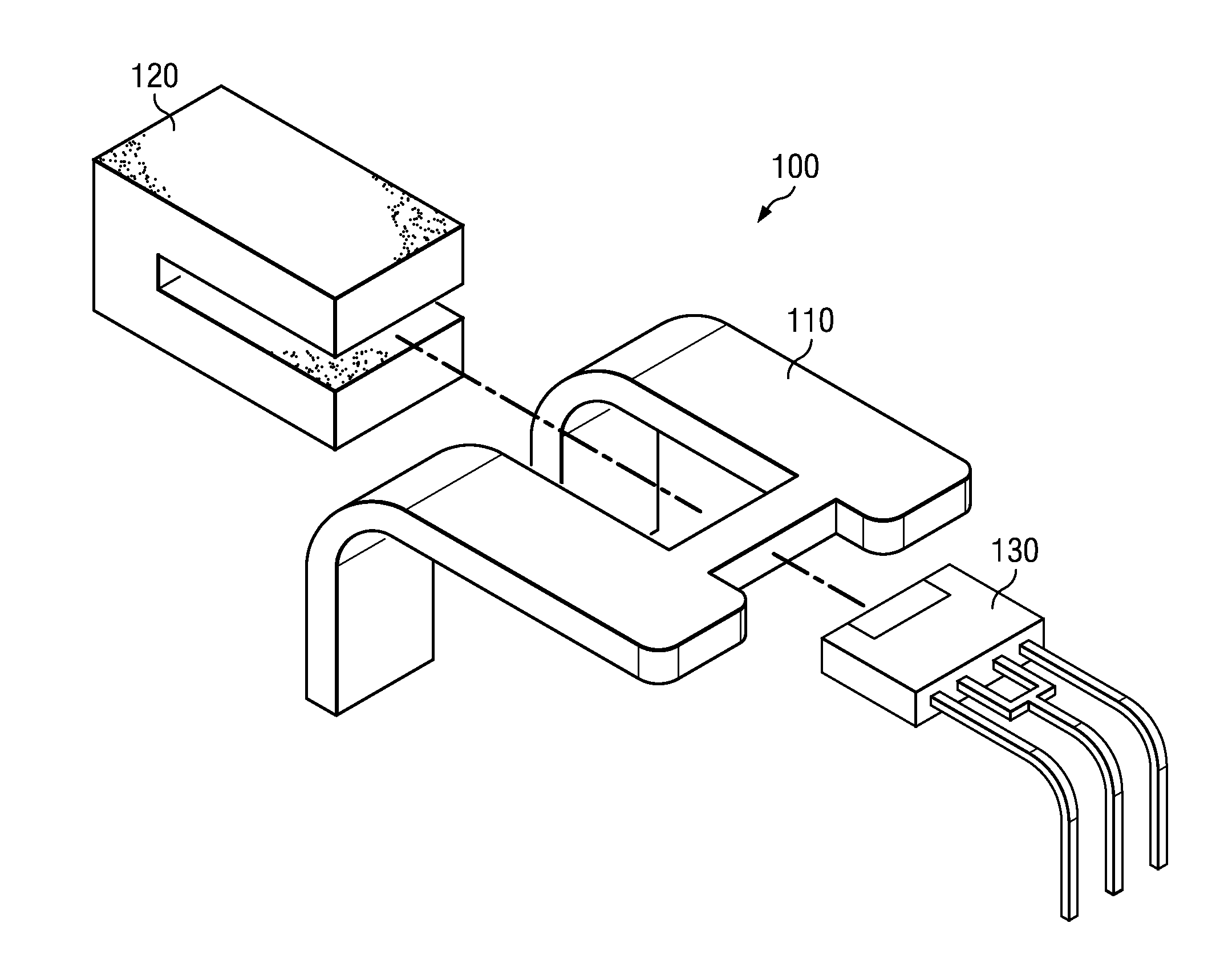

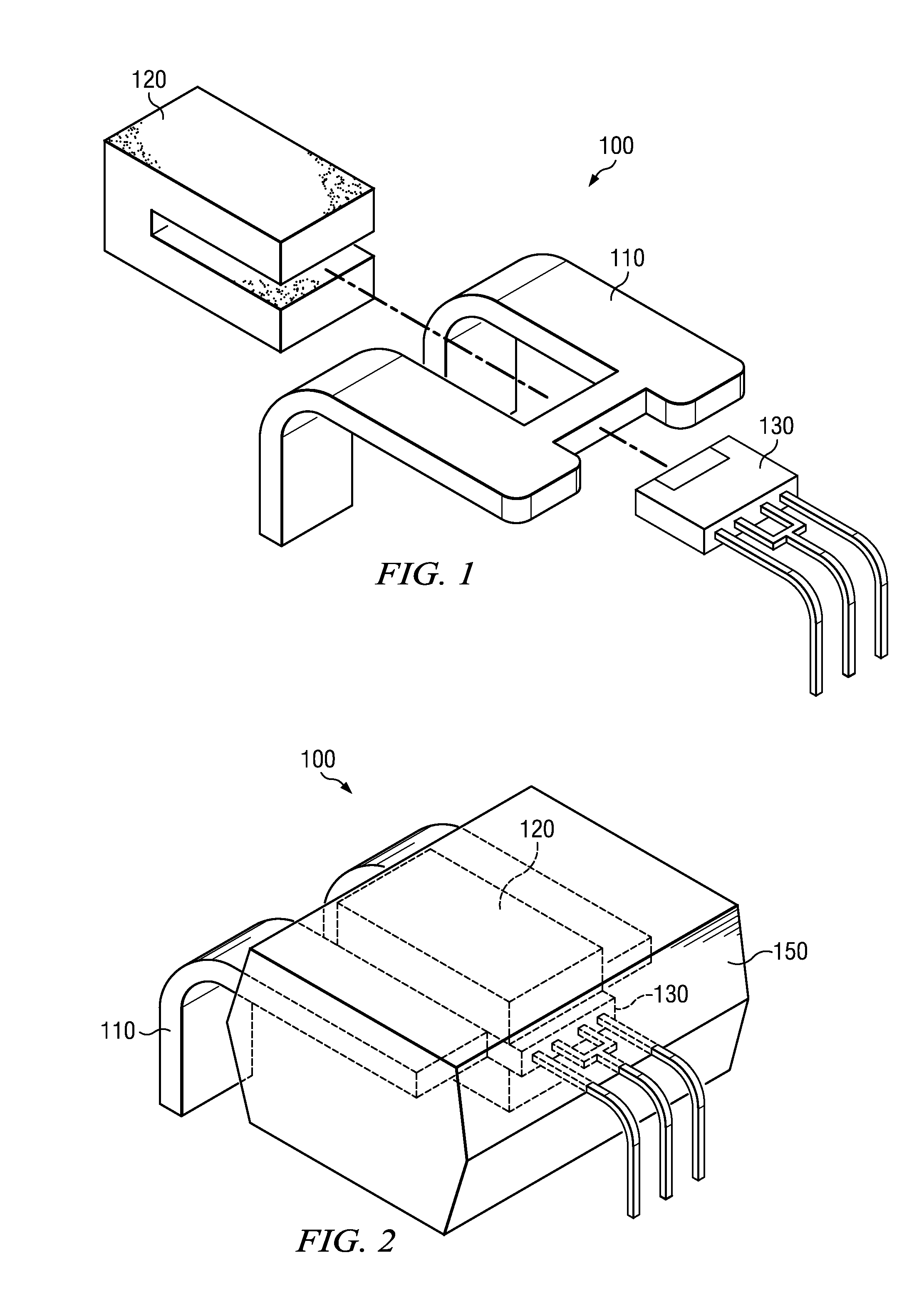

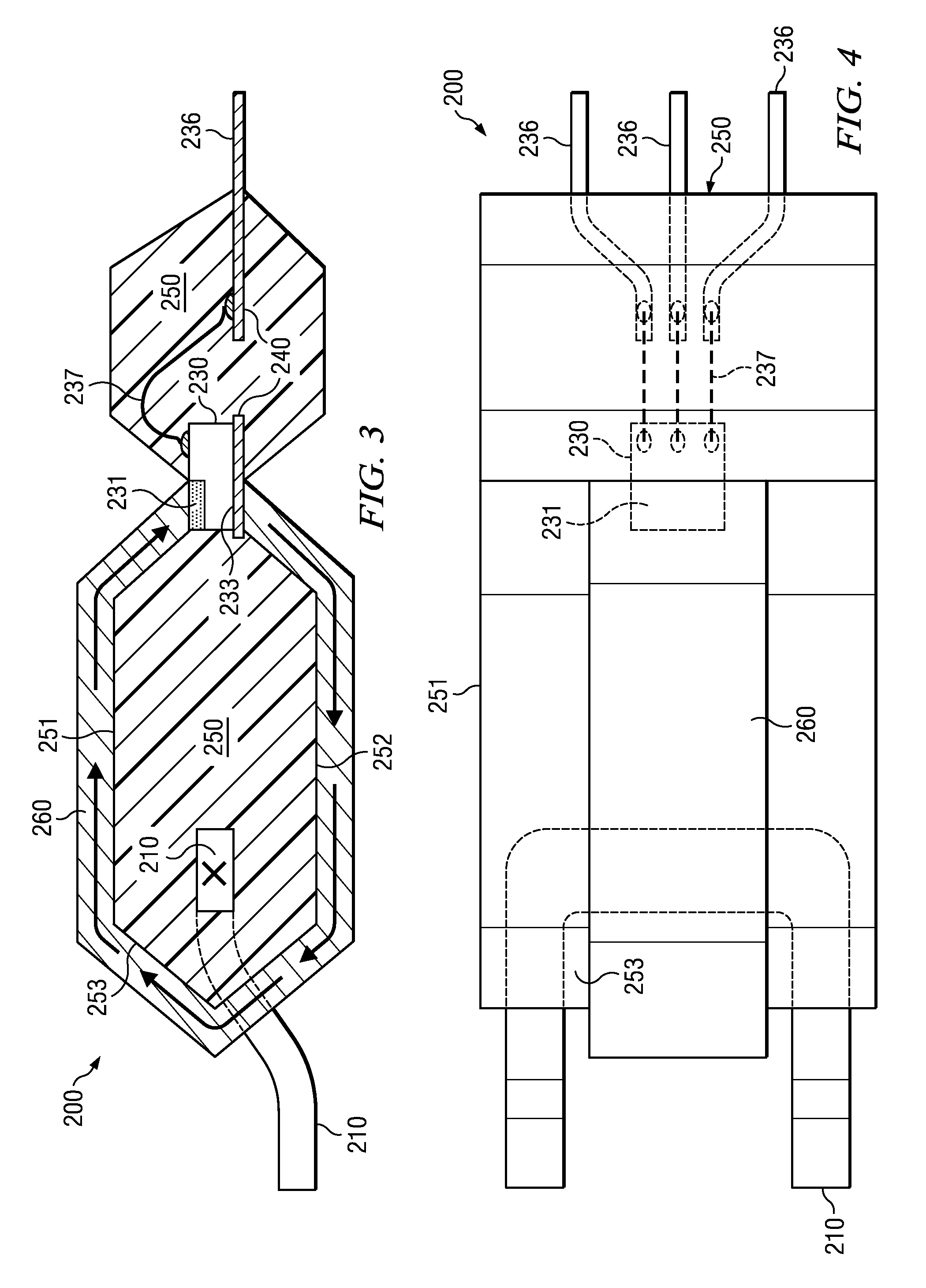

Sensor Package and Method of Manufacturing Thereof

ActiveUS20120038352A1Wave amplification devicesSolid-state devicesSoft magnetElectrical and Electronics engineering

A sensor package and a method for manufacturing a sensor package are disclosed. An embodiment comprises a sensor and a conductive line, wherein the sensor is arranged proximate to the conductive line. The sensor and the conductive line are isolated and at least partially encapsulated. A soft magnet is arranged in, on and / or around the encapsulation, wherein the soft magnet comprises a composition of an insulating material and a material having soft magnetic properties.

Owner:INFINEON TECH AG

High-efficiency soft magnetic material and method for producing the same

InactiveCN101246773AGuaranteed mechanical propertiesExcellent soft magnetic propertiesInorganic material magnetismInductances/transformers/magnets manufactureMetalMagnet

The invention relates to a highly efficient soft magnetic material and the preparing method thereof. The soft magnetic material is composed of metal soft magnetic material and soft magnetic ferrite, the metal soft magnetic material is composed of at least one selected from Fe-Ni-Me system (Me is one or more than two selected form Cu, Cr, Nb, V, W, Si, Pd, Zn, Al, Ti and Mn), Fe-Co system, Fe-Co-V system, Fe-Al system and Fe-Al-Me system (Me is one or more than two selected form Co, Cr and Mo), the soft magnetic ferrite is composed of at least one selected form Mn-Zn system, Ni-Zn system, Li-Zn system, Cu-Zn system and Mg-Zn system soft magnetic ferrites. The preparing method of the soft magnetic material comprises the steps of: cold pressing, and sintering, hot pressing or spark plasma sintering. The soft magnetic material does not have the drawbacks of low resistivity of the metal soft magnetic and low magnetic strength of the ferrite, as well as keeps the superior properties of the metal soft magnetic and low magnetic strength of the ferrite.

Owner:GRIREM ADVANCED MATERIALS CO LTD

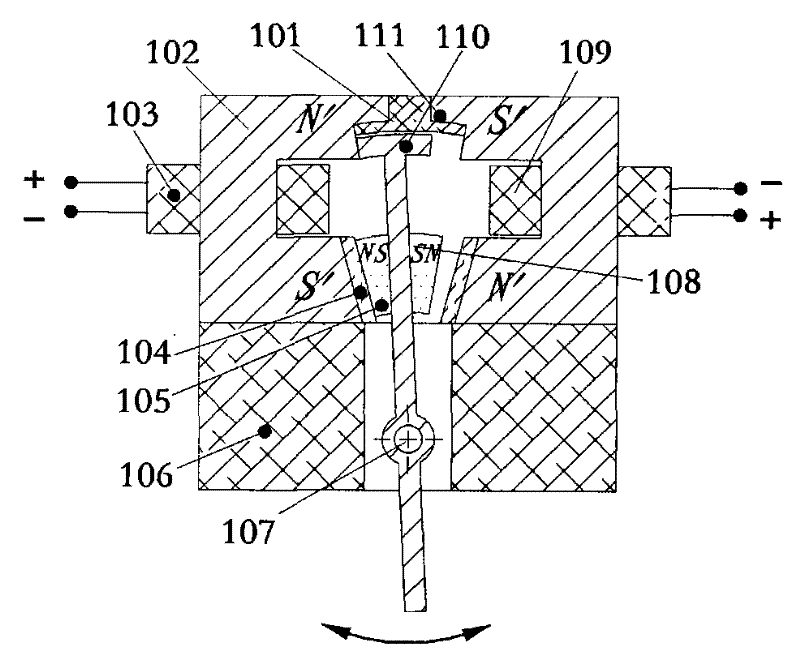

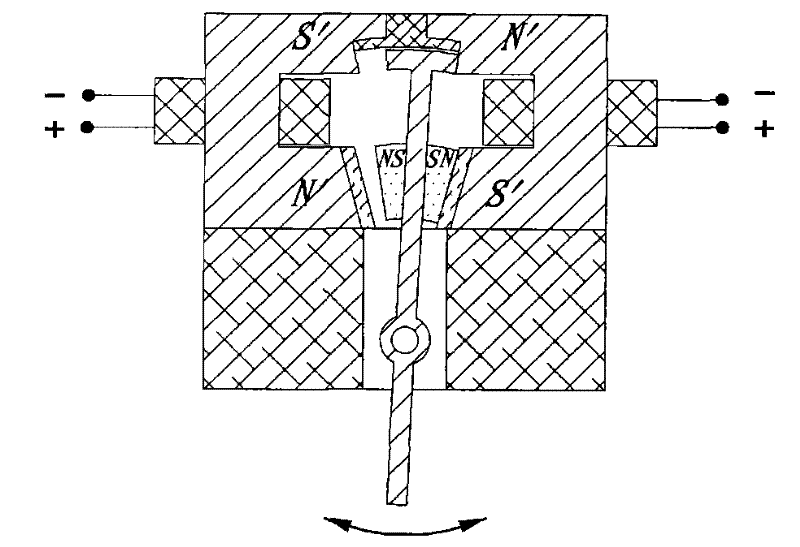

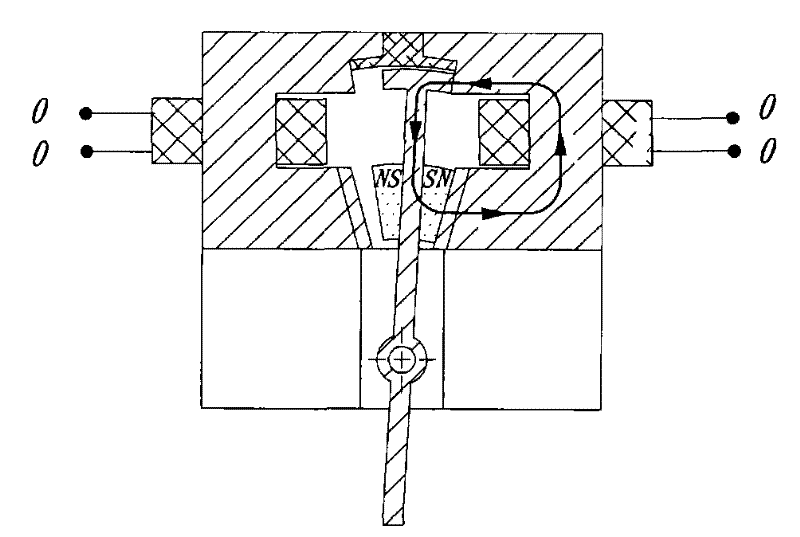

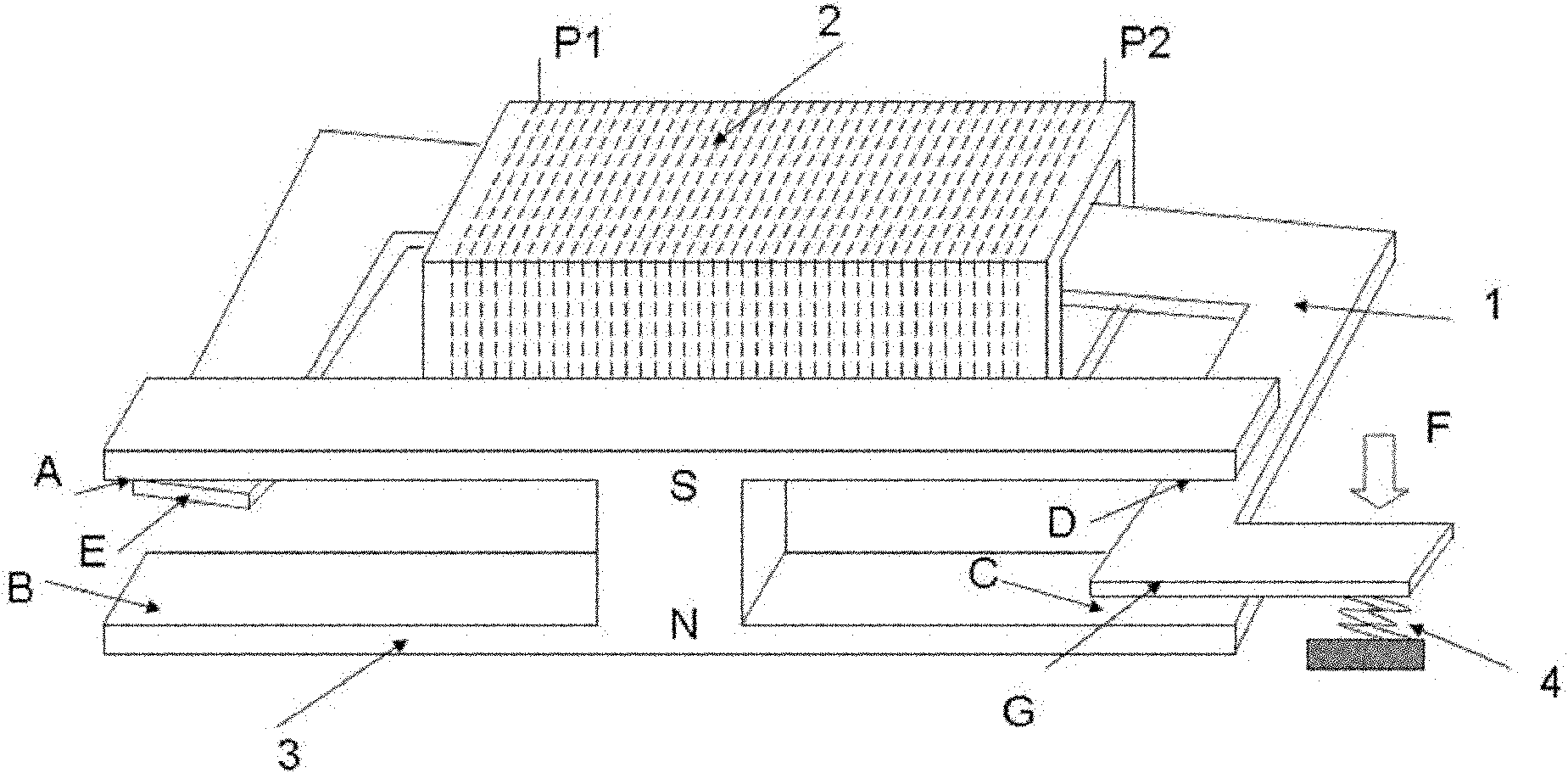

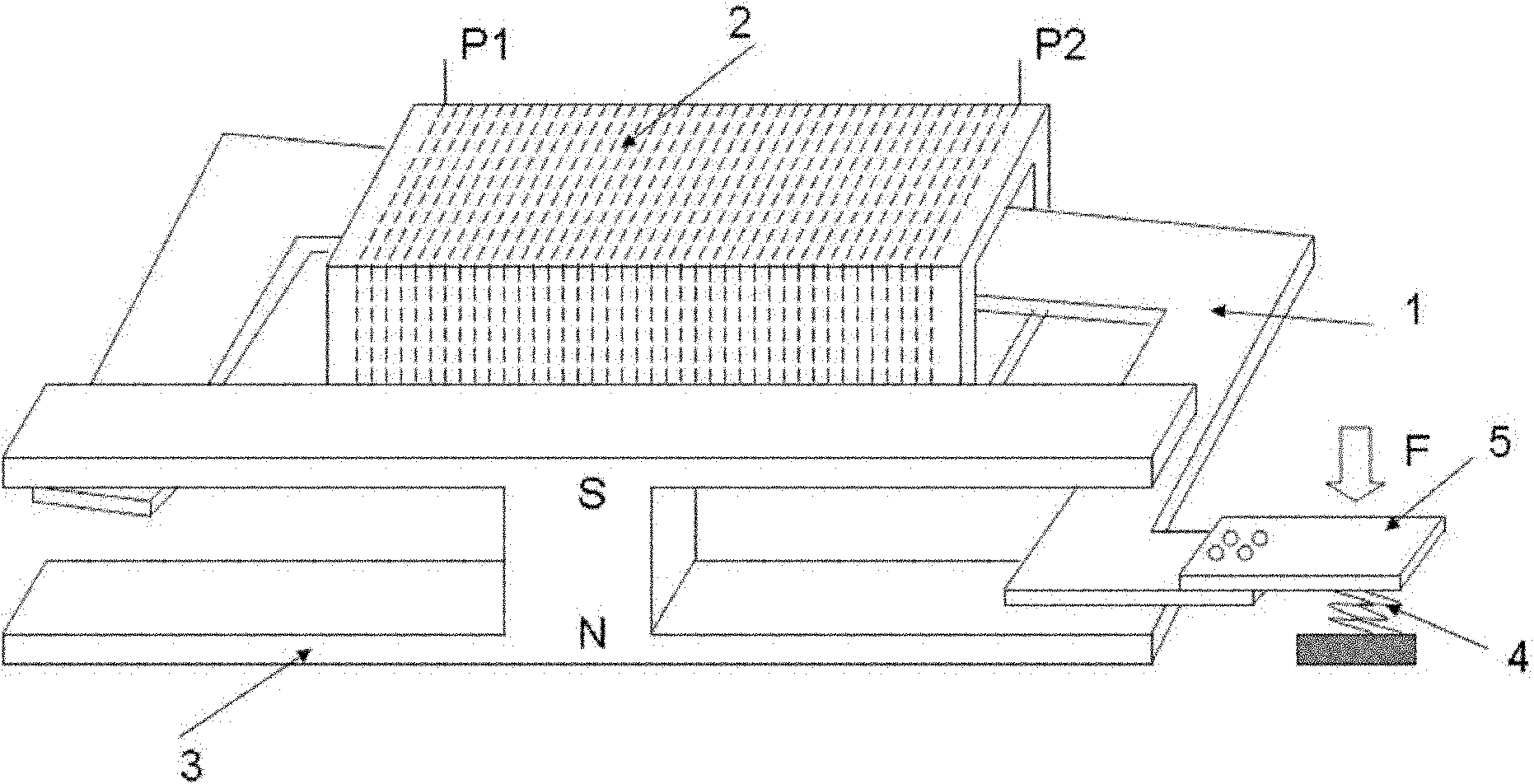

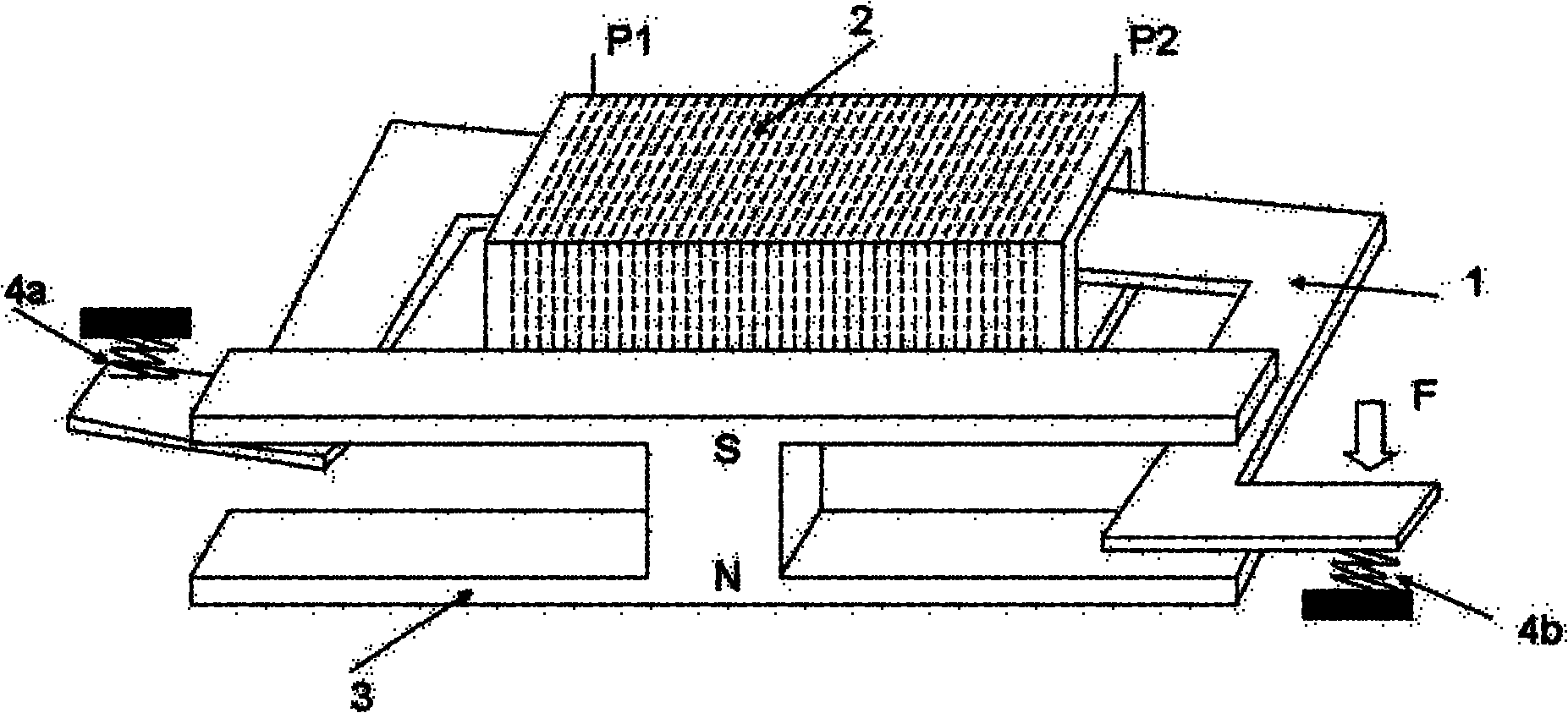

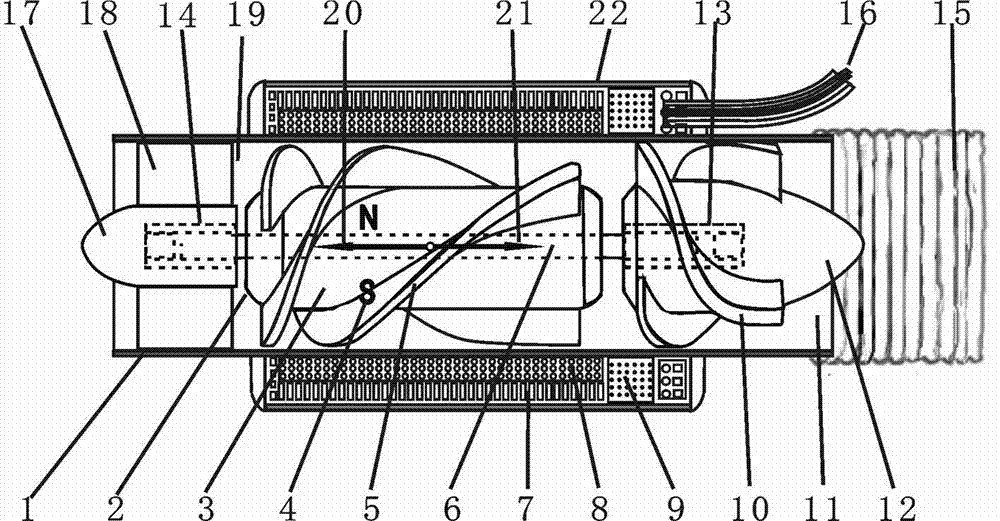

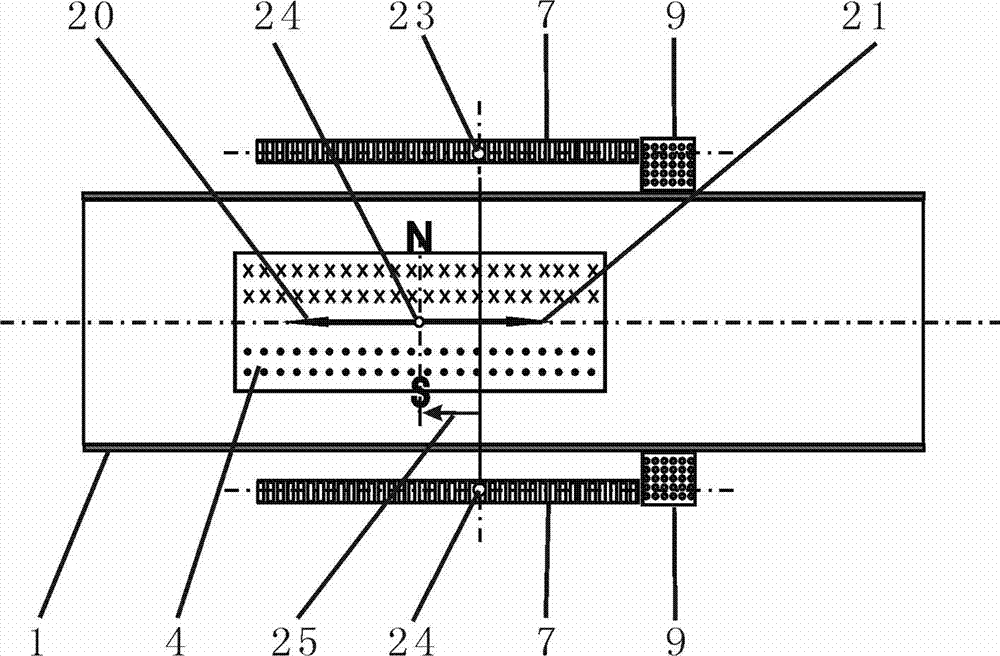

Method and device for generating mechanical reciprocating bistable motion by virtue of electromagnetism

InactiveCN102214980AEfficient use ofImprove energy efficiency ratioDynamo-electric machinesLinear motionReciprocating motion

The invention relates to a method and device for generating mechanical reciprocating bistable-state motion by virtue of electromagnetism. The method is characterized by comprising the following steps: jointing two identical permanent magnets symmetrically on a motion component; placing the parts, adhered to the permanent magnets, of the motion component between two magnetic pole air gaps of an alternating magnetic field; sucking, shutting and repelling the permanent magnets on the motion component repeatedly by virtue of two magnetic poles by the alternating magnetic field so as to drive the motion component to perform reciprocating motion; and regulating the position and structure between the motion component and the two magnetic poles of the alternating magnetic field, thus the motion component can be enabled to perform reciprocating swing and reciprocating linear motion. The invention also provides the device for generating mechanical reciprocating bistable motion by virtue of electromagnetism; through exciting or rotating the permanent magnets by an alternating power source, the alternating magnetic filed is formed on a soft magnet; and the parts, to which the permanent magnets are attached, of a swinging rod and a pushing rod are placed in the magnetic air gaps of the soft magnet. According to the invention, the characteristics of the permanent magnets that the permanent magnets are stressed in the alternating magnetic field and the permanent magnetic tends to be stable once being sucked with the magnetic poles of the alternating magnetic field are utilized, the structure of the device is simplified, and the state is maintained to be stable without energy consumption.

Owner:戴珊珊

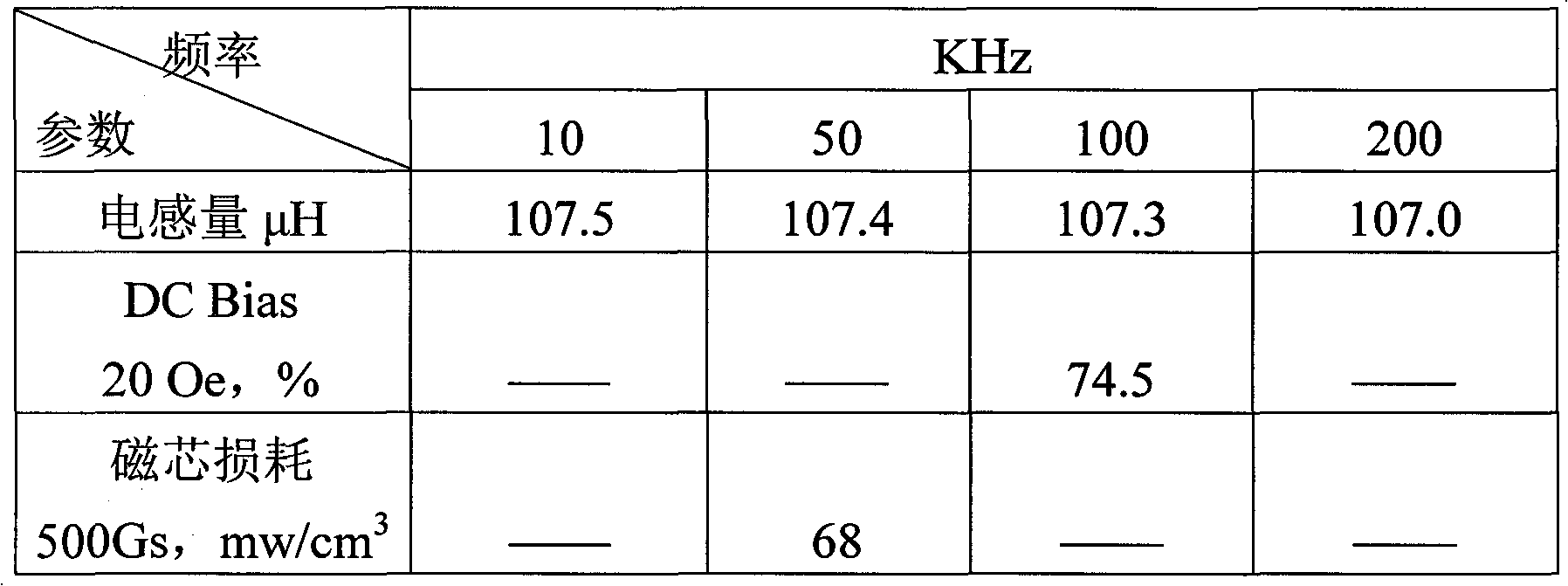

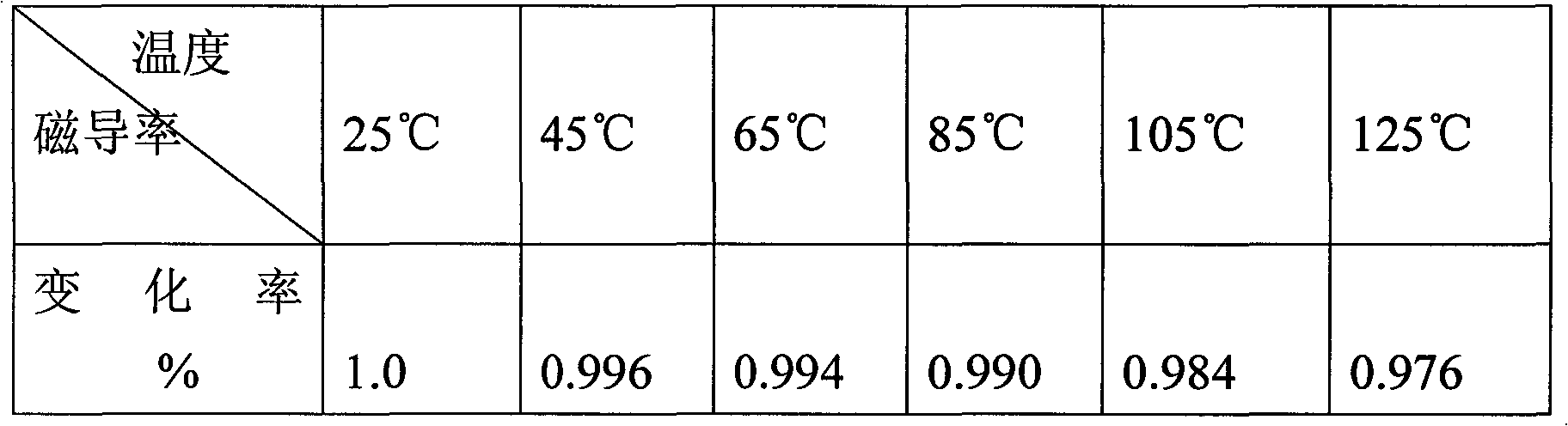

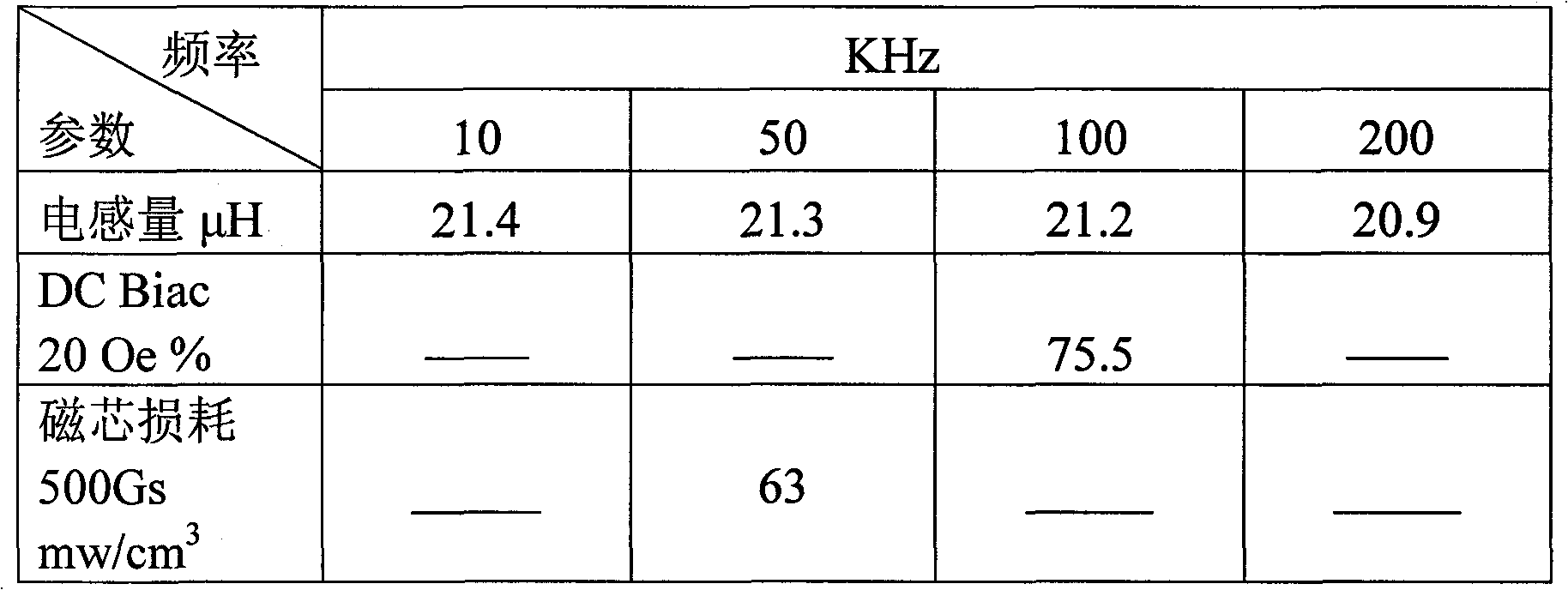

Manufacturing method of soft magnet silicon-aluminum alloy magnetic powder core with small amounts of rare earth element cerium or lanthanum

InactiveCN101871071AHigh resistivityReduce power lossInorganic material magnetismInductances/transformers/magnets manufactureCeriumWorking temperature

The invention discloses a manufacturing method of a soft magnet silicon-aluminum alloy magnetic powder core with small amounts of rare earth element cerium or lanthanum, which comprises the following steps: 1) smelting industrial pure iron, polycrystalline silicon, pure aluminum, cerium-iron alloy or lanthanum-iron alloy in a vacuum induction furnace into FeSiAl alloy cast ingots with small amounts of cerium or lanthanum, wherein the alloy cast ingots comprise the components of 9.0-9.8% of Si, 5.4-6.0% of Al, 0.02-0.25% of Ce or La, 0.006-0.015% of C, 0.008-0.010% of O2, 0.008-0.028% of S, 0.03-0.035% of P and balance of Fe; and mechanically crushing into FeSiAl alloy powder, carrying out high-heat treatment in a shielding gas atmosphere, and then screening; 2) carrying out surface passivation treatment on the FeSiAl alloy powder with phosphoric acid and alcohol, then adding 0.20% of kaolin, 0.20% of lubricant and 0.50% of parting compound, uniformly mixing, and carrying out pressure forming; and 3) carrying out heat treatment and surface spraying. The invention can increase the resistivity of the magnetic core and reduce the high-frequency eddy current loss, and has lower magnetic core loss. Besides, the invention improves the temperature stability of the magnetic permeability, and enables the decline of the magnetic permeability to be less than 3% when the working temperature rises to 125 DEG C.

Owner:惠州市科力磁元有限公司

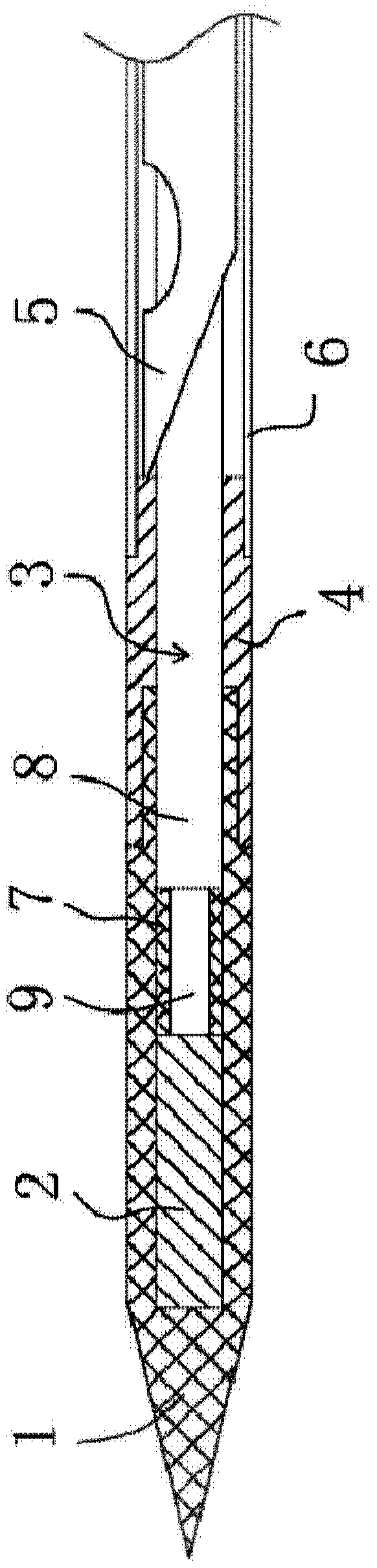

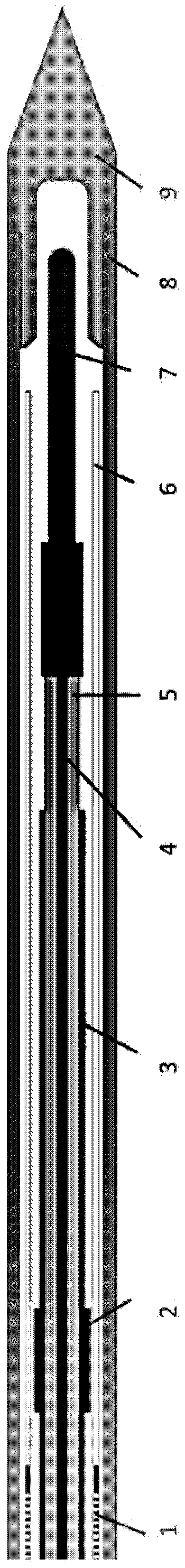

Self-powered wireless two-way communication sensor and control switch

InactiveCN102655455ASelf-poweredSolve without wiringBatteries circuit arrangementsSubstation remote connection/disconnectionMicrocontrollerSupply management

The invention discloses a self-powered wireless two-way communication sensor which comprises a microcontroller unit 9, a power supply management control unit 7 connected with the microcontroller unit 9, and a wireless signal transceiving unit 11 connected with the microcontroller unit 9, as well as soft magnet 1, a conductive coil 2, a permanent magnet 3 and a reset spring 4, wherein the wireless signal transceiving unit 11 can realize two-way communication and one-way receiving or transmitting; the positions of the conductive coil 2, the permanent magnet 3 and the reset spring 4 are fixed relatively; the conductive coil 2 is sheathed on the soft magnet 1, the fulcrum of the soft magnet 1 in the conductive coil 2 is fixed relative to the conductive coil 2, two ends of the soft magnet 1 can do certain vertical displacement around the fulcrum, and the displacement can not exceed the height of inside space at two ends of the permanent magnet 3; one end of the soft magnet 1 is connected with the reset spring 4; and the soft magnet, the coil 2, the permanent magnet 3 and the reset spring 4 forms a self-powered energy collection unit 20. According to the invention, no wiring, batteries or maintenance is required, and microniaturization can be achieved.

Owner:江苏博悦物联网技术有限公司

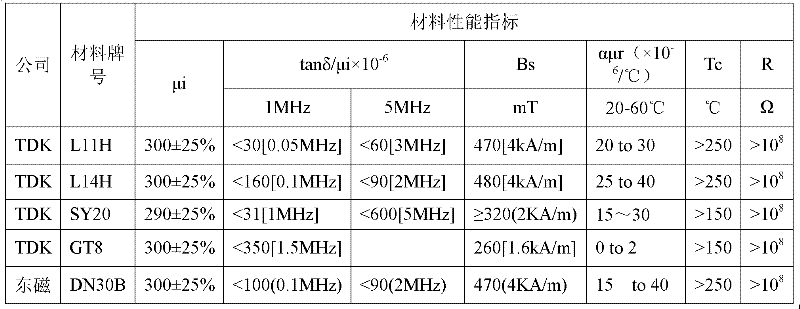

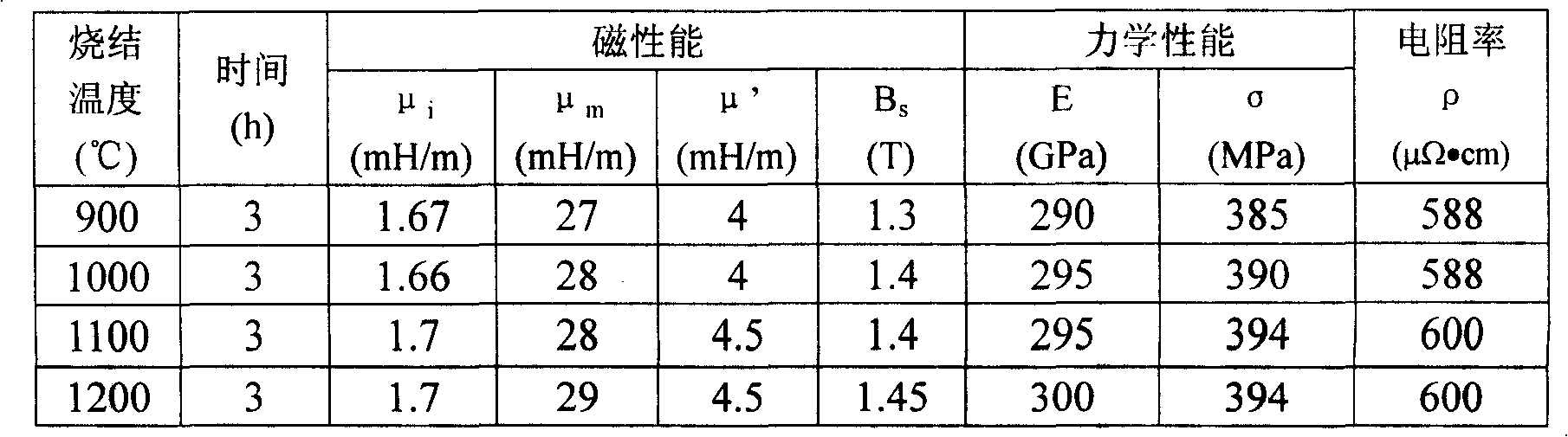

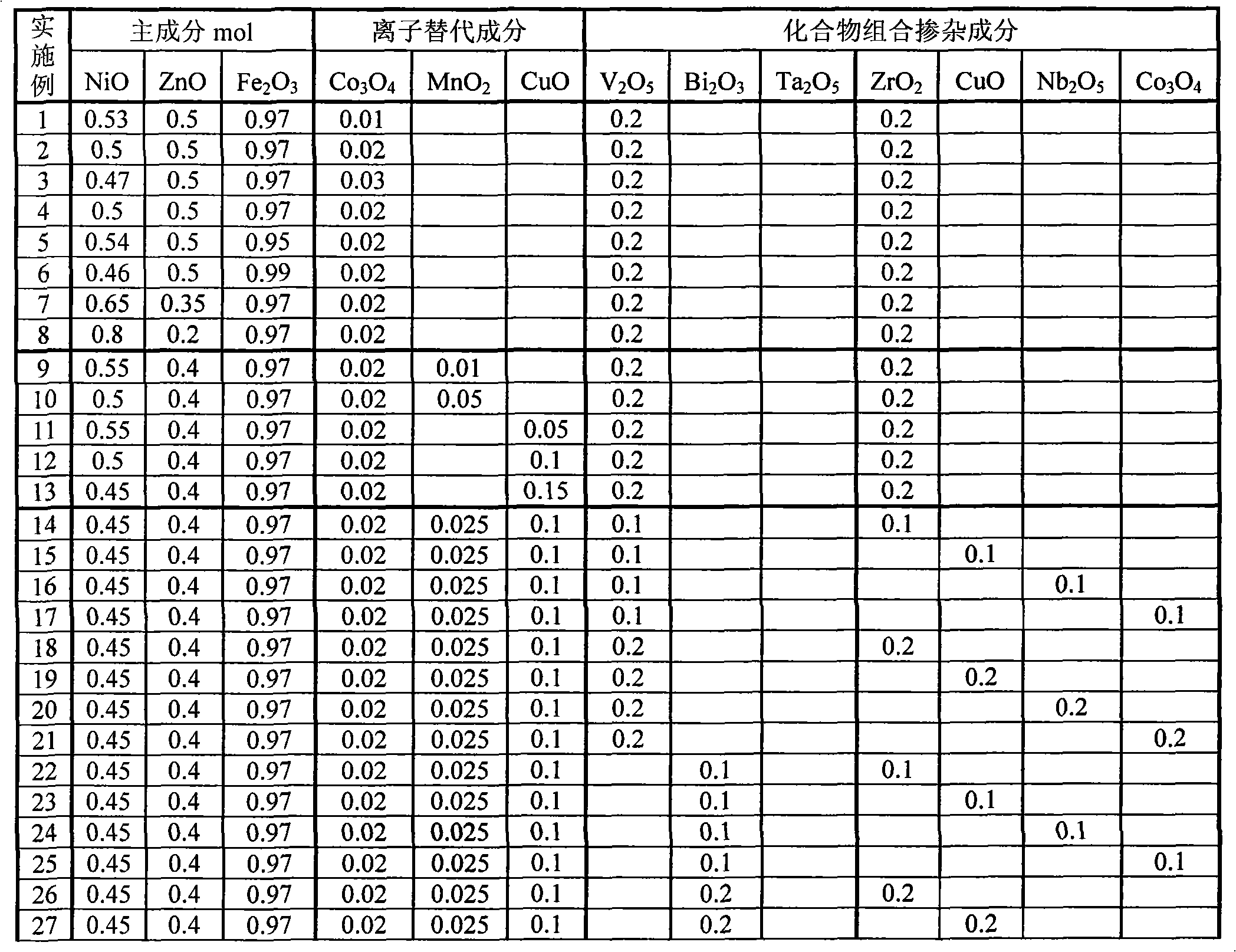

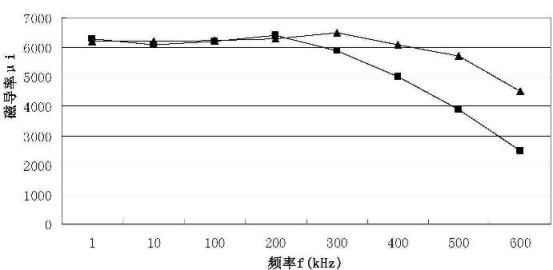

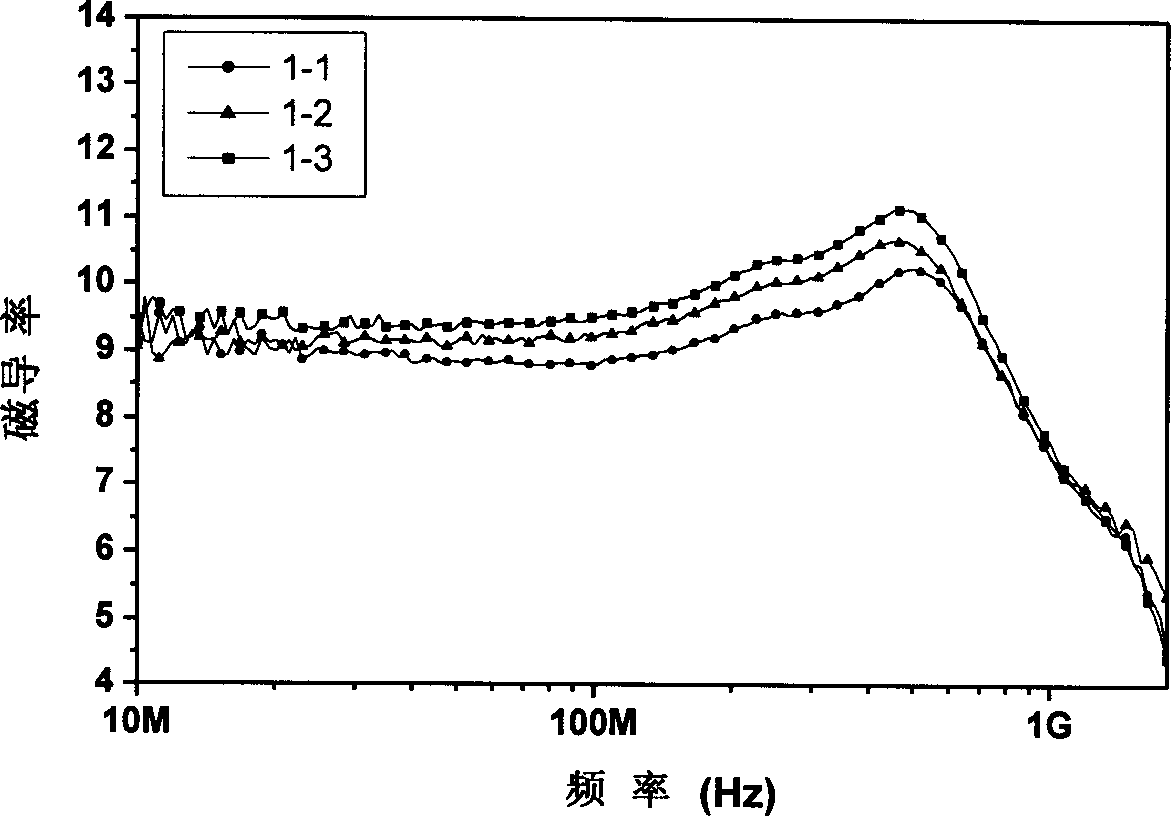

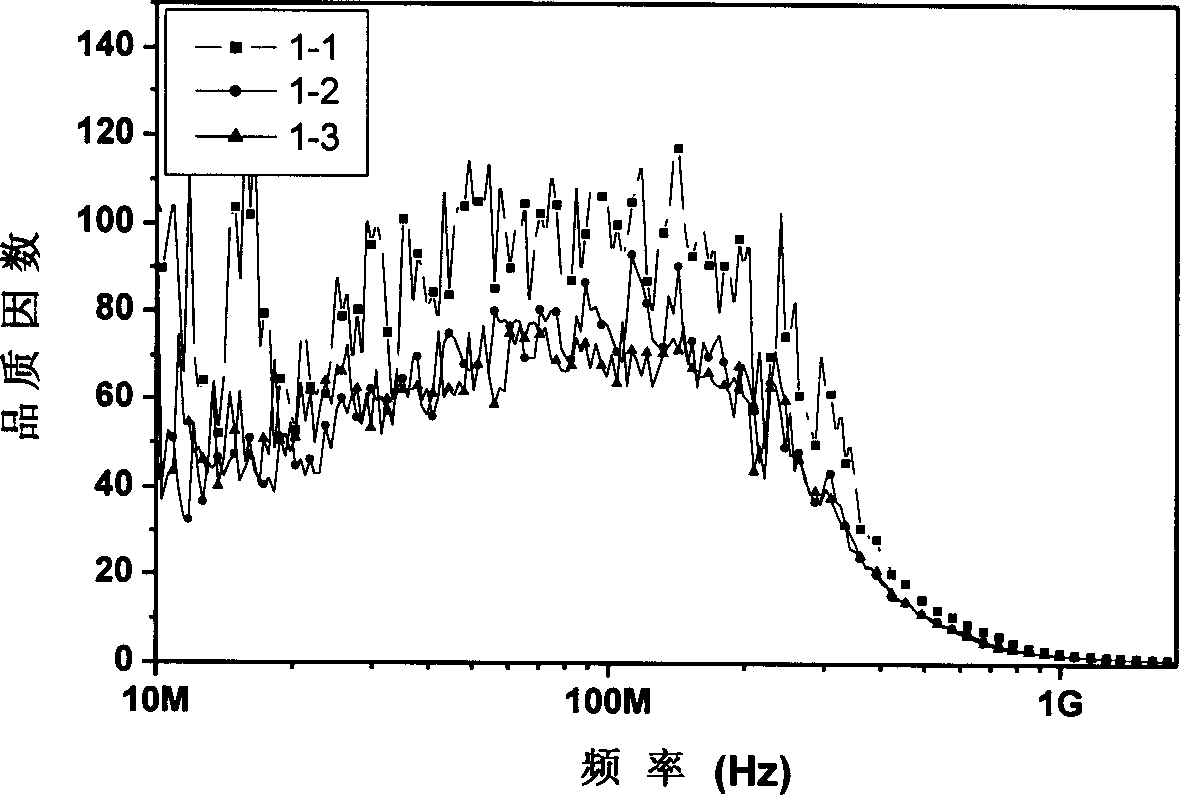

High-frequency high-power Ni-Zn base magnetic ferrite material and manufacturing method thereof

The invention discloses a high-frequency high-power Ni-Zn base magnetic ferrite material and a manufacturing method thereof. The Ni-Zn base magnetic ferrite material comprises a main ingredient, an ionic substitute ingredient and a compound composite and doped ingredient, wherein the main ingredient comprises Fe2O3, ZnO and the balance of NiO; the ionic substitute ingredient comprises one or more kinds of Co3O4, MnCO3 and CuO containing Co3O4; and the compound composite and doped ingredient comprises 2-3 kinds of V2O5, Bi2O3, Ta2O5, ZrO2, CuO, Nb2O5 and Co3O4. The manufacturing method comprises the following steps: (a) preparing a Ni-Zn base ferrite main ingredient mixture; (b) preparing a main ingredient pre-sintered material; (c) preparing micro-fine ferrite powder; (d) preparing a raw blank of a magnetic core; and (e) sintering the magnetic core. The invention obtains the Ni-Zn base magnetic ferrite material with high electromagnetic performance, high strength, high frequency and low loss by optimizing the composite design of a formulation and adopting the manufacturing method of the high-frequency high-power Ni-Zn base magnetic ferrite material. The Ni-Zn base magnetic ferrite material is used for high-power equipment of 1-30MHz and used as the magnetic core for a transformer, an inductor, a filter, a tuner, and the like.

Owner:CHONGQING MATERIALS RES INST

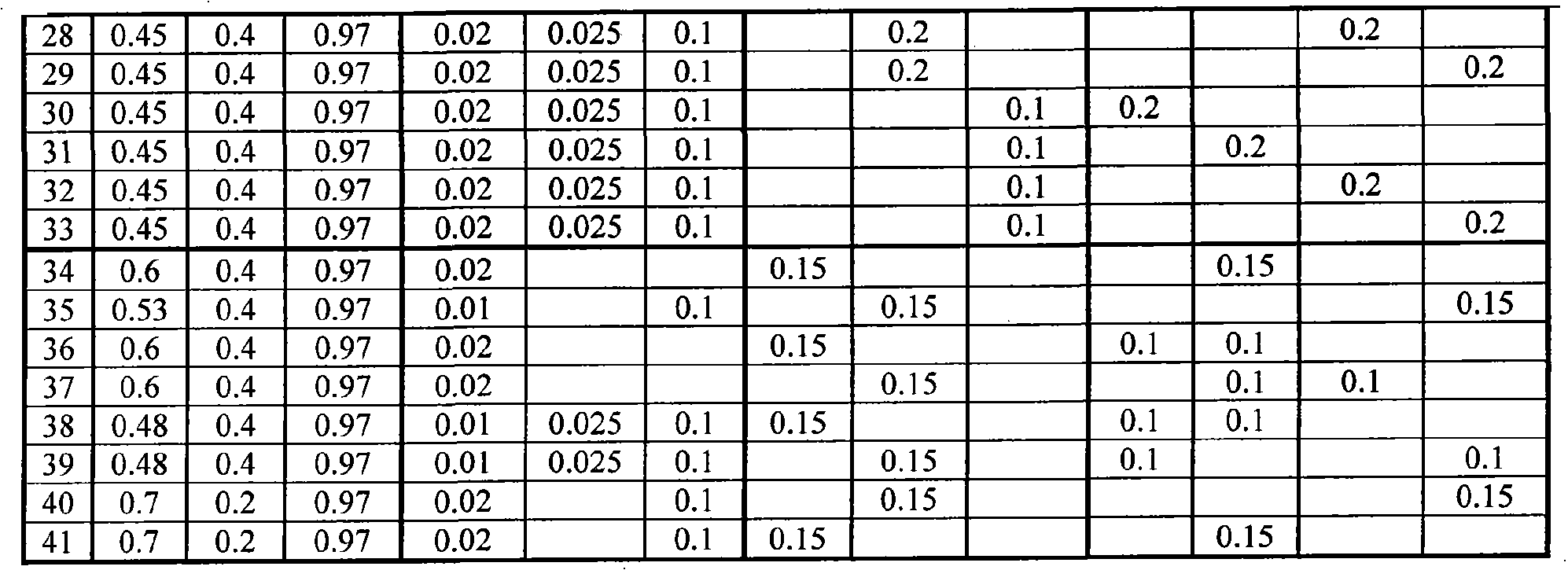

Modular permanent magnet chuck

ActiveUS20060232367A1Minimizing short-circuitingHigh levelElectromagnets without armaturesPositioning apparatusSoft magnetCentre of rotation

A permanent magnet chuck for holding or lifting workpieces is formed of two overlying / underlying flat surfaced chuck layers having a common center of rotation. In each chuck layer an even number of permanent magnet plates radiate from the center of rotation at equal angles with blocks of magnetically soft material between them. The permanent magnet plates are magnetized so that the interposed soft magnet blocks exhibit alternating N-S magnetic polarities. The organization of the permanent magnet plates and soft magnet bodies is matching and complementary so that relative rotation of the chuck layers magnetically activates or de-activates the chuck.

Owner:GM GLOBAL TECH OPERATIONS LLC

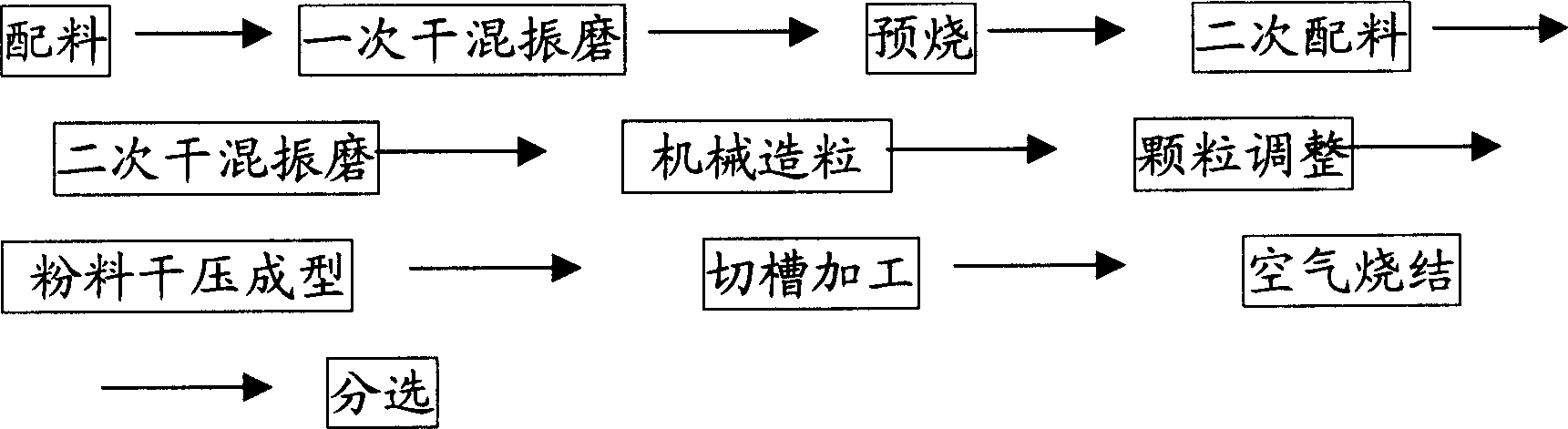

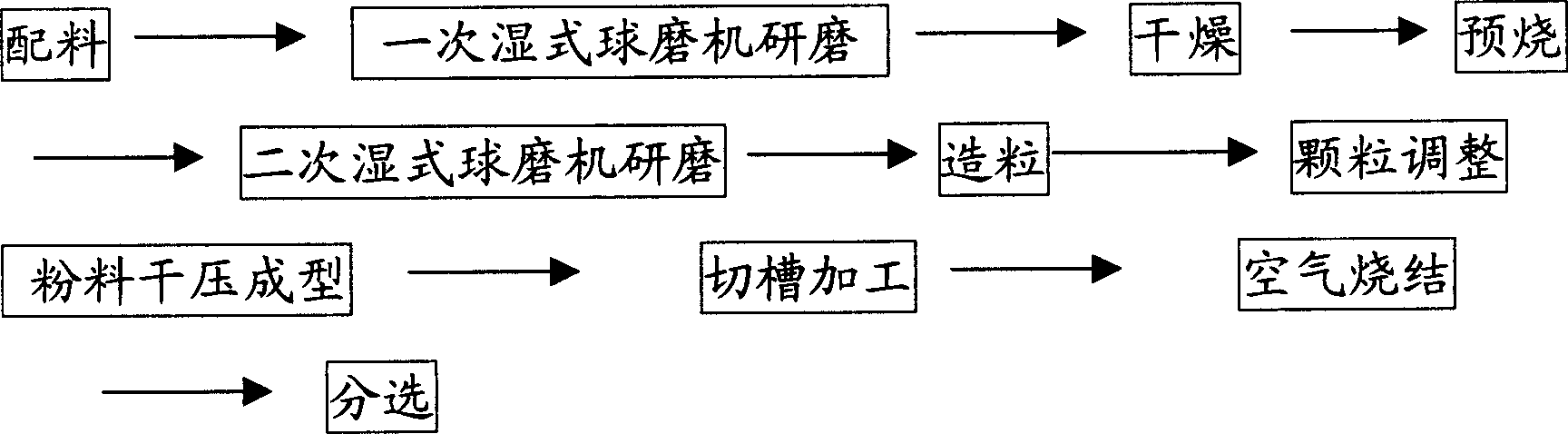

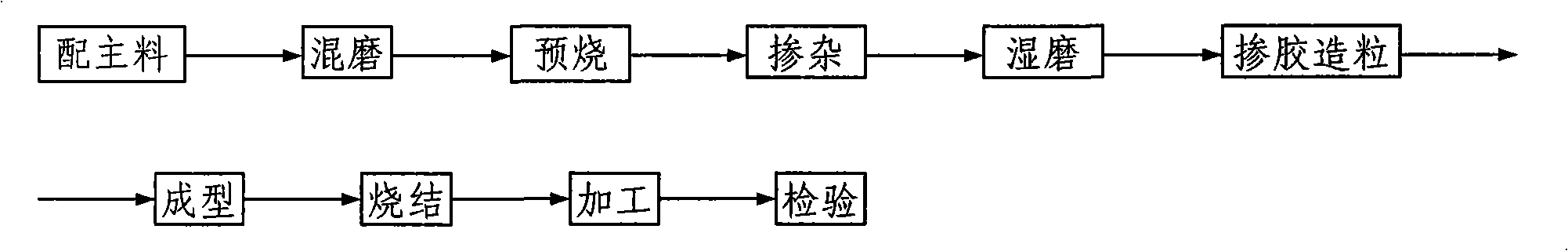

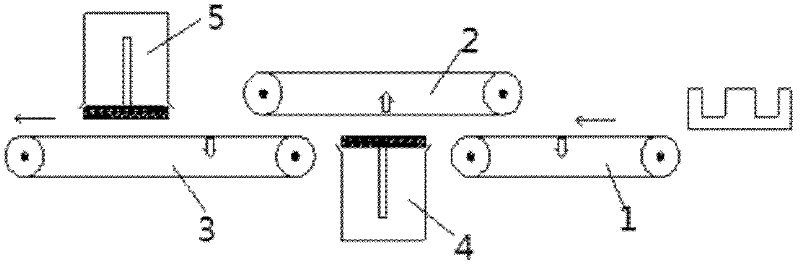

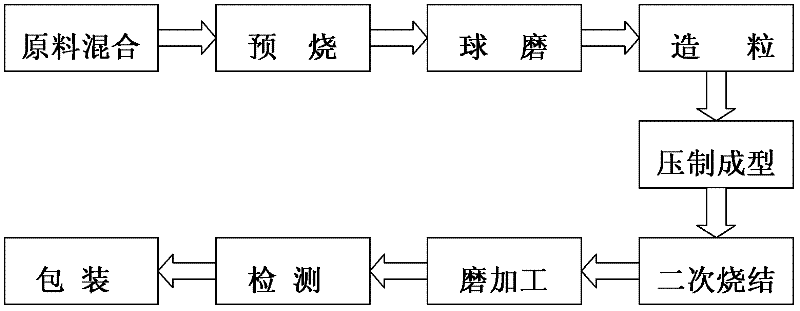

Method for producing soft magnetic ferrite core

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

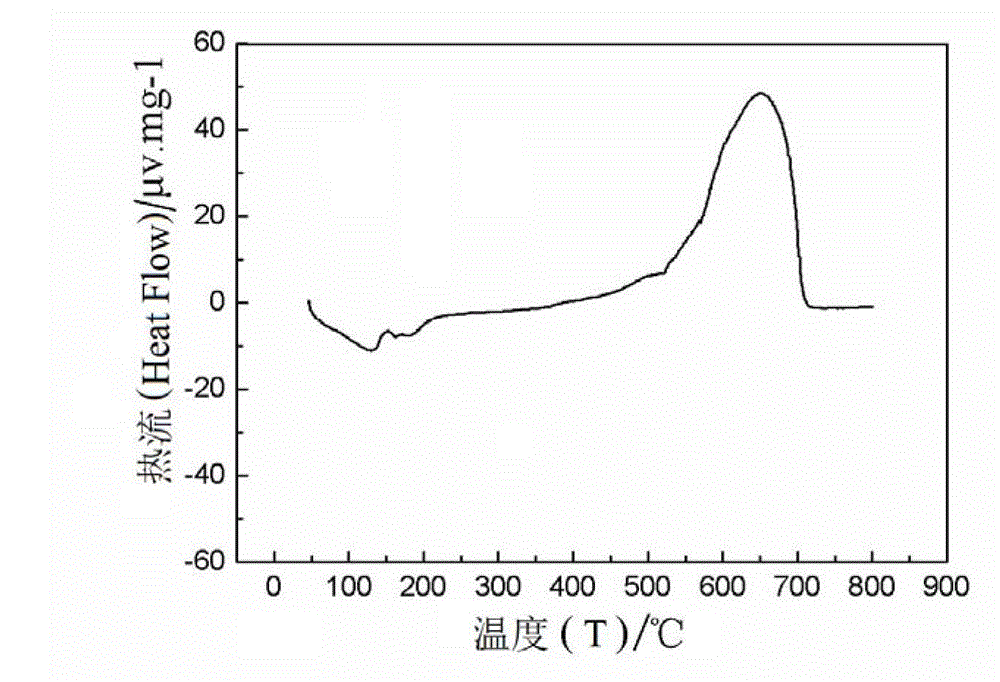

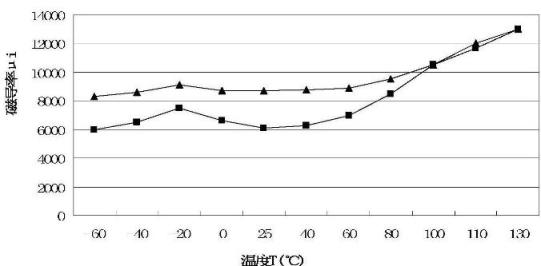

Mn-Zn ferrite material with wide temperature and high initial magnetoconductivity and preparation method thereof

The invention belongs to the field of soft magnetic ferrite, particularly relates to a Mn-Zn ferrite material and provides a Mn-Zn ferrite material with a high initial magnetoconductivity in a wide temperature scope. The Mn-Zn ferrite material is prepared by main components and auxiliary components. The main components are as follows: 51-56 mol% of ferric oxide, 16-26 mol% of zinc oxide and the balance manganese oxide; the auxiliary components comprise one or a combination of more of 50-500ppm of calcium oxide, 50-1000ppm of bismuth oxide, 50-800ppm of molybdenum oxide, 50-800ppm of vanadium oxide or 50-800ppm of indium oxide based on the total weight amount of the main components. In a preferred proposal, one or a combination of more of zirconium oxide, titanium oxide, cobalt oxide or niobium oxide is further added in the auxiliary components. The Mn-Zn ferrite material of the invention is prepared according to a production process of a conventional drying method, and has the characteristic that the initial magnetoconductivity mui is above 5000 within a temperature zone of minus 60 DEG C-130 DEG C, thereby meeting the requirement of electronic devices on a magnetic core with high magnetoconductivity at a lower temperature.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

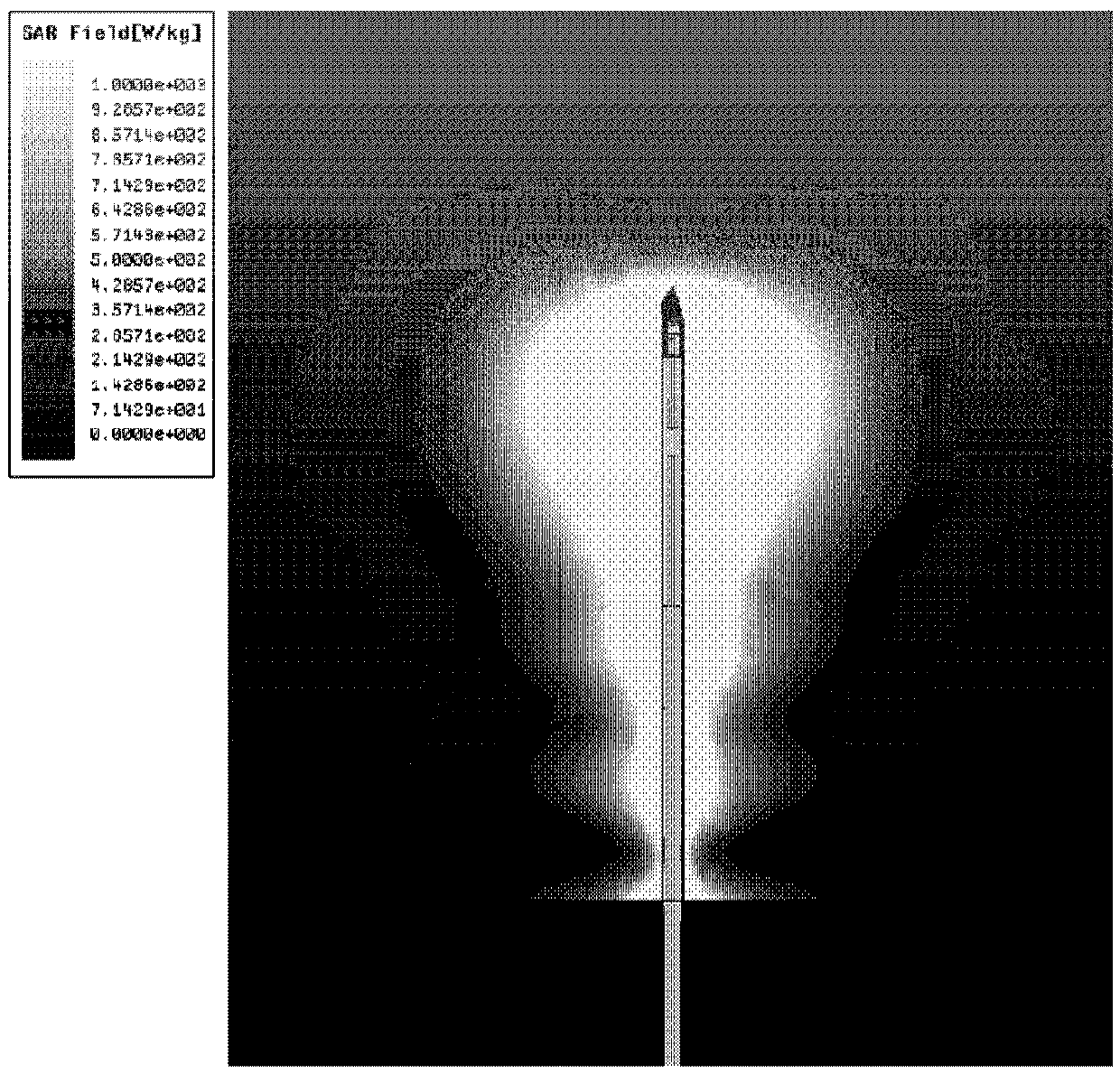

Antenna component used for microwave ablation and microwave ablation needle adopting same

ActiveCN105596079AAvoid transmissionTemperature controlSurgical needlesSurgical instruments using microwavesMicrowaveSoft magnet

The invention relates to an antenna component used for microwave ablation. The antenna component used for the microwave ablation comprises a cooling water channel, a coaxial line and a radiator, wherein a circle of soft magnetic ferrite film is plated on the outermost layer of the coaxial line. The invention also relates to a microwave ablation needle adopting the antenna component used for the microwave ablation. The antenna component used for the microwave ablation has the advantages that the soft magnetic ferrite film can effectively inhibit microwave transmitted backward along the outer wall of the coaxial line, a radiation zone does not need to be filled with a stable medium, circulating water is allowed to enter the radiation zone, temperature at the head of the ablation needle can be effectively controlled, and the ablation needle is prevented from being burned out due to overhigh temperature and a medical accident is avoided.

Owner:SINOSURGICAL HEALTHCARE TECH ZHEJIANG CO LTD

High-frequency nickel-copper-zinc ferrite and preparation thereof

The invention relates to a high frequency nickel-copper-zinc ferrite and a method for preparing the same, which belong to the technical field of nickel series soft magnetism ferrite. The main components of the ferrite are ferric oxide, nickel oxide, zinc oxide, and copper oxide, the accessory components comprise cobalt oxide, bismuth oxide, and silicon oxide, and the ferrite is prepared by an oxide method. The invention adopts an iron deficiency formulation, a low calcination temperature, and a low sintering temperature so that the prepared high frequency nickel-copper-zinc ferrite has good performances of low initial permeability, low relative dissipation factor between 50MHz and 200MHz, and high Curie temperature, and can better satisfy the use requirement of communication electronic parts and components; besides, the preparation process is stable, and the production process has low energy consumption.

Owner:TDG HLDG CO LTD

Heart auxiliary device of axial magnetic force unloading type axial flow pump

ActiveCN103877630AHigh output pressureImprove energy conversion efficiencyIntravenous devicesSuction devicesAxial-flow pumpMagnetic tension force

The invention relates to a special axial flow pump, in particular to a heart auxiliary device of an axial magnetic force unloading type axial flow pump in the field of biomedical engineering. The heart auxiliary device is implanted into the human body. The auxiliary device is a pump-machine combination body and is composed of a pump system and a motor system. The heart auxiliary device is characterized in that an impeller position control soft magnet is installed at the rear end of a stator core, when an impeller moves forwards or backwards due to external force in a pump cylinder, the impeller position control soft magnet and the stator core generate magnetic constraining force on a permanent magnet rotor in an impeller hub, and the direction of force is opposite to the axial moving direction of the impeller. When the axial flow pump works, the magnetic constraining force can form partial and even whole axial magnetic force unloading on axial force loads of the impeller and a shaft, and axial magnetic levitation of the impeller is achieved. According to the heart auxiliary device of the axial magnetic force unloading device, mechanical abrasion and the friction heat effect can be reduced, the thrombus in the pump is prevented from being formed, complications are reduced, the service life of the axial flow pump is prolonged, and stability of continuous work is improved.

Owner:CHANGZHI JIUAN ARTIFICIAL HEART TECH DEV

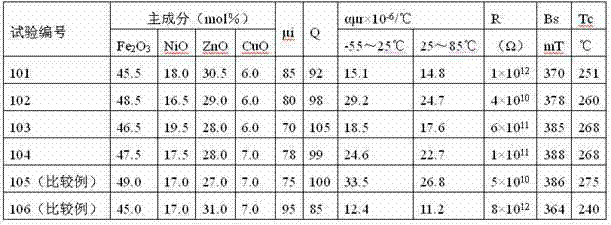

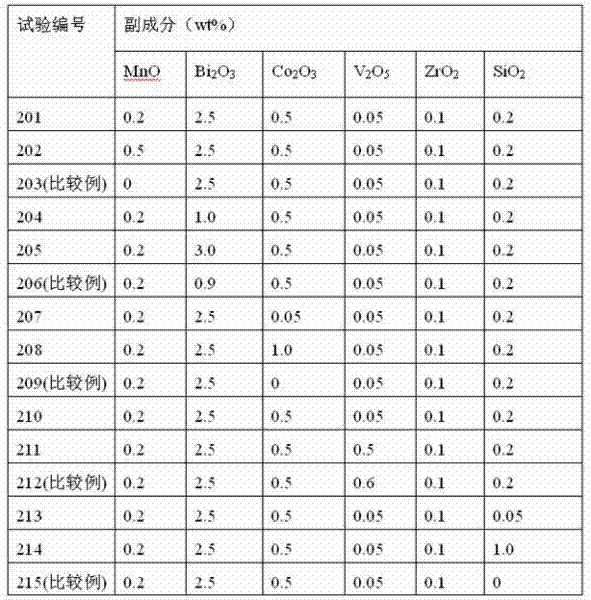

NiCuZn soft magnetic ferrite material used for low temperature co-sintering and preparation method thereof

The invention belongs to the field of soft magnetic ferrite materials, and in particular, relates to a NiCuZn soft magnetic ferrite material used for low temperature co-sintering. The material comprises major constituents and accessory constituents, wherein: the major constituents consist of ferric oxide, nickel oxide, zinc oxide and copper oxide, the molar percentage content of each major constituent being Fe2O3 45.5-48.5 mol%, NiO 16.5-19.5 mol%, ZnO 28.0-30.5 mol% and CuO 6.0-8.0 mol%; the accessory constituents comprise manganic oxide and bismuth oxide, compared with the gross weight of the major constituents, the weight percentage gross of the accessory constituents being 1.1-3.5 wt% calculated by taking MnO and Bi2O3 as standard. The invention also provides a preparation method for the ferrite material. When used for preparing MLCI devices under high frequency usage, the material of the invention has advantages in that: the material has a relatively low sintering temperature and metallic silver is not easy to diffuse during co-sintering; and the material ensures that the MLCI devices can obtain excellent magnetic properties and have a relatively good consistency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

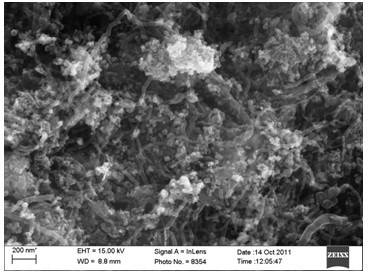

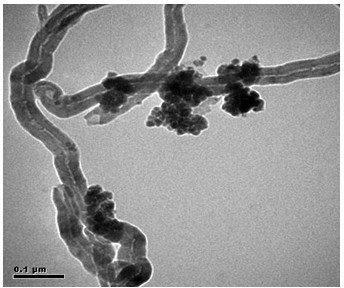

Method for removing mercury ions in water and regeneration method of adsorbent used in same

InactiveCN102432085ANanostructure, large specific surface areaLarge specific surface areaOther chemical processesCombustible gas purificationSorbentModified carbon

The invention relates to a method for removing mercury ions in water and a regeneration method of an adsorbent used in the same. An adsorbent is put in water to be treated to adsorb mercury ions in the water. The adsorbent is a palladium nanoparticle supported / iron oxide magnetic modified carbon nanotube composite material. The carbon nanotube composite material provided by the invention has nanostructure and large specific area; and after the carbon nanotube composite material is oxidized and activated, carboxyl group, hydroxyl group and other active functional groups are formed on the surface of the carbon nanotube composite material, thereby enhancing the hydrophilic property and the adsorptive capacity for positively charged metallic ions. The iron oxide is coated on the surface of the activated carbon nanotube composite material, and therefore, the activated carbon nanotube composite material has strong soft magnet property, and can easily implement solid-liquid separation of the adsorbent and the polluted water body under the action of an external magnetic field. The palladium modification strengthens the affinity of the composite material with mercury ions, and greatly enhances the adsorption capacity and selectivity of the original carbon nanotube composite material for mercury ions (the maximum adsorption capacity is 55.3mg / g).

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

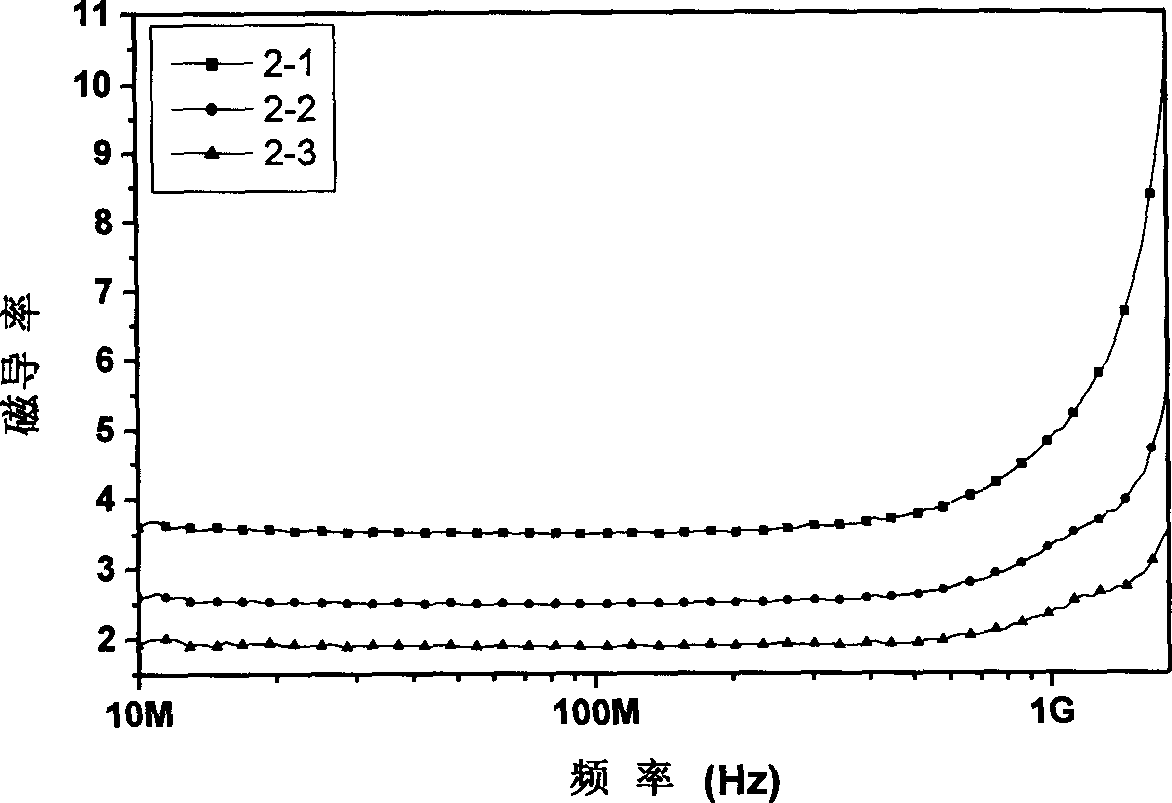

Components and preparing process of VHF plate sensor material

InactiveCN1397961AReduce performanceLower firing temperatureInorganic material magnetismCombustionSolid reaction

This invention relates to a formula of a VHF inductive chip material and its preparation method. There is not high performance low temp sintered ferrite materials at present so we have to use low dielectric ceramics as the medium instead to produce low inductance multi-chip inductors. The basis of the said material is a plane hexagon soft magnet ferrite matched with low temp combustion adjuvant processed by the solid phase reactance synthesis and the combustion adjuvant is applied with two times of doping VHF inductive material of excellent performance is got after ballmill, baking, preroast, ballmill, baking, granulation, formation sintering, realizing low temp sintering with temp below 900 deg.c.

Owner:TSINGHUA TONGFANG CO LTD +1

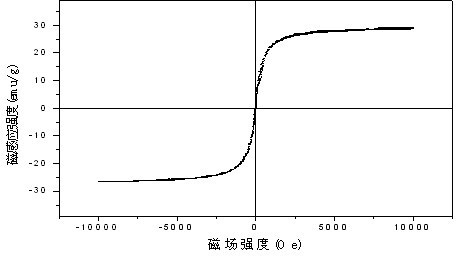

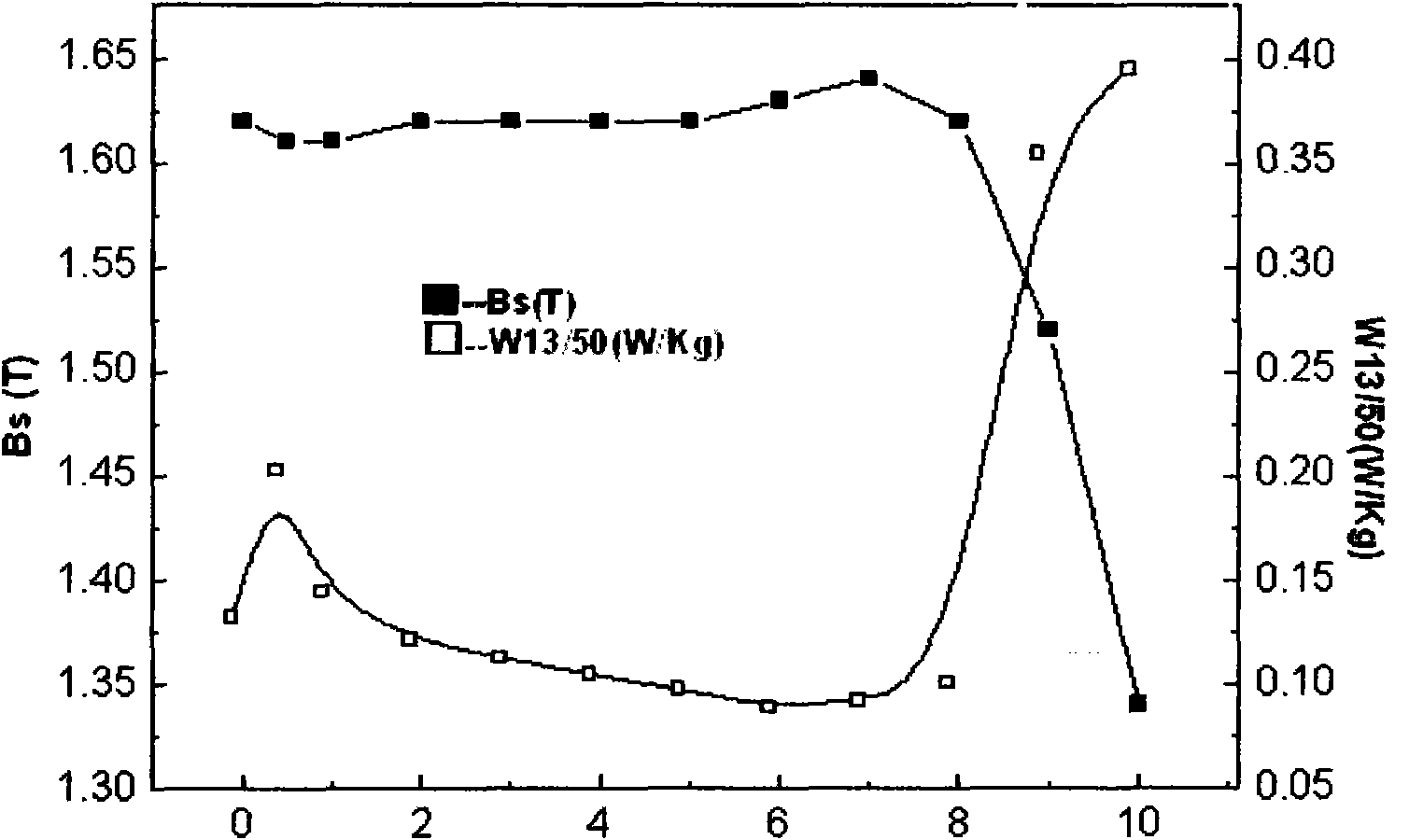

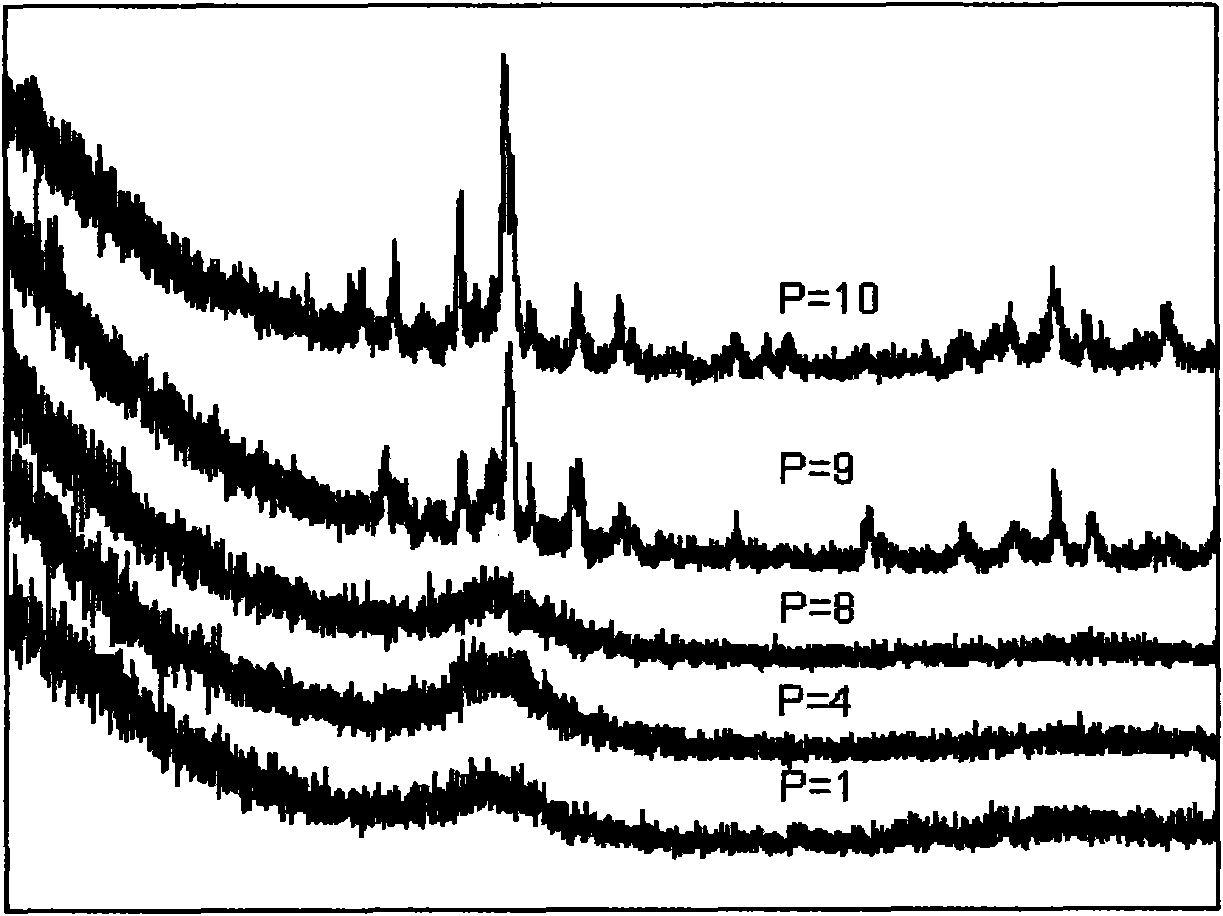

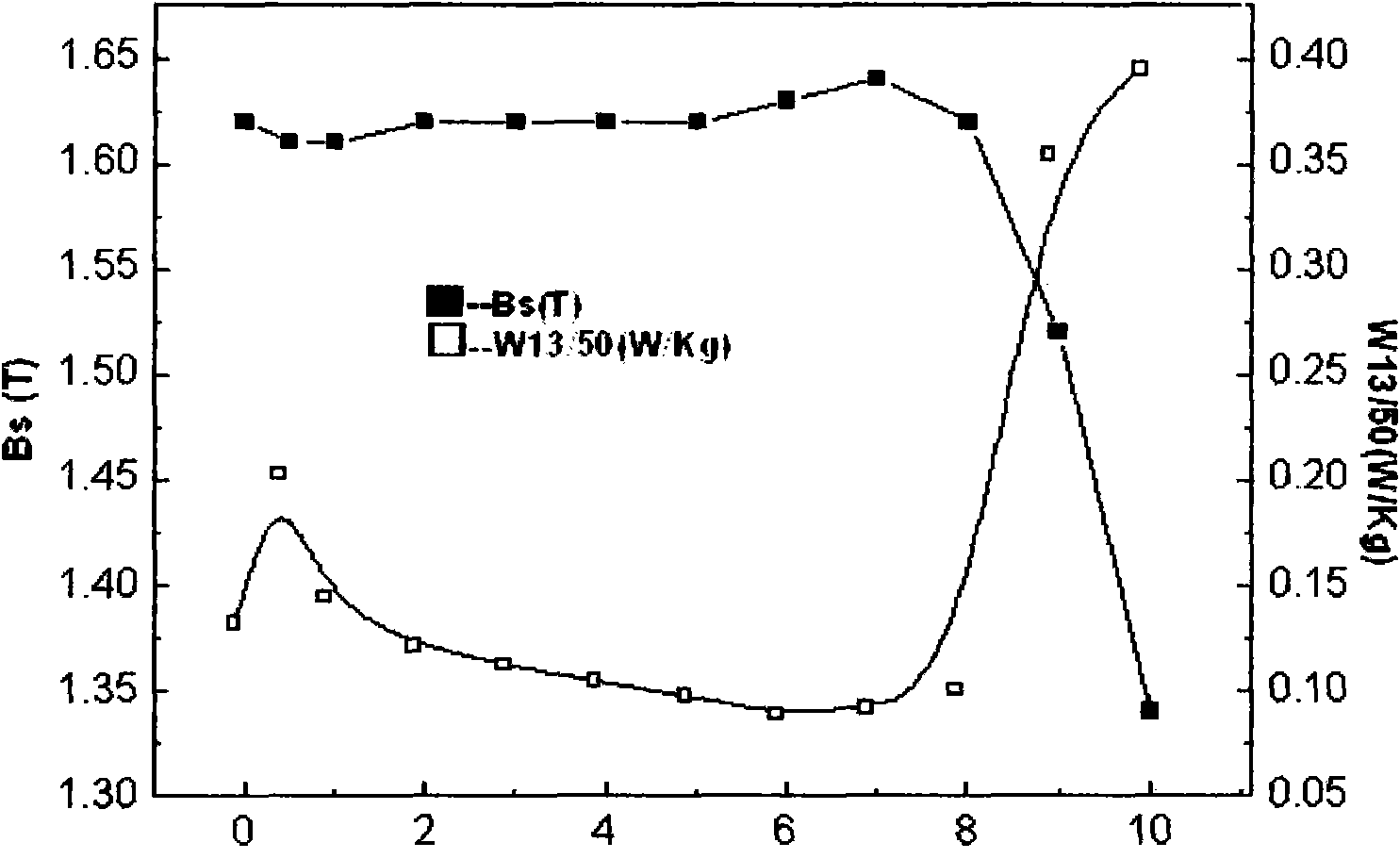

Iron-based amorphous alloy with high soft magnet performance and low cost and manufacturing method thereof

InactiveCN101800109AReduce manufacturing costGood soft magneticFurnace typesMagnetic materialsSoft magnetCurie temperature

The invention discloses an iron-based amorphous alloy with high soft magnet performance and low cost and a manufacturing method thereof. The iron-based amorphous alloy comprises the following components expressed at the atomic ratio: Fe (100-x-y-z-w) BxSiyCzPw, wherein x is 4-20, y is 3.5-5, z is 1.8-2.3, w is 0-10, and the balance is Fe; x+y+z+w is 19-23, preferably 19-20.5 or 20.5-23, more preferably 20-20.5; P is used for replacing parts of B, w is preferably 1-7, and x+w is 11-20 preferably; the components of the iron-based amorphous alloy expressed at the atomic ratio are preferably 79.5 of Fe, 12 of B, 3.5 of Si, 2 of C and 3 of P, or 79.5 of Fe, 13 of B, 3.5 of Si, 2 of C and 2 of P or 79.5 of Fe, 11 of B, 3.5 of Si, 2 of C and 4 of P; and the high-saturation magnetic induction strength Bs of the iron-based amorphous alloy is 1.3-1.64 T, iron loss is P13 / 50<0.3W / kg. Curie temperature variation is 381-418 DEG C. In the component proportioning of the alloy, cheap P is used for replacing parts of elements B so as to greatly lower manufacturing cost and keep favourable soft magnetic performance at the same time.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com